Patents

Literature

136 results about "Mold testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing injection mold

The invention belongs to the field of a frontier of mold processing and manufacturing and in particular relates to a method for manufacturing a zero FIT injection mold. The method comprises the following steps: performing CAM tool path process design, performing a numerical control machining process, performing electric spark and wire-electrode cutting machining, performing grinding machine processing and performing mold detection according to mold design, engineering drawing manufacturing, mold tolerance standard setting and mold processing. After the mold processing and manufacturing operation is finished, the assembling requirements can be met, and the manufacturing precision of the mold is greatly improved, so that qualified products are obtained at a time, and the cumbersome process of performing repeated mold testing and modifying product parameters and mold parameters is avoided after the mold processing is finished. The method is high in practicability and good in service effect and can be widely popularized and applied in the field of manufacturing of injection molds.

Owner:锦丰科技(深圳)有限公司

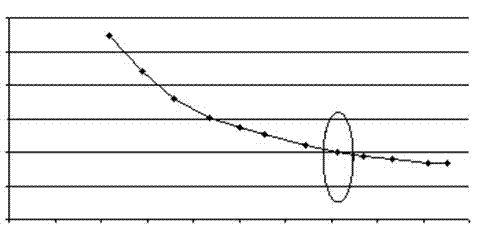

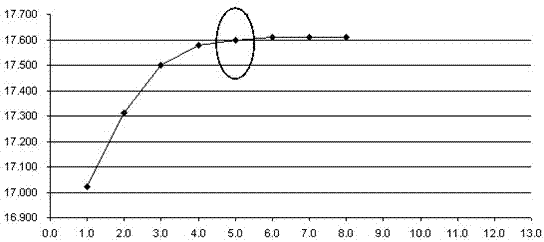

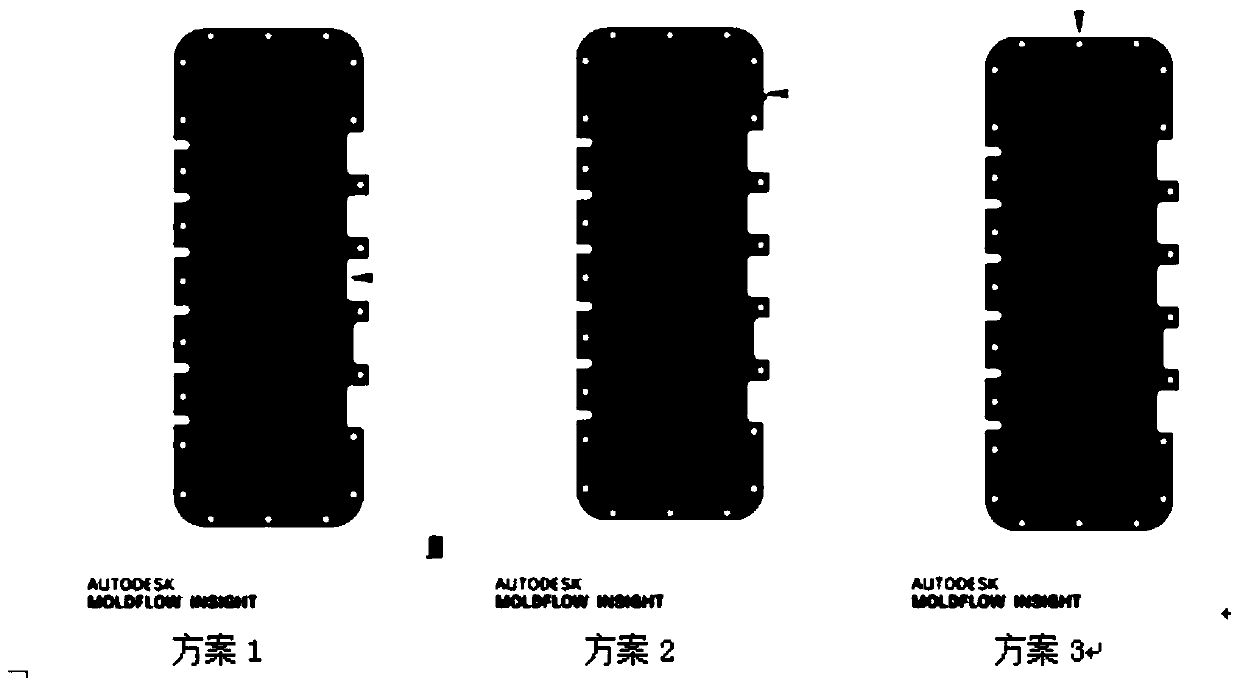

Automotive trim panel injection moulding technology based on BP (Back Propagation) neural network

InactiveCN106055787AReduce workloadImprove work efficiencyGeometric CADSpecial data processing applicationsNetwork modelEngineering

The invention discloses an automotive trim panel injection moulding technology based on a BP (Back Propagation) neural network. The automotive trim panel injection moulding technology comprises the following steps: establishing a plastic part mold flow CAE (Computer Aided Engineering) analysis model; simulating the injection moulding technical parameters of the plastic part, and determining technical parameters which can be set; preliminarily optimizing the optimum value domain, which is improved on the basis of buckling, of each technical parameter; carrying out prediction model training on an obtained experiment result by the BP neural network to obtain a prediction model; and on the basis of the optimum value domain, designing a quadratic stereo orthorhombic optimum value domain optimization scheme, applying the neural network model to predict, and directly optimizing an optimal parameter domain value. The automotive trim panel injection moulding technology aims at the problem of large buckling deformation during CAE analysis when injection imoulding is carried out, the minimum buckling and the optimal injection moulding technical parameters of the plastic part are optimized, practical injection moulding mold testing frequencies and mold testing cost are lowered, workload is lowered, and working efficiency is improved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

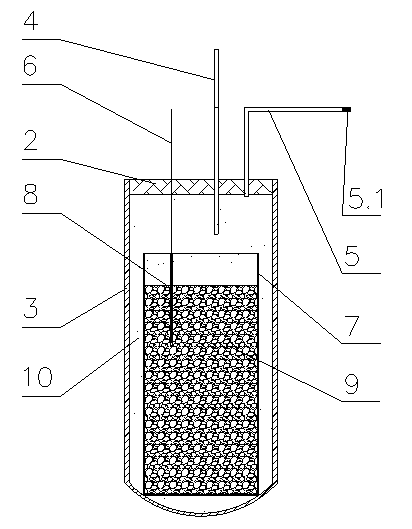

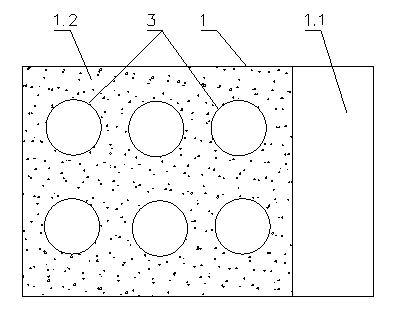

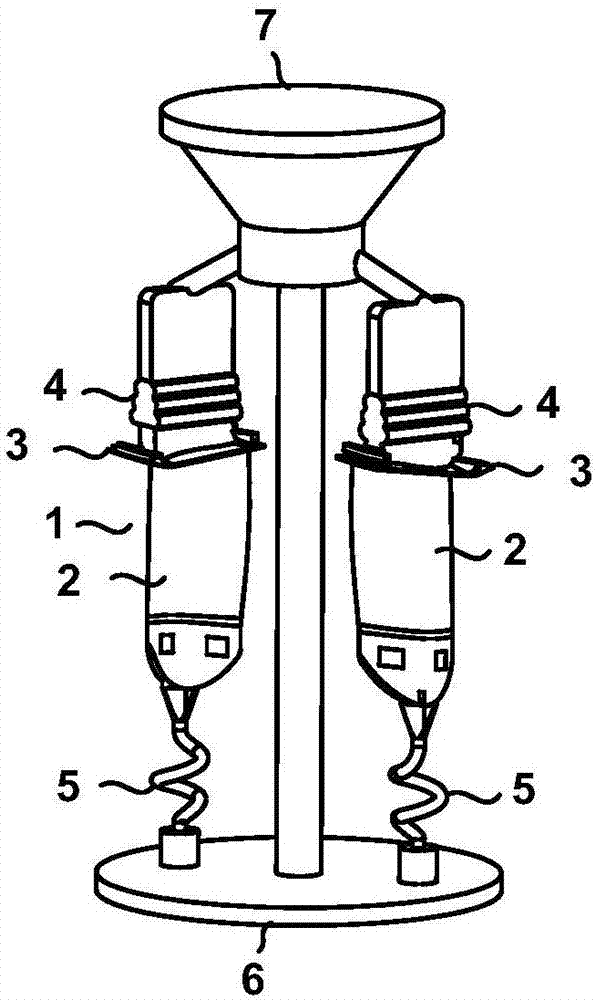

Method and device for measuring concrete or mortar volume deformation

InactiveCN103675242AEasy and precise pouringAccurately reflectMaterial testing goodsUsing fluid meansBottleMold testing

The invention discloses a method and a device for measuring concrete or mortar volume deformation. The method comprises the following steps: pouring a mixture mixed by concrete or mortar into an open mold testing box according to engineering needs; wholly putting the open mold testing box filled with the concrete or mortar mixture into a heat insulation bottle; sealing the bottle opening of the heat insulation bottle by using a sealing cover provided with a graduated tube, a gas-guide tube and a thermometer; pouring liquid which is not dissolved with water into the heat insulation bottle through the graduated tube, so that the mold testing box is totally immersed by the liquid and the liquid is full of an inner cavity of the heat insulation bottle; and putting the whole heat insulation bottle into a constant temperature water area, so that the volume expansion or shrinkage deformation conditions of the concrete or mortar under heat insulation conditions can be accurately measured through the liquid level position conditions in the graduated tube. The method has the advantages of high measurement accuracy, simple structure, convenience in operation and the like.

Owner:GUIZHOU CONSTR SCI RES & DESIGN INST OF CSCEC +1

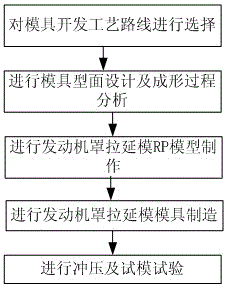

Automobile covering part mold manufacturing method

InactiveCN105689560ASolve technical problems with long production cycle and high costShorten the production cycleShaping toolsEngineeringMold testing

The invention discloses an automobile covering part mold manufacturing method. The method comprises steps as follows: step 1, selecting a mold development process route; step 2, performing mold profile design and forming process analysis; step 3, manufacturing an engine cover drawing die RP model; step 4, manufacturing an engine cover drawing die mold; step 5, performing stamping and mold testing experiments. The automobile covering part mold manufacturing method has the technical effects that the manufacturing period of an automobile covering part mold is shortened, and the production cost is reduced.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Method for preparing oil well cement test block by utilizing silicon oxynitride ceramic composite microspheres

The invention provides a method for preparing an oil well cement test block by utilizing silicon oxynitride ceramic composite microspheres. The method comprises the following steps: preparing silicon oxynitride ceramic composite obturator hollow microspheres, compounding, mixing, performing stirring and size mixing, performing mold testing and performing strength testing; uniformly mixing and stirring 40 to 50 percent by weight of G-grade oil well cement, 10 to 15 percent by weight of 13-micrometer ultrafine cement, 25 to 35 percent by weight of silicon oxynitride ceramic composite obturator hollow microspheres with the granularity of 5 to 50 micrometers, 5 to 7 percent by weight of coal ash with the burning loss of 1.1 percent, 1.5 to 2 percent by weight of calcium oxide with the purity of 99.9 percent, 0.5 to 1.0 percent by weight of sodium sulfate and 1 to 3 percent by weight of silica fume, stirring and mixing the raw materials for 40 seconds inside a stirring machine with the water-ash ratio of 0.5 to 0.6 (W / C), then pouring the mixture into a test mold, conserving for 24-48 hours in a water-bath maintenance box at a constant temperature of 52 DEG C, immersing the demolded mixture in cold water for 1 hour, and finally performing the performance test on the mixture.

Owner:SHANDONG UNIV OF TECH

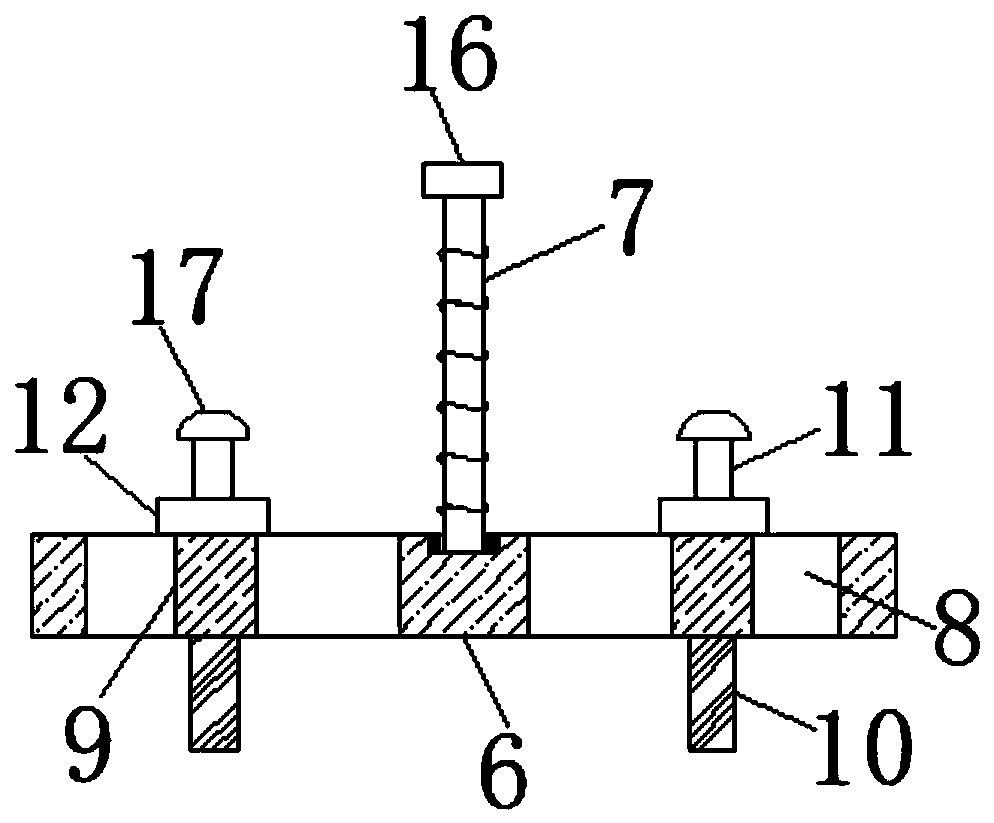

Device and method for fiber and pitch adhesion testing

ActiveCN105181585AAdhesion quantificationAdhesion performance test quantificationUsing mechanical meansMaterial analysisVertical planeFiber bundle

The invention provides a device and method for fiber and pitch adhesion testing. The testing device comprises a pitch injection groove, a mold testing base plate, a clamp block, a fiber caulked joint and a fastening device, wherein the pitch injection groove is an axisymmetric polygonal notch container component provided with a base plate and an open side wall, a closed groove is formed by the pitch injection groove and the clamp block located at the open side wall end, the open side wall end becomes narrow and is detachably arranged on the mold testing base plate, the open side wall is located on the vertical plane of the axial central line of the container component, the fiber caulked joint is a groove located at the position where the pitch injection groove and the clamp block intersect with the axial central line of the testing device and penetrates through the whole testing device, and bolts are arranged at the head side and end side of the fiber caulked joint respectively. According to the method, various fibers are bound into a fiber bundle with similar circular section diameters, the mass change of the fiber bundle before and after pitch extrusion at the pitch softening point temperature is calculated so as to test fiber and pitch adhesion in a quantified mode, and then a testing result is more objective and more comparable.

Owner:YANGZHOU UNIV

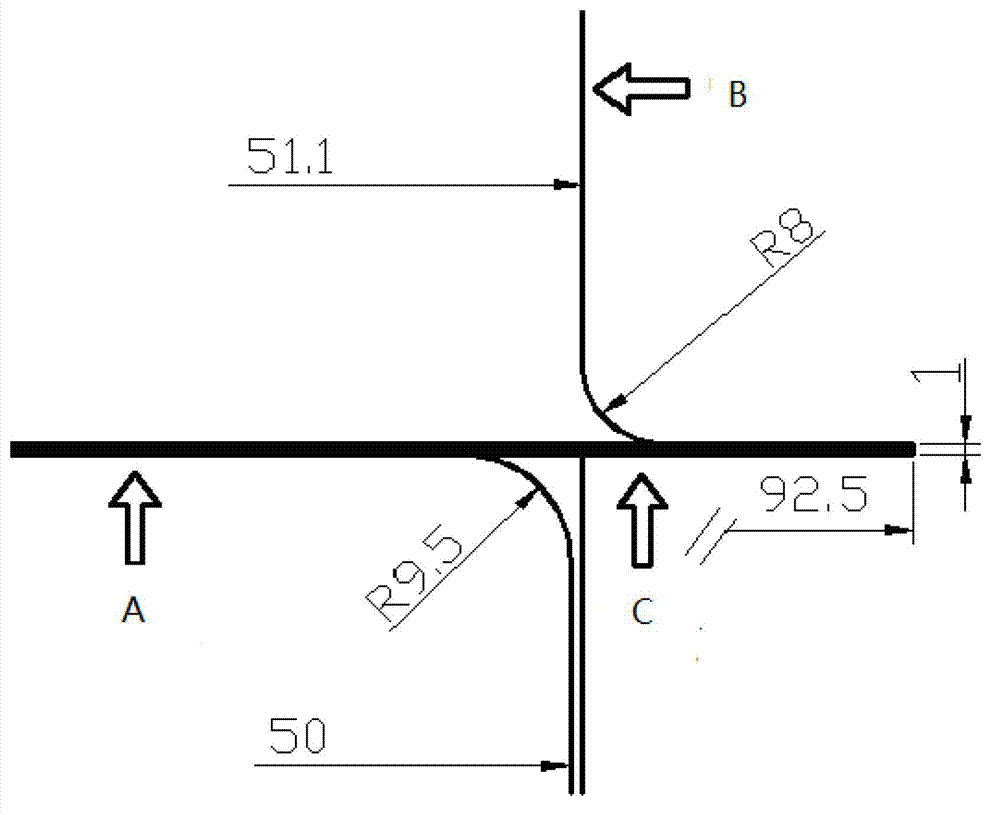

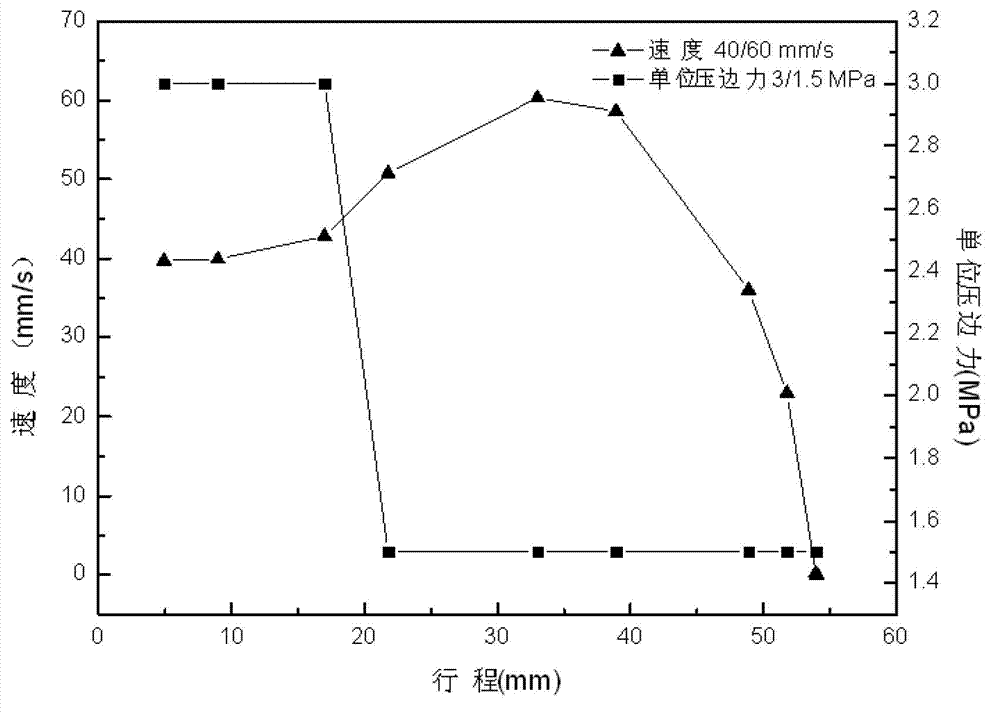

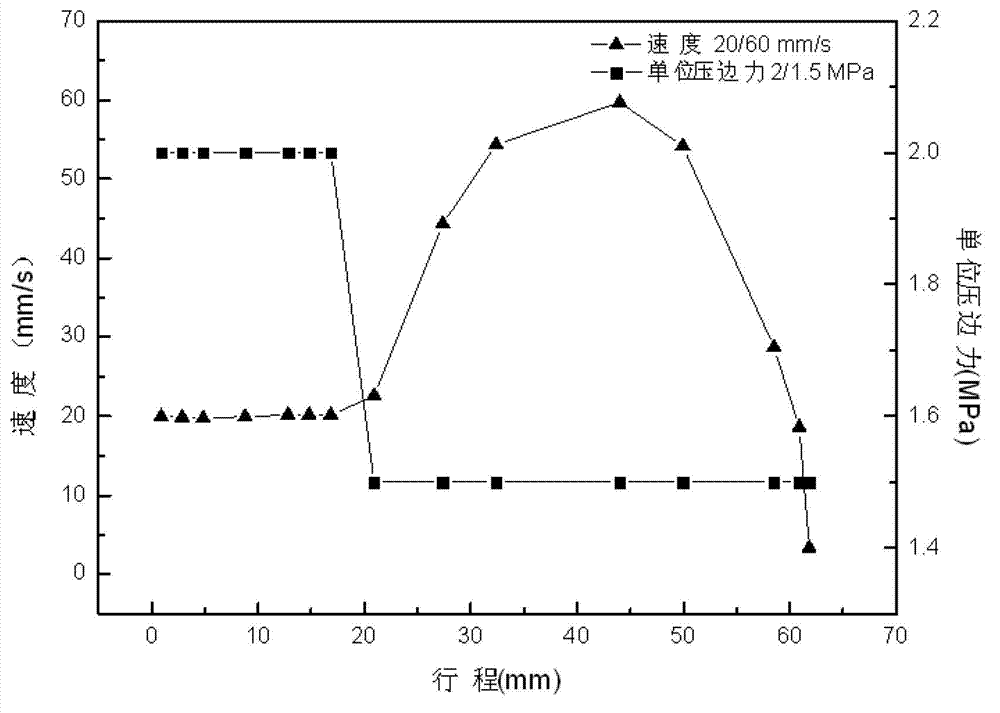

Variable speed and variable blank holder force linked sheet drawing process

The invention discloses a variable speed and variable blank holder force linked sheet drawing process. The process comprises the following steps of: performing low-speed drawing on a sheet at a severe deformation stage to guarantee that the sheet has sufficient time for plastic flowing; performing a subsequent forming stage by using higher forming speed to increase the forming efficiency; and meanwhile, realizing speed control over a sheet forming process in coordination with different blank holder forces. According to the process, the forming capacity of the sheet and the forming quality of a part are improved, variable speed and variable blank holder force are easy to realize in a forming process, the process is simple, the operability is high, and the problems of complex mold testing process, high cost and low efficiency of qualified parts existing in the conventional drawing process through repeated mold testing and repair are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing oil well cementing cement briquette with silicon carbide/boron carbide hollow ceramic microbeads

