Patents

Literature

244results about How to "Consistent time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

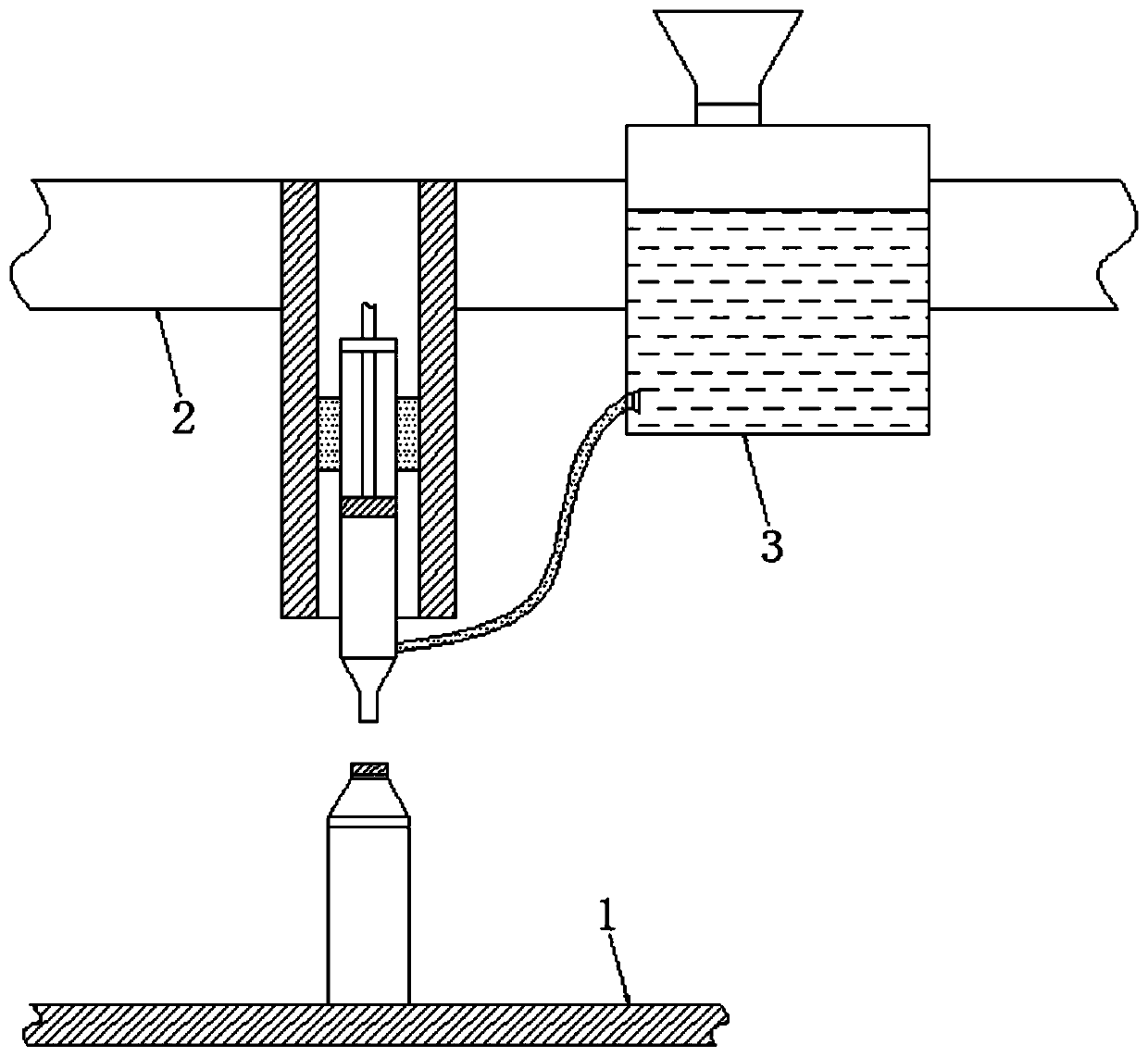

Operating method for olefin conversion device

ActiveCN102020523AFast heatingAvoid cloggingCatalyst regeneration/reactivationHydrocarbon from oxygen organic compoundsCombustorCombustion chamber

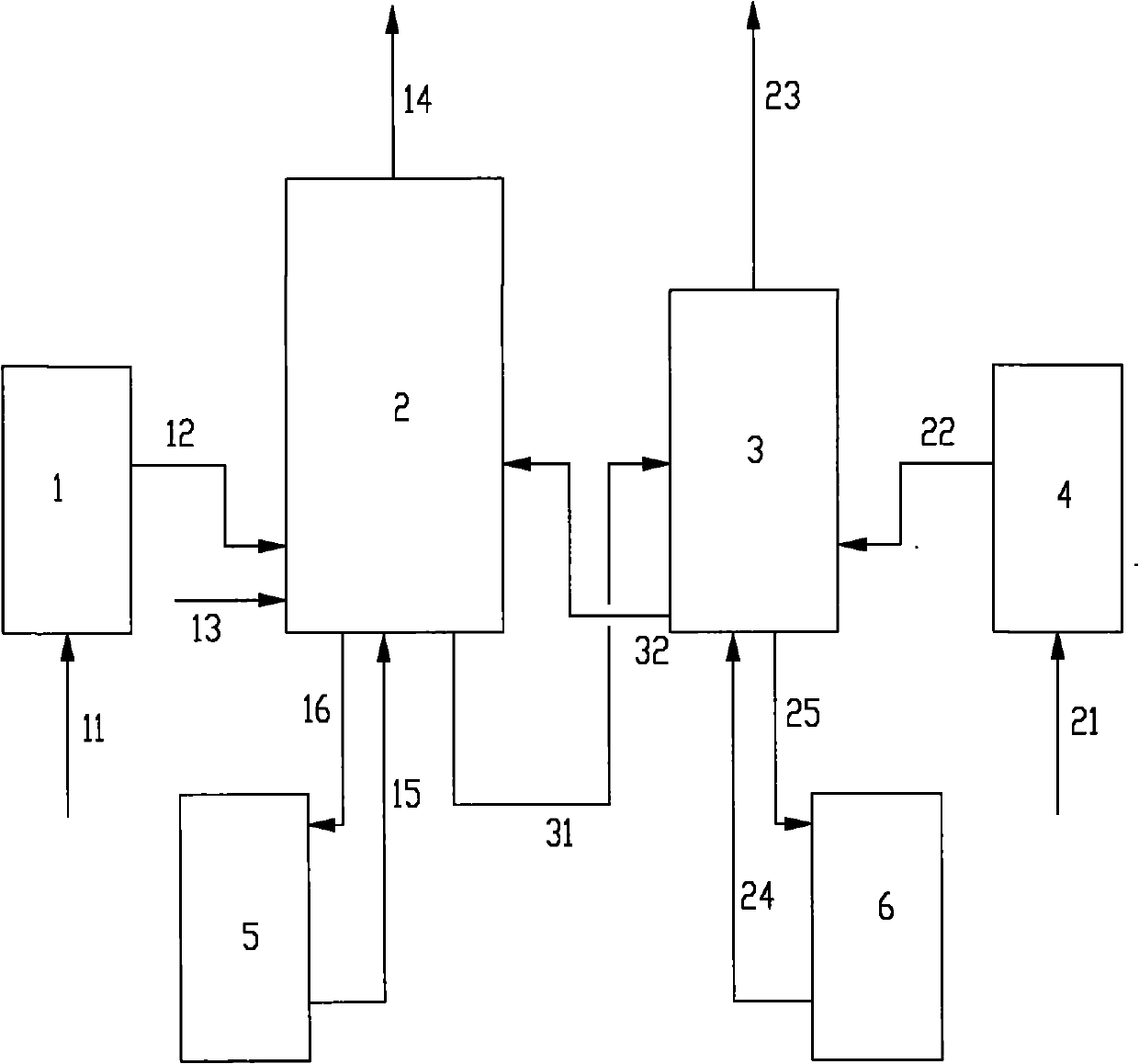

The invention belongs to an operating method for an olefin conversion device and relates to a device for preparing olefin such as methanol to olefin (MTO) and methanol to propylene (MTP) by using organic oxides such as methanol, dimethyl ether and the like. The method is characterized by comprising the following steps that: when the device is operated, catalysts of a reactor 2 and a regenerator 3are respectively introduced from respective catalyst tank and are added in two paths; and the catalysts respectively added into the reactor and the regenerator are heated depending on an external heat source and a heating medium which are independently arranged, namely, the reactor 2 is provided with an operating steam superheater 1 to heat the catalyst by using high-temperature steam and the regenerator 3 is provided with an auxiliary combustor to heat the catalyst by using high-temperature air. When added, the catalysts are not transferred from the regenerator 3 to the reactor 2, namely thecatalysts are not transferred between the reactor and the regenerator.

Owner:CHINA PETROLEUM & CHEM CORP +1

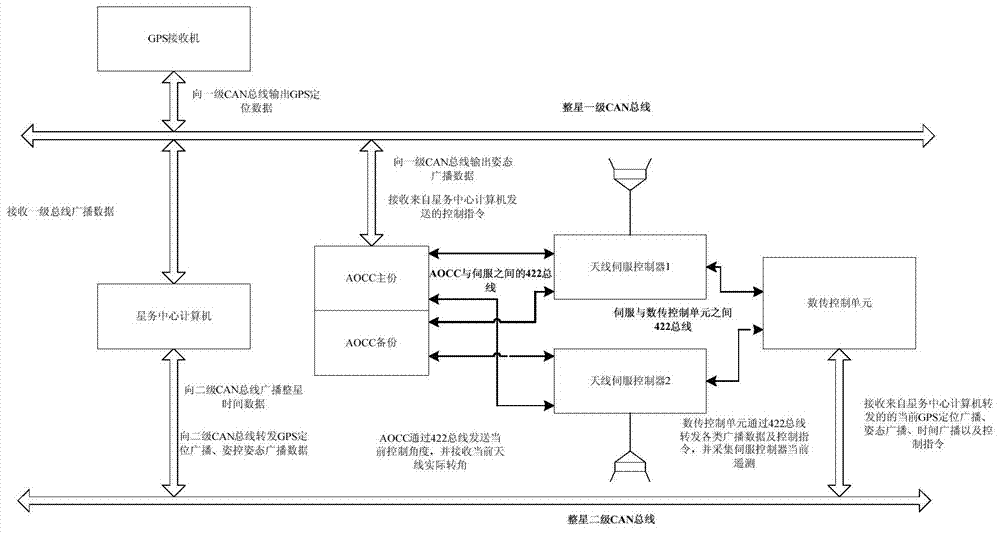

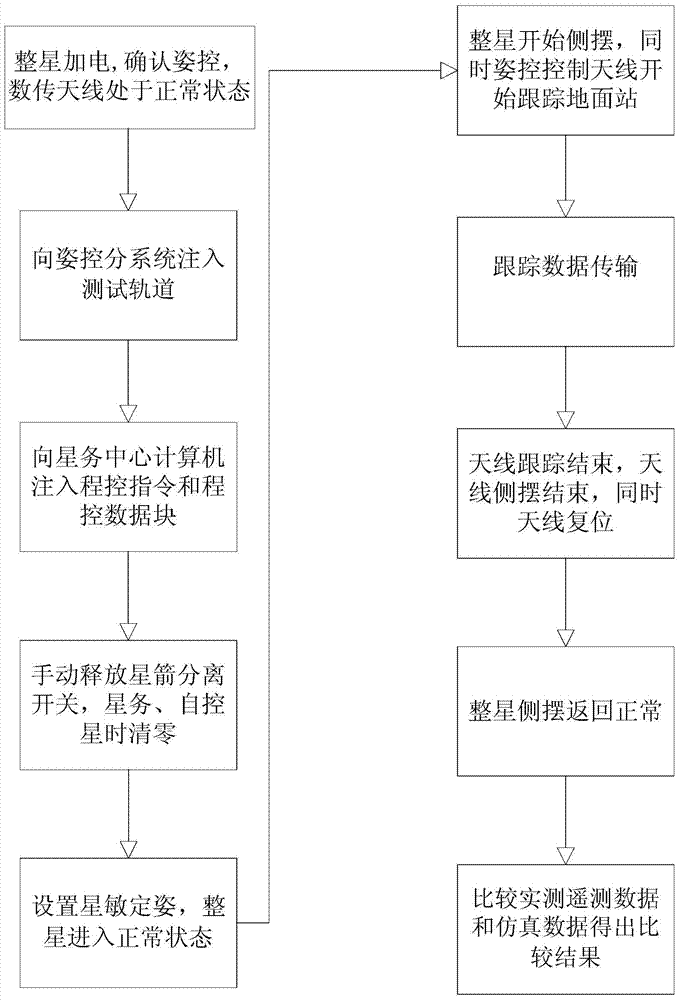

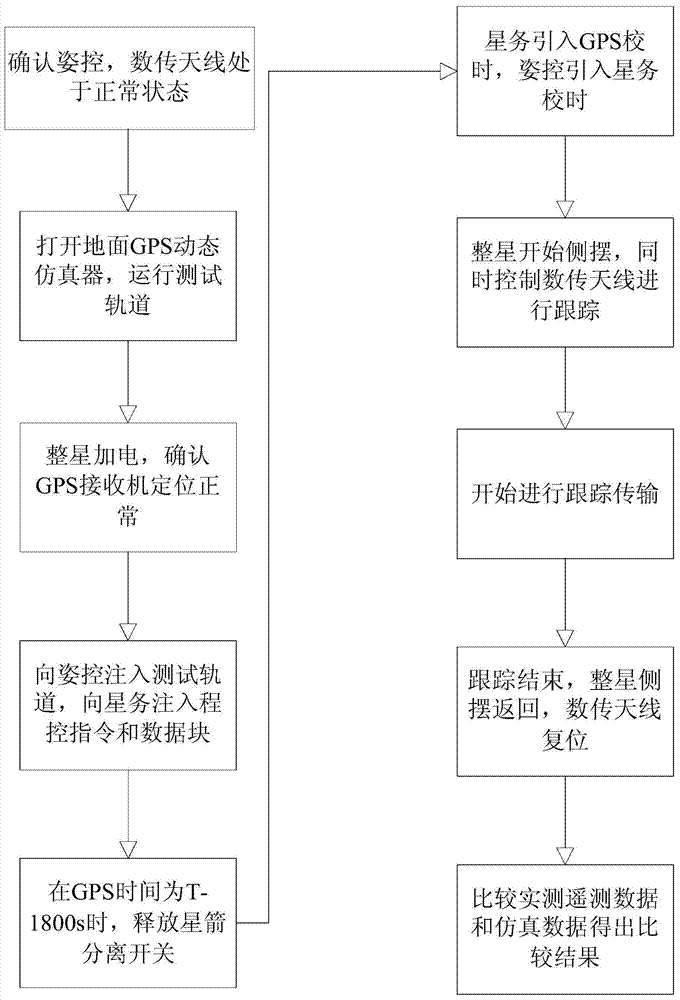

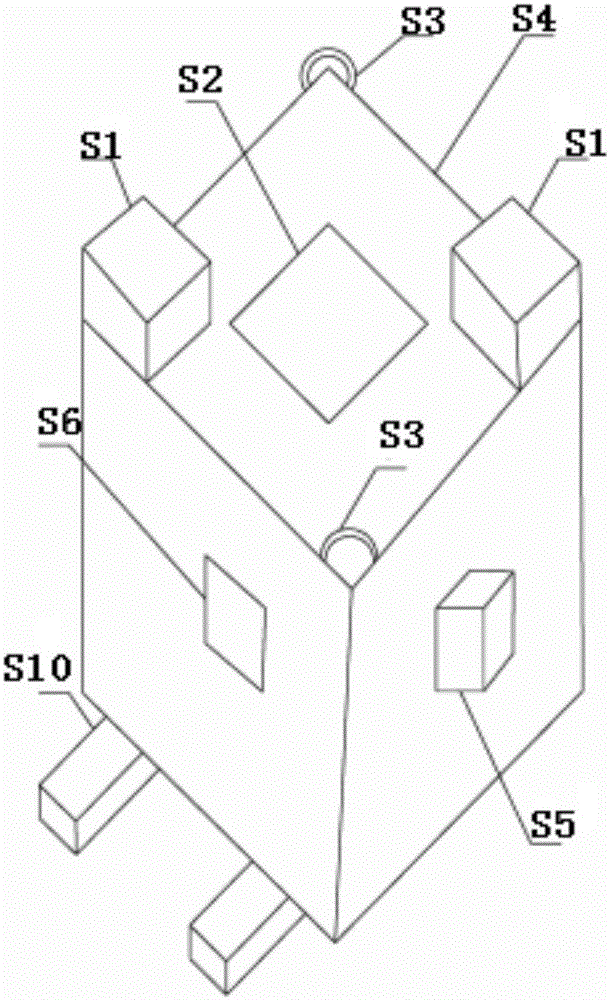

Data transmission antenna whole-satellite testing method based on minisatellite information system

ActiveCN103592533AGuaranteed control time consistency requirementsGuaranteed Conformity RequirementsElectrical testingGround stationSatellite attitude control system

The invention provides a data transmission antenna whole-satellite testing method based on a minisatellite information system. At first, orbital data are input to a satellite attitude control system and a GPS dynamic simulator, by regulating orbit parameters of the satellite attitude control system, controlling start-up time of the GPS dynamic simulator and satellite-arrow separating time, and combining a program control command and a program control data block sequence, time information, orbit information and attitude information of the satellite attitude control system, a GPS receiver and a satellite task distribution system are completely synchronized, testing data are obtained by controlling a data transmission antenna to carry out ground station tracking, and finally, by comparing theoretical data and the testing data of antenna tracking, actual antennal tracking angle errors under different orbit conditions and different satellite attitudes are obtained. According to the data transmission antenna whole-satellite testing method, the orbit and time information state of a minisatellite are accurately simulated, testing of the data transmission antenna under the whole-satellite state of the minisatellite is achieved, and the method is applied to other types of minisatellites at present.

Owner:AEROSPACE DONGFANGHONG SATELLITE

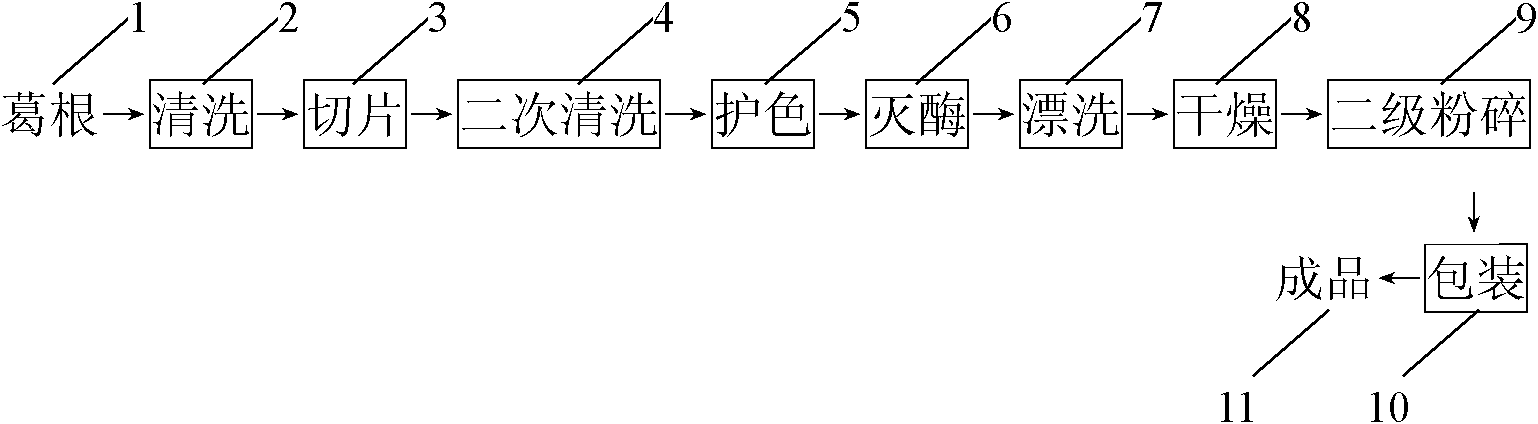

Preparation method of raw vine root whole powder

InactiveCN102160629AHas nutritional and health functionsAvoid toothacheFood shapingFood preparationCelluloseSediment

The invention discloses a preparation method of raw vine root whole powder, which is characterized by comprising the following steps of: taking the vine root without removing skins and fibrous roots as raw materials, cleaning, slicing, then cleaning sediment at cleaned gaps, then carrying out color protection, enzyme inactivation, rinsing, drying, secondary crushing and packaging and obtaining a finished raw vine root whole powder product with high content of flavonoid compounds and high content of cellulose. In the preparation method, the vine root whole powder is taken as a raw material, various health-care foods containing the vine root can be processed, and no limitation exists on the time and the region.

Owner:DAZHOU REAGAN ARROWROOT +1

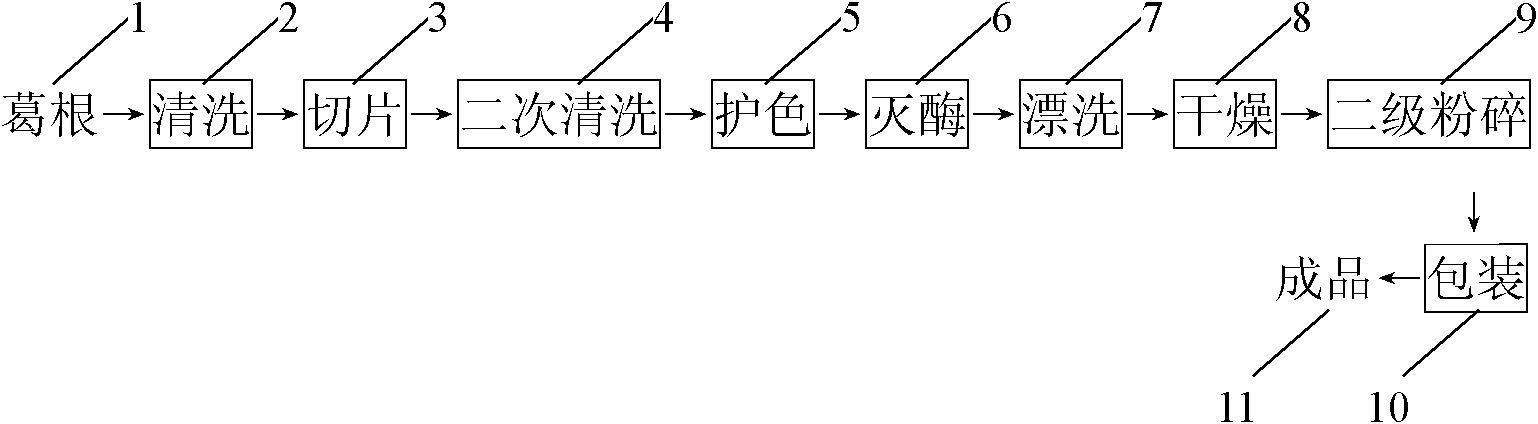

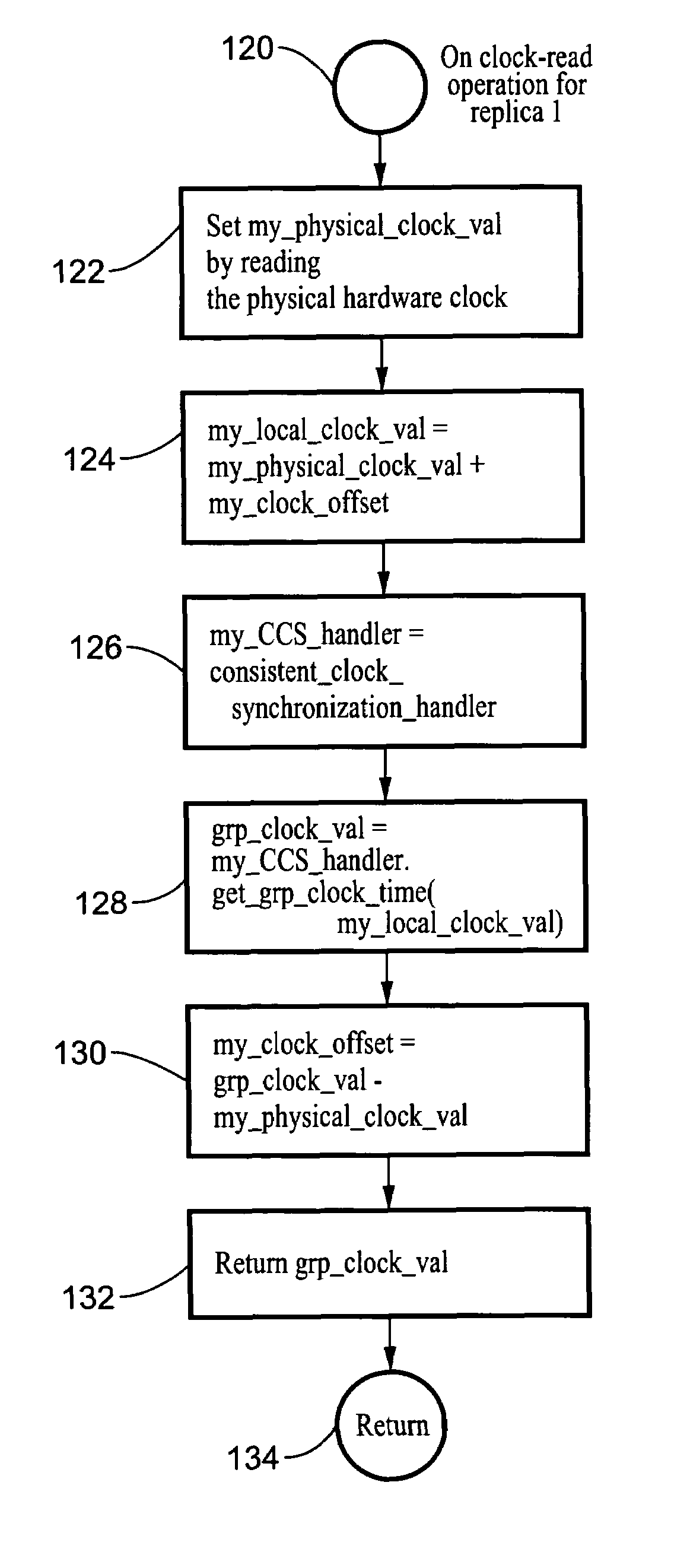

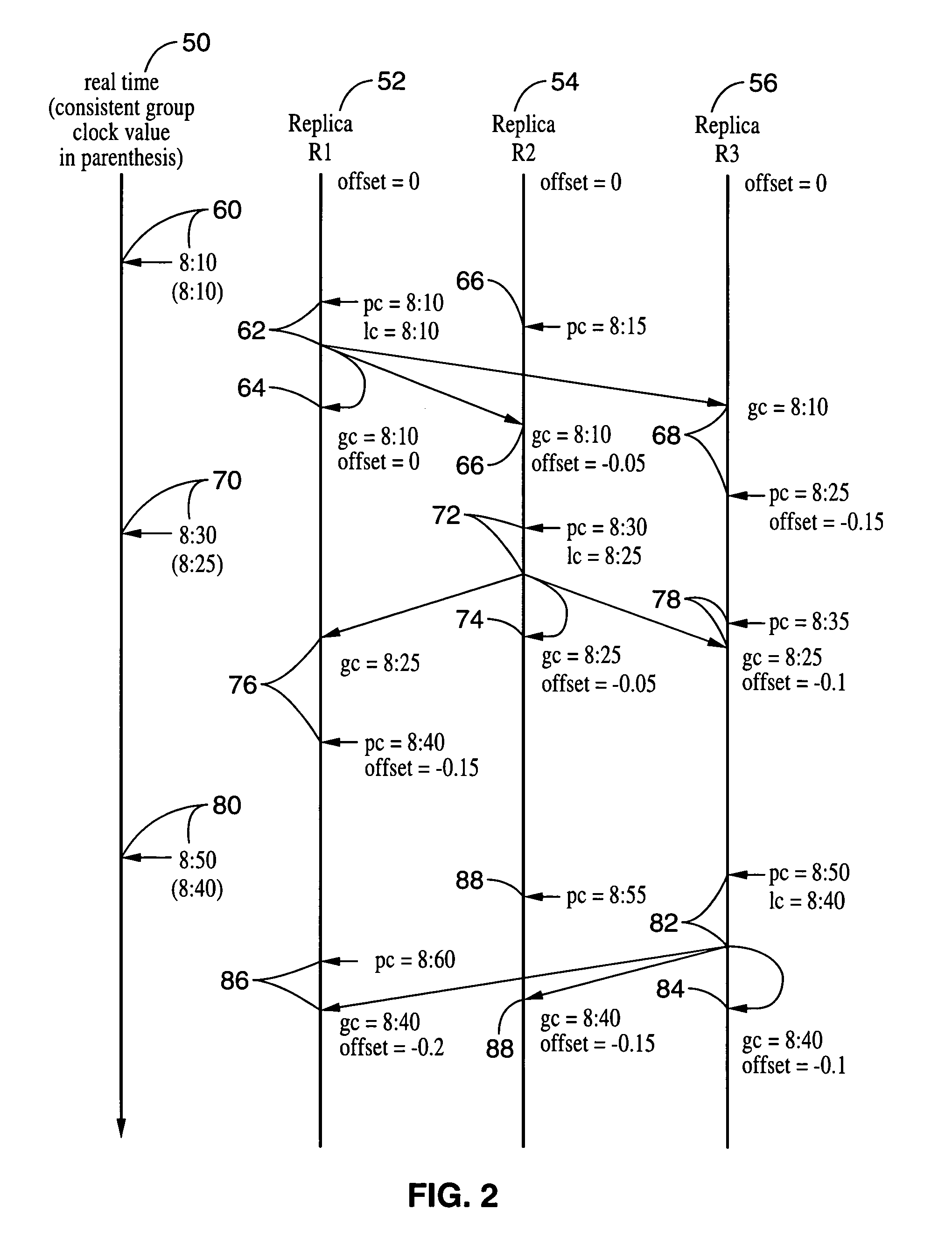

Consistent time service for fault-tolerant distributed systems

InactiveUS7334014B2Consistent timeRecording carrier detailsError detection/correctionSemi activeDeterminism

