Patents

Literature

129 results about "Homogeneous deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

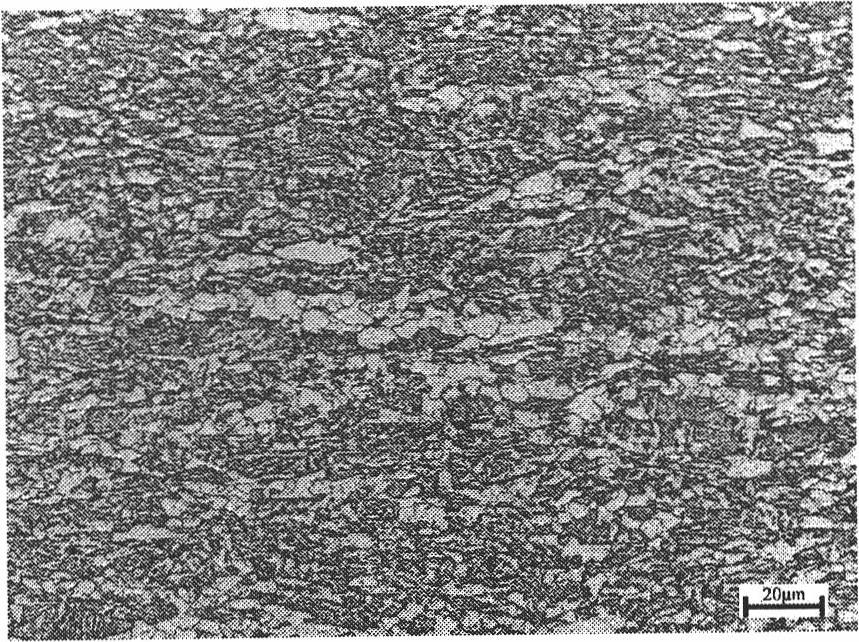

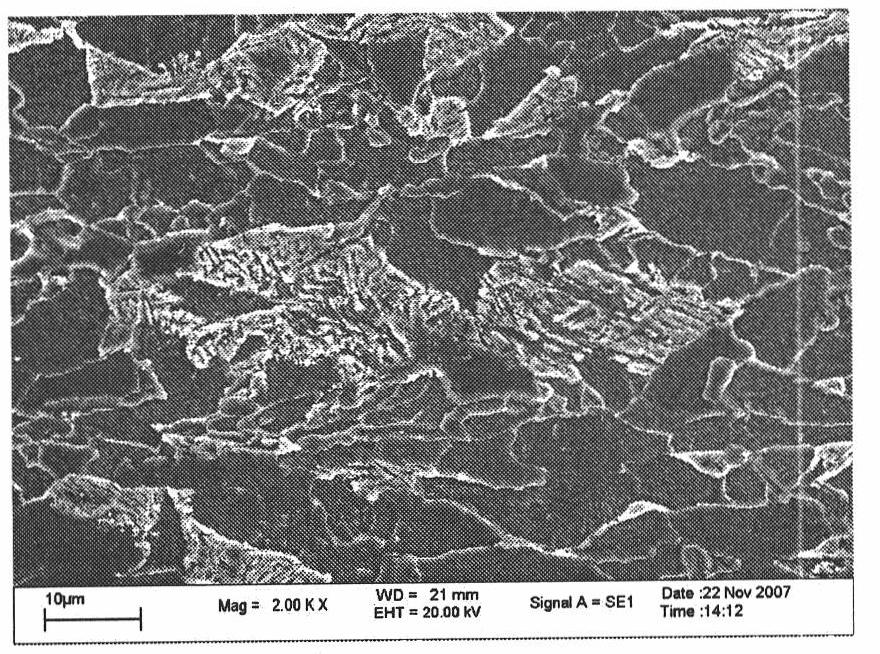

X80 level large-deformation resistance pipe line steel medium and heavy plate production method

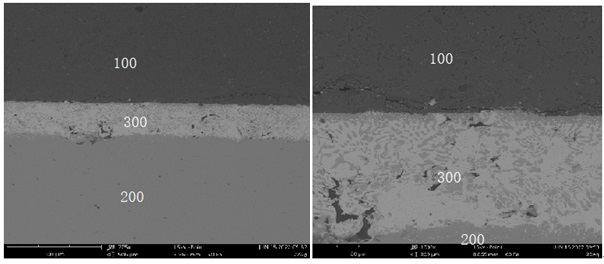

InactiveCN101456034AReduce manufacturing costGrain refinementTemperature control deviceWork treatment devicesDouble phaseYield ratio

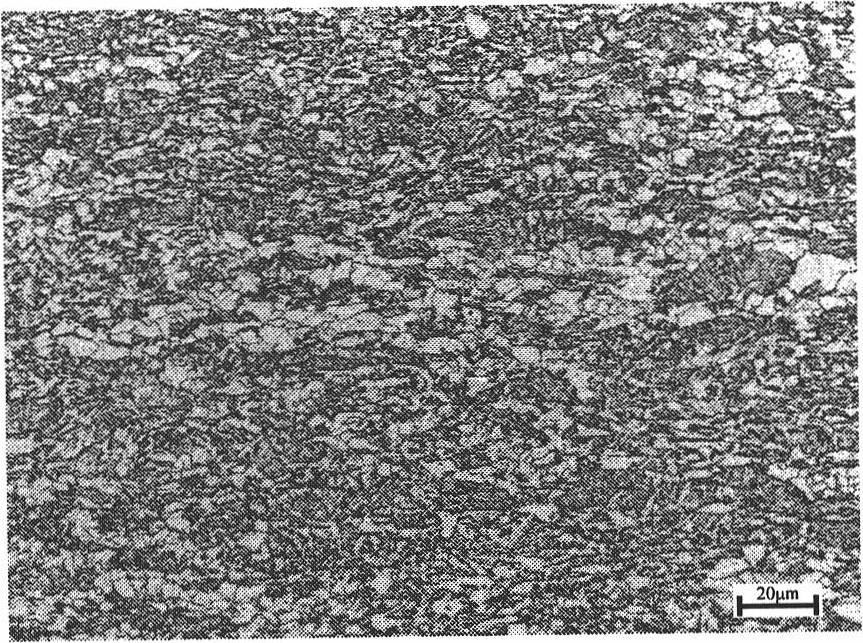

The invention relates to a method for producing an X80 grade large deformation resistant pipeline steel medium plate. The economic component design with low carbon is adopted to perform controlling and rolling stages on ingot, namely rolling the grain refined zone and the non grain refined zone. The method comprises: firstly, air cooling and relaxing after finished rolling is performed so that the temperature of a steel plate before entering water and cooled is reduced below the phase change point Ar3 between 30 and 50 DEG C, and 50 to 70 percent of austenite in the relaxing process is converted into proeutectoid ferrite; and secondly, laminar flow cooling is performed on the steel plate within the range of the cooling speed between 20 and 35 DEG C per second, the finished cooling temperature is controlled within the range of between 250 and 400 DEG C; and in the water cooling process, the remaining austenite is converted into bainite structure, and proeutectoid ferrite + bainite double-phase structure is obtained. The intensity and the plasticity index of the finished product satisfy the following requirements: the yield strength Rt0.5 is 530 to 630MPa, the intensity of tension Rm is 625 to 825 MPa, the yield ratio Rt0.5 / Rm is less than or equal to 0.80, and the homogeneous deformation tensile stretch UEL is more than or equal to 10 percent.

Owner:UNIV OF SCI & TECH BEIJING

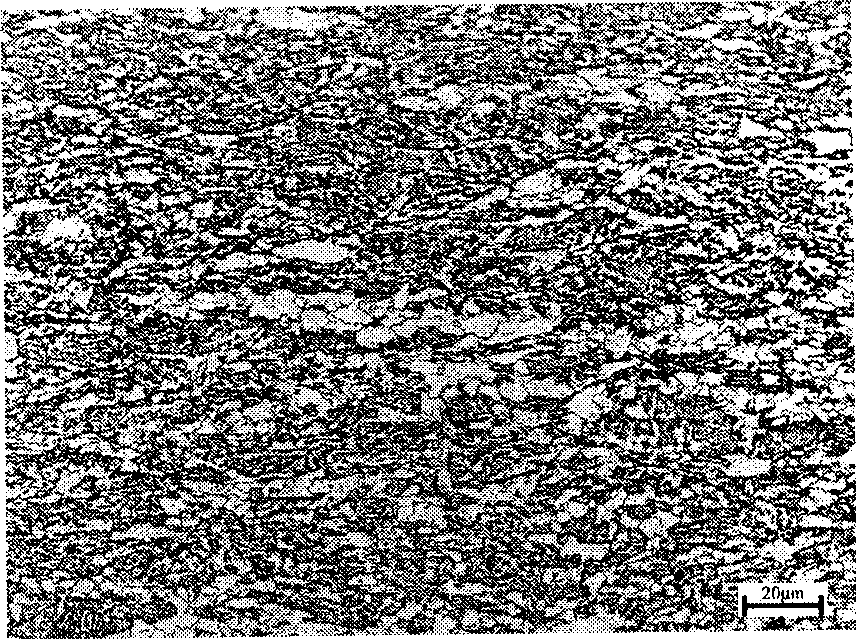

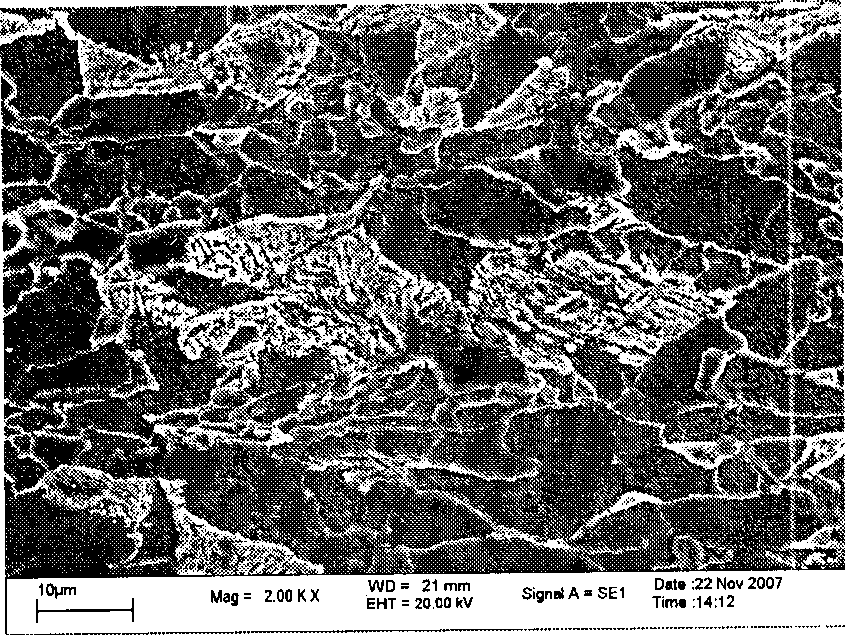

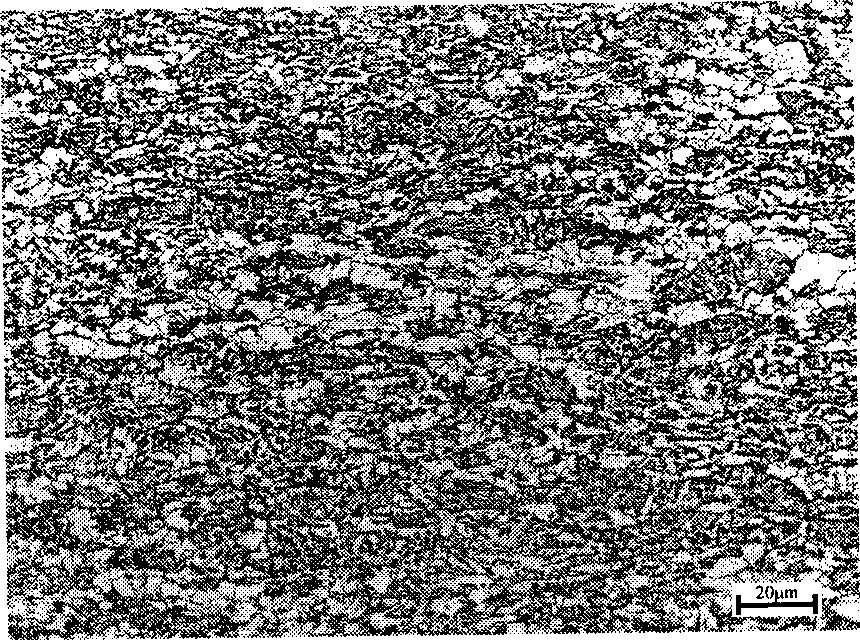

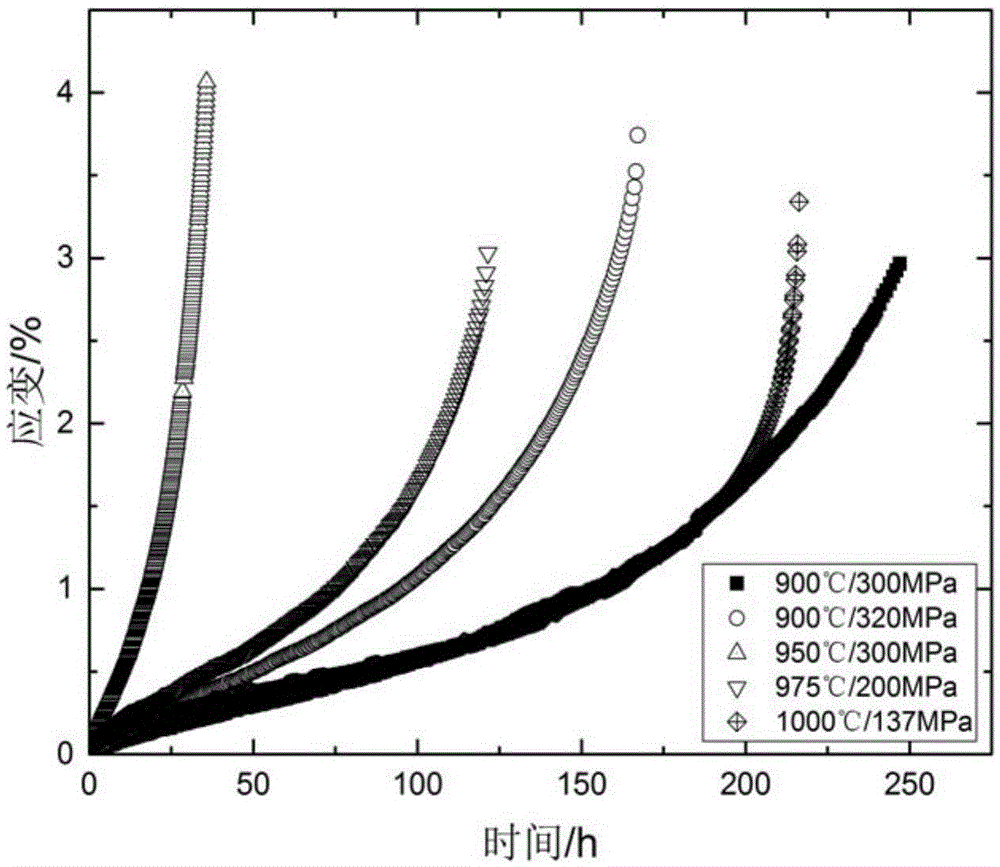

Method for forecasting high-temperature-alloy creep life

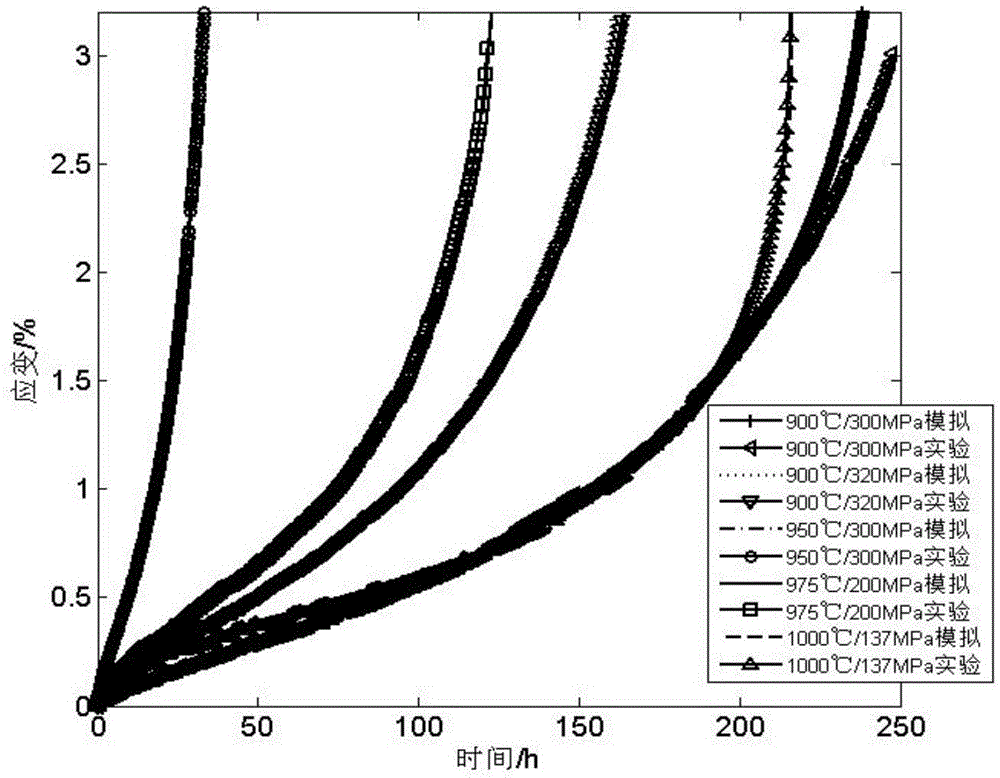

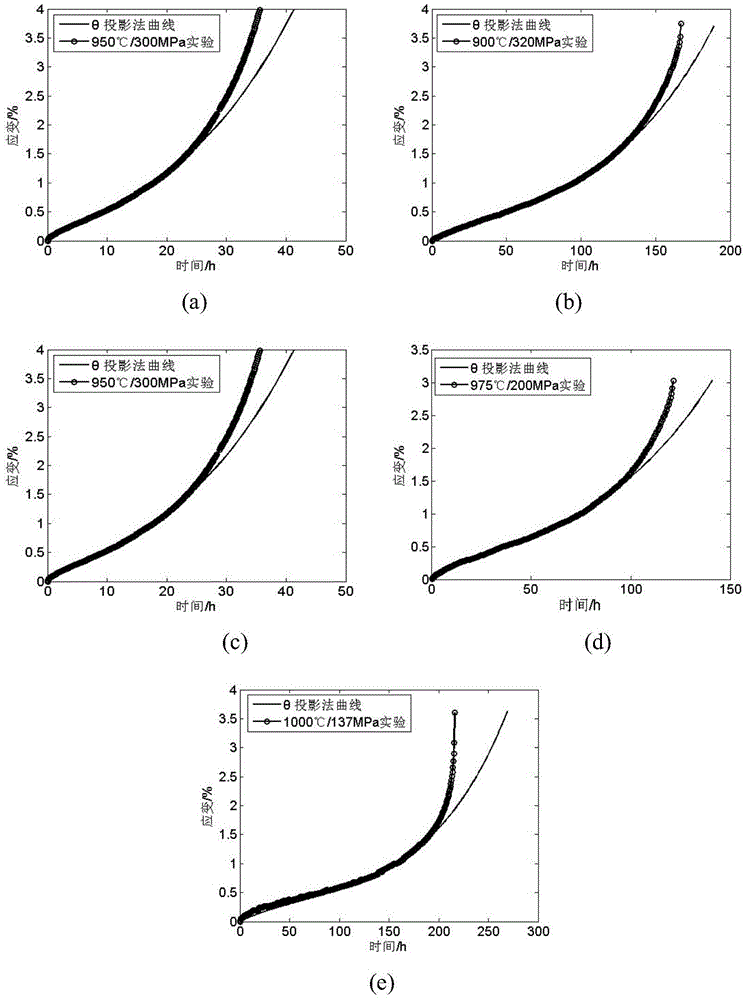

ActiveCN105628511AImprove forecast accuracyEstimated time of serviceMaterial strength using tensile/compressive forcesCreep strainPredictive methods

The invention provides a method for forecasting the high-temperature-alloy creep life. The method includes the steps that on the basis of the theta projection method, the factor that changes of true stress are caused by changes of the material shape in the creep process is introduced, the correction theta projection method is obtained, and the concrete form is epsilon= theta1*(1-exp(theta2*(1+theta5*epsilon)*t))+theta3*(exp(theta4*(1+theta5*epsilon)*t)-1). The method can be used for forecasting a creep curve at the whole homogeneous deformation stage through initial data from the first stage to the third stage of the creep curve, and the obtaining time of creep data can be shortened. Meanwhile, the method can be used for forecasting creep curves under other creep conditions, and the forecasting process comprises forecasting of the creep rupture time under the some creep condition and the creep interruption time corresponding to some creep strain. The method is simple, reliable and suitable for different-type high temperature alloy and engineering application, and has broad prospects in the aspect of high-temperature-alloy creep life management.

Owner:UNIV OF SCI & TECH BEIJING

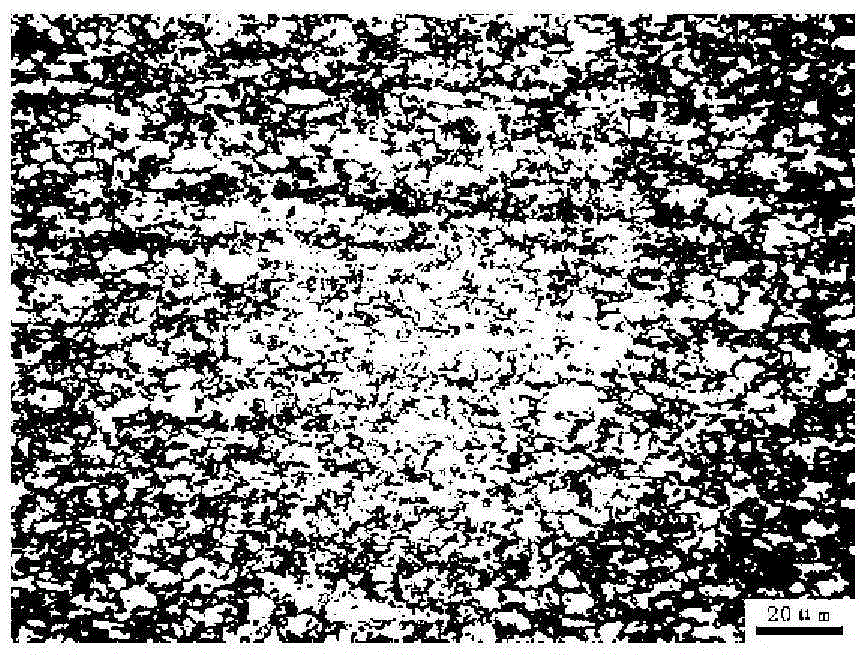

Ultralow-yield-ratio cold-rolled dual-phase steel and manufacturing method thereof

InactiveCN105420605AHigh work hardening rateUltra-low yield ratioChemical compositionDual-phase steel

The invention belongs to the technical field of steel materials, and relates to an ultralow-yield-ratio cold-rolled dual-phase steel and a manufacturing method thereof. Internal control chemical components of the dual-phase steel comprise 0.13%-0.18% of C, 0.30%-0.60% of Si, 1.7%-2.0% of Mn, 0.02%-0.070% of Al, 0.02%-0.05% of Nb and the balance Fe and other inevitable impurities. Simple chemical component design is adopted, the hot-rolling deformation heat treatment TMCP and the flexible continuous annealing process are combined to obtain a microscopic structure with fine grain ferrite, island martensite and 5%-7% of retained austenite, and therefore the uniform deformation capacity of materials is increased while the strong plasticity of the cold-rolled dual-phase steel is improved. The ultralow-yield-ratio cold-rolled dual-phase steel has the beneficial effects that good stamping performance, low process sensitivity and the ultralow yield ratio YS / TS which is smaller than or equal to 0.51 are achieved, springback generated after stamping can be reduced, and later deep machining of the automobile industry is facilitated.

