Variable speed and variable blank holder force linked sheet drawing process

A blank holder force and sheet metal technology, which is applied in the field of sheet metal deep drawing technology with variable speed and variable blank holder force linkage, can solve the problem of forming quality of parts that affect the forming performance of sheet metal, fixed and unadjustable slider motion mode, and circular die. cracks and other problems in the corners, to overcome the high cost and low efficiency, easy to implement, and improve the forming ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

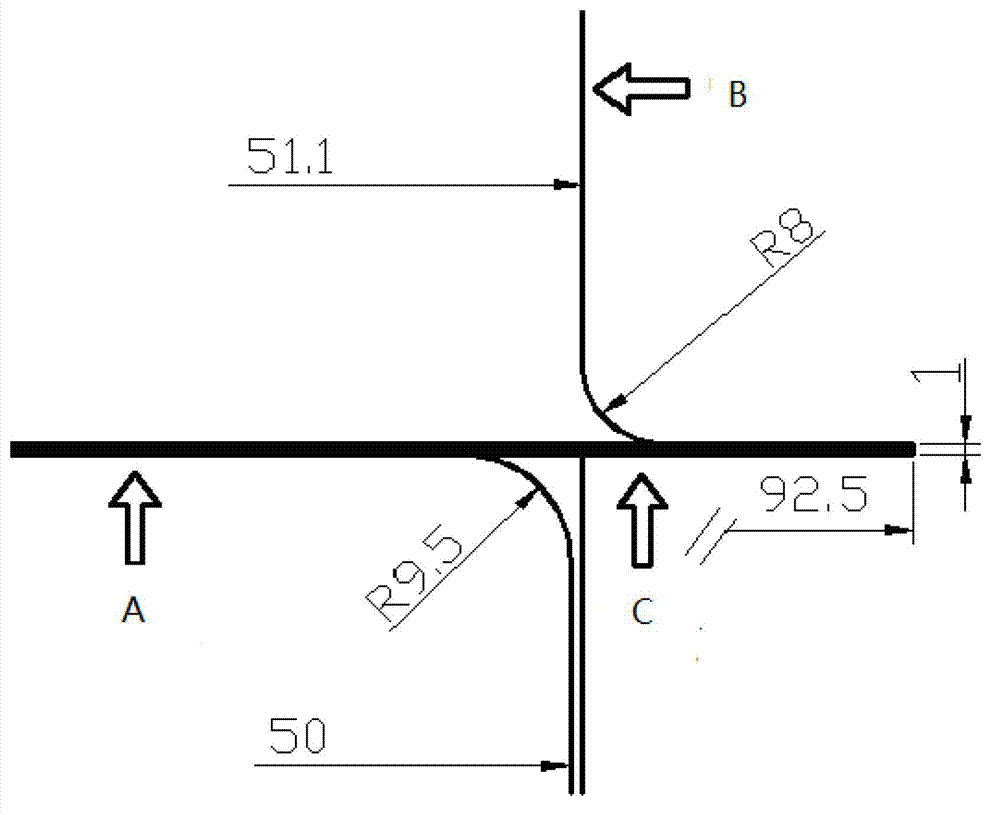

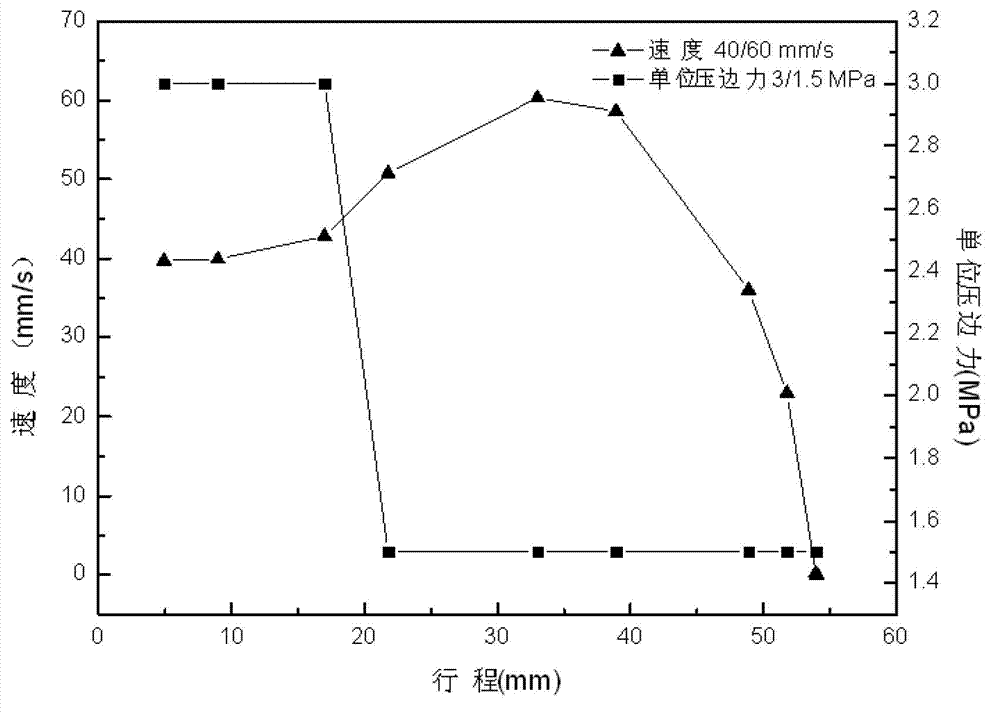

[0033] The drawing sheet C adopts B340 / 590DP steel plate, the blank diameter D is 185mm, the plate thickness t is 1mm, and the tensile strength Rm of the B340 / 590DP sheet is 612.5Mpa. figure 1 As shown (in mm), the diameter d of the punch A is 100mm, and the fillet radius of the punch A is R p 9.5mm, die B fillet radius R d is 8mm.

