Iron-based compound superconducting wire or tape prepared from silver sheath

A technology of superconducting wires and compounds, applied in superconducting devices, superconducting/high-conducting conductors, usage of superconducting elements, etc., can solve problems such as hindering superconducting current transmission and hindering current transport in superconducting cores. Achieve the effect of improving current transport performance, improving current transport capacity, and enhancing connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

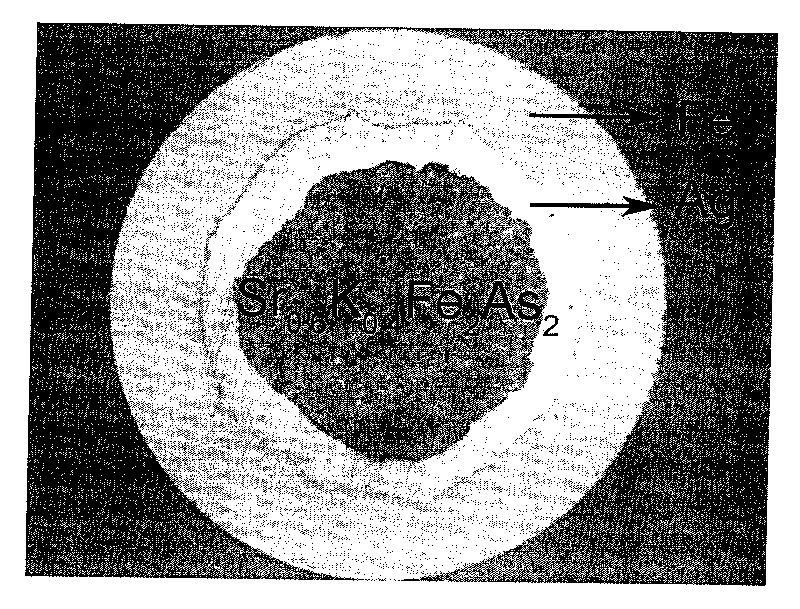

Image

Examples

example 1

[0013] First, La, Fe, As, Fe 2 o 3 and LaF 3 The powder according to the chemical formula LaO 0.9 f 0.1 The chemical ratio shown by FeAs, accurately weighed La 4.695 grams, Fe 0.781 grams, As 2.620 grams, Fe 2 o 3 1.675 g, LaF 3 0.228 g, and the powder was ground in an argon atmosphere glove box to make it fully and uniformly mixed. Put the uniformly mixed powder into a 10cm long silver tube with an inner diameter of 5mm and an outer diameter of 8mm, so that the powder can be filled and compacted in the tube, and then the two ends of the iron tube are closed, and then the mixed powder is installed. The silver tube was swaged to 4mm, and then drawn to 1mm to obtain a superconducting wire. The processed wire rod is placed in a vacuum annealing furnace, and vacuumized at room temperature until it reaches 10 -3 After the vacuum degree of Pa is filled with high-purity argon, then the temperature is raised to 500°C for 10 hours, and then the temperature is raised to 800°C ...

example 2

[0015] First Sm, Fe 2 o 3 , FeAs, As and SmF 3 The powder according to the chemical formula SmO 0.85 f 0.15 Chemical ratio shown for FeAs, accurately weighed Sm 4.800 grams, Fe 2 o 3 1.521g, FeAs 1.904g, As 1.427g, SmF 3 0.348 g, and the powder was ground in an argon atmosphere glove box to make it fully and uniformly mixed. Put the evenly mixed powder into an 8cm-long silver-iron alloy tube with an inner diameter of 6mm and an outer diameter of 7.6mm, so that the powder can be filled and compacted in the tube, then seal both ends of the silver tube, and then put the sealed alloy tube into Put it into an iron pipe with an inner diameter of 8mm and an outer diameter of 10mm, and press both ends tightly. The composite tube loaded with the initial powder was swaged to 6mm, and then drawn to 2mm to make a superconducting wire. The processed wire rod is placed in a vacuum annealing furnace, and vacuumized at room temperature until it reaches 10 -3 After the vacuum degree ...

example 3

[0017] First, Ce, Fe, As, Fe 2 o 3 and CeF 3 The powder according to the chemical formula CeO 0.8 f 0.2 The chemical ratio shown by FeAs, accurately weighed Ce 4.549 grams, Fe 0.907 grams, As 2.606 grams, Fe 2 o 3 1.481 g, CeF 3 0.457 g, and the powder was ground in an argon atmosphere glove box to make it fully and uniformly mixed. Put the powder mixed evenly into a 10cm long silver tube with an inner diameter of 6.5mm and an outer diameter of 8mm, so that the powder is full and compact in the tube, and then seal both ends of the silver tube. Put the silver tube filled with superconducting precursor powder into an iron tube with an inner diameter of 8.2 mm and an outer diameter of 10 mm, and press both ends tightly. Then the iron-silver composite tube is swaged to 3mm, and then drawn to 1mm, and processed into a wire. The processed wire rod is placed in a vacuum annealing furnace, and vacuumized at room temperature until it reaches 10 -3 After the vacuum degree of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com