Patents

Literature

38results about How to "Improve plasticizing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

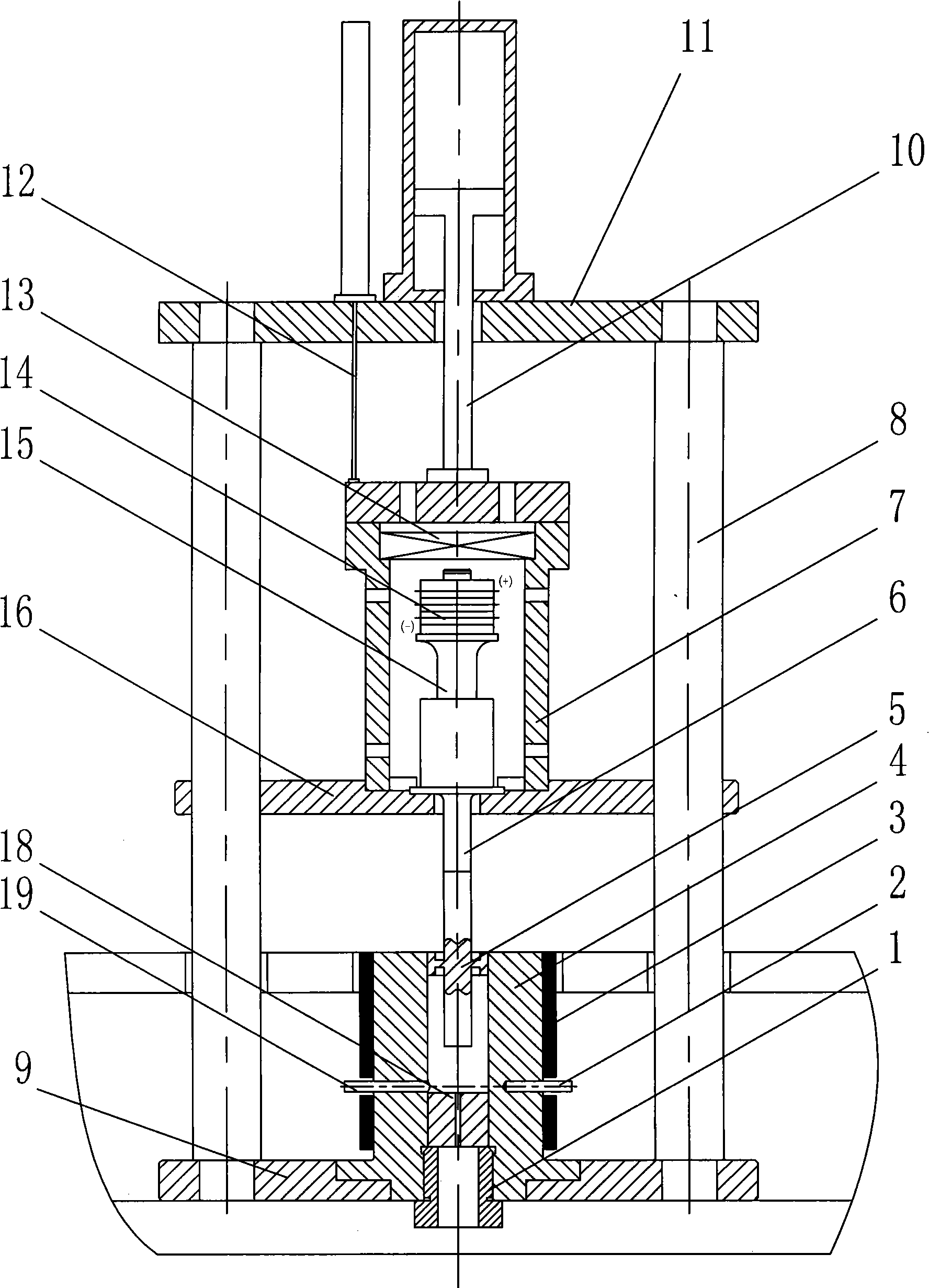

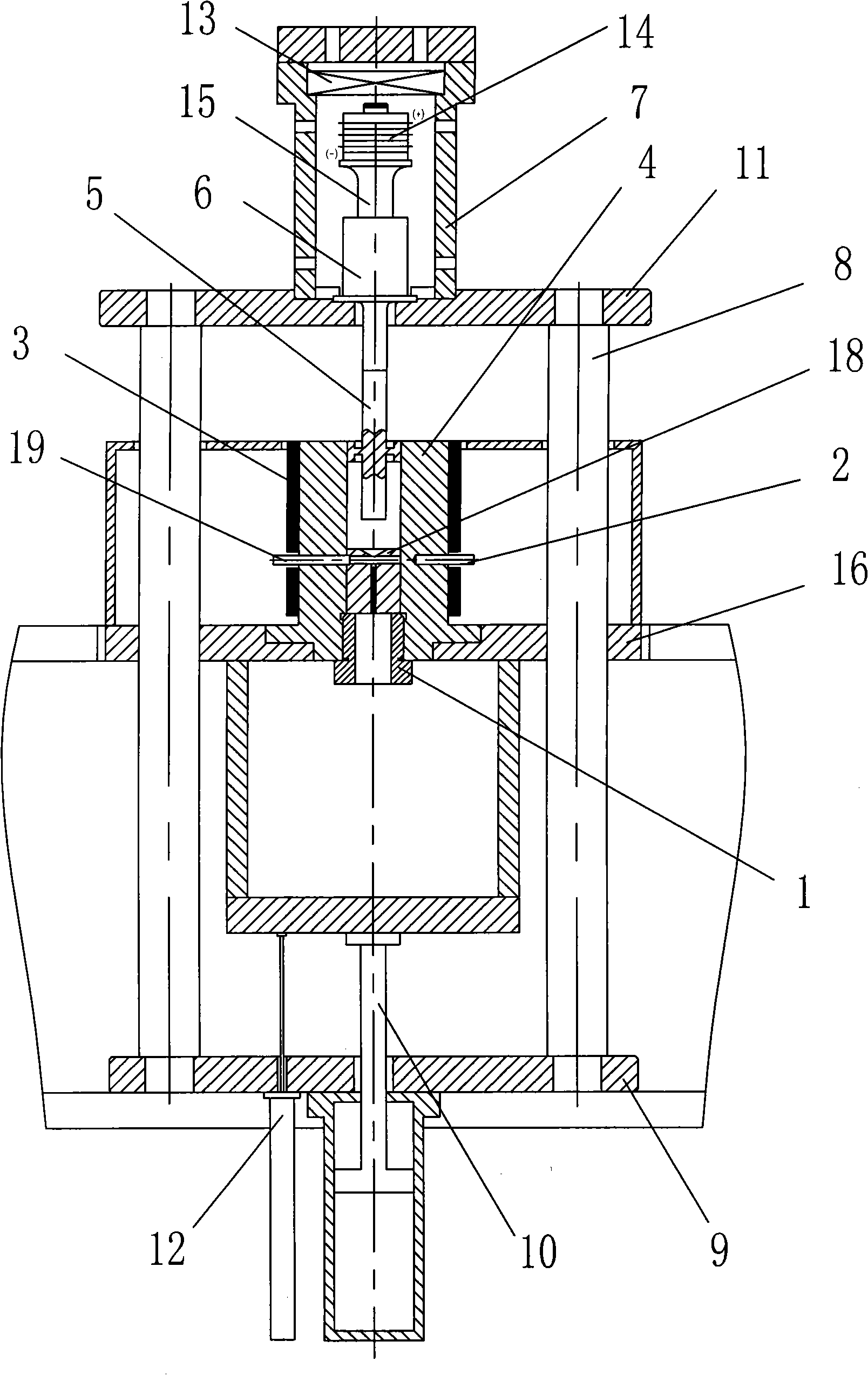

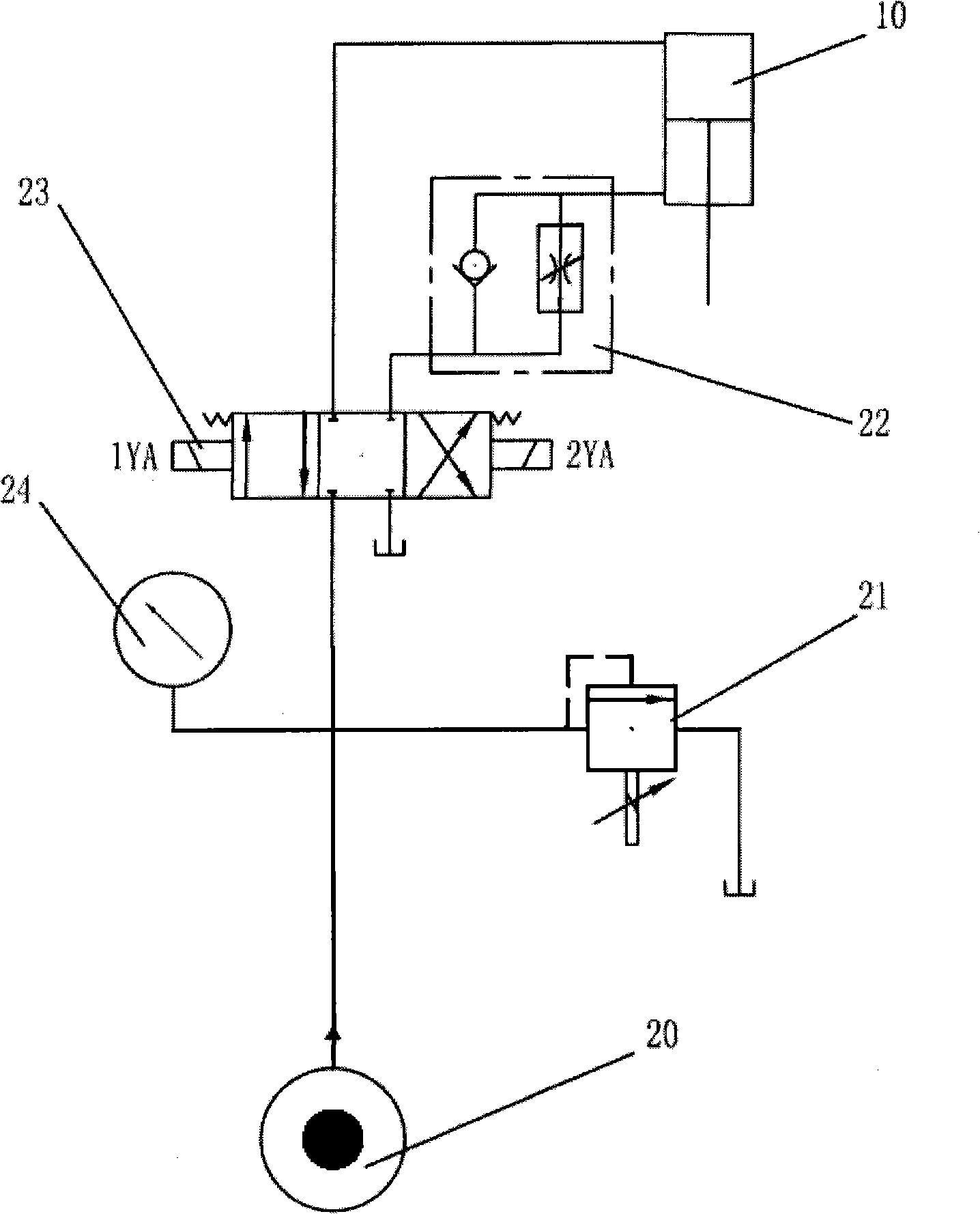

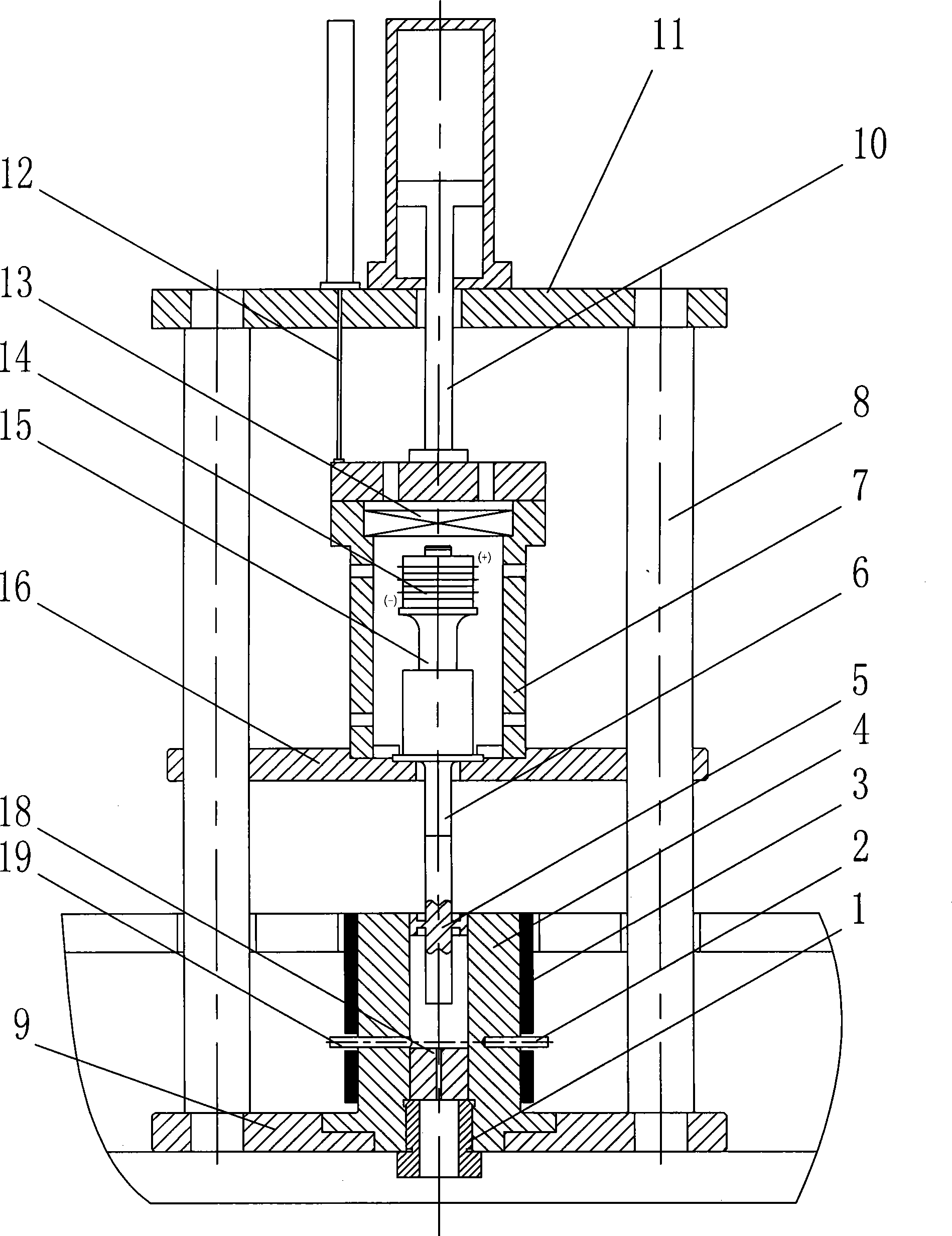

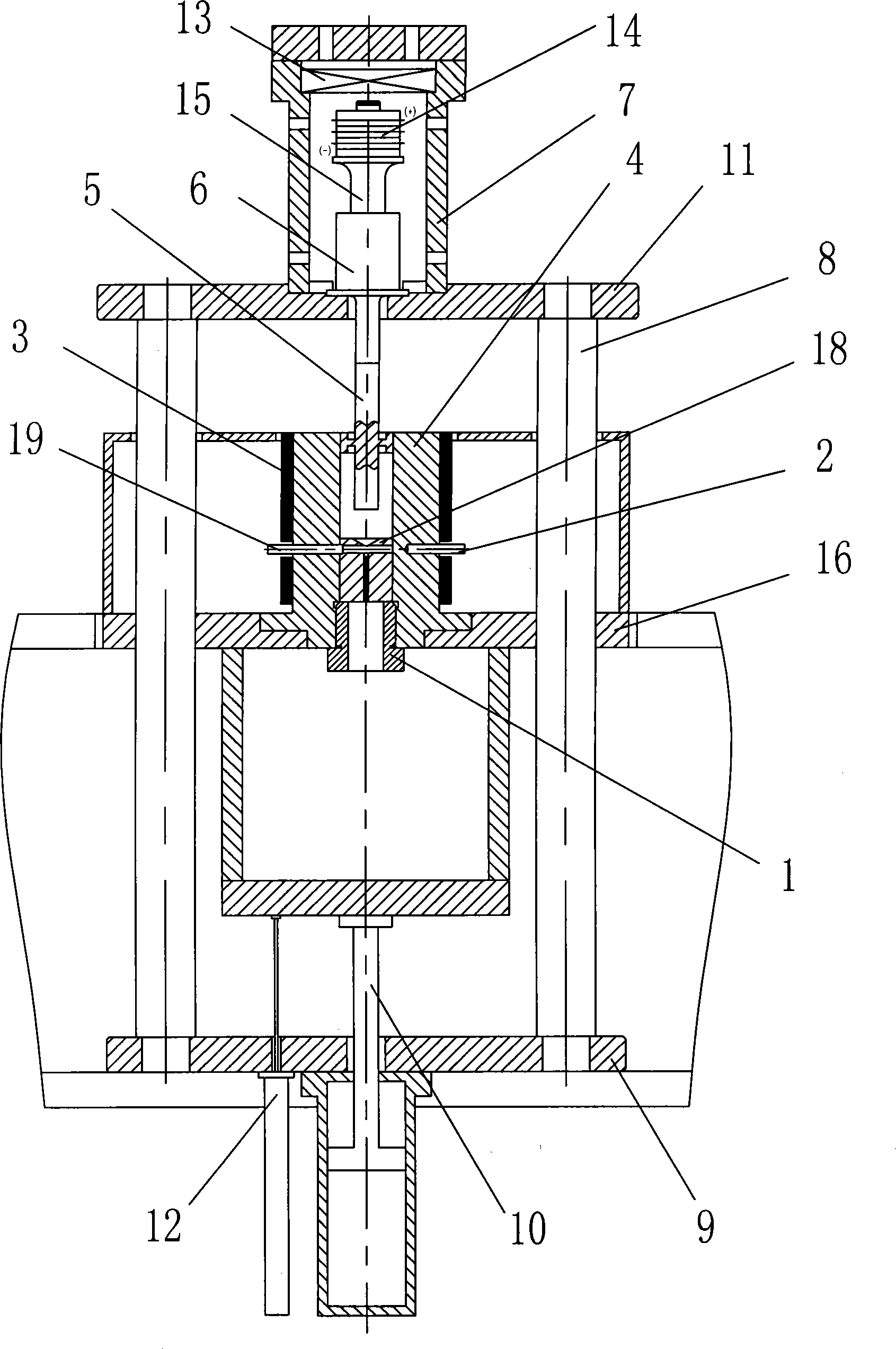

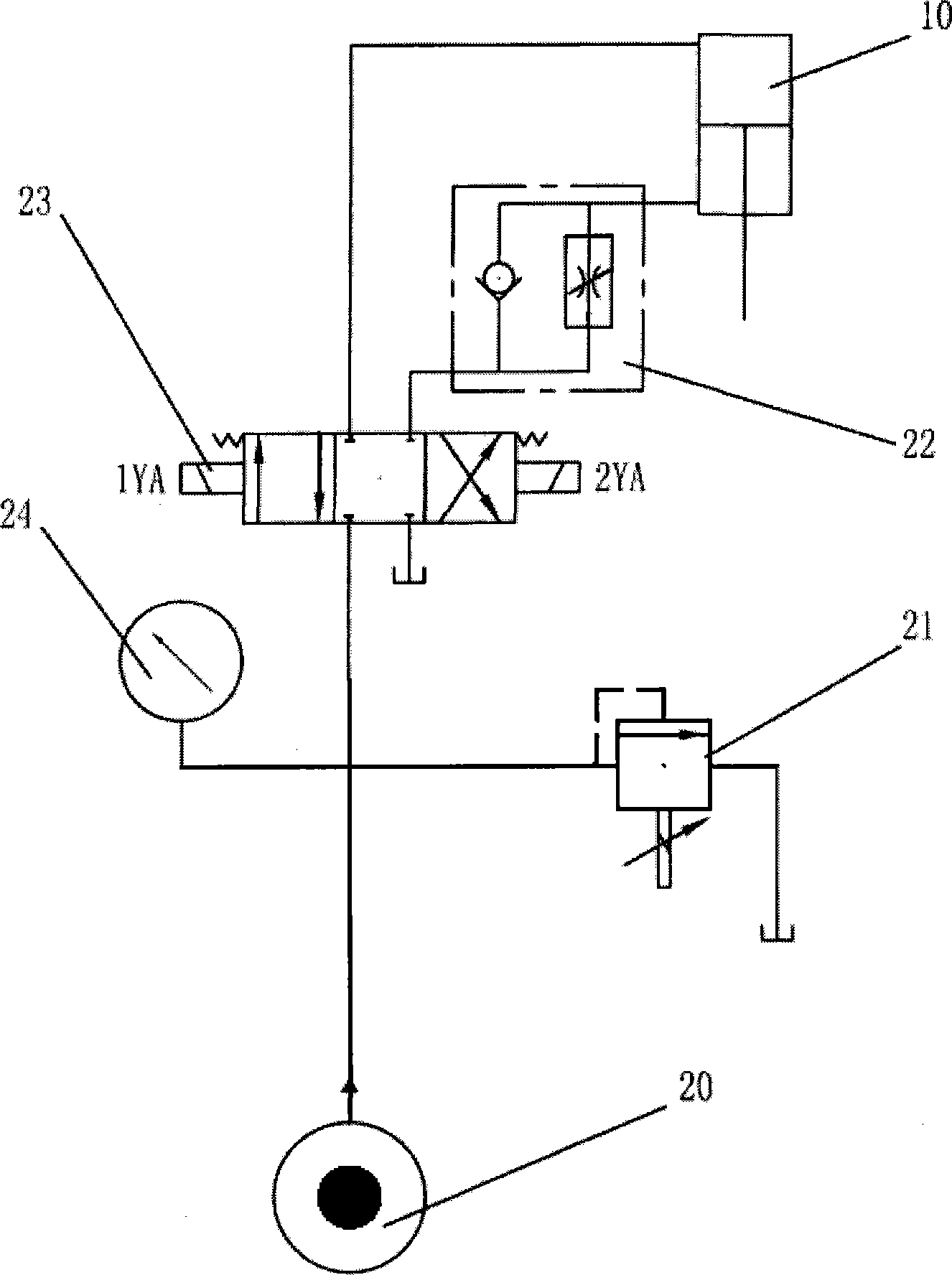

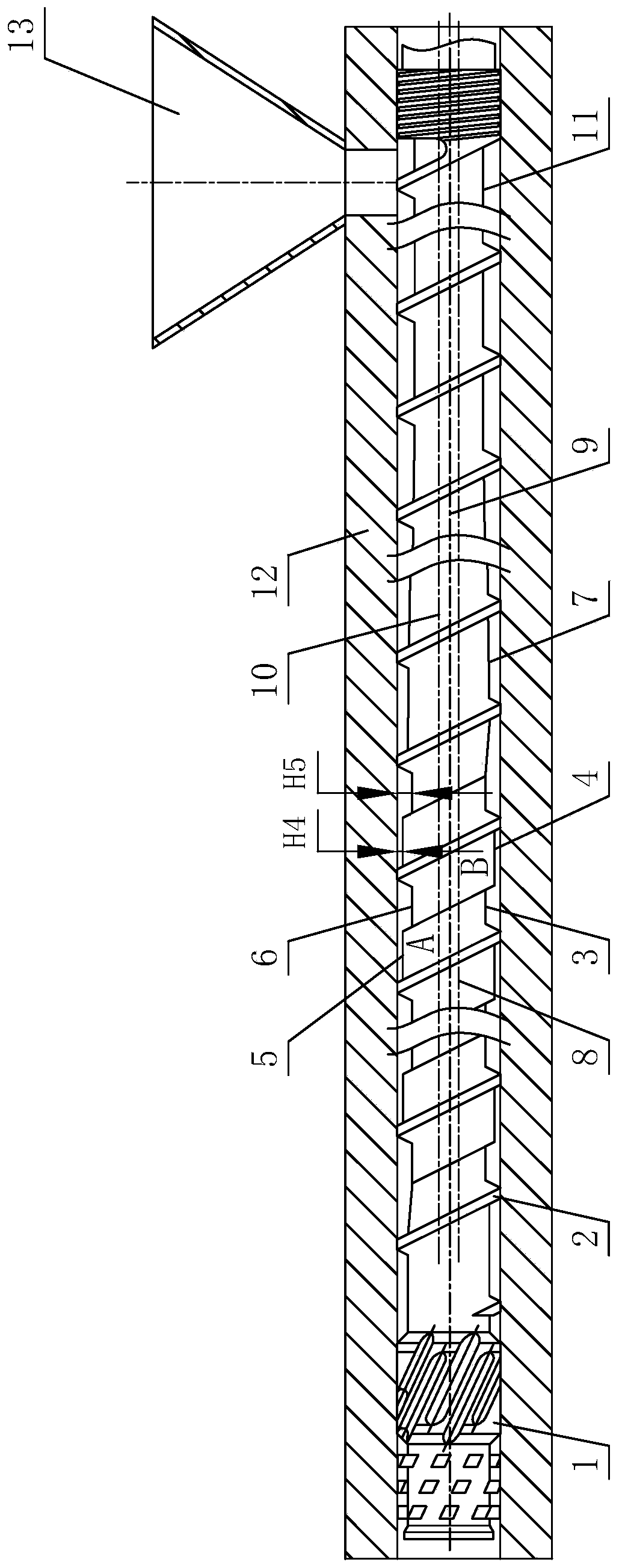

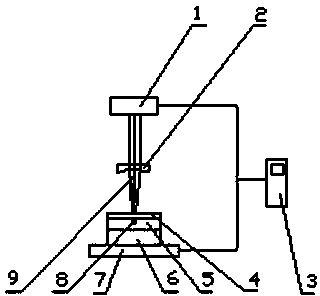

Test device for accomplishing polymer melting plasticization using superaudio vibration

InactiveCN101261266AConstant pressureRealize melt plasticizationMaterial testing goodsData acquisitionEngineering

The invention discloses a testing device that realizes the melting and plasticizing of polymers by utilizing ultrasonic frequency vibration, wherein, a material cylinder (4) is arranged on a stand (9); a capillary orifice mode (18), a tool head (5), a thermocouple (2), a heating ring (3) and a high temperature melt temperature pressure sensor (19) are arranged in the material cylinder (4); the lower end of a guide pillar (8) is arranged on the stand (9), the upper end of the guide pillar (8) is provided with a frame(11), the frame(11) is provided with a hydraulic transmission and control system, a guide bracket (16) is glidingly arranged on the guide pillar (8), the guide bracket (16) is provided with an ultrasonic vibration system, the tool head (5) is connected with the ultrasonic vibration system by a way of transmission, the ultrasonic vibration system is connected with the hydraulic transmission and control system by a way of transmission, the ultrasonic vibration system is provided with a displacement sensor (12), and the high temperature melt temperature pressure sensor (19) and the displacement sensor (12) are electronically connected with a computer data acquisition system. In terms of function, the testing device of the invention not only can simultaneously realize the melting and plasticizing of polymer materials by utilizing ultrasonic frequency vibration and detect the formability of ultrasonic plasticizing, but also can satisfy the needs of conventional processability test for the polymers.

