Mold testing method, device thereof and electronic equipment

A detection method and mold technology, applied in image data processing, instrumentation, calculation, etc., can solve problems such as mold damage, equipment production efficiency reduction, economic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

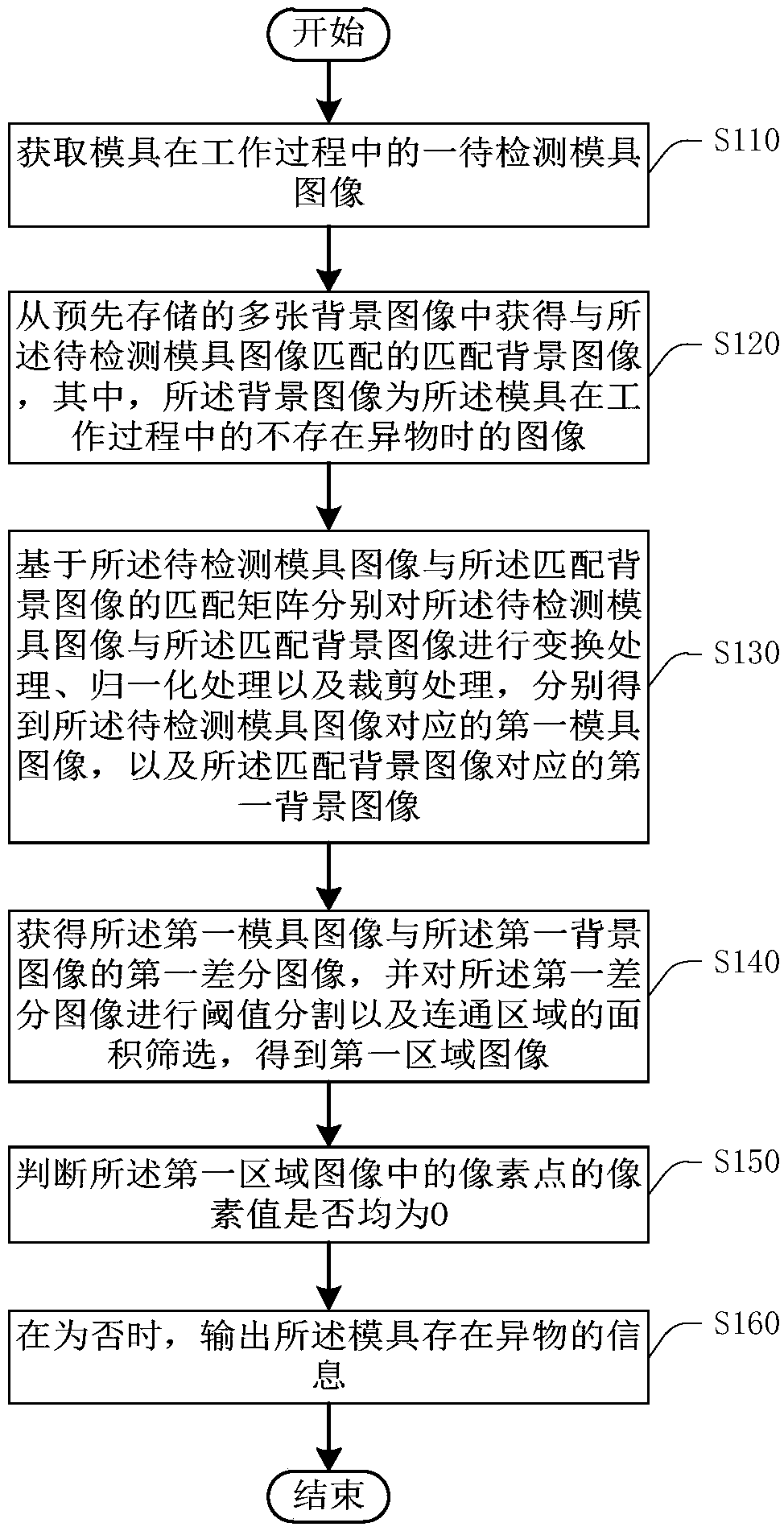

[0030] like figure 2 A flow chart provided by an embodiment of the present invention is shown. See figure 2 , the mold detection method includes:

[0031] Step S110: Obtain an image of the mold to be inspected during the working process of the mold.

