The method of adding fese1/2te1/2 to superconductor with sn to improve superconductivity

A superconducting performance and superconducting technology, applied in the field of superconducting, can solve the problem of unfavorable hexagonal superconducting equivalence, achieve the effect of simple and easy preparation method, optimize preparation process, and promote development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

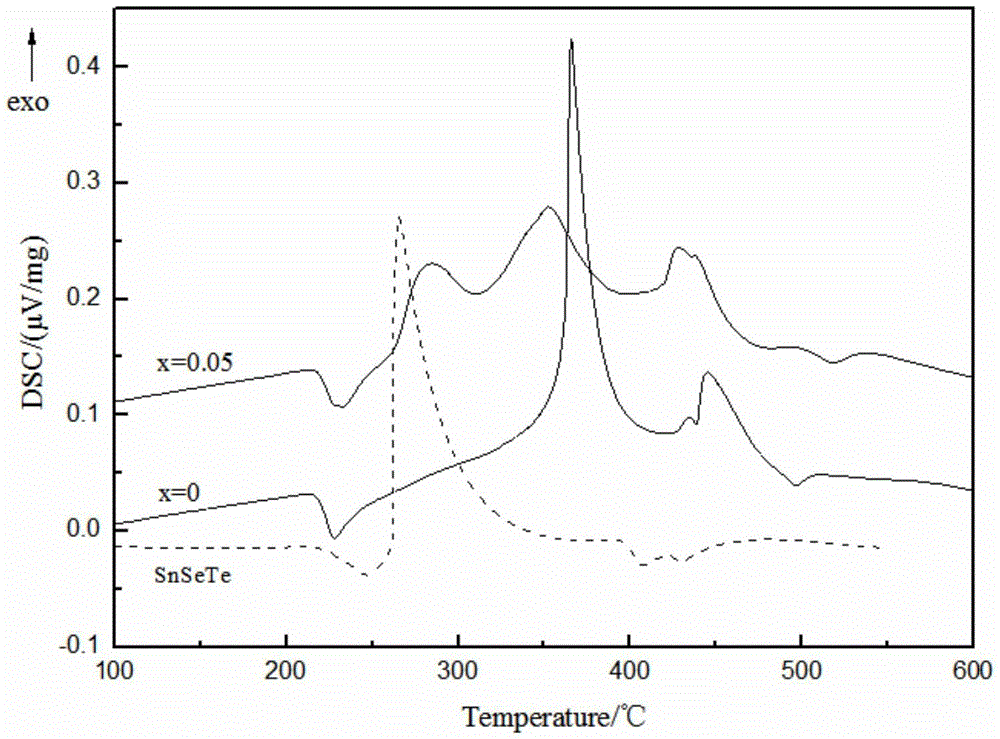

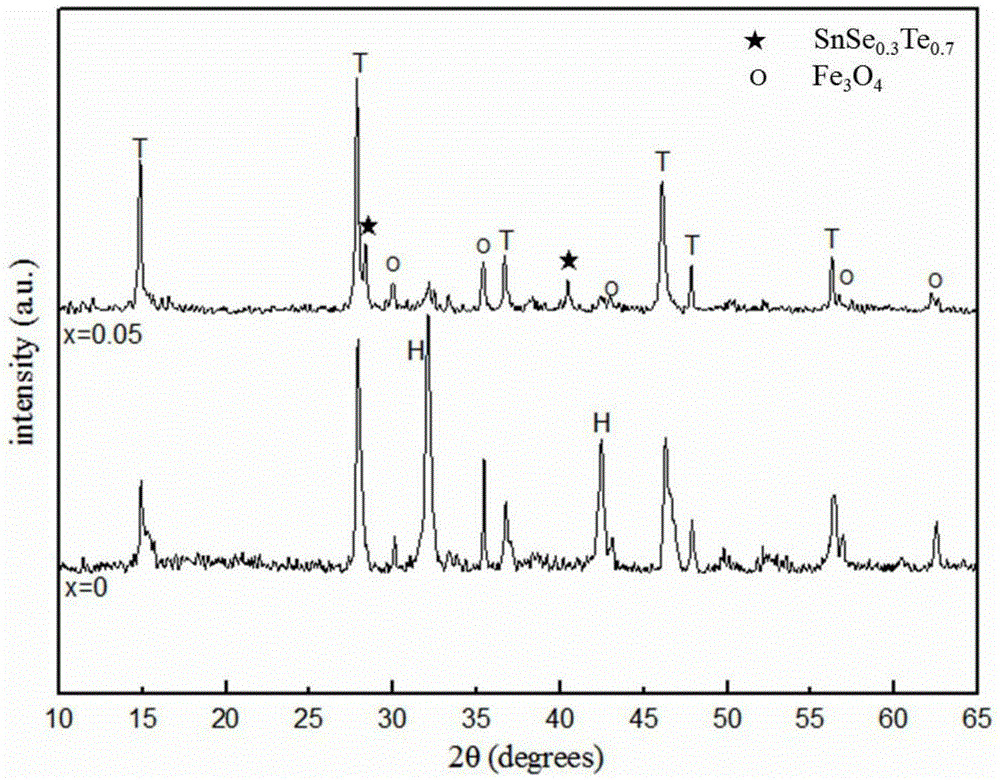

[0019] Mix Fe, Se, and Te powders in an agate mortar at an atomic ratio of 1:0.5:0.5, grind for 30 minutes, and then make thin slices under a pressure of 6MPa, and finally put the thin slices into a tube with an argon protective atmosphere After sintering in a type furnace, the temperature was raised to 500°C at a rate of 10°C / min, kept at this temperature for sintering for 18 hours, and then cooled down to room temperature at a cooling rate of 40°C / min. The sintered block is taken out and ground into powder again. Then the Sn powder and FeSe 0.5 Te 0.5 The powders were mixed in a weight ratio of 0.05:1 and thoroughly ground in an agate mortar for 20 minutes. Then make thin slices under a pressure of 6MPa, and finally put the thin slices into a high-temperature differential scanning calorimeter. Keep it warm for 5 hours, then drop to room temperature at a cooling rate of 20°C / min. From figure 2 It can be seen that in this sample (x=0.05), the intensity of the diffraction...

Embodiment 2

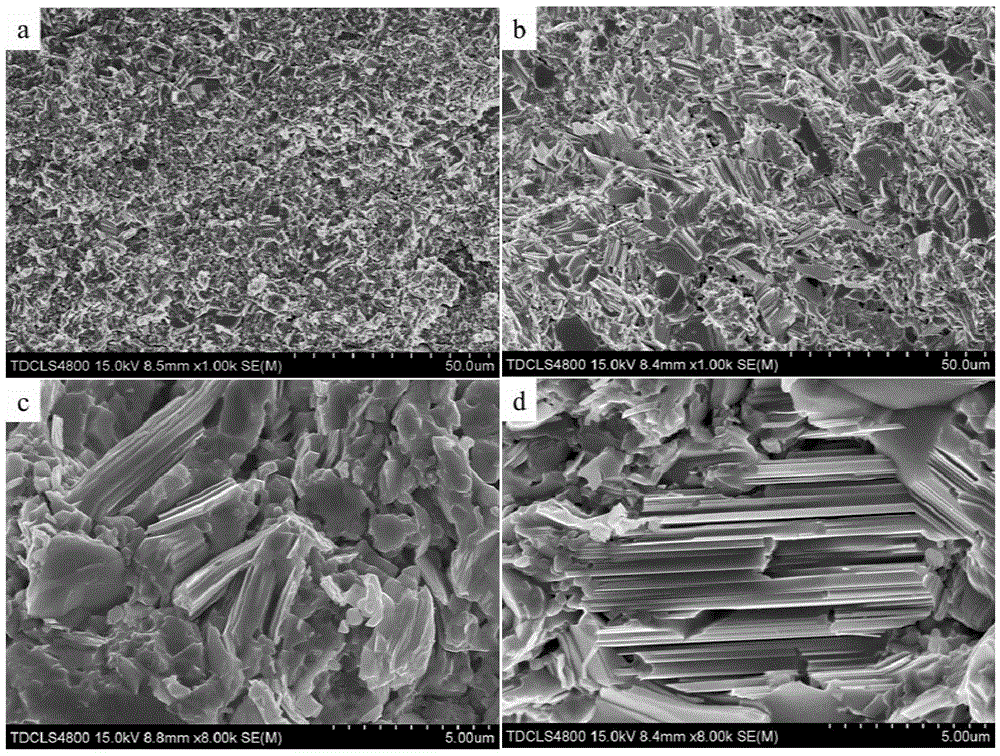

