Iron-based compound superconducting joint and preparation method thereof

A technology of superconducting joints and iron-based superconducting, applied in the usage of superconducting elements, manufacturing/processing of superconducting devices, superconducting devices, etc., can solve the problems of difficulty in making iron-based superconducting joints, and achieve joint connection The effect of high efficiency, simple preparation process and simplified experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

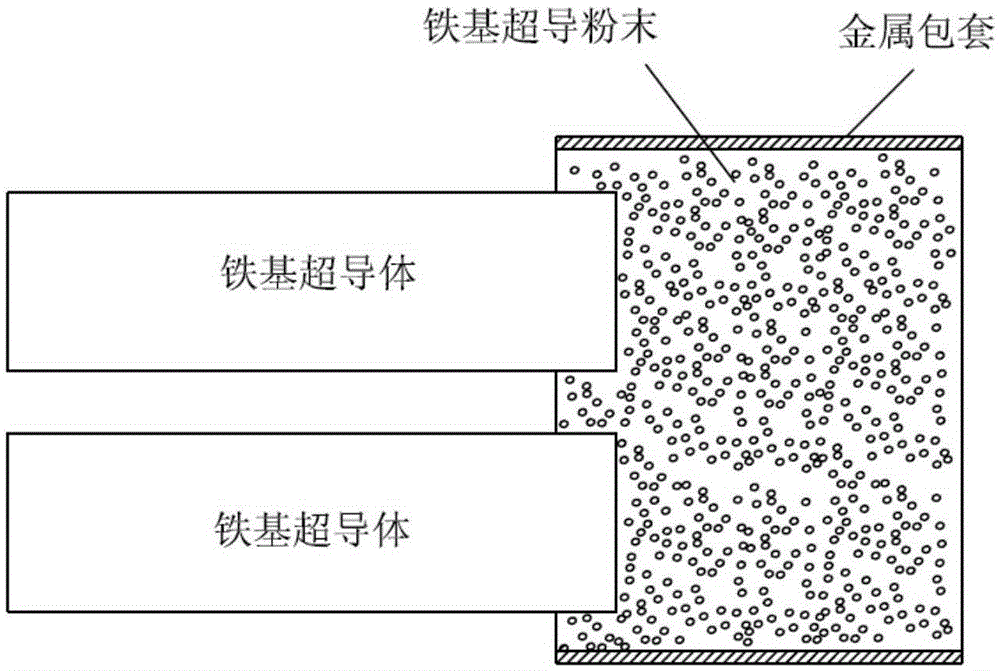

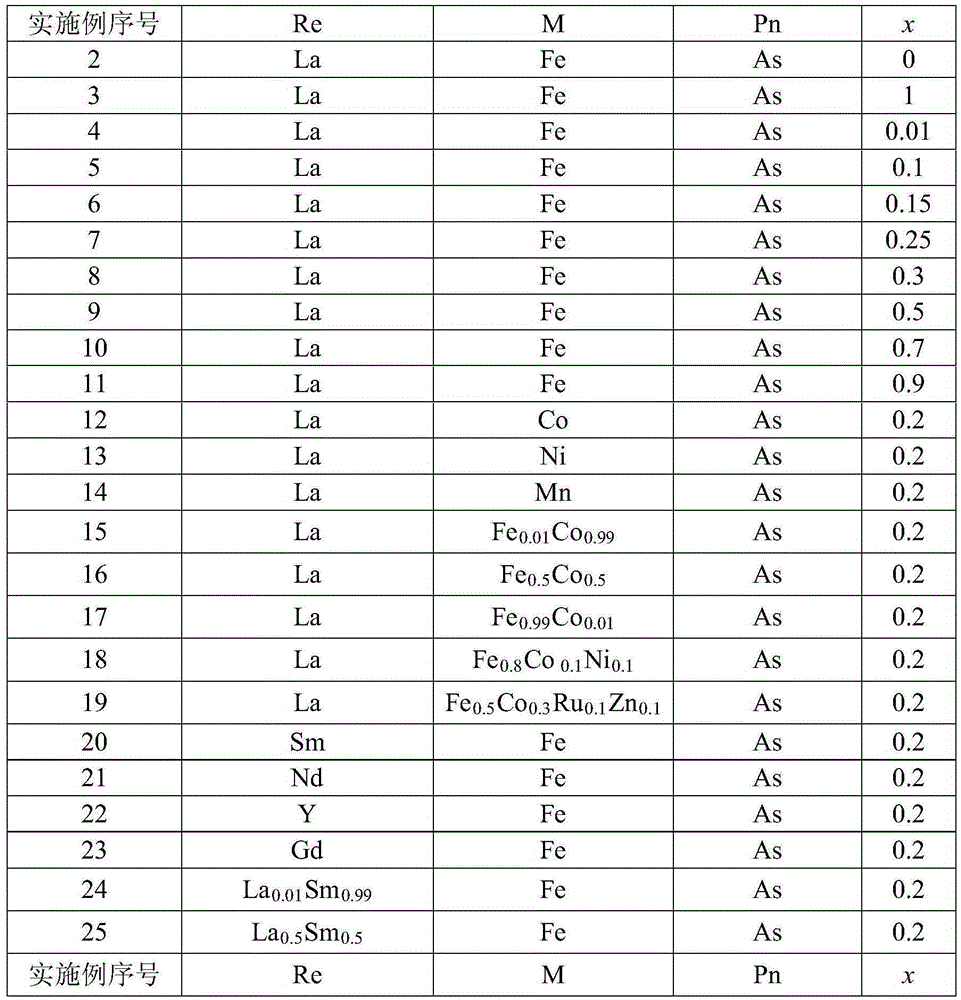

[0029] The two chemical formulas that need to be connected are the same as ReMPnO 1-x f x The surface non-superconducting layer is peeled off at the end of the iron-based superconducting block to expose the superconducting core, wherein Re is La; M is Fe; Pn is As; x is 0.2. The iron-based superconductor contains a dopant Sn, and the mass ratio of Sn to the iron-based superconductor is 10%.

[0030] Put the iron-based superconducting block end and the iron-based superconducting powder treated above with a single-layer metal sheath according to figure 2 The parallel connection shown is wrapped, and the chemical formula of the iron-based superconducting powder is ReMPnO 1-x f x , where Re is La; M is Fe; Pn is As; x is 0.2. The iron-based superconductor contains a dopant Sn, and the mass ratio of Sn to the iron-based superconductor is 10%.

[0031] The metal sheath is selected as a metal tube, and the material is silver. The pressure applied to the above-mentioned envelop...

Embodiment 301

