Patents

Literature

41results about How to "Fast plasticizing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

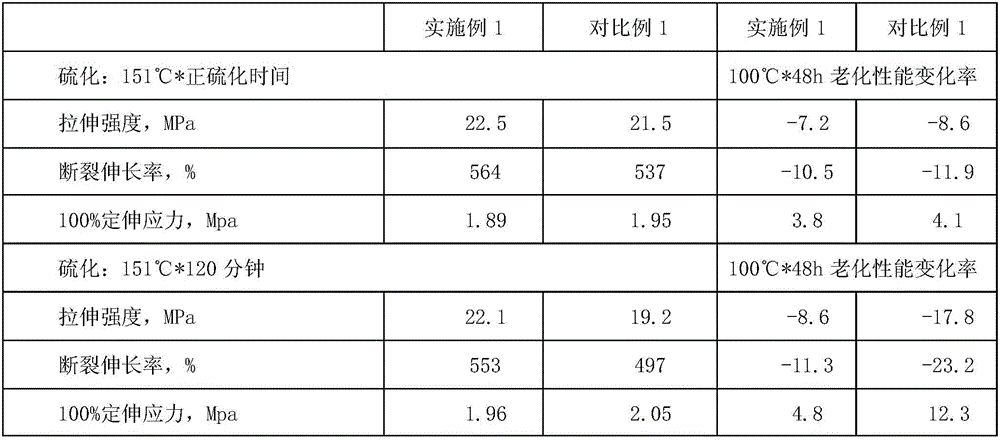

Insulating and environment-friendly PVC modified material and preparation method thereof

The invention relates to the technical field of PVC modified materials and particularly relates to an insulating and environment-friendly PVC modified material and a preparation method thereof. The insulating and environment-friendly PVC modified material contains the following raw materials: 80-120 parts of PVC resin, 40-60 parts of bulking agent, 40-60 parts of plasticizer, 10-15 parts of insulation modifier, 3-7 parts of heat stabilizer and 0.5-1.5 parts of lubricant, wherein the plasticizer is a mixture prepared from dioctyl terephthalate and tri-n-butyl citrate which are in the weight ratio of (5-7): 1; the insulation modifier is a mixture prepared from kaolin, titanium white and glass micro-beads which are in the weight ratio of (2-4): (1.5-2.5): 1, and the particle size of the glass micro-beads is smaller than 20 microns. According to the modified material prepared by the preparation method, all properties exceed the national standards, the insulating property is good, the resistivity reaches up to 5.1*10<14> omega, and the modified material is environment-friendly; the preparation method disclosed by the invention is simple in process, convenient in operation and control, stable in quality and high in production efficiency and can be applied to large-scale industrial production.

Owner:广东祺龙科技有限公司

PVC (polyvinyl chloride) foam material for sole and preparation method of PVC foam material

InactiveCN105440505AImprove temperature resistanceGood weather resistanceSolesWeather resistanceFoaming agent

The invention relates to the technical field of PVC materials, in particular to a PVC (polyvinyl chloride) foam material for a sole and a preparation method of the PVC foam material. The PVC foam material for the sole comprises raw materials in parts by weight as follows: 80-120 parts of PVC resin, 40-60 parts of a plasticizer, 20-30 parts of a filling agent, 6-10 parts of a wear-resistant modifier, 4-8 parts of a thermal stabilizer, 2-4 parts of a foaming agent, 0.8-1.2 parts of a lubricant and 1-2 parts of a processing aid. The raw materials are adopted for preparation of the PVC foam material for the sole, the weight proportion of the raw materials is controlled strictly, the performance of the prepared PVC foam material for the sole exceeds the national standards, and the PVC foam material is environment-friendly and has good temperature resistance and weather resistance, high strength, excellent anti-impact performance, good flame-retardant effect, good processing performance and excellent comprehensive performance.

Owner:广东祺龙科技有限公司

Polyvinyl chloride electrostatic film and preparation method thereof

InactiveCN106046626AHigh static resistanceImprove anti-static effectFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of electrostatic film, and in particular, relates to a polyvinyl chloride electrostatic film and a preparation method thereof, wherein the polyvinyl chloride electrostatic film comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 46-73 parts of a plasticizer, 1-3 parts of a heat stabilizer, 3-7 parts of an anti-electrostatic agent, 0.3-0.7 part of a gelatinizing agent, 0.02-0.03 part of a pigment powder, and 0.1-0.3 part of other auxiliary agents. The polyvinyl chloride electrostatic film has high electrostatic resistance, has high anti-electrostatic effect and protection functions, has high self-adhesive performance, and has excellent stable performance under high temperature conditions; the polyvinyl chloride electrostatic film also has the advantages of being ultra thin, tough, transparent, self-adhesive, good in transparency, small in watermarks and the like, has fewer crystal points and low-temperature resistance, and has excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance and preparation method of adhesive film

ActiveCN107502232AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkMechanical property

The invention relates to a solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance. The solar cell encapsulating EVA adhesive film is characterized in that the thickness of the EVA adhesive film is 0.8 mm-1.1 mm, and the EVA adhesive film is prepared from raw materials in parts by weight as follows: 100 parts of EVA resin, 0.5-2.5 parts of a plasticizer, 0.1-0.3 parts of a photoelectric conversion rate enhancer, 1-4 parts of an anti-aging agent, 1.5-2.5 parts of a blocking agent, 1-2 parts of a dispersing agent, 1-3 parts of a coupling agent and 1-3 parts of a cross-linking agent. Firstly, the raw materials are added to a mixer proportionally and mixed into uniform components, the components are subjected to melt mixing by a banbury mixer and then subjected to extrusion and pelletizing, and the EVA adhesive film is obtained. According to the prepared EVA adhesive film, the light transmittance of the adhesive film is not influenced and the mechanical properties are greatly improved while properties and photoelectric conversion efficiency of the adhesive film are improved with addition of multiple additives.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

Acrylic acid ester promoter for polyvinyl chloride use, preparation method and application thereof

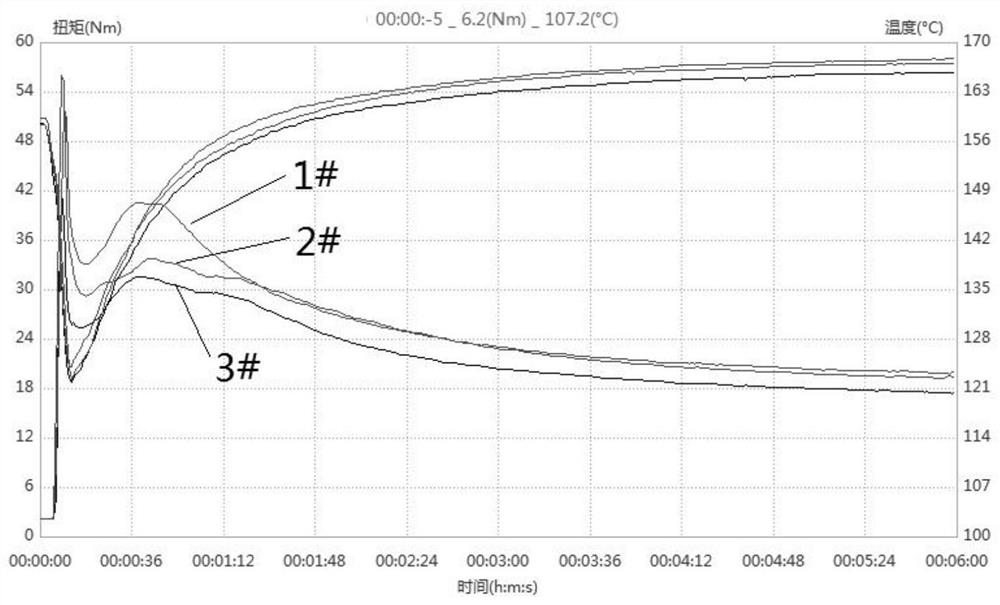

The invention relates to a copolymer of methyl methacrylate and acrylic acid esters, in particular to an acrylic acid ester promoter for polyvinyl chloride use. The acrylic acid ester promoter has an average molecular weight of 9,000,000-11,000,000, and is obtained by emulsion polymerization from the following substances by mass parts: 10-30 parts of styrene, 40-90 parts of methyl methacrylate, 5-30 parts of butyl acrylate, 0-10 parts of alpha-methyl styrene, 0-30 parts of ethyl acrylate, 0-30 parts of acrylonitrile, 0-20 parts of 2-ethylhexyl acrylate, and 0-20 parts of vinyl acetate. The invention also discloses a preparation method of the acrylic acid ester promoter and application of the acrylic acid ester promoter in a polyvinyl chloride process and foamed products. The acrylic acid ester promoter has rapid plasticizing speed, good melt fluidity, enough melt intensity, and enough later-period plasticizing ability in the polyvinyl chloride process.

