Forging process method for refining austenitic stainless steel grains

A technology of austenitic stainless steel and process method, which is applied in the field of metal forging and can solve problems such as coarse grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

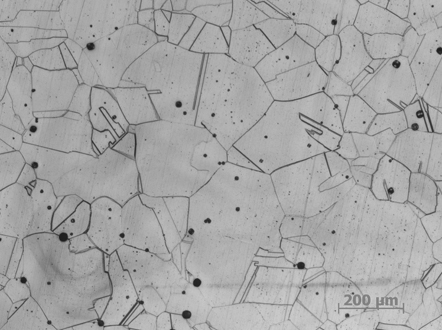

Examples

Embodiment 1

[0028] A forging process method for refining austenitic stainless steel grains, comprising the following steps:

[0029] Step 1, heating the billet to be forged;

[0030] Step 2, preheating the tools used in the forging process before forging;

[0031] Step 3. Lightly press the heated billet in step 1 when chamfering, control the amount of reduction on one side, and chamfer at high temperature to ensure that the concave surface of the billet is deformed;

[0032] Step 4. Pre-draw the billet processed in step 3, lightly tap it twice with a small reduction, and increase the deformation after the plasticity is improved;

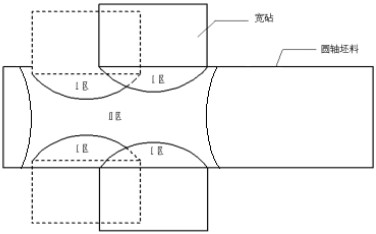

[0033] Step 5. Elongate the billet pre-drawn in step 4 using the wide anvil forced deformation method (WHF), and control the amount of anvil and reduction according to the operation requirements of the WHF method;

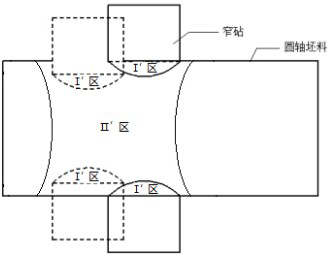

[0034] Step 6: Forging the billet processed in Step 5 using a temperature-controlled narrow anvil uniform deformation method to obtain a forging. ...

Embodiment 2

[0043] Taking a 316 stainless steel round shaft forging with a diameter of φ500mm and a length of 3200mm as an example to describe, the grain size is required to be ≥ 4 grades, and the forging process method described in the present invention is used for forging production. The specific implementation steps are as follows:

[0044] 1) 32T ingot type is selected for 316 stainless steel ingot, and the heating temperature range of the ingot is controlled. The initial forging temperature shall not exceed 1200°C, and the final forging temperature shall not be lower than 850°C. Strictly control the final forging temperature to avoid cracks.

[0045] 2) Billets are heated to control their temperature rise rate, and the temperature is raised in steps. After a period of heat preservation, the temperature is rapidly raised to the heat preservation temperature; After a period of time, the temperature is rapidly raised to the holding temperature;

[0046] 3) The tools need to be preheate...

Embodiment 3

[0053] The strong pressure with wide anvil in the present invention is beneficial for the inner layer of the forging to quickly and effectively press the internal pores and obtain a fine grain structure, but at the same time, the larger the width of the anvil, the greater the friction force on the surface of the forging, and the metal flow on the surface of the forging is subject to friction The greater the force resistance, the grain structure has not been fully deformed to refine. On the contrary, the smaller the anvil width is, the smaller the friction force is on the surface of the forging, and the metal flow on the surface of the forging is less affected by the friction force, and the grain structure It can be refined by more sufficient deformation. Therefore, the forging process method provided by the present invention is to use the wide anvil strong pressure deformation method + the temperature control narrow anvil uniform deformation method to carry out multi-pass forgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com