High-speed PB tube single screw

A technology of PB pipe and single screw, which is applied in the direction of tubular objects, other household utensils, household utensils, etc., which can solve the problems of difficult increase in productivity, lower conveying efficiency, high melt temperature, etc., and achieve high productivity and good plasticizing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

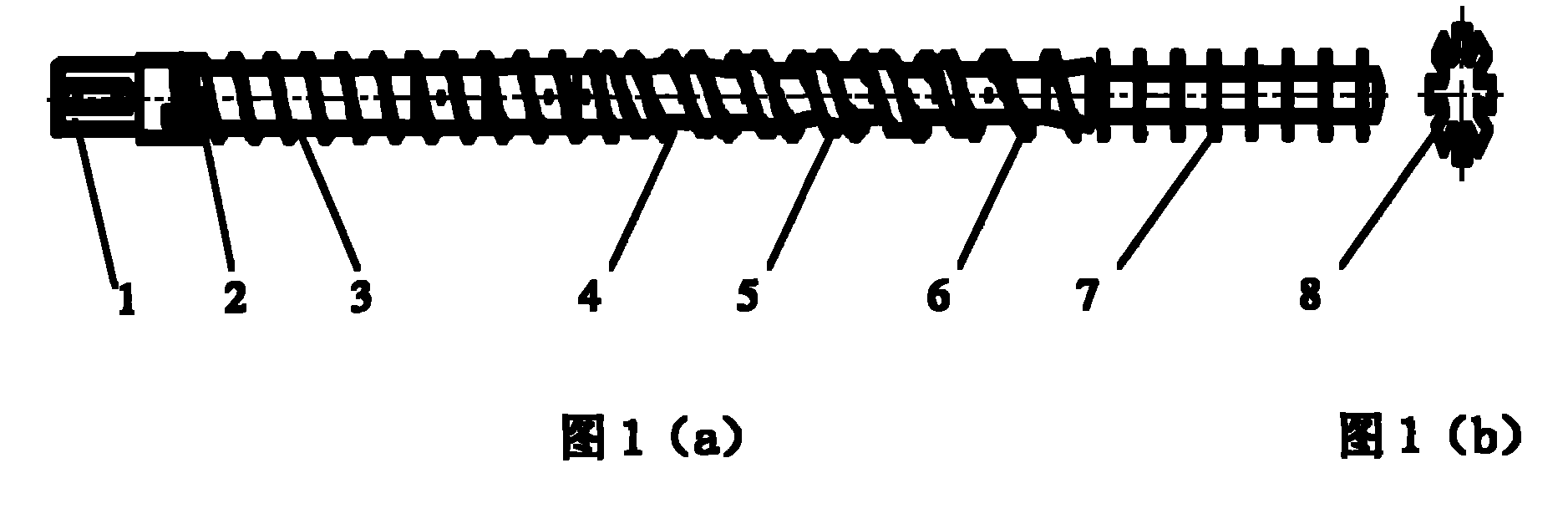

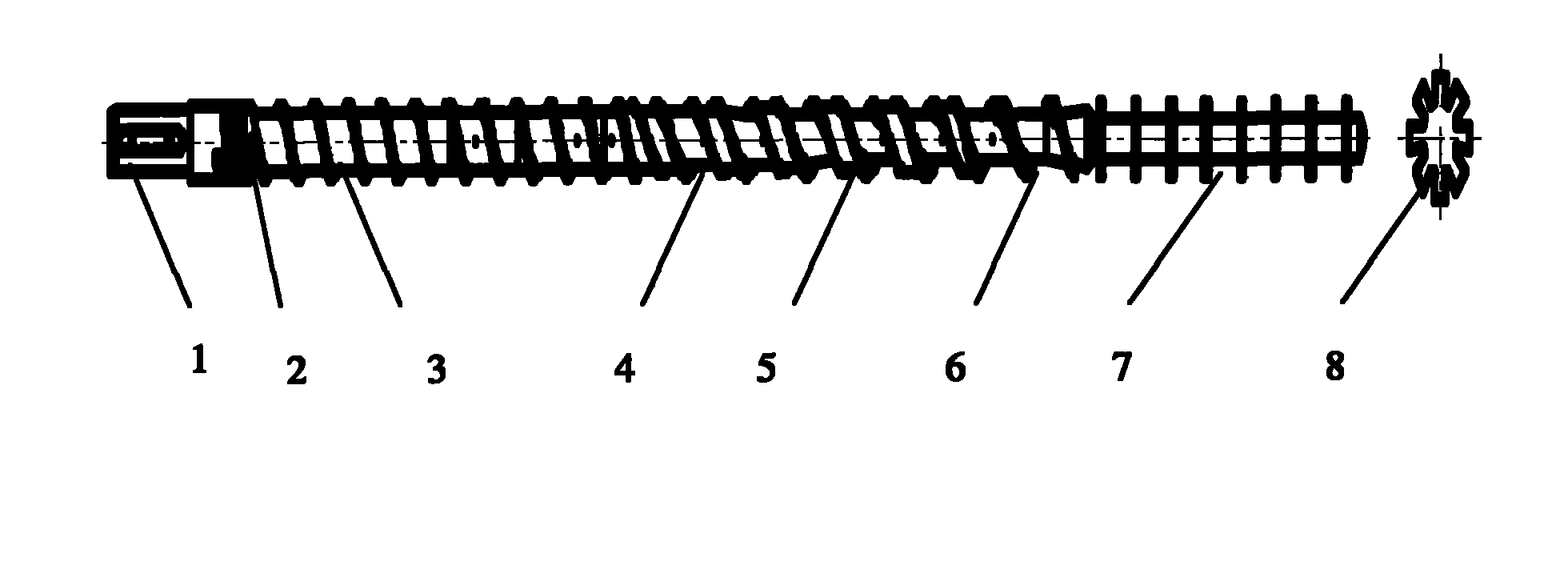

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] The structure of the present invention is shown in accompanying drawing 1, comprises keyway 1, sealing screw thread 2, solid conveying section 3, separation type screw solid phase groove 4, separation type screw liquid phase groove 5, separation type screw metering section screw groove 6, The mixing type screw head 7 and the mixing type screw head pin structure 8, the keyway 1 and the sealing thread 2 are used as the installation parts of the screw, which are the same as the prior art, and the solid conveying section 3 is used as the feeding section of the screw , the separation type screw solid phase groove 4, the separation type screw liquid phase groove 5 and the separation type screw metering section screw groove 6 are used as the melting section of the screw, and the mixing type screw head 7 is used as the extrusion section, which is provided with A multi-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com