Owner:CENT SOUTH UNIV

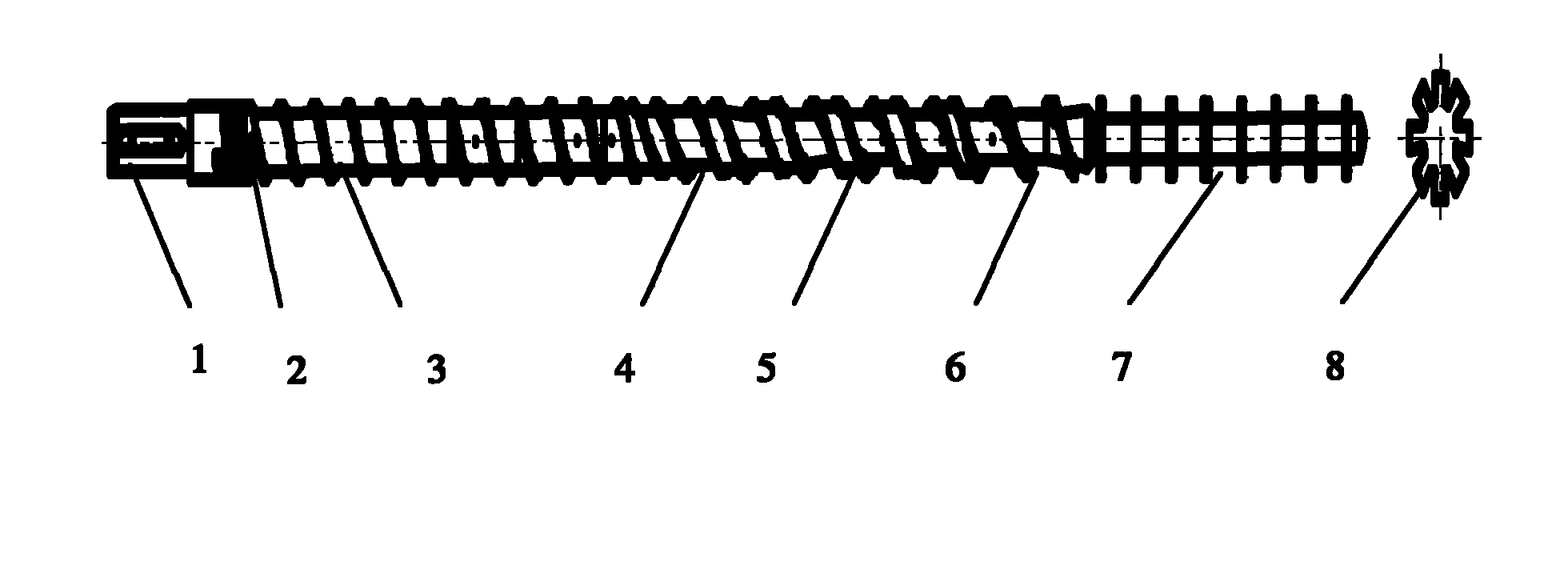

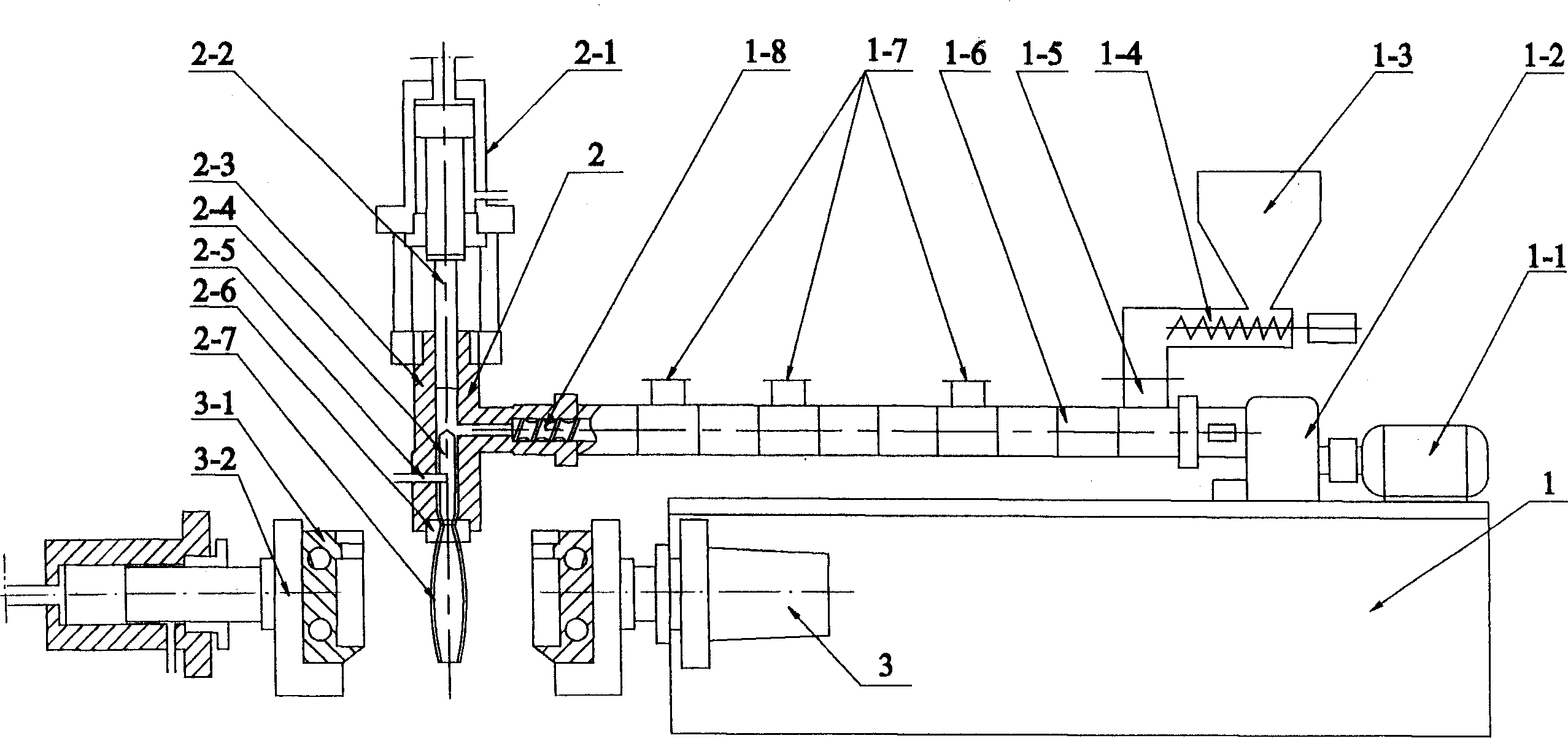

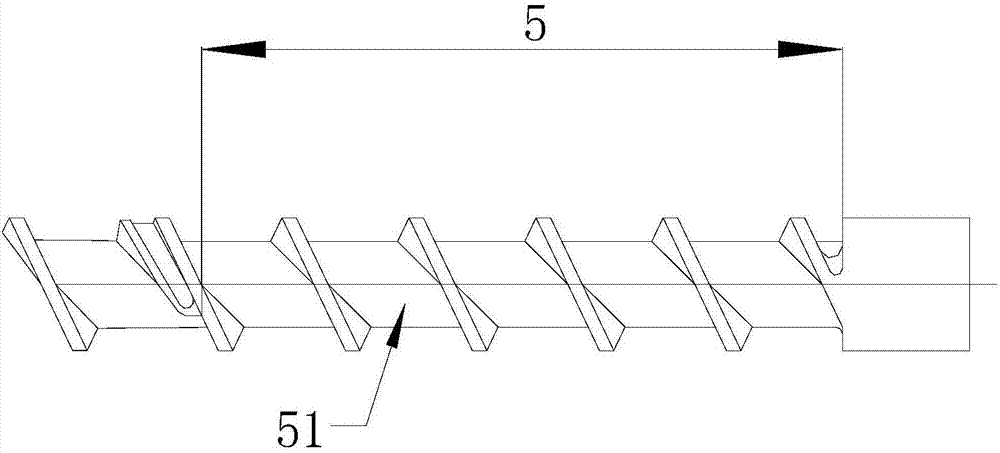

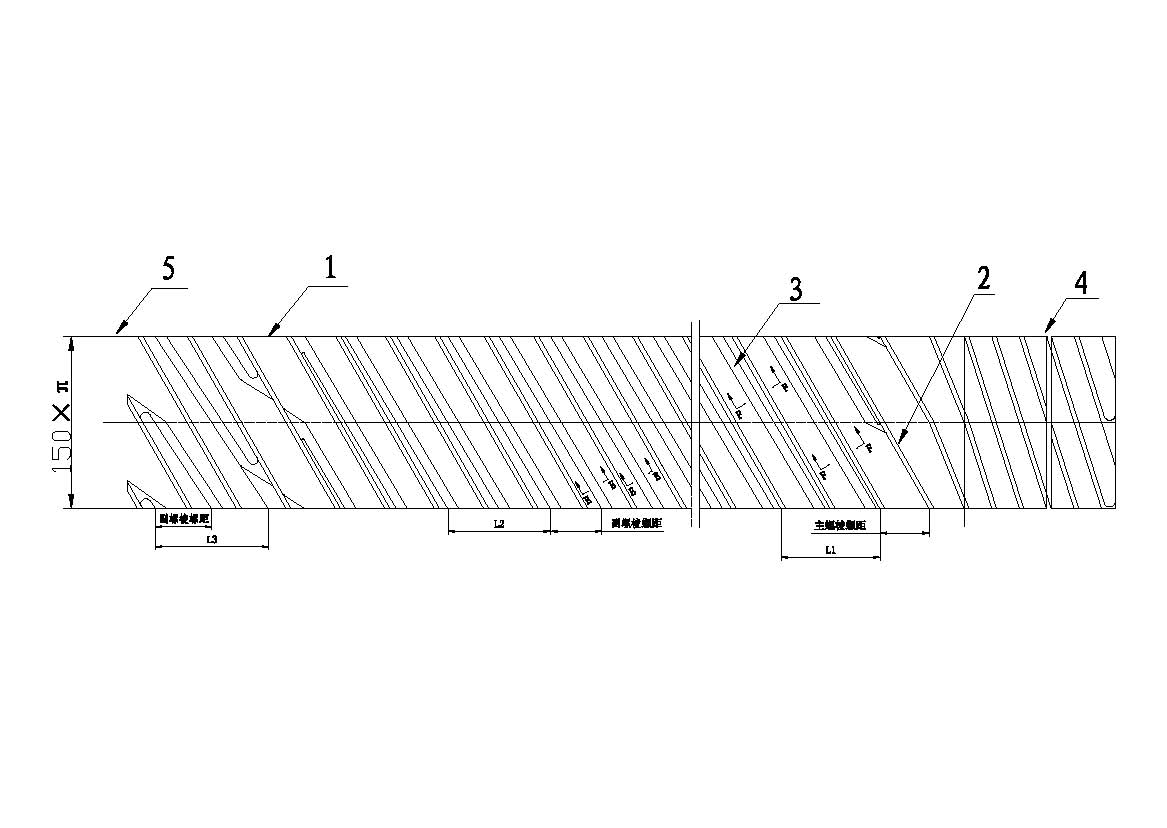

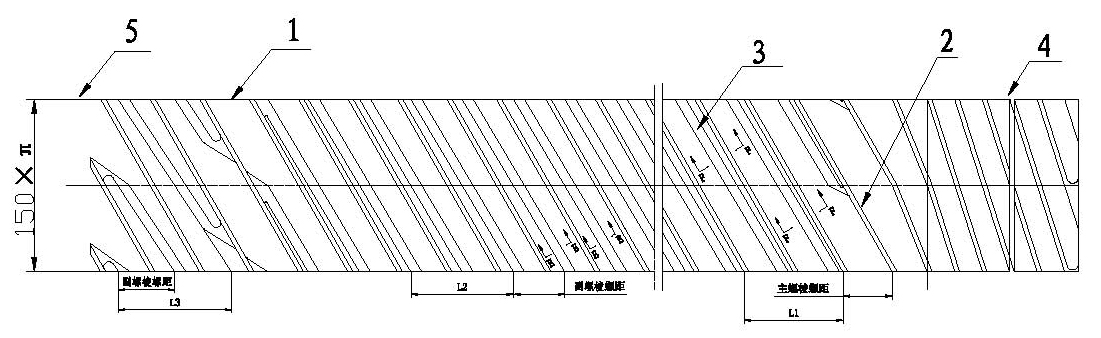

High-speed PB tube single screw

InactiveCN101774269AImprove productivityIncrease production capacityTubular articlesProduction rateEngineering

The invention provides a high-speed PB tube single screw, which comprises a feeding section, a separation-type melting section and a mixing-type extruding section, wherein the separation-type melting section is provided with a main screw edge and two auxiliary screw edges, the depth of a screw channel of the feeding section is 7mm to 8mm, the lead of the main screw edge is 105 to 110 mm, and the lead of the auxiliary screw edges is respectively 107 mm and 84 mm. The high-speed PB tube single screw solves the phenomenon of the prior PB tube screw that the productivity is difficult to be improved at the high speed, the plasticized quality is poor and the temperature of the fuse is too high, and can obtain the PB melting plastics with good plasticized quality and high productivity (300kg / hour).

Owner:GUANGDONG LIANSU MACHINERY MFG

Regeneration pelletizer for worn-out plastic

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Composite wood-plastic material blow molding machine

The composite wood-plastic material blow molding machine is one parallel double screw extruder provided with storage cylinder and mold closing device. The parallel double screw extruder has outlet communicated with the storage cylinder, and the storage cylinder has outlet over the mold closing device. The composite wood-plastic material blow molding machine has the functions of deairing, mixing, forming at low temperature and low pressure and eliminating residual stress, and is used in forming composite wood-plastic material product in high quality.

