Magnesium alloy/carbon steel pipe composite connection method based on induction heating and electromagnetic forming

An electromagnetic forming and induction heating technology, which is applied in the direction of welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., can solve the problems of limited product size, poor mechanical properties, product scrapping, etc., so as to facilitate automatic control, Effects of improving connection efficiency and improving connection formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1. Magnesium alloy / carbon steel pipe fitting composite connection method based on induction heating and electromagnetic forming

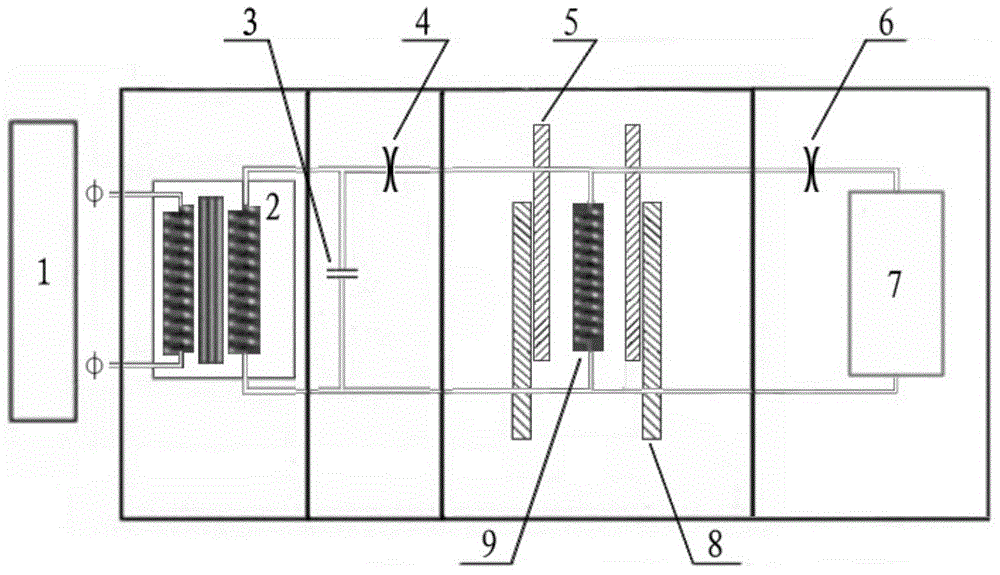

[0030] The composite connection method of magnesium alloy / carbon steel pipe fittings based on induction heating and electromagnetic forming, see figure 1 Specifically, the electromagnetic induction heating coil and the electromagnetic forming coil are the same coil device, and the charging of the capacitor of the electromagnetic forming machine and the heating process of the magnesium alloy inner tube by electromagnetic induction heating can be carried out simultaneously. First, the capacitor 4 is charged through the control circuit of the electromagnetic forming machine, and the second vacuum switch 6 is turned on at the same time, so that the electromagnetic induction heating device can realize the heating of the inner tube of the magnesium alloy. Through process control, when the charging of the capacitor 4 is completed, the magn...

Embodiment 2

[0045] Example 2 Using AZ31 magnesium alloy tubes as a thermomagnetic pulse connection experiment

[0046] 1. Experimental process:

[0047] (1) Material preparation:

[0048] The materials used in the experiment are commercially available AZ31 magnesium alloy pipes and 20 carbon steel, and the chemical composition of the magnesium alloy is shown in Table 1. The magnesium alloy tube used in the experiment is annealed, the annealing temperature is 300°C, and it is cooled with the furnace after holding for 0.5h.

[0049] (2) Forming process:

