Patents

Literature

36results about How to "Same dwell time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

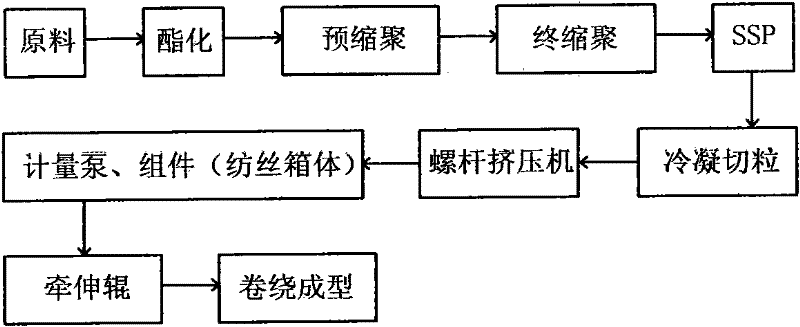

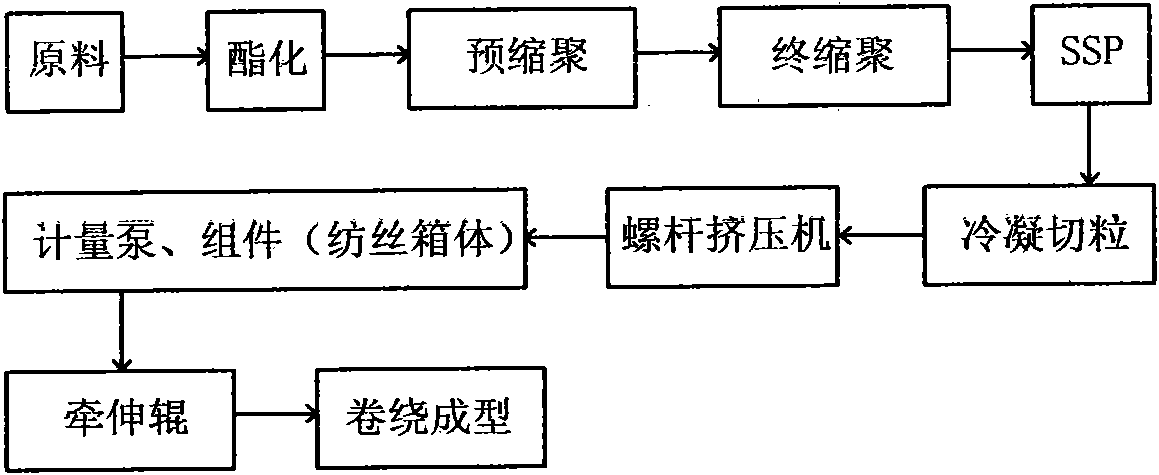

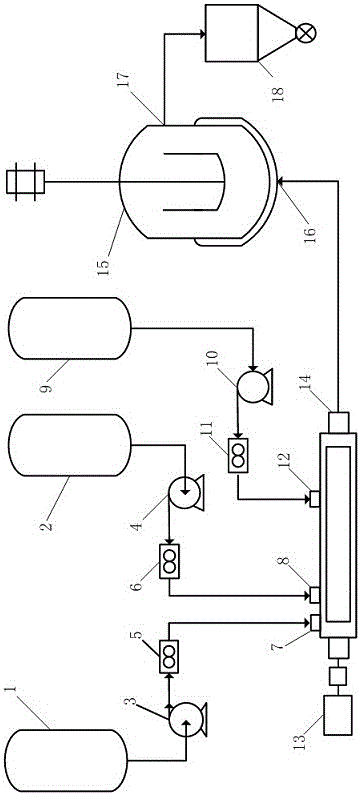

Technology for producing direct spinning terylene industrial filaments after liquid state polycondensation of prepolymer

ActiveCN101914820AShort processReduce energy costsSpinning head liquid feederMelt spinning methodsPolyesterLiquid state

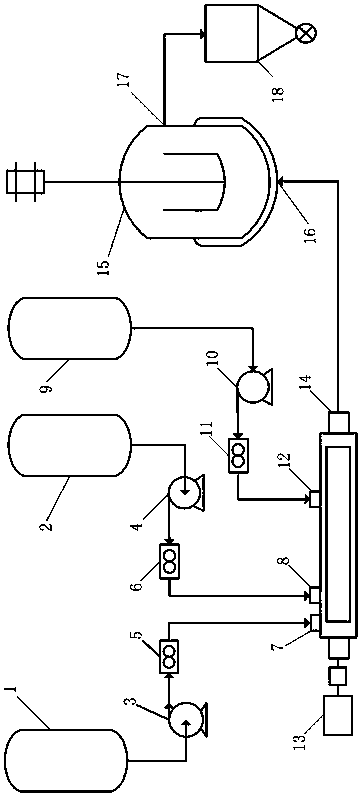

The invention discloses technology for producing direct spinning terylene industrial filaments after liquid state polycondensation of prepolymer and belongs to the technical field of spinning. The technology comprises the processes of esterification, prepolycondensation, liquid state polycondensation, and spinning, and is characterized by comprising the following steps of: performing prepolycondensation reaction on esterified ethylene glycol and phthalic acid to prepare a melt with the viscosity of 0.3 to 0.4dl / g, and conveying the melt to a liquid state polycondensation kettle for liquid state polycondensation by using a booster pump; and conveying the melt to a spinning beam for spinning through a gear pump, wherein the inherent viscosity of the polyester melt after liquid state polycondensation is 0.85 to 1.05dl / g. By directly conveying the melt into the liquid state polycondensation kettle for polycondensation and performing the production technology of directly spinning the melt, the production technology for producing the direct spinning terylene industrial filaments after the liquid state polycondensation of the prepolymer shortens the process flow, reduces the production energy consumption and production cost, and solves the technical problem of difficulty in conveying the melt simultaneously.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

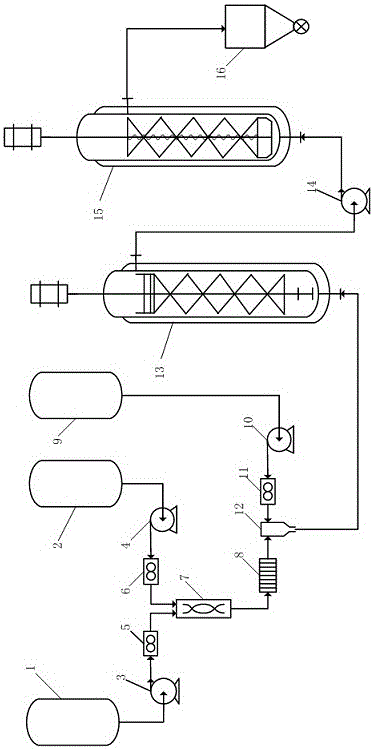

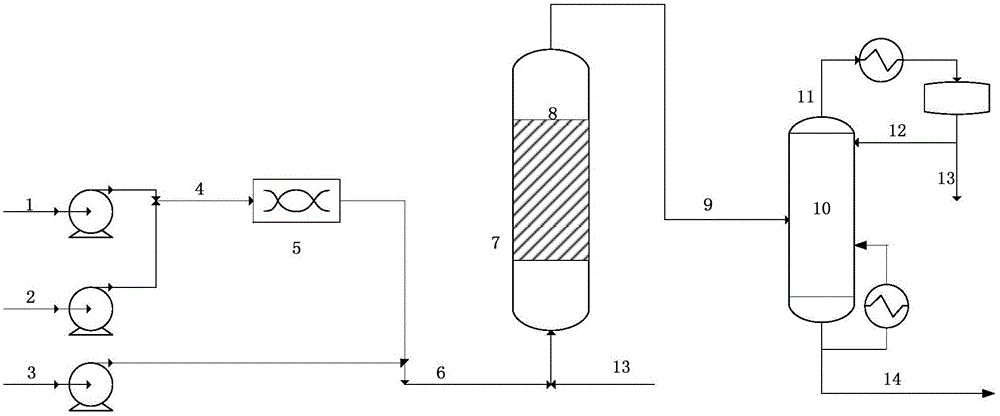

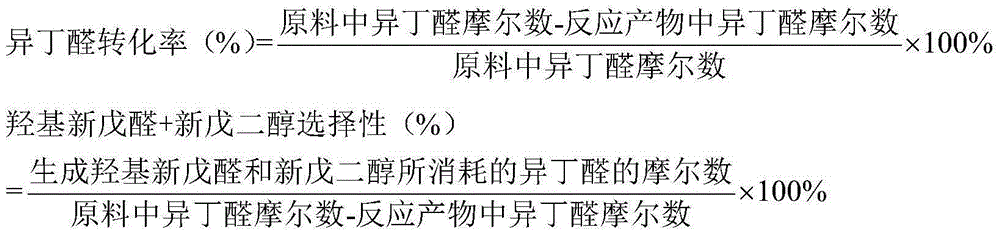

Method for preparing hydroxy neovaleraldehyde by condensing formaldehyde and isobutyraldehyde

InactiveCN105061167ALow selectivitySame dwell timeOrganic compound preparationCarbonyl compound preparationBoiling pointTower

The invention relates to a method for preparing hydroxy neovaleraldehyde by condensing formaldehyde and isobutyraldehyde, which mainly solves the problems of lower conversion rate and lower selectivity in the prior art. The technical scheme is as follows: the method comprises the following steps: mixing formaldehyde and isobutyraldehyde in a mixer, mixing with a condensation catalyst, sending into a tubular reactor with a reinforced liquid-liquid mixing internal component, reacting at 50-90 DEG C under the pressure of atmospheric pressure to 0.5 MPaG for 30-120 minutes to obtain a condensation product, sending the condensation product into a rectification tower to perform reduced pressure rectification, discharging low-boiling-point substances from the tower top, and sending the purified hydroxy neovaleraldehyde-water mixture obtained from the tower bottom into the subsequent section. The technical scheme well solves the problems, and can be used for preparing hydroxy neovaleraldehyde by condensing formaldehyde and isobutyraldehyde.

Owner:SHANGHAI HUAYI GRP CO

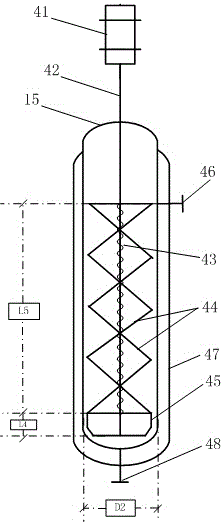

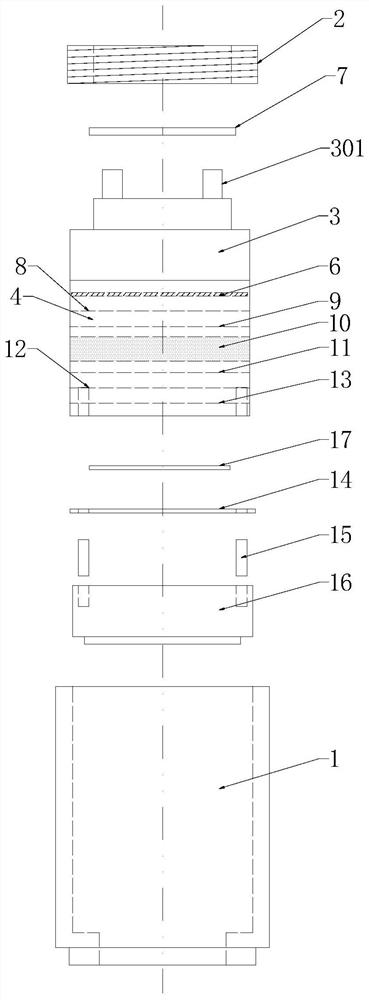

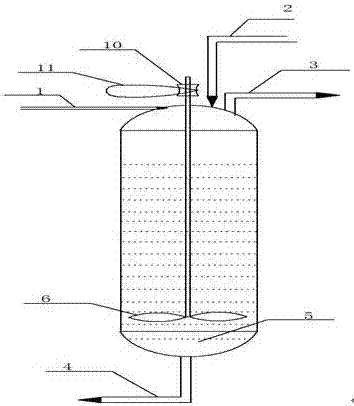

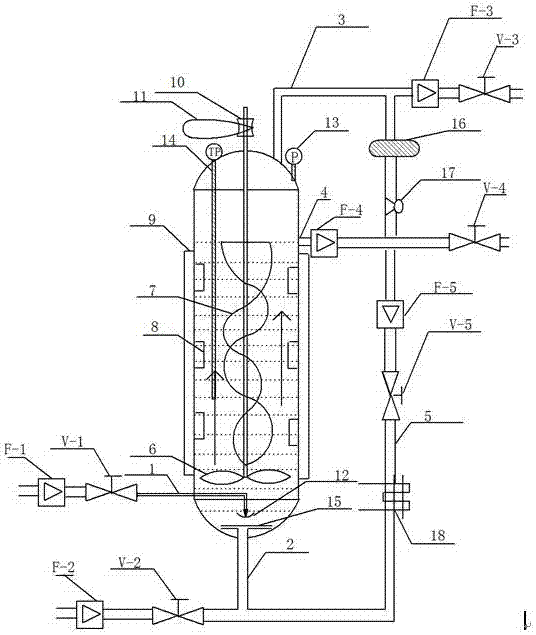

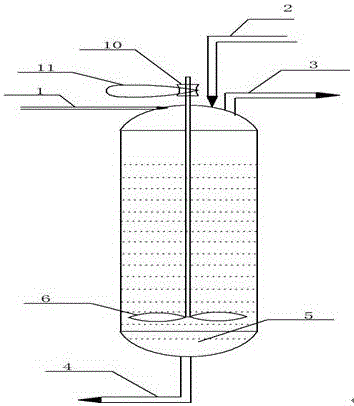

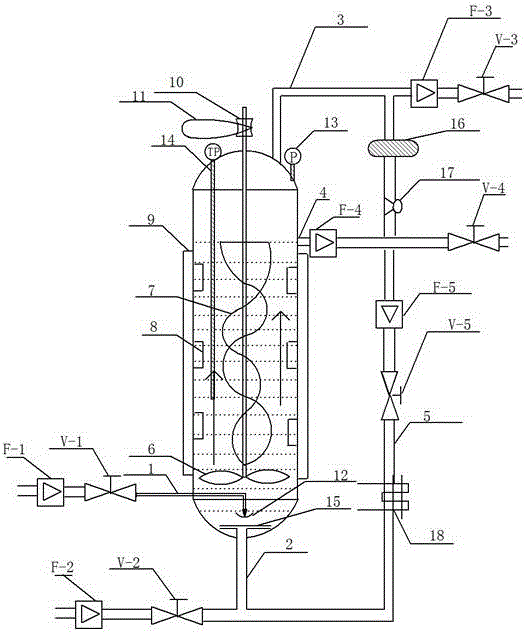

Efficient gas-liquid reaction kettle and application thereof in esterification reaction of ethylene oxide and carbon dioxide

ActiveCN106268588AImprove the mixing effectUniform and complete reactionProcess control/regulationOrganic chemistryCarbon dioxideCompound (substance)

The invention belongs to the field of chemical engineering and particularly relates to an efficient gas-liquid reaction kettle. Through the reaction kettle, the concentration gradient of a gas phase and a liquid phase in the reaction kettle can be effectively reduced, and all material components tend to be identical in staying time in the reaction kettle. The reaction kettle is provided with a stirring device, baffle plates, cooling fins, a spiral gas distributor and a liquid phase feeding nozzle, the stirring device is composed of a motor, a stirring shaft and stirring blades, and the stirring blades comprise the spiral blade and the long-strip-shaped blade. One or more gas phase feeding inlets are formed in the bottom of the reaction kettle, one or more liquid phase feeding inlets are formed in the lower part of the wall of the reaction kettle, meanwhile, the reaction kettle is provided with a pressure gauge and a thermocouple, and corresponding pipelines are each provided with a flowmeter and a control valve. Through the reaction kettle, the problems that the gas phase and the liquid phase are mixed unevenly, and staying time of materials is different are solved, meanwhile, the mixing effect of the materials is improved, a local sharp reaction is avoided, all the materials enter the reaction kettle to complete a reaction rapidly, and product quality is guaranteed.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

