20 high mill intermediate roller cone

A technology of 20-roll rolling and middle roll, which is applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the problems of the second-rib wave defect, the improvement effect of the second-rib wave is not obvious, and the lack of it, and achieve the second-rib wave defect Effects of elimination, reduction of uneven deformation, and improvement of plate shape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

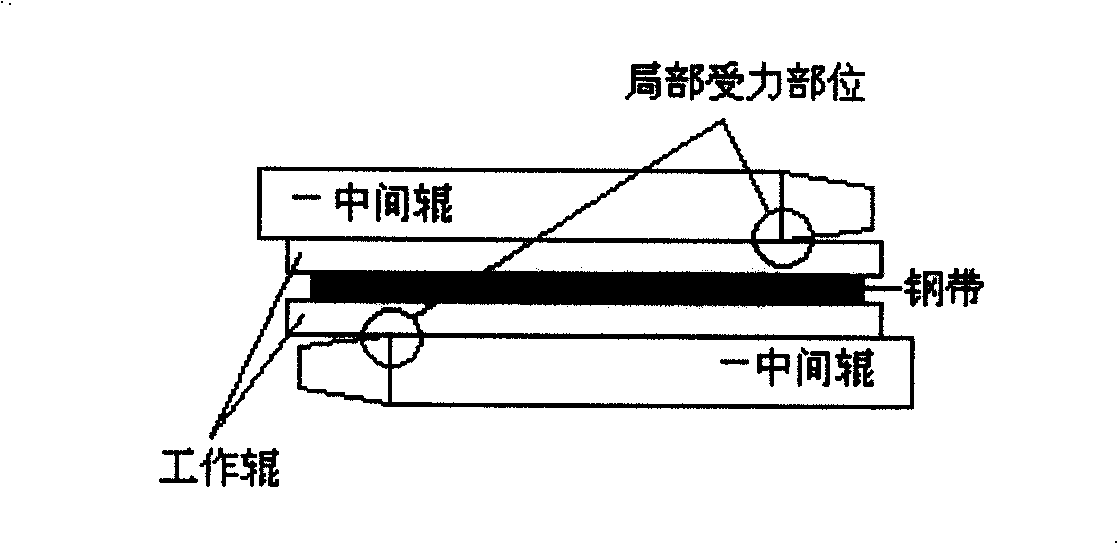

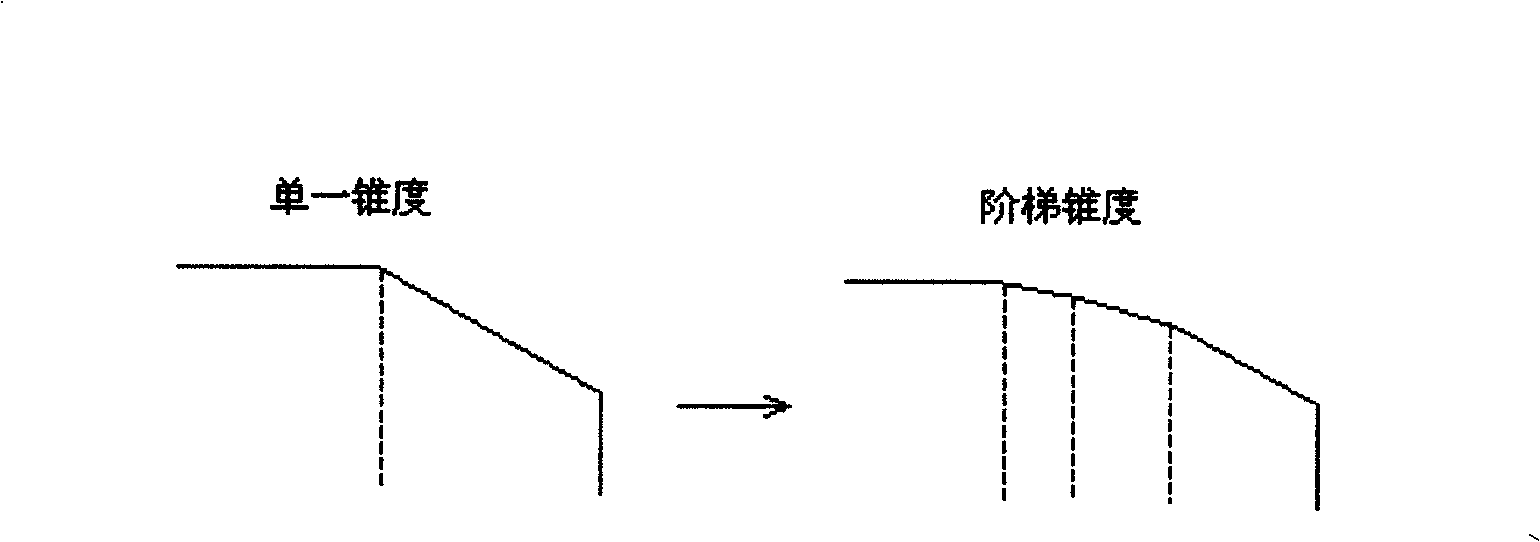

[0013] Such as figure 2 As shown, the cone part of the middle roll of the 20-high rolling mill is improved from the original single taper to a second-order taper, and the cone is a second-order taper (0.3°+0.7°). The improved step taper is as follows image 3 shown. After adopting an intermediate roll with a stepped taper, the local excessive force of the roll system has been improved, the uneven deformation of the corresponding position of the foil material has been reduced, the second rib wave defect has been eliminated, and the quality of the plate shape has been significantly improved.

Embodiment 2

[0015] Such as figure 2 As shown, the cone part of the middle roll of the 20-high rolling mill is improved from the original single taper to the second-order taper, and the cone is a third-order taper (0.2°+0.4°+0.8°). The improved step taper Such as image 3 shown. After adopting an intermediate roll with a stepped taper, the local excessive force of the roll system has been improved, the uneven deformation of the corresponding position of the foil material has been reduced, the second rib wave defect has been eliminated, and the quality of the plate shape has been significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com