Method for reducing residual stress of heterogeneous brazed joint

A technology of brazing joints and residual stress, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve joint cracks, reduce joint strength and stress fracture resistance, reduce bonding strength and service life, etc. , to achieve the effect of reducing residual stress, reducing residual stress, and reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

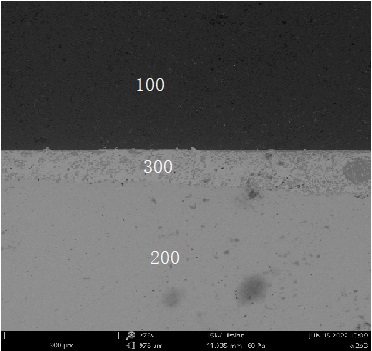

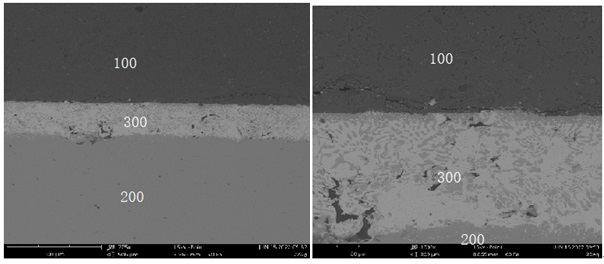

[0049] S1. Set the expansion coefficient as α 1 =18×10 -6 / ℃, the elastic modulus is E 1 = 316L stainless steel of 206GPa, the expansion coefficient is α 2 =6×10 -6 / ℃, the elastic modulus is E 2 =14.5GPa YG20 cemented carbide is ground and ultrasonically cleaned to remove surface oxide scale and impurities.

[0050] S2. Apply the silver flux to the brazing surfaces of 316L stainless steel and YG20 cemented carbide respectively, then add BAg65CuZn brazing filler metal at the brazing interface at 750°C, keep the brazing filler metal for 5 minutes after melting, and perform the brazing process on the brazed joints. Cooling stress relief treatment, check the national standard GB / T 10046-2018 silver solder, the solidus temperature of the solder BAg65CuZn used in this example is Ts=670℃;

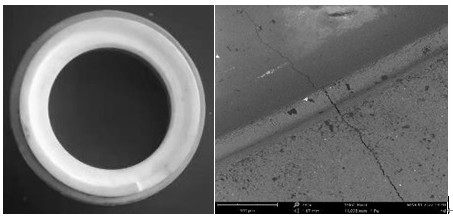

[0051] The brazed joint after brazing connection is carried out as Figure 4 The cooling cycle treatment shown, the cooling cycle treatment specifically includes the following steps:

[00...

Embodiment 2

[0061] The only difference from Example 1 is that the number of cycles of cryogenic cycle treatment is 4.

Embodiment 3

[0063] The only difference from Example 1 is that the cryogenic cycle treatment was not performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com