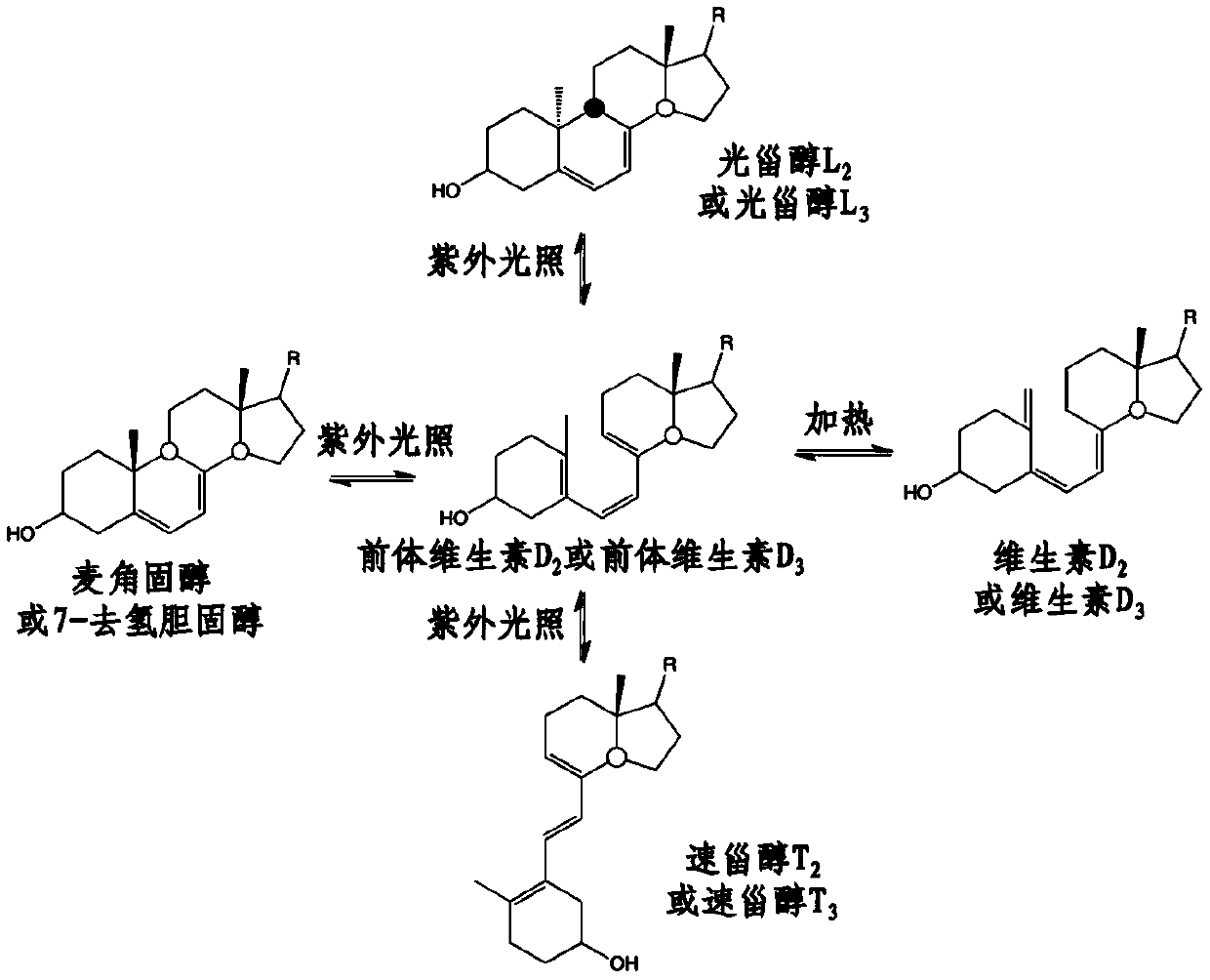

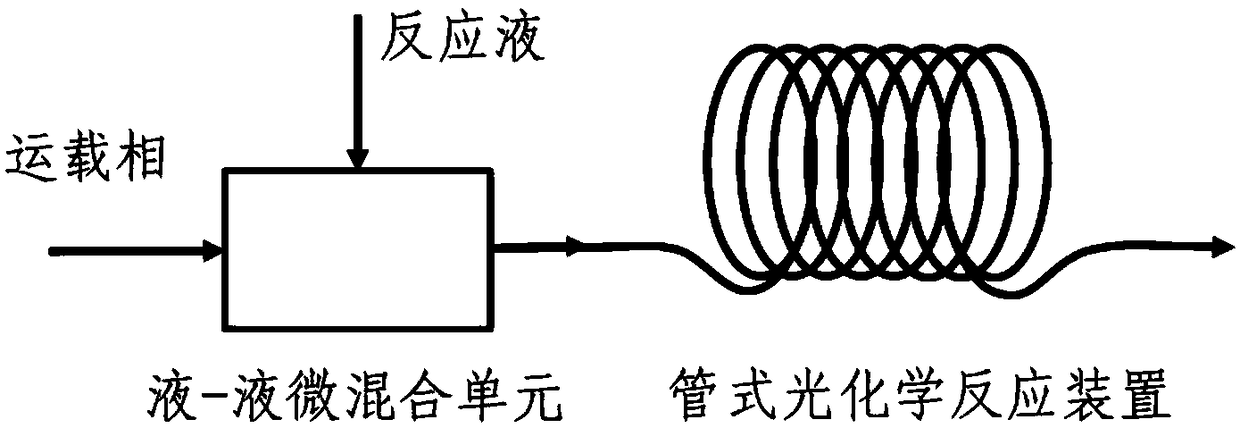

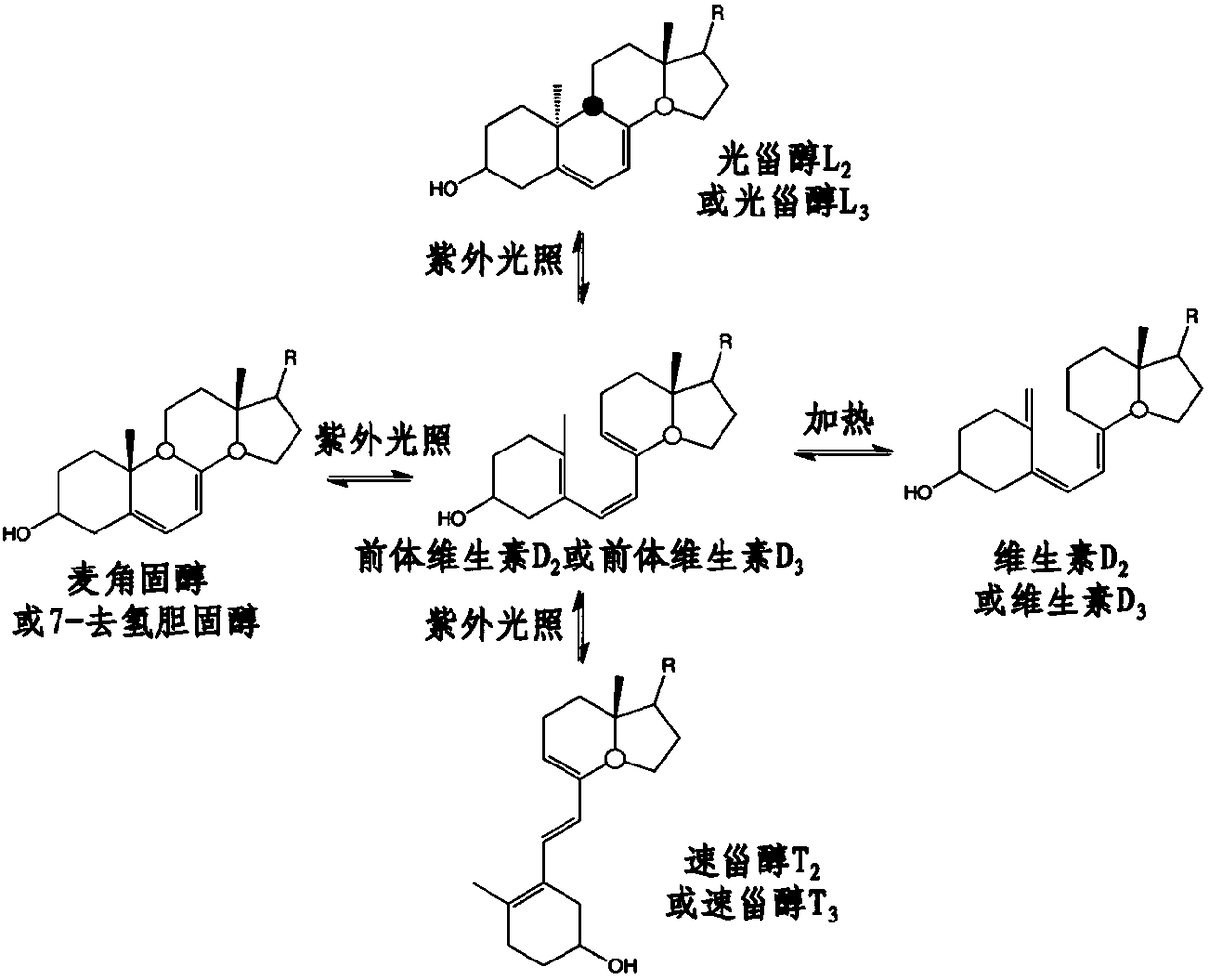

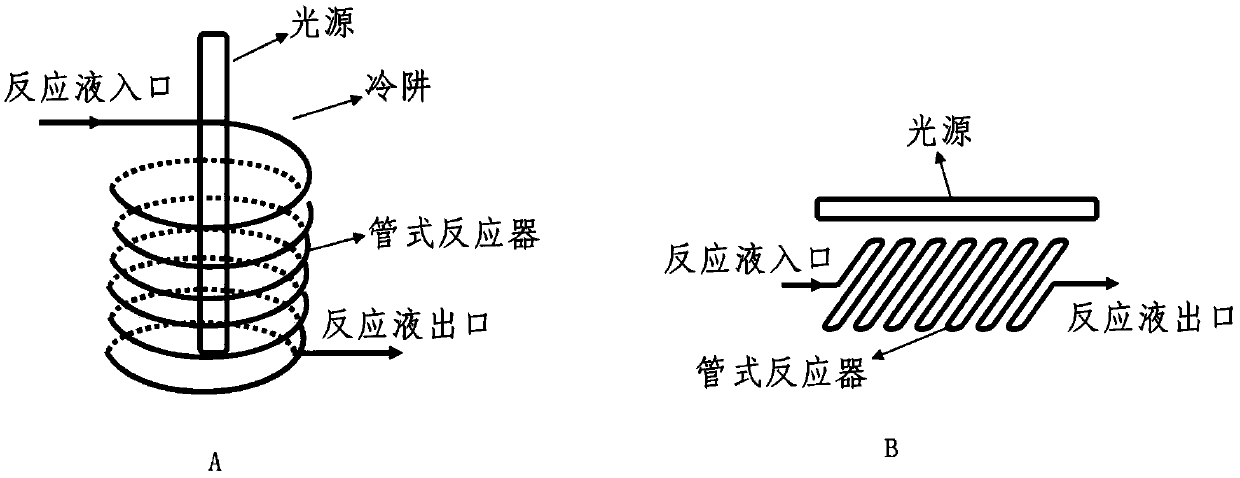

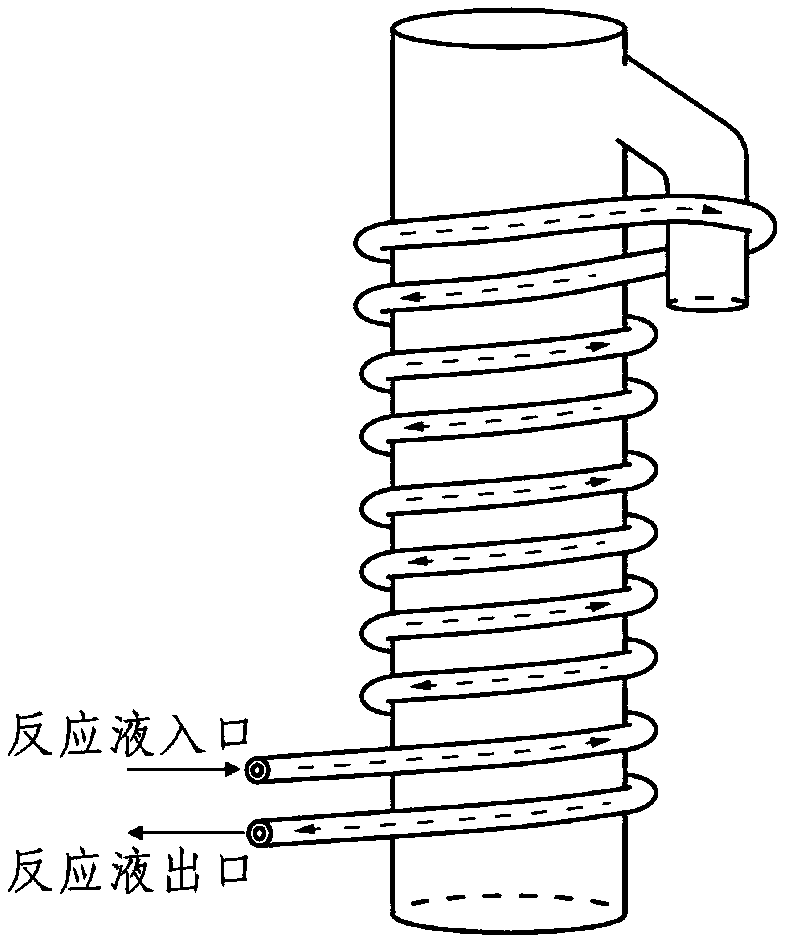

Method for photochemically synthesizing vitamin D2 and D3 in tubular reactor

The invention relates to a method for photochemically synthesizing vitamin D2 and D3 in a tubular reactor. The method is characterized in that the vitamin D2 and D3 are synthesized by ultraviolet light of different bands, the residence time of reaction liquid fed at different times in the tubular reactor is controlled to be the same by not dissolving with reaction liquid, not participating in reaction liquid separation and carrying ergosterol and 7-dehydrocholesterol reaction liquid and enhancing internal disturbance of the reaction liquid; the method has the advantages of continuous, stable and high efficiency of solar energy utilization, the operation is simple, and the process is controllable; the method has great prospect in the industrial production of the photochemically synthesizedvitamin D2 and D3.

Owner:SHANDONG TSINGCHUANG CHEMICALSCO LTD +1

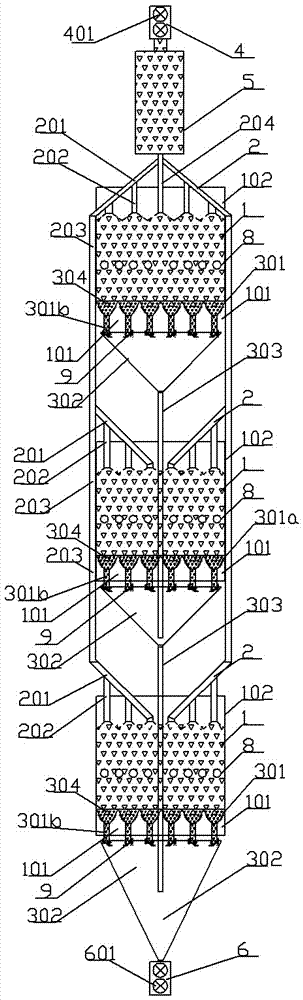

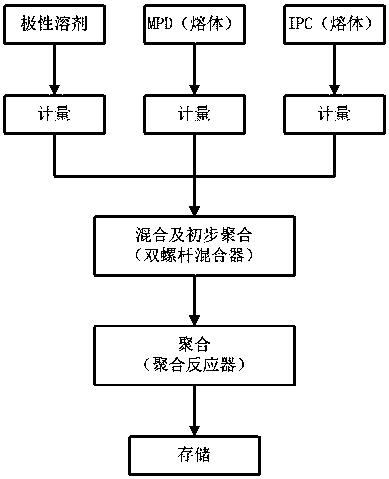

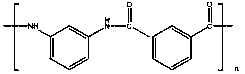

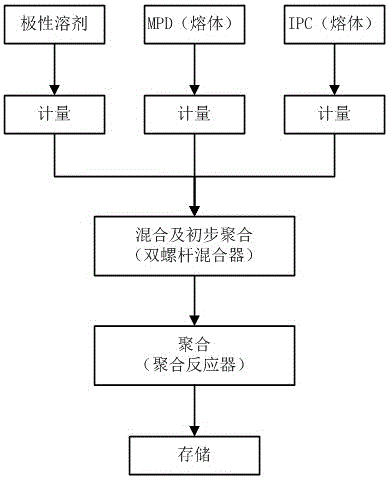

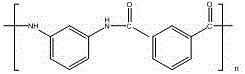

Method for continuously preparing highly-pure poly(m-phenylene isophthalamide) resin solution

The invention relates to a method for continuously preparing a highly-pure poly(m-phenylene isophthalamide) resin solution. The method comprises the following steps: respectively metering and conveying a polar solvent, m-phenylenediamine and m-phthaloyl chloride, allowing above materials to enter a double screw mixer, mixing the materials, carrying out a preliminary reaction to generate oligomer, allowing the oligomer to enter a polymerization reactor from the bottom end, continuously carrying out the reaction for a period of time, and allowing the formed poly(m-phenylene isophthalamide) resin solution to flow out from the upper lateral part of the polymerization reactor. The method can reduce at least one double screw reactor needed in the prior art, reduces the device investment cost, and realizes continuous preparation of the poly(m-phenylene isophthalamide) resin solution with uniform viscosity and high purity.

Owner:SHANGHAI HUIBO NEW MATERIAL SCI & TECH

Gas separation flow system and gas separation flow method for photochemical synthesis of 9-beta,10-alpha-dehydroprogesterone ketal

The invention relates to a gas separation flow system and a gas separation flow method for photochemical synthesis of 9-beta,10-alpha-dehydroprogesterone ketal. The method is characterized in that 9-beta,10-alpha-dehydroprogesterone ketal is synthesized in one step or two steps by utilizing ultraviolet light with different wave bands, a raw material 9-alpha,10-beta-dehydroprogesterone ketal reaction solution is separated by gas doing not participate in a reaction, the internal disturbance of the reaction solution is enhanced, and the retention time of the reaction solution in a tubular reactoris ensured to be consistent. The method has the advantages of being continuous, stable, high in light energy utilization rate, low in production cost, easy and convenient to operate and controllablein process, and has huge prospect in the industrial production of 9-beta,10-alpha-dehydroprogesterone ketal through photochemical synthesis.

