Method and device for plasticizing plastics based on Nd: YAG solid state laser

A solid-state laser and plastic technology, applied in the field of laser micro-molding, can solve problems such as the inability to achieve micro-plasticization effect, the limitation of lap welding of engineering plastics, and the inability to penetrate plastic materials, so as to achieve precise and controllable laser parameters and solve hard Point problem, high uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

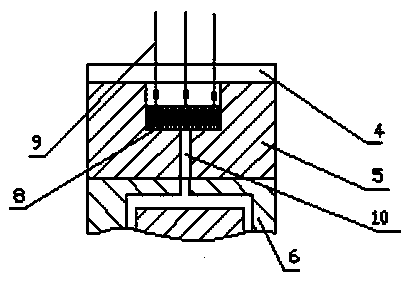

[0023] Take the plasticization of polar molecular PS (polystyrene) particles with a diameter of 2 mm, a thickness of 1 mm, and a mass of about 3.5 mg as an example.

[0024] First prepare plastic granules with a diameter of 2mm and a thickness of 1mm, which are punched by a granulator or sheet material, dried in an oven, put into a plasticizing cylinder, and covered with a constrained layer. The constrained layer is K9 glass. Light-transmitting and air-isolated to prevent the plastic from being oxidized by oxygen in the air when it melts.

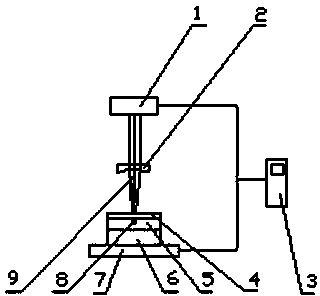

[0025] Laser parameter adjustment. Turn on the Nd:YAG SP2000 solid-state laser, the laser outputs laser with a wavelength of 1064nm, and the output laser energy is 200mJ; the controller controls the laser beam regulator to adjust the spot size of the laser beam so that the diameter of the irradiated plastic surface is 2mm.

[0026] After the parameters are adjusted, the laser energy is irradiated at the fixed point to irradiate the plasti...

Embodiment 2

[0029] Take the plasticization of non-polar molecular PE (polyethylene) particles with a diameter of 2 mm, a thickness of 2 mm, and a mass of about 7 mg as an example.

[0030] First prepare plastic granules. Polyethylene granules are plastic masterbatches with 0.7% carbon powder added, with a diameter of 2mm and a thickness of 2mm, or punched from a sheet, dried in an oven, put into a plasticizing cylinder, and capped. layer, the constraining layer is K9 glass.

[0031] Laser parameter adjustment. Turn on the Nd:YAG SP2000 solid-state laser, the laser outputs laser with a wavelength of 808nm, and the output laser energy is 300mJ; the controller controls the laser beam regulator to adjust the spot size of the laser beam so that the diameter of the irradiated plastic surface is 2mm.

[0032] After the parameters are adjusted, the laser energy is irradiated at the fixed position to irradiate the plastic in the plastic cylinder, and the burst is pulsed, the pulse width is 10ns, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com