Owner:WUXI CHANGSHENG PLASTICIZING

High heat-resistant anti-aging CPVC power cable protection tube and preparation method thereof

The invention discloses a high heat-resistant anti-aging CPVC power cable protection tube. The tube comprises the following raw materials, in parts by weight: 450-550 parts of CPVC, 200-300 parts of PVC, 150-200 parts of calcium powder, 30-50 parts of a toughening agent, 3-15 parts of nitrile rubber, 20-30 parts of a stabilizer, 10-20 parts of a flame retardant, 1-5 parts of stearic acid, and 12-18 parts of paraffin. The high heat-resistance anti-aging CPVC power cable protection tube provided by the invention has a temperature resistant to heat deformation of 98 DEG C or more, has excellent high-temperature resistance, and can adapt to high-temperature harsh environments; the flame retardant performance reaches a FV-0 level; the tube has the characteristics of good flexibility, uneasy breakage and aging, long service life, no radiation pollution and a light weight; and in addition, a preparation method provided by the invention is simple and controllable, and the production is easy tooperate.

Owner:东莞市庆隆塑胶有限公司

PVC (polyvinyl chloride) diamante shower curtain and preparation method thereof

ActiveCN104194217AReduce forceLower glass transition temperatureFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of plastic shower curtains and particularly relates to a PVC (polyvinyl chloride) diamante shower curtain and a preparation method thereof. The PVC diamante shower curtain comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 40-60 parts of a plasticizer, 5-10 parts of a thermal stabilizer, 0.05-0.5 part of a flame retardant, 0.1-0.2 part of an anti-ultraviolet agent and 0.01-0.02 part of phthalocyanine blue. The preparation method for the PVC diamante shower curtain comprises the following steps: preparing raw materials, stirring at a high speed, carrying out primary plastification, carrying out secondary plastification, filtering in a hierarchical manner, calendaring molding and cooling rolling. The shower curtain disclosed by the invention is flame-resistant, insulated, alkaline-resistant, acid-resistant, waterproof, corrosion-resistant, tensile-resistant, ageing-resistant, antistatic, clear in grain pattern, and good in 3D (three dimensional) steric effect. And the preparation method of the PVC diamante shower curtain is simple in process, convenient to operate and control, stable in quality, high in production efficiency and capable of being applied to large-scale industrial production.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Antitarnish crosslinked PVC material and preparation process thereof

