Patents

Literature

95results about How to "Good product consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

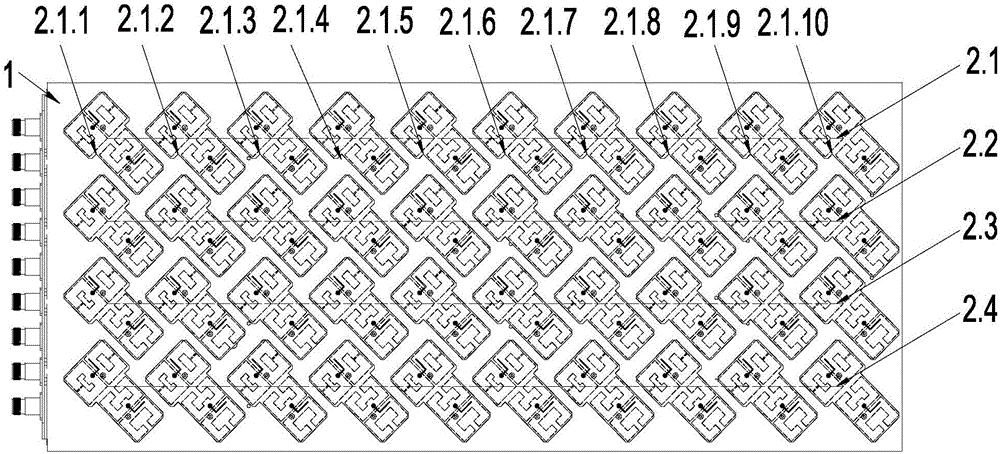

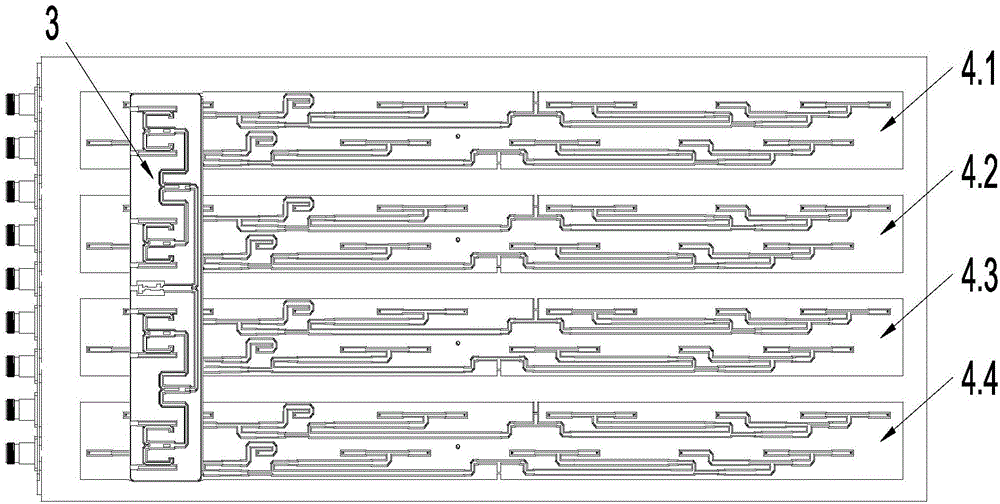

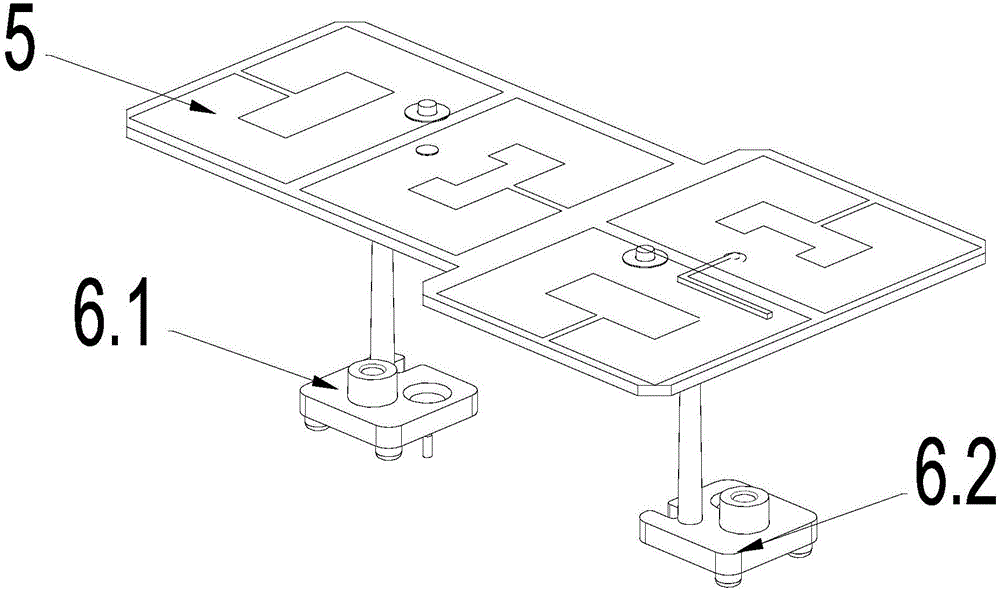

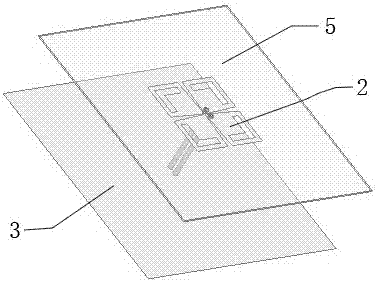

Small-scale LTE multi-array antenna

InactiveCN106329116AGuaranteed network performanceShorten the lengthParticular array feeding systemsIndividually energised antenna arraysElectricityStrong coupling

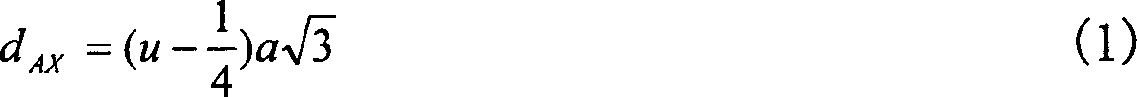

The invention provides a small-scale LTE multi-array antenna. In the small-scale LTE multi-array antenna, each radiation unit comprises a dual-polarized oscillator and baluns, the dual-polarized oscillator comprises two separate dipoles, each feeding network employs a planar structure, feeding points between network ports are located in the same horizontal line, and the radiation units are placed by employing a strong coupling mode. According to the antenna, the strong-coupling radiation unit technology is employed, the spacing between the radiation units is shortened, and the length of the whole antenna is shorter; the low-profile radiation units are employed so that the height of the antenna is reduced, the overall size of the antenna is only 50% of the size of the same kind of product through comprehensive effect, the occupation of the antenna space is greatly reduced, and the gain of unit arrays is high; and the feeding networks with the integrated planar structures are employed so that the amplitude and the phase precision are high. According to the antenna, excellent performance of mobile communication can be guaranteed.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

Low temperature coefficient, low loss and high saturated flux density ferrite material and preparing method

InactiveCN1587193AReduce lossLow costInorganic material magnetismVolumetric Mass DensityRepeatability

The present invention discloses one kind of ferrite material with low temperature coefficient, low loss and high saturated flux density and its preparation process. It is mainly spinel type structure and consists of Fe2O3 45-52 mol%, ZnO 20-35 mol%, CuO 5-15 mol%, MnO 1-3 mol%, and NiO 10-18 mol%. The preparation process includes the following steps: mixing material; pre-sintering; adding impurity; secondary ball milling; forming and sintering. The ferrite material has CuO and Mn3O4 to replace NiO and thus lowered material cost, lower pre-sintering temperature and sintering temperature and thus low power consumption, low requirement in sintering apparatus and low production cost; relatively wide pre-sintering temperature range and sintering temperature range, no need of protecting atmosphere, high technological repeatability and product consistency.

Owner:ZHEJIANG UNIV

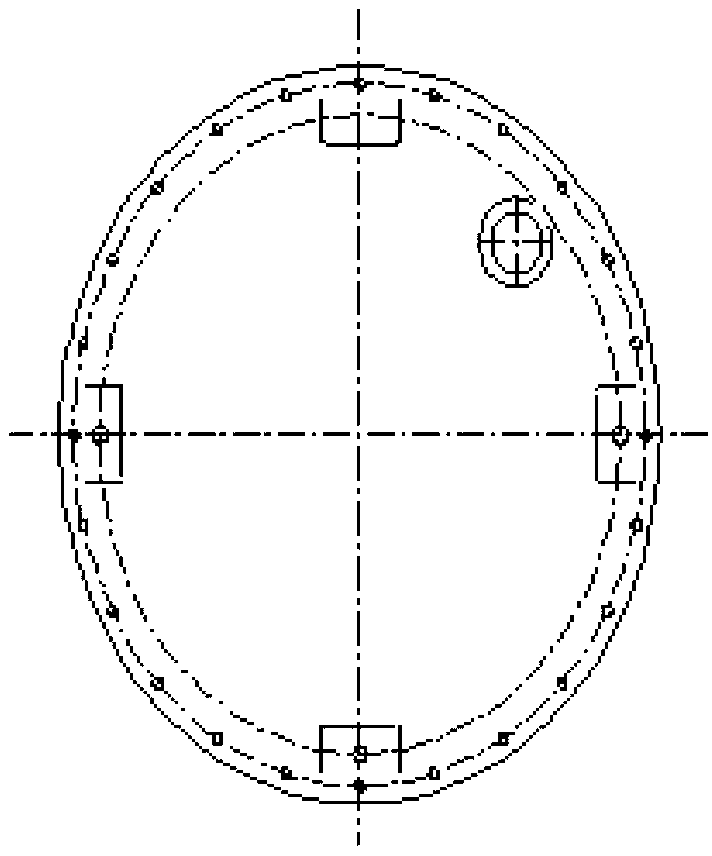

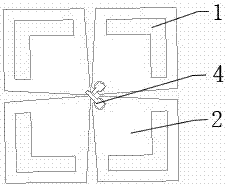

Microstrip coupled radiation unit for broadband dual-polarized directional base station antenna

InactiveCN101916902AGuaranteed communication qualityGood electrical performanceAntenna supports/mountingsRadiating elements structural formsCommunication qualityCoupling

The invention discloses a microstrip coupled radiation unit for a broadband dual-polarized directional base station antenna. The unit comprises a reflecting bottom plate, a feed baron and radiating arms fixed on the reflecting bottom plate, wherein the number of the radiating arms is four; every two of the four radiating arms are opposite to each other to form a symmetrical vibrator; the two groups of formed symmetrical vibrators are arranged in a cross shape; and the feed baron is fixed with the radiating arms so as to feed the vibrators in a coupling mode through an insulated fixing device. The microstrip coupled radiation unit has excellent gain, standing wave, isolation, cross polarization, third-order intermodulation and other electric properties. Therefore, the communication quality in a service area can be well guaranteed from the aspect of antennas.

Owner:JIANGSU JST TECH

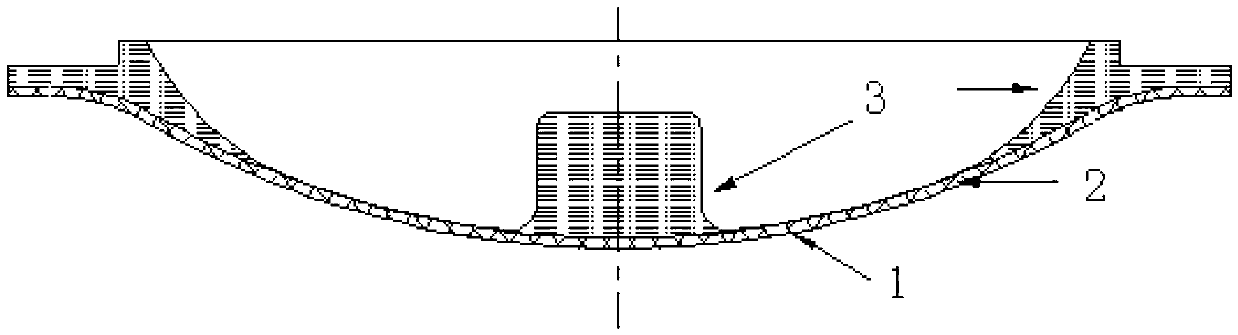

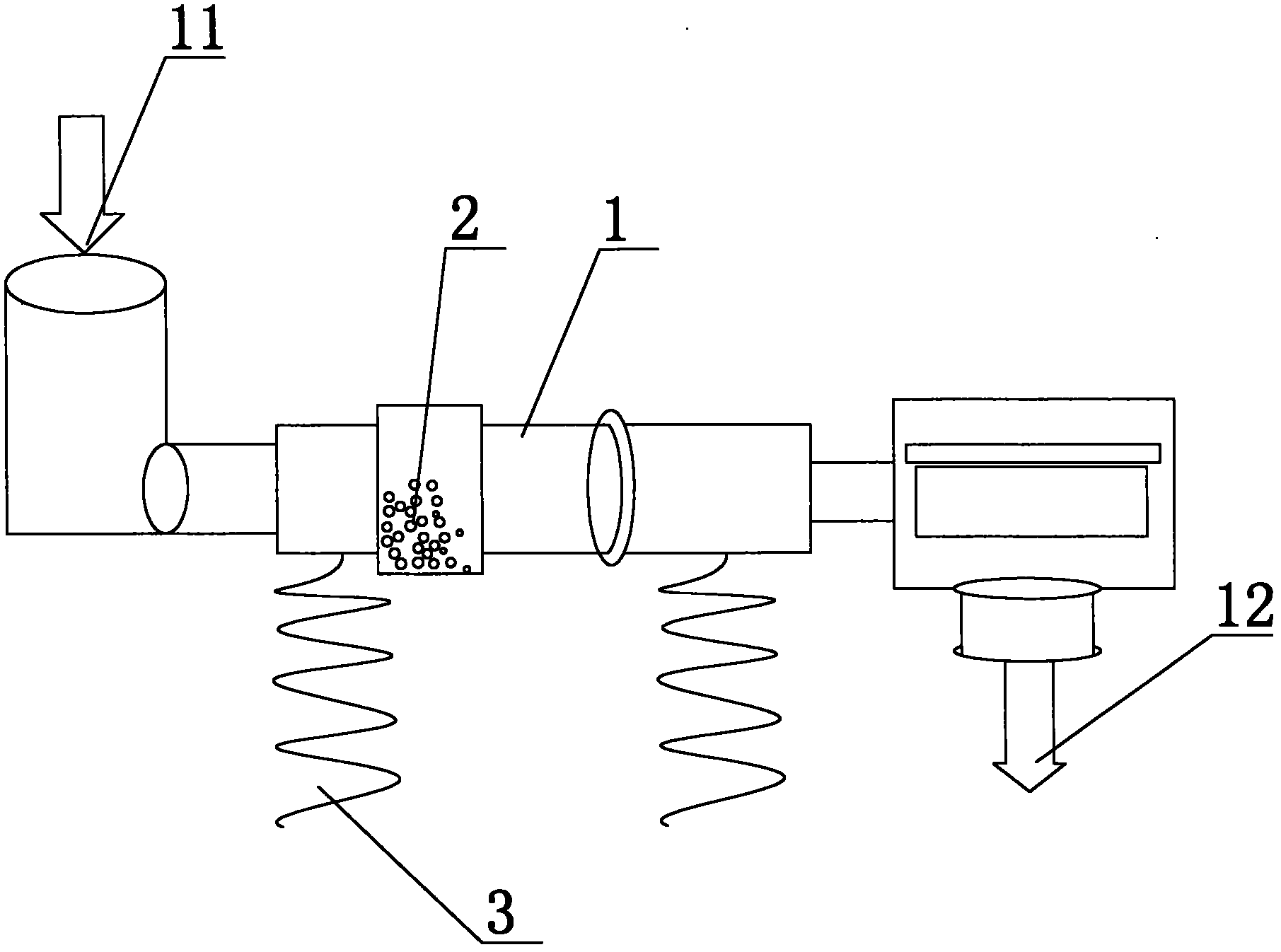

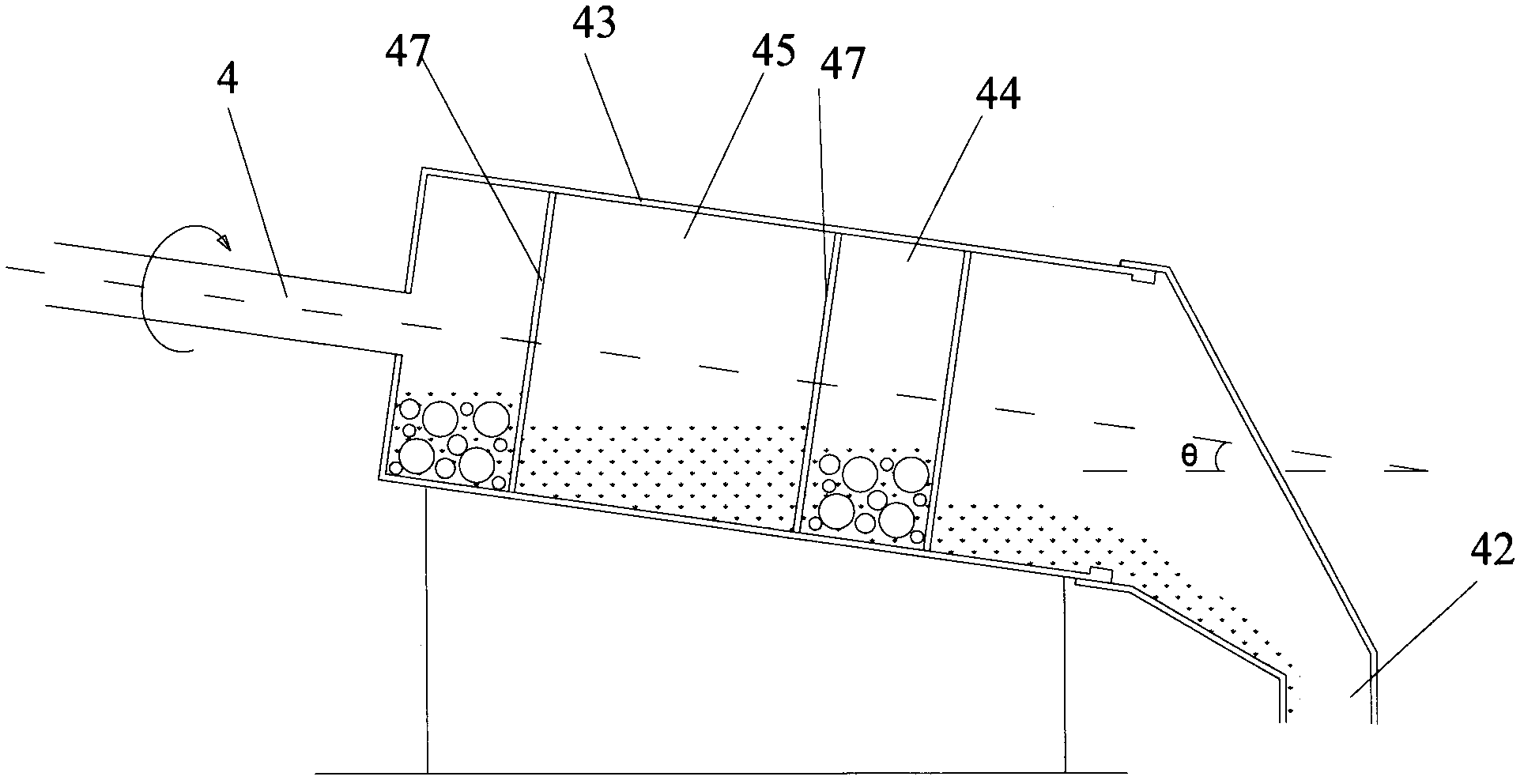

Material distribution technology of one-time forming brazing super-hard material grinding tool

ActiveCN103522206AGood effectSimple and fast operationBonded abrasive wheelsGrinding devicesWear particleMetallurgy

The invention discloses a material distribution technology of a one-time forming brazing super-hard material grinding tool. The material distribution technology includes the following steps that firstly, composite pellets are prepared for standby application, the peripheries of abrasive particles are coated with solder layers to form a composite body, and the periphery of the composite body is coated with a paraffin layer to form composite pellets; secondly, the surface of a base body is cleaned; thirdly, a material distribution area of the surface of the base body is brushed and coated with binding agents; fourthly, the composite pellets are spread in the material distribution area, obtained in the third step, of the surface of the base body, the composite pellets are tightly distributed and stuck to the material distribution area of the surface of the base body so that semi-finished products can be obtained; fifthly, the surfaces of the semi-finished products are cleaned, and the semi-finished products are prepared to be welded. According to the material distribution technology of the one-time forming brazing super-hard material grinding tool, due to the fact that the abrasive particles and solder are matched according to a certain relation and made into the composite body according to a particle preparing technology, a layer of paraffin coats the outer face of the composite body to form the composite pellets, and therefore the material distribution technology is greatly simplified; use of material distribution equipment is combined, stability of the quality of brazing is ensured, and industrial production operation is facilitated. According to the designed scheme, adaptability to workpieces is good, the brazing quality is stable, and the material distribution technology is suitable for industrial production.