Owner:CENT IRON & STEEL RES INST

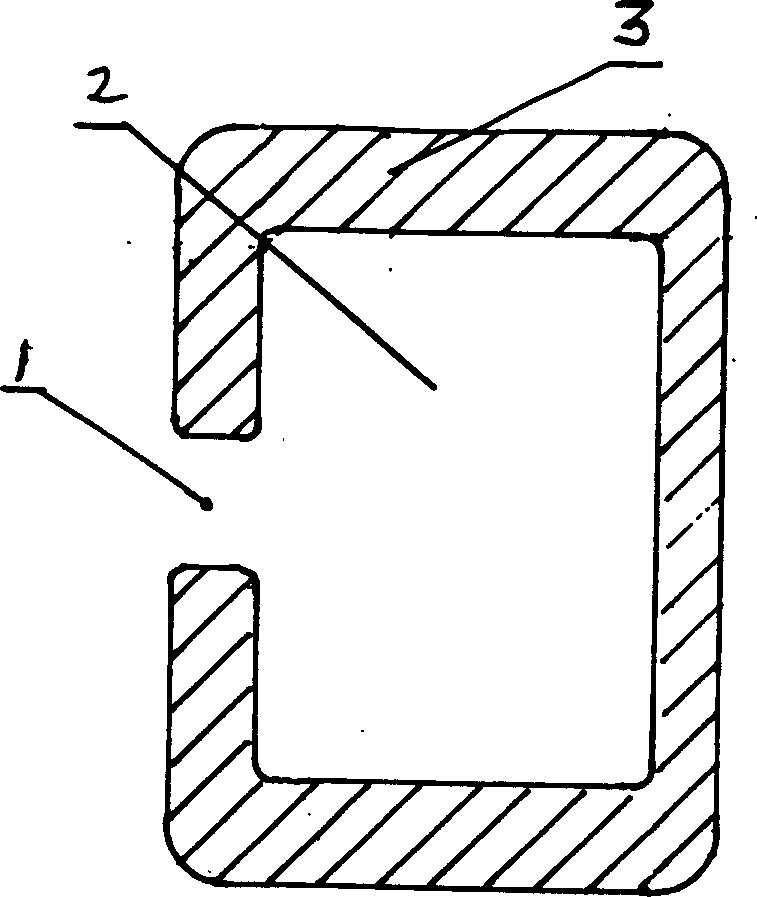

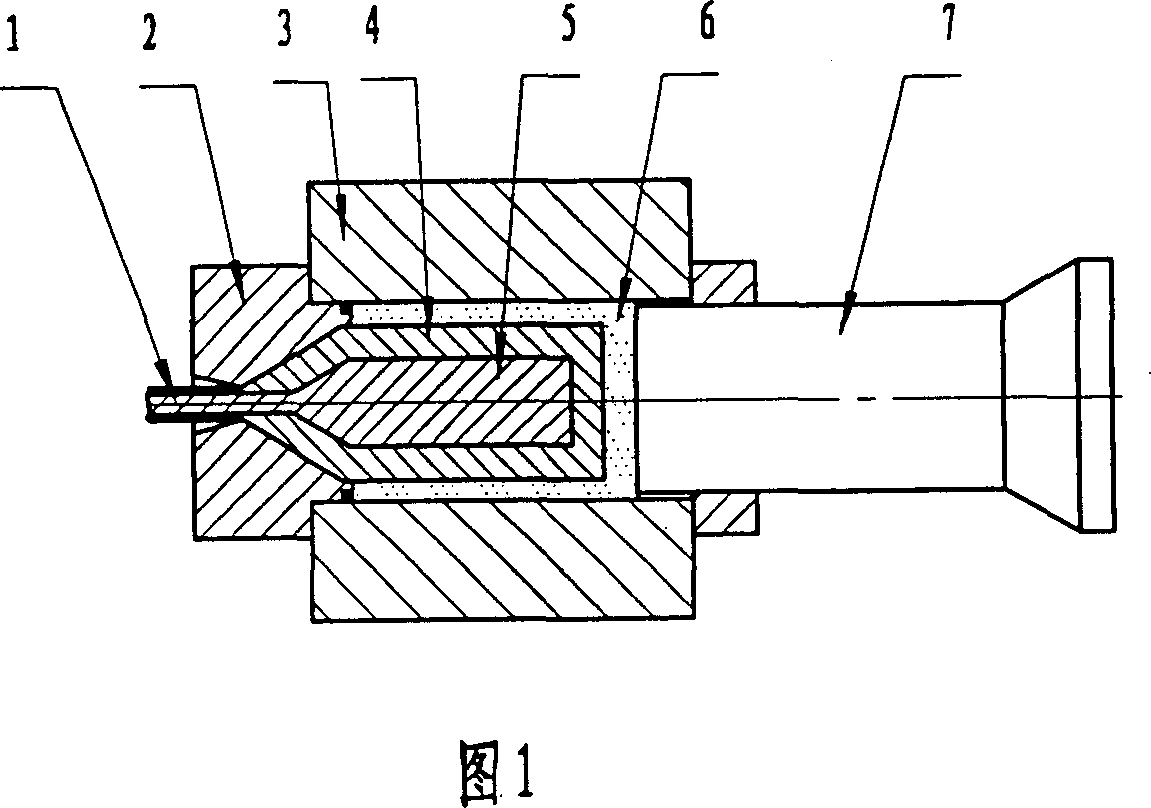

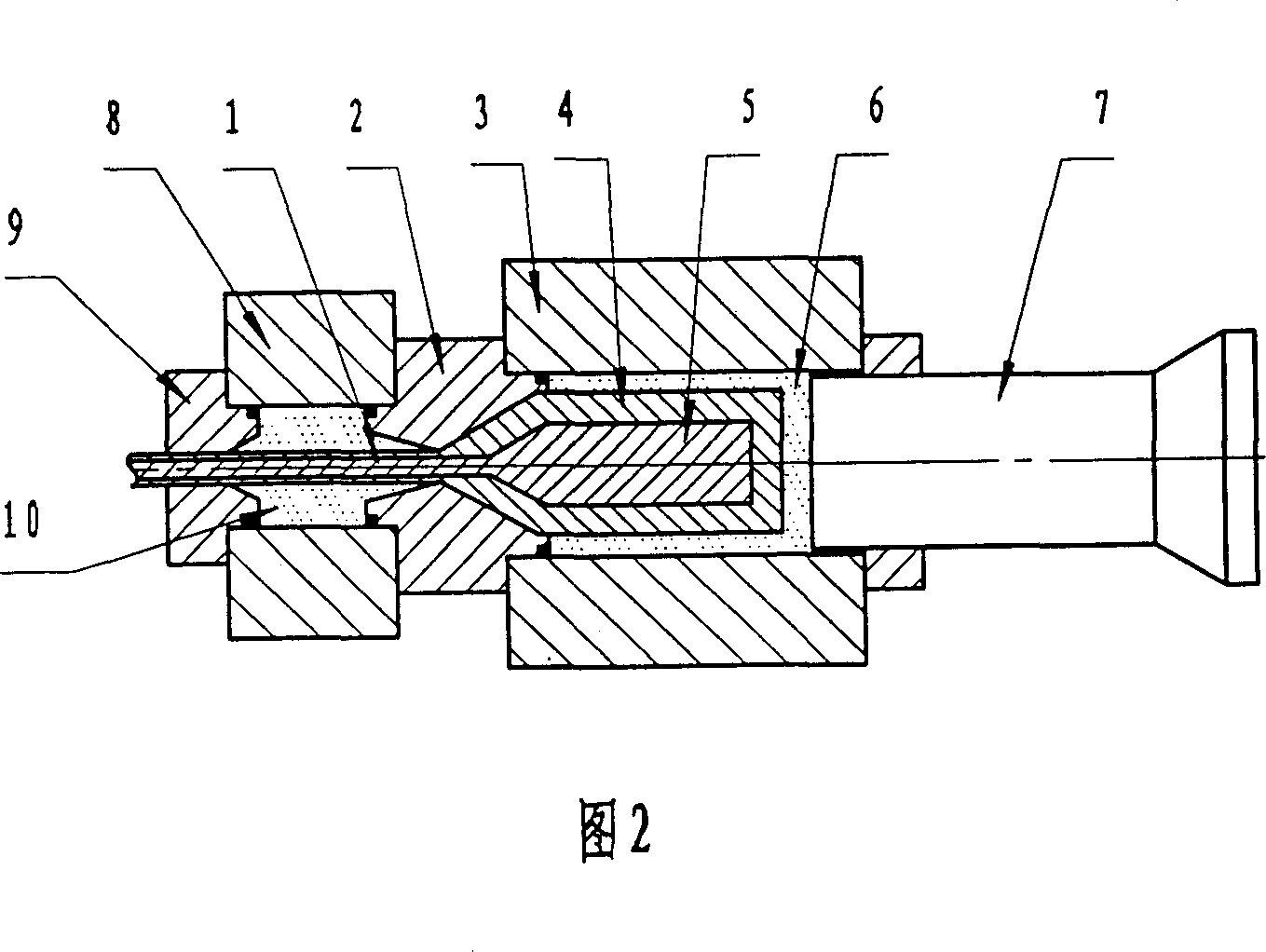

Method for producing pure copper high precision semi hollow section bar

InactiveCN1473671ASolve the strength problemGive full play to the range of plastic deformationCopper highHomogeneous deformation

The production process of high precision semi-hollow pure copper section bar includes extruding V-shaped blank in V-shaped hot extruding mold at about 850 deg.c and cold drawing in combined mold withlocating slot and core rod having hem. The V-shaped hot extruding mold has opening larger than that required in producing C-shaped section bar, and the combined mold is combined structure of separated core mold and outer mold with hem to make the blank enter to the mold cavity smoothly for homogeneous deformation. The drawn head is forged into size smaller than the aperture of the outer mold for penetrating through and is clamped with a clamp for drawing out to obtain finished product. The said method can produce section bar with precise and stable size and high strength in high yield.

Owner:董云伟

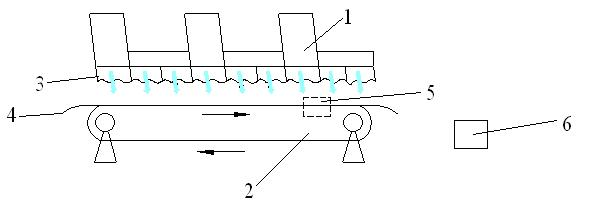

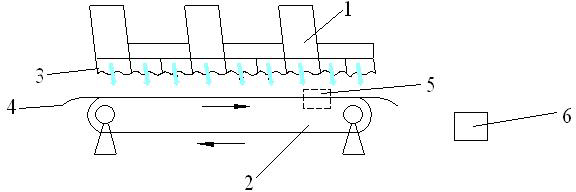

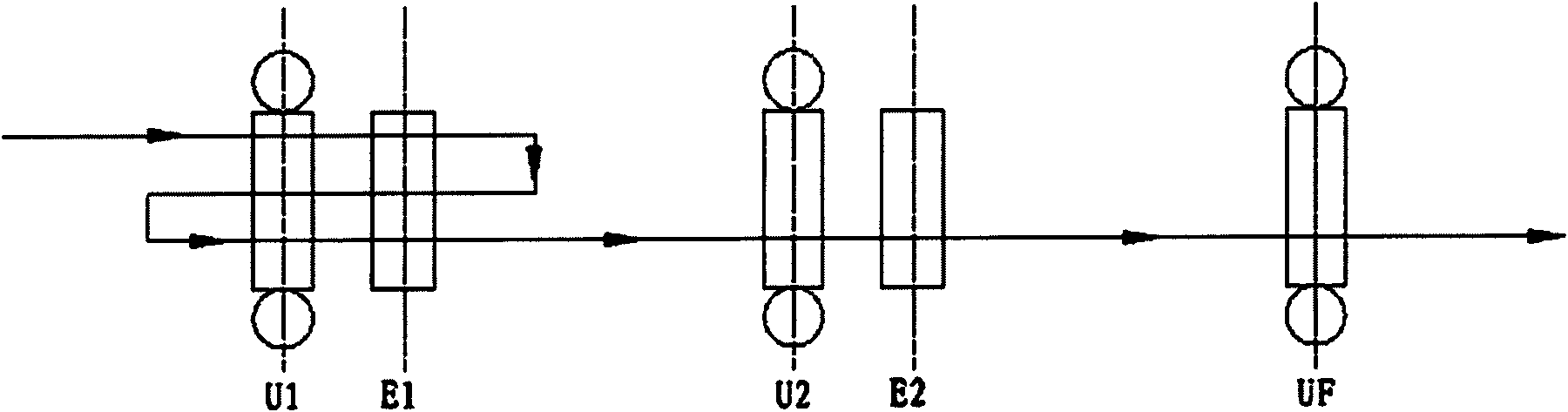

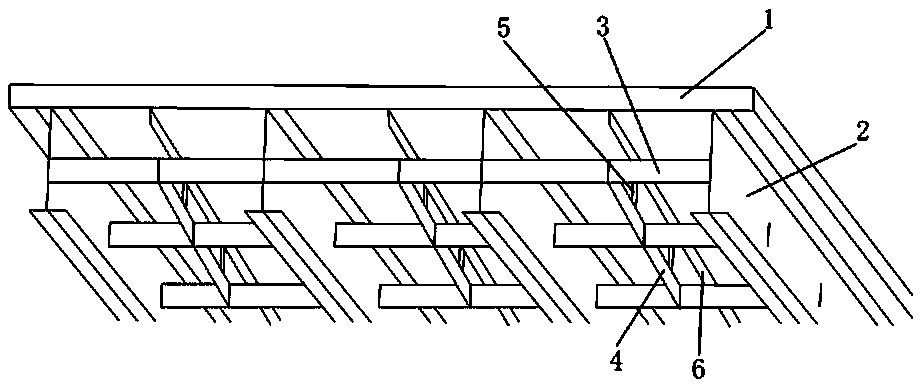

Microalloy non-quenched and tempered steel forging and cooling control technology and automatic production line

InactiveCN102397965AStability Control ForgingStable control processForging press drivesHeating/cooling devicesMetallic materialsInsulation system

The invention relates to a microalloy non-quenched and tempered steel forging and cooling control technology and an automatic production line, which belong to the field of metal materials processing, i.e., the forging deformation parameters and the post-forging cooling technology of the non-quenched and tempered steel are controlled, and the post-forging cooling technology is realized on a post-forging cooling control production line. The cooling production line consists of a cooling medium supply system, a power transmission mechanism, a temperature detection system, an industrial control computing system, a feed and discharge mechanism and a heat insulation system, can be manually and automatically operated according to the cooling velocity, the production cycle and the established procedure of non-quenched and tempered steel workpieces, and the ranges of the forging and cooling velocities can be adjusted. After the microalloy non-quenched and tempered steel forging and cooling control technology and the automatic production line are adopted, the phenomena of the uneven textures and performances of the non-quenched and tempered steel workpieces, the deformation and the like are eliminated, the problem of unqualified parts is solved, and the forging metallographical texture, the plasticity and ductility indicators, the production efficiency and the yield are improved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

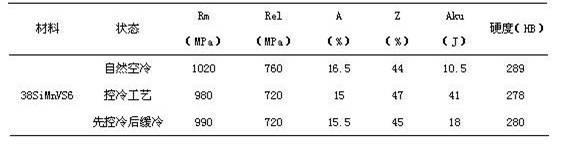

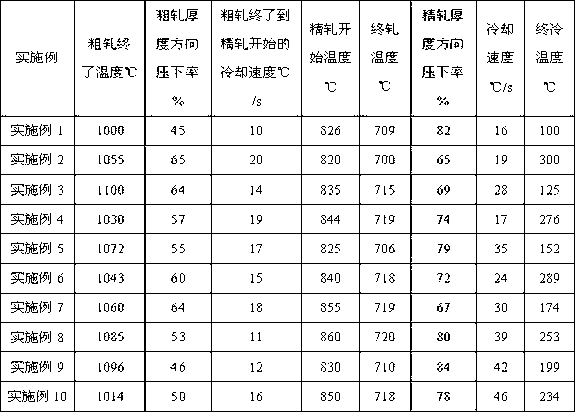

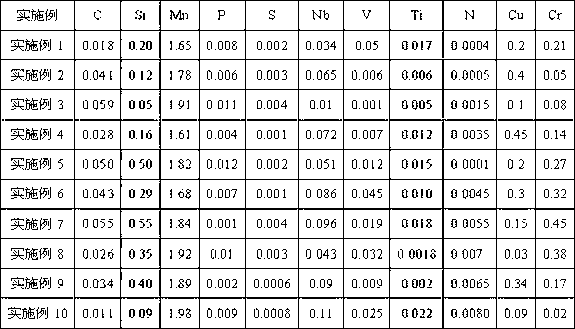

Manufacturing method of pipeline steel with high strength and toughness and high deformability

ActiveCN103160756AImprove toughnessImprove deformation abilityRoll mill control devicesMetal rolling arrangementsLine tubingYield ratio

The invention discloses a manufacturing method of pipeline steel with high strength and toughness and high deformability. The steel comprises the following components in percentage by weight: 0.01-0.06% of C, 0.05-0.55% of Si, 1.60-2.00% of Mn, not more than 0.012% of P, not more than 0.005% of S, not more than 0.11% of Nb, not more than 0.06% of V, not more than 0.025% of Ti, not more than 0.0080% of N, not more than 0.50% of Cu, not more than 0.50% of Cr and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: performing pretreatment of molten iron, smelting, refining and continuous casting to prepare a plate blank comprising the components in percentage by weight, being in line with the requirements; and manufacturing a steel plate through thermal mechanical control of rolling and control of cooling process so as to get the pipeline steel. The pipeline steel disclosed by the invention is very small in crystal grains and appropriate in soft phase-hard phase proportion and can get higher strength and toughness and excellent deformability under the situation of not containing Ni, Mo and other alloy elements and containing lower C content. The tensile strength Rm is not less than 695 and not more than 990, the yield ratio Rp0.2 / Rm is not more than 0.8, the uniform deformation elongation rate is not less than 5%, and the Charpy impact energy is not less than 300J. The pipeline steel disclosed by the invention is low in cost, and the obtained steel plate has the advantages of excellent deformability, strength, toughness and excellent welding performance.

Owner:NANJING IRON & STEEL CO LTD

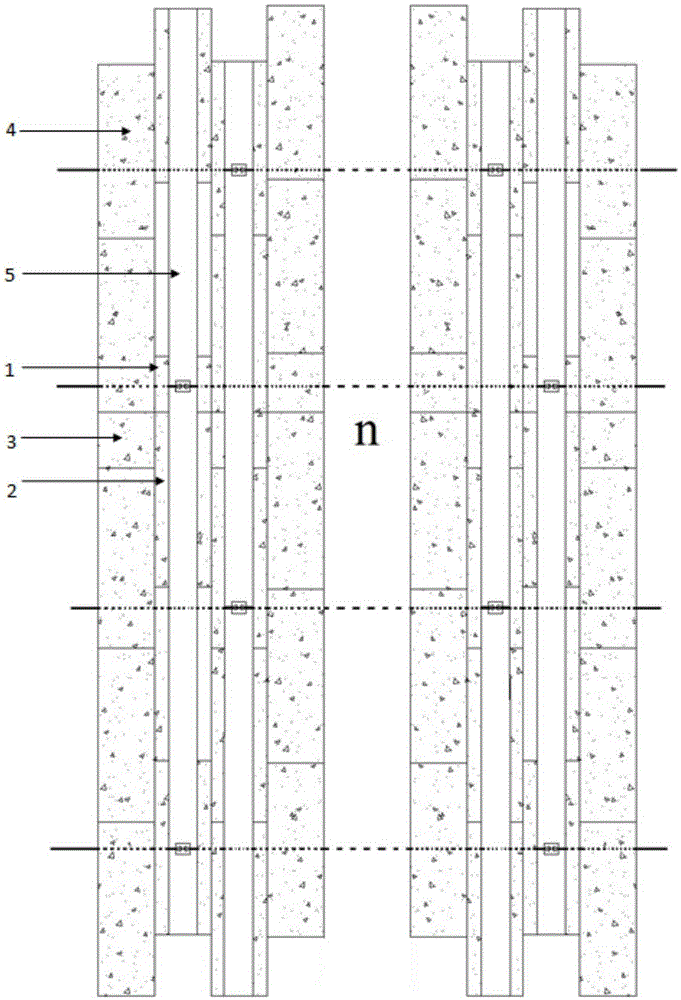

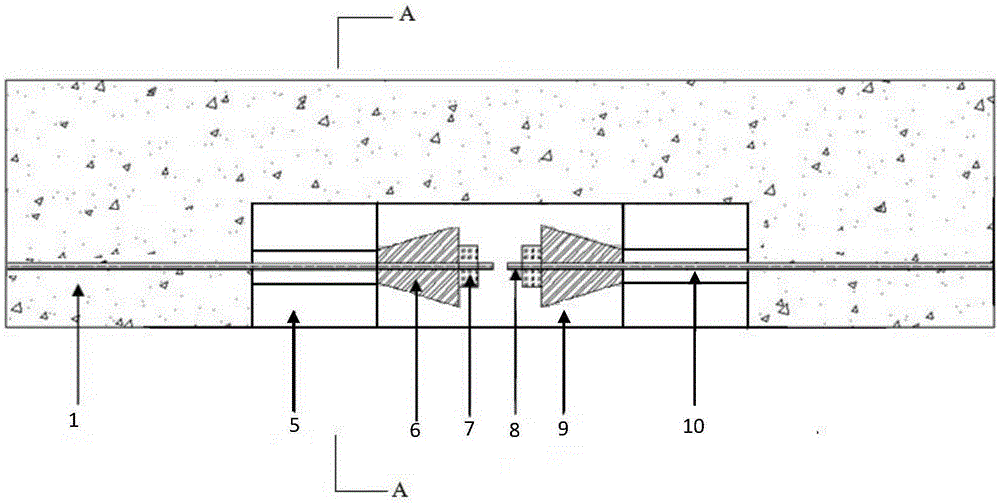

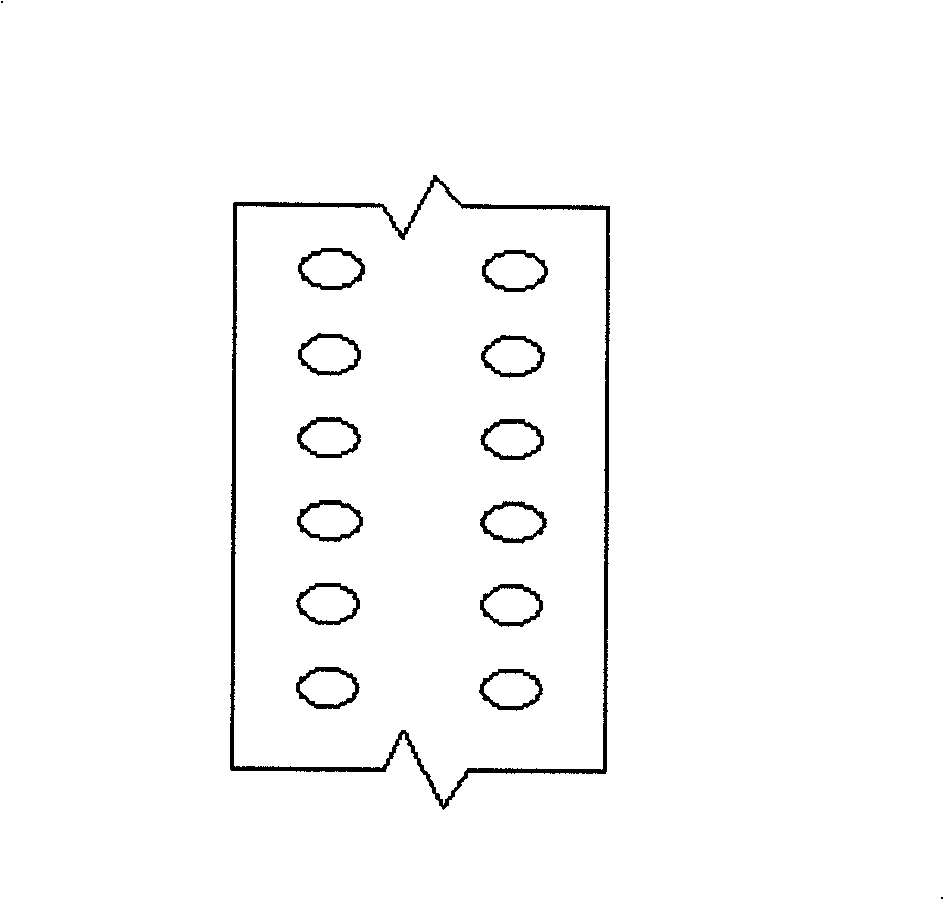

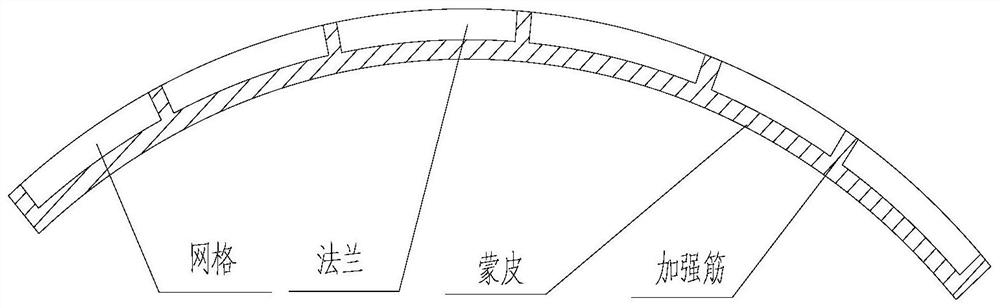

Shield tunnel duct piece both-way prestress strengthening device and construction method

ActiveCN105401957AAvoid DrawbacksTo achieve reinforcementUnderground chambersTunnel liningPre stressUltimate tensile strength

The invention discloses a shield tunnel duct piece both-way prestress strengthening device and a construction method. The device comprises a plurality of sets of combined duct pieces arranged in the circular direction, and at least one ring of special duct piece is arranged in the middle of each combined duct piece. A plurality of sets of ordinary duct pieces coaxial with the combined duct pieces are arranged between the adjacent combined duct pieces. A stress ring is embedded in each ring of special duct piece. Each stress ring comprises at least two sections of half stress rings. The two stress rings, the same in position, on every two adjacent combined duct pieces are connected through a fastening structure. The shield tunnel duct piece both-way prestress strengthening device has the beneficial effects that the stress rings are arranged in the circular direction of the duct pieces, the duct pieces are supported through the stress rings in the circular direction, and the strengthening of the duct pieces in the circular direction is achieved; in the longitudinal direction of the duct pieces, the duct pieces are tightly extruded through steel strands, and uneven longitudinal deformation of the tunnel duct pieces is limited; longitudinal and circular-direction strengthening is carried out on the duct pieces at the same time, a simply supported beam effect is formed through the duct pieces within a certain length range, the uneven settlement or uneven load resisting capability of the duct pieces is improved, and the strength of the shield tunnel duct pieces is improved.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

