Regeneration pelletizer for worn-out plastic

A waste plastic and granulator technology, applied in the direction of plastic recycling, recycling technology, etc., can solve problems such as messy, small filter surface, affecting production and application, etc., to avoid excessive impurities, improve cleanliness, and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

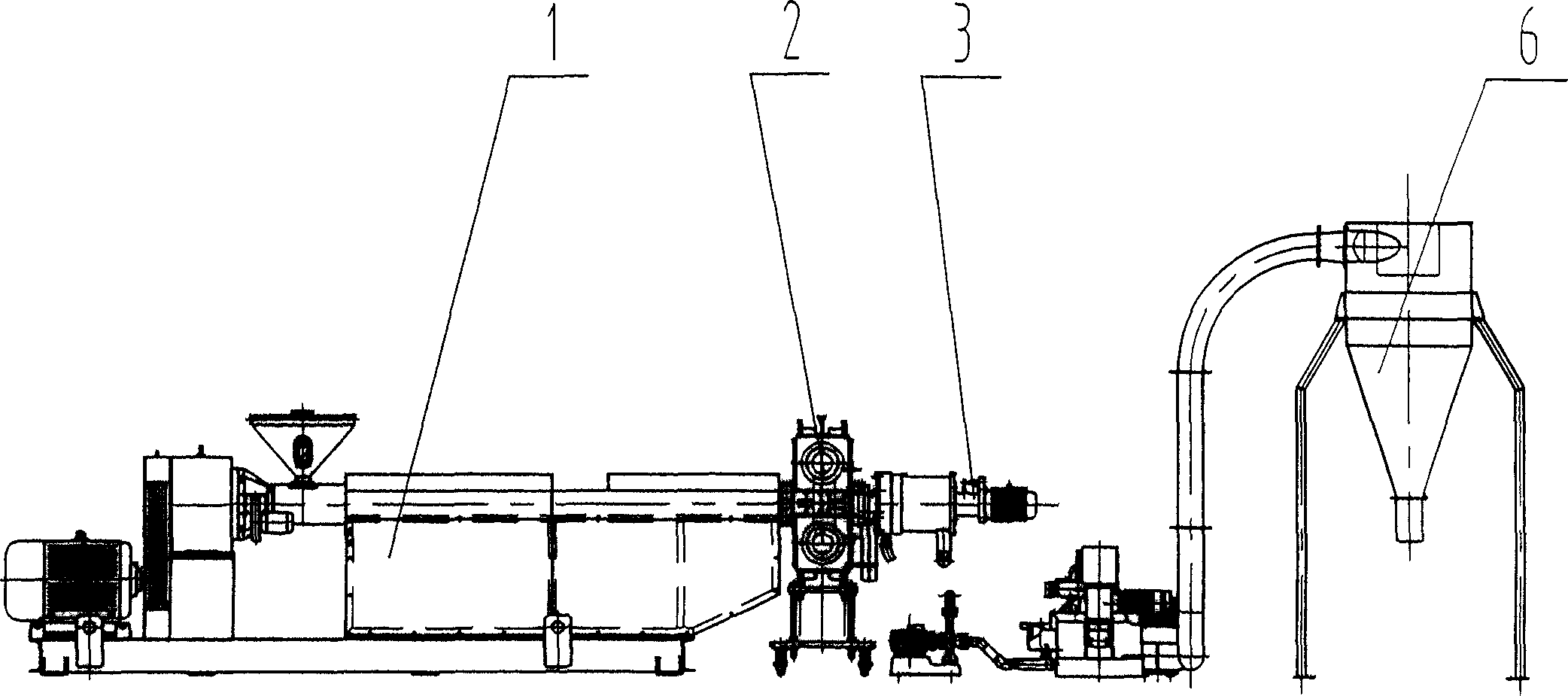

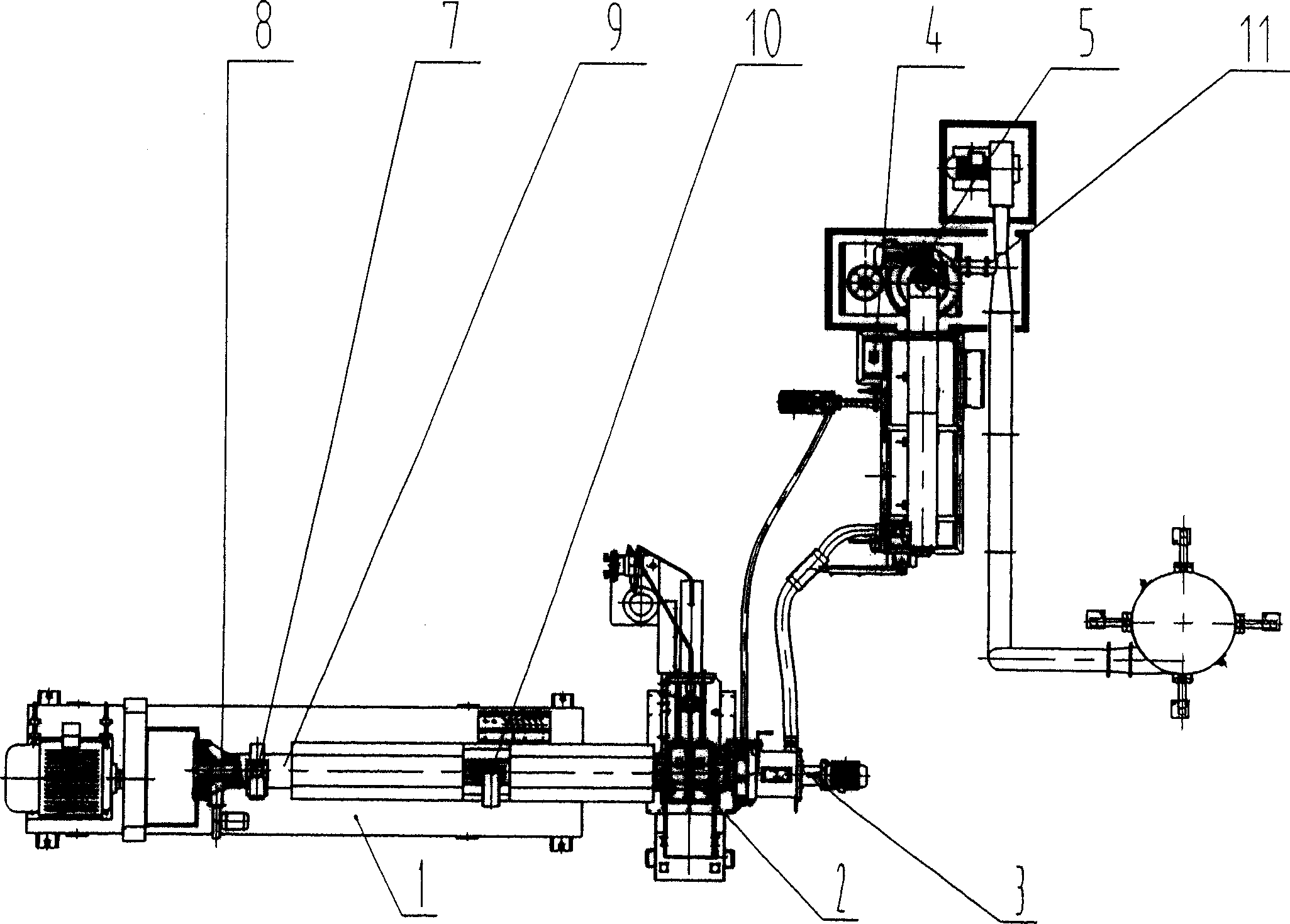

[0024] Such as figure 1 , figure 2 As shown, the present invention is composed of a vented extruder 1, a filter 2, a cutting granulator 3, a screw conveyor 4, a dryer 5 and an air delivery system 6 connected in sequence.

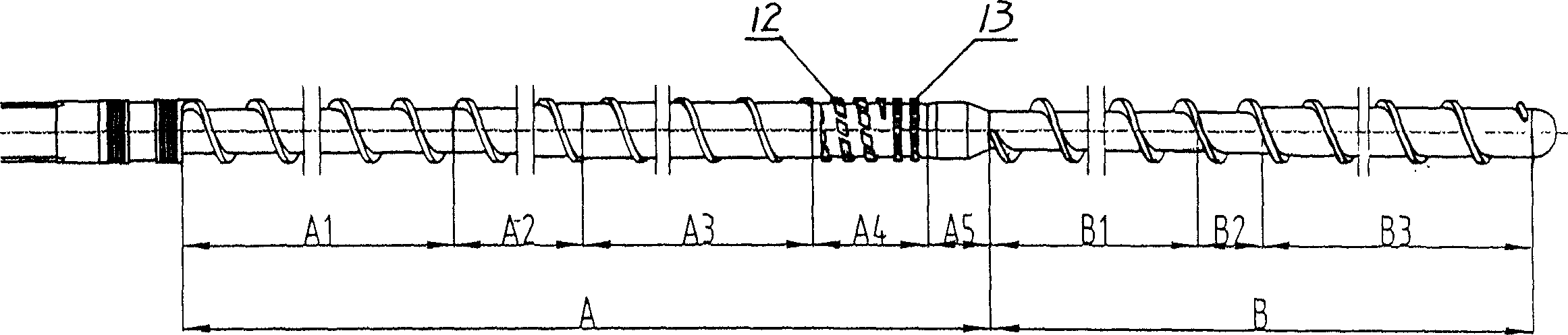

[0025] Such as image 3 As shown, the exhaust type extruder 1 includes a first-stage screw A and a second-stage screw B, and the first-stage screw A includes a feeding section A1, a compression section A2, a metering section A3, and a mixing section A4. The pressure regulating section A5 of the mixing section; the second-stage screw B includes the exhaust section B1, the sudden change section B2, and the subsequent metering section B3. The ratio of the length to the outer diameter of the screw is 35-45, and 40 is selected in this embodiment; the length ratio of the second-stage screw B to the first-stage screw A is 0.5-0.8, and 0.7 is selected in this embodiment; the mixing section A4 is composed of two The first section is a discontinuous thread section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com