Patents

Literature

60results about How to "Guaranteed feeding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

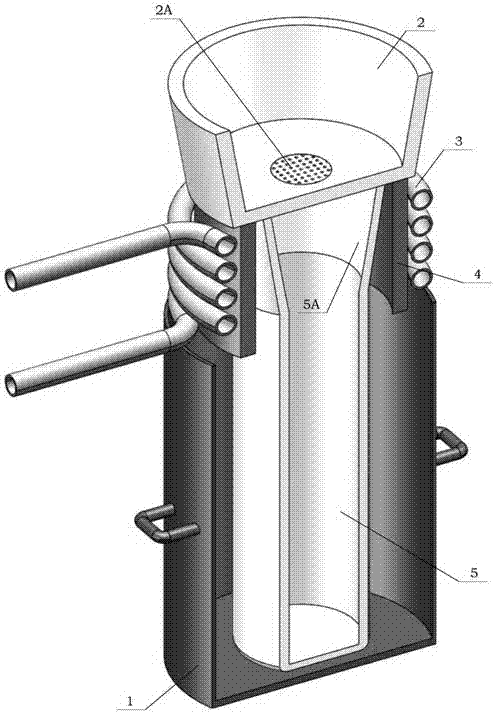

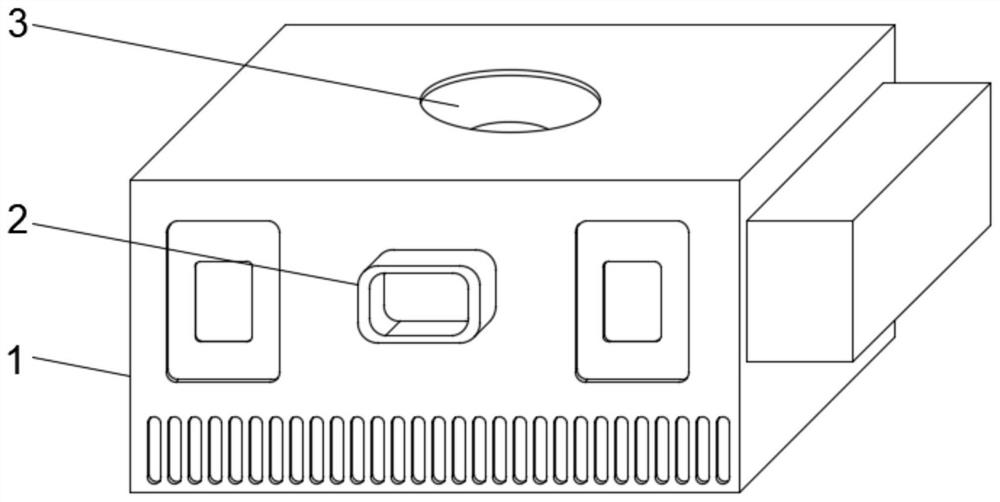

Automatic bait feeding machine for culturing marine products

InactiveCN102124980ARealize quantitative deliveryPrevent moistureAgricultural fishingPisciculture and aquariaProgrammable logic controllerControl system

The invention discloses an automatic bait feeding machine for culturing marine products, comprising a floater body (1) provided with a bait bin (2). The automatic bait feeding machine is characterized in that the upper end of the bait bin (2) is provided with a solar cell plate (3); a storage cell (4) arranged in the floater body (1) is connected with the solar cell plate (3); a PLC (programmable logic controller) control system (5) is arranged in the bait body (1); an audio transmitter (6) and a camera (7) connected with the PLC control system (5) are both arranged on the bottom of the floater body (1); a wireless data module (22) is arranged in the floater body (1); and a quantitative bait feeding device (8) is also arranged below the bait bin (2). The automatic bait feeding machine for culturing marine products provided by the invention has an artful structure, power is provided by solar energy, quantitative bait feeding is realized, and underwater conditions are monitored.

Owner:DALIAN OCEAN UNIV

Casting method of ZL101 thin-wall aluminium alloy part

The invention discloses a casting method of a ZL101 thin-wall aluminium alloy part. The method includes steps of: 1) preparing moulding sand raw materials; 2) preparing binder slurry, wherein the binder slurry comprises 36-40% by weight of starch, 6-8% by weight of furan resin, 14-16% by weight of calcium bentonite, 3-5% by weight of bagasse cellulose powder having a size of -100 meshes, 1-2% by weight of zinc stearate and 2-3% by weight of sodium tripolyphosphate, with the balance being water; 3) preparing moulding sand; 4) manufacturing a casting and gating system; 5) smelting a ZL101 alloy, wherein 0.035% of Sr is added for modification, argon is fed after slag removal, gas removal is performed by rotation, smelting is performed when the temperature is 735-745 DEG C, and the alloy is allowed to stand for 10-12 min after smelting; 6) casting, wherein the aluminum alloy casting temperature is controlled to e 720-730 DEG C, and the casting speed is controlled in a manner that the former two fifth of the total casting amount adopts a speed of 6-8 kg / s, the middle two fifth adopts a speed of 4-5 kg / s, and the last one fifth adopts a speed of 6-8 kg / s; and 7) cooling with the mould, opening the mould, cleaning and performing thermal processing.

Owner:DAYE HONGTAI ALUMINUM IND CO LTD

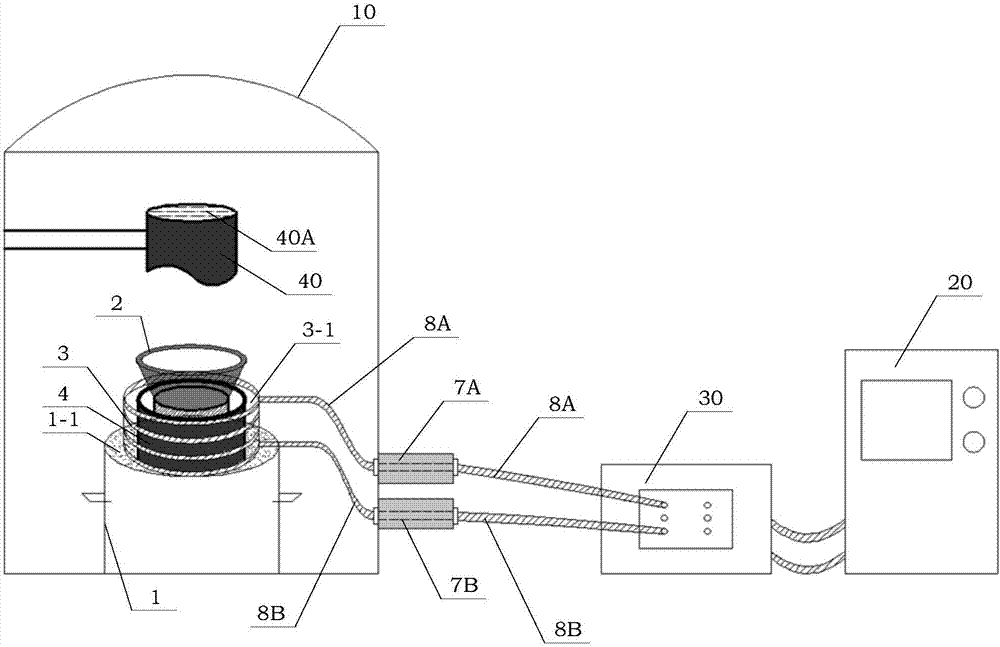

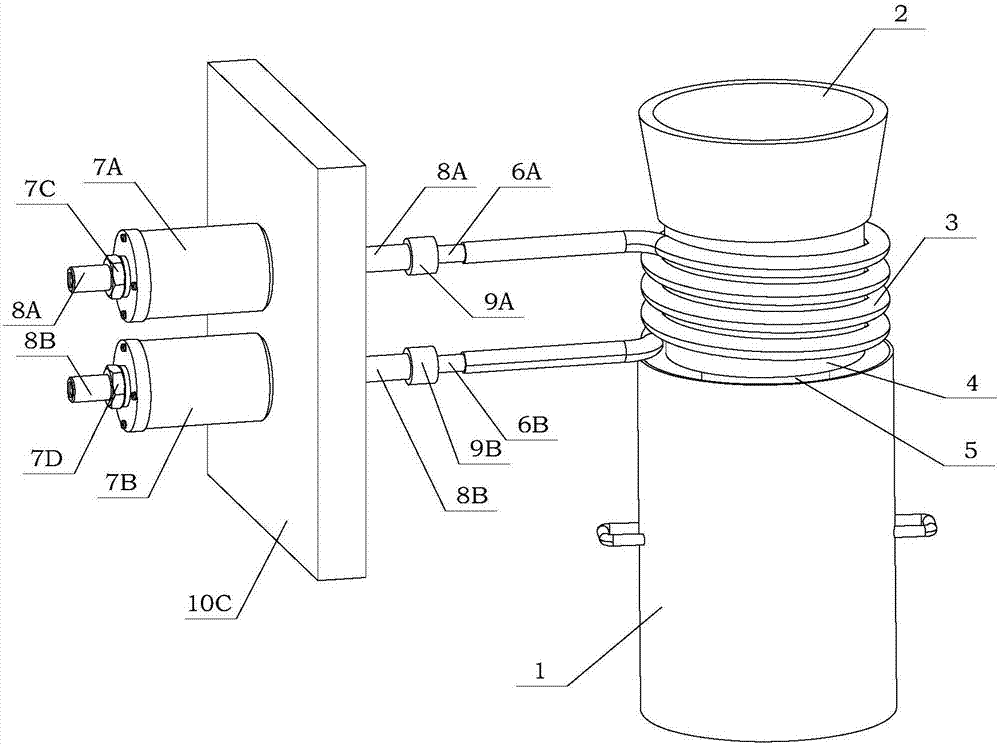

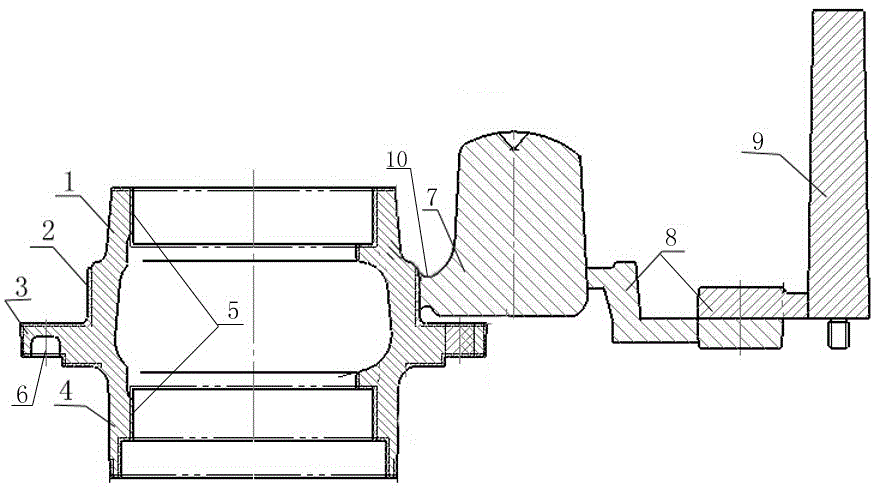

Sequential solidification technology device and method used in vacuum smelting equipment

The invention discloses a sequential solidification technology device and method used in vacuum smelting equipment. An induction heating coil is placed in a dead head section of an ingot die, and the feeding capacity of metal liquid in a dead head is enhanced through an induction heating method; a bottom cooling device with the cooling area smaller than the area of the cross section, at the bottom position of the ingot die, of a casting is arranged at the bottom of an ingot die base, the solid-liquid interface angle is reduced, and the metal liquid in the ingot die after pouring can be sequentially solidified from bottom to top. The solidification process control method is applicable to production of metal bar castings in the vacuum smelting equipment. Through the sequential solidification technology device and method, macroshrinkage and shrinkage porosity in alloy bar castings can be eliminated, the casting quality and the technology yield are improved, and the production efficiency is greatly improved.