Owner:徐凌秀

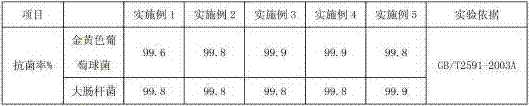

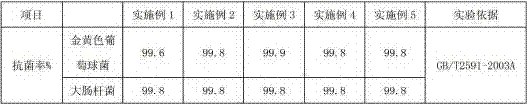

PVC board and preparation process thereof

The invention discloses a PVC board and a preparation process thereof. The PVC board is prepared from, by weight, 40-60 parts of polyvinyl chloride resin, 0.1-0.5 part of white oil, 2.5-3 parts of stabilizer, 1-3 parts of titanium dioxide, 0.1-0.5 part of stearic acid, 0.1-0.3 part of polyethylene wax, 0.01-0.5 part of octadecanamide, 0.01-0.2 part of ultraviolet absorbent, 0.01-0.03 part of colorant, 0.01-0.1 part of fluorescent whitening agent OB, 10-20 parts of activated calcium carbonate, 10-20 parts of talcum powder and 0.1-0.3 part of foaming agent. The PVC board is low in cost and good in heat stability, the rigidity is improved, the plastifying quality is improved, and the appearance is improved, so that section bars are smooth and good in weather resistance, toughness and uniformity.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

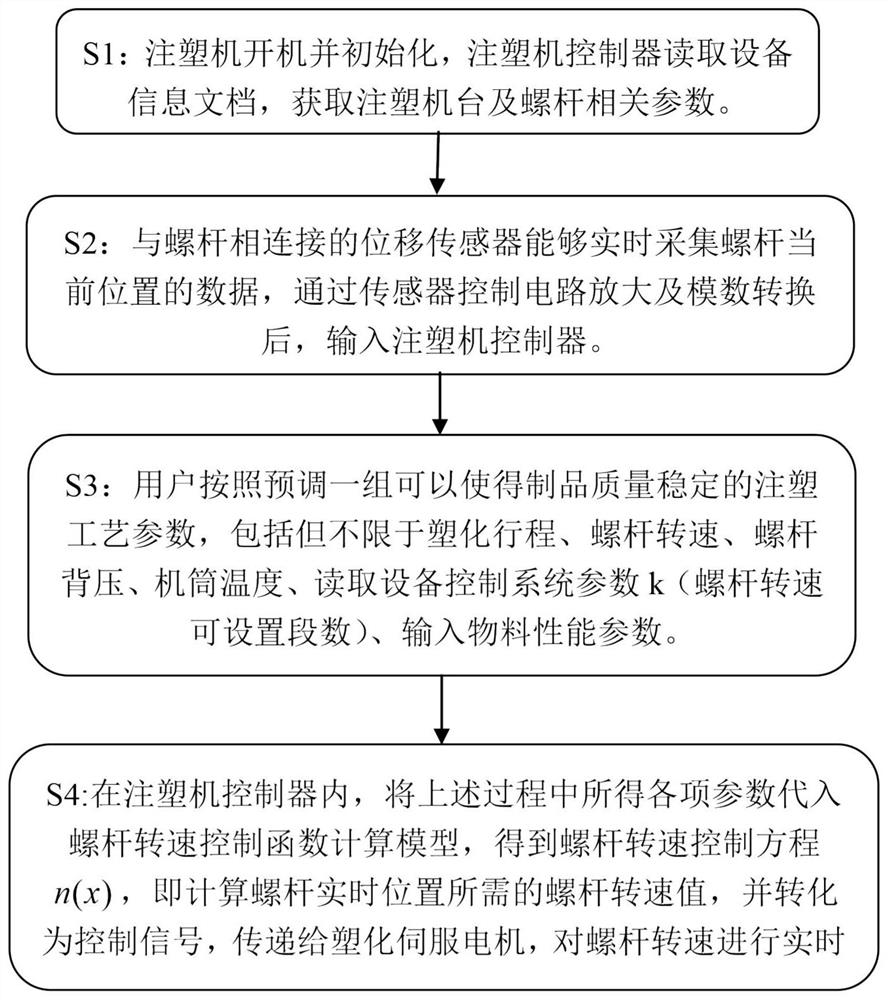

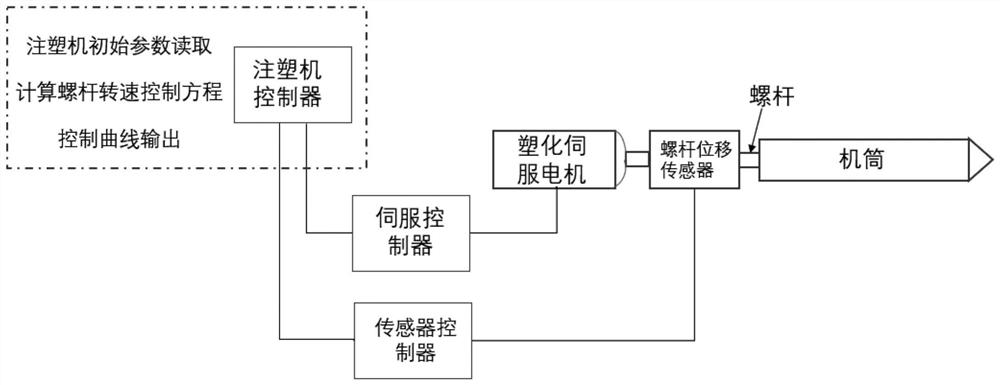

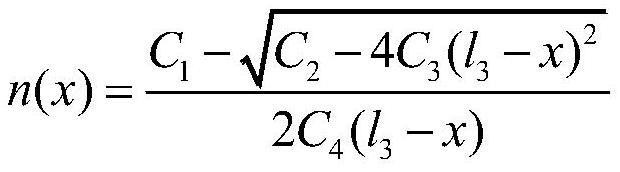

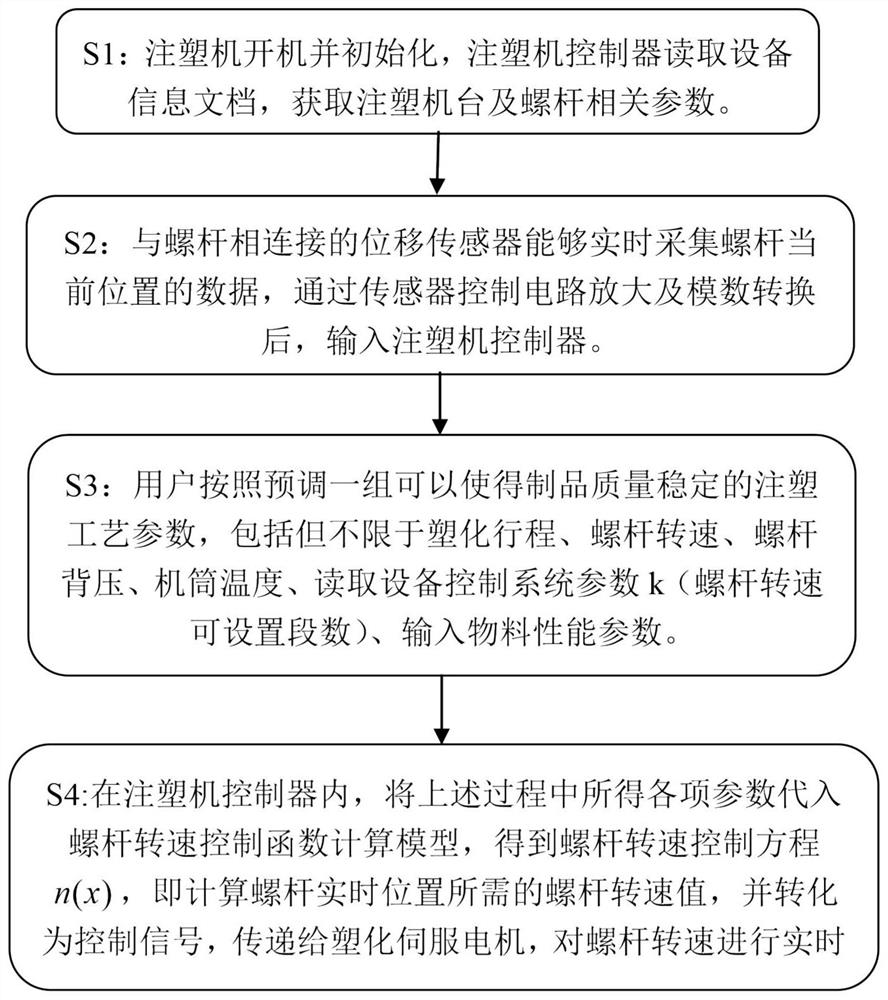

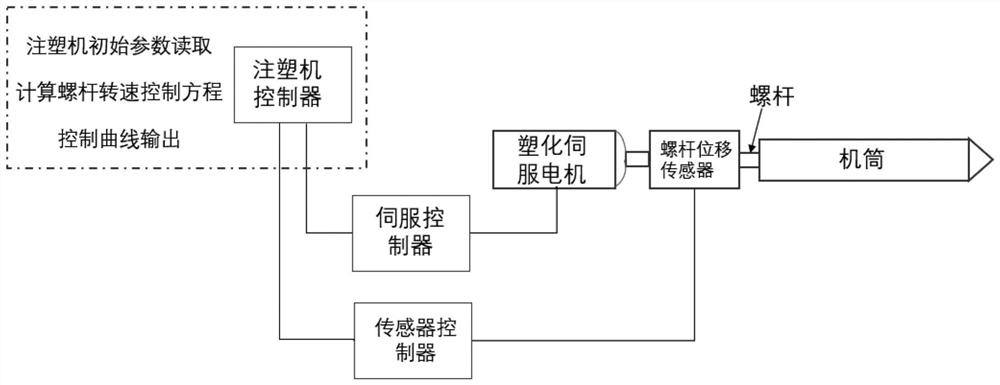

Screw rotating speed control method for improving plasticizing quality of injection molding machine

ActiveCN113414955AImprove plasticizing qualityImprove uniformity of plasticizationControl systemPlasticulture

The invention discloses a screw rotating speed control method for improving plasticizing quality of an injection molding machine, the screw rotating speed control method comprises the following steps that a current displacement value of a screw is collected through a displacement sensor arranged at the tail end of the screw, a screw structure parameter and an initial process parameter set value are read by an injection molding machine controller, and the values are substituted into a screw rotating speed control function calculation model; and a screw rotating speed control scheme about the real-time screw displacement is obtained and is transmitted to an injection molding machine plasticizing motor servo control system to control the screw rotating speed in the current period in real time, so that the uniformity of the melt plasticizing quality is realized. According to the screw rotating speed control method for improving the plasticizing quality of the injection molding machine, the plasticizing quality of a plastic melt is improved, the uniformity of the melt is improved, and the mold testing frequency caused by replacement of equipment or materials is reduced.

Owner:BEIJING UNIV OF CHEM TECH

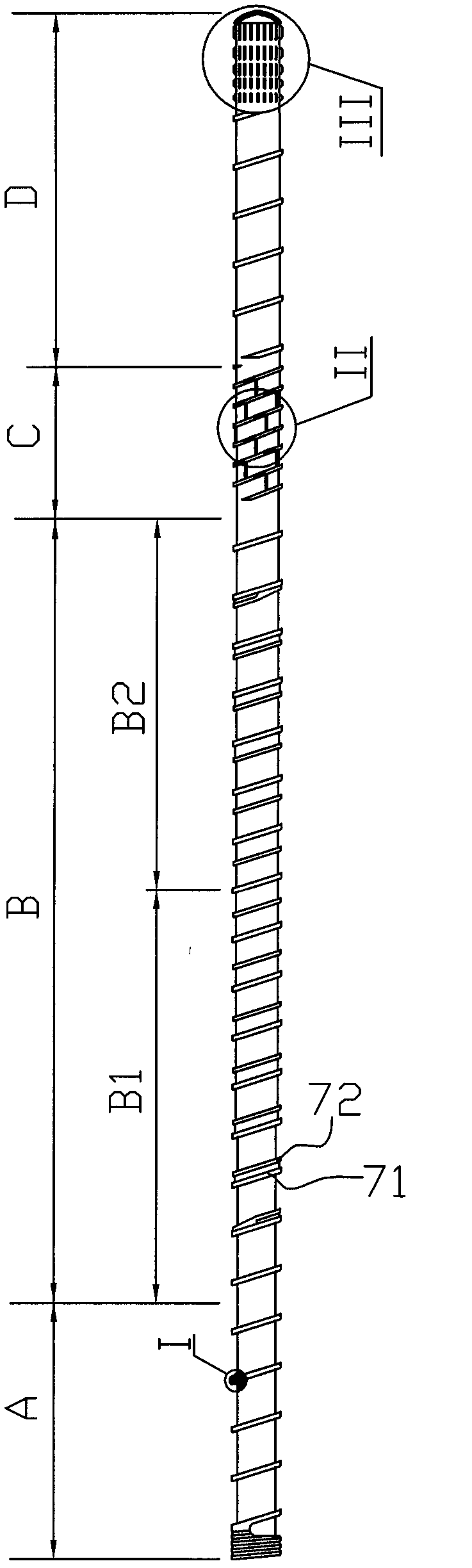

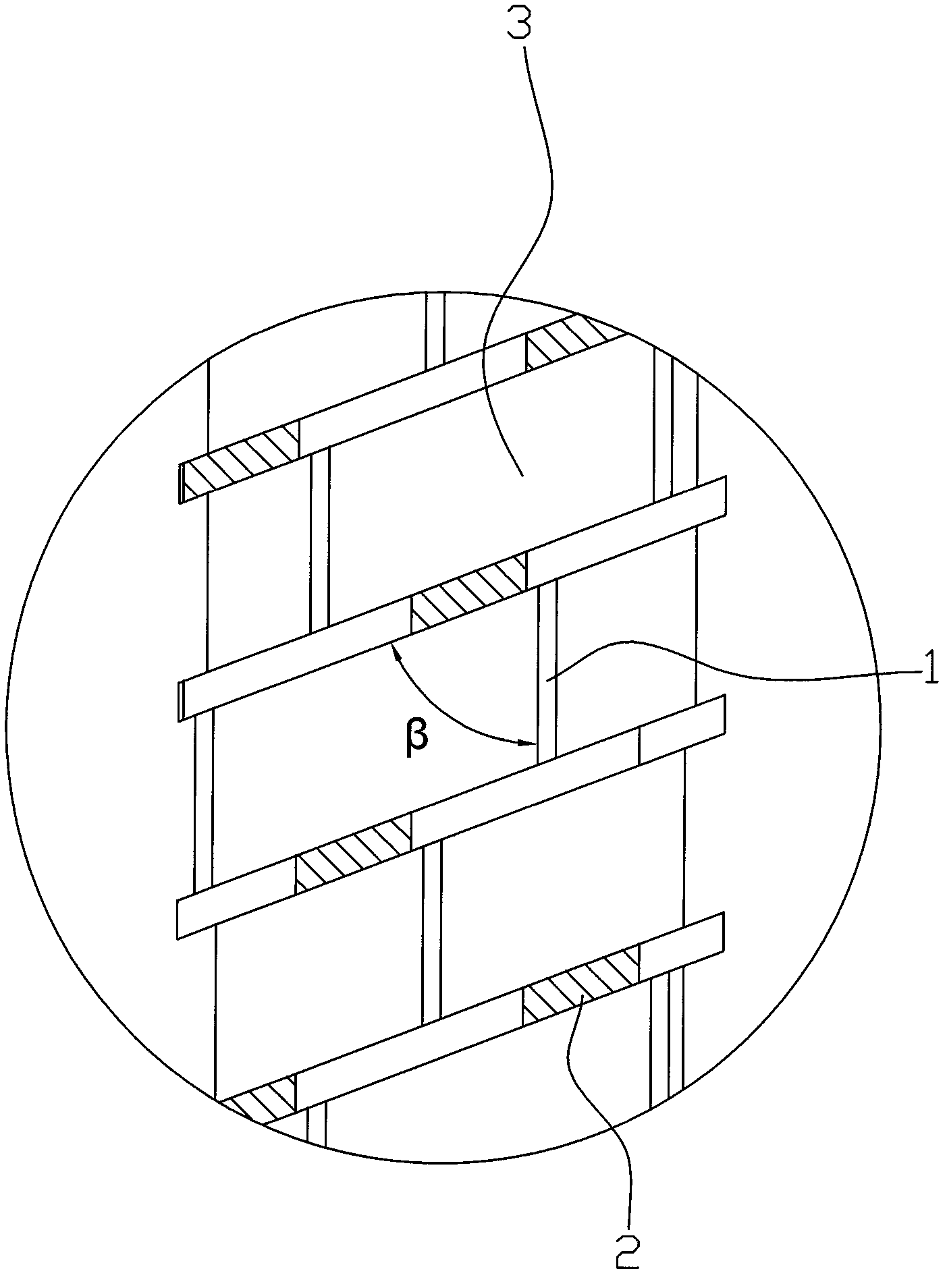

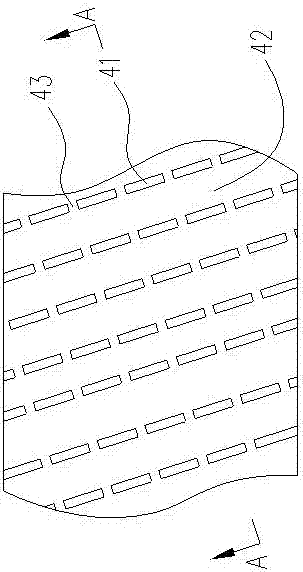

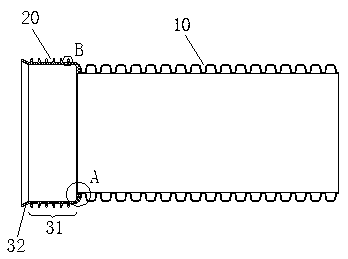

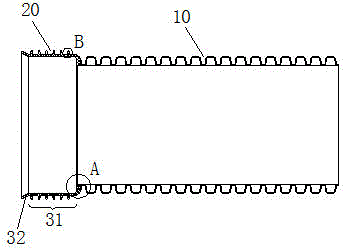

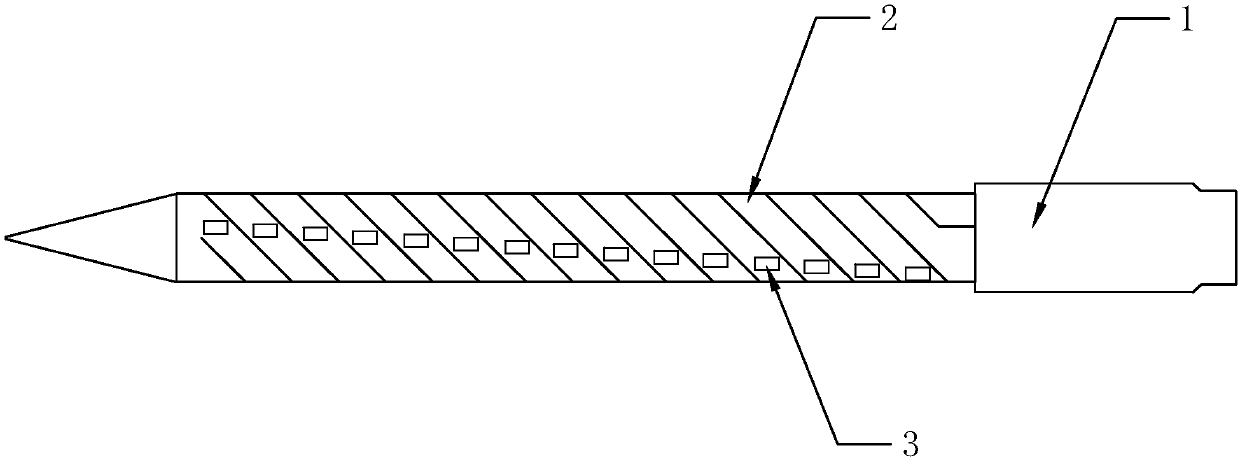

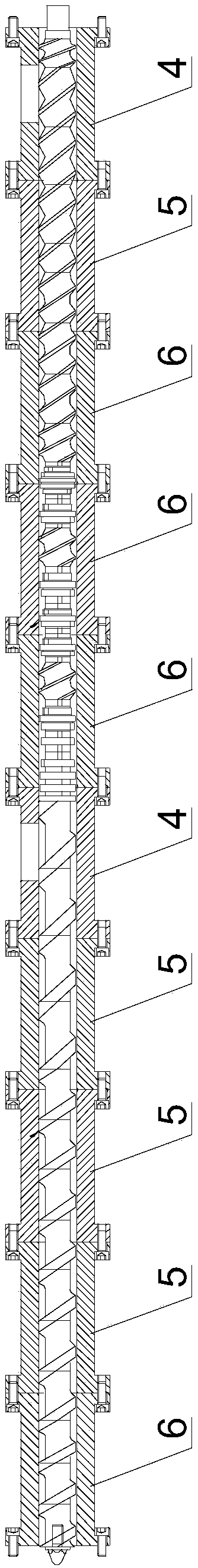

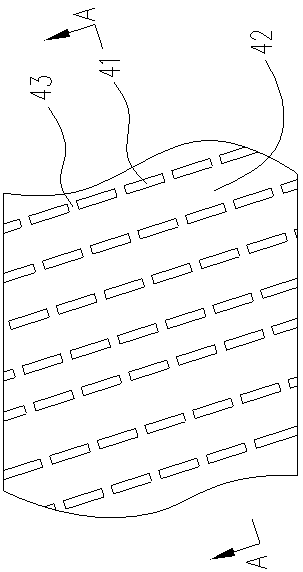

Extrusion screw

The invention relates to an extrusion screw, which is characterized in that screw rims are arranged on a charging segment (A), a melting segment (B), a plasticizing segment (C) and an extrusion segment (E). An auxiliary screw rim groove (2) is provided on the screw rim of the plasticizing segment (C) at intervals, a transverse rim (1) is axially provided between the screw rim of the plasticizing segment (C), the transverse rim and the screw rim of the plasticizing segment (C) form a plurality of main screw rim grooves (3). Compared with the prior art, the extrusion screw has the advantages that a main and auxiliary double screw rims structure realizes the separation of a solid phase of the material and a liquid phase of the material, the plasticizing quality can be effectively enhanced, the melt crystallization point can be reduced, and the higher transparent grade of the product is reached; simultaneously, the plasticizing distance and plasticizing time can be shortened, and the shear degradation of highly viscous fluid can be avoided; a protruded nailing block structure of the extrusion segment enables melt to extrude along a netted channel for realizing the stabilization and uniformity of the extrusion of the materials.

