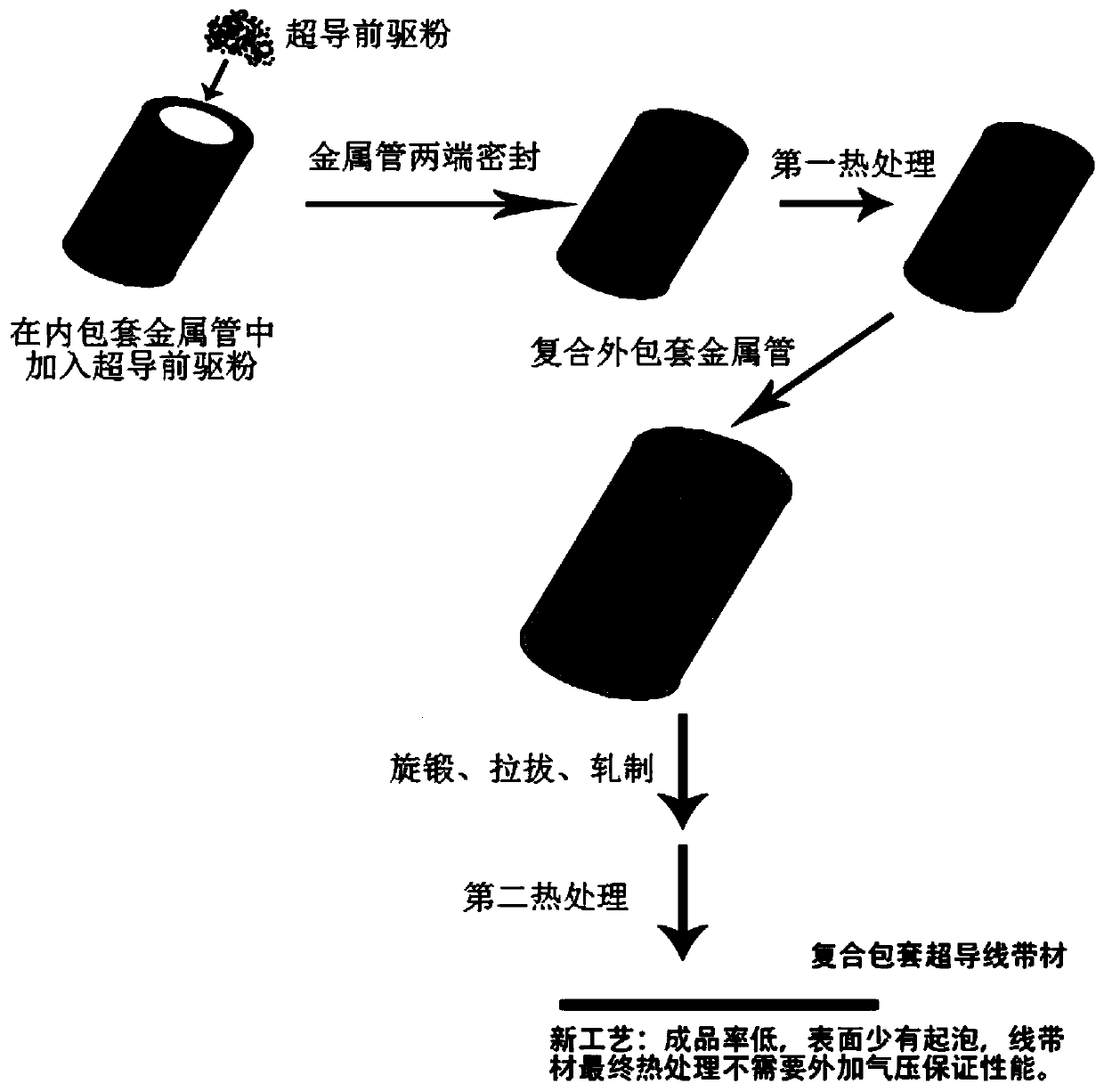

Preparation method of composite sheathed iron-based superconducting wire strip

An iron-based superconducting and sheathing technology, which is applied in superconducting devices, superconducting/high-conducting conductors, cable/conductor manufacturing, etc., can solve the problems of low product yield, high production cost, and large bulging, and achieve Reduce production costs, excellent product performance, and eliminate bulges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