Owner:BEIHANG UNIV

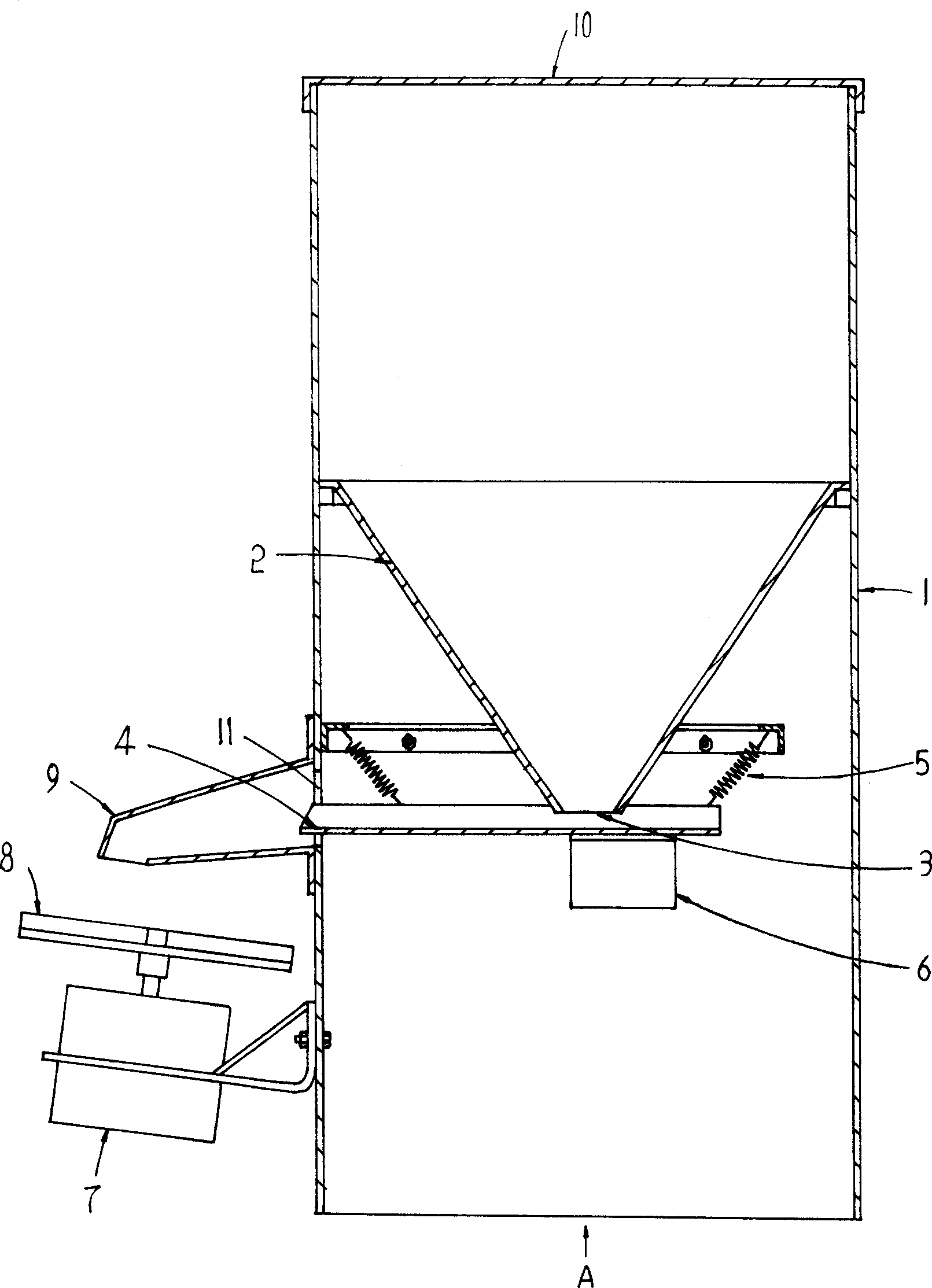

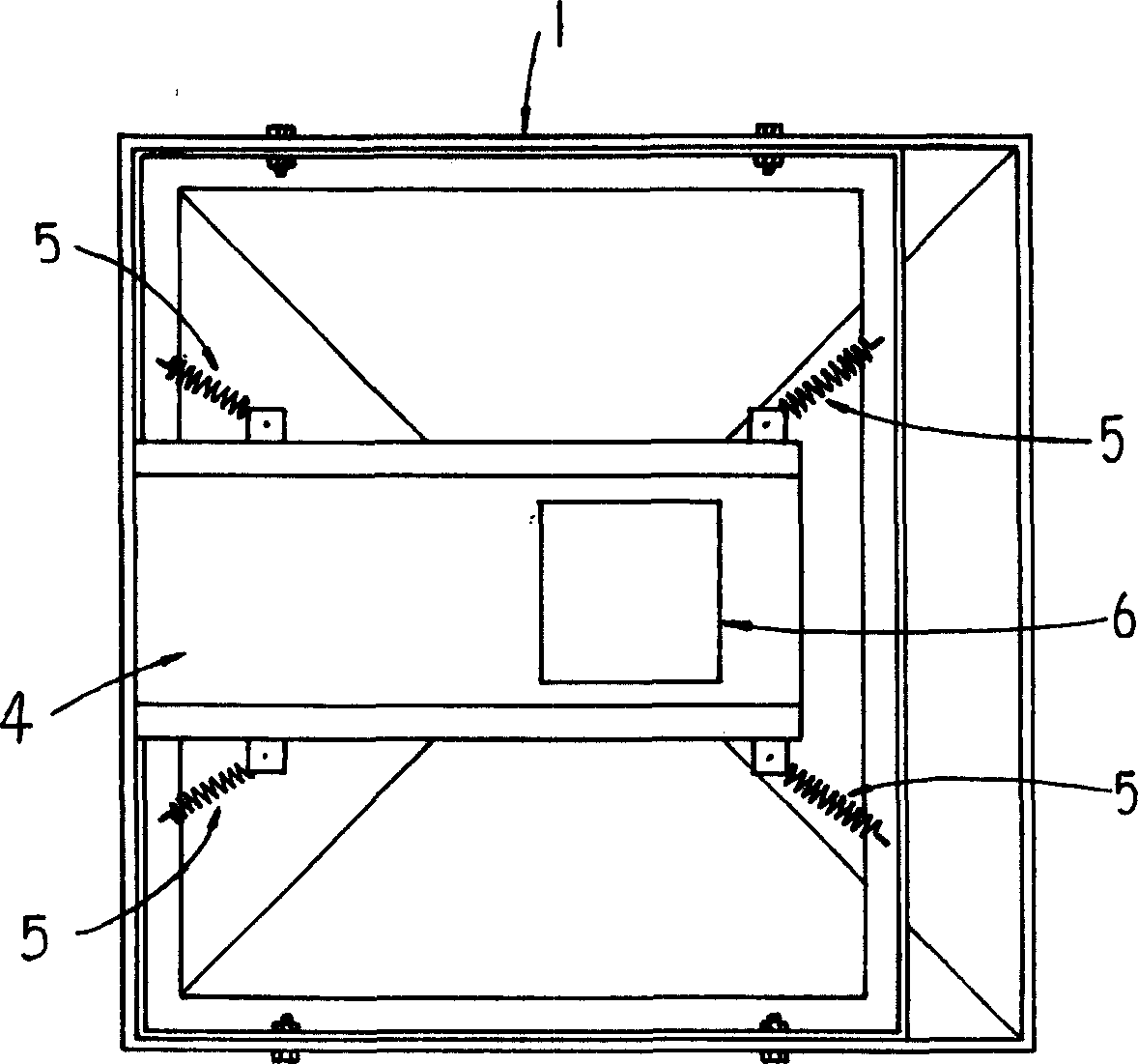

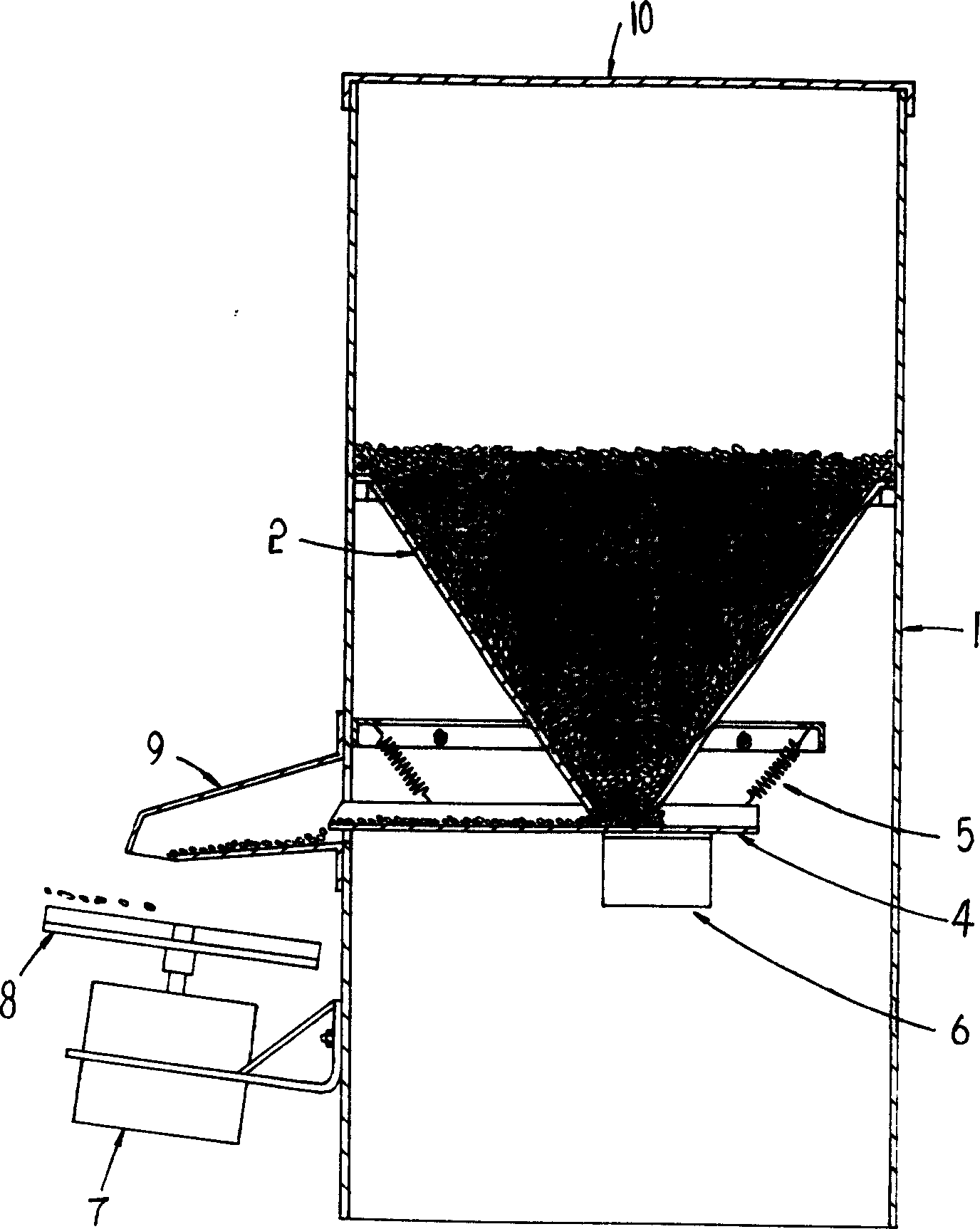

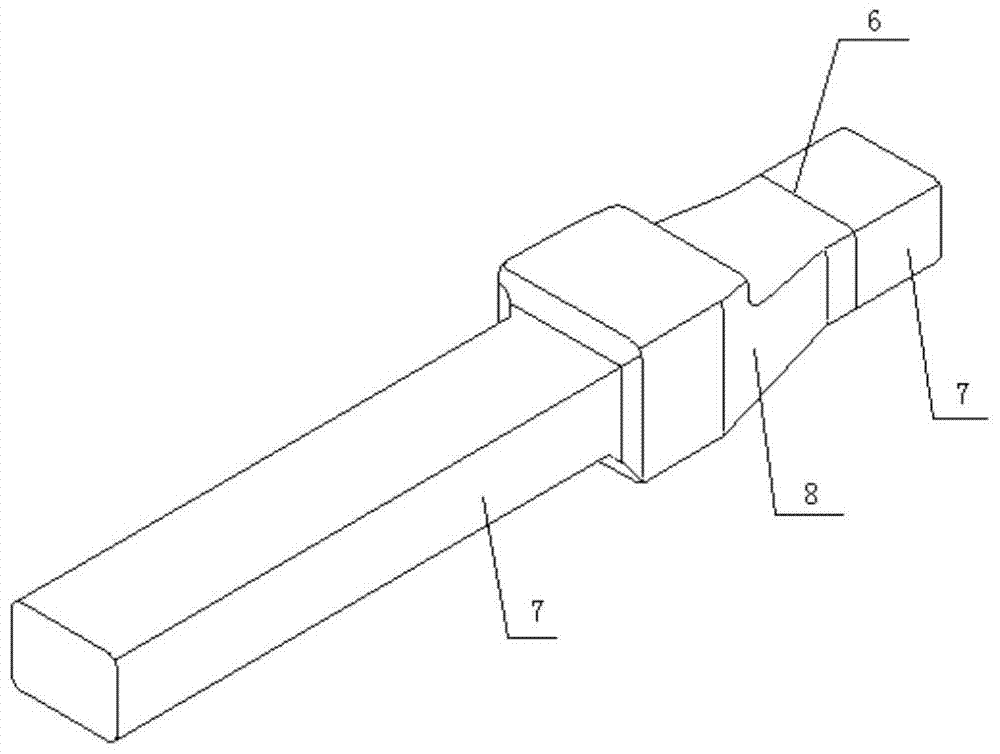

Fodder thrower

InactiveCN1820590AControl outputAvoid shear damageAnimal feeding devicesPisciculture and aquariaEngineeringFodder