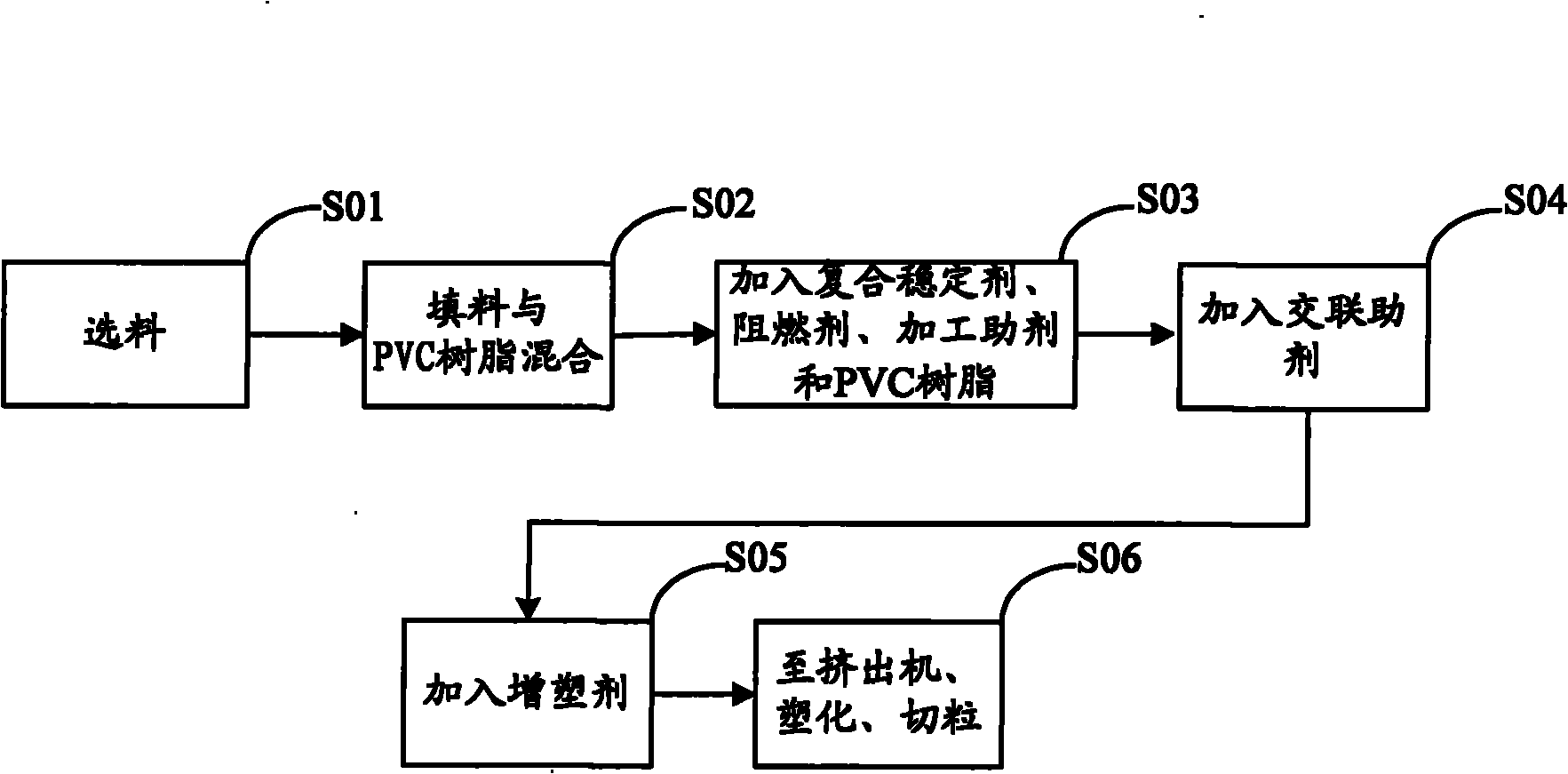

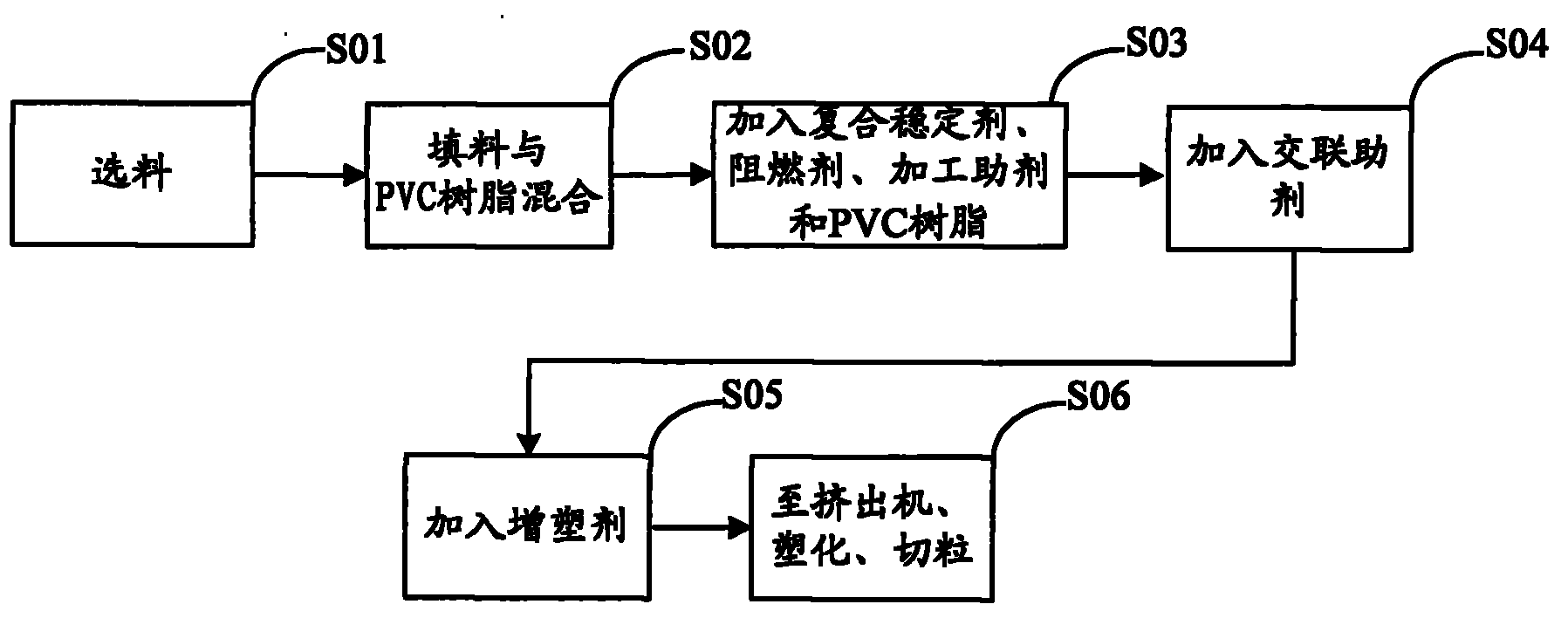

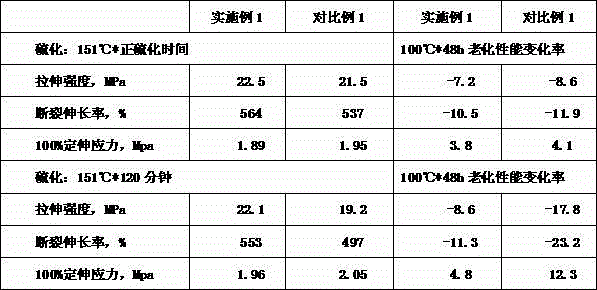

The invention provides an antitarnish crosslinked PVC (Polyvinyl Chloride) material which is prepared from the following components in parts by weight: 100 parts of PVC resin, 20-30 parts of filler, 30-50 parts of plasticizer, 5-15 parts of composite stabilizer, 3-7 parts of flame retardant, 2-6 parts of crosslinking agent and 2-6 parts of processing aid. The invention also provides a preparation process of the antitarnish crosslinked PVC material. The non-toxic composite stabilizer and the processing aid are added to the antitarnish PVC material to obviously improve the optical stability of the PVC material in radiation processing, i.e. colors are unchanged after the material is radiated. The invention has low-cost and environment-friendly raw materials and wide application prospects.

Owner:深圳市帝源新材料科技股份有限公司

Anticorrosive PVC modified material and preparation method thereof

InactiveCN105566805AImprove corrosion resistanceImprove temperature resistanceWeather resistancePlasticizer

The invention relates to the technical field of PVC materials, and concretely relates to an anticorrosive PVC modified material and a preparation method thereof. The anticorrosive PVC modified material comprises, by weight, 80-120 parts of PVC resin, 50-70 parts of a plasticizer, 20-30 parts of a filler, 4-8 parts of an impact modifier, 3-5 parts of a heat stabilizer, 1-2 parts of a synergistic agent, 0.6-1.0 part of a lubricant and 0.3-0.7 parts of an antioxidant. All performances of the anticorrosive PVC modified material prepared through strictly controlling the weight ratio of all above raw materials exceed national stands, and the anticorrosive PVC modified material has the advantages of good anticorrosion effect, environmental protection, excellent temperature and weather resistance, high strength, excellent impact resistance, good flame retardation effect, excellent processing properties and excellent comprehensive performances.

Owner:广东祺龙科技有限公司

Method for preparing multifunctional rubber assistant by recycling alkali-weight-reduction processing discharged liquor

ActiveCN104829879AFast plasticizing speedImprove anti-reversion performanceSocial benefitsActivated carbon filtration

The invention discloses a method for preparing a multifunctional rubber assistant by recycling alkali-weight-reduction processing discharged liquor. The method comprises the following steps: sequentially passing alkali-weight-reduction wastewater through a laminar-flow precipitation tank and an activated carbon filter to enter an acid precipitation tank, adding sulfuric acid or hydrochloric acid while stirring, and precipitating terephthalic acid when the wastewater becomes acidic; and adding the terephthalic acid and stearic acid into a reaction kettle, adding water and sodium hydroxide to dissolve the terephthalic acid and stearic acid into a sodium solution, adding a zinc chloride solution to crystallize and precipitate a zinc terephthalate-zinc stearate crystal mixture, centrifuging, filtering, washing and drying to obtain the multifunctional rubber assistant finished product. By using the alkali-weight-reduction processing wastewater as the raw material, the method reduces the wastewater discharge and implements resource reutilization on the premise of preparing the novel rubber assistant, and thus, has obvious economic benefit and social benefit.

Owner:江苏爱特恩高分子材料有限公司

High-strength cable protection pipe and preparation method thereof

The invention discloses a high-strength cable protection pipe and belongs to the technical field of cable protection pipes. The high-strength cable protection pipe is prepared from the following raw materials in parts by weight: 40 to 50 parts of CPVC resin, 12 to 14 parts of PVC resin, 15 to 17 parts of MBS resin, 10 to 12 parts of carbon fibers, 8 to 11 parts of silicone rubber, 5 to 7 parts of antimonous oxide, 6 to 9 parts of paraffin, 4 to 6 parts of a CPE impact modifier, 1 to 3 parts of an ACR machining modifier, 13 to 15 parts of plasticizers, 3 to 6 parts of titanium dioxide, 15 to 17 parts of sodium bicarbonate, 3 to 5 parts of heat stabilizers and 0.5 to 1 part of ultraviolet light absorbers. The invention further discloses a preparation method of the high-strength cable protection pipe. The high-strength cable protection pipe is easy to prepare, long in service life and excellent in strength.

Owner:合肥市闵葵电力工程有限公司

Mildew-resistant PVC modified material and preparation method therefor

InactiveCN105419169AGood anti-mildew effectImprove temperature resistanceWeather resistancePlasticizer

The invention relates to the PVC material technology field, and concretely relates to a mildew-resistant PVC modified material and a preparation method therefor. The mildew-resistant PVC modified material comprises the following raw materials, by weight, 80-120 parts of PVC resin, 50-70 parts of plasticizer, 20-30 parts of filler, 3-7 parts of heat stabilizer, 1-3 parts of mildew inhibitor, 0.6-1.0 part of synergistic agent and 0.2-0.6 part of lubricant. The above raw materials are employed, the weight ratios of the raw materials are controlled strictly, various performances of the prepared mildew-resistant PVC modified material exceed national standards, and the provided modified material is advantaged by good mildew-resistant effects, environmental protection, excellent temperature resistance, excellent weather resistance, high intensity, excellent shock resistance, good flame retardation effects, excellent processing property and excellent comprehensive properties.

Owner:广东祺龙科技有限公司

Orange peel glass sheet and preparation method thereof

The invention relates to the technical field of plastic sheets, and particularly relates to an orange peel glass sheet and a preparation method thereof. The orange peel glass sheet comprises the following raw materials in parts by weight: 60-100 parts of PVC resin, 30-50 parts of a plasticizer, 1-3 parts of a heat stabilizer, 1-5 parts of a fire retardant, 0.1-0.2 part of an anti-ultraviolet agent and 0.01-0.02 part of ultramarine pigment. The preparation method comprises the following steps of raw materials preparation; agitation at a high speed; primary plasticization; secondary plasticization; hierarchical filtering; calendaring and molding; cooling and rolling; laminating and embossing; and surface treatment. The sheet disclosed by the invention has the advantages of heat resistance, cold resistance, acid resistance, alkaline resistance, ageing resistance, stress resistance, smooth surface, no crack, no bubble, uniform color and luster and strong third dimension, is healthy and environmental friendly, and displays the orange peel effect. The preparation method disclosed by the invention is simple in process, convenient to operate and control, stable in quality and high in production efficiency, and large-scale industrial production can be achieved.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Corrosion-resistant environment-friendly PVC modified material

The invention discloses a corrosion-resistant environment-friendly PVC modified material. The material comprises the following raw materials in parts by weight; 50-70 parts of PVC resin, 20-40 parts of nitrile rubber, 10-15 parts of a filling agent, 2-6 parts of a heat stabilizer, 1-20 parts of a plasticizer, 20-40 parts of an elastic modifier, 2-4 parts of an antioxidant and 3-5 parts of a lubricant, wherein the PVC resin is ethylene-process PVC resin with a polymerization degree of 1000 to 1200 and a density of 1.35 to 1.45 g / cm<3>; the filling agent is one of calcium carbonate, argil, talcum powder, diatomite and silicon dioxide; the heat stabilizer is prepared from a main stabilizer, an auxiliary stabilizer and an auxiliary agent according to a weight ratio of (20-40): (4-8): 1; the plasticizer is a mixture composed of a non-migration plasticizer PN-1030 and epoxidized soybean oil according to a weight ratio of (13-16): 1; and the elastic modifier is expanded polystyrene with a glass transition temperature of 80-90 DEG C and a density of 1.04-1.06 g / cm<3>. The material has the characteristics of capability of preventing photolysis and thermal decomposition, good elasticity, high tensile strength, good plasticity, good low temperature resistance, environment friendliness and high oxidation and corrosion resistance, and materials of all the components are convenient to obtain.