Owner:浙江华业塑料机械股份有限公司

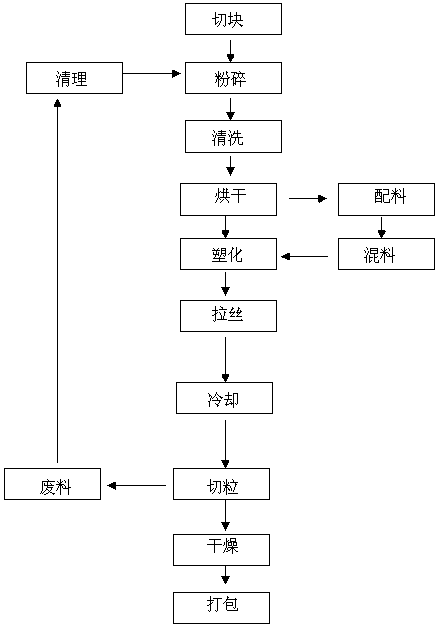

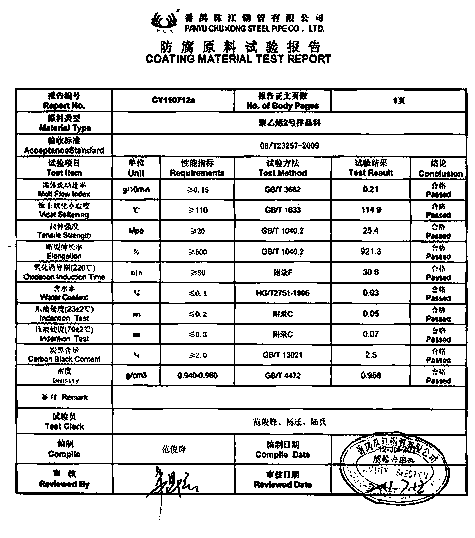

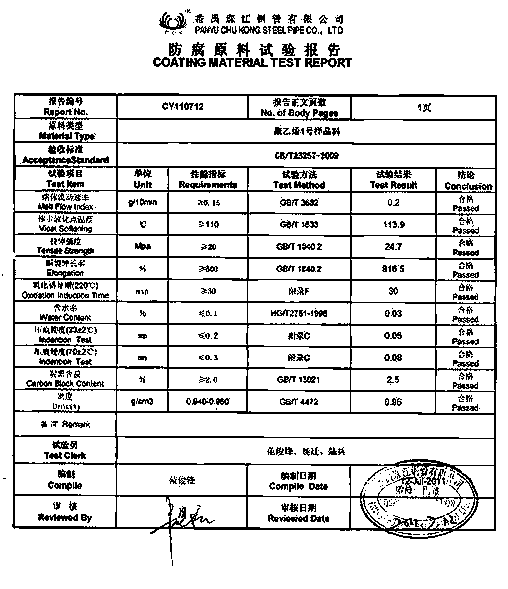

Method for recycling waste plastic for pipeline anticorrosion

ActiveCN103448159AImprove the mixing effectImprove plasticizing qualityPlastic recyclingSteel tubeEnvironmental resistance

The invention discloses a method for recycling waste plastic for pipeline anticorrosion, belonging to the technical field of high molecular materials applied to steel tube anticorrosion. The method is characterized by comprising the following steps: crushing; cleaning; re-proportioning anticorrosive 3PE (Poly Ethylene) waste plastic of a pipeline 3, namely the ratio of regenerating prilling materials: resin: an antioxygen: a processing agent=( is (80-70):(18-15):0.2:1.0. After prilling, the quality of the waste plastic satisfies the demand of technical standard (SY / T0413-2002) on the polyethylene anticorrosive layer of the buried steel pipeline, and the waste plastic can be reused to 3PE anticorrosion. The environmental pollution is eliminated and the environment problem is solved. The cost of raw materials for pipeline anticorrosion is saved, the utilization ratio of resources is improved, and the domestic blank is filled. The method belongs to circular economy, obtains good economic and social benefits, and has better popularization and application valves.

Owner:PANYU ZHUJIANG STEEL PIPE LIANYUNGANG

Continuous EPE physical foamed plate extruder

The invention provides a continuous EPE physical foamed plate extruder which comprises a first-stage extruder body, a second-stage extruder body and a pipeline. The first-stage extruder body comprises a first-stage screw barrel and a first-stage screw. The second-stage extruder body comprises a second-stage screw barrel and a second-stage screw. The first-stage screw barrel and the second-stage screw barrel communicate through the pipeline. The continuous EPE physical foamed plate extruder is characterized in that the first-stage screw sequentially forming a first feeding section, a barrier section, a first stirring section and a first mixing section in the axial direction. A plurality of pin sets are arranged on the screw groove surface of the pin stirring section. According to the continuous EPE physical foamed plate extruder, product quality can be improved while the yield is increased and production efficiency is improved, and production energy consumption can be reduced.

Owner:重庆捷泰塑胶工业有限公司

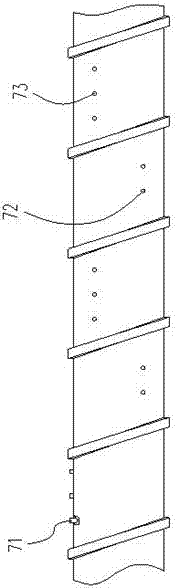

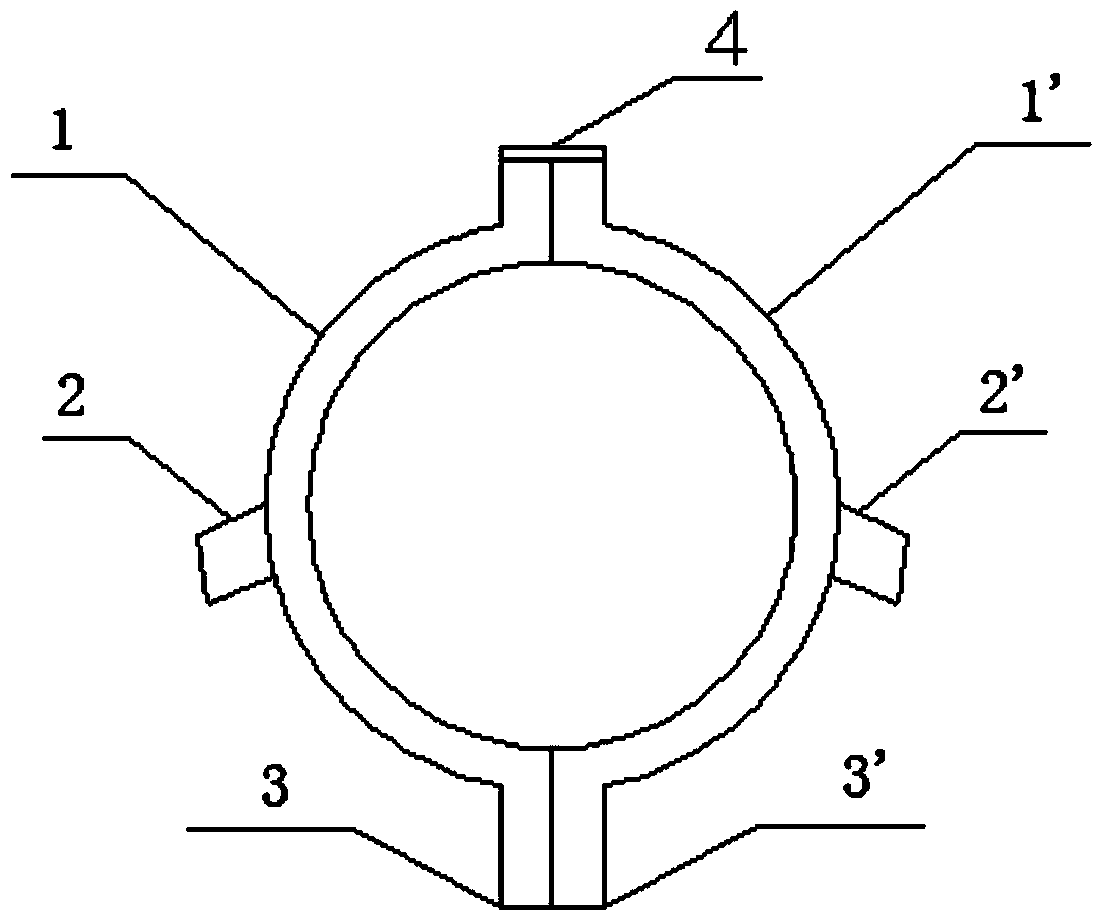

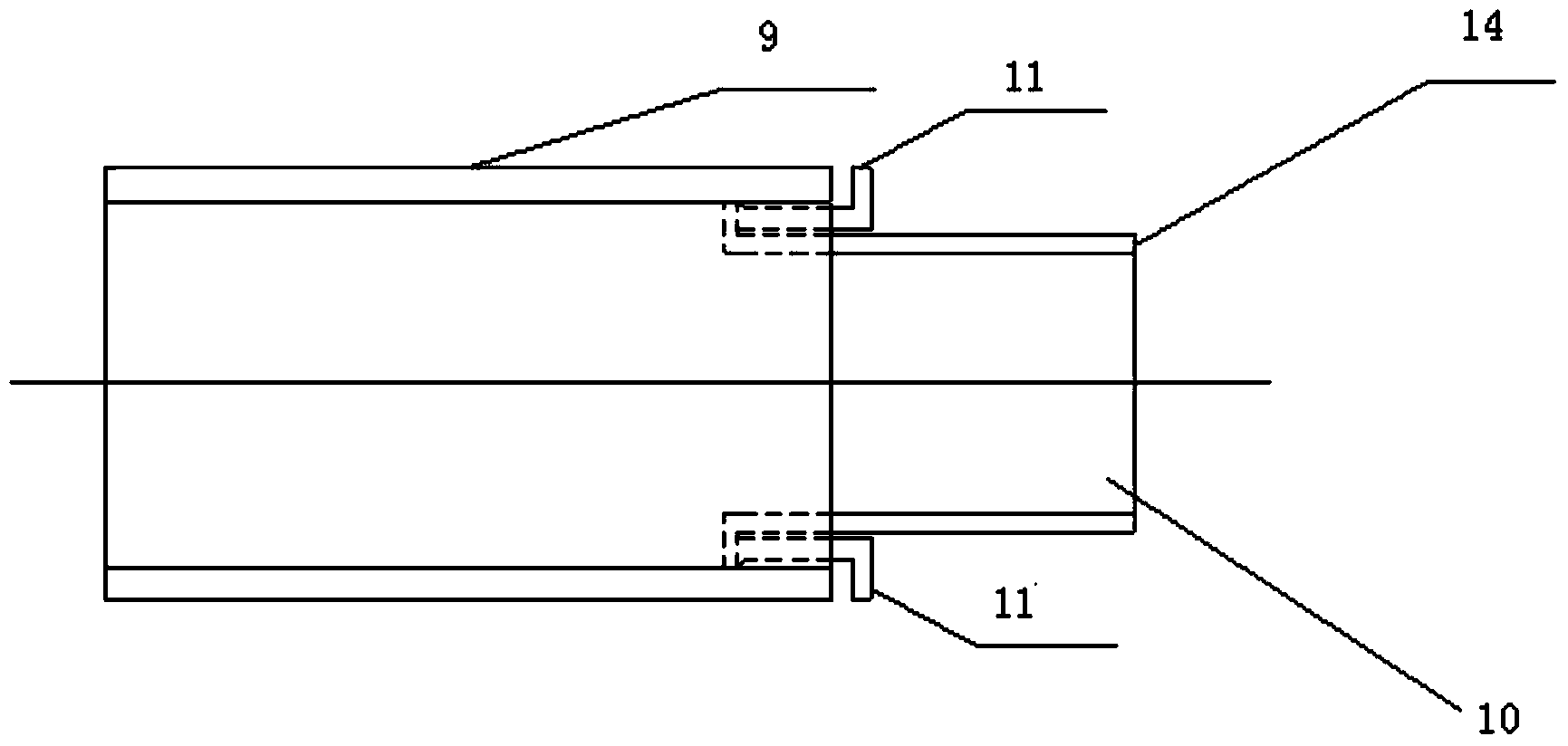

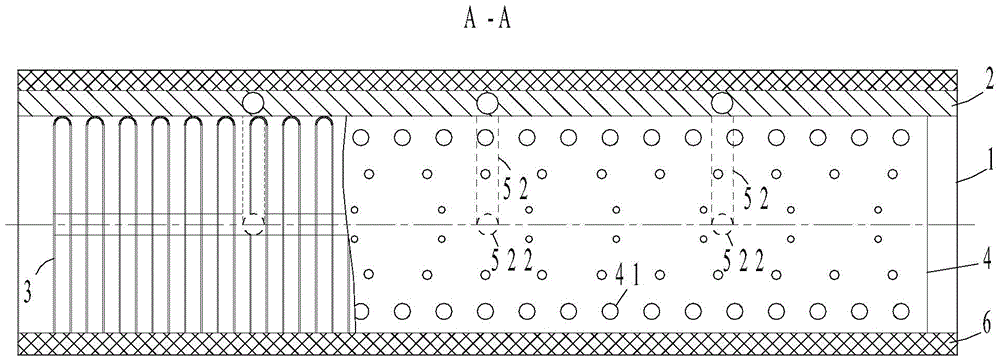

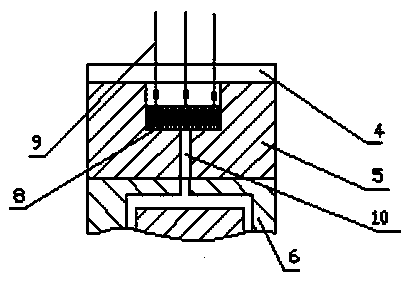

Heating device and plastifying device used for improving cable inner end plastifying quality

ActiveCN103481495AImprove plasticizing qualityEasy loading and unloadingDomestic articlesTemperature controlElectricity

The invention provides a heating device and a plastifying device used for improving the cable inner end plastifying quality. The heating device comprises an annular structure formed by at least two circular arc heaters. The heaters are connected through hinges. At least one buckling component used for connection is arranged at the connecting positions between the heaters to form an opening-closing structure to be used for being arranged on a mold of the plastifying device in a sleeved mode. Each heater is provided with an electric insertion groove used for heating. The electric insertion grooves of the heaters are jointly connected to temperature feedback devices at the corresponding positions of the plastifying device. According to the heating device and the plastifying device, the two semi-circular-arc heaters are adopted, assembly and disassembly are conveniently achieved, and therefore the mold can be conveniently assembled, disassembled and adjusted; meanwhile, a temperature control system is connected with the temperature feedback device at the feeding section or the flange position, heating control and cooling control are accurately achieved, and the product quality is guaranteed.

