Patents

Literature

41 results about "Iron-based superconductor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

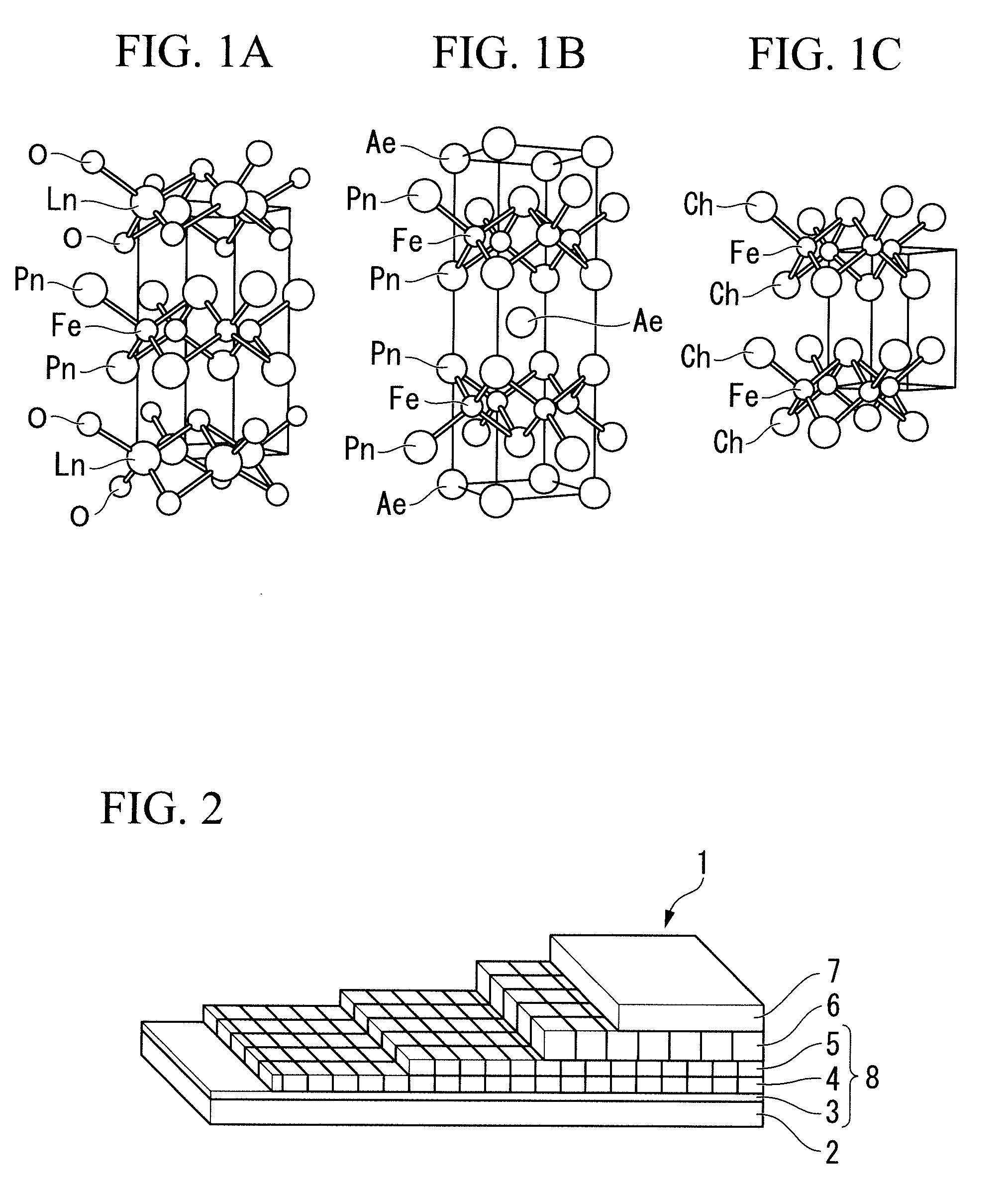

Iron-based superconductors (FeSC) are iron-containing chemical compounds whose superconducting properties were discovered in 2006. In 2008, led by recently discovered iron pnictide compounds (originally known as oxypnictides), they were in the first stages of experimentation and implementation. (Previously most high-temperature superconductors were cuprates and being based on layers of copper and oxygen sandwiched between other substances (La, Ba, Hg)).

Iron-based compound superconducting wire or tape prepared from silver sheath

ActiveCN101707083APromote growthFirmly connectedSuperconductors/hyperconductorsSuperconductor devicesAlloySingle-core

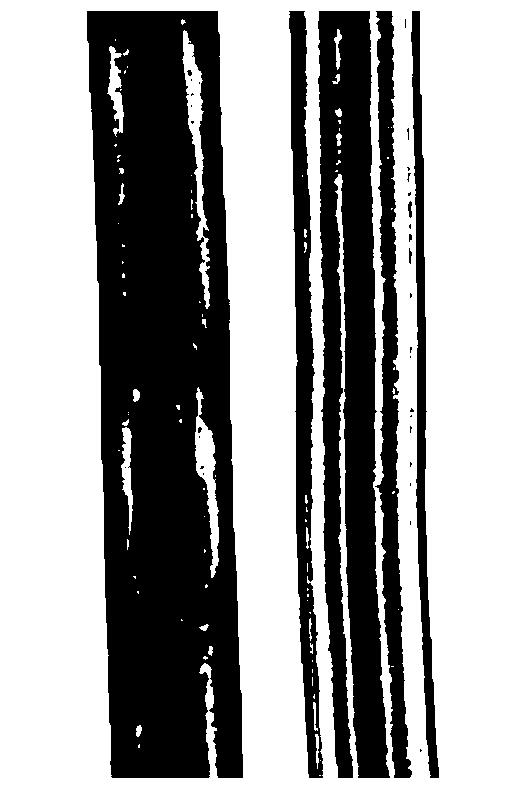

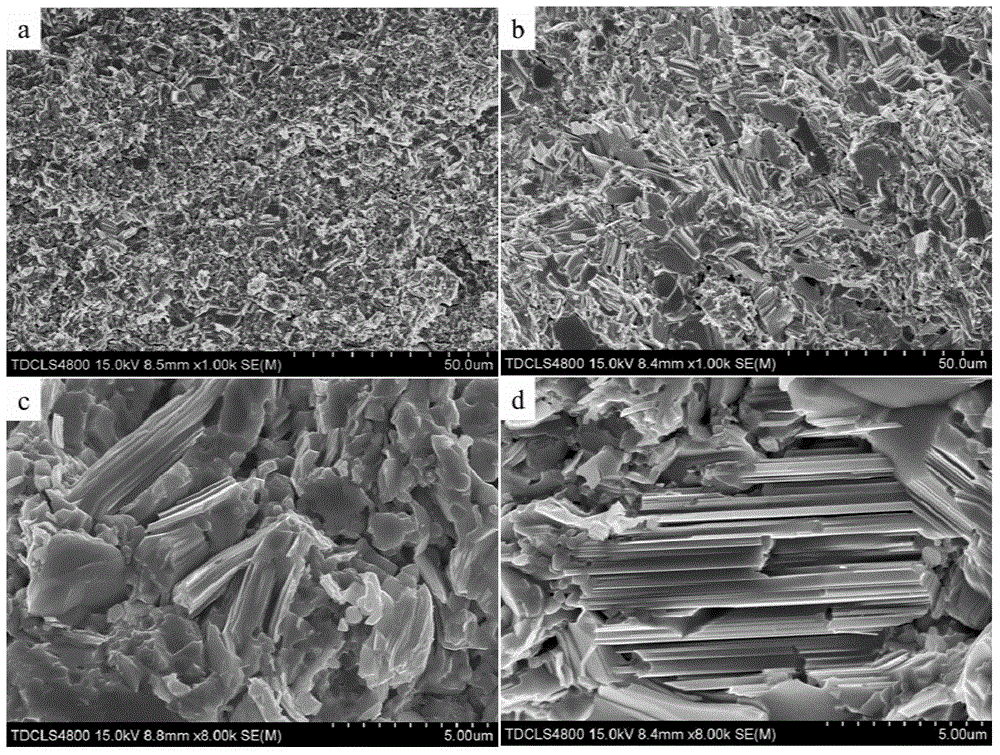

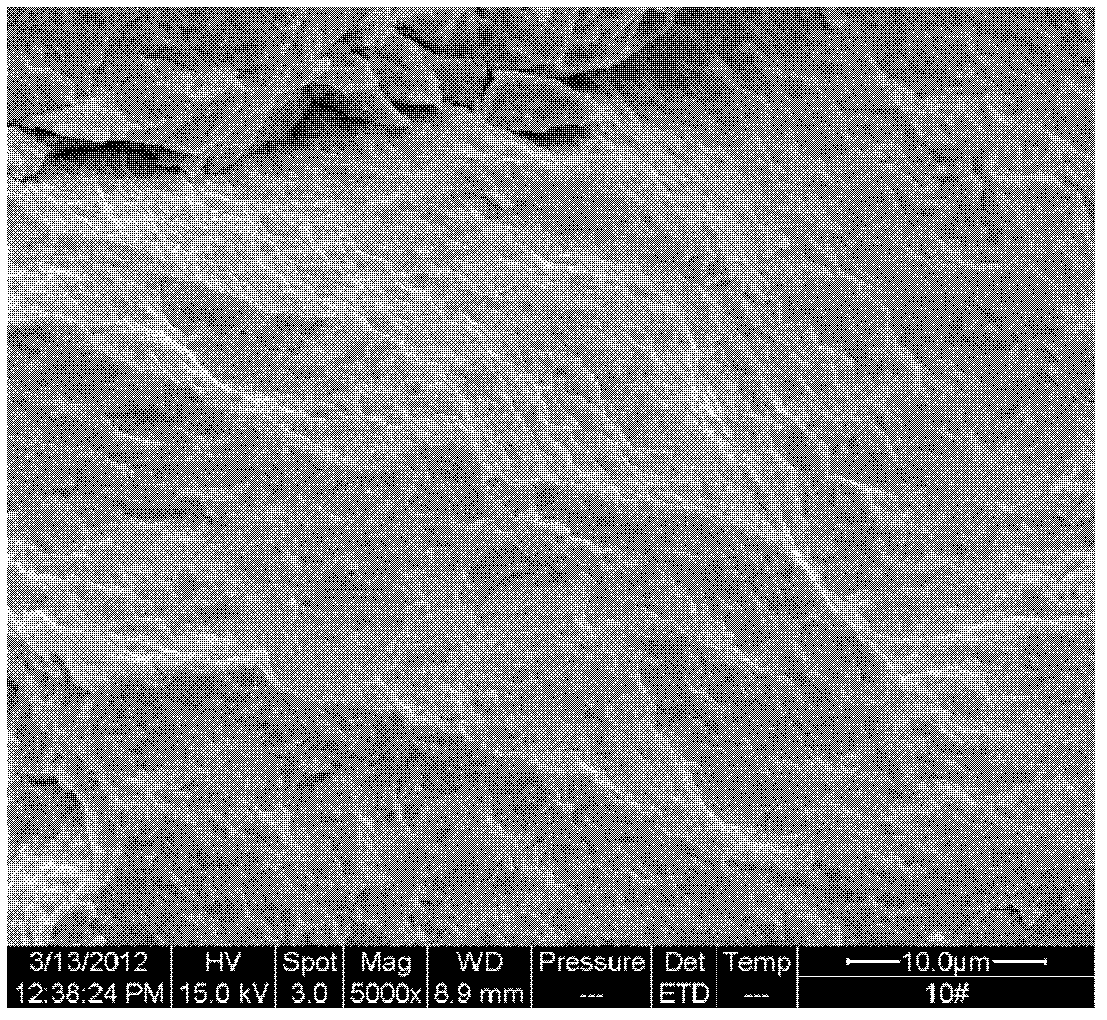

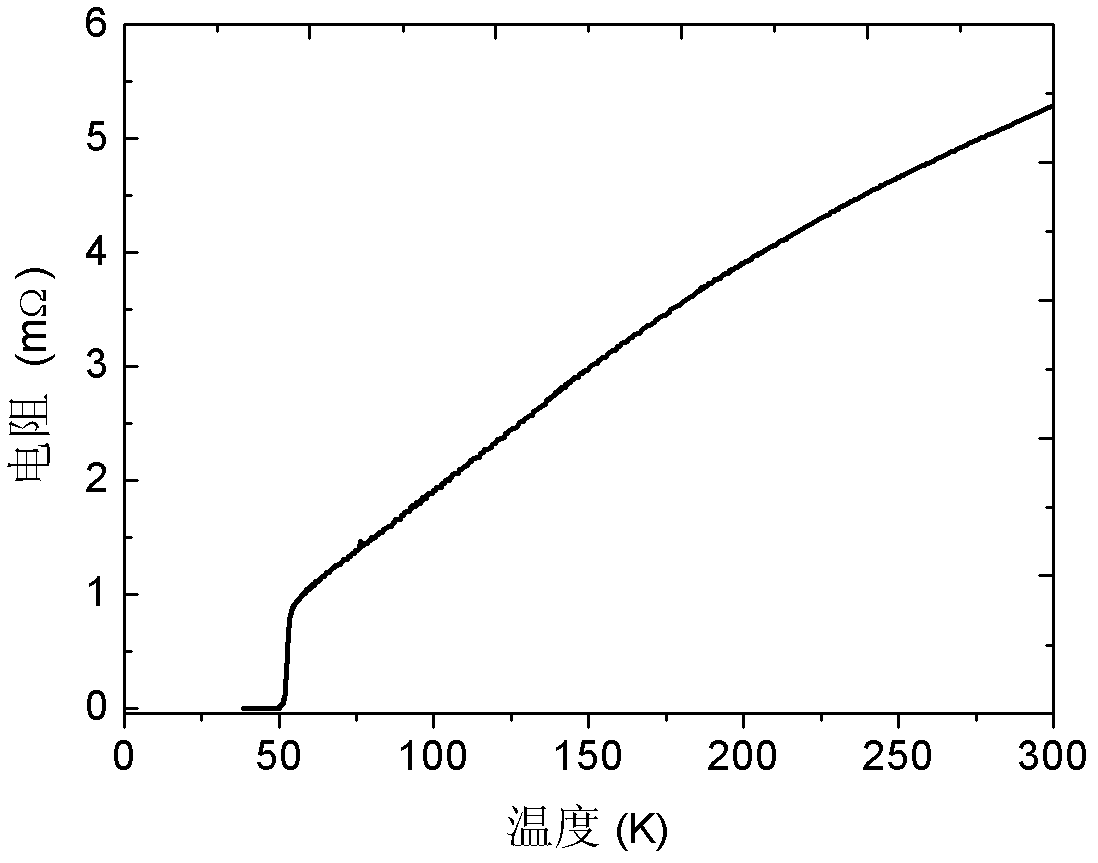

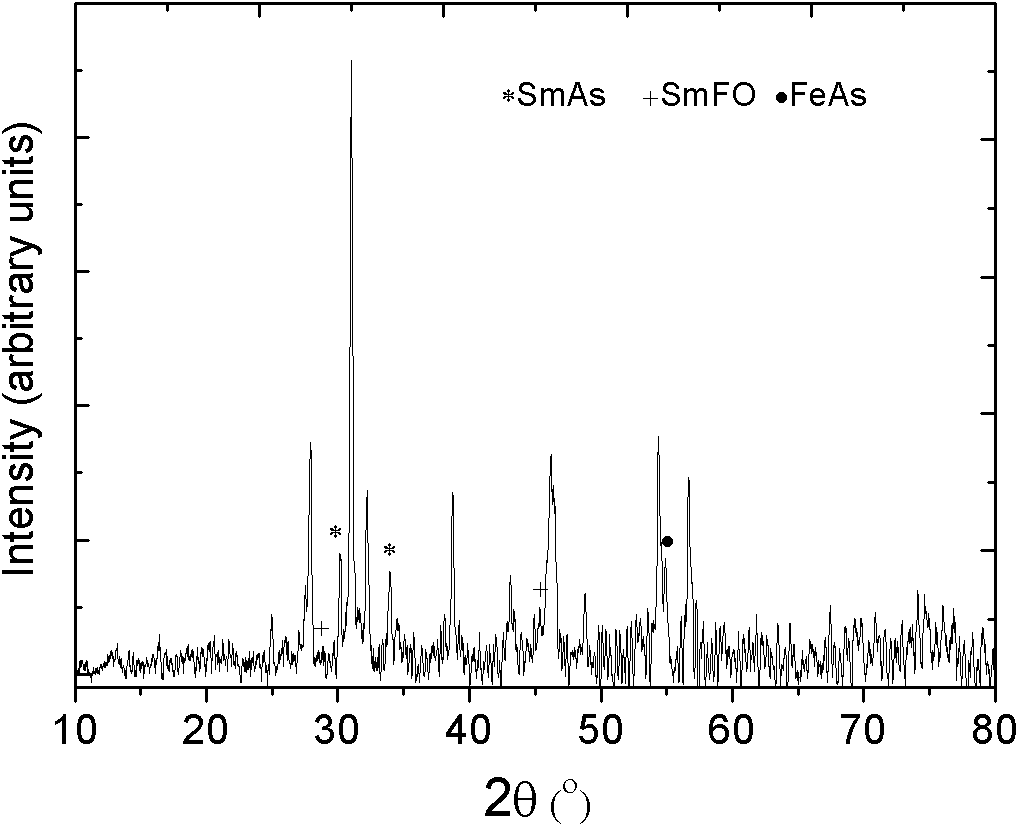

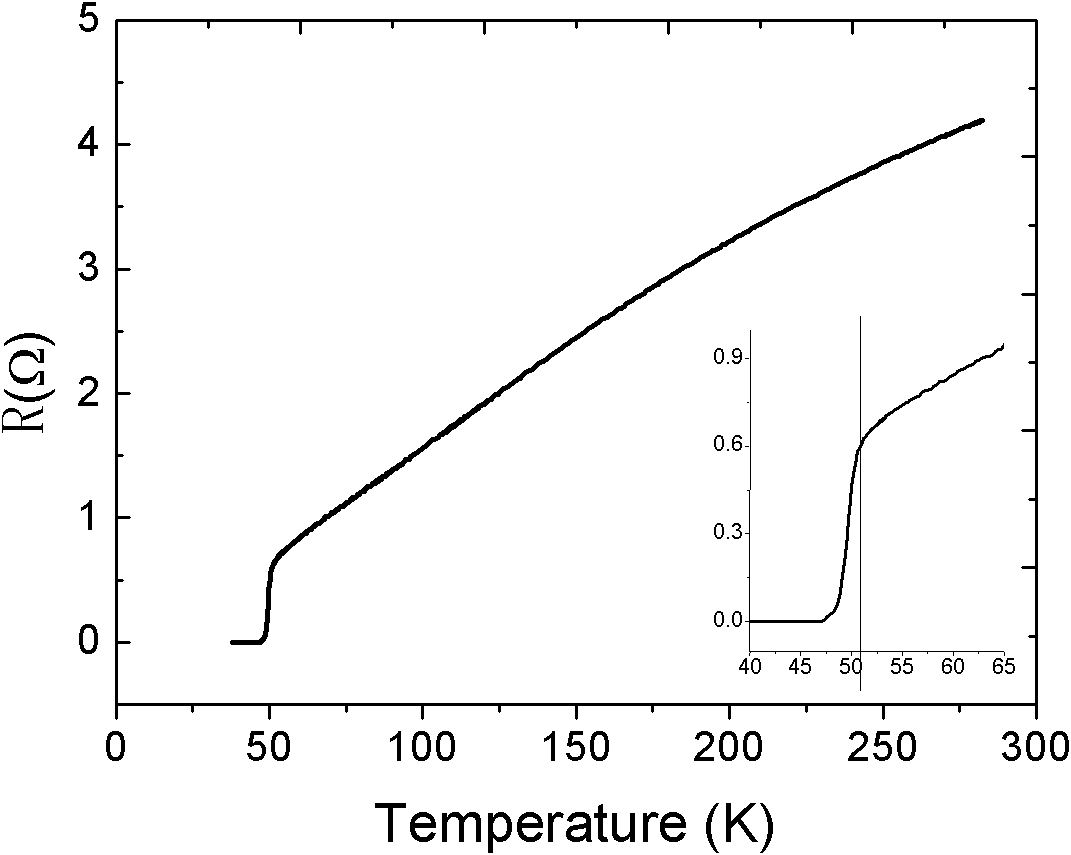

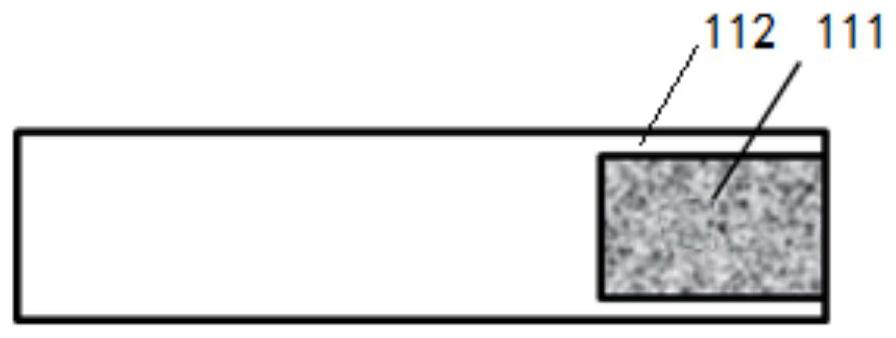

The invention relates to a single-core or multicore iron-based compound superconducting tape prepared from a silver sheath. The conductor core of the tape is an iron-based compound with superconducting property, and silver or silver alloy material is coated outside the conductor core. Other metals or alloy materials can also be coated outside a silver or silver alloy sheath. The superconducting tape is prepared by using a powder tubulated method comprising the following steps of: putting the initial powder of the iron-based compound into a silver tube, a silver alloy tube or a composited tube of silver and other metals; compactly filling the initial powder in the tube; after both ends of the tube are closed, swaging, drawing, rolling and processing the metal tube into wires and tapes; and then obtaining the superconducting tape by vacuum or inert atmosphere annealing. Due to the fact that a conversion zone does not exist between the superconducting core and the sheathed material after annealing and silver steam generated by the silver sheath at the temperature removes FeAs phase, the crystal grain connectivity of the iron-based superconductor is improved. The novel iron-based compound superconducting wire or tape has good current transportation property.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