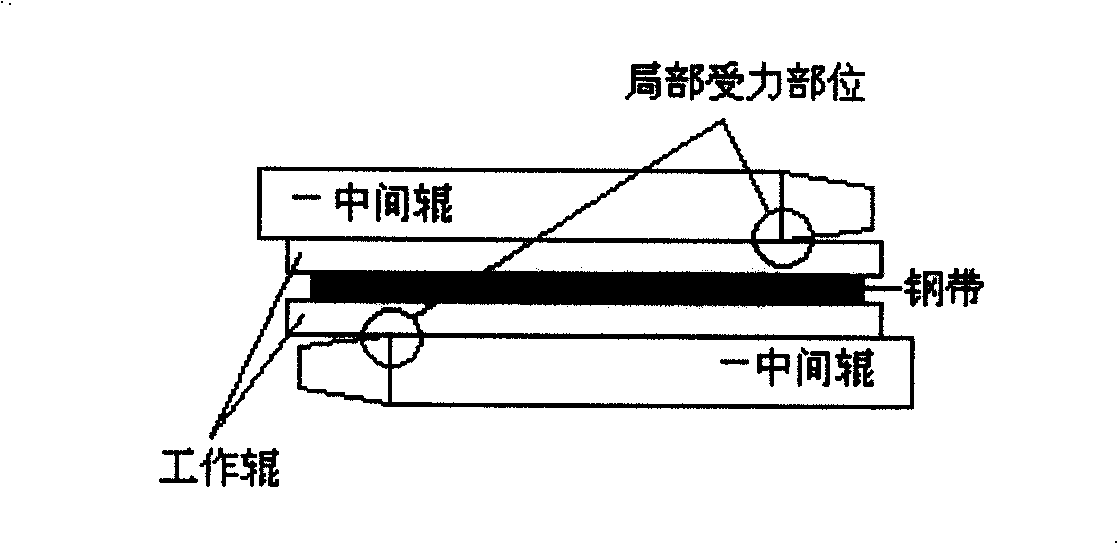

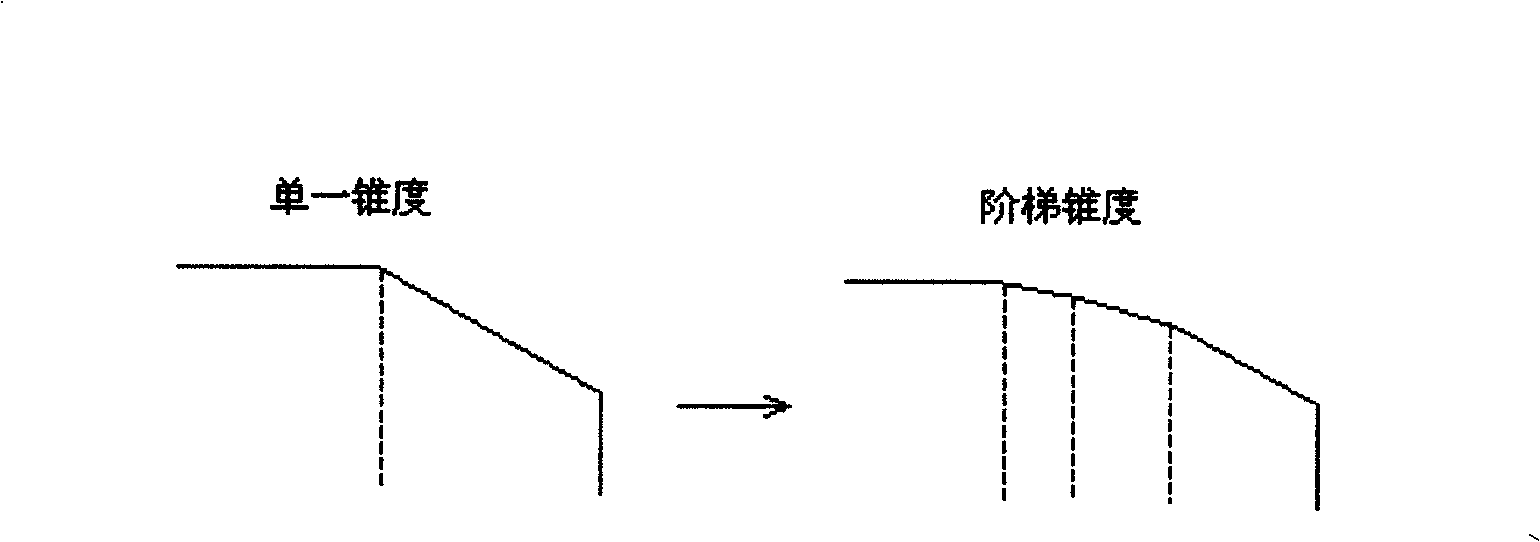

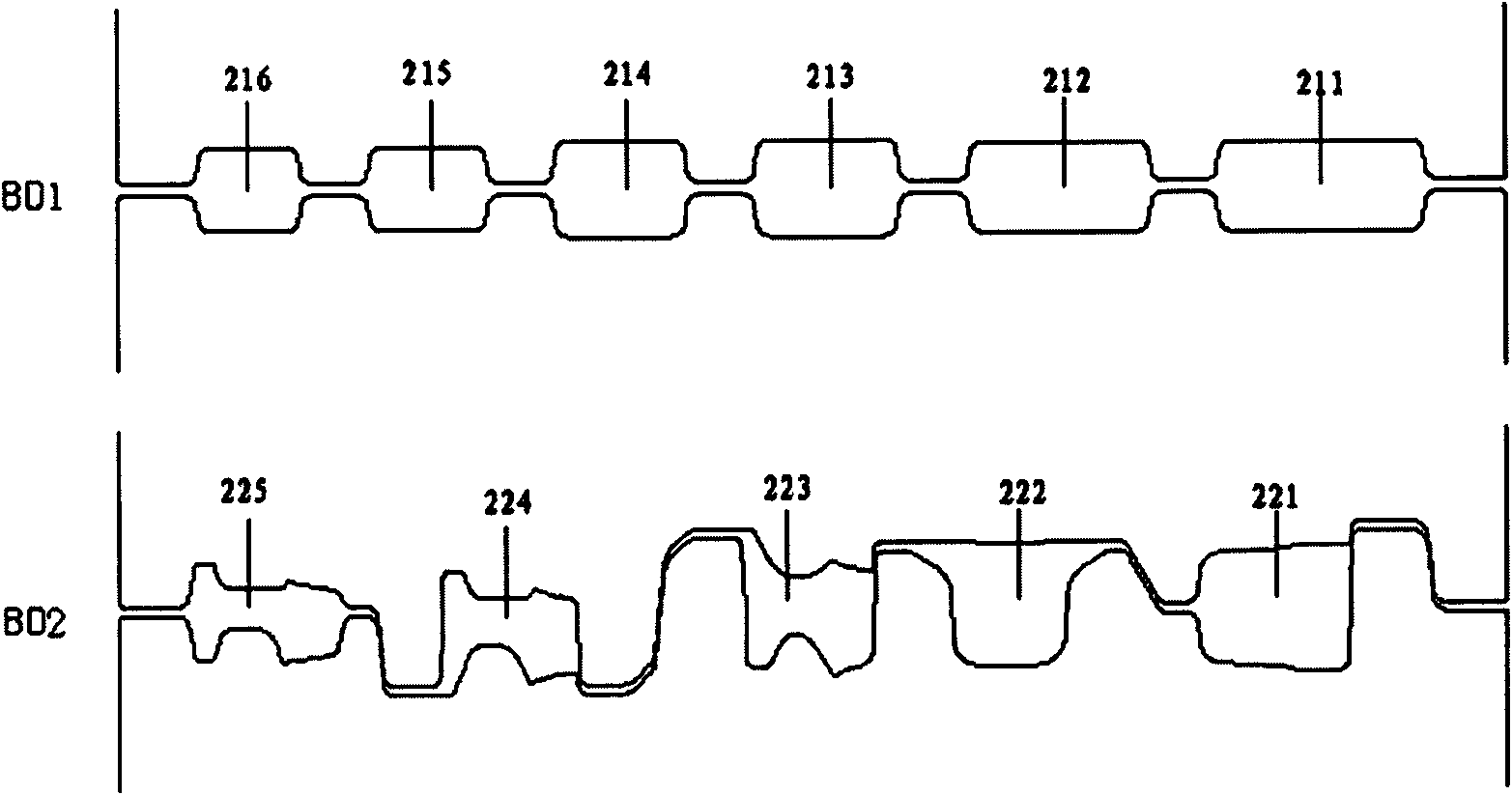

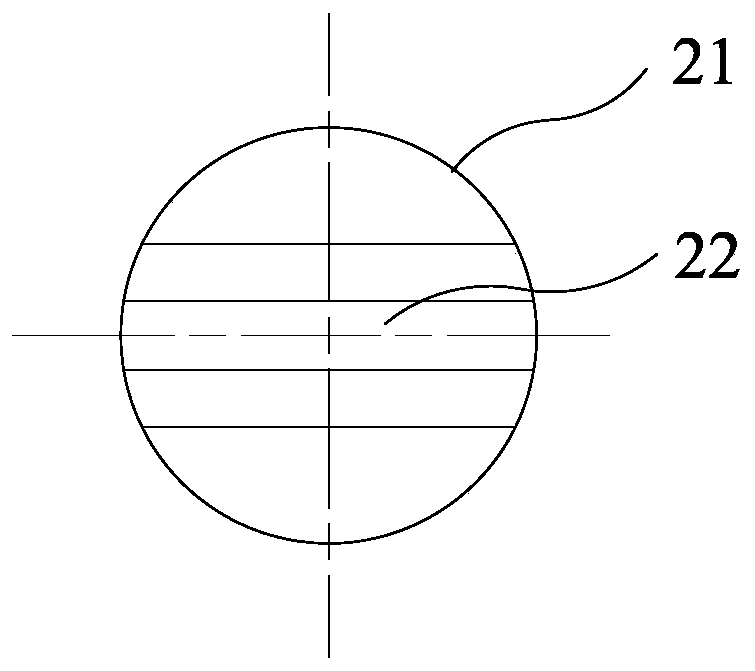

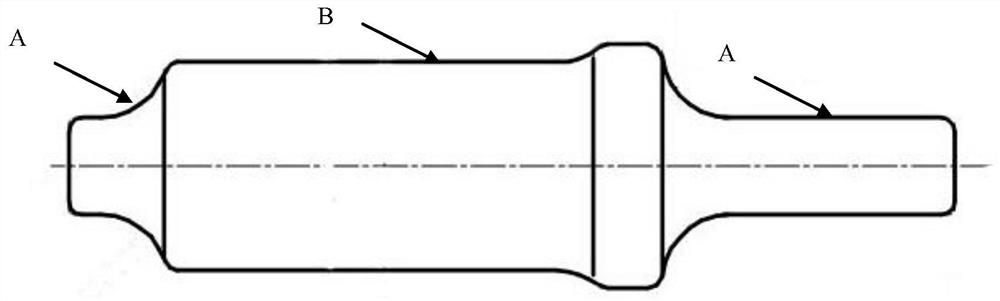

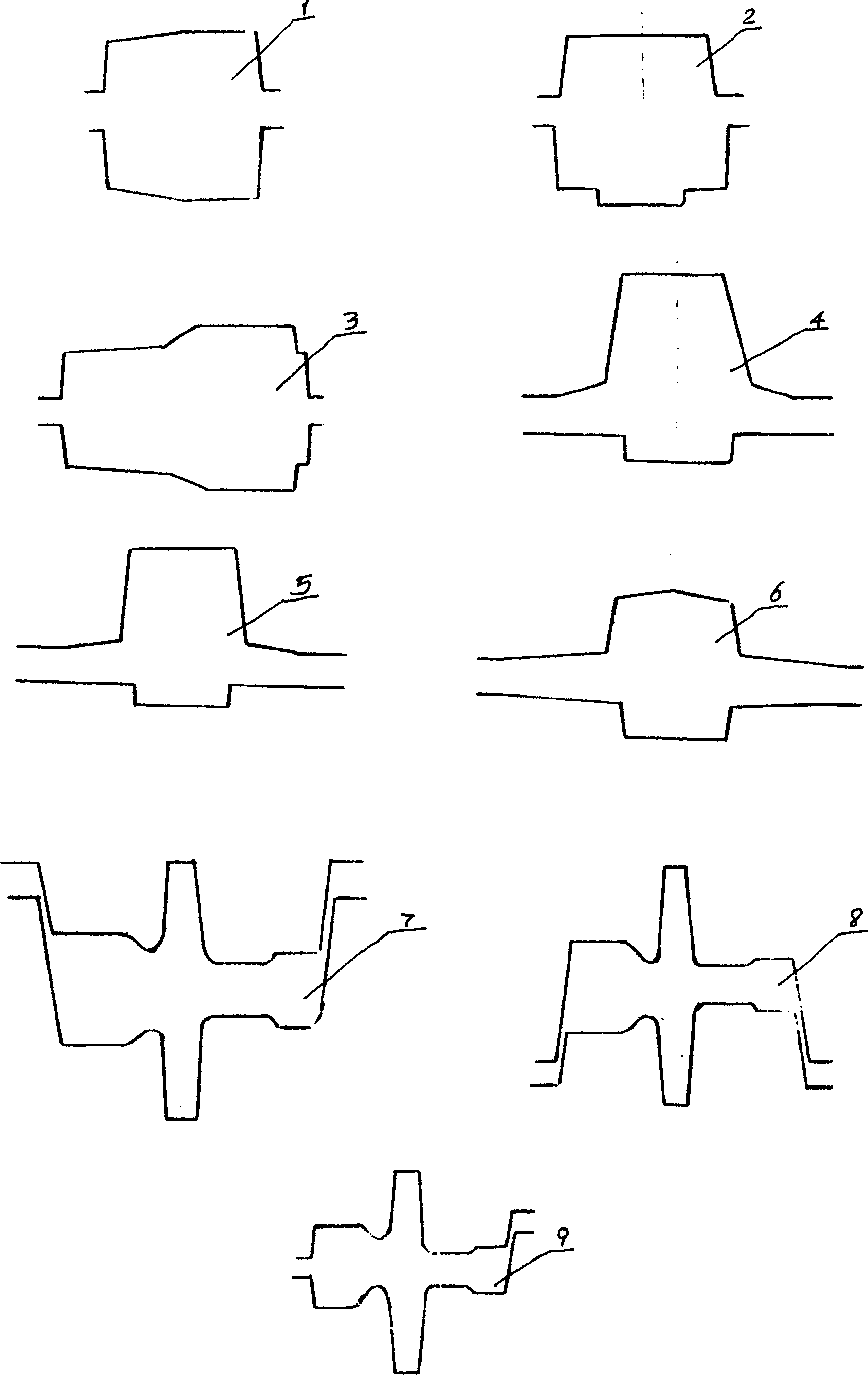

20 high mill intermediate roller cone

InactiveCN101259485ALess uneven deformationQuality improvementCounter-pressure devicesRollsEngineeringDouble stage

The invention relates to a middle roller cone of a twenty high rolling mill. The cone is a cone of multi-stage conicity and a double-stage conicity or third-stage conicity. The cone part of one middle roller of a twenty high rolling mill is improved by the invention, namely, the originally universal single conicity is improved into the double-stage conicity or the third-stage conicity; as the situation that part of a roller system is stressed too much is improved, the situation of uneven deformation of the corresponding position of a foil is lightened; a double-rib wave detect is eliminated; and the quality of the plate shape is remarkably improved.

Owner:NINGBO YONGZHENG PRECISION STAINLESS STEEL

Production line of special section wing rail and manufacturing method thereof

ActiveCN101642773AProduct quality is stableMeet construction needsGuiding/positioning/aligning arrangementsRoll mill control devicesManufacturing engineeringProduction line

The invention discloses a production line of special section wing rail and a manufacturing method thereof. The production line comprises a cogging mill and a universal machine set, and is characterized in that the cogging mill comprises an asymmetrical caliber which leads a working edge of a railhead of the special section wing rail is arranged toward the direction below a rolling line, support platforms are mounted on an upper guide and a lower guide at an outlet side of a second edger and a universal finishing mill of the universal machine set to control tapping torque. By adopting the invention, the problems such as reversing, bending and the like caused by uneven deformation due to the asymmetrical section of the special section wing rail can be effectively controlled, and the specialsection wing rail with a 75m length can be manufactured, which has stable product quality and can satisfy the requirement of high-speed railway construction.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

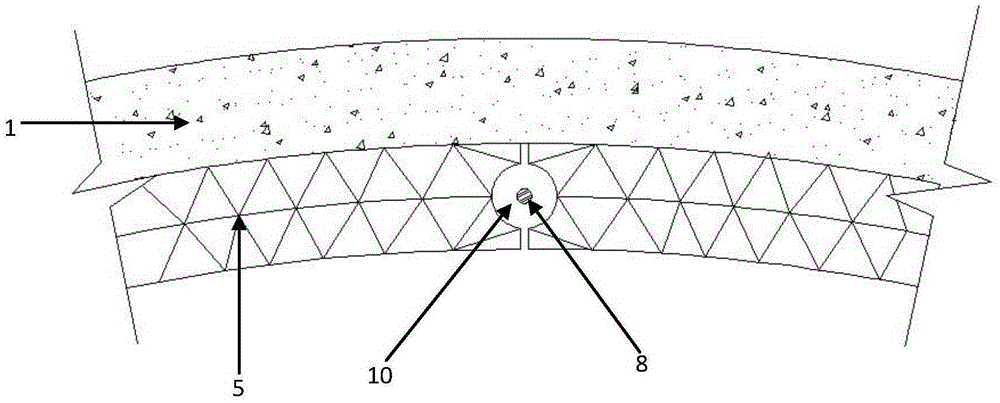

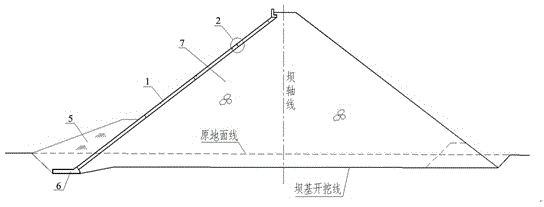

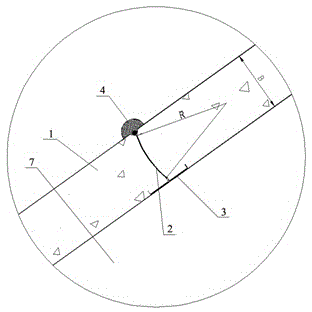

Method and structure for arranging horizontal structural joints on concrete face of rockfill dam

ActiveCN104131536ASolve deformation damageSolve the leakEarth-fill damsRock-fill damsArchitectural engineeringStructural engineering

The invention discloses a method and structure for arranging horizontal structural joints on a concrete face of a rockfill dam. According to the method and structure for arranging the horizontal structural joints on the concrete face of the rockfill dam, the concrete face is partitioned by section in sequence from bottom to top when the concrete face (1) is poured, and the horizontal arc-shaped joints (2) are arranged at the positions where the concrete face is partitioned; a plastic waterstop(4) is arranged on the outer surface of the concrete face (1) so that the outer ends of the horizontal arc-shaped joints (2) can be sealed, and a copper sheet waterstop (3) is arranged on the surface, in contact with a dam body (7), of the concrete face (1) so that the inner ends of the horizontal arc-shaped joints (2) can be sealed. According to the method and structure for arranging the horizontal structural joint of the concrete face of the rockfill dam, due to the facts that the horizontal structure joints are arranged on the concrete face and the arc-shaped joint structure is adopted, cracking, squeezing and fractureing, caused by serious uneven deformation, of the face which is in the direction perpendicular to the direction of the axis of the rockfill dam can be effectively avoided, the problem of deformation, the problem of fractures and leakage of the face of the rockfill dam can be well solved, and the reliability of the anti-leakage capacity of the concrete face of the rockfill dam is improved.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

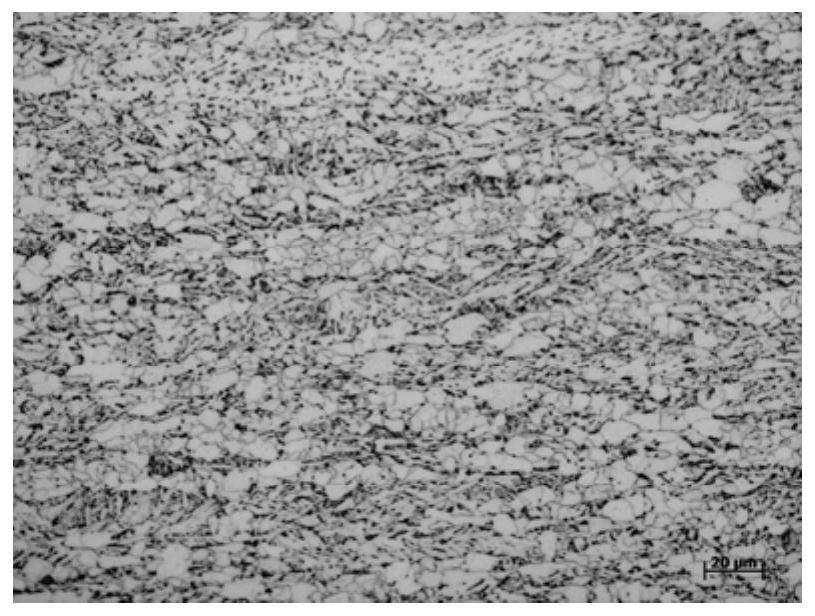

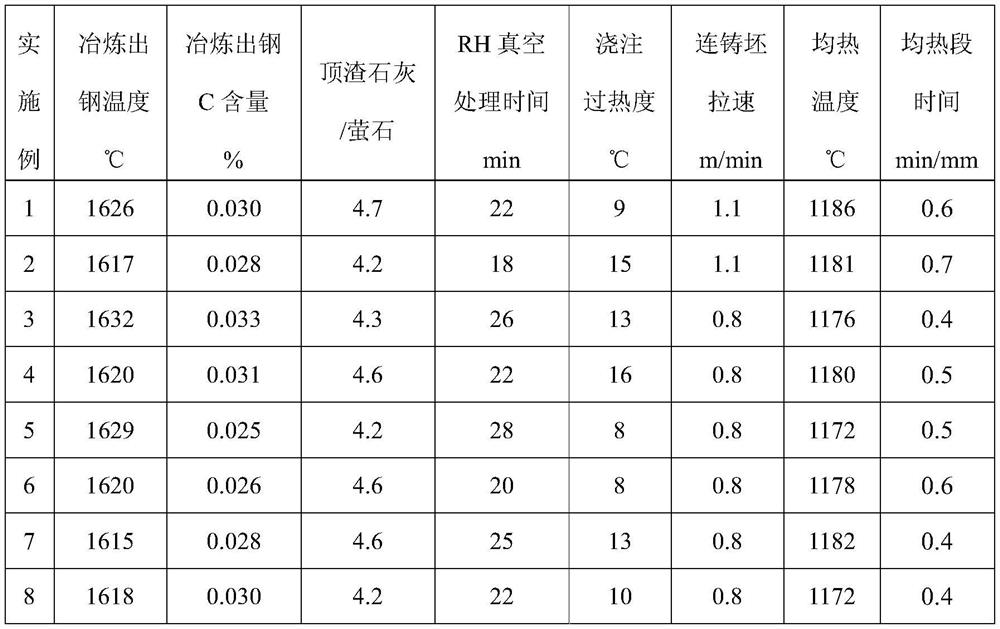

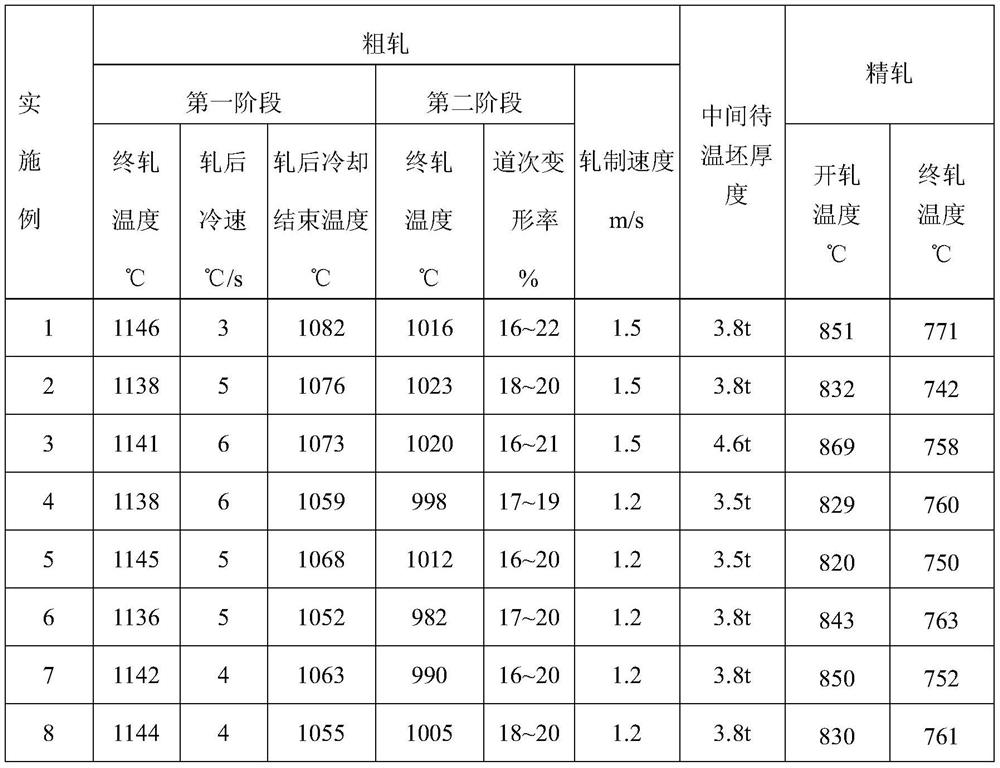

Corrosion-resistant and anti-fatigue pipeline steel for underwater oil and gas production and transportation and production method thereof

The invention provides corrosion-resistant and anti-fatigue pipeline steel for underwater oil and gas production and transportation and a production method thereof. The steel is prepared from the components including, by weight, 0.030%-0.055% of C, 0.26%-0.40% of Si, 1.10%-1.29% of Mn, less than or equal to 0.010% of P, less than or equal to 0.0015% of S, 0.035%-0.060% of Nb, 0.012%-0.025% of Ti, 0.01%-0.04% of V, 0.10%-0.19% of Ni, 0.16%-0.25% of Cu, 0.10%-0.19% of Mo, less than 0.25% of Cr, 0.010%-0.025% of Al, 0.0015%-0.0050% of Ca, 0.0010%-0.0040% of N, less than or equal to 0.00015% of H, less than or equal to 0.0020% of O and the balance Fe and inevitable impurities; the ratio of Ni / Cu is larger than or equal to 0.7, and the ratio of Ca / S is larger than or equal to 1.6. A pipeline steel plate contains 0.03%-0.09% by mass of carbonitride precipitates, and fine carbonitride precipitates with the particle size being 10 nm or below account for more than or equal to 30% of the total carbonitride precipitates. The steel plate produced from the steel has the comprehensive technical characteristics of thick wall, high strength, high toughness, low yield ratio, high uniform deformation rate, high stress ratio, excellent corrosion resistance, high fatigue strength and the like, and meets the requirements of manufacturing longitudinal submerged arc welded pipes for oil and gas production and transportation in underwater complex environments.