Owner:BEIJING HENGTONG SIBO COMM TECH CO LTD

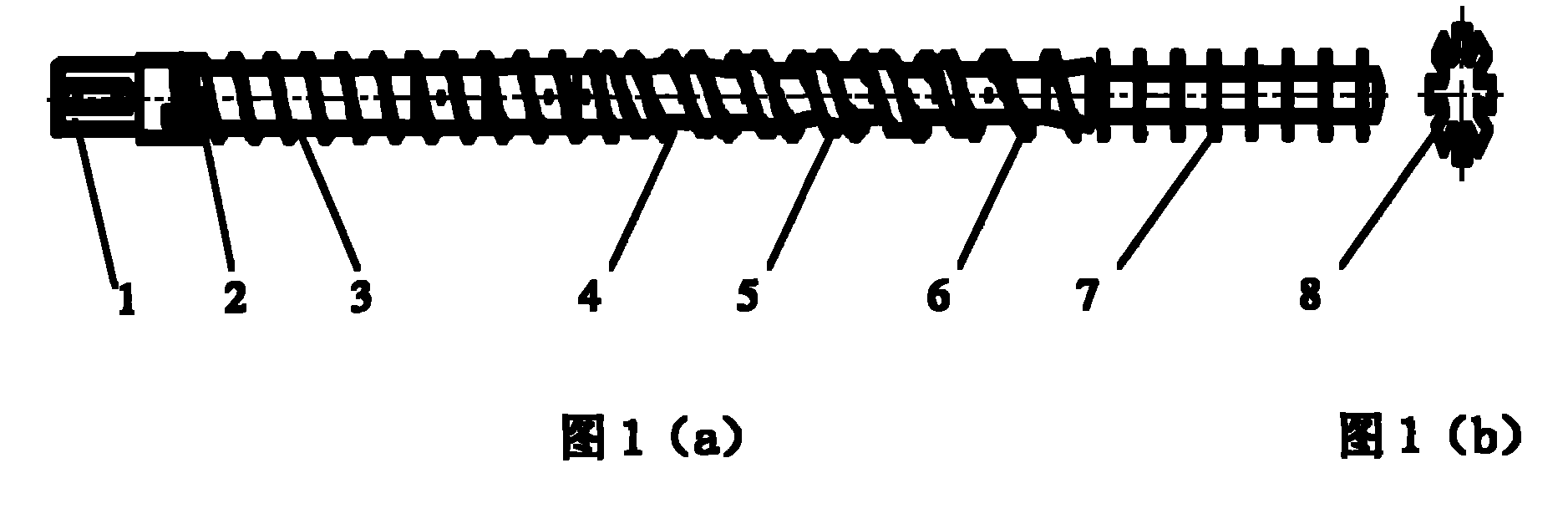

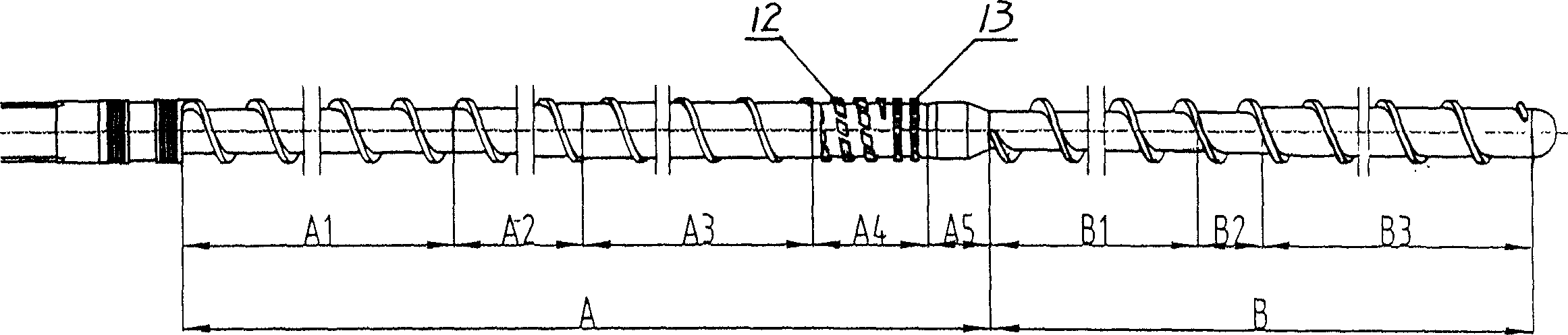

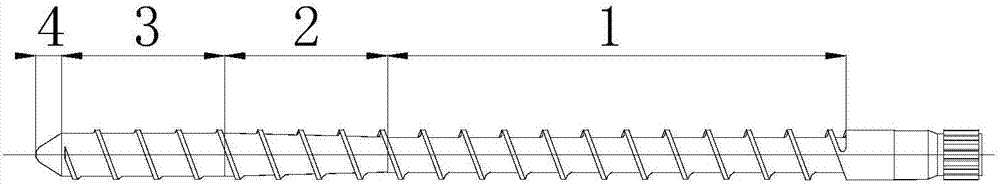

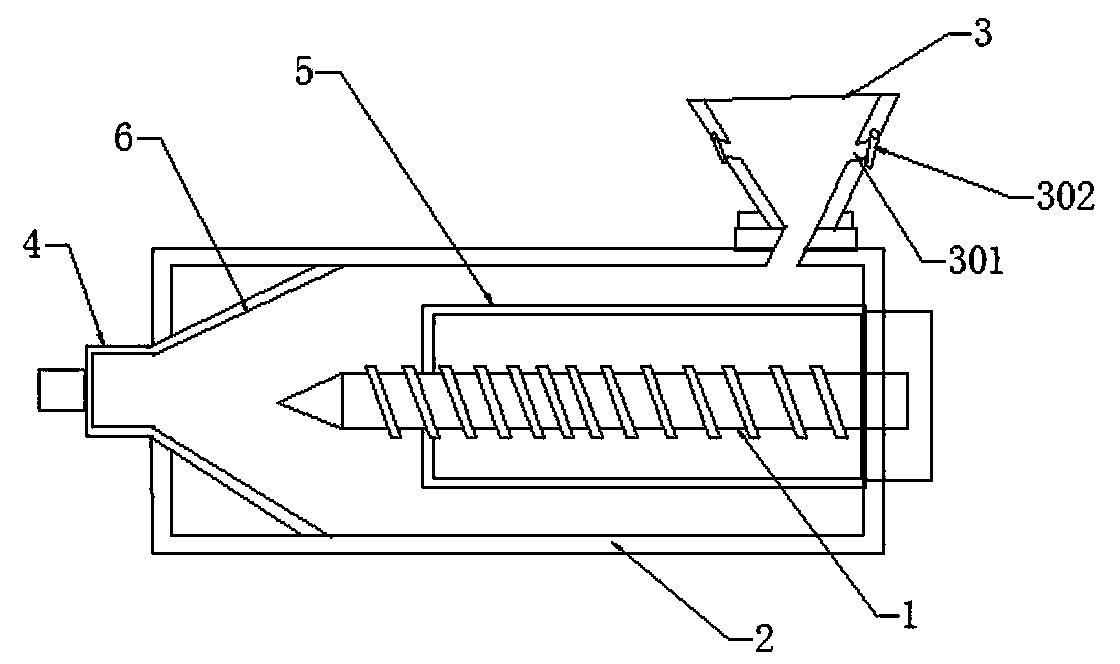

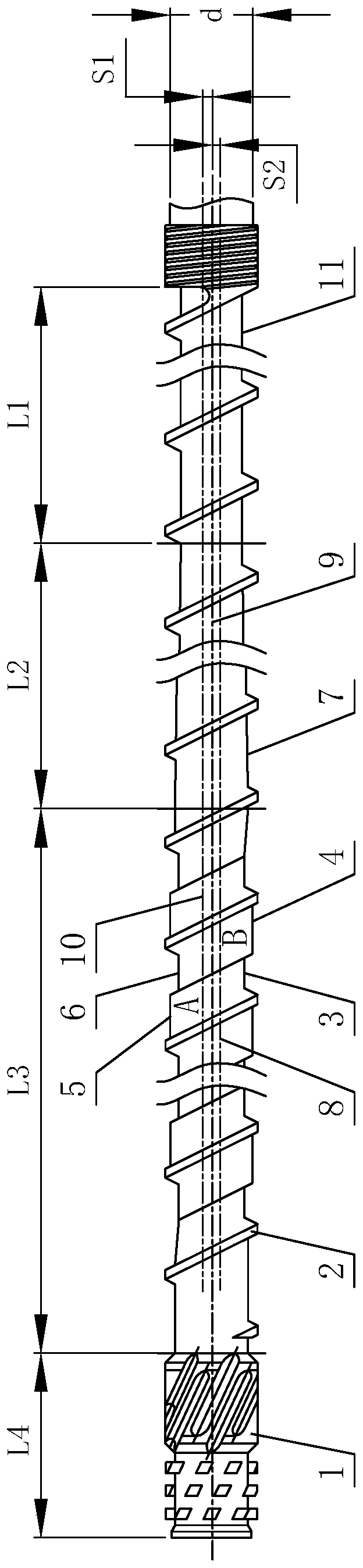

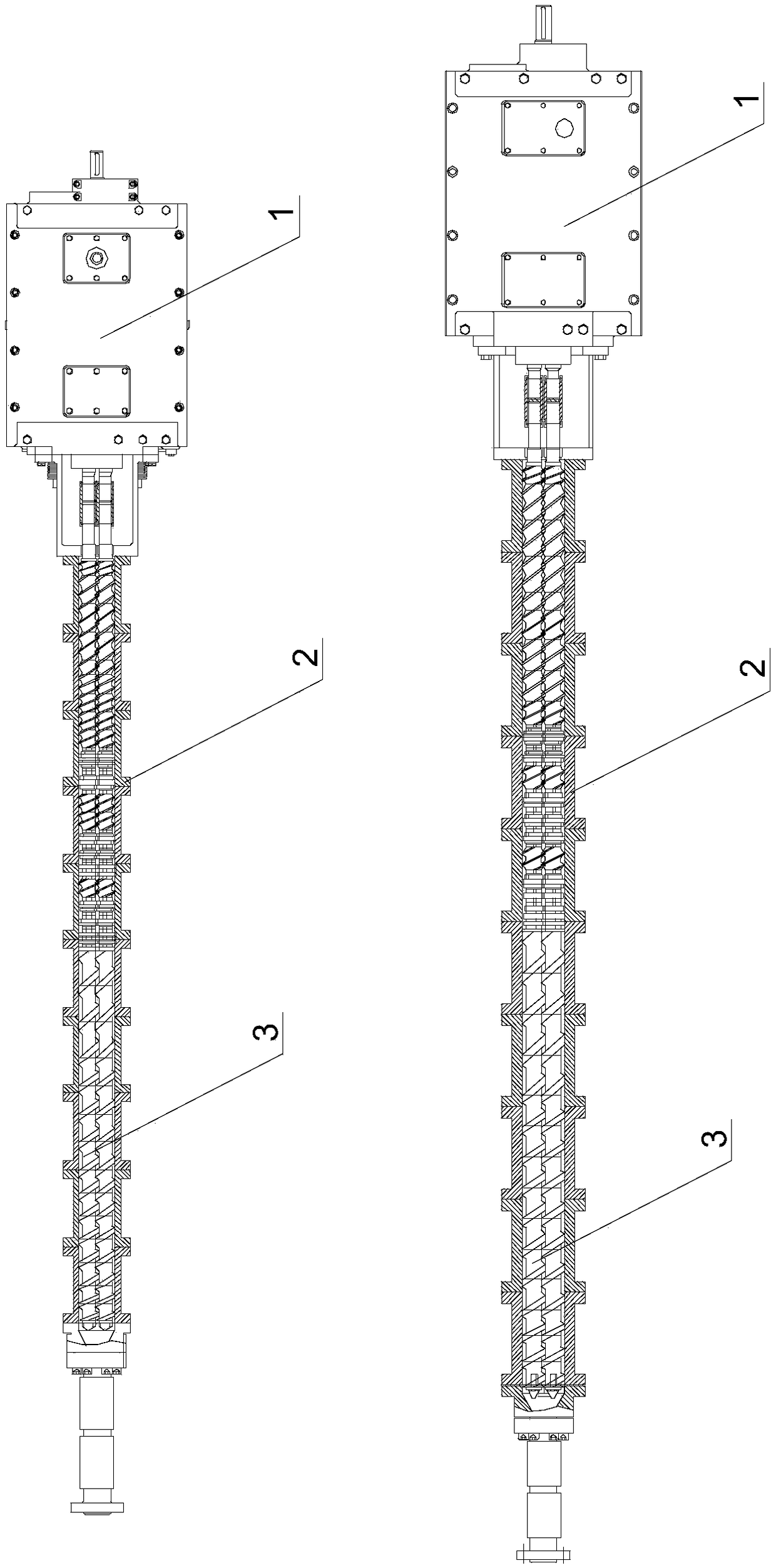

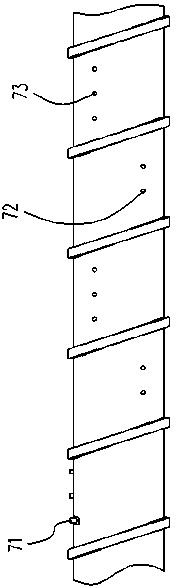

Special extrusion screw for polyethylene of raised temperature resistance and extrusion method of special extrusion screw

The invention discloses a special extrusion screw for polyethylene of raised temperature resistance (PE-RT) and an extrusion method of the special extrusion screw. The special extrusion screw comprises a feeding segment, a compression segment, a first metering segment, a pressure reducing segment, a second metering segment, a mixing segment and a screw head which are connected in sequence, wherein the feeding segment, the pressure reducing segment, the first metering segment and the second metering segment all adopt single-start thread structures; the compression segment adopts a double-start thread structure consisting of a main thread and an auxiliary thread; the auxiliary thread and the main thread intersect at one side of the feeding segment and do not intersect at one side of the first metering segment; and the mixing segment adopts a trapezoidal structure. The special extrusion screw for PE-RT is simple in structure, convenient to use, high in fusing efficiency, uniform in plasticization, high in conveying capability and high and stable in yield at a high rotational speed.

Owner:SOUTH CHINA UNIV OF TECH

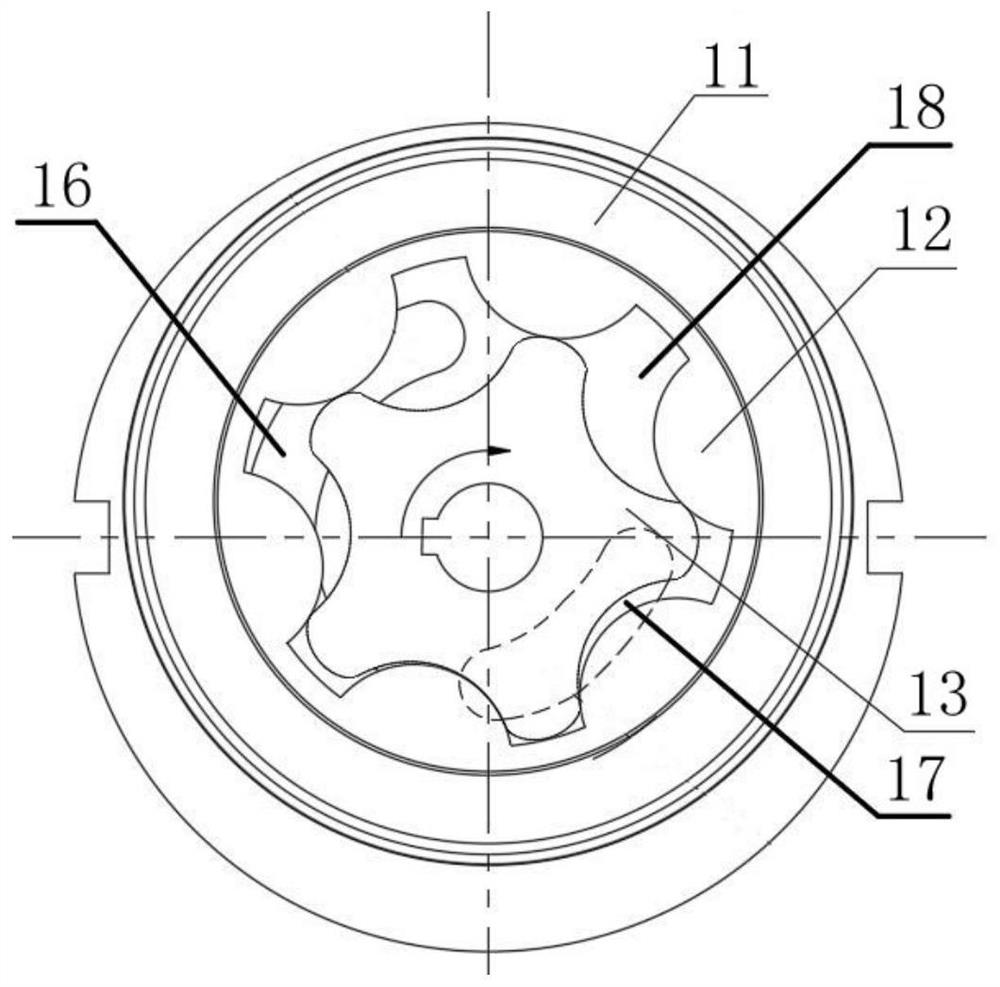

Injection screw for injection molding machine

InactiveCN104441511AImprove plasticizing qualityExtrusion stabilityInjection molding machineMechanical engineering

The invention discloses an injection screw for an injection molding machine. The injection screw comprises a screw body, wherein spiral plates are uniformly distributed on the external surface of the screw body; the screw body sequentially comprises a feeding section, a compression section and homogenization section; the spiral plate of the compression section is a spiral gear plate; a plurality of bulges are uniformly distributed on two side surfaces of the spiral gear plate. By virtue of the mode, rapid mixing and plasticizing of a fusant are enhanced, the fusant plasticizing quality is improved; furthermore, the low-temperature homogeneous fusant, extrusion stability and high plasticizing capability are obtained.

Owner:JIANGSU HONGYUAN NEW MATERIAL TECH

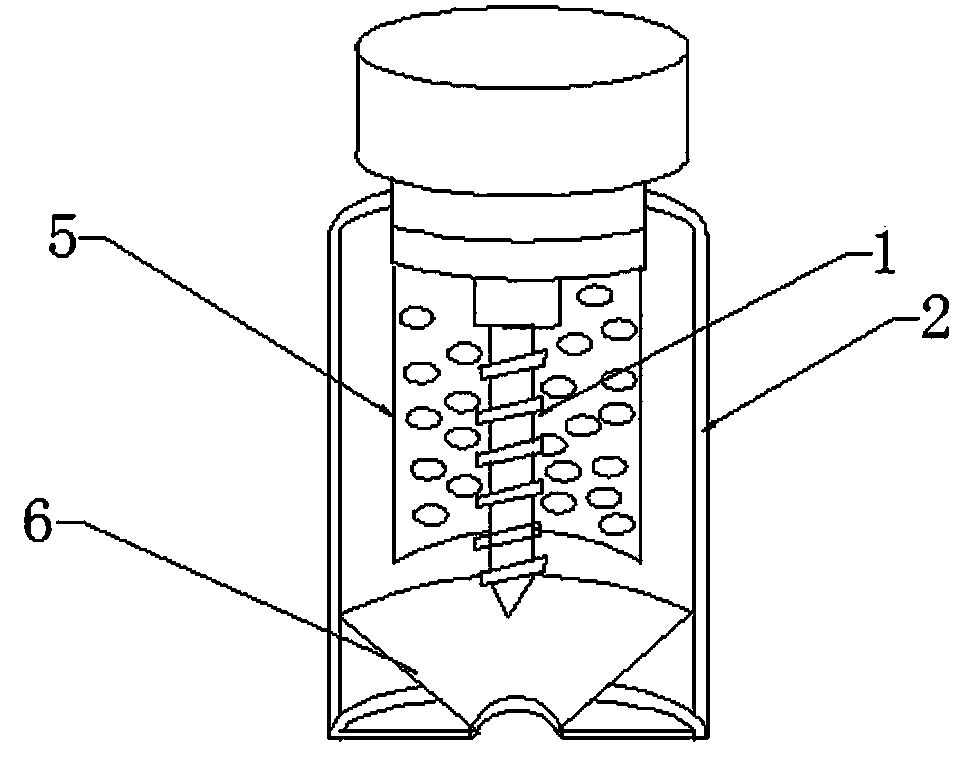

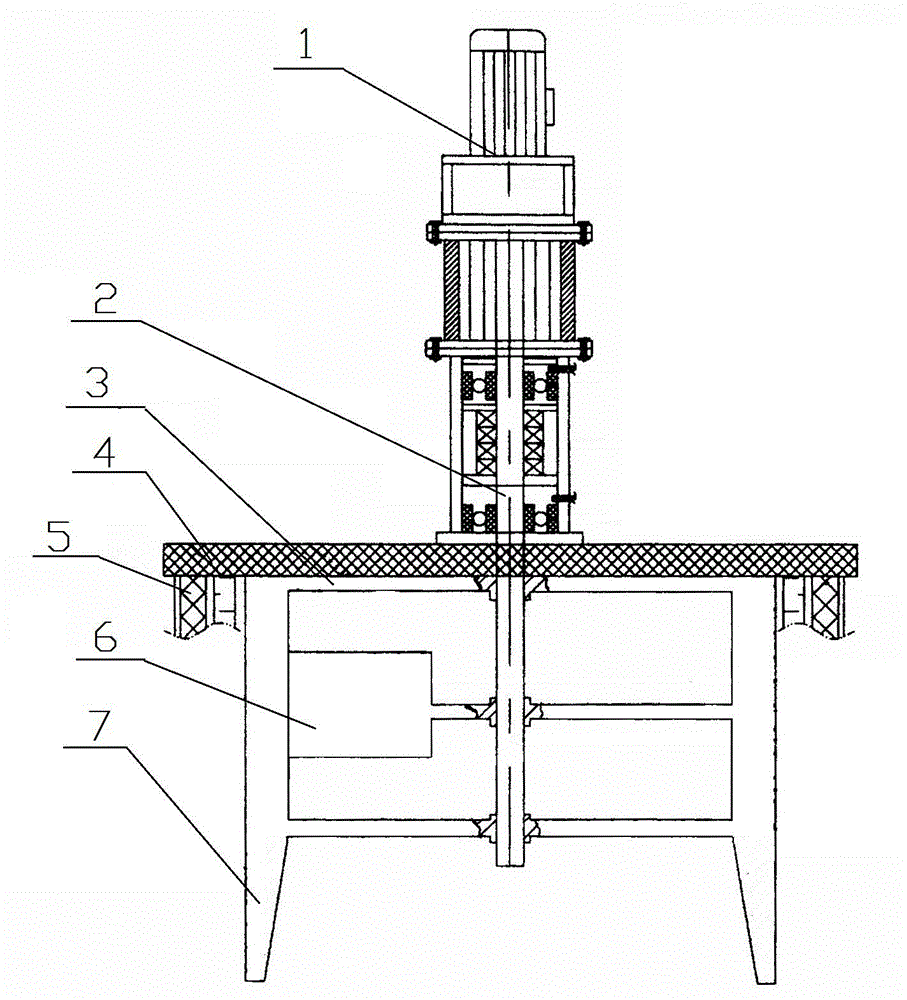

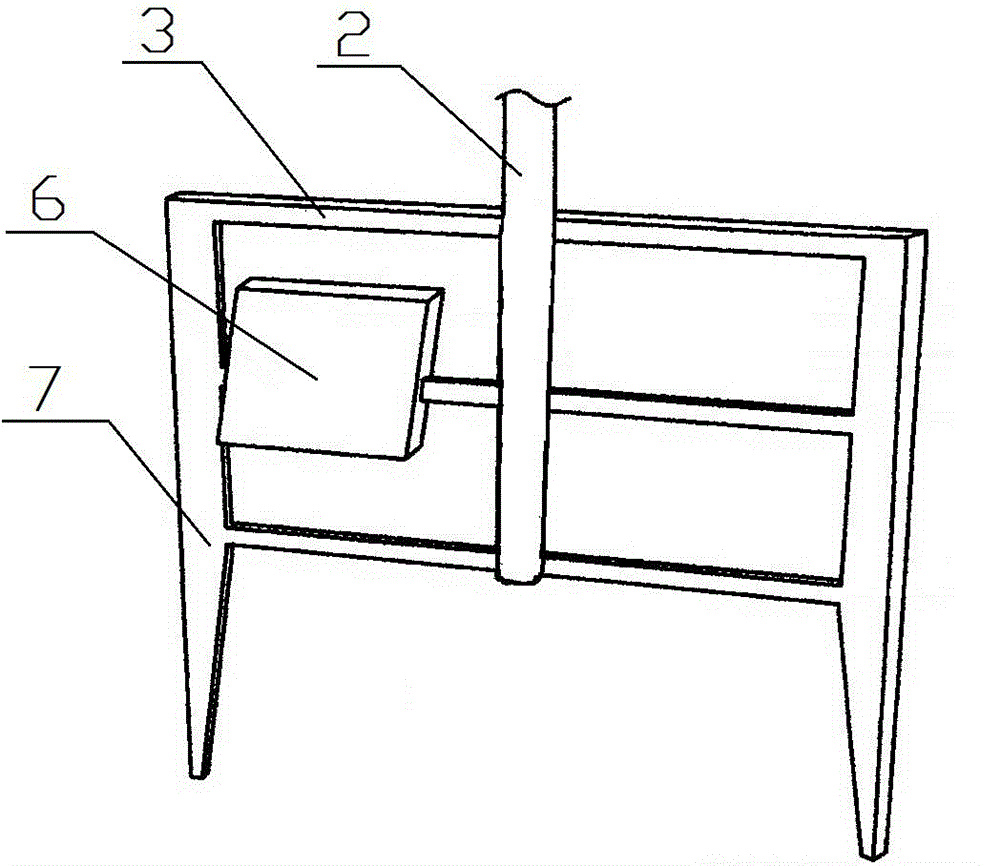

Multifunctional flow guider

InactiveCN103304842AEvenly heatedImprove plasticizing qualityPlastic recyclingVertical planeDrive shaft

The invention discloses a multifunctional flow guider. A driving shaft driven by a speed reducing motor is arranged on a head cover of a desulfuration tank, a flow guider is arranged on the driving shaft which extends into the desulfuration tank, the flow guider has the structure that the upper part of the driving shaft is provided with symmetrical horizontal scratch boards, the top surfaces of the horizontal scratch boards are matched with the inner wall of the head cover of the desulfuration tank, the outer ends of the horizontal scratch boards are respectively and fixedly connected with a vertical scratch board, the outer side faces of the vertical scratch boards are matched with the inner wall of a cylinder of the desulfuration tank, the inner side of one vertical scratch board is connected with a turbulent flow board having an inclined angle with the vertical plane, the middle of the driving shaft is provided with symmetrical horizontal support arms, one straight support arm is connected with the vertical scratch boards, the other support arm is connected with the turbulent flow board, and the symmetrical support arms arranged at the lower part of the driving shaft are respectively connected with the vertical scratch boards. After the multifunctional flow guider is used, waster rubber powder in the desulfuration tank can quickly rotate and can be rubbed with one another to generate heat under the action of the flow guider, and the track of the rotating rubber powder can be changed in a flow guide way, so that the rubber powder can be evenly heated, the plastification speed can be increased, the multifunctional flow guider is low in energy consumption, and the production cost can be reduced.