Owner:浙江金羿高分子科技有限公司

High strength plastic steel tile and preparation method thereof

InactiveCN107418094AImprove adhesionGood oil resistanceRoof covering using tiles/slatesPolyesterFiber

The invention discloses a high strength plastic steel tile and belongs to the technical field of plastic steel tiles. The high strength plastic steel tile comprises the following raw materials in parts by weight: 60-70 parts of polyvinyl chloride resin, 20-30 parts of polyacrylic resin, 8-12 parts of urea resin, 5-7 parts of nitrile rubber, 5-8 parts of light calcium carbonate, 4-5 parts of diatom ooze, 3-6 parts of polyester fibers, 1-4 parts of steel fibers, 4-5 parts of titanium dioxide, 1-3 parts of a heat stabilizer, 2-3 parts of a lubricant, 0.5-1 part of an ACR processing modifier, 6-10 parts of a CPE impact modifier, 0.5-1 part of a light stabilizer and 0.5-0.8 part of a flourescent brightener. The invention also discloses a preparation method of the high strength plastic steel tile. The high strength plastic steel tile disclosed by the invention is simple to prepare and has relatively excellent physical strength and sound-isolating effect.

Owner:温州月煌科技有限公司

Rat-proof PVC (polyvinyl chloride) modified material and preparation method thereof

The invention relates to the technical field of PVC (polyvinyl chloride) materials, in particular to a rat-proof PVC modified material and a preparation method thereof. The rat-proof PVC modified material comprises raw materials in parts by weight as follows: 80-120 parts of PVC resin, 45-65 parts of a plasticizer, 25-45 parts of a filling agent, 3-7 parts of a heat stabilizer, 2-4 parts of an impact modifier, 0.8-1.6 parts of a rat proof agent, 0.6-1.0 part of a lubricating agent and 0.3-0.7 parts of other aids. According to the rat-proof PVC modified material, each property of the prepared rat-proof PVC modified material exceeds the national standard with the adoption of the raw materials and through strict control of the weight ratio of the raw materials, the rat proof effect is good, and the rat-proof PVC modified material is environment-friendly and has excellent temperature resistance and weather fastness, high strength, excellent impact resistance, good flame retardant effect, excellent processing performance and excellent overall performance.

Owner:广东祺龙科技有限公司

Polyvinyl chloride cable material resistant to heat and shock

InactiveCN106117895AHigh tensile strengthHigh tear strengthPlastic/resin/waxes insulatorsPolyvinyl chlorideShock resistance

The invention discloses a polyvinyl chloride cable material resistant to heat and shock. The polyvinyl chloride cable material resistant to heat and shock is prepared from polyvinyl chloride, polyurethane, bisphenol-A polycarbonate, poly (tetramethylene succinate), di (2-ethylbutanoic acid) triuret gylcol ester, 2-ethylhexyl epoxystearate, montmorillonite, ammonium heptamolybdate, kaolin, aluminum hydroxide, magnesium hydroxide whisker, antioxidant, 1-azyl-4-methyl piperazine, tri methylol propane tri methacrylate, bisferrocene-base acetylene and a heat stabilizer. The heat stabilizer is prepared through mixing of rhenium complex, cerous carbonate, tribasic lead sulfate, bisphenol A diglycidyl ether, epoxy butyl stearate, lanthanum stearate, glyzinc, aceticacid,2,2',2''-[(octylstannylidyne)tris(thio)]tris-,triisooctylester, mannitol and 2,5-diphenyl-1,3,4-oxadiazole. The polyvinyl chloride cable material has high strength, heat resistance and shock resistance, is resistant to bending and torsion, and has a long service life.

Owner:ANHUI ELECTRIC GRP SHARES

High-flame-retardant PVC product containing hyperbranched polymer

InactiveCN111793307AFast plasticizing speedEffect on physical propertiesPOLYETHYLENE WAXPolymer chemistry

The invention belongs to the field of PVC products, and particularly discloses a high-flame-retardant PVC product containing a hyperbranched polymer. The high-flame-retardant PVC product containing the hyperbranched polymer, disclosed by the invention, contains 90 to 110 parts by weight of a polyvinyl chloride resin, 20 to 40 parts of dioctyl terephthalate, 30 to 50 parts of light calcium carbonate, 20 to 30 parts of hydroxide, 3 to 5 parts of a calcium-zinc stabilizer, 0.3 to 0.7 part of polyethylene wax and 1 to 3 parts of a hyperbranched polymer. According to the invention, the hyperbranched polymer is used as an additive and is added into the PVC product containing a large amount of magnesium hydroxide / aluminum hydroxide, so that the plasticizing speed of the PVC product is effectivelyincreased, the flowability of the PVC product melt is obviously improved, and the physical properties of the PVC product are not influenced.