InactiveCN103803883AChange the dependence of floating beadsLow densityMicrofine cementComposite ceramic

The invention provides a method for preparing an oil well cementing cement briquette with silicon carbide / boron carbide hollow ceramic microbeads. The method comprises preparation of silicon carbide / boron carbide closed-pore hollow composite ceramic microbeads, burdening, mixing, stirring and size mixing, mold testing and strength testing. The method is characterized in that 40-50wt% of grade G oil well cement, 10-15wt% of 13-micron superfine cement, 25-35wt% of silicon carbide / boron carbide composite ceramic microbeads having the grain size ranging from 5 to 50 microns, 5-7wt% of fly ash having the loss on ignition of 1.1%, 1.5-2wt% of calcium oxide having the purity of 99.9%, 0.5-1.0wt% of sodium sulfate and 1-3wt% of micro-silicon are stirred in a stirrer in a water cement ratio ranging from 0.5 to 0.7 (W / C) for size mixing for 40 seconds, next, the mixture is poured into a test mold and maintained in a water-bath curing box at a constant temperature of 52 DEG C for 24 hours or 48 hours, and after being demolded, the obtained material is soaked in cold water for 1 hour, and then the properties of the obtained material are tested.

Owner:SHANDONG UNIV OF TECH

Mould testing method for precise injection mould

ActiveCN102338705ALow costReduce the number of trialsStructural/machines measurementMold testingComposite material

The invention provides a mould testing method for a precise injection mould. The method is characterized by comprising the following steps of: 1, measuring the water transport flow of the mould; 2, obtaining a reasonable ejection speed of an injection moulding machine; 3, performing a glue balance test; 4, performing a pressure maintaining time test; and 5, ending the mould test. Through the mould testing method for a precise injection mould provided by the invention, the traditional mode of determining the mould repairing scheme through subjective judgment of people is changed, and the technology for a mould test of all mould testing workers is set to form a uniform standard; and thus, a reasonable technology for injection moulding can be directly found out without unnecessary efforts, and the defects of the mould can be discovered in time. The cost of twice mould tests can be saved for each set of mould on average (the repairing cost is saved since the mould testing times is reduced).

Owner:SHANGHAI GLOBAL PRECISION MOLD & PLASTICS

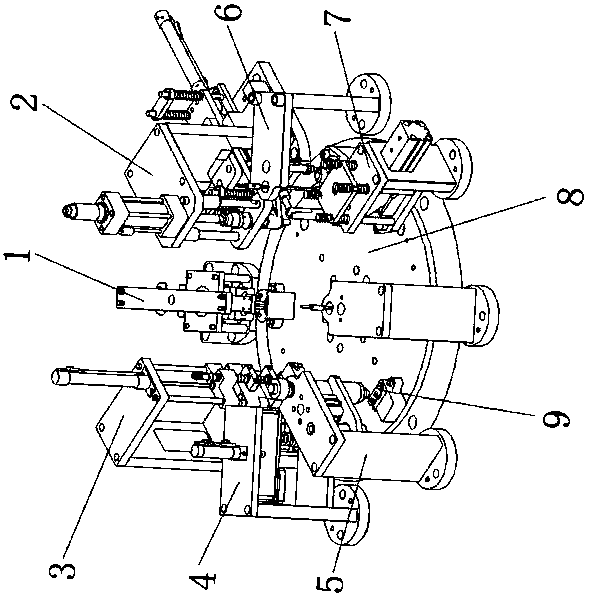

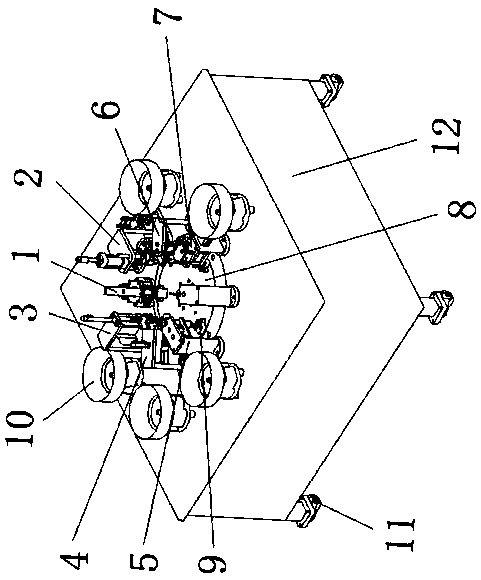

Automatic assembling machine for hasps

PendingCN107914141AImprove assembly efficiencyQuality improvementAssembly machinesMetal working apparatusEngineeringMold testing

The invention discloses an automatic assembling machine for hasps. The automatic assembling machine comprises an assembling bed, wherein universal wheels are mounted at the bottom of the assembling bed, a hasp fetching mechanism is mounted in front of the assembling mechanism, and molds are mounted on the assembling mechanism; and hasp mold detection equipment is connected to the lower part of a hasp punching mechanism, a hasp lower cover unloading device is mounted at the lower part of the hasp mold detection equipment, a hasp assembling machine spring unloading mechanism is connected to theleft side of the hasp lower cover unloading device, and a hasp cover mounting mechanism is mounted at the upper part of the hasp assembling machine spring unloading mechanism. According to the automatic assembling machine, the molds can be driven to rotate by the assembling mechanism, and assembling works of parts in the molds in each step are sequentially finished, so that the assembling efficiency of the hasp is increased; and the assembled parts can be detected by virtue of the hasp mold detection equipment, so that rejected products are avoided, and the assembling quality of the hasps is improved.

Owner:DONGGUAN D&G GARMENT ACCESSORIES

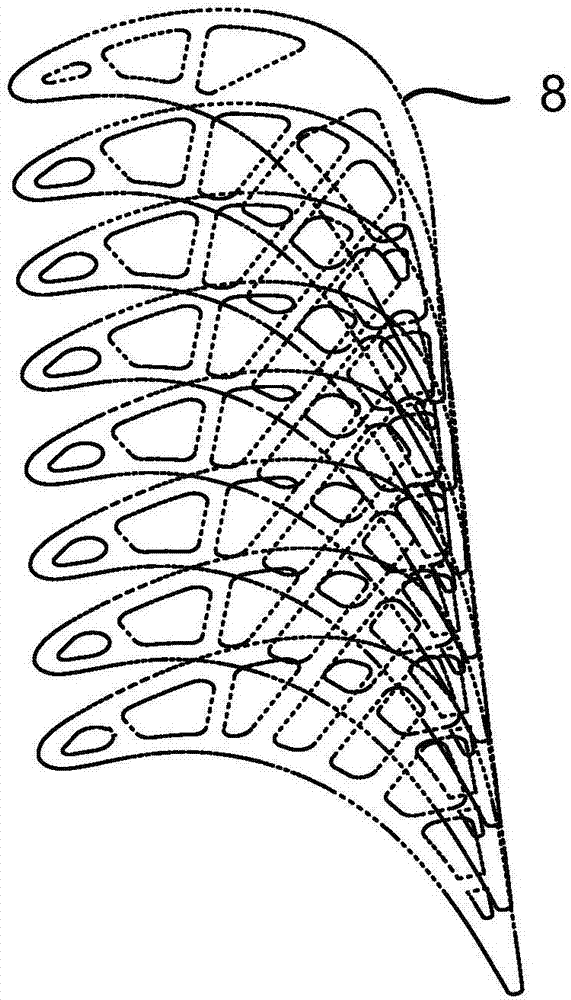

Determining method of designed shrinkage of hollow turbine blade investment casting mold

ActiveCN107577874AImprove yieldSimple designSpecial data processing applicationsInvestment castingDesign cycle

The invention discloses a determining method of designed shrinkage of a hollow turbine blade investment casting mold, and relates to hollow turbine blade investment casting molds. The method is particularly applicable to designing of a mold cavity of a hollow turbine blade investment profile mold. A deformation model of hollow blades is obtained through a finite element method, by cutting out a series of two-dimension cross sections on a blade deformation model and a design model, and making a section line discretized into points, distances among the corresponding points are obtained to builda two-dimension displacement site; bending and torsion deformation and shrinkage deformation included in the displacement site are separated. The inner cross section and the outer cross section of theblades are subjected to line connection processing, afterwards blade stopping structures and non-stopping structures are recognized, then the wall thickness of the hollow blades is calculated, and bycalculating shrinkage of different structures, the distribution of the nonlinear shrinkage is built. Finally a shrinkage model is subjected to least square fit of cubic polynomial, and the determination of the designed shrinkage of the investment casting mold is achieved. The finished product rates of the turbine blades are greatly increased, the cycle for mold testing is shortened, and the frequency for mold testing is reduced. The determining method has the advantages of being short in design cycle, high in precision and high in efficiency.

Owner:XIAMEN UNIV

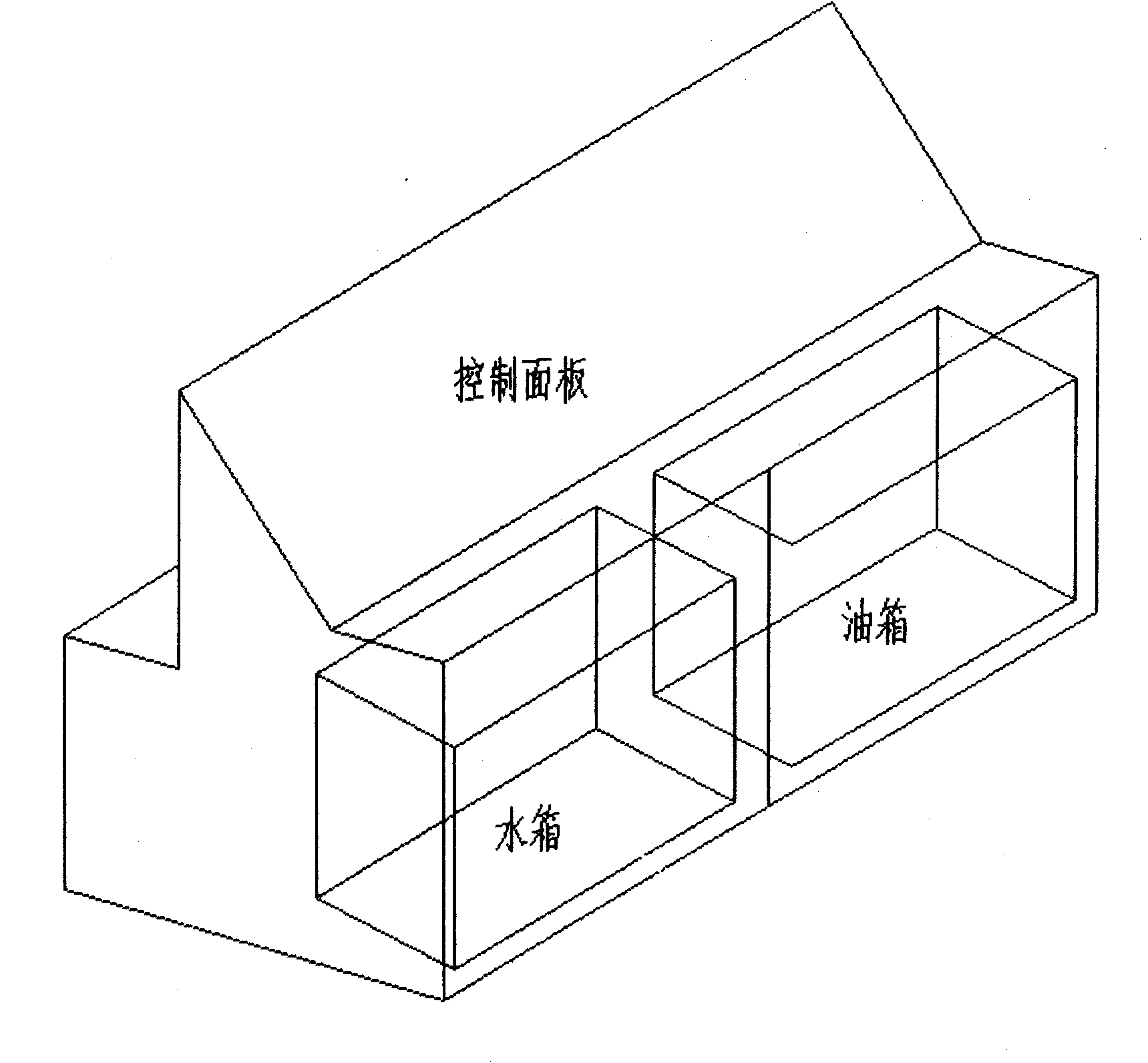

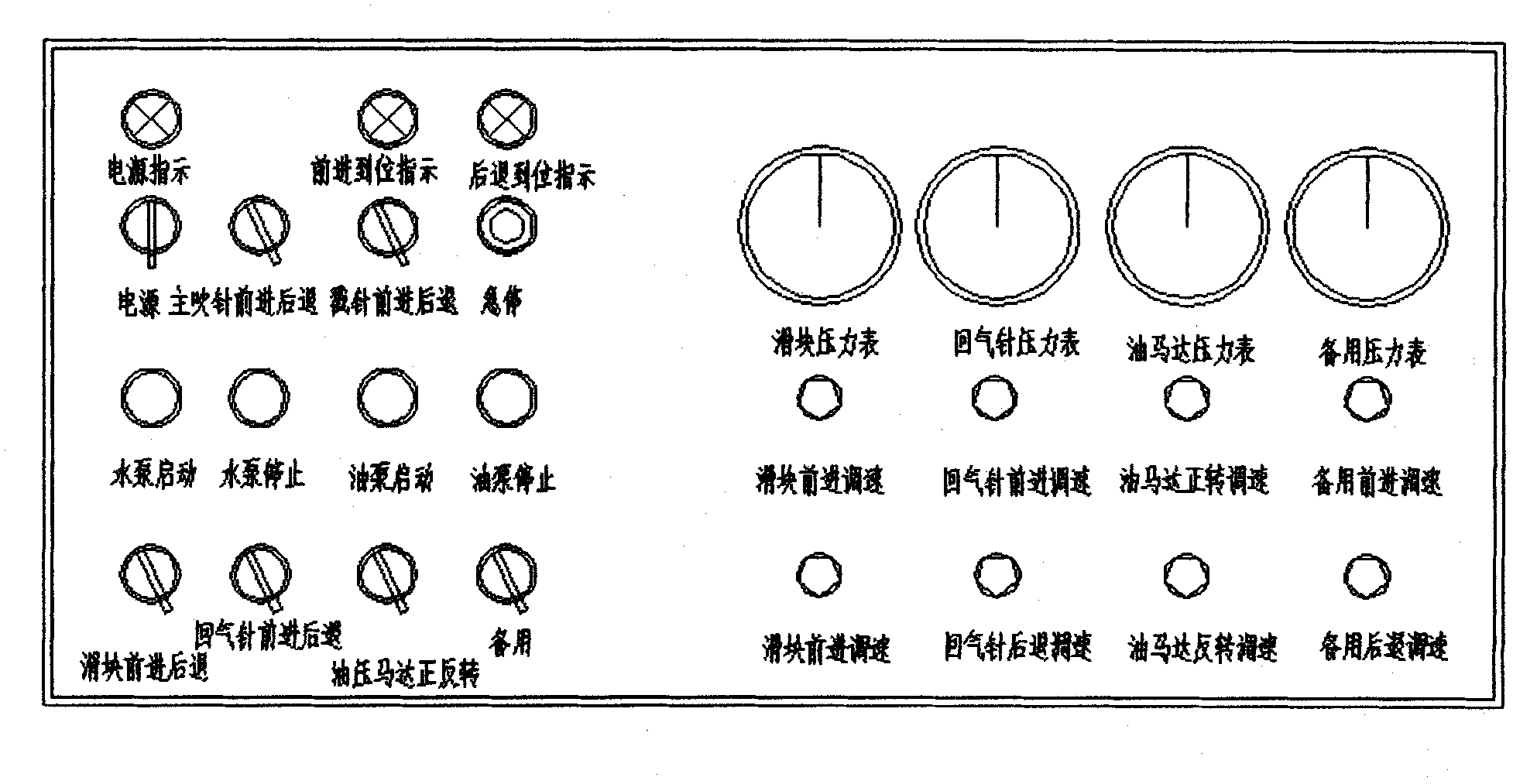

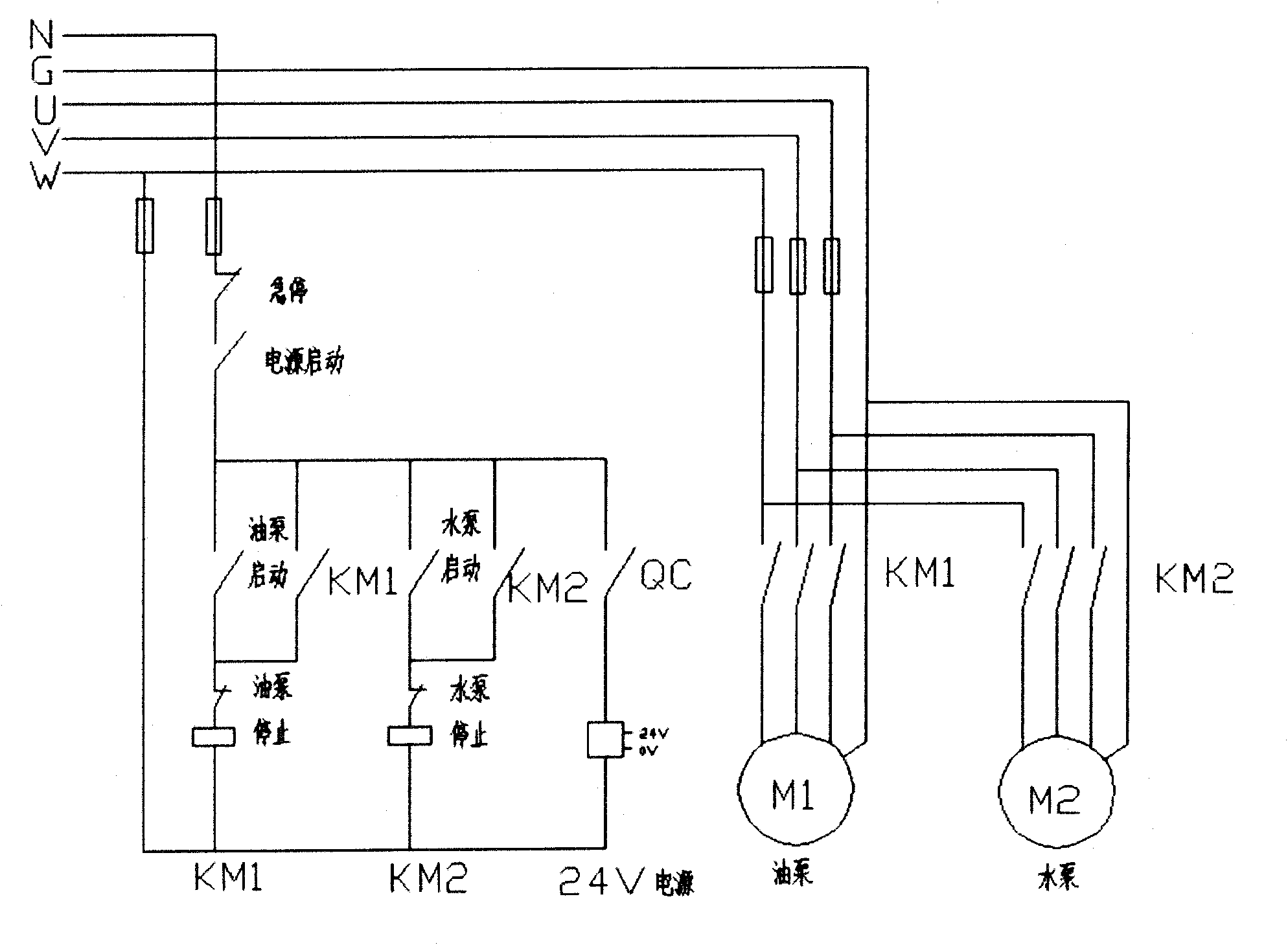

Movable device for testing state of blowing mold

InactiveCN102141481AExtended service lifeEnsure consistencyFluid-tightness measurement using fluid/vacuumMold testingAutomotive engineering

The invention aims to overcome the drawbacks of the prior art and provide a detection device for ensuring that the normalness and stability of the internal elements and movable parts of hydraulic, pneumatic, position sensing and cooling water systems of a large blowing mold are checked before use. Mold state detection car equipment can test the water path, oil path and circuit of the mold before each time of mold replacement. If the water path, oil path and circuit of the mold are normal according to the test, the mold can be replaced according to plan; otherwise, maintenance is required to be performed at once. The checking of the state of the mold by the mold testing car is independent of blowing equipment, so the mold test car can move at anytime and anywhere and can be used flexibly; and when used in checking, the mold test car is more convenient for test in the movable state than in a blowing equipment-mounted state.

