Equidirectional parallel double-screw plastic extruder unit for double-wall corrugated pipe

A double-wall corrugated pipe and extruder unit technology, applied in the field of plastic corrugated pipe manufacturing, can solve the problems of short screw length-to-diameter ratio, reduced screw service life, poor formula adaptability, etc., to optimize existing technology and improve pipe quality , The effect of plasticizing quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings. Based on the embodiments of the present invention, other embodiments obtained by persons of ordinary skill in the art without creative efforts all fall within the protection scope of the present invention.

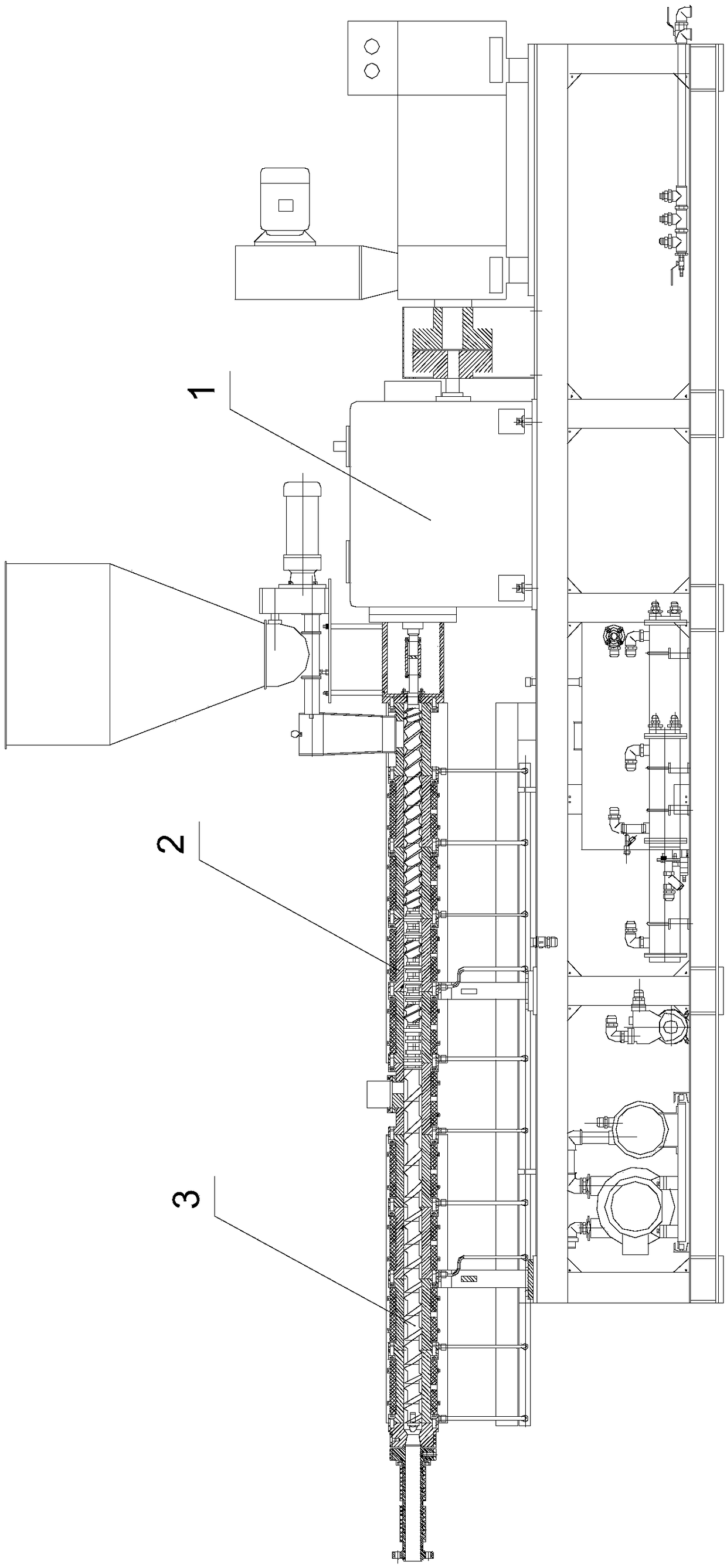

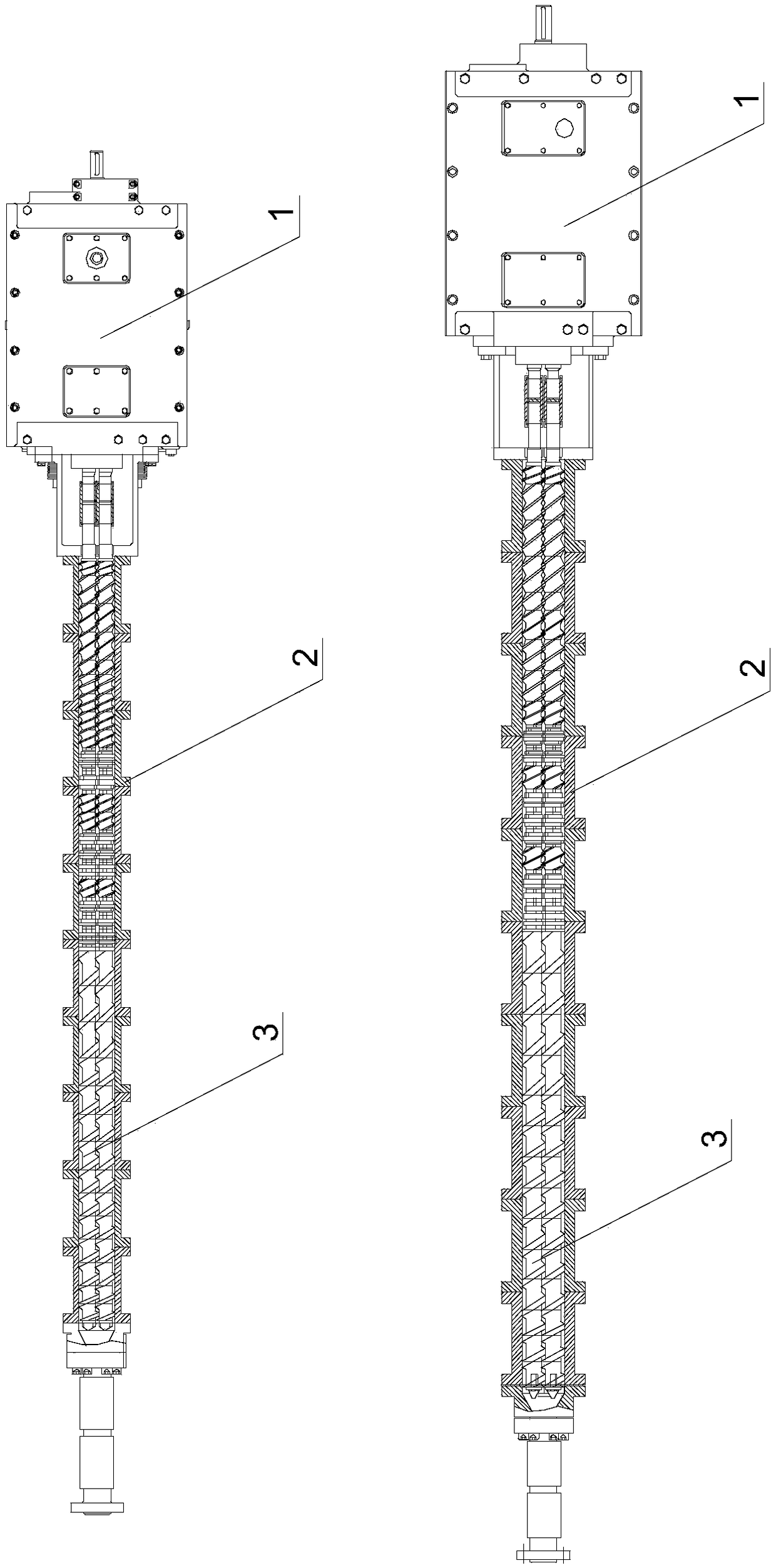

