Scientific injection molding visualization technology

A scientific and technological technology, applied in the field of scientific injection molding visualization, can solve the problems of unoptimized injection molding process parameters, unfavorable standardized data production of enterprises, lack of data support and scientific basis, etc., to achieve unmanned automatic injection molding production, Uniform volume shrinkage, optimized injection molding process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

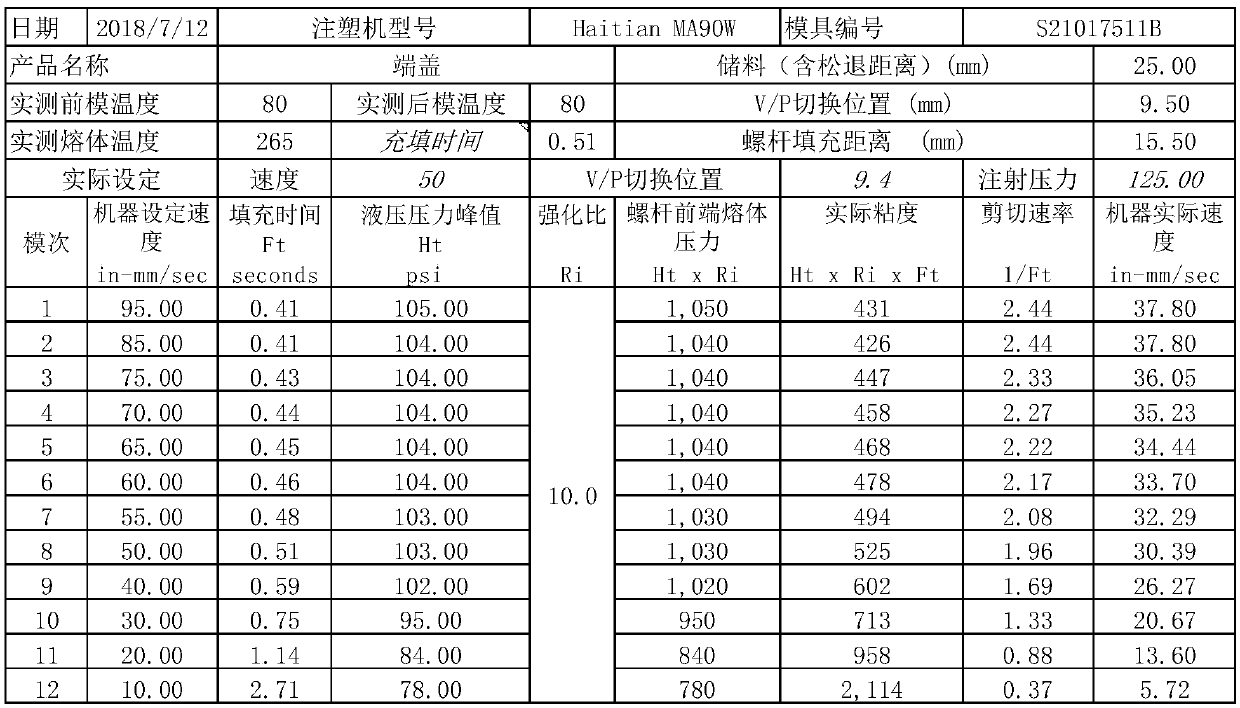

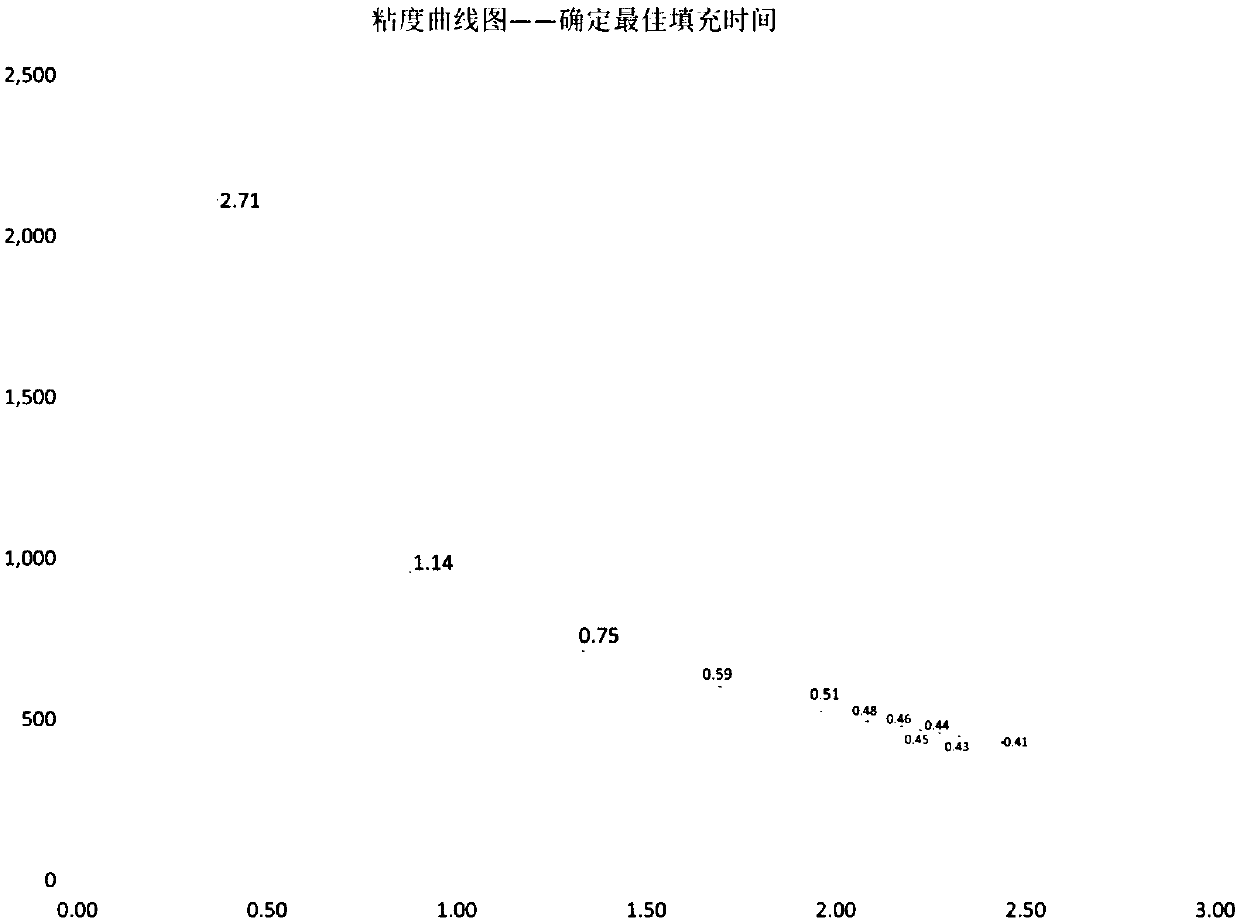

[0046] The technical scheme of the present invention will be described clearly and completely below in conjunction with the implementation case. This implementation case is an example with the injection molding process of the end cap, and the involved charts also represent the injection molding process parameters of the end cap.