Owner:芜湖亚奇汽车部件有限公司

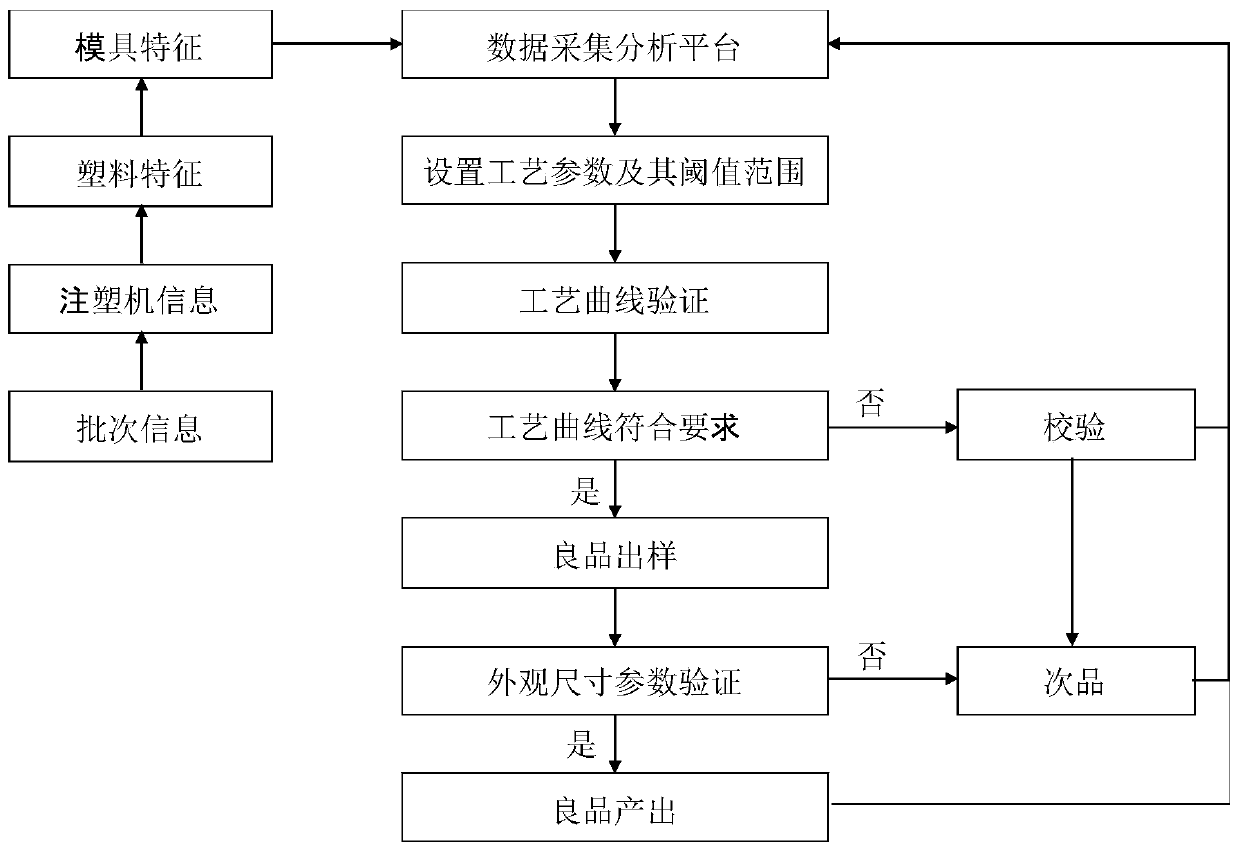

Visual injection molding production process verification method

InactiveCN110978441AImprove consistencyReduce production cost lossProcess engineeringInjection molding machine

The invention discloses a visual injection molding production process verification method. The method comprises the following steps of S1) collecting a product batch, an injection molding machine state, plastic characteristics and mold characteristic data; S2) setting injection molding process parameters and corresponding production thresholds; S3) monitoring a current process curve in real time in an injection molding process, comparing and verifying the current process curve with a standard process curve in an early mold testing stage, and if the current process curve does not accord with the standard process curve, determining that a product is a defective product; and S4) continuously verifying an appearance size parameter of the product passing process curve verification, and if an appearance size meets a requirement, determining that the product is a good product. The process curve formed in the production process can be monitored and controlled, consistency of injection moldingproducts is improved by controlling process parameters, abnormity of the whole batch is avoided, and meanwhile, good products and defective products are completely separated, and production cost of anenterprise is reduced.

Owner:上海澎睿智能科技有限公司

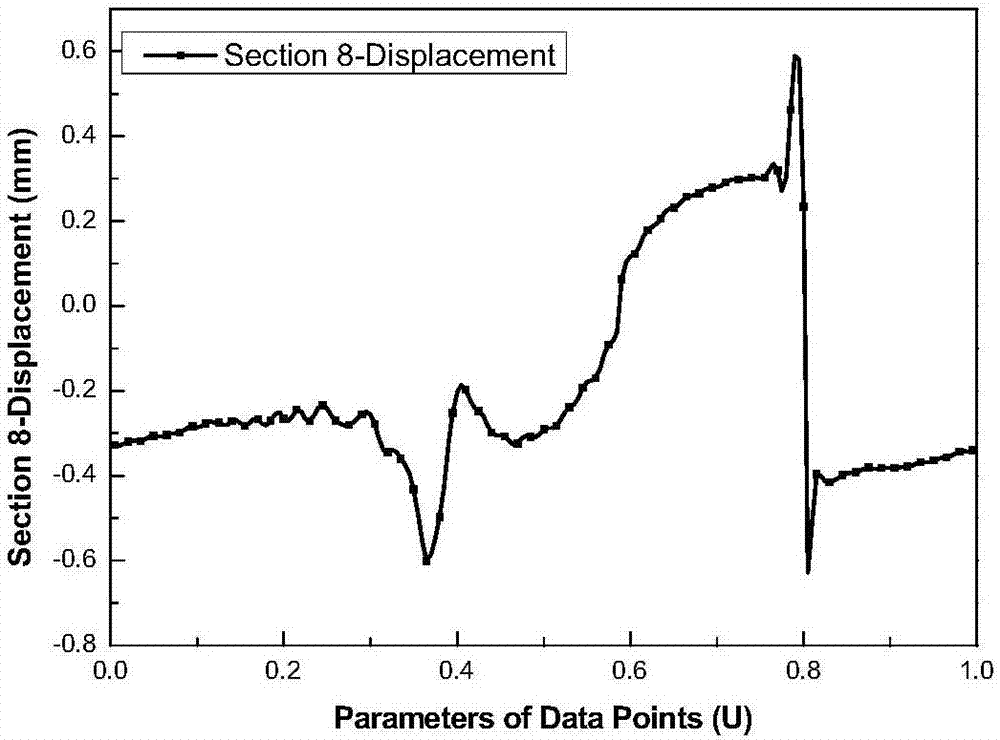

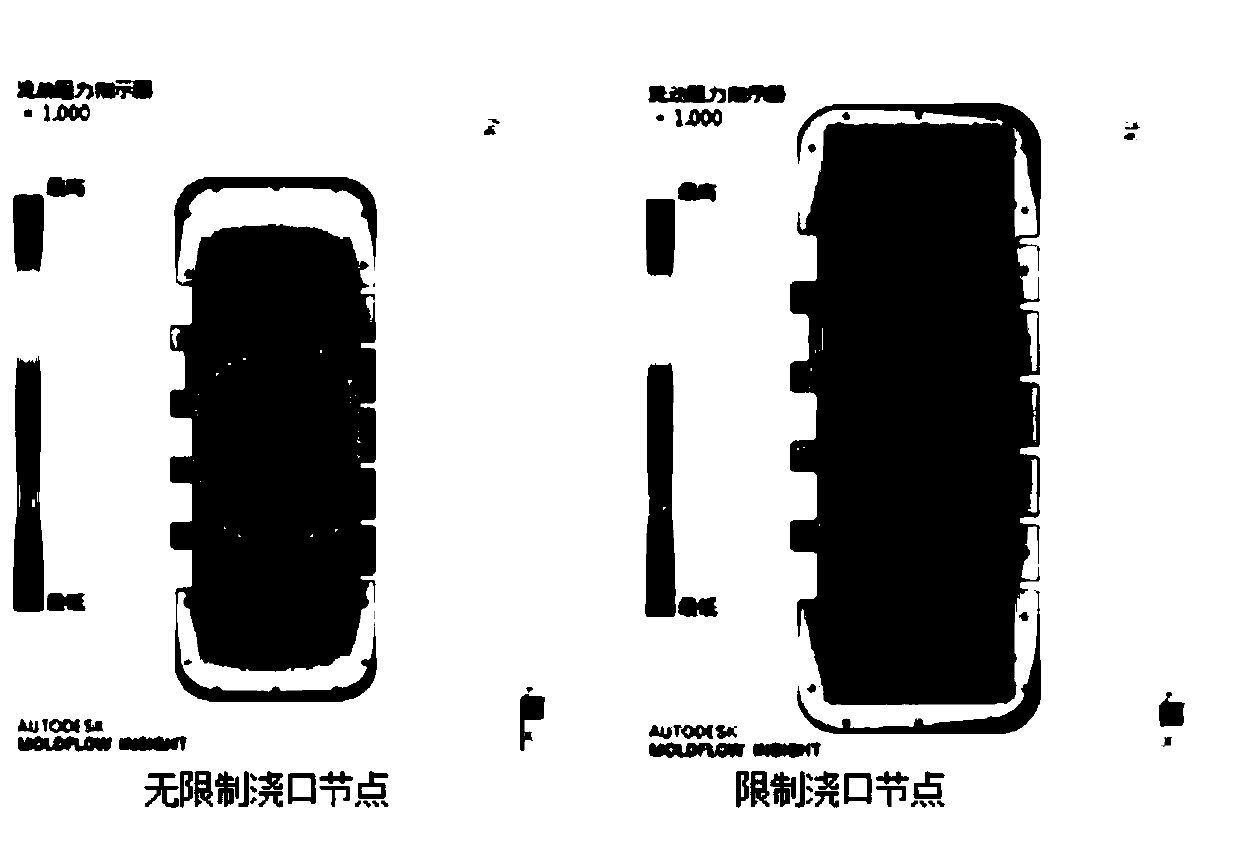

Injection molding plastic product reverse compensation production process

InactiveCN108890982AImprovement of warpage defectsImprove maintenance efficiencyCompensation effectVisual inspection

The invention discloses an injection molding plastic product reverse compensation production process. The process includes following steps: analyzing reasons be going to cause buckling deformation ofa plastic product; aiming at the reasons causing buckling deformation of the product, analyzing an area where buckling deformation of the product possibly occurs; after the area is determined basically, properly reserving steel for the area in the process of mold design for the convenience of subsequent mold maintenance; acquiring a deformation sample plate through first-time mold testing, and acquiring 3D sample plate CAD data of the deformation sample plate by means of three-dimensional scanning reverse engineering; performing preliminary gluing reverse compensation on buckling deformation by means of mirroring and reverse surface forming on mold 3D; after second-time mold testing, confirming reverse compensation effect by means of visual inspection and detection. By the above mode, theprocess is formulated mainly for the defect of buckling deformation of the plastic product, mold maintenance efficiency is improved substantially, maintenance cost is lowered, and the defect of buckling deformation of the product is improved effectively.

