Iron-based thin film superconducting cavity and preparation method thereof

An iron-based superconducting and superconducting cavity technology, applied in ion implantation plating, coating, electrical components and other directions, can solve the problem that the acceleration gradient of the thin film superconducting cavity cannot be further improved, and achieve the improvement of the working magnetic field and acceleration gradient. , Improve the effect of accelerating gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

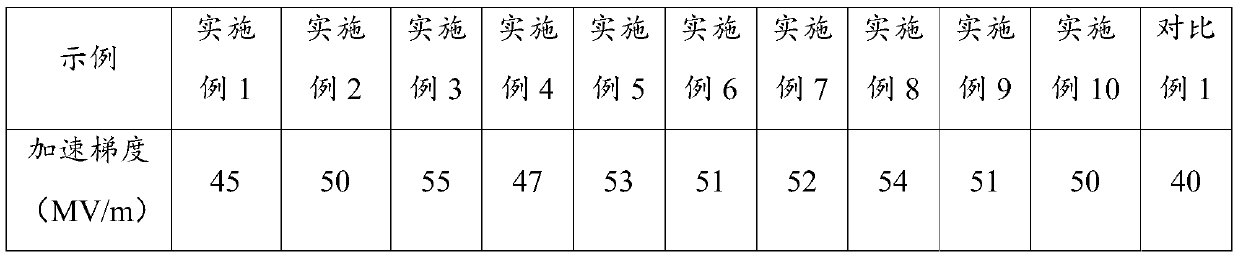

Examples

Embodiment 1

[0044] This embodiment provides an iron-based thin film superconducting cavity, including a niobium superconducting cavity, an aluminum oxide insulating layer, and an iron-based superconducting layer; the iron-based superconducting layer includes Ba(Fe 0.9 co 0.1 ) 2 As 2 , type 122;

[0045] The thickness of the iron-based superconducting layer is 300nm; the thickness of the insulating layer is 15nm;

[0046] The preparation method of the above-mentioned iron-based superconducting cavity,

[0047] Will Al 2 o 3and Ba(Fe 0.9 co 0.1 ) 2 As 2 The iron-based superconducting target is placed in the pulsed laser epitaxy cavity, and the vacuum is evacuated to 1×10 -7 Pa, adjust the oxygen pressure in the niobium cavity to 1×10 after vacuuming -2 Pa, temperature is 300°C, laser energy is 1J / cm 2 , depositing 10nm Al on the surface of the niobium cavity 2 o 3 Thin film, the deposition rate is 0.3nm / min, after the deposition is completed, the vacuum of the niobium cavity ...

Embodiment 2

[0049] This embodiment provides an iron-based thin film superconducting cavity, including a niobium superconducting cavity, an aluminum oxide insulating layer, and an iron-based superconducting layer; the iron-based superconducting layer includes Fe 0.5 Te 0.5 layer (type 11) and Ba(Fe 0.9 co 0.1 ) 2 As 2 layer (Type 122), the Fe 0.5 Te 0.5 layer and the Ba(Fe 0.9 co 0.1 ) 2 As 2 The thickness ratio of the layers is 3:2;

[0050] The thickness of the iron-based superconducting layer is 500nm; the thickness of the insulating layer is 10nm;

[0051] The preparation method of the above-mentioned iron-based superconducting cavity,

[0052] Will Al 2 o 3 , Fe 0.5 Te 0.5 (Type 11) and Ba(Fe 0.9 co 0.1 ) 2 As 2 (Type 122) iron-based superconducting target is placed in the pulsed laser epitaxy cavity, and vacuumed to 1×10 -7 Pa, adjust the oxygen pressure in the niobium cavity to 1×10 after vacuuming -2 Pa, temperature is 500°C, laser energy is 1J / cm 2 , and then...

Embodiment 3

[0054] This embodiment provides an iron-based thin film superconducting cavity, including a niobium superconducting cavity, a magnesium oxide insulating layer, and an iron-based superconducting layer; the iron-based superconducting layer includes FeSe 0.5 Te 0.5 layer (type 11), LaFeAsO layer (type 1111) and BaFe 2 (As 0.8 P 0.2 ) 2 Layer (type 122,) the thickness ratio of the three layers is 1:25:25;

[0055] The thickness of the iron-based superconducting layer is 1020nm; the thickness of the insulating layer is 20nm;

[0056] The preparation method of the above-mentioned iron-based superconducting cavity,

[0057] MgO and FeSe 0.5 Te 0.5 , LaFeAsO and BaFe 2 (As 0.8 P 0.2 ) 2 Put the iron-based superconducting layer target into the magnetron sputtering chamber, and evacuate to 1×10 -7 Pa, after the vacuum is exhausted, argon gas is introduced until the pressure is 1Pa, and the temperature in the niobium cavity is adjusted to 300°C, then the temperature in the ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com