[0032] In the embodiment of the present invention, the mold detection method can be applied to detect whether there are foreign objects in a dynamically working mold.

[0033]During the working process of the mold, the image of the mold can be collected in real time through the camera. In addition, the camera can collect the image of the mold during work according to a certain frequency. After the image of the mold is collected, it is judged whether there is foreign matter in the mold according to the collected image. The image collected above is the image of the mold to be inspected during the working process of the acquired mold.

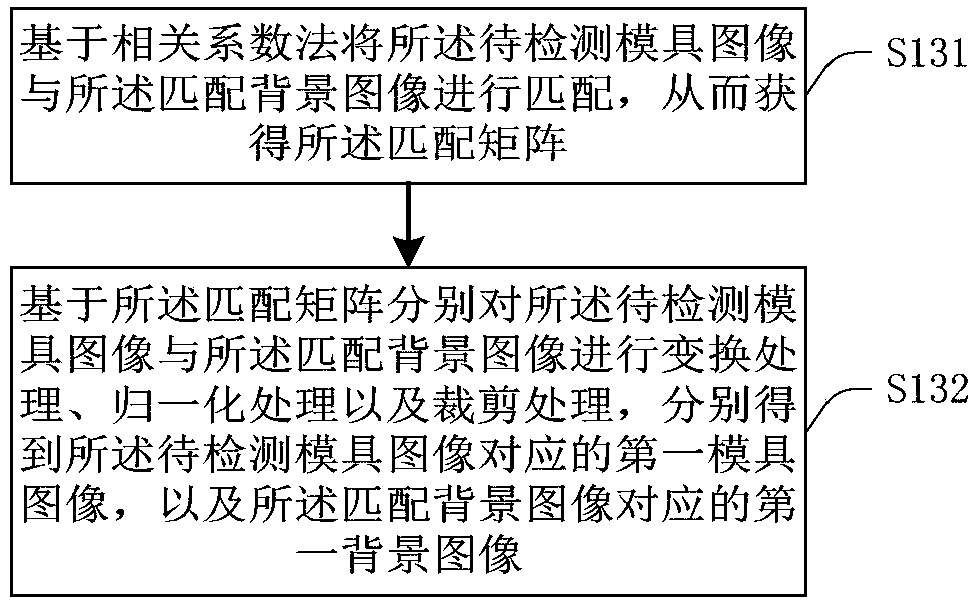

[0034] Step S120: Obtain a matching background image that matches the image of the mold to...

no. 2 example

[0086] The second embodiment of the present invention provides a mold inspection device 200, please refer to Figure 5 , the mold inspection device 200 includes: an image acquisition module 210 , an image matching module 220 , a first image processing module 230 , a second image processing module 240 , a pixel value judgment module 250 and an execution module 260 . Wherein, the image acquisition module 210 is used to acquire an image of the mold to be inspected during the working process of the mold; the image matching module 220 is used to obtain an image matching the image of the mold to be inspected from a plurality of pre-stored background images. matching the background image, wherein the background image is an image of the mold in the working process when there is no foreign matter; the first image processing module 230 is used for matching the background image based on the mold image to be detected The matching matrix performs transformation processing, normalization pr...