Owner:江苏骏伟精密部件科技股份有限公司

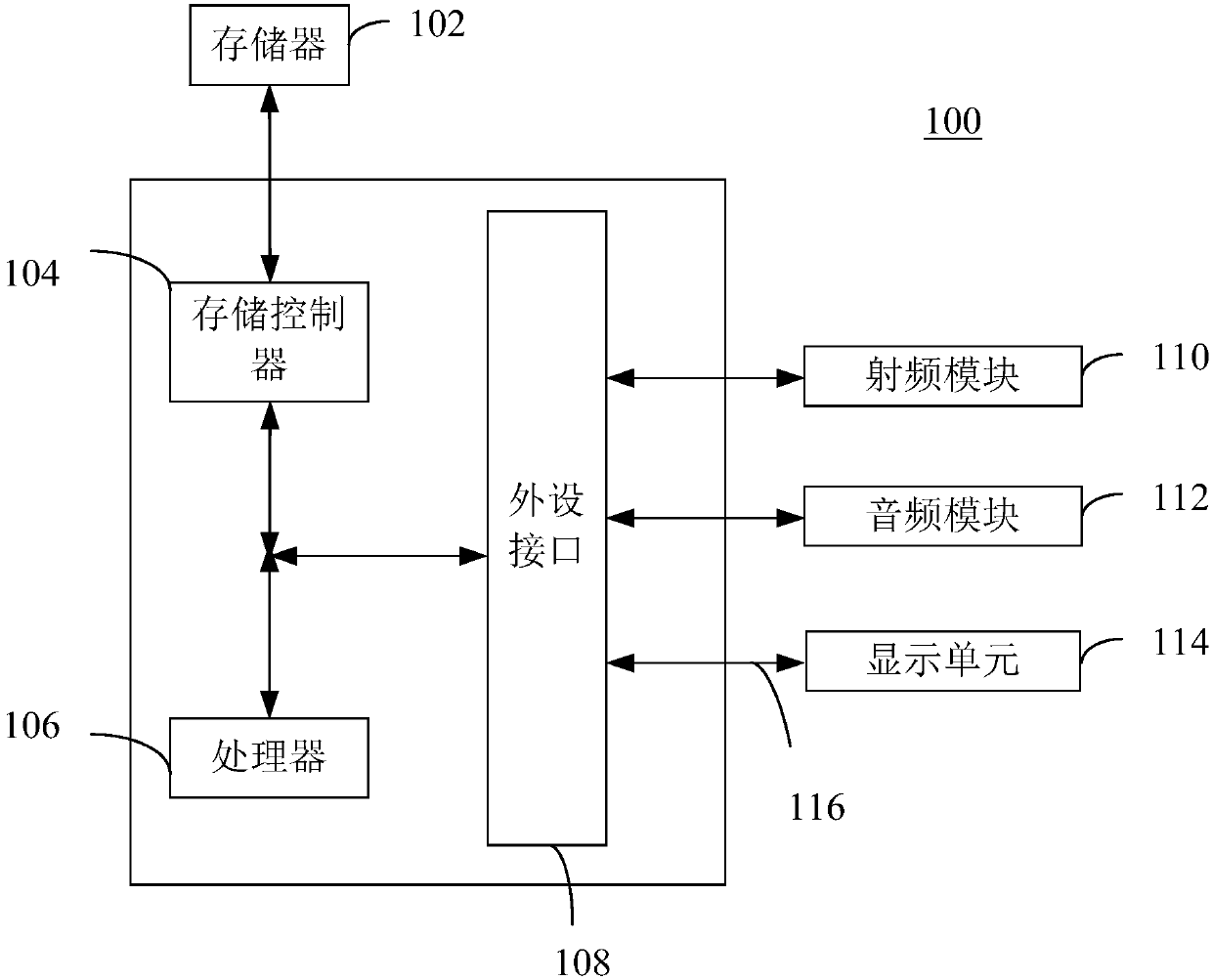

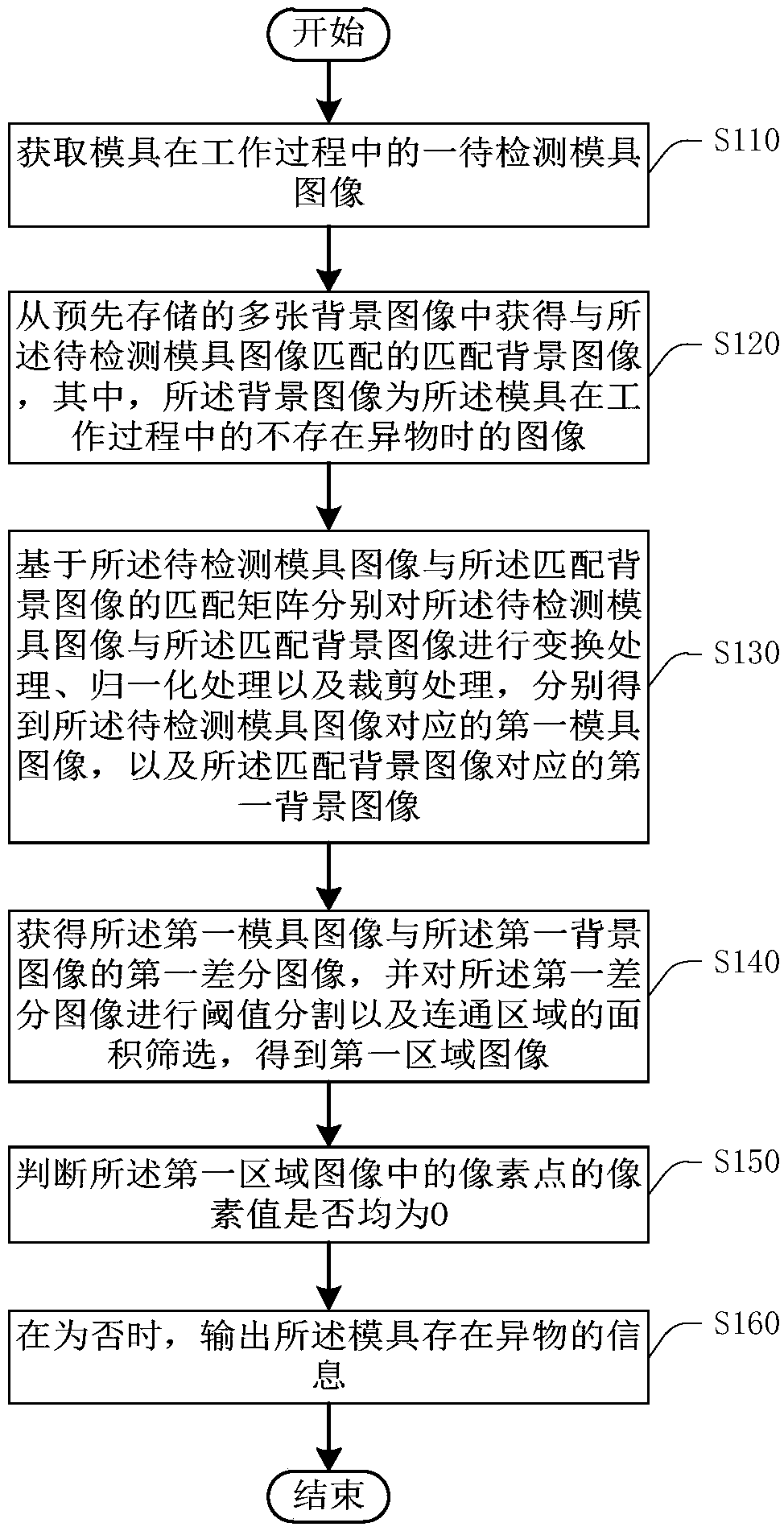

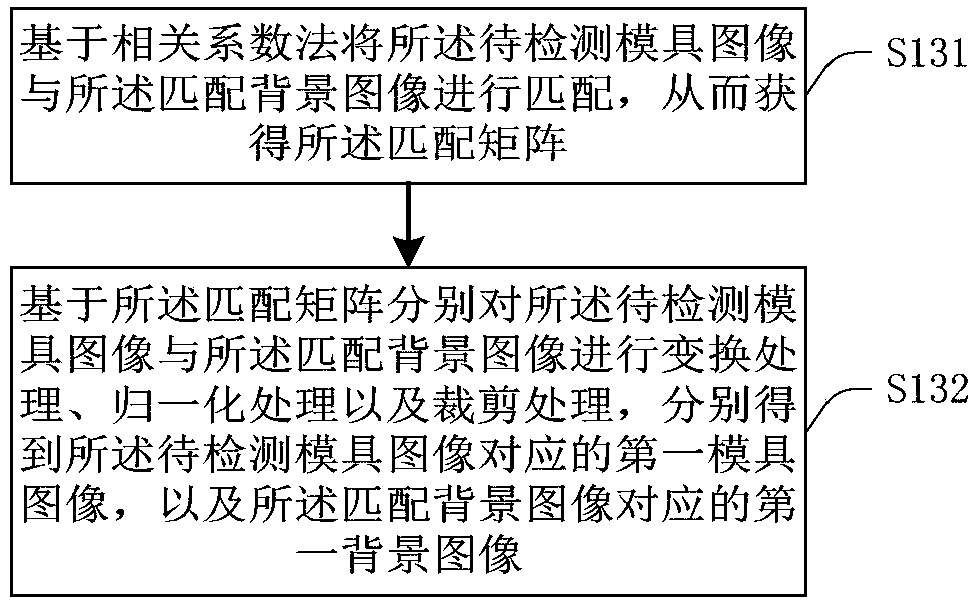

Mold testing method, device thereof and electronic equipment

The invention provides a mold testing method, a device thereof and electronic equipment, wherein the method, the device thereof and the electronic equipment relate to the field of mold testing technology. The mold testing method comprises the steps of acquiring a matched background image which matches a to-be-tested mold image in a plurality of prestored background image, wherein the background image is the image on the condition of no foreign matter in a working process; performing transformation processing, normalization processing and cutting processing on the to-be-tested mold image and the matched background image based on the matching matrix of the to-be-tested mold image and the matched background image, and obtaining a first mold image and a first background image; obtaining a first differential image of the first mold image and the first background image, performing threshold segmentation on the first differential image and communicating area screening, and obtaining a first area image; determining whether the pixel value of pixels in the first area image is zero; and if not, outputting information that the foreign matter exists in the mold. The mold testing method can realize automatic testing for the foreign matter of the mold.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

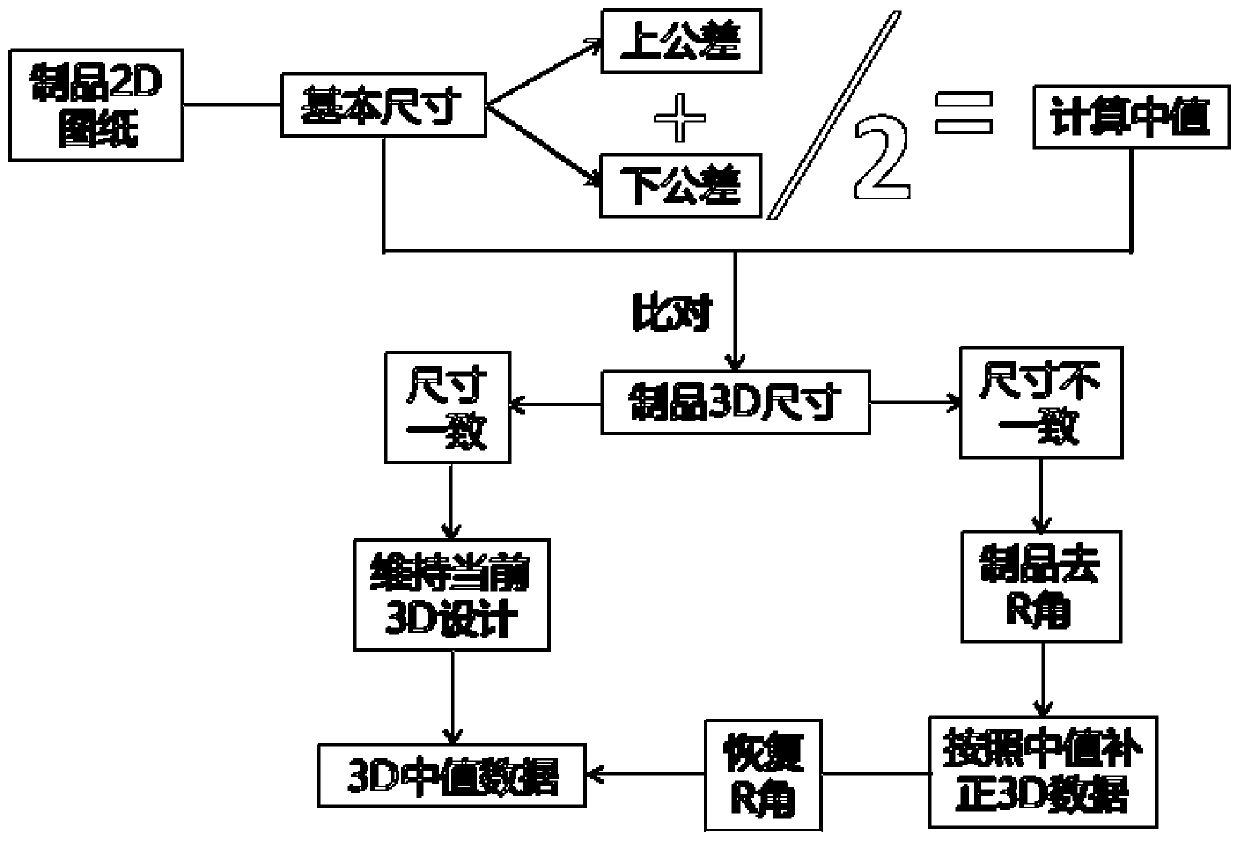

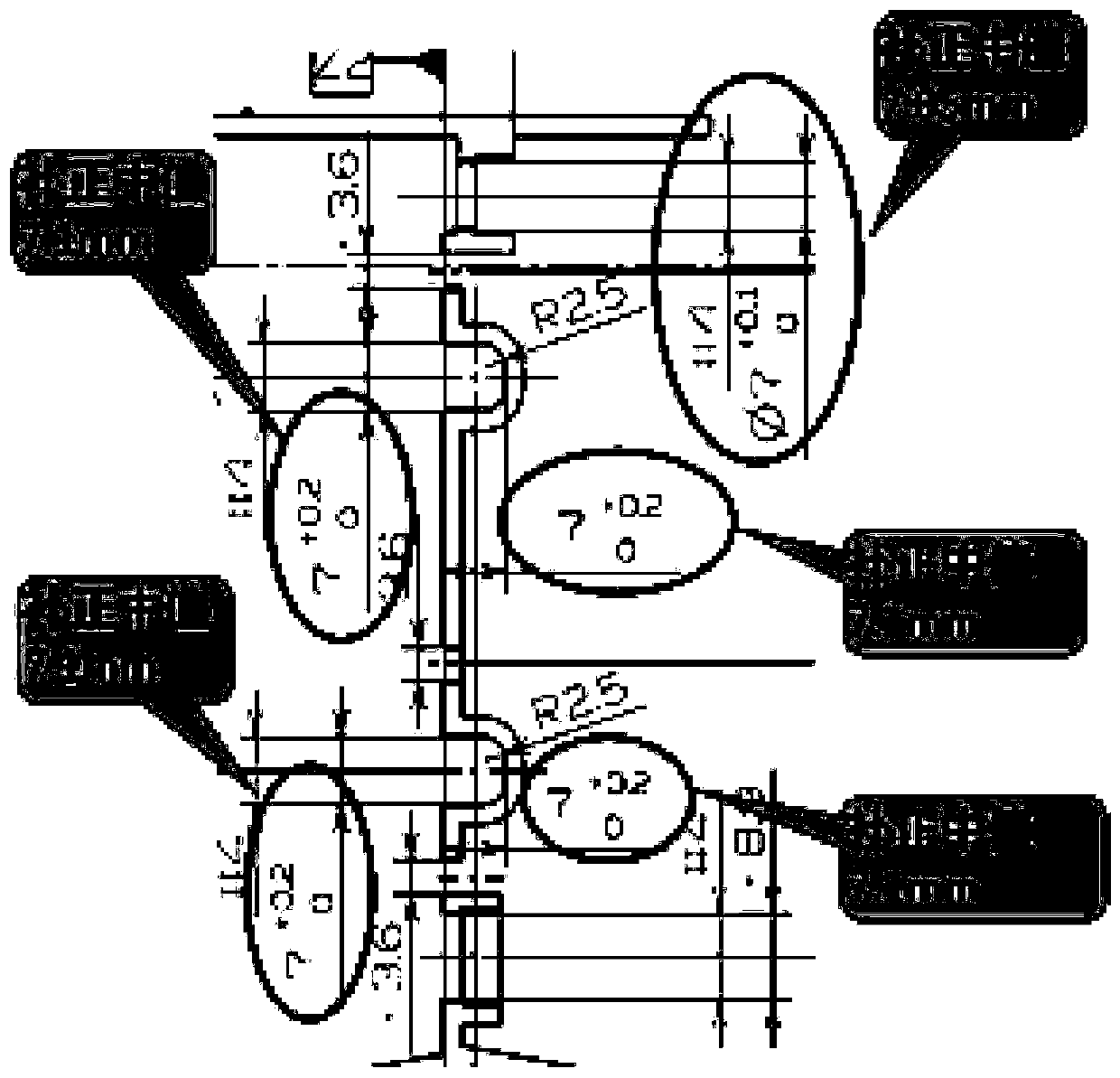

Plastic grating pre-deformation mold design method

The invention provides a plastic grating pre-deformation mold design method, and belongs to the field of molds. The method comprises the steps that 1, median correction is conducted, and 3D data is consistent with median data; 2, pre-deformation data is designed, injection molding simulation is conducted on a product, the buckling deformation result of the product is analyzed, then the pre-deformation area of the product is analyzed and determined, after the buckling deformation result conforms to CAE analysis, locking of anti-deformation data is conducted, and 3D pre-deformation data is completed; 3, mold design and manufacturing are conducted on the basis of the second step; 4, mold testing and mold repairing are conducted, the product is placed for 24H and then measured, and data adjustment of a mold 3D model is conducted on the super-difference part; and 5, mold shaping is conducted. According to the method, the mold manufacturing cost is reduced, and the requirements of the product size and the mold service life can be met through one set of mold.

Owner:TIANJIN SILVER BASSIS TECH CO LTD

Method for preparing low-density cement testing block for oil well cementation by using tantalum carbide microbeads

The invention provides a method for preparing a low-density cement testing block for oil well cementation by using closed hollow tantalum carbide microbeads. The method comprises the following steps of: preparing the hollow tantalum carbide microbeads; burdening; mixing; stirring and slurrying; mold testing; and carrying out a strength test. The method is characterized by comprising the following steps of: stirring and slurrying 55wt% to 65wt% (weight percentage) of G-grade oil well cement, 25wt% to 35wt% of the closed hollow tantalum carbide microbeads with the particle diameter from 10 to 150 mu m, 5wt% to 7wt% of coal ash with the ignition loss being 1.1%, 1.5wt% to 2wt% of calcium oxide with the purity being 99.9%, 0.5wt% to 1.0wt% of sodium sulfate and 1wt% to 3wt% of micro-silicon in a stirrer for 40 seconds according to the water-cement ratio being from 0.5 to 0.7 (W / C); pouring the mixture into a group of testing molds (comprising the two testing molds respectively having 53mm, 53mm and 53mm in length, width and height); maintaining the testing molds in a water bath maintenance box for 24 hours and 48 hours at the constant temperature of 52 DEG C; demolding and soaking in cold water for 1 hour; and then performing the strength test.

Owner:SHANDONG UNIV OF TECH

Method for determining sheet stamping springback compensation factor

InactiveCN109635362AHigh precisionRebound data is reliableDesign optimisation/simulationSpecial data processing applicationsOffset distanceEngineering

The invention discloses a method for determining a sheet stamping springback compensation factor. The method comprises: firstly, a standard stamping part model is established according to the die size; importing the model into numerical simulation software to carry out stamping springback simulation; calculating the offset distance between the part profile subjected to springback simulation and the corresponding node of the standard stamping part model, and substituting the result and the offset distance between the part profile subjected to actual stamping and the corresponding node of the standard stamping part model into a compensation factor calculation formula for calculation to finally obtain the springback compensation factor. The compensation factor obtained through the method canhelp the numerical simulation software to improve the precision of the springback compensation function of the numerical simulation software, so that a more reasonable mold is manufactured, the mold testing frequency is remarkably reduced, and the production efficiency is improved.

Owner:HARBIN UNIV OF SCI & TECH

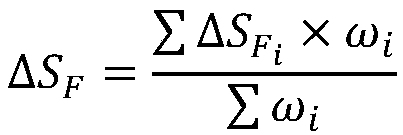

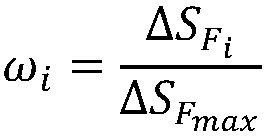

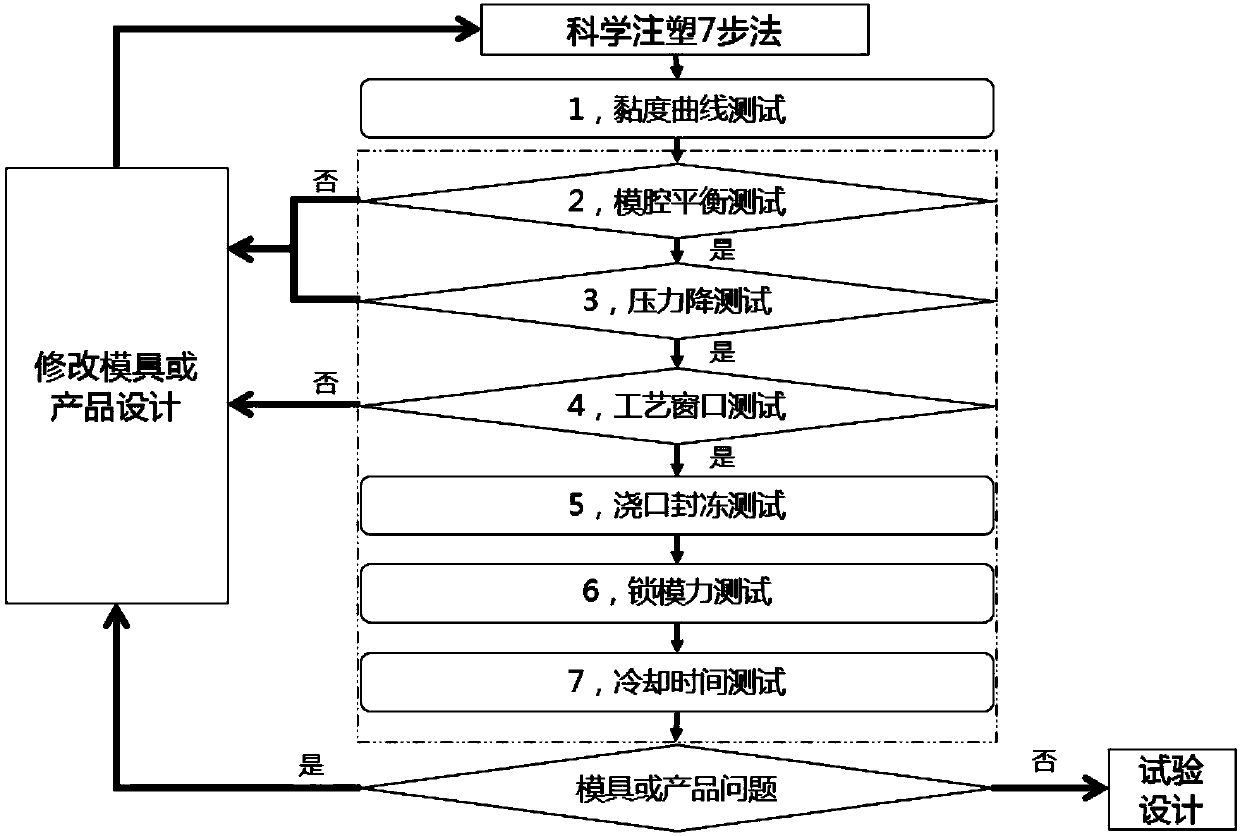

Scientific injection molding visualization technology

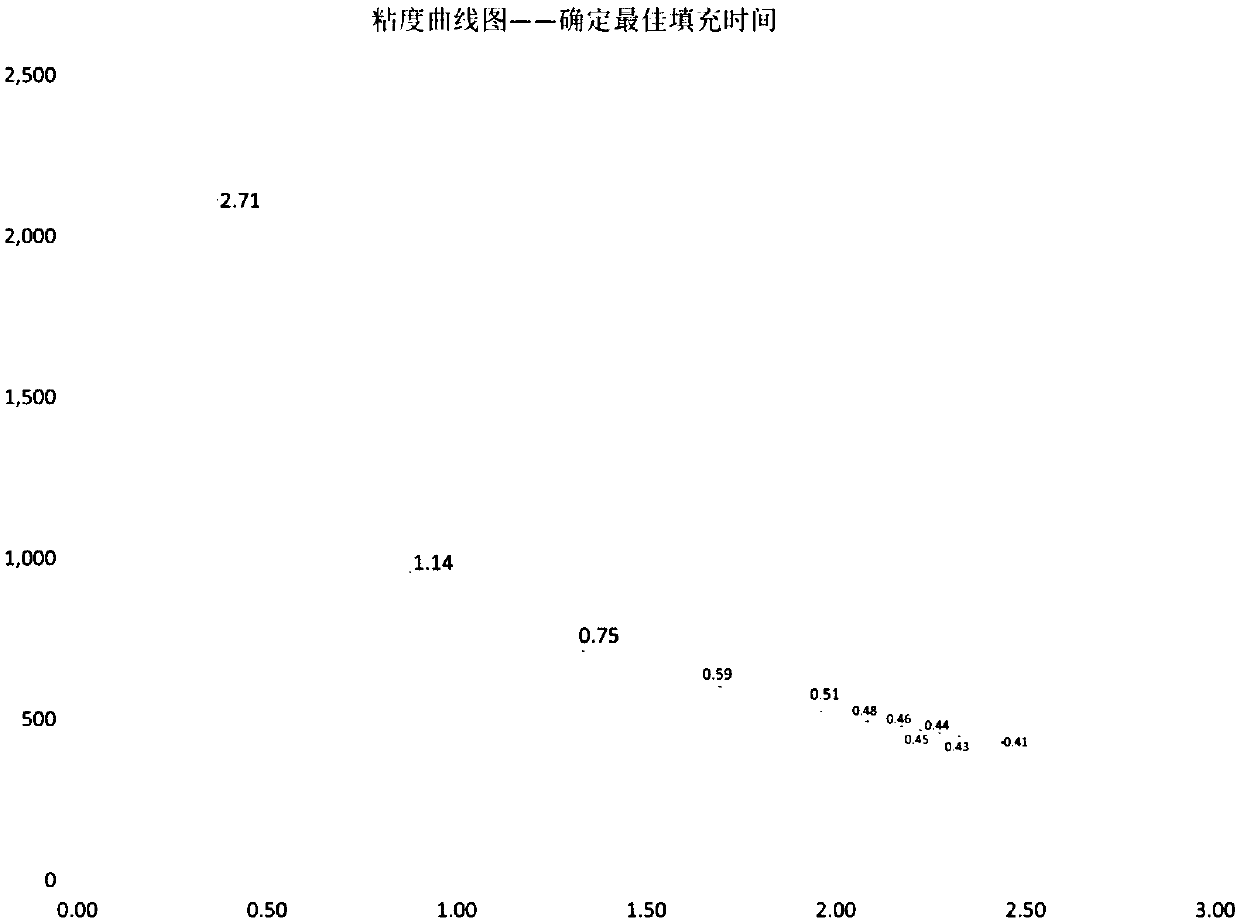

The invention provides a scientific injection molding visualization technology which comprises a design stage, a mold testing stage and a volume production stage. In the design stage, the product structure and mold design can be optimized through mold flow analysis technology (CAE emulation technology). In the mold testing stage, injection molding technological parameters are gradually tested andoptimized through a scientific injection molding seven-step method, the scientific injection molding seven-step method comprises viscosity curve testing, mold cavity balance testing, pressure drop testing, process window testing, sprue freezing testing, clamping force testing and cooling time testing, and scientific and reasonable injection molding technological parameters can be obtained throughthe scientific injection molding seven-step method; by means of staged injection molding forming technology, products which are more even in volume shrinkage rate, smaller in deformation and more stable in production are obtained; and by means of mold cavity pressure and temperature measure technology, the injection molding forming technology is optimized, real-time quality monitoring is conductedon injection molding production, and thus, unmanned automatic injection molding production is achieved.