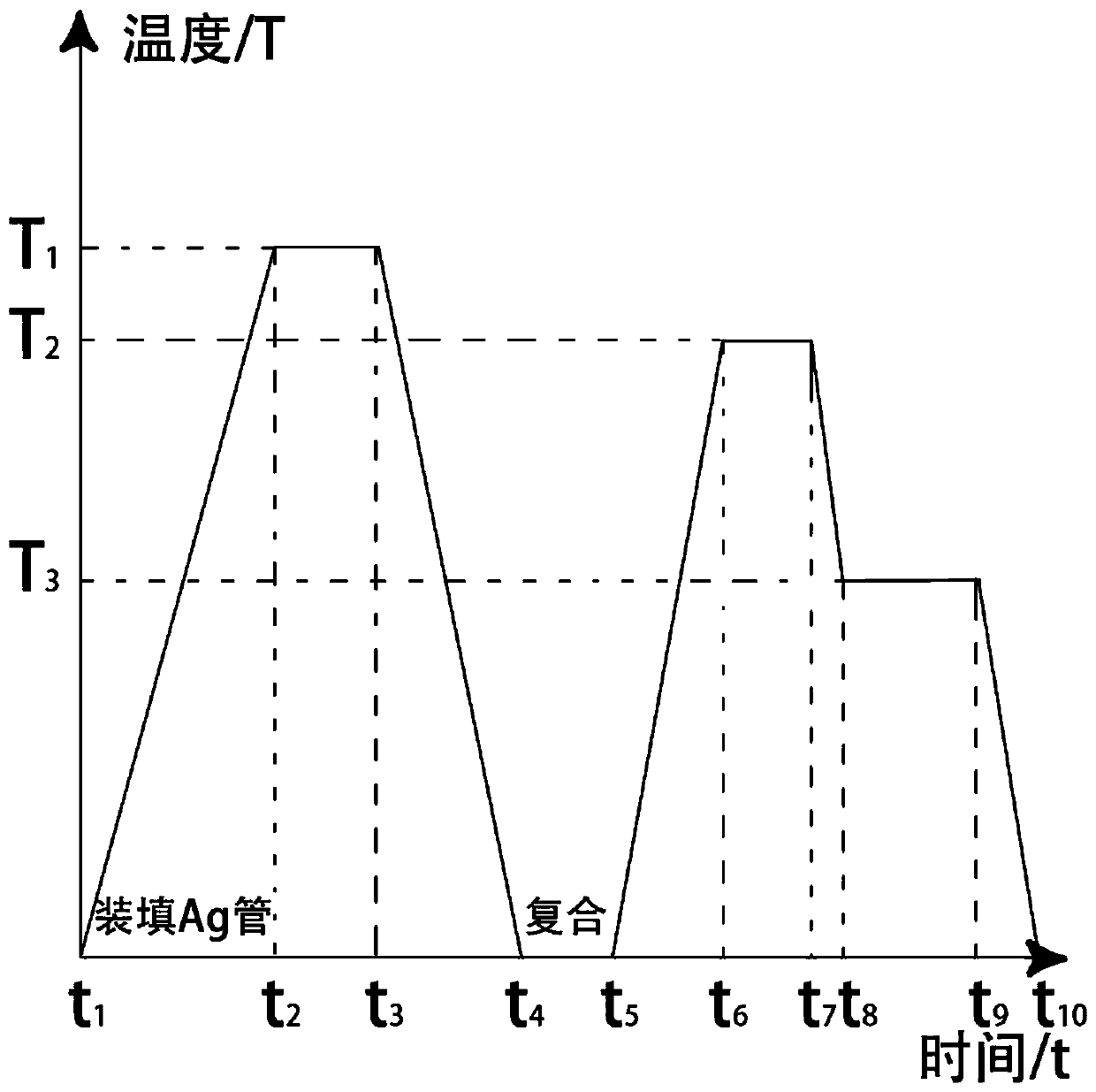

[0032] This embodiment provides a single-core copper-silver composite LaFeAsO 0.76 f 0.24 A method for preparing a superconducting wire strip, comprising the steps of:

[0033] 1) Under an Ar gas protective atmosphere, accurately weigh a total of 20 g of the iron-based superconducting raw materials La, Fe, As, O, and F according to the above stoichiometric ratio, and then put the weighed raw materials into a planetary ball mill for 10 milliseconds. hours to turn it into a powder. Put the ground powder into the Nb tube, seal both ends with copper plugs, and then heat-treat and sinter. The sintering time is 1 hour, the sintering temperature is 900°C, and the sintering pressure is normal pressure, and finally LaFeAsO is obtained.0.76 f 0.24 , crush it into powder to obtain iron-based superconducting precursor powder;

[0034] 2) The iron-based superconducting precursor powder obtained in step 1) is packed into an Ag tube, and both ends of the Ag tube are sealed. Under an argon...

Embodiment 2

[0038] Single core copper-silver composite SmFeAsO 0.76 f 0.24 A method for preparing a superconducting wire strip, comprising the steps of:

[0039] 1) Under the protective atmosphere of Ar gas, accurately weigh a total of 20 g of the iron-based superconducting raw material elements Sm, Fe, As, O, and F according to the above stoichiometric ratio, and then put the weighed elemental materials into a planetary ball mill for ball milling for 10 hours to turn it into a powder. Put the ground powder into the Nb tube, seal both ends with copper plugs, and then heat-treat and sinter. The sintering time is 200 hours, the sintering temperature is 500°C, and the sintering pressure is normal pressure, and finally SmFeAsO is obtained. 0.76 f 0.24 , crush it into powder to obtain iron-based superconducting precursor powder;

[0040] 2) The iron-based superconducting precursor powder obtained in step 1) is packed into an Ag tube, and both ends of the Ag tube are sealed. Under an argon ...

Embodiment 3

[0044] Single core copper silver composite Ba 0.6 K 0.4 Fe 2 As 2 A method for preparing a superconducting wire strip, comprising the steps of:

[0045] 1) Under an Ar gas protective atmosphere, accurately weigh a total of 20 g of the iron-based superconducting raw materials Ba, K, Fe, and As according to the above stoichiometric ratio, and then put the weighed raw materials into a planetary ball mill for ball milling for 10 hours, make it into powder. Put the ground powder into the Nb tube, seal both ends with copper plugs, and then heat-treat and sinter. The sintering time is 35 hours, the sintering temperature is 900°C, and the sintering pressure is normal pressure, and finally Ba 0.6 K 0.4 Fe 2 As 2 , crush it into powder to obtain iron-based superconducting precursor powder;

[0046] 2) The iron-based superconducting precursor powder obtained in step 1) is packed into an Ag tube, and both ends of the Ag tube are sealed. Under an argon atmosphere, the Ag tube equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical current | aaaaa | aaaaa |

| Superconducting transition temperature | aaaaa | aaaaa |

| Critical current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com