[0034] Firstly, determine the basic parameters in the deep drawing process of sheet metal C.

[0035] (1) In this example, the mold is installed on the working table of a 1000KN servo press, and the sheet is placed on the mold. The position when the slider of the servo press starts to contact the sheet is recorded as the initial drawing position, which is the starting point of the forming speed setting.

[0036] (2) Punch fillet radius R p 9.5mm, die fillet radius R d is 8mm, and the sheet thickness t is 1mm, so the turning point S of the change of speed and blank holder force k =R p +R d +t=18.5mm.

[0037] (3) The constant limit drawing...

Embodiment 2

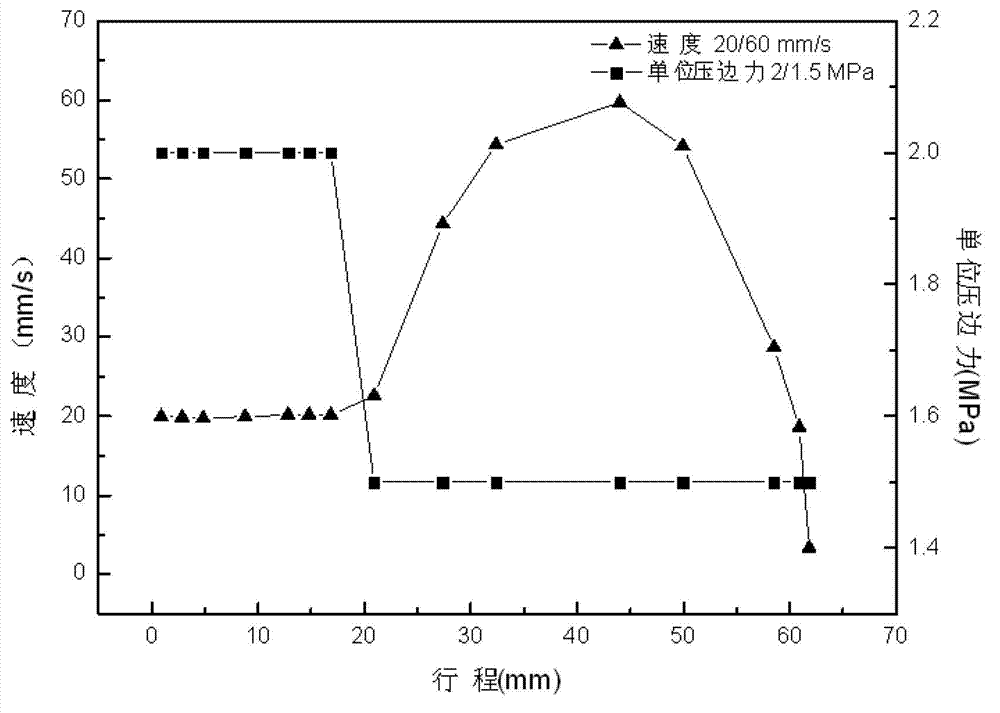

[0043] The deep drawing sheet adopts B340 / 590DP steel plate, the diameter of the blank is 190 mm, and the thickness of the plate is 1 mm. The mold used for forming is the same as that of Example 1. The curves of variable speed and variable blank holder force are as follows image 3 shown.

[0044] (1) In this example, the mold is installed on the working table of a 1000KN servo press, and the sheet is placed on the mold. The position at which the servo press slide begins to contact the sheet is recorded as the initial drawing position.

[0045] (2) Punch fillet radius R p 9.5mm, die fillet radius R d is 8mm, and the sheet thickness t is 1mm, so the turning point S of the change of speed and blank holder force k =R p +R d +t=18.5mm.

[0046] (3) The constant limit drawing speed v of sheet metal is 30mm / s.

[0047] (4) The speed change motion curve of the slider is 20 / 60mm / s, which represents the initial drawing position S from the initial drawing position to the change of ...

Embodiment 3

[0051] The deep-drawing sheet is made of H380 steel plate, the blank diameter D is 190mm, the thickness t is 1mm, and the tensile strength Rm of the sheet is 483Mpa. figure 1 Shown (in mm).

[0052] The mold used for forming is identical to embodiment 1, and the variable speed and variable blank holder force curves are as follows Figure 4 shown.

[0053] (1) In this example, the mold is installed on the working table of a 1000KN servo press, and the sheet is placed on the mold. The position at which the servo press slide begins to contact the sheet is recorded as the initial drawing position.

[0054] (2) The turning point S of the change of speed and blank holder force k = R p +R d +t=18.5mm.

[0055] (3) The constant limit drawing speed v of sheet metal is 45mm / s.

[0056] (4) The speed change motion curve of the slider is 30 / 70mm / s, which represents the initial drawing position S from the initial drawing position to the change of speed and blank holder force k The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com