Owner:苏州万库信息技术有限公司

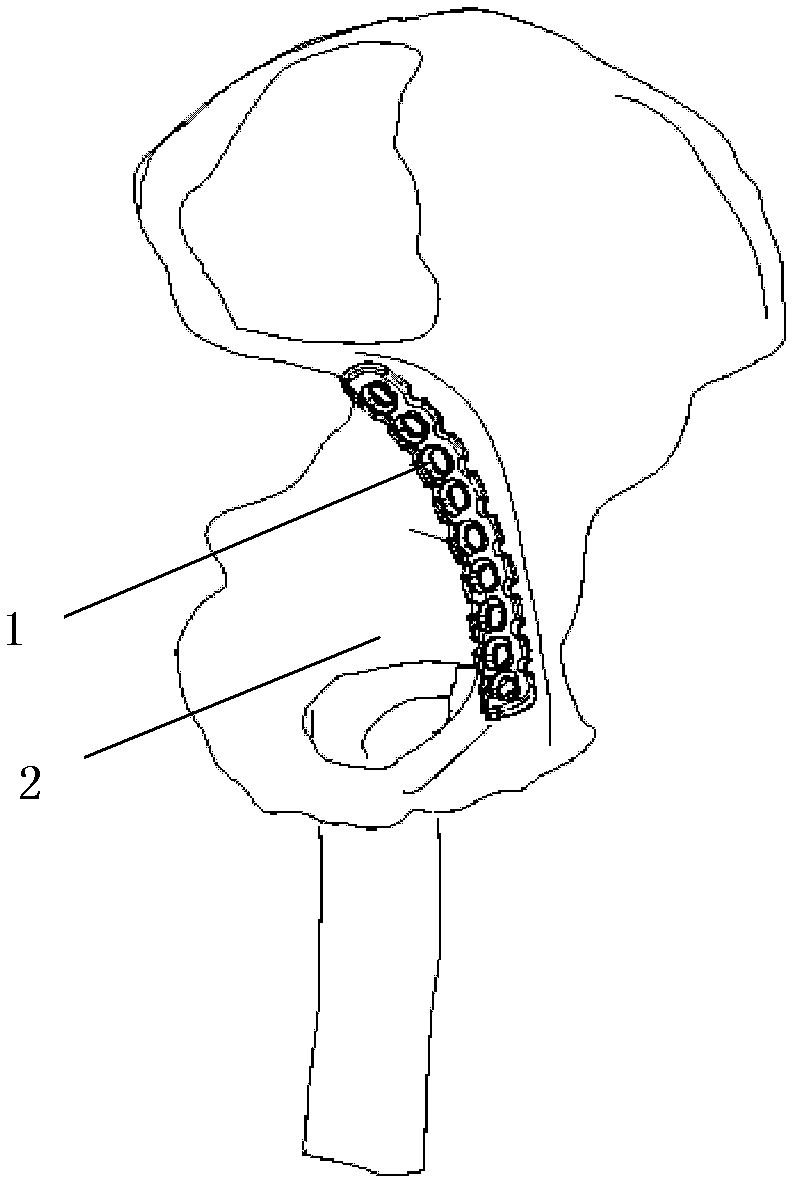

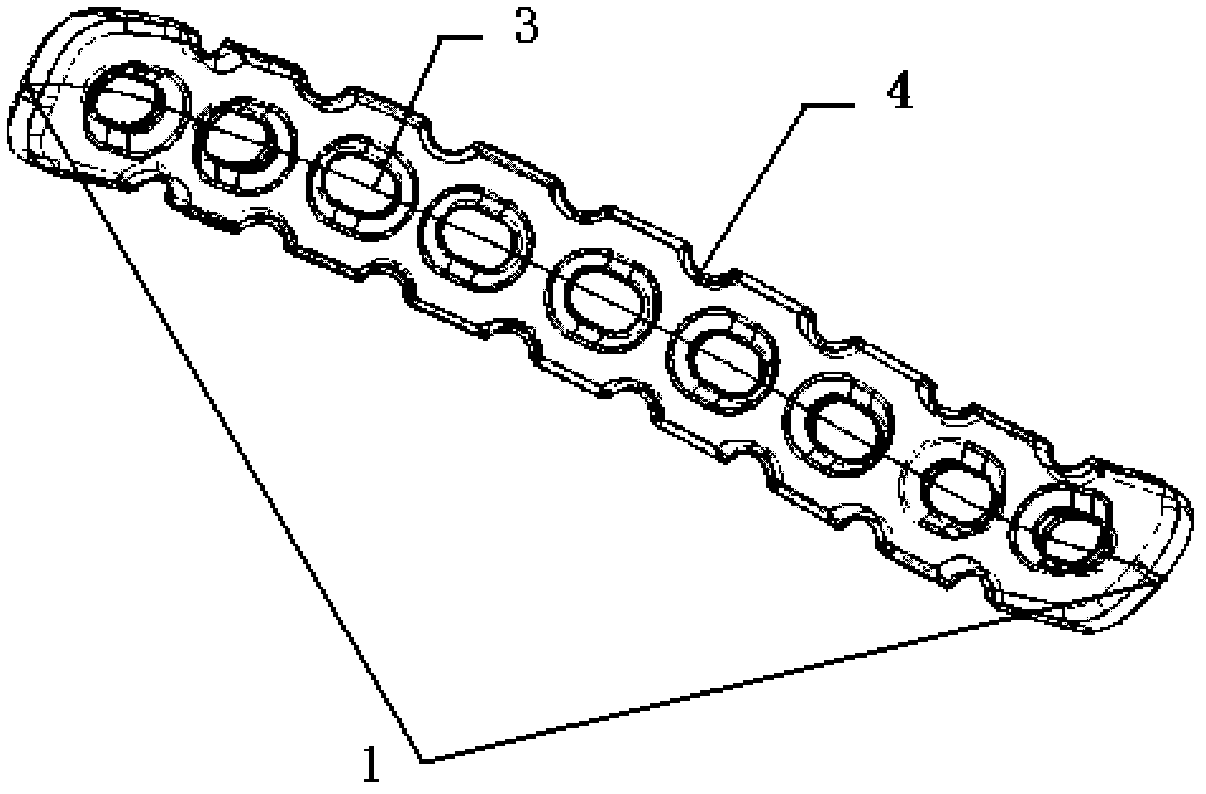

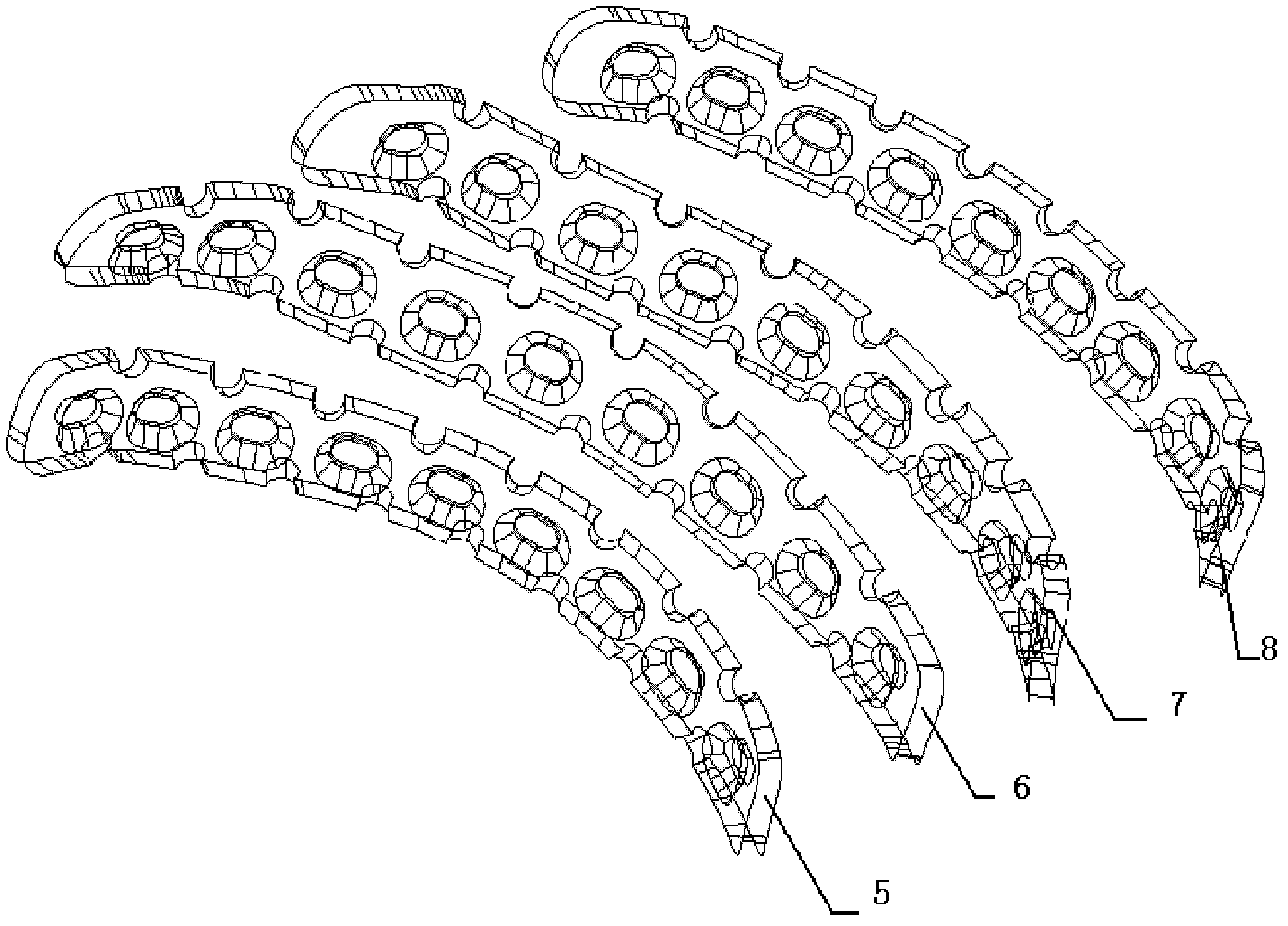

Pelvis arcuate line lower edge anatomic bone fracture plate

InactiveCN102551867AReduce time-consuming on-site shapingRelieve painBone platesHuman bodyTreatment effect

Owner:SHANGHAI FIRST PEOPLES HOSPITAL +1

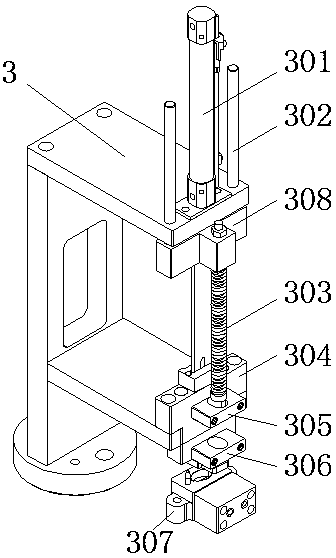

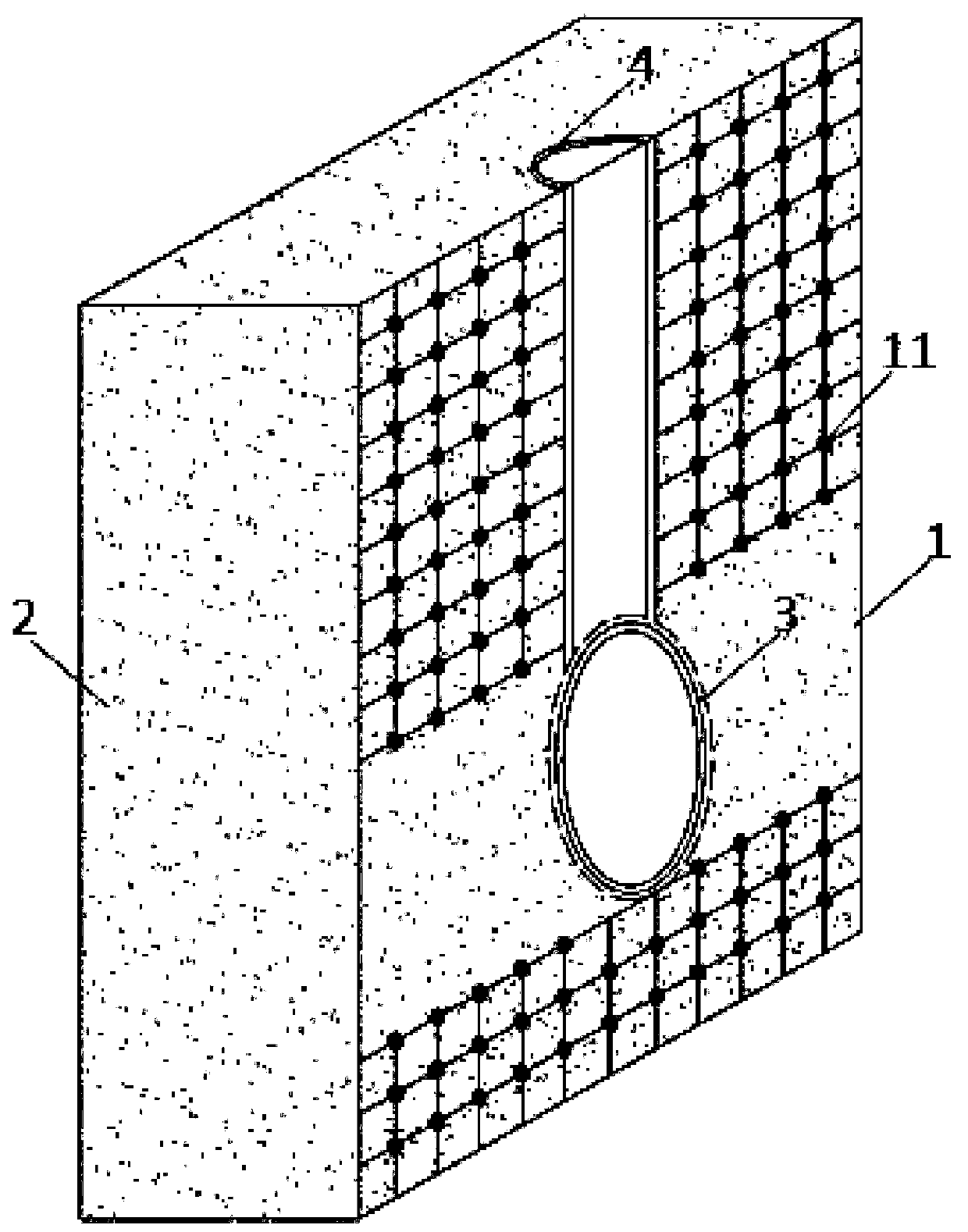

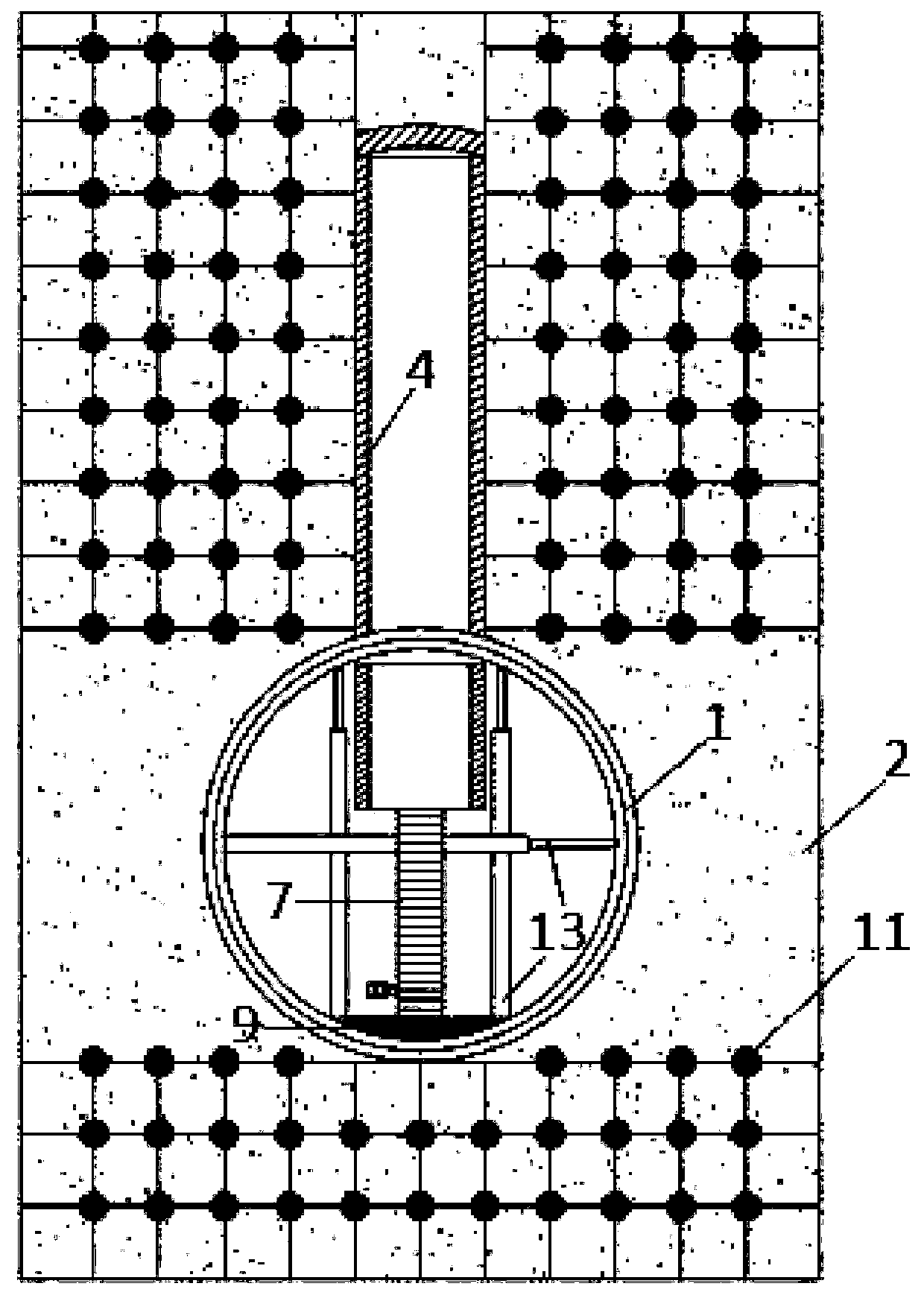

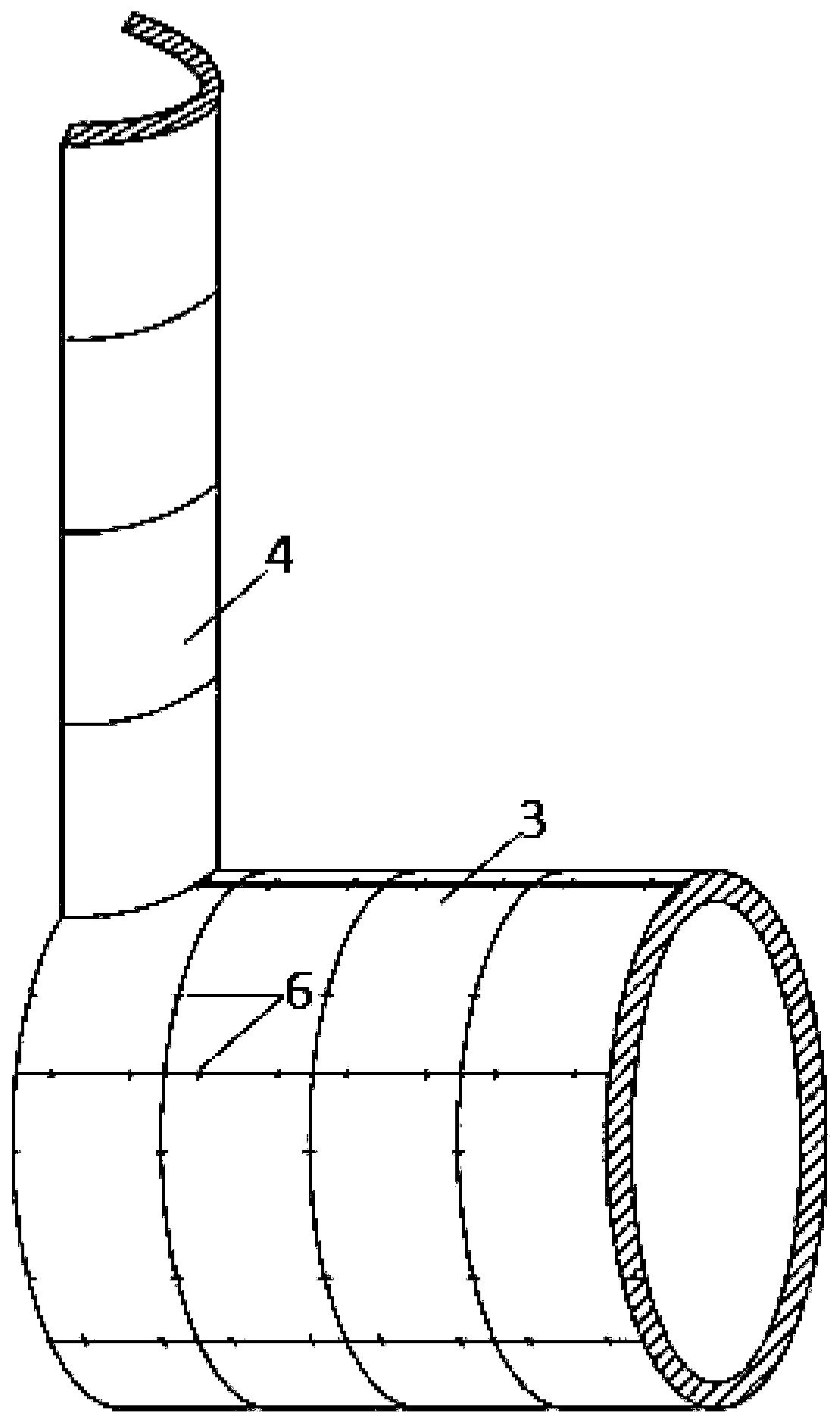

Shielding shaft vertical jacking mold testing device and method

The invention discloses a shielding shaft vertical jacking mold testing device and method. The testing device comprises a tank body, a shielding tunnel, a top tube tunnel, a soil body and a monitoringsystem. The testing device is established according to similarity theories, rigidity equivalent effect theories and symmetry, and in addition is simple in structure, and components can be replaced according to actual situations. By adopting the testing method, the actual vertical jacking process of a shielding shaft can be simulated, by adopting the monitoring system, structure change of the shielding tunnel and the soil body can be finely fed back, a tester can visibly experience the structure change of the soil body, and an effective instruction function can be achieved. The device is applied to the field of underground building construction.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