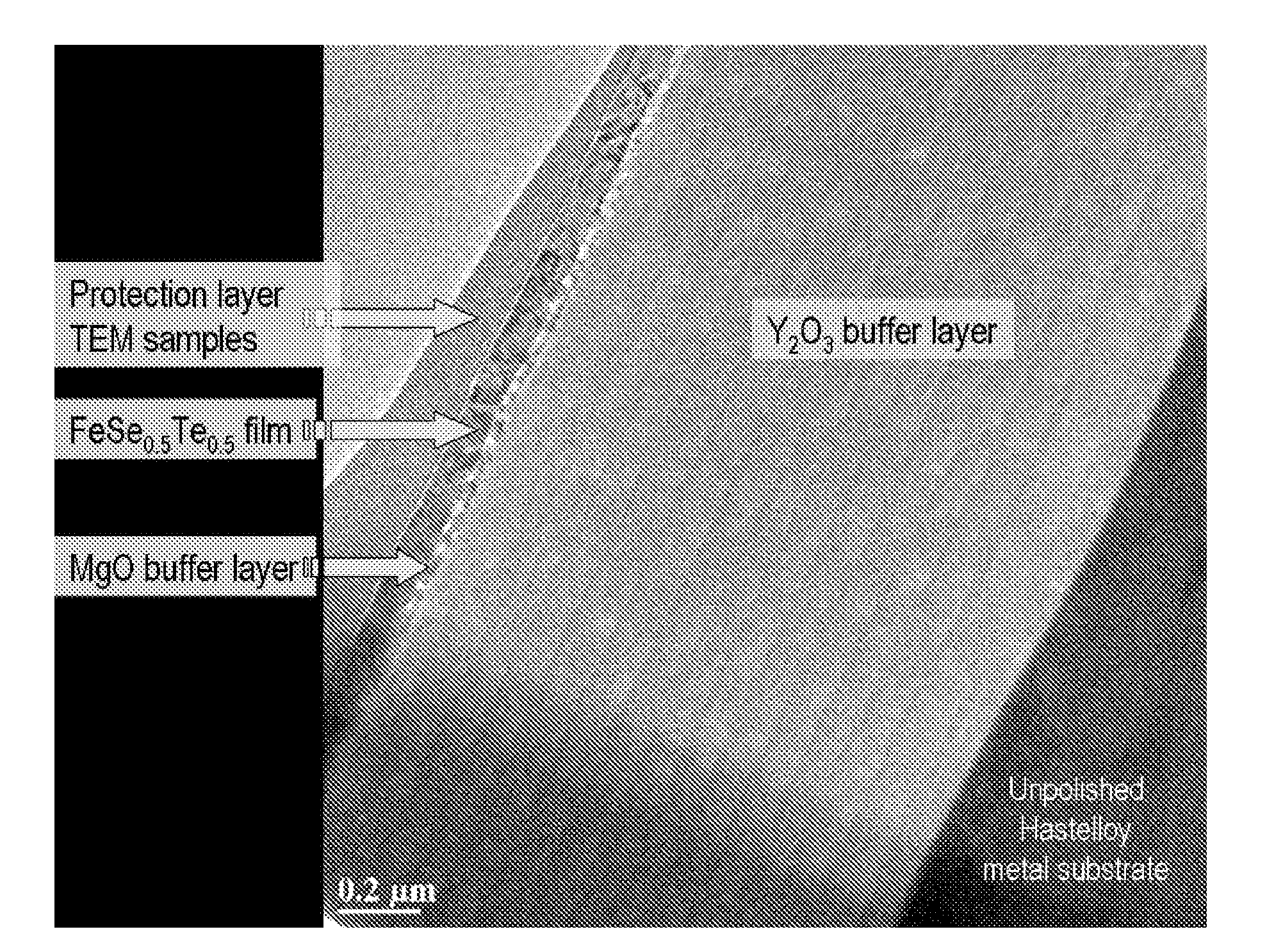

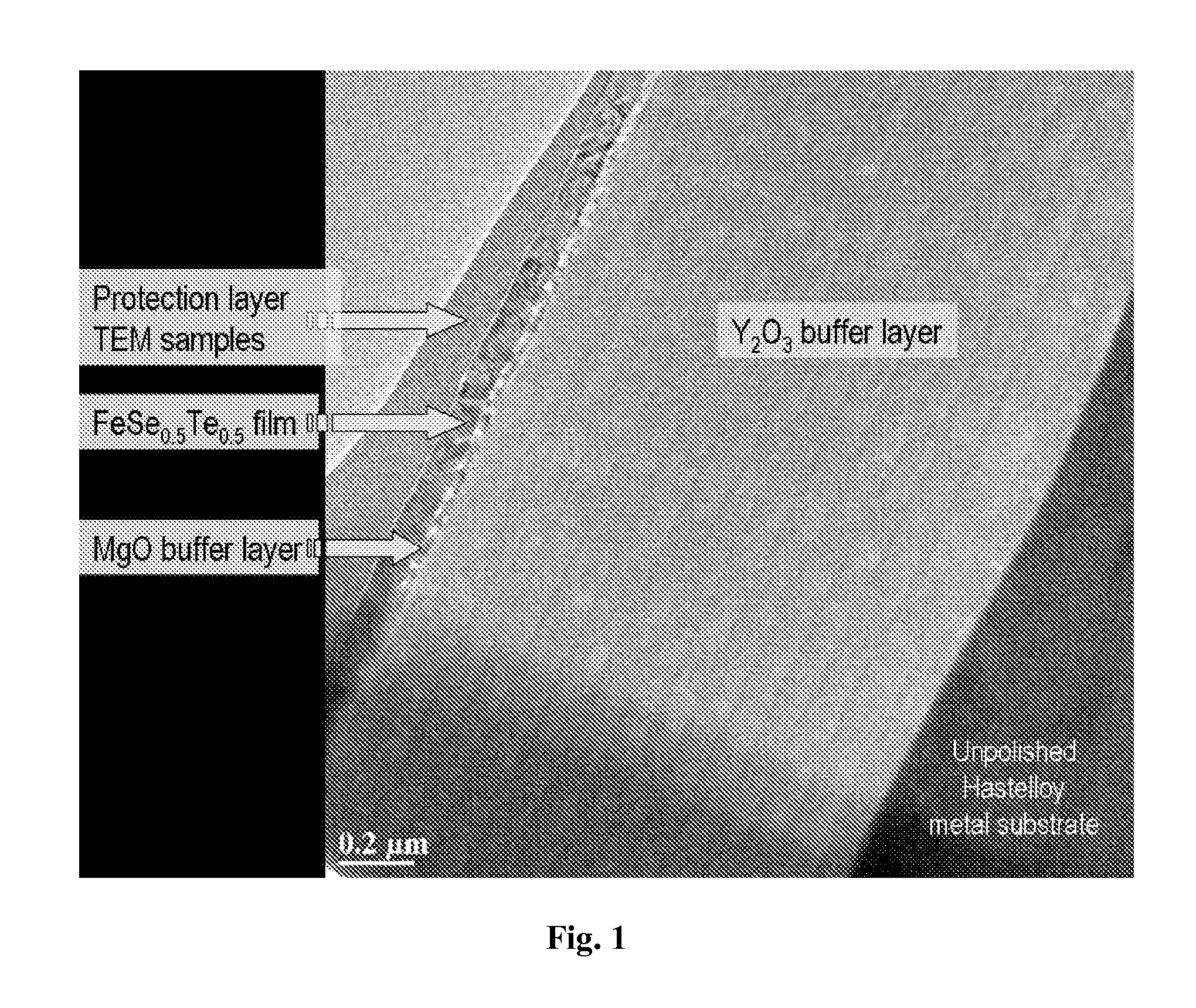

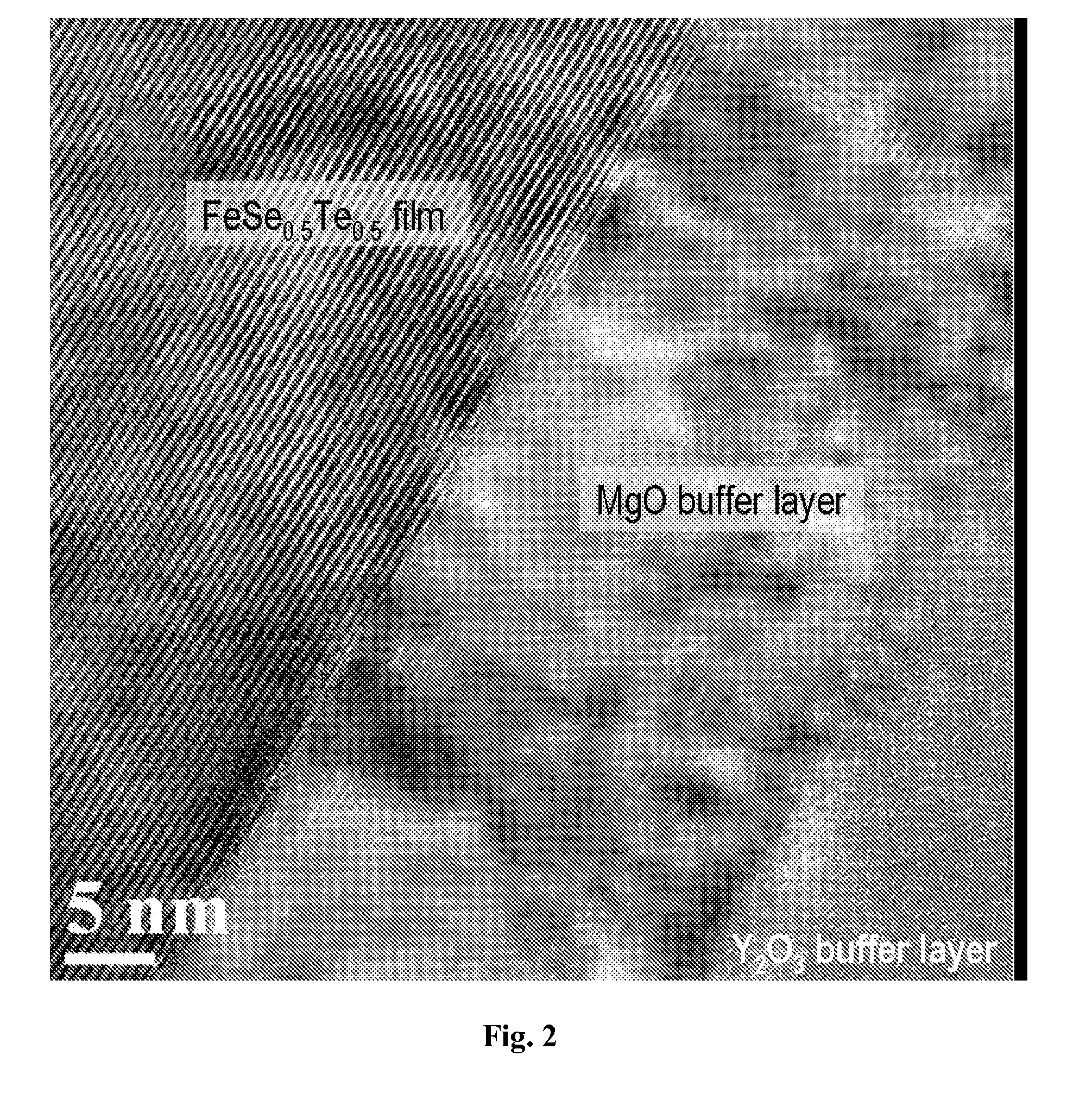

Iron based superconducting structures and methods for making the same

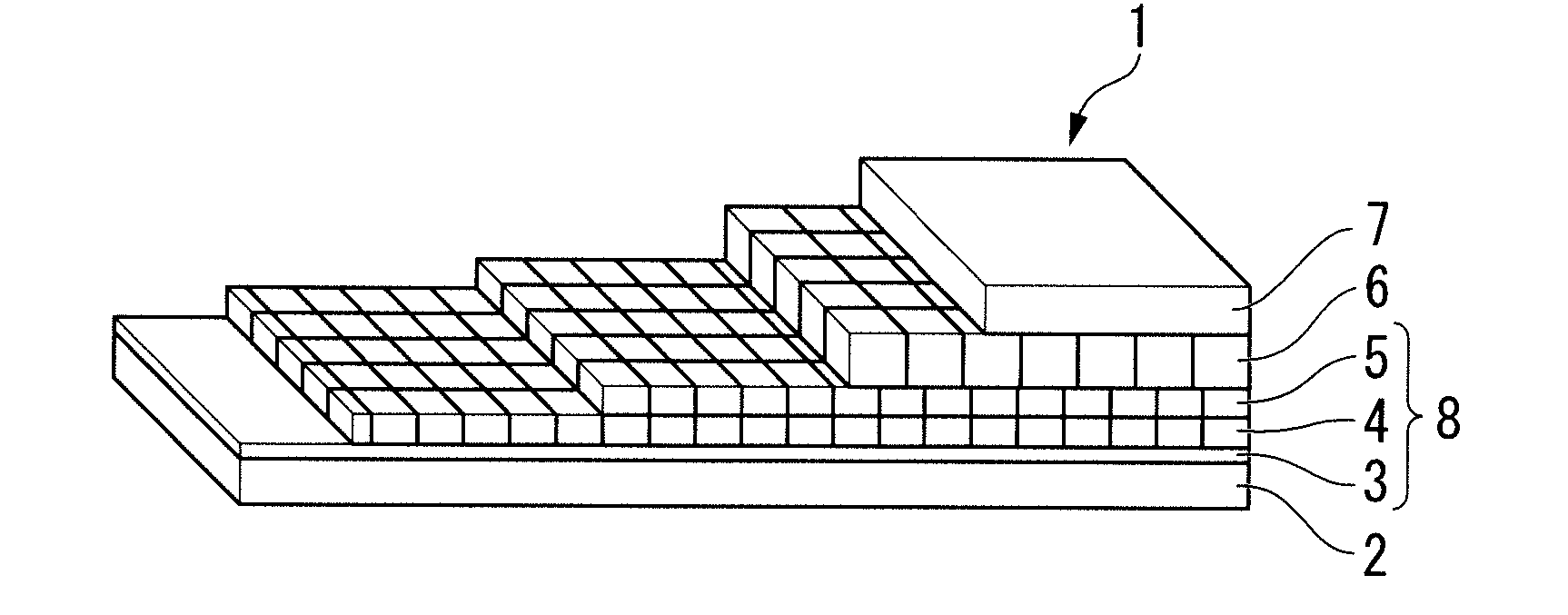

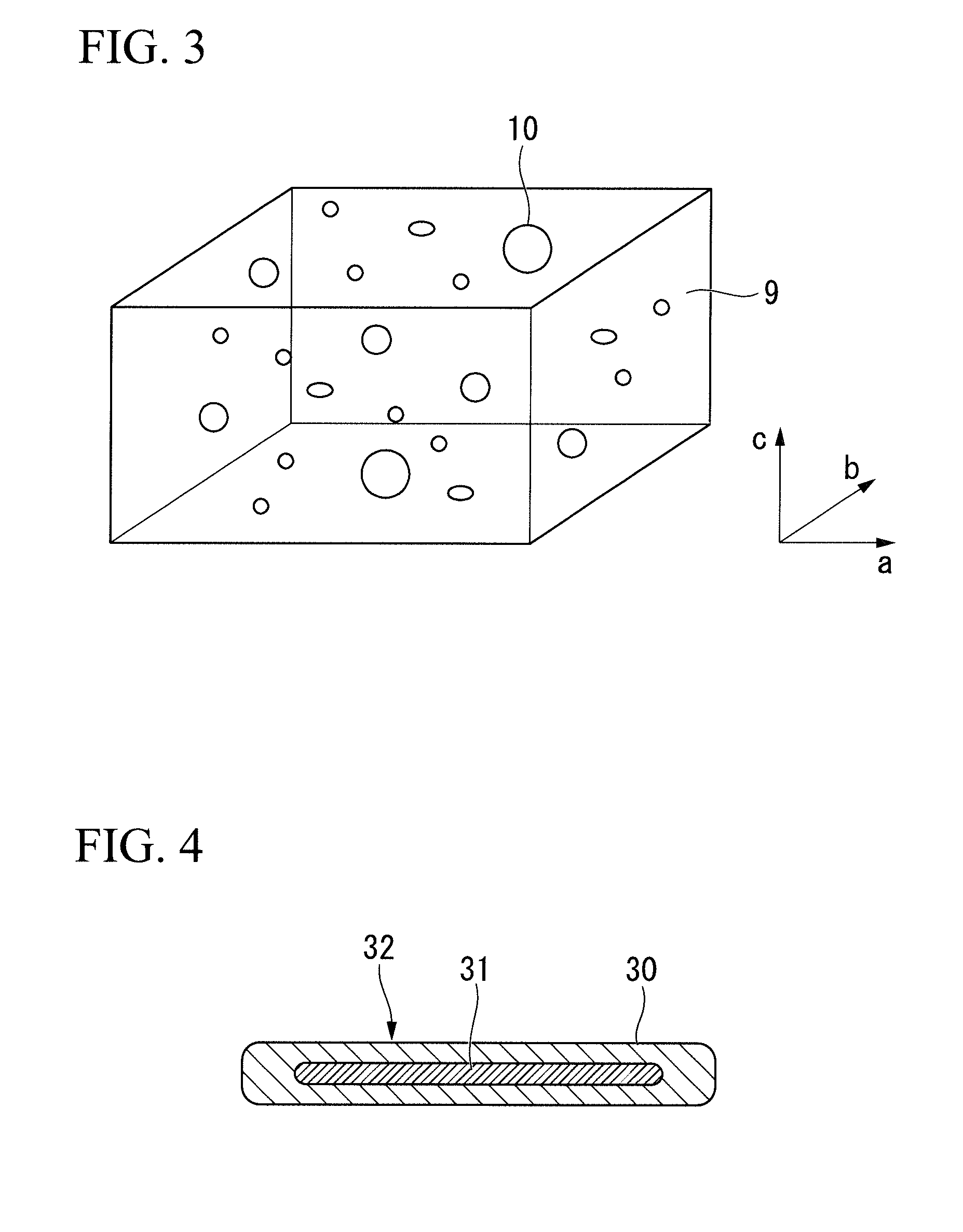

InactiveUS20130196856A1Improve textureImprove superconductivitySemiconductor/solid-state device detailsSolid-state devicesThin membraneLattice constant

In some embodiments of the invention, superconducting structures are described. In certain embodiments the superconducting structures described are thin films of iron-based superconductors on textured substrates; in some aspects a method for producing thin films of iron-based superconductors on textured substrates is disclosed. In some embodiments applications of thin films of iron-based superconductors on textured substrates are described. Also contemplated is the formation of a film of iron-based superconductor having a thickness and an in-plane lattice constant formed on a textured substrate having a thickness and an in-plane lattice constant similar to the in-plane lattice constant of the iron-based superconductor.

Owner:BROOKHAVEN SCI ASSOCS

Method for preparing iron-based superconductor

InactiveCN102082010AQuality improvementSuitable for mass productionSuperconductors/hyperconductorsSuperconductor devicesMetal stripsHydrogen

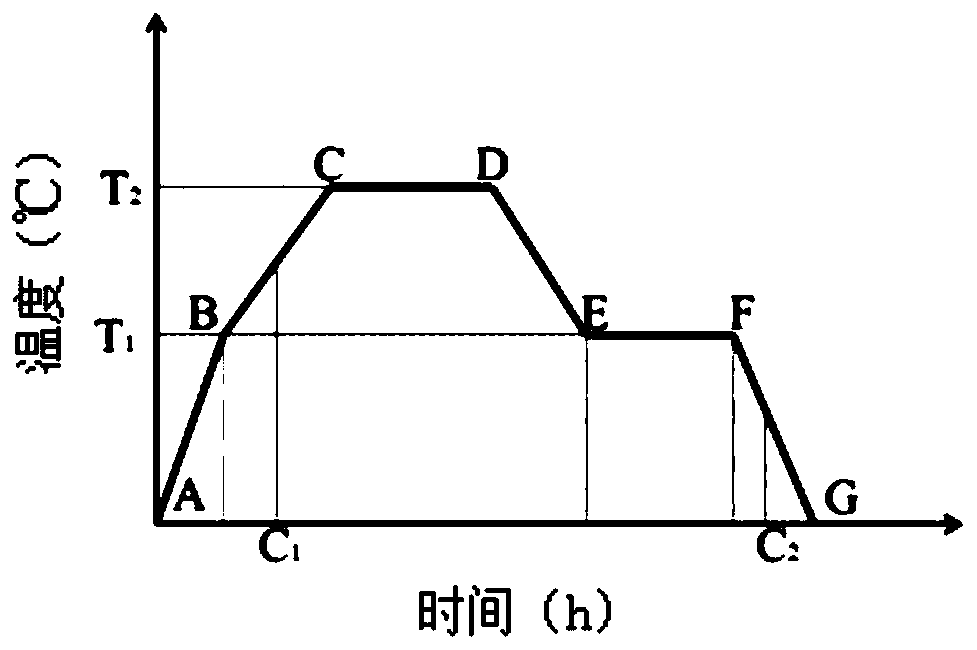

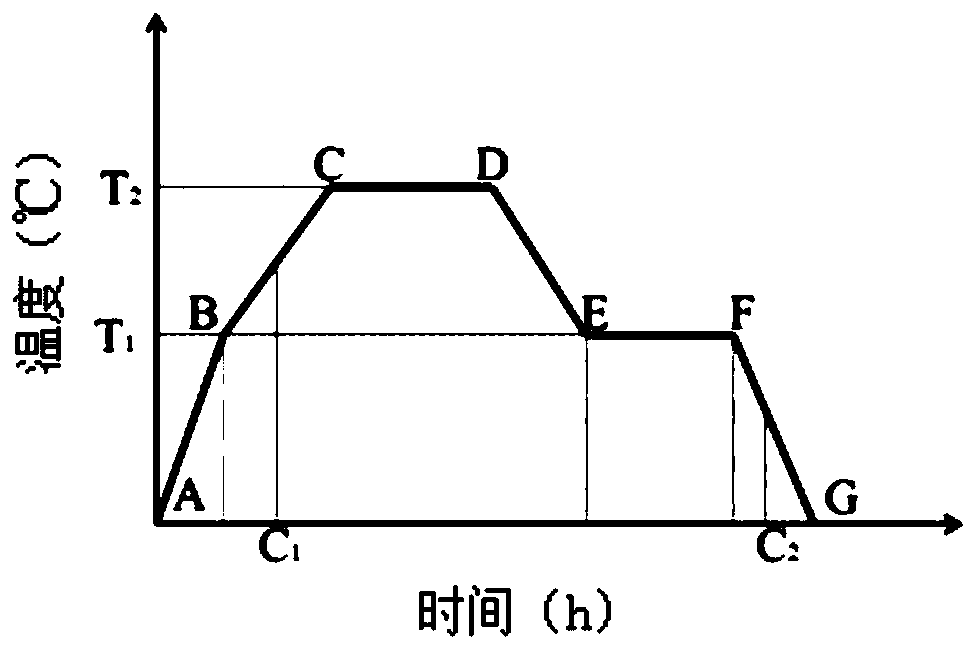

The invention relates to a method for preparing an iron-based superconductor, which comprises the following steps of: firstly, charging an iron wire or a metal strip after cleaning into a reaction chamber of a controllable atmosphere heating furnace; secondly, charging Se (Selenium) powder or Se blocks into the reaction chamber, cleaning the reaction chamber for 1 to 5 times by using high-purity argon gas or hydrogen gas, sealing the reaction chamber, raising the temperature to 200-700 DEG C, and holding the temperature for 5 minutes to 10 hours; thirdly, raising the temperature to 800-1,000 DEG C, and holding the temperature for 1 to 20 hours; fourthly, reducing the temperature to 500-200 DEG C, and holding the temperature for 1 to 24 hours; and fourthly, cutting off a heating power supply, cooling to the room temperature, and obtaining the FeSe (Ferrum-Selenium) superconductor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

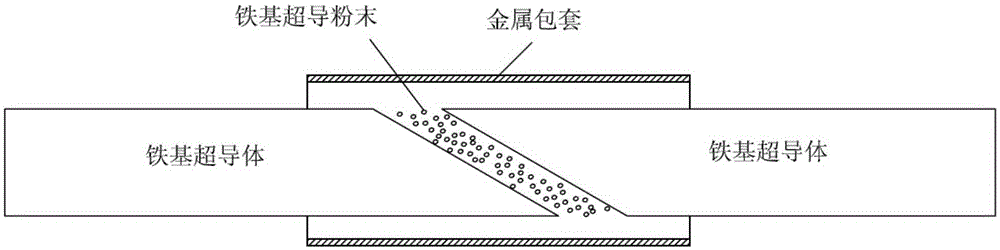

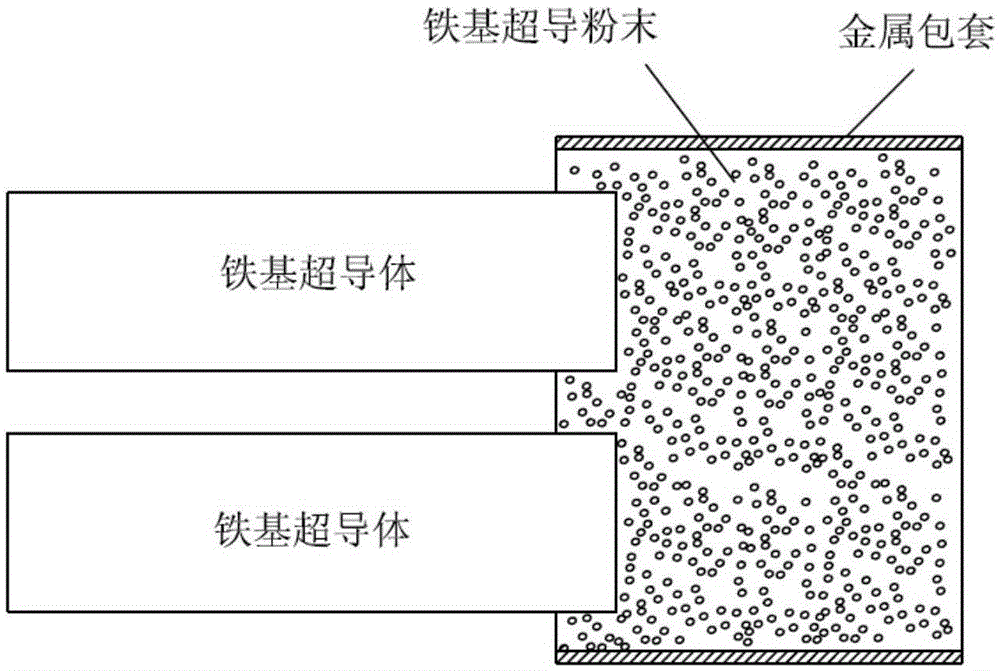

Iron-based compound superconducting joint and preparation method thereof

ActiveCN105355357AAvoid obstructionAvoid attenuationSuperconductors/hyperconductorsSuperconductor detailsHeat treatedMetal