Owner:OPEN INVENTION NEWTORK LLC

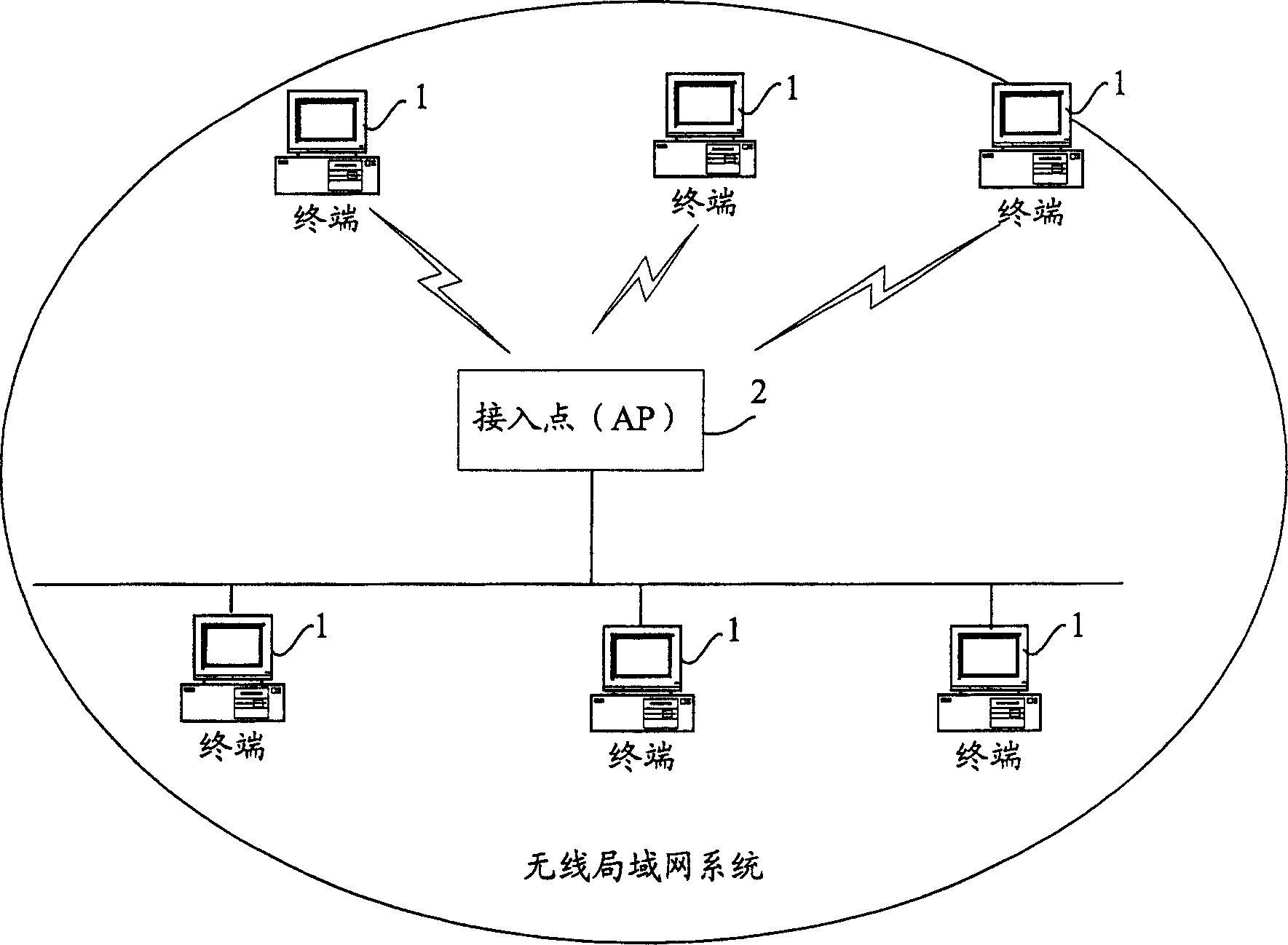

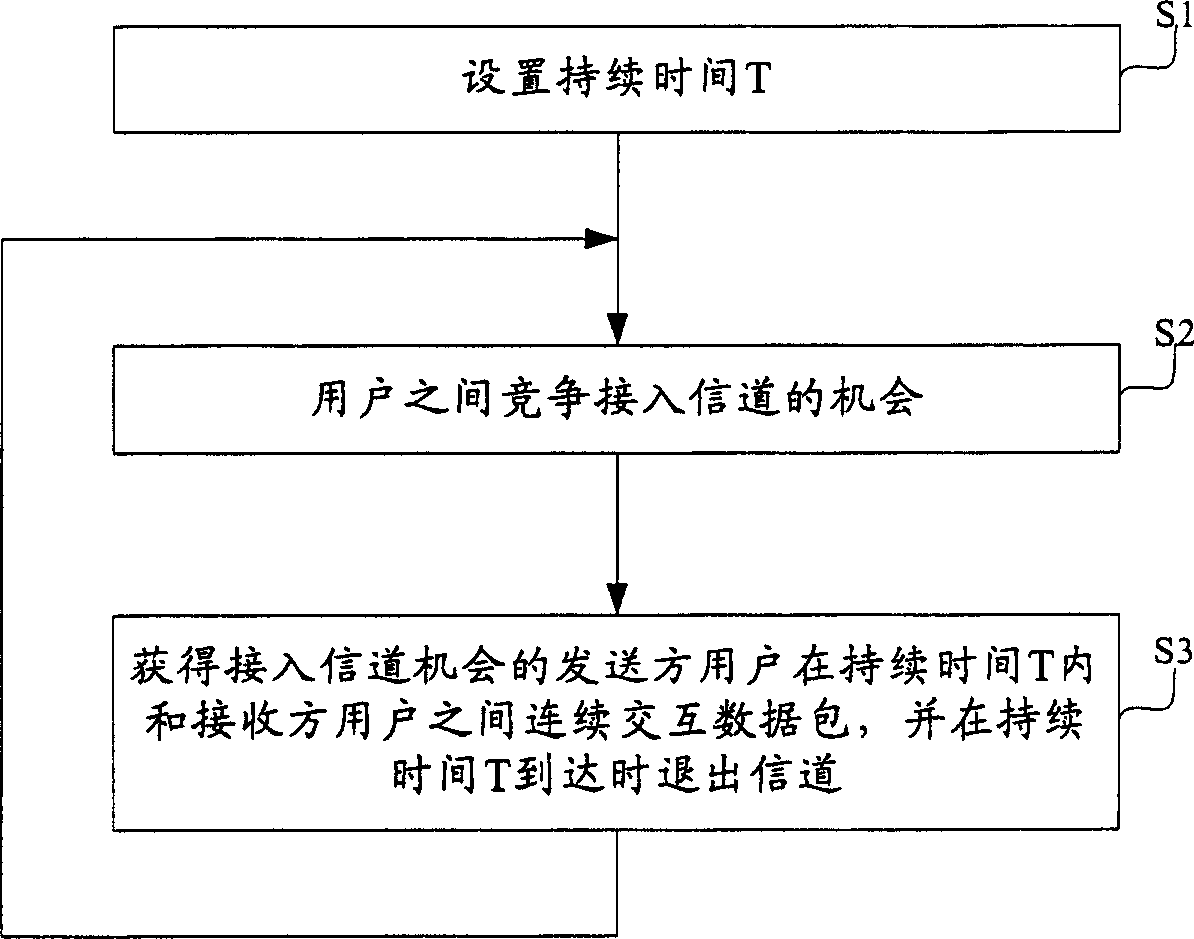

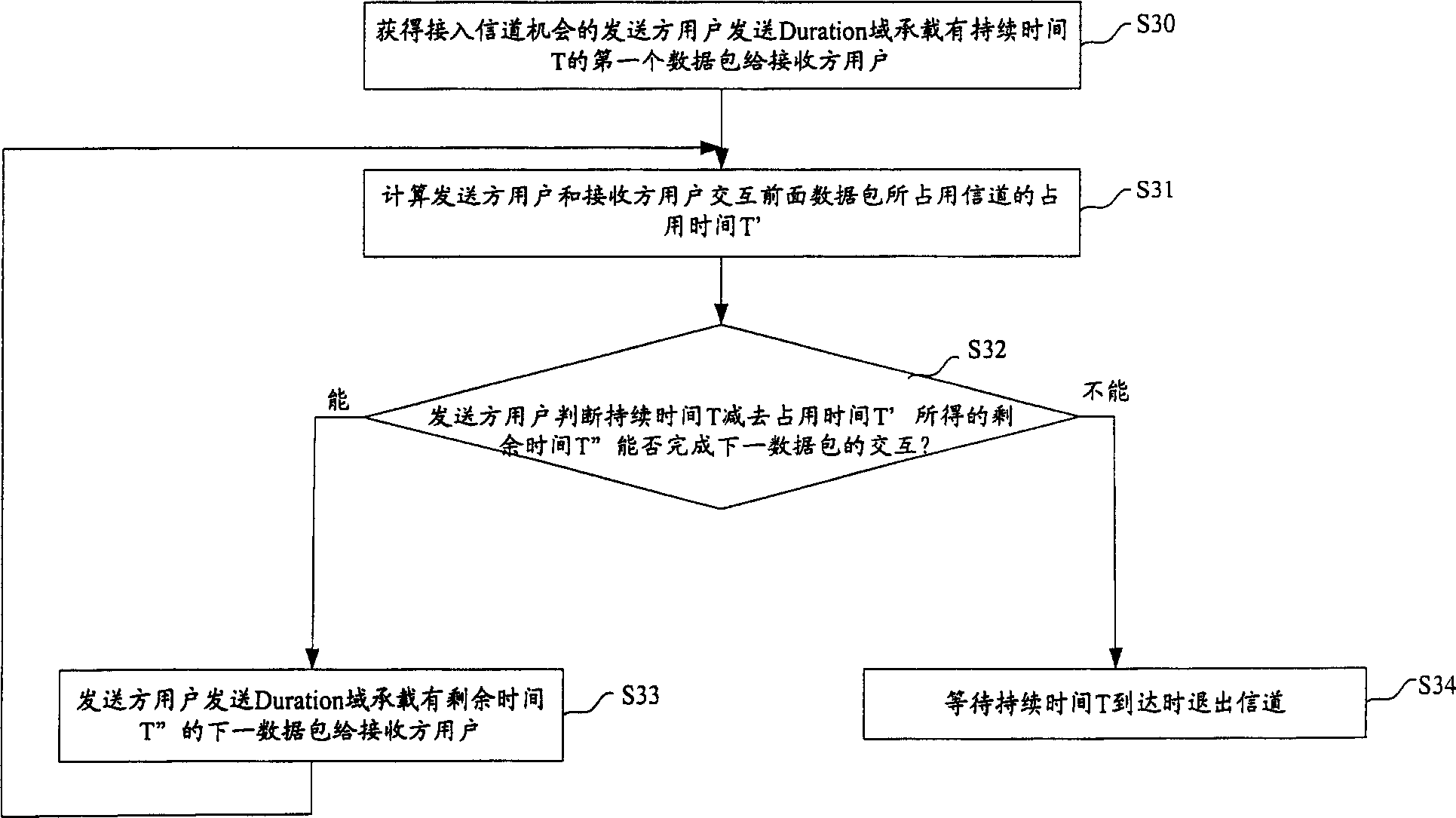

Channel distributing method in WLAN system

ActiveCN1735016AImprove utilization throughputAffects throughputData switching by path configurationLow speedInteractive processing

This invention discloses a channel allocation method in wireless LAN system, which comprises setting duration time to make sending user and receiving user complete data package interactive processing at least for one time; sending user obtained the chance to access in channel and receiving user continue to exchange data packages during set time and quit the channel when time exhausts, then it turns to the step that users compete the chance to access in channel. The invention can overcomes that the low-speed user affects the throughput of high-speed user, and increases channel utility throughput of whole system.

Owner:HUAWEI TECH CO LTD

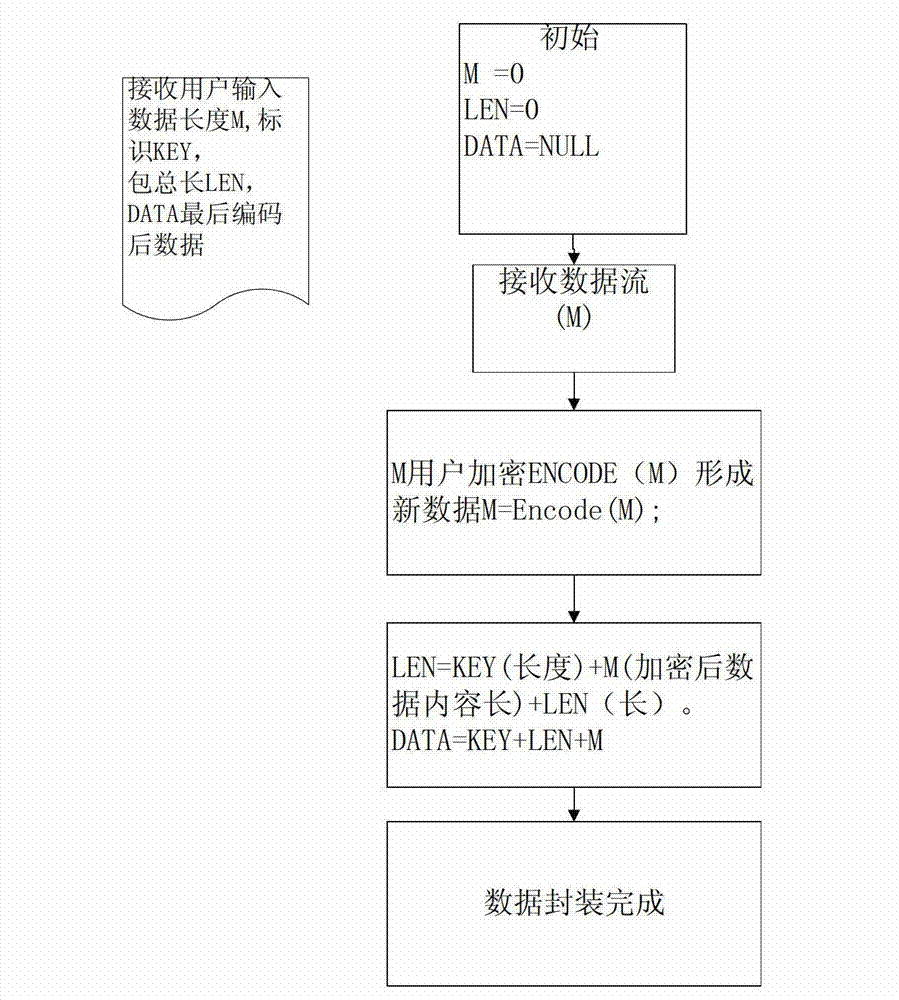

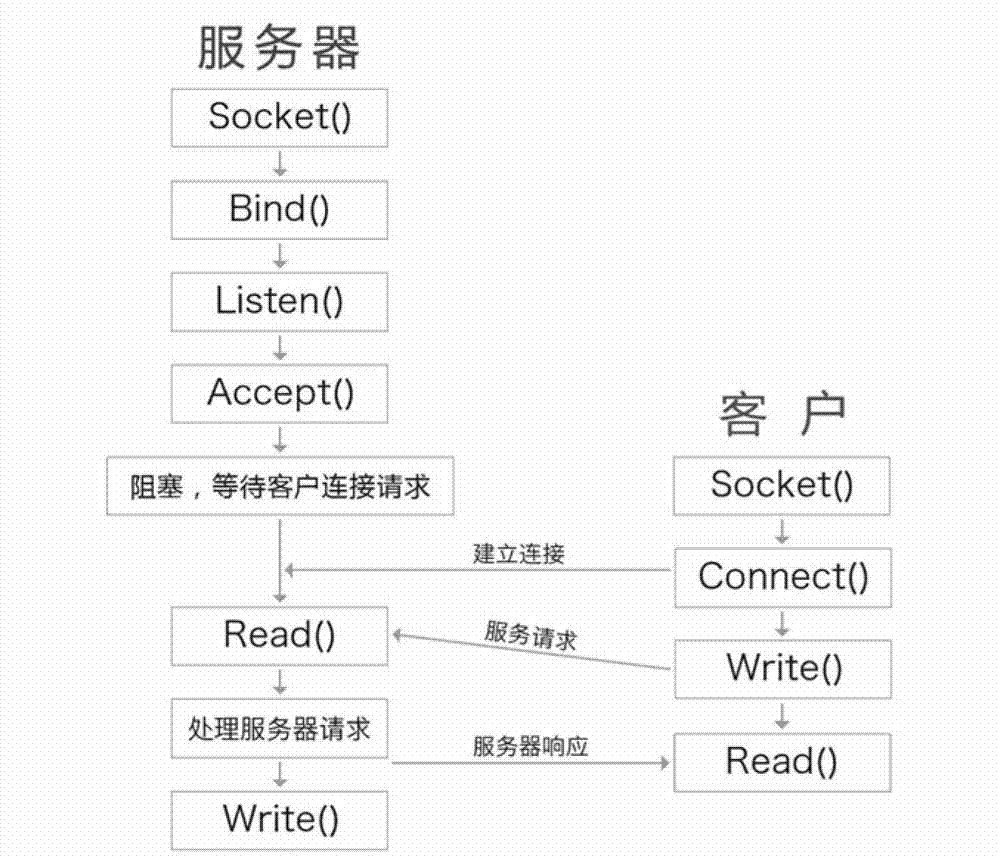

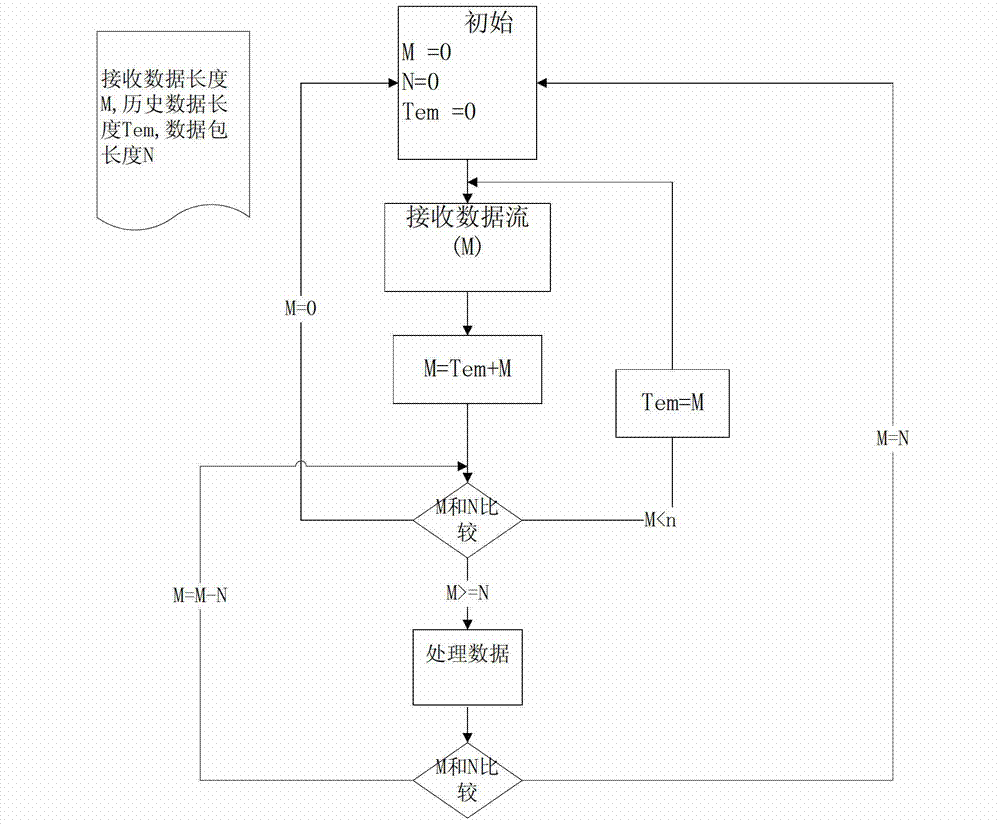

Realization method for reasonable construction and correct parse of communication data package based on alarm system

InactiveCN103095835ASolve the problem that it is difficult to distinguish correctly, and some even cannot be parsed correctlyAccurate analysisError preventionNetwork packetStream data

The invention relates to the technical field of security of computer networks, in particular to a realization method for reasonable construction and correct parse of a communication data package based on an alarm system. Fixed-length data package header identification is used as data package feature identification, the length of a fixed-length data package is set at the rear of the data package header identification, the system can parse the finial size of the package according to the length of the data package after receiving data and then parse out the whole data package, and the size of the whole package can be known without traversing to the end of the package. A coding scheme of abstract syntax markup is used for coding to divide the data into the operation type of Cmd and the operation content of Value, wherein Key corresponds to the header of data package, Length corresponds to the data length, Cmd and Value both correspond to the data, Key, Length, Cmd and Value are coded through the coding and the decoding rule to form a bit stream data package, and the data content is encrypted and decrypted through a special encryption protocol. The security and the transmission speed are obviously promoted.

Owner:成都理想科技开发有限公司

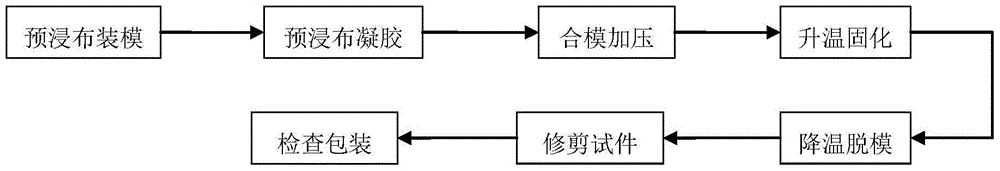

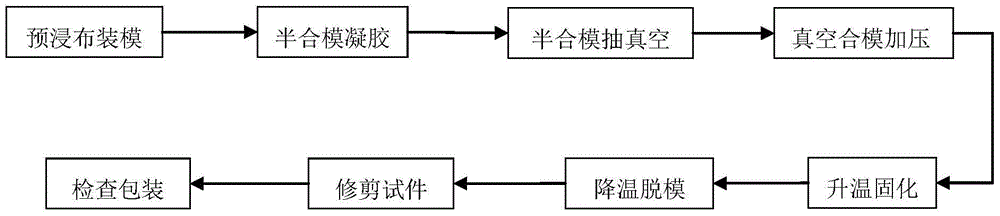

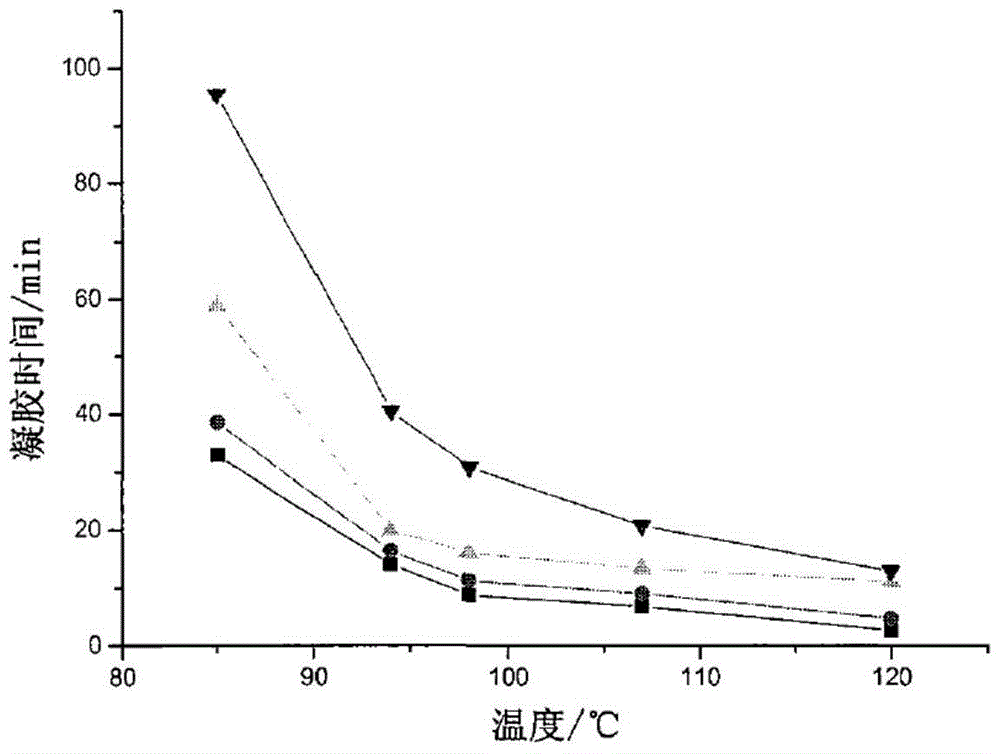

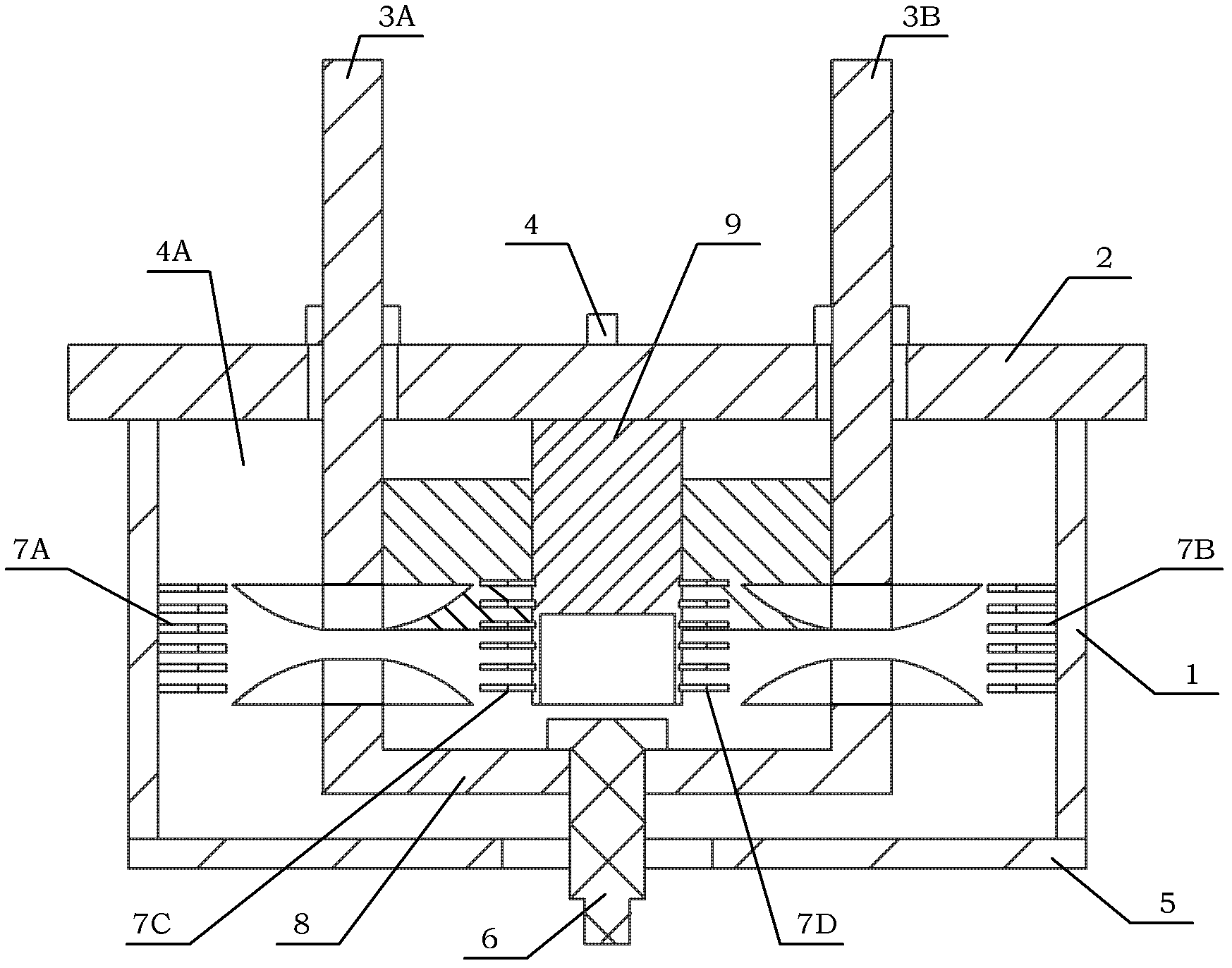

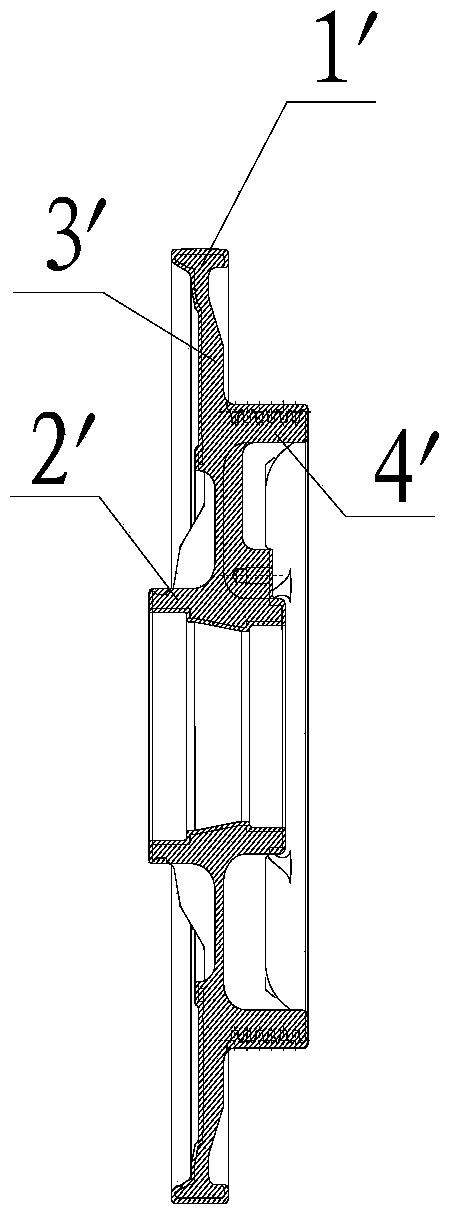

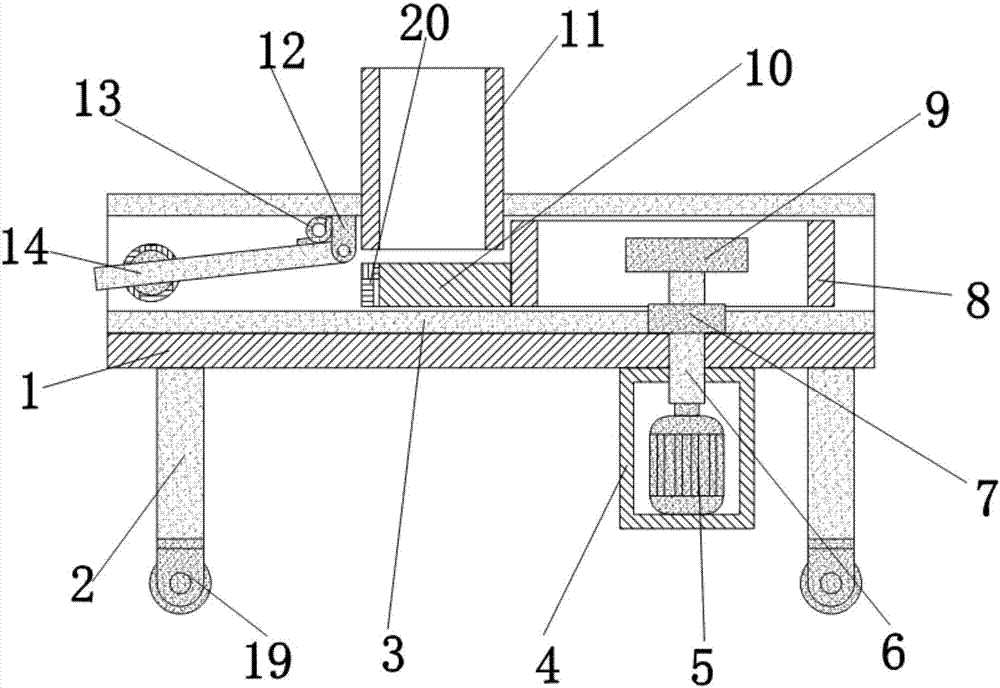

Vacuum compression molding device for carbon fiber composite

InactiveCN105034410AImprove mechanical propertiesImprove the finishCompression moldingNumerical control

The invention discloses a vacuum compression molding device for a carbon fiber composite. The vacuum compression molding device for the carbon fiber composite solves the problem that the performance of a carbon fiber composite molded test piece is poor and comprises an upper mechanism, a lower mechanism, a vacuumizing device, a temperature control device, a pressure control device and a numerical control operation platform. The upper mechanism is installed at the top end of guide posts installed in the lower mechanism through an upper heat conducting plate. Top-pasted type pressure sensors of the pressure control device adhere to the bottom face of the upper heat conducting plate and are connected with the numerical control operation platform through wires. Bottom-pasted type pressure sensors of the pressure control device adhere to a lower heat conducting plate and are connected with the numerical control operation platform through wires. Upper temperature sensors of the temperature control device adhere to the two sides of an upper male die of the upper mechanism and are connected with the numerical control operation platform through wires. Lower temperature sensors of the temperature control device adhere to the two sides of the upper surface of a lower female die and are connected with the numerical control operation platform through wires. The vacuumizing device is installed on a vacuum compression molding device base on the left side of the lower mechanism, and a one-way valve of the vacuumizing device is installed on the lower female die. The numerical control operation platform is installed on the right side of the lower mechanism.