Owner:ANGANG STEEL CO LTD

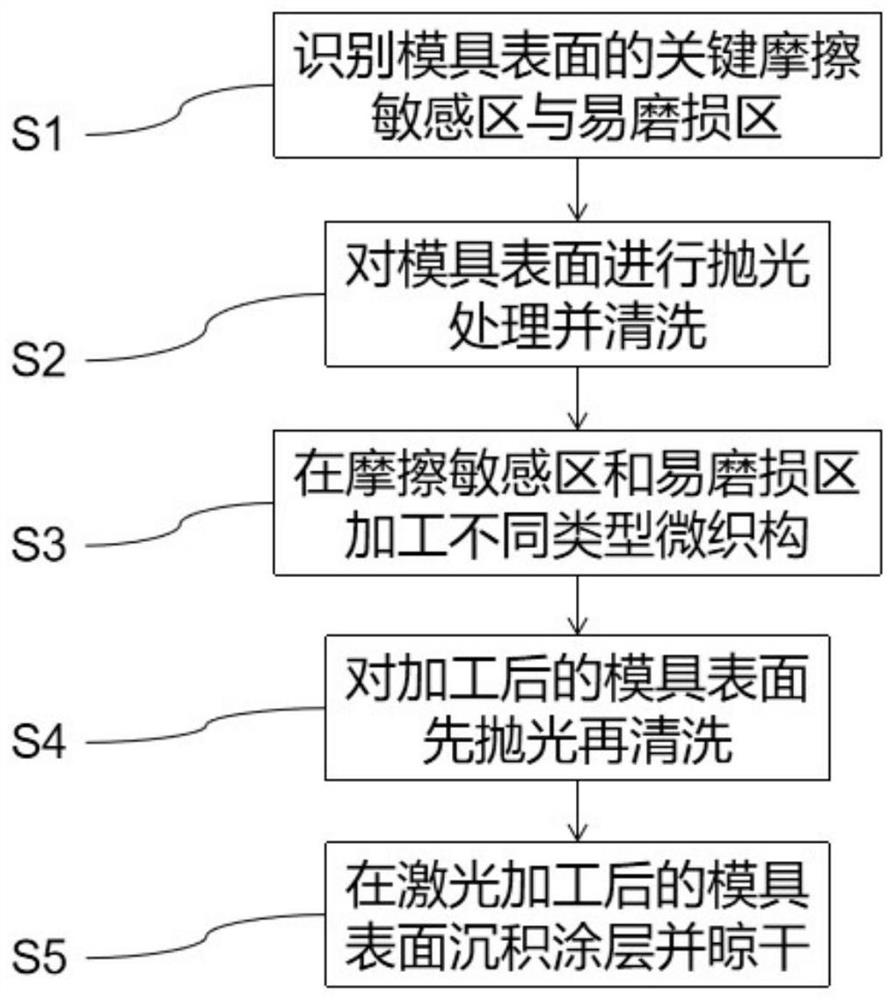

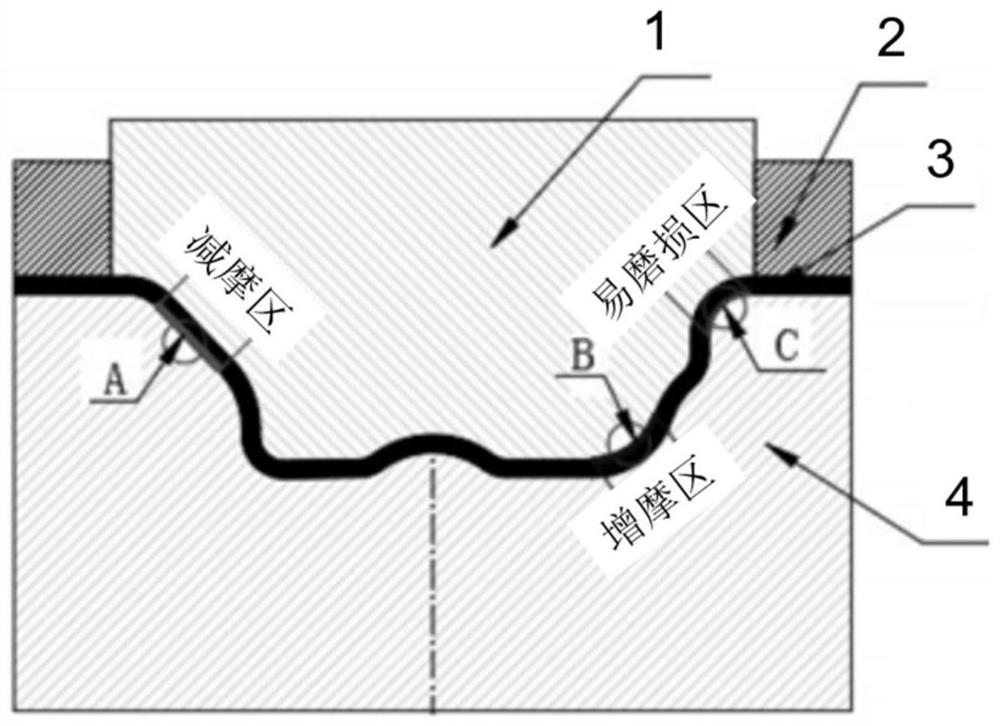

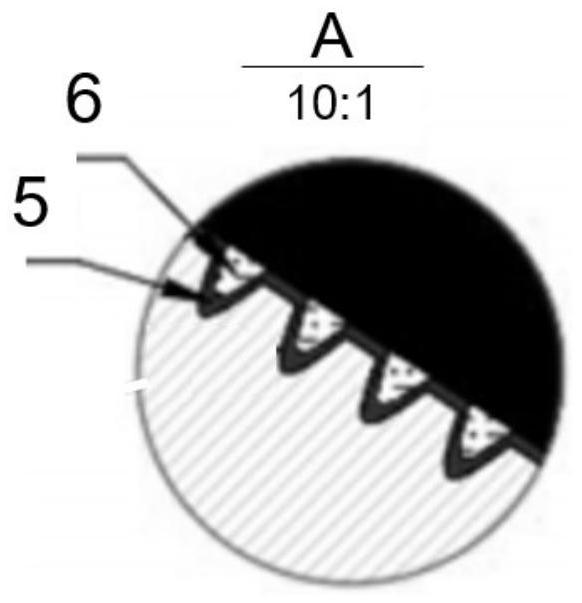

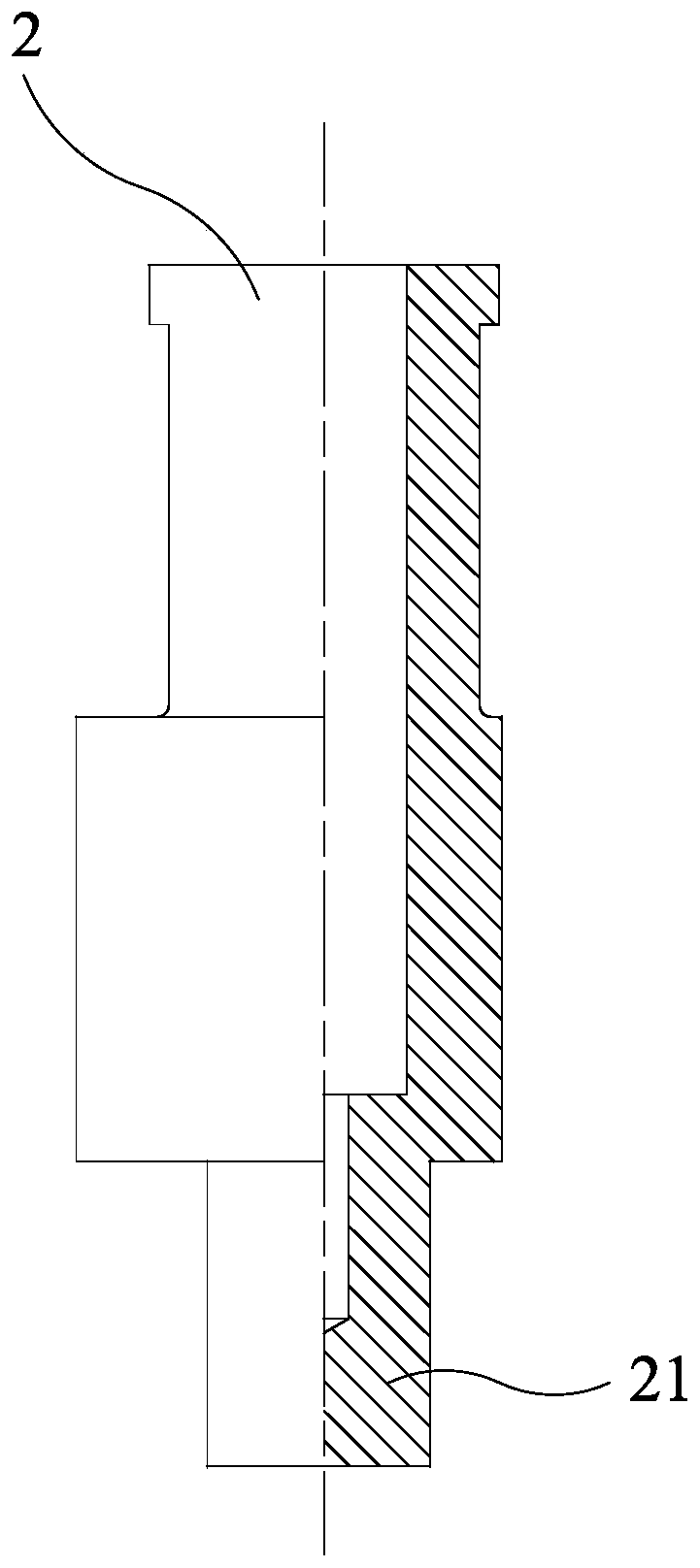

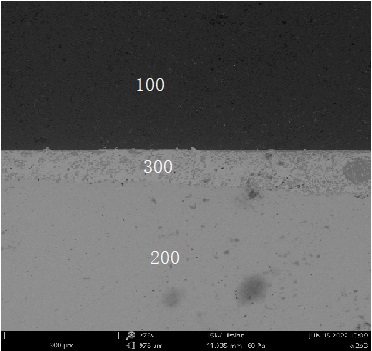

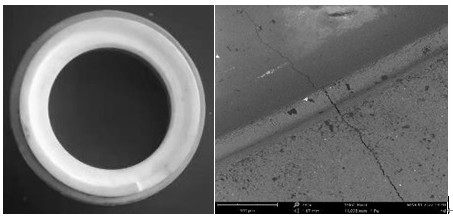

Stamping die surface treatment method with synergistic effect of laser microstructure and coating

The invention relates to a stamping die surface treatment method with a synergistic effect of a laser microstructure and a coating. The stamping die surface treatment method comprises the following steps that a key friction sensitive area and an easily-abraded area on the surface of a die are recognized; optimally matched spherical crown-shaped structure and concave structure machining is conducted on the surface of the die; and coating machining is conducted on the surface of the die, so that the coating of the key friction sensitive area of the die copies the structure morphology, and the coating of the easily-abraded area covers the structure morphology. The method has the beneficial effects that the die / workpiece interface friction characteristic is accurately regulated and controlled, the uneven deformation behavior of a workpiece material is inhibited, and the thickness uniformity of the workpiece is improved; the integrated gain effect of the structure and the coating is exerted, the mechanical engagement force of the coating and a base body is enhanced, and the service life of the die is prolonged; and the mechanical property of workpiece surface layer materials is improved, and workpiece surface scratches are prevented.

Owner:JIANGSU UNIV +1

Extrusion forming method for no-anisotropy magnesium alloy rods

ActiveCN110665984AImprove mechanical propertiesIncrease torsional deformationExtrusion diesEconomic benefitsInternal stress

The invention discloses an extrusion forming method for no-anisotropy magnesium alloy rods. The method relates to an extrusion forming mold for the no-anisotropy magnesium alloy rods; the mold comprises an insert, a convex mold connected with a press, a concave mold connected with a rotating mechanism, and an ejecting mechanism; a molding cavity is formed in the concave mold, and is provided witha feed port; an extrusion working belt is arranged in the molding cavity; and the insert is mounted on the extrusion working belt. The torque is applied based on traditional extrusion; the rotating lap number can be increased through change of the rotating speed, so that the gradient structure is improved under rotating formation, and the uniform deformation of the structure is realized; the higher shearing strain is generated through change of internal stress and strain states of a deformation body to form a fine crystal structure with large-angle grain boundary, so that the anisotropy of components is reduced; and insert can be timely replaced after wear to prevent the cost increment of the scrapped concave mold, so that the mold life is prolonged, and the popularization and economical benefit in the forging industry is prominent.

Owner:ZHONGBEI UNIV

Production method of heavy plate of X80 level large-deformation resistance pipe line steel

InactiveCN101456034BReduce manufacturing costGrain refinementTemperature control deviceWork treatment devicesDouble phaseYield ratio

The invention relates to a method for producing an X80 grade large deformation resistant pipeline steel medium plate. The economic component design with low carbon is adopted to perform controlling and rolling stages on ingot, namely rolling the grain refined zone and the non grain refined zone. The method comprises: firstly, air cooling and relaxing after finished rolling is performed so that the temperature of a steel plate before entering water and cooled is reduced below the phase change point Ar3 between 30 and 50 DEG C, and 50 to 70 percent of austenite in the relaxing process is converted into proeutectoid ferrite; and secondly, laminar flow cooling is performed on the steel plate within the range of the cooling speed between 20 and 35 DEG C per second, the finished cooling temperature is controlled within the range of between 250 and 400 DEG C; and in the water cooling process, the remaining austenite is converted into bainite structure, and proeutectoid ferrite + bainite double-phase structure is obtained. The intensity and the plasticity index of the finished product satisfy the following requirements: the yield strength Rt0.5 is 530 to 630MPa, the intensity of tension Rm is 625 to 825 MPa, the yield ratio Rt0.5 / Rm is less than or equal to 0.80, and the homogeneous deformation tensile stretch UEL is more than or equal to 10 percent.

Owner:UNIV OF SCI & TECH BEIJING

Scientific injection molding visualization technology

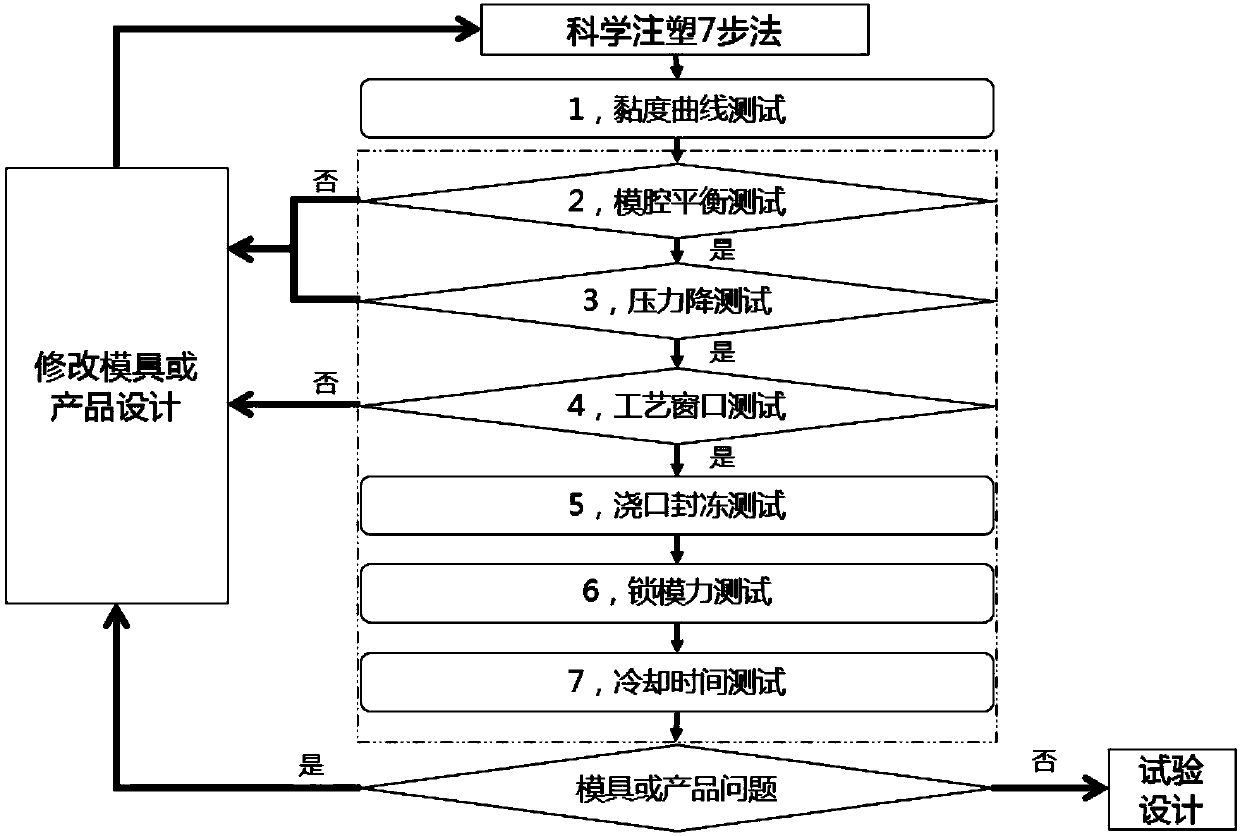

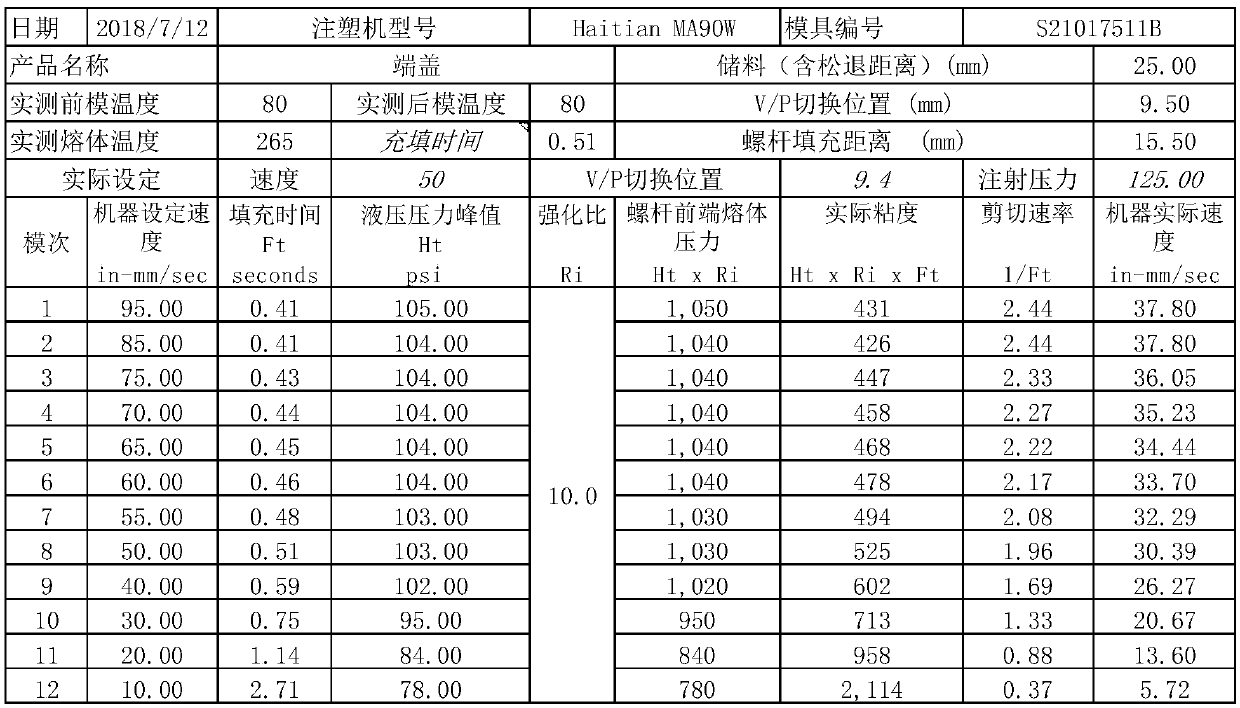

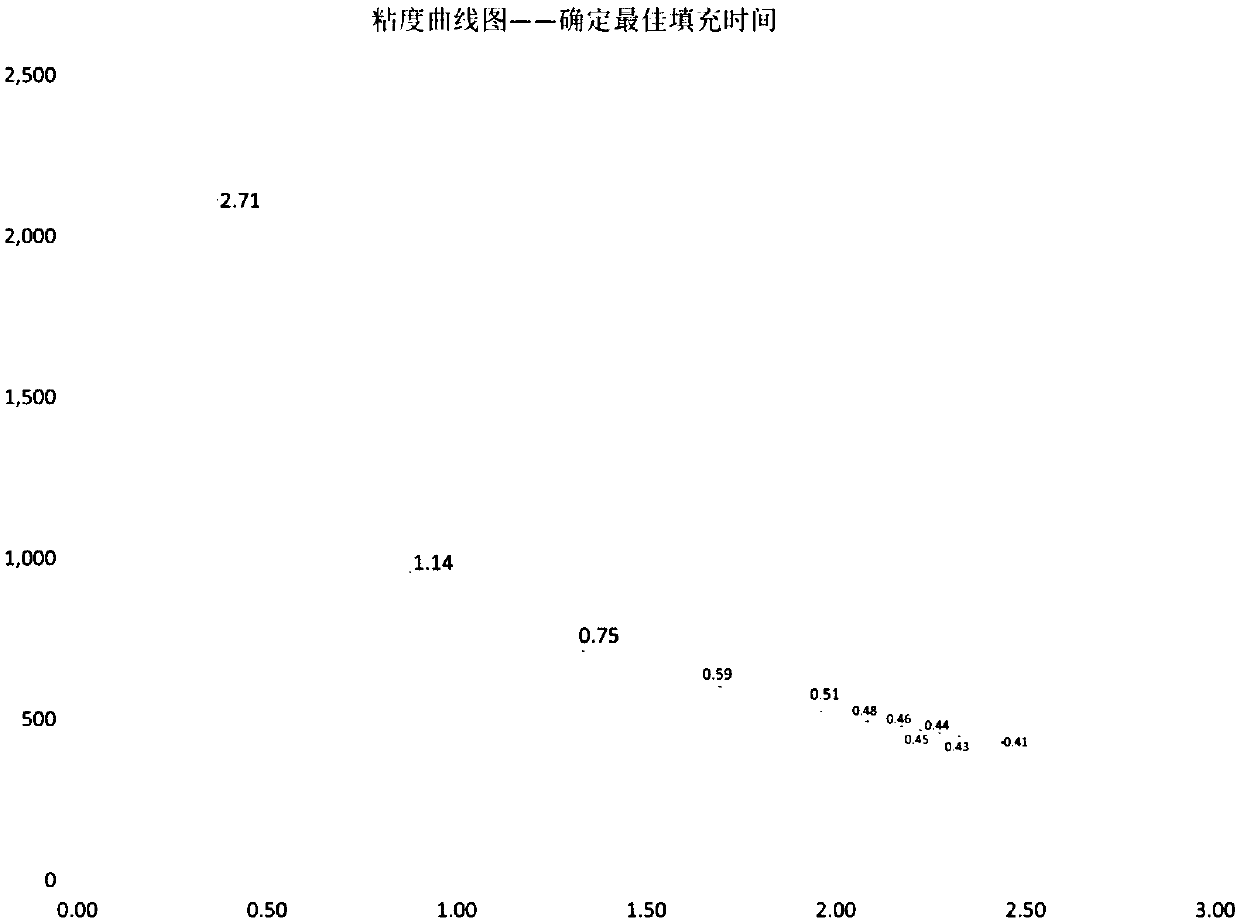

The invention provides a scientific injection molding visualization technology which comprises a design stage, a mold testing stage and a volume production stage. In the design stage, the product structure and mold design can be optimized through mold flow analysis technology (CAE emulation technology). In the mold testing stage, injection molding technological parameters are gradually tested andoptimized through a scientific injection molding seven-step method, the scientific injection molding seven-step method comprises viscosity curve testing, mold cavity balance testing, pressure drop testing, process window testing, sprue freezing testing, clamping force testing and cooling time testing, and scientific and reasonable injection molding technological parameters can be obtained throughthe scientific injection molding seven-step method; by means of staged injection molding forming technology, products which are more even in volume shrinkage rate, smaller in deformation and more stable in production are obtained; and by means of mold cavity pressure and temperature measure technology, the injection molding forming technology is optimized, real-time quality monitoring is conductedon injection molding production, and thus, unmanned automatic injection molding production is achieved.