Owner:SHANDONG TSINGCHUANG CHEMICALSCO LTD +2

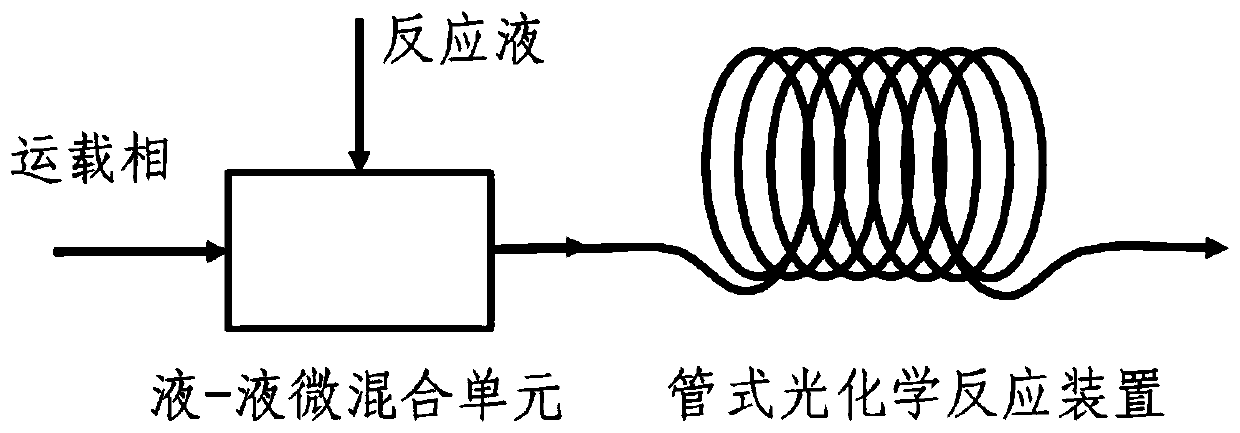

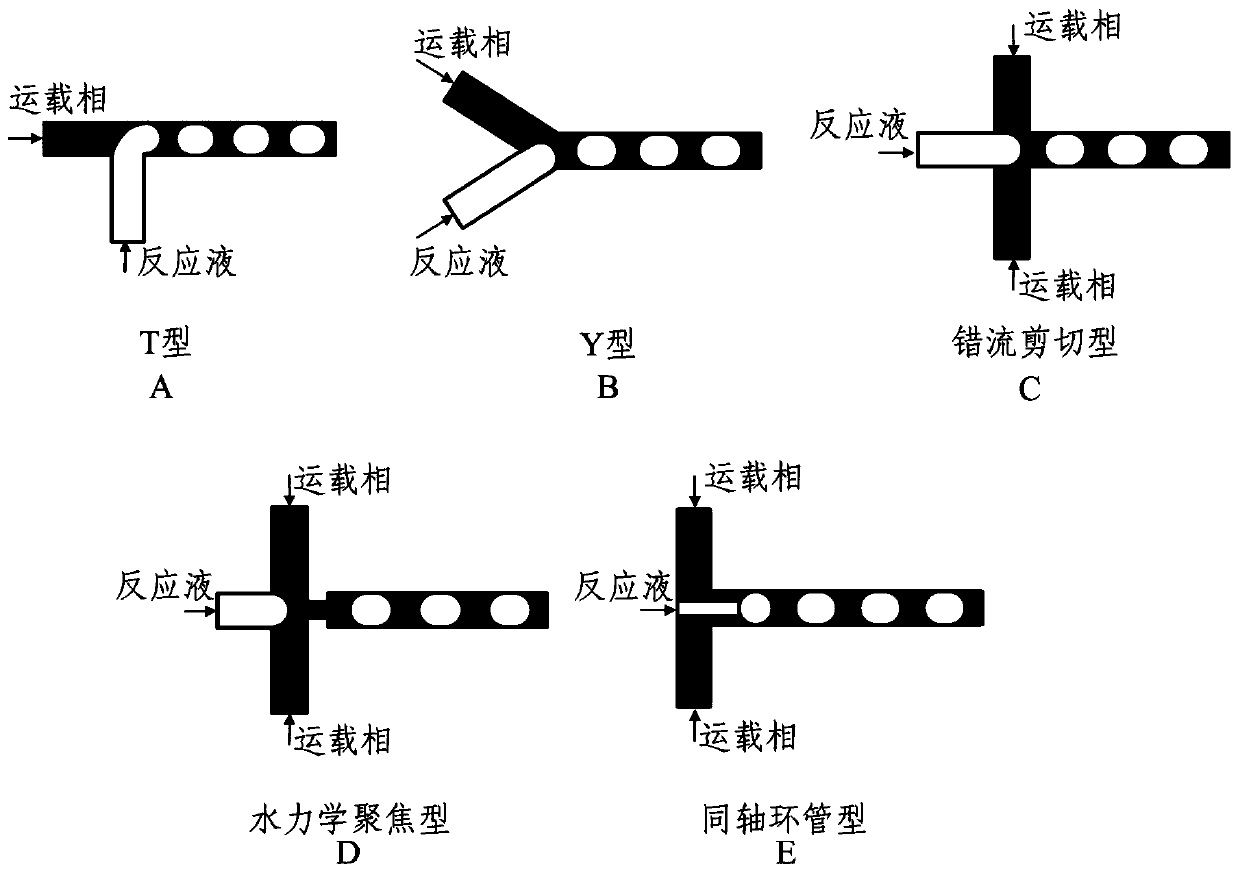

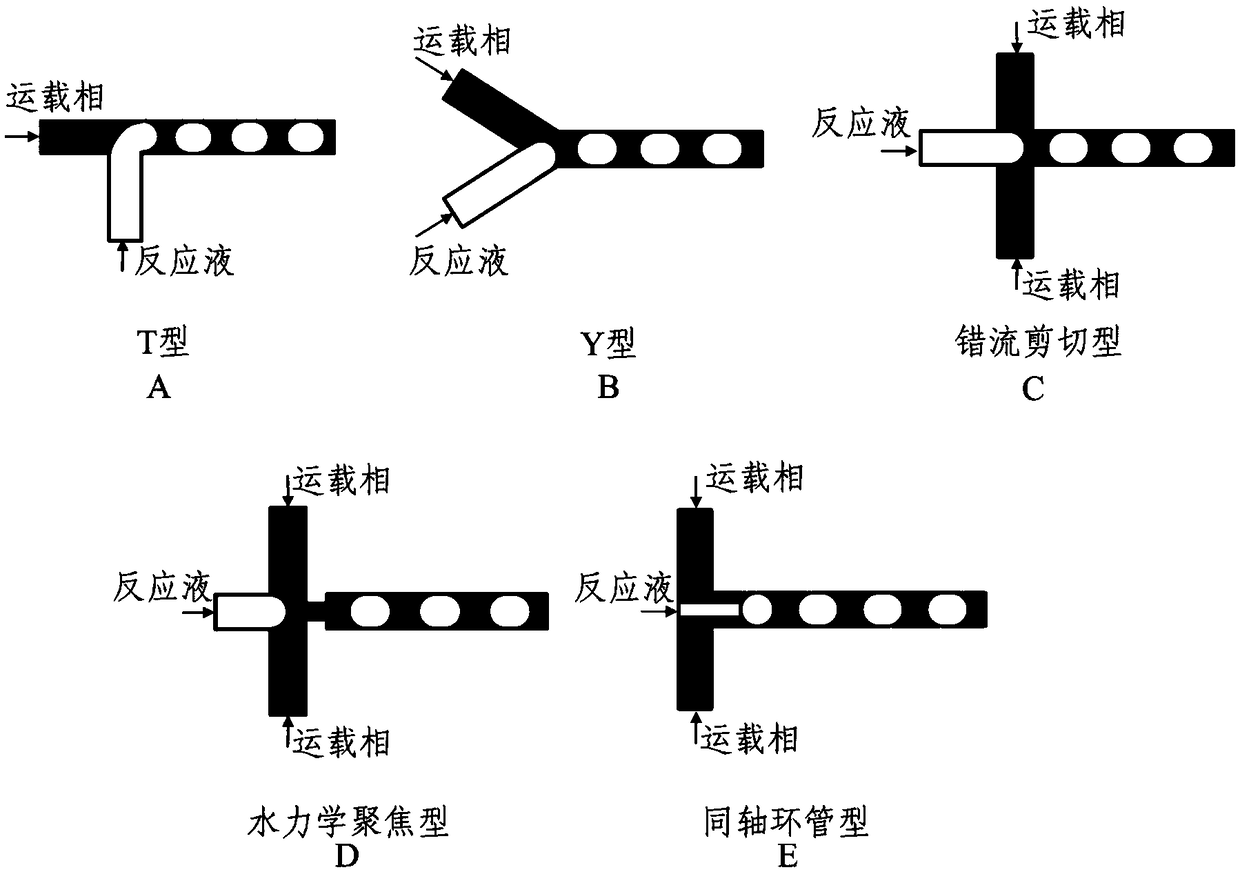

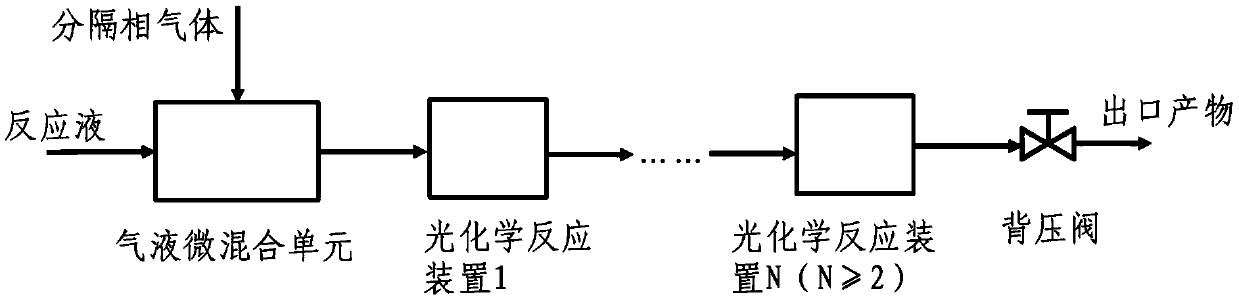

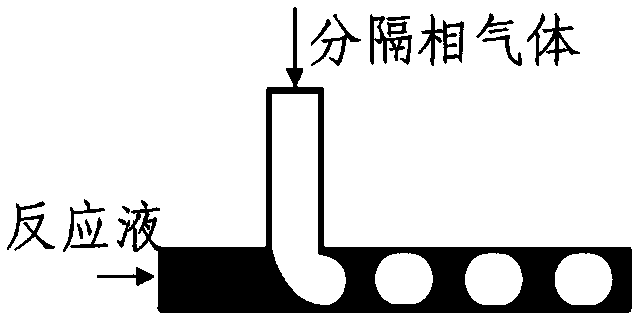

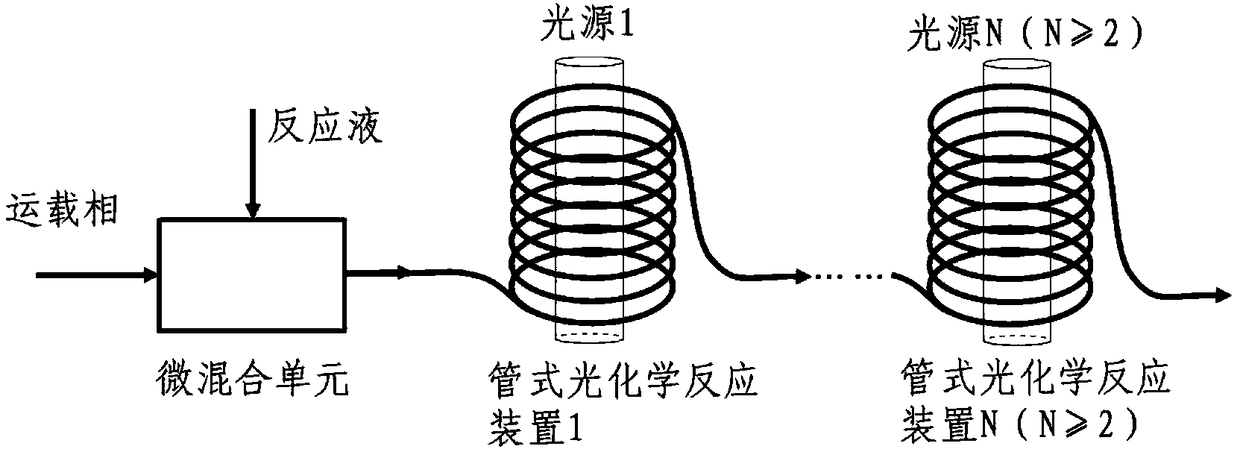

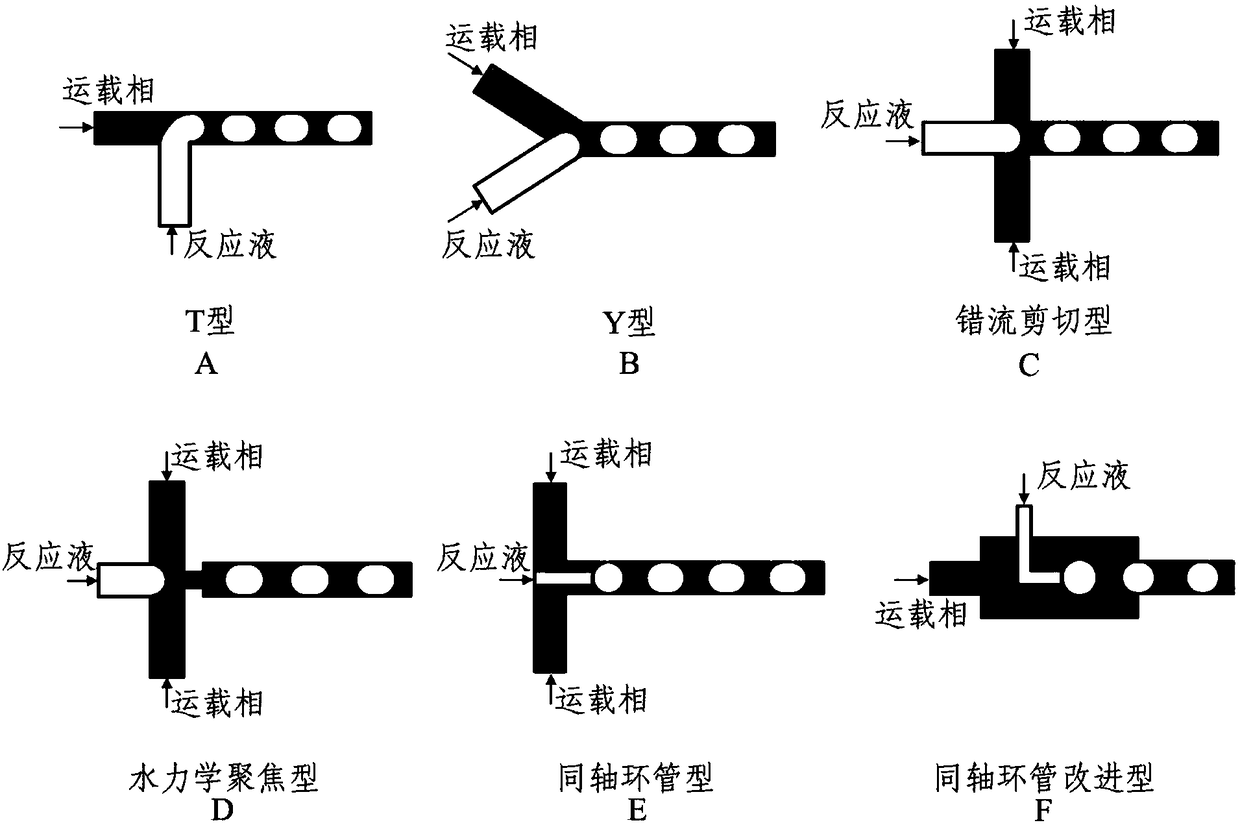

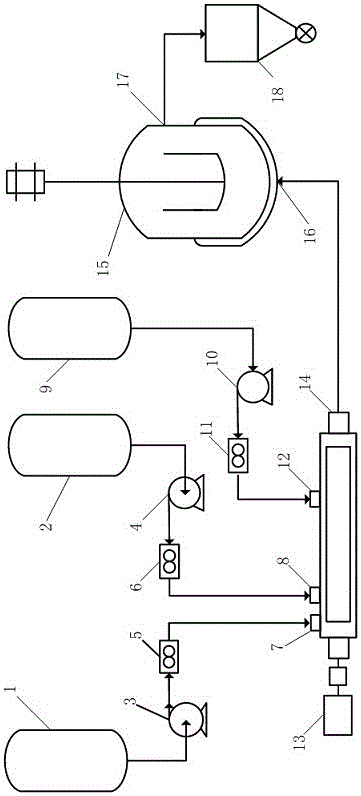

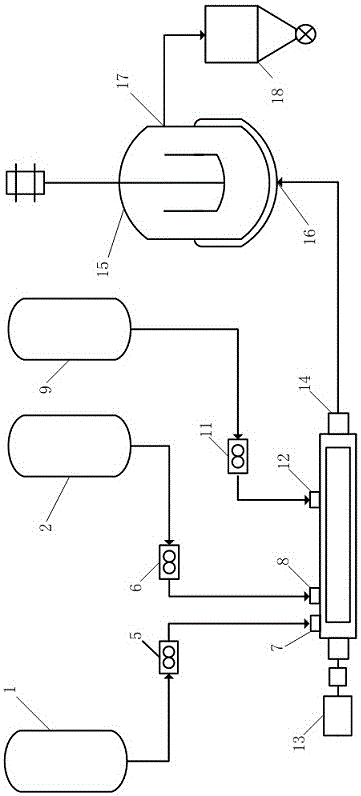

Micro-mixing system and method for photochemical reaction in tubular reactor

PendingCN108993342ASame dwell timeAvoid it happening againChemical/physical/physico-chemical microreactorsEnergy based chemical/physical/physico-chemical processesChemical reactionGas phase

The invention relates to micro-mixing system and method for a photochemical reaction in a tubular reactor. The system is composed of a micro-mixing unit and a tubular photochemical reaction apparatusthat are connected in series. In the micro-mixing unit, a gas-phase or liquid-phase carrier, that is insoluble with a reaction liquid, can shear the reaction liquid into liquid columns. The system iscontinuous and stable and has high photo-energy utilization rate. By means of the system, the reaction liquid can be fully irradiated under a light source, wherein internal disturbance in the reactionliquid is effectively reinforced, and the photochemical synthesis process is enhanced. The system is low in production cost, is simple in operation and is controllable in process, and has great prospect in industrial application of photochemical reaction.