Owner:武时家

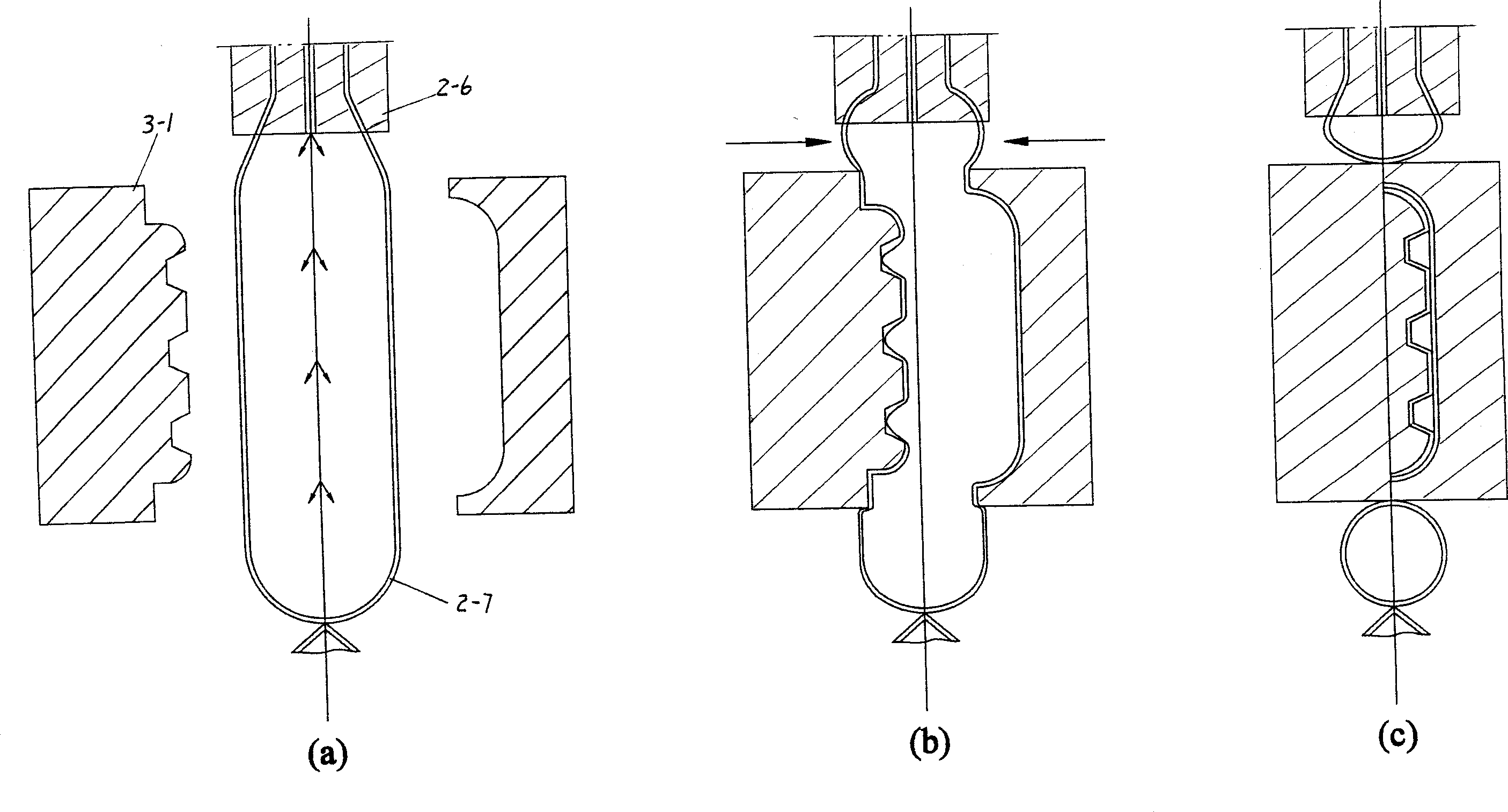

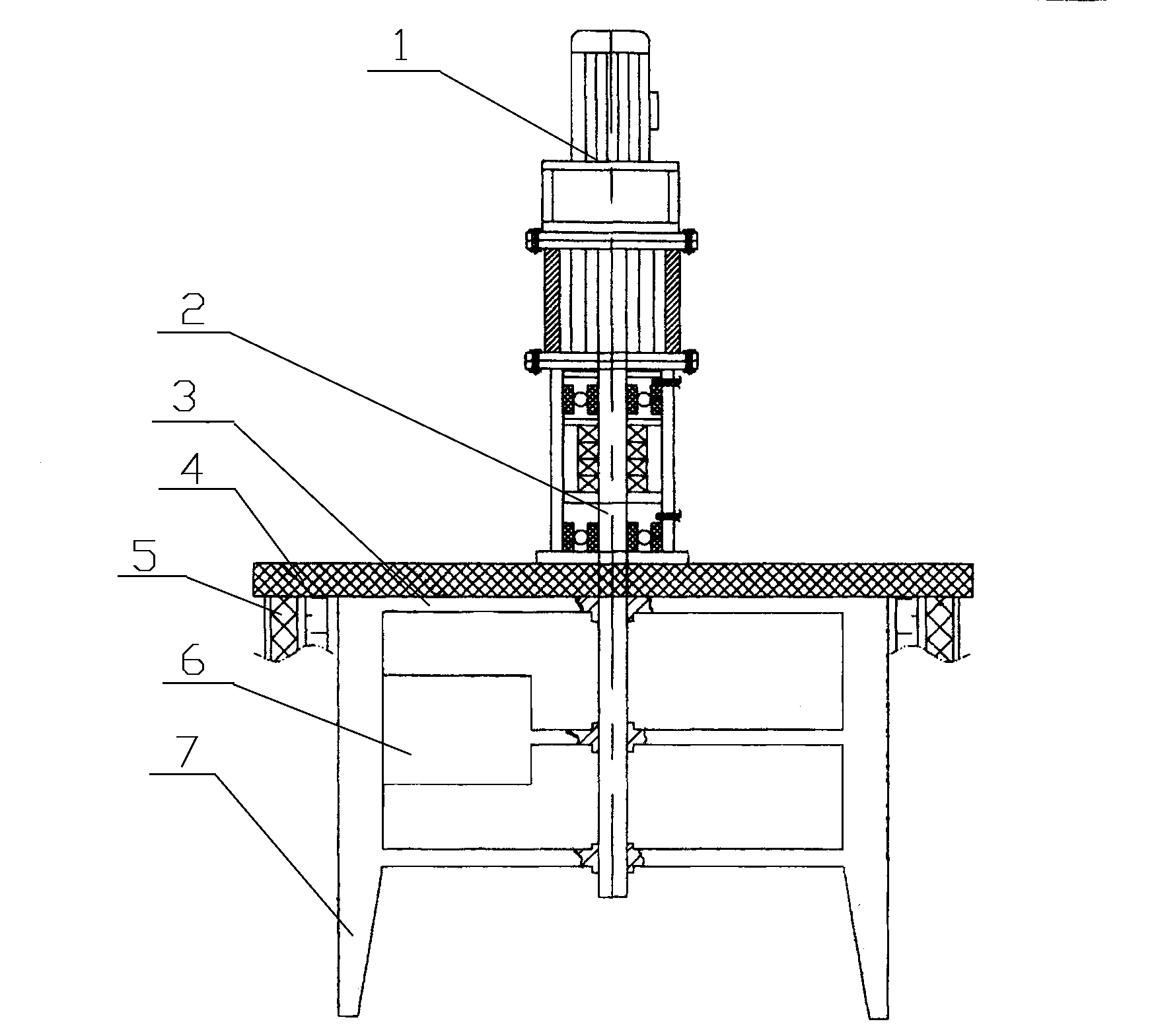

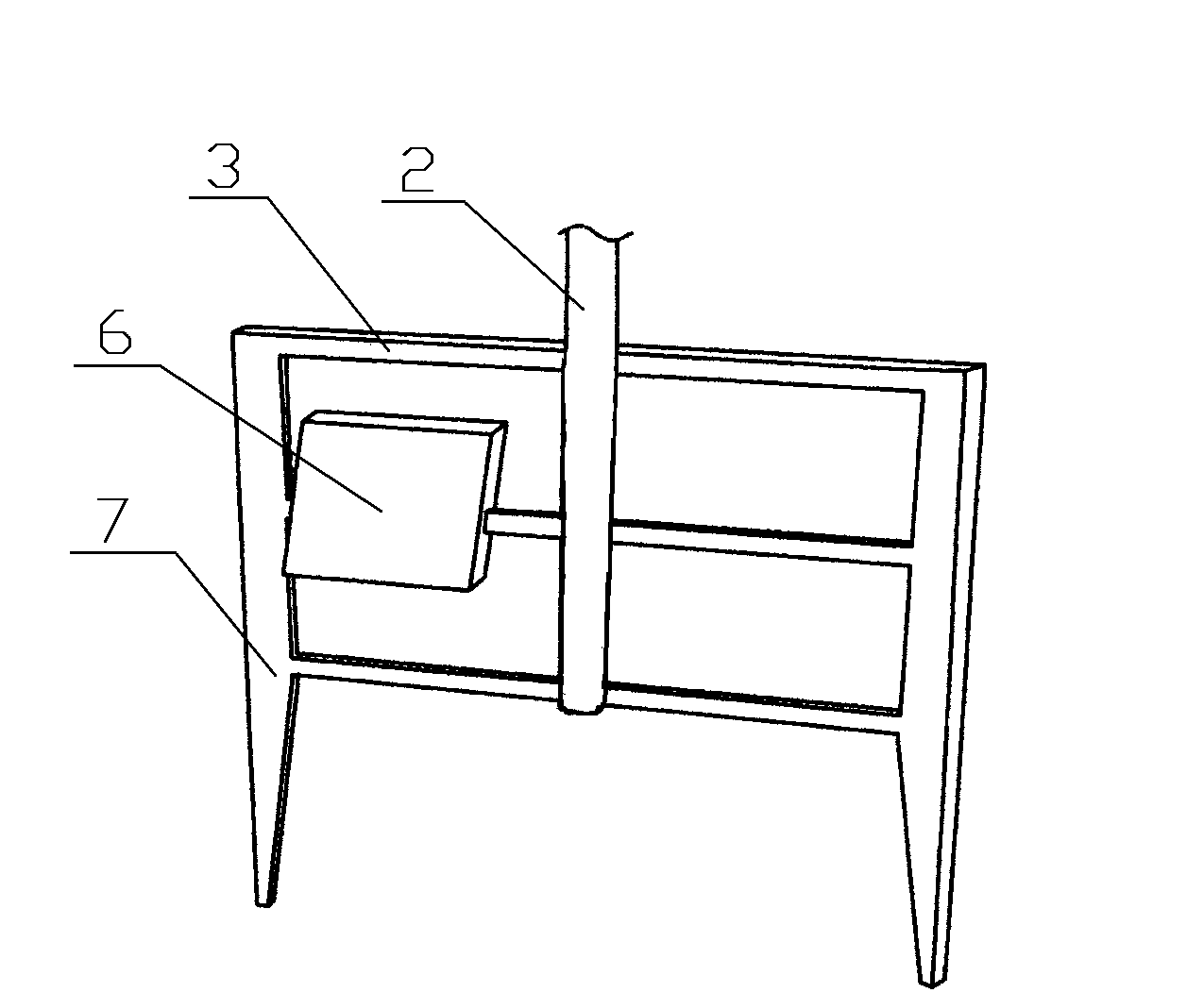

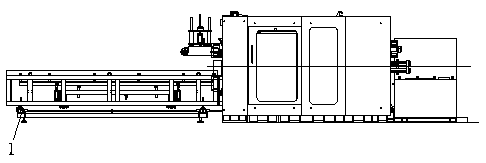

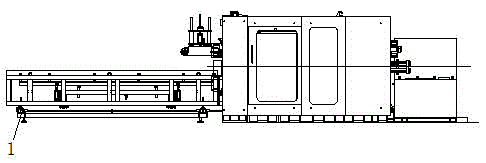

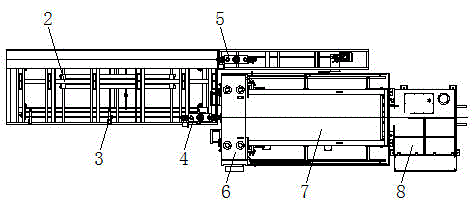

Double-wall corrugated pipe injection molding flaring machine

ActiveCN103286968AImprove plasticizing qualityQuality assuranceTubular articlesEngineeringManufacturing engineering

The invention relates to the technical field of pipeline connection structures and equipment thereof, and relates to a double-wall corrugated pipe injection molding flaring machine. The double-wall corrugated pipe injection molding flaring machine comprises a feeding mechanism, a conveying mechanism and an extrusion mechanism which are sequentially connected, wherein the extrusion mechanism comprises a mold-locking mechanism which is connected with the conveying mechanism, and a single-screw extruder; after entering the mold-locking mechanism, a material is extruded by the single-screw extruder; the single-screw extruder is connected with a hydraulic station. The double-wall corrugated pipe injection molding flaring machine adopts the single-screw extruder which is made of polyethylene (PE) and is high in efficiency and low in power consumption, so that the material amount required by a flaring part of a PE double-wall corrugated pipe is realized at high speed and with high yield, the material is high in plasticizing quality, and the flaring quality is ensured. According to the double-wall corrugated pipe injection molding flaring machine, in an injection molding flaring manner, the defects of the PE double-wall corrugated pipe for flaring in the conventional manner can be overcome, the flaring quality is high, the length of a pipe material is changeable, and the flaring shape can be determined by a customer.

Owner:GUANGDONG LIANSU MACHINERY MFG

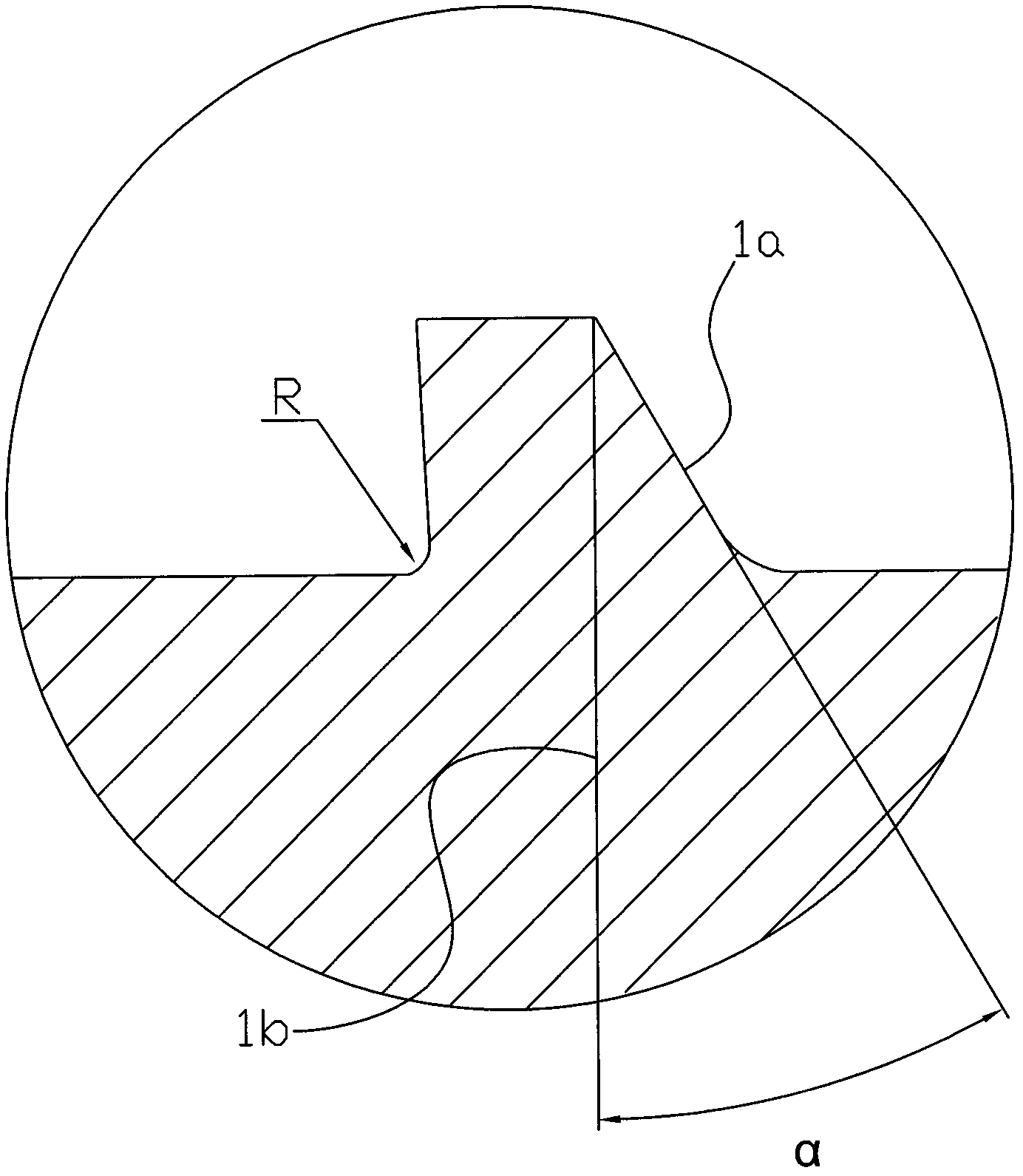

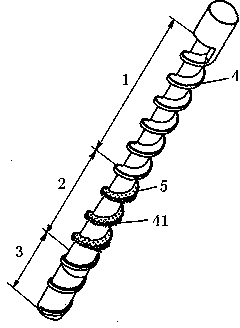

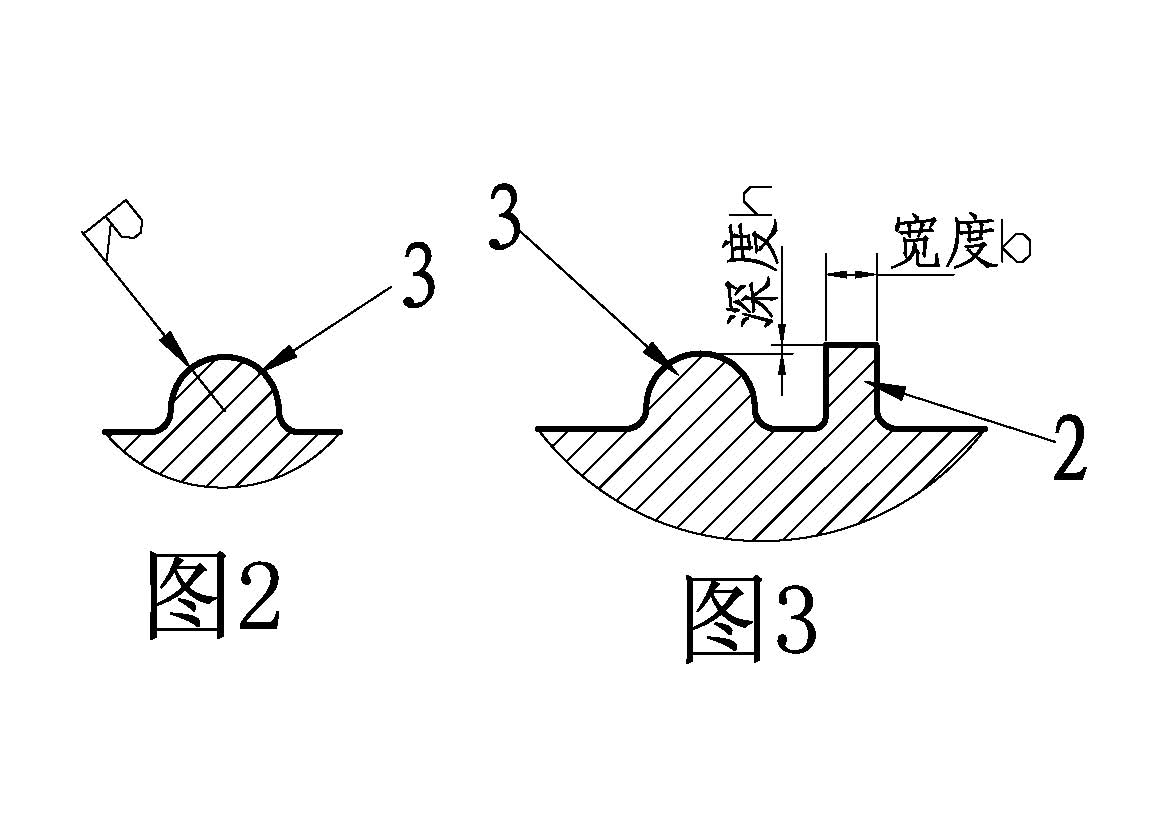

Semicircular-edge screw for plastic extruder

The invention provides a semicircular-edge screw for a plastic extruder, which comprises a screw body (1), wherein two identical primary screw edges (2) and two identical secondary screw edges (3) are arranged at the overall length of the screw body (1); the two secondary screw edges (3) and the two primary screw edges (2) corresponding to the two secondary screw edges (3) are connected and closed at the discharging end (5) of the screw body (1); the semicircular-edge screw is characterized in that the bottom diameter of the spiral groove of the screw body (1) is gradually changed from an feeding end (4) to the discharging end (5); and the normal section of the secondary screw edges (3) are in a semi-circular structure which ensures that the materials can be overturned more smoothly.

Owner:南京艺工电工设备有限公司

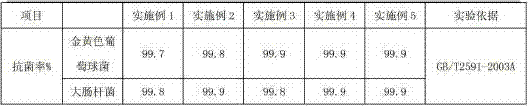

Plastic section bar and technology for processing same

The invention discloses a plastic section bar and a technology for processing the same. The plastic section bar comprises, by weight, 100-120 parts of polyvinyl chloride resin, 2-3 parts of organic tin carboxylate, 1-2 parts of polyacrylate resin, 8-10 parts of chlorinated polyethylene, 5-10 parts of activated calcium carbonate, 4-6 parts of rutile type titanium dioxide, 0.5-1 part of polyethylene wax and 0.5-1 part of antibacterial and bacterium inhibition additives. The plastic section bar and the technology have the advantages that the plastic section bar is low in cost and good in heat stability, weather resistance, toughness and uniformity and is smooth; the rigidity of the plastic section bar can be improved, the plasticizing quality can be enhanced, and the appearance can be improved; antibacterial and bacterium inhibition effects can be realized by the plastic section bar, and accordingly the plastic section bar is applicable to sterile places.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

A double-wall corrugated pipe injection flaring machine

ActiveCN103286968BImprove plasticizing qualityImprove flaring qualityTubular articlesLocking mechanismDouble wall

The invention relates to the technical field of pipeline connection structures and equipment thereof, and relates to a double-wall corrugated pipe injection molding flaring machine. The double-wall corrugated pipe injection molding flaring machine comprises a feeding mechanism, a conveying mechanism and an extrusion mechanism which are sequentially connected, wherein the extrusion mechanism comprises a mold-locking mechanism which is connected with the conveying mechanism, and a single-screw extruder; after entering the mold-locking mechanism, a material is extruded by the single-screw extruder; the single-screw extruder is connected with a hydraulic station. The double-wall corrugated pipe injection molding flaring machine adopts the single-screw extruder which is made of polyethylene (PE) and is high in efficiency and low in power consumption, so that the material amount required by a flaring part of a PE double-wall corrugated pipe is realized at high speed and with high yield, the material is high in plasticizing quality, and the flaring quality is ensured. According to the double-wall corrugated pipe injection molding flaring machine, in an injection molding flaring manner, the defects of the PE double-wall corrugated pipe for flaring in the conventional manner can be overcome, the flaring quality is high, the length of a pipe material is changeable, and the flaring shape can be determined by a customer.