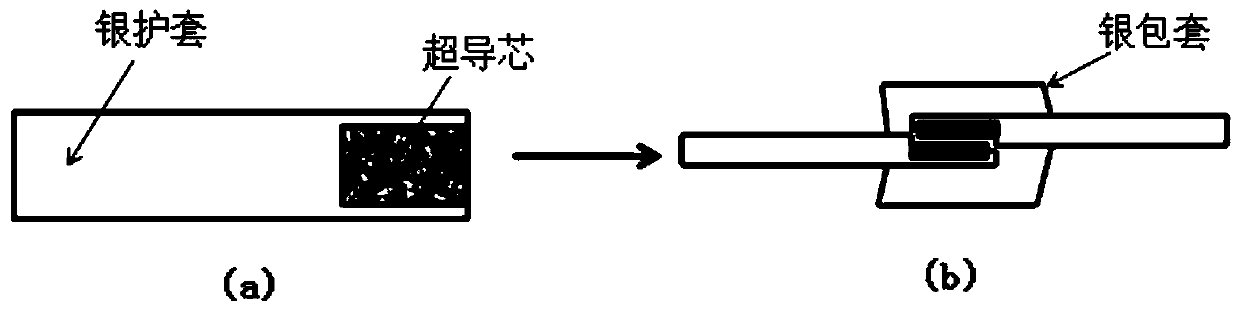

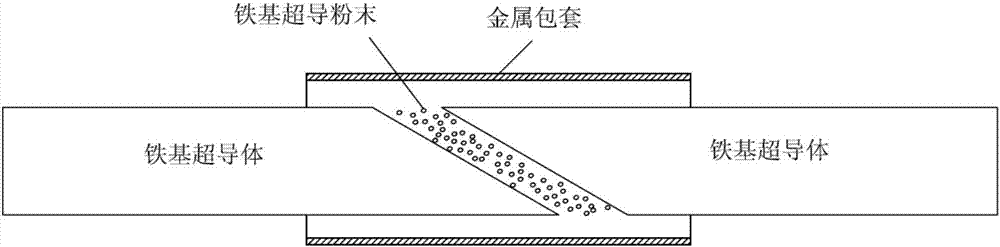

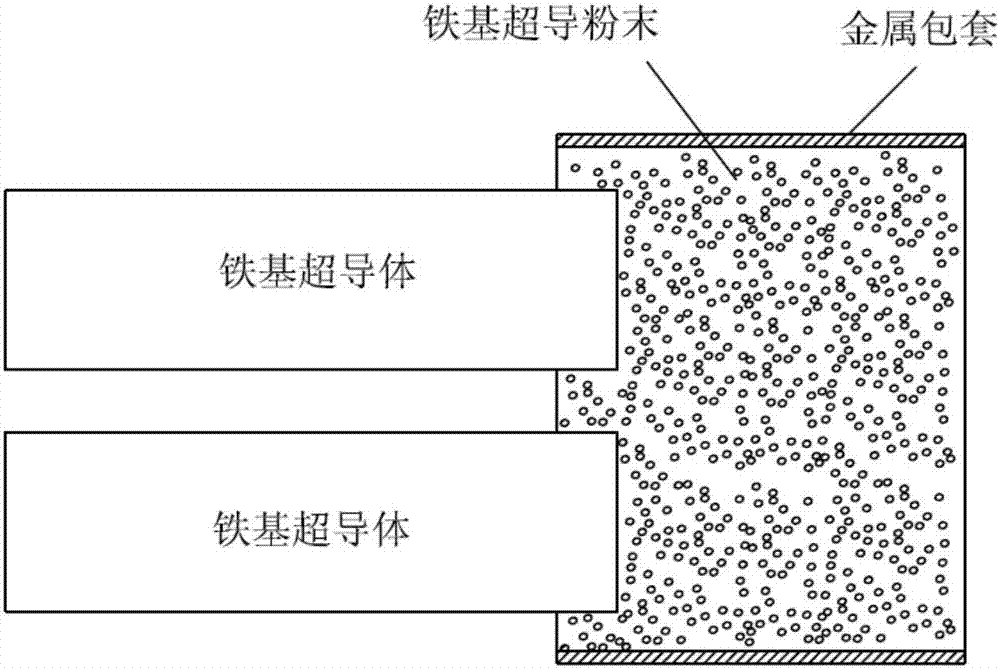

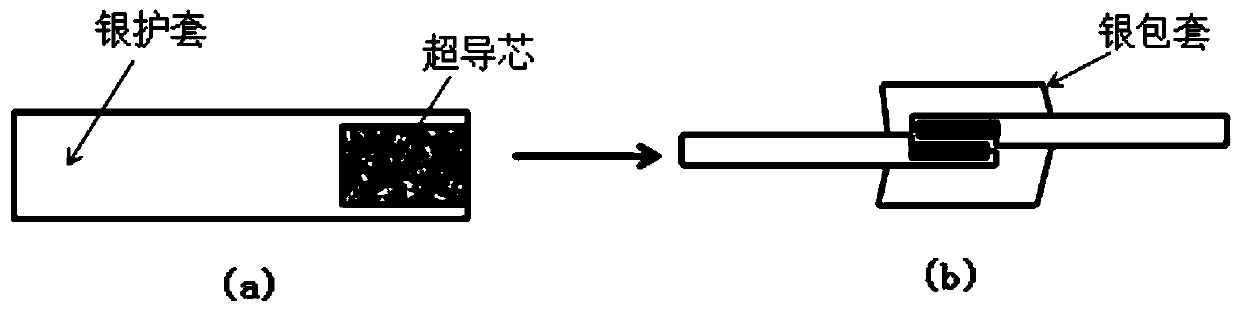

Provided is an iron-based compound superconducting joint. The superconducting joint comprises connected iron-based superconductors, iron-based superconducting powder and a metal sheath. The position between tail ends of the connected iron-based superconductors is filled up with iron-based superconducting powder and wrapped up by a signal-layer or multi-layer metal sheath. The preparation method of the superconducting joint comprises following steps of: (1) peeling non-superconducting layers on surfaces of tail ends of the iron-based superconductors needed to be connected to expose superconducting cores; (2) filling iron-based superconducting powder between tail ends of processed tail ends of the iron-based superconductors and utilizing the multi-layer metal sheath to wrap up tail ends of the iron-based superconductors and the iron-based superconducting powder; (3) welding or not welding the metal sheath processed by the step (2); (4) applying pressure to shrink crease the cross section of the metal sheath prepared by the step (3); and (5) carrying out heat treatment on the metal sheath prepared by the step (4) during or after pressure is applied or not necessarily performing heat treatment.The invention is very suitable for making a superconducting joint in the engineering field.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Preparation method for iron-based super conductor

ActiveCN102522154AHigh purityReduce generationSuperconductors/hyperconductorsSuperconductor devicesMaterials scienceIron based

Owner:深创超导(深圳)科技有限公司

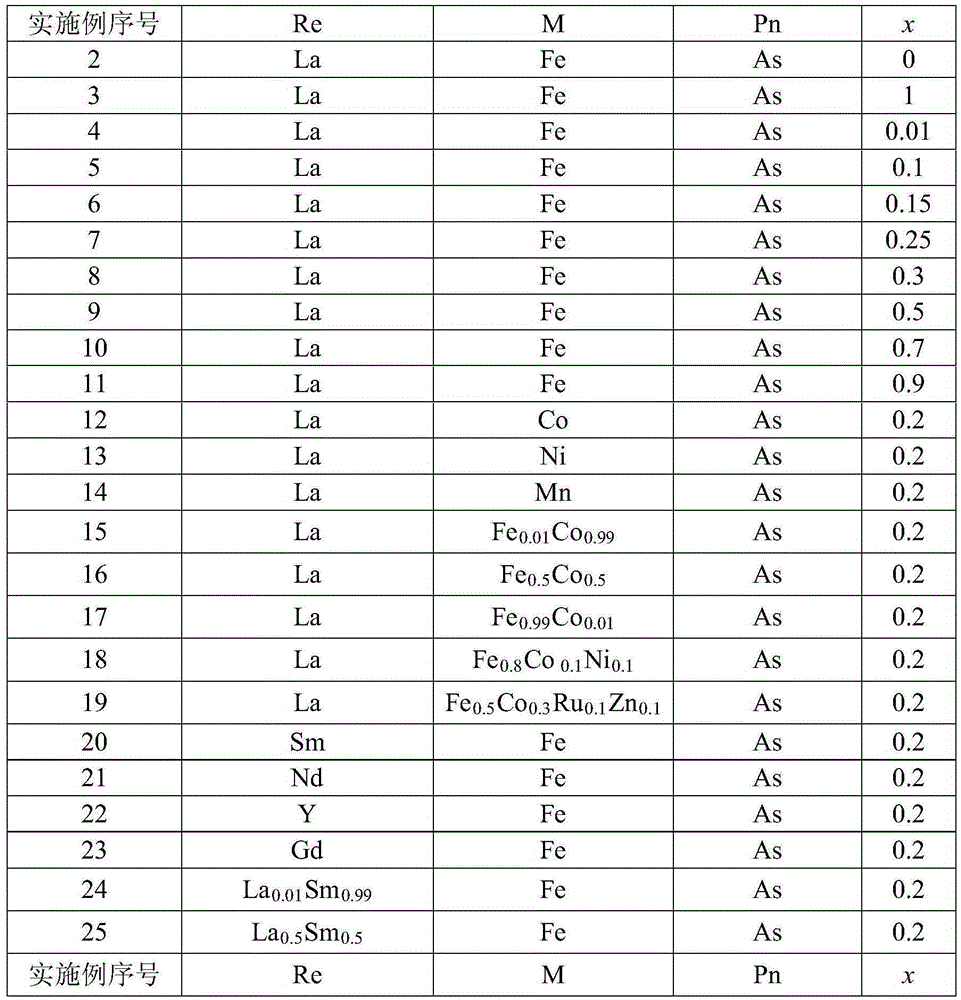

Iron-based superconducting material, iron-based superconducting layer, iron-based superconducting tape wire material, and iron-based superconducting wire material

InactiveUS20140349854A1Little dependencySuppress a decrease in JSuperconductors/hyperconductorsConductive materialWire rodSuperconducting magnet

Owner:INT SUPERCONDUCTIVITY TECH CENT

Processing technology for improving performance of Fe-based compound superconductive tape

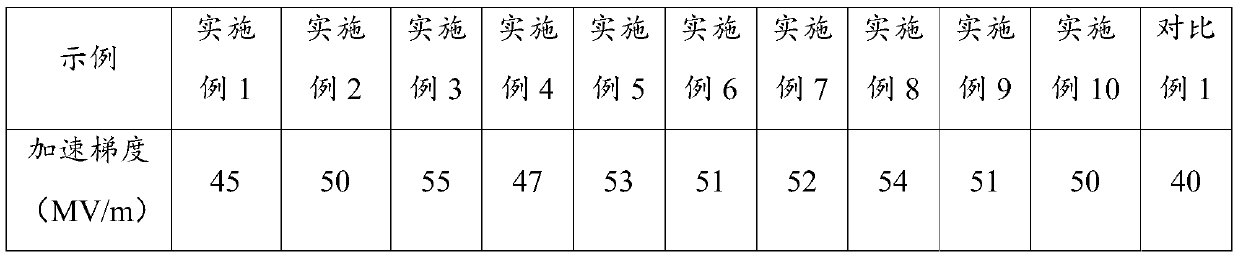

ActiveCN108962487AGuaranteed stabilityGuaranteed transmission performanceSuperconductors/hyperconductorsSuperconductor devicesThermal treatmentSingle-core

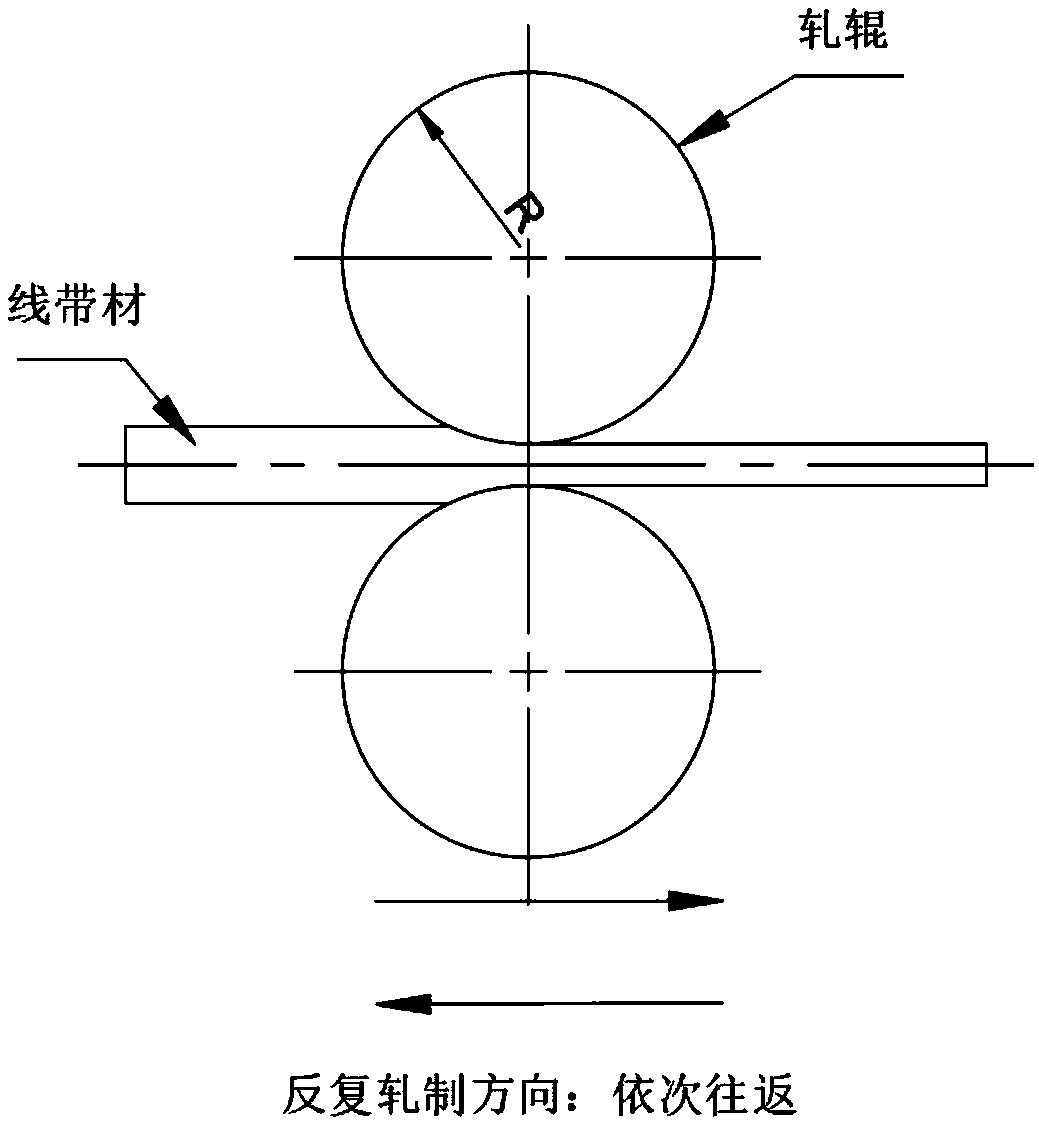

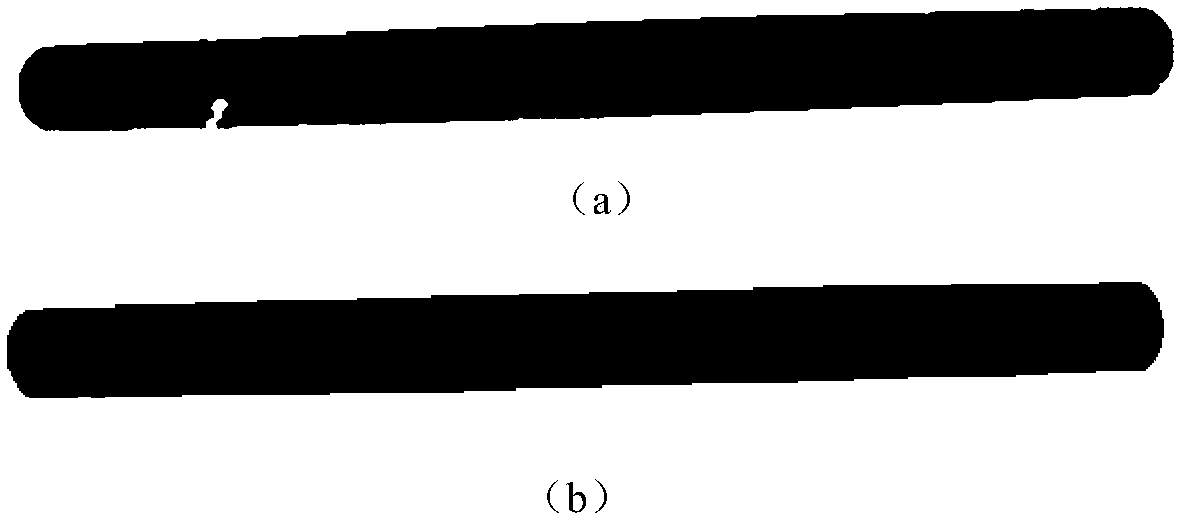

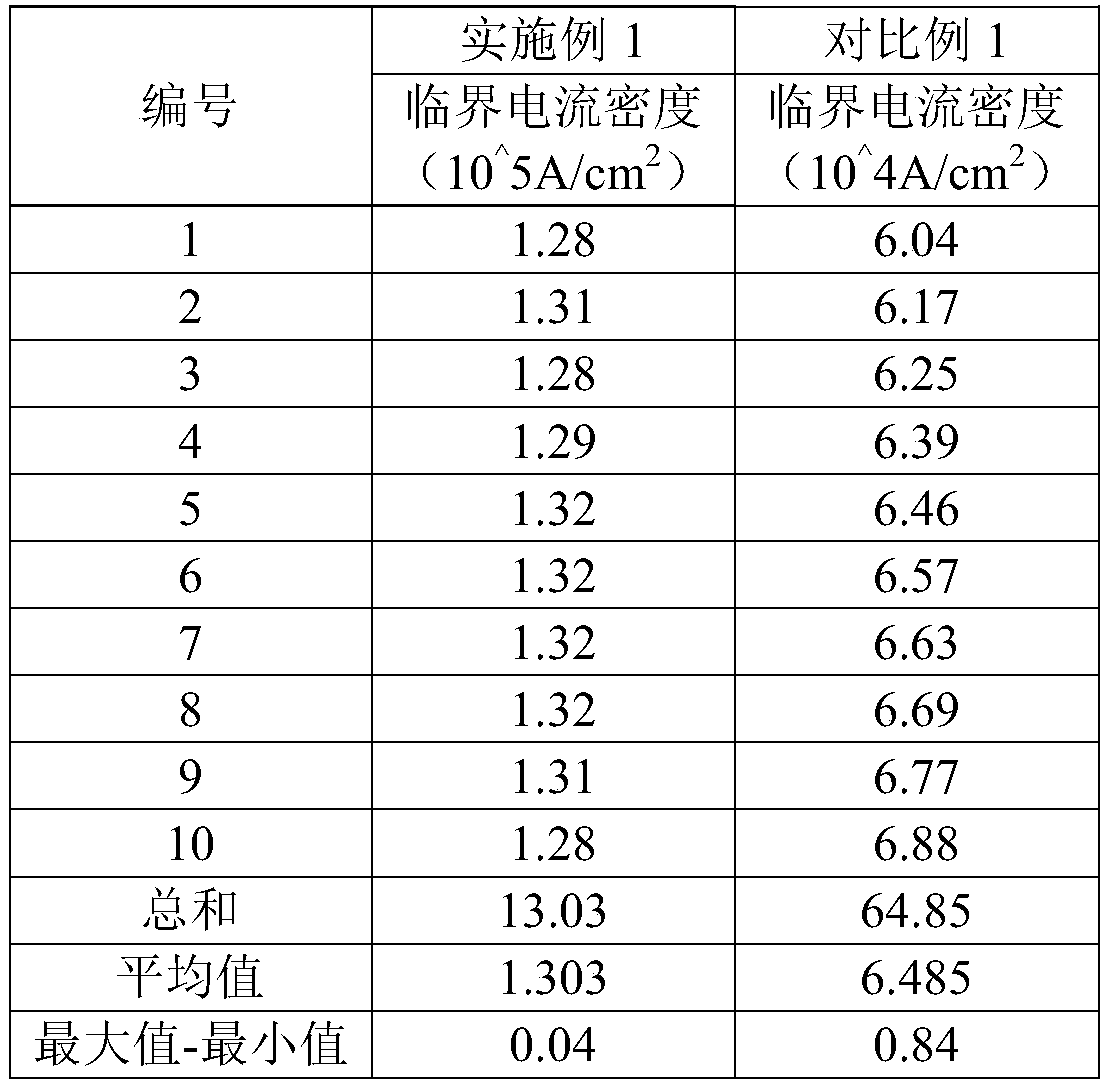

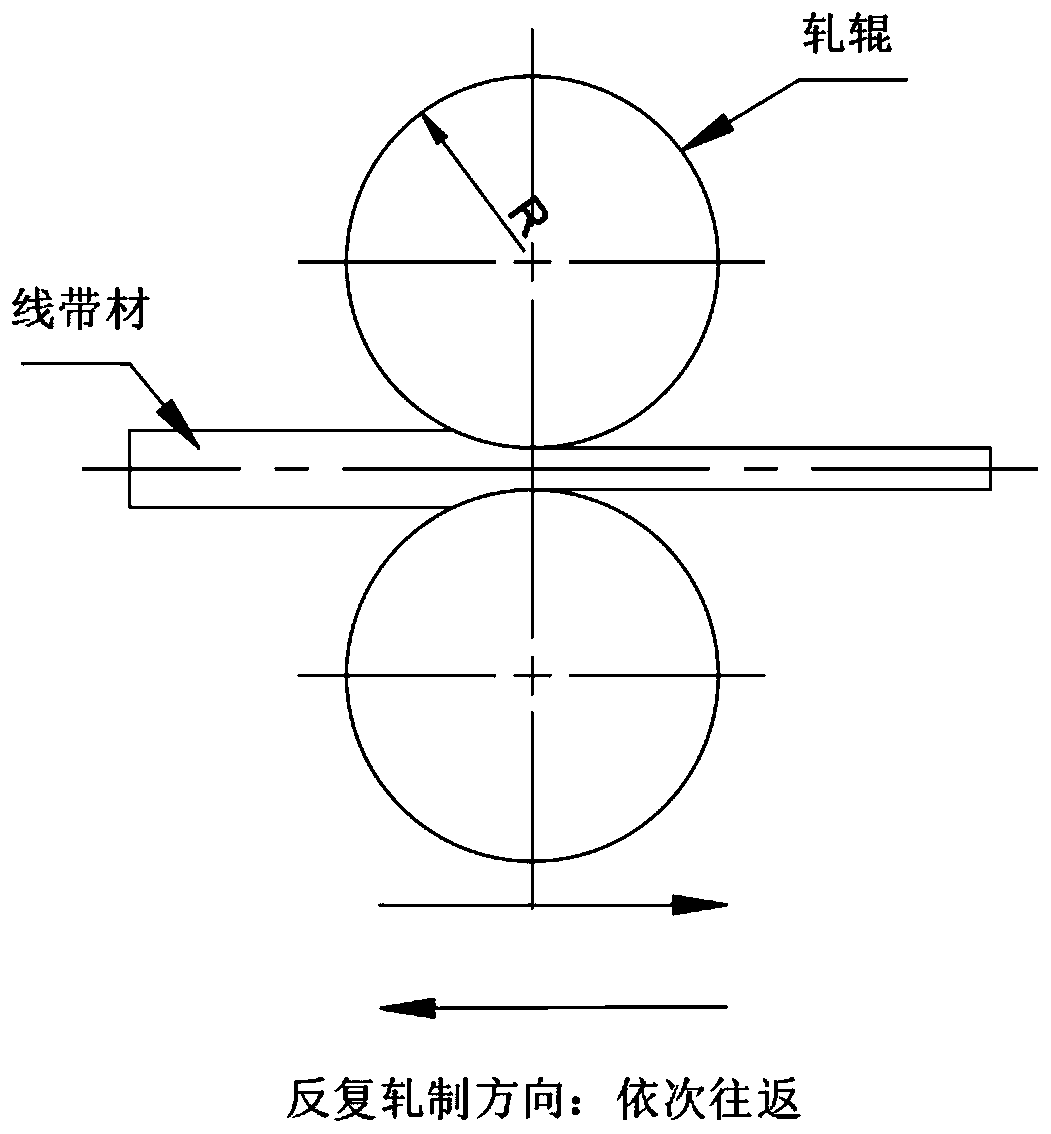

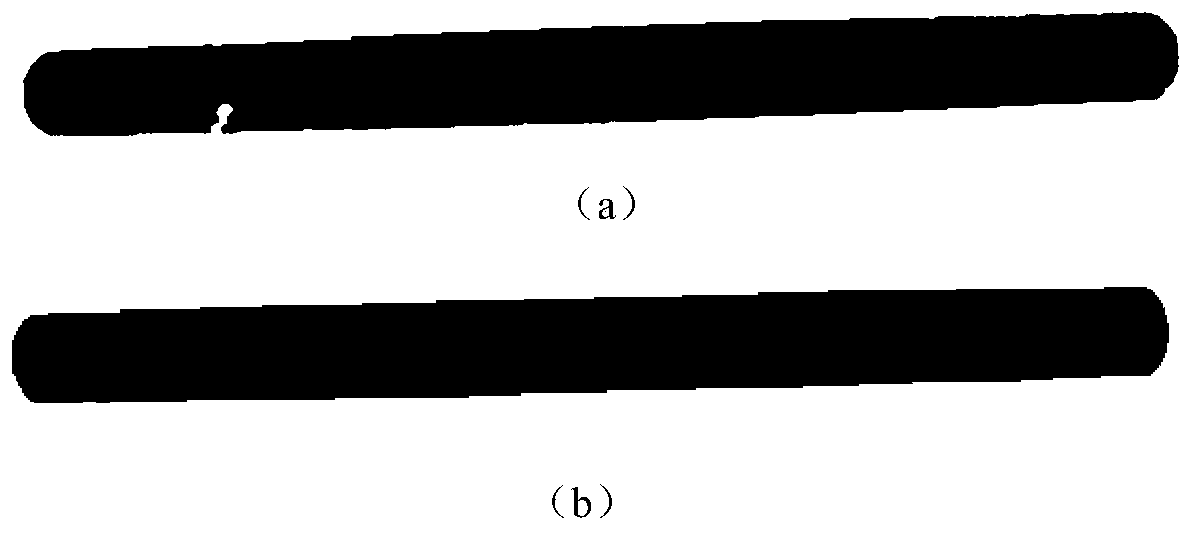

The invention relates to a processing technology for improving performance of a Fe-based compound superconductive tape. The processing technology for improving performance of a Fe-based compound superconductive tape includes the steps: preparing Fe-based superconductor precursor powder; filling a sheath with the precursor powder to obtain a tube-loading composite; drawing the tube-loading composite into a single-core wire; cutting the single-core wire into a plurality of identical short samples, inserting the identical short samples into the outer sheath to obtain a multi-core composite tube;after the composite tube is drawn into a wire of a certain diameter, repeatedly rolling the wire (during the rolling process, the two ends of the samples are bitten into the roller in turn), and thenobtaining a multi-core tape with certain thickness; and under an Ar atmosphere at 500 to 1100 DEG C, performing final thermal treatment on the obtained Fe-based multi-core tape. Compared with a multi-core tape obtained by a unidirectional rolling technology, the multi-core tape obtained by the processing technology for improving performance of a Fe-based compound superconductive tape through the repeated rolling mode has no cracking phenomenon in each superconductive core of the multi-core tape, and the integrity of the superconductive core is preferable, and the critical transmission currentIc of the tape and the critical engineering current density Je of the tape are significantly improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

