Method for recycling waste plastic for pipeline anticorrosion

A technology of waste plastics and pipes, which is applied in the field of reuse of steel pipe 3LPE anti-corrosion waste plastics, can solve the problems of unavoidable waste PE scraps and powder materials, affect the factory environment, and occupy a large storage area, so as to achieve good promotion and application value and eliminate environmental pollution , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

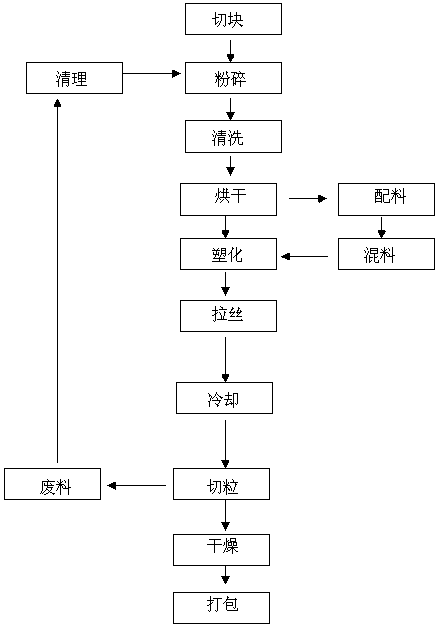

Method used

Image

Examples

Embodiment 1

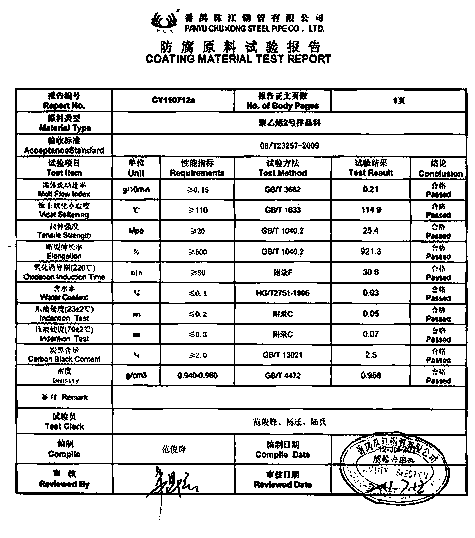

[0015] Use large pieces of recycled granulated materials that have been cut and crushed: remove the epoxy layer and adhesive, cut them into thin slices and strips with woodworking saws, or initially cut large pieces of waste with mechanical knives; then use powerful special The plastic crusher is crushed into pieces with a size of 1cm*1cm or less than 1cm; and then cleaned with automatic cleaning equipment to remove harmful impurities such as sand and metal inside; then, after drying, add the required additives and Additives, specifically: polyethylene resin: antioxidant 1010: PE wax = 80: 18.8: 0.2: 1.0, after batching, use special plastic granulation equipment to plasticize, granulate, cool, and pelletize to make Products, packaged and classified for 3PE anti-corrosion. After testing: density 0.958g / cm 3 ; Melt flow rate 0.21 g / 10min; Oxidation induction period 30.8min; 100 ℃, 2400h heat aging 27%. Meet the technical standard requirements of SY / T0413-2002 polyethylene anti...

Embodiment 2

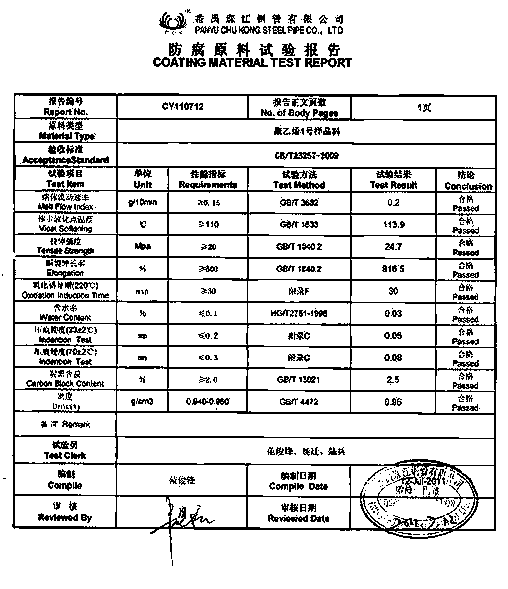

[0017] Use the pipe end peeling strips stripped of the epoxy powder layer and adhesive and recycled granulated material after crushing the leftovers: strip off the epoxy layer and adhesive, cut into thin slices or strips with a woodworking saw, or Preliminary cutting of large pieces of waste with mechanical knives; then use a powerful special plastic crusher to crush into pieces within 1cm*1cm or within 1cm; then clean with automatic cleaning equipment to remove harmful impurities such as sand and metal inside ; Then, after drying, add the required additives and auxiliary agents according to the needs of the product, specifically: polyethylene resin: antioxidant 1010: PE wax = 75: 23.8: 0.2: 1.0, after batching, it is made of special plastic again The granulation equipment is then plasticized, granulated, cooled, and pelletized to make products, packaged and classified for 3PE anti-corrosion. After testing: density 0.960g / cm3; melt flow rate 0.2 g / 10min; oxidation induction pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Oxidation induction period | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com