[0020] Such as figure 1 , figure 2 , the present invention is a co-direction parallel twin-screw plastic extrusion unit for double-wall corrugated pipes, comprising a twin-screw ultra-high torque gearbox 1, a split combined barrel 2, and a combined screw 3. The combined screw 3 includes two identical structures, Screws with the same diameter, the two shafts of the combination screw 3 are respectively connected with the two output shafts of the twin-screw ultra-high torque gearbox 1, and the outer sides of the two sets of combination screws 3 are respectively equipped with a two-component combined barrel 2 that cooperates with it .

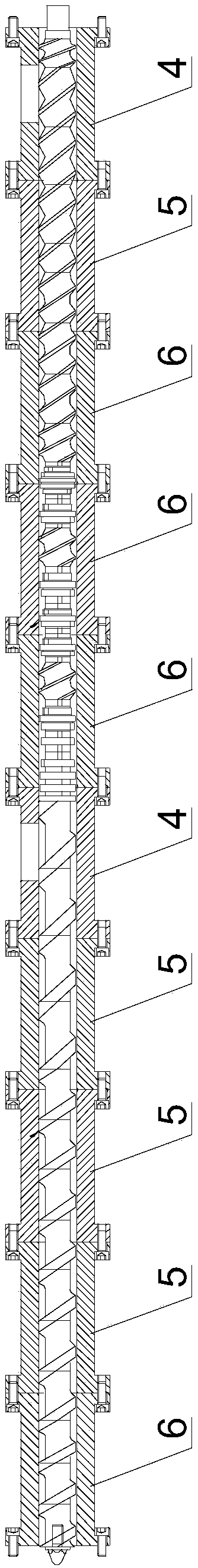

[0021] Such as image 3 , is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com