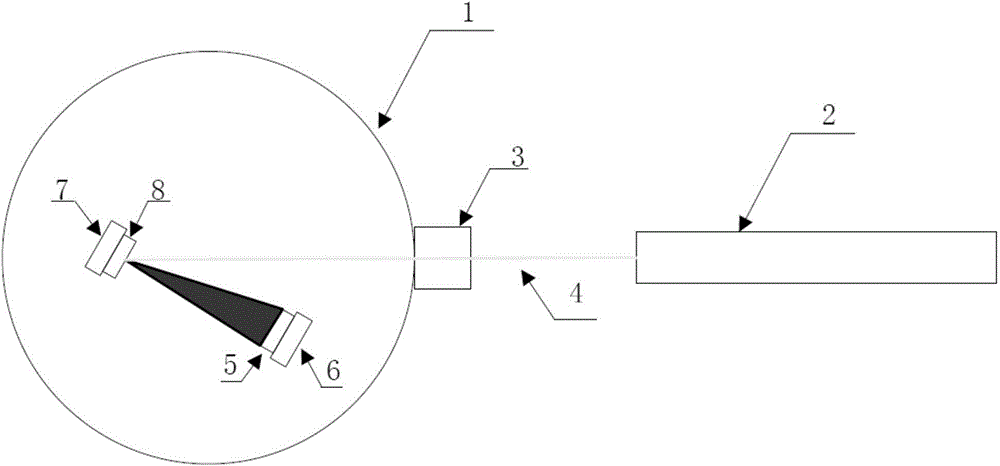

Method for preparing FeSeTe film by pulse laser deposition coating technology

InactiveCN104928630AEasy to useFast coating speedVacuum evaporation coatingSputtering coatingPre treatmentPulsed laser deposition

The invention belongs to the field of novel Fe-based superconductors and particularly relates to a method for preparing a FeSeTe film by a pulse laser deposition coating technology. The method comprises the following steps: firstly, uniformly mixing and grinding Fe powder, Se powder and Te powder at a certain molar ratio; secondly, sintering the ground powder in a vacuum quartz tube at 700DEG C for 24 hours, performing quenching treatment when the sintered powder is at 400DEG C, grinding the sintered powder into powder again, pressing the powder in the size of a required target material, sintering the powder in the vacuum quartz tube at 700DEG C for 24 hours, and performing quenching treatment when the powder is at 400DEG C; adjusting laser parameters, performing pretreatment of the obtained target material, and performing film growth on a substrate within a certain time; and performing natural cooling in vacuum to obtain the required film. According to the method, the FeSeTe superconductive film is grown by utilizing the pulse laser deposition coating technology. The method has the advantages that the use is convenient, the coating speed is high, films of different components can be prepared, and the target material and the substrate are kept consistent in component more easily.

Owner:NANJING UNIV

High-performance iron-based superconducting strip and preparation process thereof

InactiveCN109949999AHigh densityImprove current carrying capacitySuperconductors/hyperconductorsSuperconductor devicesSingle-coreHeat treated

The invention discloses a high-performance iron-based superconducting strip and a preparation process thereof. The process in particular comprises steps of preparing an iron-based superconductor precursor powder; injecting the precursor powder into a metal pipe to obtain a pipe-loaded composite body, and obtaining a single-core wire by extruding and drawing; cutting the single-core wire into a plurality of equal-length single-core wires, loading the equal-length single-core wires into the metal pipe to form a multi-core composite pipe, and obtaining multi-core wires by extruding and drawing; performing four-roller rolling on the single-core wires or multi-core wires to obtain a single-core strip or multi-core strip; and obtaining the high-performance iron-based superconducting strip afterthe heat treatment of the single-core strip or the multi-core strip. The multi-core strip is prepared by four-roll rolling, is subjected to the uniform pressing force in four directions, which obviously increases the density of the superconducting strip, and obtains high textured degree and density while ensuring the superconducting core of the strip. Thus, the current carrying property of the strip is improved, and the critical transfer current and the critical engineering current density of the superconducting strip are improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

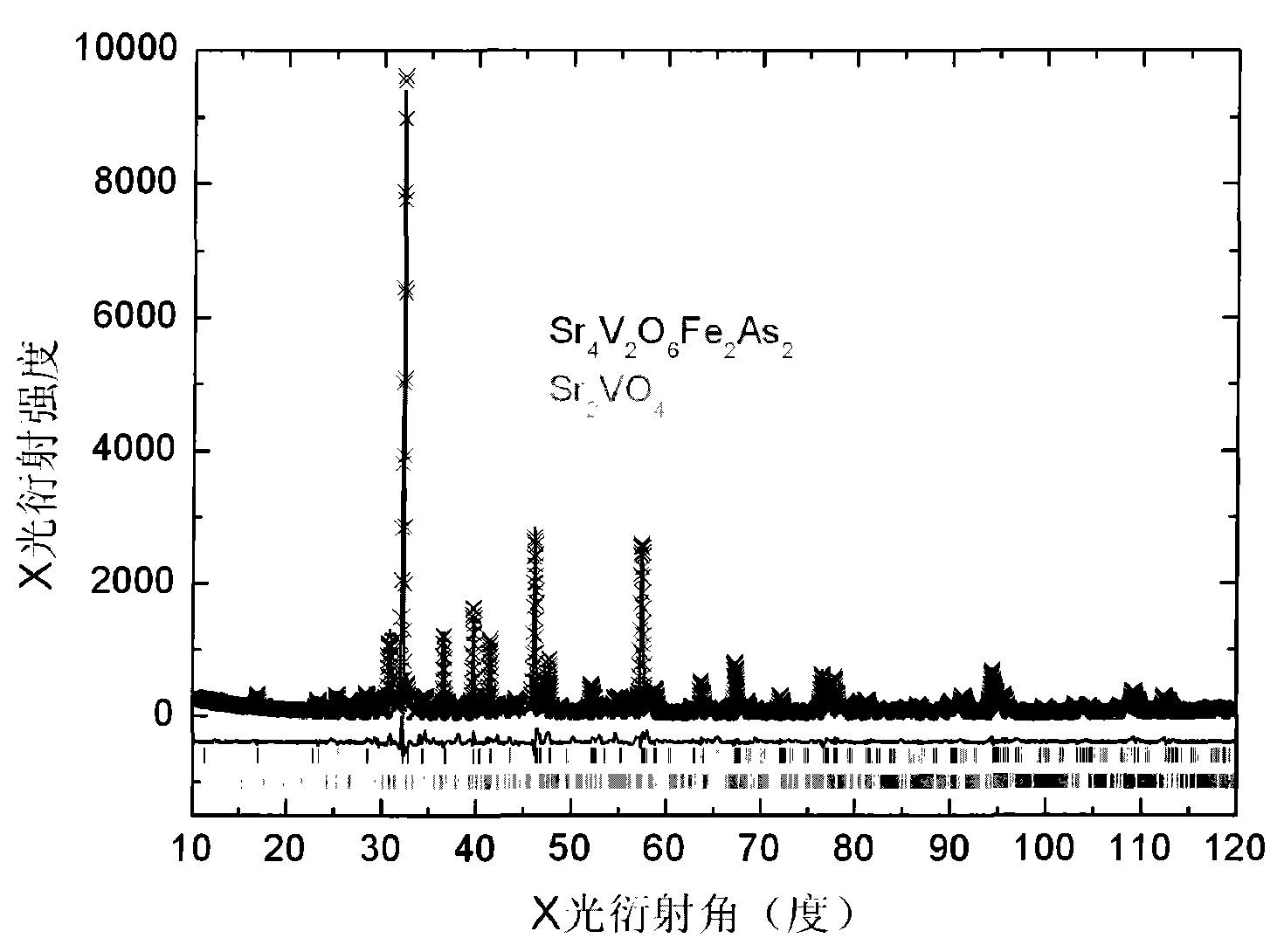

Perovskite structure-based single-phase iron-based superconductive material and preparation method thereof

InactiveCN101993247AGood superconducting stabilityHigh critical fieldChemical reactionSuperconducting transition temperature

The invention relates to a perovskite structure-based single-phase iron-based superconductive material and a preparation method thereof. The material has a two-dimensional laminar structure, and the composition is shown by the formula of Sr4V2O6Fe2As2. The preparation method of the material comprises the following steps of: preparing a SrAs precursor sample and an FeAs precursor sample; mixing the precursors, Sr0, V2O3, Fe and the like by using a solid-state chemical reaction method; and reacting at a high temperature to directly synthesize a perovskite layer-based iron-based superconductive material. Compared with other known iron-based superconductors, the material has higher bidimensionality. The material has electronic carrier characteristics, carrier concentration of 1,020 to 1,022 / cm<3> and superconductive transformation temperature of about 40K. An upper critical magnetic field of the material at a low temperature is estimated to be greater than 250 teslas, so that the material is probably applied to superconductive power transmission, strong magnetic field generation and the like. In addition, the material can also be used in a superconductive filter and the like. The preparation method is simple.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