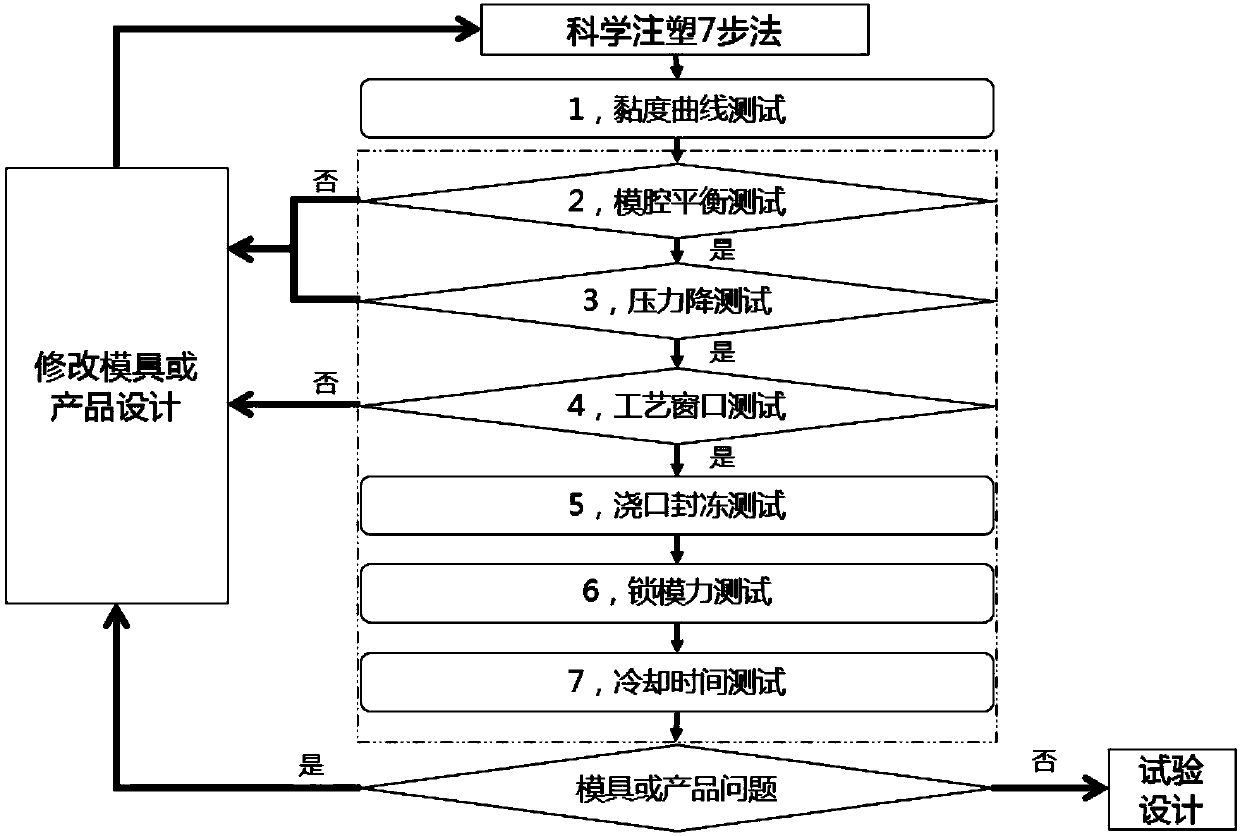

[0047] The scientific injection molding process of the present invention mainly includes a design stage, a mold trial stage and a mass production stage:

[0048] 1. Design stage: use mold flow analysis technology (CAE simulation technology) to optimize product structure and mold design, such as product wall thickness, mold runner system, mold cooling system, etc. Mold flow analysis technology is a commonly used technology, and will not be expanded in detail here.

[0049] 2. Mold trial stage: optimize the injection molding process, verify and optimize the injection mold by using the seven-step method of scientific injection molding, segmented injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com