Macromolecule plasticizing transportation method based on extrusion and stretching, and macromolecule plasticizing transportation module, device and equipment

An extrusion stretching and polymer technology, applied in the field of plasticization and transportation of polymer materials, can solve the problems of increased energy consumption, prolonged thermomechanical history, and large equipment structure, and achieves improved transportation efficiency, volume and floor space. Small, improve the effect of plasticizing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

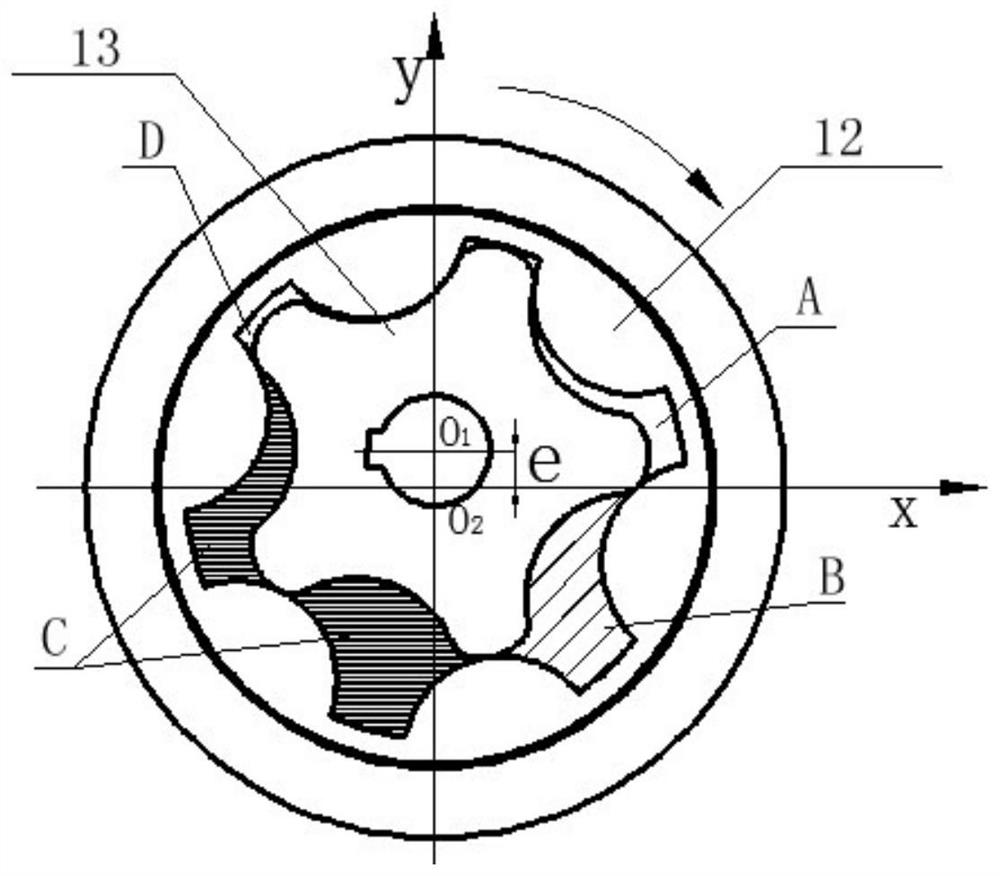

[0036] In this embodiment, a polymer plasticizing transport method based on extrusion stretching, the volume of the transport space used to transport polymer materials realizes periodic changes from small to large and then from large to small; in the transport space When the volume changes from small to large, polymer materials are forced into the transport space; during the process of changing the volume of the transport space from large to small, polymer materials are compacted and plasticized by normal stress, and then forced to Discharge, so as to rely on the volume change of the transport space to realize the positive displacement transport and plastic transport of polymer materials.