Owner:SHANDONG TSINGCHUANG CHEMICALSCO LTD

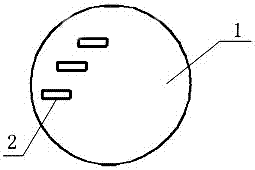

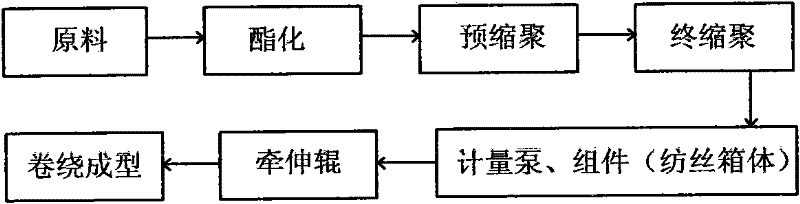

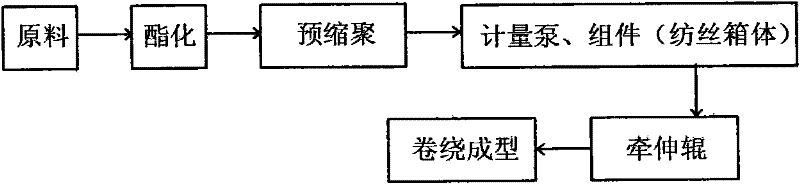

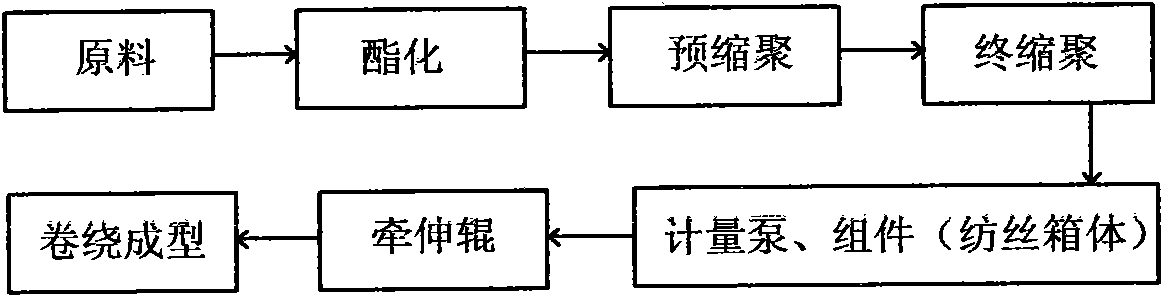

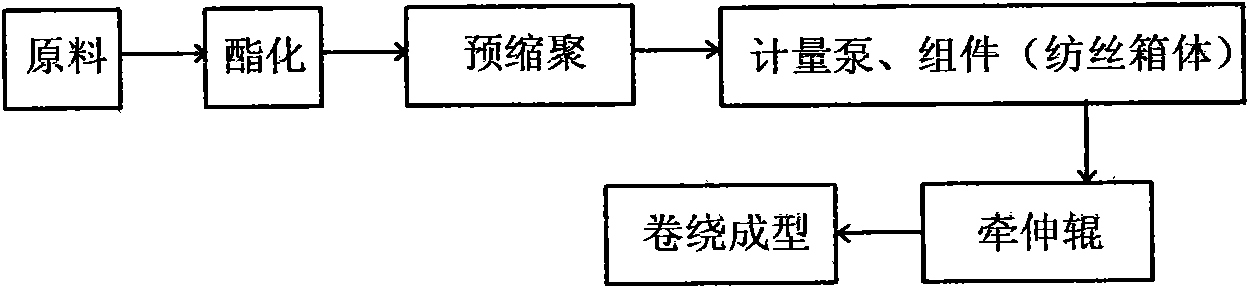

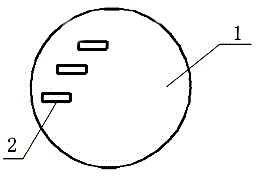

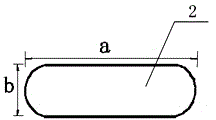

Production method of melt direct spinning flat polyester industrial filaments

ActiveCN104451918AShort processLess investmentMelt spinning methodsMonocomponent polyesters artificial filamentYarnPolyester

The invention discloses a production method of melt direct spinning flat polyester industrial filaments. A spinneret plate with special '-' shaped section spinneret orifice is applied. Products are made by tackifying of molten fluid, melt spinning and tension winding molding. By using the production method of melt direct spinning flat polyester industrial filaments, the reaction time is decreased, technological process is effectively lessened, the efficiency is increased, energy consumption is reduced, and the cohesive property is greatly increased on the basis of keeping advantages of common industrial yarn. Because of the approximate rectangle section, the space between yarns is small, the contact area is added, the arrangement is more smooth and compact, and thus the yarn has great raw erectness and high cohesive property, relative good bending rigidity and flexibility. Because of compact arrangement of yarns and increased flatness, the aesthetics after blade coating is greatly increased, the production process is reduced and the production art is simplified.

Owner:ZHEJIANG UNIFULL IND FIBER

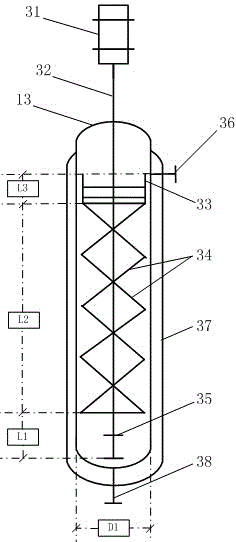

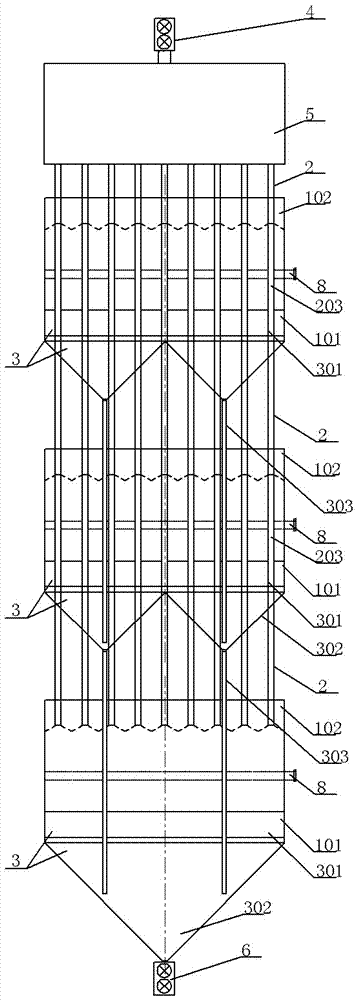

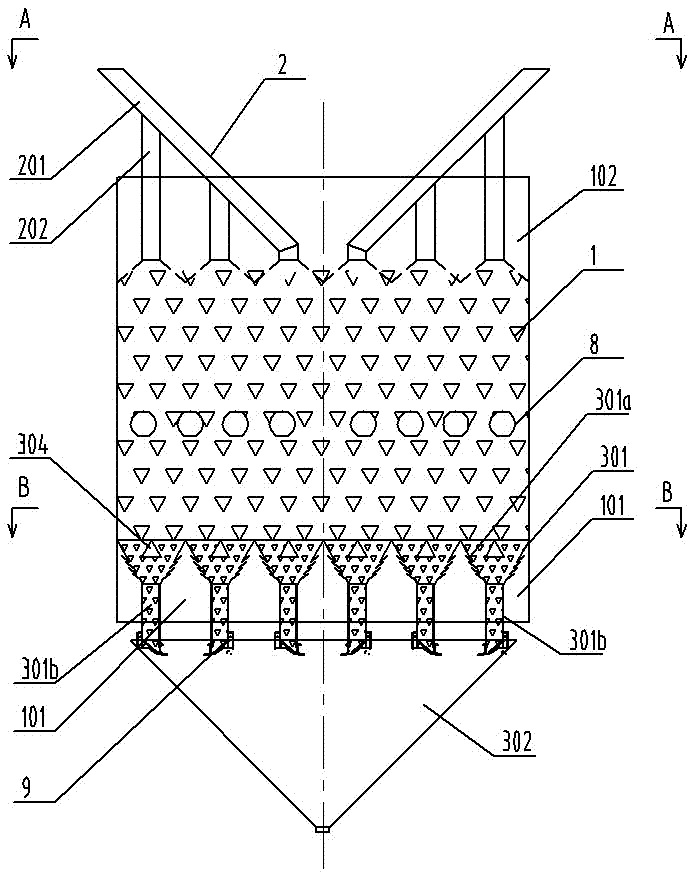

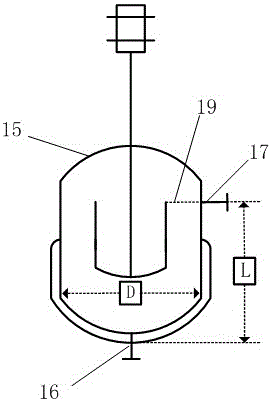

Device for continuously preparing high-purity polyisophthaloyl metaphenylene diamine resin solution

ActiveCN106076232ALow costSame dwell timeChemical/physical/physico-chemical stationary reactorsFeed devicesChlorideSolvent

The invention relates to a device for continuously preparing a high-purity polyisophthaloyl metaphenylene diamine resin solution. The device comprises a solvent metering conveying system, an m-phenylenediamine metering conveying system, an m-phthaloyl chloride metering conveying system, a double-screw mixer and a polymerization reactor, wherein the double-screw mixer is cooperated with the polymerization reactor for use; the polymerization reactor adopts a mode that materials are fed from the bottom and discharged from the upper side part; the investment cost of equipment is reduced; the polyisophthaloyl metaphenylene diamine resin solution with uniform viscosity can be continuously prepared.

Owner:SHANGHAI HUIBO NEW MATERIAL SCI & TECH

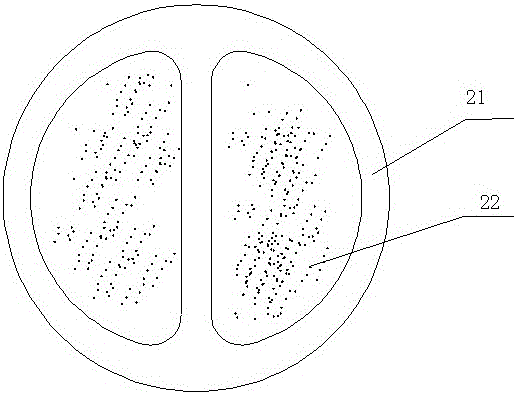

Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer

ActiveCN103601886ASolve the problem of low molecular weightHigh molecular weightMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention relates to a preparation method of a poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer. The preparation method comprises two steps of prepolymerization reaction and post-polycondensation reaction. The reaction time of a prepolymer in a double-screw extruder is 10-60 minutes, and the double-screw extruder is provided with three temperature zones according to a sequence from a feeding port to a discharging port, wherein the temperatures of the tree temperature zones are respectively 160-180 DEG C, 180-190 DEG C and 190-200 DEG C. According to the preparation method, the double-screw extruder is used for carrying out the post-polycondensation reaction, and specific temperature and time are used for controlling parameters, so that the intrinsic viscosity [eta] of the PIPD polymer obtained in the end is 28-30dL / g, the molecular weight of the polymer is greatly increased, meanwhile, the stirring is facilitated, and the PIPD polymer can be easily conveyed and transferred to a spinning working section, thus the production efficiency is improved, and the production cost is reduced.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