The fodder thrower as one cultivation machine includes a casing, a fodder bin fixed inside the casing and with fodder outlet in the bottom, a fodder discharging board set below the fodder outlet and supported with several elastic supports, and a vibrator installed on the fodder discharging board. The casing has through hole in the front part for the front end of the fodder discharging board to stretch beyond the casing, and on the casing wall below the through hole, a fodder distributing motor is fixed and a fodder distributing pan is installed onto the fodder distributing motor and in the position corresponding to the front end of the fodder discharging board. The fodder thrower is used in pond cultivation and has the advantages of easy control of the discharged fodder amount, high utilization rate of fodder and convenient use.

Owner:莫洪林

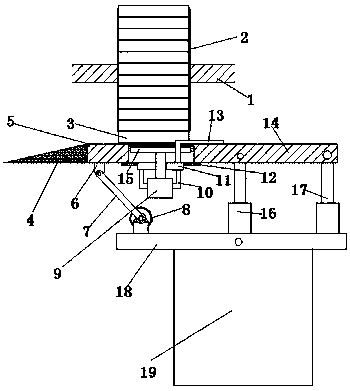

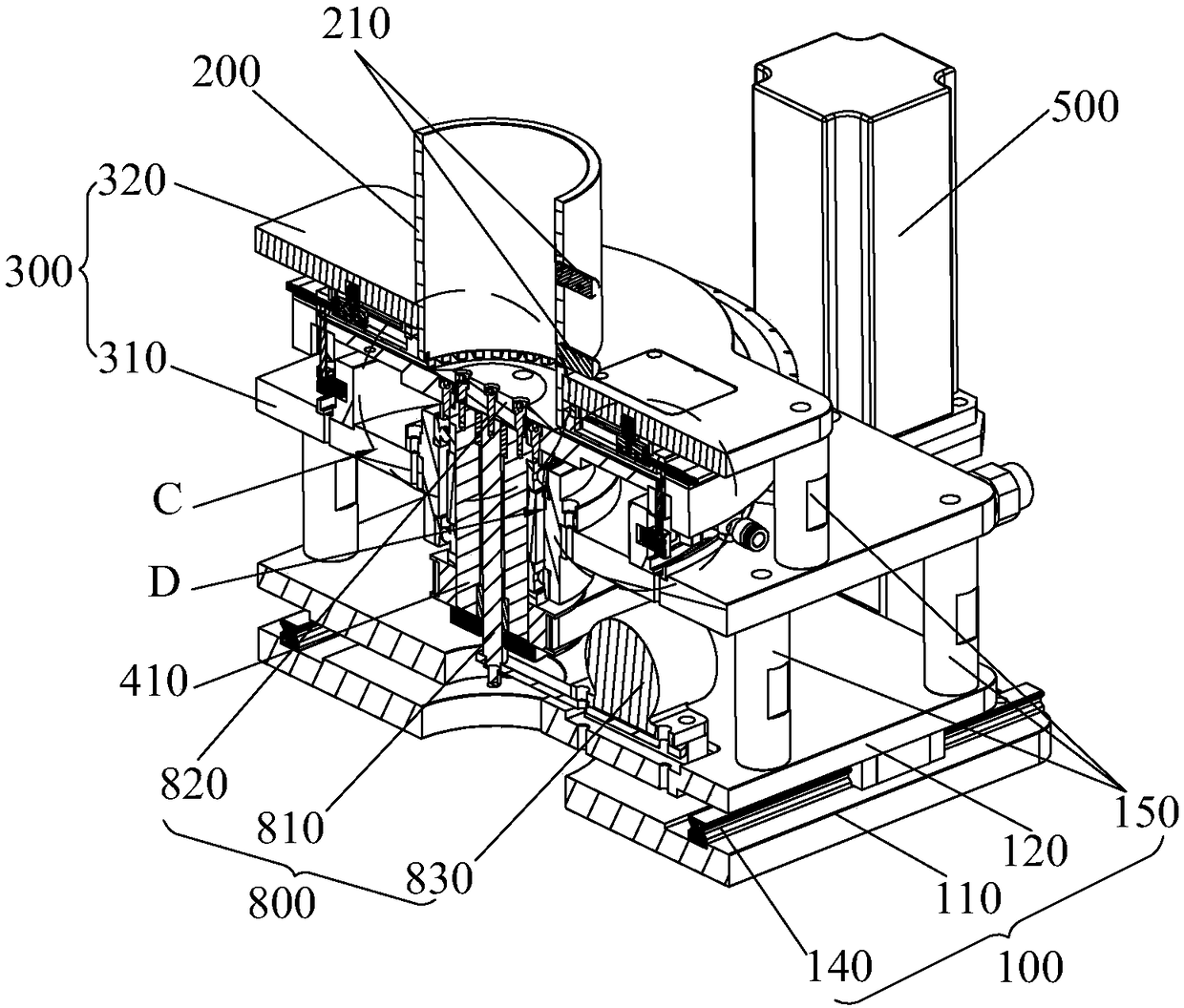

Automatic feeding device

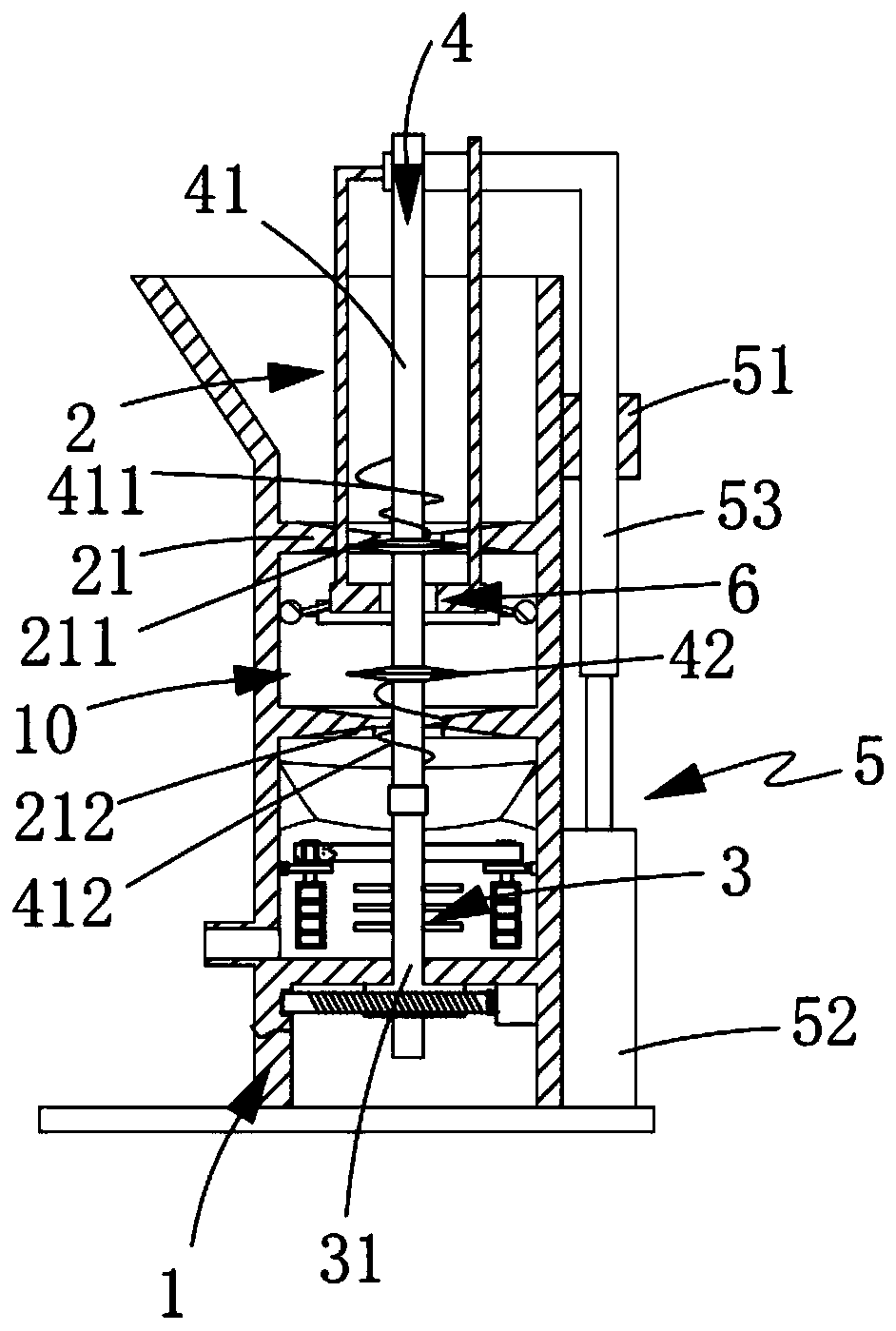

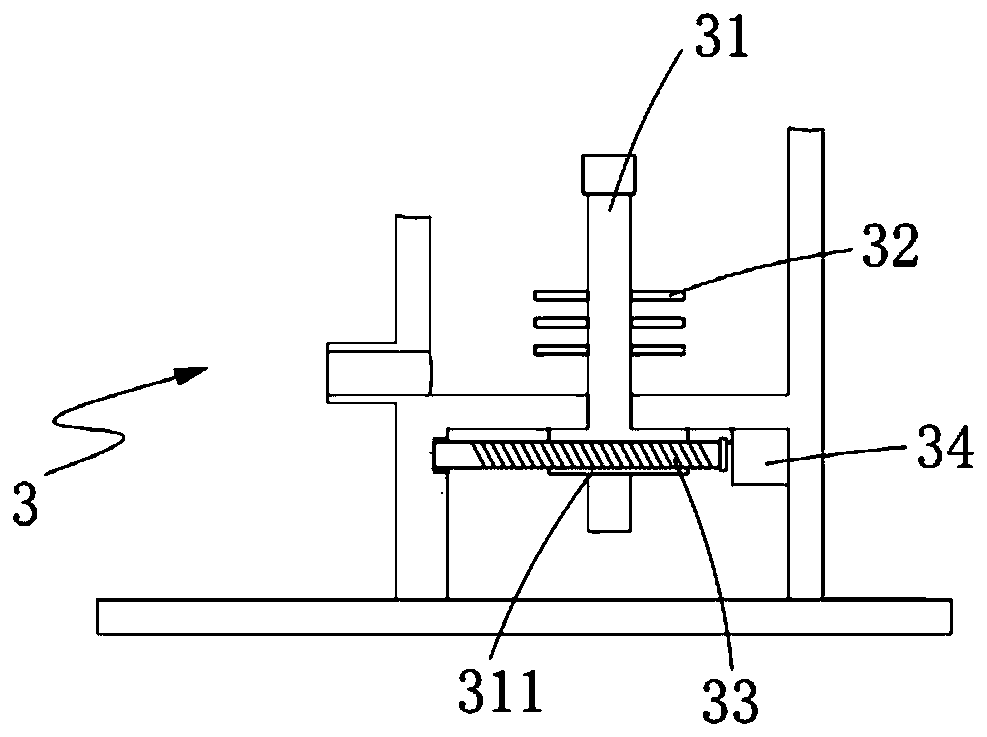

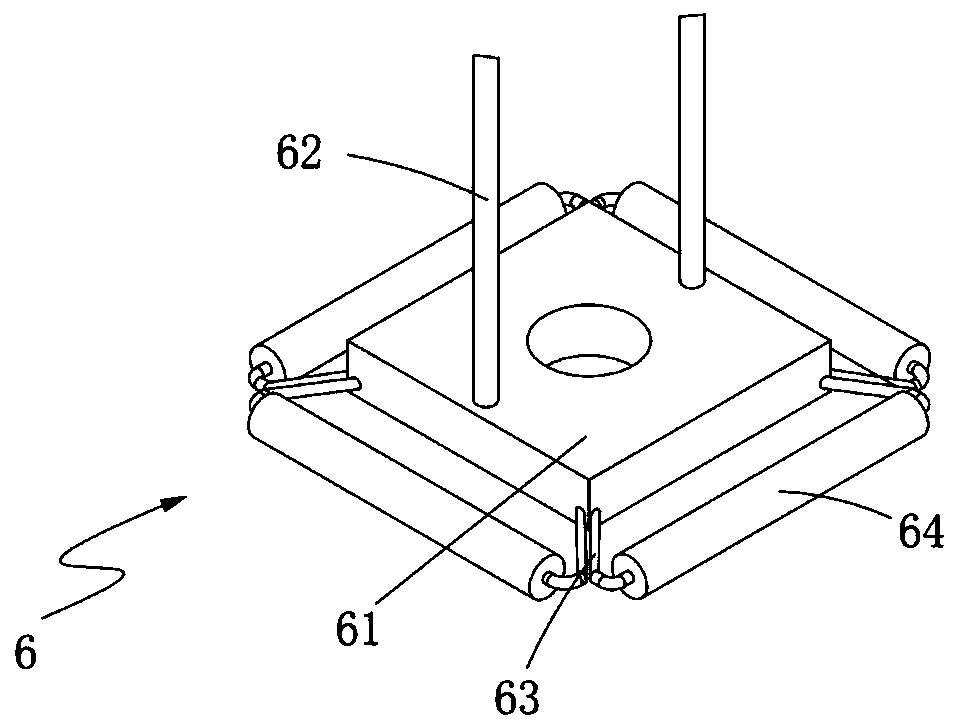

ActiveCN109230375AFully automatedRealize oscillating feedingConveyor partsEngineeringAutomatic processing

The invention discloses an automatic feeding device which can automatically feeding objects, can be applied not only to automatic processing of machinery, but also can be applied to equipment for material transportation, material batching and the like, thereby greatly improving the material feeding efficiency and accuracy. The automatic feeding device can realize the orderly feeding of the materials one by one. A material toggling method is used, can not only reduce an occupied space, but also is accurate and reliable in toggling operation. Further, a support material plate can be tilted whenfeeding, so that feeding efficiency can be improved ax required and the materials is prevented from being stuck on a feeding plate when fed. For the objects that are difficult to fall, the reciprocating rotation frequency of a rotating cylinder can be controlled by a controller, thereby realizing the oscillating feeding of the support material plate and ensuring a feeding effect. The counting control of the feeding objects can be realized. The automatic feeding device realizes the automation of the feeding and the automation of the management.

