A molding runner with a wax discharge port and its preparation and plugging method

A technology of wax discharge port and runner, which is used in casting molding equipment, molds, cores, etc. to accelerate the dewaxing efficiency and quality, reduce wax residue, and reduce shrinkage cavities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

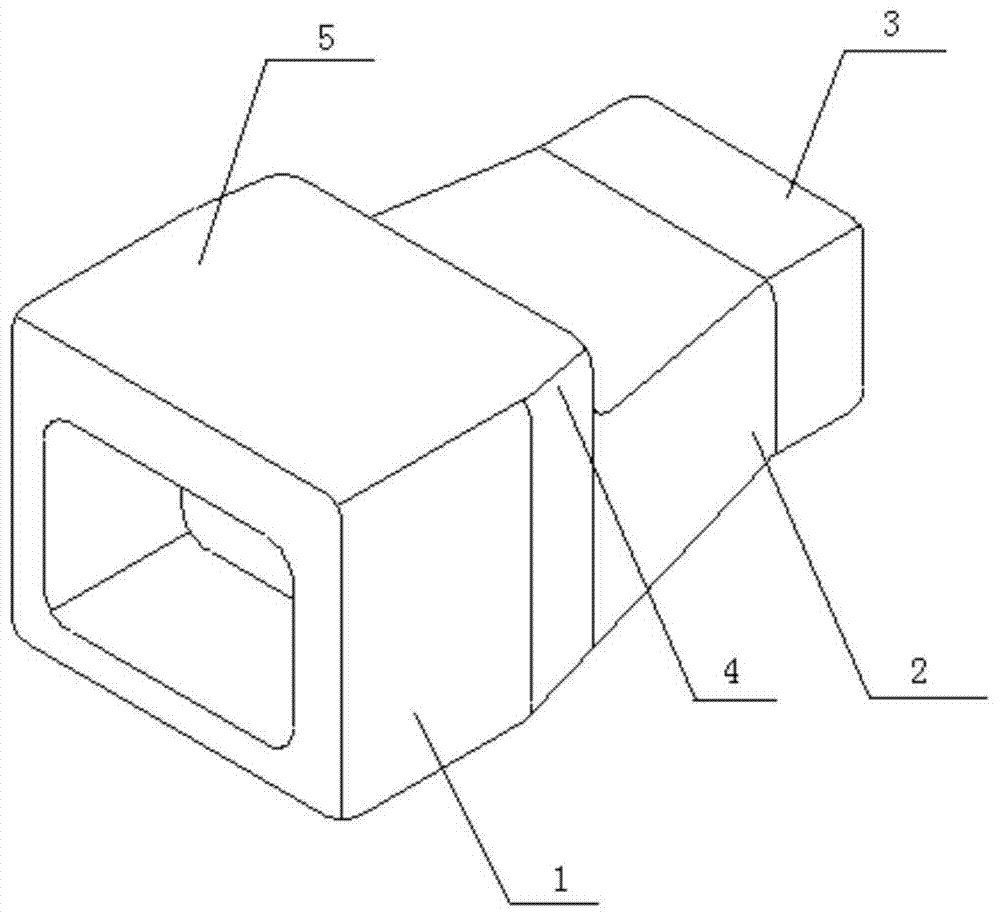

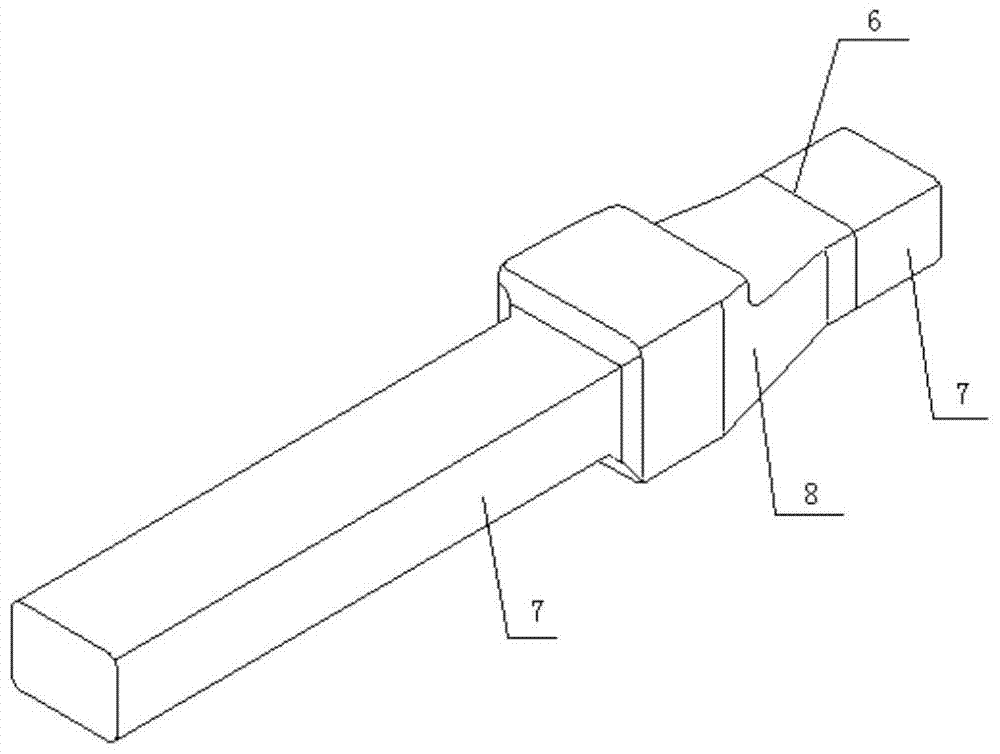

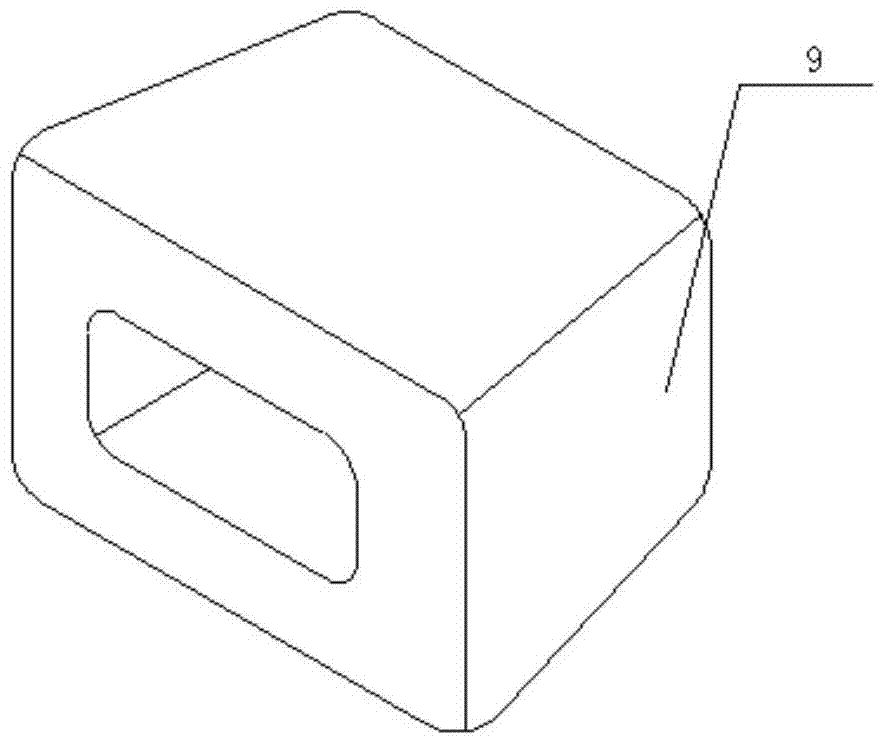

[0031] A molding sprue with a wax drain, such as figure 1 As shown, it is a near-rectangular wax pipe with openings at both ends, consisting of left section 1, middle section 2 and right section 3; right section 3 is the cavity of the wax pipe, with a size of 35mm×25mm×10mm; middle section 2 is one end The thicker end is thin and the quadrangular truss-shaped wax pipe cavity, the thinner end is connected with the right section, the thicker end is connected with the left section, the middle section 2 is 30mm long, the size of the thick end is 50mm×30mm, and the size of the thin end is 35mm× 25mm; the left section 1 is a wax pipe cavity with a boss 4 on the side wall, the upper surface of the boss 4 is the unopened wax discharge port 5, the size of the left section is 50mm×40mm×40mm, and the molding runner is located in the left section The opening of 1 closes the edge in the radial direction of the pipeline, and the size of the formed opening is 35mm×25mm, which is the same as ...

Embodiment 2

[0033] The above-mentioned preparation method of the molding runner containing the wax discharge port, the steps are as follows:

[0034] 1) Heat the mold of the forming runner to 25°C; heat and melt the wax material into a fluid state, and maintain the temperature of the wax material at 72°C, and then use a manual wax press machine to inject the wax material into the mold at a pressure of 0.8MPa Medium, and keep warm for 30s;

[0035] 2) After the heat preservation is completed, open the mold and take it out to obtain the molding runner.

Embodiment 3

[0037] The above-mentioned preparation method of the molding runner containing the wax discharge port, the steps are as follows:

[0038] 1) Heat the mold for forming the sprue to 33°C; heat and melt the wax material into a fluid state, and maintain the temperature of the wax material at 69°C, and then use a high-pressure wax press machine to inject the wax material into the mold at a pressure of 1.2MPa Medium, and keep warm for 23s;

[0039] 2) After the heat preservation is completed, open the mold and take it out to obtain the molding runner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com