Owner:JILIN UNIV

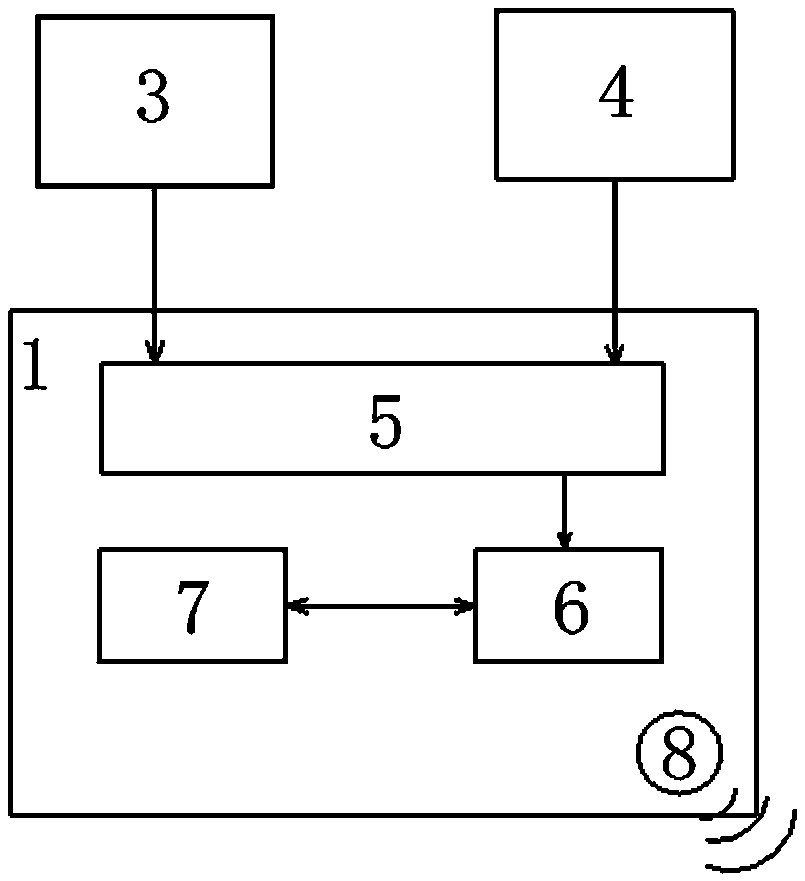

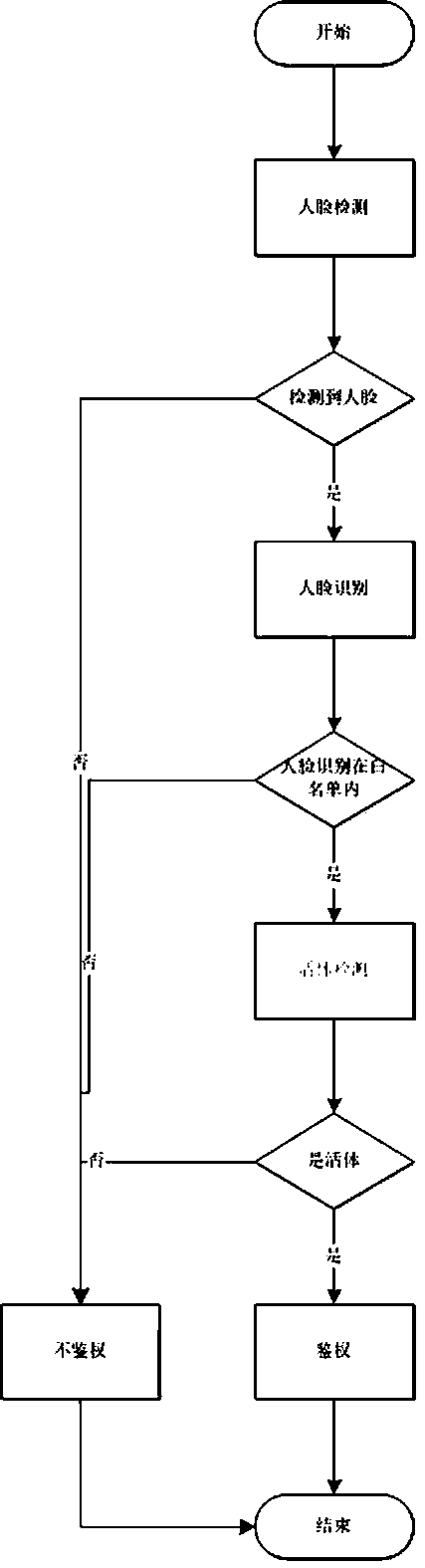

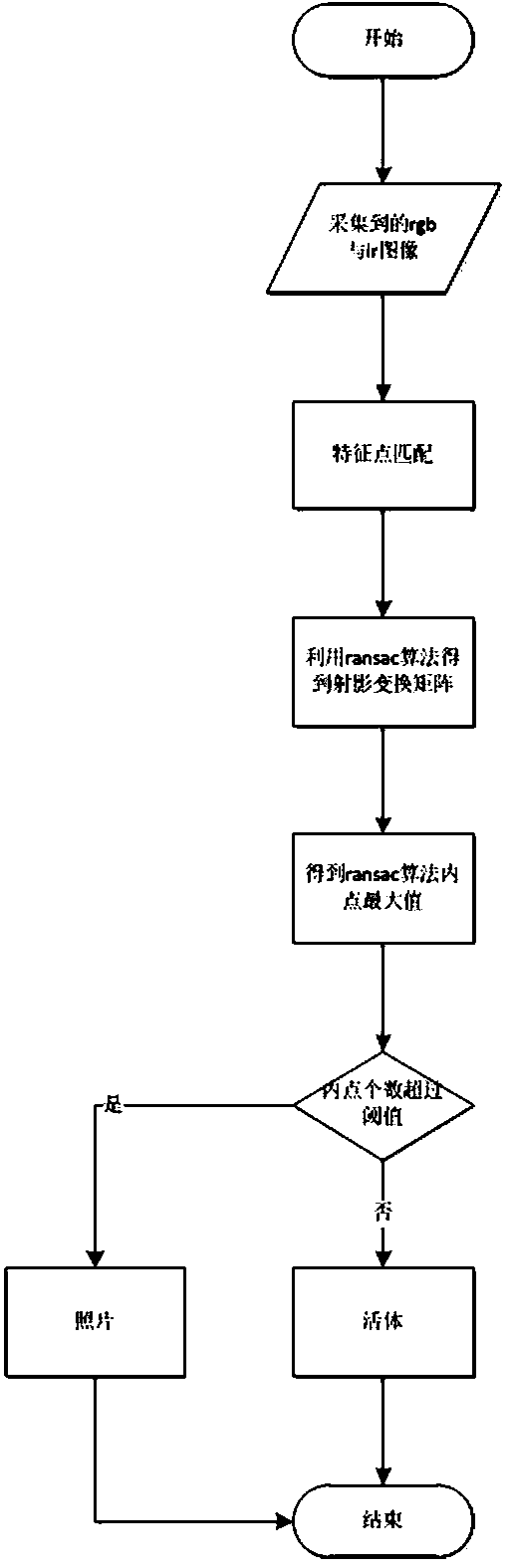

Elevator-scene-based binocular camera face identification and authentication system and method

The invention provides an elevator-scene-based binocular camera face identification and authentication system. The system comprises a binocular image acquisition device, a processor and a comparison data platform, the binocular image acquisition device comprises an RGB camera device and an IR camera device which conduct real-time synchronous acquisition on video images entering the identificationrange, the output ends of the RGB camera device and the IR camera device are connected to the processor, acquisition results are sent to the processor, the processor conducts face identification and data processing on the acquisition results of the RGB camera device and the IR camera device, comparison is conducted with data stored in the comparison data platform, and whether authentication is conducted or not is judged. The invention further provides an elevator-scene-based binocular camera face identification and authentication method. Accordingly, face image acquisition is conducted throughtwo different kinds of image acquisition devices, whether a living face or a photo or video which is used for camouflage exists can be judged, and then the security of elevator control authenticationis guaranteed.

Owner:ZHEJIANG NEW ZAILING TECH CO LTD

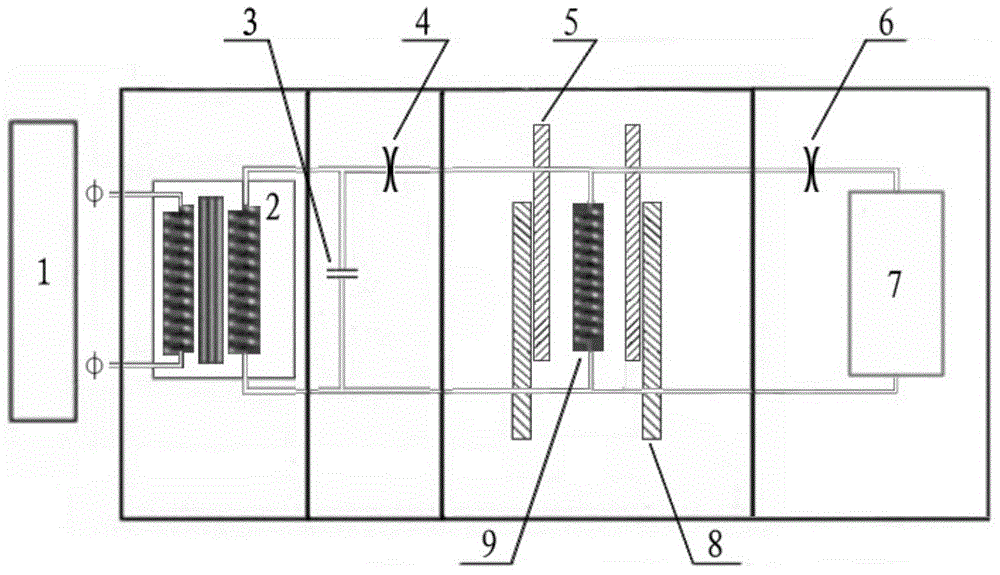

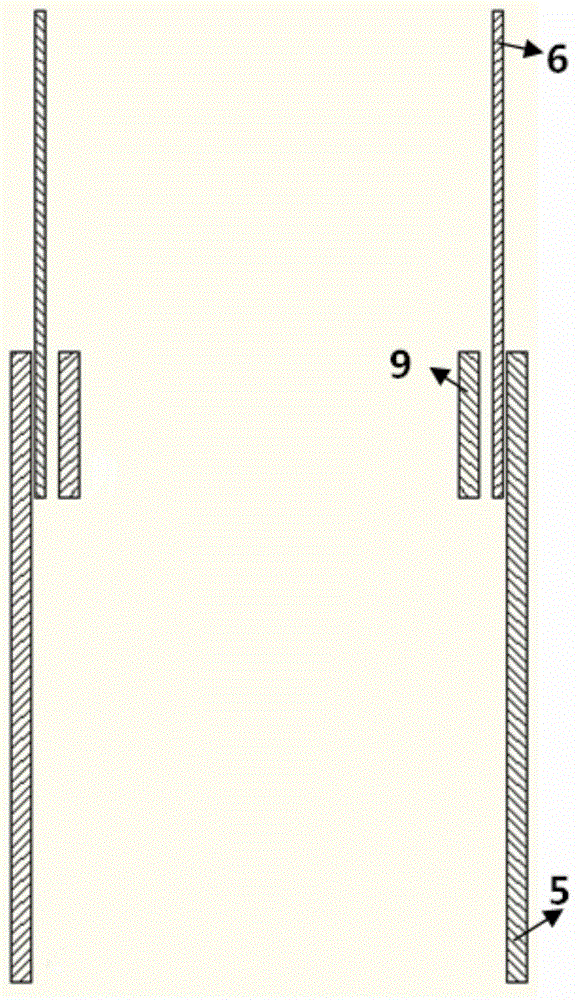

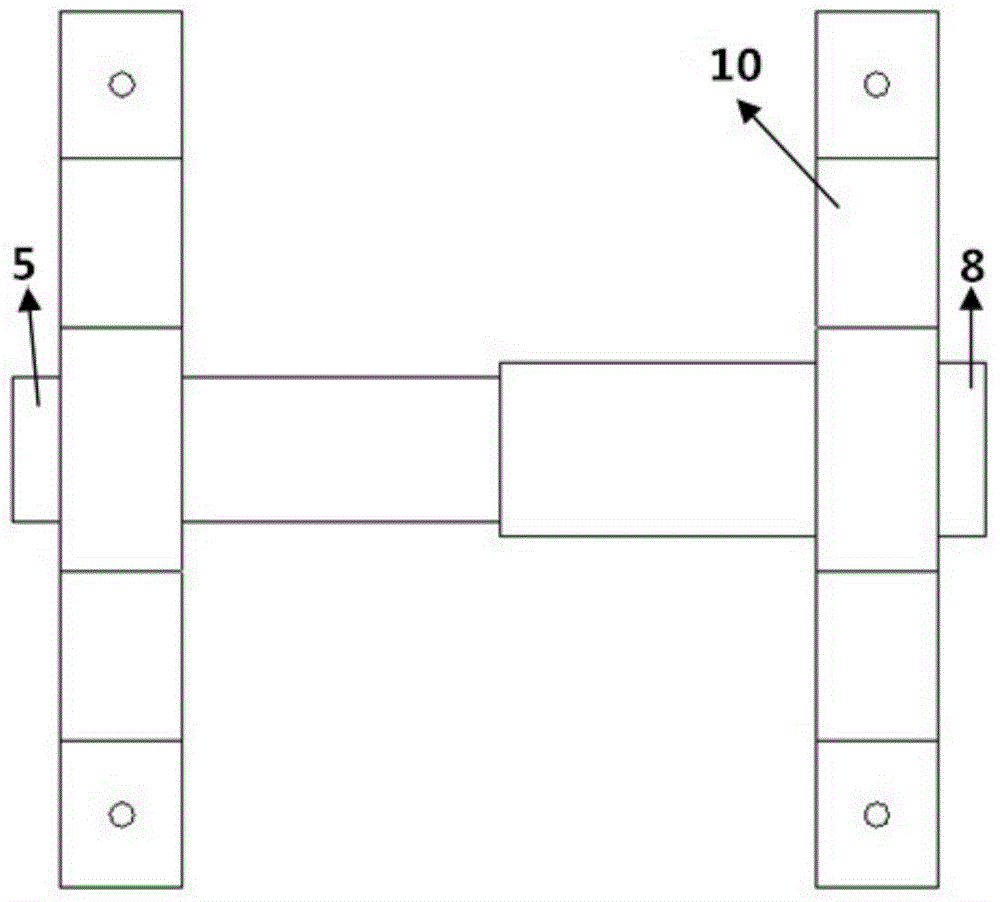

Magnesium alloy/carbon steel pipe composite connection method based on induction heating and electromagnetic forming

ActiveCN104384701AImprove connection efficiencyEasy to automateWelding/soldering/cutting articlesNon-electric welding apparatusElectromagnetic inductionCapacitance

The invention relates to a magnesium alloy / carbon steel pipe composite connection method based on induction heating and electromagnetic forming. A warm electromagnetic forming method is utilized to increase the magnesium alloy forming performance, additionally, electromagnetic induction heating and electromagnetic forming are combined, the induction heating and forming functions are realized by utilizing a same coil, so as to increase the connecting efficiency of a heterogeneous metal tube and facilitate the automation control, and additionally, a warm forming process and an electromagnetic forming process are combined during forming, so that the connecting forming performance is increased. According to the magnesium alloy / carbon steel pipe composite connection method, a magnesium alloy pipe is overlapped with a carbon steel pipe, and after the magnesium alloy inner pipe reaches the set temperature through the electromagnetic induction heating of the coil, the magnesium alloy inner pipe is discharged by the electromagnetic forming coil, so that severe plastic deformation of the magnesium alloy inner pipe occurs, and the magnesium alloy inner pipe after plastic deformation collides and connects with an outer pipe. According to the method, the electromagnetic forming coil is instantaneously discharged through an energy storage capacitor, so as to generate a strong pulsed magnetic field, so that the warm inner pipe is formed at high speed under the action of electromagnetic force and collides with the carbon steel outer pipe with higher rigidity at high speed to generate combination.