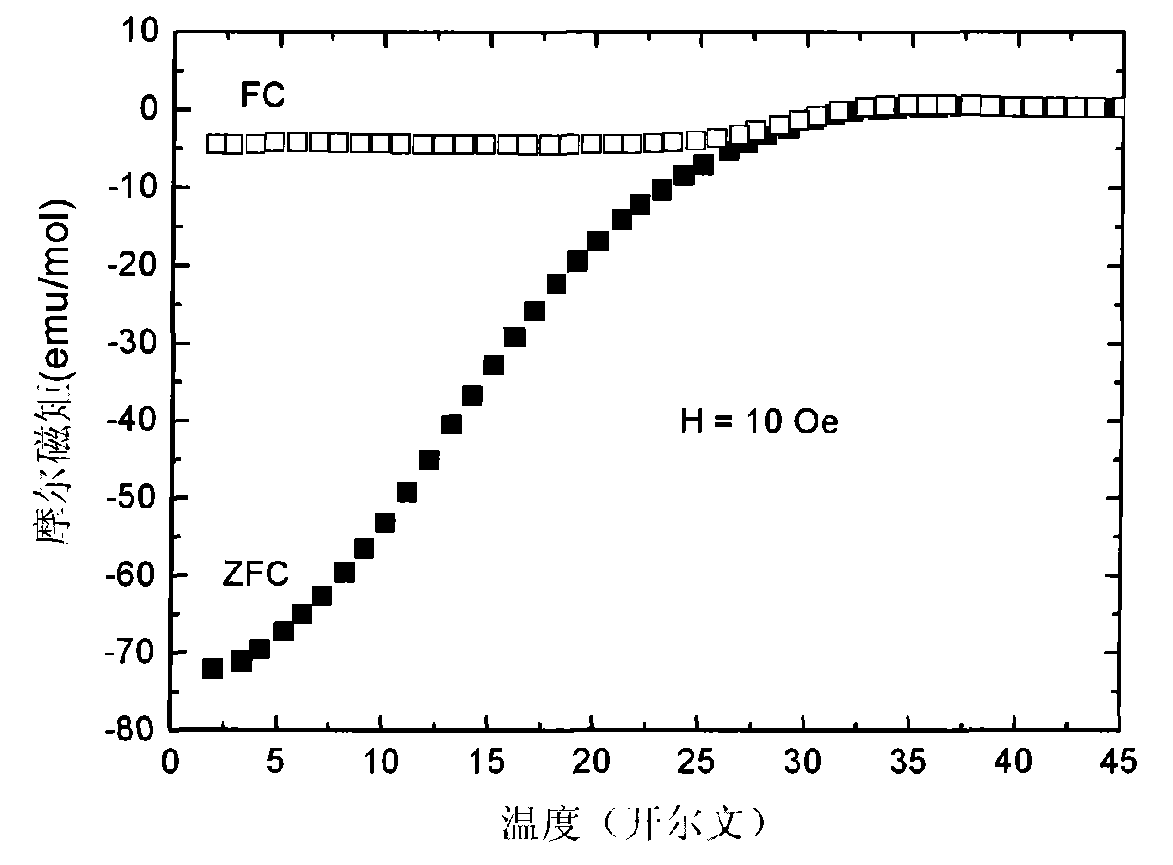

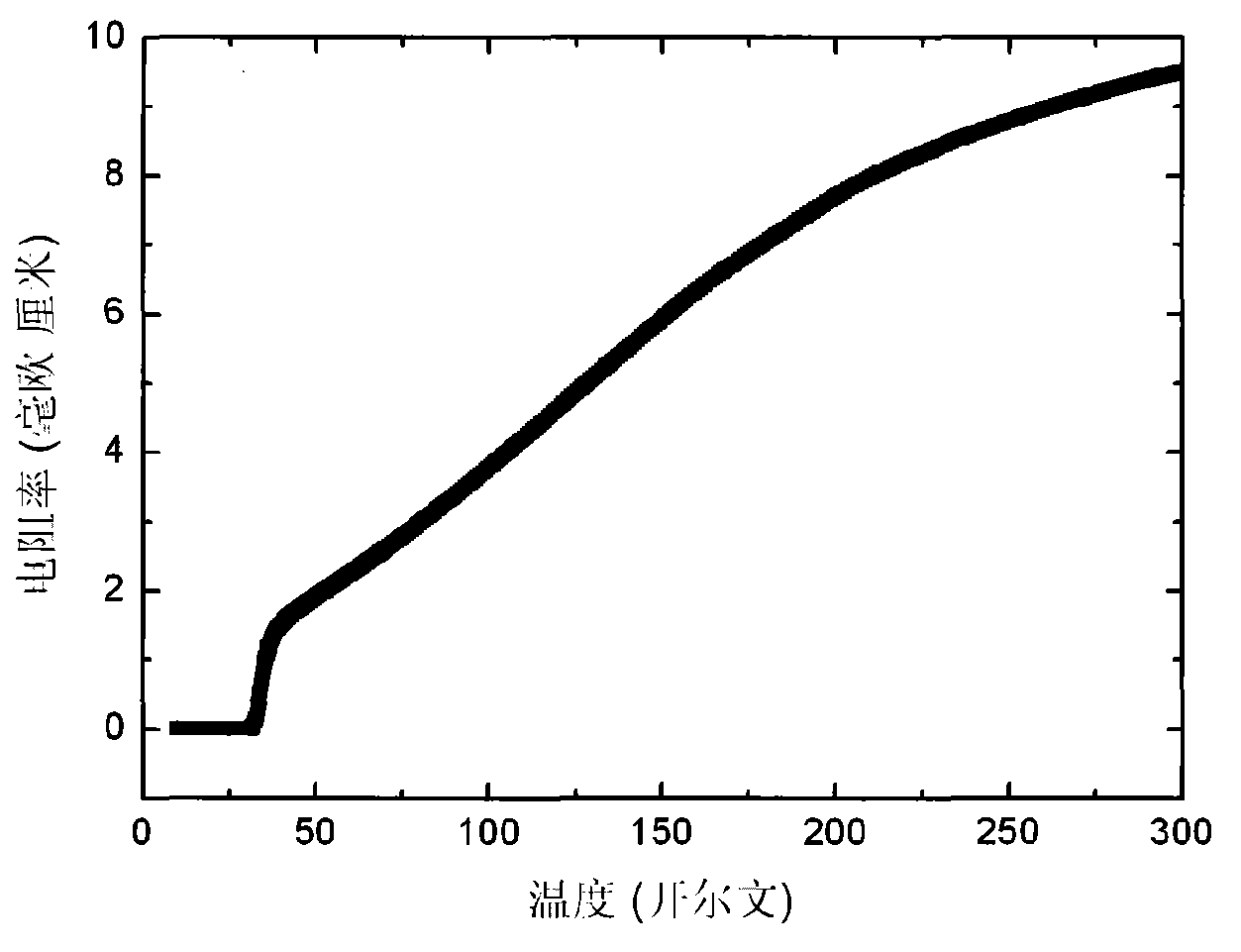

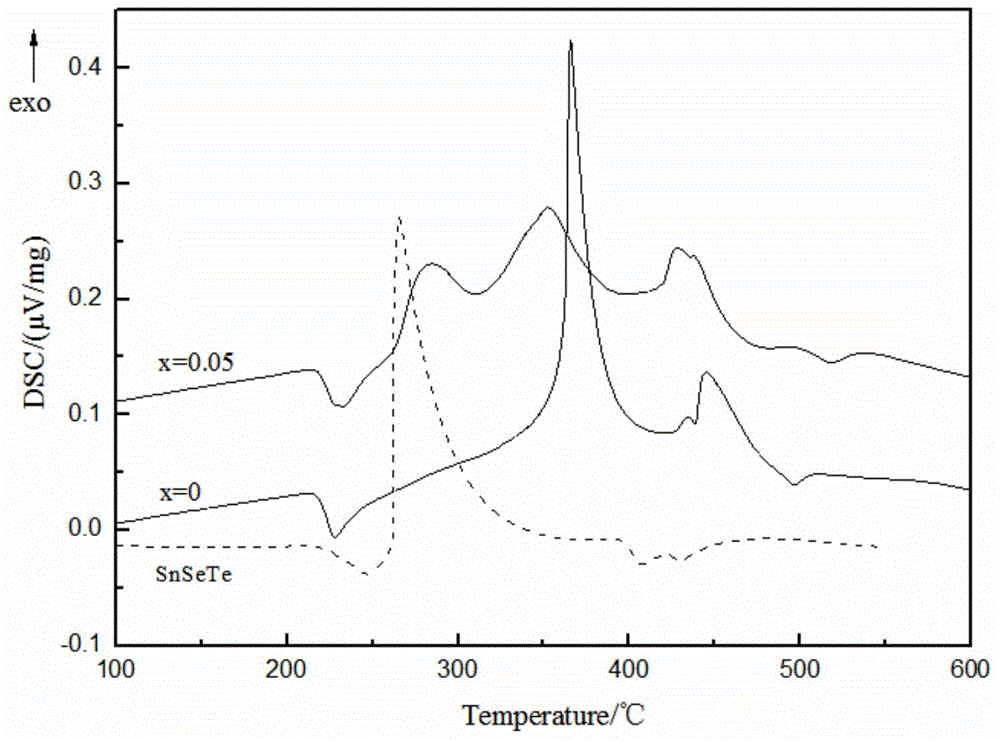

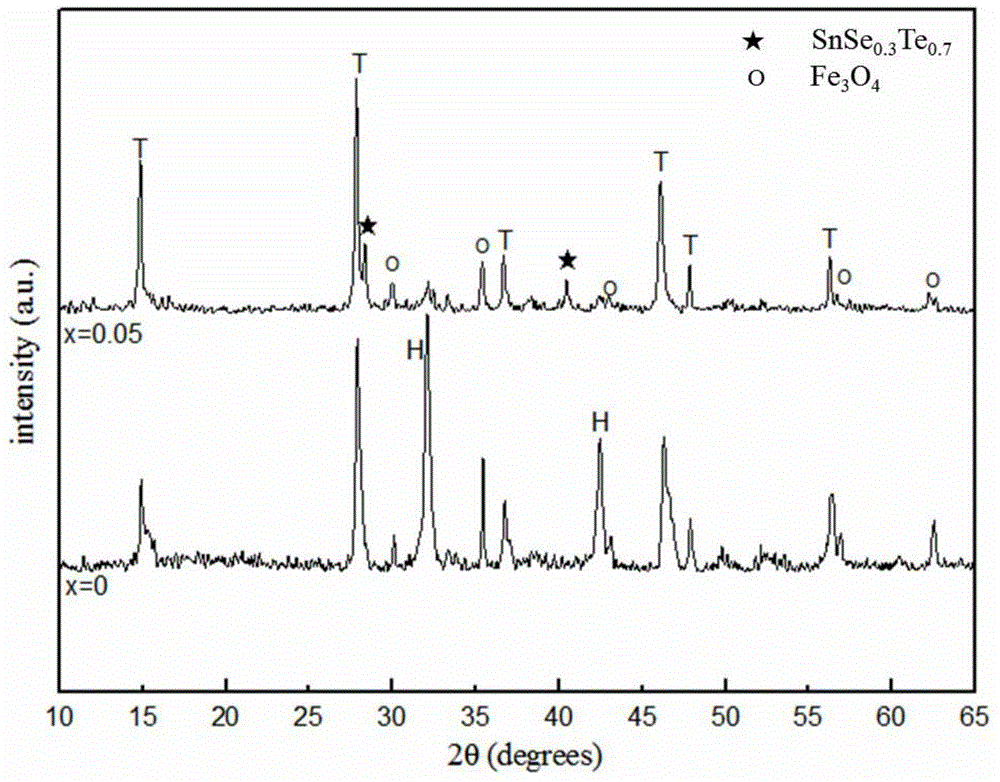

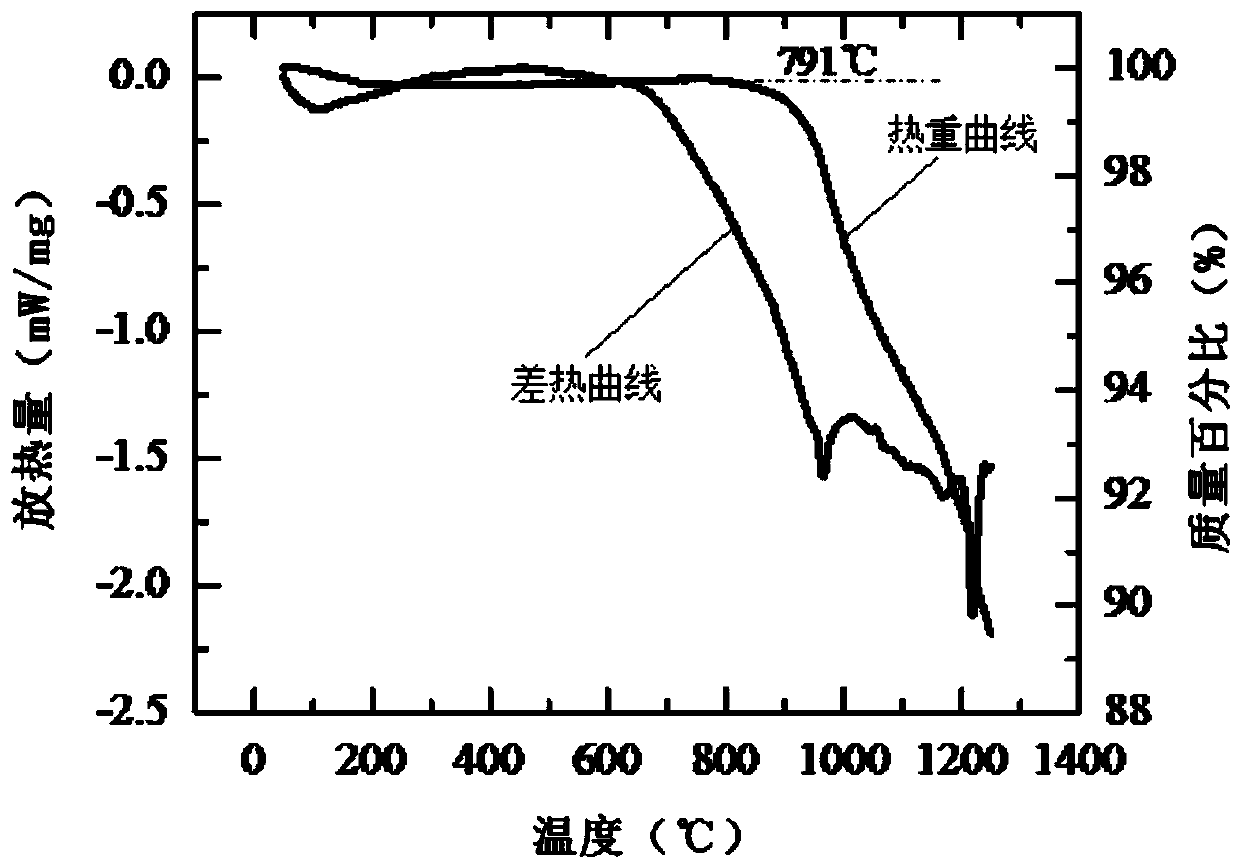

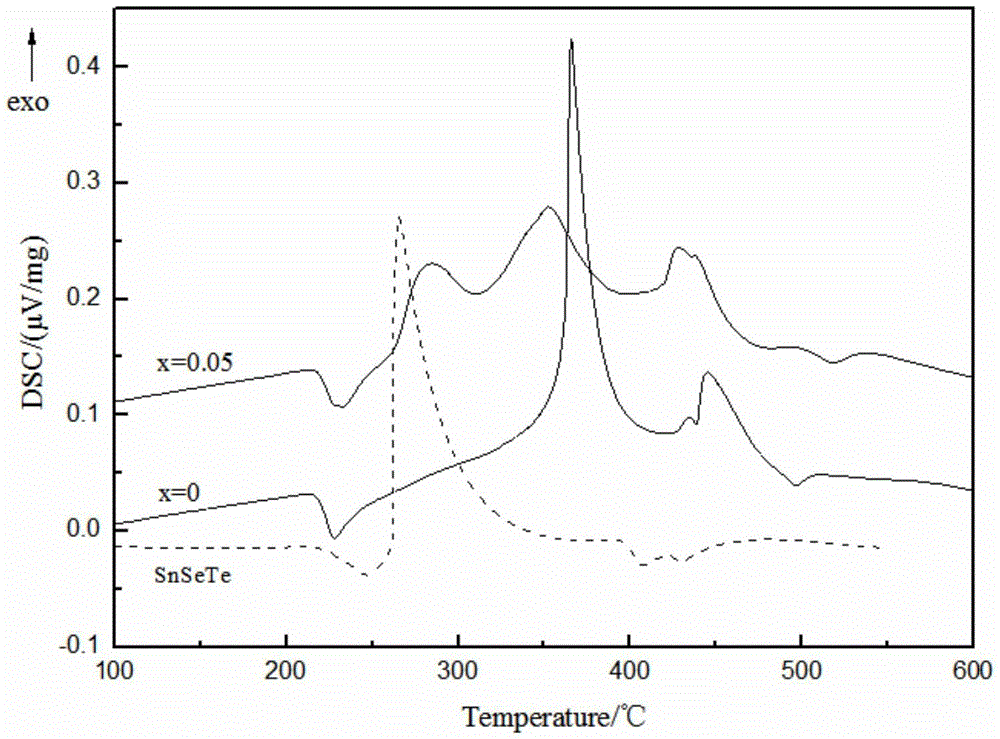

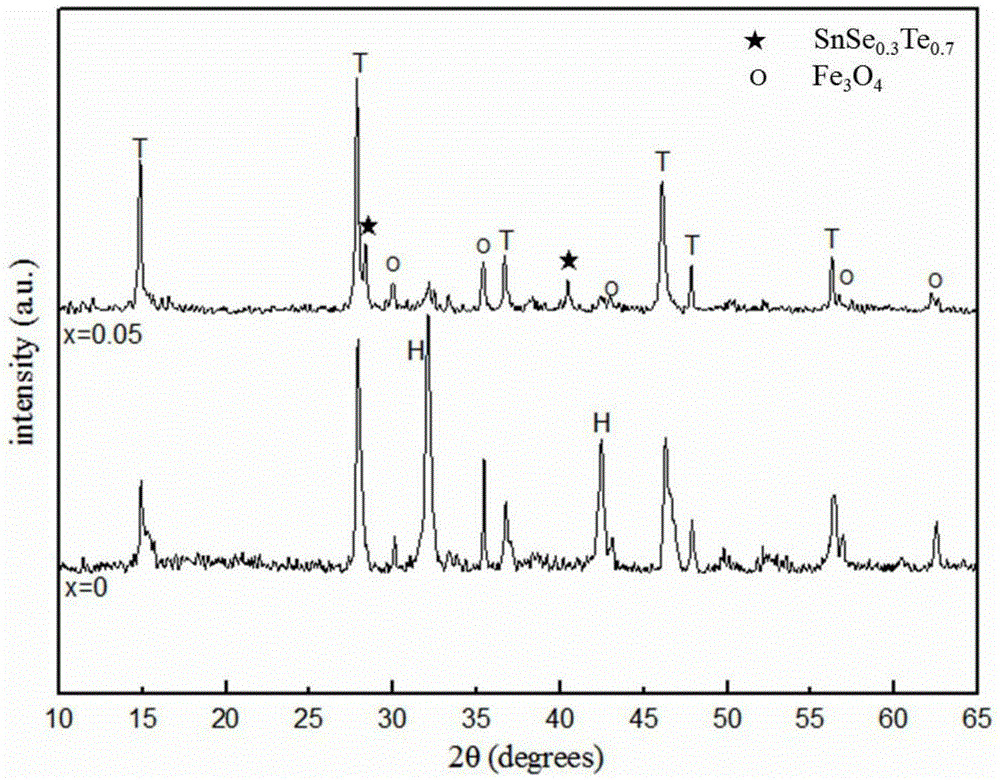

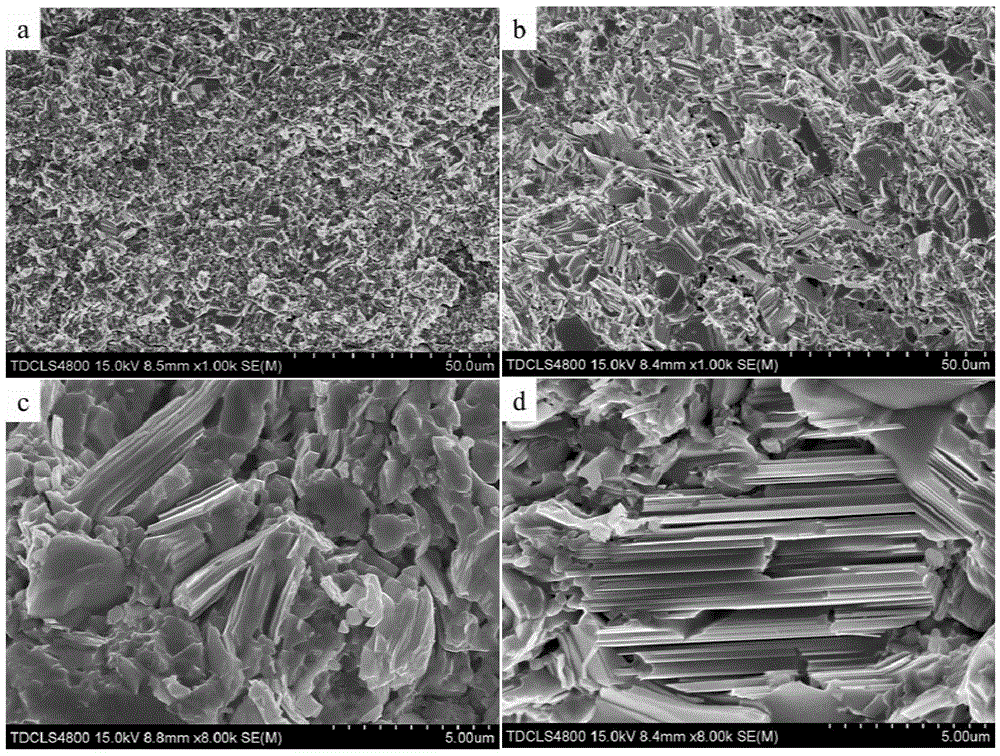

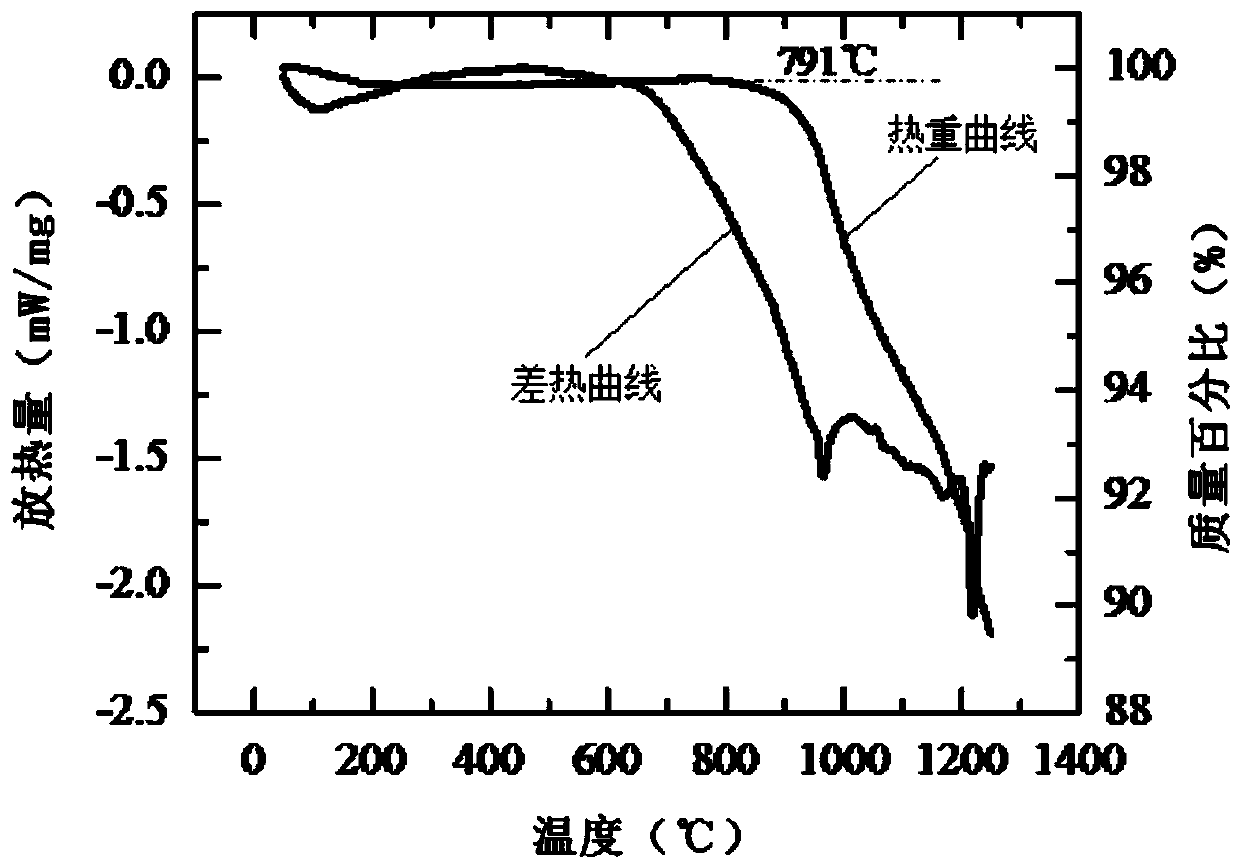

Method for improving superconducting performance of Sn-added FeSe1/2Te1/2 superconductor

ActiveCN104445097APromote formationSimple manufacturing methodSelenium/tellurium compundsRoom temperatureSuperconducting transition temperature

The invention relates to a method for improving the superconducting performance of a Sn-added FeSe0.5Te0.5 superconductor. The method comprises the steps of mixing Sn powder and FeSe0.5Te0.5 powder in a weight ratio of 0.05: 1, and sufficiently grinding the mixture in an agate mortar for 20-30 minutes; and then preparing into a flake under the pressure of 6-8MPa, finally putting the flake into a high-temperature differential scanning calorimeter, heating to 600 DEG C under the protection of flowing high-purity argon, preserving the heat for 5-10 hours, and cooling to room temperature. A fact that a Sn-Se-Te liquid phase generated by reaction between Sn and FeSe0.5Te0.5 can accelerate the transformation from a non-superconducting phase to a superconducting phase is discovered for the first time and is favorable for forming a superconducting laminar structure so that the superconducting transition temperature of the structure is finally significantly improved, thus providing an important clue for optimizing a preparation process of an iron-based superconductor, illuminating an iron-based superconducting mechanism and promoting the development of the superconducting theory.

Owner:TIANJIN UNIV

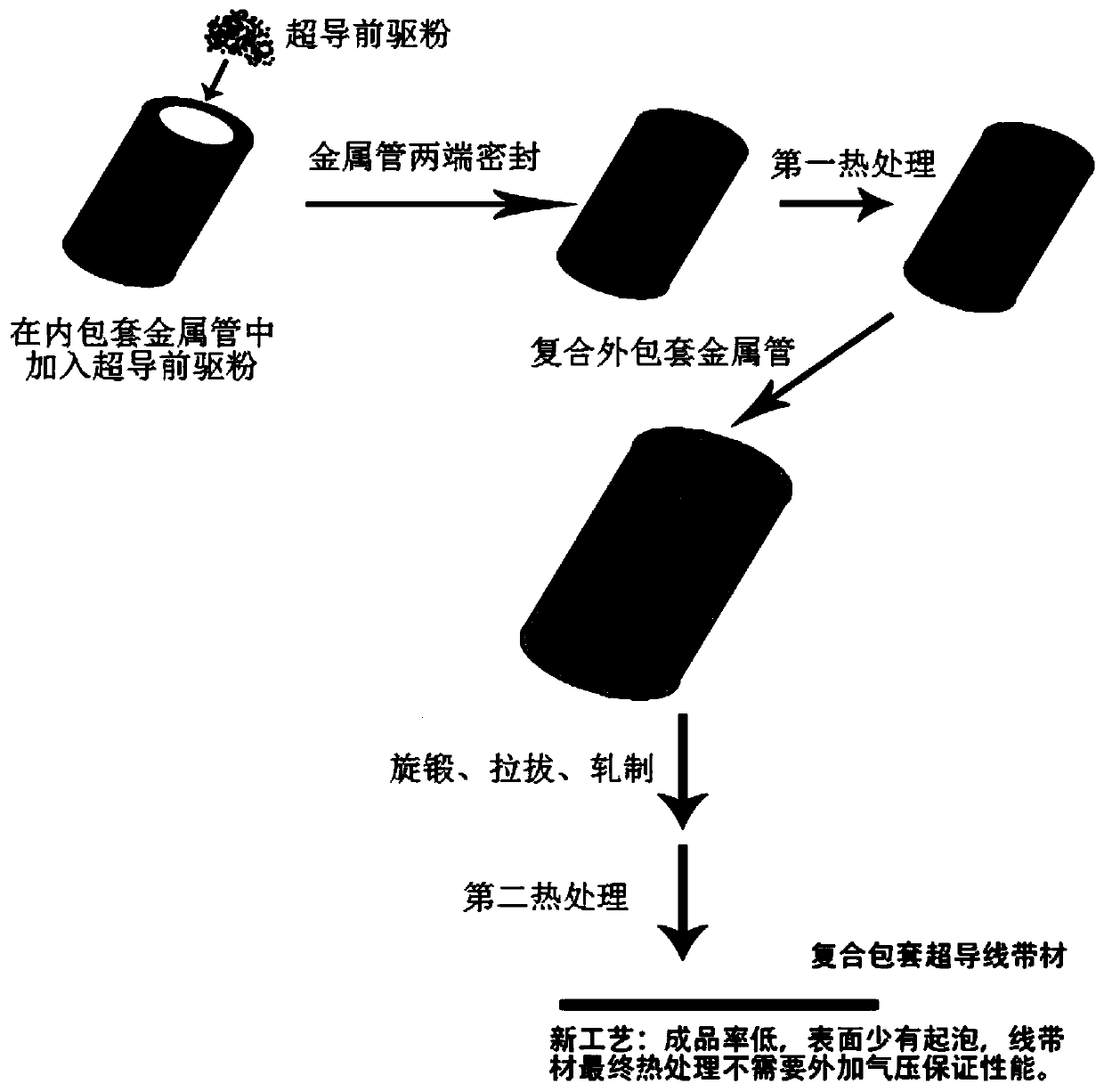

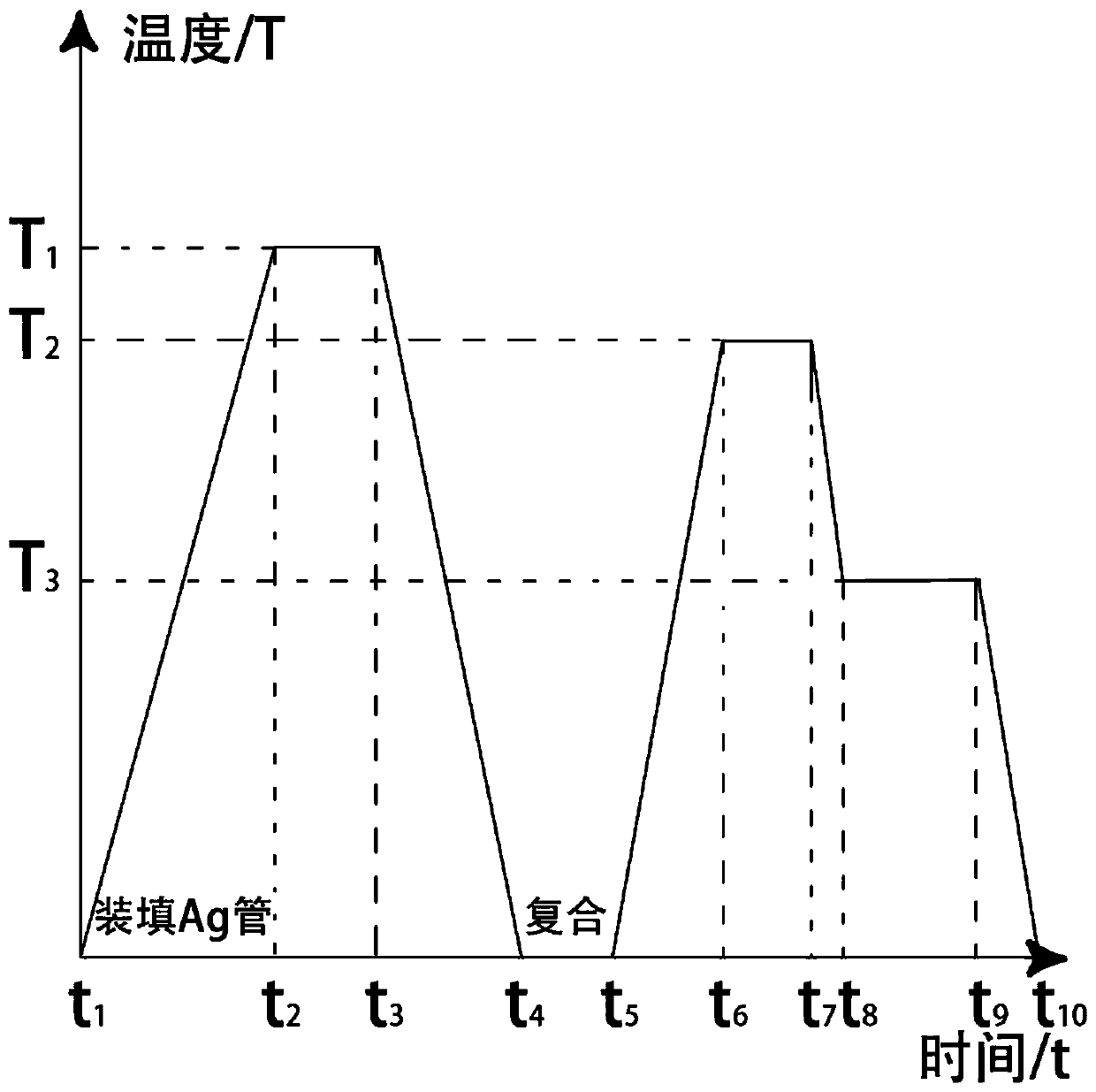

Preparation method of composite sheathed iron-based superconducting wire strip

InactiveCN109903927AEliminate compound stressEfficient removalSuperconductors/hyperconductorsSuperconductor devicesAtmosphereMetal

The invention relates to the technical field of iron-based superconductors, in particular to a preparation method of a composite sheathed iron-based superconducting wire strip. The preparation methodof the composite sheathed iron-based superconducting wire strip provided by the invention comprises a step of carrying out first heat treatment on iron-based superconducting precursor powder in an inert atmosphere. According to the method, the iron-based superconducting precursor powder placed into an inner sheath metal tube is subjected to pre-heat treatment in the inert atmosphere, so that bumpscan be effectively eliminated, and the product yield is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