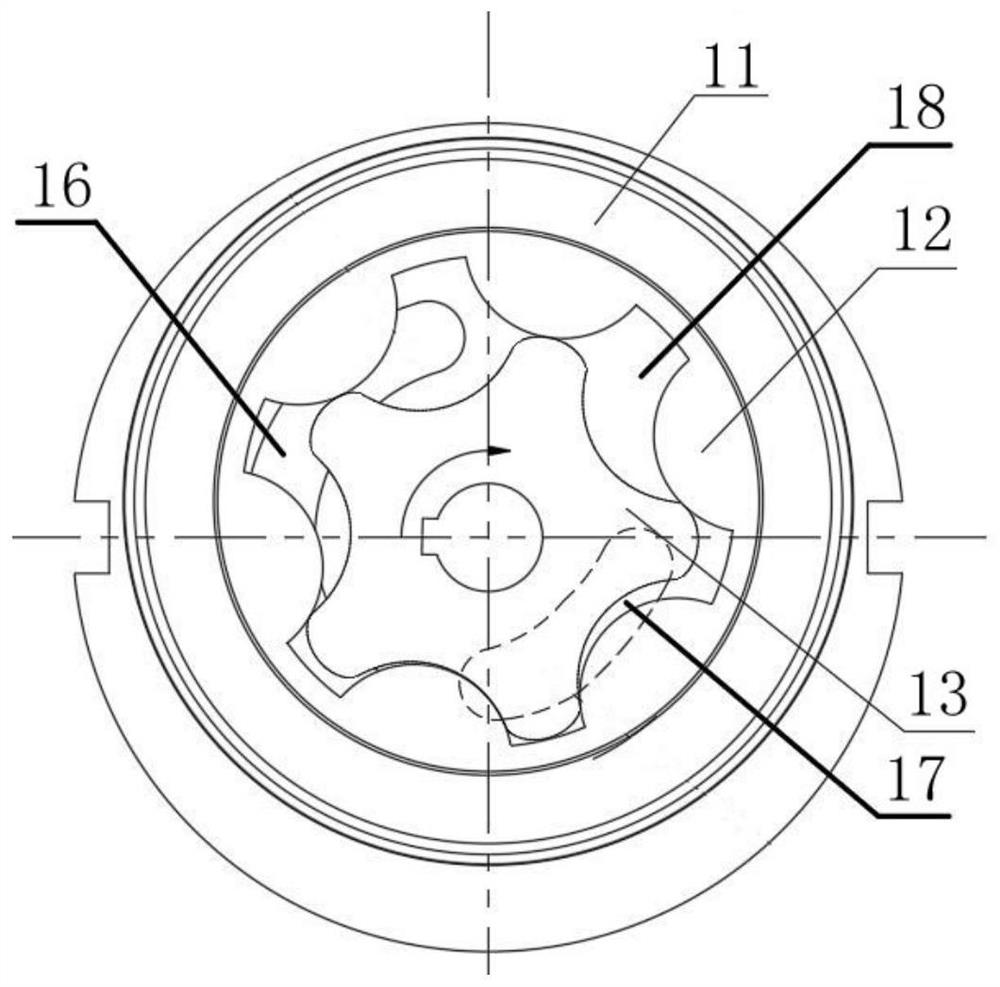

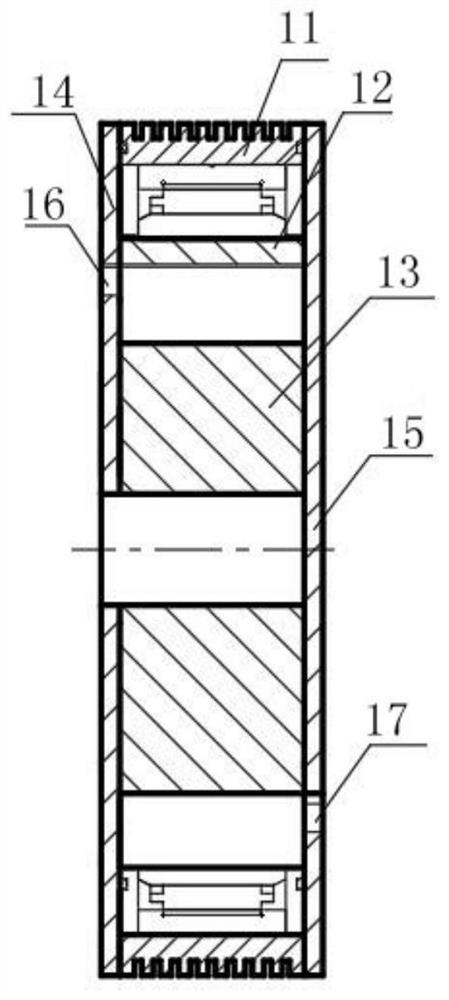

[0037] In order to realize the polymer plasticization transportation method based on extrusion stretching, this embodiment provides a polymer plasticization transportation module, such as Figure 1 to Figure 3As shown, a set of transport unit 1 is included; the transport unit 1 includes a s...

Embodiment 2

[0044] This embodiment is a polymer plasticizing transport module, the difference from Embodiment 1 is that in this embodiment, the feed port 16 is not arranged on the stop plate 1, but is arranged in the stator 11, and the feed port 16 communicates with the head end of the transport space 18, such as Figure 4 shown. In practical applications, the discharge port may not be arranged on the second retaining plate, but on the stator, and the discharge port communicates with the end of the transport space. The rest of the structure of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0046] This embodiment is a polymer plasticizing transportation method based on extrusion stretching, the difference from Embodiment 1 is that in this embodiment, multi-stage transportation spaces are used to transport polymer materials in series in phase sequence; each stage The volume of the transport space realizes periodic changes from small to large and then from large to small; during the process of changing the volume of the transport space from small to large, polymer materials are forcibly incorporated into the transport space; when the volume of the transport space changes from small to large In the process of changing from large to small, the polymer material is compacted and plasticized by normal stress, and then forced to discharge, so as to realize the plasticized transportation of the polymer material with multi-stage pressurization and speed-up.

[0047] In order to realize the polymer plasticizing and transporting method based on extrusion and stretching, furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com