Owner:WUHAN UNIV OF TECH

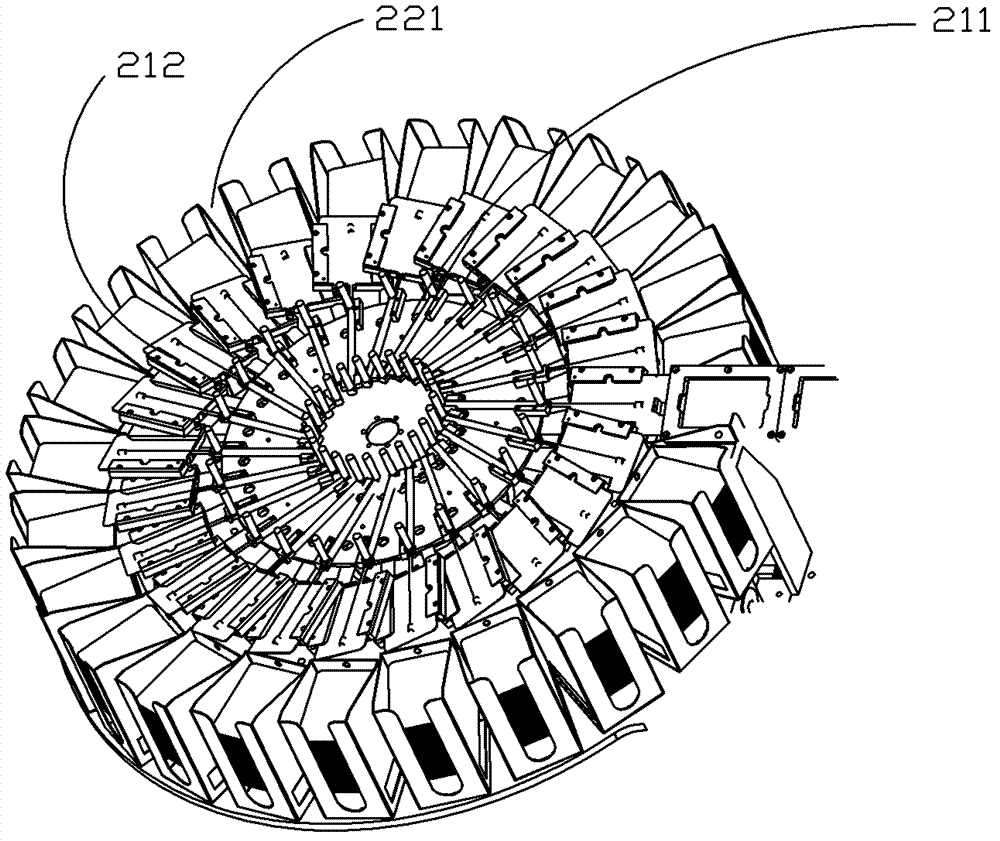

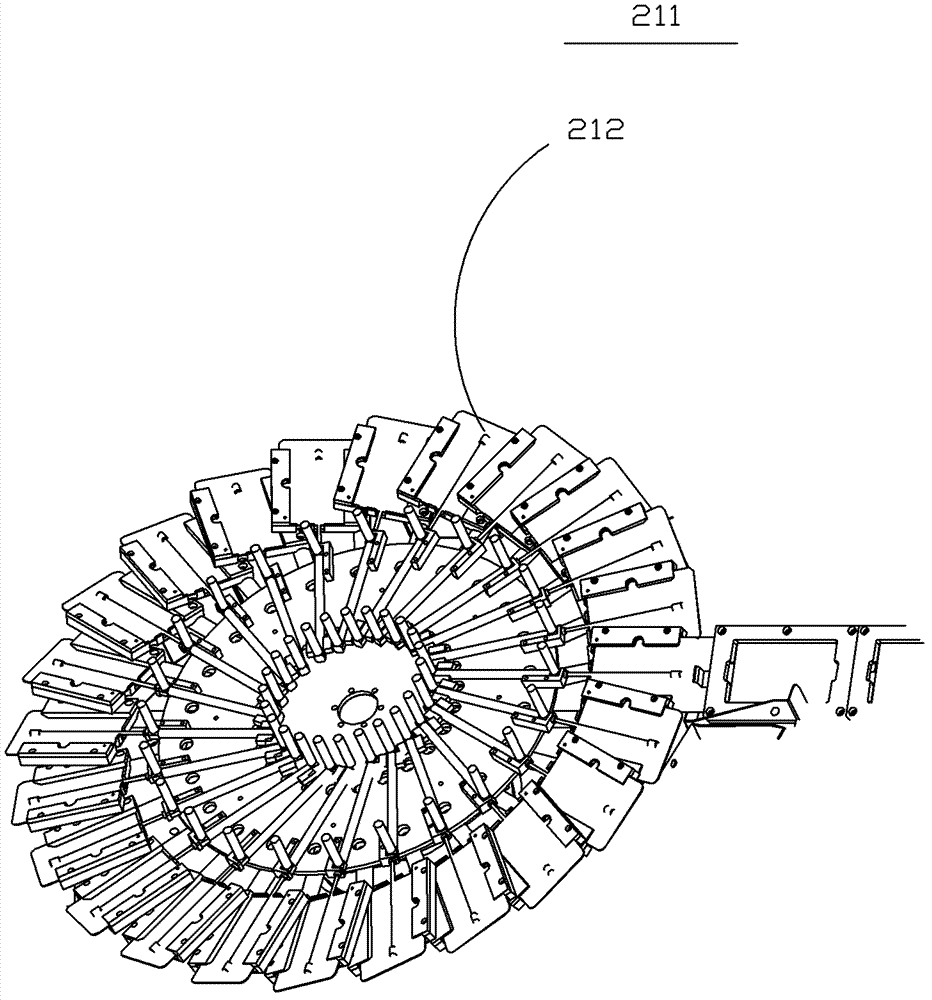

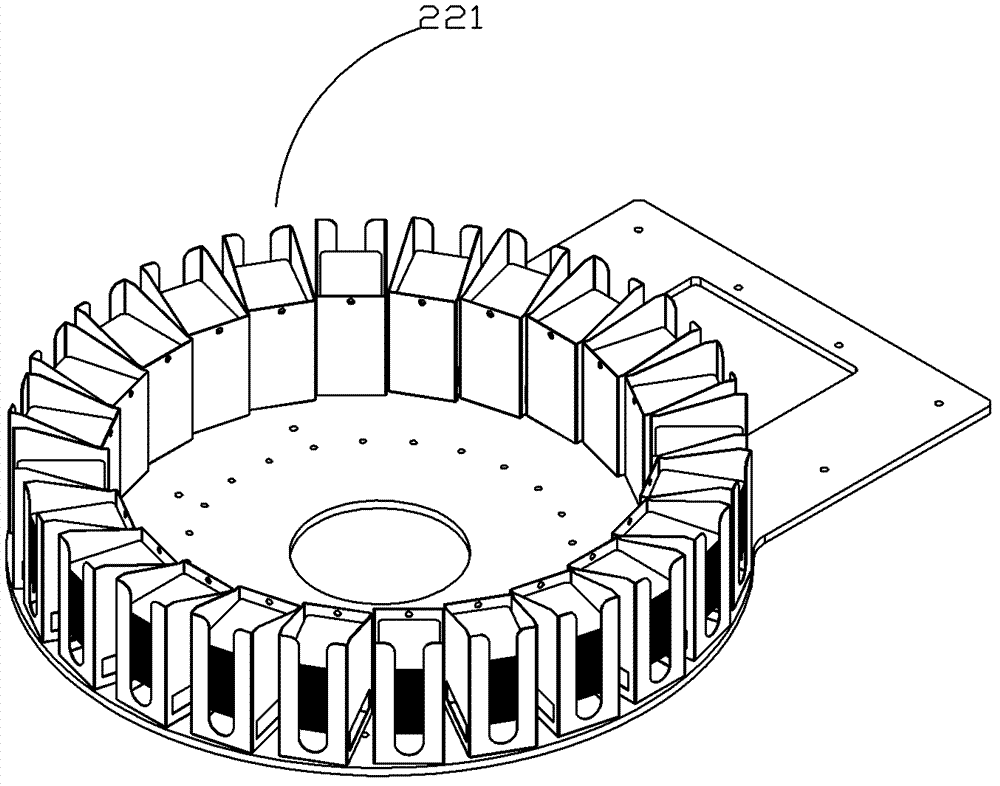

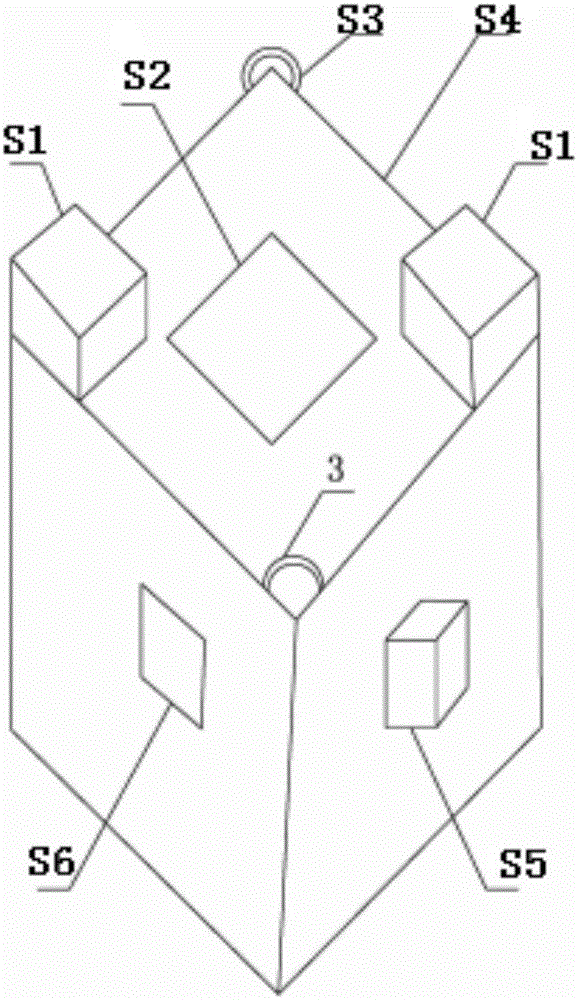

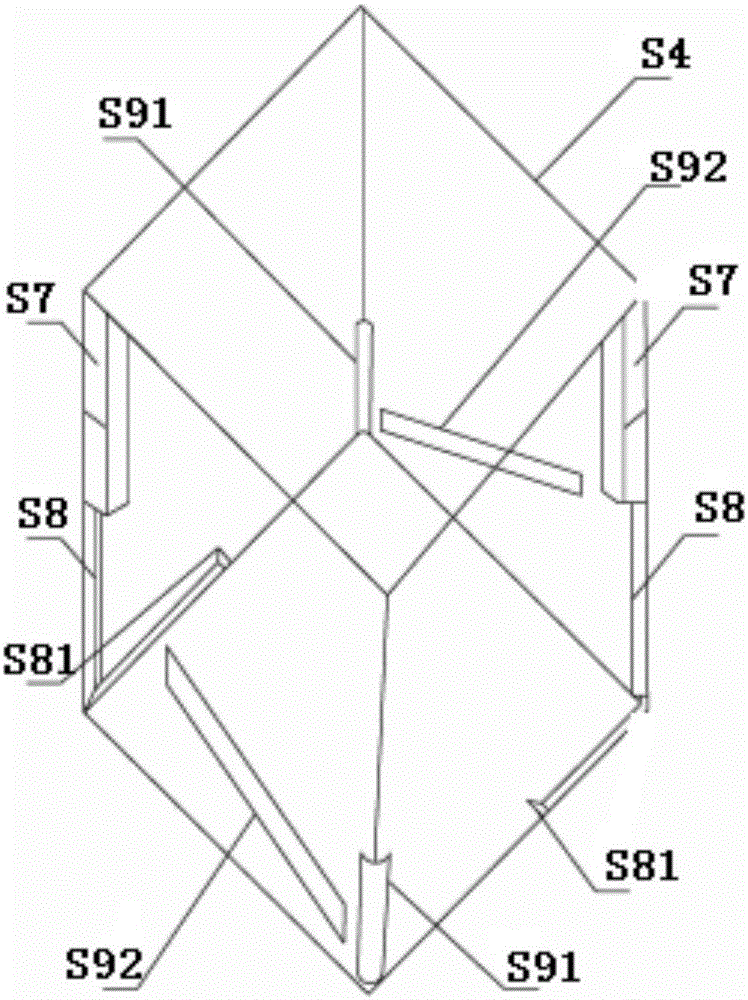

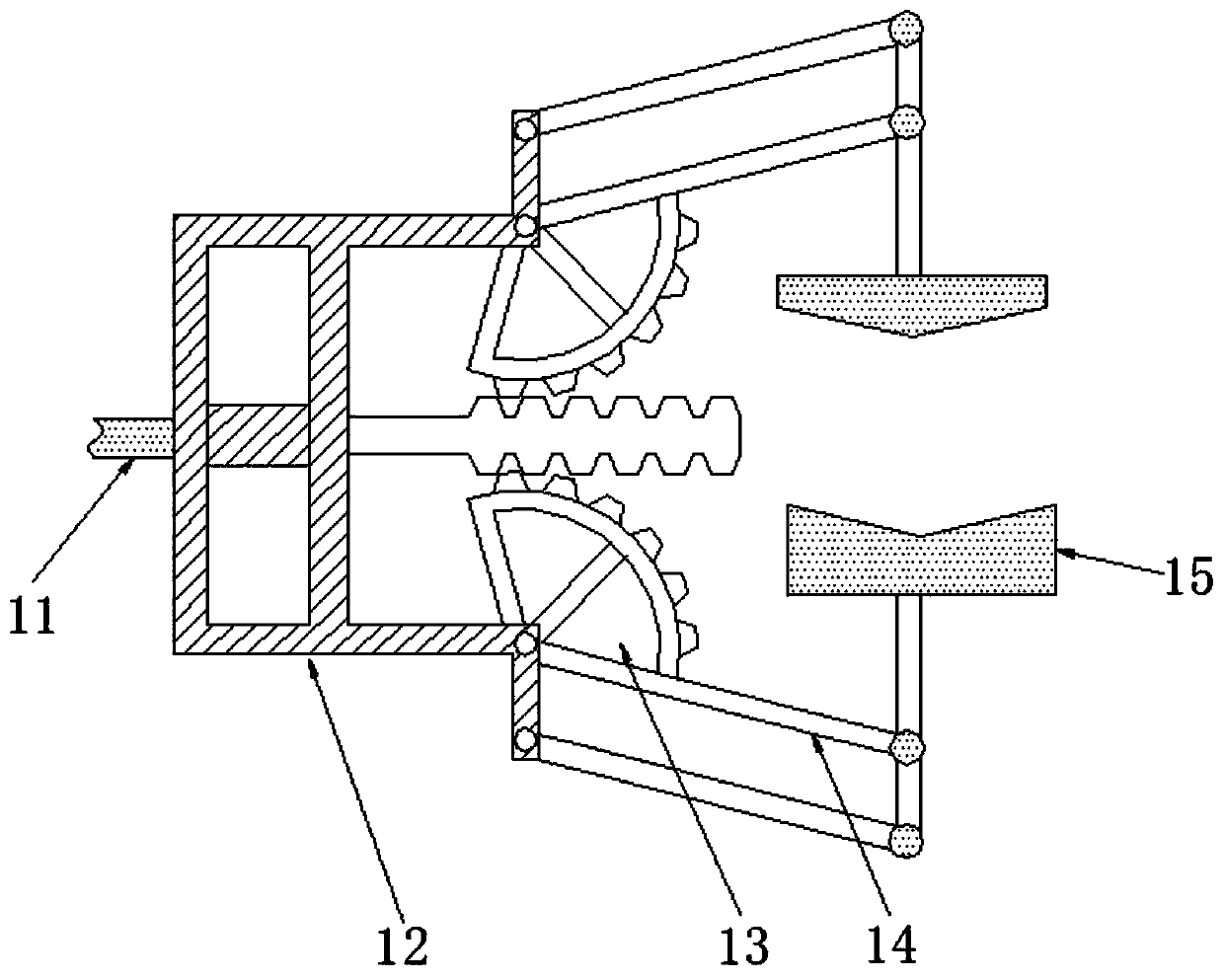

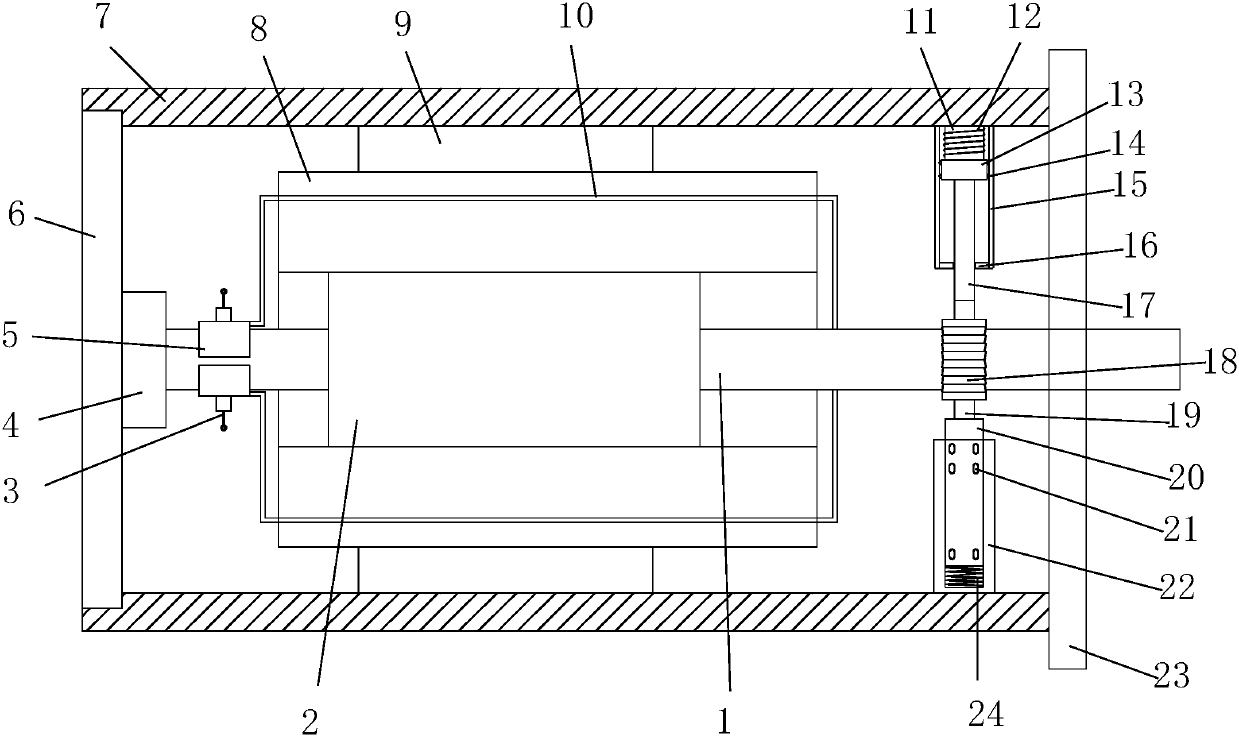

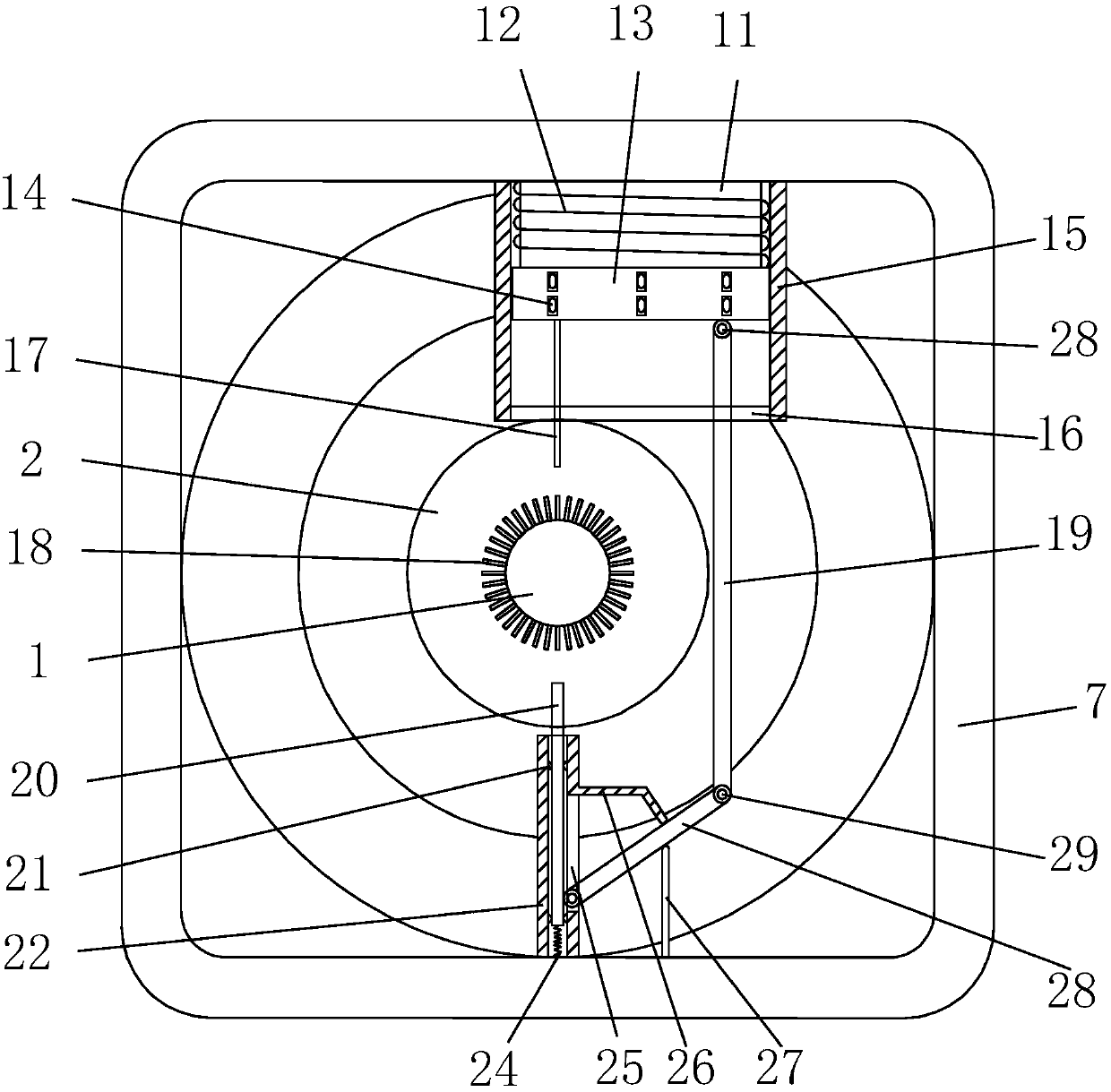

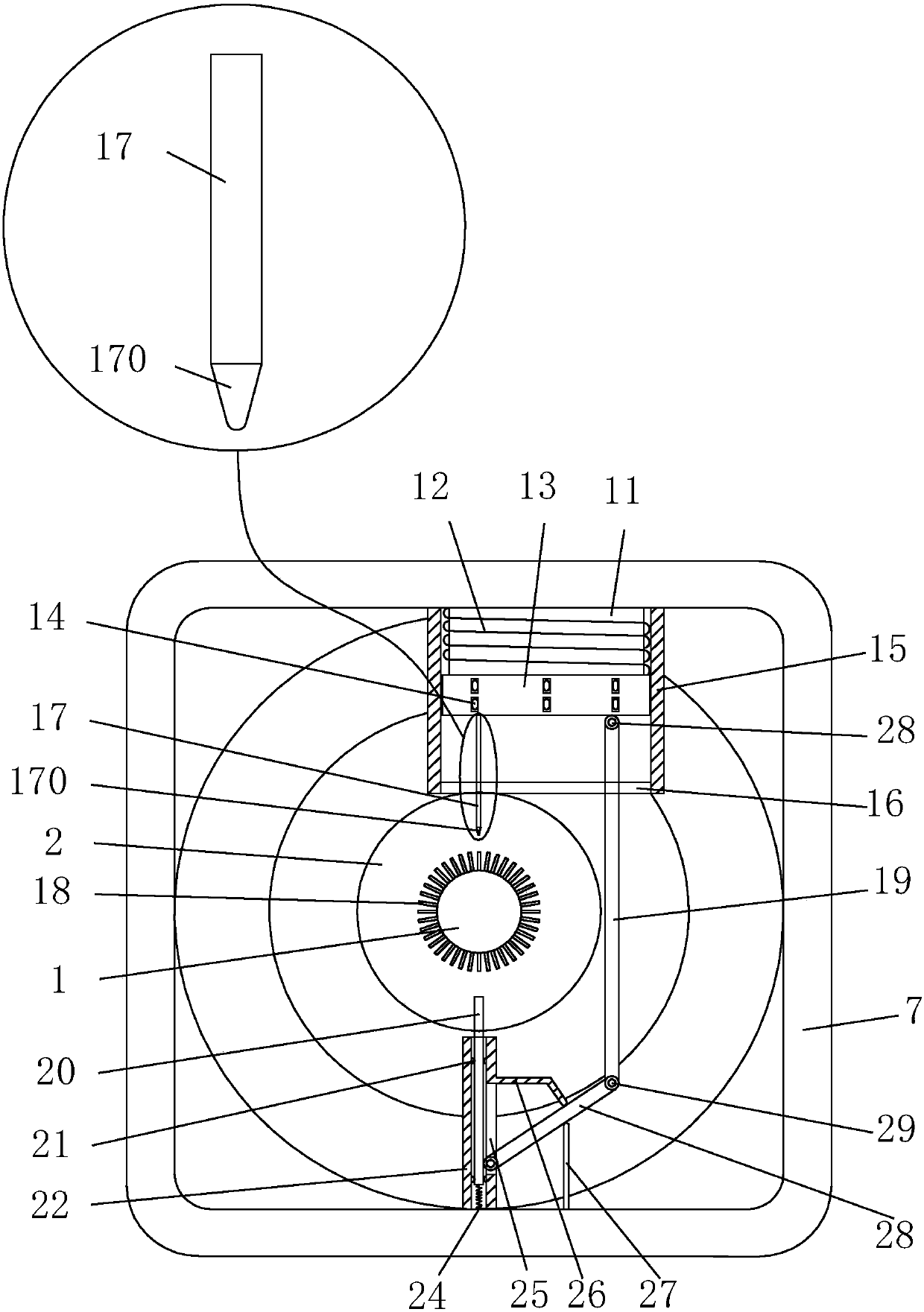

Card sorting device and automatic electric writing device with same

ActiveCN102950119ARealize intelligent classificationSolve the difficulty of classificationDigitally marking record carriersSortingElectricityInformation processing

The invention provides a card sorting device and an automatic electric writing device with the same. The card sorting device comprises a card sorting plate and a rotating shaft, wherein the rotating shaft is horizontally positioned at the lower part of the card sorting plate; the card sorting plate is divided into two layers, namely, a first layer for installing an identification card temporary storage slot, and a second layer for installing a card storage slot, and the first layer can be rotated relative to the second layer; bulges, which are arranged along the circumference, are arranged at the lower bottom part of the first layer of the card sorting plate; a card pushing device for pushing an identification card out of the temporary storage slot is arranged on the card sorting plate; cam mechanisms in match with the bulges at the lower bottom part of the first layer of the card sorting plate are arranged at the end part of the rotating shaft; the automatic electric writing device comprises a base, a card feeding device, a card writing device, an information verifying device, an information processing device and the card sorting device, and the information processing device is positioned in the base; the card feeding device is positioned on the base; the card writing device and the information verifying device are positioned at the upper part of the card feeding device; and the card sorting device is positioned at the tail end of the card feeding device. The card sorting plate has the advantages of being stable, high in sorting capacity, high in efficiency, and small in size.

Owner:INT SECURITY TECH SHENZHEN +1

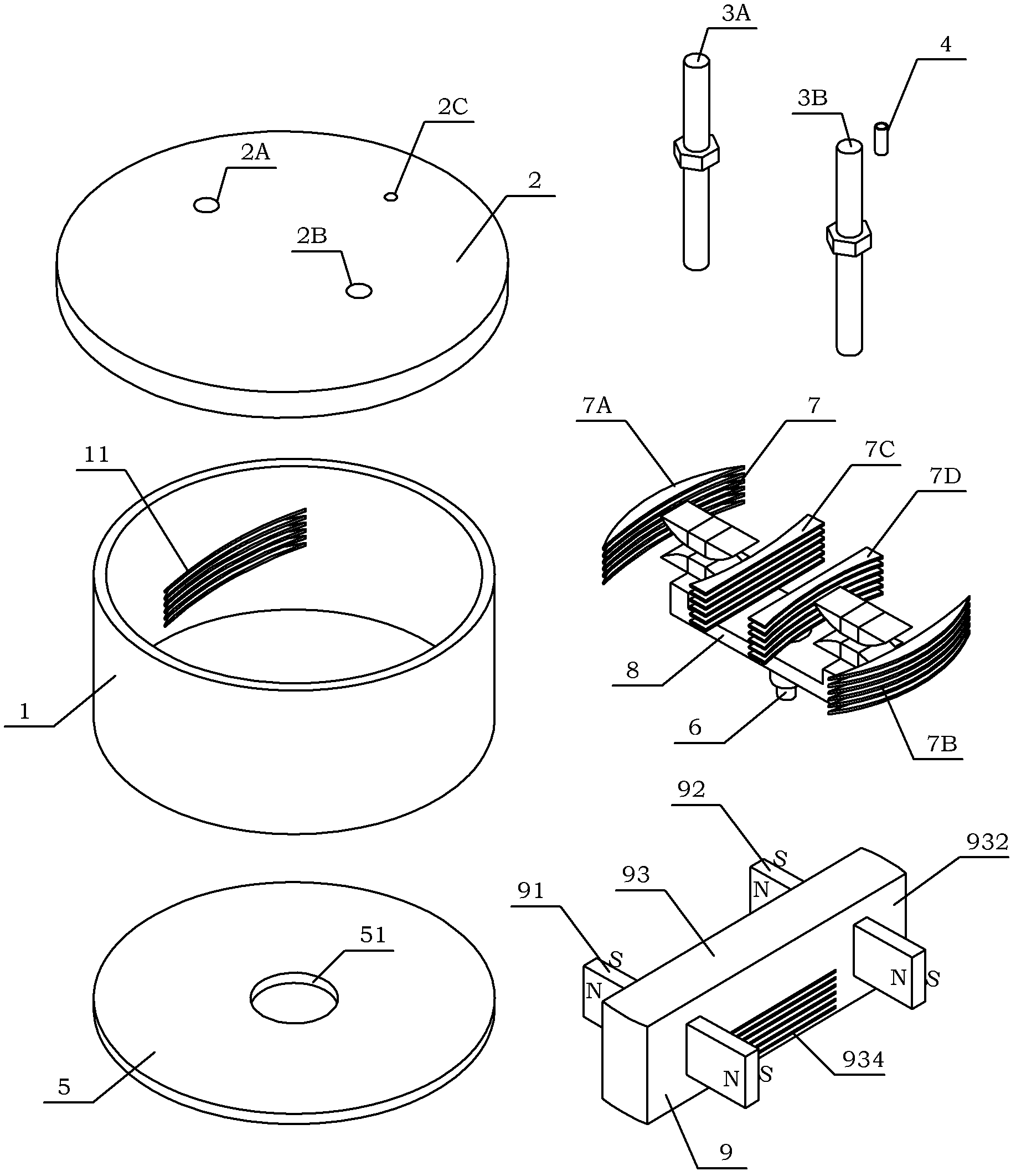

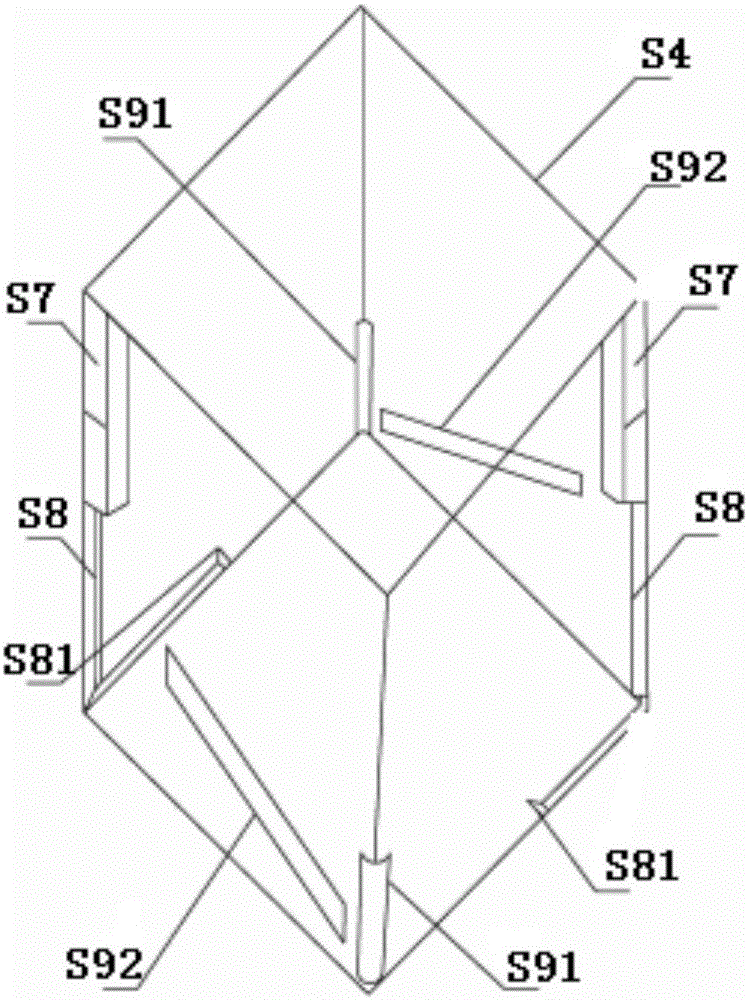

Non-polar hydrogen mixed gas DC (direct-current) arc extinction system for DC contactor

ActiveCN102592890AEasy accessIncrease contactElectric switchesElectromagnetic relay detailsBreaking capacityArc extinction

The invention discloses a non-polar hydrogen mixed gas DC (direct-current) arc extinction system for a DC contactor. The DC arc extinction system comprises a moving contact, four pairs of moving and static arc striking contacts, a static contact, a grid group and a permanent magnet. The non-polar hydrogen mixed gas DC arc extinction system is non-polar, namely the arc extinguishing property can not be influenced by the change of the current direction. According to the non-polar hydrogen mixed gas DC arc extinction system, the arc striking contacts strike electric arc to smoothly move along a track of the arc striking contacts, the arc striking contacts, the grid group and the permanent magnet are reasonably arranged, and the electric arc between the moving contact and the static contact is better and rapidly extinguished, thus the short circuit caused by sudden reversing of current is solved, and the breaking capacity is further improved. Hydrogen or a hydrogen mixed gas can be inflated into the non-polar hydrogen mixed gas DC arc extinction system for realizing arc extinguishing.

Owner:BEIHANG UNIV

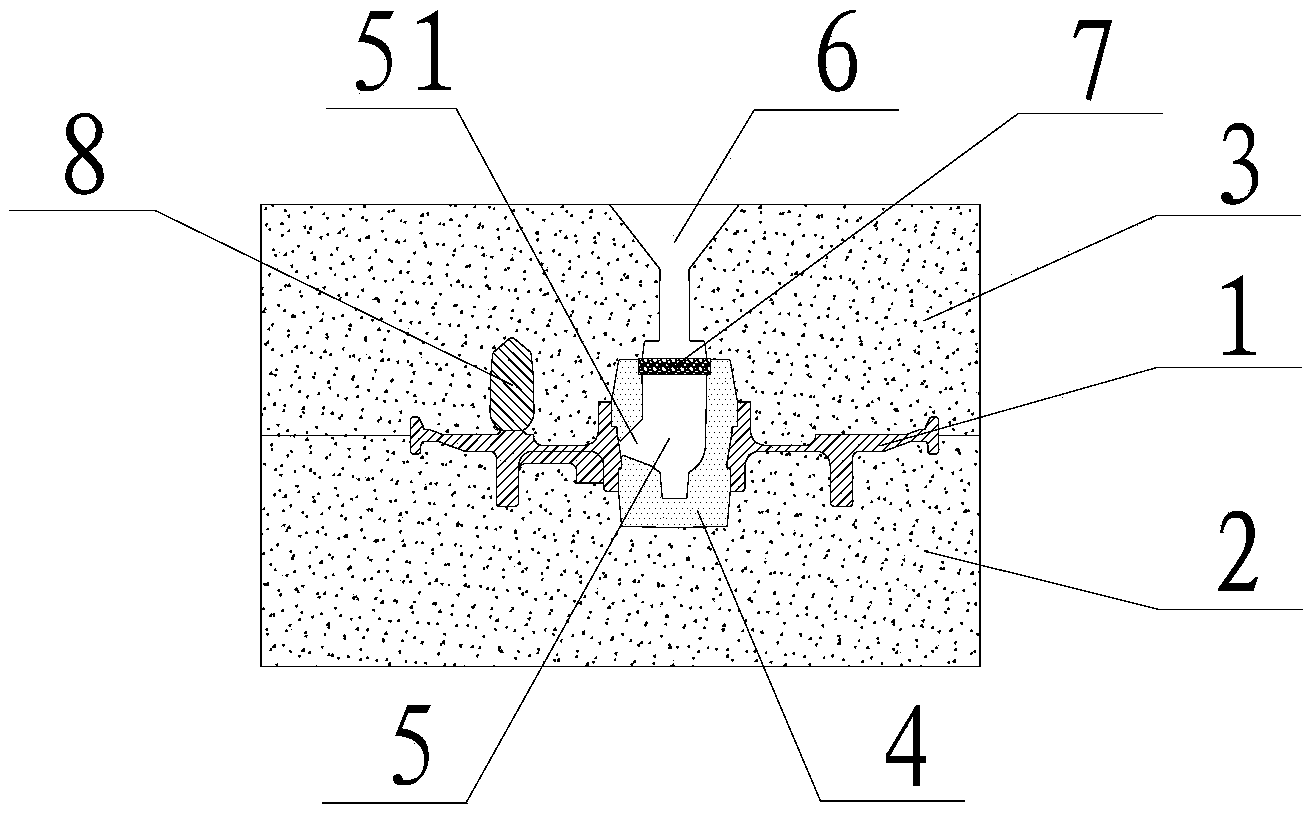

Selenium-rich culture medium for hericium erinaceus and method for producing hericium erinaceus

InactiveCN106242763AHigh nutritional valueIncrease selenium contentCalcareous fertilisersFungiNutritive valuesEnrichment methods

The invention provides a selenium-rich culture medium for hericium erinaceus. The selenium-rich culture medium for hericium erinaceus is mainly prepared from wood flour, bran, selenium-rich fungus grass and gypsum. The invention further provides a method for producing hericium erinaceus with the selenium-rich culture medium for hericium erinaceus. A traditional production method of a hericium erinaceus strain is changed, a liquid strain technology is utilized in hericium erinaceus strain production, and a selenium-rich liquid strain is prepared; meanwhile, the solid selenium-rich culture medium and a secondary selenium enrichment method are adopted, and produced hericium erinaceus is high in selenium content and high in nutritive value. Production efficiency is improved, and production cost is greatly reduced; besides, the production method is simple in process, and the produced strain is high in utilization rate and low in contamination rate.