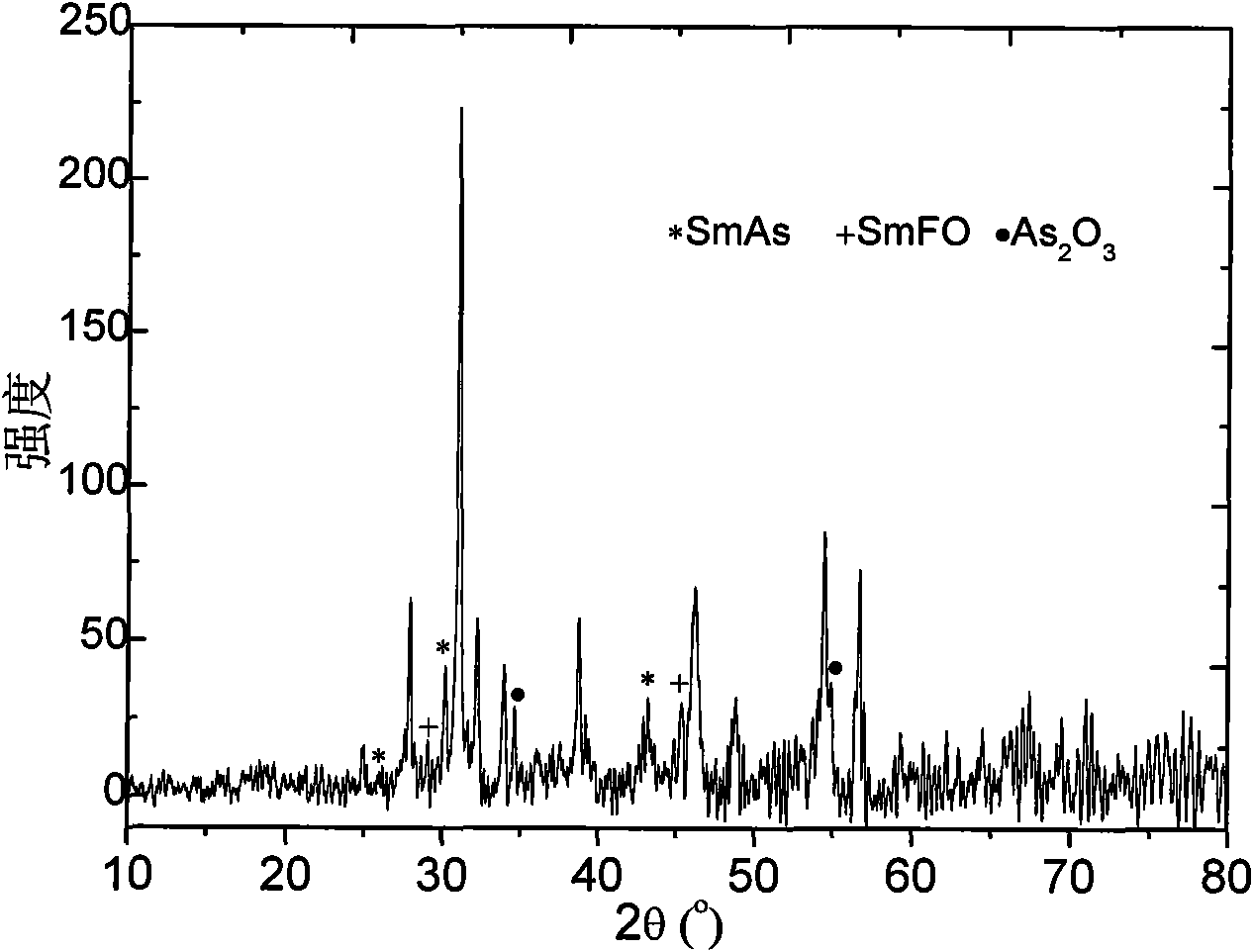

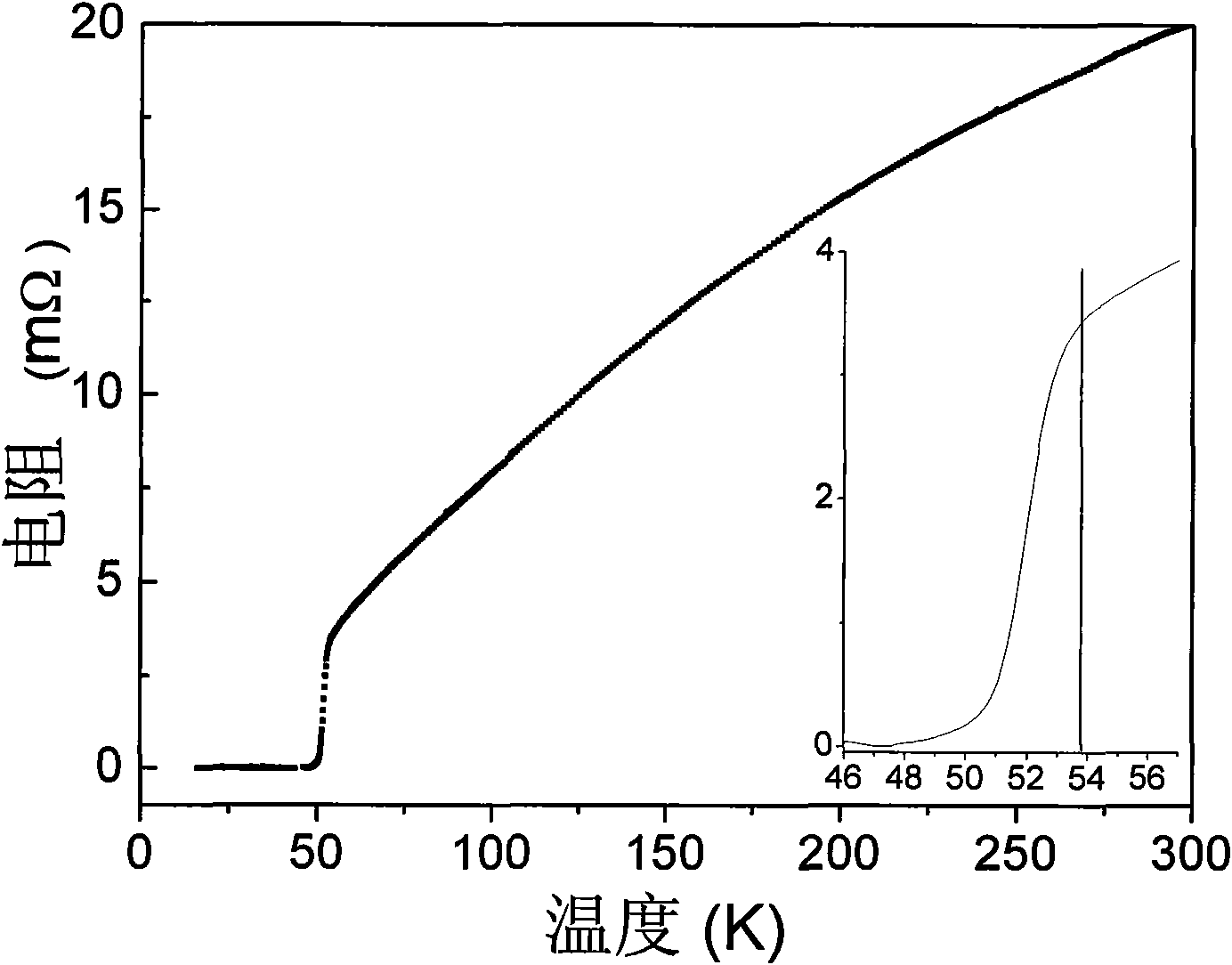

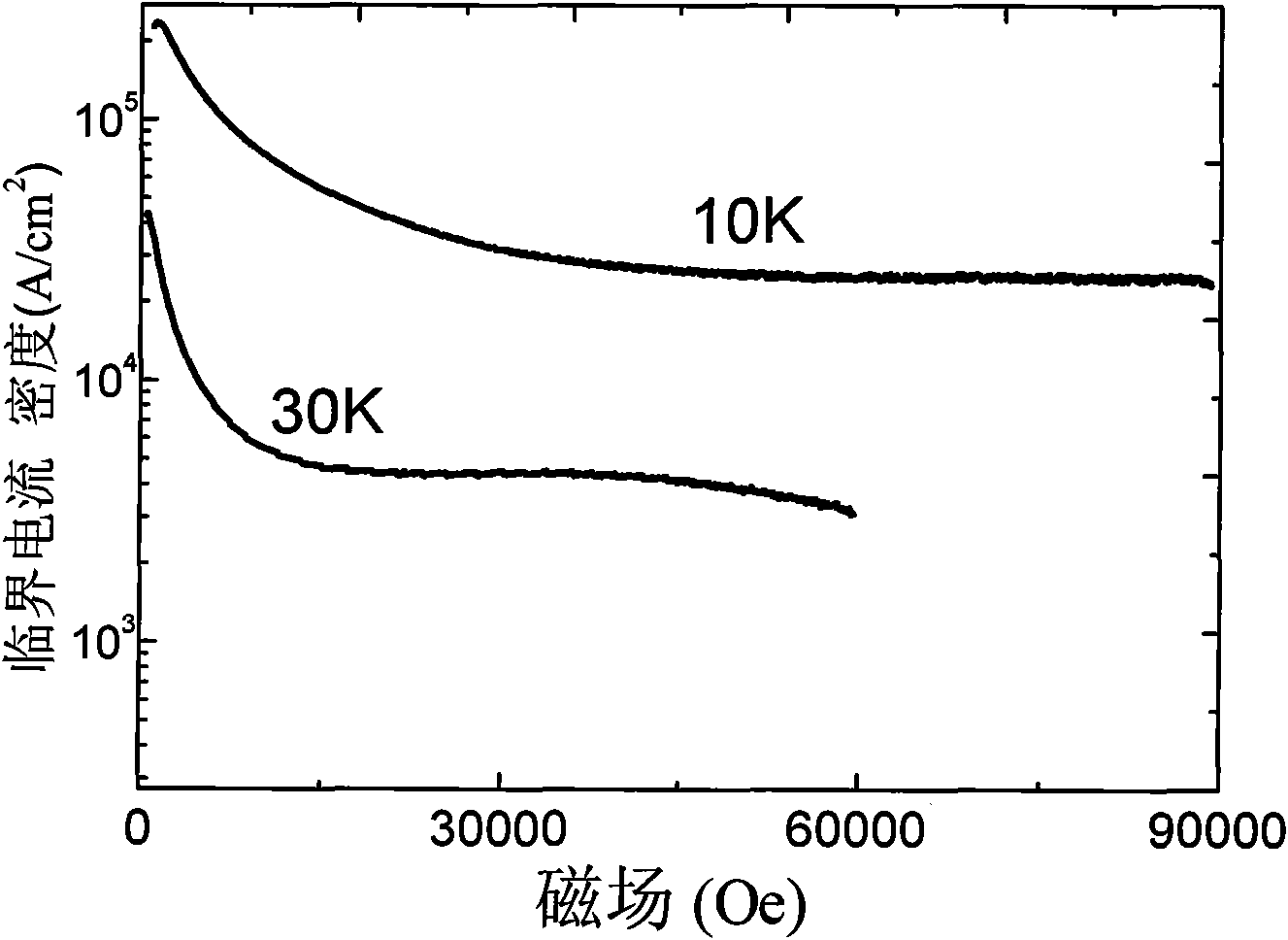

Method for manufacturing iron-based superconductor by using SPS (Spark Plasma Sintering) technology

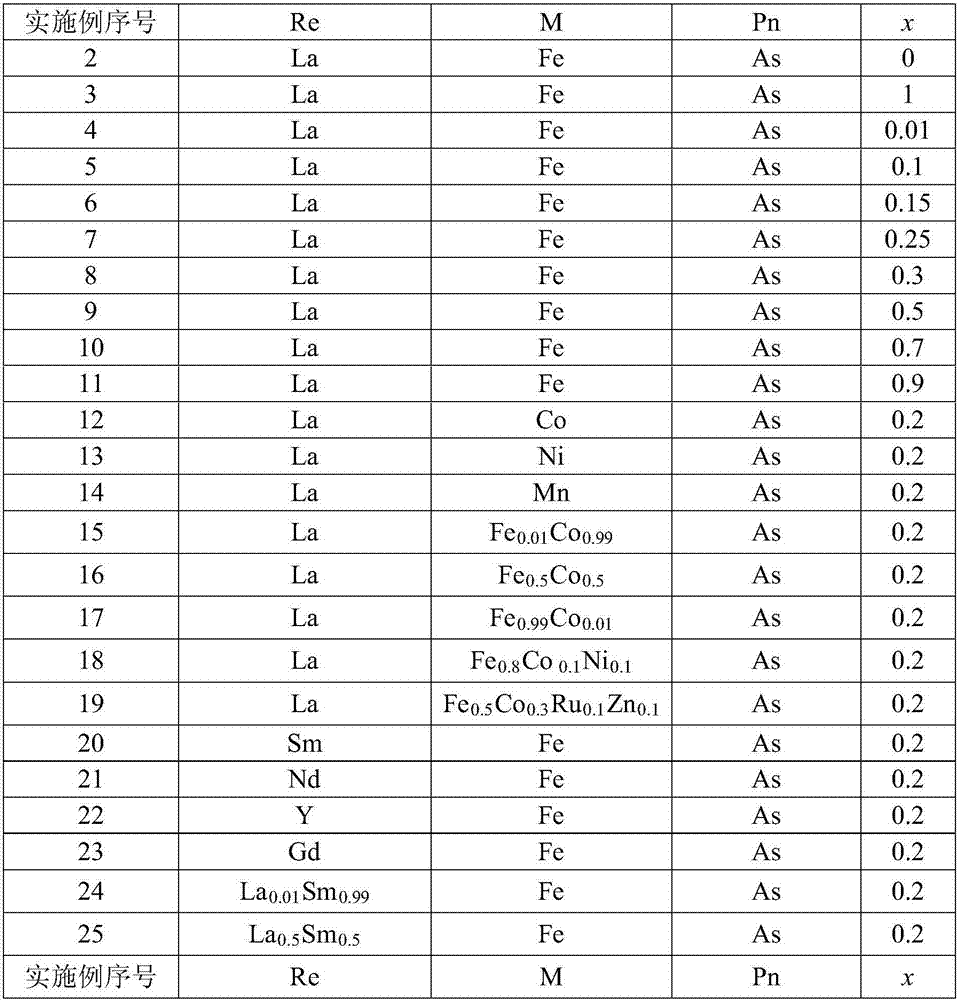

The invention discloses a method for manufacturing an iron-based superconductor by using an SPS (Spark Plasma Sintering) technology and belongs to the technical field of high-temperature superconductive materials. The method comprises the following steps of: carrying out thermal treatment on rare earth powder Ln and As powder according to the ratio being 1:(1-1.1) in a high vacuum quartz tube to prepare initial powder LnAs; carrying out ball milling on LnAs and Fe powder, Fe2O3 powder and FeF3 powder according to mol ratio being 3:(1+x):(1-x):x; placing a die filled with powder into sintering equipment; manufacturing the iron-based superconductor by adopting a spark plasma sintering technology; and pressurizing and sintering at a sintering pressure of 30-50Mpa and the sintering temperature of 900-1100DEG C for 5-60 minutes under vacuum conditions. According to the method disclosed by the invention, the sintering time is short, so that the loss of component elements is reduced and the compactness of the material is reduced, thus the high-performance iron-based superconductor is obtained.

Owner:BEIJING UNIV OF TECH

Iron-based superconduction connector and fabrication method thereof

ActiveCN110061367APrevent volatilizationChurn ControlConnection formation by deformationSuperconducting magnets/coilsEngineeringAg element

The invention discloses an iron-based superconduction connector and a fabrication method thereof. The fabrication method of the iron-based superconduction connector comprises the steps of stripping atail end of the iron-based superconductor to expose a superconduction core, connecting the superconduction core, wrapping a connection region, performing thermal processing on the connection region, and applying pressure to the connection region. In the step of thermal processing on the connection region, the connection region is arranged in a pressure-applying state within a range larger than a preset temperature, and the preset temperature is a run-off temperature of a doping component in the iron-based superconductor. The connection region is enabled to be in the pressure-applying state within the range which the thermal processing temperature is larger than the run-off temperature of the doping element in the iron-based superconductor in the step of thermal processing on the connectionregion, volatilization of the doping element of the connection region caused by that the temperature is raised and exceeds the preset temperature during the thermal processing process is prevented, the run-off condition of the doping element of the connection region is favorably controlled, and the superconduction connection efficiency is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Method for preparing iron-based superconductor through short-time solid-phase sintering technology

The invention discloses a method for preparing an iron-based superconductor through a short-time solid-phase sintering technology, which comprises the following steps: mixing Ln and As powder by the molar ratio of 1: (1 to 1.1) under the high-purity Ar protection atmosphere, sealing the mixed powder in a high-vacuum quartz tube for hot treatment, finally furnace cooling to room temperature to obtain LnAs powder; in a glove box protected by high-purity argon, mixing and grinding the LnAs powder, Fe powder, Fe2O3 powder and FeF3 powder by the molar ratio of 3: (1+x): (1-x): (1.1 to 1.5)x and tabletting the mixed powder; then annealing under high vacuum, furnace cooling to room temperature to finally prepare the LnO1-xFxFeAs superconductor, wherein Ln=La, Ce, Pr, Nd, Sm and Eu, and x is more than 0 and less than 0.6. The method improves the performance of the iron-based superconductor, and simultaneously improves the iron-based superconductor preparation efficiency.

Owner:BEIJING UNIV OF TECH

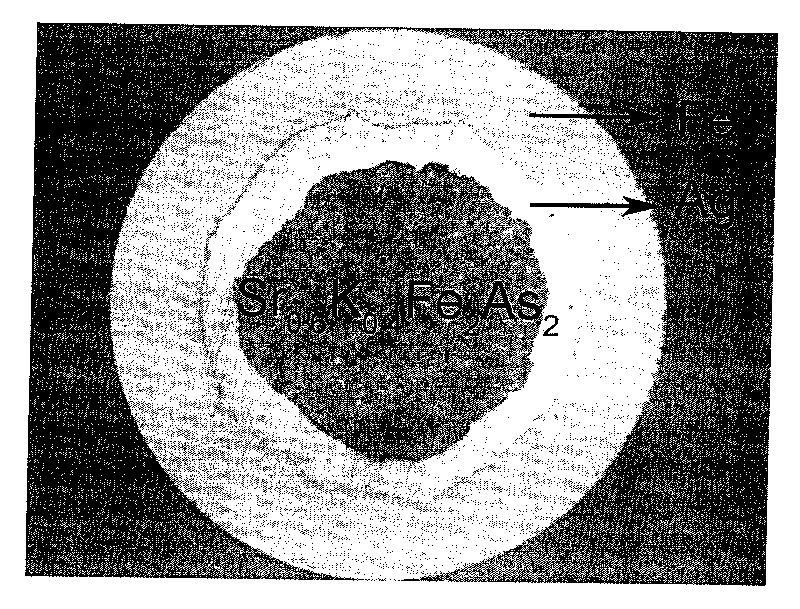

Novel superconducting material

The present invention discloses a novel superconducting material, which is prepared from the following main components: iron, arsenic, selenium, potassium and rare earth elements in the molar ratio of 1:0.8-1.2:0.1-0.4:0.1-0.4:0.01-0.05. The preparation method of the novel superconducting material can improve the phase purity and crystal connection performance of the iron-based superconductors.

Owner:常熟市东方特种金属材料厂

Iron-based superconductor preparation method based on cold isostatic pressing and directional solidification technology

PendingCN108728678AImprove performanceHigh densityCable/conductor manufactureVolumetric Mass DensitySilica gel

The invention provides an iron-based superconductor preparation method based on a cold isostatic pressing and directional solidification technology, and belongs to the field of material preparation. The main preparation process of the preparation method comprises the steps of 1, proportioning: mixing raw materials proportionally; 2, ball-milling: ball-milling the mixed raw materials in vacuum or protective atmosphere to form uniformly mixed powder; 3, sealing of a silicon case: filling the uniformly mixed powder into the silicon case in the vacuum or protective atmosphere and sealing the silicon case; 4, cold isostatic pressing: putting the silicon case filled with the powder into cold isostatic pressing equipment, and pressurizing and pressing the silicon case into a high-density formingblank; and 5, directional solidification: directionally solidifying the blank formed by pressing, and finally obtaining an iron-based superconducting bar with high performance. The iron-based superconducting material preparation method disclosed by the invention is simple in technology and high in controllability, and iron-based superconducting materials with large size, and high density and orientation can be prepared. The prepared iron-based superconducting materials are excellent in performance, and specially have the feature of high critical current density.

Owner:UNIV OF SCI & TECH BEIJING

Simple preparation method for iron-based superconducting wire/tape

InactiveCN102543308AQuality improvementReduce manufacturing costSuperconductors/hyperconductorsSuperconductor devicesSuperconducting magnetRare earth

A simple preparation method for an iron-based superconducting wire / tape belongs to the technical field of superconducting wires / tapes. Under high-purity Ar, rare earth powder and As powder are uniformly mixed in a quartz tube to prepare LnAs through heat treatment; under the protection of high-vacuum or high-purity argon gas, LnAs, Fe powders, Fe2O3 powders and FeF3 powders are matched and grinded in a molar ratio of 3:(1+x):(1-x):(1.1-1.5)x, and then are encapsulated in a copper pipe to prepare a wire / tape; the prepared wire / tape is subject to annealing processing under the high-vacuum environment of (10-4)-(10-6)Pa; and finally, the LnO1-xFxFeAs superconducting wire / tape is prepared. According to the method provided by the invention, the forming is easy, and the high-quality iron-based superconducting wire / tape can be prepared, with reduced preparation cost and improved production efficiency.

Owner:BEIJING UNIV OF TECH

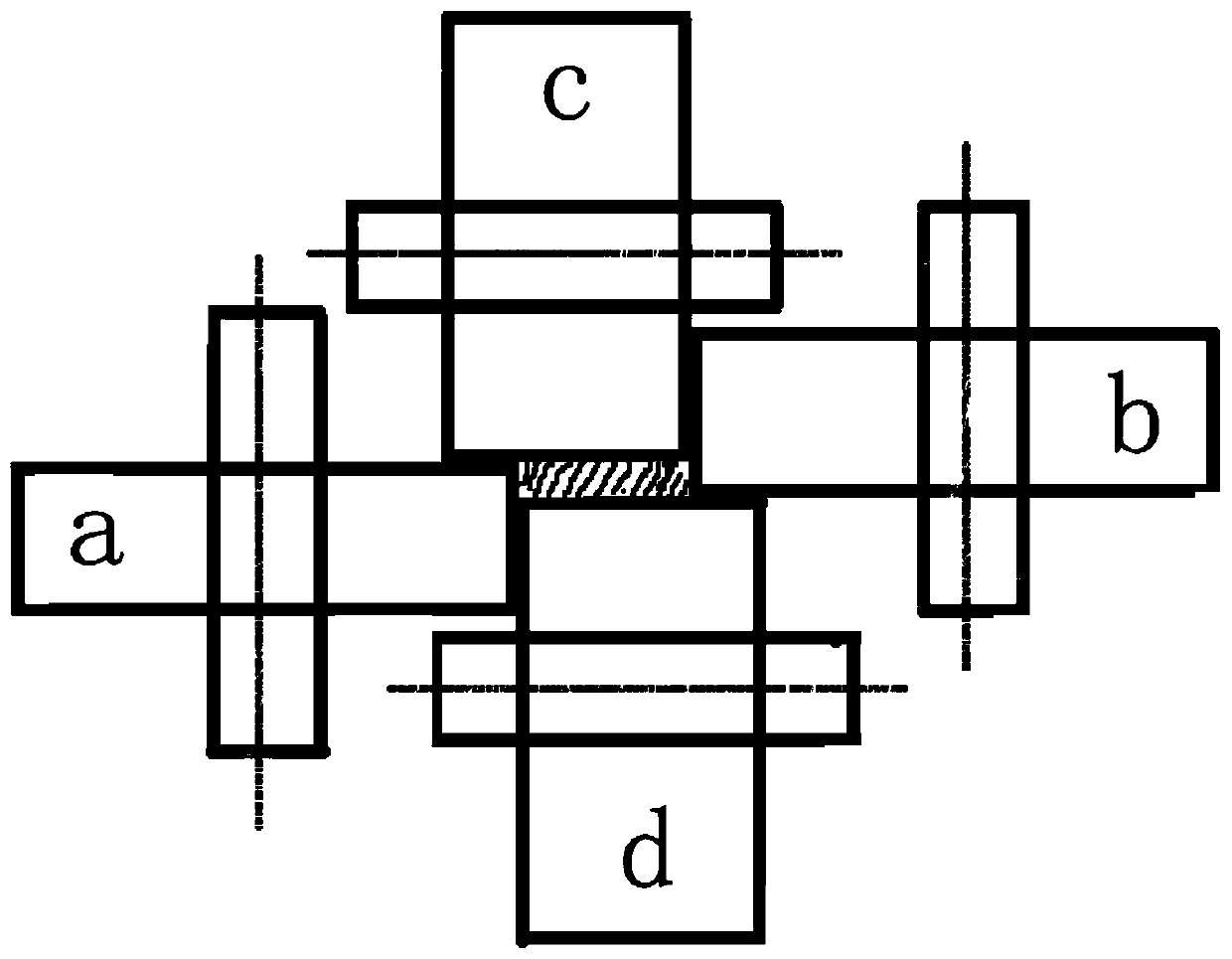

Preparation method and rolling device of iron-based superconducting long wire

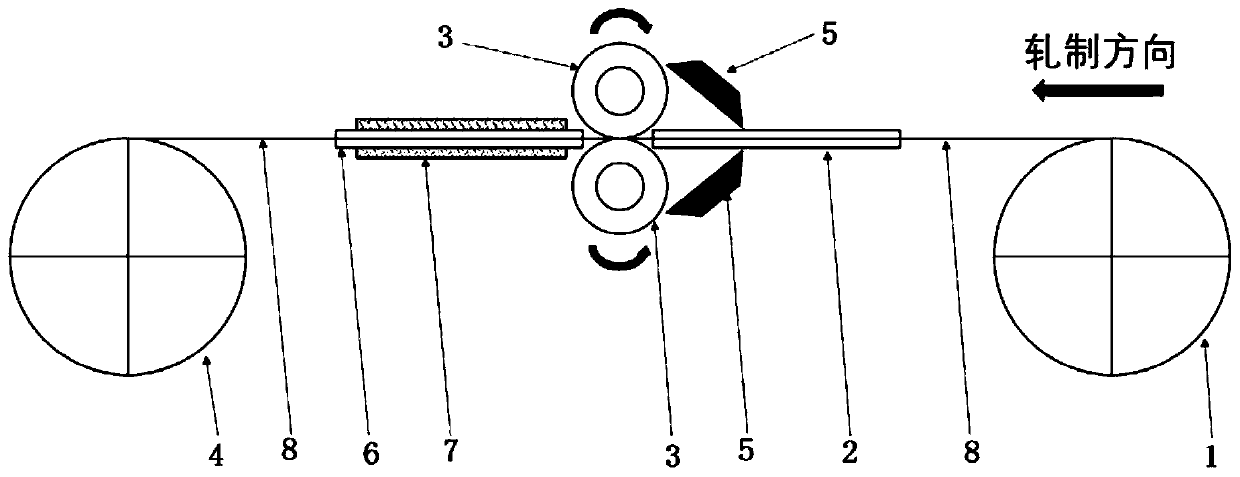

ActiveCN111403106AConsistent hot rolling effectGuaranteed uniformitySuperconductors/hyperconductorsTransportation and packagingWire rodTransmission performance

The invention provides a preparation method and a rolling device of an iron-based superconducting long wire. The preparation method of the iron-based superconducting long wire comprises the followingsteps: sequentially carrying out hot rolling, cooling and heat treatment on an iron-based superconductor precursor wire, and keeping the temperature of a roller and the temperature of the iron-based superconductor precursor wire consistent in the hot rolling process. The invention provides a preparation method of an iron-based superconducting long wire. The temperature of a roller and the temperature of an iron-based superconductor precursor wire rod are kept consistent in the rolling process; heat conduction between the roller and the iron-based superconductor precursor wire is avoided; constant-temperature rolling is achieved, it is guaranteed that the hot rolling effect of each point of the whole iron-based superconducting long line in the length direction is kept consistent, and therefore the uniformity of the critical current density of the iron-based superconducting long line in the length direction is guaranteed, and the overall transmission performance of the iron-based superconducting long line is further improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

