Iron-based superconduction connector and fabrication method thereof

An iron-based superconductor and iron-based superconductor technology, which is applied in the direction of connecting contact materials, superconducting magnets/coils, and completing connection and connection by deformation, can solve the problems of loss of doping elements, affecting the efficiency of superconducting connection, etc. The effect of improving microcracks, improving superconducting connection efficiency and avoiding brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Sr 0.6 K 0.48 Fe 2 As 2 (122 system) the preparation method of iron-based superconducting joint, comprises the following steps:

[0035] a pretreatment step, using mechanical methods to remove the non-superconducting layer at the end of the iron-based superconductor to be connected, so as to expose the superconducting core;

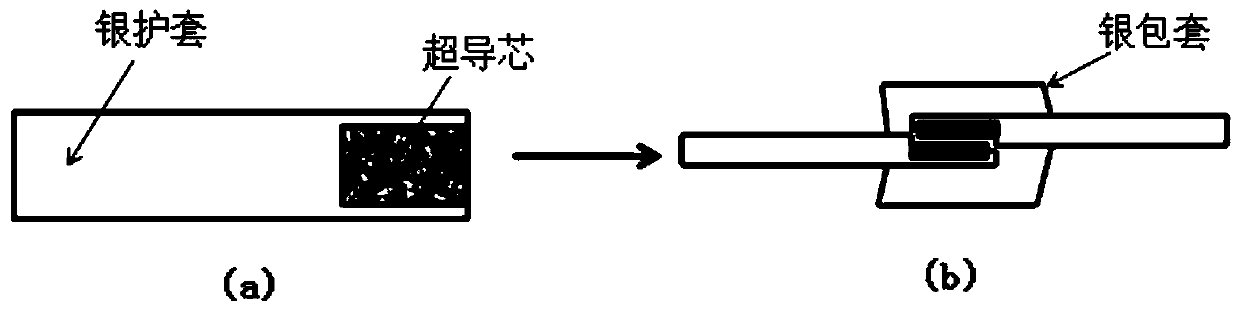

[0036] In the connection step, the superconducting cores obtained in the pretreatment step are filled with precursor powder for connection, and the connection area is wrapped with a metal sheath. The specific operations are as follows figure 1 shown;

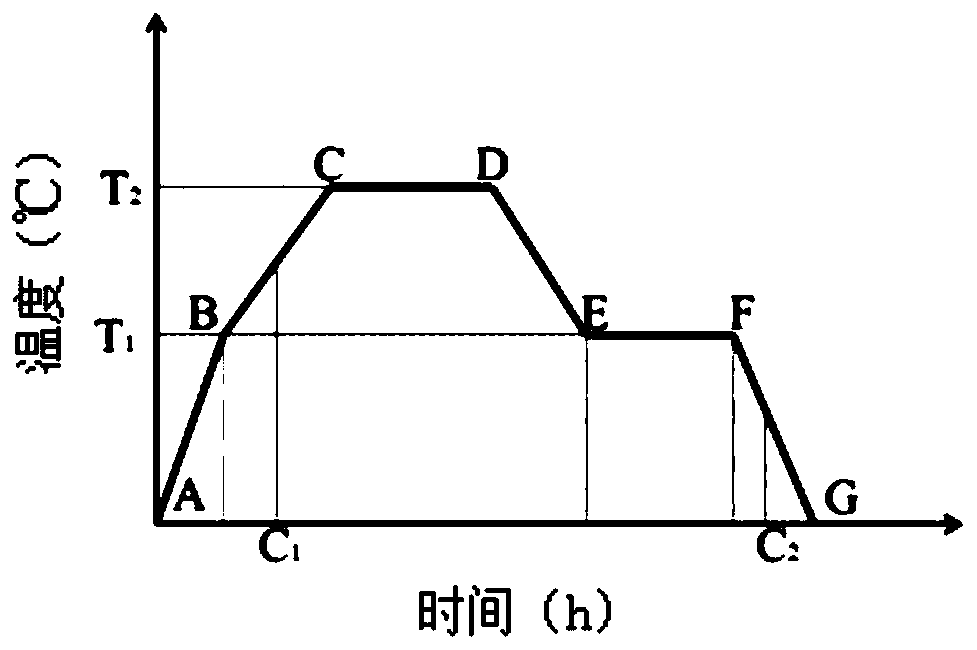

[0037] The heat treatment step, heat treatment of the connection area, the temperature change process of the heat treatment is as follows figure 2 shown (A-B warmed to T 1 , 1 hour; B-C warmed to T 2 , 1.5 hours; C-D was kept for 1 hour; D-E was cooled to T 1 , 1 hour; E-F was kept for 2 hours; F-G was cooled to room temperature, 1 hour, where T 1 =600℃,T 2 =880℃), the heat treatment proce...

