Stamping die surface treatment method with synergistic effect of laser microstructure and coating

A synergistic, stamping die technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of excessive thinning rate, poor wear resistance, and no improvement in wear resistance of the die surface, to suppress unevenness Deformation behavior, improving mechanical properties, preventing the effect of scratching the workpiece surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

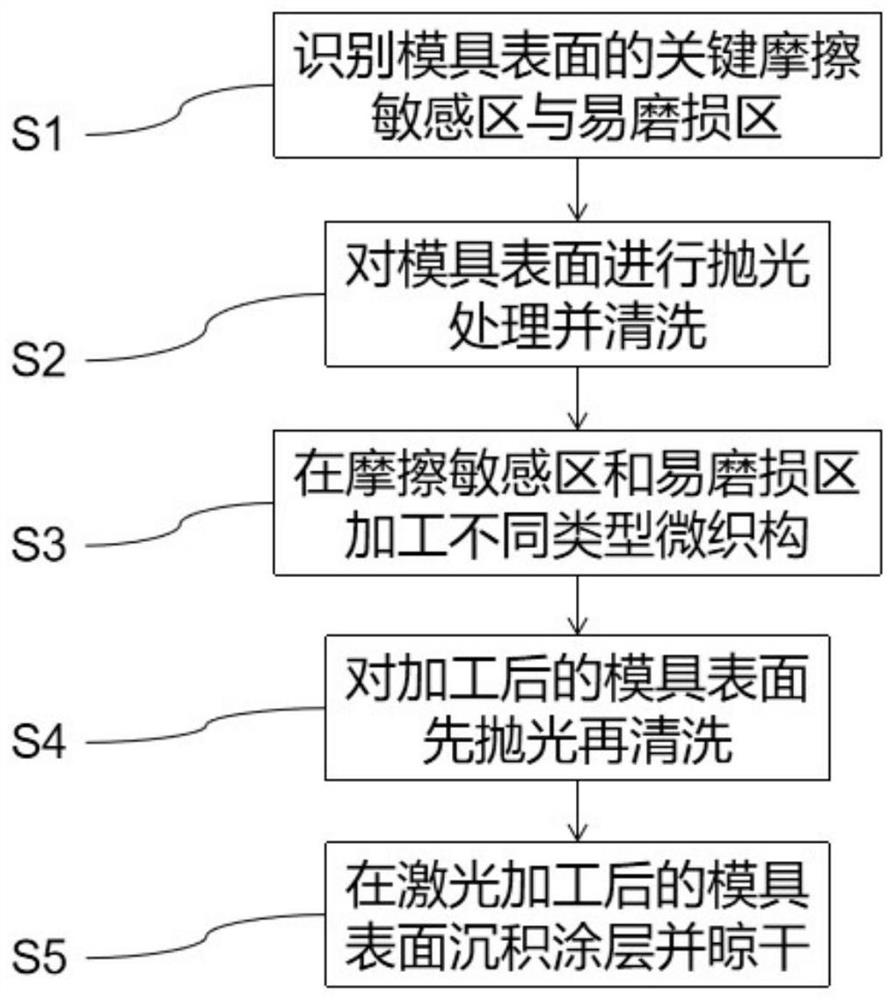

[0044] Such as figure 1 As shown, the stamping die surface treatment method of laser micro-texture and coating synergistic effect of the present invention comprises the following steps:

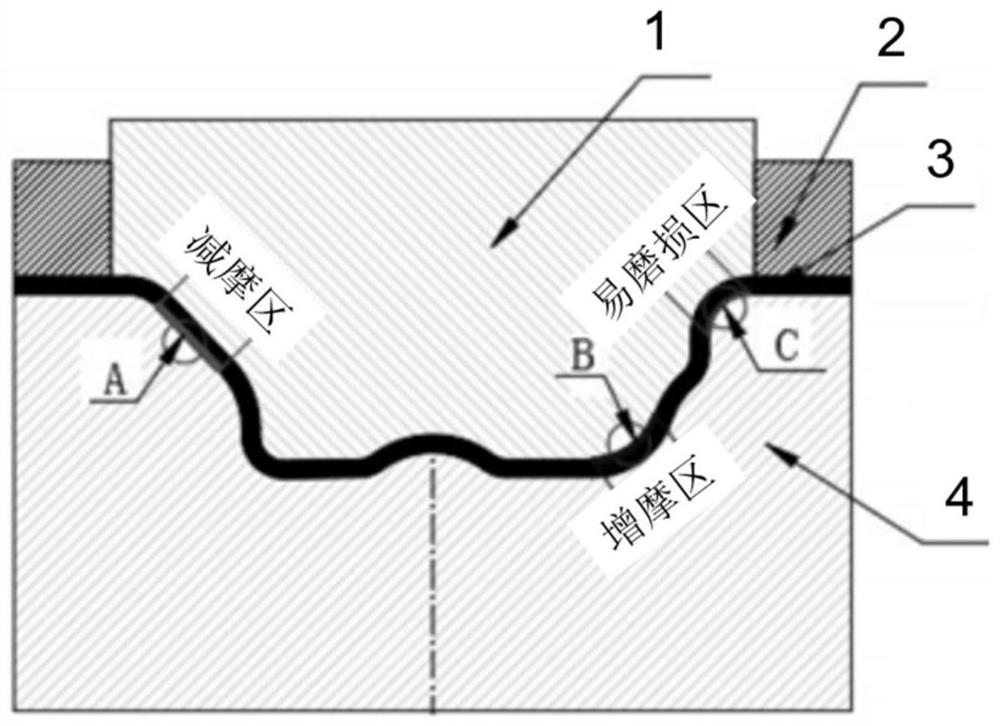

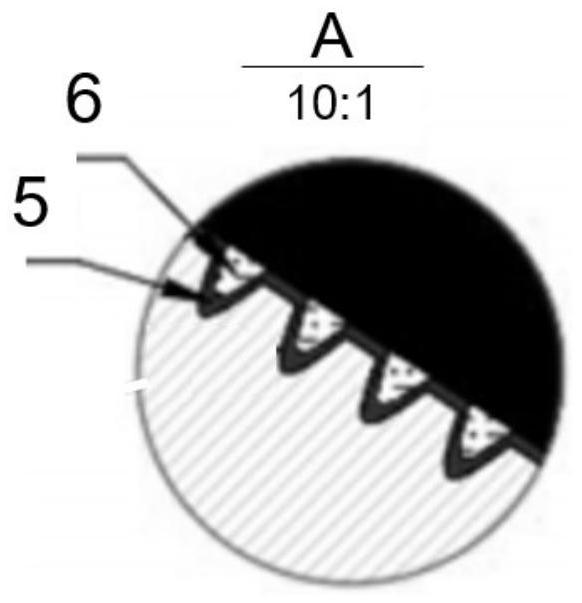

[0045] S01: If figure 2As shown, for the dynamic simulation analysis of the stamping process, the key friction sensitive area of the mold surface is determined according to the change in the maximum thinning rate of the formed part or the change in the maximum thickness increase rate of the formed part obtained from the analysis. Divided into: flange area, punch and die fillet area, side wall area and bottom area; using single factor rotation method, set different friction coefficients for each divided area, that is, set different friction coefficients in each area according to diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com