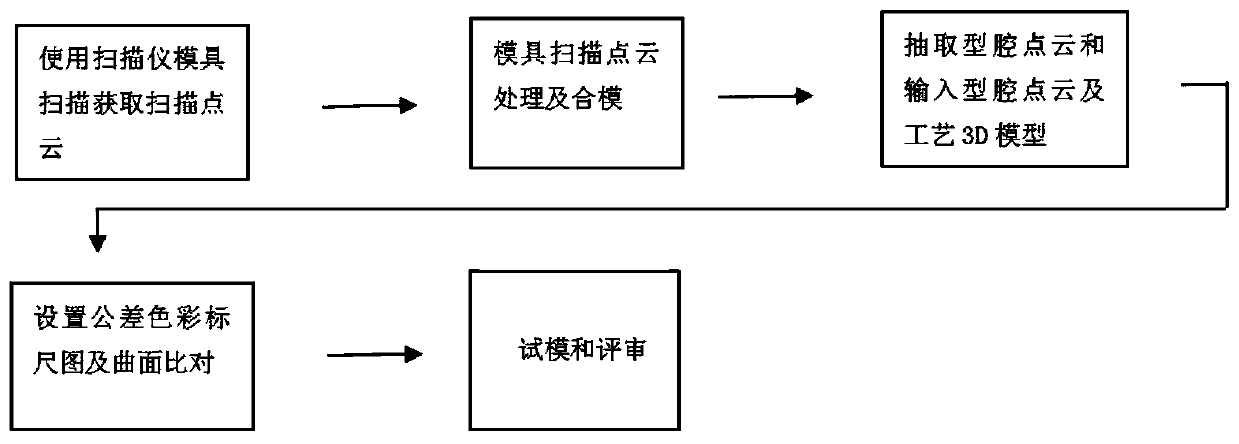

Method for digitally and quickly detecting and analyzing sand core

InactiveCN111595264AQuality improvementFix missing shape facesDetails involving processing stepsUsing optical meansColor ScaleProcess engineering

The invention discloses a method for digitally and quickly detecting and analyzing a sand core. A scanner is used for scanning a mold to obtain scanning point cloud; the mold scanning point cloud performs processing and mold closing; the cavity point cloud is extracted, the cavity point cloud and a process 3D model are input, the tolerance color scale map is set, and the curved surface comparisonis performed; the mold testing and the evaluation method can intuitively analyze whether the cavity is consistent with the process model or not, so that the problem that the mold lacks a shape surfacein the machining process is solved. According to the method, the problems of misalignment of the sand core and burrs of the sand core can be quickly and directly analyzed, so that the quality of thesand core is improved, the requirement of avoiding burr trimming is met, and the productivity is improved. And meanwhile, as long as the comparison result is consistent with the process 3D model, theproblems of core assembly interference and interference with a tool and other auxiliary tools in core shooting and core assembly can be avoided, so that the phenomena of core assembly and sand core scraping and changing are rapidly and accurately solved. According to the method, the cost can be reduced, and qualified castings can be cast at a time.

Owner:GUANGXI YUCHAI MASCH CO LTD

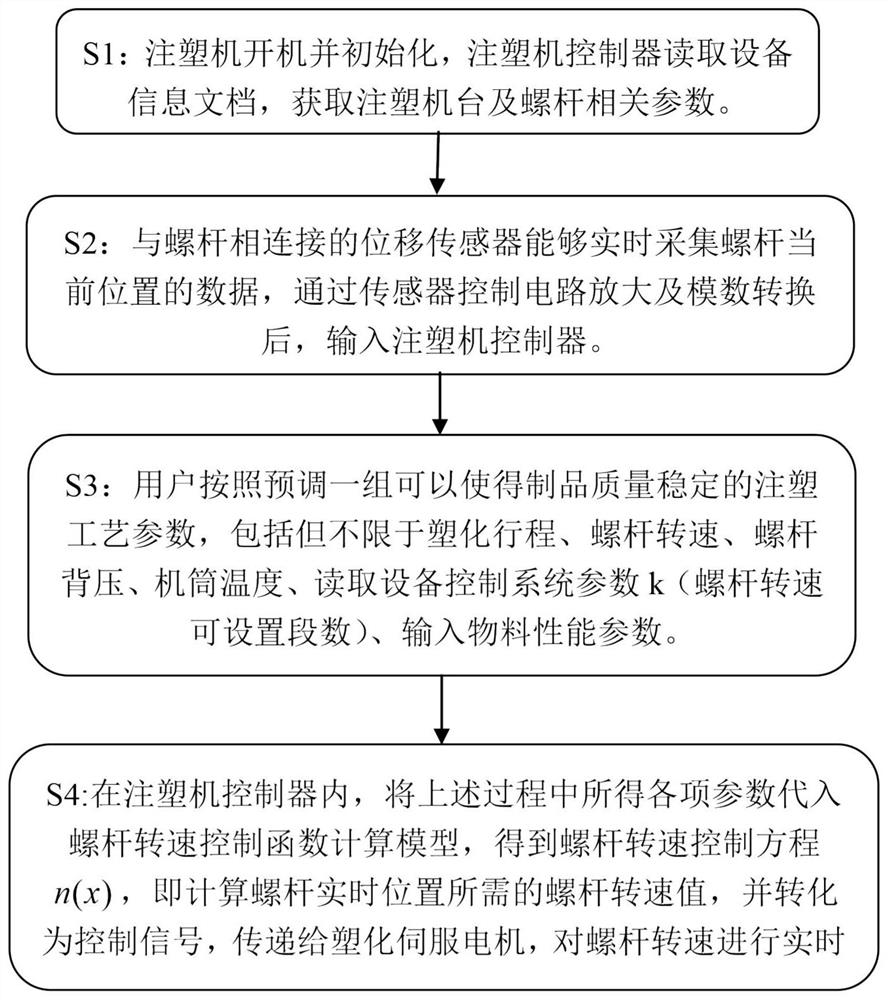

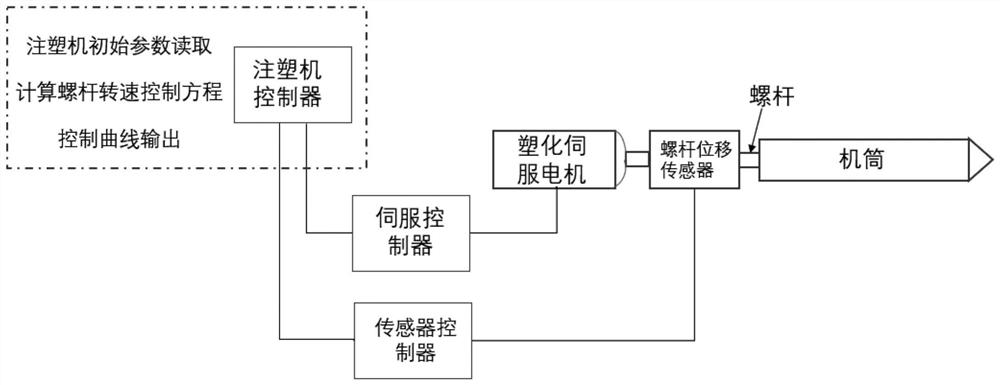

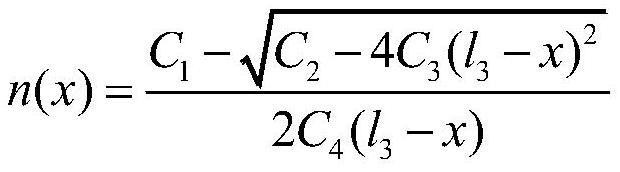

Screw rotating speed control method for improving plasticizing quality of injection molding machine

ActiveCN113414955AImprove plasticizing qualityImprove uniformity of plasticizationControl systemPlasticulture

The invention discloses a screw rotating speed control method for improving plasticizing quality of an injection molding machine, the screw rotating speed control method comprises the following steps that a current displacement value of a screw is collected through a displacement sensor arranged at the tail end of the screw, a screw structure parameter and an initial process parameter set value are read by an injection molding machine controller, and the values are substituted into a screw rotating speed control function calculation model; and a screw rotating speed control scheme about the real-time screw displacement is obtained and is transmitted to an injection molding machine plasticizing motor servo control system to control the screw rotating speed in the current period in real time, so that the uniformity of the melt plasticizing quality is realized. According to the screw rotating speed control method for improving the plasticizing quality of the injection molding machine, the plasticizing quality of a plastic melt is improved, the uniformity of the melt is improved, and the mold testing frequency caused by replacement of equipment or materials is reduced.

Owner:BEIJING UNIV OF CHEM TECH

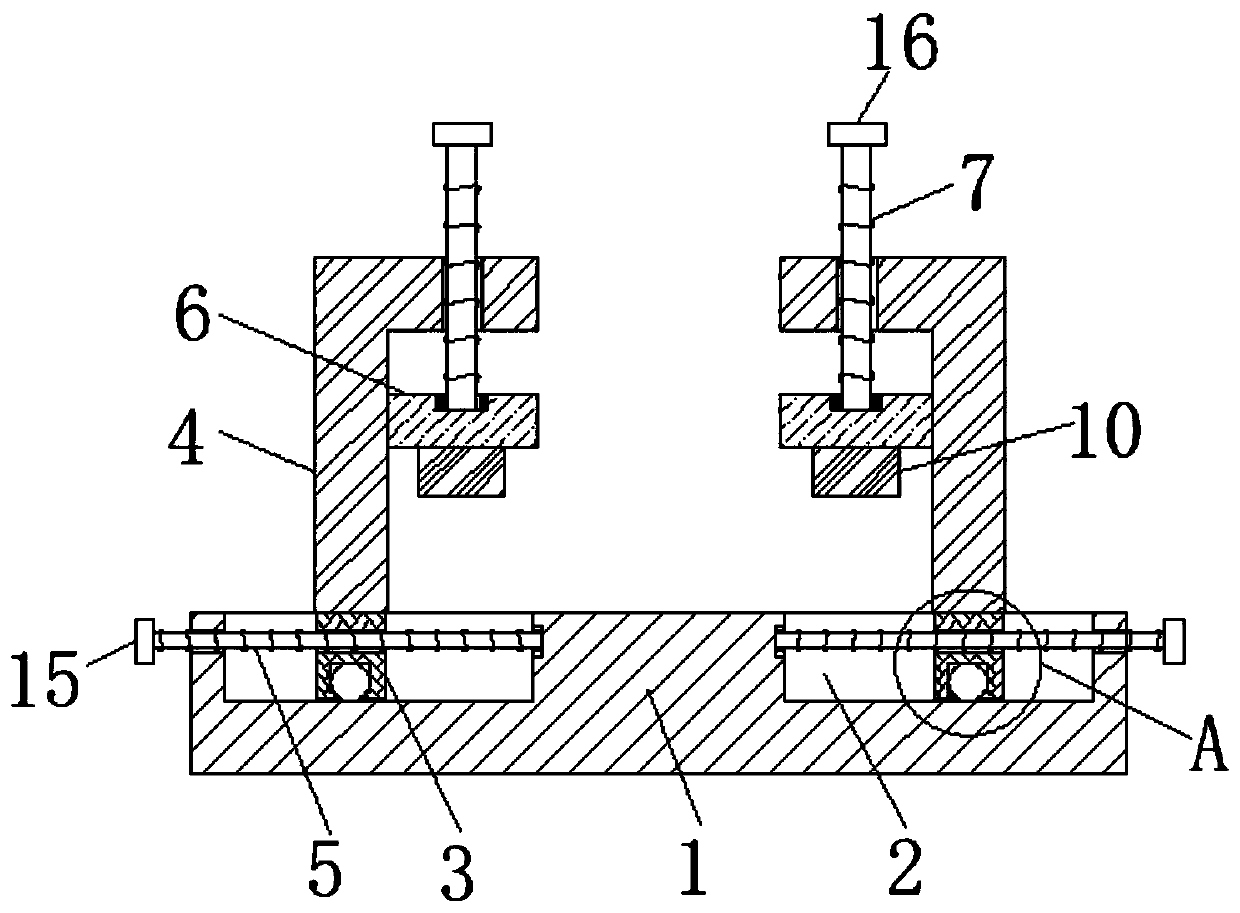

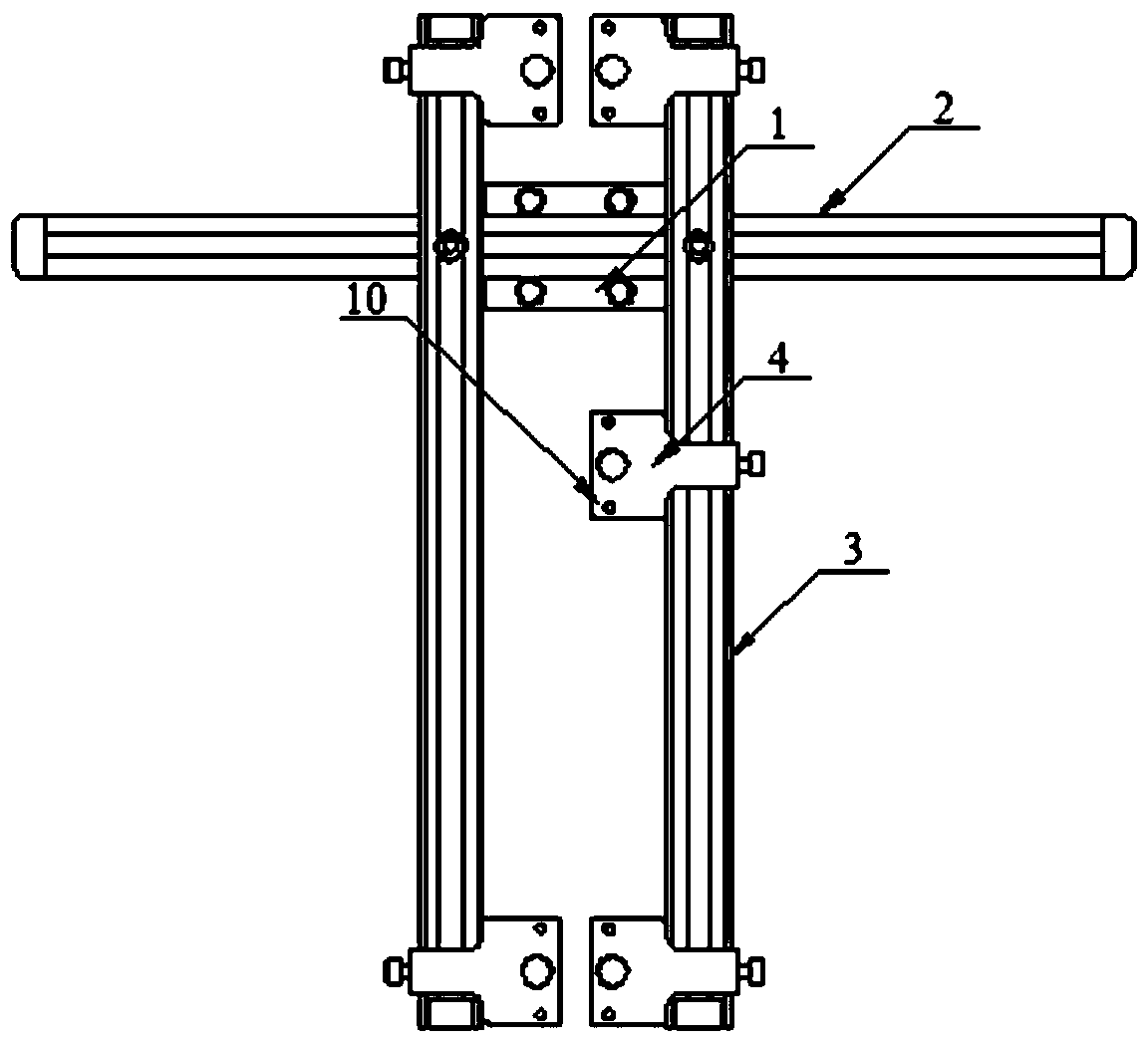

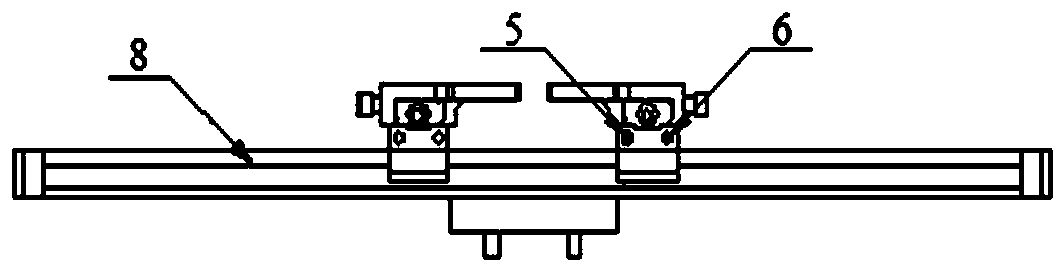

Convenient mold testing device

InactiveCN109975053AEasy to fixConvenient to press the limit up and downStructural/machines measurementStable fixationEngineering

The invention relates to the technical field of molds, and discloses a convenient mold testing device. The device includes a fixing plate; the upper surface of the fixing plate is provided with two symmetric slide grooves; matching slide blocks are slidingly connected to the slide grooves; the upper surfaces of the slide blocks are fixedly connected to L-shaped plates; the lower surfaces of the L-shaped plates are slidingly connected to the upper surface of the fixing plate; the slide grooves are rotatably connected to screw rods; the screw rods pass through the slide blocks and extend to theouter sides of the slide grooves; the screw rods are in threaded connection with the slide blocks; the sidewalls of the L-shaped plates are slidingly connected to pressure plates; the upper surfaces of the pressure plates are rotatably connected to threaded rods through bearings; the other ends of the threaded rods pass through the tops of the L-shaped plates and extend upward; the threaded rods are in threaded connection with the tops of the L-shaped plates; and the pressure plates are provided with two T-shaped through grooves which are symmetric to the threaded rods. Thus, molds with different sizes can be conveniently, rapidly and stably fixed on the fixing plate, and therefore, mold testing efficiency can be enhanced.