Owner:广东省电力线路器材厂有限公司

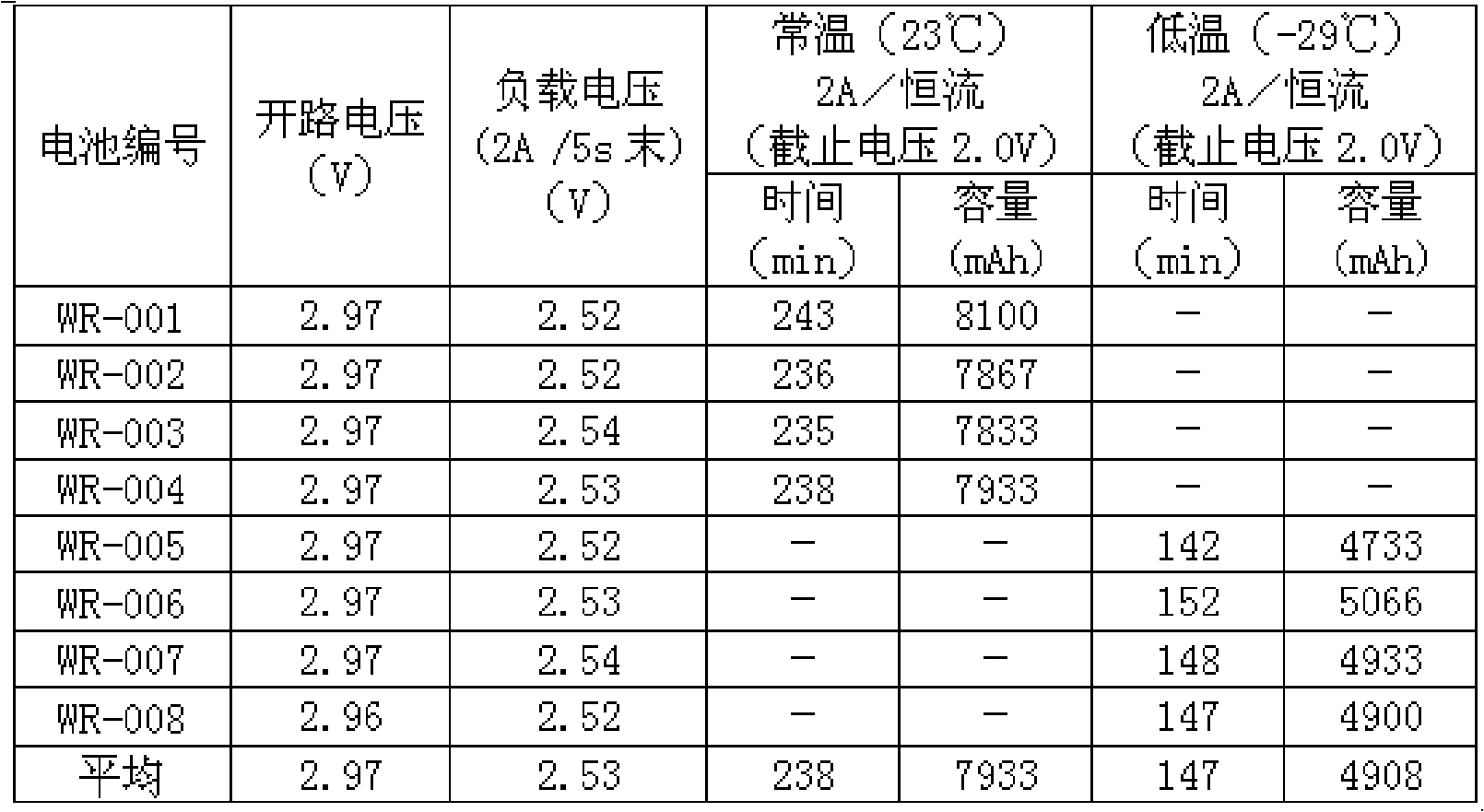

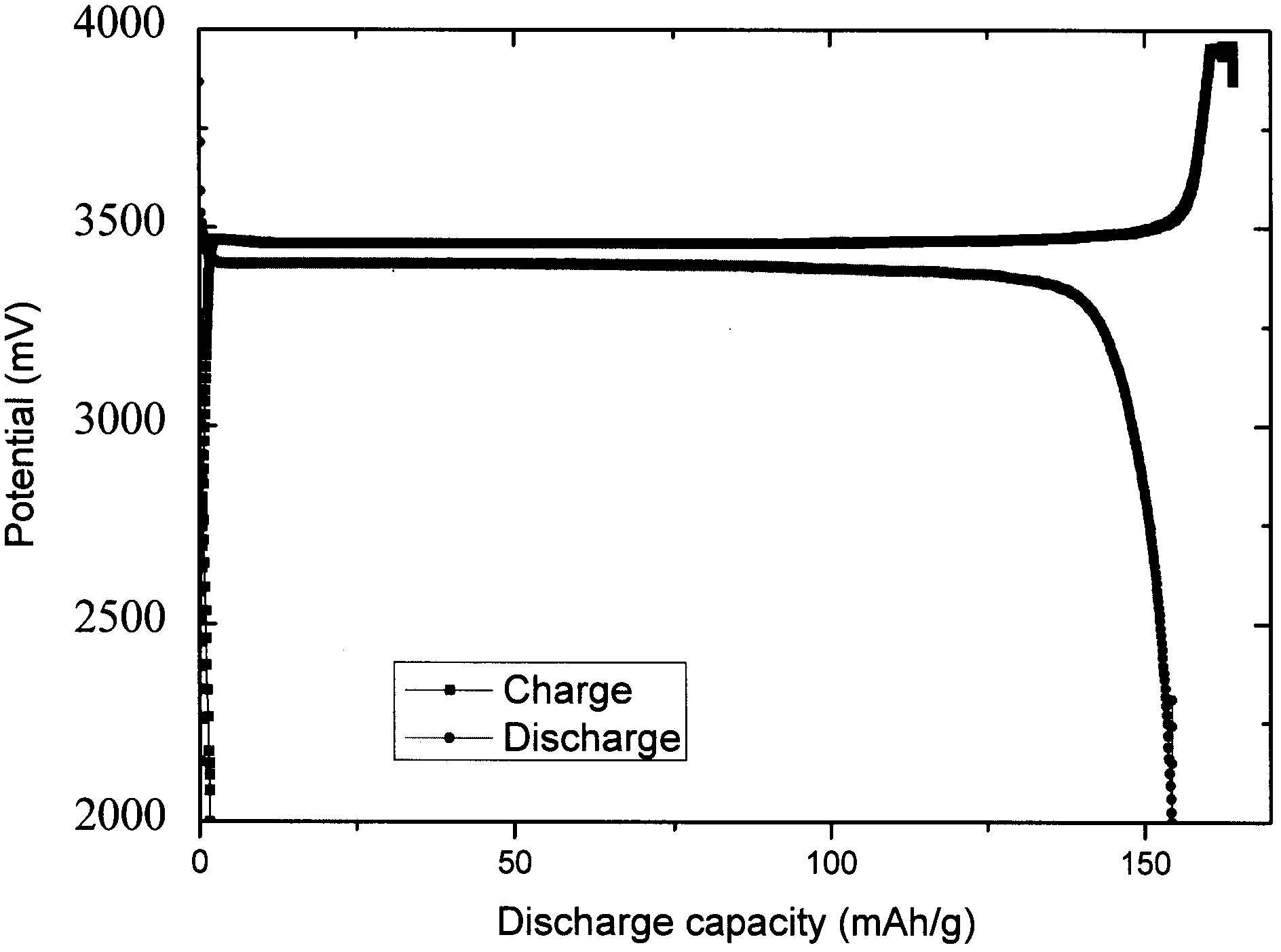

Method for preparing lithium cell cathode and lithium cell made by the same

InactiveCN101281963AImprove material utilizationGood product consistencyElectrode manufacturing processesNon-aqueous electrolyte cellsPolytetrafluoroethyleneContinuous production

The invention relates to a method for preparing a lithium battery cathode and a lithium battery prepared from the cathode belonging to field of battery preparation. The invention provides a preparation method, which is capable of continuously producing, with low material loss and less discharge of the three wastes for the lithium battery cathode and the lithium battery prepared from the cathode. The preparation method includes steps: A. material mixing: sequentially stirring and mixing emulsifying agent, deionized water, acetylene black and polytetrafluoroethylene(PTFE) suspension solution by weight ratio of 1-3:71-76:20:4-6 to obtain a cream; B. drying; C. impregnating; D. pole sheet filming: tabletting and drying the cream particles and a metal afflux net to obtain the battery pole sheet. Advantages of the method are that material utilization rate is high, products consistency is good, continuous and automatic working is easy to be realized, the three wastes discharge is reduced, and applied prospect is wide.

Owner:汪以道

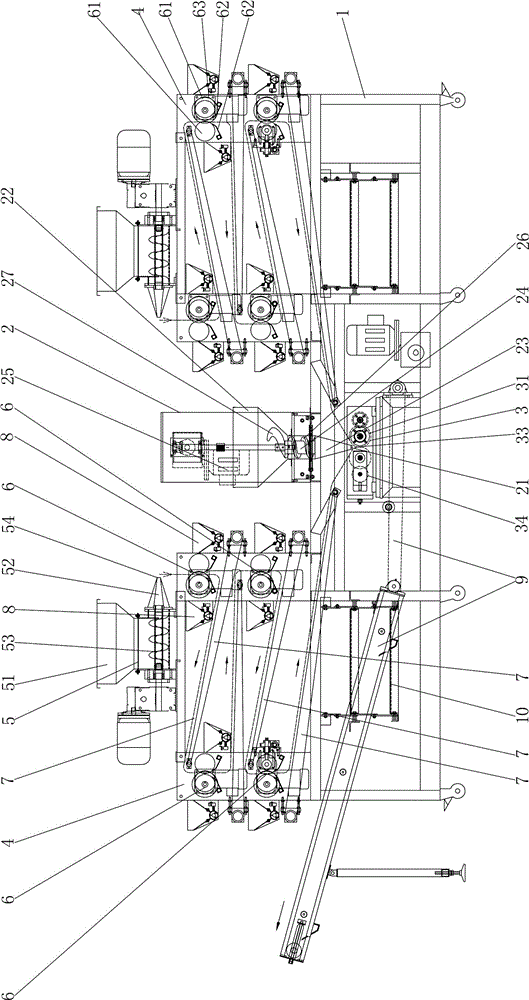

Full-automatic wrapper pressing and stuffing integrated forming machine

The invention discloses a full-automatic wrapper pressing and stuffing integrated forming machine which comprises a stand, a stuffing supply mechanism and a forming and pressing-cutting mechanism, wherein the forming and pressing-cutting mechanism comprises two forming and pressing-cutting rollers, and a plurality of forming die units are arranged on the forming and pressing-cutting rollers; the forming machine is characterized by further comprising two wrapper pressing and conveying mechanisms; the two wrapper pressing and conveying mechanisms are respectively arranged on two sides of the forming and pressing-cutting mechanism, and wrappers pressed by the wrapper pressing and conveying mechanisms are conveyed to a space between the two forming and pressing-cutting rollers; and the material outlet of the stuffing supply mechanism is in correspondence with the forming and pressing-cutting mechanism in position. The forming machine disclosed by the invention, which integrates functions of pressing wrappers, stuffing, forming and the like, can be directly used for making wrappers and for stuffing and forming; the forming machine is high in automation degree, and capable of saving labor, reducing cost and improving production efficiency; moreover, the made wrappers can be immediately used for stuffing and forming, so that the forming machine is conducive to guaranteeing product quality and is good in product consistency. The forming machine disclosed by the invention is applicable to the production of dumplings (such as pork dumplings) and other foods with stuffing covered in wrappers.

Owner:SHANTOU DELONG MACHINERY EQUIP

Composite material bracket body and preparation method thereof

The invention provides a composite material bracket body and a preparation method thereof, and the composite material bracket body is used for solving the various problems such as large density and low strength of a metal material bracket body. The composite material bracket body comprises three parts, namely an air-tight layer, a bearing layer and a structure layer, wherein the air-tight layer is formed by curing bisphenol A epoxy resin, methyl tetrahydrophthalic anhydride, a glass fiber surfacing mat and glass fiber plain cloth; the bearing layer is formed by curing 3K carbon fiber epoxy plain prepreg; the structure layer is formed by curing 12K carbon fiber epoxy plain prepreg. The preparation method of the composite material bracket body comprises the following steps: 1, designing and manufacturing a compression molding mold from the product structure; 2, performing layer lay-up design according to the structure of the bracket body; 3, cutting the prepreg; 4, simultaneously laying up upper and lower dies of the mold; 5, closing and curing; 6, demolding; 7, deburring and deflashing. The composite material bracket body has the advantages of stable product structure and product size, heat resistance, corrosion resistance and weight of only 1 / 5 of that of a metal material.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

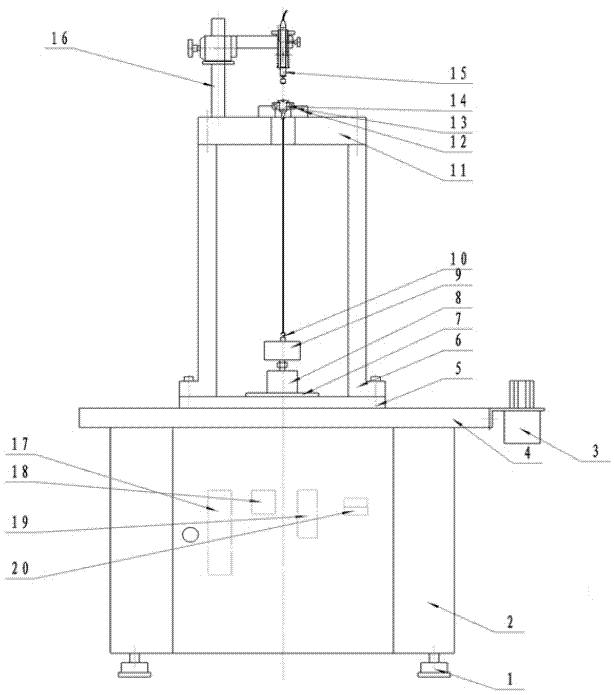

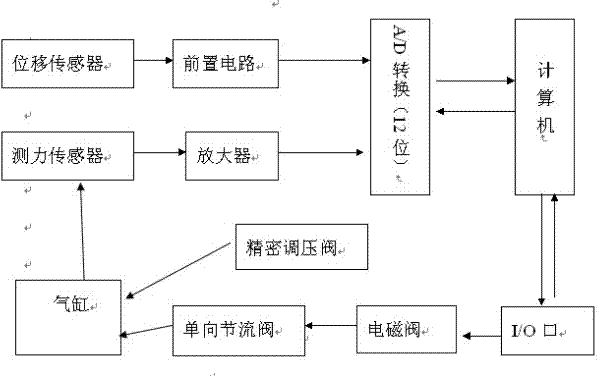

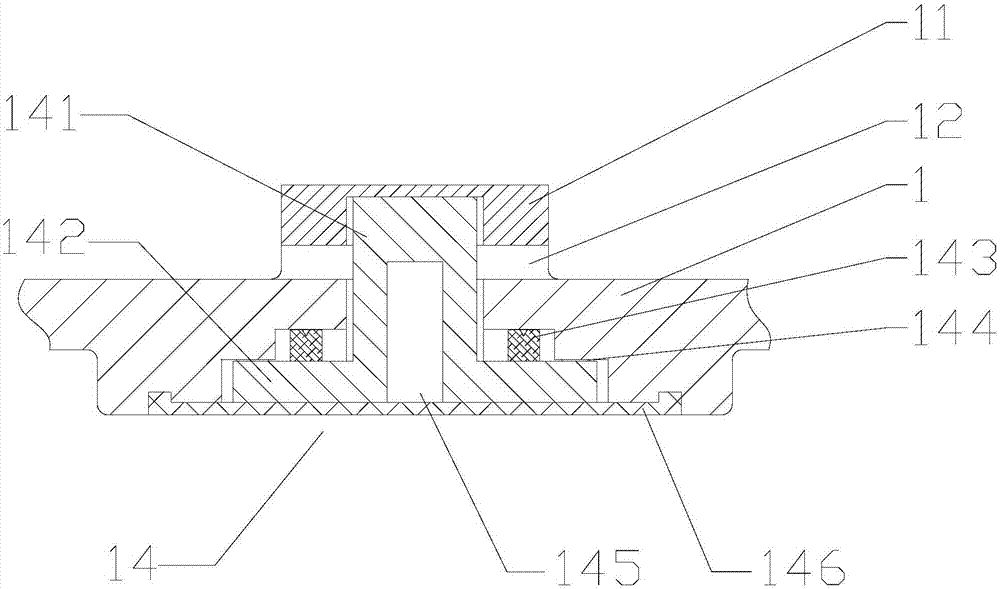

Stiffness curve test method for axial displacement of micro bearing under continuously progressively increased axial force

ActiveCN103674710AEliminate the effects ofDirect and reliable axial tensionMaterial strength using tensile/compressive forcesAxial displacementPull force

The invention discloses a stiffness curve test method for the axial displacement of a micro bearing under continuously progressively increased axial force and relates to a test device and a monitoring device. A force measurement sensor is connected to the output shaft end of a cylinder, so that the cylinder, the force measurement sensor, the micro bearing and a displacement sensor are positioned on the same perpendicular line; the force measurement sensor can directly measure the axial tension generated by the cylinder; therefore, the advantage that the tension measured by the force measurement sensor is the axial force applied to the micro bearing can be achieved; the possible influence caused in other indirect processes can be effectively eliminated; the measured axial force is direct and reliable; the axial force is measured and recorded by the force measurement sensor; the displacement sensor also records the axial displacement of the micro bearing under the corresponding axial force in real time; finally, a stiffness curve is automatically generated through storage and processing of a computer; the stiffness curve supplies an important reference basis to optimizing the design of the micro bearing, reducing the noise of the micro bearing and prolonging the service life of the micro bearing.