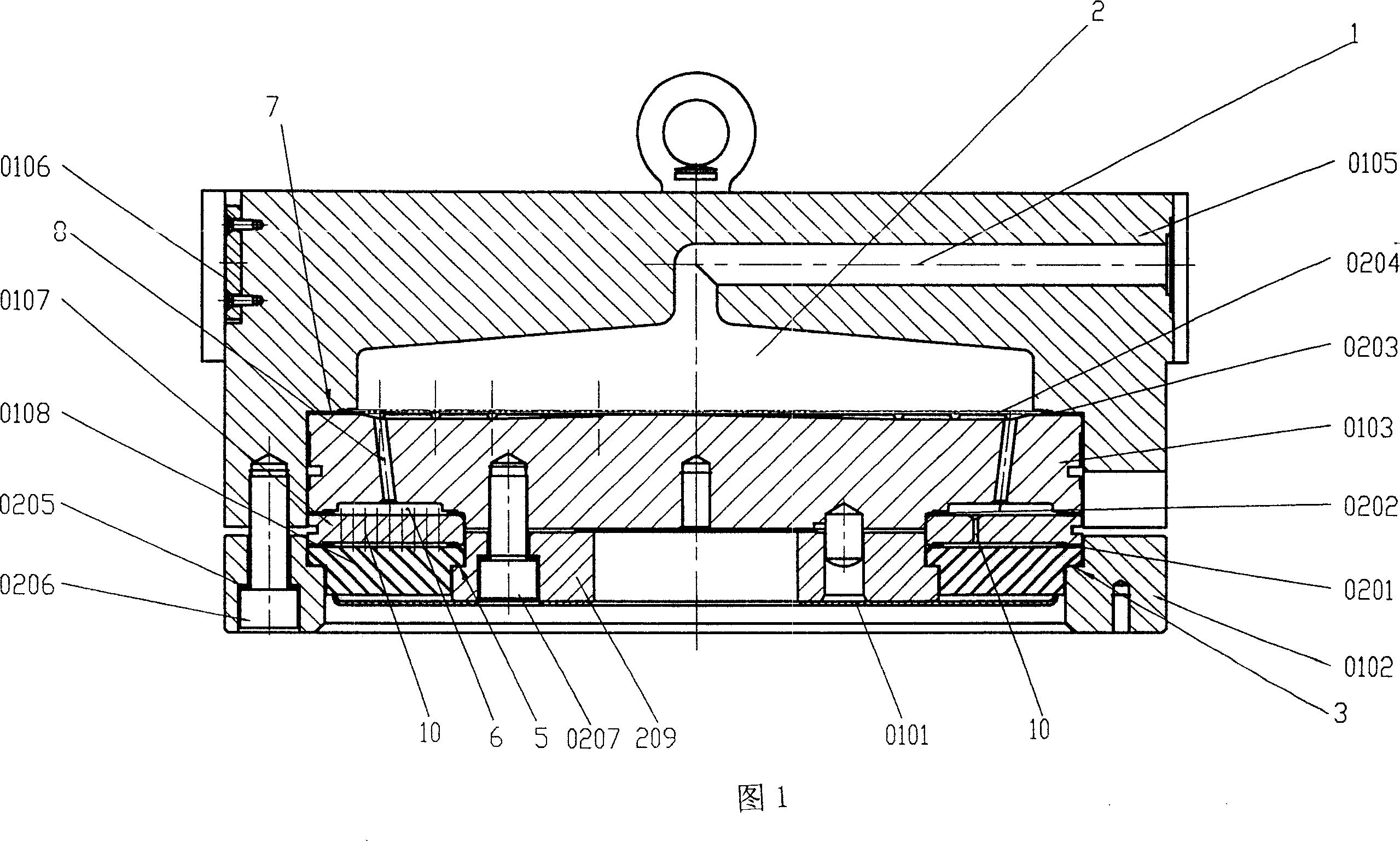

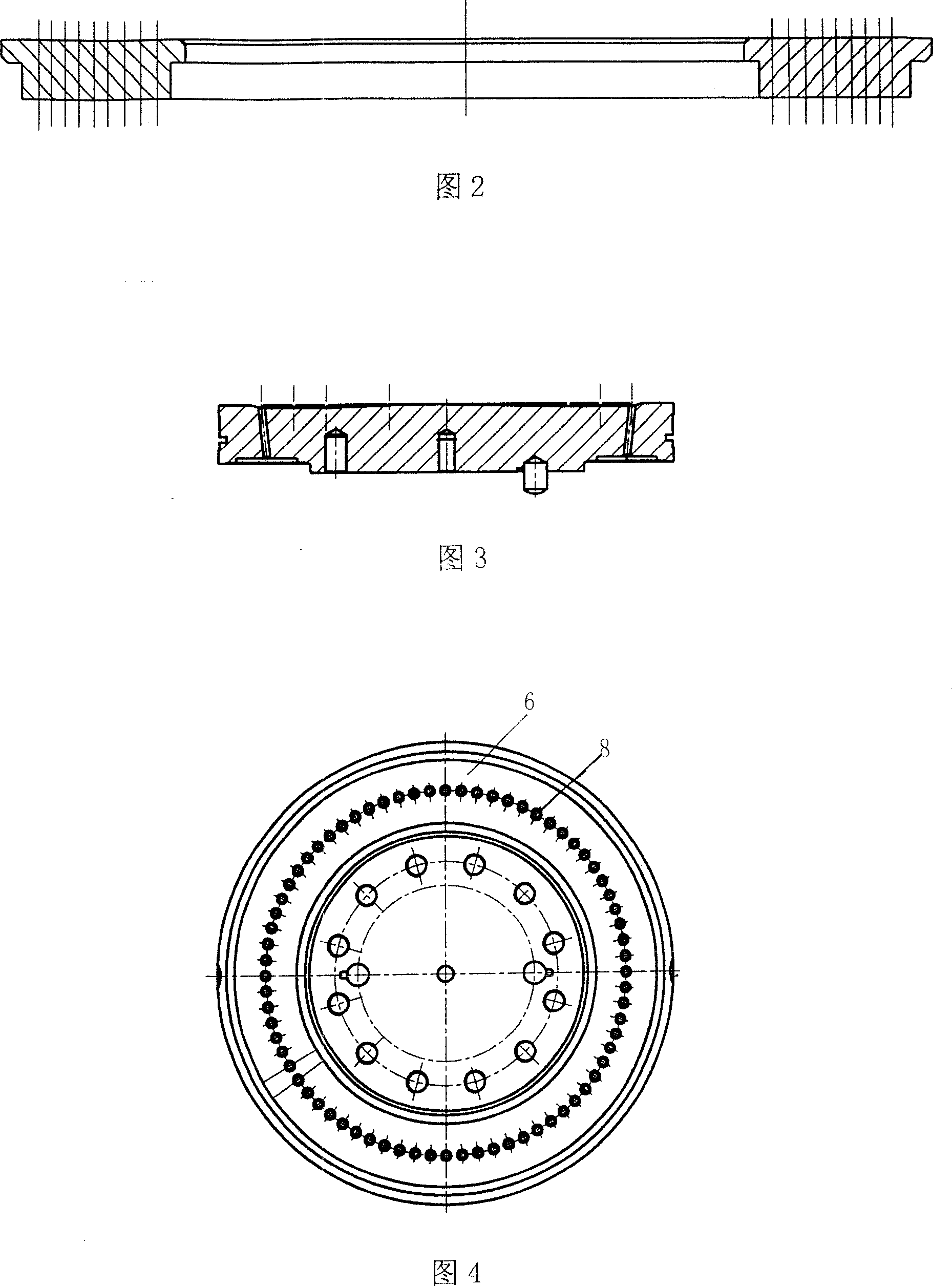

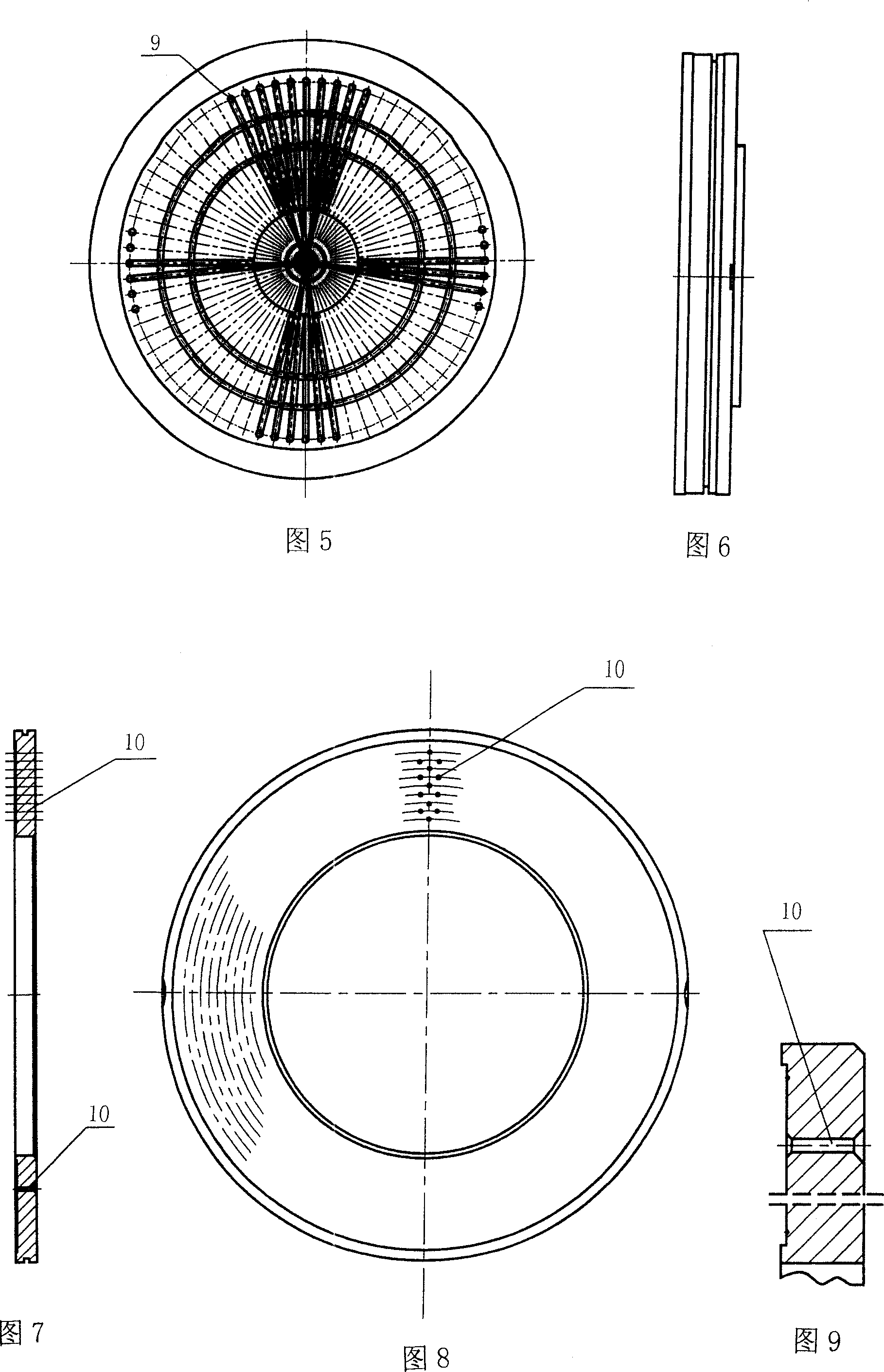

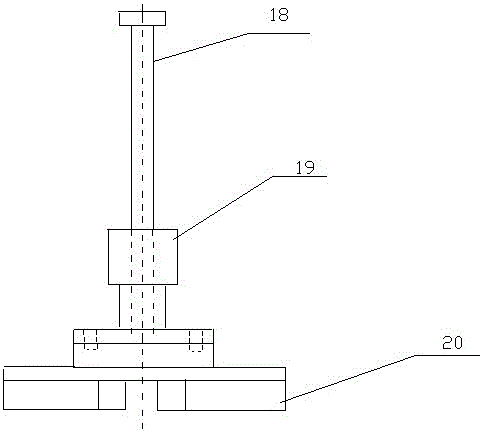

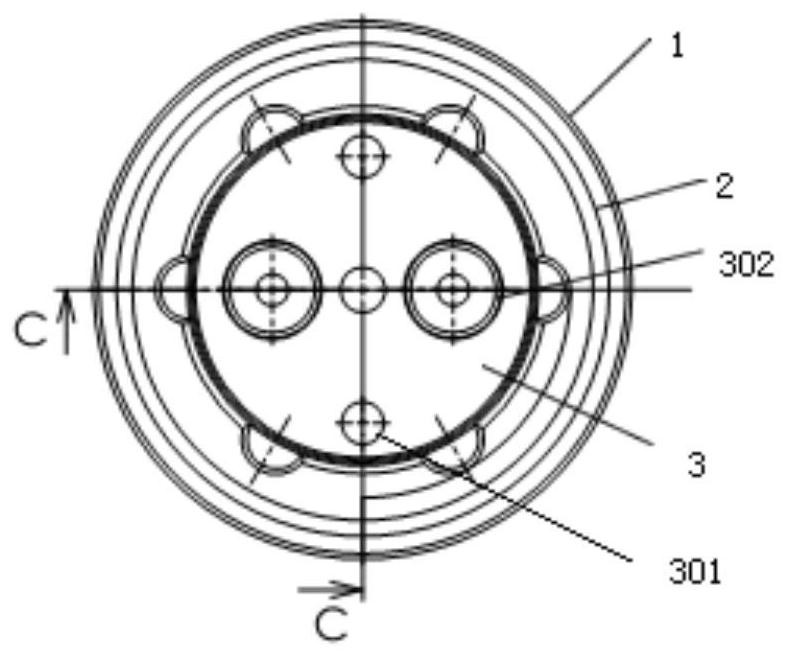

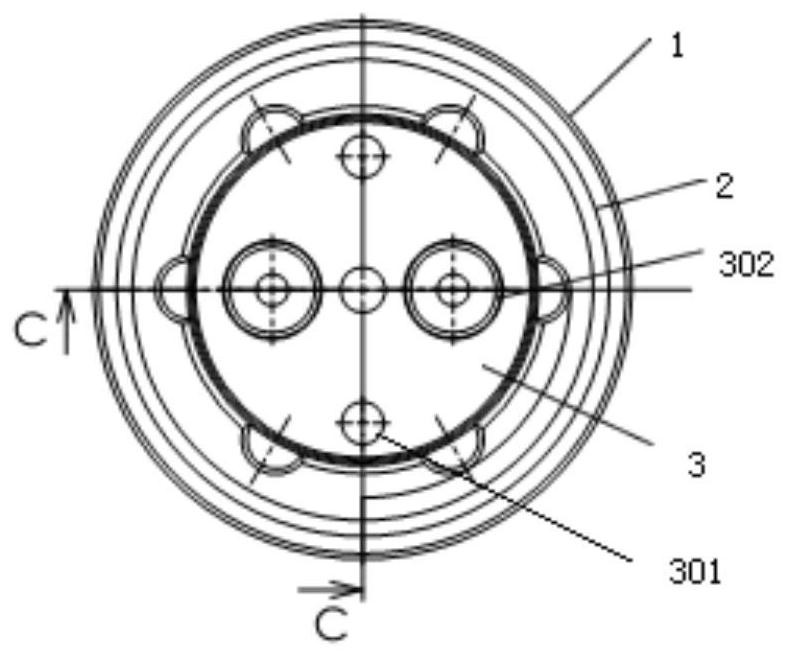

Bolt fastening type high-productivity compact top-mounted spinning assembly

ActiveCN100368606CBest pressure dropSame dwell timeSpinnerette packsInternal pressureMechanical engineering

The invention discloses spinning components of bolt-fixing pattern to produce over 170 tons daily, which is characterized by the following: connecting head-cap seat (0105) and external ring of external pressure ring (0102) through high-strength bolt (206); opening melt canal (1) and distribution-cavity (2) in connection with melt canal (1) on the seat body of head-cap seat (0105); connecting the internal pressure ring (209) and pressure-resistant demarcation strip (0103) through high-strength bolt (0207) in order to locate the spinning plate (0108), demarcation strip (0107) and demarcation strip (0103) within the component of head-cap seat (0105) and external pressure ring (0102). The spinning component structure is simple and the bulk is small, which keeps stable productivity.

Owner:SINOPEC YIZHENG CHEM FIBER

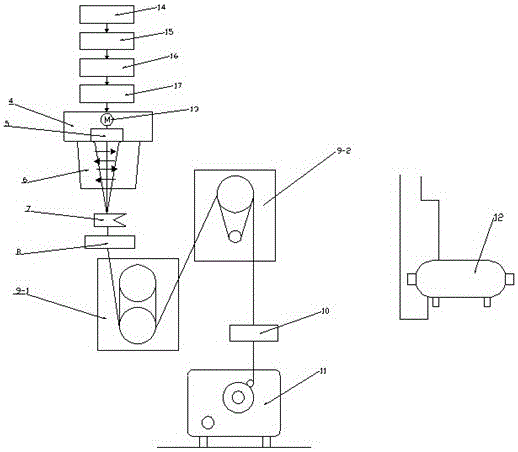

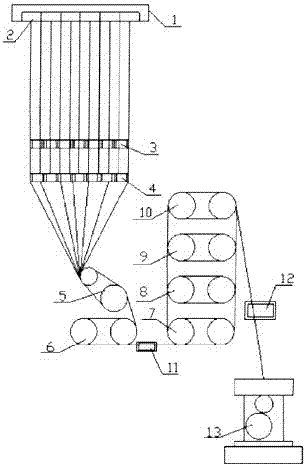

Ultra-fine denier fdy spinning equipment and technology

ActiveCN104141175BIncrease success rateSame dwell timeSpinnerette packsArtificial thread manufacturing machinesYarnMetering pump

The invention relates to a textile equipment and a process thereof, in particular to an ultra-fine denier FDY spinning equipment and a process thereof, belonging to the field of textiles. Ultra-fine denier FDY spinning equipment mainly includes melt conveying equipment and spinning equipment. The melt conveying equipment mainly includes melt filters, booster pumps, and melt heat exchangers. The spinning equipment mainly includes spinning boxes , metering pumps, spinning components, ring blowing devices and biphenyl evaporators. Process steps: (1), melt conveying, (2), metering, filtering, extrusion, (3), cooling and solidification, (4), cluster oiling, (5), network, winding. The present invention improves the equipment and process simultaneously, so that the success rate of assembly on the machine is high, the cross section of the finished yarn is normal, the number of hairs is less, the index and the like can be significantly improved, and the product quality is improved.