Owner:苏州万库信息技术有限公司

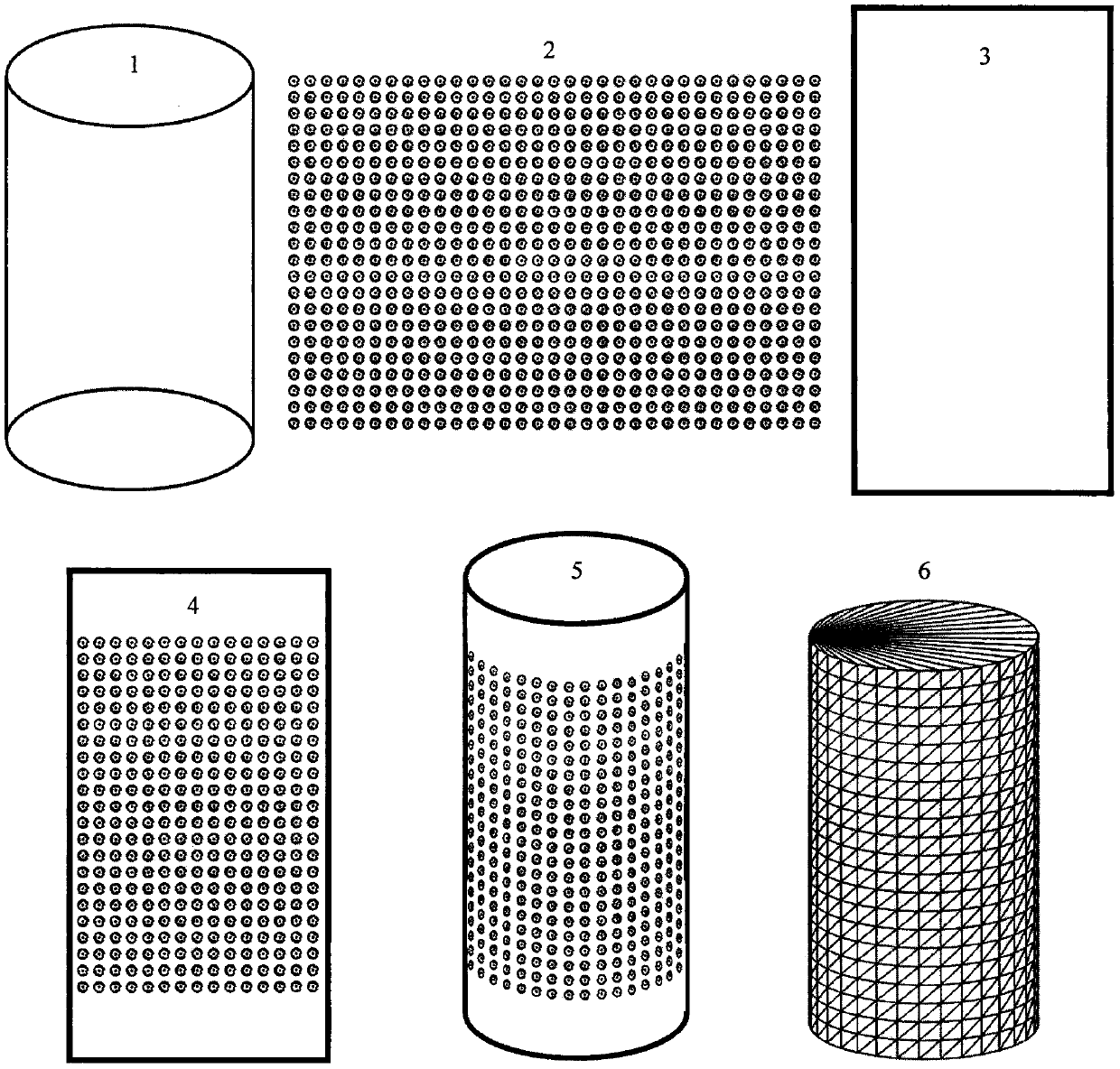

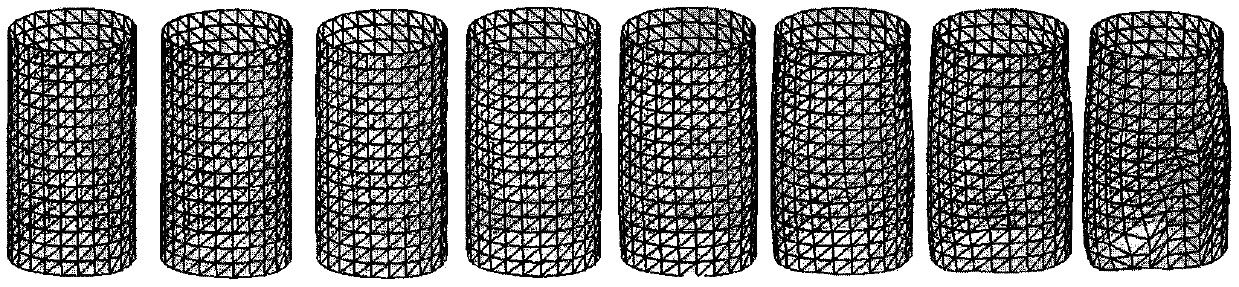

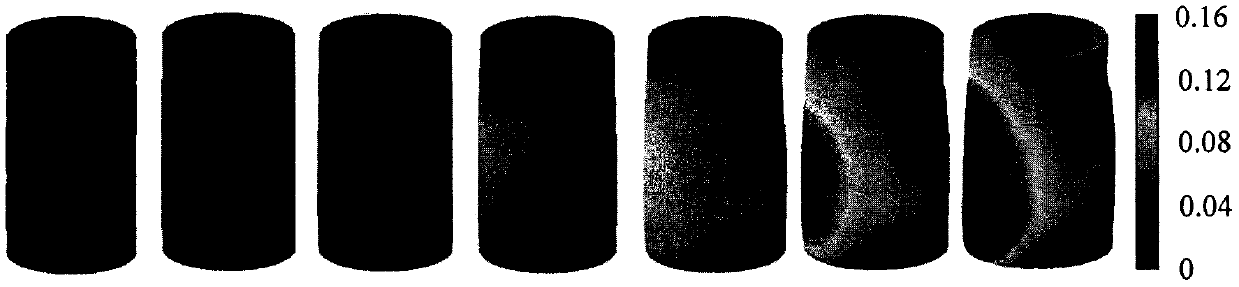

Method for automatically acquiring volume and strain cloud diagram of cylindrical test piece in loading process

PendingCN110715855ASolving the challenge of deformation measurementLow costImage analysisPreparing sample for investigationMarking outEngineering

The invention provides a method for automatically acquiring the volume and a strain cloud diagram of a cylindrical test piece in loading process. According to the method, a mark point matrix which canbe identified by software only needs to be arranged on the surface of a rubber film for wrapping the cylindrical test piece, a photogrammetry method is used for obtaining the three-dimensional positions of all marked points before, during and at the end of an experiment, and through the initial position analysis of the mark point matrix before the experiment, a triangular mesh is automatically established and further calculation is performed to obtain the volume and the strain cloud diagram of the test piece in different forms. The method has the main advantages of low cost, simple operation,clear logic, high accuracy and high efficiency. According to the method, the problem of deformation measurement of the test piece of the stress-strain test experiment is solved, and a reliable and effective tool is provided for in-depth analysis of the uneven deformation of the test piece and the effect of the uneven deformation on the stress-strain characteristics of materials.

Owner:NANJING FORESTRY UNIV

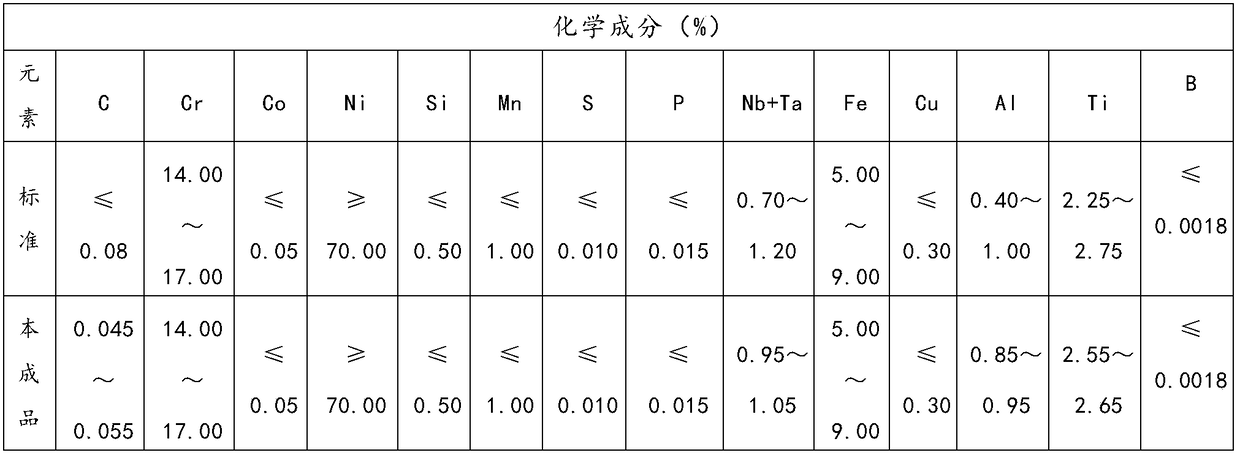

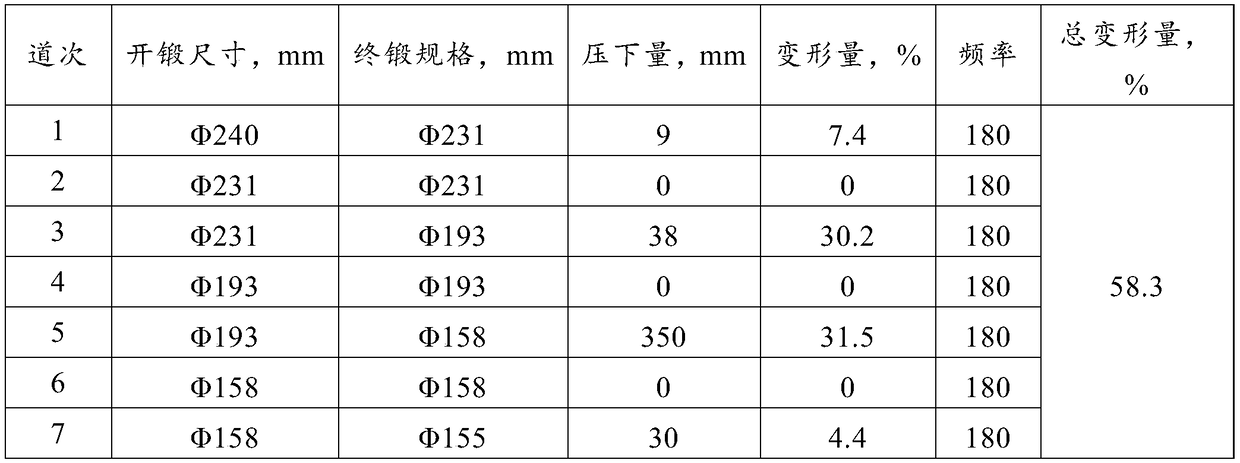

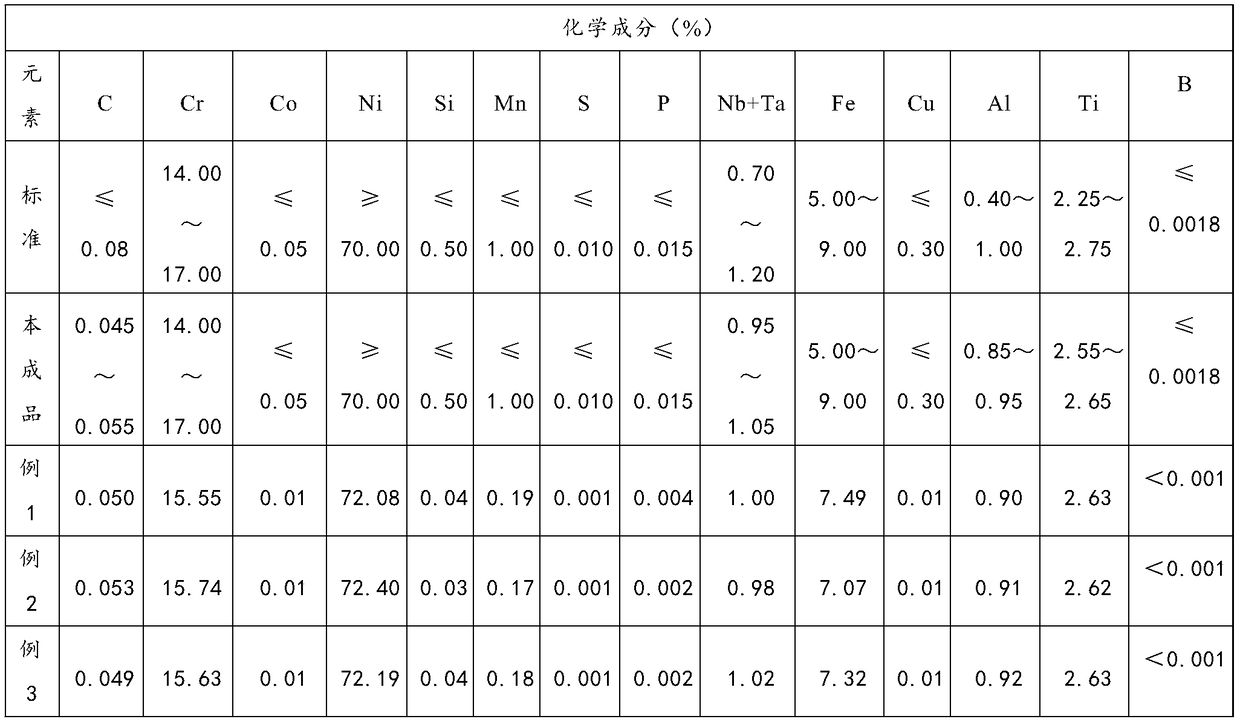

Manufacturing method for rolled products for nuclear grade in-pile U-shaped embedded part locating pins

The invention discloses a manufacturing method for rolled products for nuclear grade in-pile U-shaped embedded part locating pins, and aims to obtain the rolled products with uniform, fine and small-range grain structures and qualified tensile properties. The composition proportion is optimized; 3150-ton fast forging large deformation amount and single hammer reduction amount cogging is adopted, and four hammers are adopted in a 1800-ton diameter forging machine to achieve isothermal forging; the finished product rolling heating temperature is controlled at 1160 DEG C to 1180 DEG C, and secondary carbide and a gamma' strengthening phase generated by an alloy are re-dissolved, so that dynamic recrystallization of grains in the final rolling process is more uniform; small deformation mount quick rolling is adopted for the final-heating number rolling of finished products, it is guaranteed that all heating number rolling deformation is controlled to be uniform, the deformation amount is between 30% and 50%, the roller rotating speed is increased, and it is ensured that the final forging temperature is not lower than 950 DEG C. The manufacturing method has the beneficial effects that the carbon content is appropriately controlled, alloy elements such as aluminum, titanium and niobium are highly controlled, the hammer cogging and rolling processes are reasonably controlled, and thealloy rolled products with the uniform grain size structures and excellent performance are manufactured.