Owner:HUIZHOU AIMSEA NEWWAY TECH CO LTD

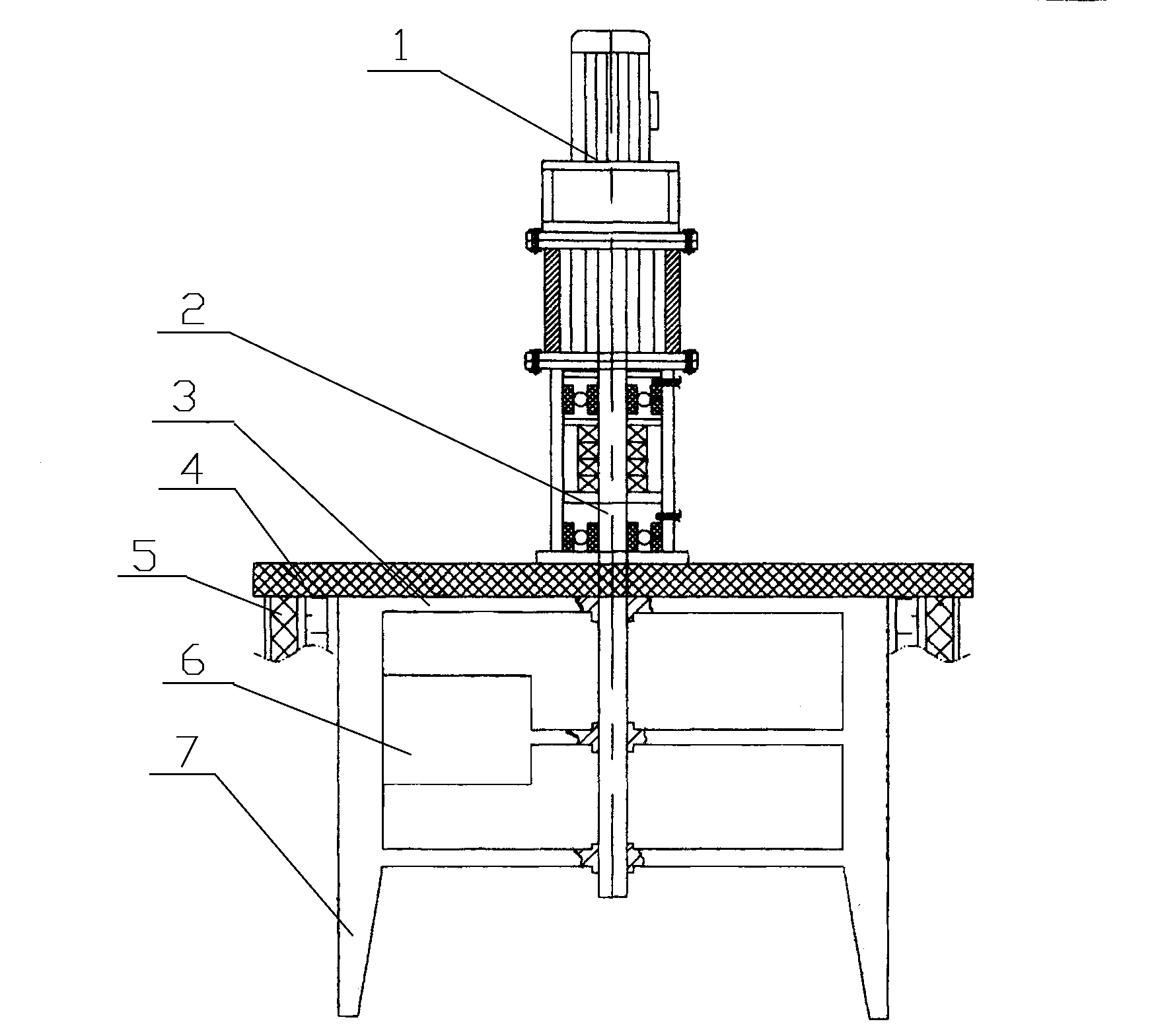

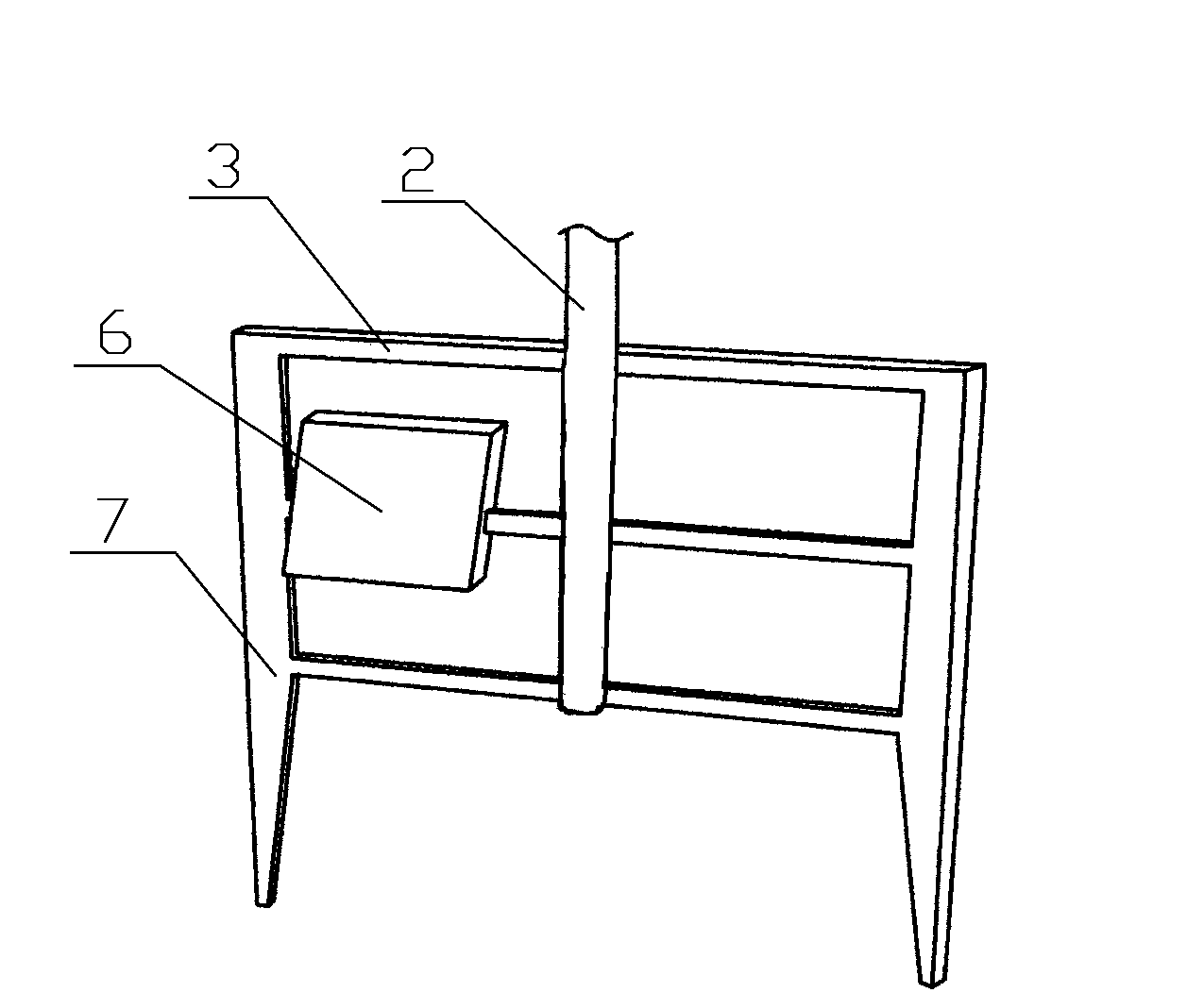

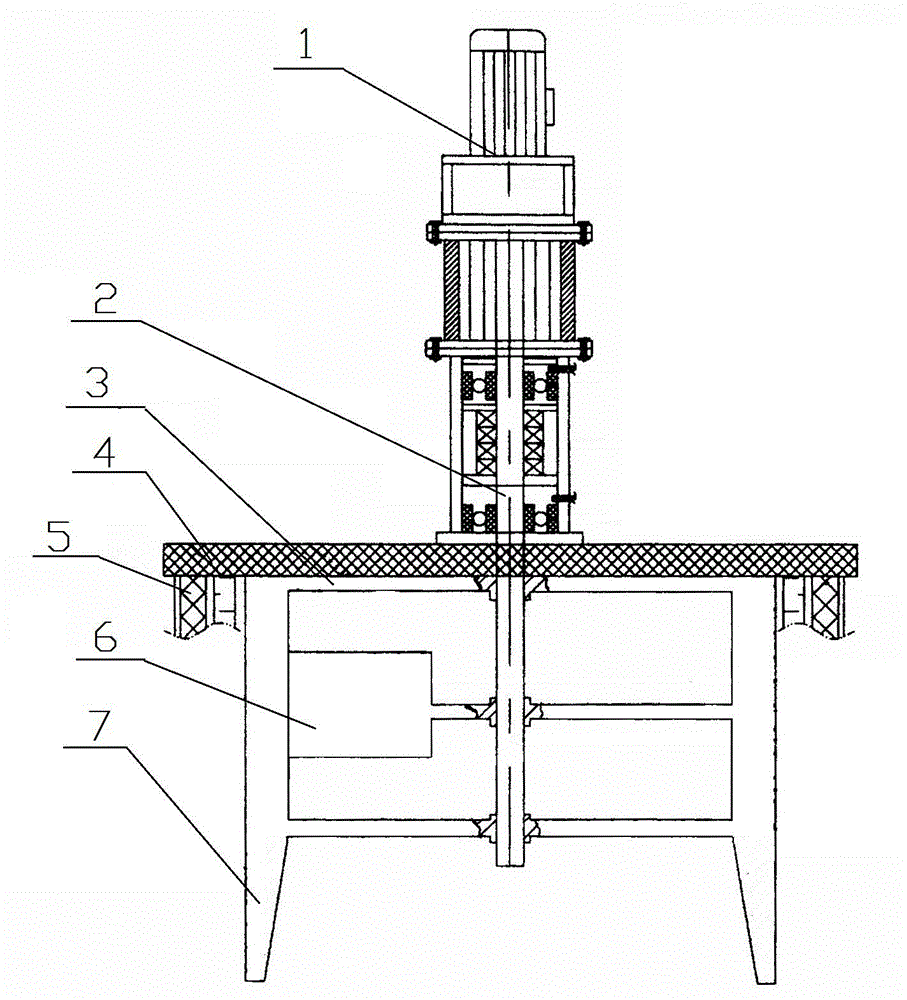

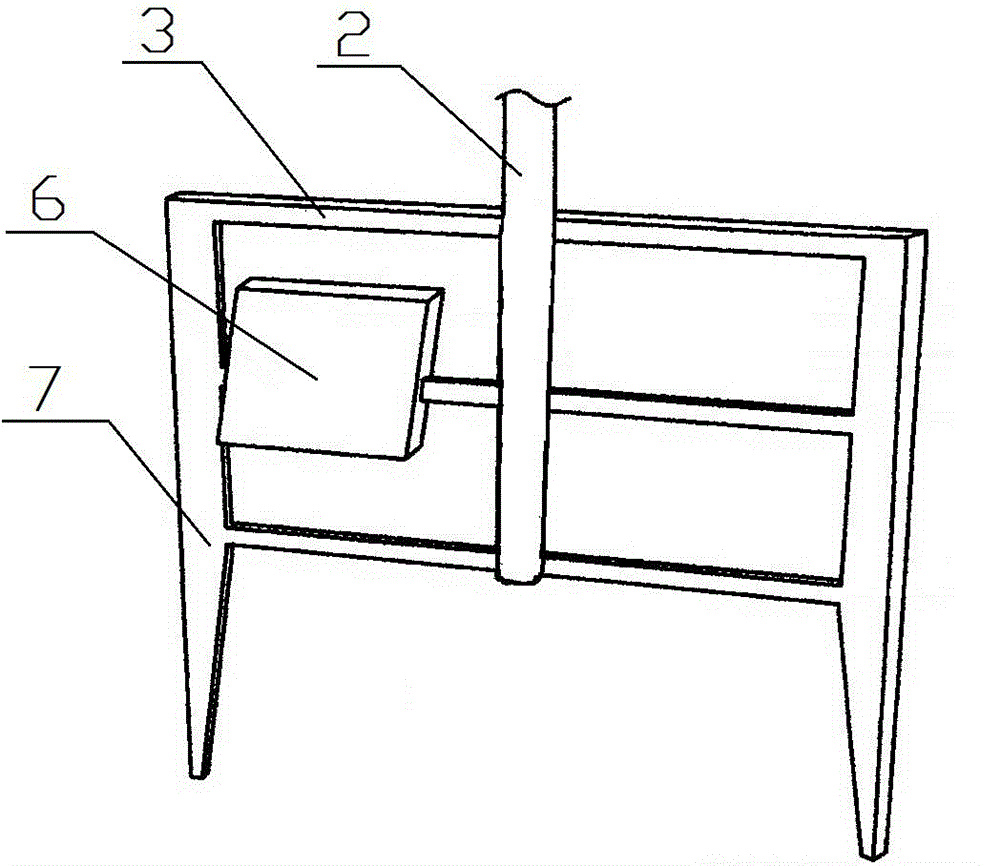

Multifunctional flow guider

InactiveCN103304842AEvenly heatedImprove plasticizing qualityPlastic recyclingVertical planeDrive shaft

The invention discloses a multifunctional flow guider. A driving shaft driven by a speed reducing motor is arranged on a head cover of a desulfuration tank, a flow guider is arranged on the driving shaft which extends into the desulfuration tank, the flow guider has the structure that the upper part of the driving shaft is provided with symmetrical horizontal scratch boards, the top surfaces of the horizontal scratch boards are matched with the inner wall of the head cover of the desulfuration tank, the outer ends of the horizontal scratch boards are respectively and fixedly connected with a vertical scratch board, the outer side faces of the vertical scratch boards are matched with the inner wall of a cylinder of the desulfuration tank, the inner side of one vertical scratch board is connected with a turbulent flow board having an inclined angle with the vertical plane, the middle of the driving shaft is provided with symmetrical horizontal support arms, one straight support arm is connected with the vertical scratch boards, the other support arm is connected with the turbulent flow board, and the symmetrical support arms arranged at the lower part of the driving shaft are respectively connected with the vertical scratch boards. After the multifunctional flow guider is used, waster rubber powder in the desulfuration tank can