Owner:JIANGSU DELI CHEM FIBER CO LTD

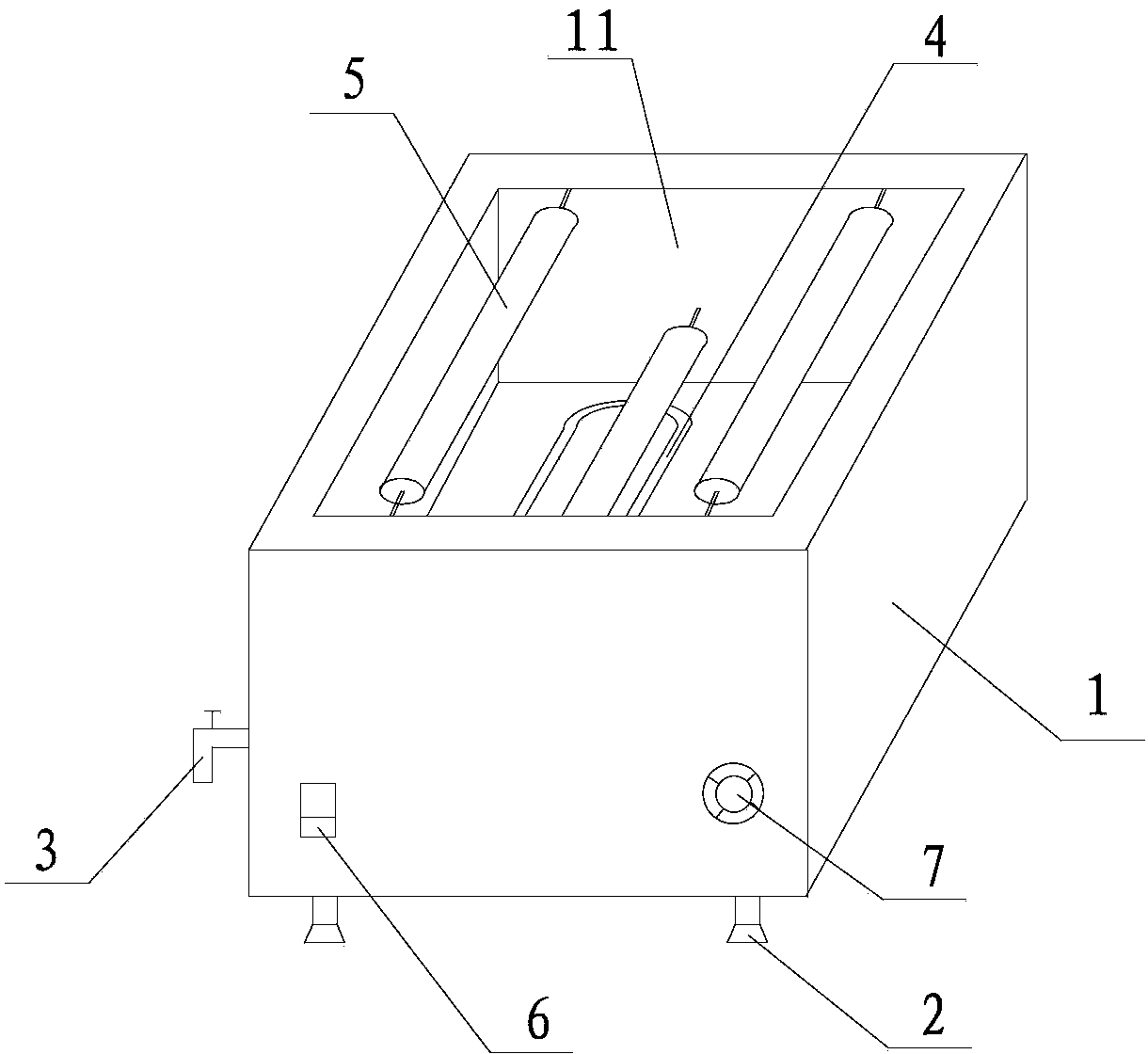

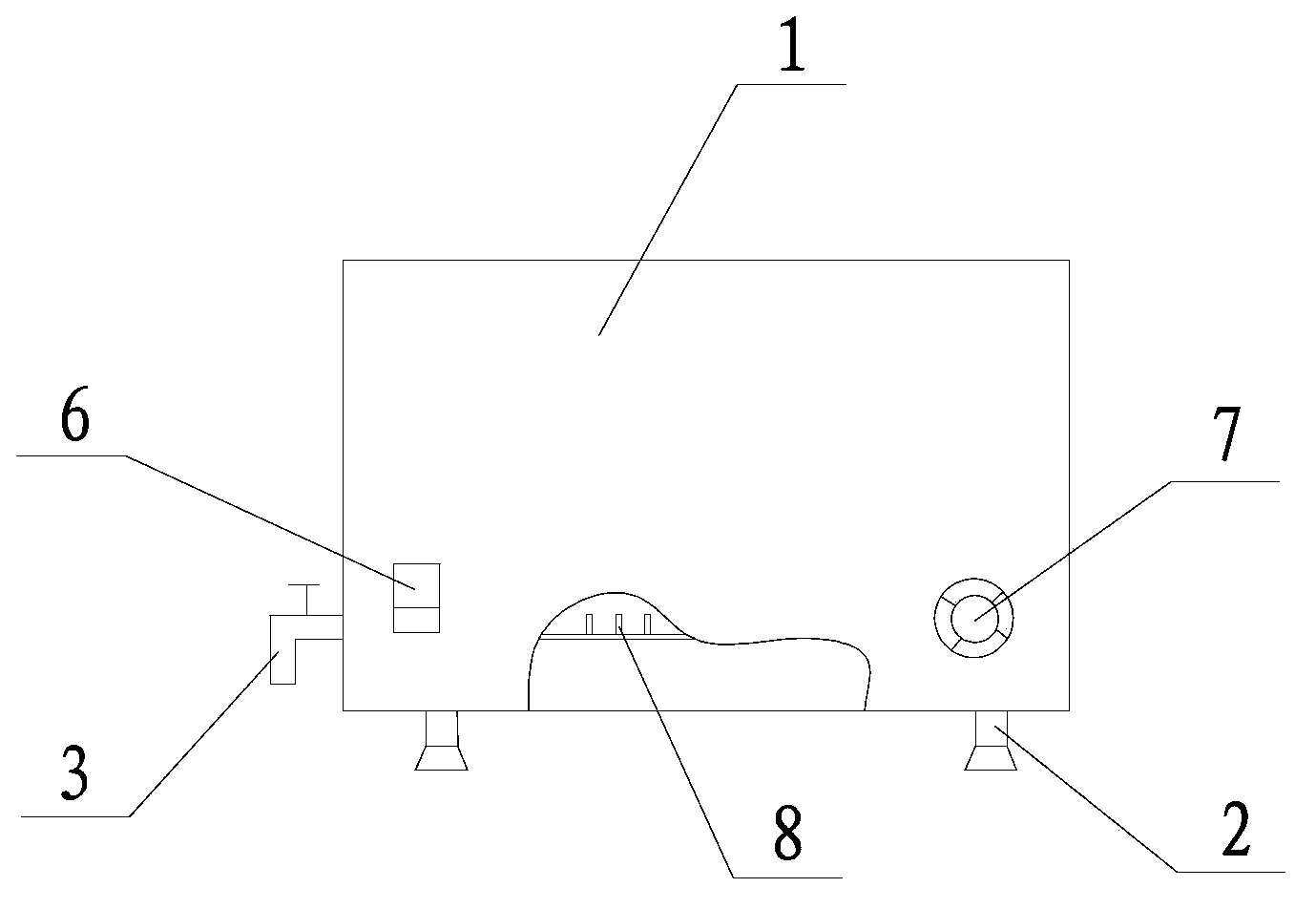

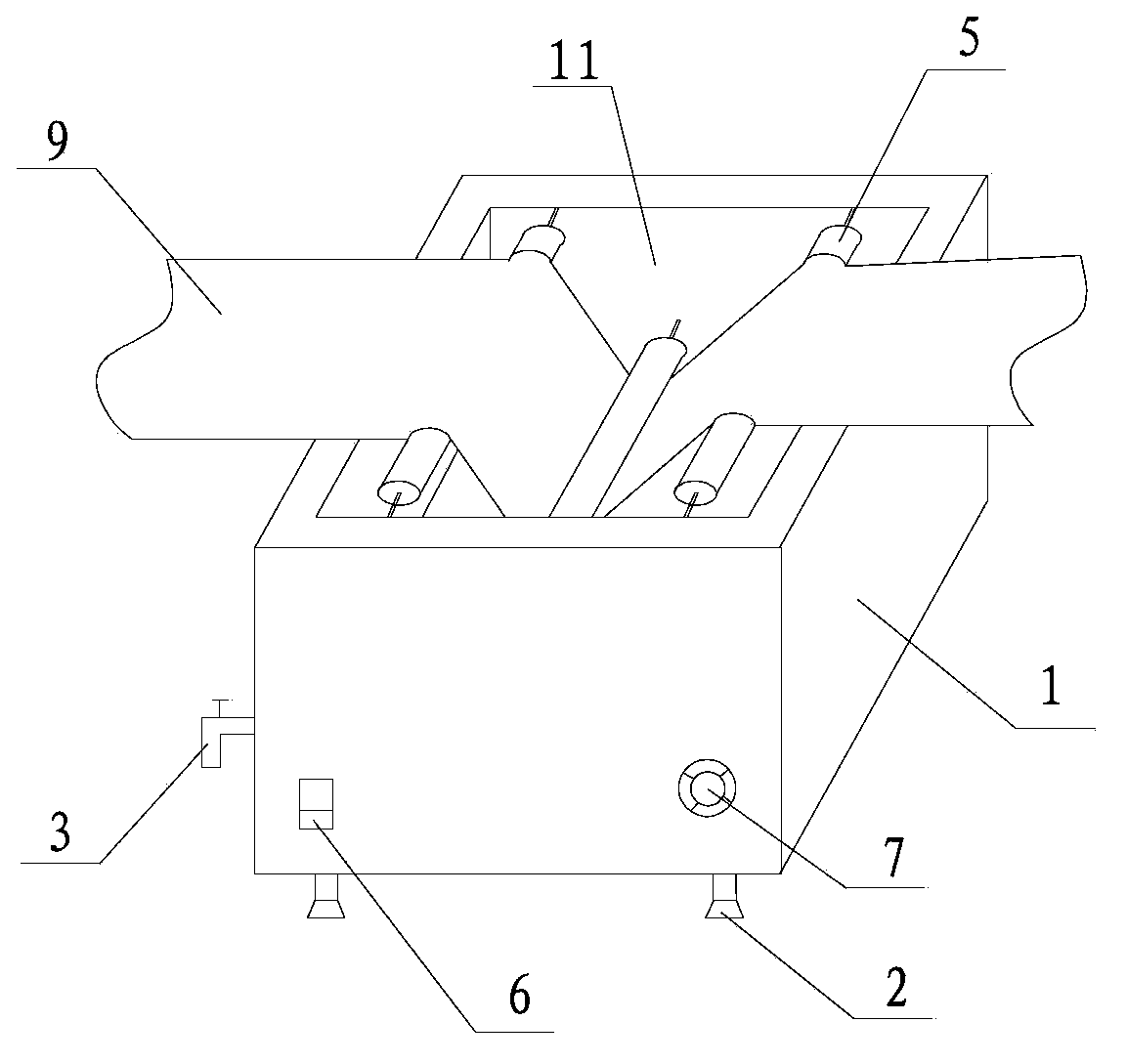

Coral velvet cloth dyeing device

InactiveCN103352340ASame dwell timeSimple structureTextile treatment carriersLiquid/gas/vapor textile treatmentState of artRetention time

The invention relates to a coral velvet cloth dyeing device which comprises a box body, a liquid storage tank, a base, a liquid outlet, a heater, three idler wheels, a power source switch and a temperature regulation switch. The liquid storage tank is arranged on the top face of the box body in a concave mode and used for containing a dye solution, the base is fixed at the bottom of the box body and used for supporting the box body, the liquid outlet is formed in the lower portion of the side face of the box body and used for discharging the dye solution in the liquid storage tank, the heater is arranged at the bottom of the liquid storage tank and used for heating the dye solution, the three idler wheels in parallel mutually are installed on the side wall of the liquid storage tank in a rotatable mode and used for providing tension for coral velvet cloth, and the power source switch and the temperature regulation switch are arranged on the side face of the box body. Two of the three idler wheels are fixed on the two sides of the upper portion of the liquid storage tank, and another one is fixed in the center of the lower portion of the liquid storage tank. By the adoption of the technical scheme, compared with the prior art, the coral velvet cloth dyeing device has the advantages of being simple in structure and low in cost, the three idler wheels effectively provide the tension for the coral velvet cloth and enable the coral velvet cloth to be taut, therefore the retention time of the coral velvet cloth in the dye solution is same, and dyeing is even.

Owner:CHANGSHU HULIAN PRINTING & DYEING

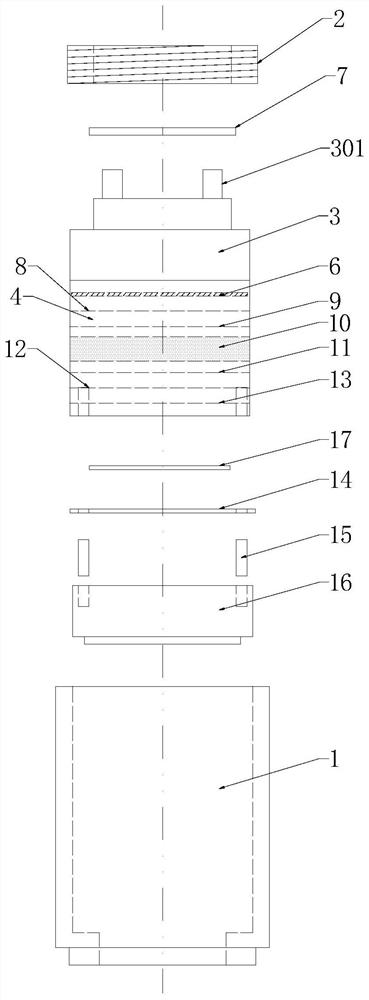

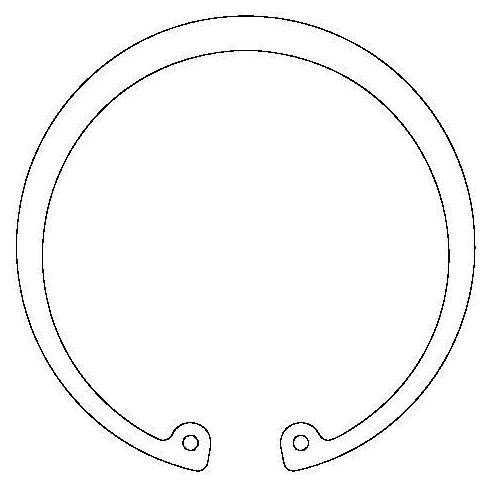

Spinning assembly for polyester fibers and assembling device and method thereof

ActiveCN112647138AHigh success rateImprove dispersion uniformitySpinning solution de-aeratingSpinnerette packsPolyesterFiber

The invention relates to a spinning assembly for polyester fibers and an assembling device and method thereof. The spinning assembly comprises an assembly body, and a fastening ring, a limiting pin, an upper cover, a sand cup sleeve piece, a spot welding net, a sealing gasket, a positioning pin I and a spinneret plate are sequentially arranged in the assembly body; the sand cup sleeve piece comprises a sand cup, and a pressing block, a sealing ring, a single-layer net, filter sand, an extrusion ring, an edge covering net sheet and a single-layer coarse net sheet which are sequentially arranged in the sand cup; a spring retainer ring is arranged between the fastening ring and the upper cover, and is buckled and pressed on the upper cover by the fastening ring; the spring retainer ring is in a C shape, and holes are formed in the inner sides of C-shaped openings respectively; and two concave cavities are formed in the outer bottom of the sand cup, bosses are arranged on the peripheries of the two concave cavities, and continuous grooves are formed in the upper surfaces of the bosses. According to the spinning assembly for the polyester fibers, an automatic integrated device capable of evenly stabilizing the internal pressure of the assembly is used in the assembly process, it is guaranteed that the residence time of a melt in the assembly body is consistent, the melt fluidity is good, and the temperature difference of the surfaces of spinneret plates is small.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Device for continuously preparing high-purity meta-position aramid fiber resin solution

ActiveCN106084212ALow costSame dwell timeSpinning solutions preparationSecondary stageProcess engineering

The invention relates to a device for continuously preparing a high-purity meta-position aramid fiber resin solution. The device comprises a solvent metering and conveying system, a metaphenylene diamine metering and conveying system, an isophthaloyl dichloride metrering and conveying system, a mixing system, two stages of series connection polymerization reactors and the like. The primary-stage polymerization reactor and the secondary-stage polymerization reactor are provided with different combined stirrers, and a mode of bottom feeding and upper side discharging is adopted to the primary-stage polymerization reactor and the secondary-stage polymerization reactor. A double-screw reactor and other devices in the prior art are avoided, the effects that the equipment investment cost is reduced and the reaction time is stabilized are achieved, and the prepared meta-position aramid fiber resin solution is uniform in viscosity and high in purity.

Owner:吐鲁番市晶芳新材料科技有限公司

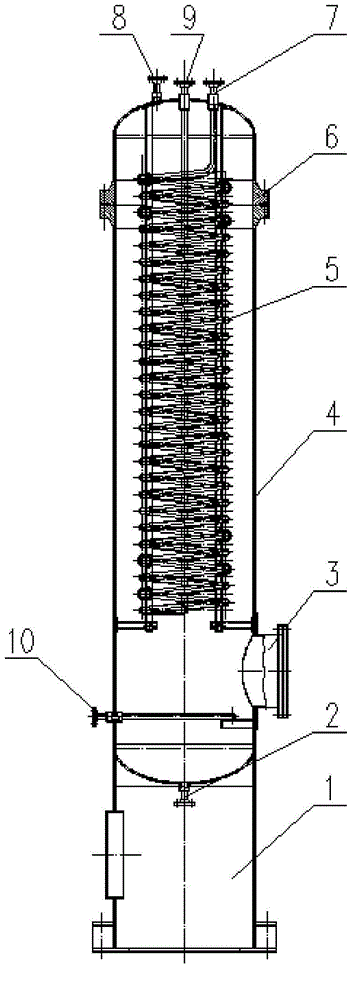

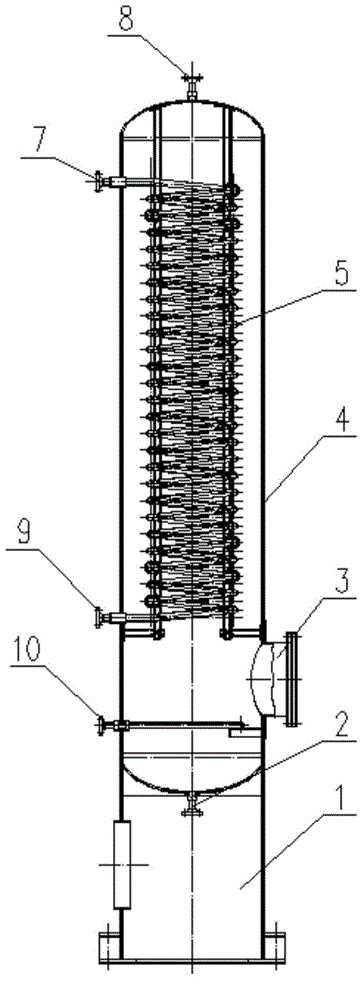

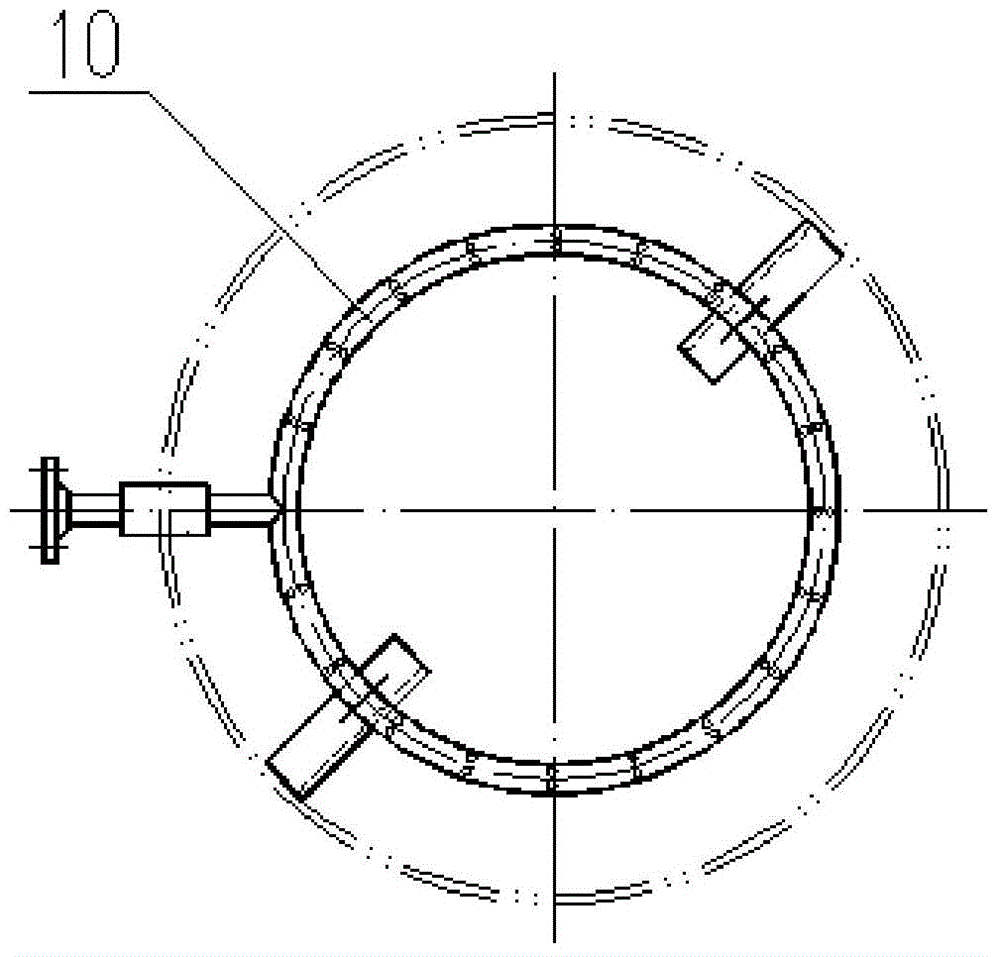

Hydrolysis reactor

InactiveCN104944556ASame dwell timeComplete hydrolysis reactionWater/sewage treatment by heatingCyanideRetention time

The present invention relates to a hydrolysis reactor, which is used for carrying out hydrolysis on cyanides in desulfurization waste liquids so as to reduce the cyanide content in the desulfurization waste liquid. The hydrolysis reactor comprises a tower body, a skirt, a heater and a waste liquid inlet, wherein the skirt is arranged below the tower body, the bottom portion of the tower body is provided with an emptying port, a waste liquid inlet is arranged above the emptying port and adopts an annular pipe so as to increase the material feeding uniformity, the lower portion of the tower body is provided with a manhole, the heater is arranged inside the tower body, adopts a hosepipe type heater, and is provided with a heating medium inlet and a heating medium outlet, and the top portion of the tower body is provided with a waste liquid outlet. With the hydrolysis reactor of the present invention, the cyanide in the desulfurization waste liquid and the water can be subjected to the hydrolysis reaction to decompose into harmless formate and ammonia, the waste liquid inlet adopts the annular pipe, it is ensured that the retention time of the waste liquid in the tower is the same, the heat exchange is uniform through the hosepipe type heater, and the cyanide hydrolysis reaction is complete.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