Owner:GUANGDONG LIANSU MACHINERY MFG

Test device for accomplishing polymer melting plasticization using superaudio vibration

InactiveCN101261266BConstant pressureRealize melt plasticizationPreparing sample for investigationMaterial testing goodsData acquisitionEngineering

The invention discloses a testing device that realizes the melting and plasticizing of polymers by utilizing ultrasonic frequency vibration, wherein, a material cylinder (4) is arranged on a stand (9); a capillary orifice mode (18), a tool head (5), a thermocouple (2), a heating ring (3) and a high temperature melt temperature pressure sensor (19) are arranged in the material cylinder (4); the lower end of a guide pillar (8) is arranged on the stand (9), the upper end of the guide pillar (8) is provided with a frame(11), the frame(11) is provided with a hydraulic transmission and control system, a guide bracket (16) is glidingly arranged on the guide pillar (8), the guide bracket (16) is provided with an ultrasonic vibration system, the tool head (5) is connected with the ultrasonic vibration system by a way of transmission, the ultrasonic vibration system is connected with the hydraulic transmission and control system by a way of transmission, the ultrasonic vibration system is provided with a displacement sensor (12), and the high temperature melt temperature pressure sensor (19) and the displacement sensor (12) are electronically connected with a computer data acquisition system. In terms of function, the testing device of the invention not only can simultaneously realize the melting and plasticizing of polymer materials by utilizing ultrasonic frequency vibration and detect the formability of ultrasonic plasticizing, but also can satisfy the needs of conventional processability test for the polymers.

Owner:CENT SOUTH UNIV

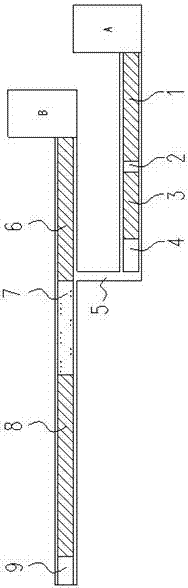

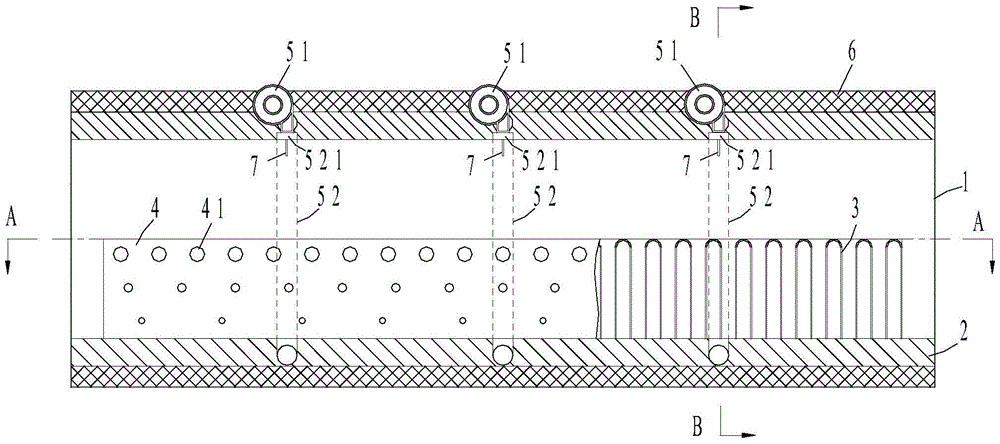

Injection molding mechanism capable of evenly heating and efficiently plastifying

ActiveCN103909633AAvoid enteringPrevent excessive pressure and cause safety problemsMotor driveEngineering

The invention discloses an injection molding mechanism capable of evenly heating and efficiently plastifying. The injection molding mechanism comprises a heating screw rod (1), a heating cavity (2), a charging barrel (3) and a sprue bush connection end (4), and also comprises a rafael net (5), wherein the heating screw rod (1) is horizontally arranged inside the rafael net (5); one end of the rafael net is connected with a motor; the motor drives the rafael net (5) to rotate; the rotation direction of the rafael net (5) is reverse to that of the heating screw rod (1); a screw cooling water pipe is arranged on the outer surface of the lower end of the charging barrel (3); a conical baffle plate (6) of which the top and the bottom are communicated is arranged inside the heating cavity (2); the narrow end of the conical baffle plate (6) is communicated with the sprue bush connection end (4); the round edge of the wide end of the conical baffle plate (6) is connected with the heating cavity (2). The injection molding mechanism can fully agitate, the plastifying homogeneity is improved, the situation that the injection molding particles are fused in the charging barrel to block a discharge hole is avoided, the pressure at the end of the sprue bush is kept constant, and the actual injection molding amount is accurate.

Owner:丁方方

Screw of injection molding machine

The invention discloses a screw of an injection molding machine. The screw comprises a body and a feed chute spirally embracing the surface of the body. The diameter of the body is equal from head totail. The depth of the feed chute is gradually increased from head to tail. Multiple grooves with square openings are formed in the feed chute at intervals. The surface of the body and the surface ofthe feed chute are covered with ceramic coatings. By means of the screw of the injection molding machine, molten plastic can smoothly flow to the discharge end conveniently, resistance is low, the molten plastic is not likely to be stagnated, and the production efficiency is high. The molten plastic is evenly mixed, bubbles are not likely to be generated, and the plastifying quality is high. The screw is high in corrosion resistance, resistant to abrasion and high temperature and more durable.

Owner:JIANGMEN MAXWELL MAGNET IND CO LTD

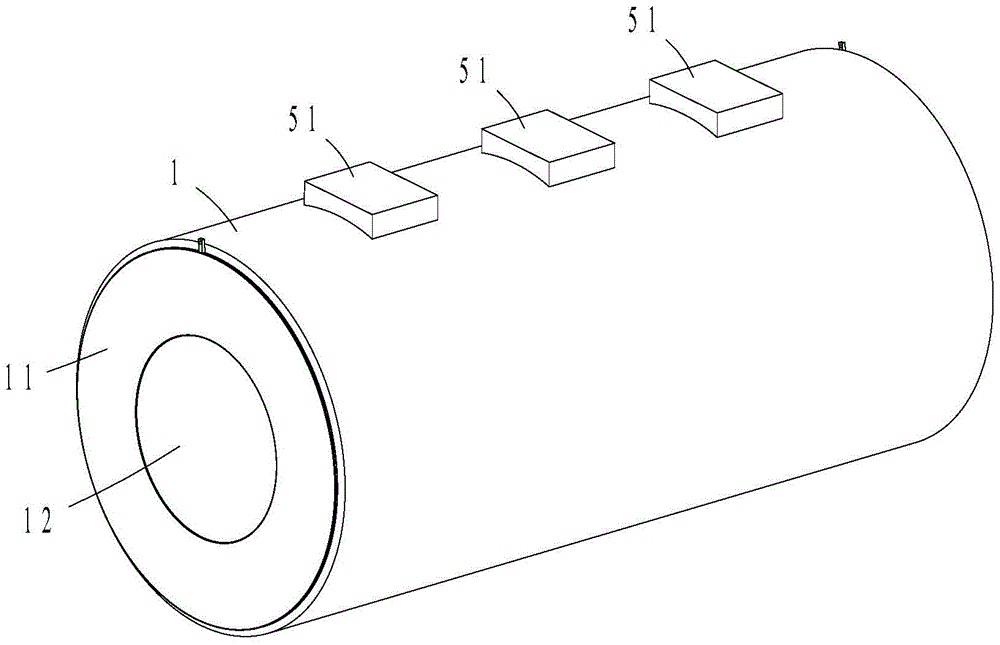

Constant temperature device for plasticizing air duct cloth

The invention relates to a constant temperature device for plasticization of an air tubing cloth. The constant temperature device comprises a hollow barrel body, wherein annular sealing discs are arranged at two ends of the hollow barrel body, the annular sealing discs and the side wall of the barrel body can form a channel through which the air tubing cloth can penetrate, a circulating device is arranged on the barrel body and comprises at least two air ducts arranged in the side wall of the barrel body, an air inlet and an air outlet of each air duct are communicated with the channel, each air inlet is connected with a fan, a heating pipe located on the surface of the side wall of the barrel body is arranged above the air outlet, a perforated plate is adaptively arranged above the heating pipe, a plurality of exhaust holes are distributed in the perforated plate, and a temperature sensor is arranged in the barrel body. According to the constant temperature device for plasticization of the air tubing cloth, gas in the barrel body can circulate and be heated continuously through cooperation of the air ducts and the fan and the adaptation of the heating pipe and the perforated plate, temperature or heat in the barrel body can be distributed uniformly, and the plastifying quality of the air tubing cloth in the barrel body can be improved; and besides, the power of the heating pipe can be adjusted by the temperature sensor, and automatic constant temperature adjustment in the barrel can be realized.

Owner:成都众成新型复合材料有限公司

Multifunctional flow guider

InactiveCN103304842BEvenly heatedImprove plasticizing qualityPlastic recyclingVertical planeDrive shaft

The invention discloses a multifunctional flow guider. A driving shaft driven by a speed reducing motor is arranged on a head cover of a desulfuration tank, a flow guider is arranged on the driving shaft which extends into the desulfuration tank, the flow guider has the structure that the upper part of the driving shaft is provided with symmetrical horizontal scratch boards, the top surfaces of the horizontal scratch boards are matched with the inner wall of the head cover of the desulfuration tank, the outer ends of the horizontal scratch boards are respectively and fixedly connected with a vertical scratch board, the outer side faces of the vertical scratch boards are matched with the inner wall of a cylinder of the desulfuration tank, the inner side of one vertical scratch board is connected with a turbulent flow board having an inclined angle with the vertical plane, the middle of the driving shaft is provided with symmetrical horizontal support arms, one straight support arm is connected with the vertical scratch boards, the other support arm is connected with the turbulent flow board, and the symmetrical support arms arranged at the lower part of the driving shaft are respectively connected with the vertical scratch boards. After the multifunctional flow guider is used, waster rubber powder in the desulfuration tank can quickly rotate and can be rubbed with one another to generate heat under the action of the flow guider, and the track of the rotating rubber powder can be changed in a flow guide way, so that the rubber powder can be evenly heated, the plastification speed can be increased, the multifunctional flow guider is low in energy consumption, and the production cost can be reduced.

Owner:武时家

Plastic injection moulding machine and injection screw thereof

The invention provides a plastic injection moulding machine and an injection screw thereof. The injection screw comprises a thread part and a mixing member which are connected mutually, an external thread is arranged on the thread part, and the thread part is sequentially provided with a feeding segment, a compression segment and a wave homogenizing segment in the spiral direction of the externalthread; and at least six waves are arranged on the wave homogenizing segment, each wave is composed of a first wave segment and a second wave segment with a 180-degree phase difference, and the firstwave segments and / or the second wave segments are arranged eccentrically and are composed of wave troughs and wave crests which are uniformly distributed along the circumference of the screw. Throughthe improvement of the structure, the problem of plastic uniformity of the injection screw in the plasticating process is achieved, the plastic performance can further be protected, so that the effectthat the injection screw realizes performance complementation in four aspects of plasticizing quality, rapidness and high efficiency, universality and energy consumption is achieved; and meanwhile, the injection screw can further be widely applied to universal type various reciprocating type screw plastic injection moulding machines, and various shear sensitivity high molecular materials or highmolecular materials and inorganic fillers are machined.

Owner:广东伊之密精密注压科技有限公司 +1

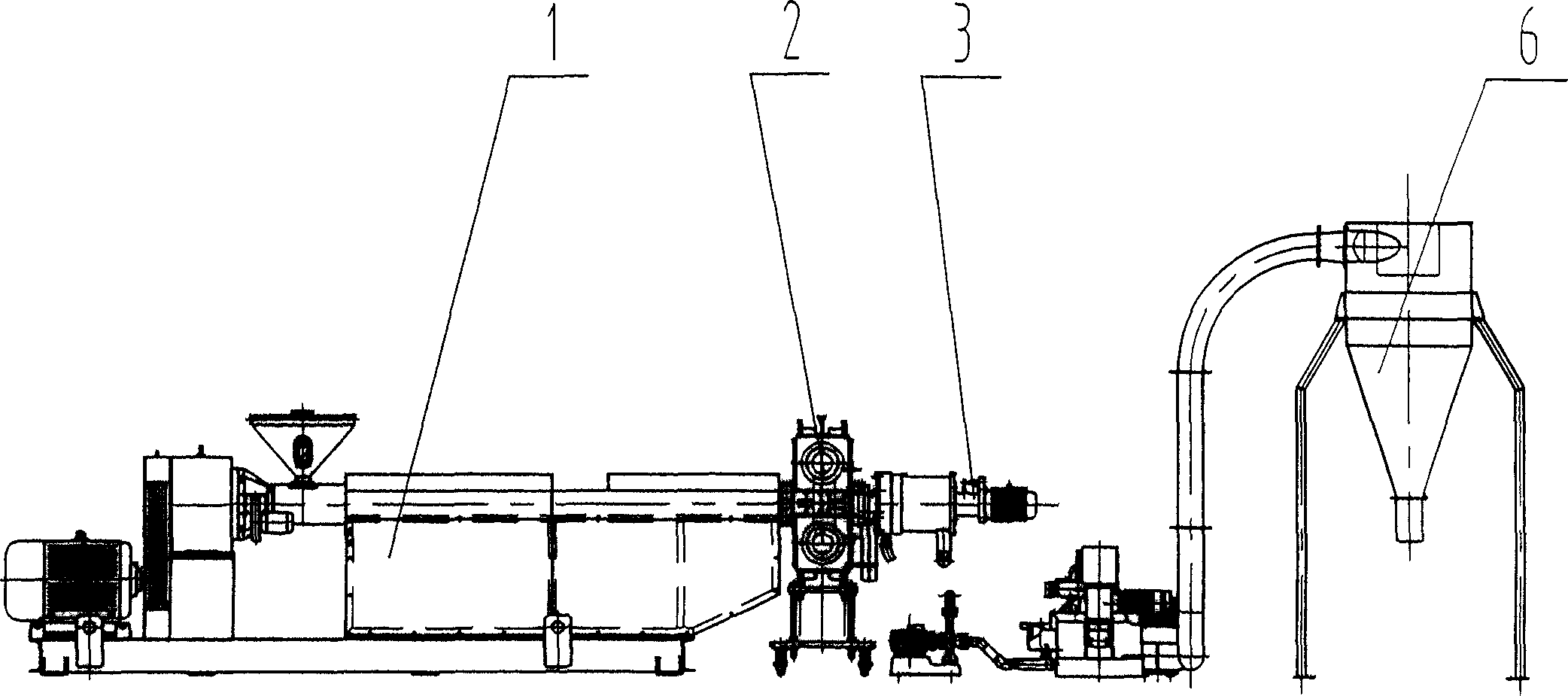

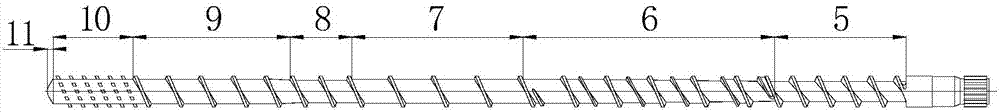

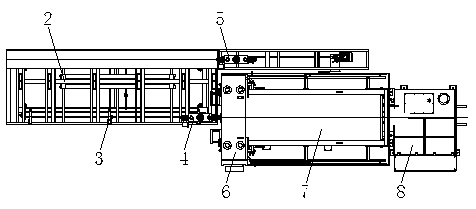

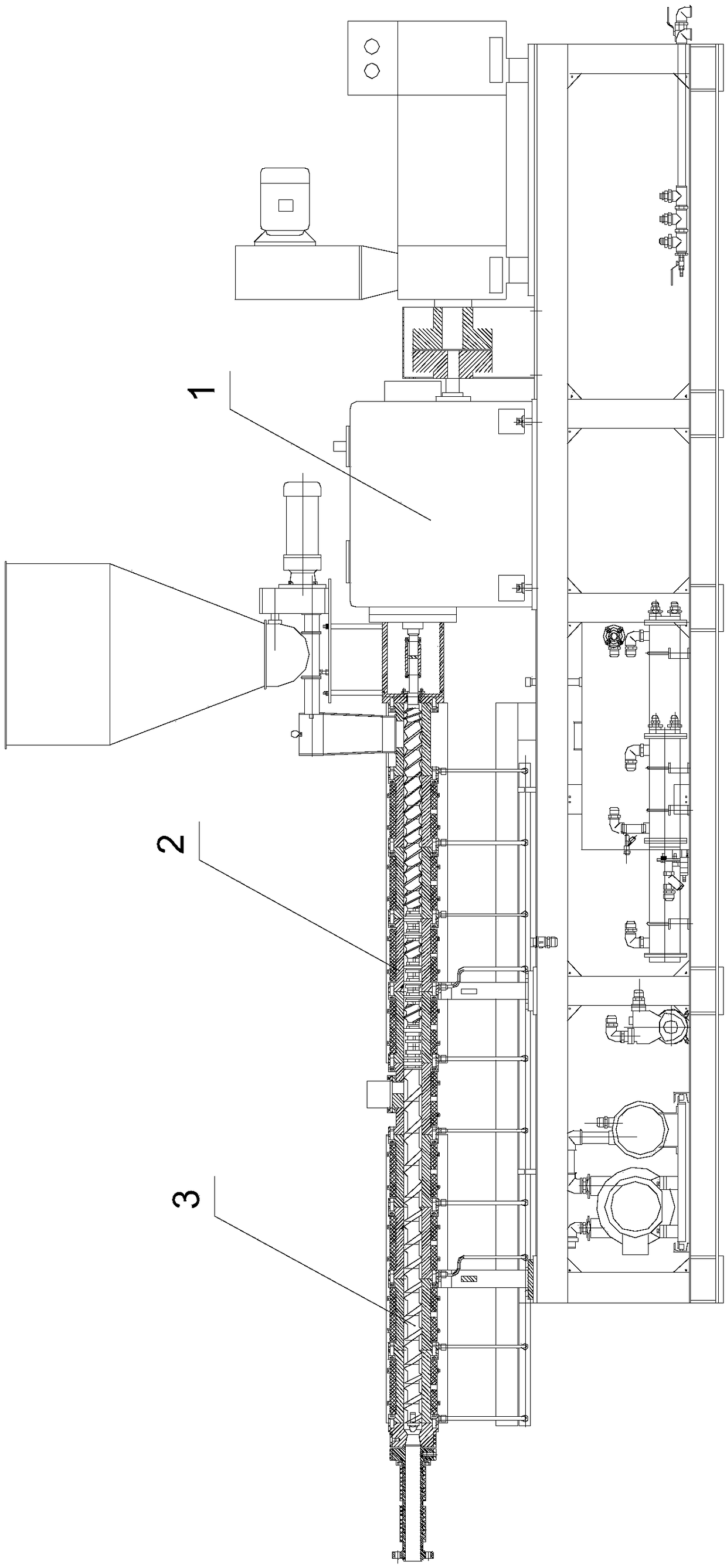

Equidirectional parallel double-screw plastic extruder unit for double-wall corrugated pipe

PendingCN108556303AImprove plasticizing qualityReduce manufacturing costCorrugation articlesTubular articlesPlastic materialsDouble wall

The invention provides an equidirectional parallel double-screw plastic extruder unit for a double-wall corrugated pipe. The equidirectional parallel double-screw plastic extruder unit comprises a twin-screw super-high torque gear box, split combination machine barrels and combination screws; the combination screws comprise two screws having identical structures and diameters; two shaft rods of the combination screws are connected with two output shafts of the twin-screw super-high torque gear box correspondingly; and the split combination machine barrels cooperating with the two combination screws are arranged on the outer sides of the two combination screws correspondingly. Through optimization on the prior art, inner layer and outer layer plastic materials of the double-wall corrugatedpipe can be provided at the same time, the equidirectional parallel double-screw plastic extruder unit is simple in structure and good in plastification effect, the granulating process is omitted, andthe double-screw plastic extruder unit can directly use grains or powder to produce the double-wall corrugated pipe, so that the plastification quality of the double-wall corrugated pipe is improvedsubstantially, the pipe production cost is lowered significantly, and the pipe quality is improved substantially.