Owner:SHENZHEN HADESHENG PRECISION TECH

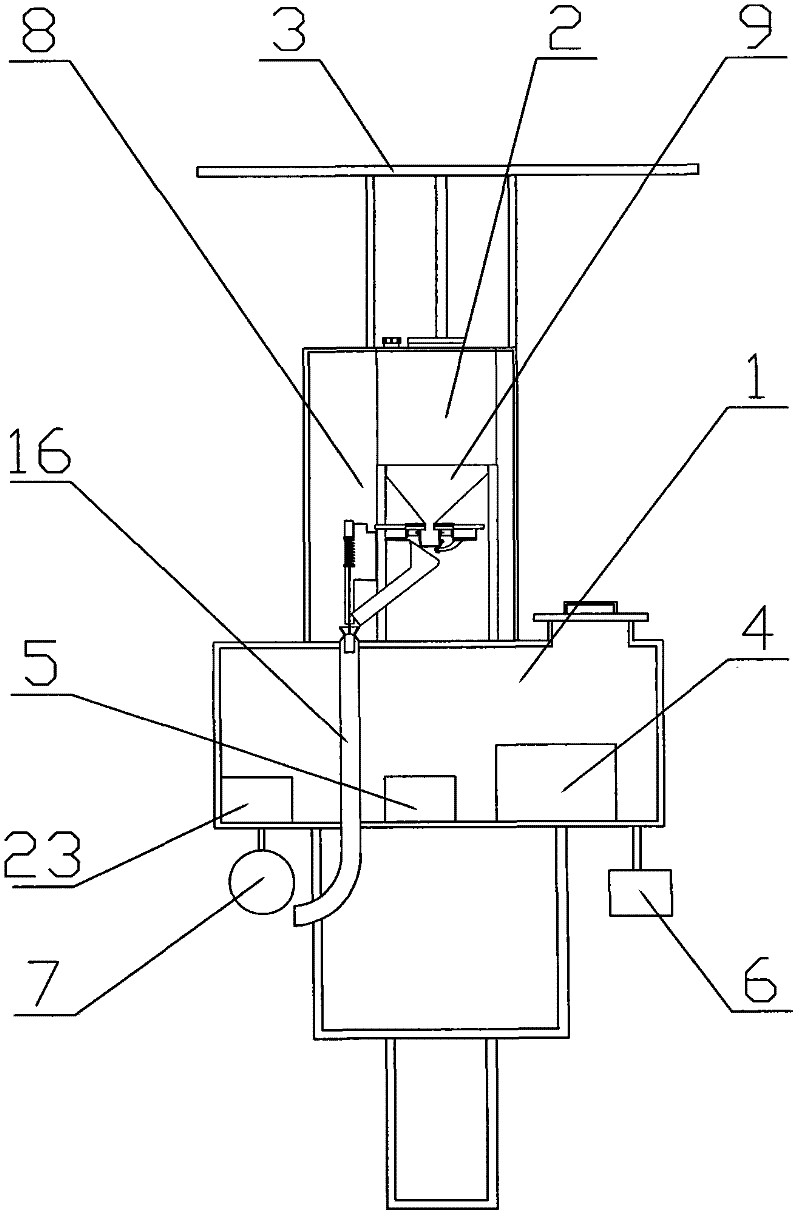

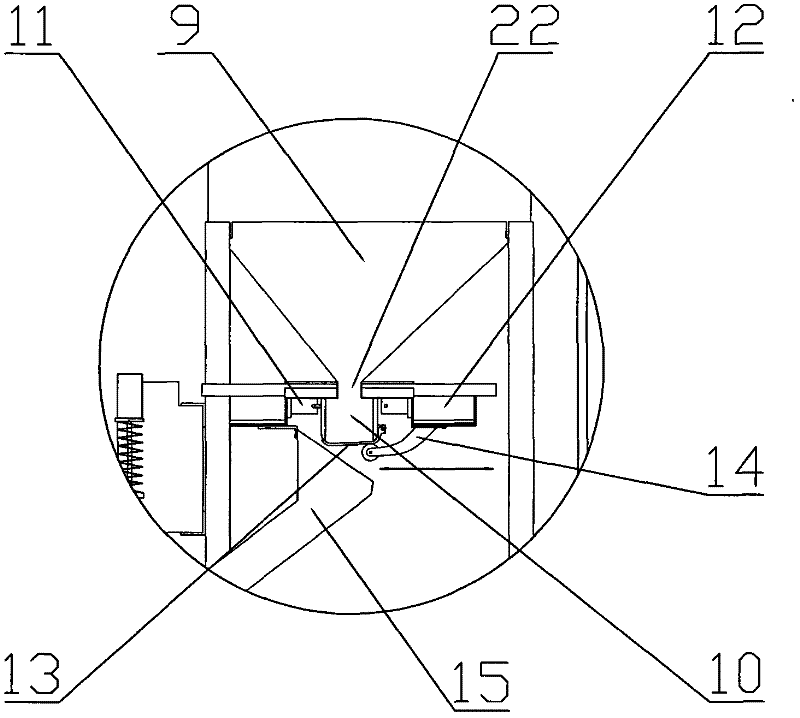

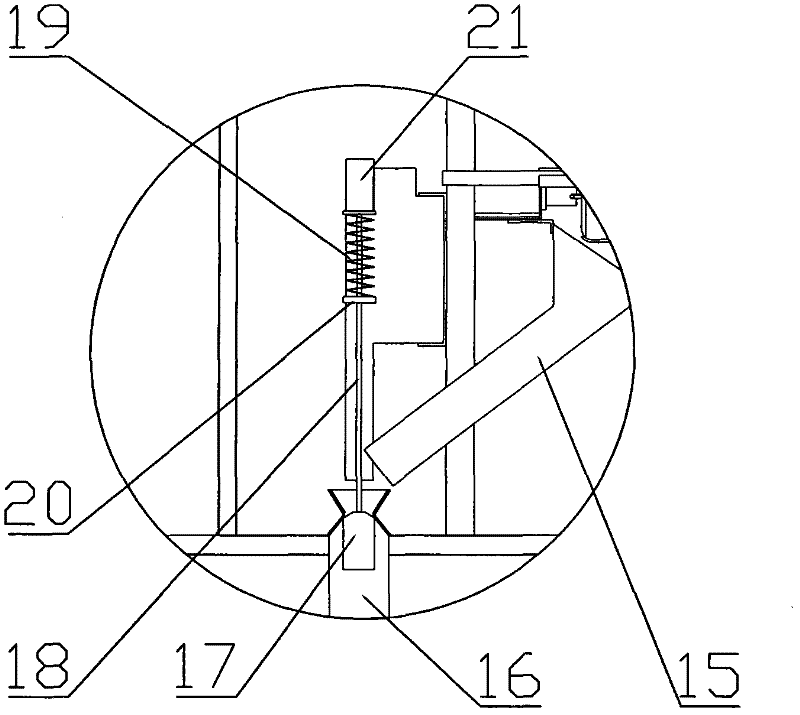

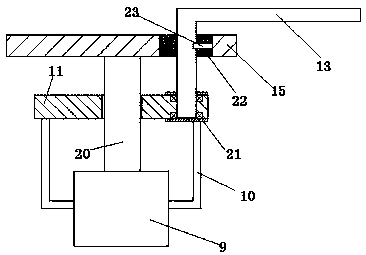

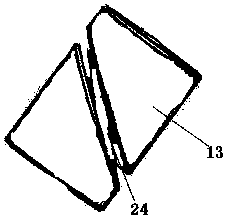

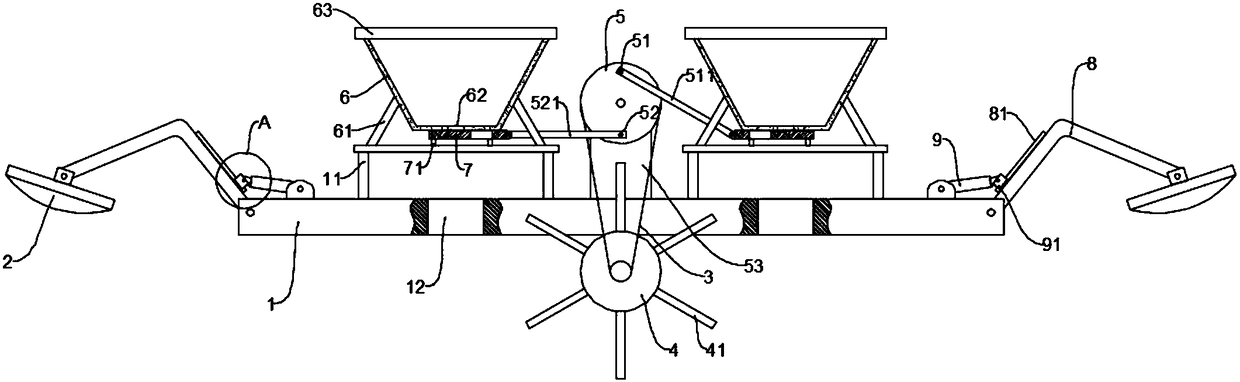

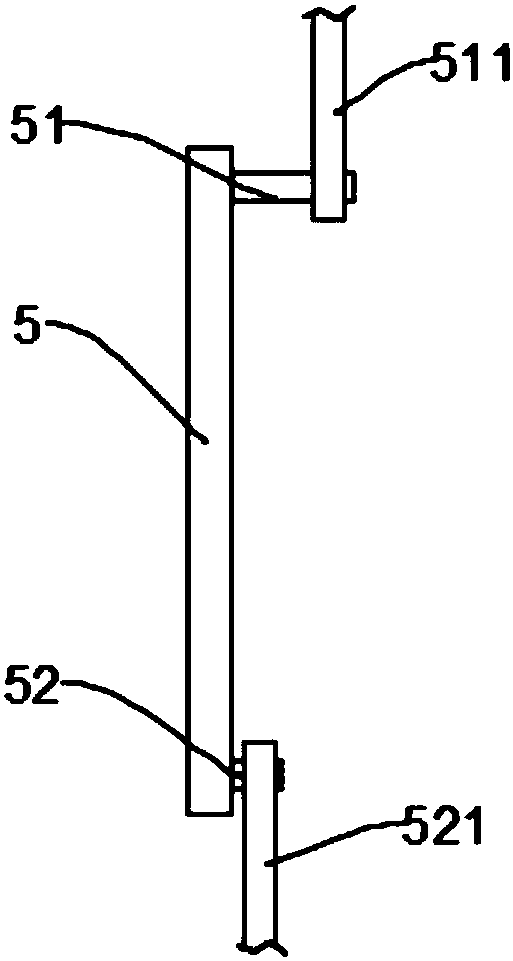

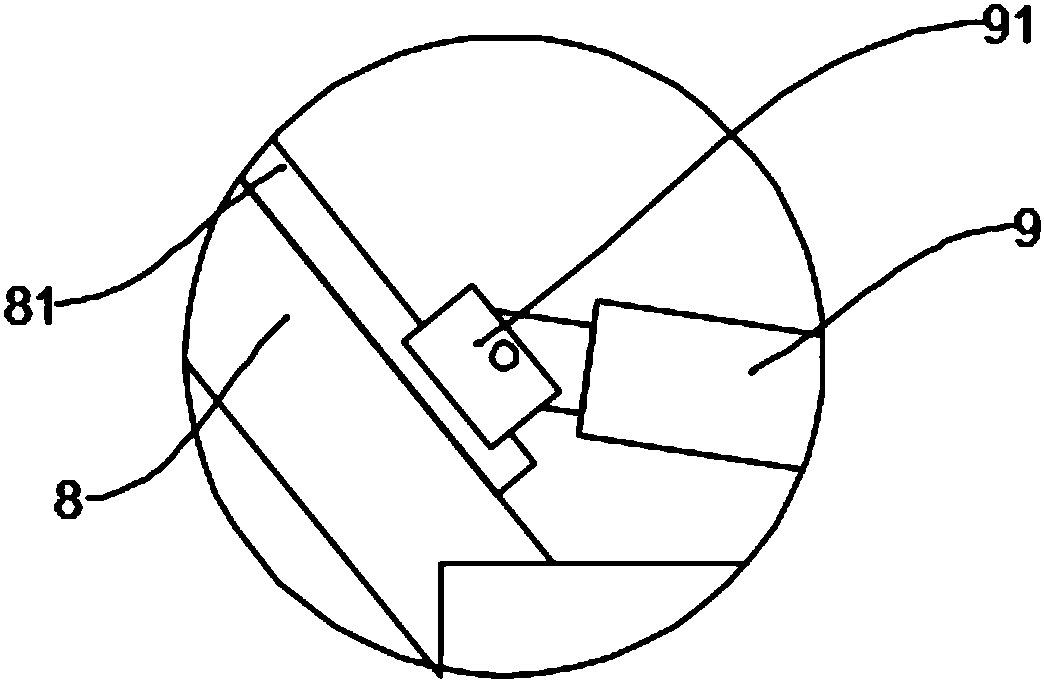

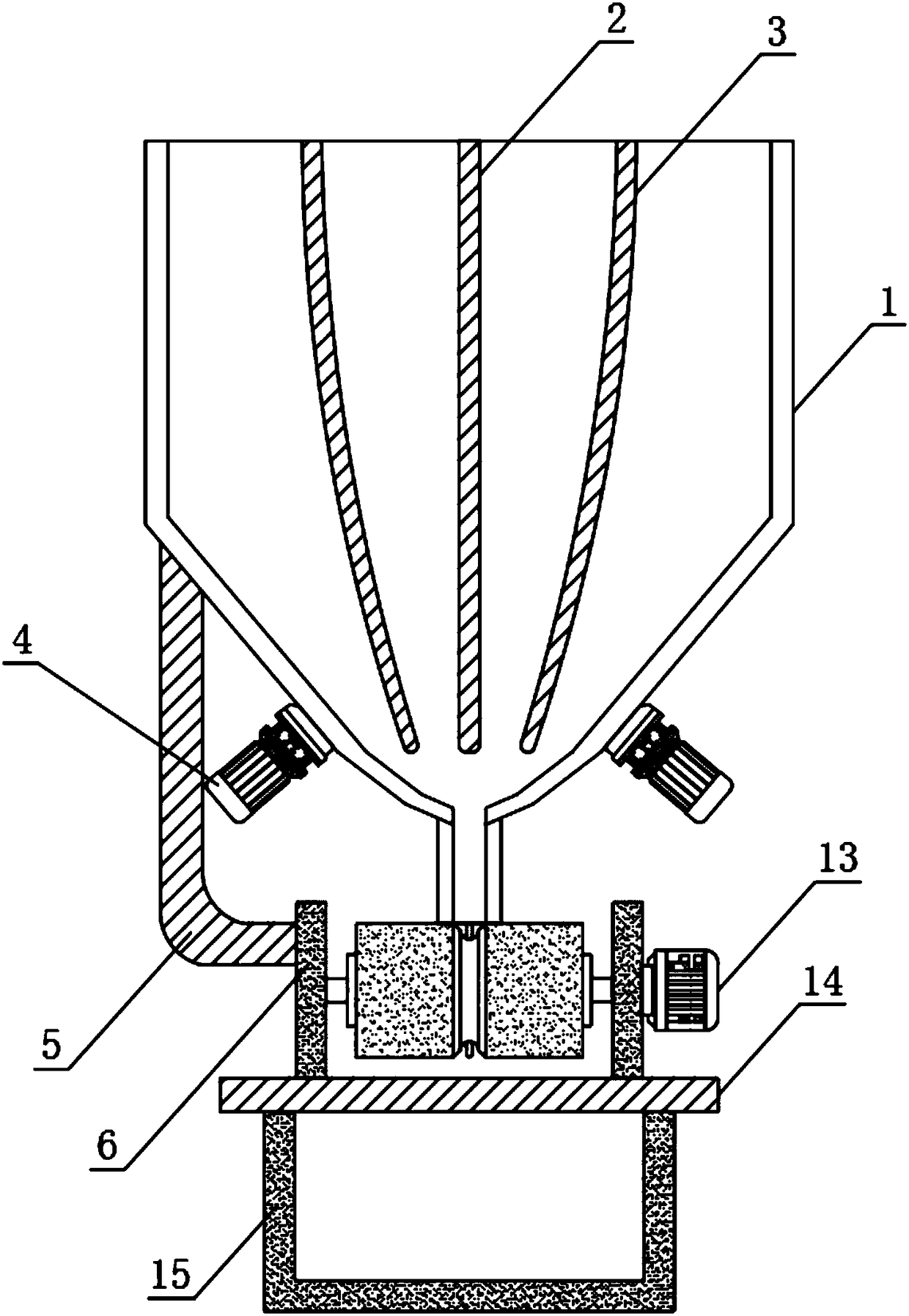

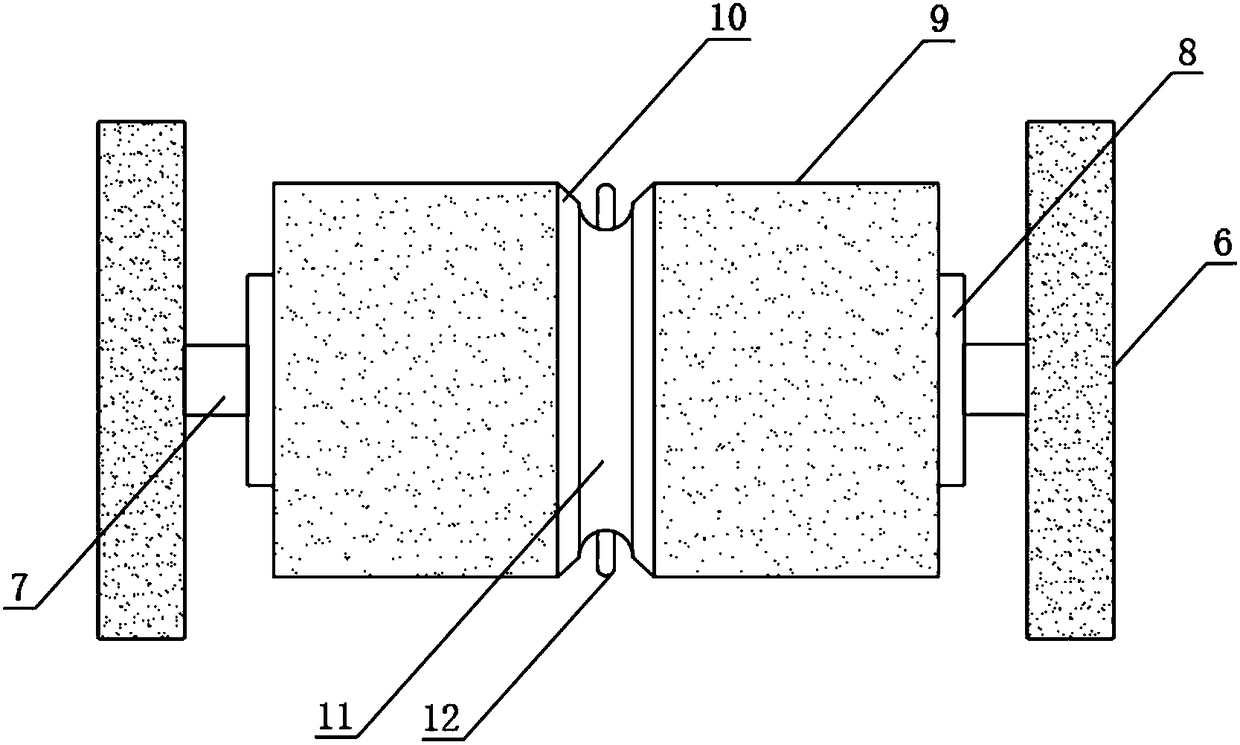

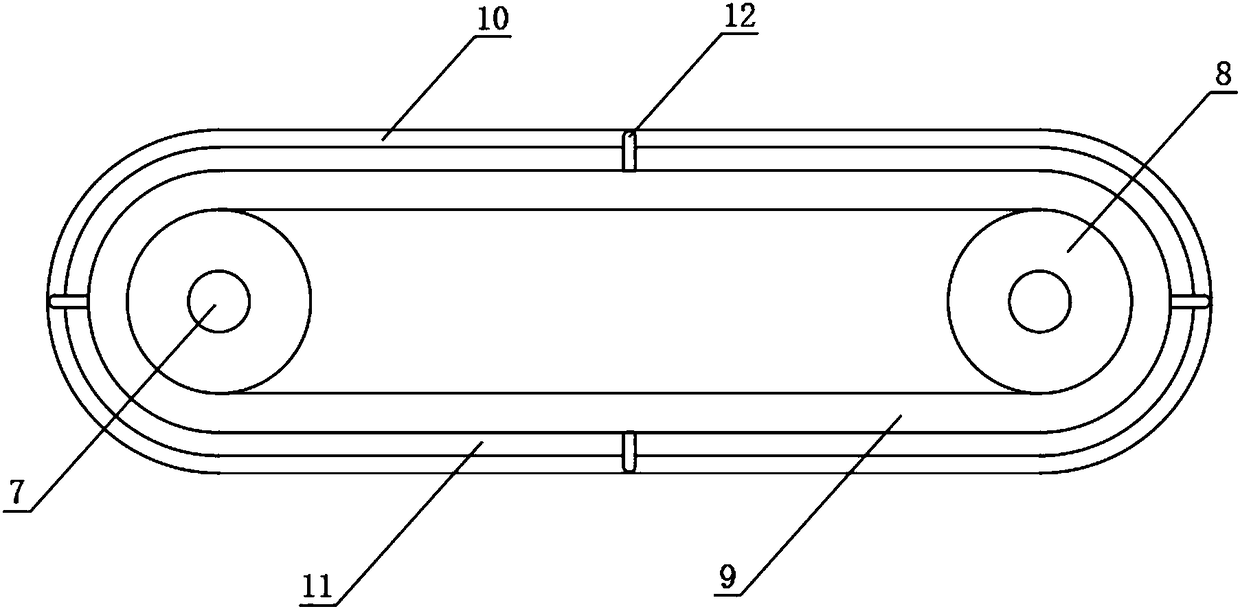

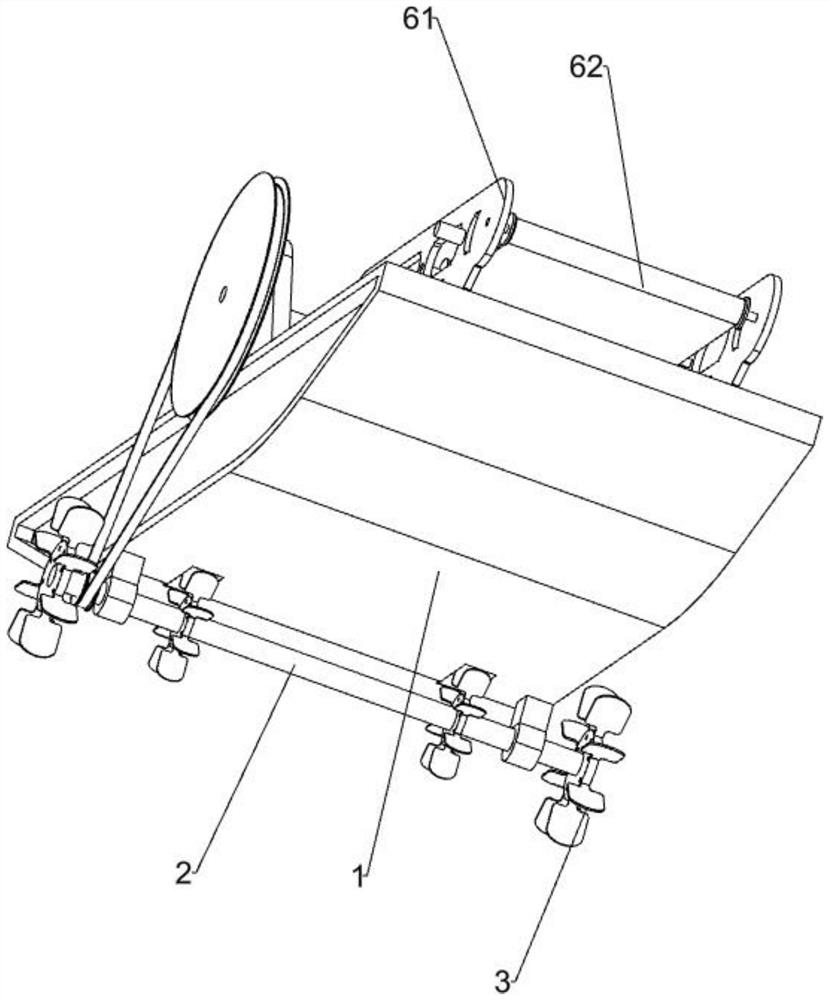

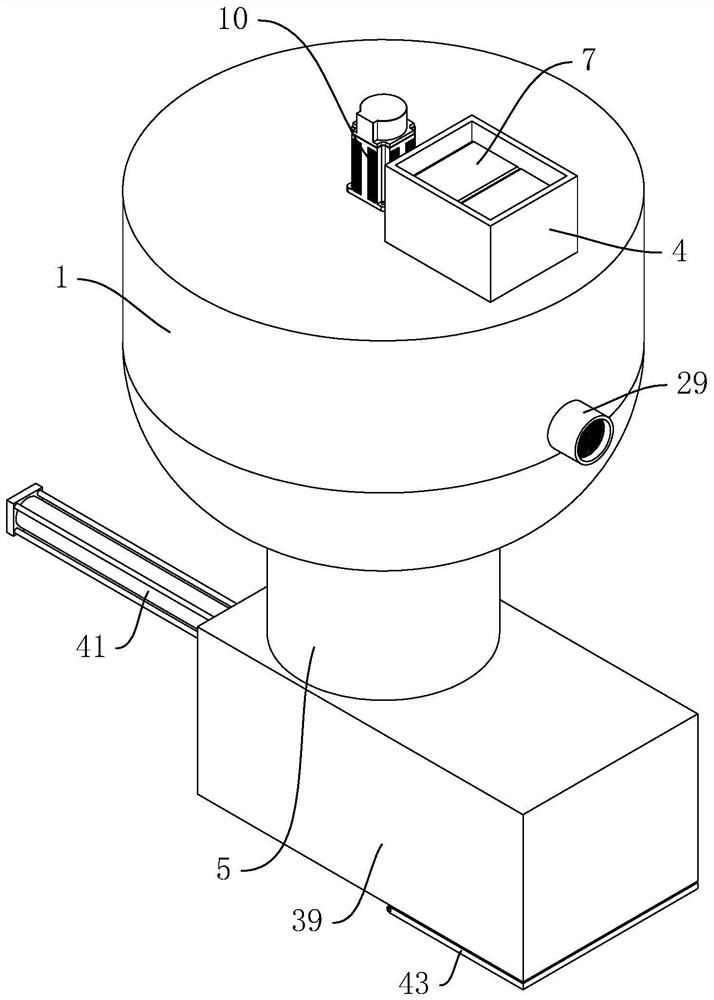