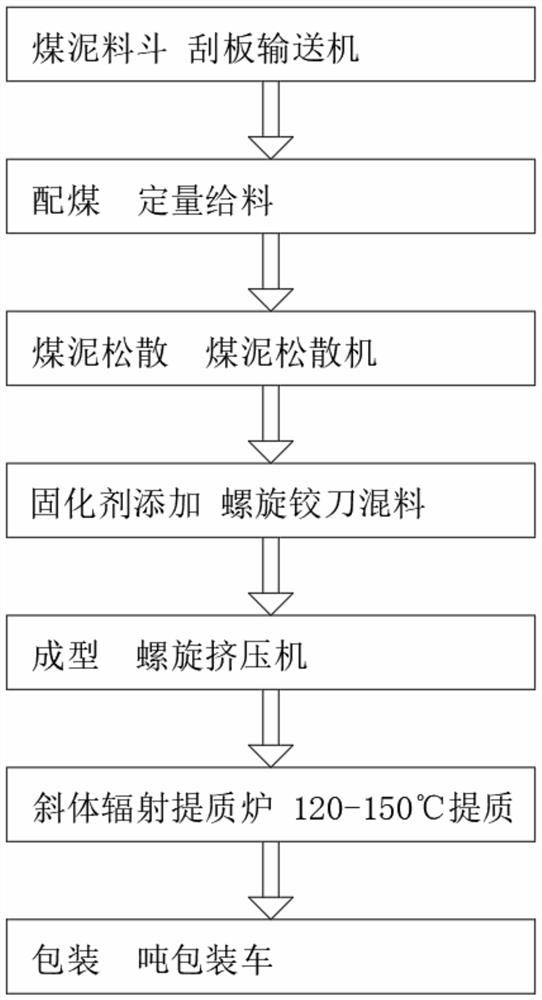

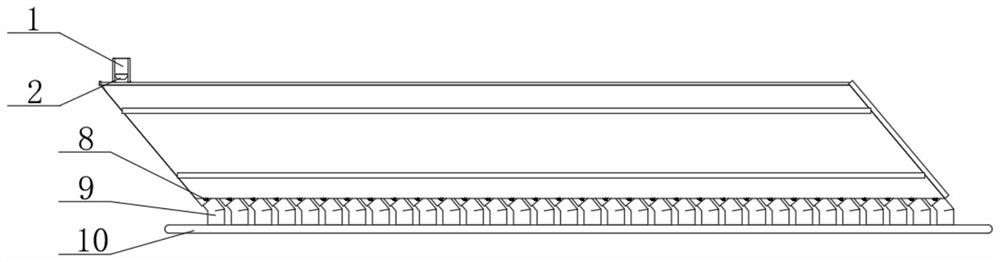

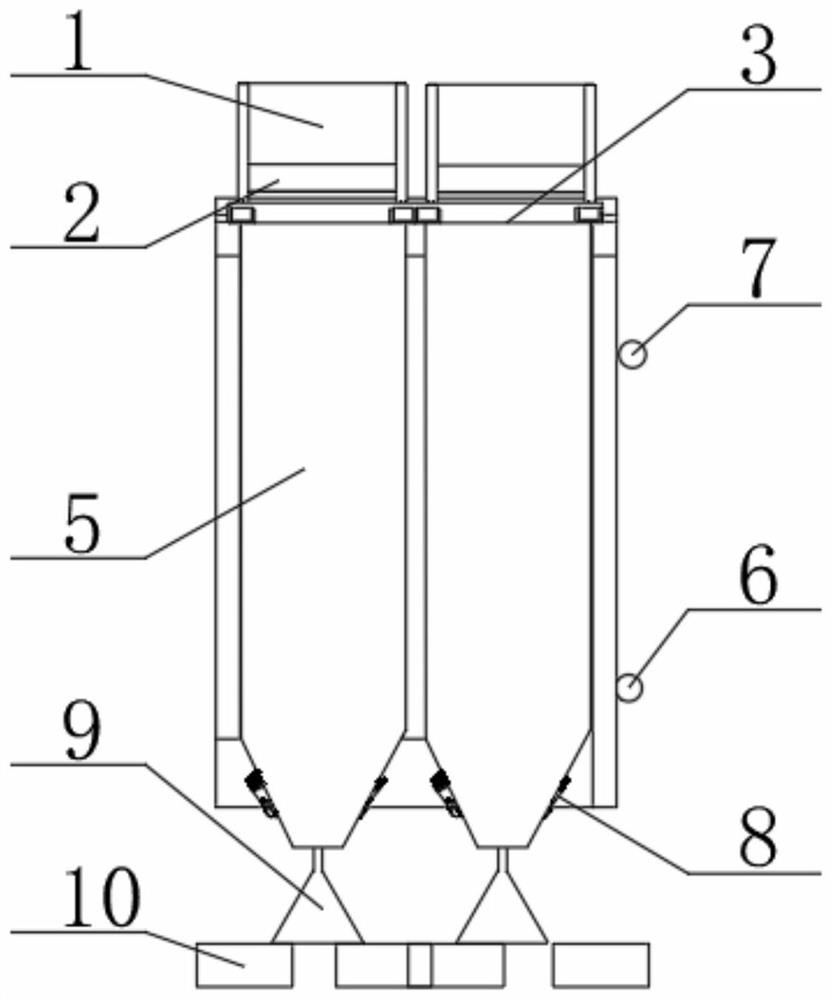

Coal slime solidifying and upgrading process and device thereof

InactiveCN112812870APromote productionReduce spontaneous combustionDrying solid materials with heatSolid fuelsProcess engineeringMaterial distribution

The invention relates to the technical field of coal slime treatment, in particular to a coal slime solidifying and upgrading process and a device thereof. The process comprises the steps that coal slime cakes are conveyed to a single-shaft spiral stirrer through a scraper machine to be stirred, and the composition of coal slime is improved by adding a certain amount of dehydration auxiliaries and sulfur-fixing agents; the coal slime is formed in the extruding machine and is extruded and molded into a cylinder or a plum blossom shape; molded coal slime is conveyed to the oblique radiation upgrading furnace and dehydrated at 90-150 DEG C, the calorific value can be increased by 1500-2000 kcal / kg, the strength can be increased from 100 N to 1000 N or above, meanwhile, due to the fact that the sulfur-fixing agent is added, SO2 emission in the coal slime is greatly reduced, and the coal slime can be recycled. The inclined radiation upgrading furnace in the coal slime solidification upgrading process comprises a material distribution trolley, a plurality of bin bodies, a heat conduction plate internally provided with a plurality of heat conduction pipes, four discharging openings on each single bin body, and a discharging belt. The coal slime solidifying and upgrading process provided by the invention has the advantages of low cost, capability of remarkably improving the coal slime quality, low dust content, high thermal efficiency and strong feasibility.

Owner:刘明锐

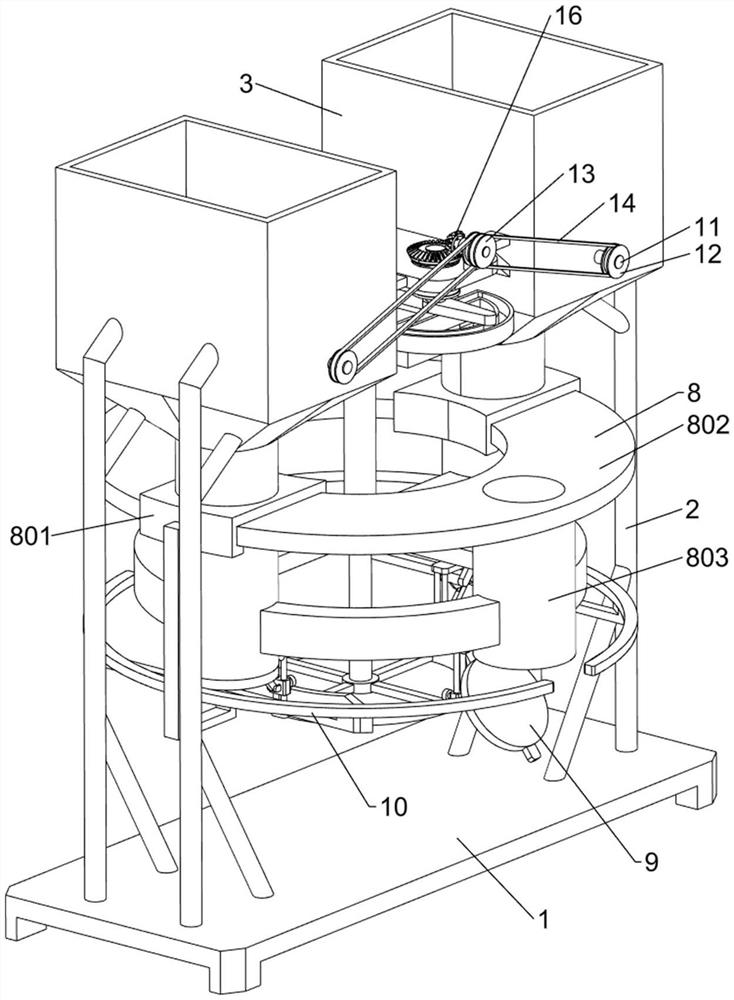

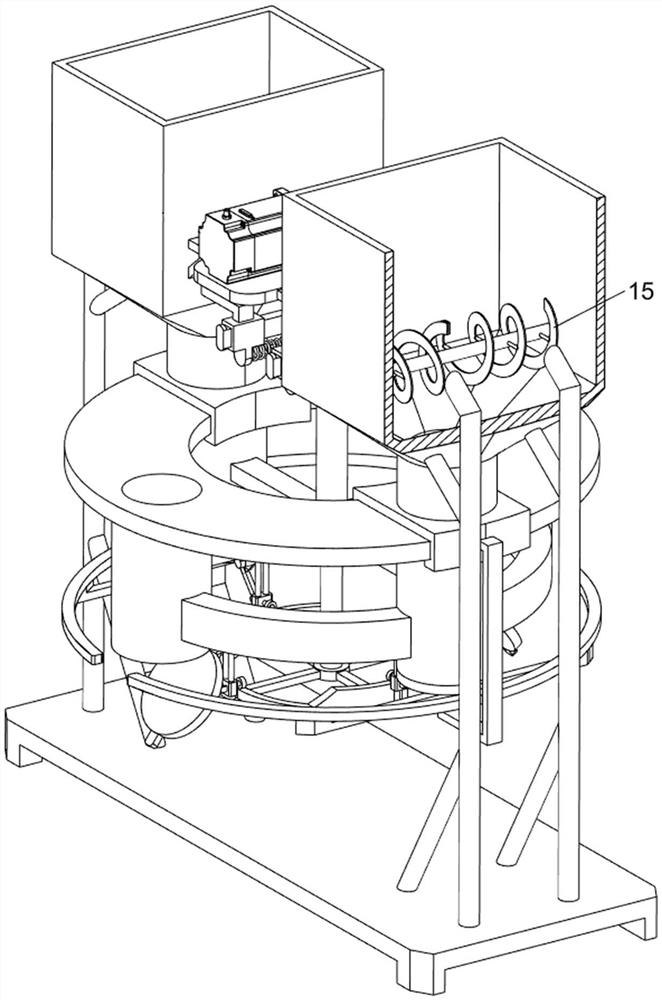

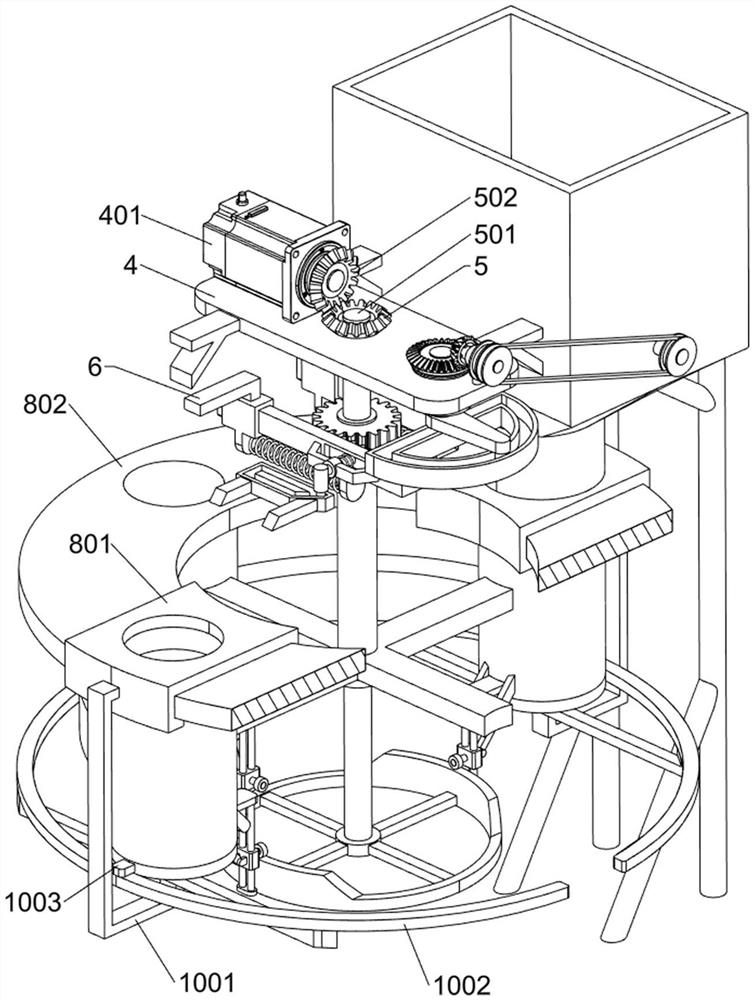

A kind of extruder raw material quantitative blanking equipment

The invention relates to a blanking device, in particular to a quantitative blanking device for raw materials of an extruder. The technical problem of the present invention is to provide a quantitative feeding device for extruder raw materials that can mix plastic particles of two different colors together for feeding. A quantitative feeding equipment for extruder raw materials, comprising: a bottom plate, on which a support is symmetrically connected; a material storage box, a material storage box is connected to the upper part of the support; a support plate, a support plate is connected between the material storage boxes; a servo For the motor, a servo motor is fixed on one side of the support plate; for the drive assembly, a drive assembly is arranged between the support plate and the output shaft of the servo motor. The invention achieves the effect of mixing plastic particles of two different colors together for feeding, and through the intermittent rotation of the feeding cylinder, the time of each feeding cylinder staying at the bottom of the storage box on both sides is the same, Therefore, the amount of plastic particles of the two colors is also the same.

Owner:江苏丰远新材料科技有限公司

Photochemical synthesis of vitamin D in a tubular reactor 2 、d 3 Methods

Owner:SHANDONG TSINGCHUANG CHEMICALSCO LTD +1

A spinning component for polyester fiber and its assembly device and method

ActiveCN112647138BHigh success rateImprove dispersion uniformitySpinning solution de-aeratingSpinnerette packsPolyesterEngineering

The invention relates to a spinning component for polyester fiber and its assembly device and method. The spinning component includes a component body, and inside the component body are: fastening ring, limit pin, upper cover, sand cup set, spot welding net, sealing gasket, positioning pin I and spinneret; the sand cup kit includes the sand cup and the briquetting block, sealing ring, single-layer net, filter sand, extrusion ring, edge-wrapped mesh and single-layer coarse Mesh; there is a spring retaining ring between the fastening ring and the upper cover, and the fastening ring buckles the spring retaining ring on the upper cover; the shape of the spring retaining ring is "C", and the inner side of the "C"-shaped opening There are two concave cavities on the outer bottom of the sand cup, and bosses are arranged around the two concave cavities, and continuous grooves are arranged on the upper surface of the bosses. An automatic integrated device that uniformly stabilizes the internal pressure of the component is used in the assembly of a spinning component for polyester fiber of the present invention, which ensures that the melt stays in the component body for a consistent time, the melt has good fluidity, and each spinneret The temperature difference on the board surface is small.

Owner:JIANGSU DELI CHEM FIBER CO LTD

A kind of production method of melt direct spinning flat special-shaped polyester industrial filament

ActiveCN104451918BShort processLess investmentMelt spinning methodsMonocomponent polyesters artificial filamentConductor CoilEnergy consumption

The invention discloses a production method of melt direct spinning flat polyester industrial filaments. A spinneret plate with special '-' shaped section spinneret orifice is applied. Products are made by tackifying of molten fluid, melt spinning and tension winding molding. By using the production method of melt direct spinning flat polyester industrial filaments, the reaction time is decreased, technological process is effectively lessened, the efficiency is increased, energy consumption is reduced, and the cohesive property is greatly increased on the basis of keeping advantages of common industrial yarn. Because of the approximate rectangle section, the space between yarns is small, the contact area is added, the arrangement is more smooth and compact, and thus the yarn has great raw erectness and high cohesive property, relative good bending rigidity and flexibility. Because of compact arrangement of yarns and increased flatness, the aesthetics after blade coating is greatly increased, the production process is reduced and the production art is simplified.

Owner:ZHEJIANG UNIFULL IND FIBER

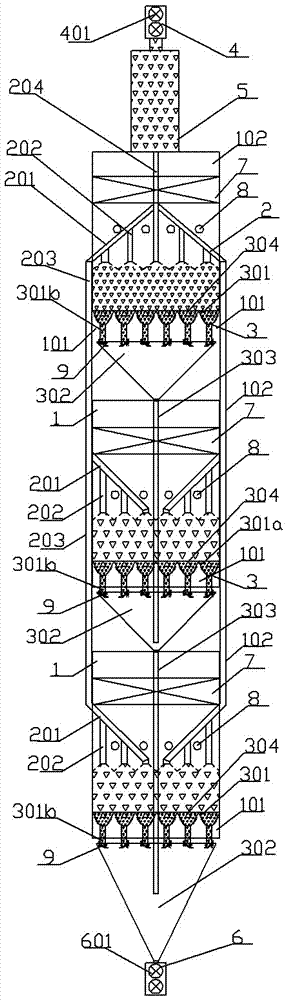

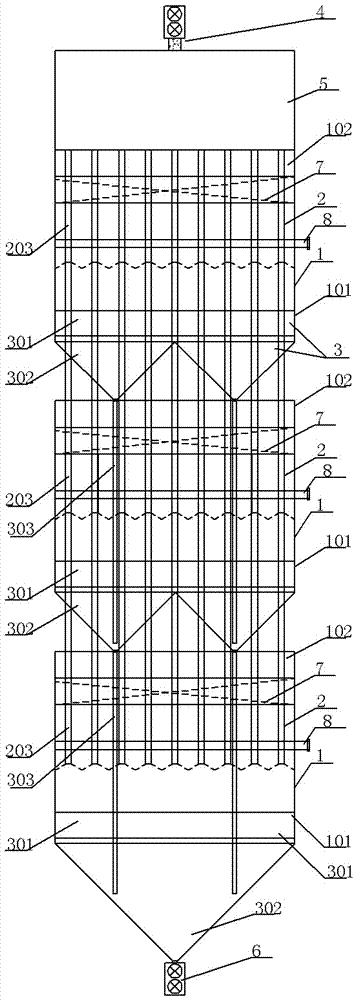

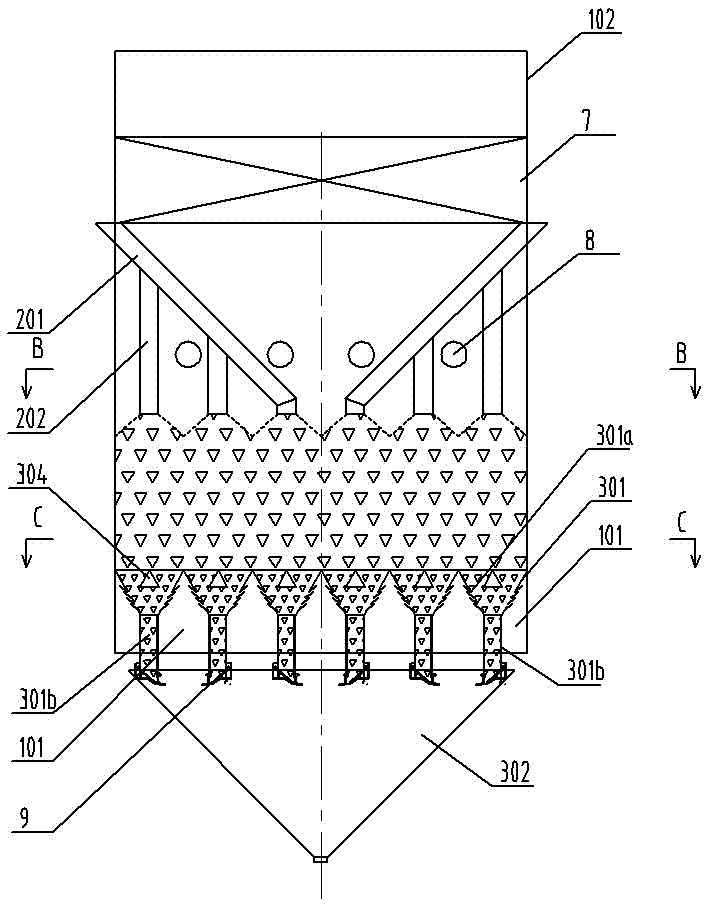

A catalytic bed flue gas purification device and its purification unit

ActiveCN104941445BLower the altitudeGuaranteed supplementDispersed particle separationActivated carbonFlue gas

The invention discloses a catalytic bed flue gas purification device and its purification unit. The catalytic bed flue gas purification device includes at least two vertically arranged purification units. system and the catalyst bed located above the ammonia gas distribution system. The upper part of the purification tower body is equipped with an activated carbon distribution system. The distribution system includes a distribution main pipe that is inclined downward. The openings of the purification towers are on the same horizontal line, and there are vertical feeding pipes between the distribution main pipes of each purification tower body. Above, the lower part of the purification tower body is equipped with a discharge system. The discharge system includes a discharge cone and a collection hopper below the discharge cone. The bottom of the collection hopper of the previous purification unit is connected to the next purification unit. The discharge pipe in the collecting hopper.