Owner:FUSHUN SPECIAL STEEL SHARES

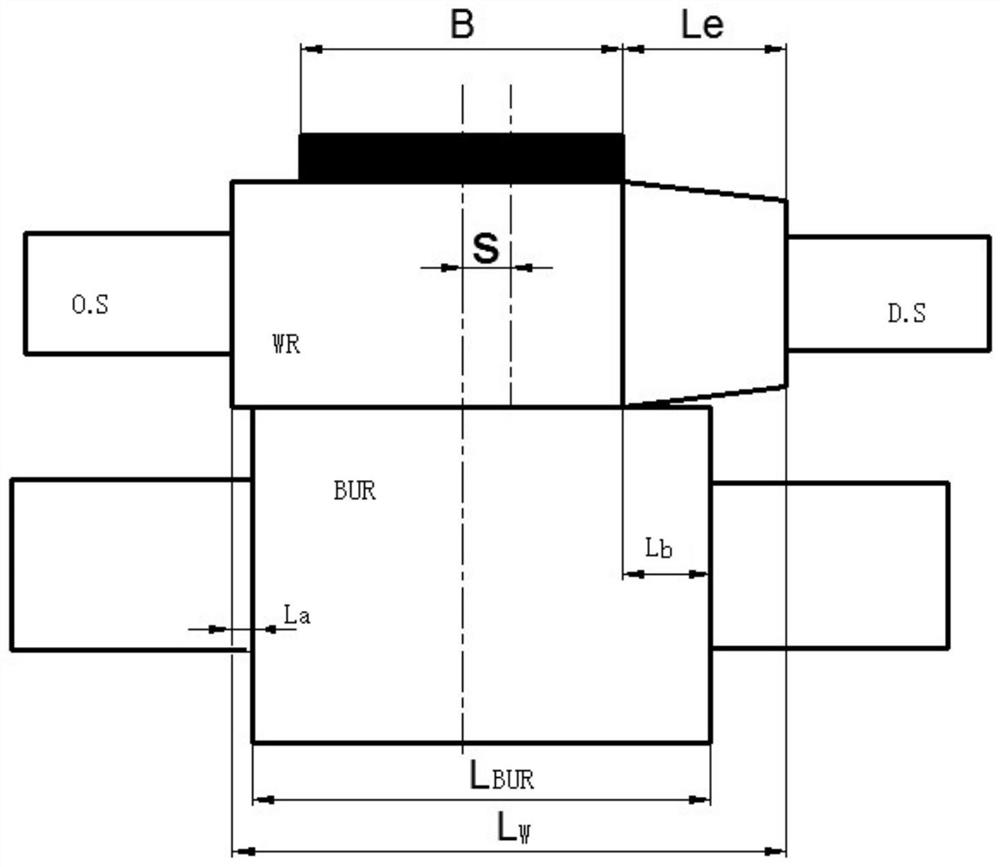

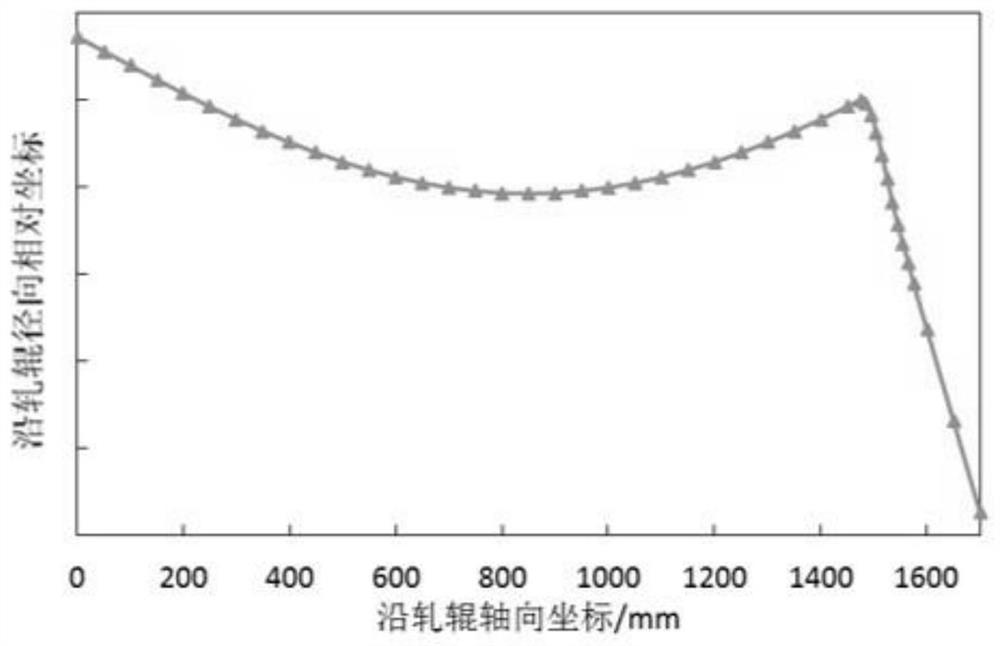

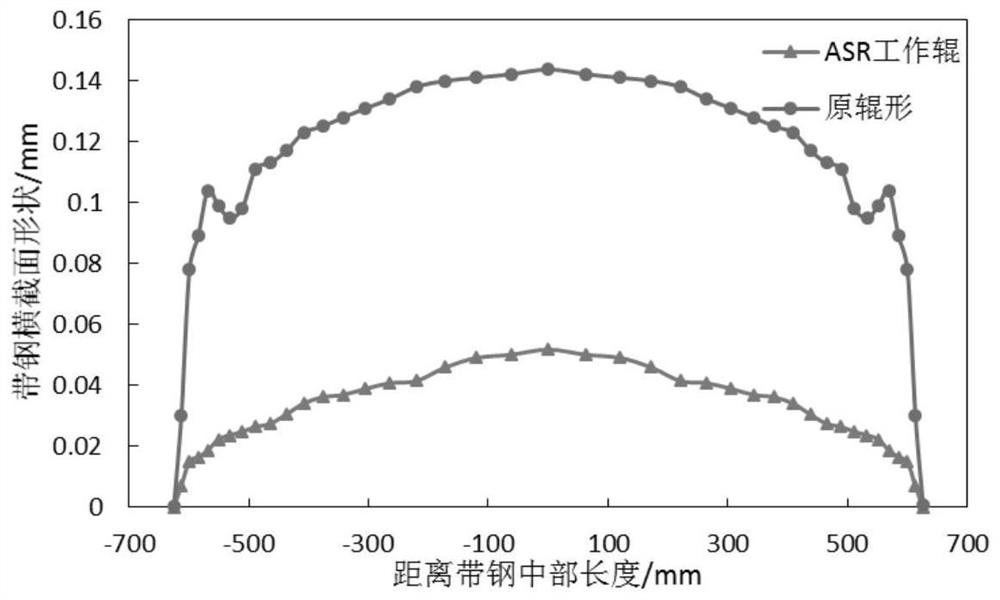

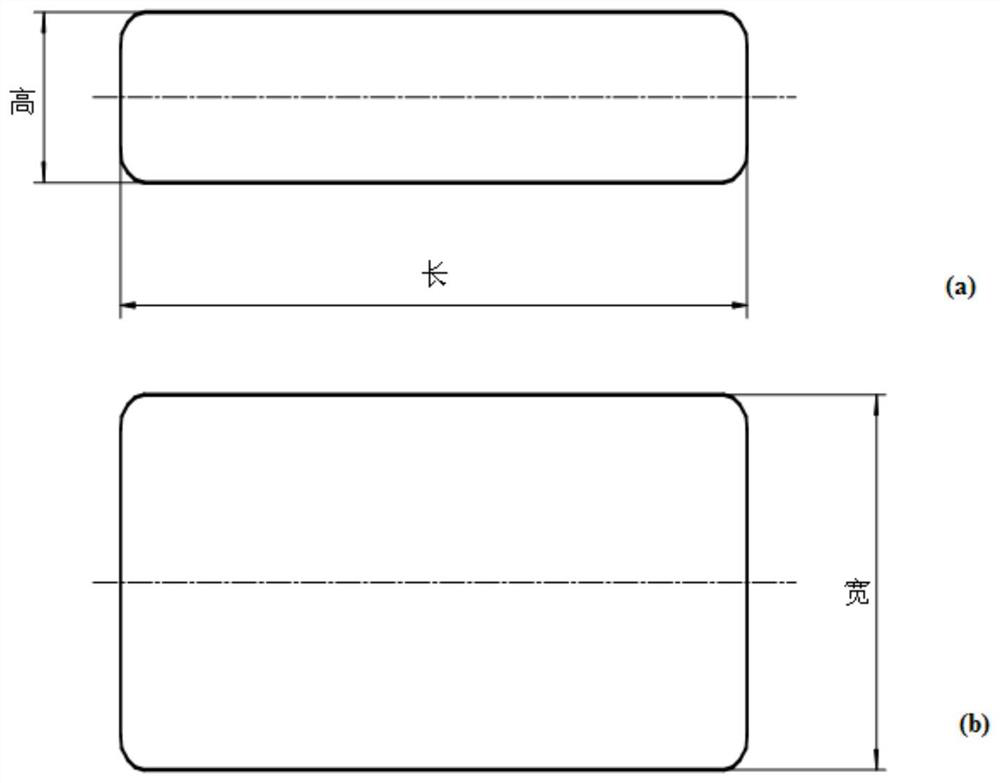

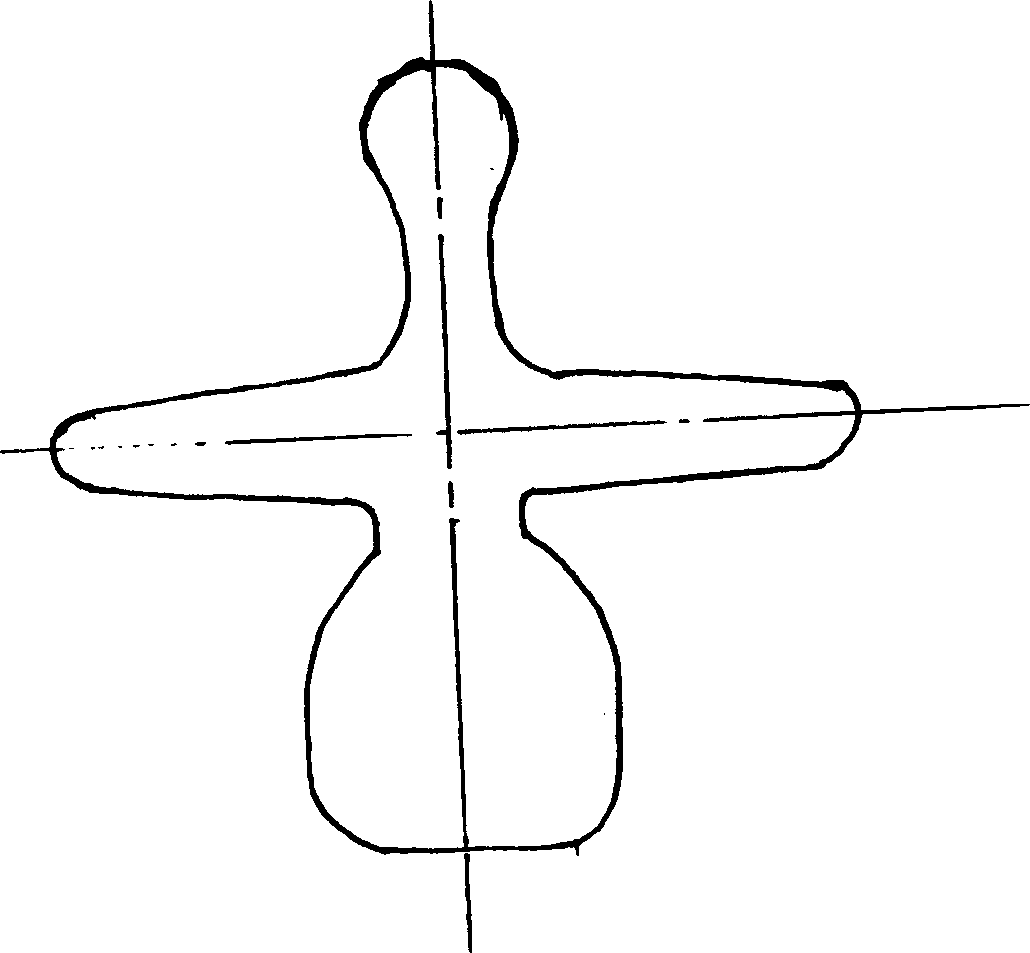

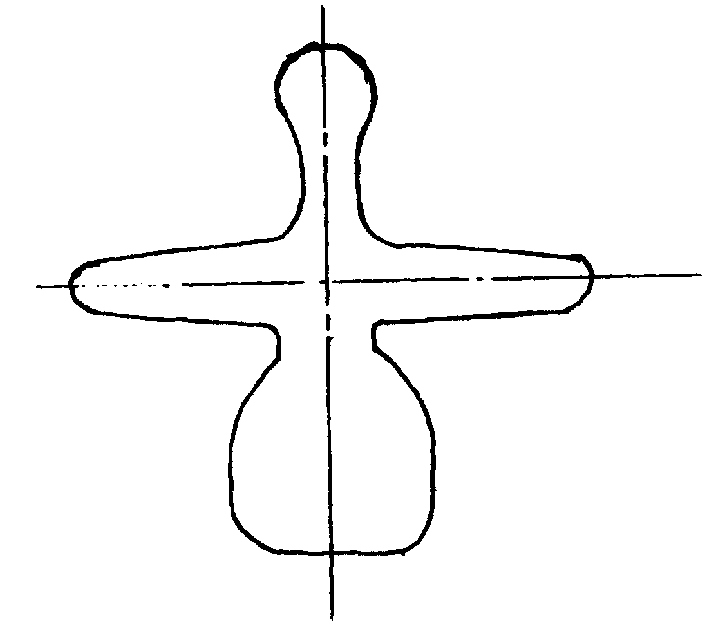

Asymmetric self-compensating rolling working roll applicable to short-stroke roll shifting and implementation method thereof

ActiveCN112588838AEasy to shapeImprove controlRollsProfile control deviceWork rollStructural engineering

The invention discloses an asymmetric self-compensating rolling working roll applicable to short-stroke roll shifting and an implementation method thereof. The working roll comprises a convexity adjusting section, an abrasion control section and a structural process section which are connected in sequence, wherein all roll shape sections are respectively positioned at the transmission side and theoperation side of a rolling mill; an upper working roll and a lower working roll respectively shift towards the middle of the rolling mill every time when a roll of strip steel is rolled; and a unidirectional aperiodic roll shifting strategy is adopted. The roll shape and the roll shifting strategy of the working roll are designed according to the width of the rolled strip steel; the asymmetry ofthe roll shape and the roll shifting can be utilized; the abrasion form of the working roll is effectively changed; multiple control on uneven deformation convexity, edge drop and uneven abrasion isachieved; the shape of a bearing roll gap is improved; the effective regulation and control on the roll bending force is guaranteed; the rolling unit is expanded; and the strip steel plate shape control capability is improved. The requirement for free regulation rolling plate shape control under the conditions of wide strip steel hot rolling short-stroke roll shifting machine type and rolling unitexpansion can be met.

Owner:UNIV OF SCI & TECH BEIJING

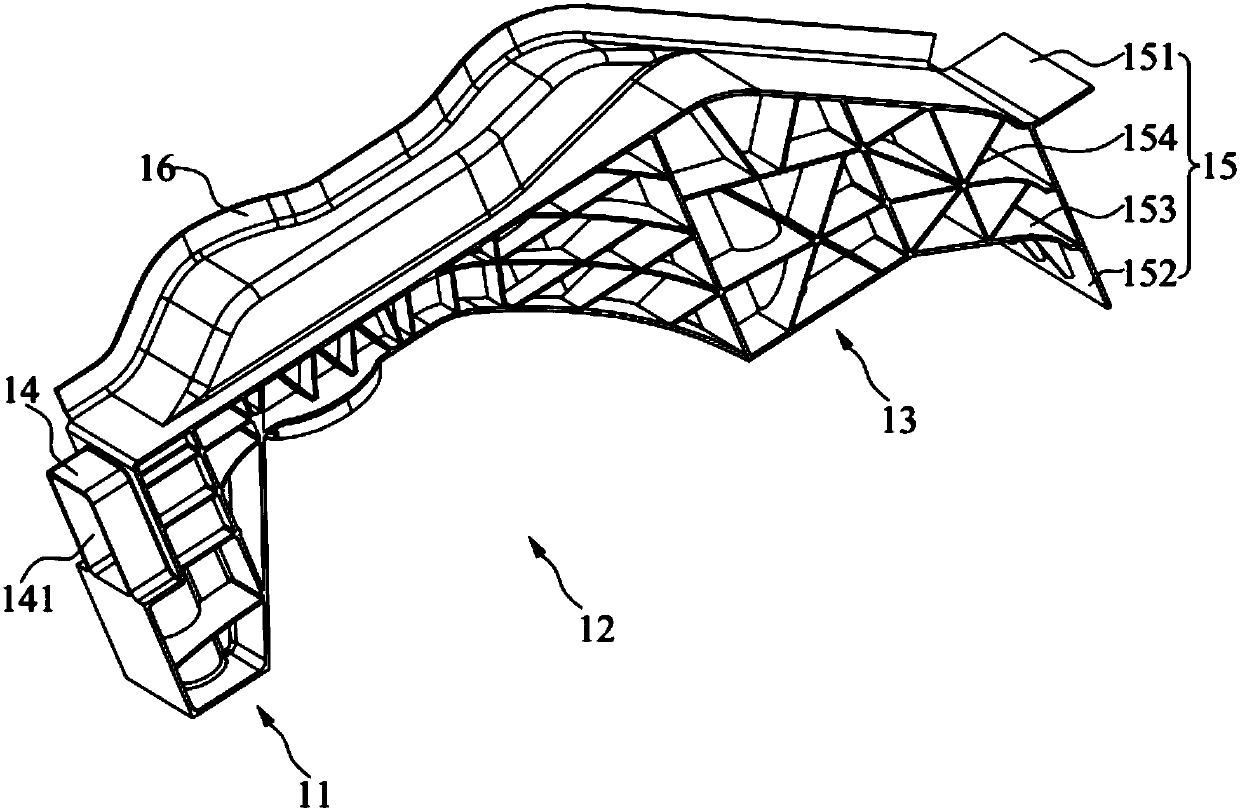

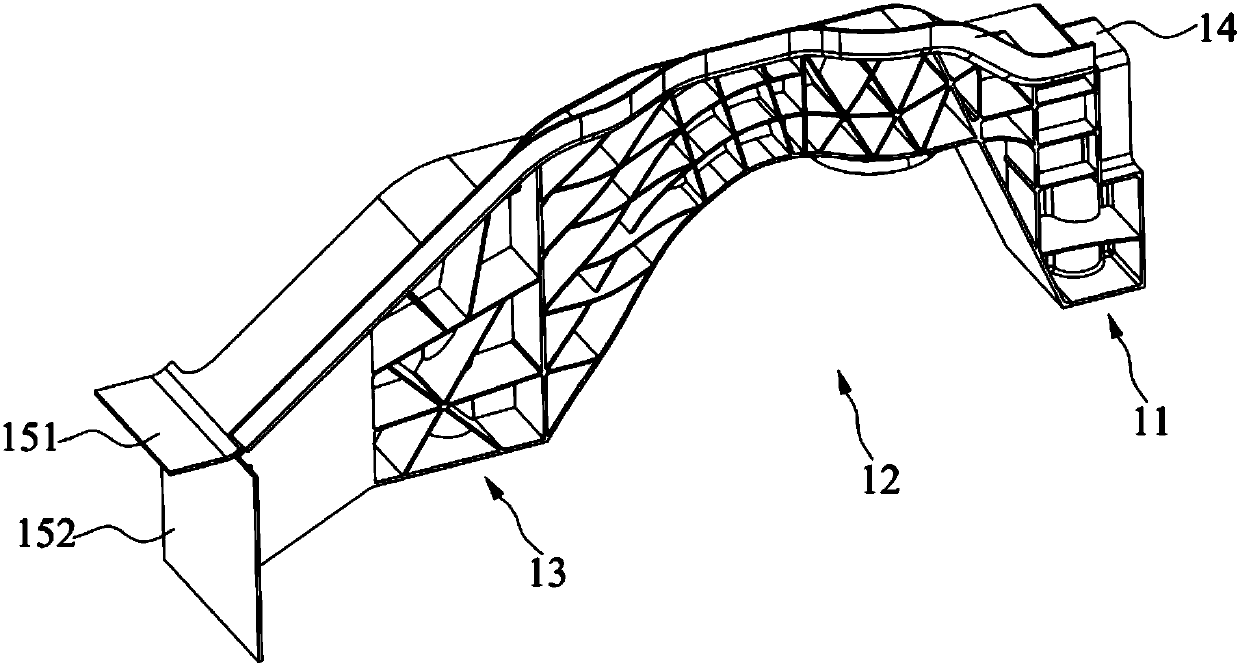

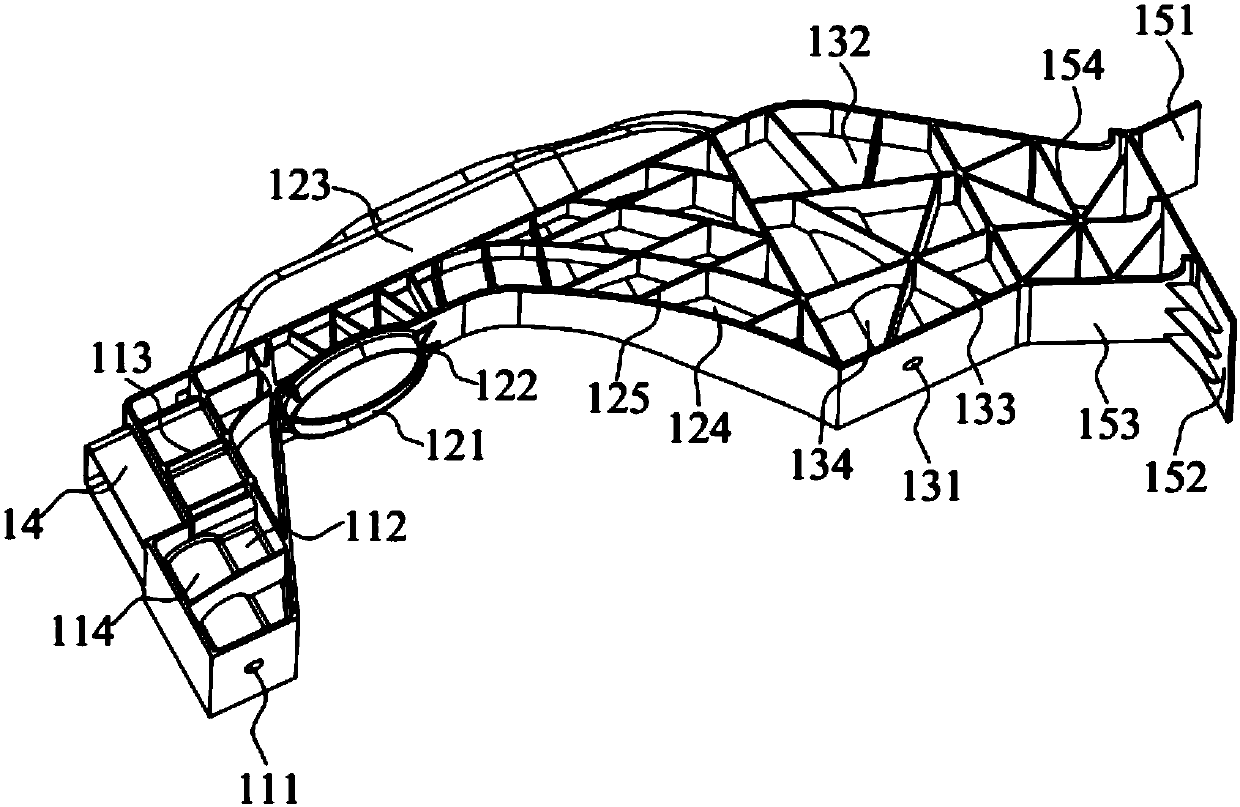

Rear longitudinal beam and vehicle body

The invention discloses a rear longitudinal beam and a vehicle body, and belongs to the technical field of vehicles. The rear longitudinal beam includes a rear longitudinal beam body cast by aluminumalloy in an integrated mode, and is high in strength, short in working time, low in mass, low in cost and great in anti-corrosion performance; the rear longitudinal beam body includes a first stress bearing part, a second stress bearing part and a third stress bearing part which are sequentially connected with one another; the structure of the rear longitudinal beam is designed according to actualstress bearing situations, the stress is performed evenly, the deformation amount is less, the stress bearing surface of the first stress bearing part is a first plane, and a first connecting hole isformed in the first plane; the stress bearing surface of the second stress bearing part is a curved surface sinking inwards, the curved surface is provided with an annular connector, and a reinforcedpart is arranged on the surface opposite to the curved surface to ensure the thickness of the stress bearing part of the second stress bearing part; the stress bearing surface of the third stress bearing part is a second plane, and a second connecting hole is formed in the second plane. Since the vehicle body adopts the rear longitudinal beam, the structural strength is high, the mass of the vehicle body is low, the maintenance cost is low, the service life is long, and the safety and reliability are improved.

Owner:SUZHOU ZIJING QINGYUAN NEW ENERGY AUTOMOBILE TECH

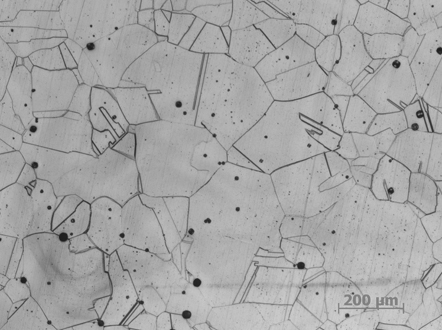

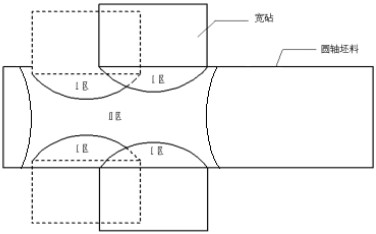

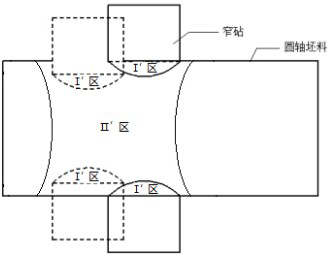

Forging process method for refining austenitic stainless steel grains

The invention provides a forging process method for refining austenitic stainless steel grains, which can solve the problem of coarse grain structures of a forged piece and improve the corrosion resistance of austenitic stainless steel. A wide anvil strong pressure deformation method and a temperature control narrow anvil uniform deformation method are provided according to the flow deformation situations of metals in different regions of the forged piece in the forging process. The method comprises the following steps of firstly, forging by adopting the wide-anvil strong-pressure deformationmethod, so that the inner layer of the forged piece is fully deformed; and then finishing subsequent forging according to the temperature control narrow anvil uniform deformation method, so that the surface layer of the forged piece is fully deformed. According to the operation steps and key points of the method, internal pores of the forged piece can be quickly laminated. Meanwhile, fine grain structures are achieved on the surface layer and the inner layer of the forged piece, and the grain size is larger than or equal to the fourth grade.

Owner:洛阳中重铸锻有限责任公司 +1

Centrifugal model test simulation method and system for barrier dam

ActiveCN110716028AReveal deformation failure characteristicsRealize simulationEarth material testingHydraulic modelsPotassium nitrateClassical mechanics

A centrifugal model test simulation method for a barrier dam is characterized by simulating a barrier body by using a mixed material of gravel and sand in a model box, randomly arranging potassium nitrate powder in the model box, placing the model box in a basket of a centrifugal machine, injecting water into the model box after a centrifugal acceleration is stable at a set value, dissolving the potassium nitrate powder, forming a pore structure in uneven distribution in the barrier body, and simulating the generation of uneven deformation. The invention also provides a centrifugal model testsimulation system for the barrier dam. The centrifugal model test simulation method and the centrifugal model test simulation system of the invention aim at the characteristics that the barrier dam material has complex characteristics, and has unevenly distributed large pore structures and uneven deformation in the inner part, and realize simulation of the unevenly distributed pore structures of the barrier dam in a geotechnical centrifugal machine.

Owner:TSINGHUA UNIV

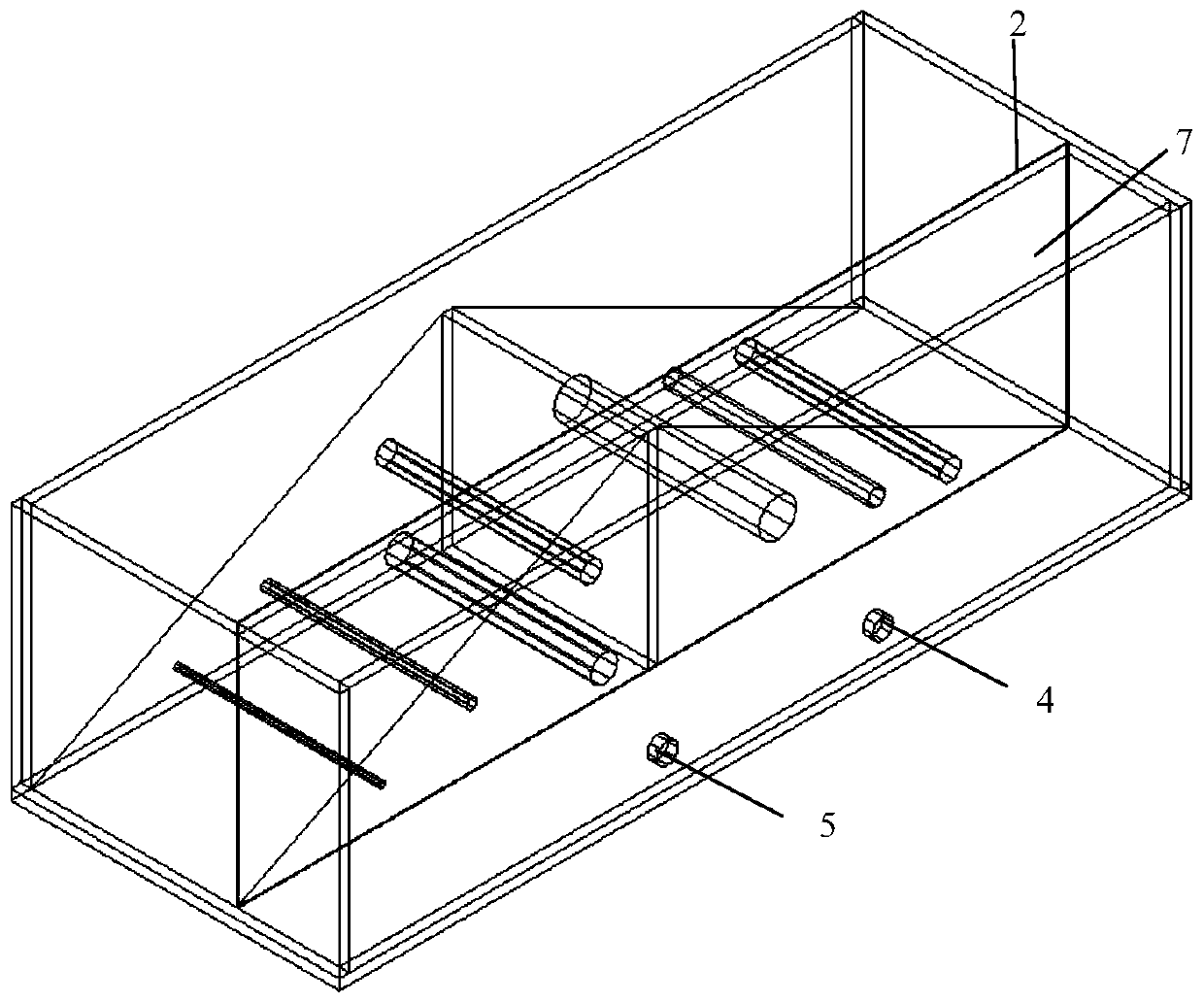

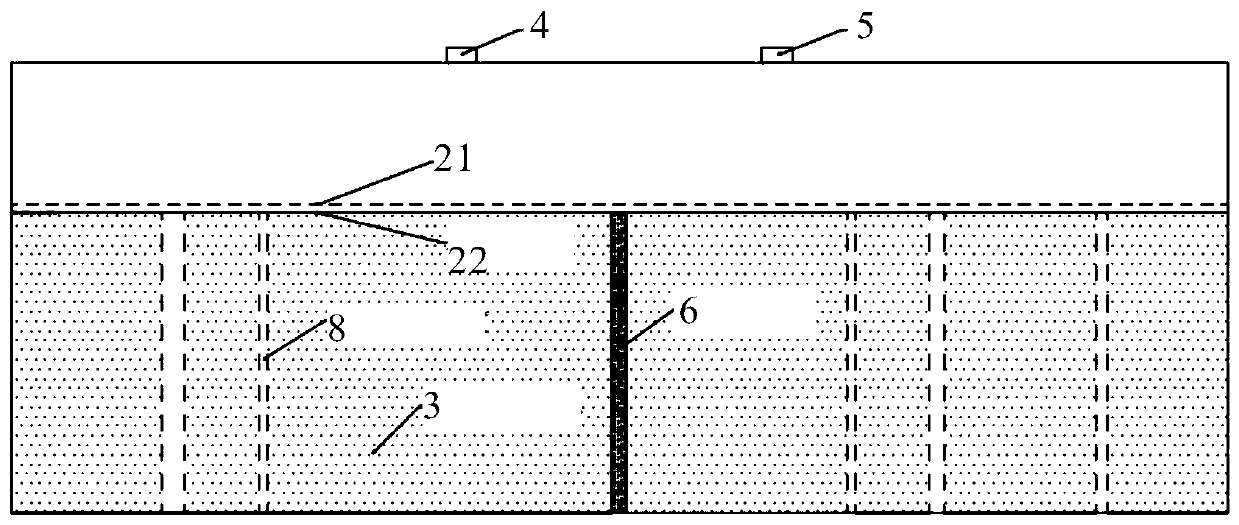

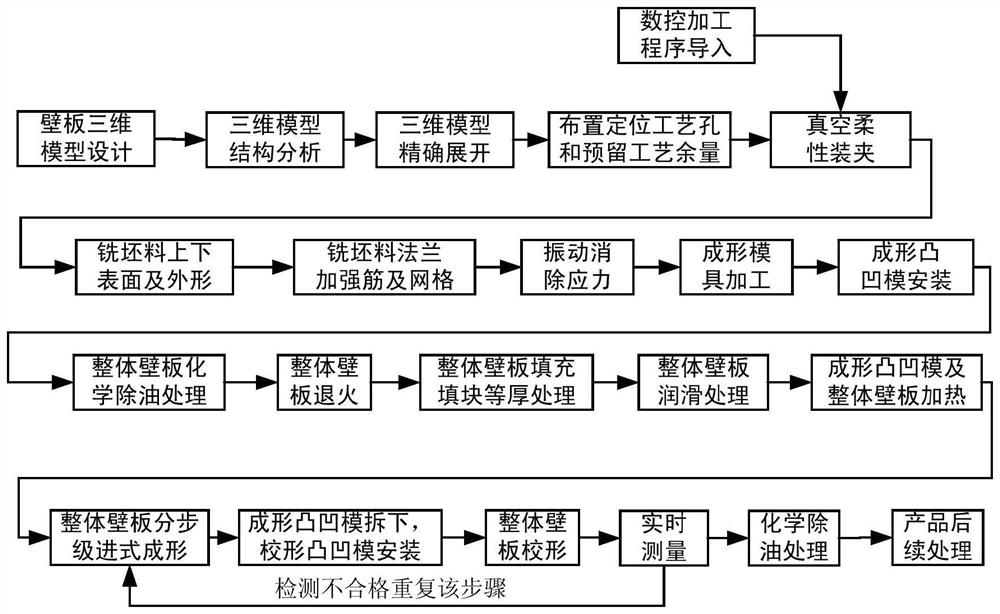

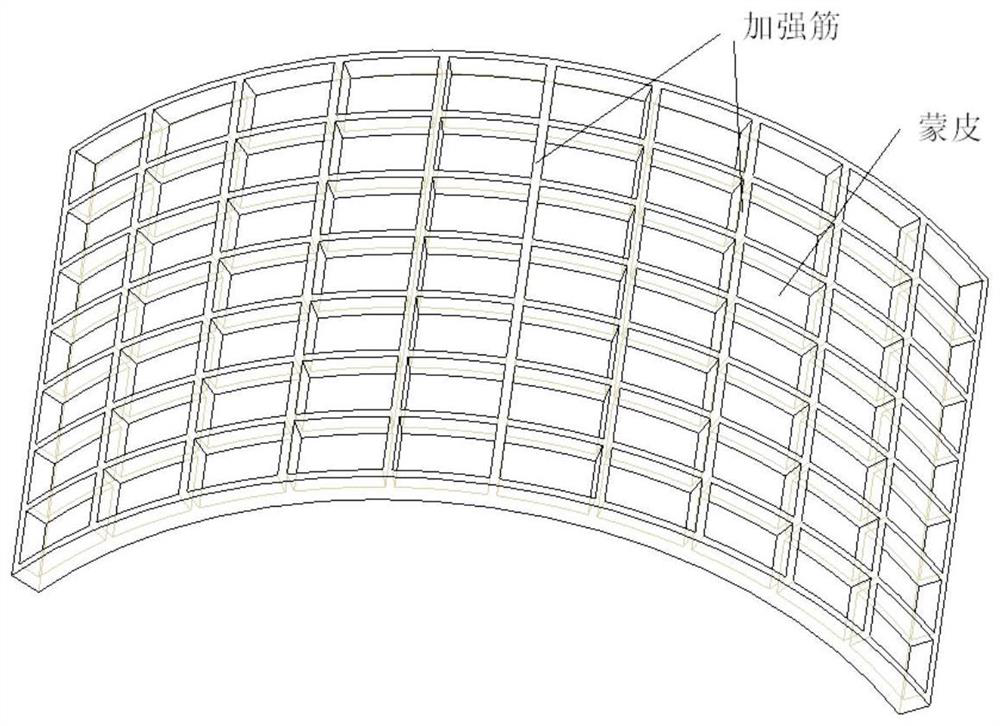

Step-by-step progressive hot forming and hot correcting integrated method for thin-wall integral wall plate with ultrahigh reinforcing ribs and oversized flanges