Owner:LUOYANG BEARING RES INST CO LTD

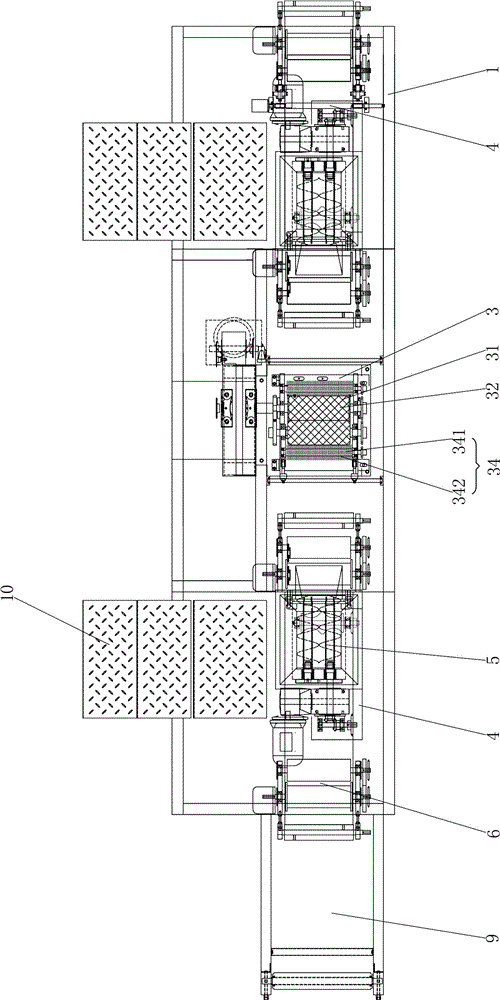

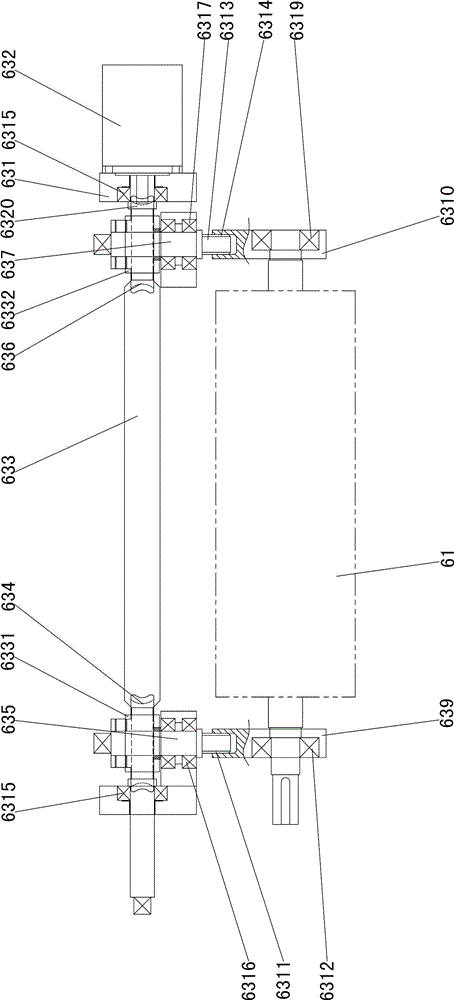

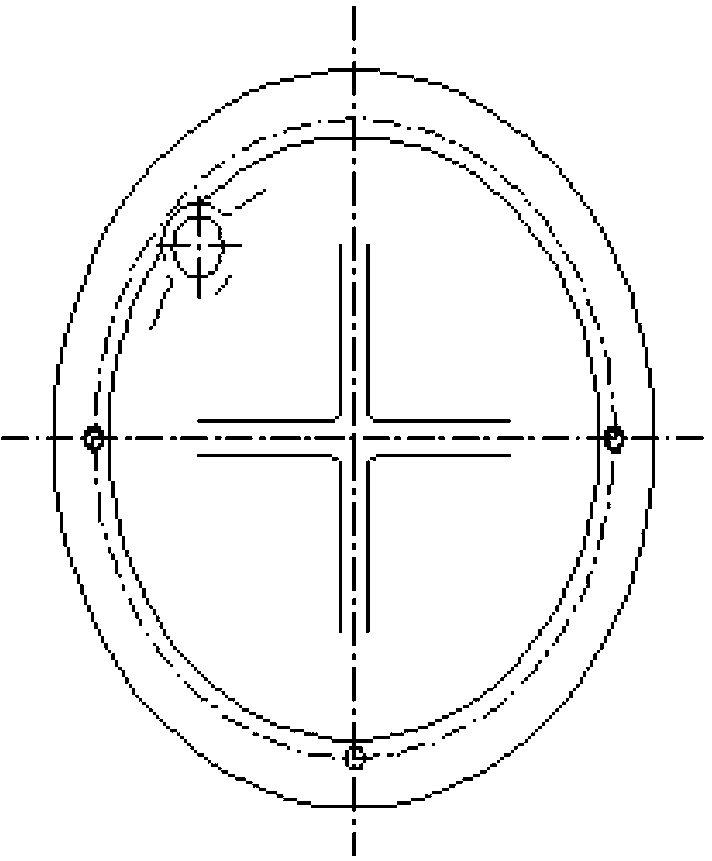

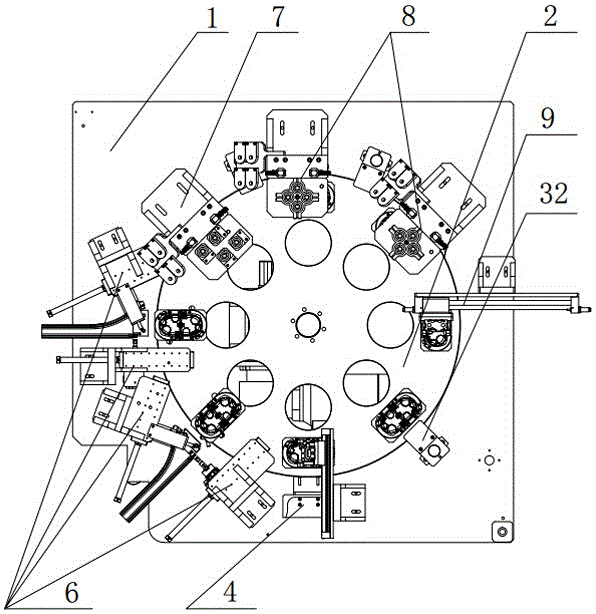

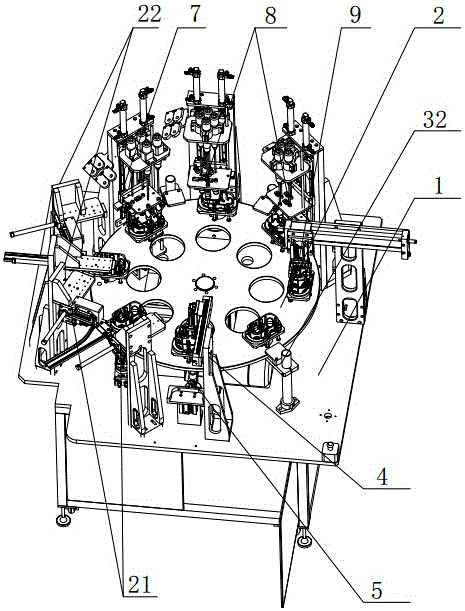

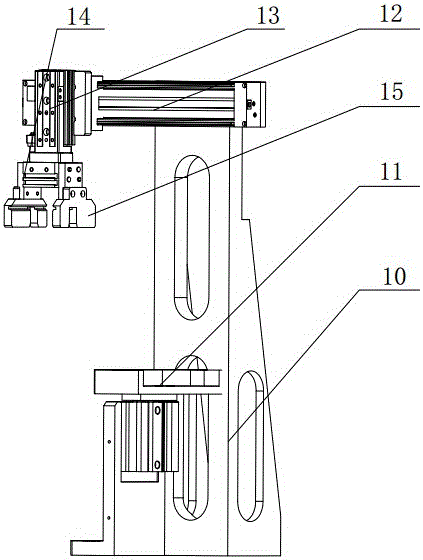

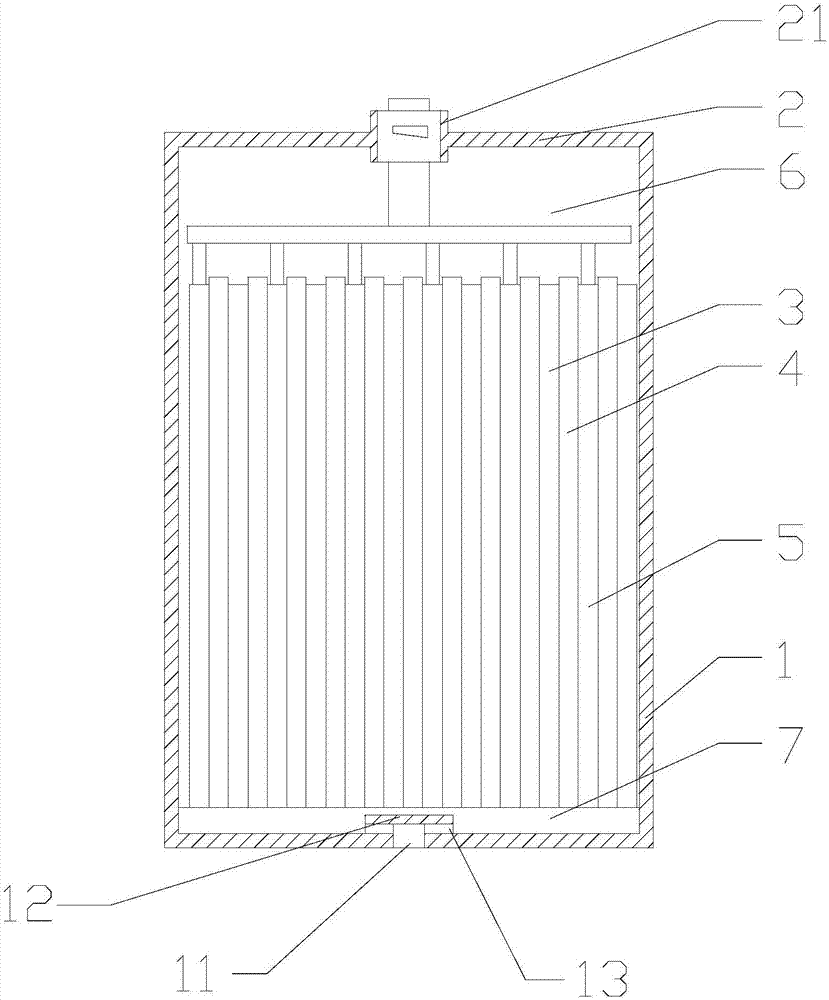

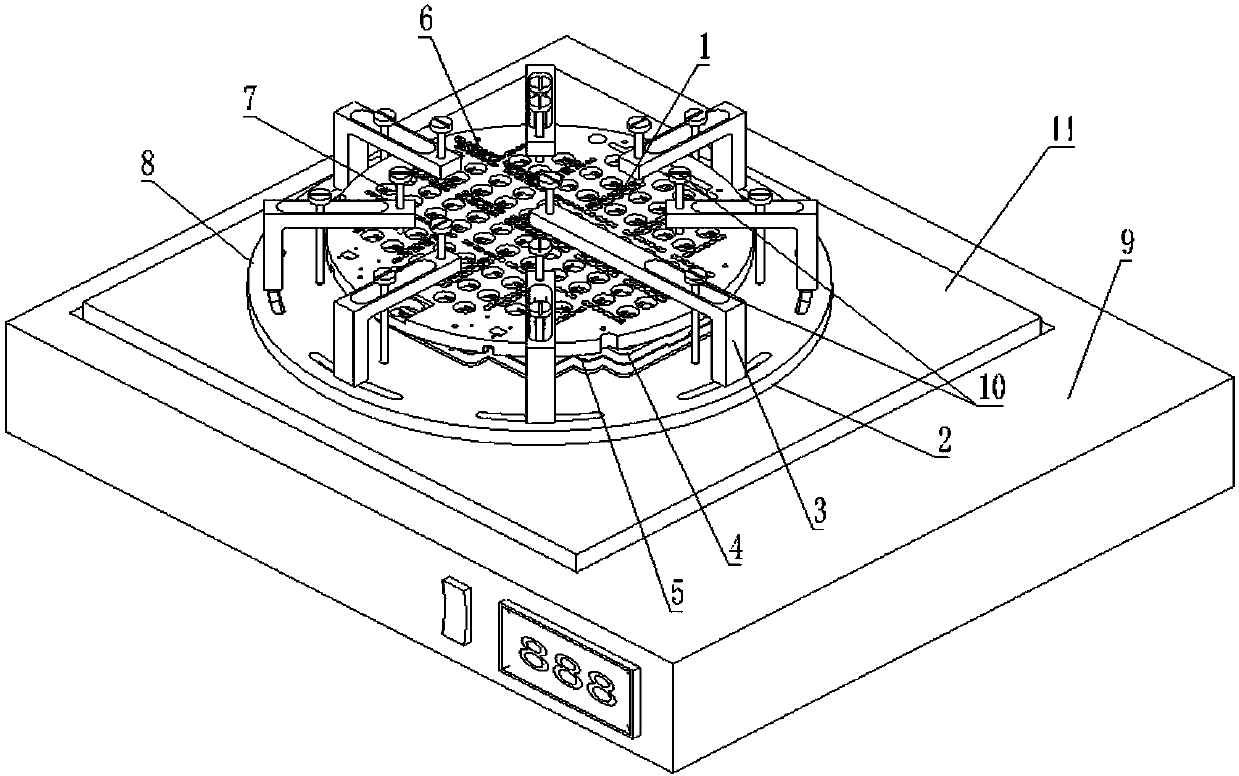

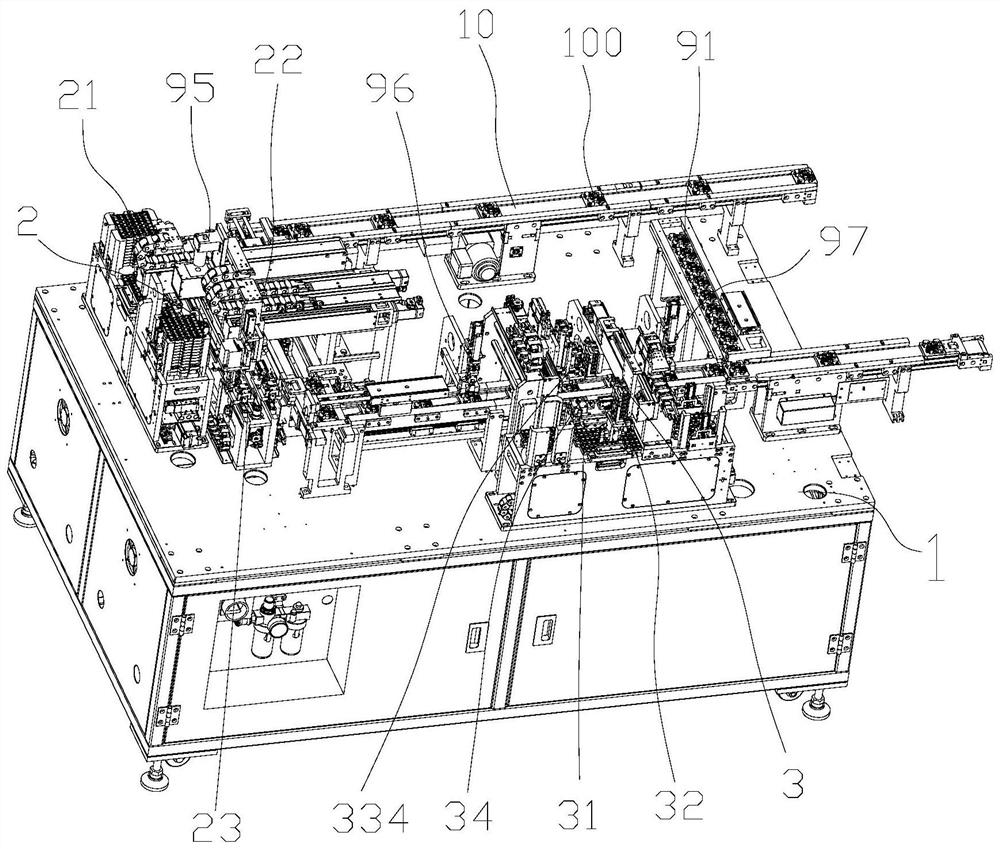

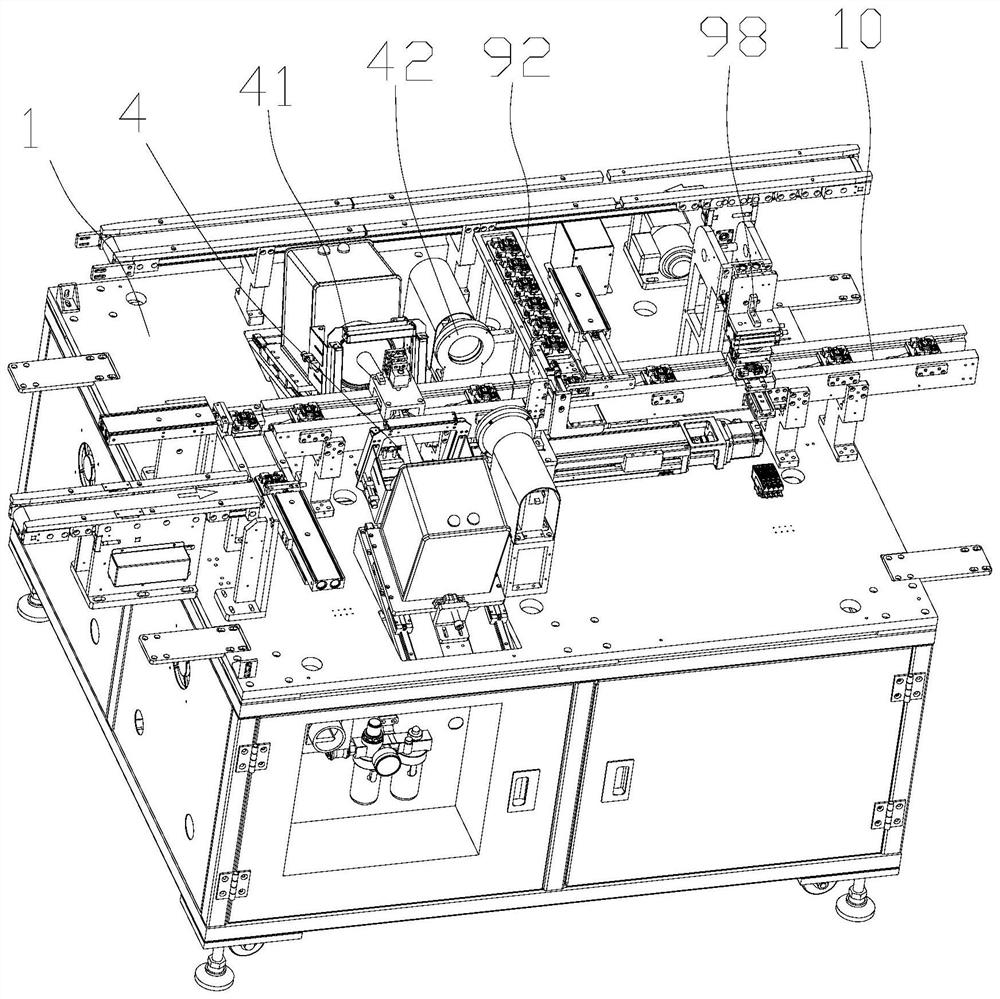

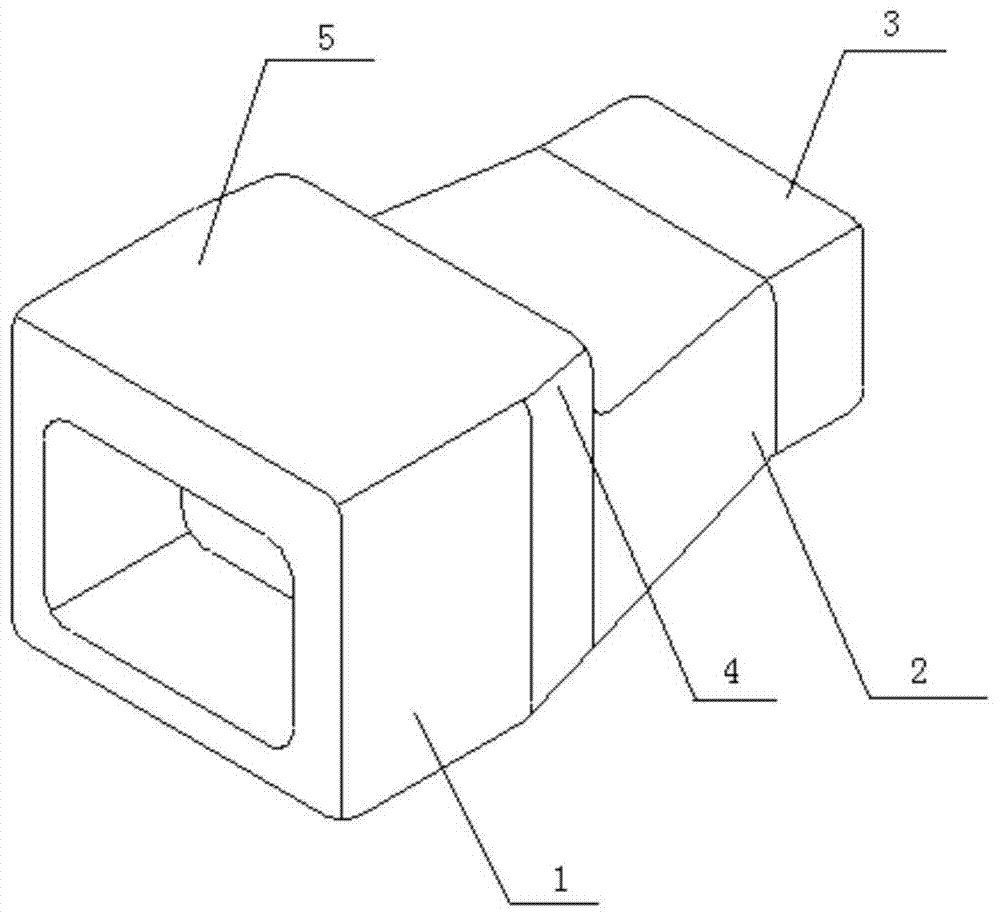

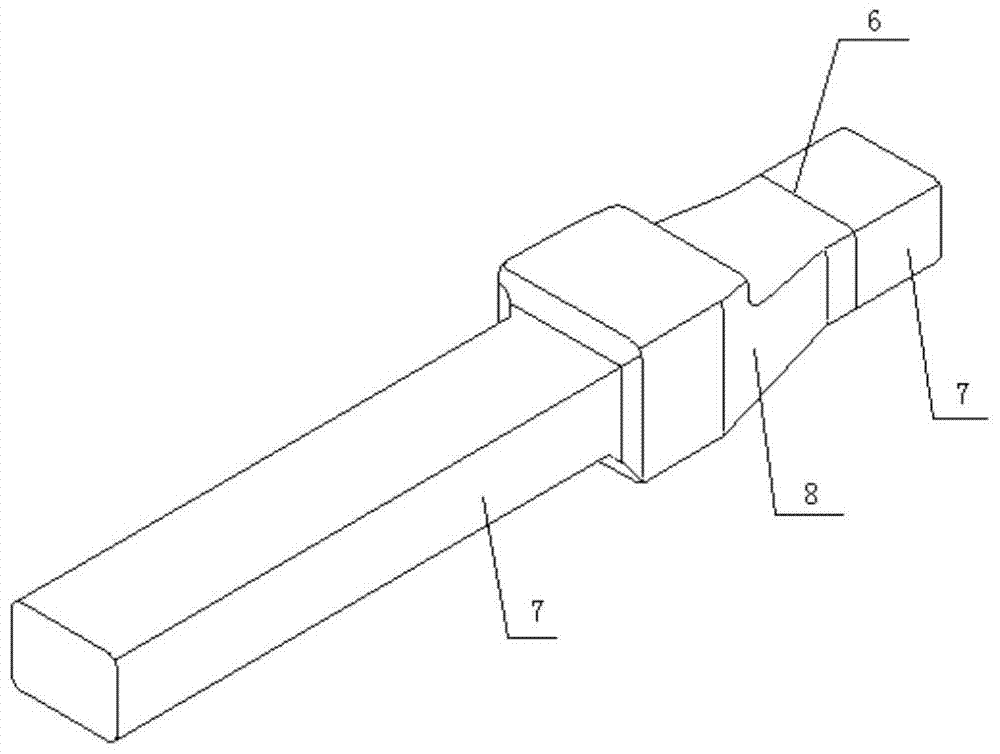

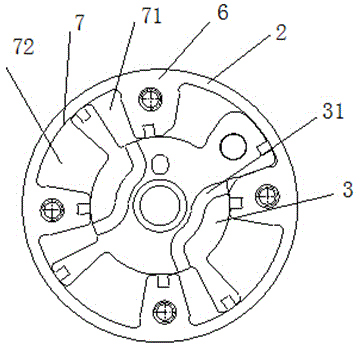

Switch cassette assembling machine

ActiveCN106584100AImprove assembly efficiencyGood product consistencyAssembly machinesMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of assembling of switch cassettes, in particular to a switch cassette assembling machine. The switch cassette assembling machine comprises a controller, a workbench (1), a rotary platform (2), a first power mechanism, a clamp assembly (3), a feeding mechanism (4), a rotary mechanism (5), an iron buckle placement mechanism (6), a first screw installing mechanism (7), a second screw installing mechanism (8) and a discharging mechanism, wherein the first power mechanism, the feeding mechanism (4), the rotary mechanism (5), the iron buckle placement mechanism (6), the first screw installing mechanism (7), the second screw installing mechanism (8) and the discharging mechanism are all electrically connected with the controller. The switch cassette assembling machine is high in assembling efficiency, and assembled switch cassettes are high in consistency.

Owner:NINGBO KINGS INDAL

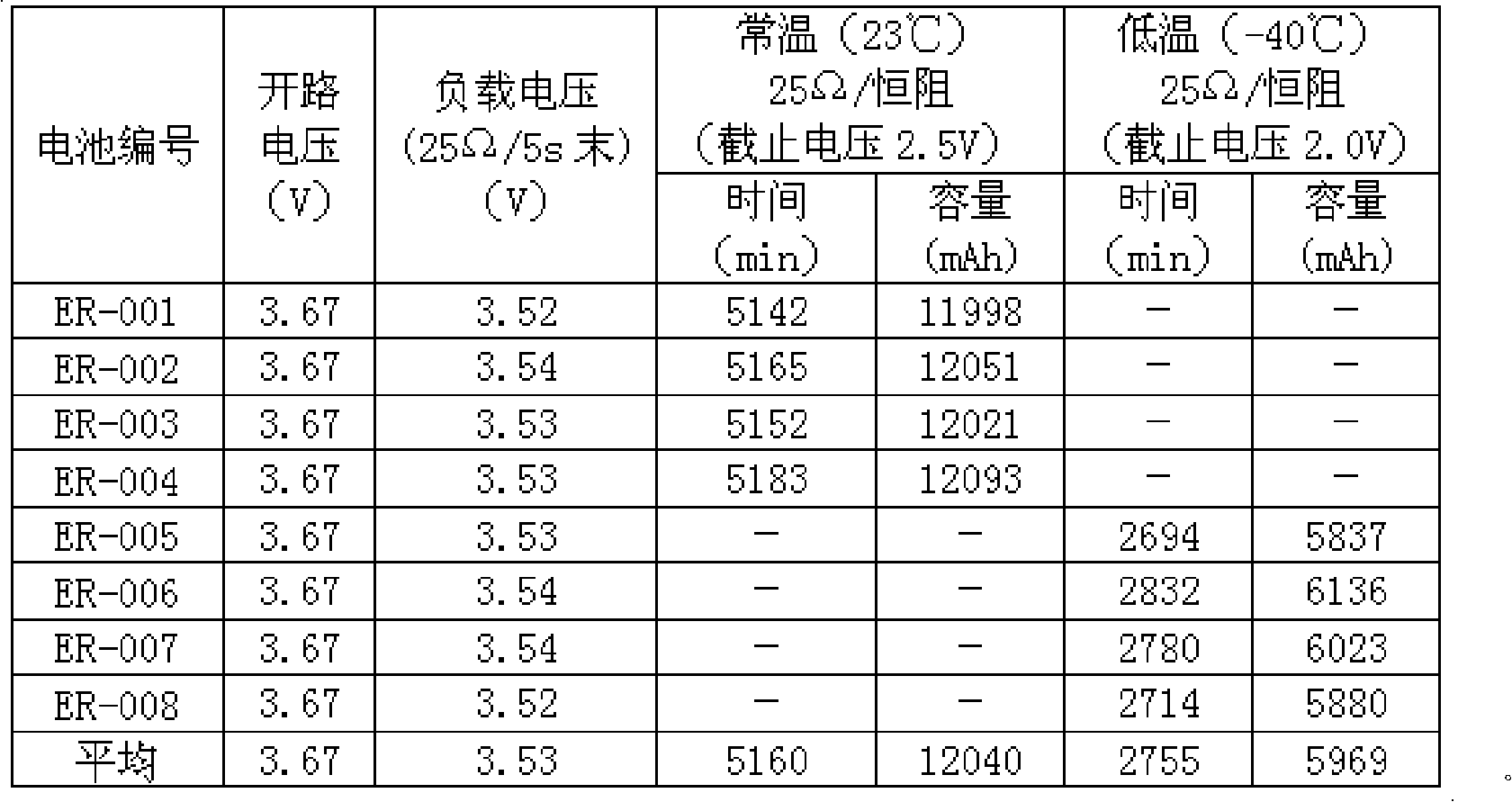

Method for manufacturing electrochemical active material

InactiveCN101916860ASynthesis fastGood product consistencyElectrode thermal treatmentPhosphorus compoundsReaction timingCarbon dioxide

The invention discloses a method for manufacturing an electrochemical active material. The method is characterized by comprising the following steps of: (1) smashing and mixing ferric salt, lithium salt or phosphor salt compounds in a vibrating ball mill according to the molar ratio of ferrum element to lithium element to phosphor element of 1:1:1; and circulating the operation; and (2) after the uniformly mixing process in the step (1), putting a mixture into a ball milling rotary furnace and sintering the mixture in an inert atmosphere. The method has the characteristics of short processing reaction time, low energy consumption and excellent performance of processed product, simultaneously improves material purity, reduces the emission of carbon dioxide and contributes to environmental protection by adopting a carbon-free processing process.