Owner:南京泽众环保科技有限公司

Technology for producing direct spinning terylene industrial filaments after liquid state polycondensation of prepolymer

ActiveCN101914820BShort processReduce energy costsSpinning head liquid feederMelt spinning methodsPolyesterCharacteristic viscosity

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

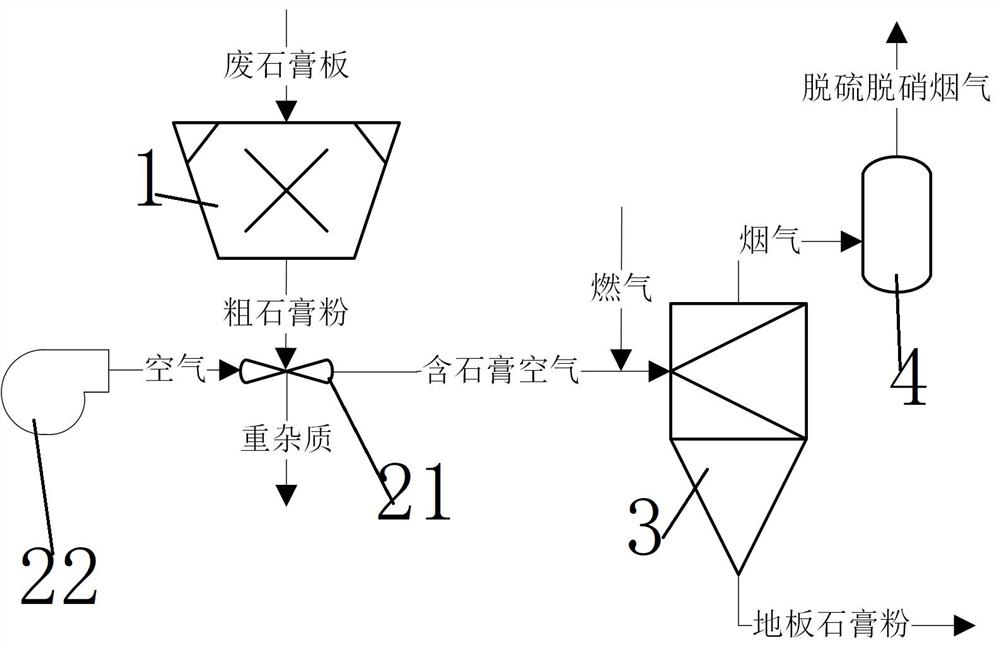

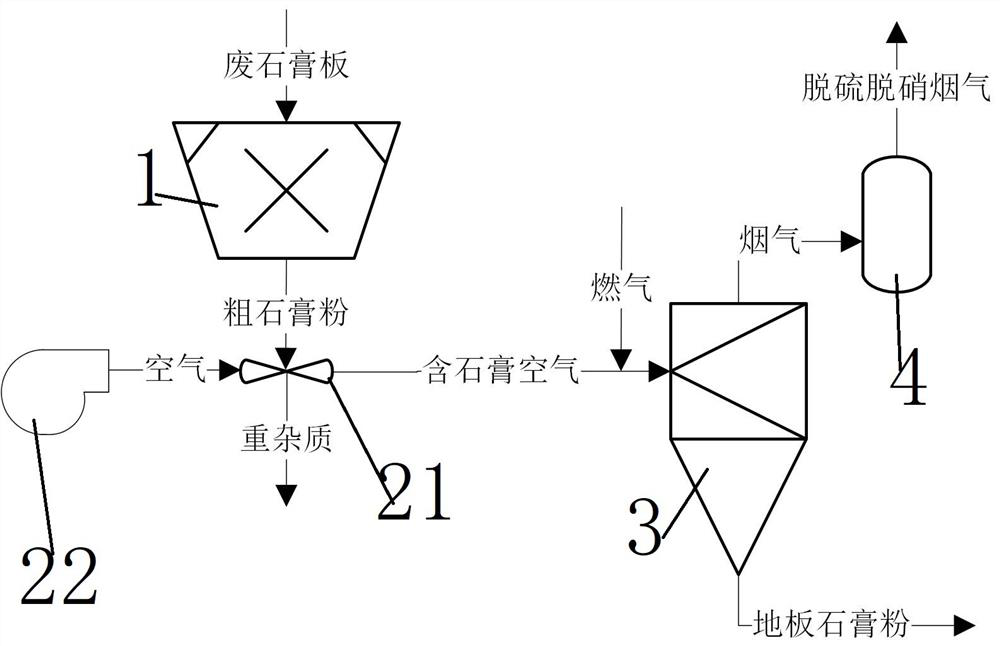

Preparation system for preparing floor gypsum powder from construction waste and use method of preparation system

ActiveCN114345521ACompact structureIncrease productivitySolid waste managementGrain treatmentsFlue gasProcess engineering

The invention relates to the technical field of methods or equipment specially suitable for incinerating waste or low-grade fuel, and discloses a preparation system for preparing floor gypsum powder from construction waste and a use method of the preparation system. Comprising a crushing subsystem for crushing waste gypsum boards into coarse gypsum powder, an airflow sorting device for removing heavy impurities in the coarse gypsum powder, and a cyclone boiler for removing light impurities in the coarse gypsum powder, a discharge port of the crushing subsystem is communicated with a feed port of the airflow sorting device along the conveyor; and a flue gas outlet of the cyclone boiler is communicated with the desulfurization and denitrification device. According to the invention, light impurities and gypsum in the coarse gypsum powder are blown out through the Venturi tube to form a pneumatic conveying mixture with air, and then the mixture is mixed with fuel gas for combustion in the cyclone boiler, so that the removal of the light impurities, the calcination of gypsum particles and the collection of the gypsum particles are completed in one step.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

A high-efficiency gas-liquid reactor and its application in the esterification reaction of ethylene oxide and carbon dioxide

ActiveCN106268588BWell mixedSame dwell timeProcess control/regulationOrganic chemistryGas phaseConcentration gradient

The invention belongs to the field of chemical engineering and particularly relates to an efficient gas-liquid reaction kettle. Through the reaction kettle, the concentration gradient of a gas phase and a liquid phase in the reaction kettle can be effectively reduced, and all material components tend to be identical in staying time in the reaction kettle. The reaction kettle is provided with a stirring device, baffle plates, cooling fins, a spiral gas distributor and a liquid phase feeding nozzle, the stirring device is composed of a motor, a stirring shaft and stirring blades, and the stirring blades comprise the spiral blade and the long-strip-shaped blade. One or more gas phase feeding inlets are formed in the bottom of the reaction kettle, one or more liquid phase feeding inlets are formed in the lower part of the wall of the reaction kettle, meanwhile, the reaction kettle is provided with a pressure gauge and a thermocouple, and corresponding pipelines are each provided with a flowmeter and a control valve. Through the reaction kettle, the problems that the gas phase and the liquid phase are mixed unevenly, and staying time of materials is different are solved, meanwhile, the mixing effect of the materials is improved, a local sharp reaction is avoided, all the materials enter the reaction kettle to complete a reaction rapidly, and product quality is guaranteed.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

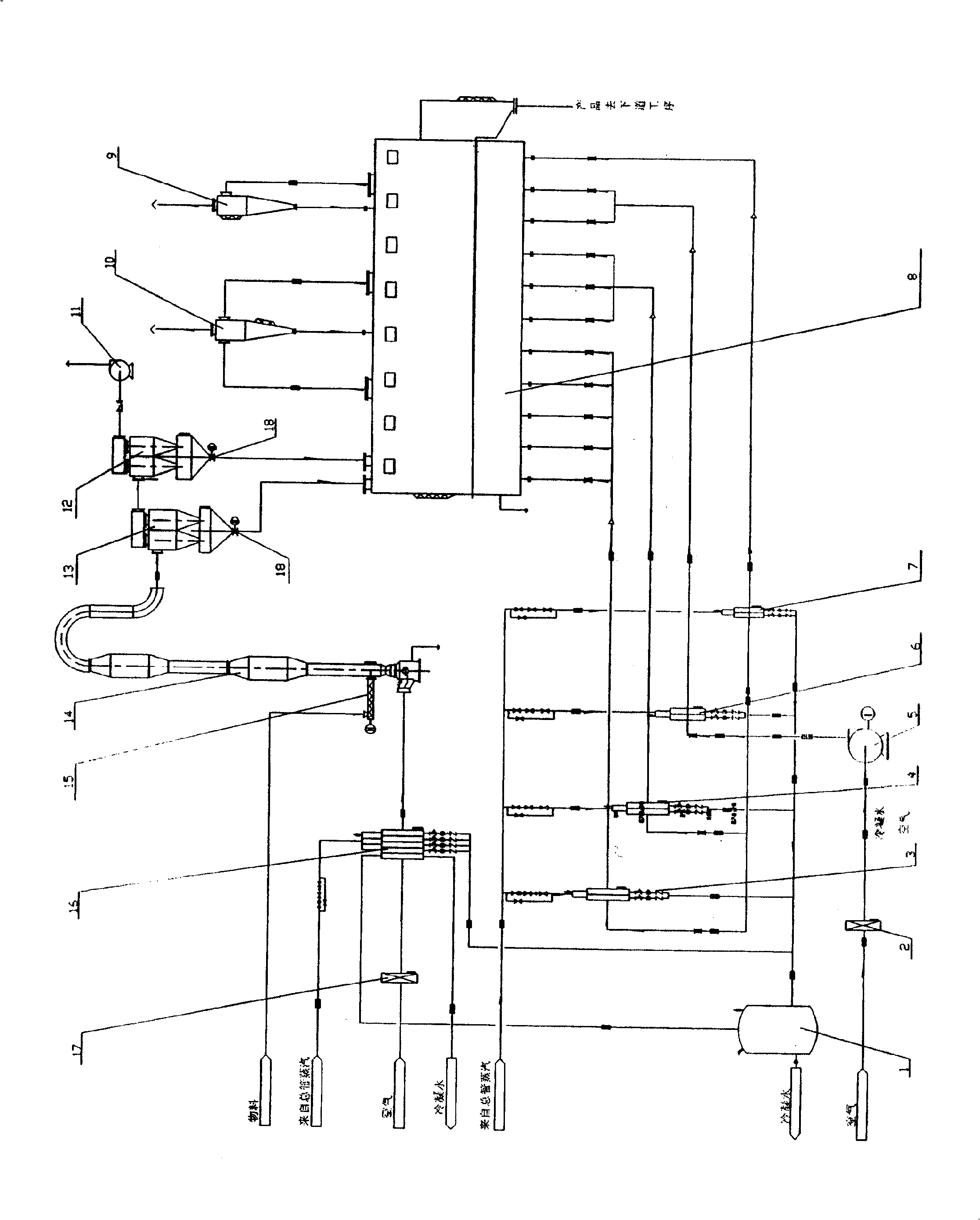

Chlorinated polyethylene drying process

The present invention discloses one chlorinated polyethylene drying process. The chlorinated polyethylene drying process with hot air as drying medium includes the first stage of pulse airflow drying and the second stage of fluidized bed drying to dry chlorinated polyethylene with 30-55 % water content into product with 0.3 % below water content. The present invention has simple drying apparatus, high heat efficiency, low water content in product and other advantages.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

A preparation system for making floor gypsum powder from construction waste and using method thereof

ActiveCN114345521BCompact structureIncrease productivitySolid waste managementGrain treatmentsFlue gasPhysical chemistry

The invention relates to the technical field of a method or equipment specially suitable for incinerating waste or low-grade fuel, and discloses a preparation system for making floor gypsum powder from construction waste and a method for using the same. A crushing subsystem for crushing waste gypsum boards into coarse gypsum powder, an air separation device for removing heavy impurities in coarse gypsum powder, and a cyclone boiler for removing light impurities in coarse gypsum powder; the output of the crushing subsystem The material port leads to the feed port of the air separation device along the conveyor, and the flue gas outlet of the cyclone boiler leads to the desulfurization and denitrification device. In the present invention, the light impurities and gypsum in the coarse gypsum powder are swept out through a venturi tube to form a mixture that can be transported pneumatically with air, and then mixed and burned with gas in a cyclone boiler to complete the removal of light impurities and the removal of gypsum particles in one step. Calcination, and collection of gypsum particles.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

A counterflow flue gas purification device and its purification unit

ActiveCN104857854BLower the altitudeGuaranteed supplementDispersed particle separationActivated carbonFlue gas

The invention discloses a reverse-flow type flue gas purifying device and purifying units thereof. The reverse-flow type flue gas purifying device comprises at least two vertical purifying units, wherein each purifying unit comprises a purifying tower body, an activated carbon distribution system is arranged at the upper part of the purifying tower body and comprises downwards inclined main distribution pipes, branch distribution pipes with downward openings are arranged on the main distribution pipes, and the openings of all the branch distribution pipes are located in the same horizontal line; vertical discharge pipes are arranged between the main distribution pipes of the purifying tower bodies, discharge ends of the main distribution pipes of the top purifying unit and feed ends of the main distribution pipes of the rest purifying units are connected onto the discharge pipes, discharge systems are arranged at lower parts of the purifying tower bodies, each discharge system comprises a conical discharge hopper and a collection hopper arranged below the conical discharge hopper, and bottoms of the collection hoppers of previous purifying units are connected with discharge pipes fed into the collection hoppers of the next purifying units. The utilization rate of upper space of the purifying units is high, and bottom discharge uniformity is realized.

Owner:南京泽众环保科技有限公司

Method for continuously preparing high-purity polym-phenylene isophthalamide resin solution

The invention relates to a method for continuously preparing a highly-pure poly(m-phenylene isophthalamide) resin solution. The method comprises the following steps: respectively metering and conveying a polar solvent, m-phenylenediamine and m-phthaloyl chloride, allowing above materials to enter a double screw mixer, mixing the materials, carrying out a preliminary reaction to generate oligomer, allowing the oligomer to enter a polymerization reactor from the bottom end, continuously carrying out the reaction for a period of time, and allowing the formed poly(m-phenylene isophthalamide) resin solution to flow out from the upper lateral part of the polymerization reactor. The method can reduce at least one double screw reactor needed in the prior art, reduces the device investment cost, and realizes continuous preparation of the poly(m-phenylene isophthalamide) resin solution with uniform viscosity and high purity.

Owner:SHANGHAI HUIBO NEW MATERIAL SCI & TECH

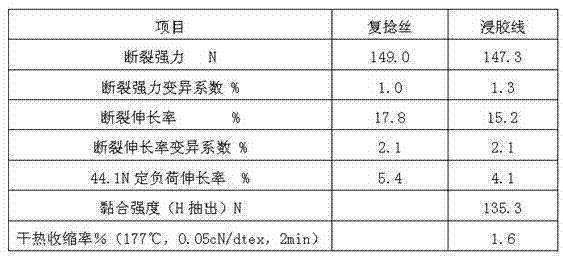

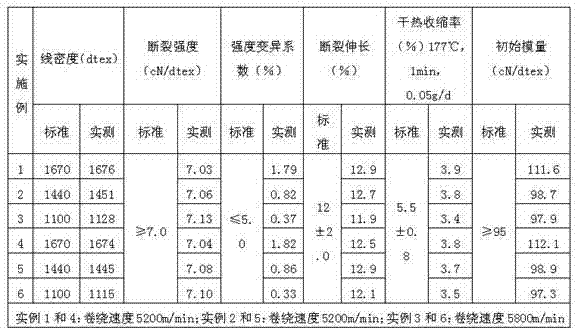

Production method of melt direct spinning high-modulus low-shrinkage polyester industrial filament

ActiveCN103088454BSame conditionsSame dwell timeNew-spun product collectionFilament forming substance formingPolyesterPolymer science

The invention discloses a production method of a melt direct spinning high-modulus low-shrinkage polyester industrial filament, and belongs to the technical field of polyester industrial yarns. The production method is used for a tyre cord. The method comprises melt liquid tackifying, melt direct spinning, draft heat shaping and winding molding. A spinning machine is four heads / position and six heads / position, due to the fact that melt direct spinning is achieved, and limit of the flow of spinning by a spinning screw does not exist. High-modulus low-shrinkage polyester industrial filaments produced according to the technical scheme of the production method are stable in product quality and high in production efficiency, improve the yield of unit time, and lower production energy consumption and production cost. Products can be used as good materials such as tyre cords, geogrids and polyester cords.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer](https://images-eureka.patsnap.com/patent_img/d0f58cdd-7ce6-4dd0-8c91-b0f4bbca9a4a/2013106175895100002DEST_PATH_IMAGE001.PNG)

![Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer](https://images-eureka.patsnap.com/patent_img/d0f58cdd-7ce6-4dd0-8c91-b0f4bbca9a4a/2013106175895100002DEST_PATH_IMAGE002.PNG)