Owner:ANHUI ANLAN MOLD

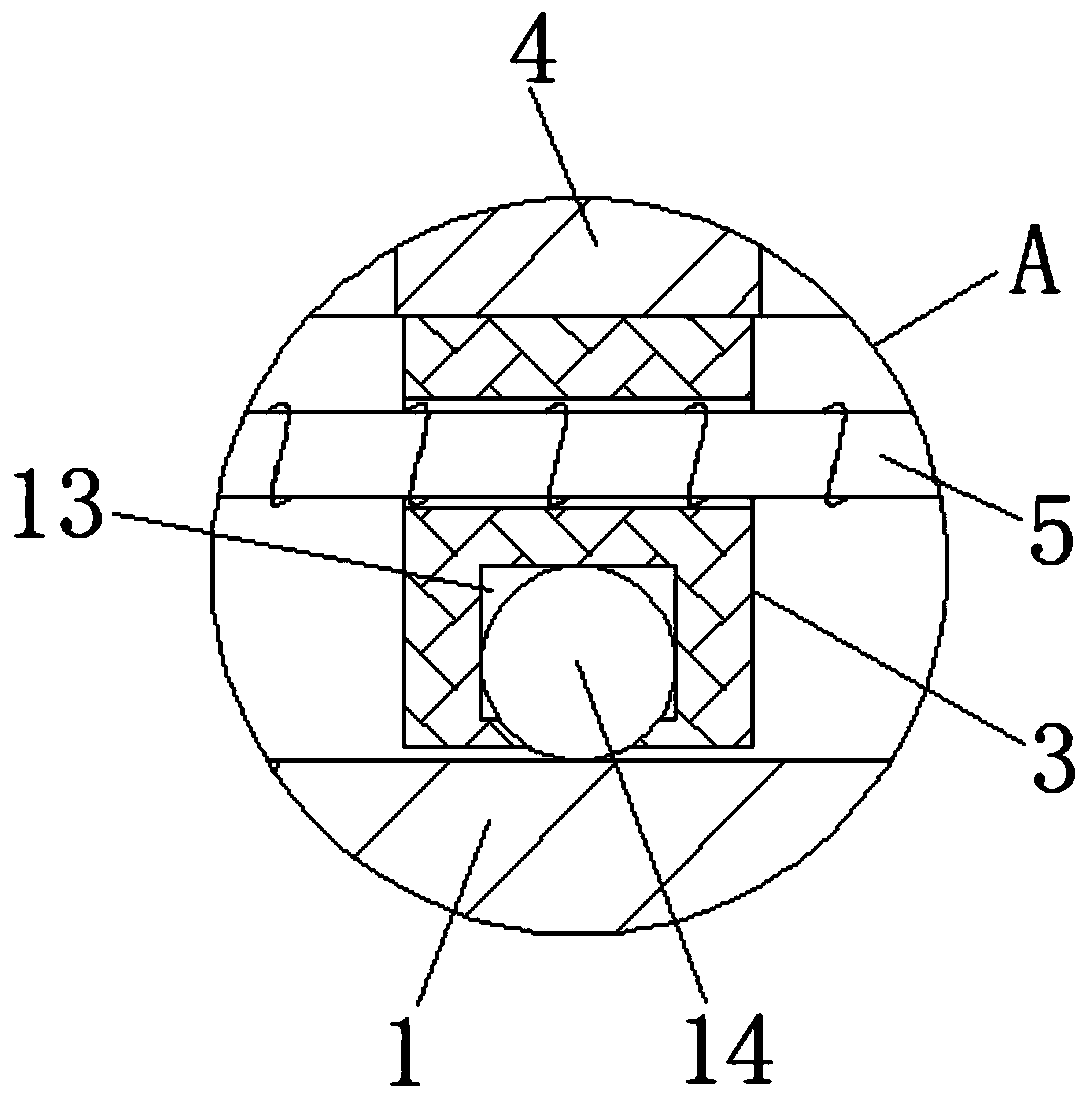

In-mold injection molding method of curved window

ActiveCN110587909AAvoid ink flushingMeet adhesion requirementsCoatingsProcess optimizationEngineering

The invention relates to an in-mold injection molding method of a curved window in the technical field of display window product processing. The in-mold injection molding method comprises the following steps of (1), carrying out mold flow analysis research and structure optimization by utilizing Moldflow software; (2) designing a curved window IMR mold; and (3) performing curved window product mold testing, production process optimization and mold testing and analyzing the mounting, adjusting and sample testing processes of a mold and equipment. The curved window IMR process is reliable, molddesign optimization is reasonable, IMR forming of a curved window product is successfully achieved, the production efficiency is high, and beneficial experience is provided for IMR technology and molddesign of large plastic products in the future.

Owner:遵义群建塑胶制品有限公司

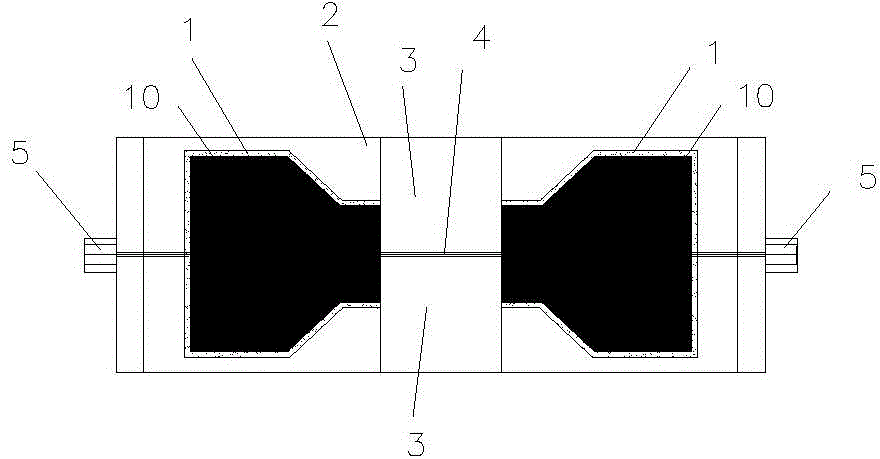

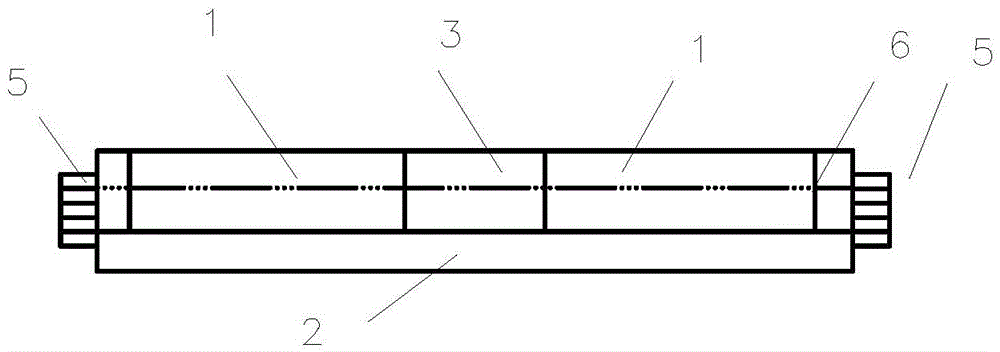

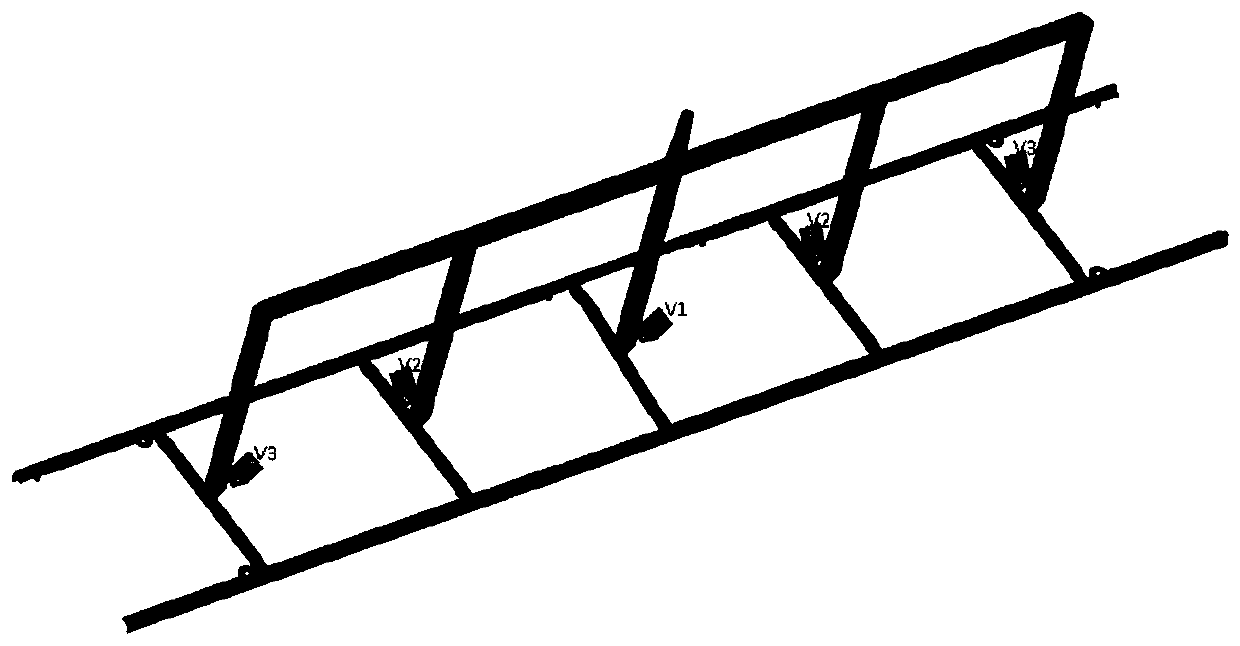

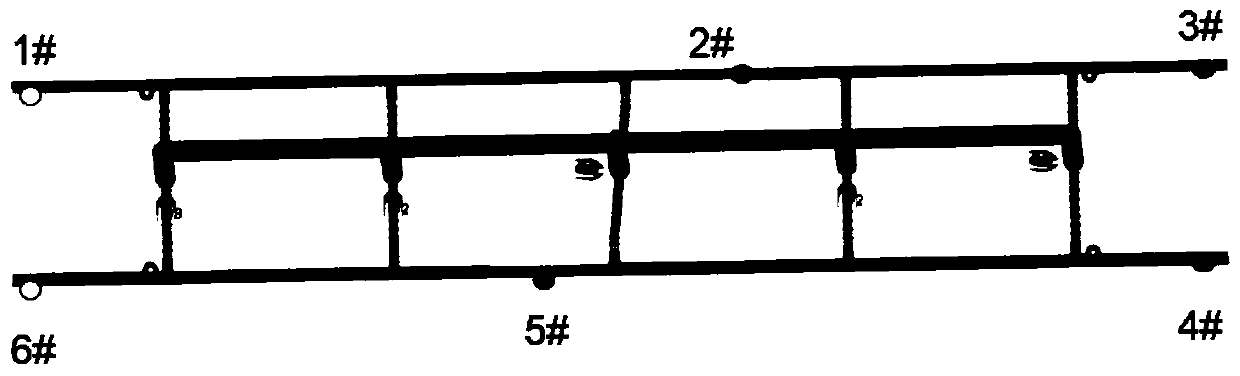

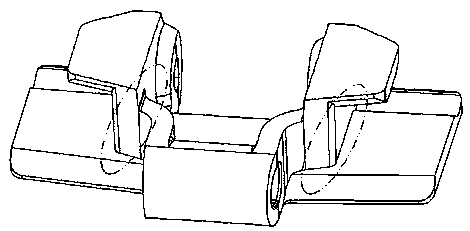

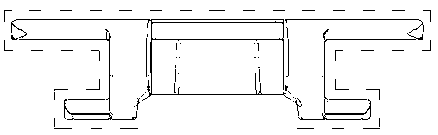

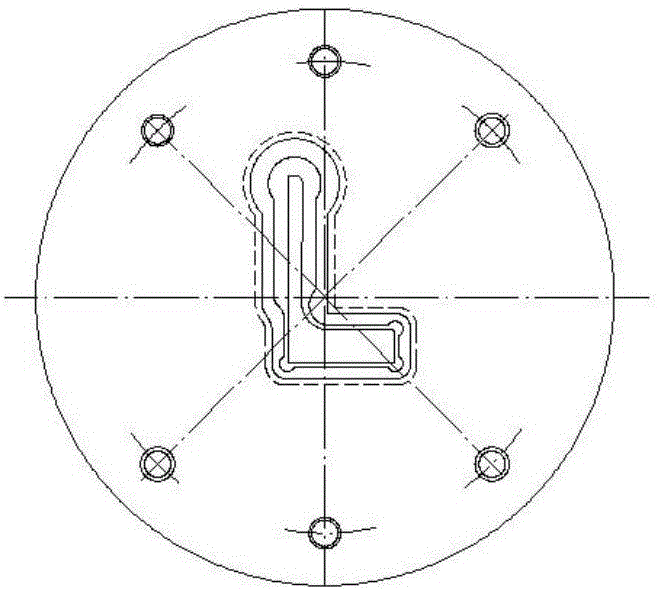

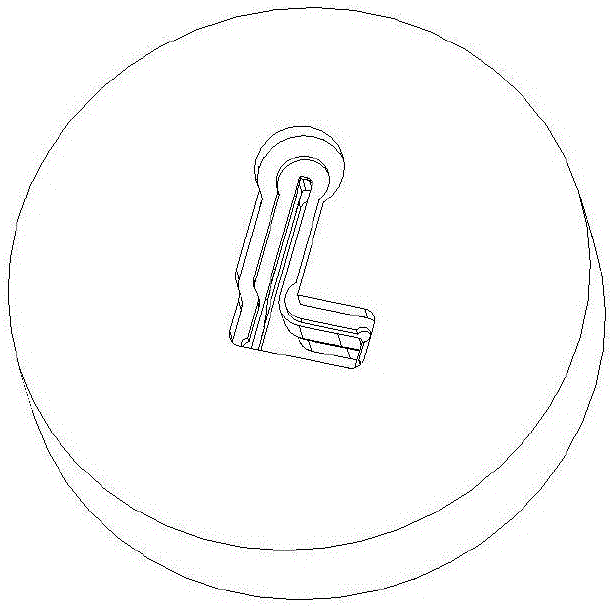

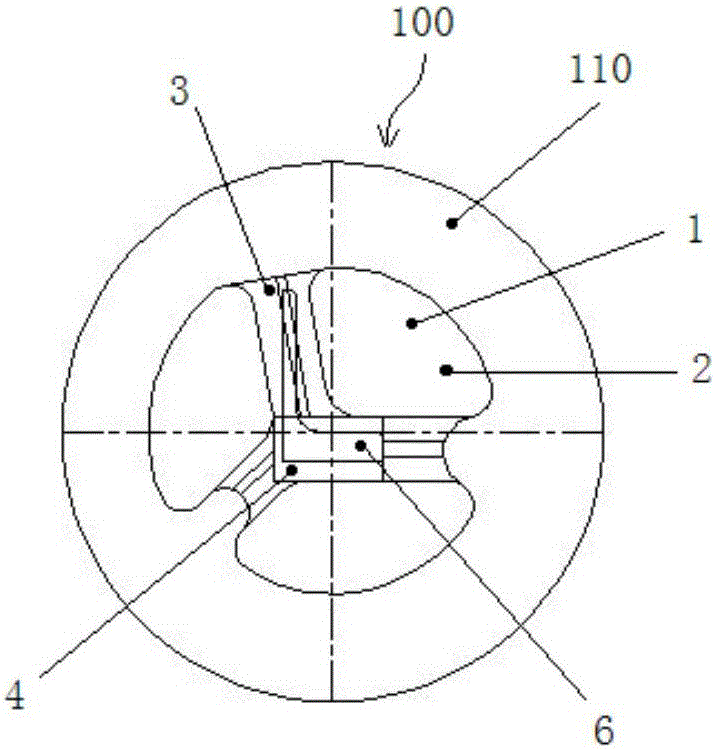

5-series L-shaped large-wall-margin profile extruding mold and manufacturing method thereof

ActiveCN106378362ASolve extrusion problemsSolve the bendExtrusion diesVertical projectionEngineering

The invention discloses a 5-series L-shaped large-wall-margin profile extruding mold and a manufacturing method thereof and belongs to the technical field of an aluminum alloy extruding mold. The extruding mold consists of an upper die and a lower die which are connected with each other; the upper die is provided with an extrusion chamber and a plurality of flow separating bridges; the lower die is provided with a welding chamber and a working belt hole; the joint of the flow separating bridges is arranged in a manner of being deviated from the axial center of the upper die; one end, far away from the welding chamber, of the joint is provided with a fake die core; the fake die core is exposed out of the surface of a feeding end of the upper die; the vertical projection, on the lower die, of the fake die core covers one side of a relatively large L-shaped hole chamber of the working belt hole. The 5-series L-shaped large-wall-margin profile extruding mold disclosed by the invention is capable of solving the extrusion problem of a 5-series L-shaped large-wall-margin profile; by adopting the extruding mold, the problems of flexure and twisting of the profile during an extrusion process can be solved, so the extrusion yield is increased, subsequent shaping workload is reduced, and the work efficiency is greatly improved; an analogue simulation method is used for replacing a mold testing step, so the economic efficiency is effectively improved.

Owner:CHINA ZHONGWANG

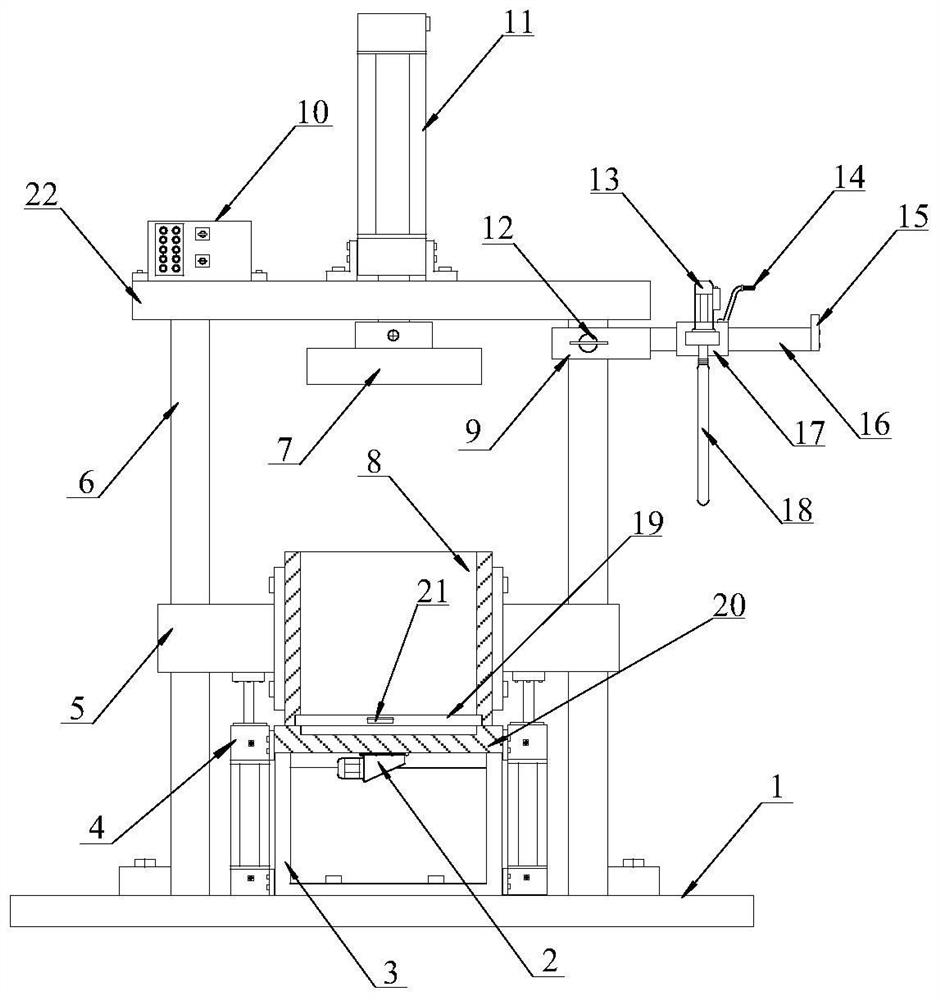

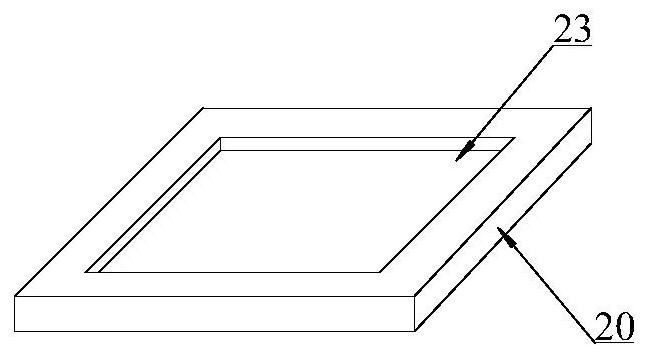

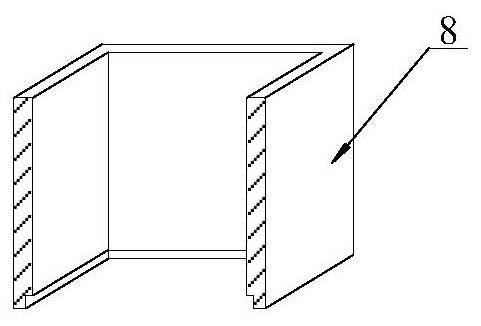

Concrete test block manufacturing device and implementation method thereof

PendingCN112297192AGood molding effectSolve pressure instabilityDischarging arrangementPreparing sample for investigationMold testingStructural engineering

The invention discloses a concrete test block manufacturing device. The concrete test block manufacturing device comprises a mounting base plate (1), a controller (10), a mold cavity bearing table, alifting hydraulic cylinder (4), a vibration mechanism and the like. The invention further discloses an implementation method of the concrete test block manufacturing device. The implementation methodcomprises the steps that the inner walls of a mold testing cavity (8) are coated with a layer of mold releasing liquid, and first-time concrete pouring is carried out on the interior of the mold testing cavity (8); and the vibration mechanism is rotated and lowered, and a vibration rod of the vibration mechanism is inserted into concrete in the mold testing cavity to the position 2-3cm away from the bottom of the mold testing cavity. According to the concrete test block manufacturing device and the implementation method thereof, mold releasing can be well completed through the lifting hydraulic cylinder, during use, the mold testing cavity is lifted upwards through the lifting hydraulic cylinder, a formed test block is firmly pressed through a pressing plate of a flat pressing mechanism, the mold testing cavity can be separated from the test block, and the integrity of the test block is effectively ensured.