Owner:井冈山井祥菌草生态科技股份有限公司

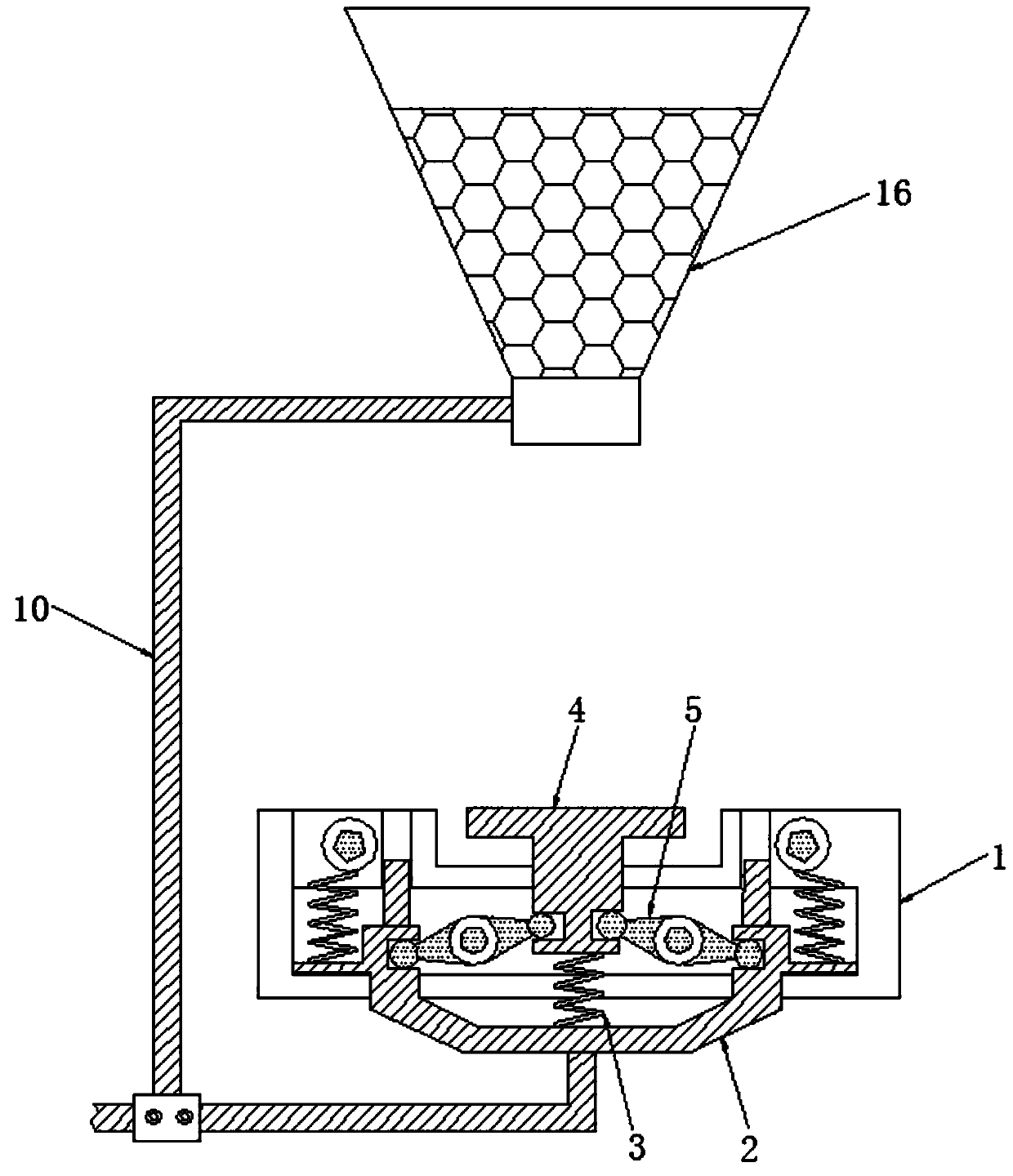

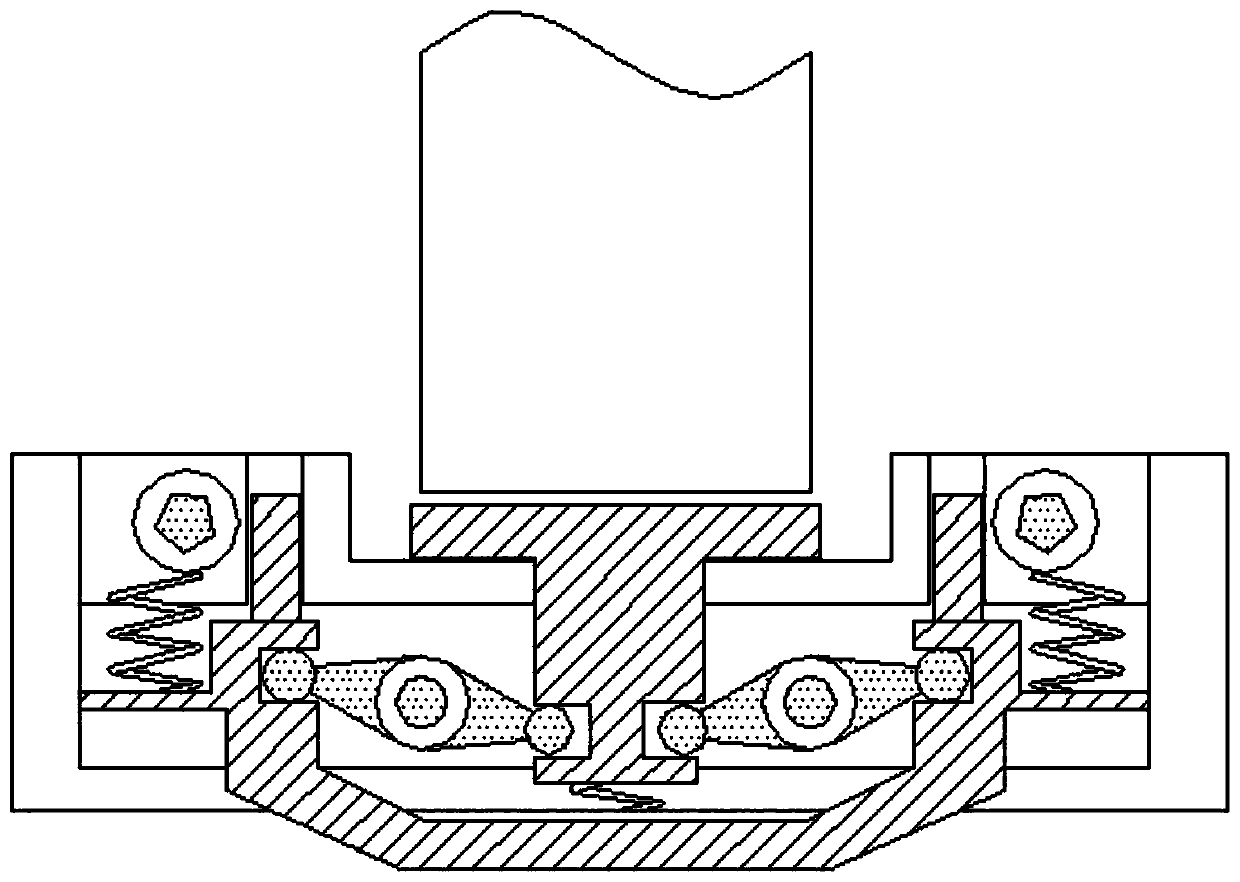

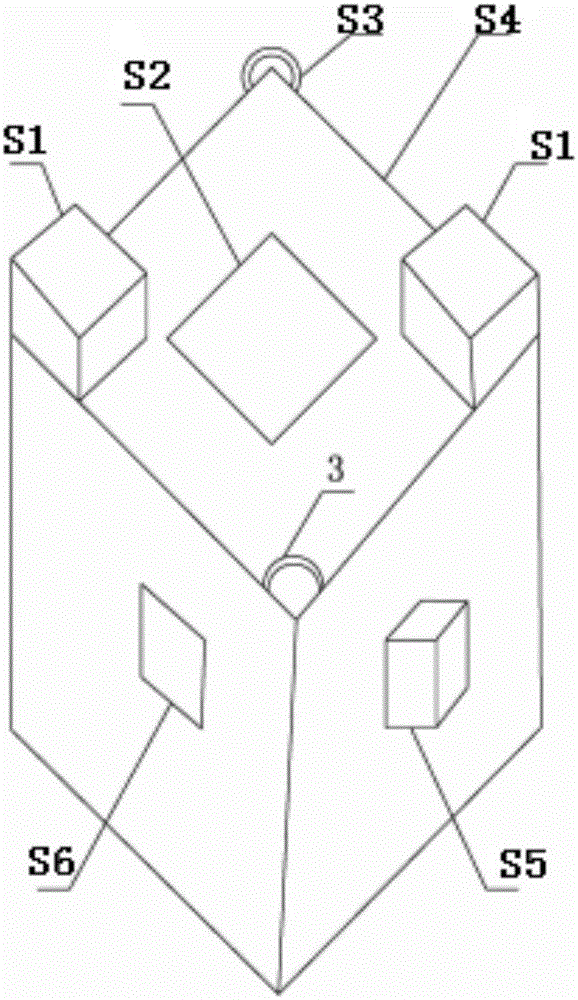

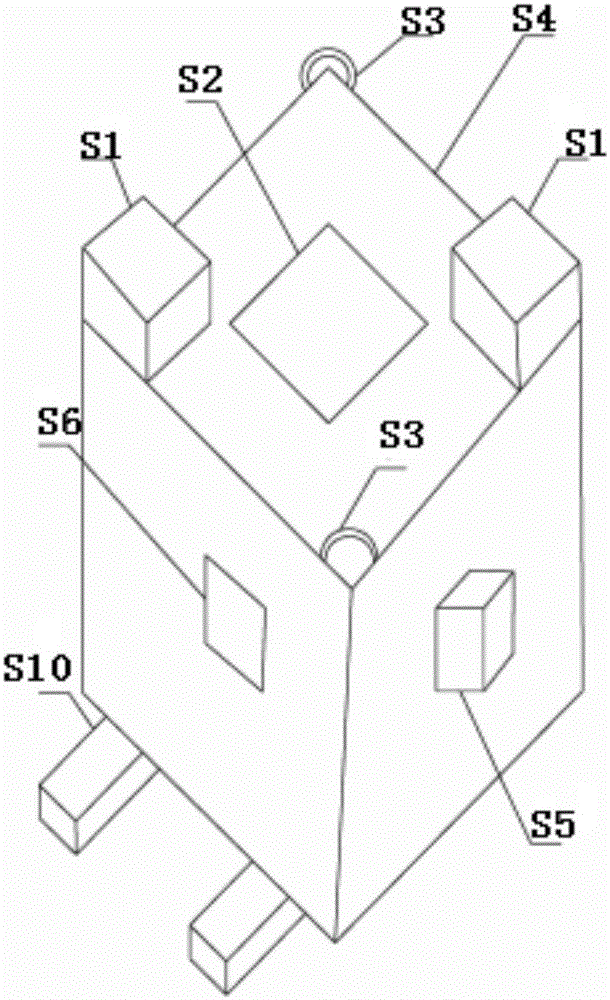

Gravity based device for quantitative weighing and feeding of feed

ActiveCN110432168AReduce workloadConsistent timeAnimal feeding devicesAvicultureEngineeringMechanical engineering

The invention relates to the technical field of breeding industry and discloses a gravity based device for quantitative weighing and feeding of feed. The gravity based device comprises a base, a lowerplate is movably connected to the inside of the base, the feed is received by placing a container on a load bearing table, the feed is moved downwards after being subjected to the gravity, and two partition plates are closed finally. The weight of each weighing of the feed is the same assuredly, the working efficiency is improved, the device can be driven to move according to the change of the gravity, the whole device is more energy-saving and environmentally friendly in the process of operation, the lower part of the load bearing table is provided with an L-shaped hook, the load bearing table is hooked by the hook when moving down to the final position and is limited in position, and the impact of weighing results is avoided; the device is more sensitive and practical by setting both ends of the load bearing table and the lower plate with grooves and supporting rods to be spherical.

Owner:湖北晶鹿牧业股份有限公司

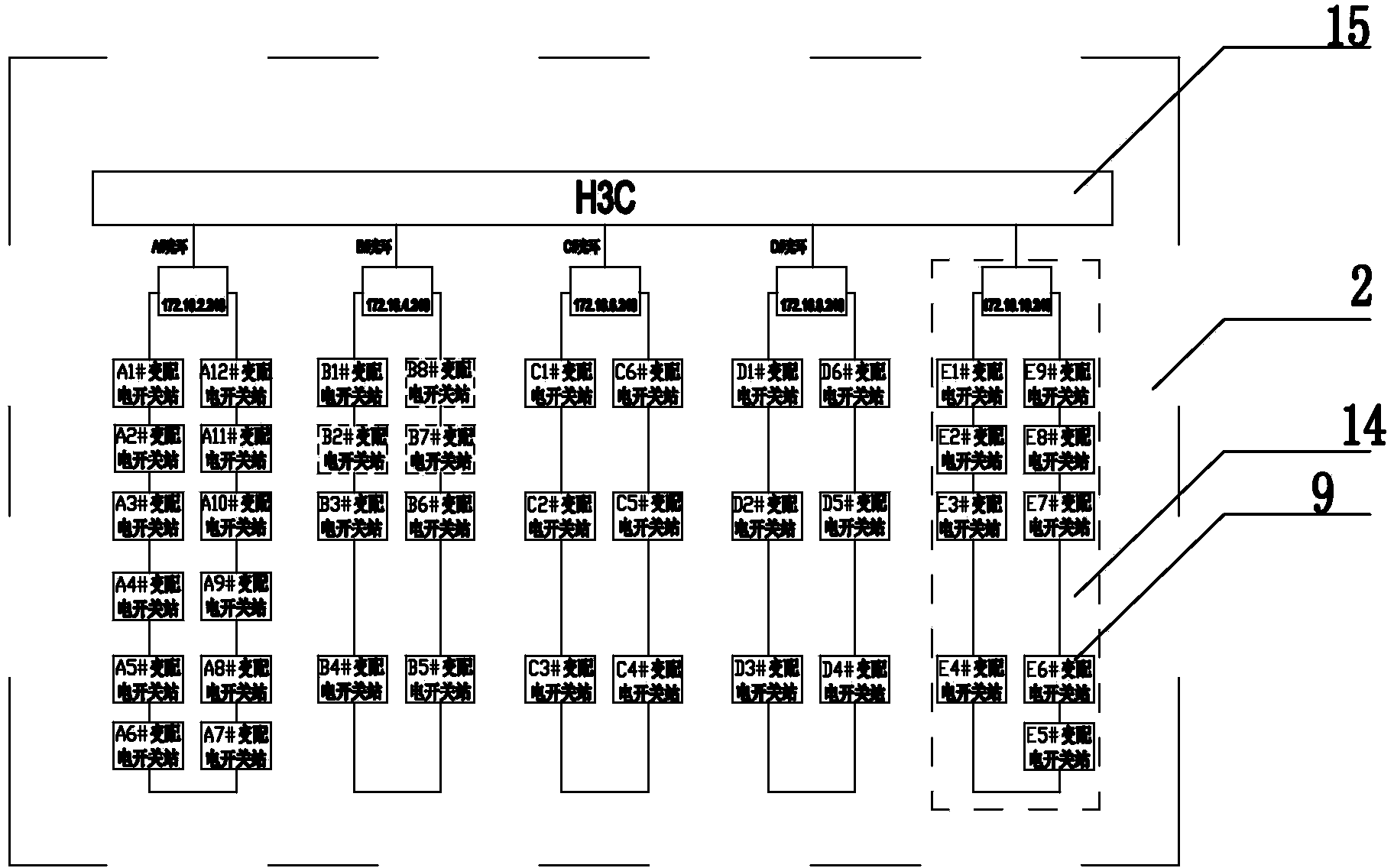

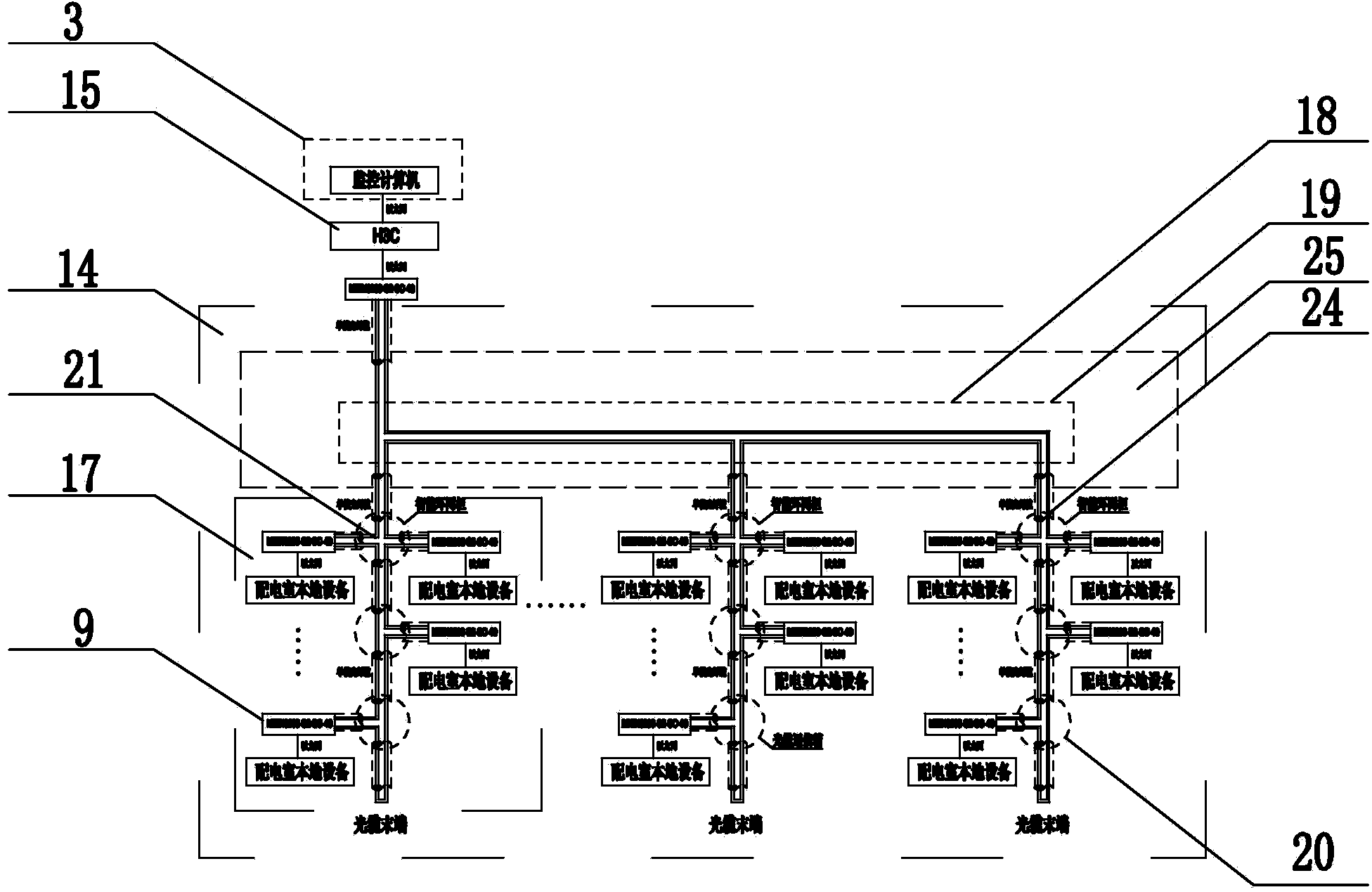

Substation distribution room full-view inspection-tour monitoring system and management method thereof

ActiveCN103545934AAvoid the problem of refusal and misoperationLightning protectionCircuit arrangementsPower factorHigh pressure

The invention provides a substation distribution room full-view inspection-tour monitoring system and a management method of the substation distribution room full-view inspection-tour monitoring system, and belongs to the field of substation distribution room full-view inspection-tour monitoring systems. The substation distribution room full-view inspection-tour monitoring system comprises a terminal control system, a branch-shaped looped-network optical-fiber communication system and a dispatching monitoring center. According to the substation distribution room full-view inspection-tour monitoring system, dispatching personnel in front of a dispatching computer can remotely see voltage values, current values, power values, phase-angle values and power factor values of power supply circuits, the input and exit situation of the protection function and a protection constant value of a switch, the working state of the switch and the on-site video of electricity transformation and distribution switching stations, and send a remote-control instruction to a high-voltage switch, and the five-remote-control function which integrates telecommands, telemetering, remote control, remote regulation and remote vision is achieved.

Owner:山东兰德勘察设计有限公司

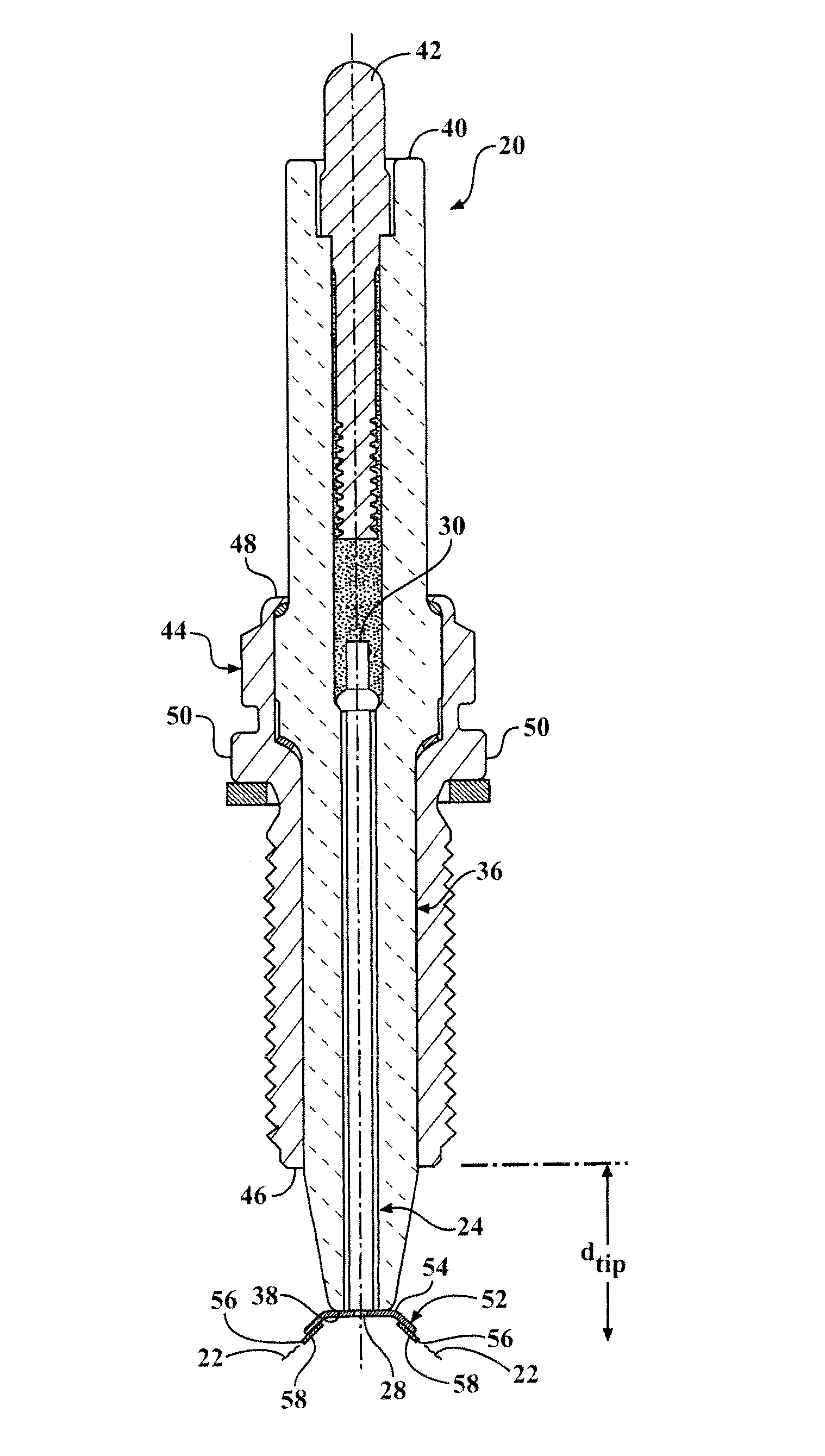

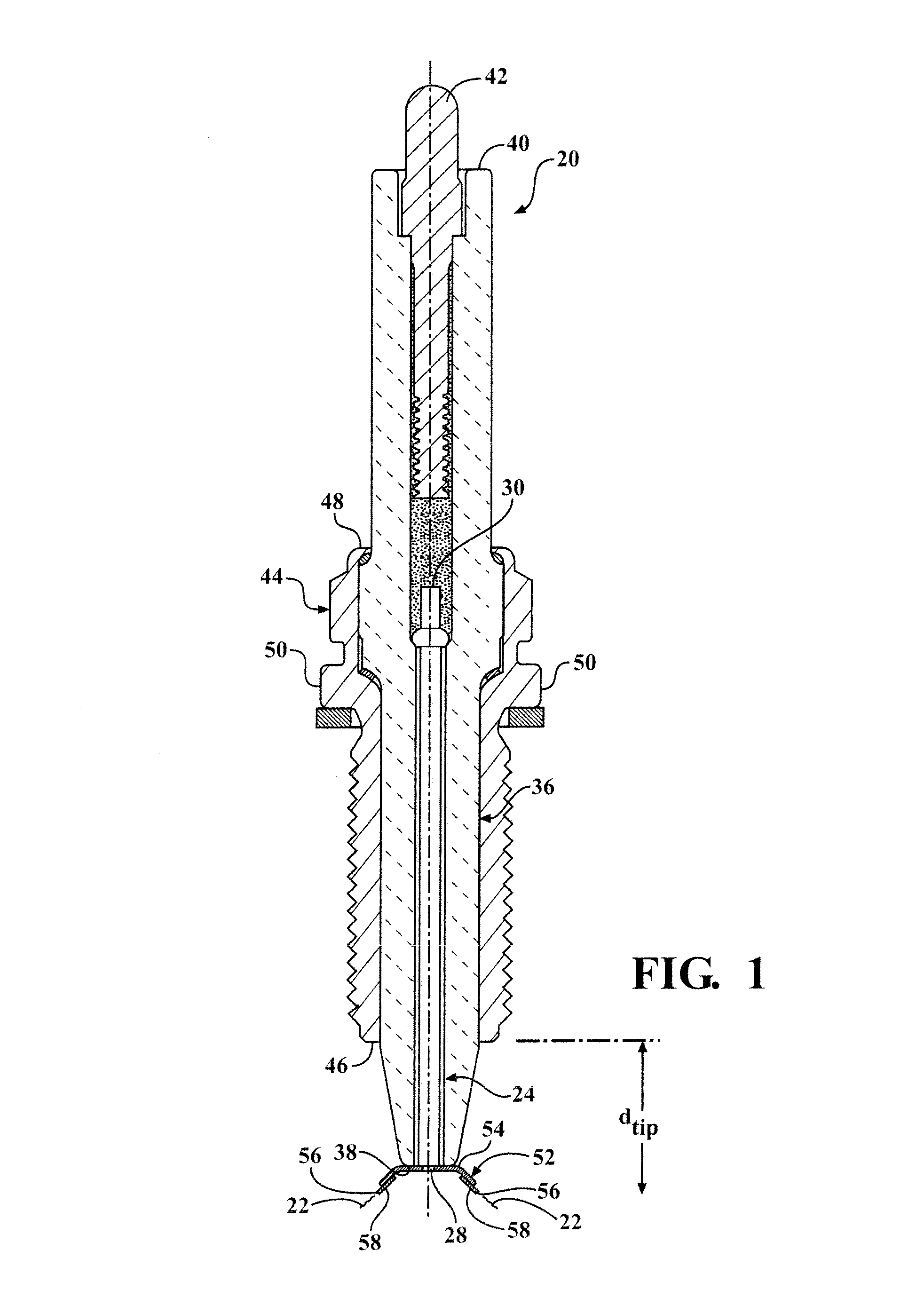

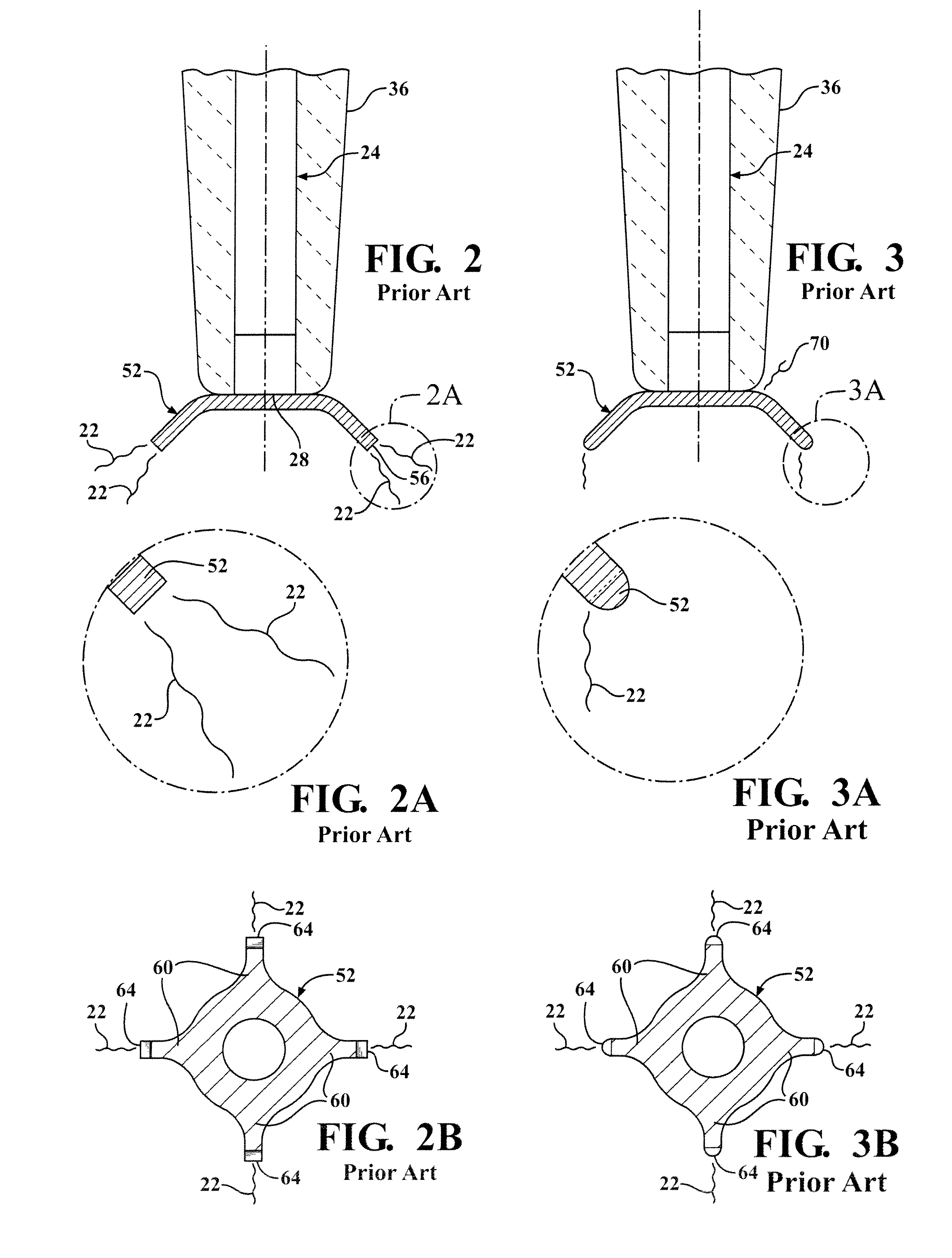

Igniter including a corona enhancing electrode tip

ActiveUS8776751B2Reduce erosion rateStrong electrical fieldWave amplification devicesAnti-theft devicesElectrical field strengthErosion rate

An igniter (20) emitting an electrical field including a plurality of streamers forming a corona includes a corona enhancing tip (52) at an electrode firing end (28). The corona enhancing tip (52) includes an emitting member (58) such as a wire, layer, or sintered mass, formed of a precious metal and disposed on a base member (54). The base member (54) is formed of a nickel alloy. The emitting member (58) has a lower electrical erosion rate and chemical corrosion rate than the base member (54). The emitting member (58) presents the smallest spherical radius of the corona enhancing tip (52) at the outermost radial point (56) to concentrate the electrical field emissions and provide a consistently strong electrical field strength over time.