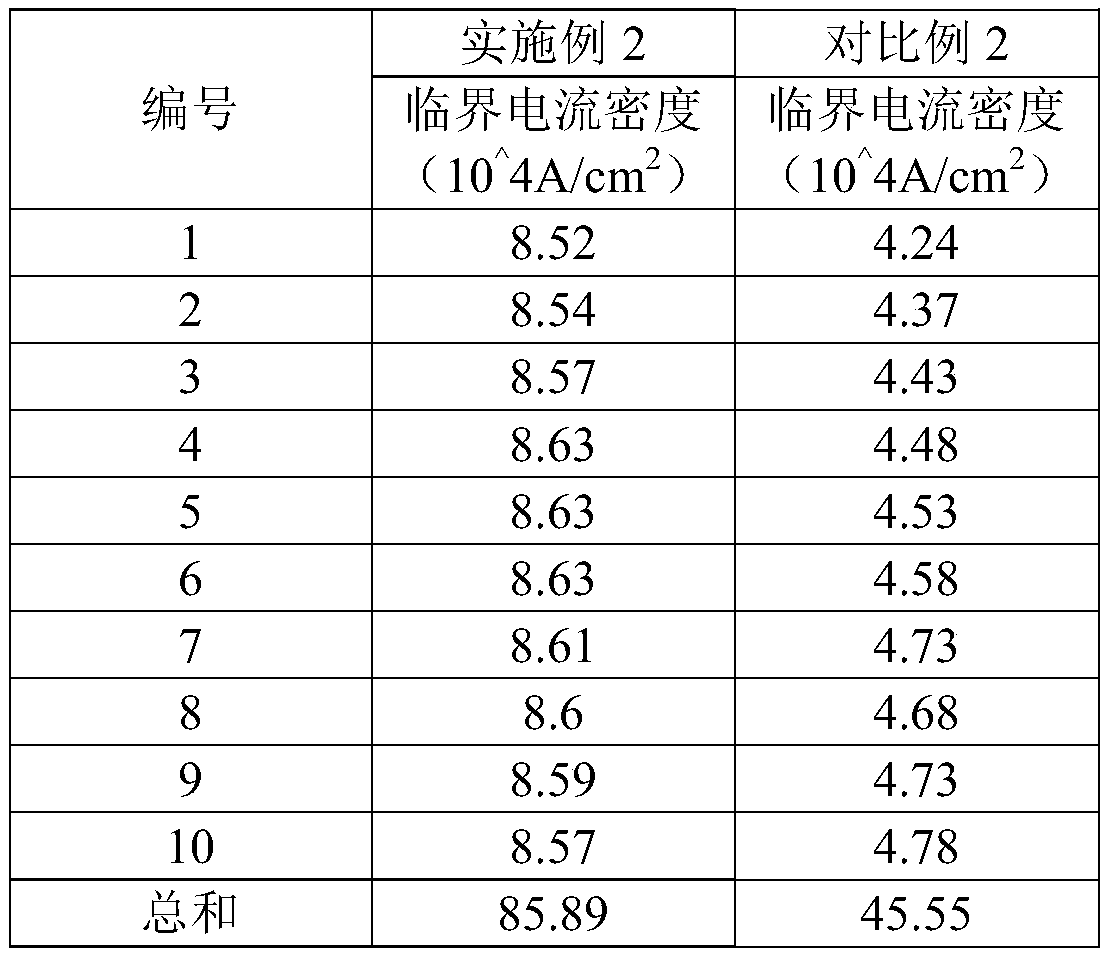

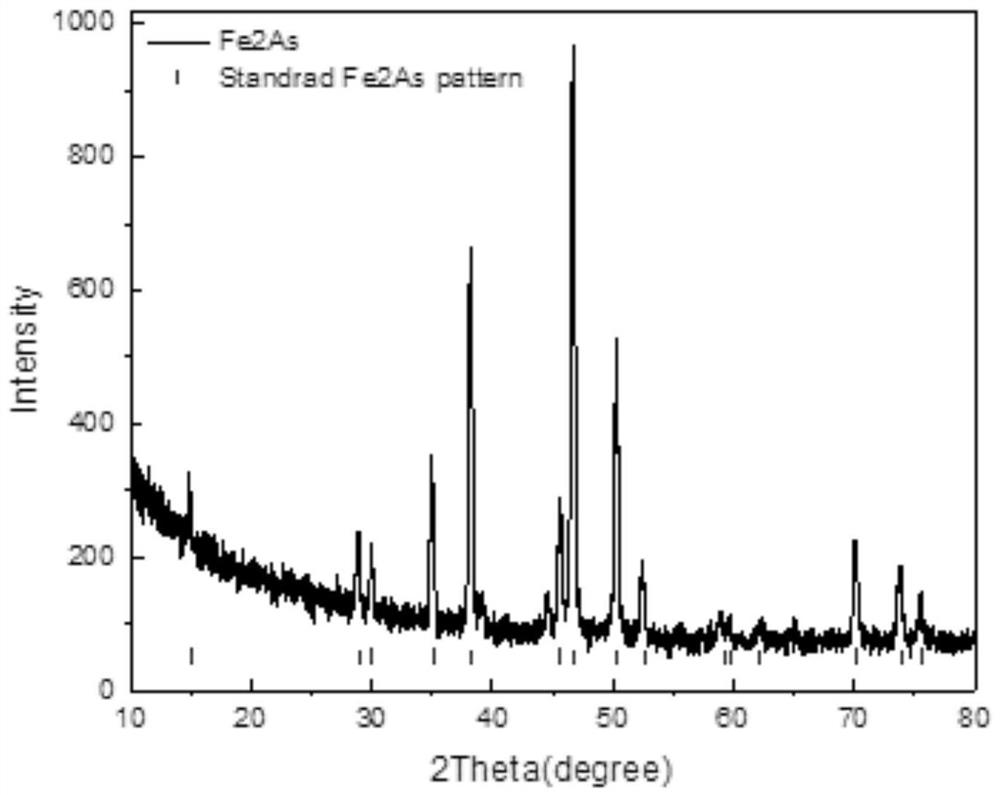

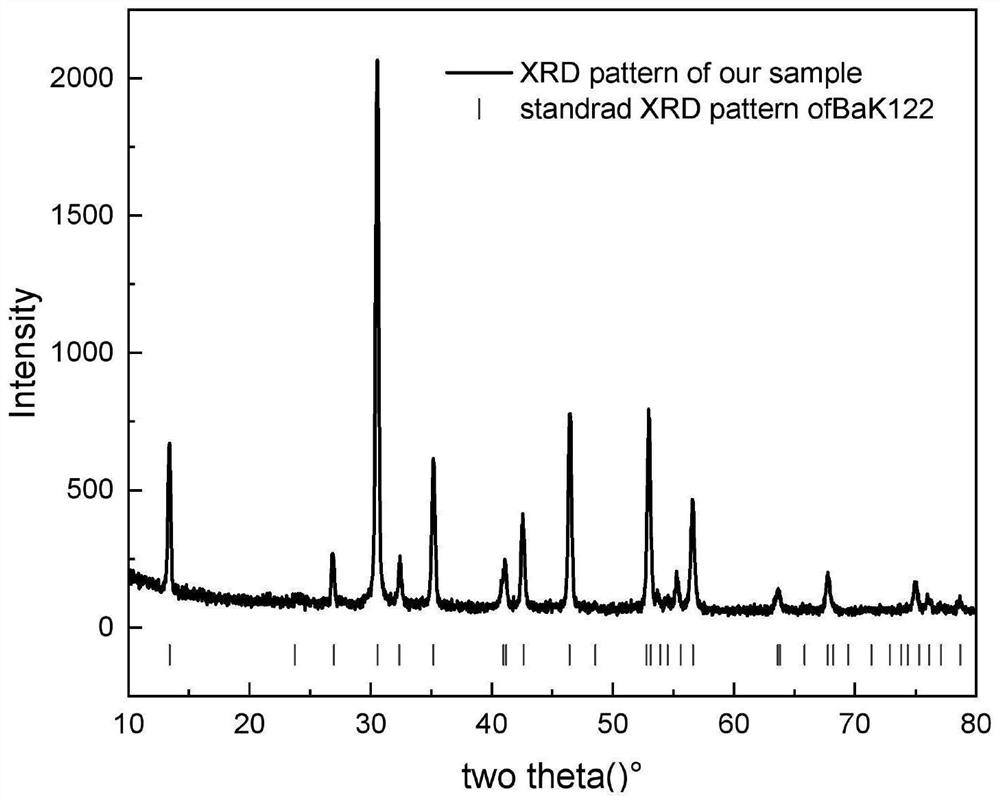

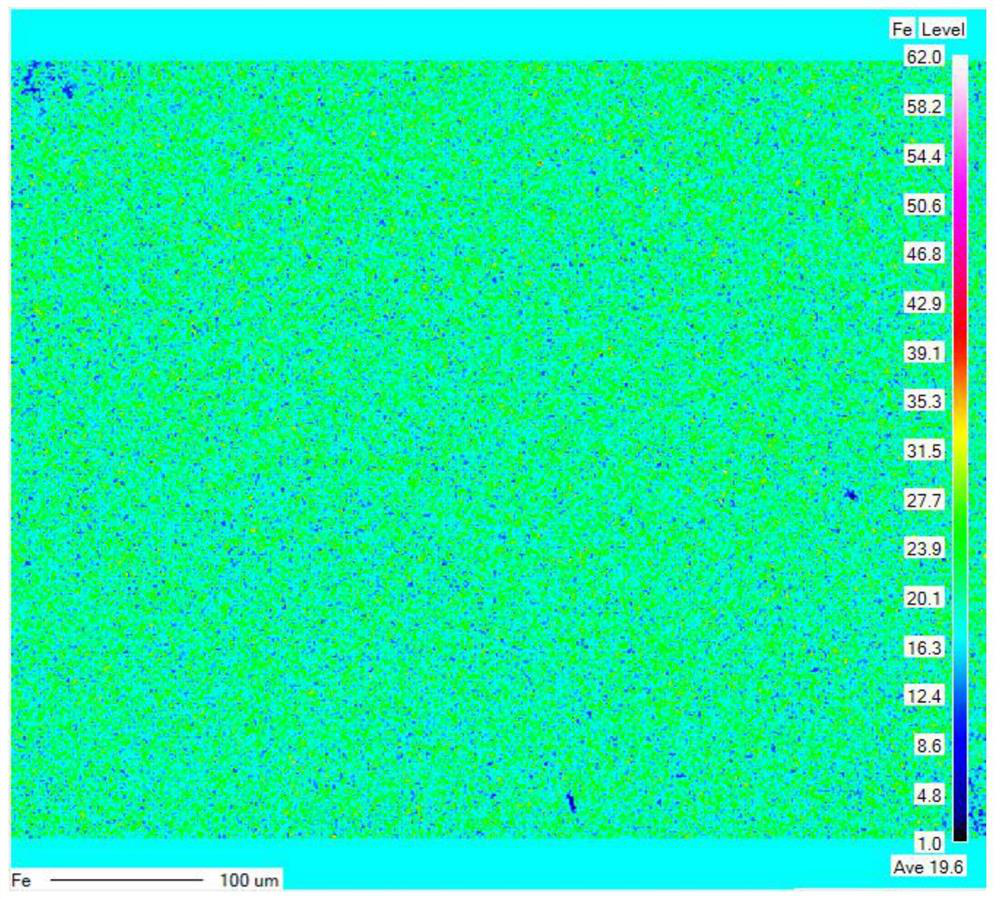

122 type iron-based superconductor and preparation method thereof

PendingCN113860872AImprove distribution uniformityImprove practicalityCable/conductor manufactureMaterials scienceChemical activity

The invention belongs to the technical field of superconductors, and provides a 122 type iron-based superconductor and a preparation method thereof. According to the preparation method provided by the invention, the 122 type iron-based superconductor is Ba0. 6K0. 4Fe2As2, and the preparation method comprises the following steps: mixing an iron elementary substance and a first arsenic elementary substance, and sequentially carrying out first ball milling and first sintering to obtain a Fe2As blank; and mixing the Fe2As blank, a barium elementary substance, a potassium elementary substance and a second arsenic elementary substance, and sequentially carrying out second ball milling, pressing and second sintering to obtain Ba0.6K0.4Fe2As2. Before the Ba0. 6K0. 4Fe2As2 main phase is formed, the iron element with a high melting point and low chemical activity and a component element arsenic form chemical bonds to form a pre-reacted Fe2As intermediate product, so that iron particles are refined, the iron component is purified, the distribution uniformity of the iron component in a final superconductor is greatly improved, and the practical performance of the iron-based superconducting wire strip is further improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Iron-based thin film superconducting cavity and preparation method thereof

InactiveCN110042352AWork lessHigh gradientVacuum evaporation coatingSputtering coatingNiobiumWorking temperature

The invention belongs to the technical field of superconducting cavity preparation, and particularly relates to an iron-based thin film superconducting cavity and a preparation method thereof. The iron-based thin film superconducting cavity comprises a superconducting cavity body, an insulating layer and at least one iron-based superconducting layer, and belongs to a superconducting cavity with anSIS structure; and the iron-based superconducting layer can shield an external magnetic field, reduce a surface magnetic field of niobium, and improve a thermodynamic critical field and accelerationgradient of the iron-based thin film superconducting cavity. An iron-based superconductor has higher transition temperature, an overheat field, and wider working temperature, and is beneficial to improving the magnetic field and the acceleration gradient of the iron-based superconductor layer; when two or more iron-based superconducting layers are used, the magnetic field can be shielded by the iron-based superconducting layers for multiple times, so that the magnetic field and the acceleration gradient of the iron-based thin film superconducting cavity are improved accordingly.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

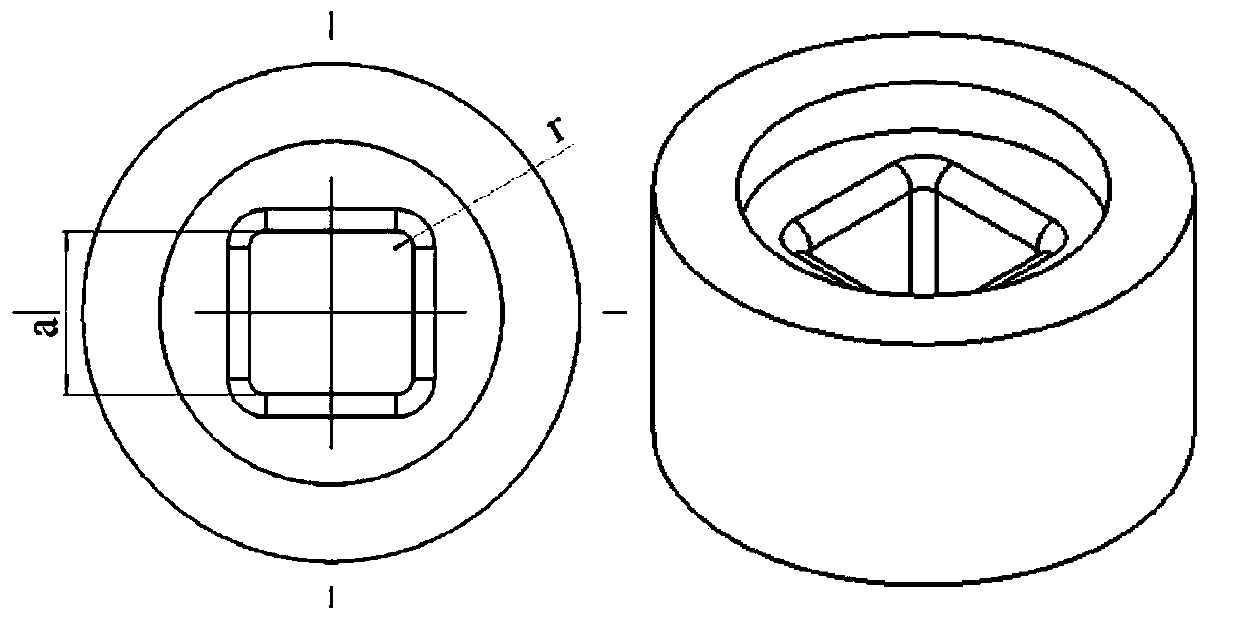

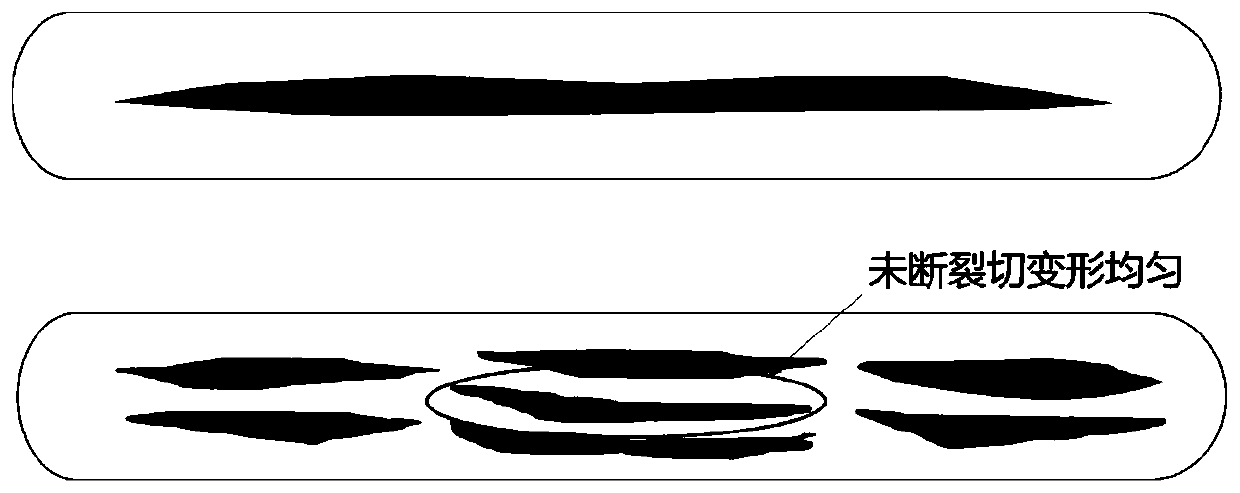

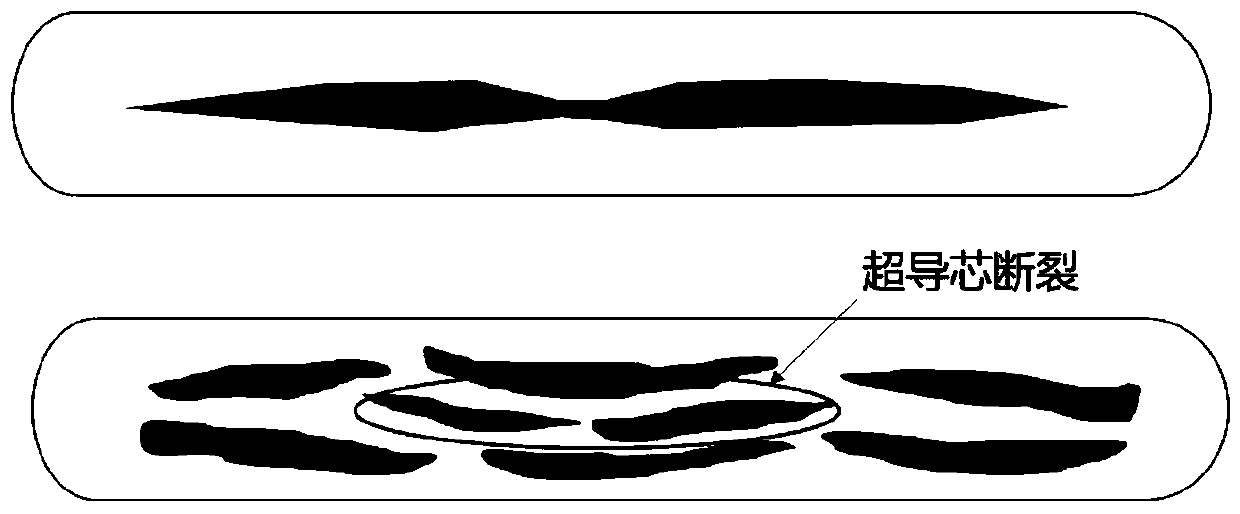

Iron-based superconducting tape and preparation method thereof

ActiveCN110993184AChange section shapeConsistent deformationSuperconductors/hyperconductorsSuperconductor devicesSwagingHomogeneous deformation

The invention belongs to the technical field of iron-based superconductors, and particularly relates to an iron-based superconducting tape and a preparation method thereof. The method comprises: in aninert atmosphere, carrying out rotary swaging, circular drawing, square drawing, rolling and sintering on iron-based superconducting precursor powder to obtain the iron-based superconducting tape. Inthe prior art, the superconducting material is processed in a round wire manner; square drawing is adopted in the invention, so the section shape of the superconducting material is changed; the section shape is square before rolling, in the rolling process, the upper side face and the lower side face of the superconducting strip make contact with a roller at the same time, the deformation amountof the middle and the edge of the superconducting strip is consistent, deformation of the superconducting core is more uniform, the problems that the middle superconducting core is broken, the edge superconducting core is not compact and the phase texture degree is low are solved, and the superconducting performance of the superconducting strip is improved; and the processing mode of enabling thesuperconducting core to deform more uniformly makes it possible to prepare a long wire with higher uniformity.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

A Processing Technology for Improving the Properties of Iron-based Compound Superconducting Tape

ActiveCN108962487BGuaranteed stabilityGuaranteed transmission performanceSuperconductors/hyperconductorsSuperconductor devicesThermal treatmentSingle-core

The invention relates to a processing technology for improving performance of a Fe-based compound superconductive tape. The processing technology for improving performance of a Fe-based compound superconductive tape includes the steps: preparing Fe-based superconductor precursor powder; filling a sheath with the precursor powder to obtain a tube-loading composite; drawing the tube-loading composite into a single-core wire; cutting the single-core wire into a plurality of identical short samples, inserting the identical short samples into the outer sheath to obtain a multi-core composite tube;after the composite tube is drawn into a wire of a certain diameter, repeatedly rolling the wire (during the rolling process, the two ends of the samples are bitten into the roller in turn), and thenobtaining a multi-core tape with certain thickness; and under an Ar atmosphere at 500 to 1100 DEG C, performing final thermal treatment on the obtained Fe-based multi-core tape. Compared with a multi-core tape obtained by a unidirectional rolling technology, the multi-core tape obtained by the processing technology for improving performance of a Fe-based compound superconductive tape through the repeated rolling mode has no cracking phenomenon in each superconductive core of the multi-core tape, and the integrity of the superconductive core is preferable, and the critical transmission currentIc of the tape and the critical engineering current density Je of the tape are significantly improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

An iron-based compound superconducting joint and its preparation method

ActiveCN105355357BAvoid obstructionAvoid attenuationSuperconductors/hyperconductorsSuperconductor detailsCondensed matter physicsMaterials science

An iron-based compound superconducting joint, the superconducting joint includes a connected iron-based superconductor, iron-based superconducting powder and a metal sheath. The ends of the connected superconductors are filled with iron-based superconducting powder and wrapped by a single-layer or multi-layer metal sheath. The preparation steps of the superconducting joint are as follows: (1) peel off the non-superconducting layer on the surface of the iron-based superconductor end to be connected to expose the superconducting core; (2) remove the iron-based superconductor end treated in step (1) Fill the iron-based superconducting powder between them, and wrap the iron-based superconductor end and the iron-based superconducting powder with a metal sheath at the same time; (3) Welding step (2) The processed metal sheaths, or does not need to be welded; (4) Apply pressure , reducing the cross-section of the metal sheath prepared in the above step (3); (5) during or after applying pressure, the metal sheath prepared in the above step (4) is subjected to heat treatment, or heat treatment is not necessary. The invention is very suitable for making superconducting joints at engineering sites.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Preparation method for iron-based super conductor

ActiveCN102522154BHigh purityReduce generationSuperconductors/hyperconductorsSuperconductor devicesMetallurgyIron-based superconductor