no. 3 example

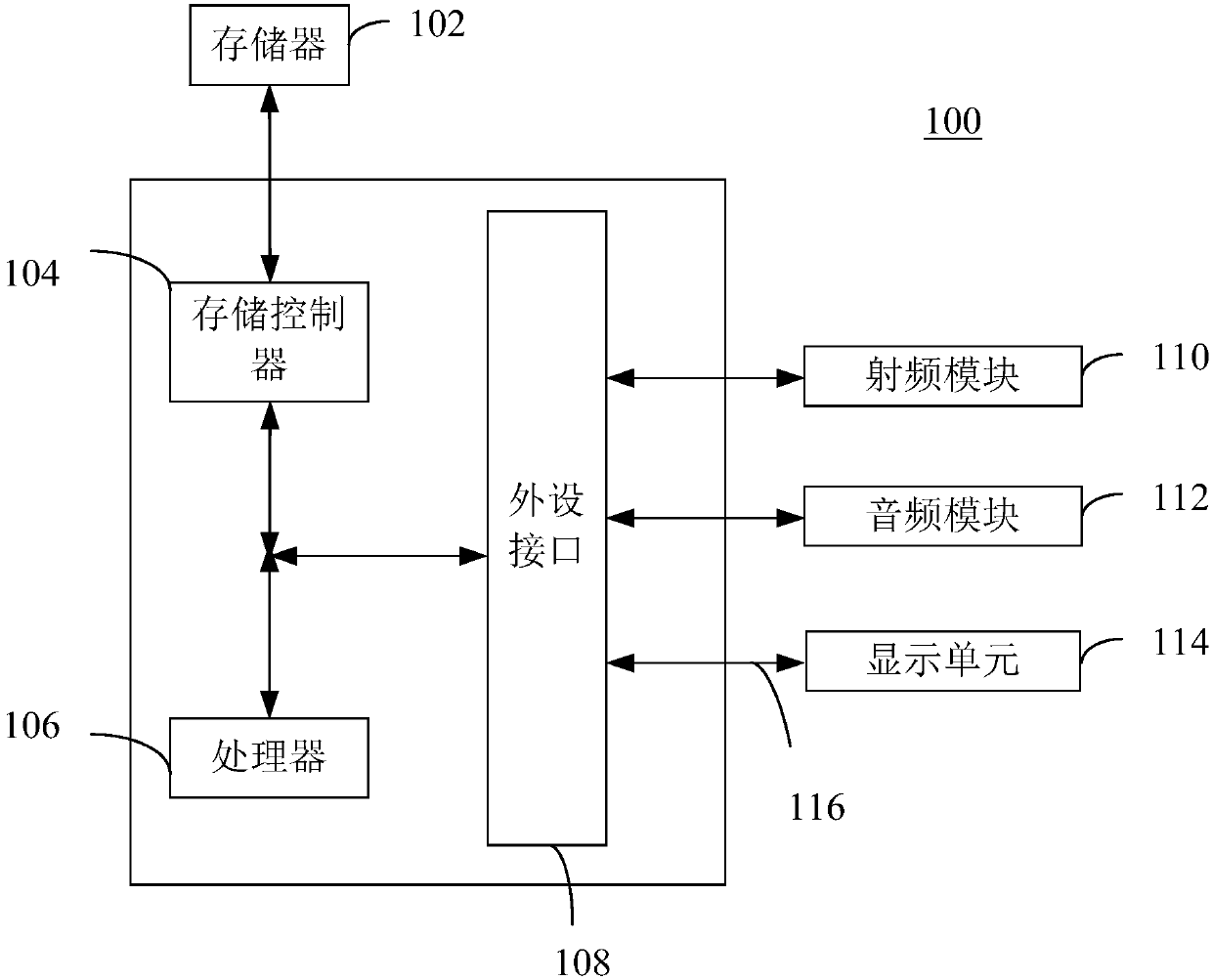

[0095] The third embodiment of the present invention provides an electronic device 100, please refer to figure 1 , the electronic device 100 includes a memory 102 and a processor 106, the memory 102 stores computer instructions, and when the computer instructions are read and executed by the processor 106, the processor 106 is made to execute the first embodiment of the present invention. The mold detection method that embodiment provides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com