Owner:DALIAN SUNLIGHT TECH CO LTD

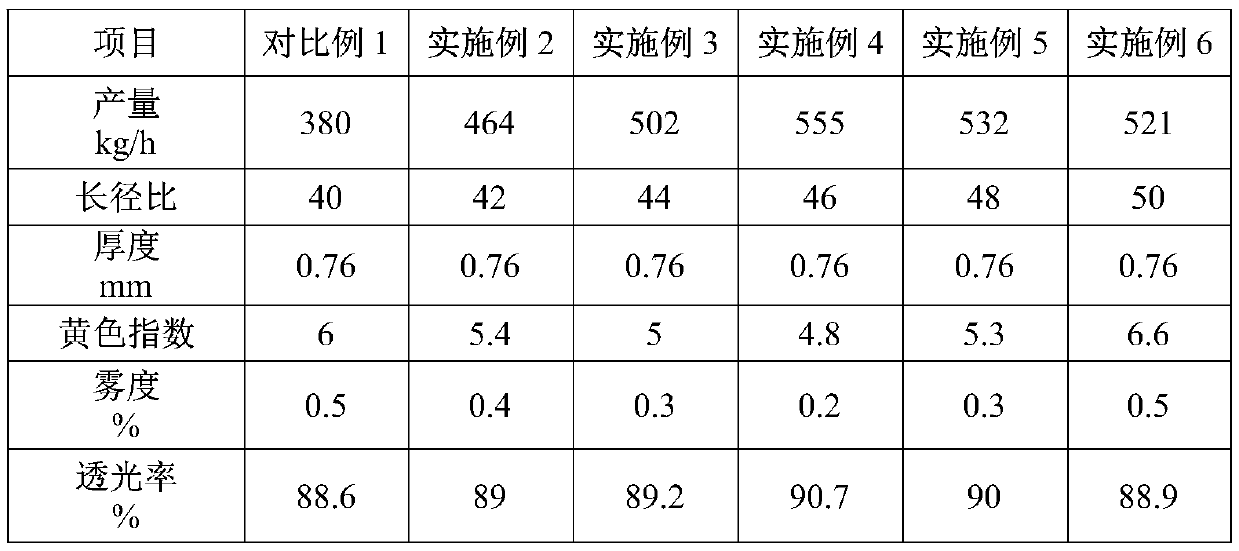

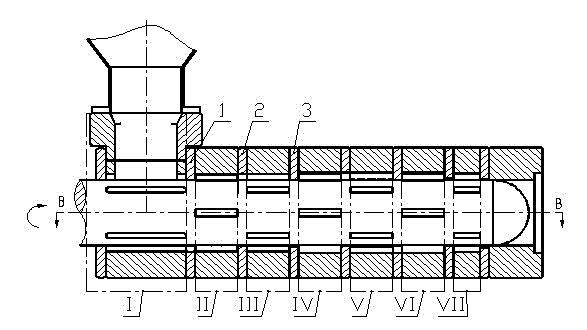

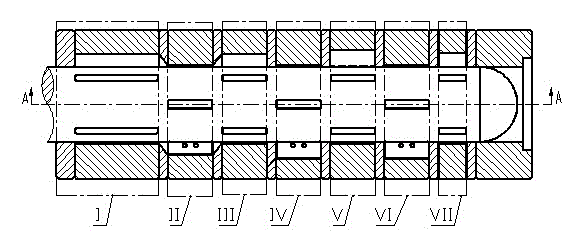

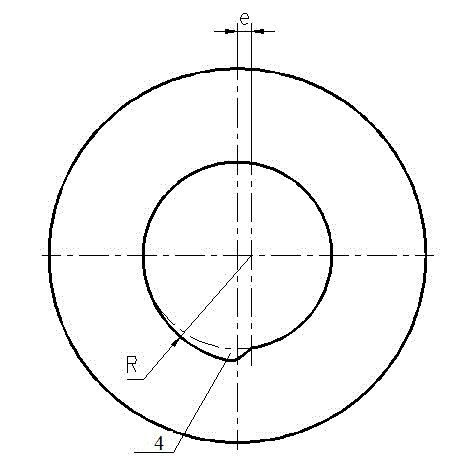

Method for improving yield of PVB film extruder

ActiveCN110587949AImprove plasticizing qualityIncrease productionBiochemical engineeringDiameter ratio

The invention discloses a method for improving the yield of a PVB film extruder. The length-diameter ratio of a screw rod is changed by increasing the effective length of the screw rod of the PVB filmextruder so as to improve the yield of the PVB film extruder. According to the method, the yield of the PVB film extruder can be improved by 20-50%, the production efficiency of the extruder is greatly improved, the cost is saved, and the plasticizing quality of a PVB film can be remarkably improved through the method.

Owner:安徽皖维皕盛新材料有限责任公司

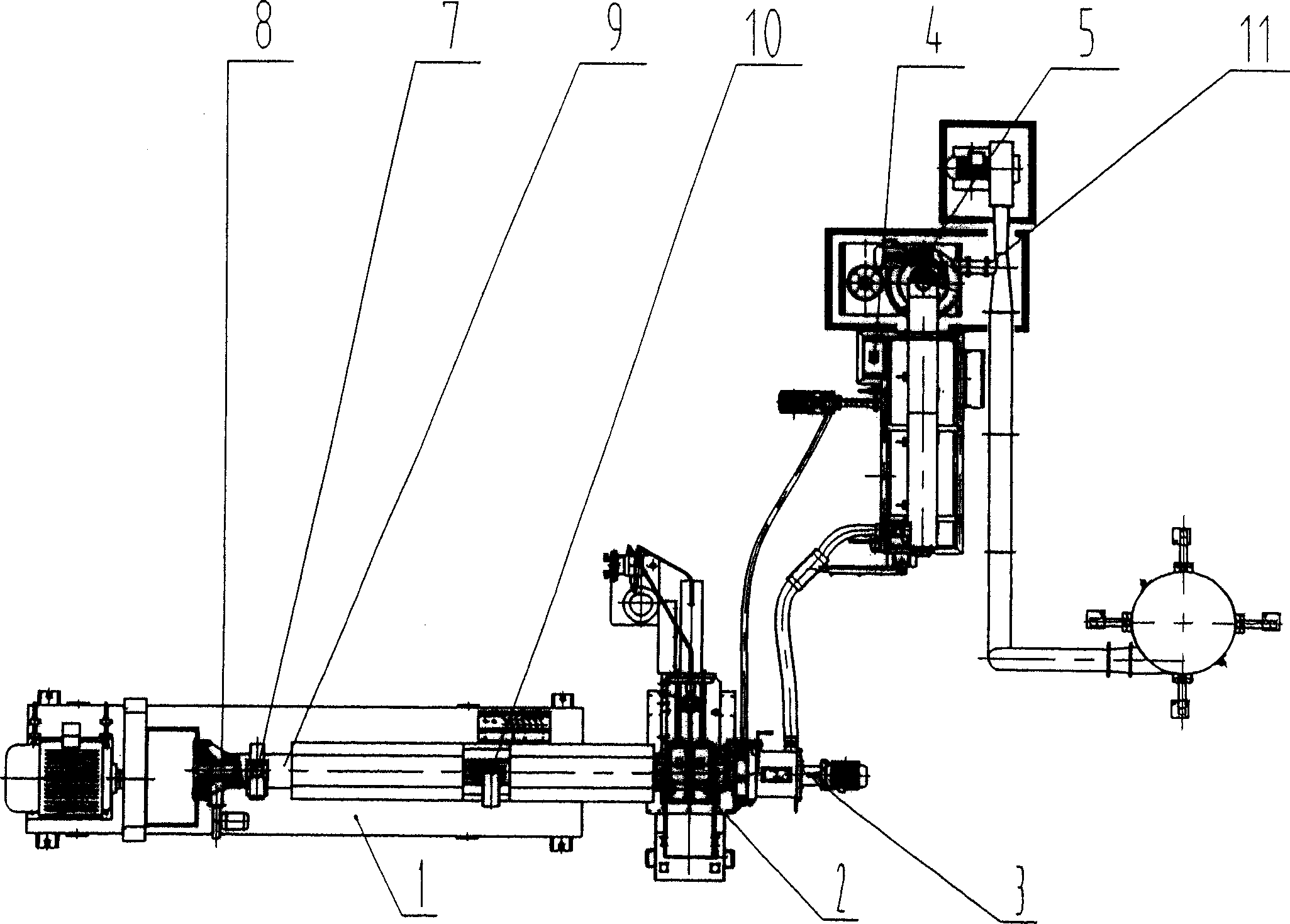

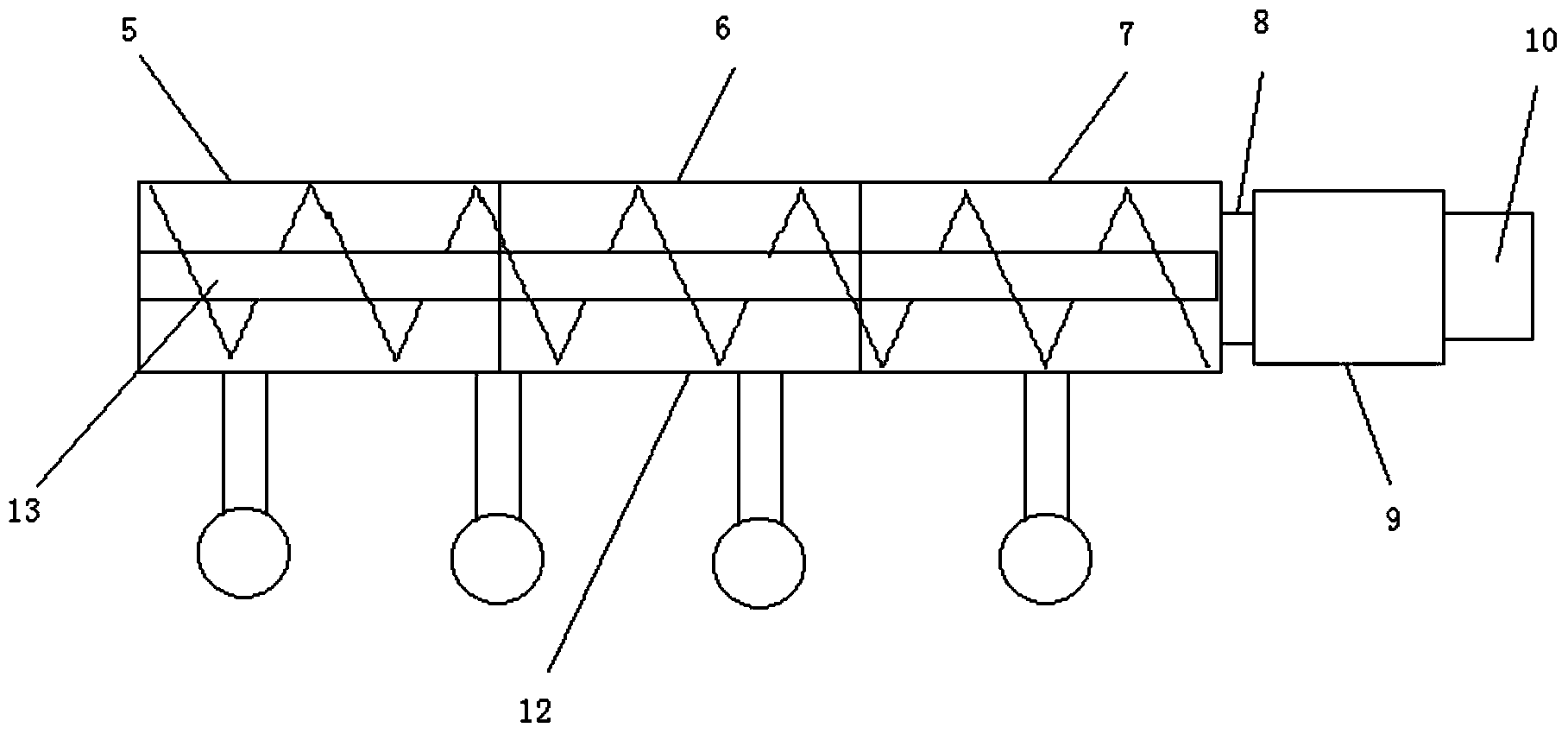

Method and device for matching materials among adjacent blade plasticization transportation units of blade squeezer

The invention relates to a method and a device for matching materials among adjacent blade plasticization transportation units of a blade squeezer. The blade squeezer consists of a group of blade feeding units and a plurality of blade plasticization transportation units, which are connected in series in an overlapping manner; the adjacent blade plasticization transportation units are connected through baffles having stream guidance and sealing effects; and the materials of the blade units on the upstream smoothly flow into the blade units on the downstream through material outlets in the baffles, so that the transition of the materials among the adjacent blade plasticization transportation units can be realized. With the adoption of the method provided by the invention, a plasticization transportation mechanism of entire positive displacement transportation of the blade squeezer can be realized; and meanwhile, the flow dead angle in a molding process can be avoided; the remaining time of the materials at a high temperature is reduced; the distribution of remaining time of the materials is uniform; and the thermal degradation of the materials can be reduced.

Owner:SOUTH CHINA UNIV OF TECH +1

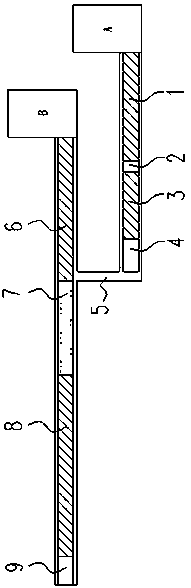

Method and device for plasticizing plastics based on Nd: YAG solid state laser

The invention discloses a method and a device for plasticizing plastics based on a Nd: YAG solid state laser, relates to the laser micro-molding field, and is suitable for plasticizing, molding and processing micro-scale plasticized micro-plastics, such as miniature gears, connectors, chips and the like. According to the invention, the heat effect caused by interacting of a laser energy field and a polymer can be used, the plastic is irradiated under the laser with high energy density to absorb light energy, a rapid temperature rising is realized to reach the fusing temperature so that the micro-molding processing can be completed. The device of the invention comprises an Nd: YAG laser, a laser beam regulator, a restraint layer, a plasticizing cylinder, a molding die, a work bench and a controller. The method of the invention is used for plasticizing or molding plastics, and has the characteristics of high plasticizing efficiency of plastics, good quality, energy saving, environmental protection, simple and easy operation and good processing flexibility, and can realize the plastic micro-molding processing with high efficiency and environmental protection.

Owner:JIANGSU UNIV

Continuous epe physical foam sheet extruder

The invention provides a continuous EPE physical foamed plate extruder which comprises a first-stage extruder body, a second-stage extruder body and a pipeline. The first-stage extruder body comprises a first-stage screw barrel and a first-stage screw. The second-stage extruder body comprises a second-stage screw barrel and a second-stage screw. The first-stage screw barrel and the second-stage screw barrel communicate through the pipeline. The continuous EPE physical foamed plate extruder is characterized in that the first-stage screw sequentially forming a first feeding section, a barrier section, a first stirring section and a first mixing section in the axial direction. A plurality of pin sets are arranged on the screw groove surface of the pin stirring section. According to the continuous EPE physical foamed plate extruder, product quality can be improved while the yield is increased and production efficiency is improved, and production energy consumption can be reduced.

Owner:重庆捷泰塑胶工业有限公司

A kind of screw speed control method for improving plasticizing quality of injection molding machine

ActiveCN113414955BImprove plasticizing qualityImprove uniformity of plasticizationControl systemPlasticulture

The invention discloses a screw speed control method for improving the plasticizing quality of an injection molding machine. Substitute it into the screw speed control function calculation model to obtain the screw speed control scheme of the speed with respect to the real-time screw displacement, and transmit it to the servo control system of the plasticizing motor of the injection molding machine to control the screw speed of the current cycle in real time, so as to realize the melting process. Uniformity of body plasticization quality. The method for controlling the screw rotation speed for improving the plasticizing quality of the injection molding machine of the present invention is beneficial to improve the plasticizing quality of the plastic melt, improve the melt uniformity, and reduce the number of mold trials caused by equipment or material replacement.

Owner:BEIJING UNIV OF CHEM TECH

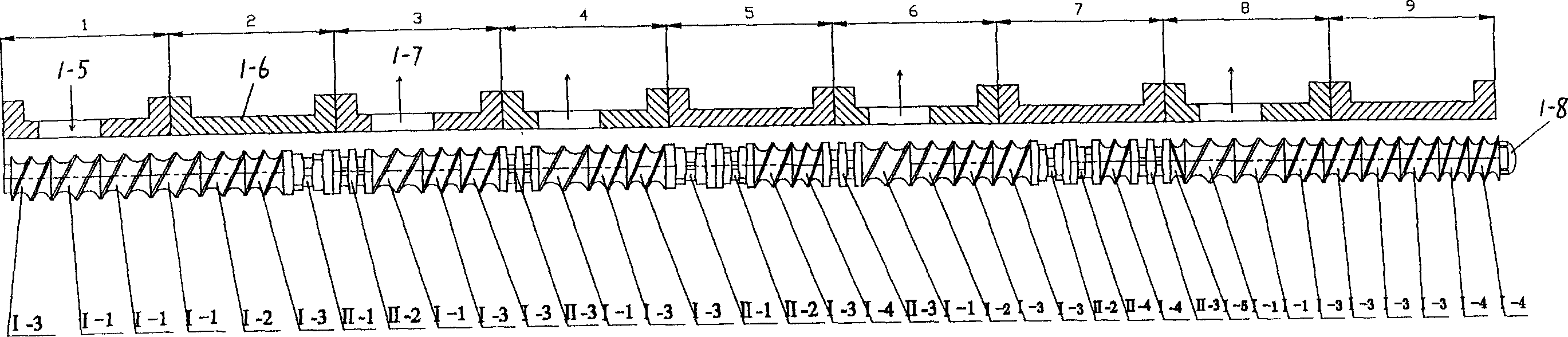

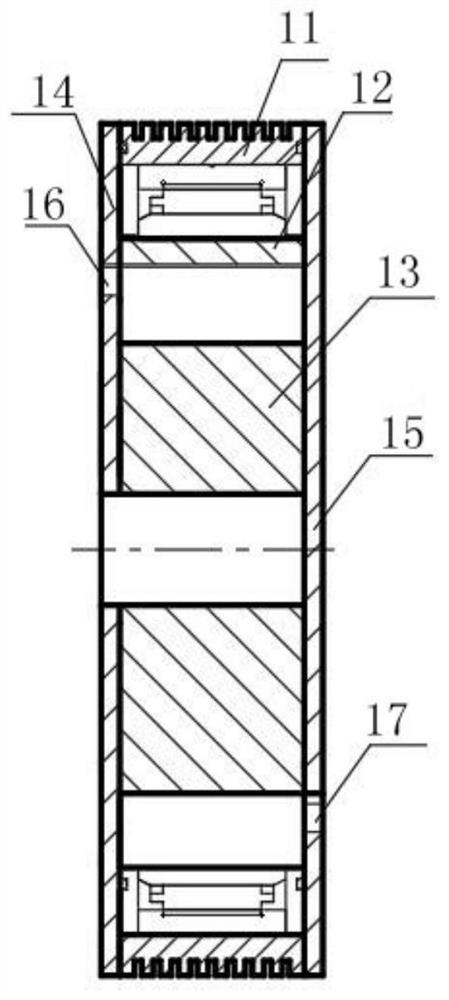

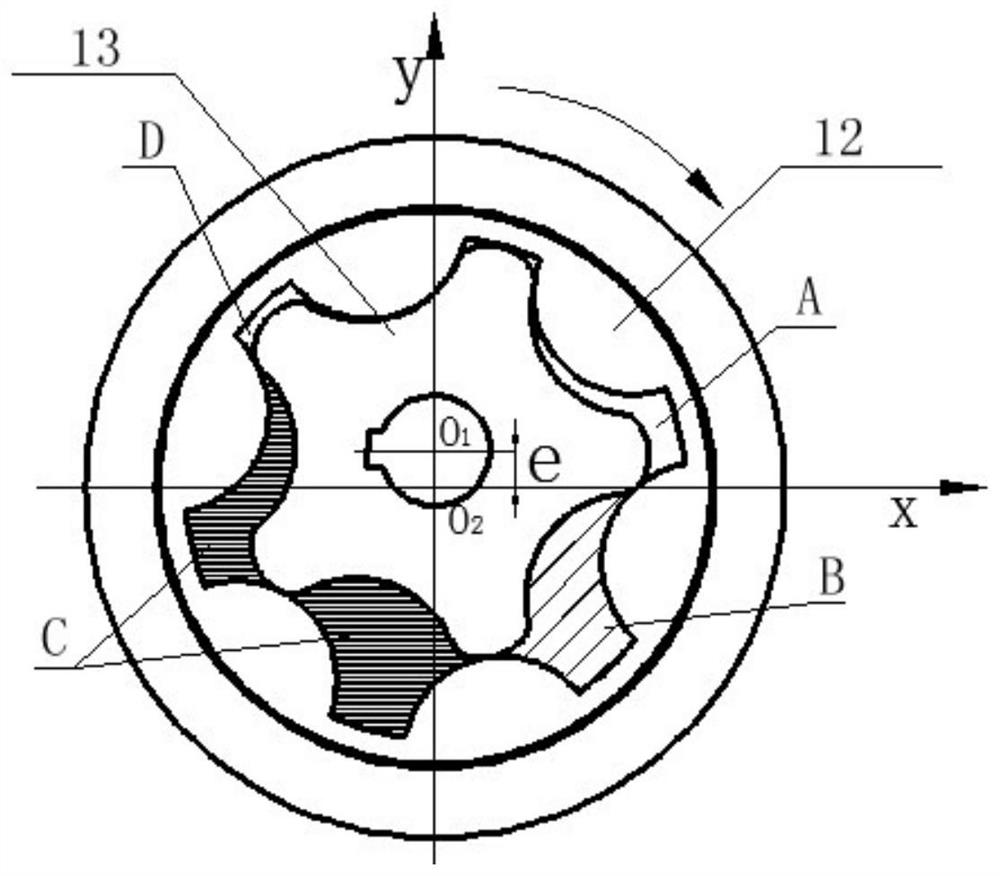

Macromolecule plasticizing transportation method based on extrusion and stretching, and macromolecule plasticizing transportation module, device and equipment

The invention provides a macromolecule plasticizing transportation method based on extrusion and stretching, and a macromolecule plasticizing transportation module, device and equipment. The method comprises the steps that the size of a transportation space for transporting macromolecular materials is periodically changed from small to large and then from large to small in sequence; in the processthat the size of the transportation space is changed from small to large, the macromolecular materials are forcibly contained in the transportation space; and in the process that the size of the transportation space is changed from large to small, the macromolecular materials are compacted and plasticized under the action of normal stress and then are forcibly discharged, and therefore forward transportation and plasticized conveying of the macromolecular materials are achieved through size change of the transportation space. According to the method, the module, the device and the equipment,the thermo-mechanical process of the plasticizing transportation process can be shortened, the plasticizing transportation energy consumption is reduced, the transportation efficiency is improved, andthe equipment size and occupied space are reduced.

Owner:FOSHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com