Owner:NANOCHEM SYST SUZHOU

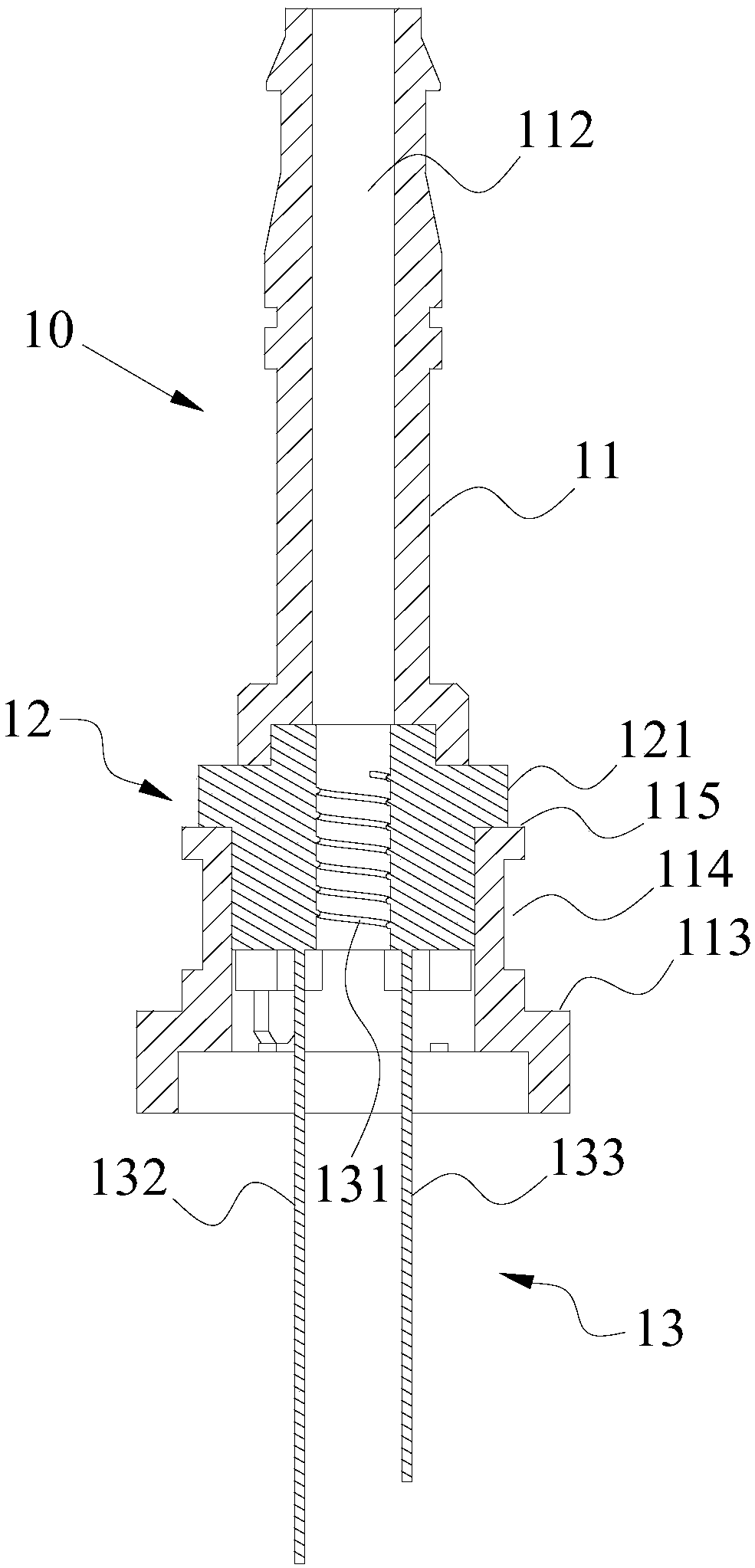

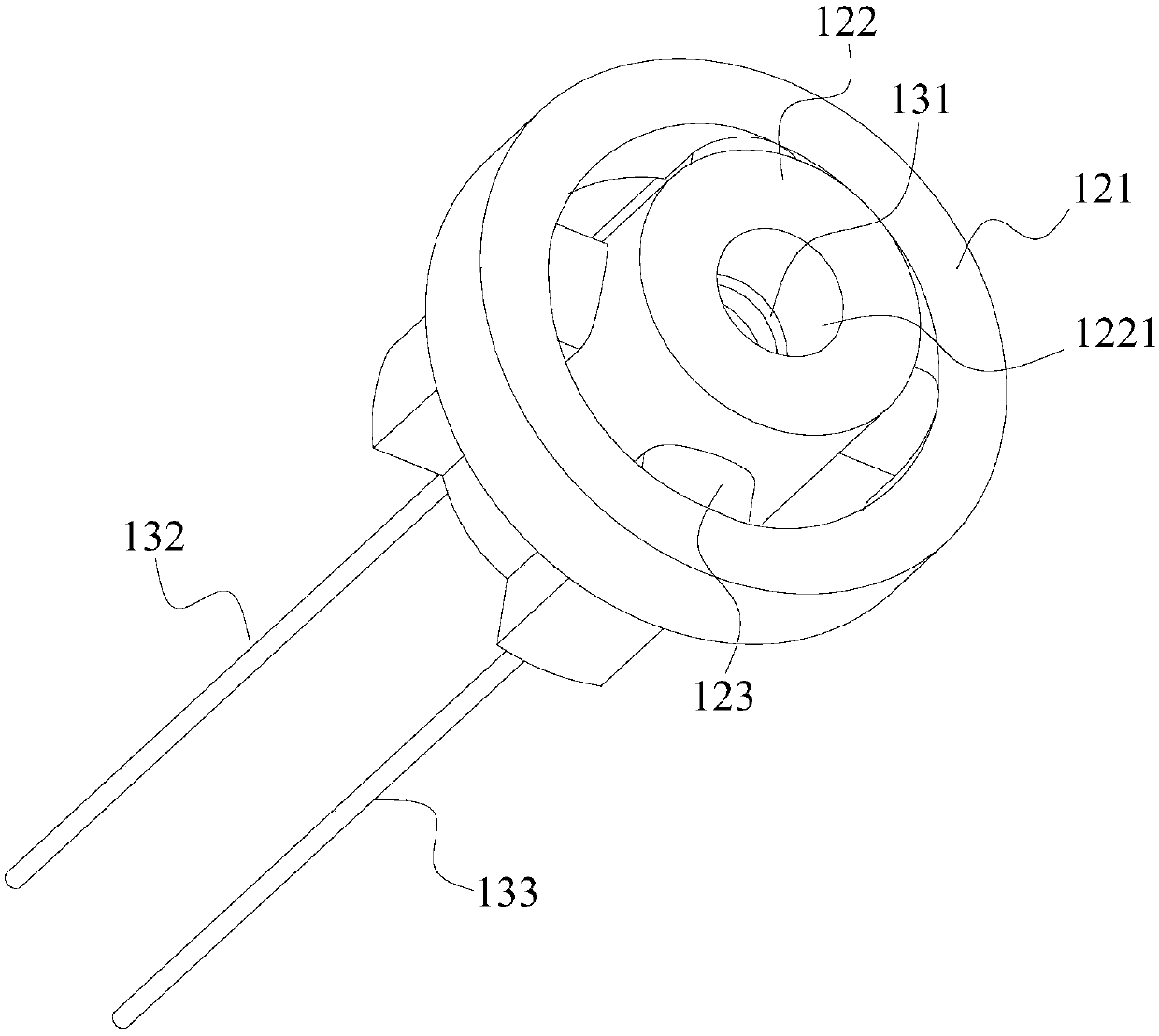

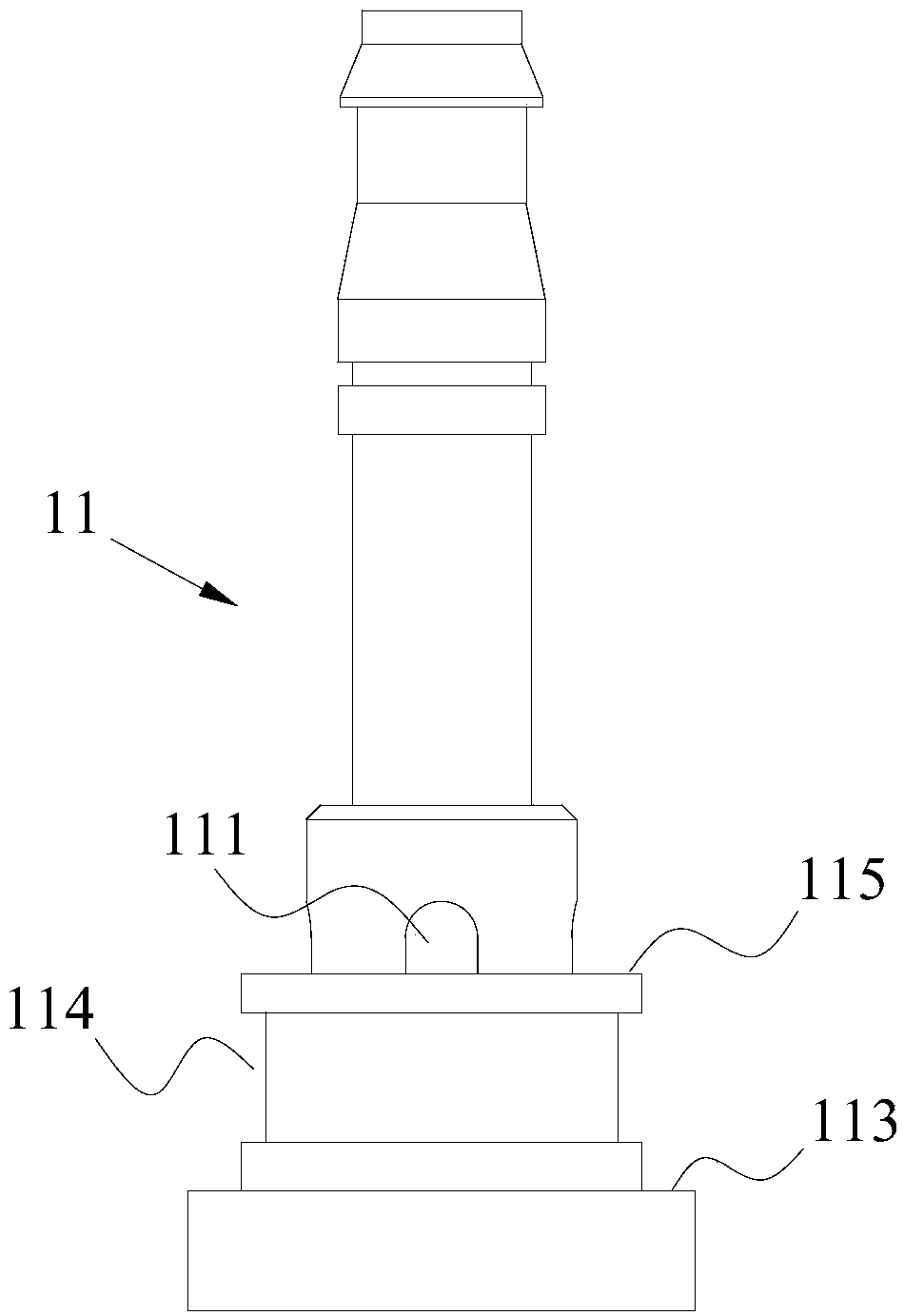

Atomization core, atomizer and electronic cigarette

PendingCN109619685AEvenly guide the oilNot easy to burnTobacco devicesMetallurgyElectronic cigarette

The invention is suitable for the technical field of electronic cigarettes and provides an atomization core, an atomizer and an electronic cigarette. The atomization core comprises a base rod of an internal hollow structure, a porous ceramic part and a heating body arranged on the inner wall of the porous ceramic part, the heating body, the porous ceramic part and the base rod are integrally formed, the porous ceramic part tightly fits the inner wall of the base rod, a part of the porous ceramic part extends out of the base rod, and the portion, extending out of the base rod, of the porous ceramic part wraps the outer wall of the base rod. According to the atomization core, the porous ceramic part is directly adopted for guiding an atomization substance to the heating body, so that oil guide is evener, burning does not easily occur, and no residue of the atomization substance exists; in addition, the heating body, the porous ceramic part and the base rod are integrally formed, manual cotton wrapping is not needed, the production efficiency is high, and the production consistency is good.

Owner:SMISS TECH

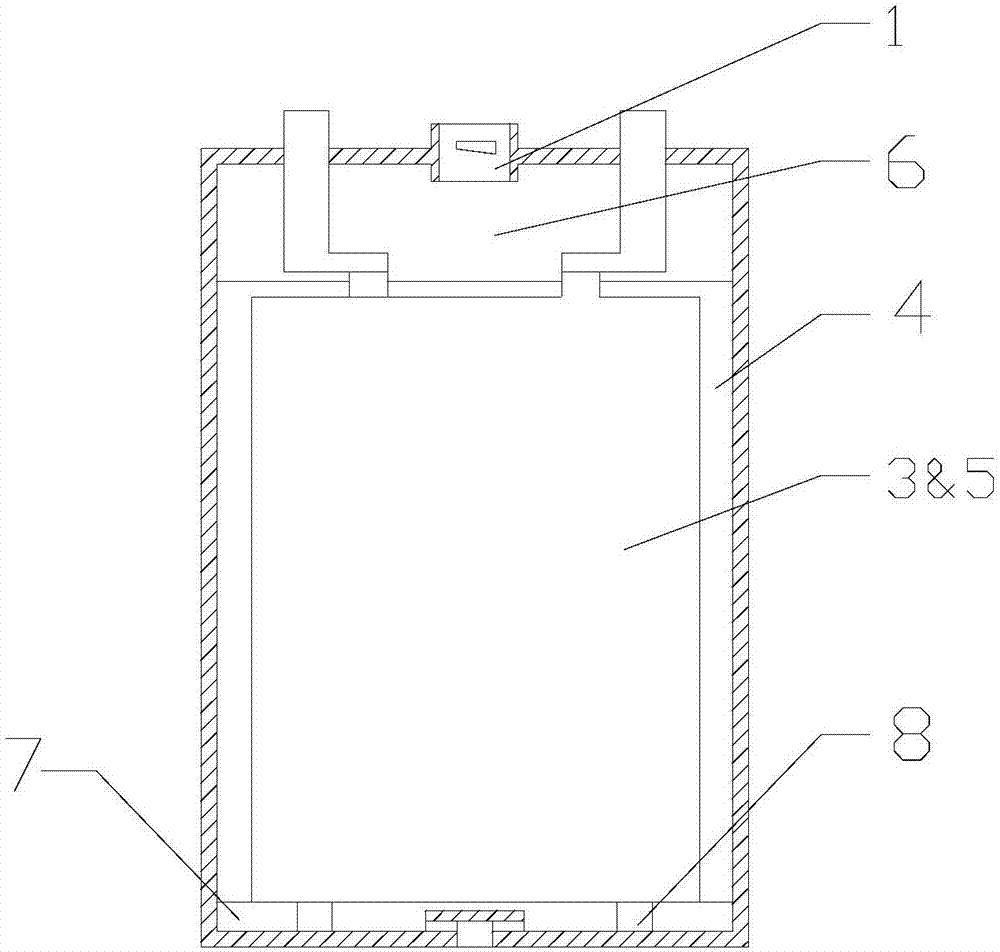

Solid acid battery with absorbed partition plate and high-efficiency internal formation process thereof

ActiveCN106981689AEfficient glue filling processGood product consistencyFinal product manufactureSecondary cells charging/dischargingEngineeringSafety valve

The invention relates to the field of a lead acid storage battery, and discloses a solid acid battery with an absorbed partition plate and a high-efficiency internal formation process of the solid acid battery. The solid acid battery with the absorbed partition plate comprises a battery groove, a battery cover and a pole group, wherein the pole group is arranged in the battery groove and comprises a positive pole plate, the absorbed partition plate and a negative pole plate which are laminated, a safety valve hole is formed in the battery cover, an upper reserved space is arranged between the safety valve hole and the pole group, a liquid injection hole is formed in a bottom part of the battery groove, a lower reserved space is arranged between the bottom part of the battery groove and the pole group, a liquid injection hole cover is arranged on an inner wall of the bottom part of the battery groove and above the liquid injection hole, at least two acid through holes are formed between the liquid injection hole cover and the inner wall of the bottom part of the battery groove, and a sealing plug is arranged in the liquid injection hole. With regard to the battery employing the absorbed partition plate, the original appearance of the battery is basically maintained, and the battery is simple in structure and better in sealing performance and is easy to produce. The internal formation process and a glue pouring process of the solid acid battery with the absorbed partition plate are more efficient, and the fabricated product is better in consistency.

Owner:CHAOWEI POWER CO LTD

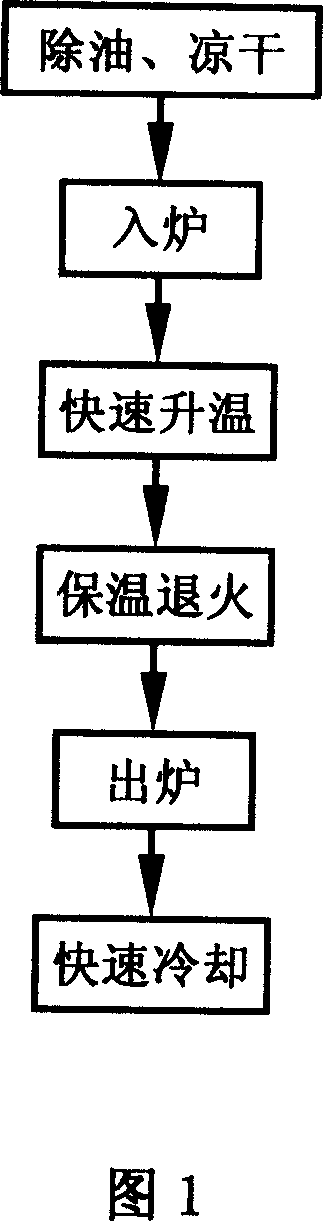

Quick annealing method for titanium seamless pipe

InactiveCN101086056AIncrease productivityReduce energy consumptionIncreasing energy efficiencyFurnace typesAutomatic controlIntermediate frequency

This invention discloses a method for annealing ti-seamless tubes. It comprises following steps: putting titanium tube into intermediate frequency induction annealing furnace orderly, heating to crystallization temperature rapidly when crossing intermediate frequency induction annealing furnace, restraining 'recovery' process, finishing recrystallization rapidly, cooling to room temperature fast, restraining ' grain growth' and high temperature oxidation. It only need several minutes for heating, thermal insulating and cooling for one titanium tube. It solves the technical problems of low production efficiency and high cost in background technology. The invention is characterized by automatic control, suitability for different length tubes annealing, mass or small production and excellent performance.

Owner:WESTERN TITANIUM TECH

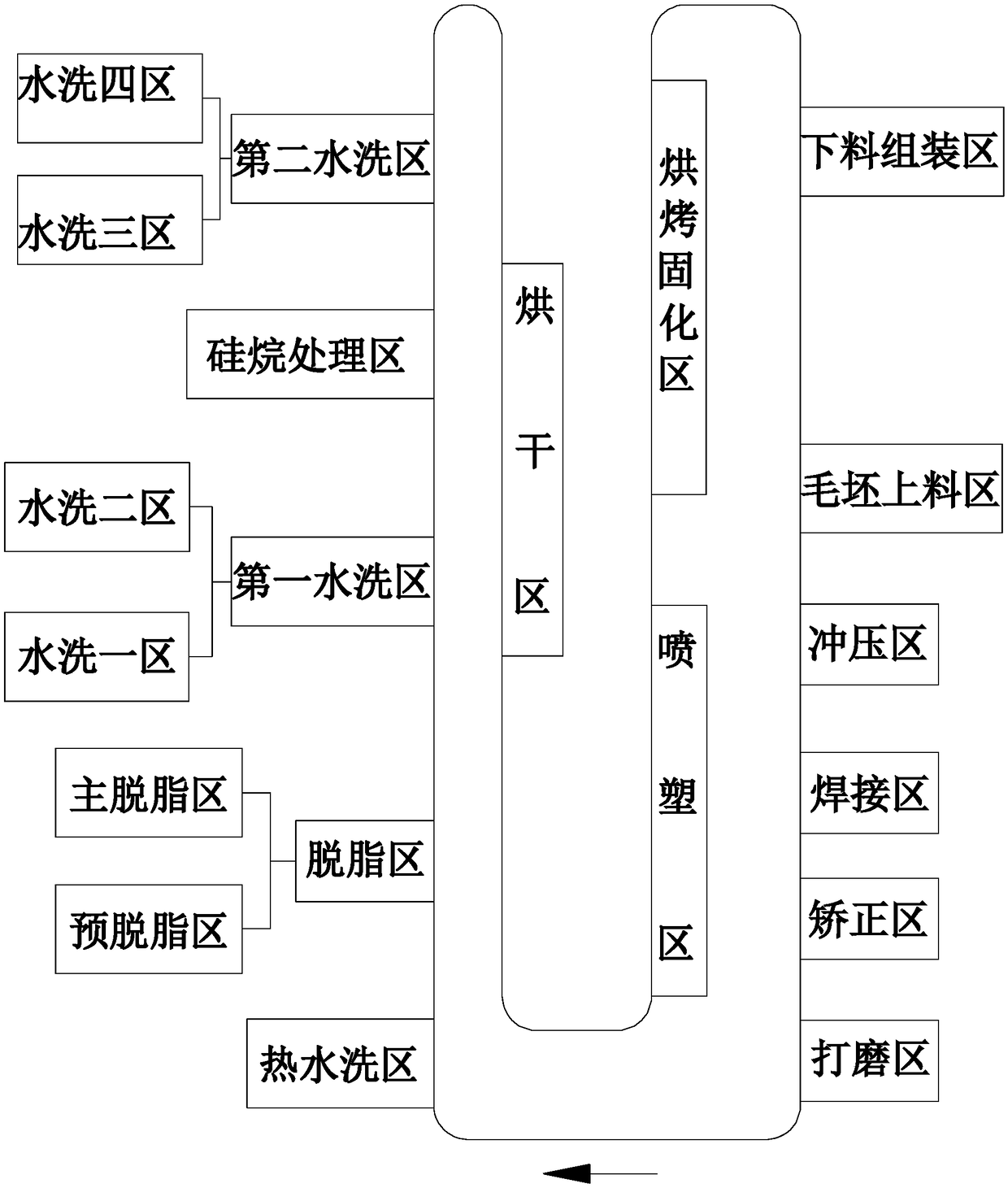

Network cabinet production assembly line and production process

PendingCN109433491AIncrease productivityGood product consistencySpray boothsCleaning using liquidsAssembly lineManufacturing engineering

The invention discloses a network cabinet production assembly line and a production process. The network cabinet production assembly line comprises a workblank loading area, a punching area, a weldingarea, a correcting area, a polishing area, a hot water washing area, a degreasing area, a first water washing area, a silane treating area, a second water washing area, a drying area, a plastic spraying area, a baking solidifying area and a material unloading assembling area which are arranged in sequence and further comprises a conveying chain and a driving device, wherein the conveying chain passes through all the above-mentioned areas in sequence, the driving device drives the conveying chain to perform circulation motions, and workpieces are hung on the conveying chain. The production process comprises the following steps of workblank loading, punching, welding, correcting, polishing, hot water washing, degreasing, first water washing, silane treating, second water washing, drying, plastic spraying, baking solidifying and material unloading assembling. The network cabinet production assembly line and the production process have the advantages that compared with a distributed machining method in the prior art, the network cabinet production assembly line and the production process are high in production efficiency and good in product consistency.