quickly rotate and can be rubbed with one another to generate heat under the action of the flow guider, and the track of the rotating rubber powder can be changed in a flow guide way, so that the rubber powder can be evenly heated, the plastification speed can be increased, the multifunctional flow guider is low in energy consumption, and the production cost can be reduced.

Owner:武时家

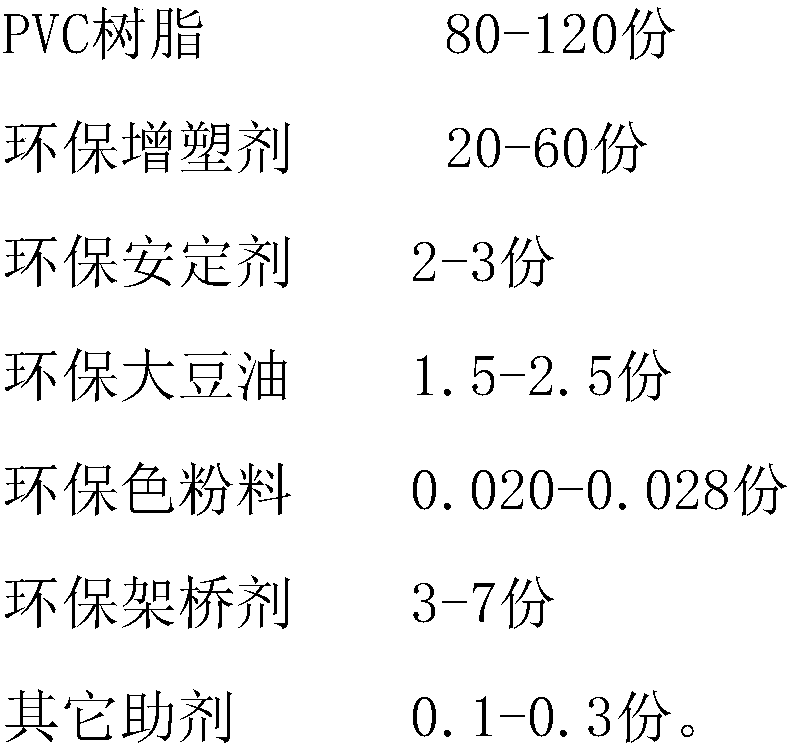

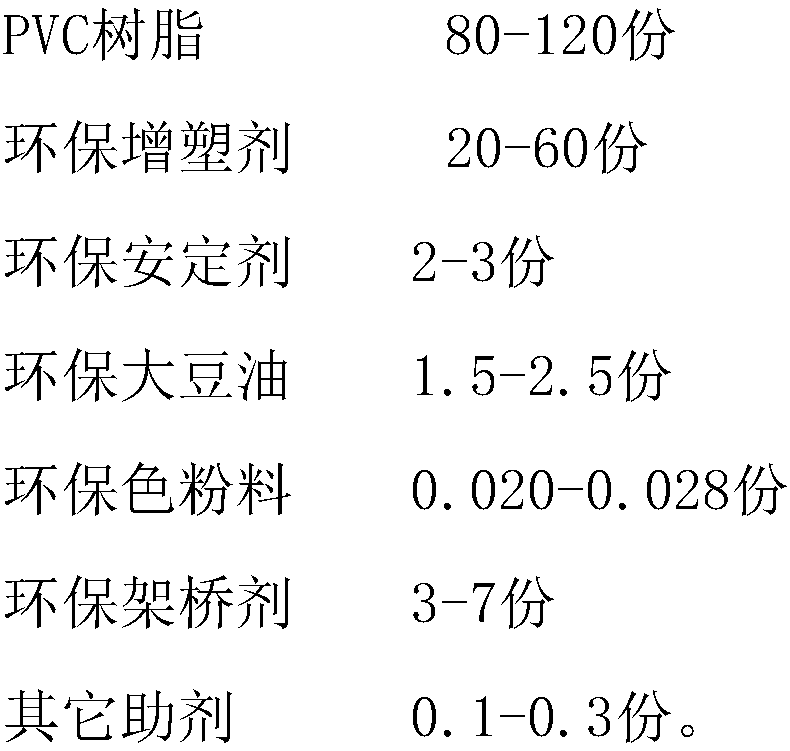

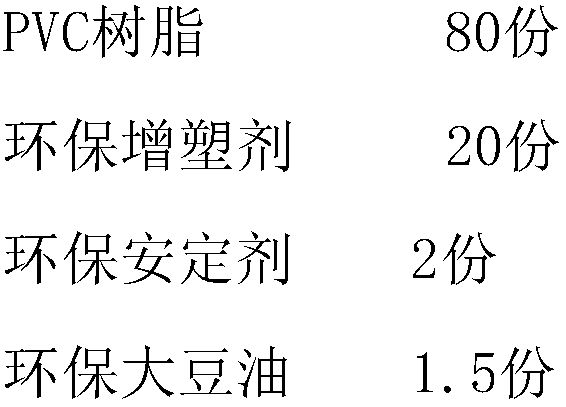

Food-grade polyvinyl chloride film and calendaring process thereof

InactiveCN107698891AFeel goodImprove visual effectsFlat articlesEnvironmental resistancePolyvinyl chloride

The invention relates to the technical field of films, in particular to a food-grade polyvinyl chloride film and a calendaring process thereof. The food-grade polyvinyl chloride film is prepared from,by weight, 80-120 parts of PVC (polyvinyl chloride) resin, 20-60 parts of an environment-friendly plasticizer, 2-3 parts of an environment-friendly stabilizing agent, 1.5-2.5 parts of environment-friendly soybean oil, 0.020-0.028 part of environment-friendly toner, 3-7 parts of an environment-friendly bridging agent and 0.1-0.3 part of other additives. The food-grade polyvinyl chloride film is environmentally friendly, great in handfeel and visual effects and excellent in ultraviolet resistance and water resistance and has advantages of flame retardation, insulation, alkali and acid resistance, cold and mould proofing, corrosion resistance, static resistance, tensile resistance, aging resistance and the like, thereby being excellent in comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