ActiveCN111804786AImprove processing efficiencySimple methodShaping toolsMetal working apparatusThin walledHomogeneous deformation

The invention provides a step-by-step progressive hot forming and hot correcting integrated method for a thin-wall integral wall plate with ultrahigh reinforcing ribs and oversized flanges. An original blank of the integral wall plate in a flat state is clamped on a three-axis numerical control machine tool through a vacuum flexible clamping technology, and numerical control milling machining is conducted on the ultrahigh reinforcing ribs, the oversized flanges and grids of the thin-wall integral wall plate. Then, vibration is adopted for stress relieving, the influence of material internal stress on machining deformation is eliminated. Through the equal-rigidity reinforcing technology and the step-by-step progressive hot forming and hot correcting integrated technology, the following problems are solved that when the aluminum alloy thin-wall integral wall plate with the ultrahigh reinforcing ribs and the oversized flanges is formed, the forming resistances of the reinforcing ribs andthe flanges of the wall plate are greatly different, serious uneven deformation is likely to happen, a transition area around the flange is likely to break in the deformation process, and the formingdifficulty is very large. The method achieves low-stress manufacturing of the thin-wall integral wall plate structure with the ultrahigh reinforcing ribs and the oversized flanges.

Owner:BEIJING SATELLITE MFG FACTORY

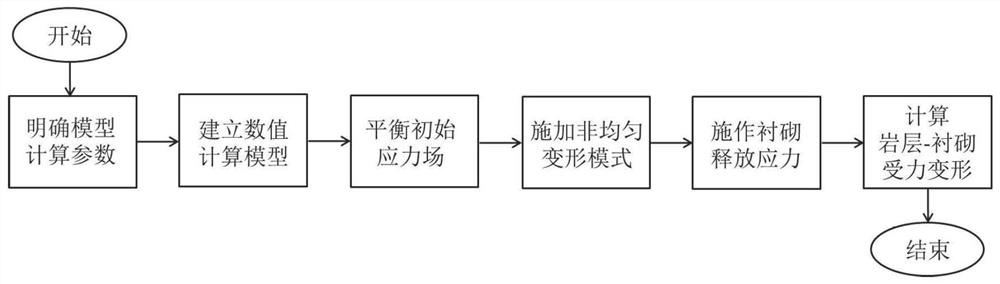

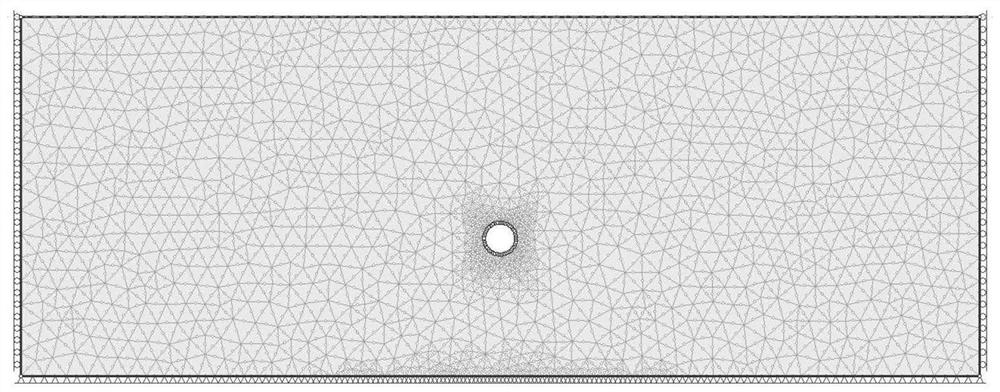

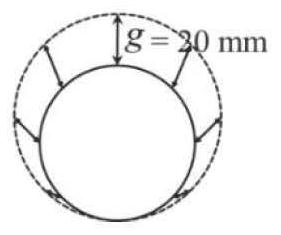

Numerical solution method for rock stratum-lining stress deformation of shield subway tunnel

ActiveCN112613210AReduce computing timeReduce the space required for storageGeometric CADDesign optimisation/simulationClassical mechanicsGeological survey

The invention relates to a numerical solution method for rock stratum-lining stress deformation of a shield subway tunnel, which comprises the following steps of: 1) defining geometrical parameters and material parameters of a tunnel structure according to geological survey data; 2) establishing a two-dimensional numerical calculation model, dividing model grids, defining model boundary conditions and stress field conditions, and calculating the model to balance; 3) applying gravity load according to material attributes, resetting the displacement of the model and calculating the model to be balanced; 4) excavating a tunnel in the model, defining a non-uniform deformation convergence mode based on gap parameters, controlling a displacement boundary by debugging the stress of each node of a rock stratum boundary, and calculating the model to be balanced; (5) applying a lining to the tunnel boundary, releasing tunnel boundary stress to reduce the tunnel boundary stress to 0, and calculating the model to be balanced, and (6) extracting a rock stratum-lining stress and deformation distribution rule according to the balanced model.By simplifying the three-dimensional numerical method of the shallow-buried shield subway, a beneficial reference can be provided for the design of a shield subway structure.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

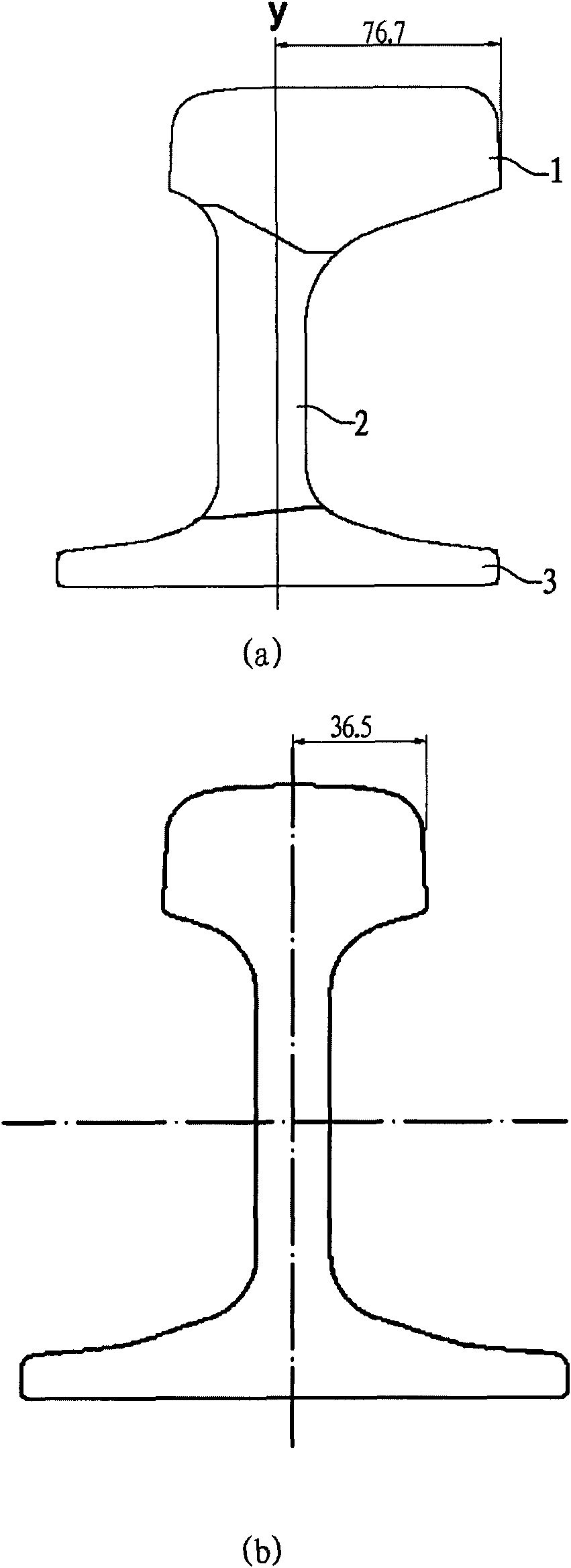

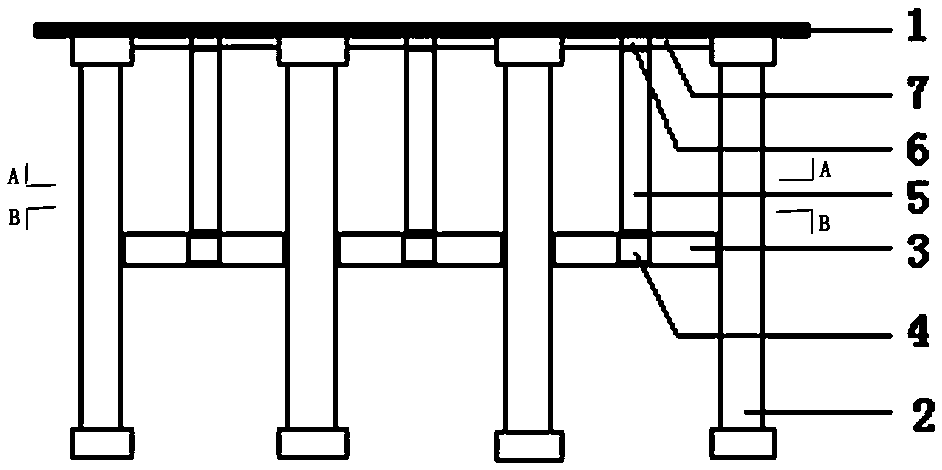

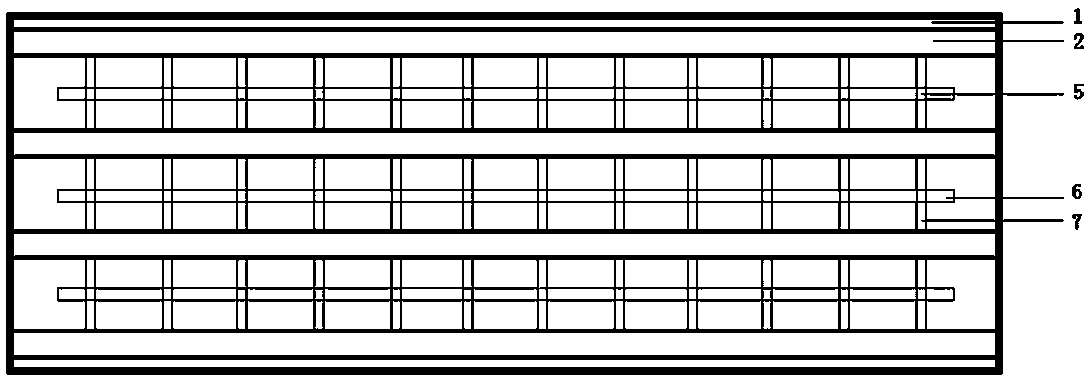

Method for reducing uneven deformation of orthogonal steel bridge deck slab and deck slab

ActiveCN110983969AReduce deformationAvoid damageBridge structural detailsBridge materialsHomogeneous deformationMetallurgy

The invention relates to a method for reducing uneven deformation of an orthogonal steel bridge deck slab and the deck slab. Girder I-shaped steel is arranged on the bottom surface of the deck slab, the length direction of the girder I-shaped steel is consistent with the length direction of the deck slab, and a top wing plate of the girder I-shaped steel is in contact with the deck slab to reduceoverall deformation of the deck slab. Fourth I-shaped steel and fifth I-shaped steel which are orthogonal are arranged on the bottom surface of the deck slab. The deformation of the deck slab betweenthe two pieces of girder I-shaped steel is borne by the fourth I-shaped steel and the fifth I-shaped steel which are orthogonal, and the force borne by the fourth I-shaped steel and the fifth I-shapedsteel is transmitted through third I-shaped steel to first I-shaped steel and second I-shaped steel which are orthogonal. Because the first I-shaped steel is fixed on a web plate of the girder I-shaped steel, the force is finally borne by the girder I-shaped steel. The girder I-shaped steel bears the pressure received by the deck slab through the girder I-shaped steel arranged side by side and the I-shaped steel orthogonally arranged between the girder I-shaped steel, uneven deformation of the deck slab is prevented, and therefore the deck slab or a truss structure is prevented from being damaged.

Owner:梁成龙

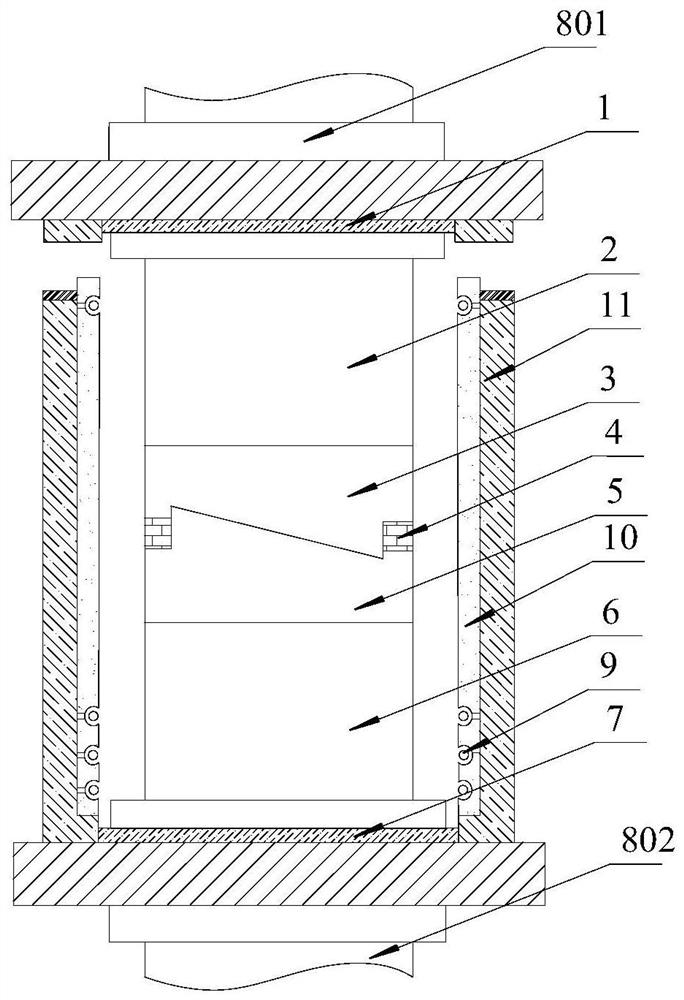

TiAl-based alloy stator blade isothermal forming manufacturing method and device thereof

InactiveCN112122523ARealize forgingReduce consumptionFurnace typesForging/hammering/pressing machinesIsothermal forgingMachining

The invention discloses a TiAl-based alloy stator blade isothermal forming manufacturing method and a device thereof, and belongs to the field of isothermal forming manufacturing methods. The method comprises the steps of machining blank manufacturing, isothermal pre-forging, isothermal final forging and heat treatment. The invention further provides a TiAl-based alloy stator blade isothermal forming device. Compared with a commonly-adopted machining mode that a square blank is extruded and then machined into a part, and due to the fact that the extruded square blank is not deformed, the structure and the performance of a prepared stator blade cannot meet the design requirements, according to the method provided by the invention, blade forging forming is achieved through machining blank manufacturing and isothermal forming, and then the blank is machined into a part. Due to the fact that a TiAl-based alloy is large in deformation resistance and poor in shaping, a common forming methodcannot be achieved, so that the blank manufacturing process is a major problem needing to be solved. According to the method, turning is adopted for blank manufacturing, the blank shape is close to the shape of a final forging, isothermal forging forming is adopted, and uniform deformation of all parts of a blade is achieved, so that the structure and the performance of the blade forging are greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for reducing residual stress of heterogeneous brazed joint

ActiveCN114833410AReduce residual stressReduce stressWelding/cutting auxillary devicesAuxillary welding devicesHomogeneous deformationMaterials science

The invention belongs to the technical field of welding, and relates to a method for reducing residual stress of a heterogeneous brazed joint. According to the method, when the temperature of the brazed joint is reduced to a certain temperature, the temperature of the joint is reduced and the residual stress of the joint is reduced in the circulating process by firstly carrying out heating treatment, generating micro plastic deformation and micro precipitation, reducing the residual stress, carrying out cooling again, generating the residual stress and then reducing the stress by raising the temperature, so that the temperature of the joint is reduced and the residual stress of the joint is reduced in the circulating process. According to the cryogenic circulation treatment, through heating and cooling circulation between (0.1-0.4) T and-(75-150) DEG C, movable dislocation in the tissue is eliminated through uneven deformation generated by the thermal expansion and cold contraction effect, fixed dislocation entanglement is achieved, value is increased, and residual stress in the brazed joint tissue is reduced.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD +1