Owner:ANHUI FEIKAI ELECTRONICS TECH CO LTD

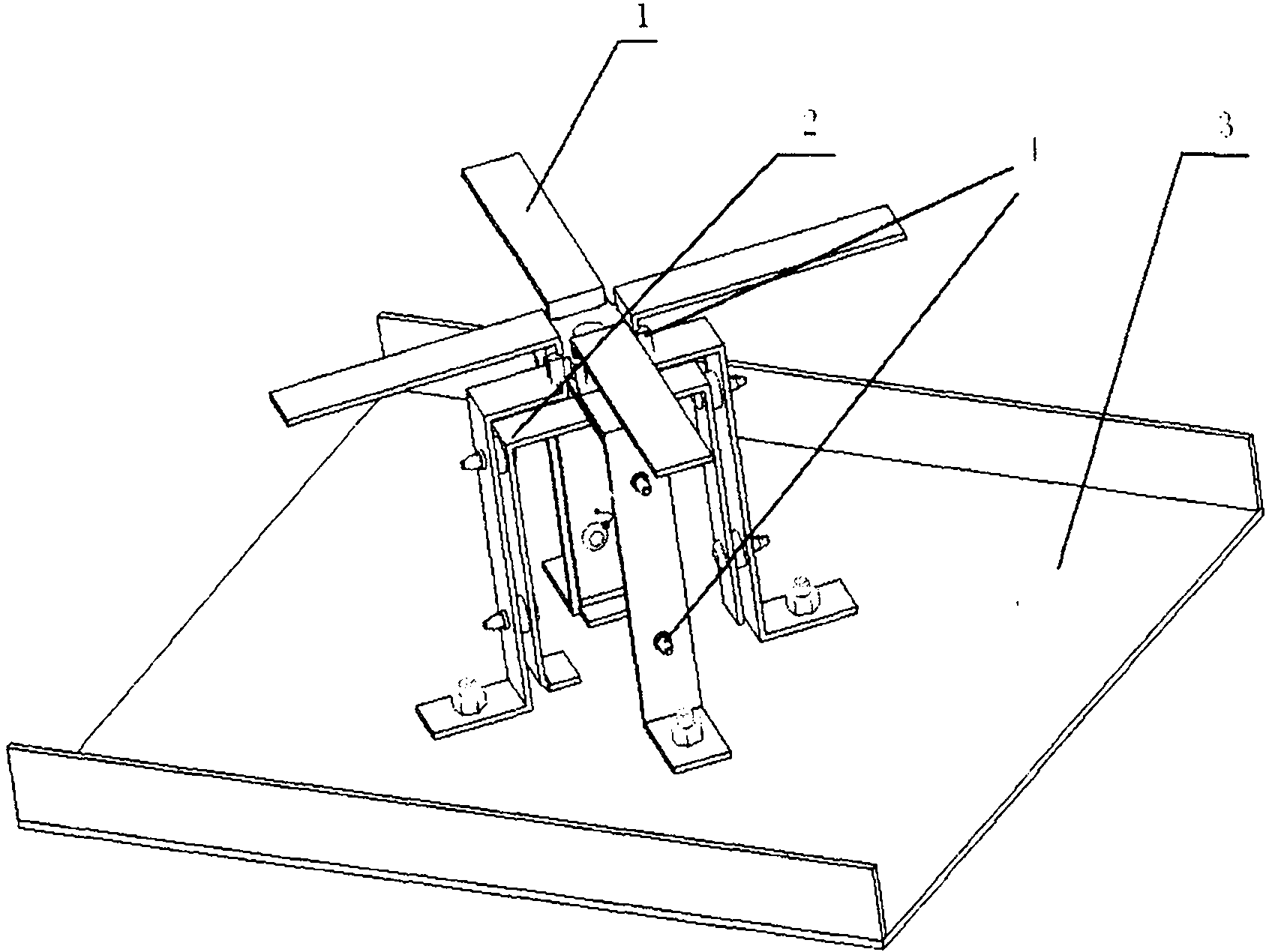

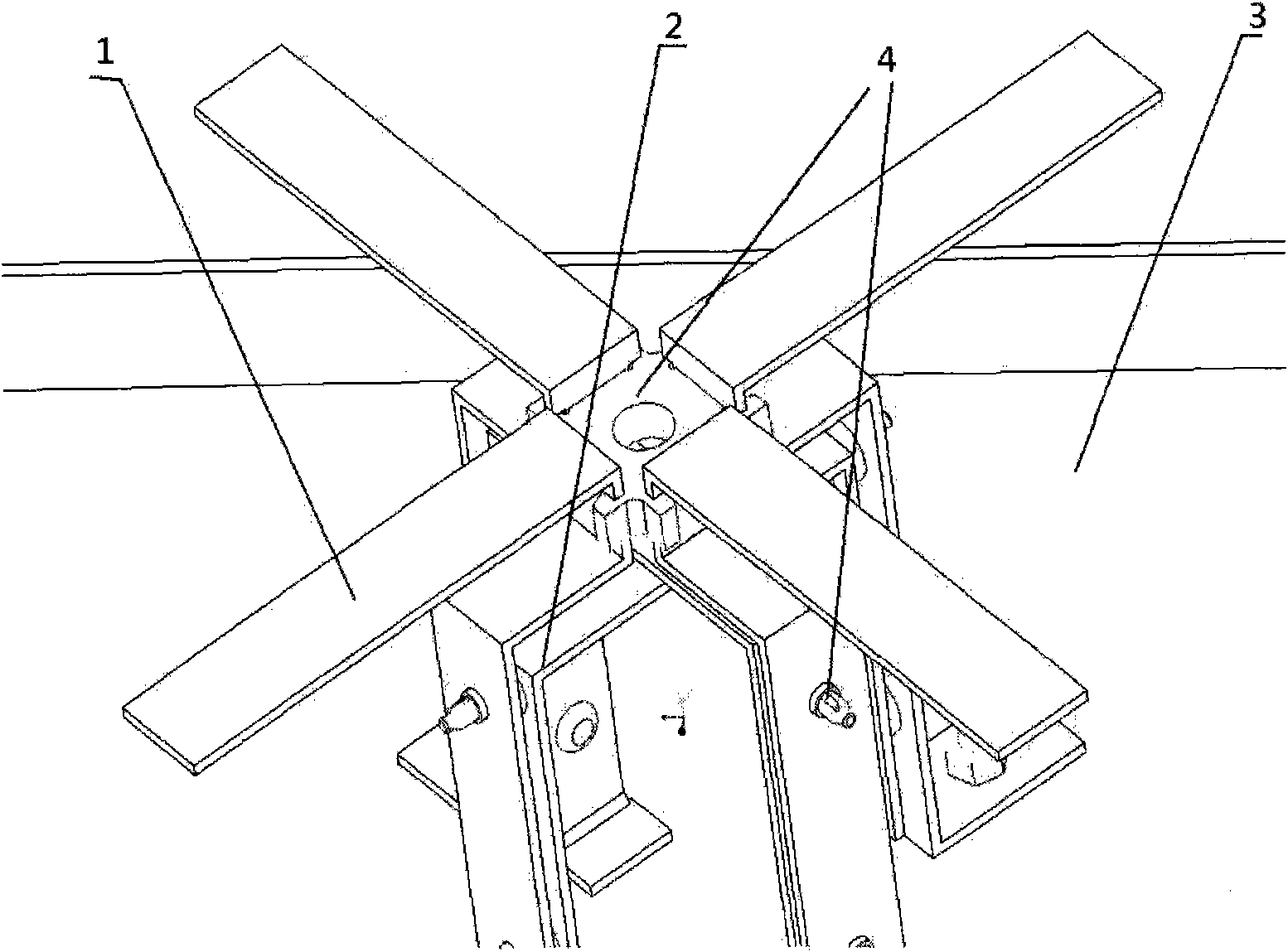

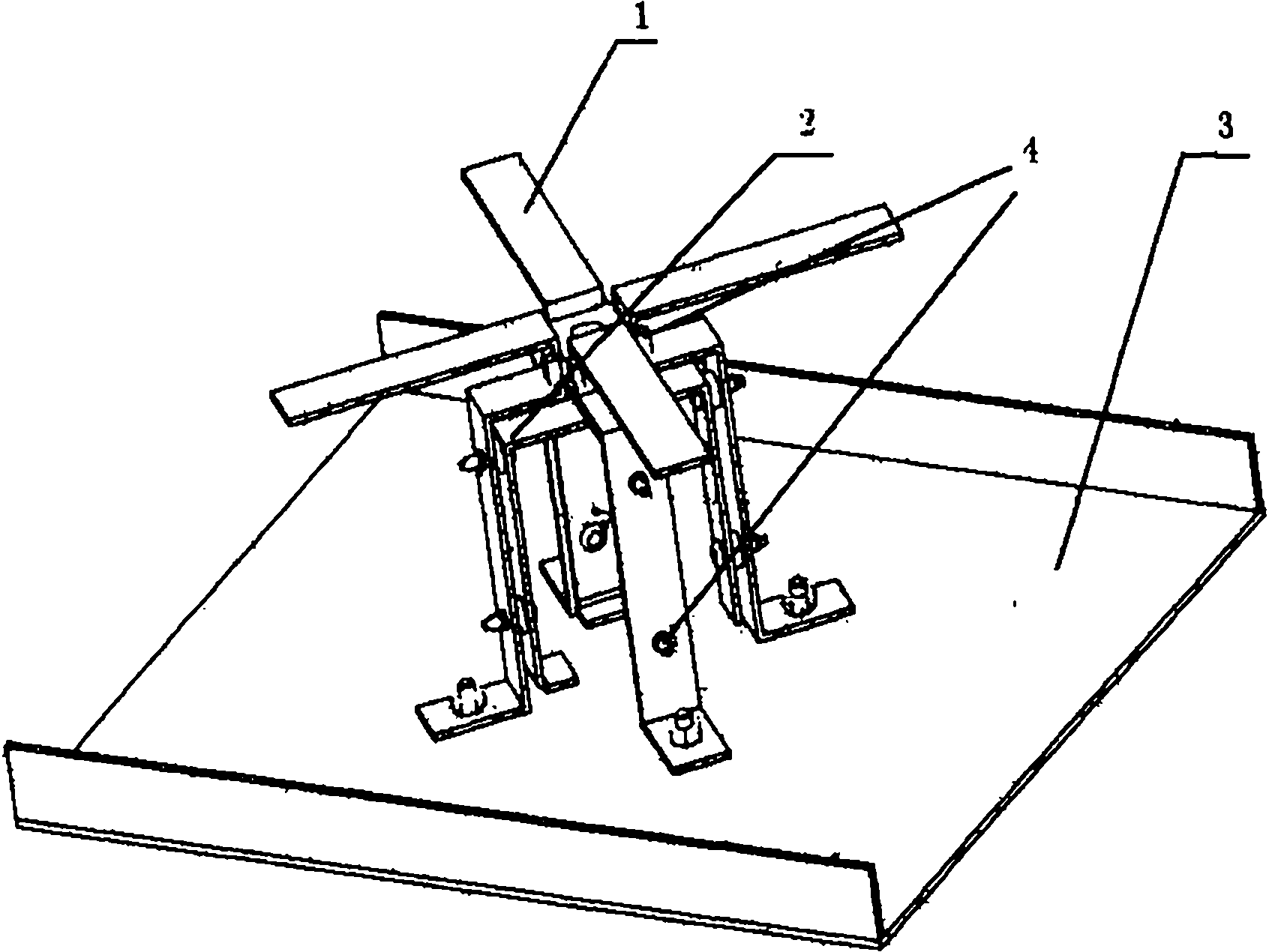

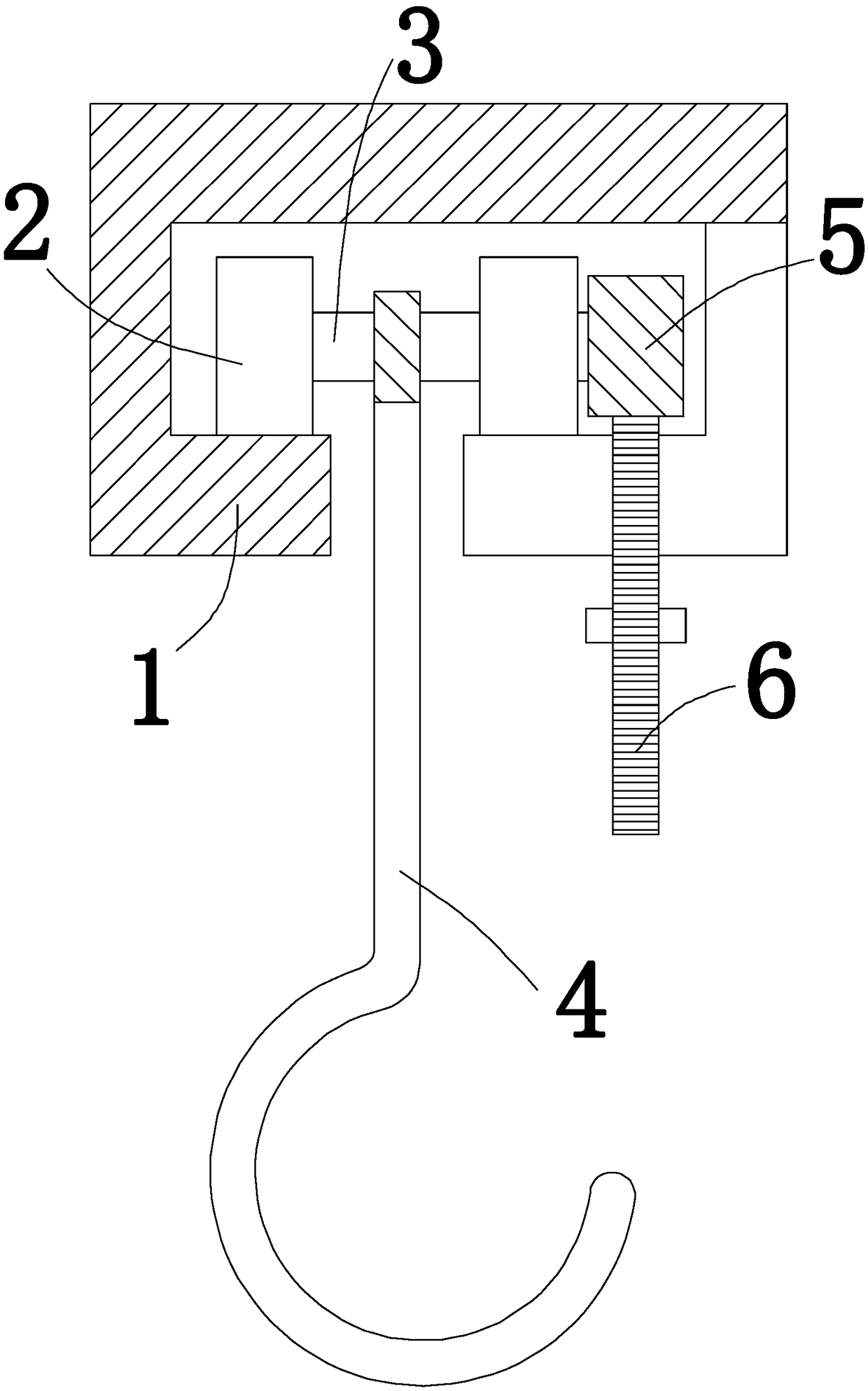

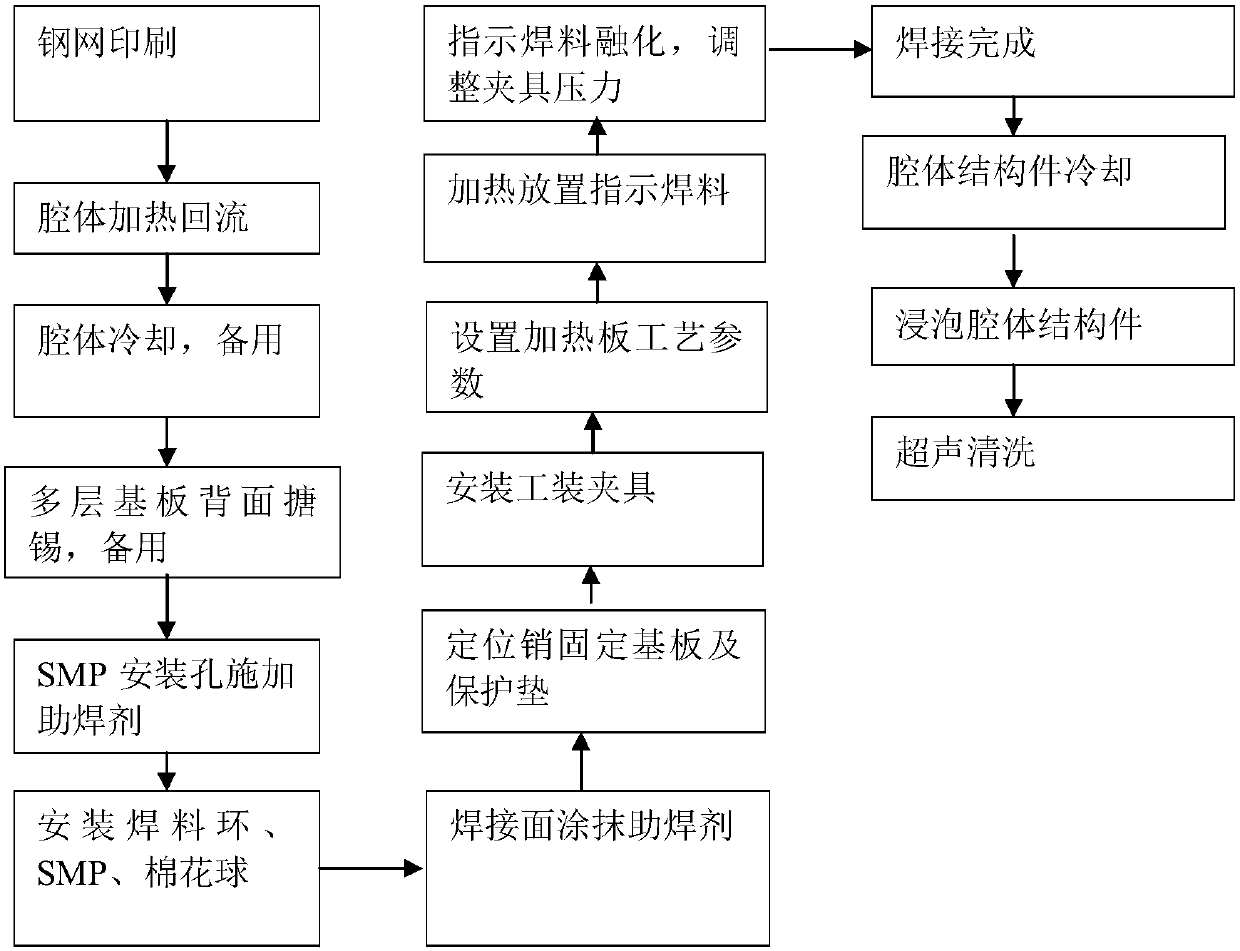

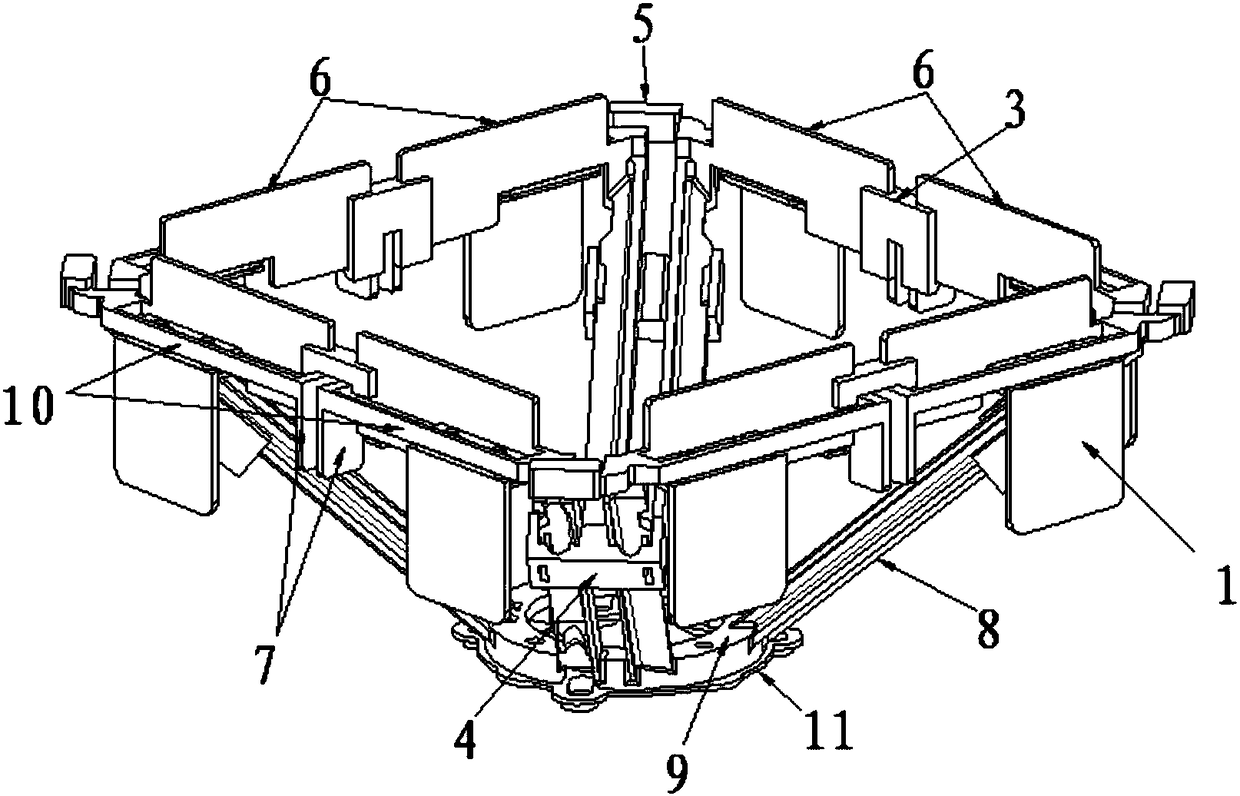

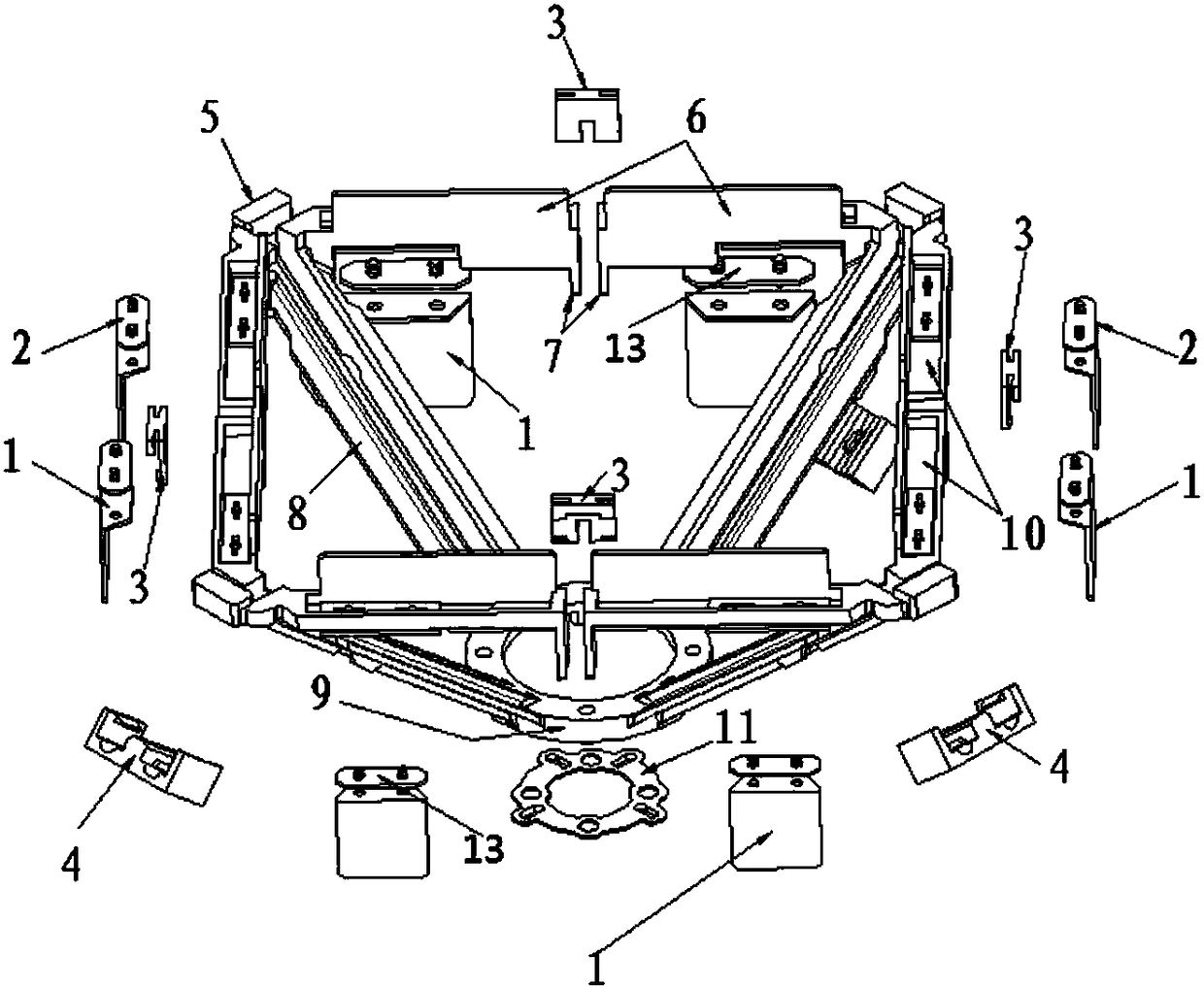

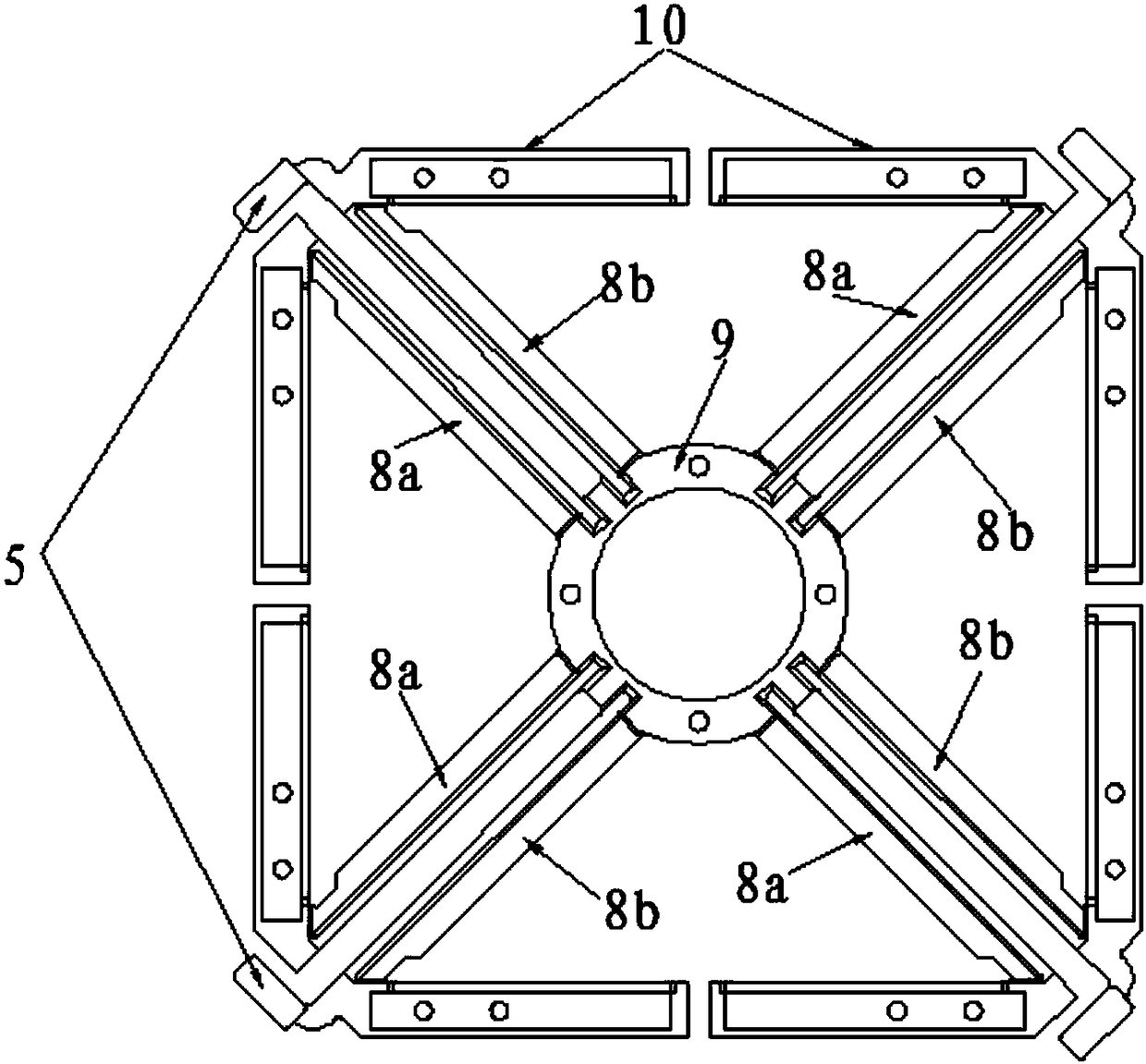

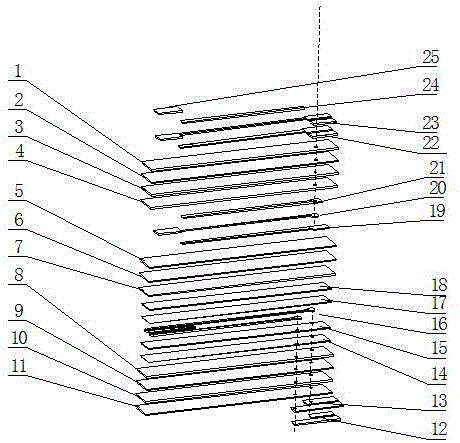

Welding method of multilayer copper-clad substrate of phased array active antenna array

ActiveCN107745166AGood welding performancePromote infiltrationWelding/cutting auxillary devicesAuxillary welding devicesRefluxEngineering

The present invention provides a welding method of a multilayer copper-clad substrate of a phased array active antenna array, and aims at providing a welding method capable of effectively preventing unstable welding quality of the multilayer copper-clad substrate. The welding method is implemented by the following technical scheme that a tool having the same shape with the multilayer copper-clad substrate and L-shaped clamps, an circular array of which is distributed on a tool pedestal, are prepared; steel mesh printing solder is applied to a front surface welding area of a cavity structural member and disposed on a reflux heating plate of a heater; the tool having the same shape with the multilayer copper-clad substrate and L-shaped clamps, the circular array of which is distributed on the tool pedestal, are prepared; the surface of the multilayer copper-clad substrate equipped with an SMP solder side is upward, the multilayer copper-clad substrate is fixed on a projection surface ofthe tool pedestal, solder rings and SMP radio frequency connectors are disposed in SMP installing holes in the reverse side of the cavity structural member, and soldering flux is applied; the back side of the multilayer copper-clad substrate is tinned, and the multilayer copper-clad substrate is fixed on the solder side of the cavity structural member coated with the soldering flux through pins and disposed on the reflux heating plate of the heater; and front surface welding of the multilayer copper-clad substrate and the cavity structural member is performed by hot reflux, and cavity back surface welding of the SMP radio frequency connectors to the cavity structural member is performed.

Owner:10TH RES INST OF CETC

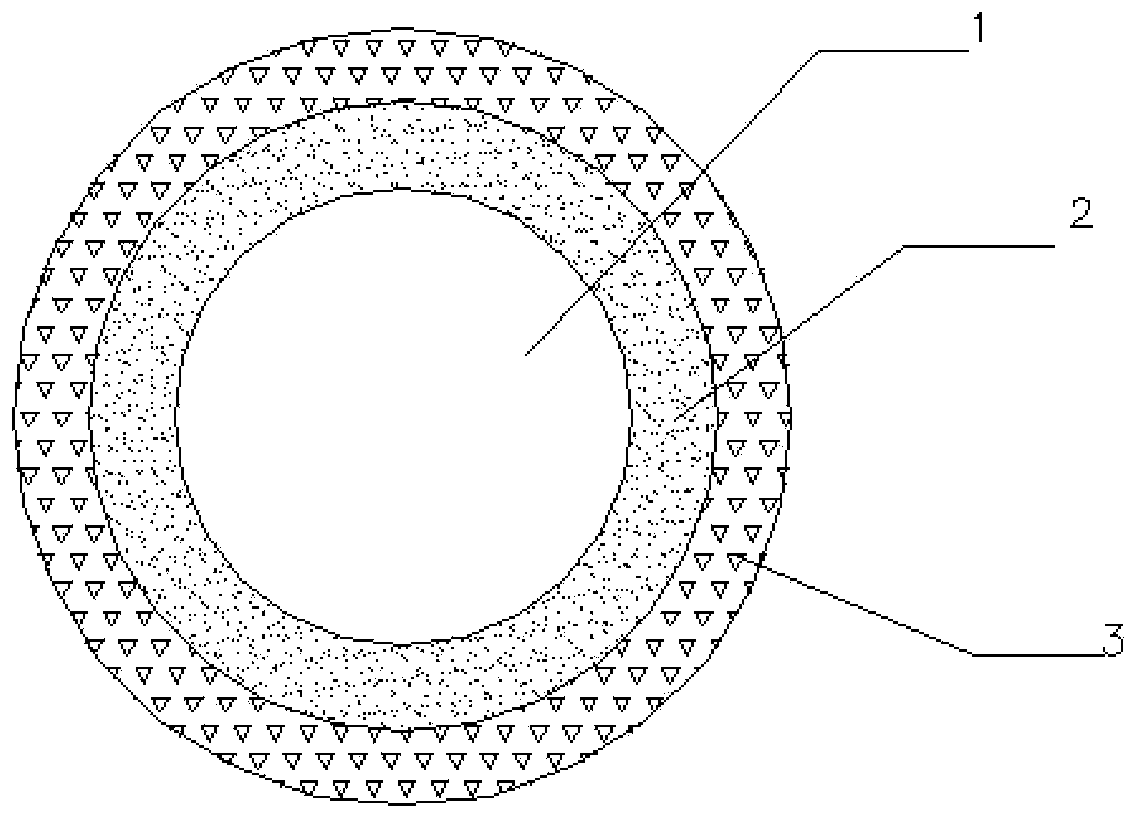

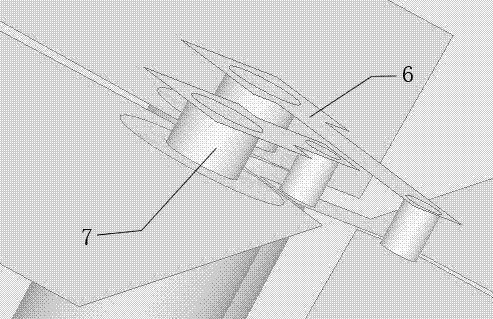

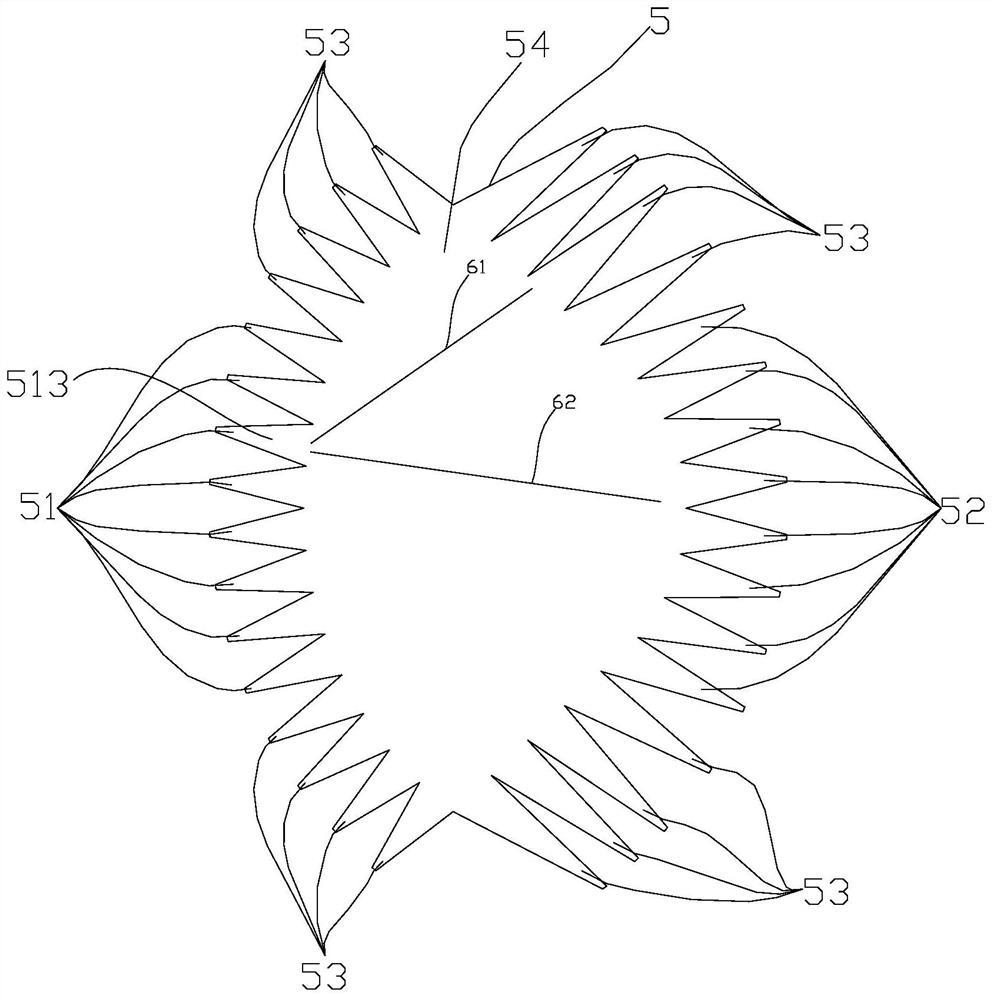

Ultra wide band radiation unit applied to low-frequency band antenna

PendingCN108461904AImprove bandwidth performanceHigh structural reliabilityRadiating elements structural formsIndividually energised antenna arraysResonanceCoupling

The present invention discloses an ultra wide band radiation unit applied to a low-frequency band antenna. The ultra wide band radiation unit comprises radiators having radiation directions which areperpendicular to each other, the lower portions of the radiators are connected with a pedestal through support parts, each radiator comprises one radiation arm, one resonance body and one coupling sheet, the resonance bodies and the coupling sheets are vertically arranged on the radiation arms, and the horizontal planes of the radiation arms are provided with grooves. The ultra wide band radiationunit is compact in structure, large in bandwidth, good in radiation index, firm and durable in structure, wide in application range, high in universality and good in production consistency; and antenna formed based on the radiators has good radiation features.