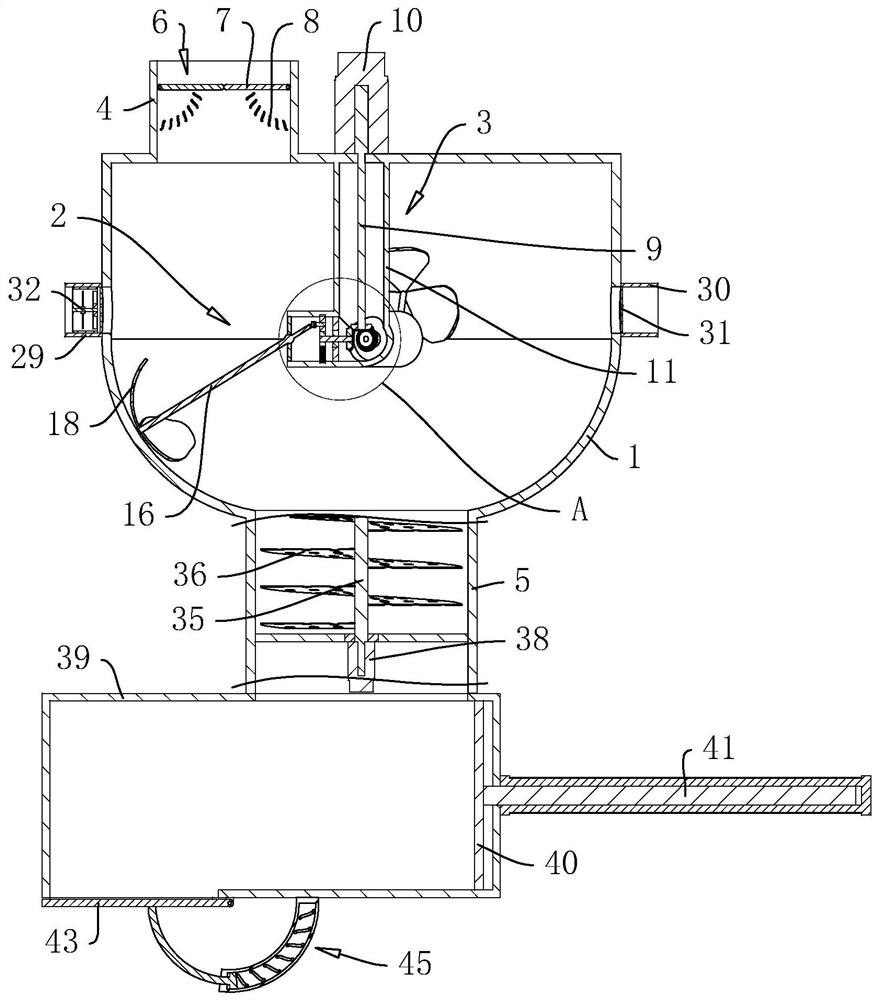

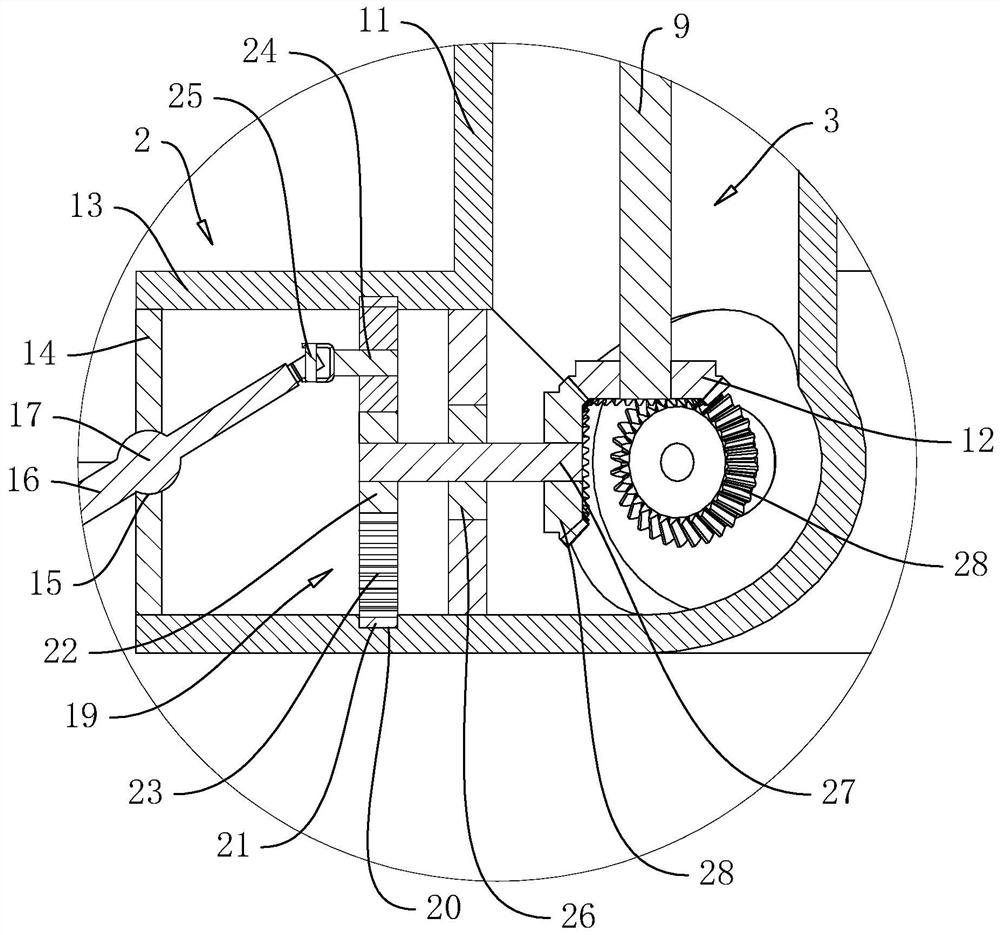

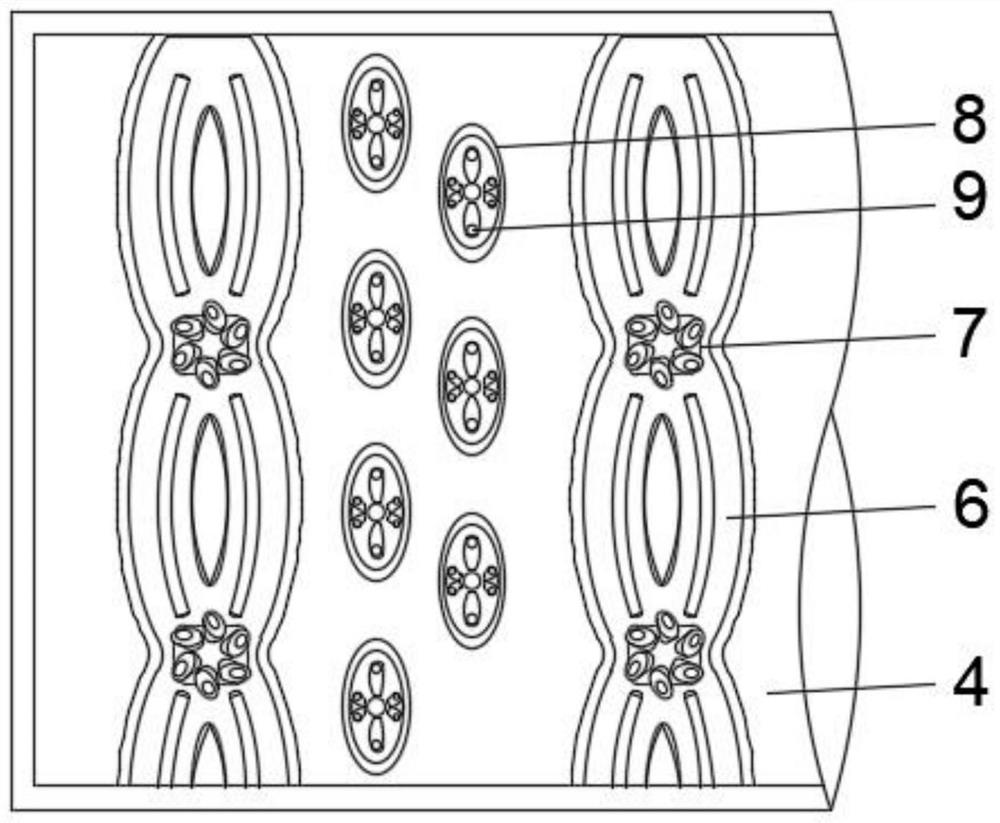

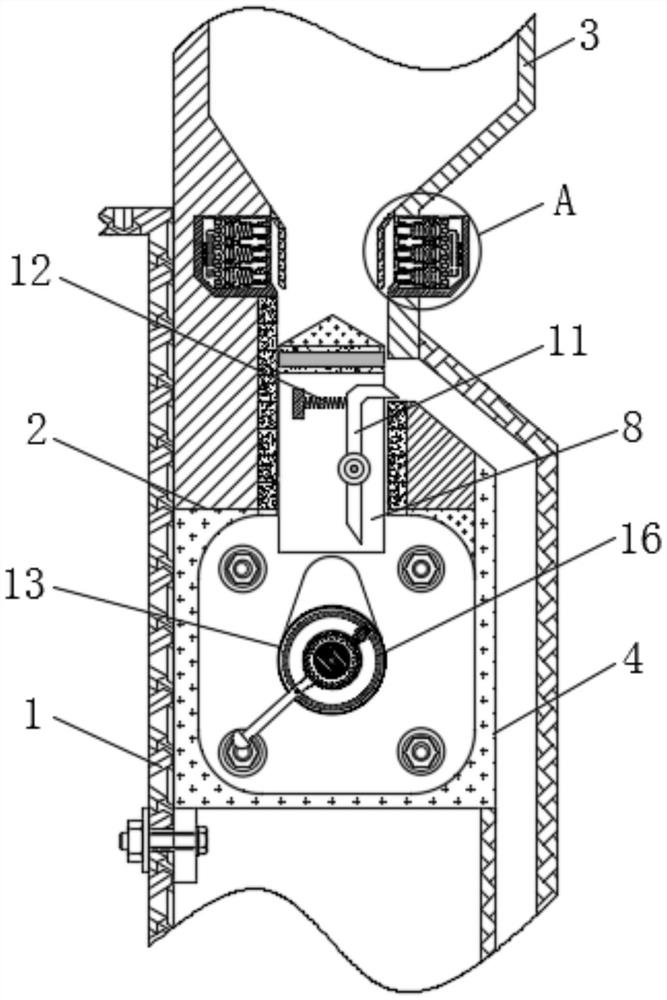

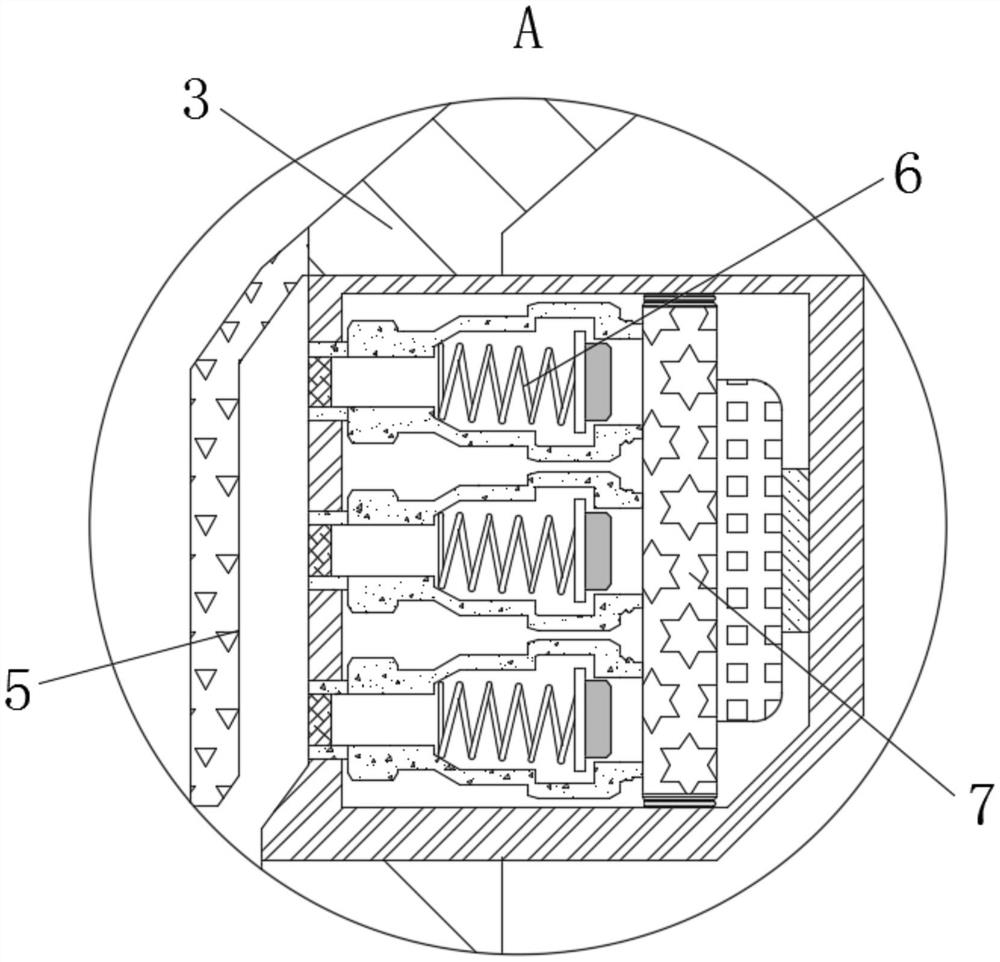

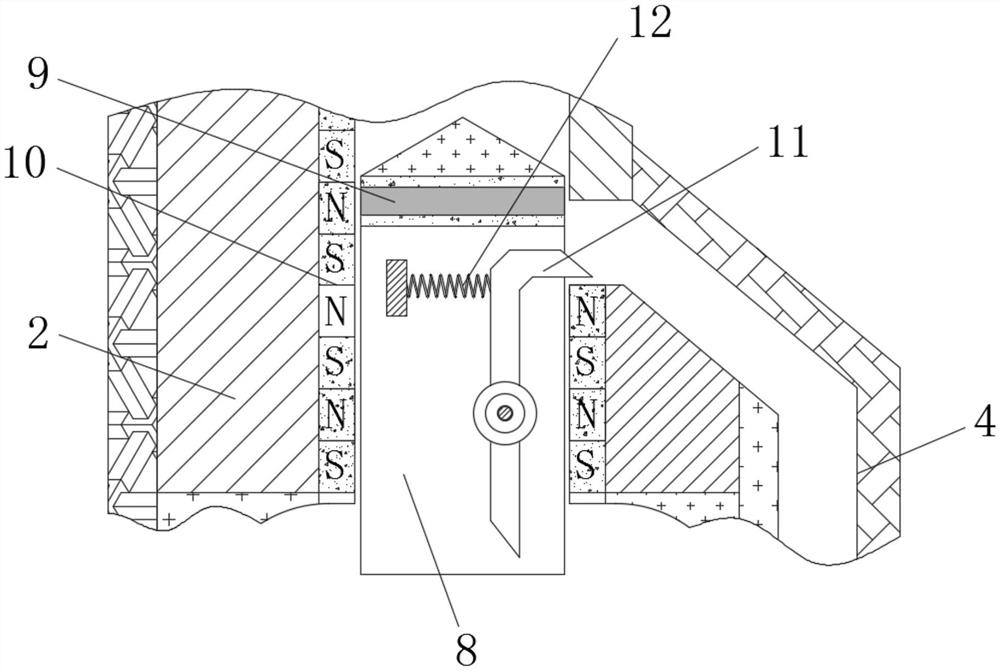

Floating and linkage type fish feed feeding device

InactiveCN108522396AContinuous deliveryGuaranteed feeding effectClimate change adaptationPisciculture and aquariaDrive wheelEngineering

The invention discloses a floating and linkage type fish feed feeding device. The floating and linkage type fish feed feeding device comprises a base, a drive wheel, a rotary disc, two feed storage tanks and sealing plates and is characterized in that air bags are symmetrically arranged on the left side and the right side of the base; the two feed storage tanks are symmetrically arranged on the left side and the right side of the top of the base; each sealing plate attaches to the bottom of the corresponding feed storage tank; the rotary disc is rotatably connected to the front side of a vertical plate; the drive wheel is mounted at the center of the lateral side of the base. The floating and linkage type fish feed feeding device has the advantages that fish feed feeding is performed in afloating manner, so that fish feed can cover a whole pond, and the feeding effect is guaranteed; by arranging protruding columns which are different in length on the rotary disc, the sealing plates ontwo sides can work alternately so as to achieve continuous fish fed feeding; meanwhile, the rotary disc is in linkage with the drive wheel, so that advancing of the whole device and feeding can be performed at the same time, and convenience in operation is achieved; when the whole device is not used, the air bags can be retracted to facilitate storage.