[0055] The two chemical formulas that need to be connected are the same as Ae 1-x A x m 2 Pn 2 And the end of the single-core iron-based superconducting tape is peeled off the surface non-superconducting layer, so that the superconducting core is exposed. Wherein Ae is Sr; A is K; M is Fe; Pn is As; x is 0.4. The iron-based superconductor contains dopants Sn, K and As, wherein the mass ratio of Sn to the iron-based superconductor is 5%; the mass ratio of K to the iron-based superconductor is 1.5%; the mass ratio of As to the iron-based superconductor is 3 %.

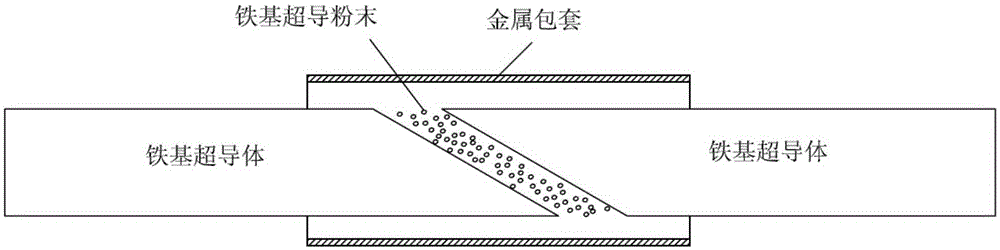

[0056] Put the iron-based superconducting tape end and iron-based superconducting powder treated above with a double-layer metal sheath according to figure 1 The straight line connection shown is welded, and the chemical formula of the iron-based superconducting powder is Ae 1-x A x m 2 Pn 2 , where Ae is Sr; A is K; M is Fe; Pn is As; x is 0.4. The iron-based superconductor contains dopants Sn, K and As, where...

Embodiment 706

[0085] The two chemical formulas that need to be connected are the same as Ae 1-x A x m 2 Pn 2 The end of the single-core iron-based superconducting tape is peeled off the surface non-superconducting layer to expose the superconducting core. Wherein Ae is Ba; A is K; M is Fe; Pn is As; x is 0.4. The iron-based superconductor contains dopants K and As, wherein the mass ratio of K to the iron-based superconductor is 1.4%; the mass ratio of As to the iron-based superconductor is 2.6%.

[0086] Put the iron-based superconducting tape end and iron-based superconducting powder treated above with a double-layer metal sheath according to figure 1 The connection method is welded, and the chemical formula of iron-based superconducting powder is Ae 1-x A x m 2 Pn 2 , where Ae is Ba; A is K; M is Fe; Pn is As; x is 0.4. The iron-based superconductor contains dopants K and As, wherein the mass ratio of K to the iron-based superconductor is 1.4%; the mass ratio of As to the iron-ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com