[0021] Mix Fe, Se, and Te powders in an agate mortar at an atomic ratio of 1:0.5:0.5, grind for 30 minutes, and then make thin slices under a pressure of 6MPa, and finally put the thin slices into a tube sintering furnace for argon gas Protective atmosphere sintering with a heating rate of 20°C / min. After rising to 550°C, keep the temperature for sintering for 20 hours, and then cool down to room temperature at a cooling rate of 20°C / min. The sintered block is taken out and ground into powder again. Then the Sn powder and FeSe 0.5 Te 0.5 Powders were mixed in a weight ratio of 0.05:1 and ground thoroughly in an agate mortar for 30 minutes. Then make thin slices under a pressure of 6MPa, and finally put the thin slices into a high-temperature differential scanning calorimeter. Keep it warm for 5 hours, then cool down to room temperature at a cooling rate of 40°C / min. From image 3 It can be seen that in this sample (x=0.05), the layered superconducting crystal grows obviou...

Embodiment 3

[0023]Mix Fe, Se, and Te powders in an agate mortar at an atomic ratio of 1:0.5:0.5, grind for 20 minutes, and then make thin slices under a pressure of 8MPa, and finally put the thin slices into a tube with an argon protective atmosphere After sintering in a type furnace, the temperature was raised to 600°C at a rate of 40°C / min, kept at this temperature for sintering for 24 hours, and then cooled down to room temperature at a cooling rate of 20°C / min. The sintered block is taken out and ground into powder again. Then the Sn powder and FeSe 0.5 Te 0.5 The powders were mixed in a weight ratio of 0.05:1 and thoroughly ground in an agate mortar for 20 minutes. Then make thin slices under a pressure of 8 MPa, and finally put the thin slices into a high-temperature differential scanning calorimeter. Insulate for 10 hours, then cool down to room temperature at a cooling rate of 10°C / min. From Figure 4 It can be seen from the label in the lower right corner that the zero resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com