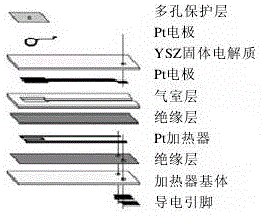

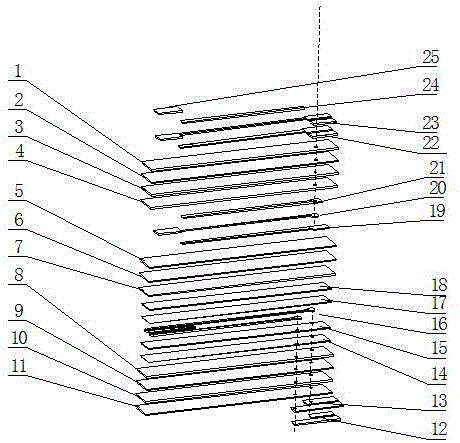

Novel chip type potentiometric automobile oxygen sensor and preparation method thereof

PendingCN106706743ACompact structureReduce volumeMaterial analysis by electric/magnetic meansPunchingOxygen sensor

The invention relates to a novel chip type potentiometric automobile oxygen sensor. The sensor comprises a protective layer, a signal layer and a heating layer, which are sequentially superposed, wherein the signal layer comprises seven layers of tape casting substrates which are sequentially laminated, the protective layer, an upper reactive electrode insulating layer, an outer reactive electrode and a lower reactive electrode insulating layer are sequentially arranged on the upper surface of the first layer of tape casting substrate from top to bottom, and an upper reference reactive electrode insulating layer, a reference reactive electrode and a lower reference reactive electrode insulating layer are sequentially arranged on the lower surface of the fourth layer of tape casting substrate from top to bottom; the heating layer comprises fourth layers of tape casting substrates which are sequentially laminated, and a heating electrode and a heating electrode pin are respectively arranged on the upper surface of the uppermost layer of tape casting substrate and the lower surface of the lowermost layer of tape casting substrate. The sensor is prepared by preparation of multiple kinds of tape casting slurry, tape casting forming, edge removal slitting, punching, printing, superposition, vacuum sealing molding, hot isostatic pressing, slitting and sintering. The oxygen sensor has the advantages of being more stable in performance and higher in production consistency.

Owner:莱鼎电子材料科技有限公司

PVC (polyvinyl chloride) profile for anti-cracking impact-resistant back net reinforcing ribs and treatment technique thereof

The invention discloses a PVC (polyvinyl chloride) profile for anti-cracking impact-resistant back net reinforcing ribs, which comprises a PVC substrate and a reinforcing agent. The reinforcing agent is composed of the following components in parts by weight: 5-10 parts of high-efficiency impact modifier based on acrylic ester polymer, 0.5-1 part of organotin stabilizing agent, 1-1.5 parts of light calcium carbonate, 0-0.5 part of active calcium, 0.05-0.1 part of toughener, 3 parts of chlorinated polyethylene, 0.08 part of oxidized wax, 0.3 part of polyethylene wax, 0.6-0.9 part of organic wax and 0.1-0.3 part of modifier. Ethyl silicate and heat-resistant pigment and filler are added into the modifier. The heat-resistant pigment and filler comprises nano smectite silicate and blocking functional filler in a mass ratio of 1.5:1:1. Compared with the prior art, the PVC profile for anti-cracking impact-resistant back net reinforcing ribs effectively reduces the problem of cracking of the reinforcing ribs due to long-time usage, and enhances the cracking resistance and impact resistance of the reinforcing ribs.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

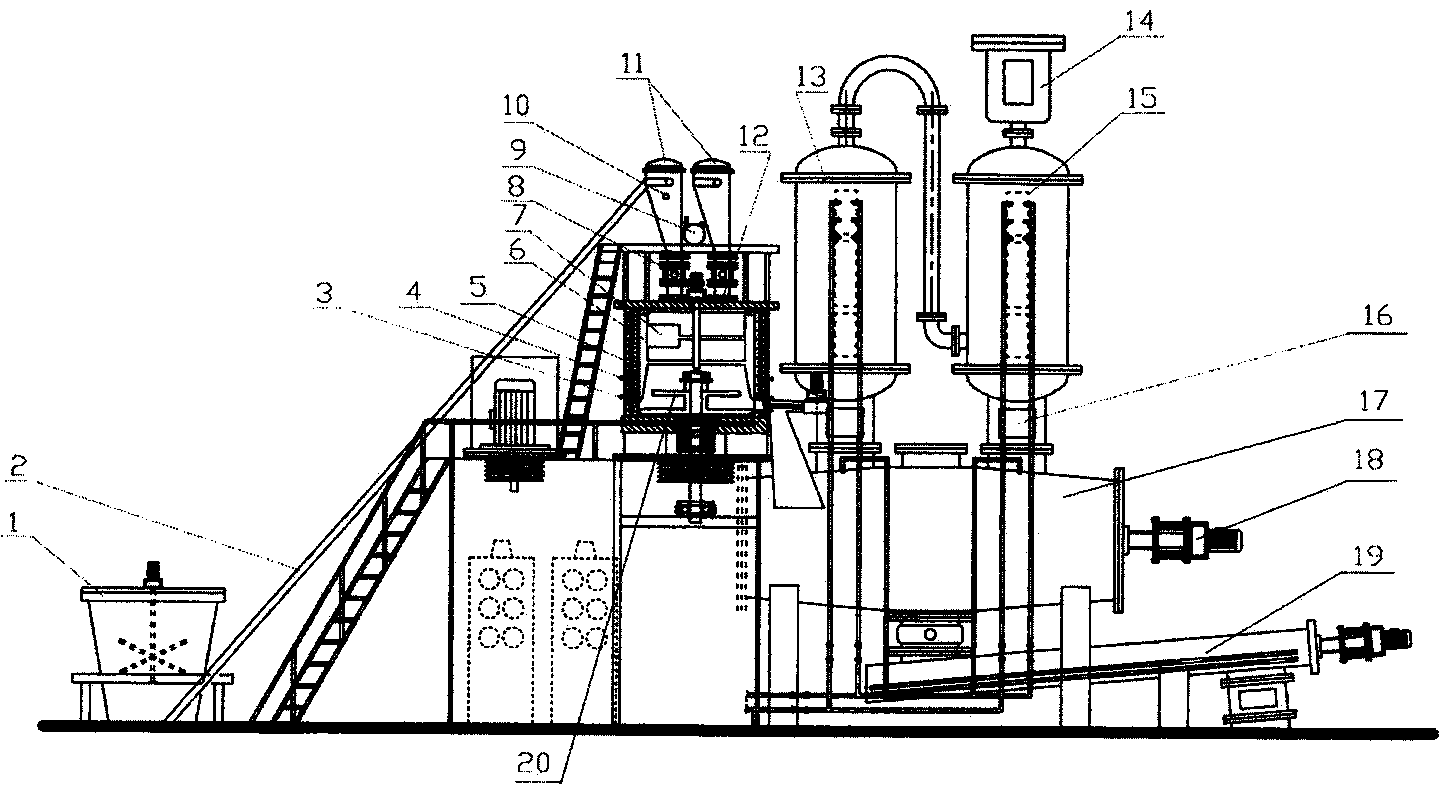

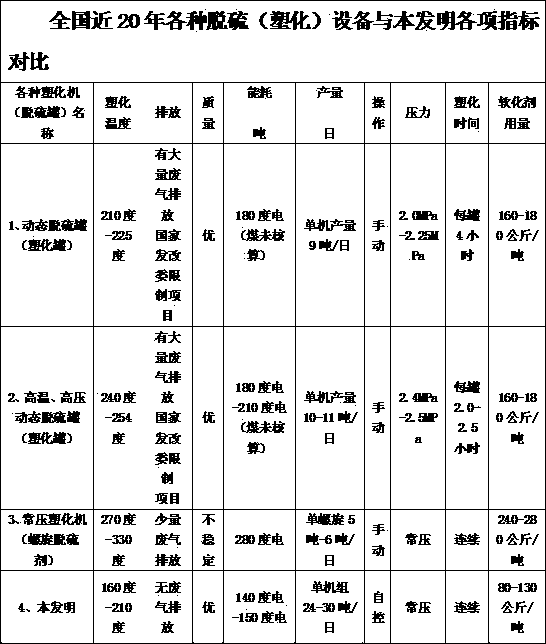

Intelligent environment-friendly constant-pressure medium-temperature fast rubber plasticizing unit

InactiveCN103408790AFast plasticizing speedReduce energy consumptionChemical industryPlastic recyclingExhaust gasScrew conveyor

The invention discloses an intelligent environment-friendly constant-pressure medium-temperature fast rubber plasticizing unit, wherein the outlet of a pre-treatment tank is connected with an airtight storage tank installed on a frame, the outlet of the airtight storage tank connected with a vacuum feeding device driven by a motor is connected with a feed inlet of a waste rubber friction plasticizing reaction kettle through an airtight feeding valve, heating oil is arranged in an interlayer of the tank body of the reaction kettle, the material outlet of the reaction kettle is connected with a cooling tank through the airtight feeding valve, and air outlets uniformly distributed on the upper tank body of the cooling tank are respectively connected with a first-level exhaust treatment tank and a second-level exhaust treatment tank. The outlet at the top of the first-level exhaust treatment tank is connected with the inlet of the side wall of the second-level exhaust treatment tank through a pipeline, the outlet of the second-level exhaust treatment tank is connected with a third-level exhaust treatment tank, and the material outlet at the lower part of the cooling tank is connected with a cooling screw conveyer through the airtight feeding valve. Regenerated rubber is produced in a totally airtight condition in a dry state without wastewater and exhaust gas, so that the unit is high in production efficiency, energy-saving and environment-friendly.