Owner:FEDERAL MOGUL IGNITION

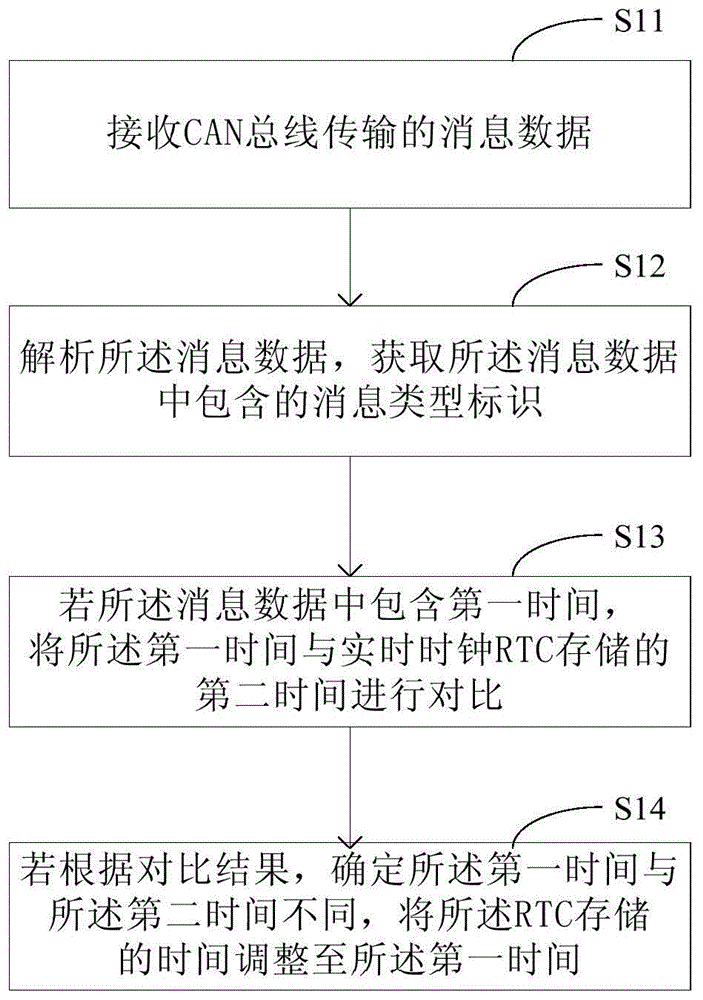

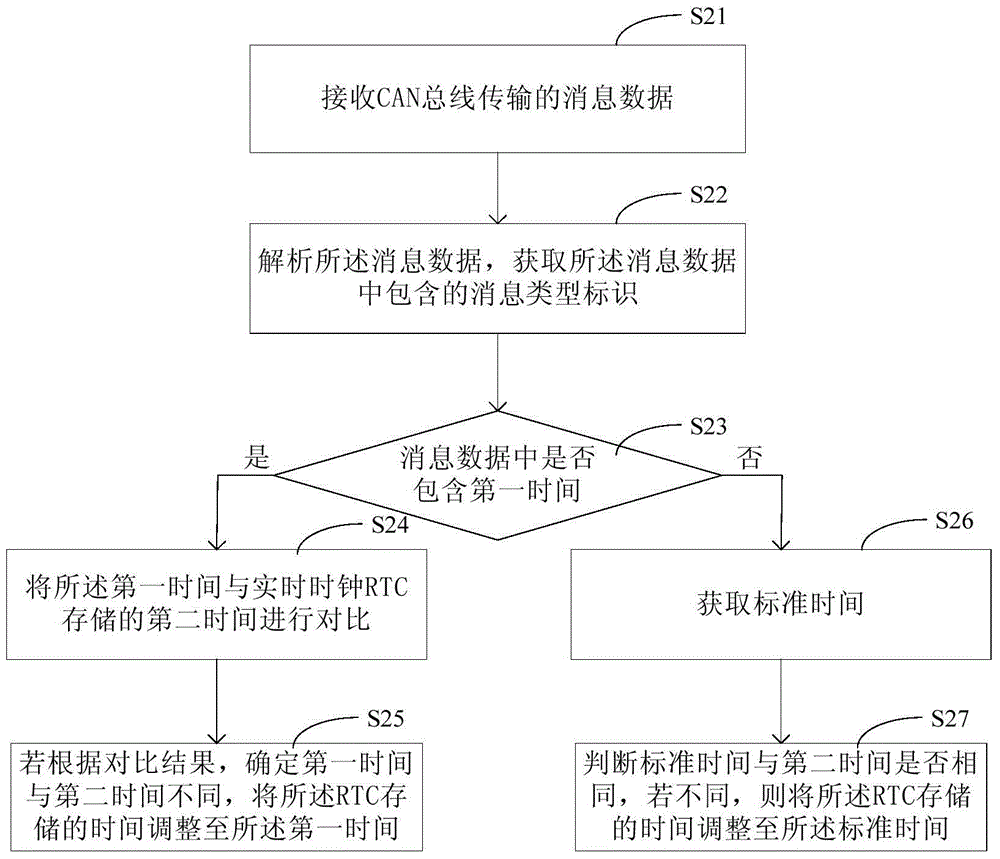

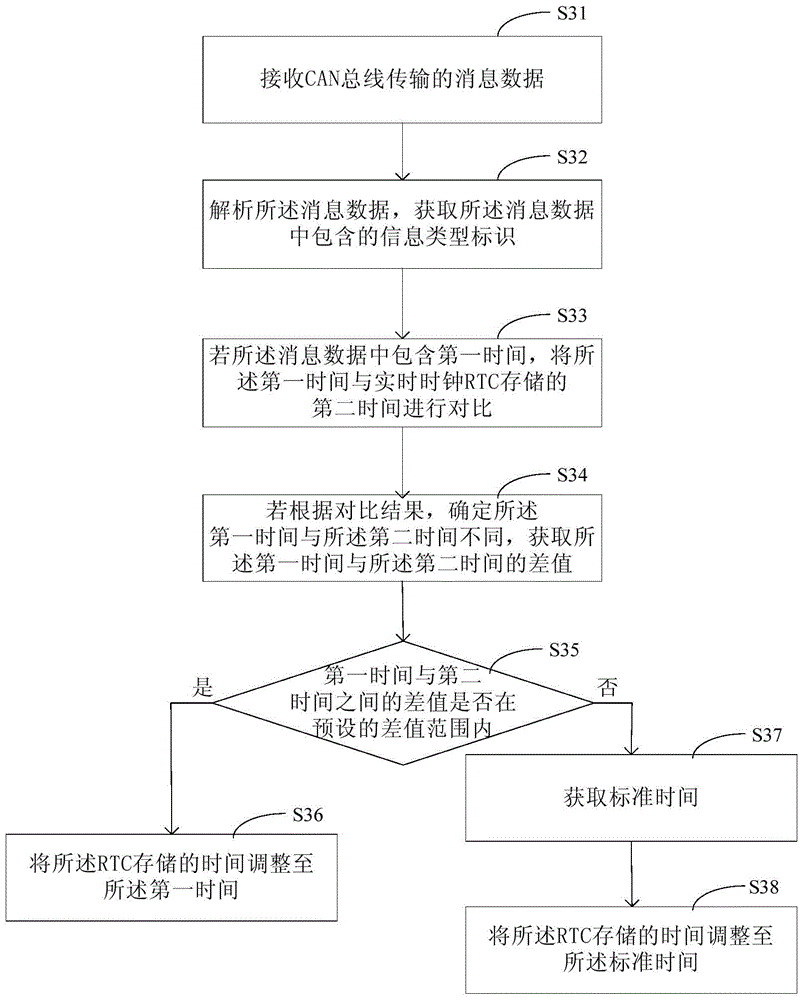

Clock synchronization method and device applied to vehicle-borne terminal

ActiveCN105700337AConsistent timeSynchronous motors for clocksTime-division multiplexComputer terminalClock synchronization

The present invention discloses a clock synchronization method and device applied to a vehicle-borne terminal. The method and the device are applied to the MCU arranged in the vehicle-borne terminal. Through the method and the device, the MCU receives the message data transmitted by a CAN bus, the message data is analyzed, the first time comprised in the message data is obtained, the first time and the second time stored by an RTC are compared, and when the first time and the second time are different, the time stored by the RTC is adjusted to the first time. Through the invention, the adjustment of the RTC by the MCU is realized, the time stored by the RTC after adjustment is the first time, the first time is the time generated by the terminal arranged in the vehicle, thus the time obtained by the MCU is consistent with other terminals arranged in the vehicle, and the problem of a large deviation between the time obtained by the MCU and an actual time in the prior art is solved.

Owner:NEW SINGULARITY INT TECHN DEV

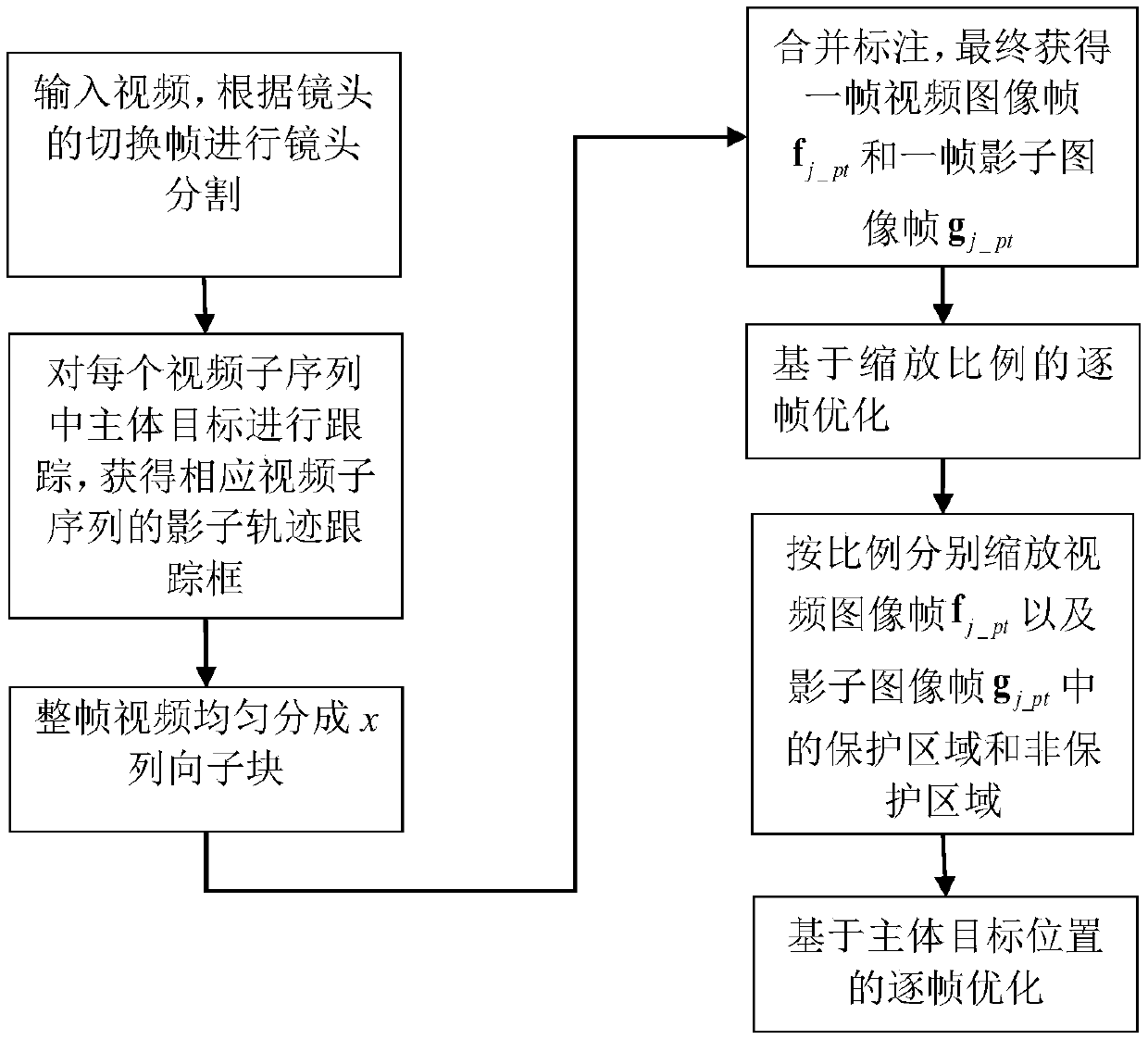

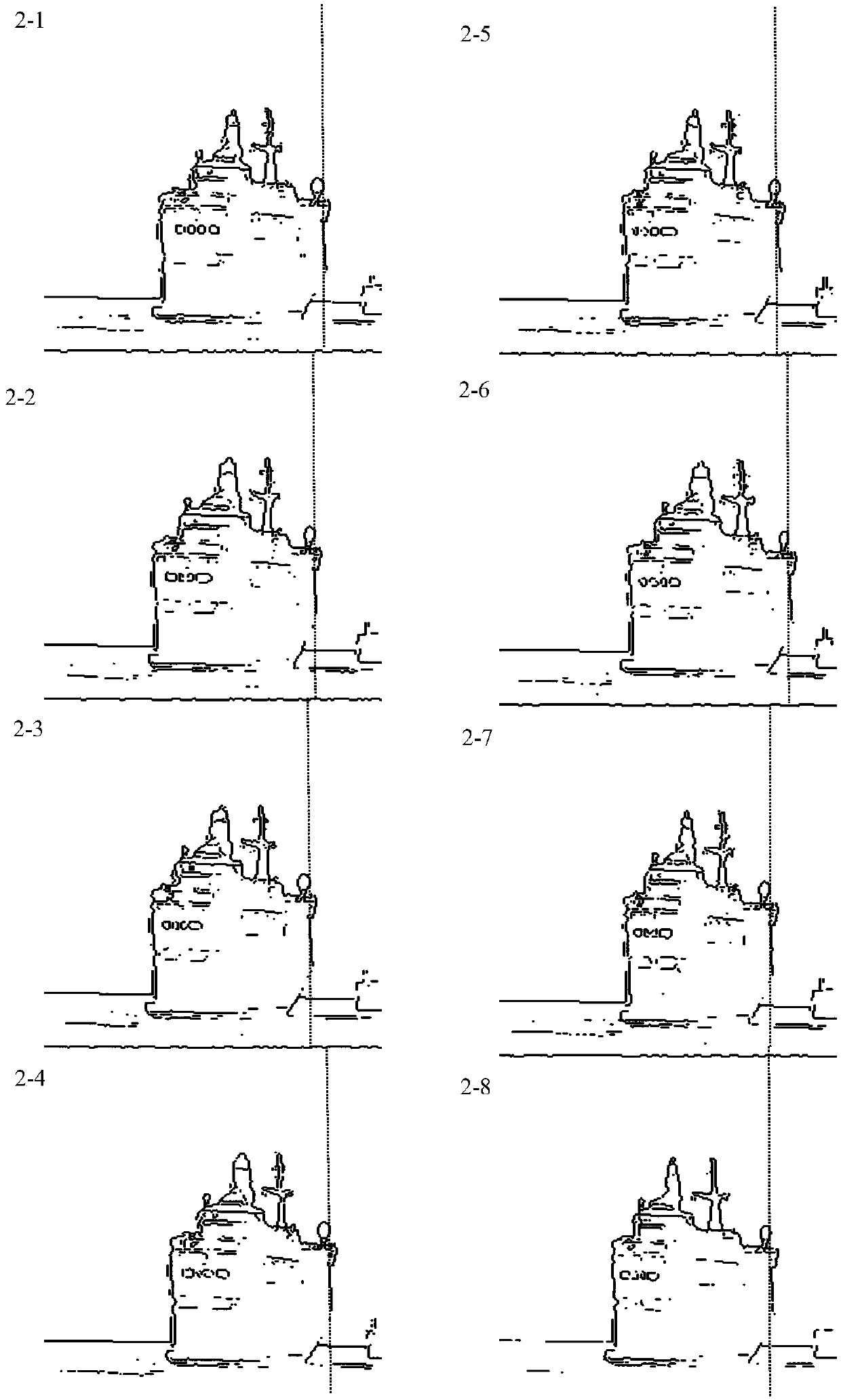

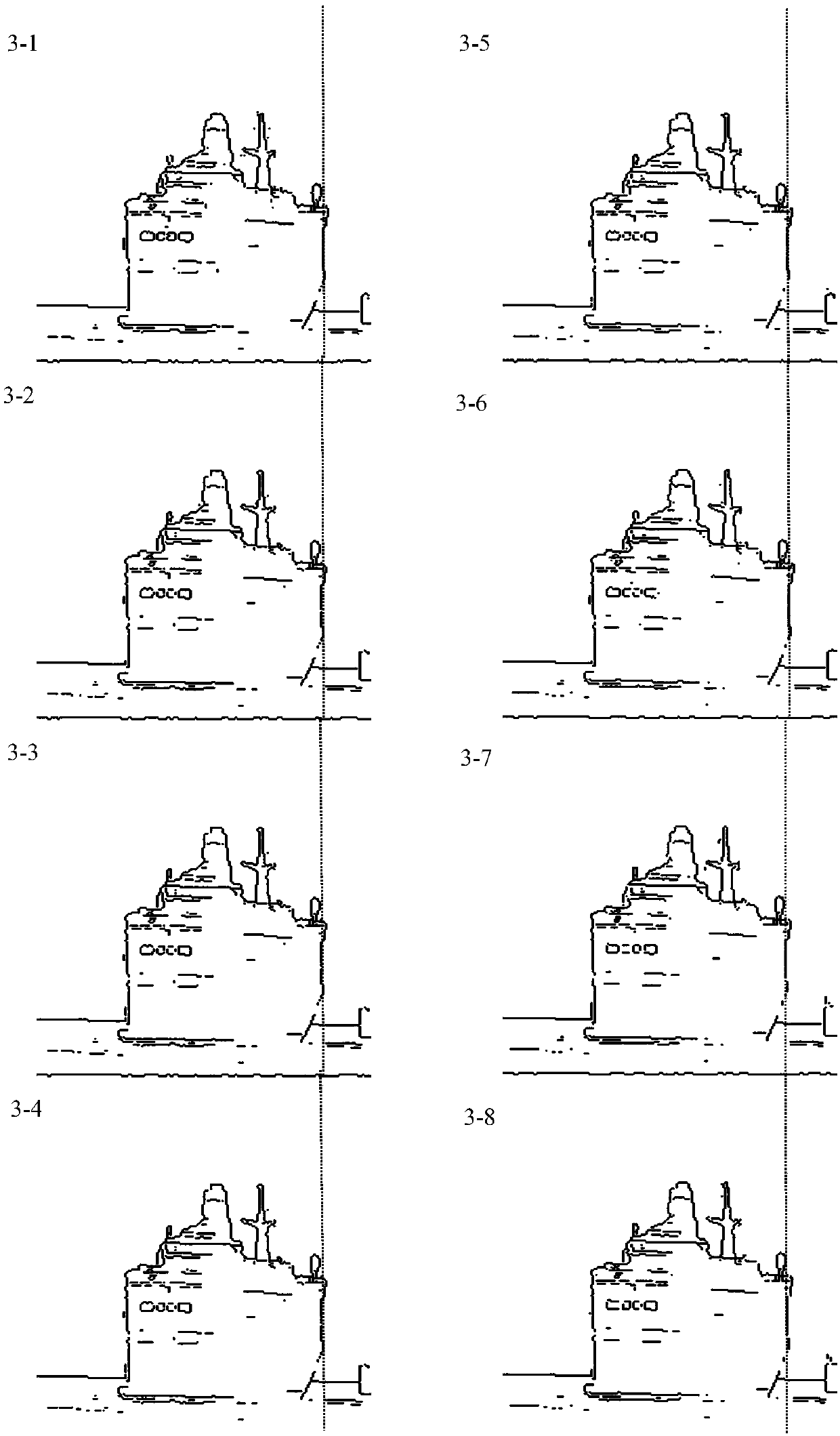

Video scaling method based on block segmentation and frame-by-frame optimization

InactiveCN108447021AImprove protectionImprove scalabilityImage enhancementImage analysisVideo imageImaging data

The invention provides a video scaling method based on block segmentation and frame-by-frame optimization and relates to common image data processing. The method is characterized by segmenting a videosequence into N video subsequences according to shot cut, and carrying out scaling and optimization on the video subsequences in the horizontal direction and vertical direction respectively. The method comprises the following steps: inputting a video, and carrying out shot segmentation according to shot switching frames; tracking a video main body target in each video subsequence to obtain a video trajectory tracking box of the corresponding video subsequence; uniformly dividing the whole frame of video into x column-wise sub-blocks; merging labels and finally obtaining a frame of video imageframe fj_pt and a frame of shadow image frame gj_pt; carrying out frame-by-frame optimization based on scaling proportion; scaling a protection area and a non-protection area in the video image framefj_pt and the shadow image frame gj_pt according to the proportion respectively; and carrying out frame-by-frame optimization based on the main body target position. The method overcomes the defectsof video jitter and serious inconsistency between the target image and an original image in video scaling in the prior art.

Owner:HEBEI UNIV OF TECH

Casting technology capable of reducing hardness difference of traction wheel rope groove face

ActiveCN103464693AReduce hardness differenceLittle difference in temperatureFoundry mouldsFoundry coresHardnessMulti point

The invention relates to a casting technology capable of reducing the hardness difference of a traction wheel rope groove face. The casting technology comprises the following technical steps: manufacturing an upper sand box; manufacturing a lower sand box; making a core; milling a molten iron casting passage; assembling a mould; (f) casting; cleaning. A water inlet is formed in the sand core of an inner cavity in a milling manner, so that a feed head is in multi-point communication with a sand cavity; on one hand, the sand core of the inner cavity is positioned in the center of the cavity, and thus casting molten iron flows in from the middle of the cavity; one the other hand, the feed head is in multi-point communication with a sand cavity, so that the times spent on the molten iron in different directions reaches the same horizontal plane of the rope groove face are the same, the temperatures at the circle of the rope groove face are small in difference and relatively uniform, the subsequent solidification processes are basically the same, the hardness difference of the traction wheel rope groove face is reduced, and the product quality of castings is improved.

Owner:SUZHOU TORIN MACHINERY CASTING

Liquid fermentation culture medium for shiitake mushrooms and method for producing shiitake mushrooms through the same

ActiveCN105110961AOvercome technical shortcomings that cannot be used as an optimal carbon sourceOptimized formulaHorticultureFertilizer mixturesShiitake mushroomsChemistry

The invention provides a liquid fermentation culture medium for shiitake mushrooms. The liquid fermentation culture medium is composed of main raw materials including bran, bean pulp, glucose, monopotassium phosphate, magnesium sulfate and sodium carboxymethylcellulose. The invention further provides a method for producing the shiitake mushrooms through the liquid fermentation culture medium for the shiitake mushrooms with the liquid strain technology. By means of the liquid fermentation culture medium and the method, a traditional method for producing shiitake mushroom strains is changed, the liquid strain technology is adopted in shiitake mushroom strain production, the production efficiency is improved, and the production cost is greatly saved; in addition, the production method is simple in technology, the produced strains are high in use rate, and the pollution rate is low.

Owner:井冈山井祥菌草生态科技股份有限公司

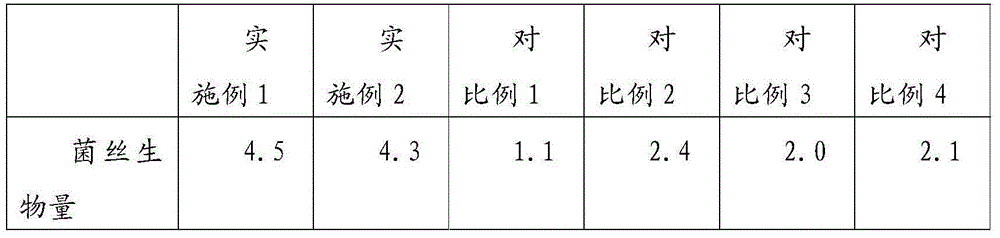

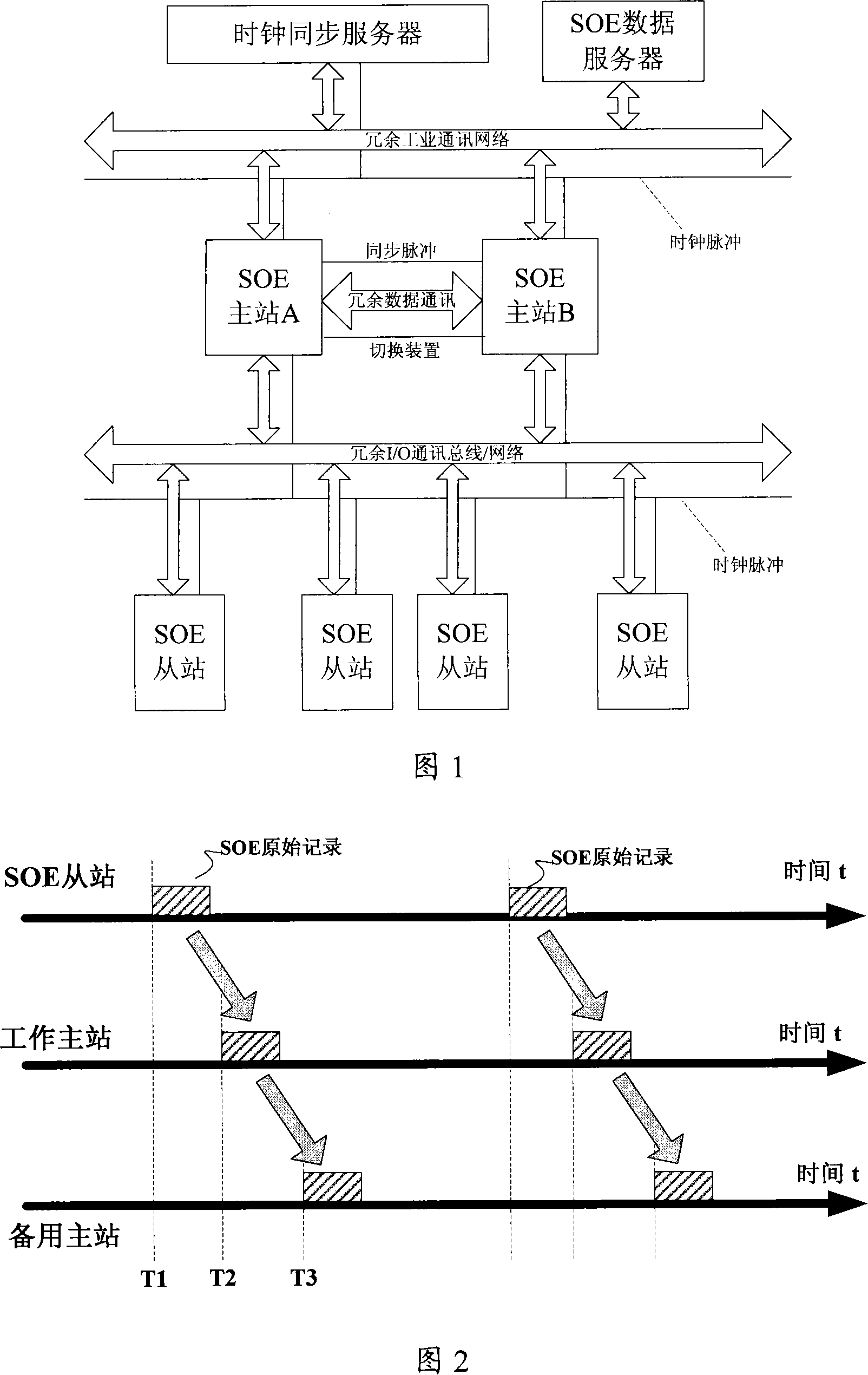

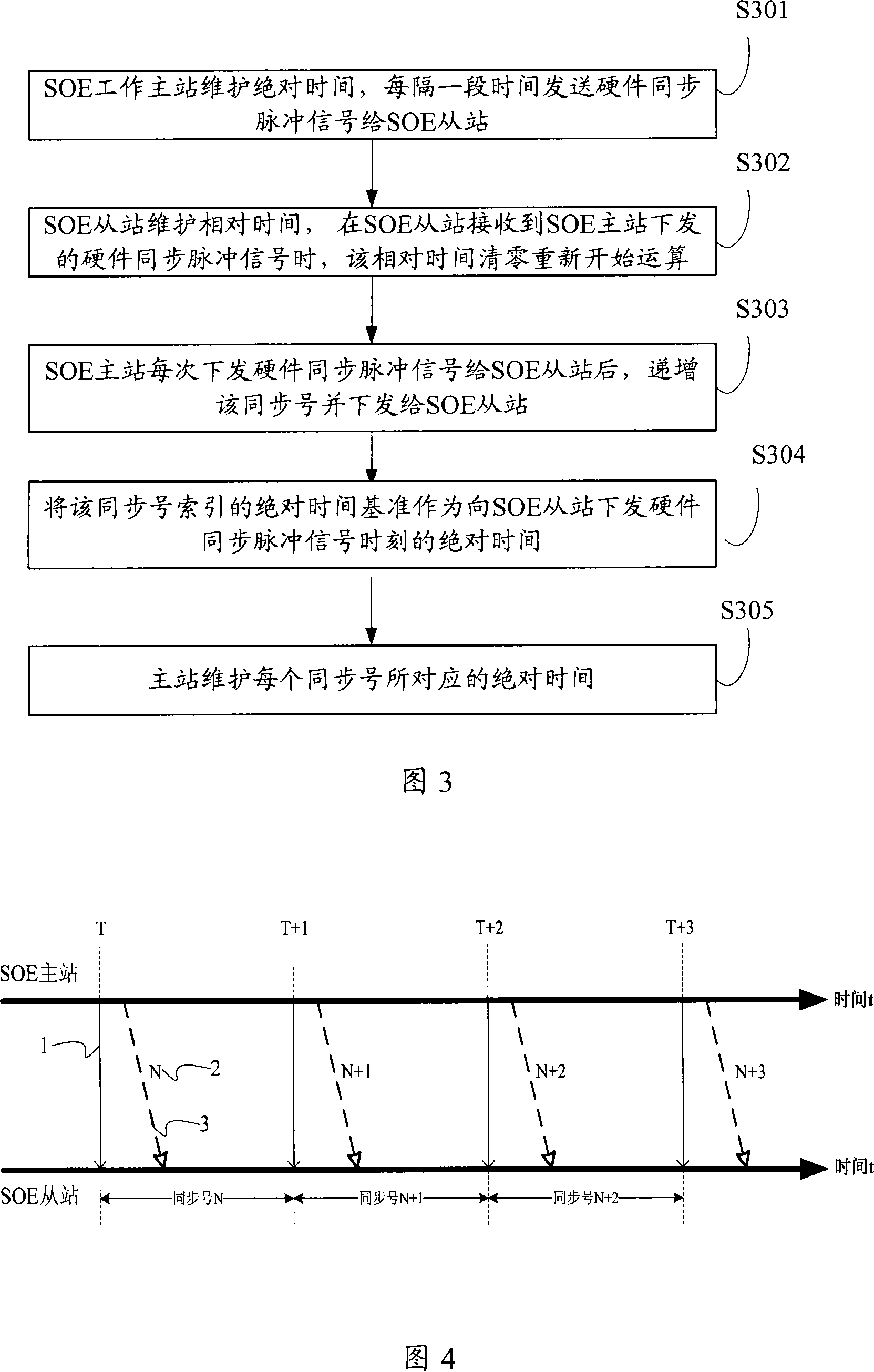

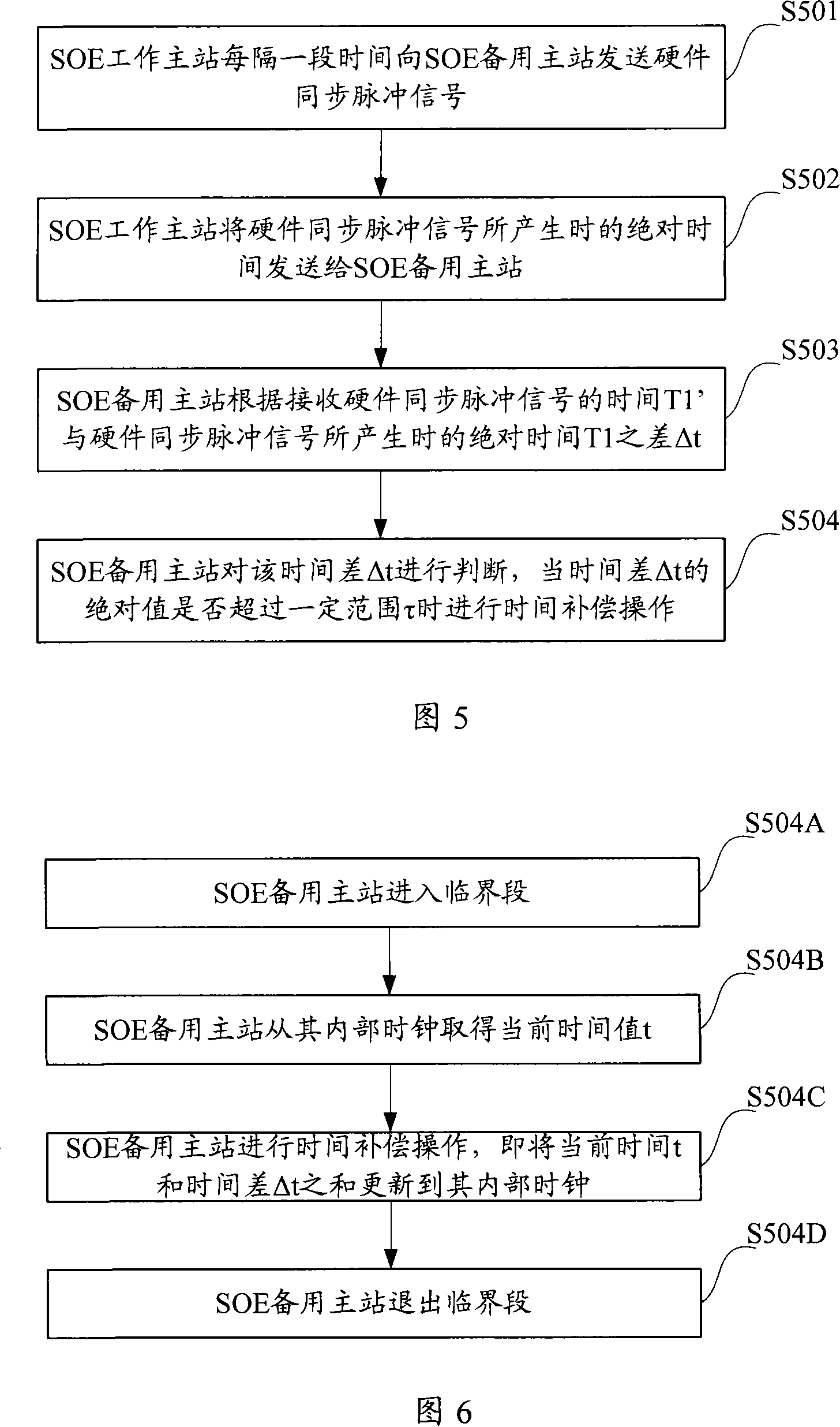

Method for implementing working main station and standby main station synchronous recording

ActiveCN101122798ARecord synchronizationThe records are exactly the sameSafety arrangmentsTotal factory controlMaster stationEngineering

The invention discloses a method of making records in a synchronous way for a work master station and a spare master station. Steps included are as follow: a SOE work master station sends a hardware synchronous pulsing signal to a SOE spare master station; the SOE work master station sends an absolute time required to send the hardware synchronous pulsing signal to the SOE spare master station; the spare master station calculates time difference (Delta t) between the time (T1) of receiving the hardware synchronous pulsing signal and the absolute time required to send the hardware synchronous pulsing signal. The spare master station judges the time difference (Delta t). When the absolute time difference (Delta t) is beyond a specified limit to an extent, the SOE spare master station perform time compensation; the SOE work master station sends the original record from a SOE slave station to the SOE spare master station. The invention can help the work master station and the spare master station make records in a synchronous way, realizing a redundant function of the SOE spare master station for the SOE work master station.