Owner:JIANGSU JST RF SYST

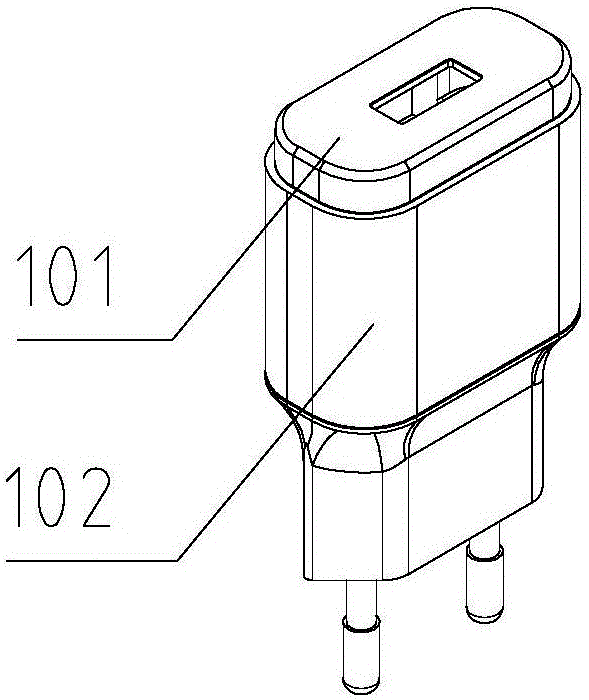

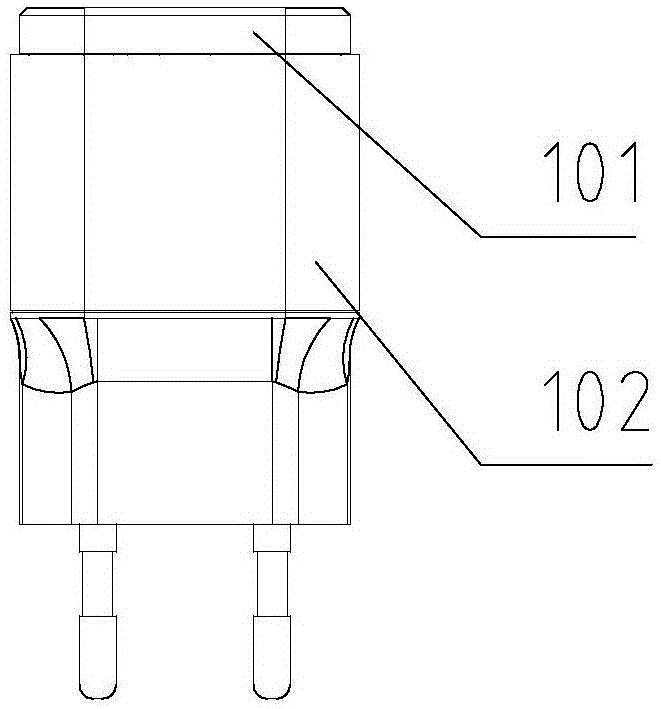

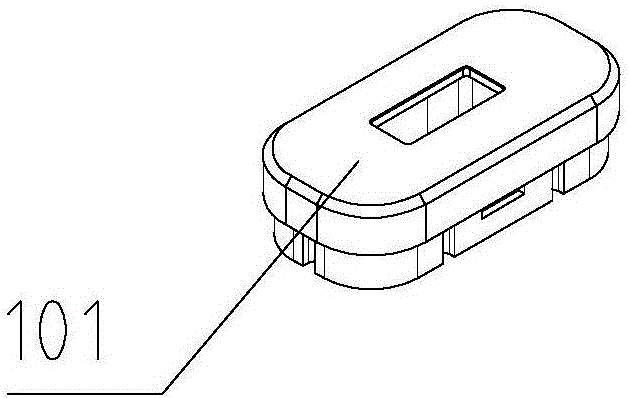

Automatic feeding device for upper cover shell of charger

ActiveCN106494881AEasy to grab individuallyIncrease productivityJigging conveyorsConveyor partsEngineeringUltimate tensile strength

Owner:威海志航机电科技有限公司

Process for artificially cultivating ant maggots

InactiveCN102792926AEasy to industrialize automatic controlGood product consistencyAnimal husbandryIndustrial scaleAutomatic control

The invention discloses a process for artificially cultivating ant maggots and relates to a process for artificially cultivating insects. The process for artificially cultivating the ant maggots, which is disclosed by the invention, solves the problem generated when ants are used as traditional Chinese medicine currently by the following technical scheme that the process comprises the following steps of: (1) grinding the ants into powder; (2) mixing the powder and water and stirring into paste; (3) carrying out high temperature sterilization on the paste; (4) processing grain brans by traditional Chinese medicine and generating maggot eggs; (5) cultivating larvae; (6) cultivating the maggots; (7) separating, cleaning and inactivating the maggots; (8) drying the maggots; and (9) packaging the maggots. According to the invention, macromolecules of the ants are converted into micromolecule components by a bioengineering technology under the mild condition, the allergen and toxic and side effects of ant organisms are eliminated and the ant resources are sufficiently utilized. The production process is easy to industrially and automatically control, the products have good consistency, energy is saved, no environmental pollution is generated and the process is suitable for the industrial scale production.

Owner:HARBIN INST OF TECH

Assembly line assembly technology of automobile front differential mechanism assembly

InactiveCN106312542AImprove assembly accuracyGood product consistencyAssembly machinesAssembly lineEngineering

The invention discloses an assembly line assembly technology of an automobile front differential mechanism assembly. The assembly line assembly technology is characterized by comprising the following steps: oil stain and rust on to-be-assembled parts are removed away, the to-be-assembled parts are dried by compressed air, placed on corresponding stations of an assembly line, and assembled in sequence; the to-be-assembled parts are mounted in the inner cavity of a differential mechanism shell, the clearance between a planetary gear and a half axle gear is adjusted, clamping stagnation and loosening are avoided when the half axle gear is rotated, locking pins are hit into small holes in a planetary gear shaft and the differential mechanism shell in an alignment manner, two ends of the locking pins are punched and riveted for fastening; a special tool is used for pressing a driven gear into the differential mechanism shell on a hydraulic machine, a driven gear connecting bolt is mounted and fastened to a specified torque; and the special tool is used for pressing bearings on two sides of a differential mechanism into two ends of the differential mechanism shell one by one, and the mounted differential mechanism assembly is taken down from the assembly line to be a finished product. The assembly line assembly technology is high in assembling accuracy and production efficiency, excellent in product consistency, low in cost and simple and convenient to operate, and has popularization and application value.