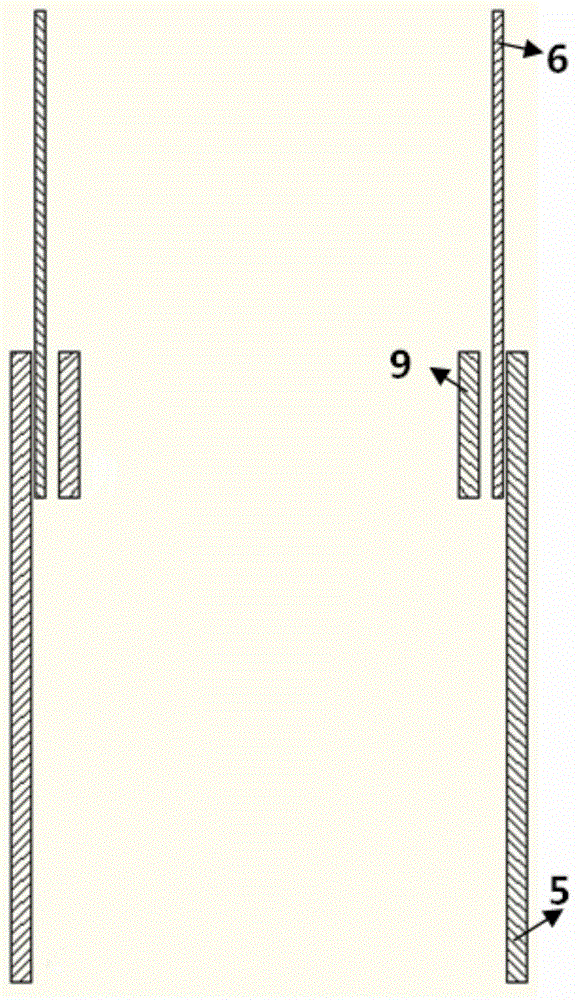

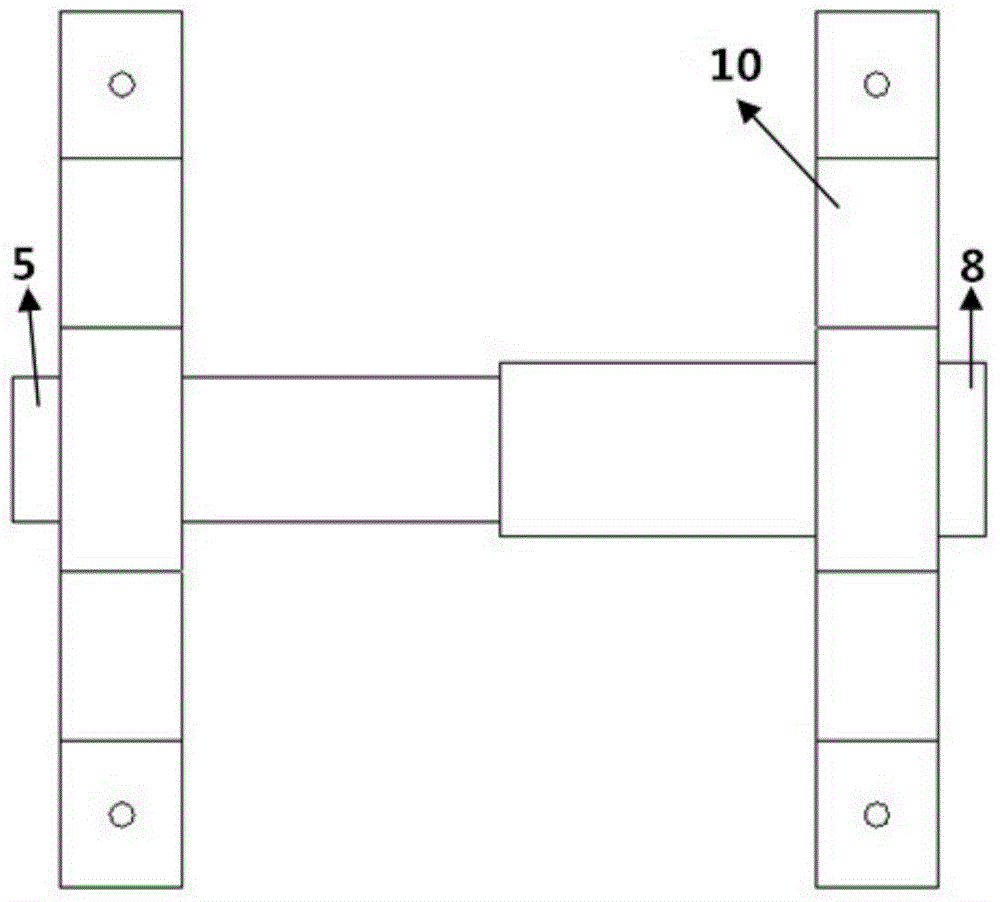

[0050] Magnetic pulse connection test in such as image 3 Carried out on the tooling structure shown. The electromagnetic forming coil used in the experiment is as Figure 4 with Figure 5 As shown, the coil interface is a rectangle of 2×5 mm, which is machined from a copper tube, the number of coil turns is n=20, the outer diameter of the coil is 80 mm, the inner diameter D is 78 mm, and the width is 60 mm. The pipe fittings are 1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com