Owner:ZHEJIANG SUPCON TECH

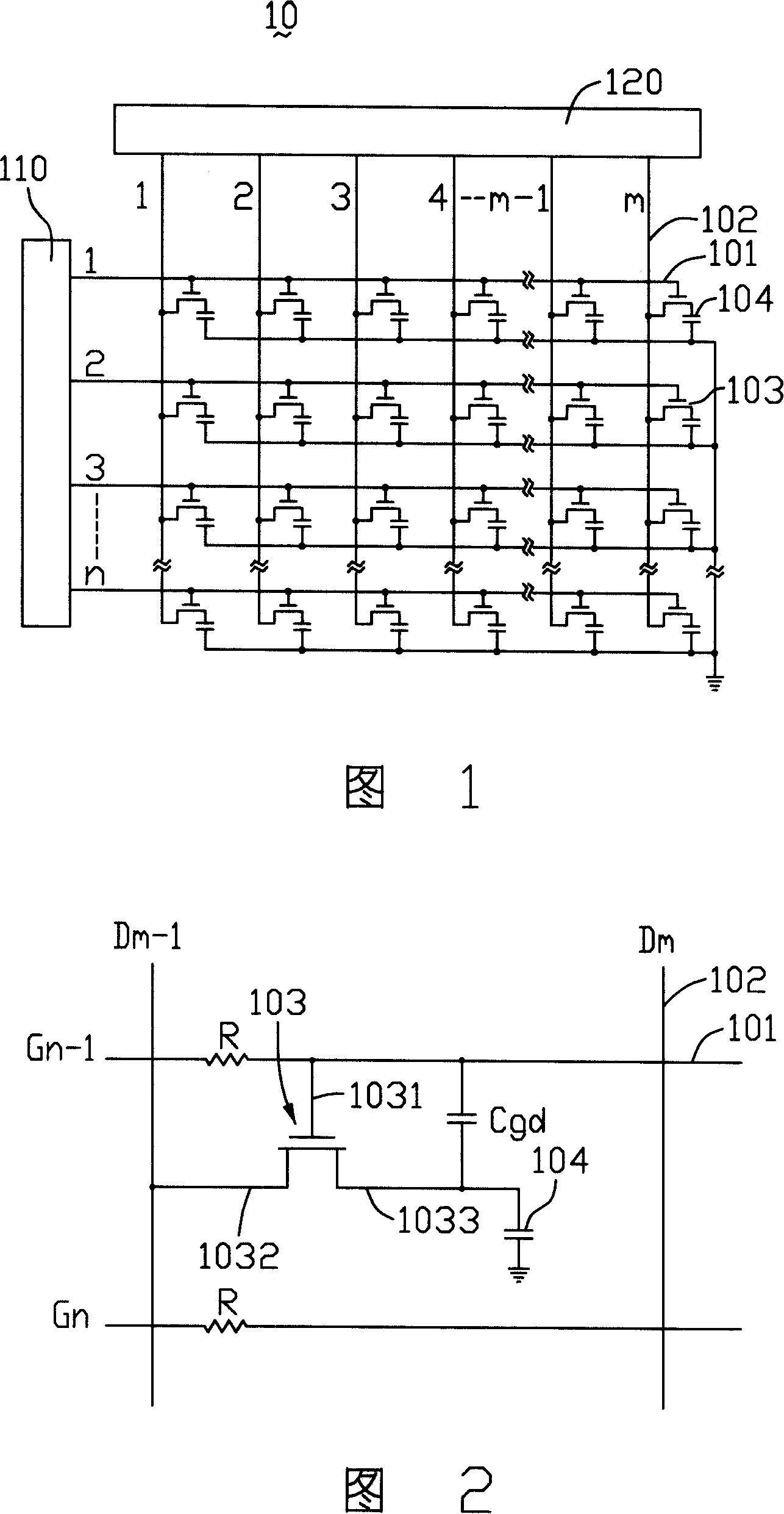

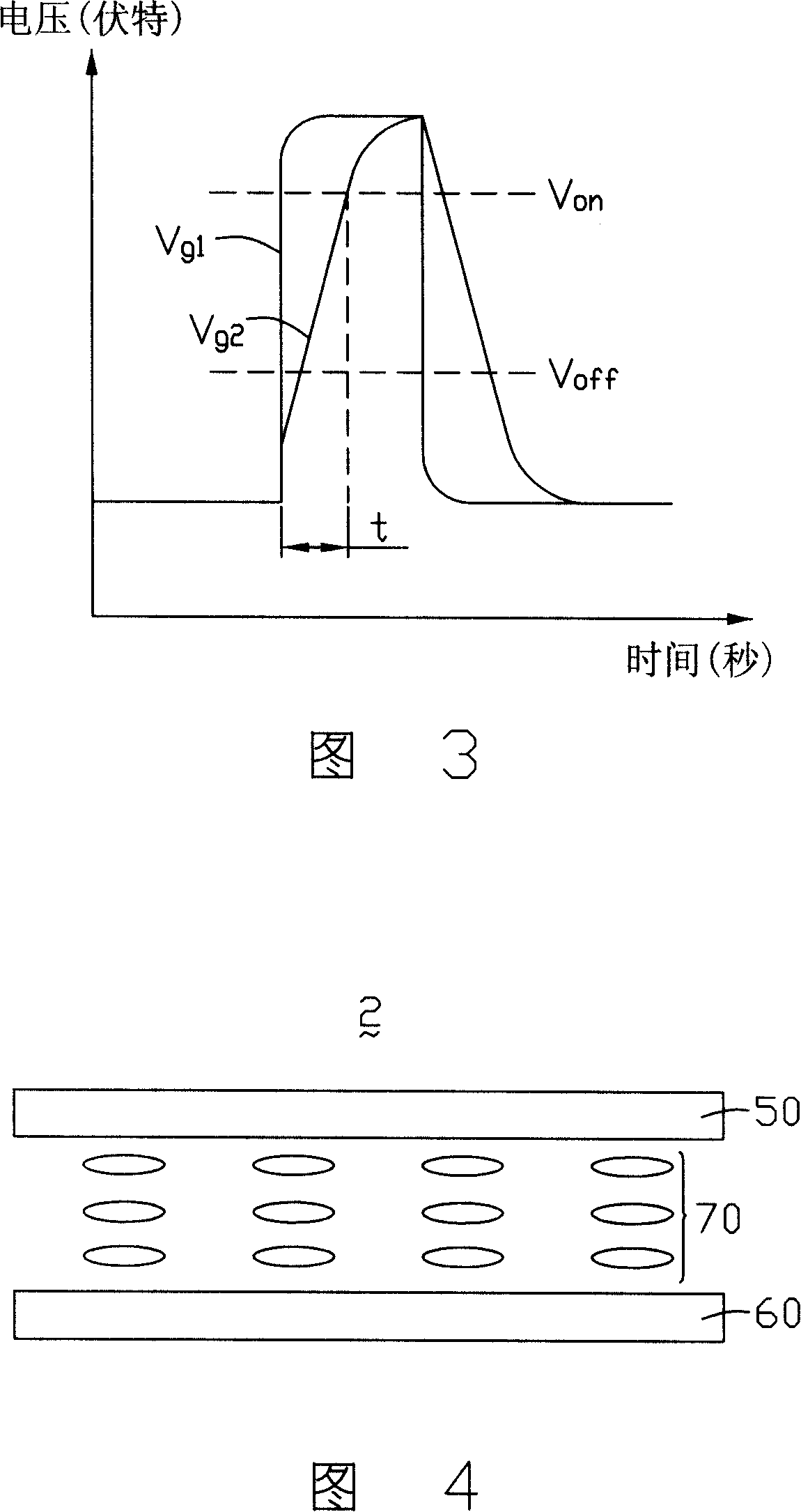

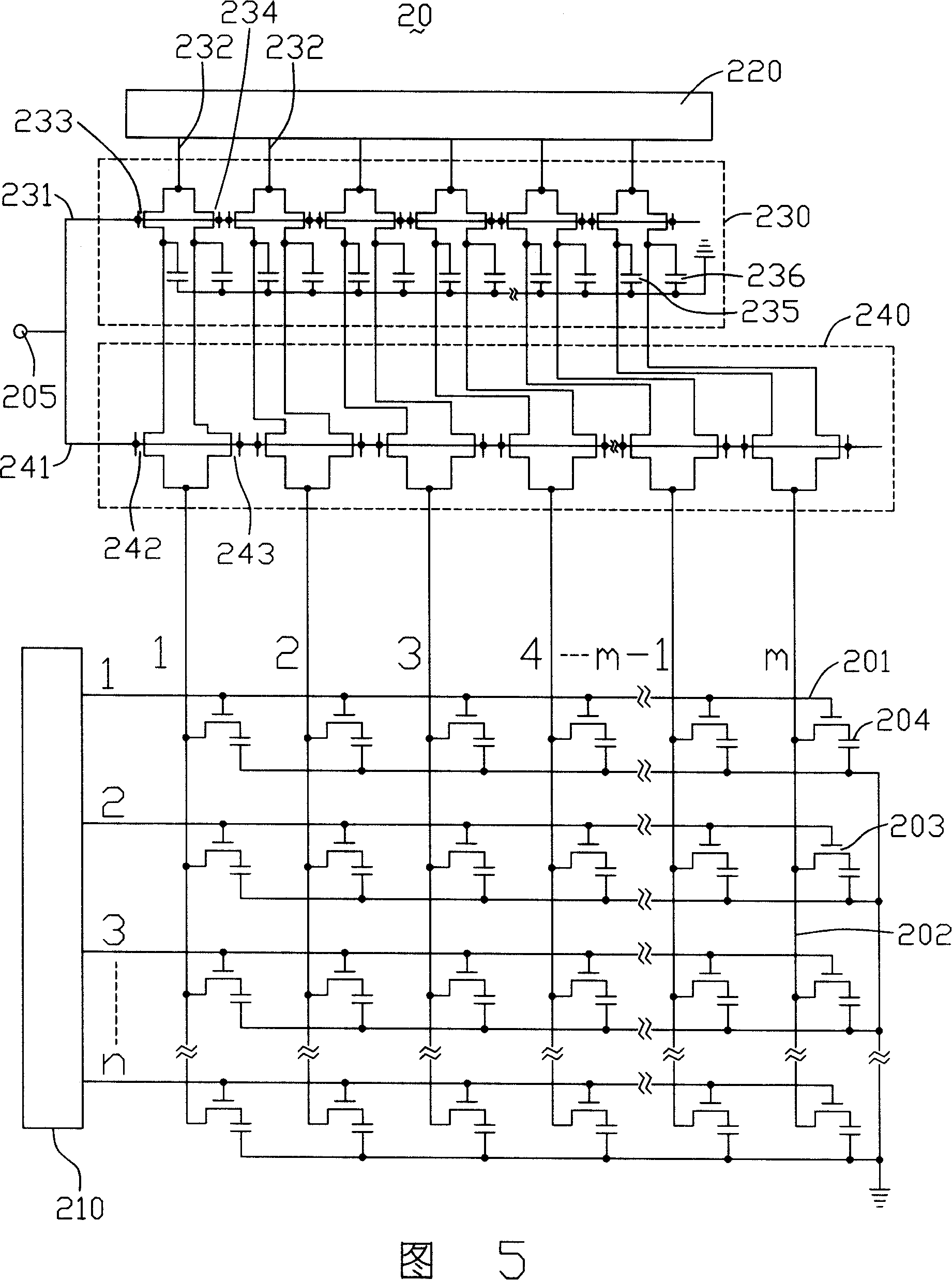

Liquid crystal display panel and its driving circuit

InactiveCN101149906AConsistent timeSame opening timeStatic indicating devicesLiquid-crystal displayData signal

The liquid crystal display- panel drive circuit comprises a plurality of scanning lines, a plurality of first data lines insulated intersecting the scanning lines, a plurality of film transistors at the cross point of the scanning lines and the first data lines, a scanning drive circuit, a data drive circuit, an access unit and an output control unit. The scanning drive circuit is used for producing a plurality of scanning signals. The data drive circuit is used for producing a plurality of data signals. The access unit is used for accessing multiple signals output by the data drive circuit. The output control unit is used for receiving the data signals accessed by the access unit and controlling the time for outputting the data signals to the first data lines to make the time in accordance with turn-on time of multiple film transistors.

Owner:INNOCOM TECH SHENZHEN +1

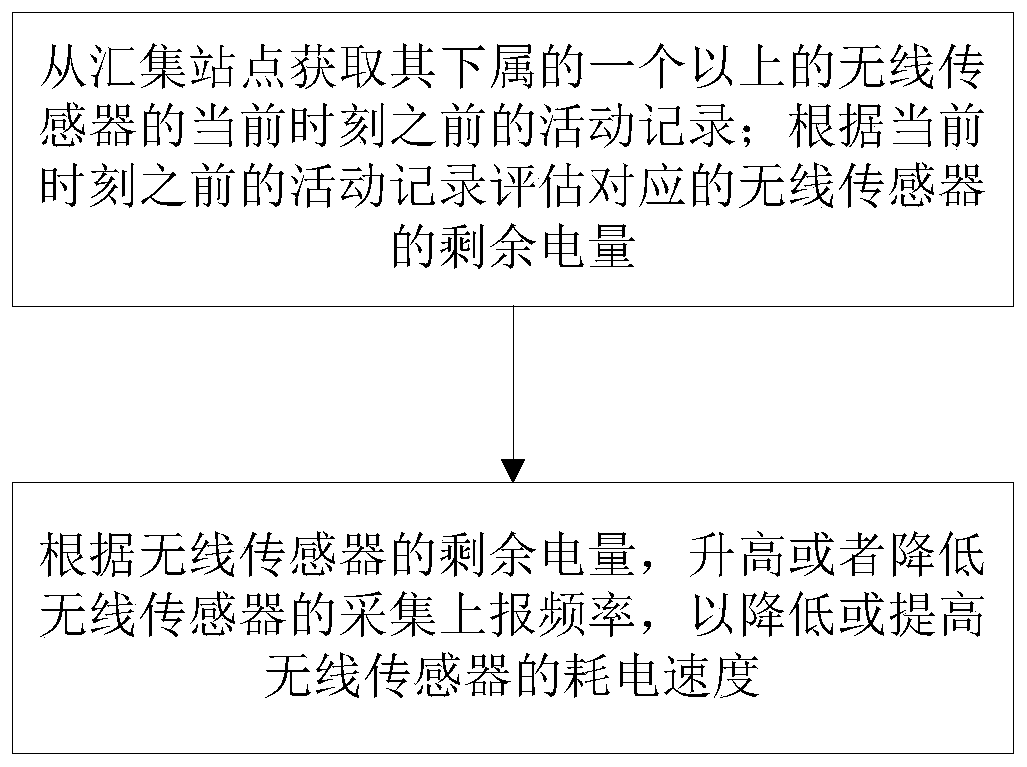

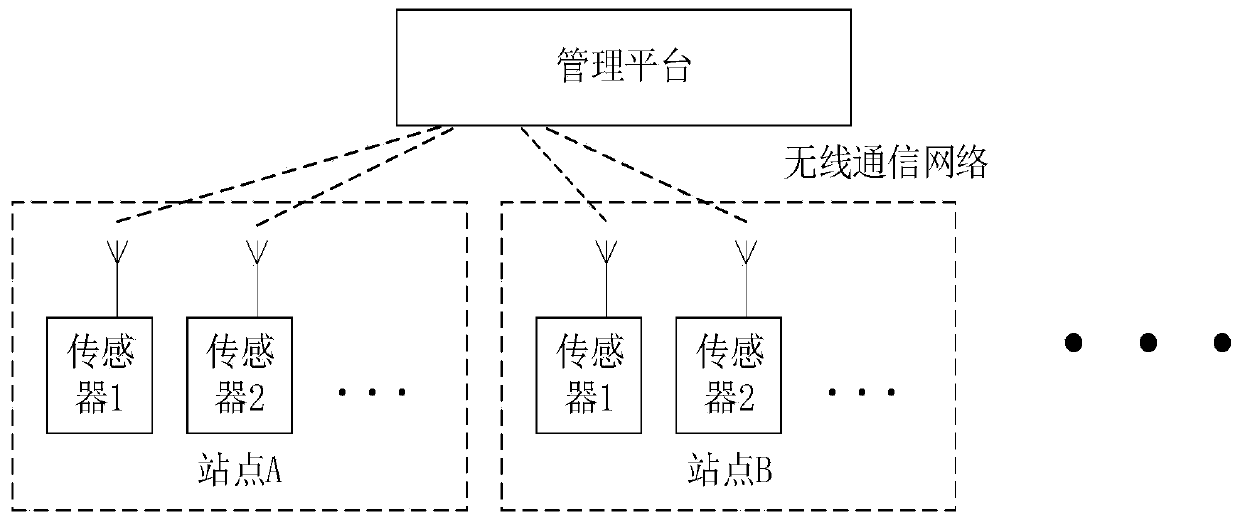

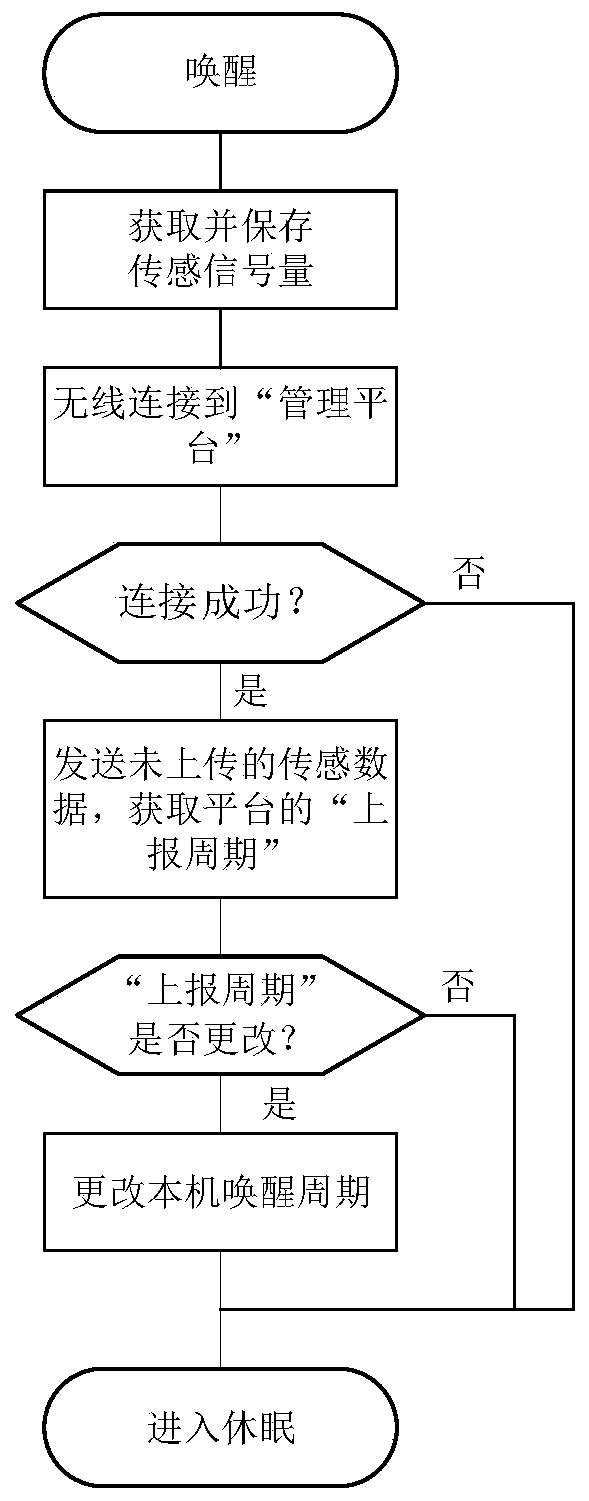

Management method and system for wireless sensors of power environment monitoring system

PendingCN110139235AReduce maintenance workloadConsistent timePower managementParticular environment based servicesLine sensorMonitoring system

The invention discloses a management method and system for the wireless sensors of a power environment monitoring system. The method comprises the steps of obtaining the activity records of more thanone wireless sensor subordinate to a collection site before the current moment from the collection site; evaluating the residual electric quantity of the corresponding wireless sensor according to theactivity record before the current moment; and according to the residual electric quantity of the wireless sensor, increasing or decreasing the acquisition and reporting frequency of the wireless sensor so as to reduce or increase the power consumption speed of the wireless sensor. According to the invention, the residual electric quantity of the sensor can be estimated, and the power consumptioncompletion time of the wireless sensors subordinate to the same collection station is basically consistent, so that the maintenance workload of the workers of the wireless communication battery powersupply sensors can be reduced.

Owner:湖南晟睿景智能科技有限公司

Braking device for motor driven mechanism

The invention discloses a braking device for a motor driven mechanism. The braking device has a structure that includes a rotating shaft, a rotor core, electric brushes, a bearing, a commutator segment, a rear end cover, a housing, a stator winding, a stator core, a winding coil, an iron core, a coil, an armature, rollers I, an upper guide rail, a limit block, an upper brake pad, a blade, a connecting rod I, a lower brake pad, rollers II, a lower guide rail, a front end cover, a spring, a slotting, a baffle, a vertical plate, connecting rods II, and a hinge. The rear end cover is embedded to the rear end of the housing. The front end cover is arranged at the front end of the housing and connected with the housing through a bolt. The rotating shaft penetrates through the front end cover. The rotating shaft is arranged on the central axis of the housing. According to the invention, the braking device for the motor driven mechanism is capable of quickly braking the rotating shaft throughthe upper brake pad and the lower brake pad, with small energy loss and with no need to worry about the aging of the spring, the spring at the bottom of the lower brake pad enables the lower brake padto rise more quickly, and through the acceleration of the rising process, the rotating shaft can be quickly braked.

Owner:TAIZHOU SUMING VALVES CO LTD

Product filling device suitable for different concentrations based on displacement differential motion principle

The invention relates to the technical field of kitchen utensils, and discloses a product filling device suitable for different concentrations based on the displacement differential motion principle.The product filling device comprises a supporting seat, and the upper portion of the supporting seat is movably connected with a cross rod. A filling barrel and a storage bin are supported, and the product filling device moves inwards to clamp a filling bottle; a bottle body is prevented from inclining or falling down in the filling process, and the stability of the bottle body is increased; and afirst rotary shaft rotates to drive a first gear to vibrate in a second gear, and therefore vibration of the filling bottle is driven, and it is avoided that bubbles are generated in the filling process, and consequently the product quality is influenced. By means of cooperative use of the filling barrel, a sliding plate, a push rod and a second rotary wheel, the filling barrel is driven to movedownwards into the filling bottle, so that filling is more precise, and raw materials are prevented from being spilled; the subsequent push rod moves downwards, and therefore filling is completed; anddue to the fact that the movement time of the push rod is kept consistent all the time, it is guaranteed that quantitative filing is completed.