Owner:HENGYANG FENGSHUN AXLE CO LTD

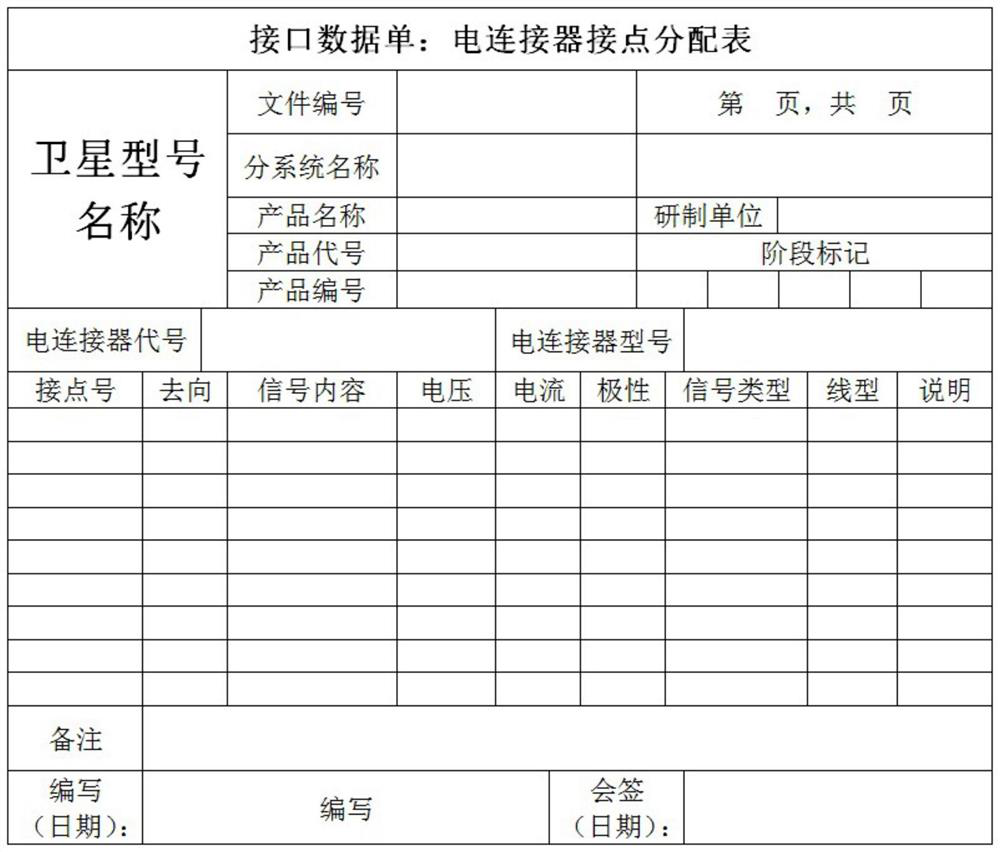

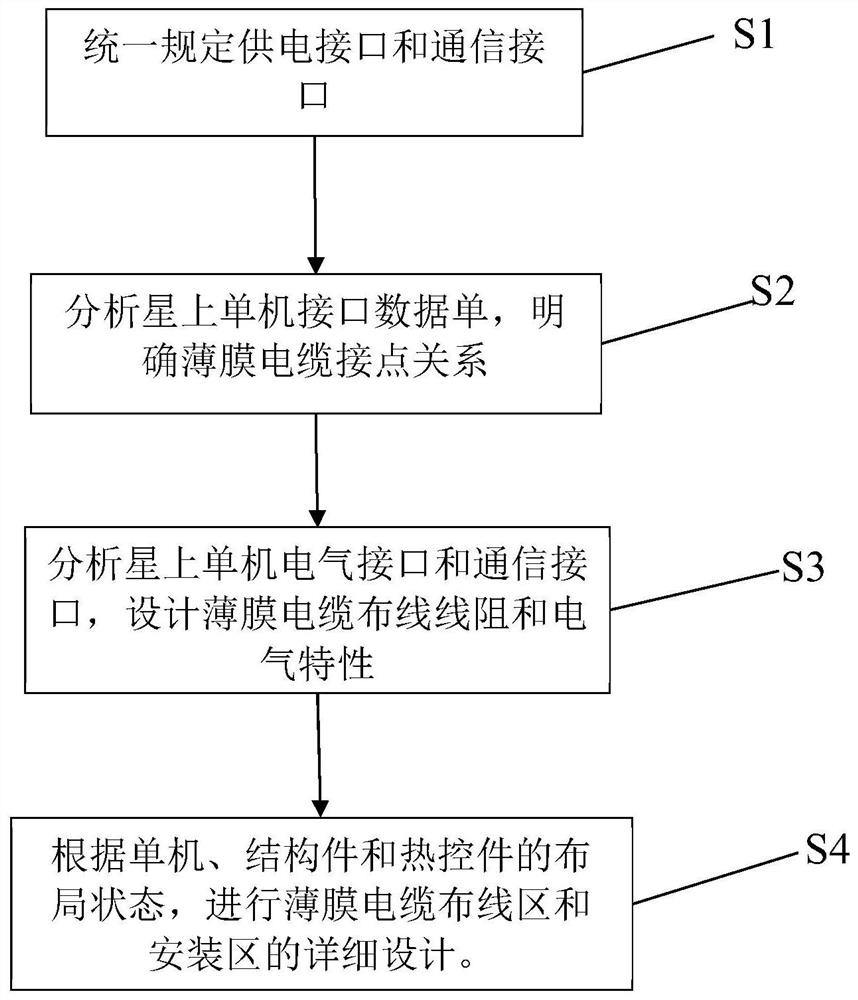

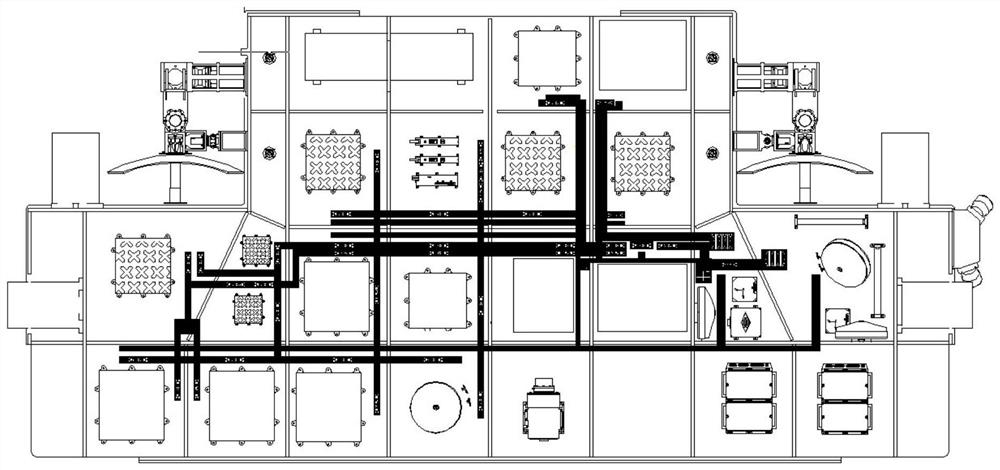

Method for batch production of moonlet cable network

PendingCN113761688ASaving shieldingReduce volumeGeometric CADSpecial data processing applicationsCommunication interfaceHigh density

The invention provides a method for batch production of a moonlet cable network, which comprises the following steps: according to the design characteristics of small space and light weight of a moonlet, paving a film cable on a satellite bottom plate to serve as an interconnection medium between single machines of the whole satellite to replace the traditional high-frequency and low-frequency cable networks on the satellite; according to the layout state of the structural member and the thermal control member, determining the wiring shape and the fixing position of the film cable and the arrangement form of the connector, and achieving power and signal transmission among single machines of the whole satellite by adopting a power supply and communication interface standardization form; the thin film cable solves the problems of heavy weight, large volume, high cost, weak batch production capability, long assembly time and the like of a cable network taking a wire as a main body, eliminates the hidden danger of layout limitation caused by small space of a stacked high-density launching satellite, and effectively meets the characteristics of light weight, small volume, low single-satellite launching cost and the like of the satellite; the cable-free, lightweight, integrated and integrated design of satellites is realized, and batch and large-scale application of satellites with multiple satellites in one rocket is promoted.

Owner:SHANGHAI SATELLITE ENG INST

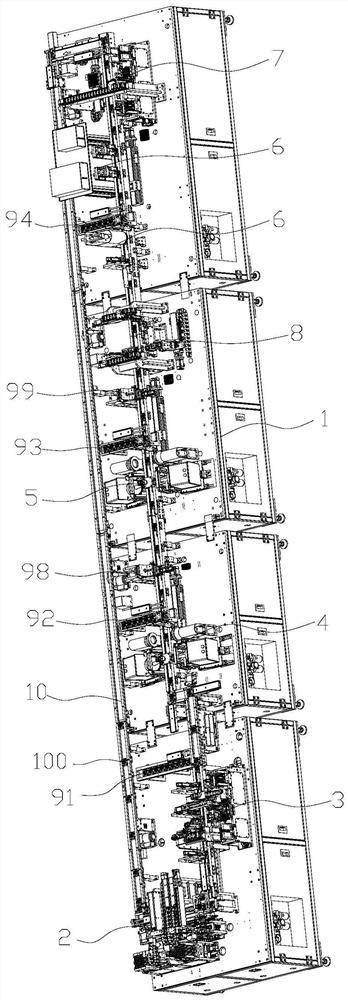

Full-automatic assembling and welding production line

PendingCN112192173AHigh degree of automationImprove the excellent rateMetal working apparatusLaser beam welding apparatusProduction lineMachine

The invention discloses a full-automatic assembling and welding production line which comprises a machine frame, a jig circulating conveying line mechanism, a shell feeding mechanism, a stator feedingand assembling mechanism, a first stator welding mechanism, a second stator welding mechanism, a finished product detection mechanism, a finished product discharging mechanism and an abnormal temporary storage mechanism. The jig circulating conveying line mechanism, the shell feeding mechanism, the stator feeding and assembling mechanism, the first stator welding mechanism, the second stator welding mechanism, the finished product detection mechanism, the finished product discharging mechanism and the abnormal temporary storage mechanism are fixedly installed on the machine frame. The jig circulating conveying line mechanism comprises product jigs used in cooperation, and the product jigs can circularly move in the jig circulating conveying line mechanism. The full-automatic assembling and welding production line has the advantages of being high in automation degree, high in production efficiency, low in equipment cost, low in working intensity, capable of saving labor cost, good in product consistency and the like which cannot be achieved in the prior art.

Owner:SHENZHEN HUADONGXING TECHNOLOGY CO LTD

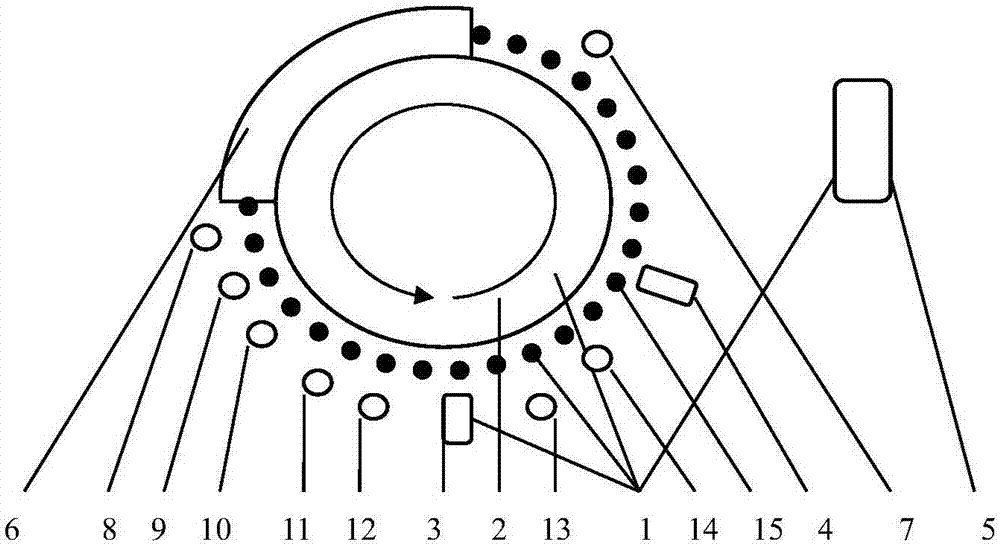

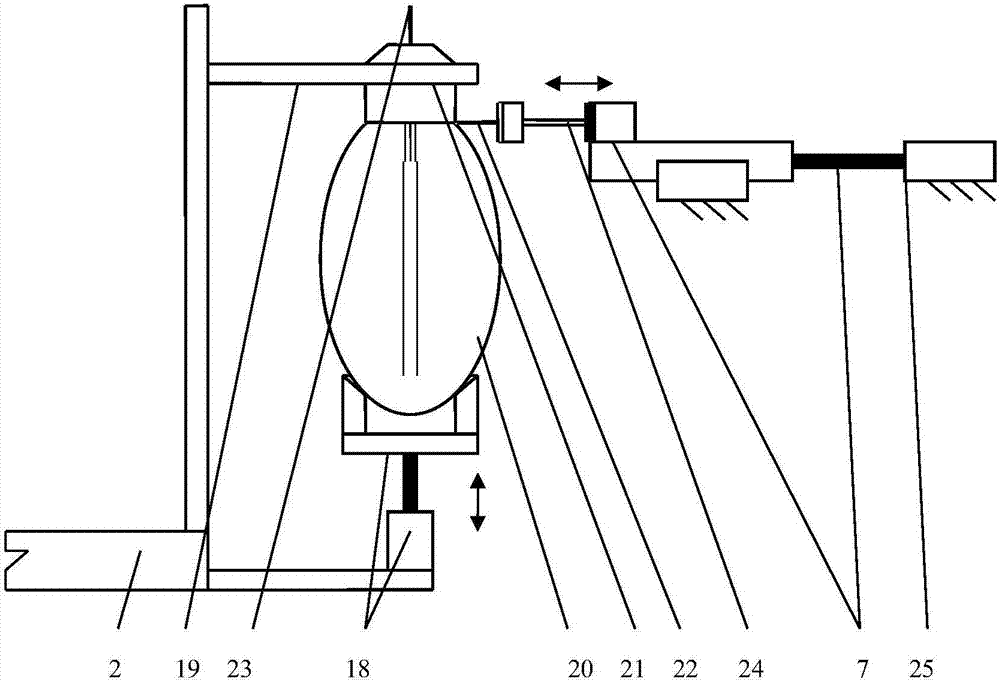

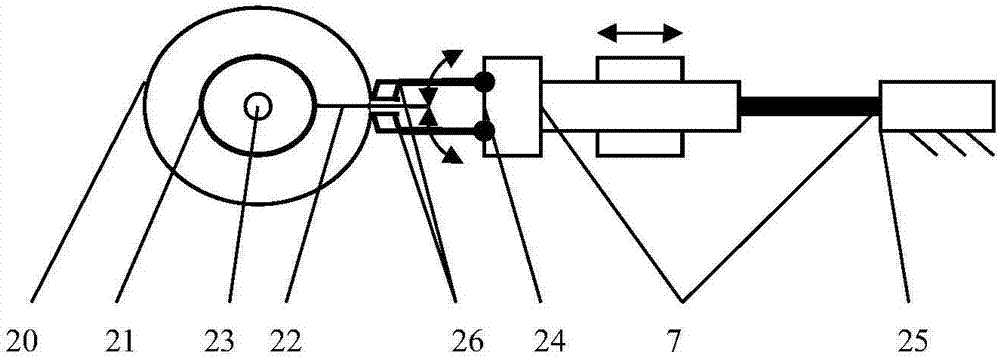

Lamp manufacturing robot

The invention discloses a lamp manufacturing robot. The lamp manufacturing robot comprises a primary rotary platform as well as a side wire pre-welding treatment facility, a top wire pre-welding treatment facility, a side wire automatic welding mechanism, a top wire automatic welding mechanism and a control system which are arranged at the periphery of the primary rotary platform; a wire dragging mechanism comprises a pneumatic clamp; a wire erecting mechanism comprises a pushing rod; a side wire shearing mechanism comprises a pair of pneumatic scissors; a side wire bending mechanism comprises a pushing rod; a side wire pressing mechanism comprises a pushing rod mould; the side wire automatic welding mechanism comprises a side wire soldering machine; a top wire shearing mechanism comprises a pair of pneumatic scissors and a pneumatic element; a top wire pressing mechanism comprises a pushing rod and a pneumatic element; the top wire automatic welding mechanism comprises a top wire soldering machine; the primary rotary platform rotates by an angle every certain time according to an order of a host machine of the control system; and each mechanism acts. The lamp manufacturing robot operates with two shifts, so that 14 to 20 workers can be saved, and therefore, 0.4-0.8 million of labor cost can be saved per year.

Owner:HAINING XINYU SOLAR ENERGY EQUIP

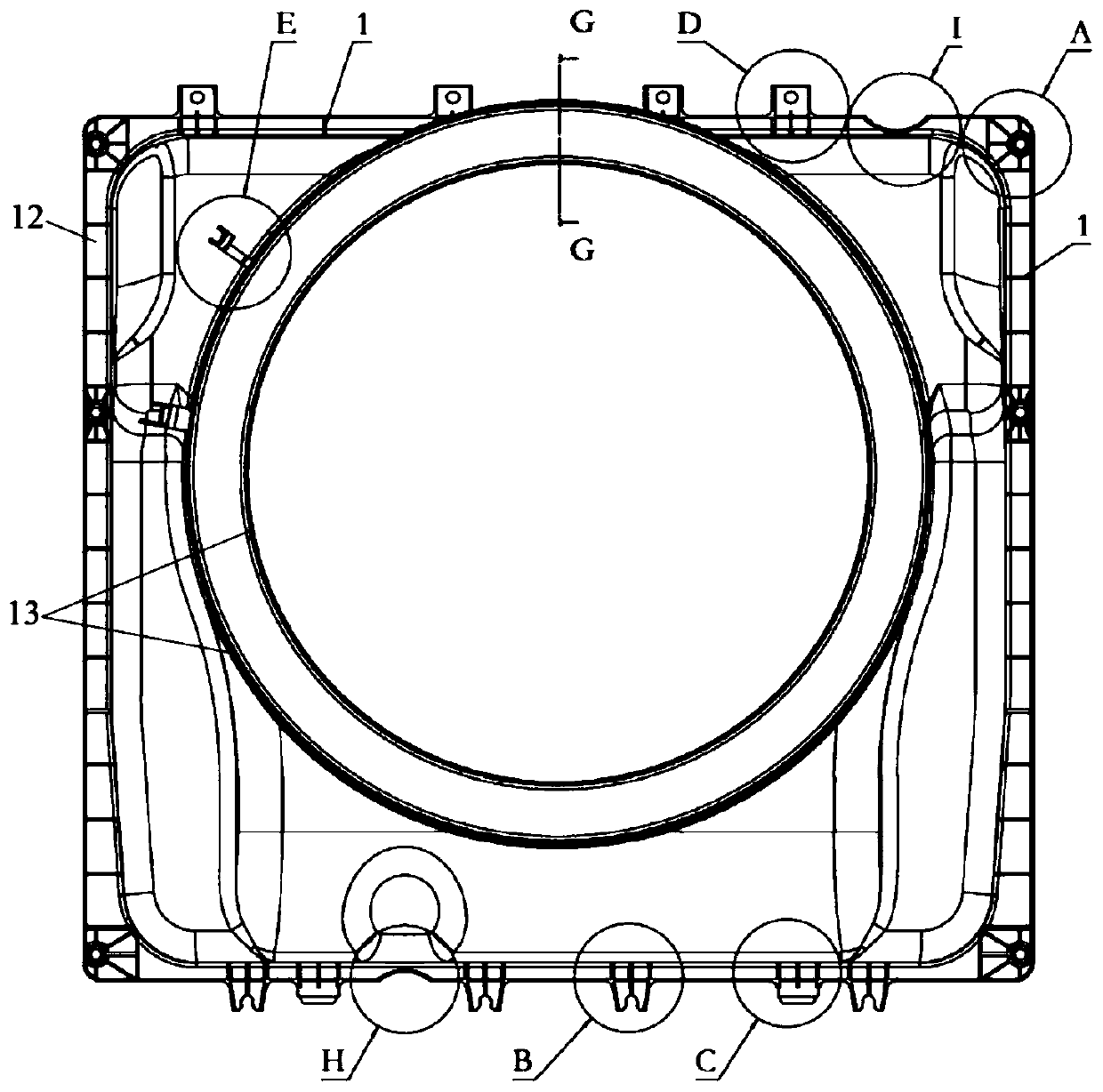

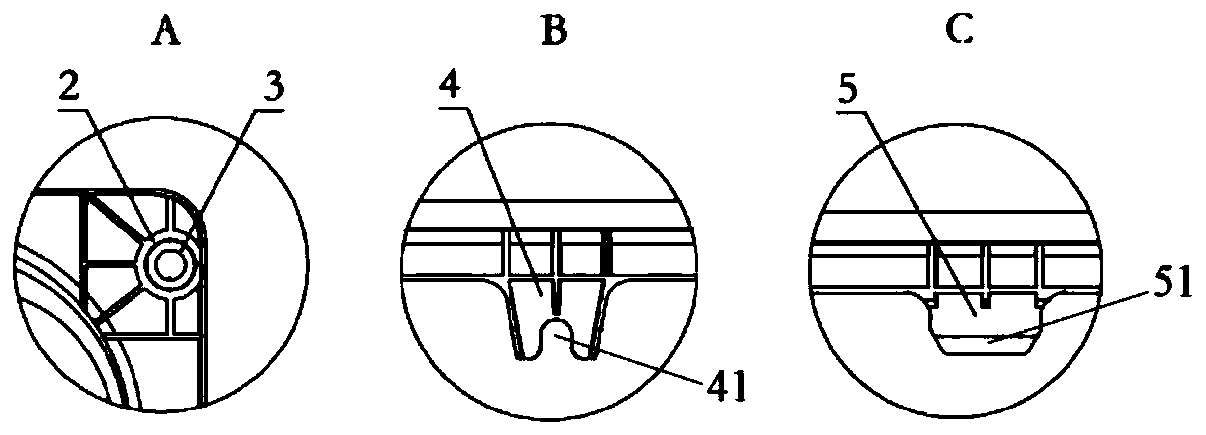

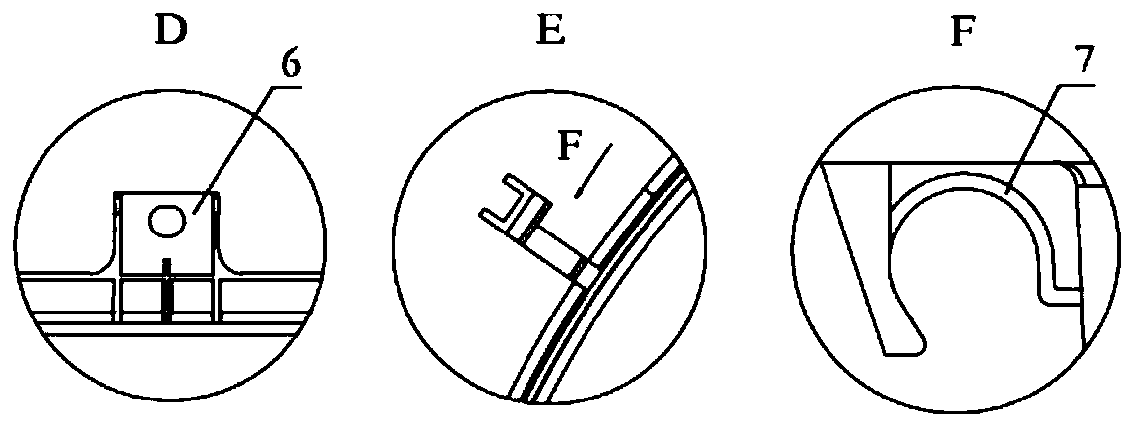

Wind shield

InactiveCN111520223AIncrease productivityGood product consistencyMachines/enginesEngine cooling apparatusPhysicsAir volume

The invention relates to a wind shield which comprises a wind shield body made of PP materials. The wind shield body adopts an integral injection molding one-step forming technology and comprises a wind shield ring, the wind shield ring comprises an inner ring and an outer ring, the inner ring is shorter than that of the outer ring, the inner ring and the outer ring are combined to form a C-shapedgroove, and an engine fan ring is arranged in the middle of the C-shaped groove. According to the wind shield, integral injection molding one-step forming is carried out without secondary processing,the production efficiency is high, the product consistency is good, the size precision is high, and the structure is reliable; the matching position of the wind shield and an engine fan is designed into a C-shaped structure, so that the air quantity loss is reduced; and the problems of large air loss and poor assembly process of a traditional wind shield are solved, and the effective supply air rate and production efficiency are improved.

