A kind of high chromium cast iron composite cast steel product roll and preparation method thereof

A technology of composite casting and high chromium cast iron, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of limited output of section steel rolls, high requirements for worn rolls, and drop in hardness, so as to improve performance and eliminate compounding Stress, yield and quality enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

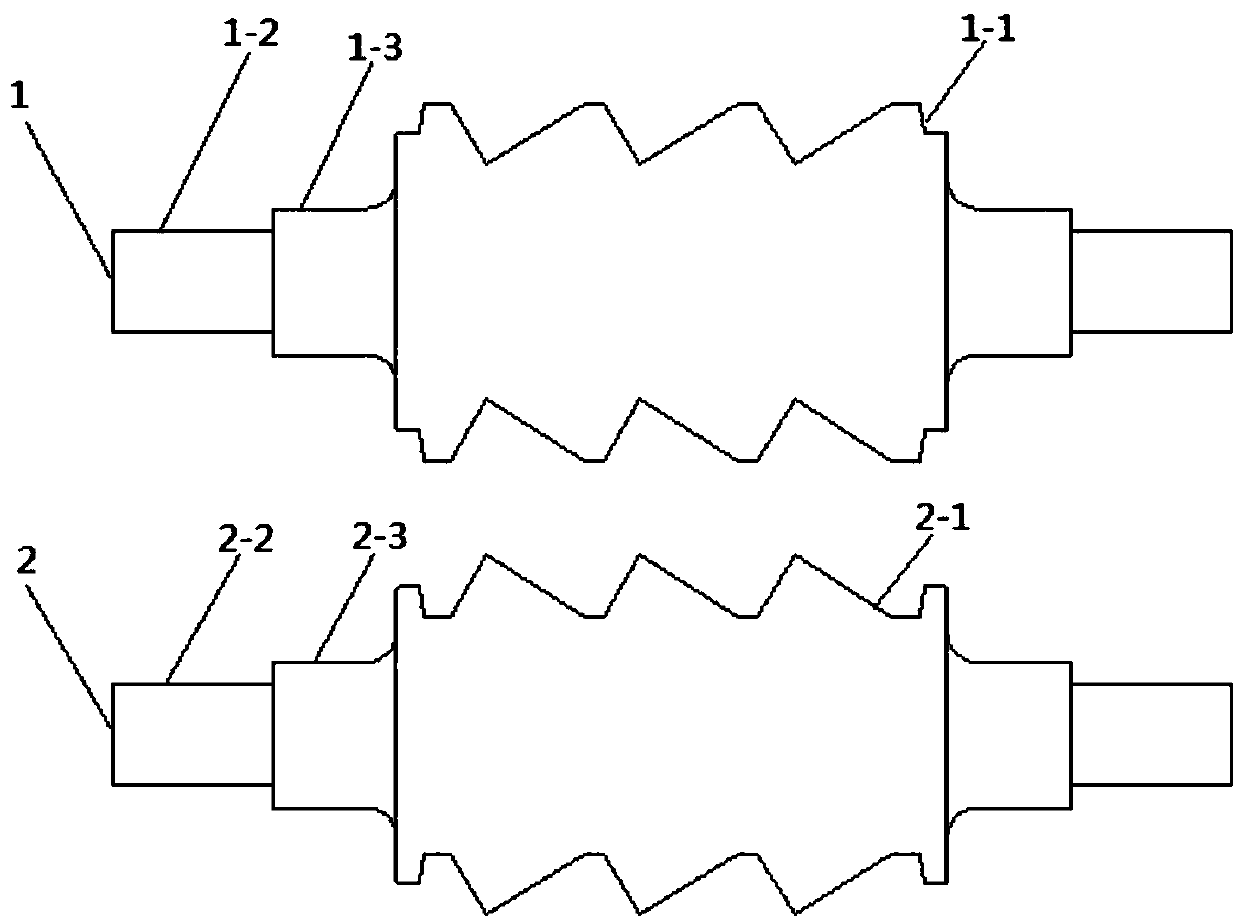

[0028] [Example 1] The structure of the high chromium cast iron composite cast steel product roll of the present embodiment is as follows figure 1 Shown: A high chromium cast iron compound cast steel product roll assembly: including two metallographic matrix structures of Cr 7 C 3 、Mo 2 C, VC, NbC fine-grained carbide + bainite + a small amount of martensite high-chromium cast iron compound cast steel product rolls, one of which is used as the main shaft 1, and the other is used as the auxiliary shaft 2, and the two mesh with each other; the main shaft includes The roll body 1-1 located in the middle, the roll neck 1-2 located at both ends of the roll body, and the bearing stop roll neck 1-3; the auxiliary shaft 2 includes the roll body 2-1 located in the middle and the roll neck 2-2 located at both ends of the roll body 2. Bearing retaining roll neck 2-3.

[0029] The main shaft roll body 1-1 of the assembly of the roll includes 4 teeth surrounding the roll body 1-1, and t...

Embodiment 2

[0039] [Example 2] The configuration chemical composition of the high chromium cast iron composite cast steel product roll of this embodiment is: the chemical composition of the outer layer is: C: 3.00%; Si: 0.70%; Mn: 0.80%; Cr: 13.00%; Ni : 2.00%; Mo: 1.30%; V: 0.40%; Nb: 0.30%; P: 0.02%; S: 0.015%; the chemical composition of the core is: C: 3.13%; Nb: 0.16%; Ni: 0.35%; P: 0.01%; S: 0.015%; Mg: 0.05%; the balance is Fe and a small amount of residual elements.

[0040] The design value of the working layer hardness of the high-chromium cast iron composite casting steel product roll is 65-75HSD, and the actual product is 73.5HSD; the design value of the hardness drop from the roll surface to the groove bottom is ≤2HSD, and the actual product is 1.2HSD; The design value of the working layer thickness of the high-chromium cast iron compound casting steel product roll is 80-180mm, and the actual product is 102mm.

[0041] The preparation method of the high-chromium cast iron co...

Embodiment 3

[0042] [Example 3] The configuration chemical composition of the high-chromium cast iron composite cast steel product roll of this embodiment is: the chemical composition of the outer layer is: C: 3.30%; Si: 0.90%; Mn: 1.10%; Cr: 15.00%; Ni : 1.70%; Mo: 1.30%; V: 0.50%; Nb: 0.10%; P: 0.01%; S: 0.02%; the chemical composition of the core is: C: 3.40%; Nb: 0.23%; Ni: 0.42%; P: 0.02%; S: 0.015%; Mg: 0.06%; the balance is Fe and a small amount of residual elements.

[0043] The design value of the working layer hardness of the high-chromium cast iron composite casting steel product roll is 65-75HSD, and the actual product is 74.5HSD; the design value of the hardness drop from the roll surface to the groove bottom is ≤2HSD, and the actual product is 1.1HSD; The design value of the working layer thickness of the high-chromium cast iron compound casting steel product roll is 80-180mm, and the actual product is 146mm.

[0044] The preparation method of the high-chromium cast iron com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com