Method and device for matching materials among adjacent blade plasticization transportation units of blade squeezer

A blade extruder and blade plasticizing technology, which is applied in the field of material matching between adjacent blade plasticizing and transporting units of the blade extruder, can solve the problem of prolonging the melt residence time, increasing the degradation of polymer materials, and prone to dead ends, etc. problems, to achieve uniform distribution of residence time, improve plasticization quality, and reduce material residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

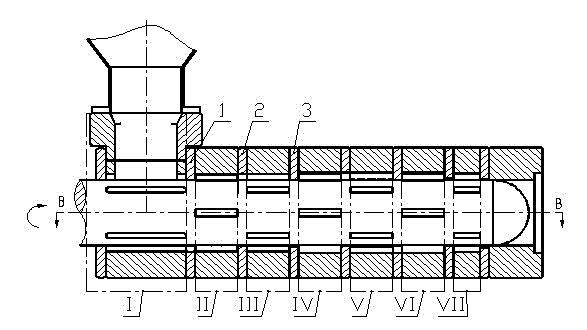

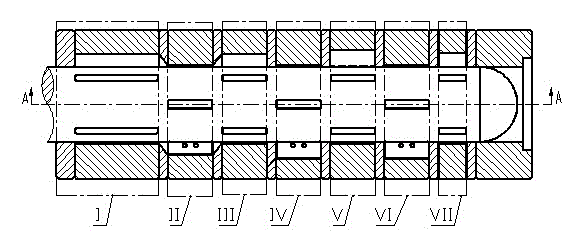

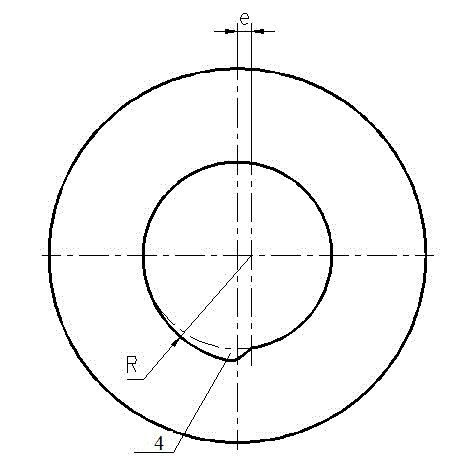

[0020] see figure 1 , figure 2 , the vane extruder is composed of the vane feeding unit I and several groups of vane plasticizing and transporting units (II~VII) stacked in series. The eccentric direction of the rotor of the adjacent two vane plasticizing and transporting units is opposite to that of the stator. The size of the eccentric distance can be inconsistent, and two adjacent groups of blade plasticizing transport units are connected by baffles. Since the eccentric directions of adjacent two groups of blade units are opposite, the positions of the discharge openings of the two groups of units are symmetrical with respect to the central axis of the rotor.

[0021] The plasticizing transport of the vane extruder is volumetric transport, and the baffles between two adjacent sets of vane plasticizing transport units play the role of sealing and diversion. When the rotor rotates, when the space volume surrounded by the stator, rotor, blades and baffles in the vane plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com