Owner:武时家

Environment-friendly calcium-zinc compound stabilizer

The invention relates to an environment-friendly calcium-zinc composite stabilizer, which is characterized in that composite calcium stearate zinc soap, a chelating agent, a nano co-stabilizer, a lubricant and an antioxidant are taken as raw materials of the stabilizer, and the mixture ratio of the raw materials is as follows: 15 to 40 percent of the composite calcium stearate zinc soap, 14 to 20 percent of the chelating agent, 28 to 40 percent of the nano co-stabilizer, 15 to 20 percent of the lubricant, and 3 to 5 percent of the antioxidant. A composite calcium-zinc organic substance is formed by reaction of a nano organic auxiliary thermal stabilizer, an organic substance with chelating function, and calcium-zinc ions. The environment-friendly calcium-zinc composite stabilizer has strong commonality, quick plasticizing speed, smooth and bright surface, is nonmigratory, ageing-resistant and not tarnishable, and can be applied to various white PVC products.

Owner:HANGZHOU OIL & FAT CHEM

CPVC power cable protecting tube and preparation method thereof

InactiveCN107254129AImprove mechanical propertiesGuaranteed high temperature performanceFiberCarbon fibers

The invention discloses a CPVC power cable protecting tube and belongs to the technical field of protecting tubes. The CPVC power cable protecting tube comprises the following raw materials in parts by weight: 60-70 parts of CPVC resin, 8-10 parts of methacrylic-butadiene-styrene ternary copolymerized resin, 11-15 parts of polyether-ether-ketone, 12-14 parts of poly para phenylene benzo bioxazole fibers, 9-11 parts of carbon fibers, 15-17 parts of calcium carbonate, 7-9 parts of silicon dioxide, 3-6 parts of glass-ceramic powder, 5-7 parts of aluminium oxide, 2-4 parts of white oil, 1-5 parts of ethylene bis stearamide, 7-9 parts of a CPE impact modifier, 6-10 parts of an ACR processing aid, 13-17 parts of a plasticizer, 1-4 parts of a heat stabilizer and 1-2 parts of an ultraviolet adsorbent. The invention also discloses a preparation method of the CPVC power cable protecting tube. The CPVC power cable protecting tube disclosed by the invention is excellent in mechanical strength and has relatively excellent high-temperature flame retardance.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Method for preparing multi-functional rubber additives by recycling alkali reduction processing drainage liquid

ActiveCN104829879BFast plasticizing speedImprove anti-reversion performanceActivated carbon filtrationChloride

Owner:江苏爱特恩高分子材料有限公司

Multifunctional flow guider

InactiveCN103304842BEvenly heatedImprove plasticizing qualityPlastic recyclingVertical planeDrive shaft

The invention discloses a multifunctional flow guider. A driving shaft driven by a speed reducing motor is arranged on a head cover of a desulfuration tank, a flow guider is arranged on the driving shaft which extends into the desulfuration tank, the flow guider has the structure that the upper part of the driving shaft is provided with symmetrical horizontal scratch boards, the top surfaces of the horizontal scratch boards are matched with the inner wall of the head cover of the desulfuration tank, the outer ends of the horizontal scratch boards are respectively and fixedly connected with a vertical scratch board, the outer side faces of the vertical scratch boards are matched with the inner wall of a cylinder of the desulfuration tank, the inner side of one vertical scratch board is connected with a turbulent flow board having an inclined angle with the vertical plane, the middle of the driving shaft is provided with symmetrical horizontal support arms, one straight support arm is connected with the vertical scratch boards, the other support arm is connected with the turbulent flow board, and the symmetrical support arms arranged at the lower part of the driving shaft are respectively connected with the vertical scratch boards. After the multifunctional flow guider is used, waster rubber powder in the desulfuration tank can quickly rotate and can be rubbed with one another to generate heat under the action of the flow guider, and the track of the rotating rubber powder can be changed in a flow guide way, so that the rubber powder can be evenly heated, the plastification speed can be increased, the multifunctional flow guider is low in energy consumption, and the production cost can be reduced.

Owner:武时家

A kind of insulating environment-friendly PVC modified material and preparation method thereof

The invention relates to the technical field of PVC modified materials and particularly relates to an insulating and environment-friendly PVC modified material and a preparation method thereof. The insulating and environment-friendly PVC modified material contains the following raw materials: 80-120 parts of PVC resin, 40-60 parts of bulking agent, 40-60 parts of plasticizer, 10-15 parts of insulation modifier, 3-7 parts of heat stabilizer and 0.5-1.5 parts of lubricant, wherein the plasticizer is a mixture prepared from dioctyl terephthalate and tri-n-butyl citrate which are in the weight ratio of (5-7): 1; the insulation modifier is a mixture prepared from kaolin, titanium white and glass micro-beads which are in the weight ratio of (2-4): (1.5-2.5): 1, and the particle size of the glass micro-beads is smaller than 20 microns. According to the modified material prepared by the preparation method, all properties exceed the national standards, the insulating property is good, the resistivity reaches up to 5.1*10<14> omega, and the modified material is environment-friendly; the preparation method disclosed by the invention is simple in process, convenient in operation and control, stable in quality and high in production efficiency and can be applied to large-scale industrial production.

Owner:广东祺龙科技有限公司

Impact-resistant modified polyvinyl chloride tubular product for supplying water

InactiveCN102627815BHigh impact strengthReduce the effect of rigidityRigid pipesWhitening AgentsPolyvinyl chloride

The invention relates to an impact-resistant modified polyvinyl chloride tubular product for supplying water. The tubular product comprises the following components in parts by weight: 100 parts of polyvinyl chloride, 5-10 parts of an efficient impact-resistance modifier based on an acrylic ester polymer, 0.5-1 part of an organic tin stabilizer, 1-1.5 parts of light calcium carbonate, 0-0.5 part of active calcium, 0-0.1 part of a toughening agent, 3 parts of chlorinated polyethylene, 0.08 part of oxidized paraffin, 0.5-0.8 part of a fluorescent whitening agent, 0.3 part of polyethylene wax, 0.5-1 part of organic wax, 0-0.3 part of a modifier, 0-0.25 part of a ground material and 0.2 part of carbon black. The impact-resistant modified polyvinyl chloride tubular product for supplying water provided by the invention has high strength, high toughness and cracking resistance, can be applied in various fields, and has a wide popularization range.

Owner:新疆通利塑业有限公司

Rat-bite-preventing special power pole tower formula

The invention relates to the technical field of power pole towers, and concretely discloses a rat-bite-preventing special power pole tower formula, which is prepared from the following raw materials in parts by weight: 100 parts of SG resin, 2 to 4 parts of tribasic lead sulfate, 35 to 45 parts of nanometer calcium carbonate, 0.5 to 1.5 parts of dibasic lead phosphite, 1 to 2 parts of DOP, 1 to 3parts of epoxidized soybean oil, 1 to 2 parts of metallic soap, 1.5 to 2 parts of triphenyl phosphite, 0.2 to 0.6 part of triazine-5UV-9, 0.3 to 0.8 part of polyethylene wax, 2 to 4 parts of ACR, 4 to6 parts of CPE, 3 to 5 parts of calcium carbonate, 0.7 to 1.5 parts of capsaicine, 2 to 6 parts of O-isopropylphenyl methyl carbamate and 1 to 2 parts of 2-dimethyl cyclopropane carboxylate. The formula provided by the invention overcomes the defects in the prior art; rat-repelling ingredients prepared from the capsaicine, the O-isopropylphenyl methyl carbamate and the 2-dimethyl cyclopropane carboxylate are added; nontoxicity and harmlessness are realized; the environment pollution cannot occur; for the best advantage, rat repelling effects can be achieved; the plastic power pole tower is prevented from being bit by rats.

Owner:HEFEI HAIYIN TOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com