Owner:深创超导(深圳)科技有限公司

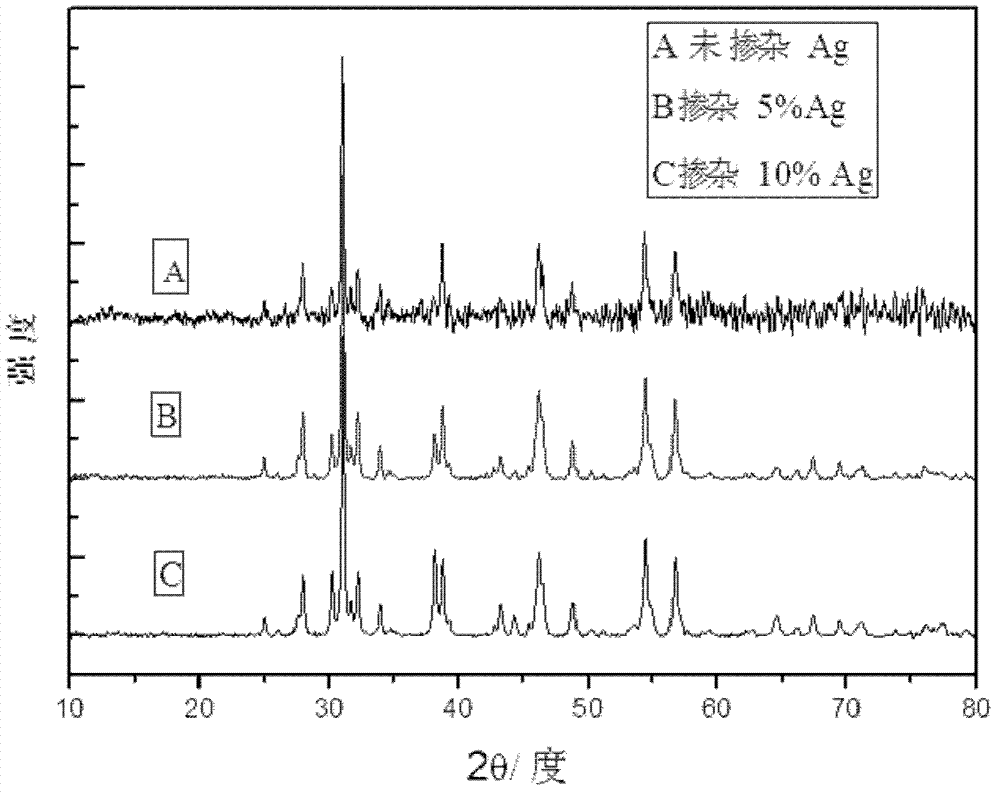

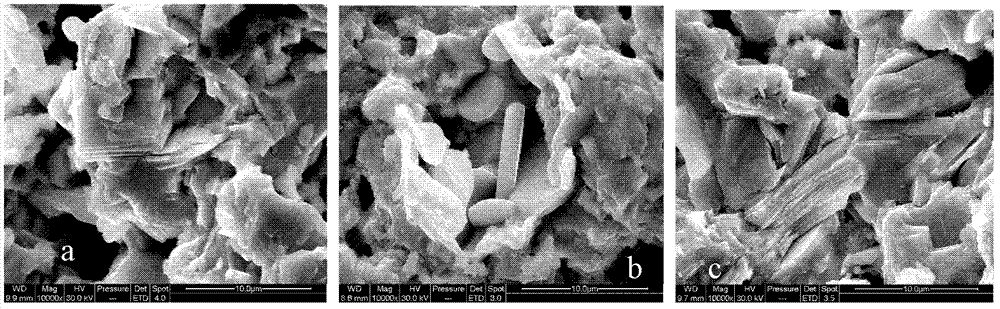

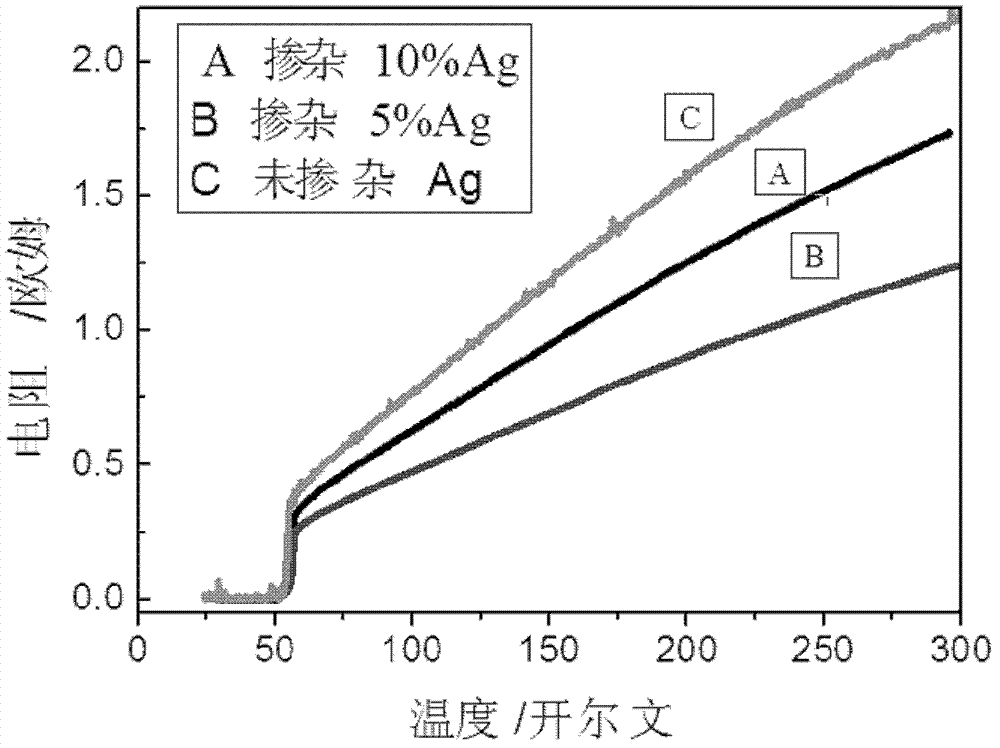

Preparation method for silver-doped iron-based superconductor

InactiveCN102354572BReduce generationHigh puritySuperconductors/hyperconductorsSuperconductor devicesRoom temperatureRare earth

A preparation method for a silver-doped iron-based superconductor belongs to the technical field of iron-based superconductive materials. The preparation method includes the following steps: under argon shield, rare earth and As powder are packaged in a quartz tube and heated to prepare LnAs powder; in a glove box with argon shield, LnAs and Fe powder, Fe2O3 powder and FeF3 powder are blended according to the molar ratio of 3:(1 plus x):(1 minus x):(1.1 to 1.5)x (x is greater than 0 and less than 0.6), silver is added, and the materials are ground and pressed into the shape of a sheet; annealing is carried out under high vacuum, more specifically, the heating rate is 1 DEG C / min to 5 DEG C / min from 0 DEG C to 600 DEG C, the heating rate is 1 DEG C / min to 3 DEG C / min from 600 DEG C to 900 DEG C, the temperature of 900 DEG C is kept for 5 to 15 hours, the heating rate is 1 DEG C / min to 3 DEG C / min from 900 DEG C to a temperature from 1100 DEG C to 1200 DEG C, and the temperature from 1100 DEG C to 1200 DEG C is kept for 20 to 30 hours; and the furnace is cooled to the room temperature. By adding the silver, the method can enhance the electromagnetic properties and practicability of the iron-based superconductor.

Owner:BEIJING UNIV OF TECH

The method of adding fese1/2te1/2 to superconductor with sn to improve superconductivity

ActiveCN104445097BPromote formationSimple manufacturing methodSelenium/tellurium compundsRoom temperatureSuperconducting transition temperature

The invention relates to a method for improving the superconducting performance of a Sn-added FeSe0.5Te0.5 superconductor. The method comprises the steps of mixing Sn powder and FeSe0.5Te0.5 powder in a weight ratio of 0.05: 1, and sufficiently grinding the mixture in an agate mortar for 20-30 minutes; and then preparing into a flake under the pressure of 6-8MPa, finally putting the flake into a high-temperature differential scanning calorimeter, heating to 600 DEG C under the protection of flowing high-purity argon, preserving the heat for 5-10 hours, and cooling to room temperature. A fact that a Sn-Se-Te liquid phase generated by reaction between Sn and FeSe0.5Te0.5 can accelerate the transformation from a non-superconducting phase to a superconducting phase is discovered for the first time and is favorable for forming a superconducting laminar structure so that the superconducting transition temperature of the structure is finally significantly improved, thus providing an important clue for optimizing a preparation process of an iron-based superconductor, illuminating an iron-based superconducting mechanism and promoting the development of the superconducting theory.

Owner:TIANJIN UNIV

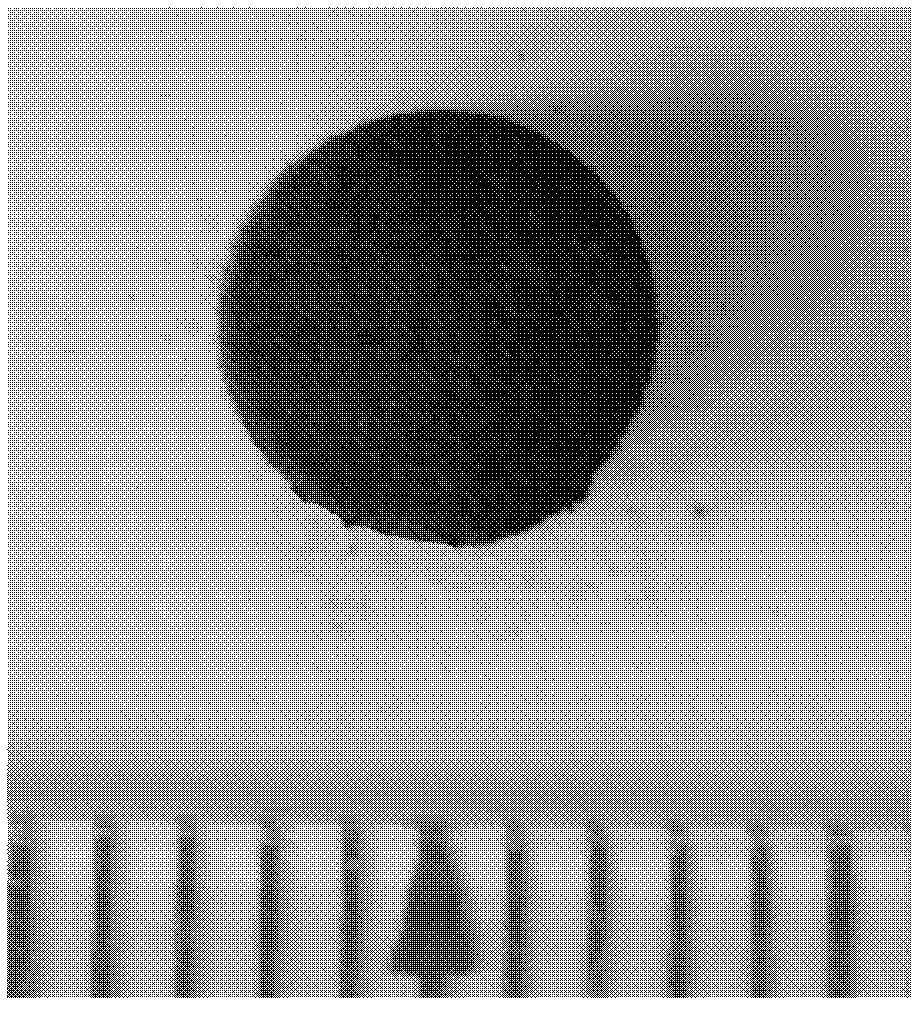

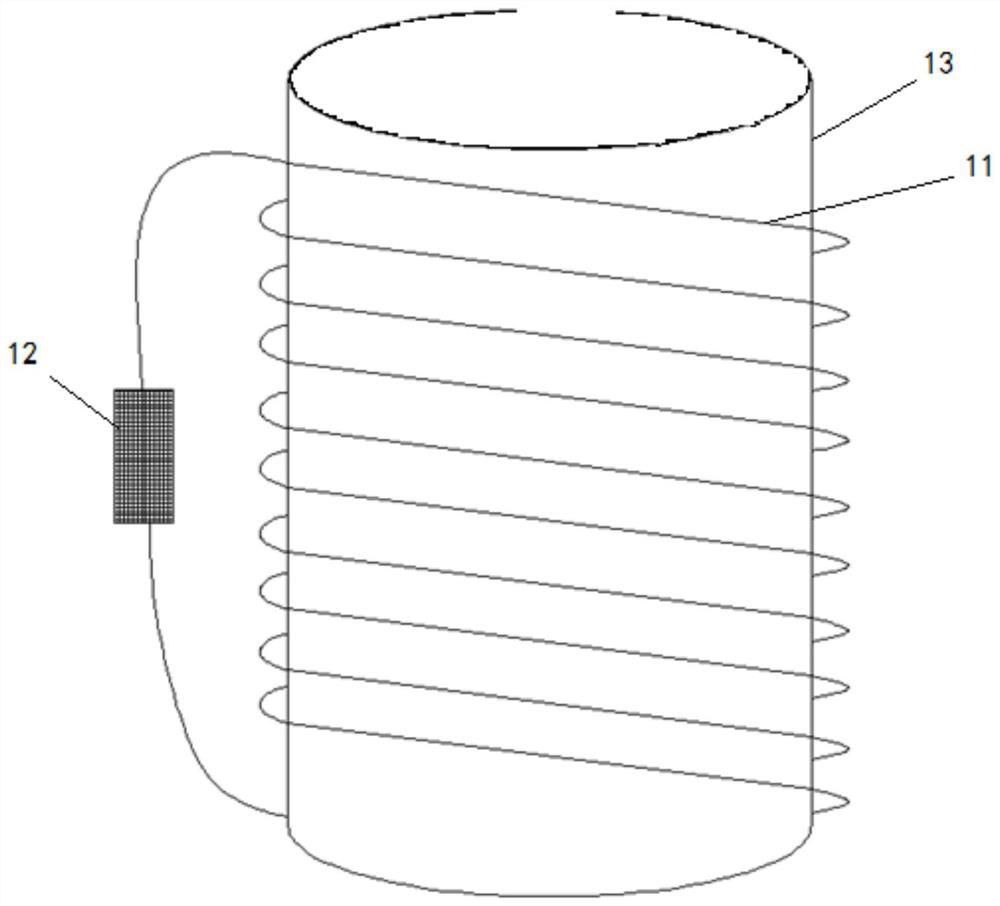

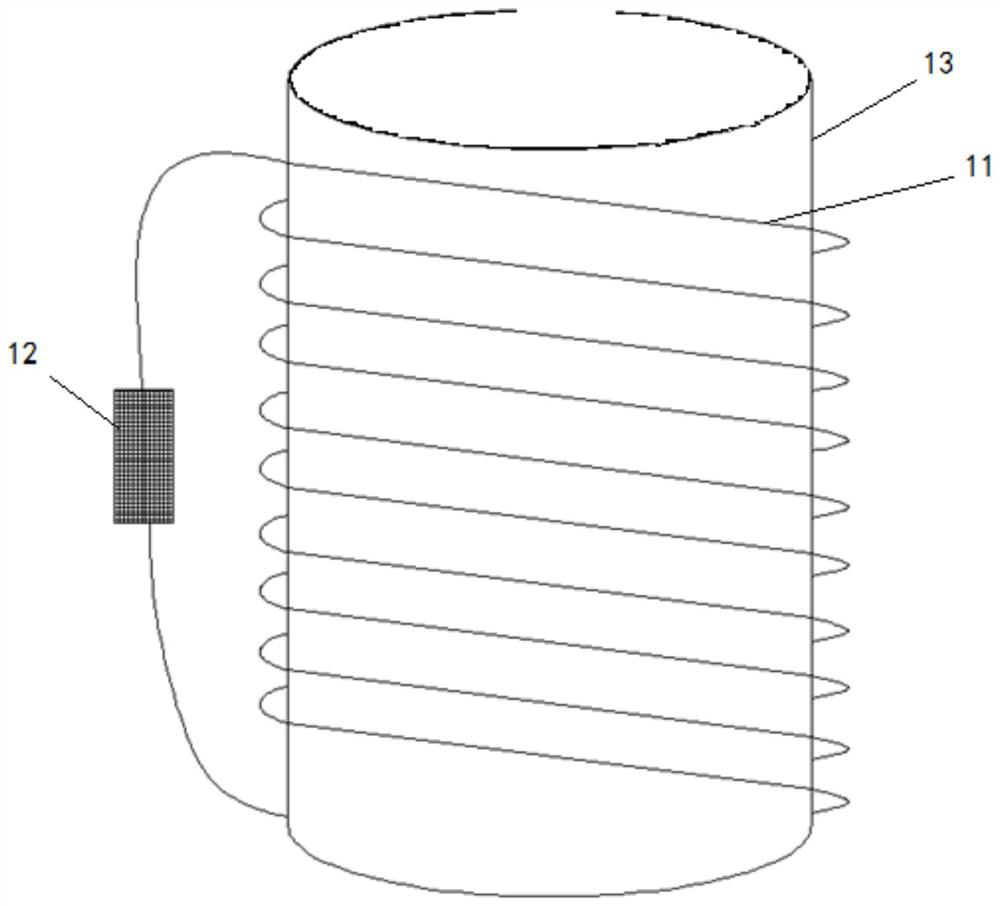

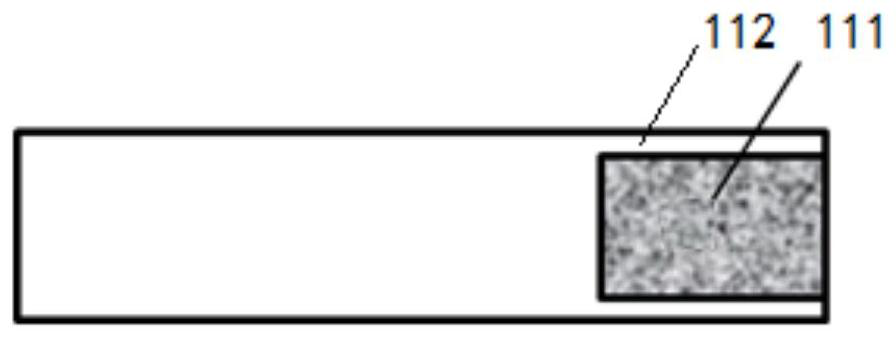

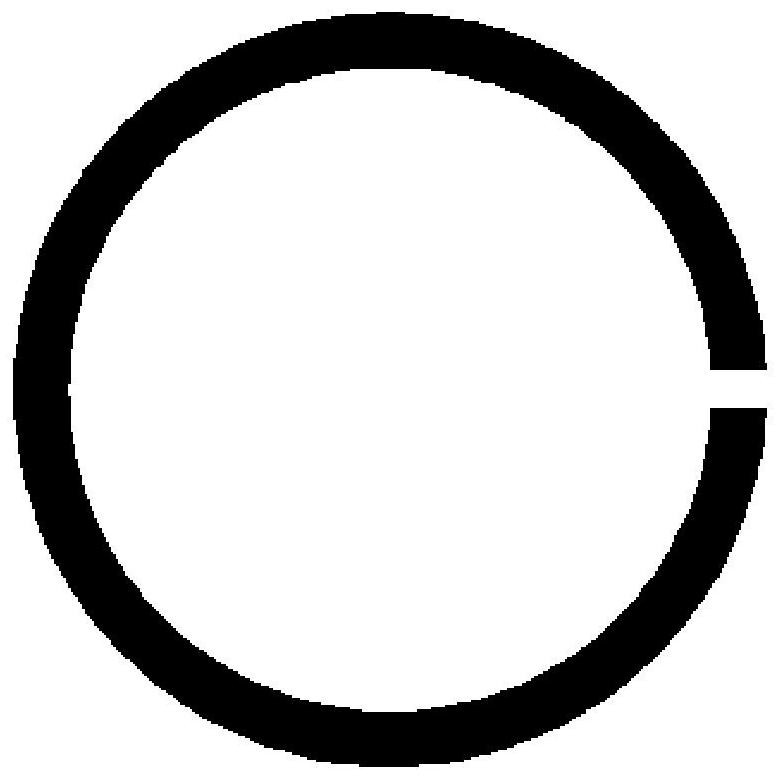

Iron-based superconducting coil, preparation method and method for measuring resistance of iron-based superconducting joint

ActiveCN111681848AMagnetic field effectRealize closed-loop operationResistance/reactance/impedenceTransformers/inductances magnetic coresWire rodElectrical resistance and conductance

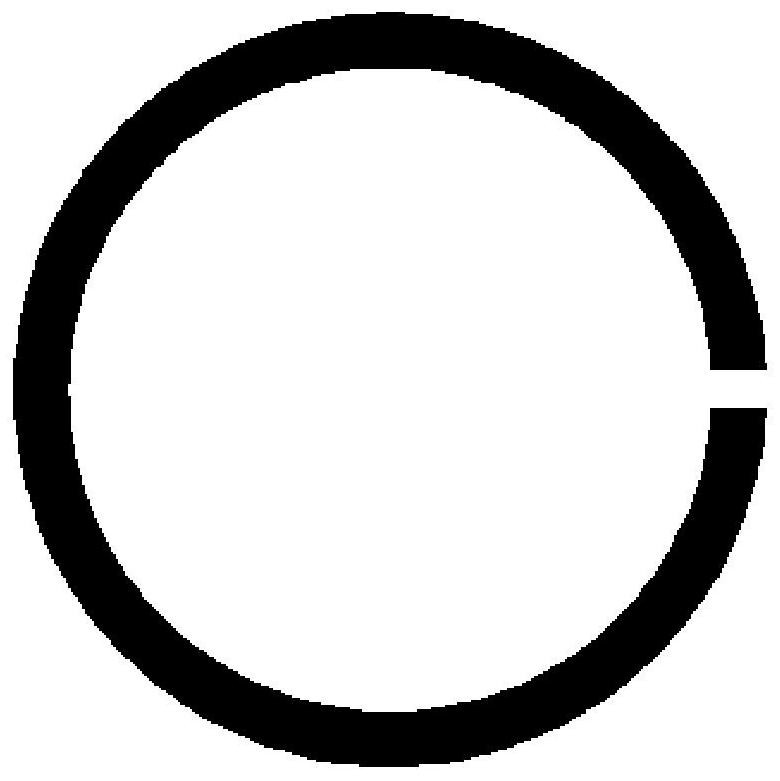

The invention discloses an iron-based superconducting coil, a preparation method and a method for measuring the resistance of an iron-based superconducting joint. The iron-based superconducting coil comprises an iron-based superconducting wire, and two ends of the iron-based superconducting wire are connected through a joint; and the iron-based superconducting wire is wound on the iron core, and the cross section of the iron core is in a non-closed shape. The embodiment of the invention discloses an iron-based superconducting coil, a preparation method and a method for measuring the resistanceof an iron-based superconducting joint. An iron-based superconducting wire is wound on an iron core; the cross section of the iron core is in a non-closed shape. Two ends of the iron-based superconducting wire are connected through a joint; an iron-based superconducting coil is prepared; closed-loop operation of the iron-based superconductor is achieved, the cross section of the iron core is arranged to be in a non-closed shape, so that when the iron-based superconducting coil is used, the iron core does not generate a magnetic field, the magnetic field generated by the iron-based superconducting coil is not affected, and the prepared iron-based superconducting joint can be used for accurately measuring the resistance of the iron-based superconducting joint.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

A kind of iron-based superconducting joint and preparation method thereof

ActiveCN110061367BPrevent volatilizationChurn ControlSuperconducting magnets/coilsConnection formation by deformationEngineeringMechanical engineering

The invention discloses an iron-based superconduction connector and a fabrication method thereof. The fabrication method of the iron-based superconduction connector comprises the steps of stripping atail end of the iron-based superconductor to expose a superconduction core, connecting the superconduction core, wrapping a connection region, performing thermal processing on the connection region, and applying pressure to the connection region. In the step of thermal processing on the connection region, the connection region is arranged in a pressure-applying state within a range larger than a preset temperature, and the preset temperature is a run-off temperature of a doping component in the iron-based superconductor. The connection region is enabled to be in the pressure-applying state within the range which the thermal processing temperature is larger than the run-off temperature of the doping element in the iron-based superconductor in the step of thermal processing on the connectionregion, volatilization of the doping element of the connection region caused by that the temperature is raised and exceeds the preset temperature during the thermal processing process is prevented, the run-off condition of the doping element of the connection region is favorably controlled, and the superconduction connection efficiency is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Iron-based superconducting coil, preparation method and method for measuring iron-based superconducting joint resistance

ActiveCN111681848BMagnetic field effectRealize closed-loop operationResistance/reactance/impedenceTransformers/inductances magnetic coresElectrical resistance and conductanceWire rod

The invention discloses an iron-based superconducting coil, a preparation method thereof, and a method for measuring the resistance of an iron-based superconducting joint. The iron-based superconducting coil comprises: an iron-based superconducting wire, and two ends of the iron-based superconducting wire are connected through joints; The iron core, on which the iron-based superconducting wire is wound, has a non-closed cross-section. In the iron-based superconducting coil, its preparation method and the method for measuring the resistance of the iron-based superconducting joint in the embodiments of the present invention, the iron-based superconducting wire is wound on the iron core, and the cross-section of the iron core is an open shape. The two ends of the superconducting wire are connected by joints, and the iron-based superconducting coil is prepared, which realizes the closed-loop operation of the iron-based superconductor, and by setting the cross-section of the iron core to a non-closed shape, the iron-based superconducting coil, when in use, The iron core itself does not generate a magnetic field, so it does not affect the magnetic field generated by the iron-based superconducting coil, so that the prepared iron-based superconducting joint can be used to accurately measure the resistance of the iron-based superconducting joint.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com