Owner:SHAANXI HEAVY DUTY AUTOMOBILE

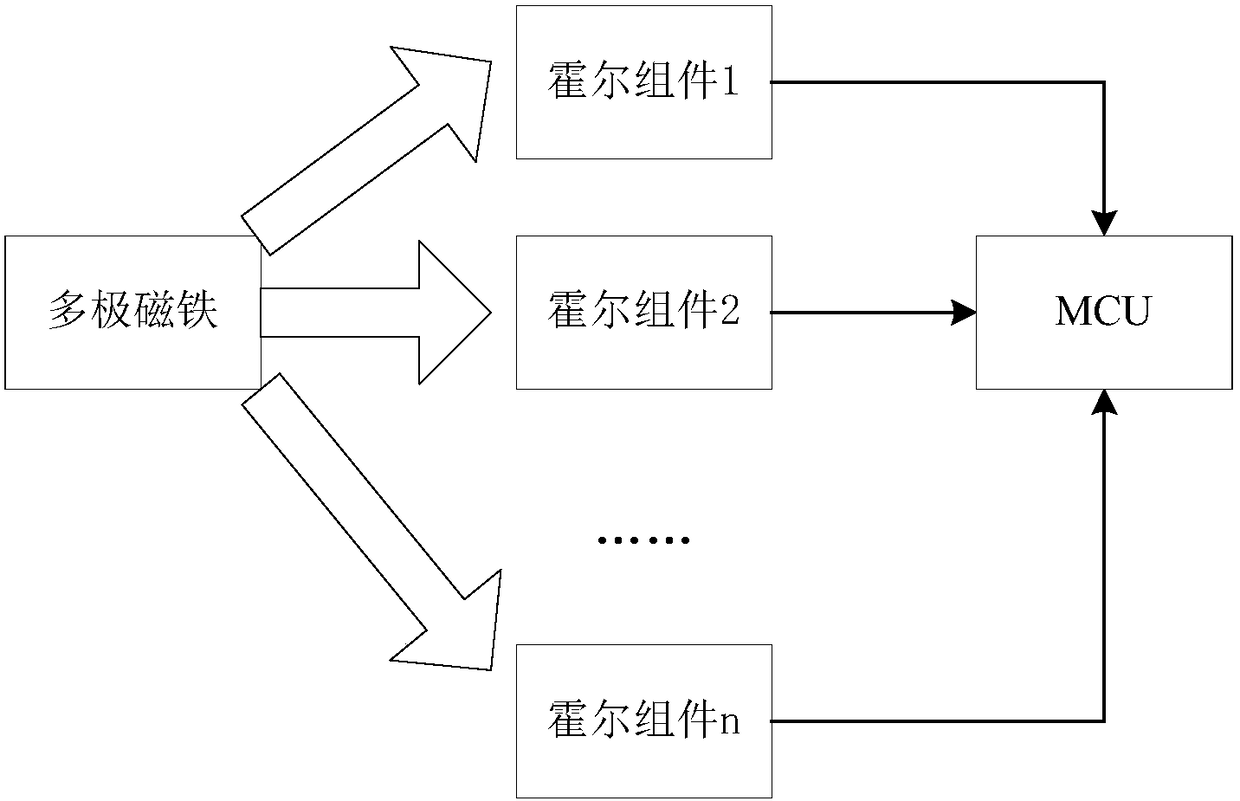

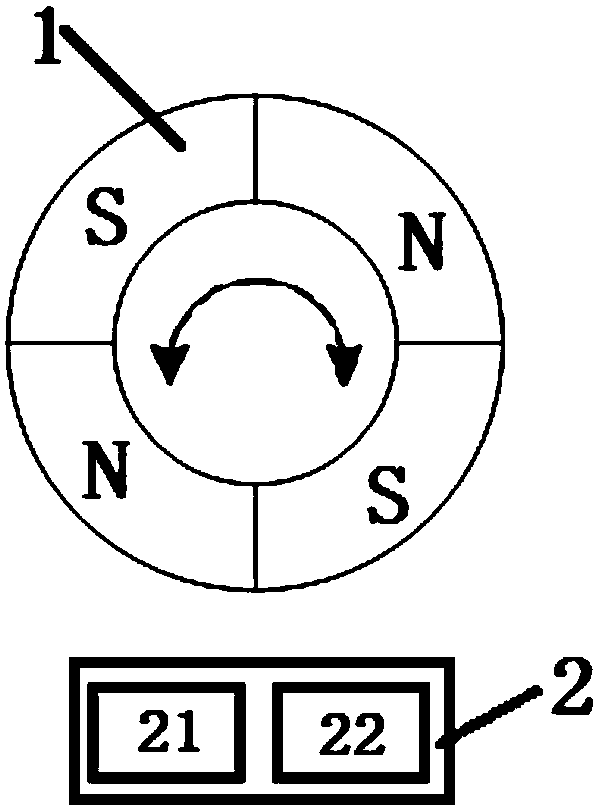

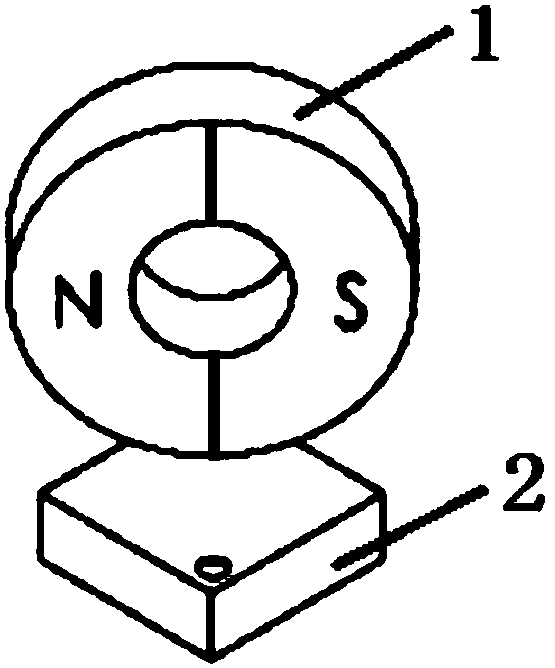

Magnetic roller device and rotating information calculation method thereof

PendingCN108152525AOvercome the disadvantage of large sizeReduce volumeIndication/recording movementDevices using electric/magnetic meansDevice formElectrical polarity

The invention discloses a magnetic roller device and a rotating information calculation method thereof. The magnetic roller device comprises a multi-pole magnet, an MCU, a plurality of Hall componentsand a roller arranged on a handwriting device. The multi-pole magnet is arranged on the roller and comprises at least a pair of magnetic poles opposite in polarity, and output ends of the Hall components are all connected with an input end of the MCU. The magnetic roller device formed by the multi-pole magnets and the roller replaces a mechanical roller and a touch roller to realize data regulation of the handwriting device, and rotating information calculation and acquisition of the magnetic roller device are realized by cooperation with the Hall components and the MCU, so that the defect oflarge size of the mechanical roller is overcome while problems of proneness to interference and accidental touching of the touch roller and poor production uniformity are solved, and small size, lessproneness to interference, low accidental touching rate and high production uniformity are realized. The magnetic roller device is widely applicable to the field of handwriting devices.

Owner:HANVON UGEE TECH CO LTD

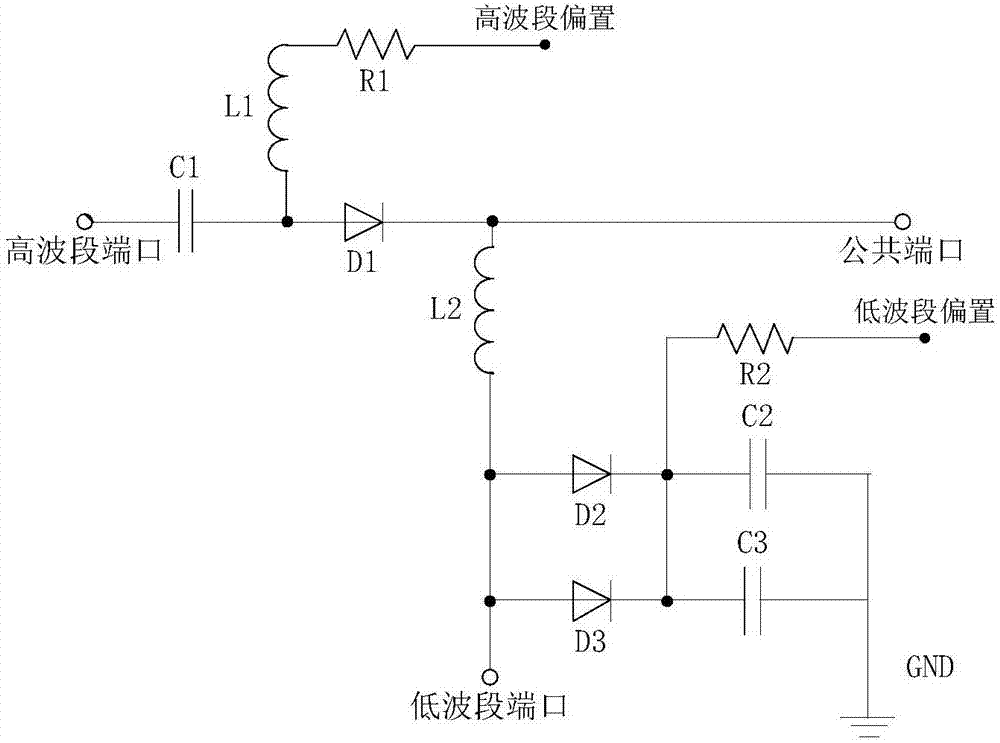

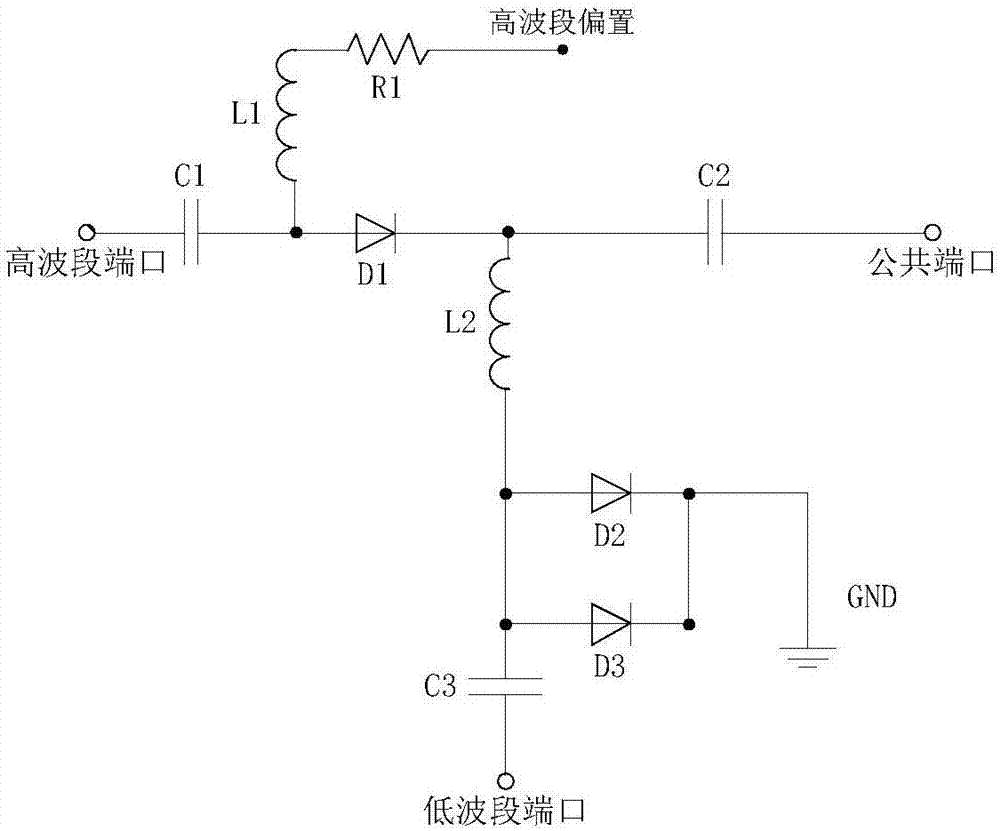

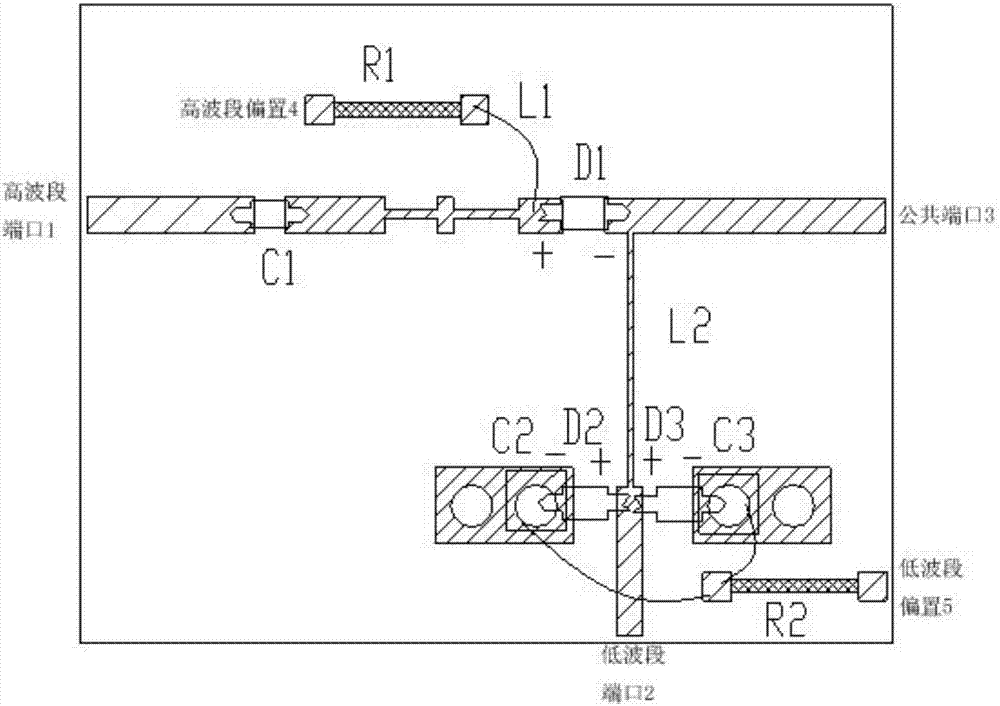

Broadband microwave switch duplex circuit with low video feed through leakage

The invention relates to a microwave switch duplex circuit, and specifically relates to a broadband microwave switch duplex circuit with low video feed through leakage. The broadband microwave switch duplex circuit comprises a high waveband port, a high waveband bias circuit, a low waveband port, a low waveband bias circuit and a public port; a high waveband PIN diode adopts a serial structure, a low waveband PIN diode adopts a parallel structure, the PIN diode control of the switch duplex circuit adopts a positive and negative balance power supply mode, and the technical problem that a bias voltage fast step change will generate a low-frequency video feed through signal at a switch conversion state to cause interference to the normal transmission of signals in the prior art is solved.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Wideband dual polarized base station antenna

PendingCN106981721AMiniaturizationExtended current pathRadiating elements structural formsPolarised antenna unit combinationsSoftware engineeringMiniaturization

The invention discloses a wideband dual polarized base station antenna, and belongs to the technical field of mobile communication base station antennas. The wideband dual polarized base station antenna comprises a radiation unit and a reflecting plate, and is characterized in that the radiation unit is composed of a dipole antenna provided with L-shaped slots, the reflecting plate is arranged below the dipole radiation unit, and the reflecting plate and the radiation unit feed in a coaxial connection mode; the radiation structure of the dipole antenna is formed by placing dipoles inclining by 45 degrees in a crossed manner, openings of the L-shaped slots of the dipole antenna are oppositely arranged, and crossed opposite corners of the dipole antenna are connected through two connecting pieces. By adopting the structure disclosed by the invention, the dipole radiation unit provided with the L-shaped slots increases a current path and realizes miniaturization of the antenna, the radiation structure is formed by placing the two dipoles inclining by 45 degrees in a crossed manner, thereby forming large coupling, and realizing wideband characteristics. The wideband dual polarized base station antenna is simple in design, convenient to process and assemble, good in production conformity, convenient for batch production and high in production efficiency, and has the advantages of wide band, dual polarization and the like.

Owner:JIANGSU MINGLIAN ELECTRONICS TECH

A molding runner with a wax discharge port and its preparation and plugging method

ActiveCN105458180BPrevent leakageGood product consistencyFoundry mouldsFoundry coresInvestment castingEngineering

The invention aims at solving the problems existing in blockage of a dewaxing opening in the prior art, provides a forming pouring gate with a dewaxing opening and a preparing and blocking method of the forming pouring gate, and belongs to the field of large thin-wall casting investment castings. The forming pouring gate is a wax pipeline with openings in the two ends and is composed of a left section, a middle section and a right section. The right section is a wax pipeline cavity. The middle section is a wax pipeline cavity with a thick end and a thin end, the thin end is connected with the right section, and the thick end is connected with the left section. The left section is a wax pipeline cavity with a boss on the side wall, and the dewaxing opening not opened is formed in the upper surface of the boss. The production consistency of the forming pouring gate is good, and the production process can be conveniently controlled. Meanwhile, the dewaxing opening is blocked through a special ceramic stop block, appropriate coatings are matched, the pheromone of leakage of molten steel during casting can be prevented, the feeding effect is guaranteed, and metallurgical defects such as hole shrinkage, loosening and blending can be reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

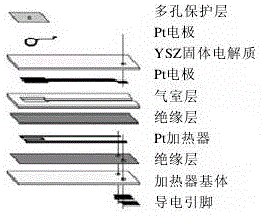

Novel chip type potentiometric automobile oxygen sensor and preparation method thereof

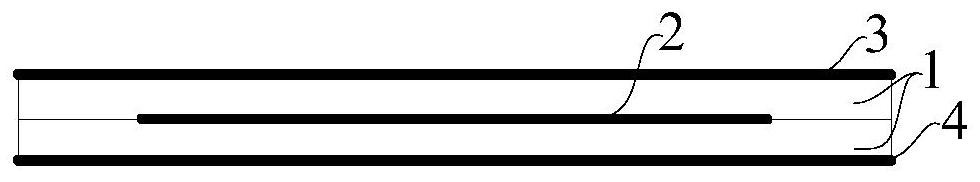

PendingCN106706743ACompact structureReduce volumeMaterial analysis by electric/magnetic meansPunchingOxygen sensor

The invention relates to a novel chip type potentiometric automobile oxygen sensor. The sensor comprises a protective layer, a signal layer and a heating layer, which are sequentially superposed, wherein the signal layer comprises seven layers of tape casting substrates which are sequentially laminated, the protective layer, an upper reactive electrode insulating layer, an outer reactive electrode and a lower reactive electrode insulating layer are sequentially arranged on the upper surface of the first layer of tape casting substrate from top to bottom, and an upper reference reactive electrode insulating layer, a reference reactive electrode and a lower reference reactive electrode insulating layer are sequentially arranged on the lower surface of the fourth layer of tape casting substrate from top to bottom; the heating layer comprises fourth layers of tape casting substrates which are sequentially laminated, and a heating electrode and a heating electrode pin are respectively arranged on the upper surface of the uppermost layer of tape casting substrate and the lower surface of the lowermost layer of tape casting substrate. The sensor is prepared by preparation of multiple kinds of tape casting slurry, tape casting forming, edge removal slitting, punching, printing, superposition, vacuum sealing molding, hot isostatic pressing, slitting and sintering. The oxygen sensor has the advantages of being more stable in performance and higher in production consistency.

Owner:莱鼎电子材料科技有限公司

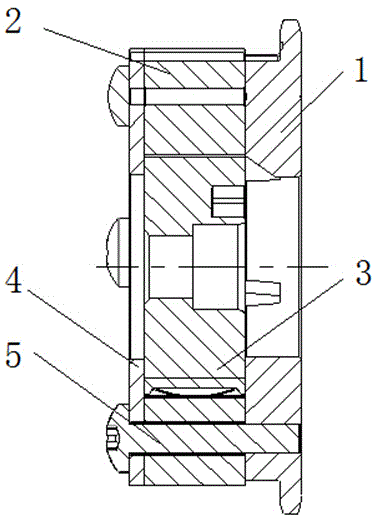

Oil duct of novel camshaft phase regulator

InactiveCN105626182AReduce manufacturing costImprove work efficiencyValve arrangementsMachines/enginesCamshaftPetroleum engineering

The invention relates to an oil duct of a novel camshaft phase regulator. The oil duct comprises a chain wheel, a stator, a rotor and a rear cover, wherein the stator is connected to the rear end of the chain wheel; the rear cover is connected to the rear end of the stator; the rotor is arranged in a cavity formed by the chain wheel, the stator and the rear cover; the rear cover, the stator and the chain wheel are fixed by screws; special-shaped ends for the screws to penetrate through are arranged at the inner circumference of the stator; a special-shaped cavity is formed between every two adjacent special-shaped ends; special-shaped claws which are arranged in the special-shaped cavities and are attached to the inner walls of the special-shaped cavities are arranged at the outer circumference of the rotor; each special-shaped cavity is divided into an inlet angle cavity and a lag angle cavity by the special-shaped claw; special-shaped oil grooves communicating with the inlet angle cavities or the lag angle cavities are formed in the upper surface of the rotor; and oil holes are formed between the specials-shaped oil grooves and the upper surface of the rotor. The oil duct has the advantages that the oil holes are changed into the special-shaped oil grooves and are formed in the end face of the rotor; in addition, a die can be obtained, the manufacturing cost of the rotor is reduced, and the working efficiency is improved; and good consistency of production by the die is realized.

Owner:JIANGSU HAILONG ELECTRICAL APPLIANCE

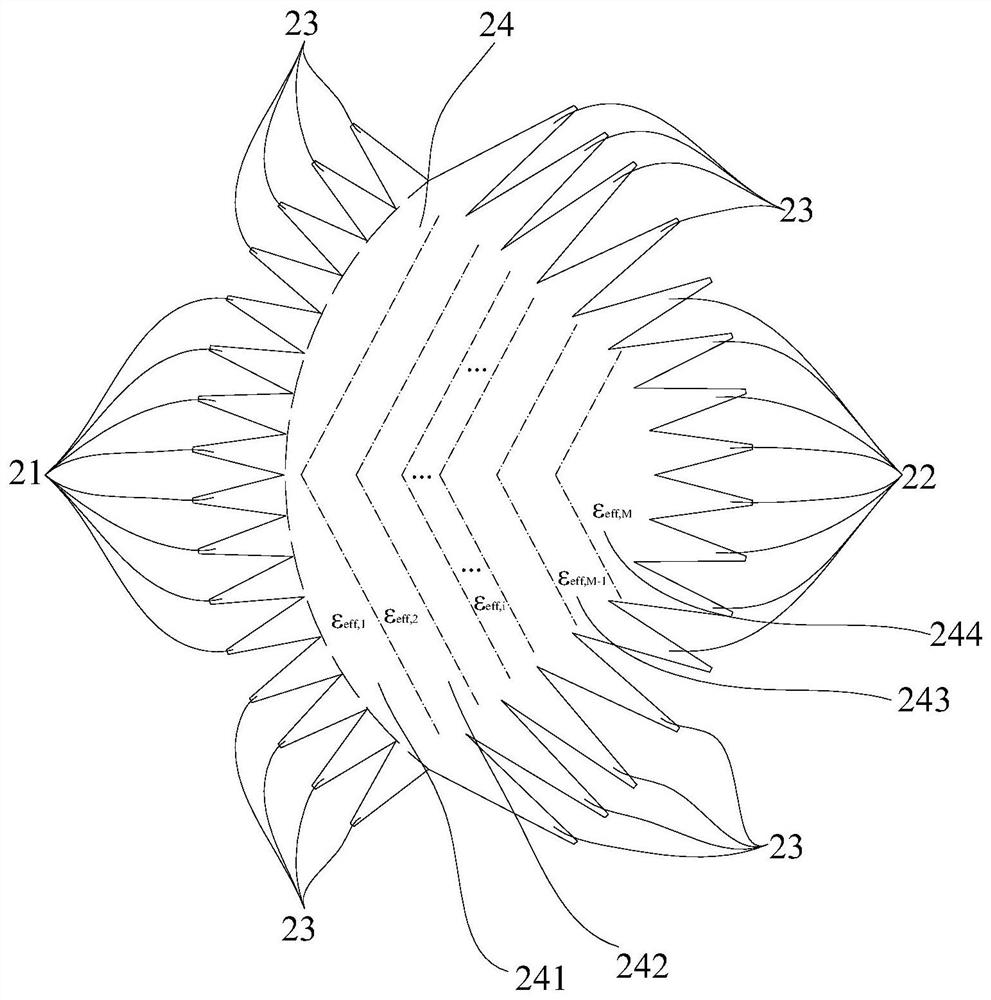

Low-profile low-loss Rotman lens

ActiveCN113363731AStable energy transmissionGood consistencyRadiating elements structural formsDielectric substrateSi substrate

The invention provides a low-profile and low-loss Rotman lens. The low-profile and low-loss Rotman lens comprises two layers of non-metallized dielectric substrates and three layers of metallized copper-clad planes; the two layers of non-metallized dielectric substrates are an upper layer non-metallized dielectric substrate and a lower layer non-metallized dielectric substrate; the three-layer metalized copper-clad plane comprises an upper layer metalized ground-clad plane, a middle layer printed metal plane lens and a lower layer metalized ground-clad plane; the middle-layer printed metal plane lens comprises a lens body, an input port and an output port which are located on the two sides of the lens body, and a vacant port located between the input port and the output port. The lens body is divided into M areas, and a non-metallized dielectric substrate area corresponding to each area has an equivalent relative dielectric constant partition design; and the input port, the output port and the vacant port are realized based on a strip line structure. The Rotman lens realized through lens body partition and the strip line structure has the characteristics of low profile and low loss.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com