Novel chip type potentiometric automobile oxygen sensor and preparation method thereof

An automotive oxygen sensor and sensor technology, which is applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of high molding cost, complex gas chamber layer structure, inconvenient miniaturization of oxygen sensors, etc., and achieve good production consistency and shorten the starting time. burning time, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

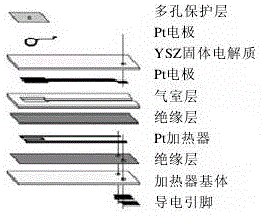

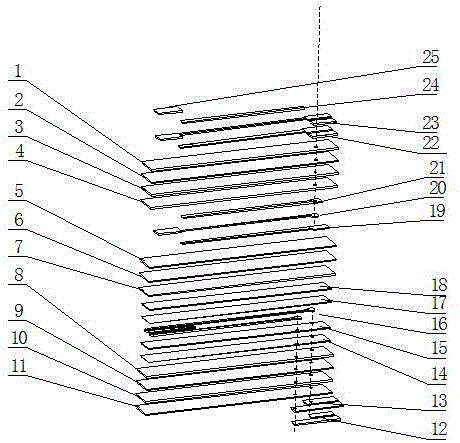

[0048] The new chip concentration type automobile oxygen sensor of this embodiment, as figure 2 As shown, the sensor includes a protective layer, a signal layer and a heating layer that are sequentially stacked from top to bottom and then sintered;

[0049] The signal layer includes the first layer of cast substrate 1, the second layer of cast substrate 2, the third layer of cast substrate 3, the fourth layer of cast substrate 4, and the fifth layer stacked sequentially from top to bottom. Casting substrate 5, the sixth layer of casting substrate 6 and the seventh layer of casting substrate 7, an external reaction electrode 23 is arranged on the upper surface of the first layer of casting substrate 1, and the upper surface of the external reaction electrode 23 An upper outer reaction electrode insulating layer 24 and a lower outer reaction electrode insulating layer 22 are respectively arranged on the lower surface, and a protective layer 25 is also laminated on the upper sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com