Owner:遂宁明强商品混凝土有限公司

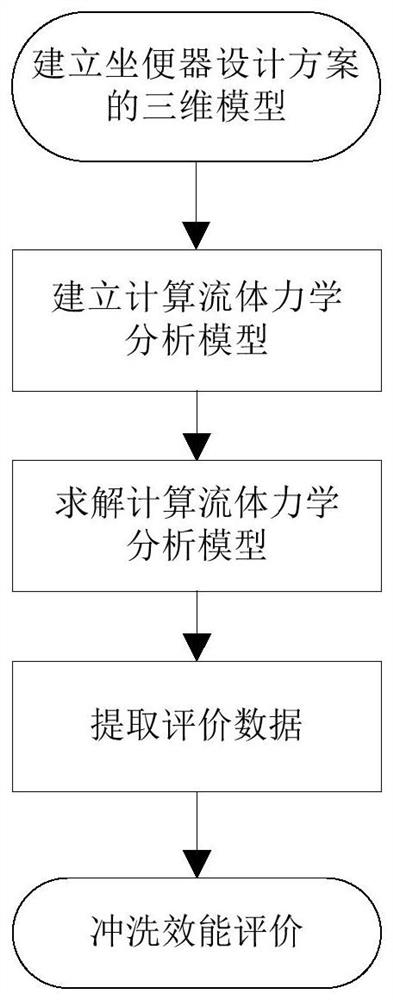

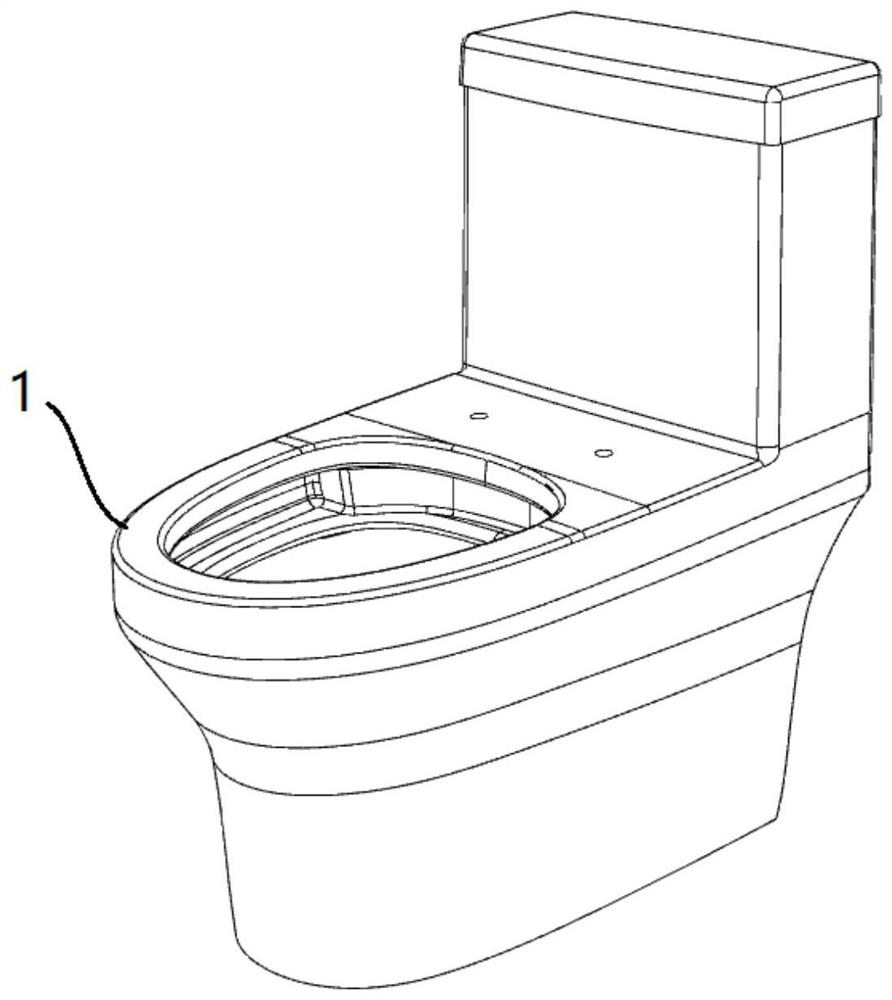

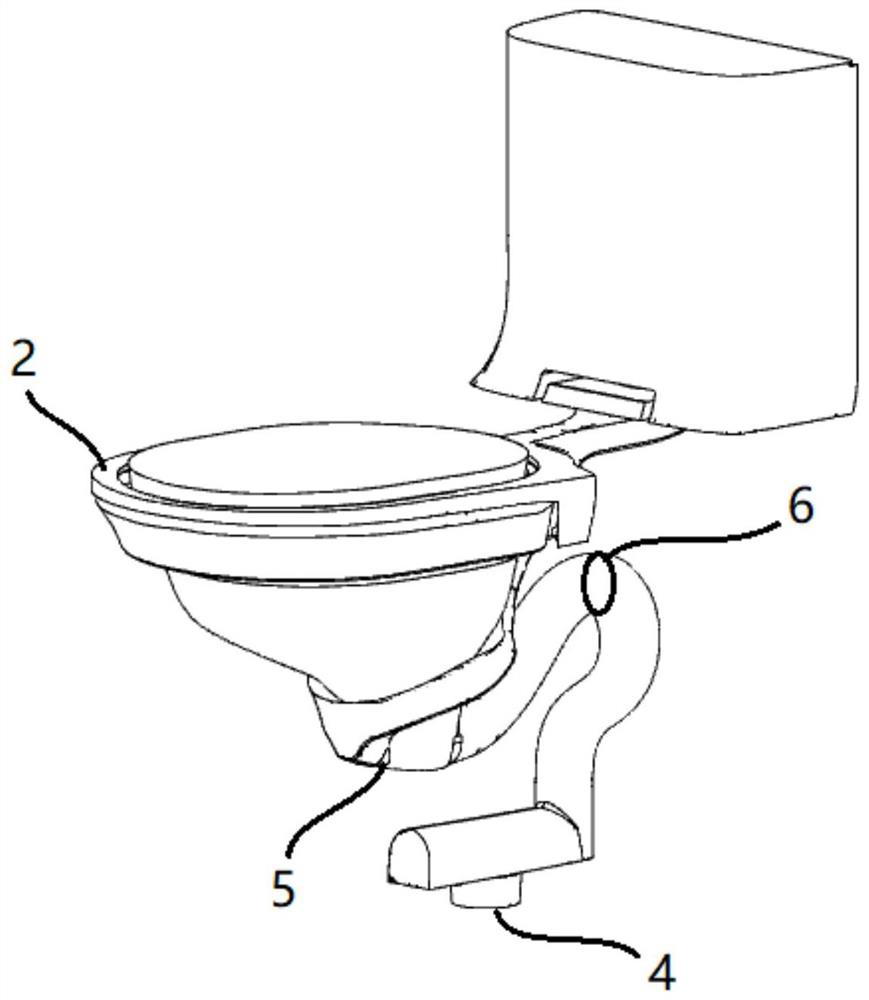

Pedestal pan flushing efficiency evaluation method

ActiveCN113033115AReduce mold repair linksShorten the development cycleDesign optimisation/simulationDesign planModel extraction

The invention relates to a pedestal pan flushing efficiency evaluation method. The method comprises the following steps: establishing a three-dimensional model of a pedestal pan design scheme; establishing a computational fluid mechanics analysis model based on the three-dimensional model; Solving and calculating the fluid mechanics analysis model; extracting evaluation data; and performing flushing efficiency evaluation based on the evaluation data. The flushing efficiency evaluation method is provided by means of simulation analysis, is mainly applied to the jet siphon type pedestal pan, and can complete flushing efficiency evaluation of a design scheme in a design stage, so that mold testing and mold repairing links are reduced, the development cycle and cost of products are reduced, and the invention has good application and popularization values.

Owner:HUIDA SANITARY WARE

General-purpose product taking tool for injection molding process

PendingCN108381882AMeet the needs of mold trial in timeSatisfy the needs of mold trial and so onGeneral purposeEngineering

Relating to the technical field of injection mold equipment, the invention discloses a general-purpose product taking tool for injection molding process. The general-purpose product taking tool consists of a fixed seat and support arms, the fixed seat is installed on a mechanical arm of injection mold equipment, the support arms are fixed on the fixed seat, the support arms are equipped with a plurality of working arms, the working arms and the support arms are in perpendicular arrangement, the working arms are disposed on the support arms through a sliding mechanism, and can slide on the support arms under the driving of the sliding mechanism, the working arms are equipped with a plurality of moving blocks through moving mechanisms, the moving blocks can move on the working arms under thedriving of the moving mechanisms, and the moving blocks are equipped with clamp parts for taking injection molding products. The product taking tool provided by the invention can be adjusted according to the product structure to meet the mold testing timeliness requirement of new projects, and can reduce the tool management and use cost during project batch production.

Owner:SHANGHAI KUFENG AUTO PARTS

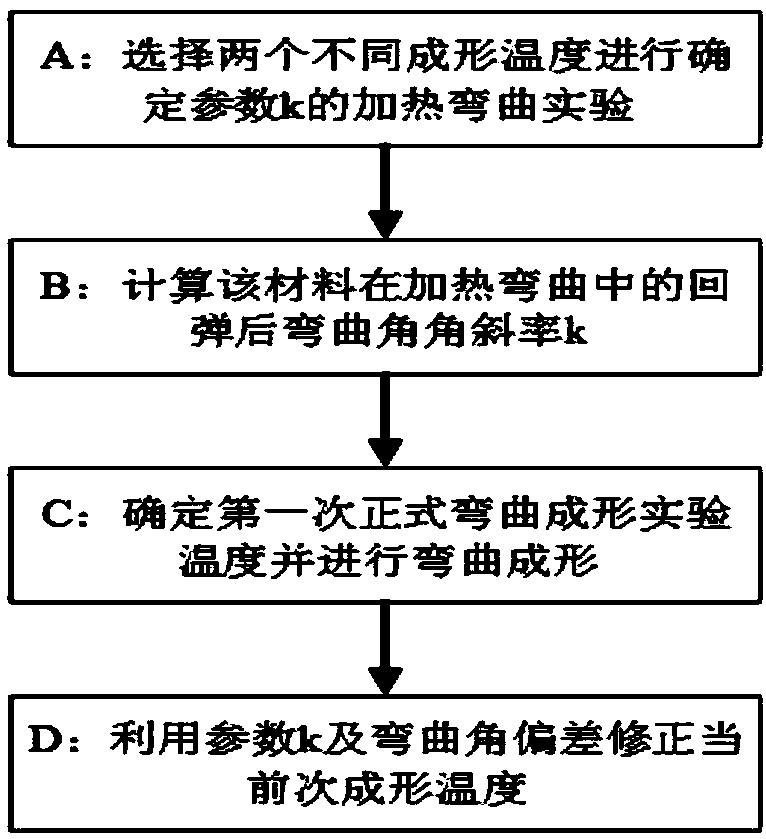

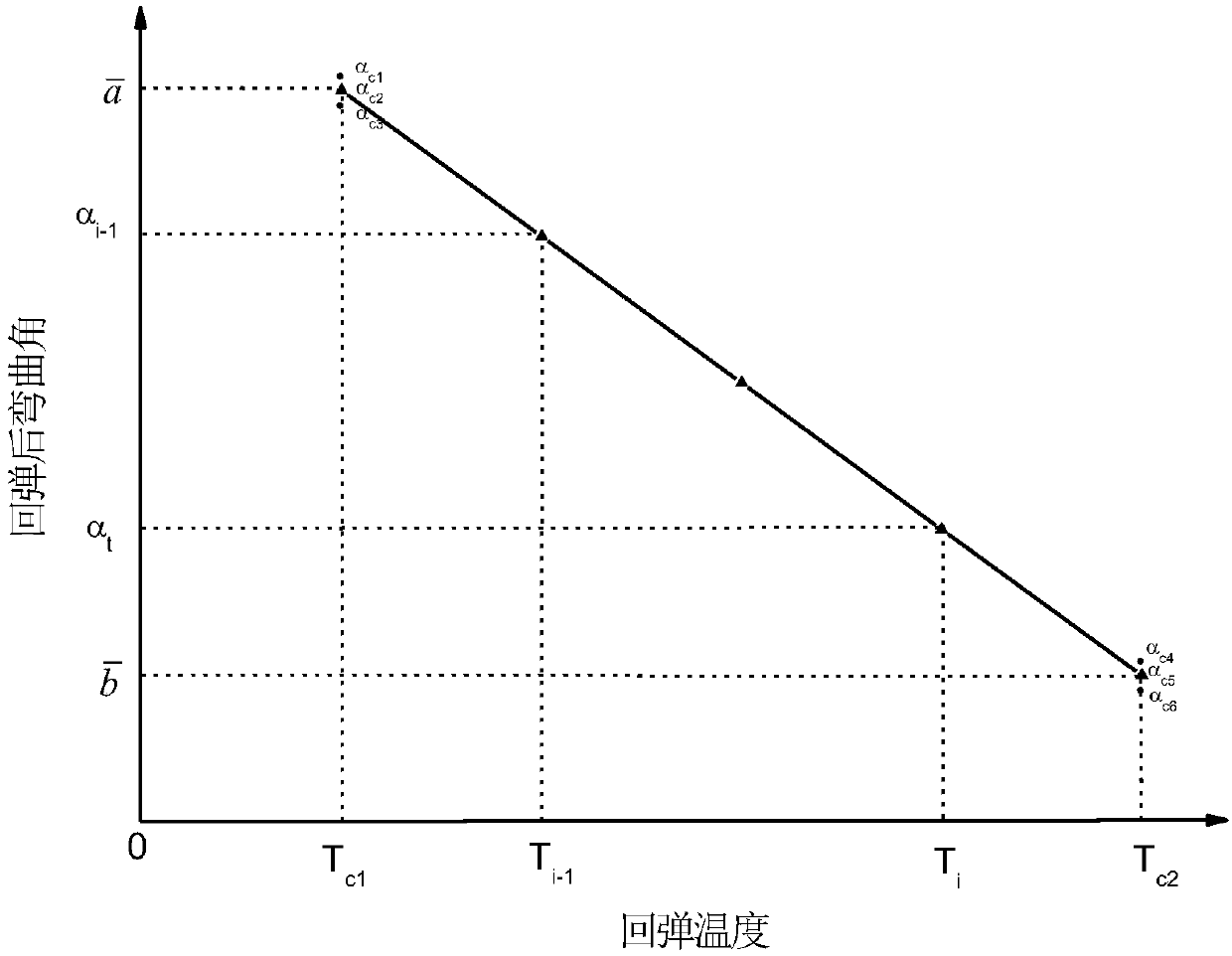

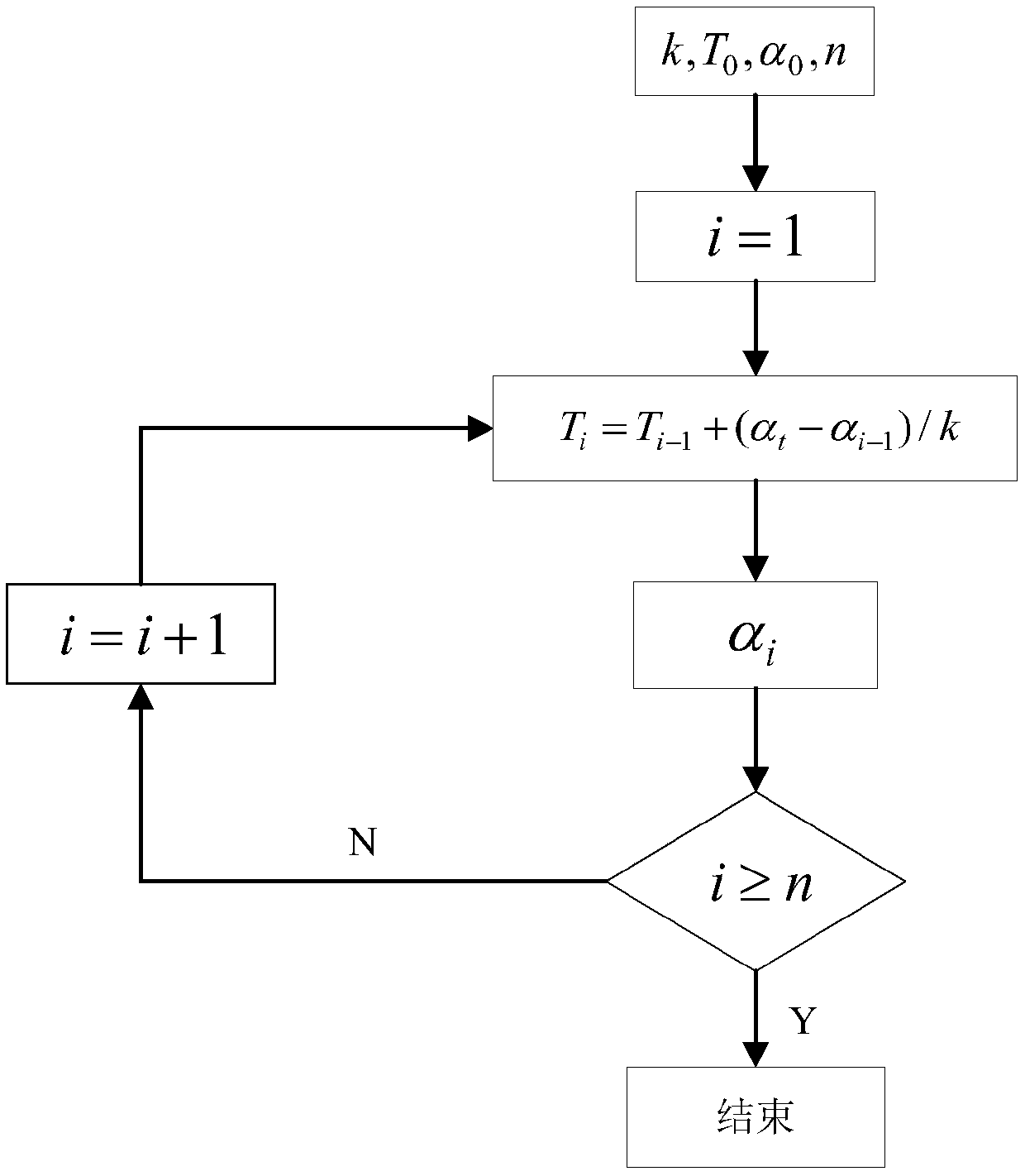

Springback compensation method in heating bending technology

ActiveCN109622682AImprove consistencyImprove flexibilityShaping toolsMetal working apparatusTwo temperatureEngineering

The invention discloses a springback compensation method in a heating bending technology. The method includes the following steps that two different forming temperatures are selected, and the bendingangles after springback at the two temperatures are measured respectively; the angle slopes of the bending angles after springback of a material during heating bending forming are calculated by the aid of the selected forming temperatures and the corresponding bending angles after springback; the first-time formal bending forming temperature is determined according to the angle slopes of the bending angles, and the bending angles after springback at the corresponding temperatures are measured; and the current-time forming temperature is corrected by the aid of the deviation of the last-time bending angle after springback from the target bending angle until the number of bending forming times reach the preset number of formed pieces. According to the method, under the condition that mold parameters in a mold bending technology are not changed, the bending angle after springback in the mold bending technology can be compensated through adjustment of the temperature applied to a plate, sothat the consistency of angles of bent pieces after forming is improved, the time for mold repairing and mold testing is saved, and the flexibility for forming plates made of different materials by the aid of one set of molds is improved.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com