Embodiment 2

[0040] Sr 0.6 K 0.48 Fe 2 As 2 (122 system) the preparation method of iron-based superconducting joint, comprises the following steps:

[0041]a pretreatment step, using mechanical methods to remove the non-superconducting layer at the end of the iron-based superconductor to be connected, so as to expose the superconducting core;

[0042] In the connection step, the superconducting cores obtained in the pretreatment step are filled with precursor powder for connection, and the connection area is wrapped with a metal sheath. The specific operations are as follows figure 1 shown;

[0043] In the heat treatment step, heat treatment is performed on the connection area, and the temperature change process of the heat treatment is the same as that in Example 1, and the heat treatment process is a protective atmosphere;

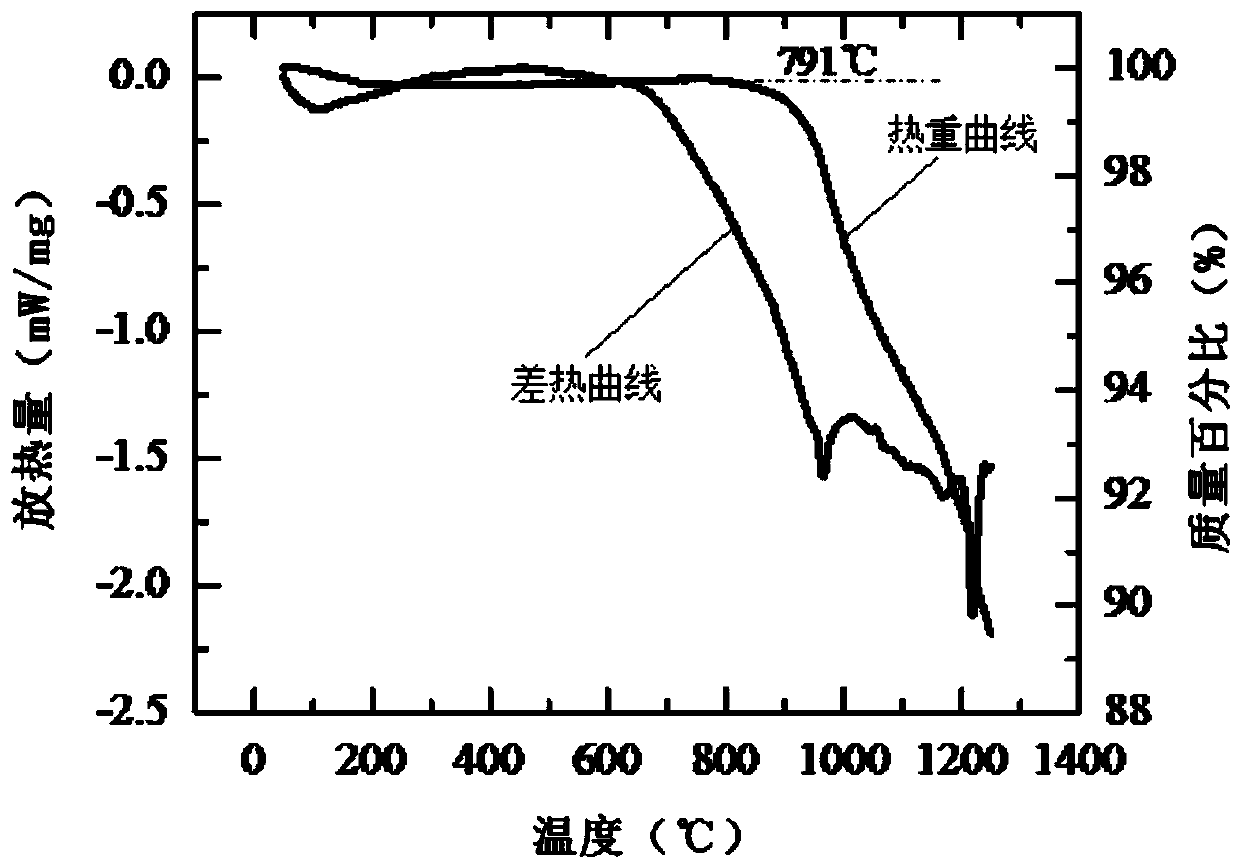

[0044] The pressing step is the same as the analysis result in Example 1. During the heat treatment process, when the temperature is higher than 791° C., it is ...

Embodiment 3

[0046] Sr 0.6 K 0.48 Fe 2 As 2 (122 system) the preparation method of iron-based superconducting joint, comprises the following steps:

[0047] a pretreatment step, using mechanical methods to remove the non-superconducting layer at the end of the iron-based superconductor to be connected, so as to expose the superconducting core;

[0048] In the connection step, the superconducting cores obtained in the pretreatment step are filled with precursor powder for connection, and the connection area is wrapped with a metal sheath. The specific operations are as follows figure 1 shown;

[0049] In the heat treatment step, heat treatment is performed on the connection area, and the temperature change process of the heat treatment is the same as that in Example 1, and the heat treatment process is a protective atmosphere;

[0050] The pressing step is the same as the analysis result in Example 1. During the heat treatment process, when the temperature is higher than 791° C., it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com