Owner:蒋瑞雪

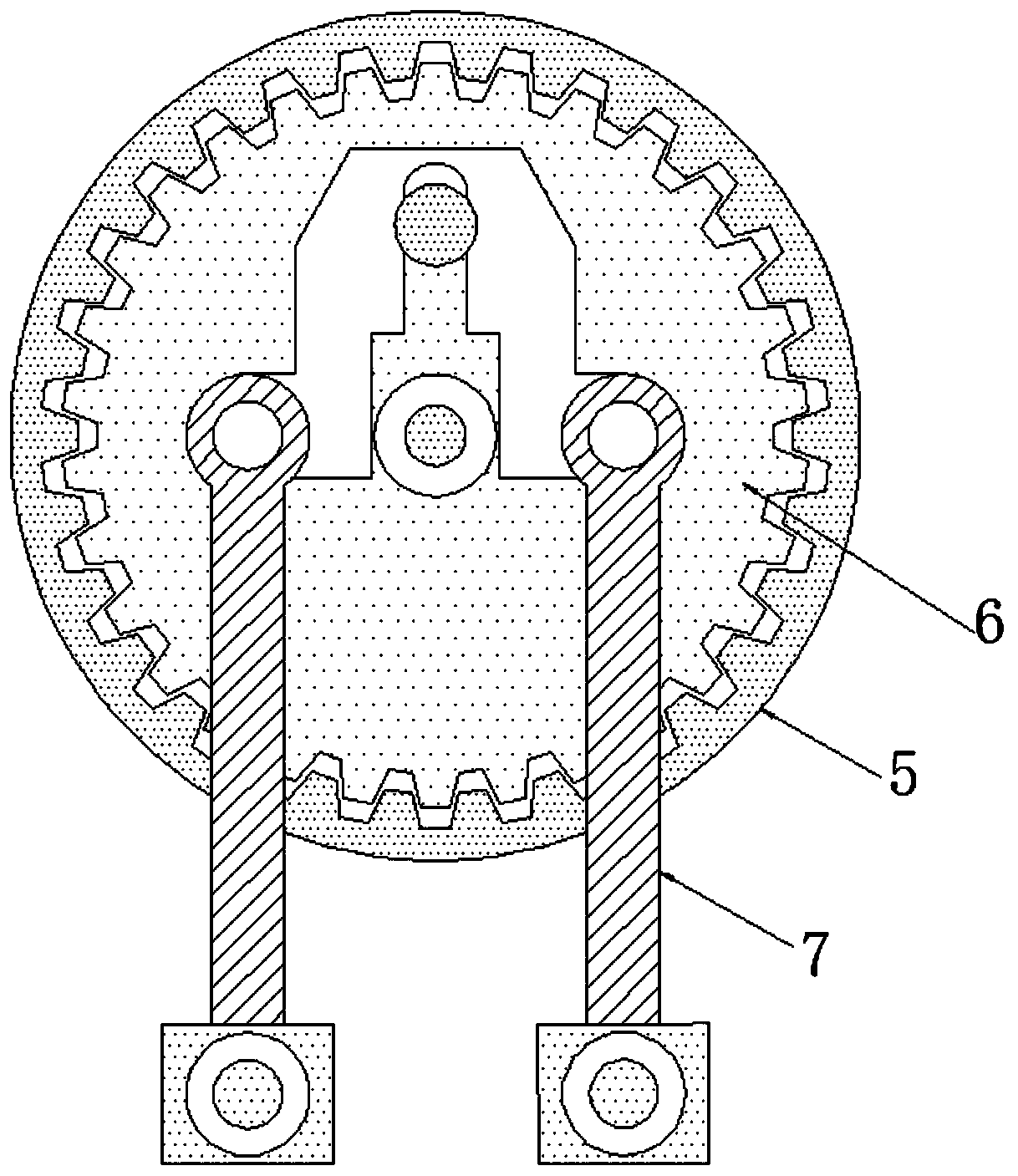

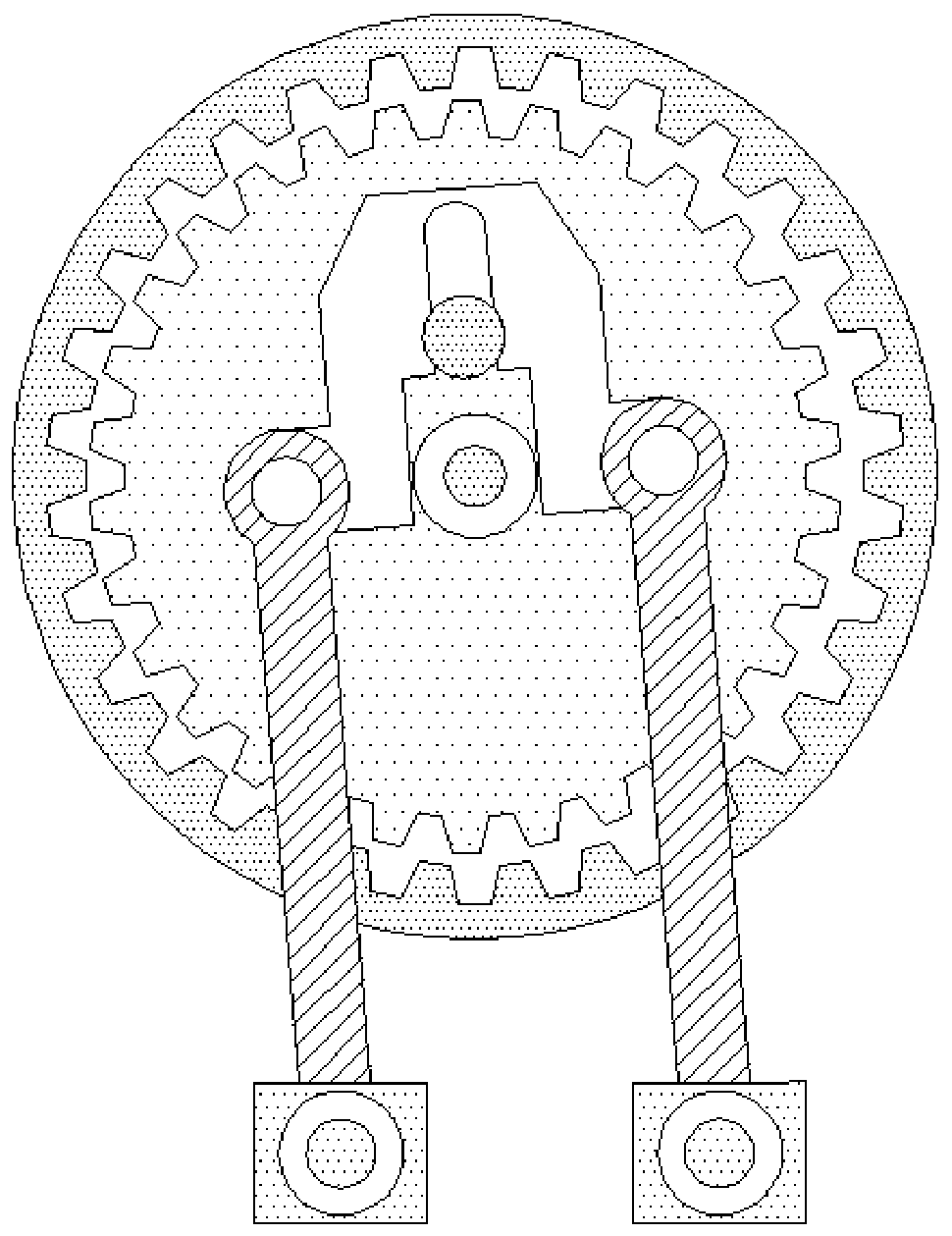

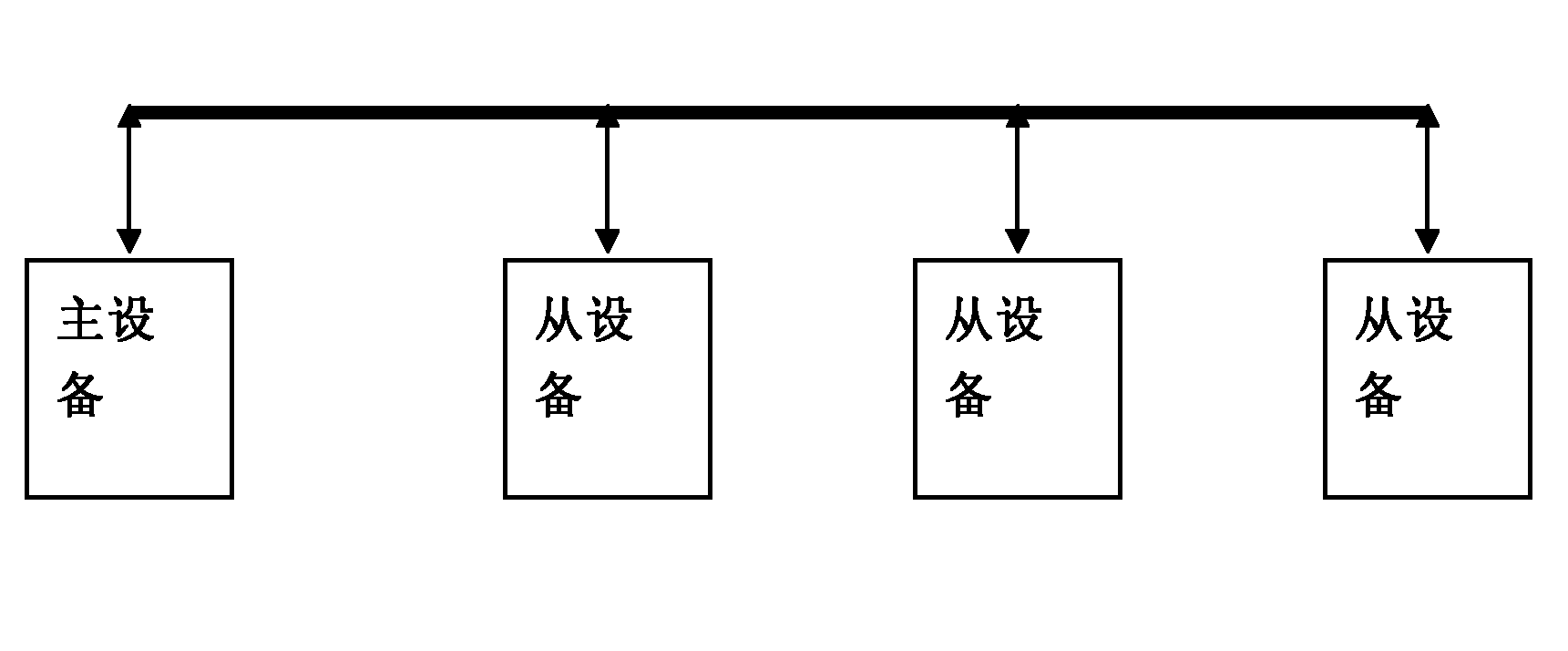

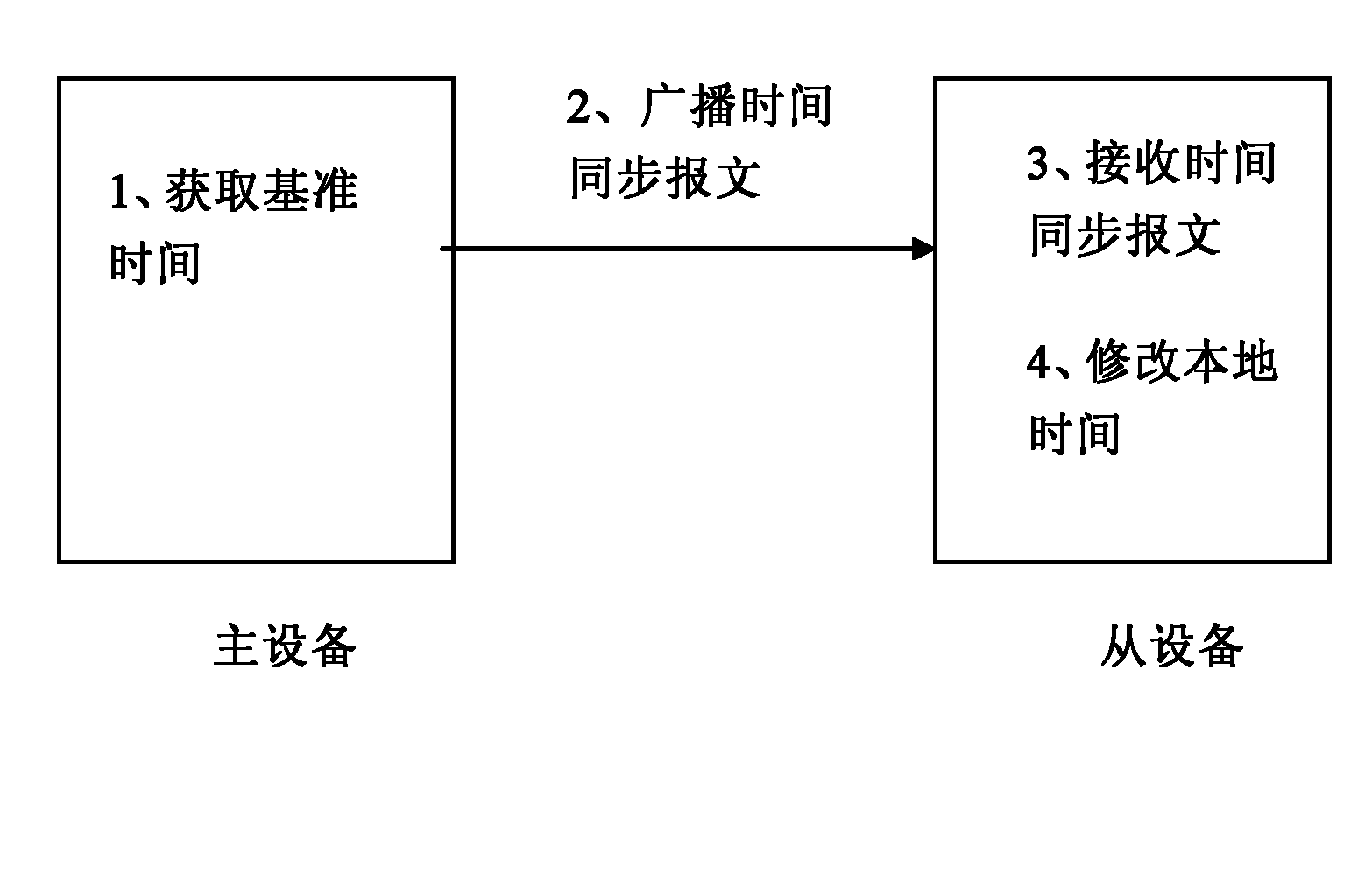

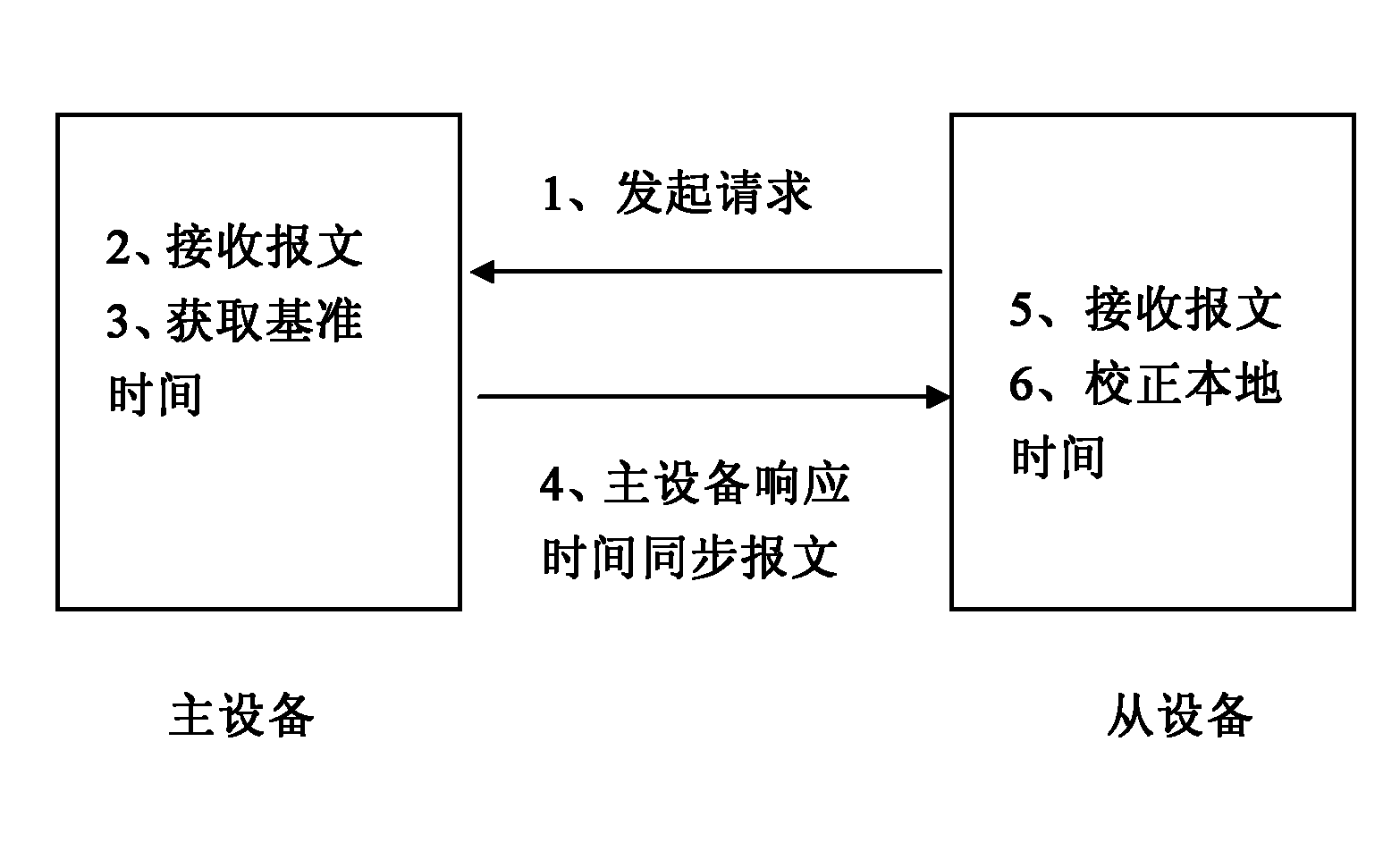

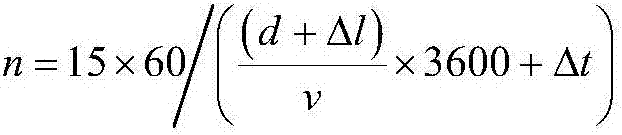

Time synchronization method for downhole instrument

InactiveCN102647269AGuaranteed clock consistencyReduce couplingSynchronising arrangementTimestampWell logging

The invention discloses a data transmission method used for multiple well logging devices and a control device, wherein the multiple well logging devices comprises a first well logging device and a second well logging device. The method comprises the following steps: the first well logging device obtains reference time; the first well logging device sends a time synchronization message; the second well logging device receives the time synchronization message; the second well logging device modifies local time; the first well logging device and the second well logging device print a timestamp for well logging data; and the first well logging device and the second well logging device convey the well logging data to the control device.

Owner:CNPC GREATWALL DRILLING ENG

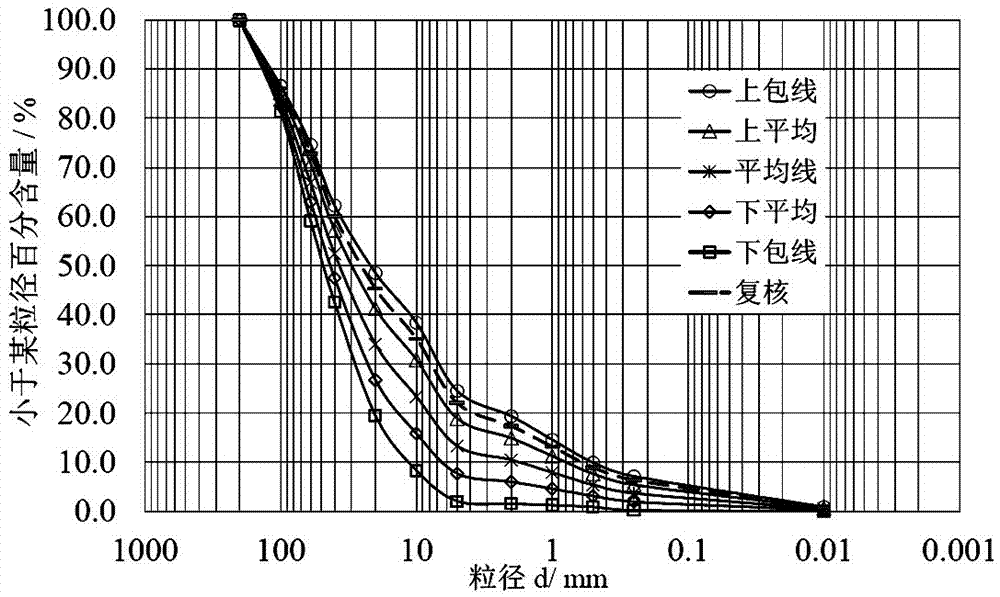

Method for determining maximum dry density of natural-gradation sand and gravel materials for damming

InactiveCN106908349AAvoid deformationAvoid leaningSpecific gravity measurementMaterials scienceRaw material

The invention relates to the technical field of sand and gravel material soil tests, and discloses a method for determining the maximum dry density of natural-gradation sand and gravel materials for damming. The method comprises the following steps: preparing density barrels according to the size of the sand and gravel material, digging a groove in a test site, laying fine sand on the bottom surface of the groove, and performing static rolling, leveling and compaction; arranging the density barrels at intervals in an extension direction of the groove, and marking positions of center points of the density barrels; manually mixing raw materials according to test required gradation, sequentially filling the density barrels and the groove around the density barrels with the raw materials, performing forward and backward driving vibration rolling for 26 times, performing precise calculation to determine residual rolling times, performing driving vibration rolling again, performing barrel top leveling after rolling completion, measuring the volume of each density barrel, weighing the mass of the sand and gravel materials in each density barrel, and then performing calculation to obtain the maximum dry density of the sand and gravel materials. The method adopts a more reasonable rolling manner, and can rapidly and accurately determine the maximum dry density of the sand and gravel materials, thereby avoiding damage to relevant equipment.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Selenium-rich Mythic Fungus medium, and method for producing Mythic Fungus

InactiveCN106242683AHigh nutritional valueIncrease selenium contentCalcareous fertilisersFungiBiotechnologyGanoderma pseudoferreum

The invention provides a selenium-rich Mythic Fungus medium. The medium mainly comprises wood chips, wheat bran, selenium-rich fungal grass and gypsum. The invention also provides a method for producing Mythic Fungus by using the selenium-rich Mythic Fungus medium. Traditional production methods of Mythic Fungus strains are changed, liquid selenium-rich strains are prepared by using a liquid strain technology in the Mythic Fungus strain production process, and Mythic Fungus produced by adopting the solid selenium-rich medium through a secondary selenium enrichment technology has the advantages of high content of the selenium content, and high nutrition values. The production method has the advantages of production efficiency increase, great saving of the production cost, simple process, high utilization rate of produced strains, and low pollution rate.

Owner:井冈山井祥菌草生态科技股份有限公司

Full-automatic continuous conveyance mechanism with automatic tightly-pressing device

The invention discloses a full-automatic continuous conveyance mechanism with an automatic tightly-pressing device. The full-automatic continuous conveyance mechanism with the automatic tightly-pressing device comprises a base and supporting columns. The left side and the right side of the base are provided with the supporting columns. The top end of the base is provided with a sliding rail. The right side of the bottom end of the base is provided with a motor box. A motor is installed in the motor box. A sliding block is arranged on the right side in the sliding rail. The sliding block is inlap joint with the sliding rail. According to the full-automatic continuous conveyance mechanism with the automatic tightly-pressing device, through cooperation of a feeding opening and an ejection plate, after workers conduct feeding, raw materials needing machining can be automatically pushed leftwards to be machined one by one; through cooperation of a baffle and a torsion spring, the raw materials can be tightly pressed and stably move in the conveyance process, the situation that the raw materials generate violent shake, so that the materials are disengaged from the rail or deviate is avoided, and the machining precision is prevented from being influenced; and in this way, the quality of a machined finished product is greatly improved, and the demand of a client is met.

Owner:中山市榄商置业发展有限公司

Alkene conversion apparatus start-working catalyst adding method

ActiveCN103588607AFlexible adjustment of dosing methodsDifferent dosing speedHydrocarbon from oxygen organic compoundsEthylene productionAlkeneOrganic chemistry

The invention relates to an alkene conversion apparatus start-working catalyst adding method. An alkene conversion apparatus comprises: (A) an alkene conversion reactor (3); and (B) a catalyst reactivator (4), wherein the alkene conversion reactor (3) is connected with the catalyst reactivator (4) via a regeneration catalyst conveying pipe and a to-be regenerated catalyst conveying pipe. The method comprises: (a) adding a catalyst into the catalyst reactivator (4), heating and storing heat; (b) when the catalyst reactivator (4) is heated for heat storing, adding a catalyst and heating; (c) after the heating of the catalyst reactivator (4) and the alkene conversion reactor (3) is finished, transferring the catalyst in the catalyst reactivator (4) to the alkene conversion reactor (3). The catalyst adding manner can be flexibly adjusted according to the catalyst temperature in the reactor and in the reactivator by employing the method provided by the invention.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

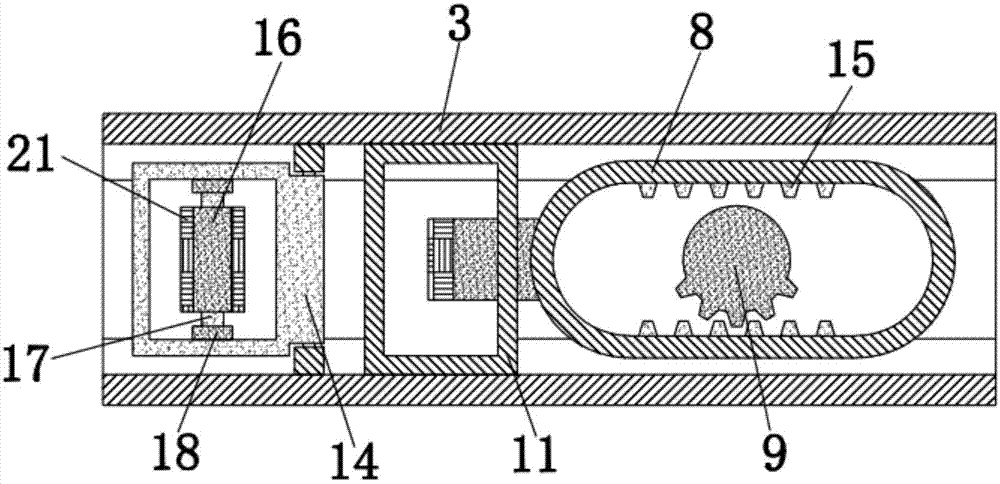

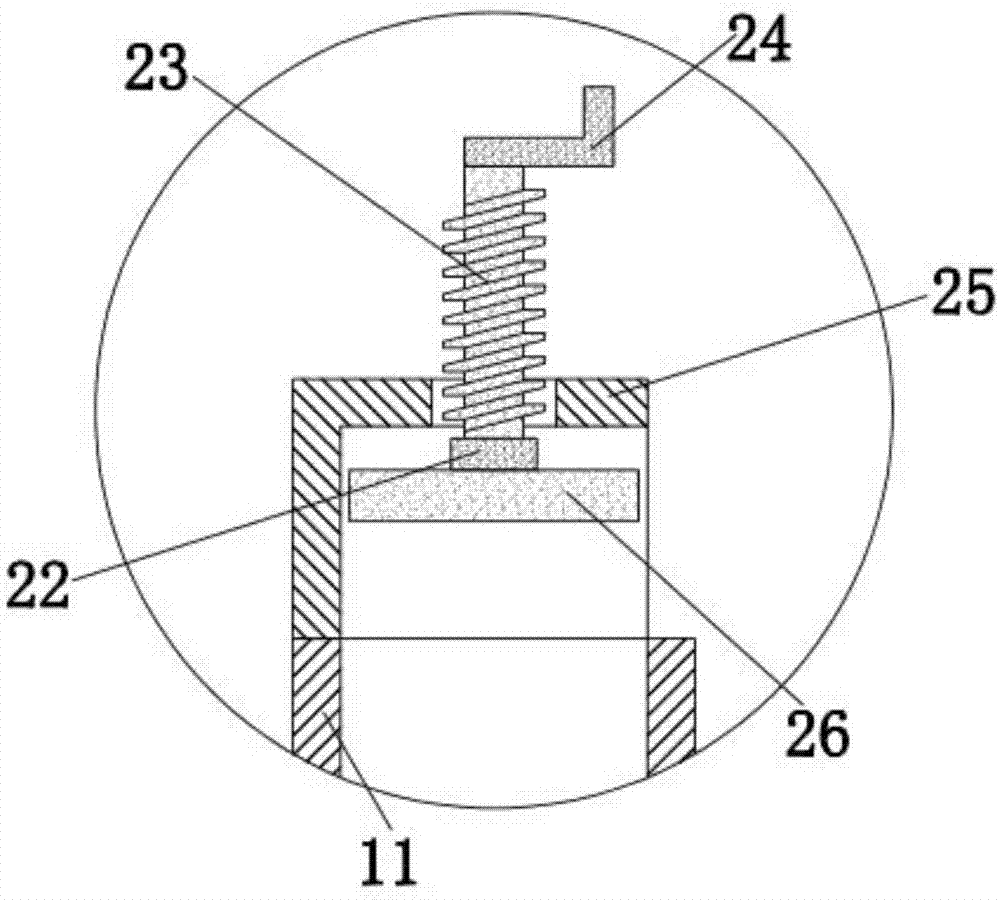

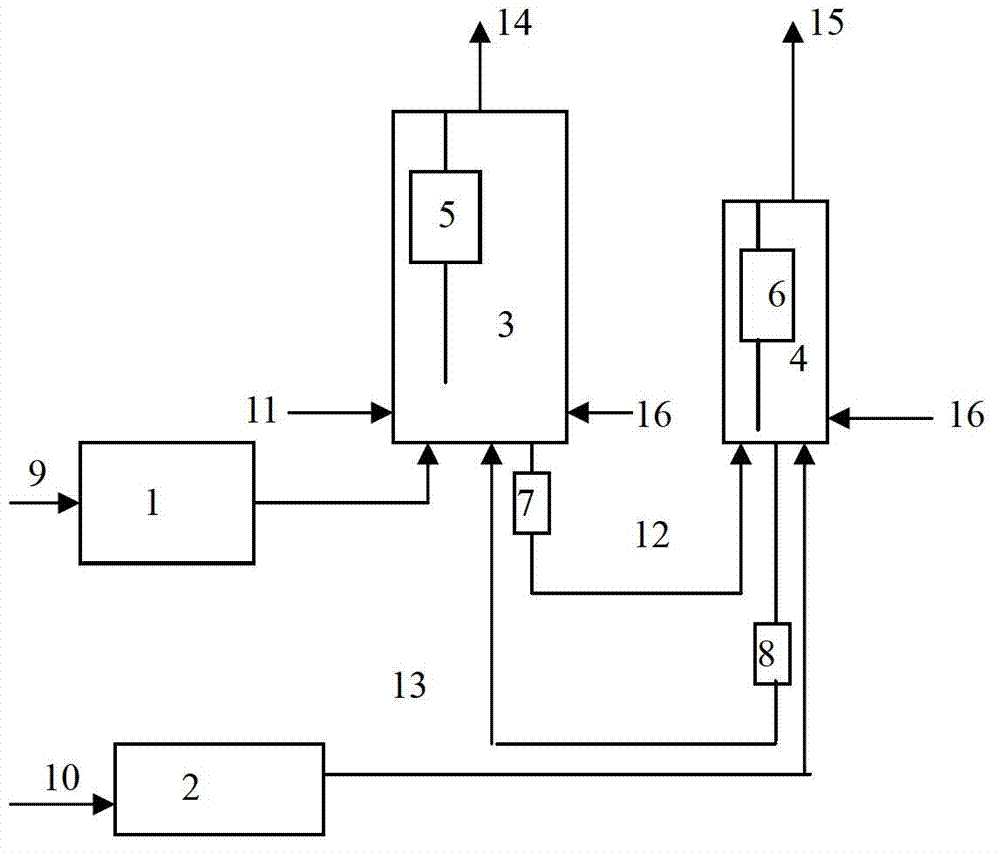

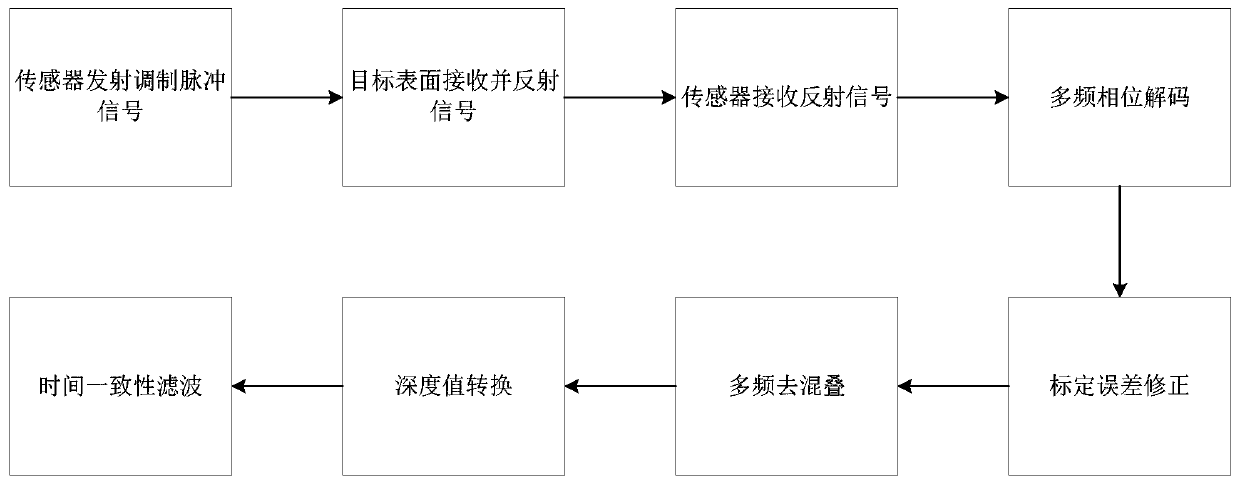

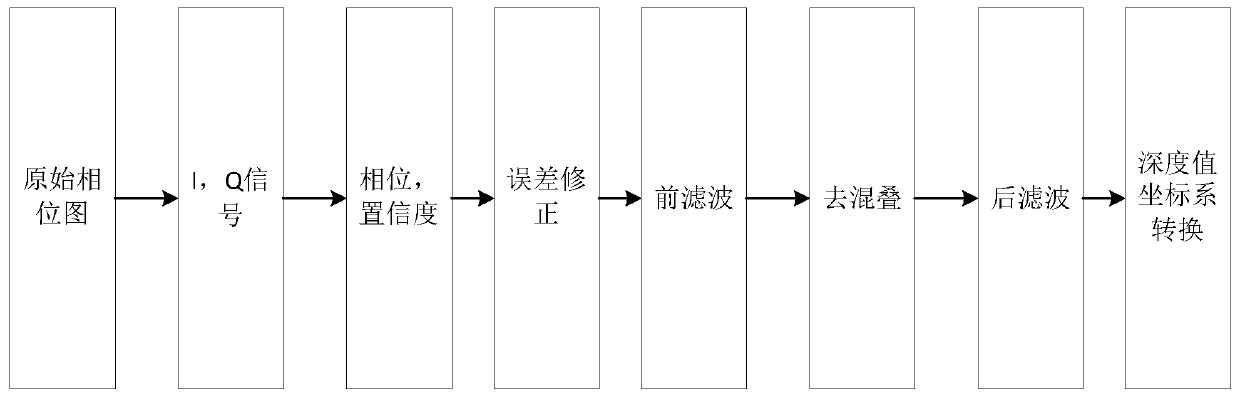

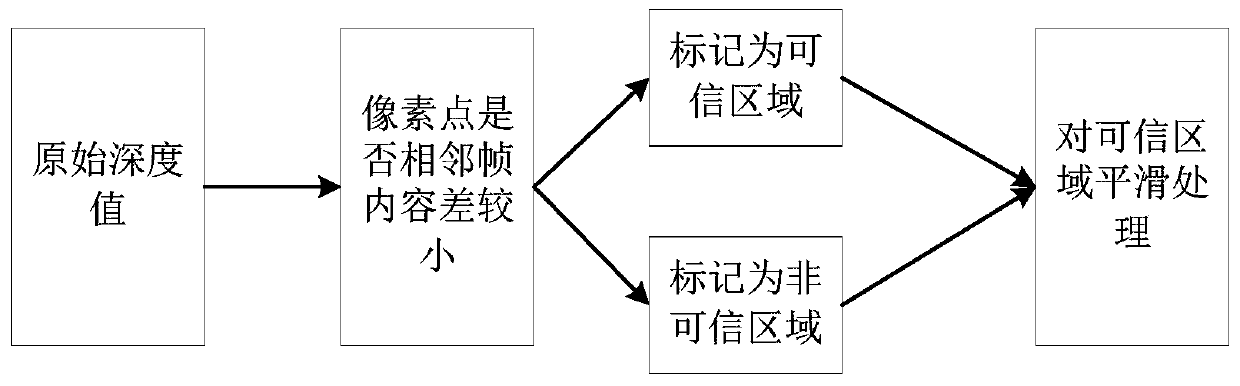

Depth map processing method and device

ActiveCN110390690AGuaranteed time consistencyEnsure that the depth value error after image frame filtering has time consistencyImage enhancementImage analysisImage frameTime based

The invention provides a depth map processing method and device. The method comprises the following steps: obtaining a first depth image frame and a second depth image frame adjacent to the first depth image frame, determining a first content value of each first pixel and a second content value of a corresponding second pixel, and obtaining a content difference between the first content value andthe second content value, determining a credible pixel in the first depth image frame according to the content difference, determining a smoothing factor corresponding to the credible pixel, and performing filtering processing on the depth value of the credible pixel according to the smoothing factor and the depth value of the pixel corresponding to the credible pixel in the second depth image frame. Therefore, time-based consistency filtering is carried out on the depth value in the depth slow change area based on the change condition of the depth value. The depth value of the depth smooth area in the time dimension is smoother effectively, and the original high dynamic property of the depth fast change area is kept.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com