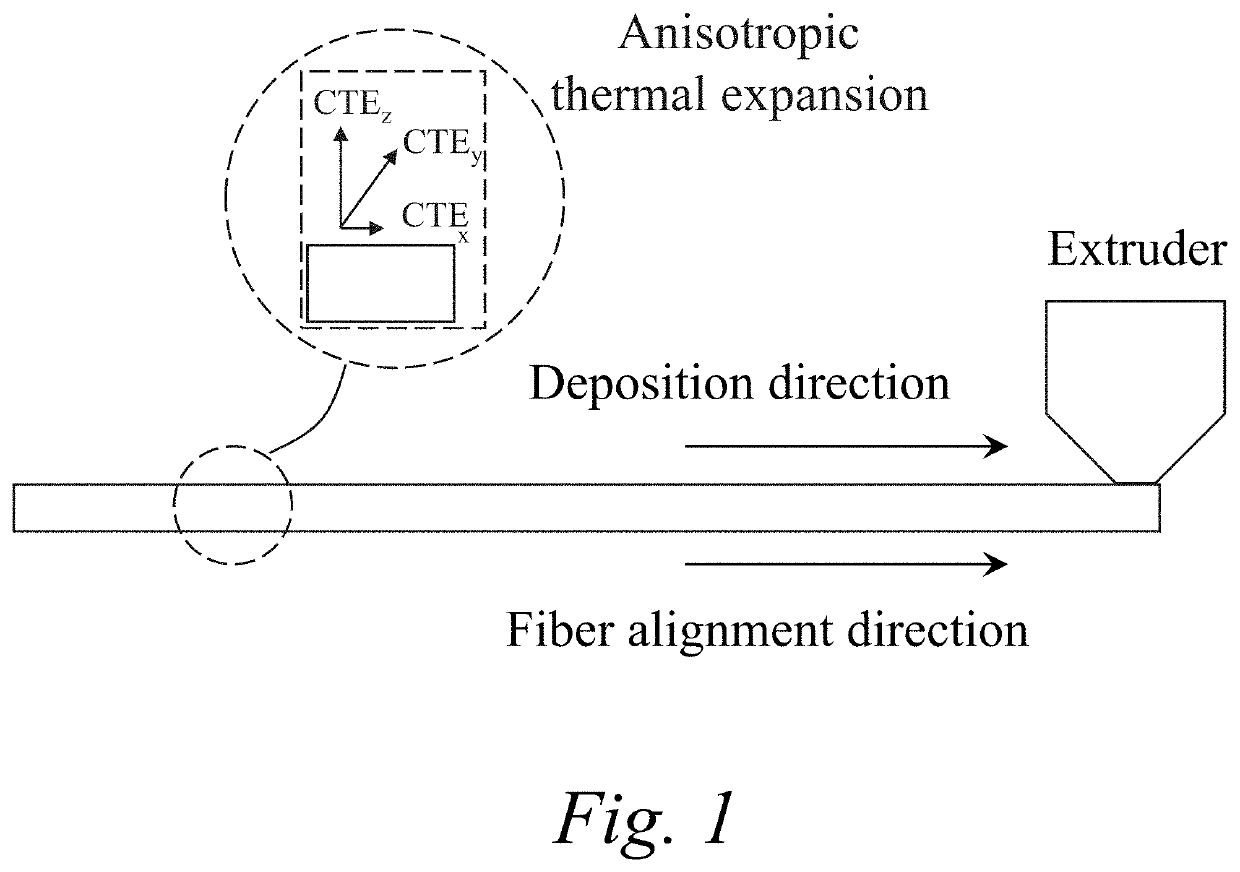

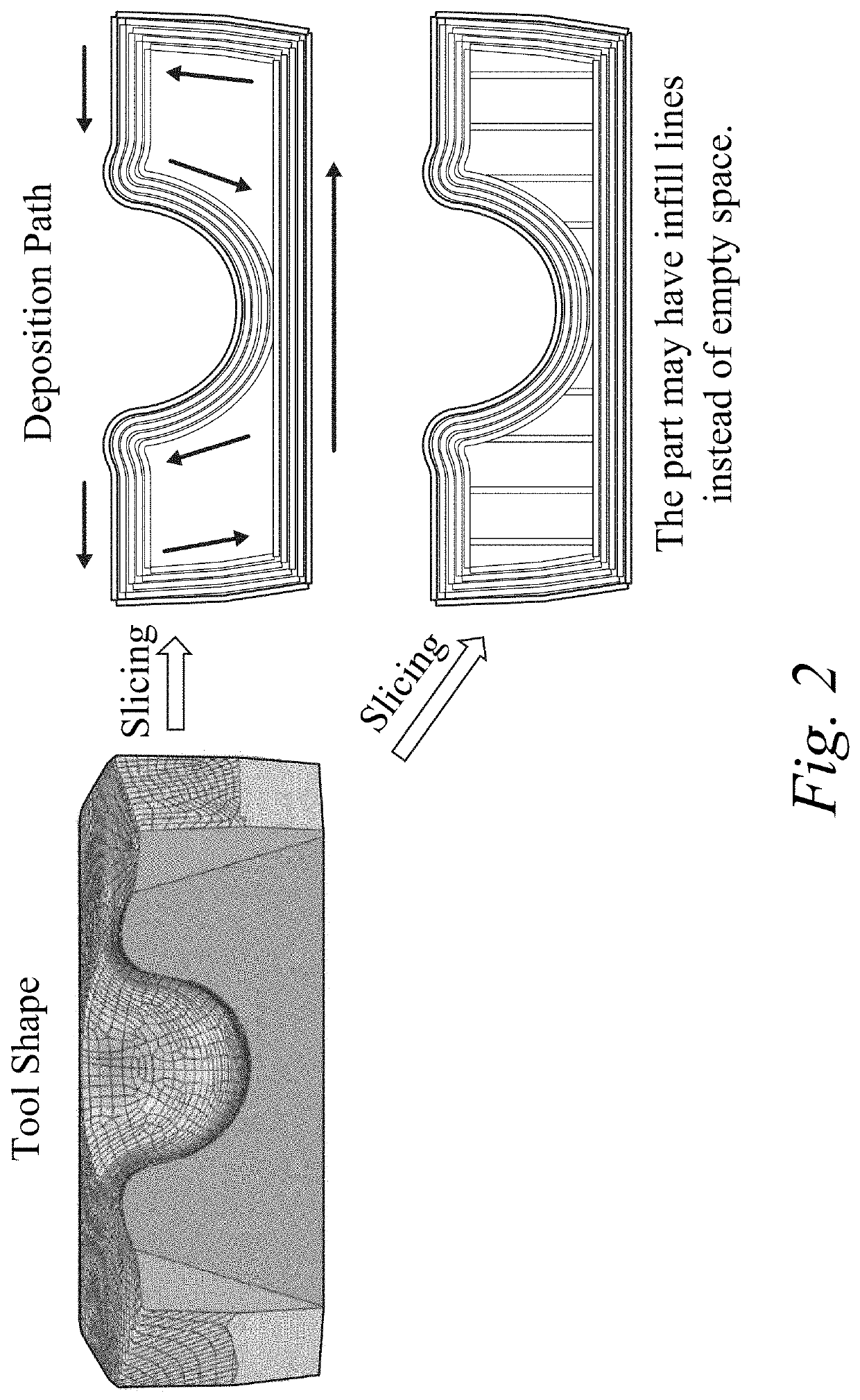

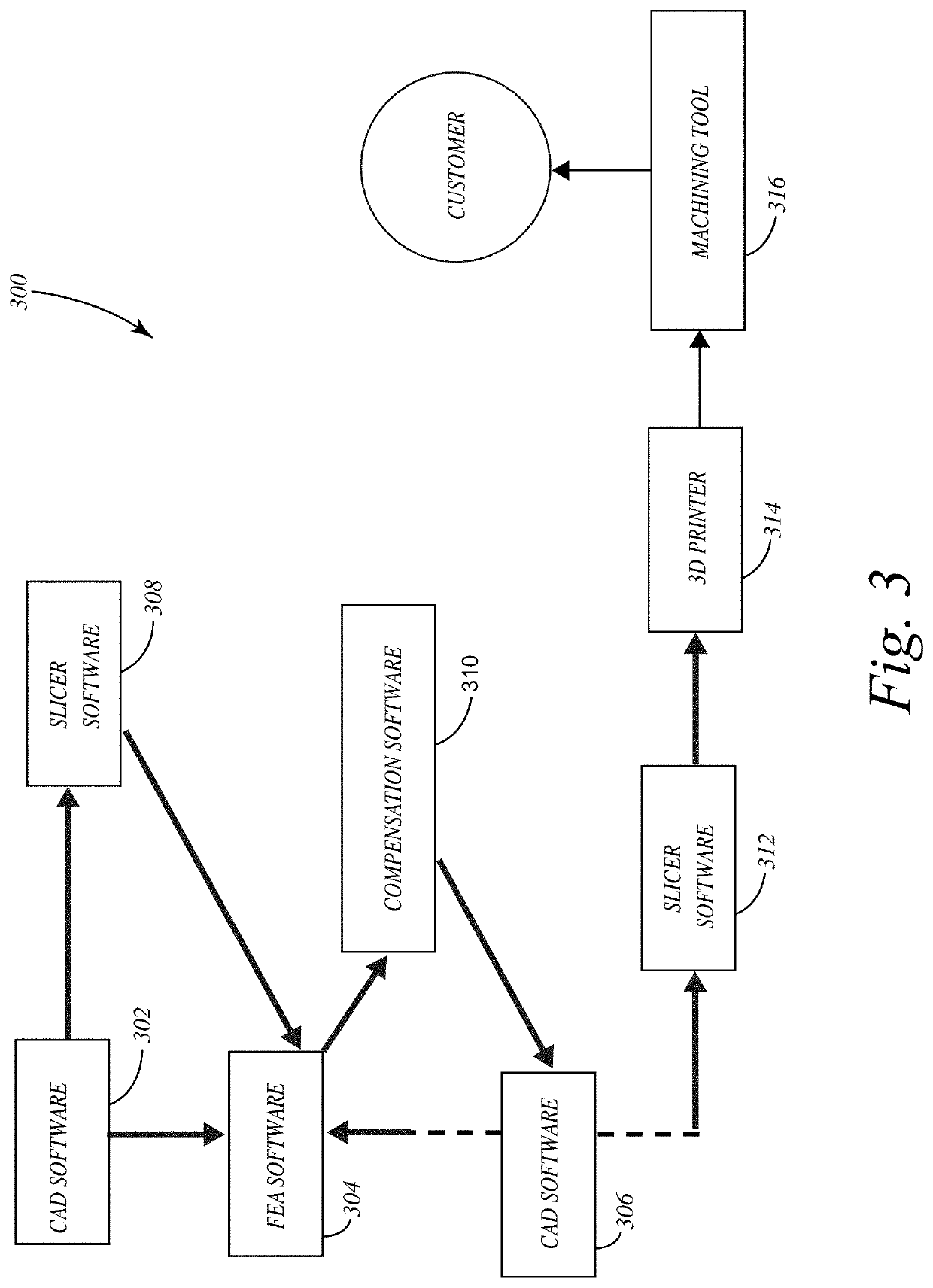

System and method for simulation-assisted additive manufacturing

PendingUS20220088881A1Efficient in process timeEfficient in manual laborAdditive manufacturing apparatusDesign optimisation/simulationRegression analysisProcess engineering

A simulation-assisted additive manufacturing system and method for generating an anisotropic compensation to account for non-uniform deformation due to additive manufacturing and service loading. The predicted deformation may not be fully defined. The present disclosure provides a system and method for estimating the missing deformation data through regression analysis. The present disclosure also provides an integrated framework where the various simulated-assisted design modules are configured for two-way communication and sharing access to changes to the model.

Owner:UT BATTELLE LLC

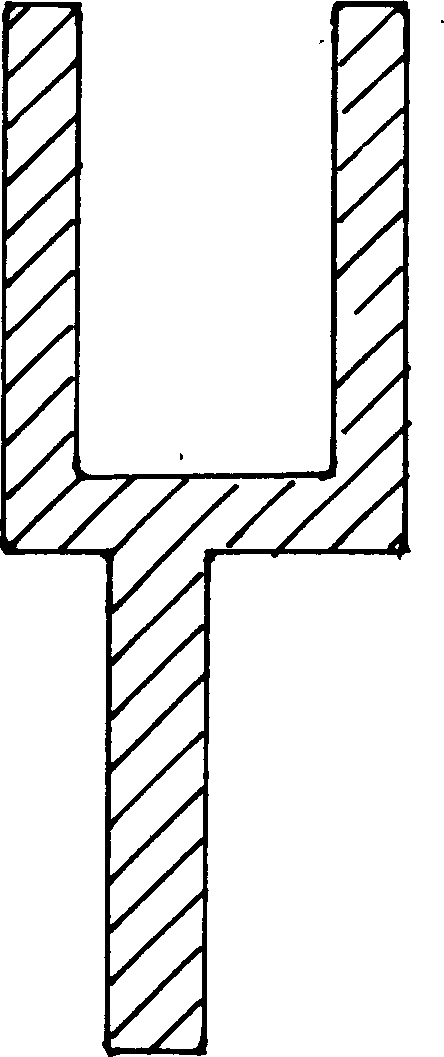

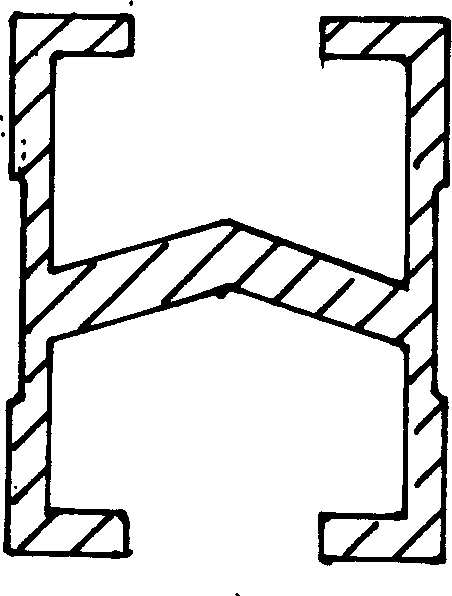

Hot rolling process of crossed steel

InactiveCN1387963ASolve the costSolve efficiency problemsMetal rolling arrangementsSystem configurationHomogeneous deformation

In the hot rolling process of crossed steel, systemic caliber configuration of open-train mill roller is utilized and the caliber system includes common trapezoid hole, cap-shaped under hole and raised trapezoid hole in the coarse rolling part as well as double-wedged caliber combination in precision rolling part. The hot rolling processing can form in once process and has homogeneous deformation, no need correction of rolled product and low cost. It is suitable for various mill with roller of 32-500 mm diameter.

Owner:齐齐哈尔金河轧钢厂 +1

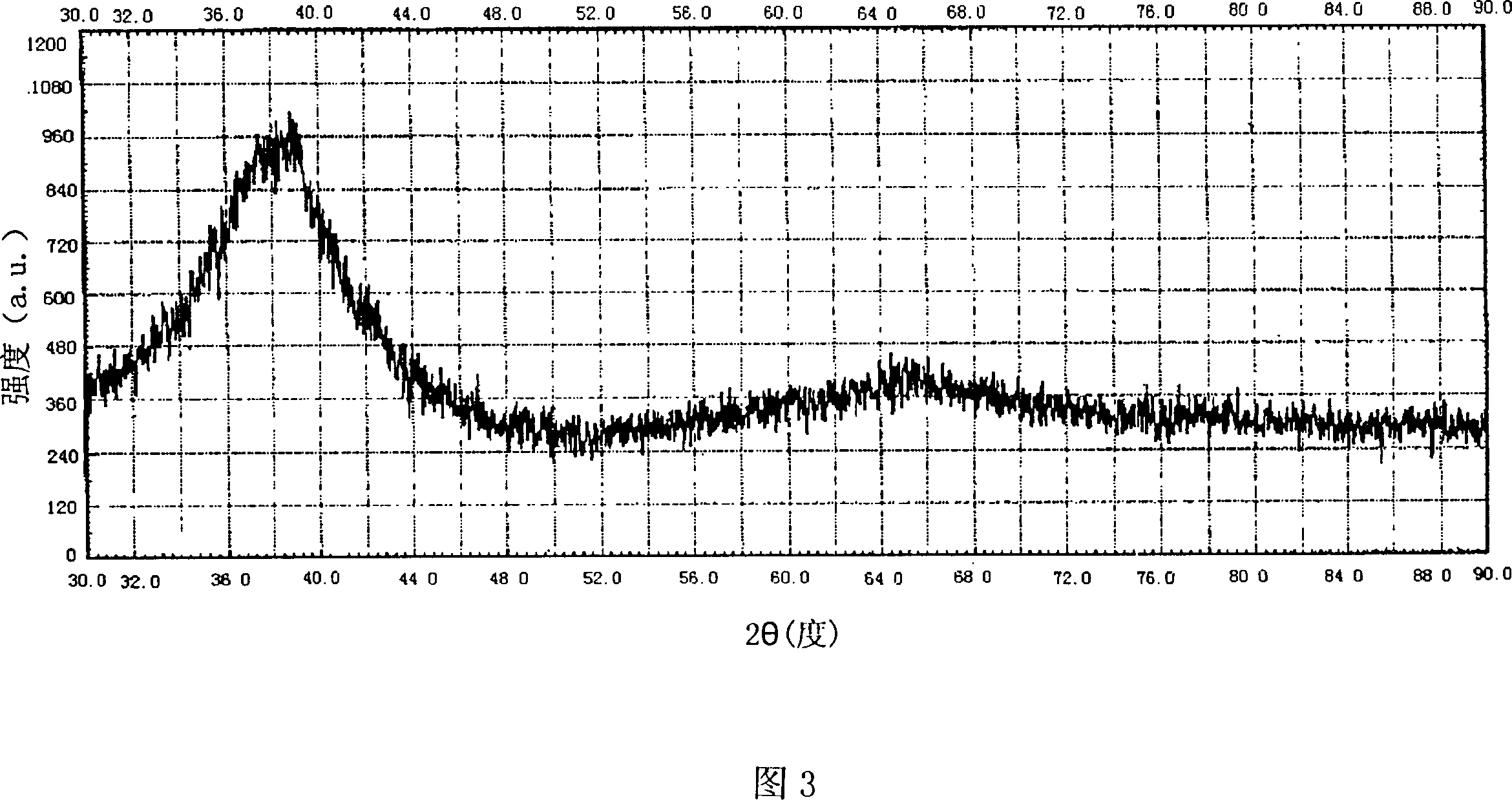

Method for processing lump non-crystal alloy blank and its device used thereof

InactiveCN1308096CImprove stress statusUniform deformationExtrusion control devicesMachining deformationCooling effect

The present invention relates to processing method of lump non-crystal alloy blank and the apparatus thereof. Hydrostatic extruder with high pressure liquid is used in the processing, non-crystal alloy rod blank is closed inside a canning, heated to extrusion temperature or the overcooling liquid phase area temperature of the non-crystal material, extruding medium is added to the mold cavity of the hydrostatic extruder for extrusion processing, and the canning is finally eliminated to obtain the lump non-crystal alloy blank. The hydrostatic extruder has one increased reverse extruding unit. The present invention solves the problem of forming lump non-crystal alloy and composite material without crystallization. The workpiece of the present invention his good stress state, homogeneous deformation, good lubrication, excellent cooling effect of high pressure liquid, precisely controlled processing temperature and no crystallization.

Owner:GRIMAT ENG INST CO LTD

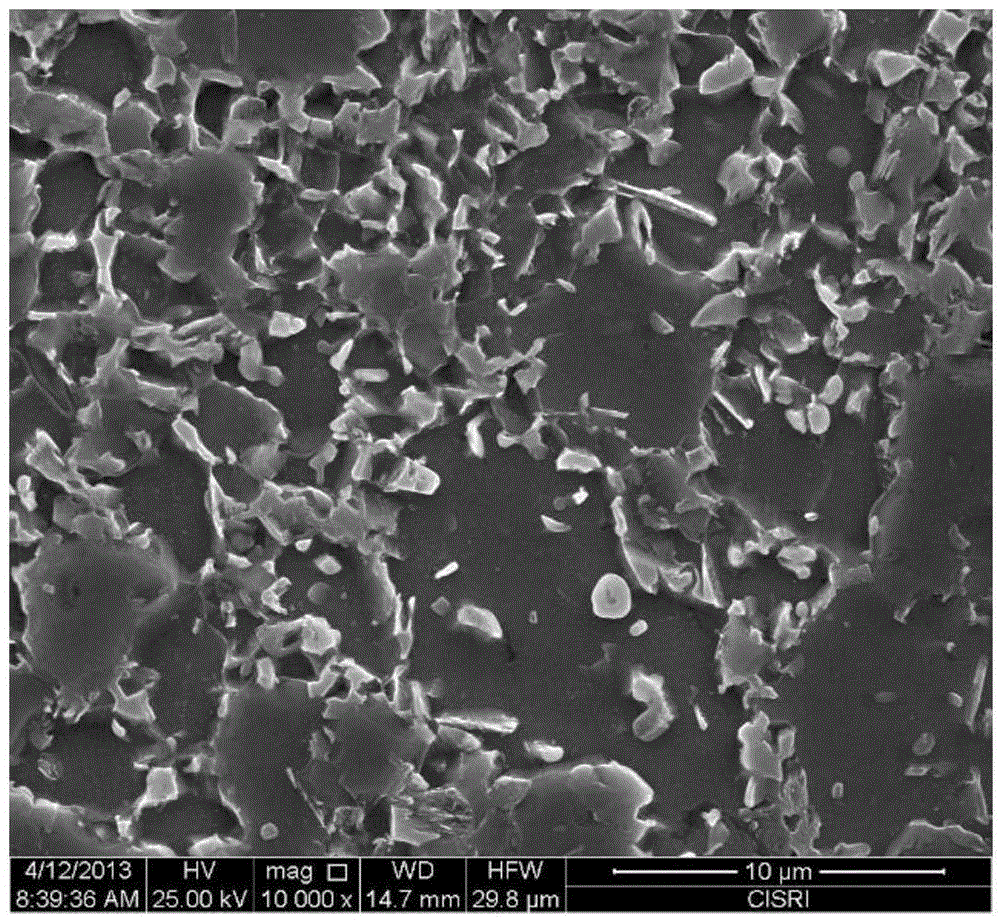

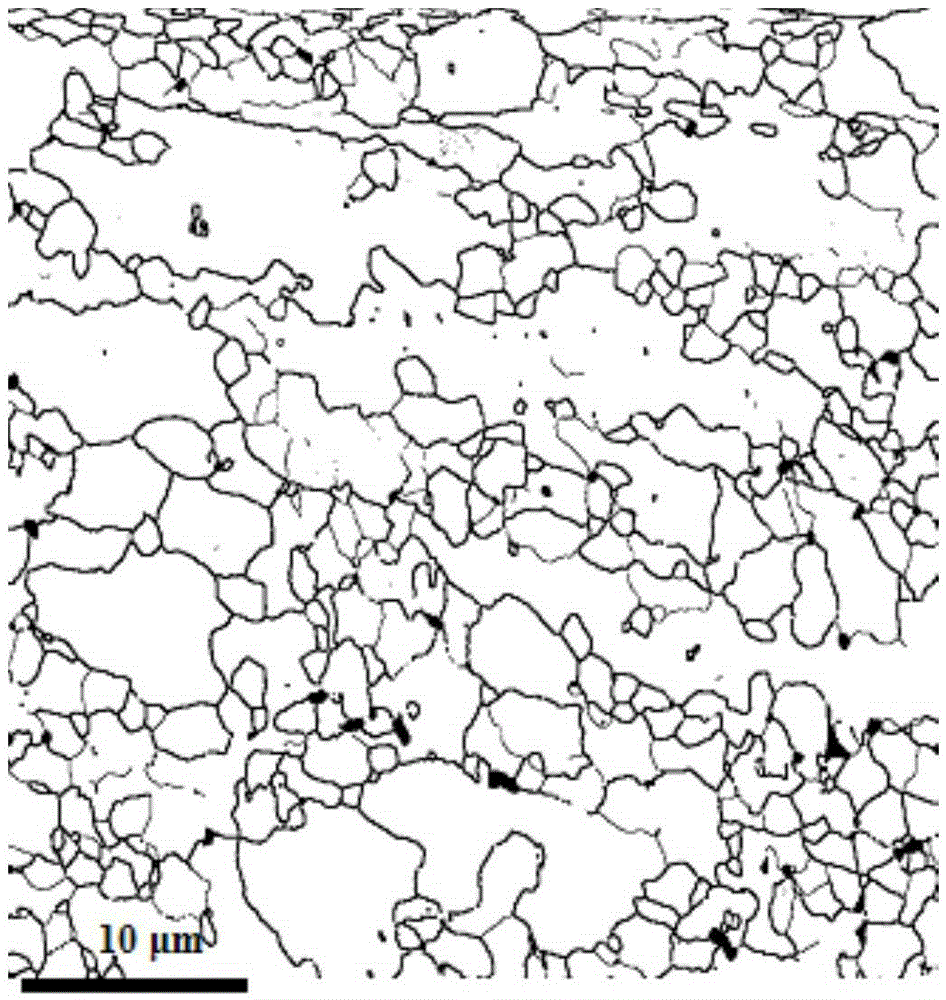

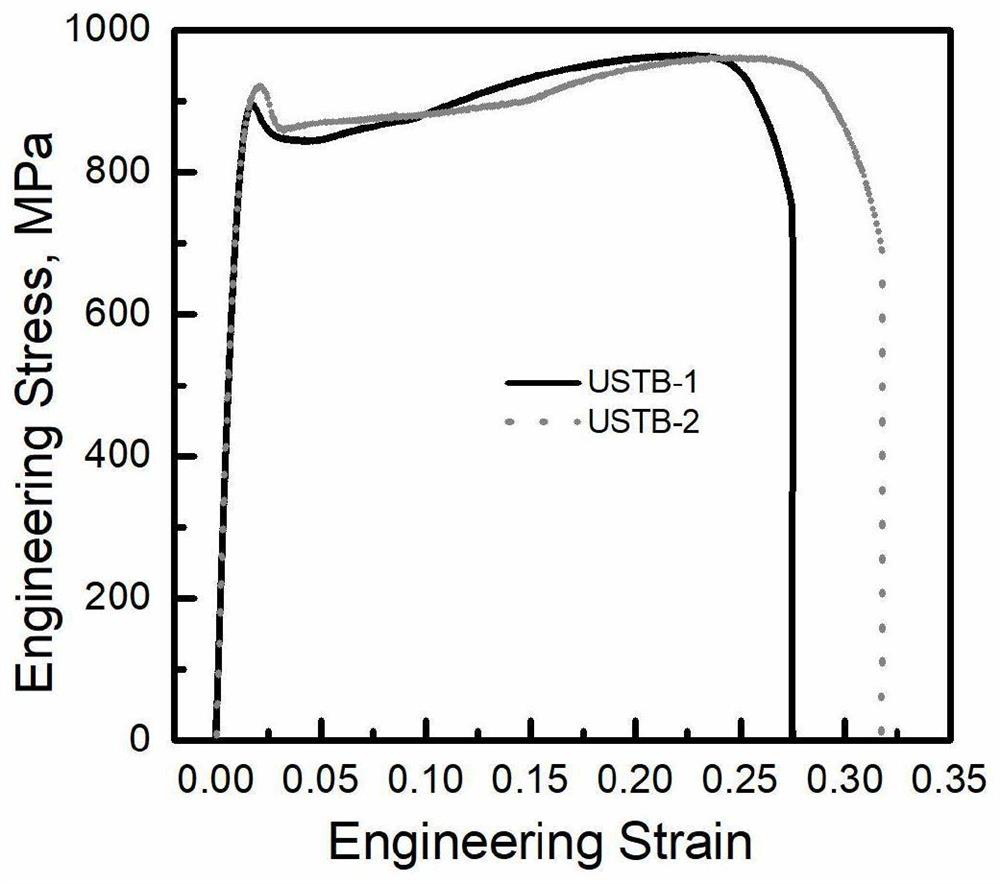

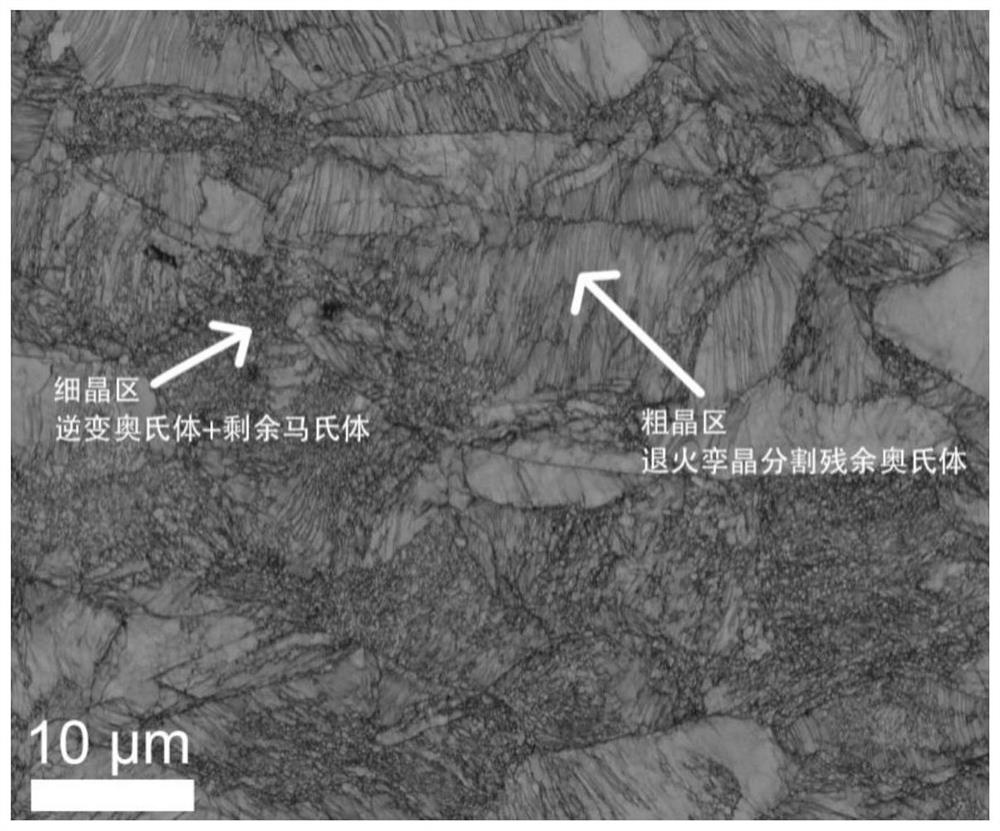

Heterostructure-based multi-type reinforced austenitic stainless steel and manufacturing method

ActiveCN113755753ALow alloy contentLow costMetal rolling arrangementsSS - Stainless steelSolid solution strengthening

Heterostructure-based multi-type reinforced austenitic stainless steel is characterized by comprising the following chemical components in percentage by mass: less than 0.05% of C, less than 0.50% of Si, less than 1.3% of Mn, 14-16% of Cr, 7-9% of Ni, 1-3% of Mo, less than 1.4% of Cu, less than 0.01% of S, less than 0.02% of P and the balance of Fe and inevitable impurity elements. The martensite transformation temperature of the austenitic stainless steel is more than-60 DEG C and less than 40 DEG C. According to the high-strength austenitic stainless steel, austenite is stabilized by refining grains and increasing dislocation and other defects. Compared with the existing austenitic stainless steel, the heterostructure-based multi-type reinforced austenitic stainless steel needs less alloy content and has better economic efficiency. Through multiple types of strengthening modes (including fine grain strengthening, second phase strengthening, precipitation strengthening, solid solution strengthening and non-uniform deformation strengthening) based on a heterostructure, only a small amount of work hardening capacity is sacrificed, and the austenite can still keep the uniform elongation exceeding 20% while reaching the 125 steel grade (862 MPa).

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com