Owner:黄森

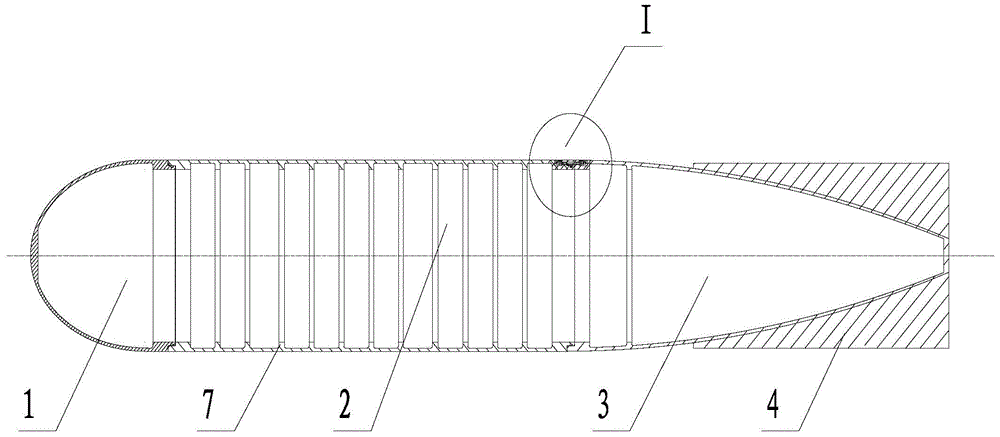

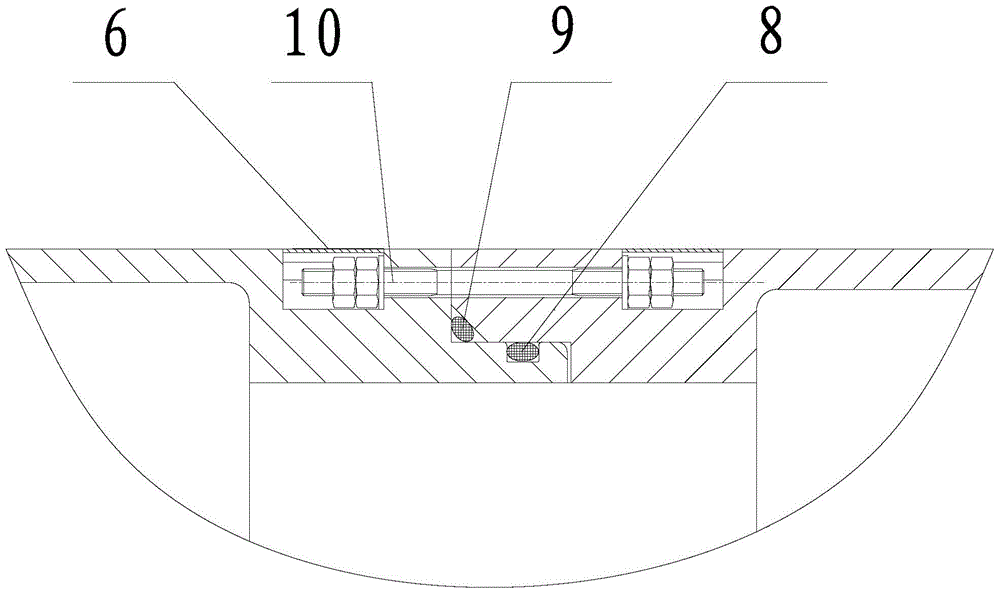

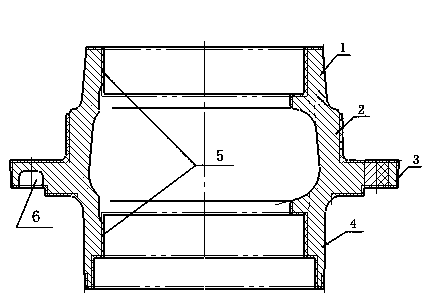

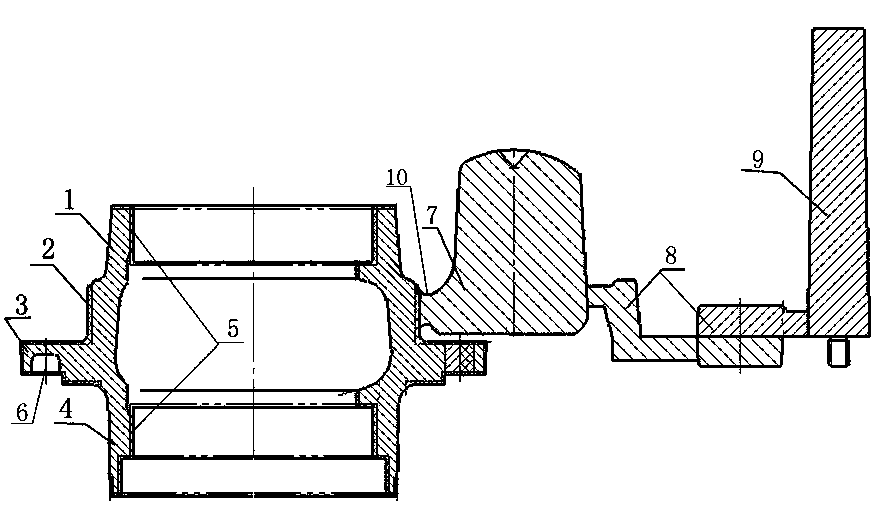

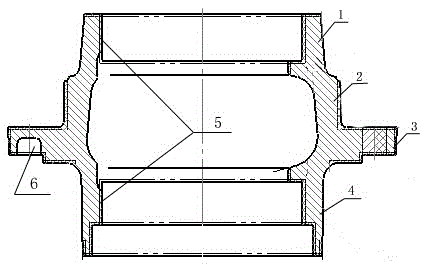

Underwater pressure-bearing sealed cylinder and preparation method thereof

ActiveCN104787271AGood fluid shapeHigh strengthFoundry mouldsFoundry coresEngineeringUltimate tensile strength

The invention discloses an underwater pressure-bearing sealed cylinder and a preparation method thereof. The underwater pressure-bearing sealed cylinder comprises a front part, a middle part and a rear part, wherein the front part takes the shape of a centrosymmetric spherical cap; the middle part is cylindrical; the rear part adopts a convergent shape; the front, middle and rear parts are all connected with one another through convex platforms and concave platforms; the convex and concave platforms are mutually matched in shape; grooves used for placing of sealing rings are formed in the contact planes of the convex and concave platforms, and lower than the sealing rings; sealing rings used for angle sealing are also arranged at the contact ridges of the convex and concave platforms. The underwater pressure-bearing sealed cylinder has the characteristics of being beautiful in fluid appearance, high in strength, pressure resistance and water tightness, relatively light in structural weight, relatively large in internal accommodating space, low in cost, and the like; the requirements for a relatively high depth of underwater sinking, high navigation maneuverability and the like can be met; the maximum fluid static loads and dynamic loads during sinking and navigation can be born.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

Bamboo wood sharpening machine feeding device

InactiveCN108557423ASimple structureLow costWooden sticks manufactureConveyorsAgricultural engineeringNoise pollution

The invention discloses a bamboo wood sharpening machine feeding device comprising a hopper. A first partition plate is fixedly arranged in the hopper, second partition plates are arranged on the twosides of the first partition plate, first motors are fixedly arranged at the bottom ends of the two sides of the hopper, a connecting curved rod is fixedly arranged on the side face of the hopper, a mounting plate is fixedly arranged at the bottom end of the connecting curved rod, a rotating rod is arranged on the mounting plate in a penetrating mode, and the outer side of the rotating rod is connected with a conveying roller in a sleeved mode; and a conveying belt is arranged on the outer side of the conveying roller, guiding grooves are formed in the conveying belt, an accommodating groove is formed between the guiding grooves, a pushing block is fixedly arranged on the accommodating groove, a second motor is fixedly arranged on the side face of the mounting plate, and a bottom plate isfixedly arranged at the bottom of the mounting plate. The bamboo wood sharpening machine feeding device is simple is structure, low in cost, convenient to operate and good in using effect, the stability of the feeding process can be effectively maintained, the feeding effect is ensured, meanwhile, noise is small, and thus noise pollution in the using process of the bamboo wood sharpening machine feeding device is reduced.

Owner:ANHUI SHUCHENG HUAZHU IND

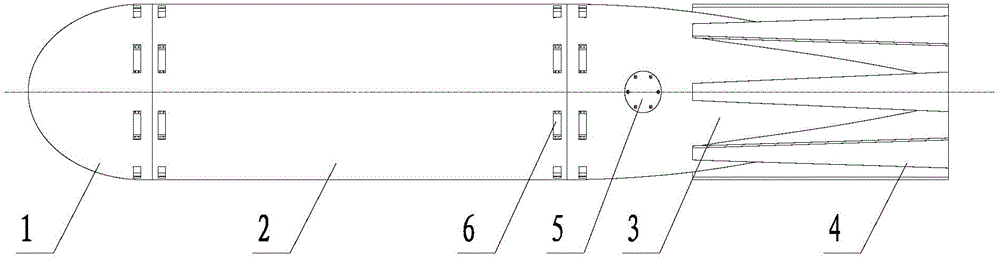

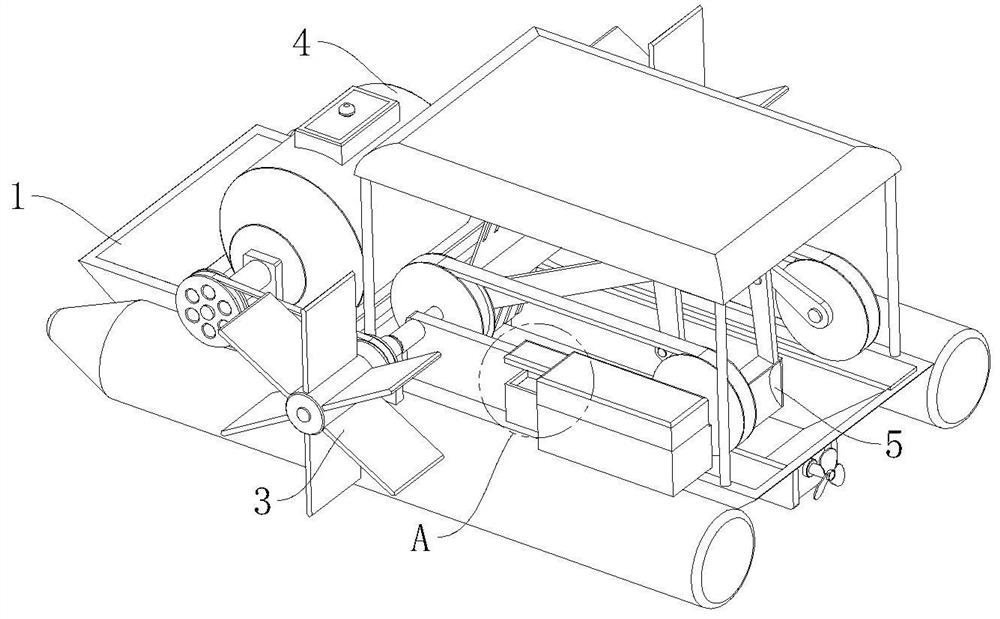

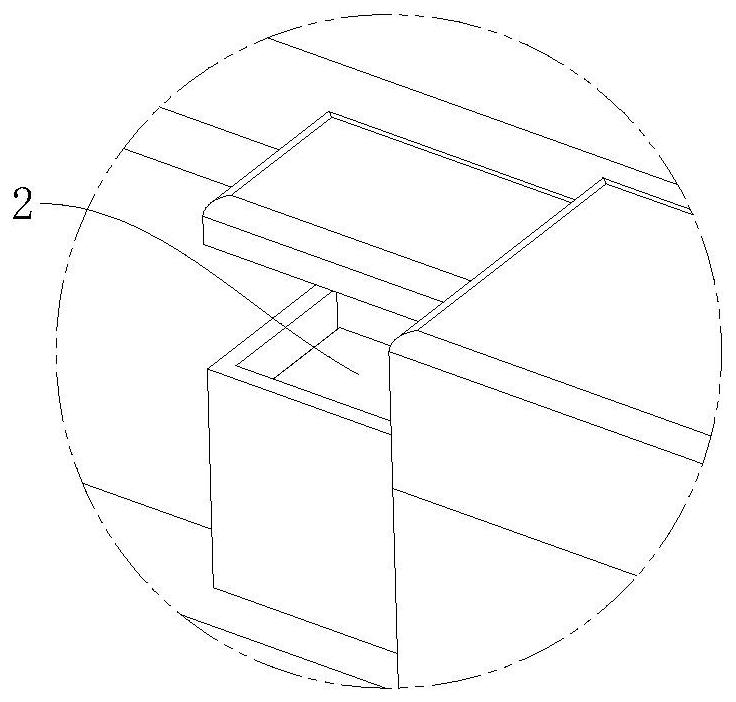

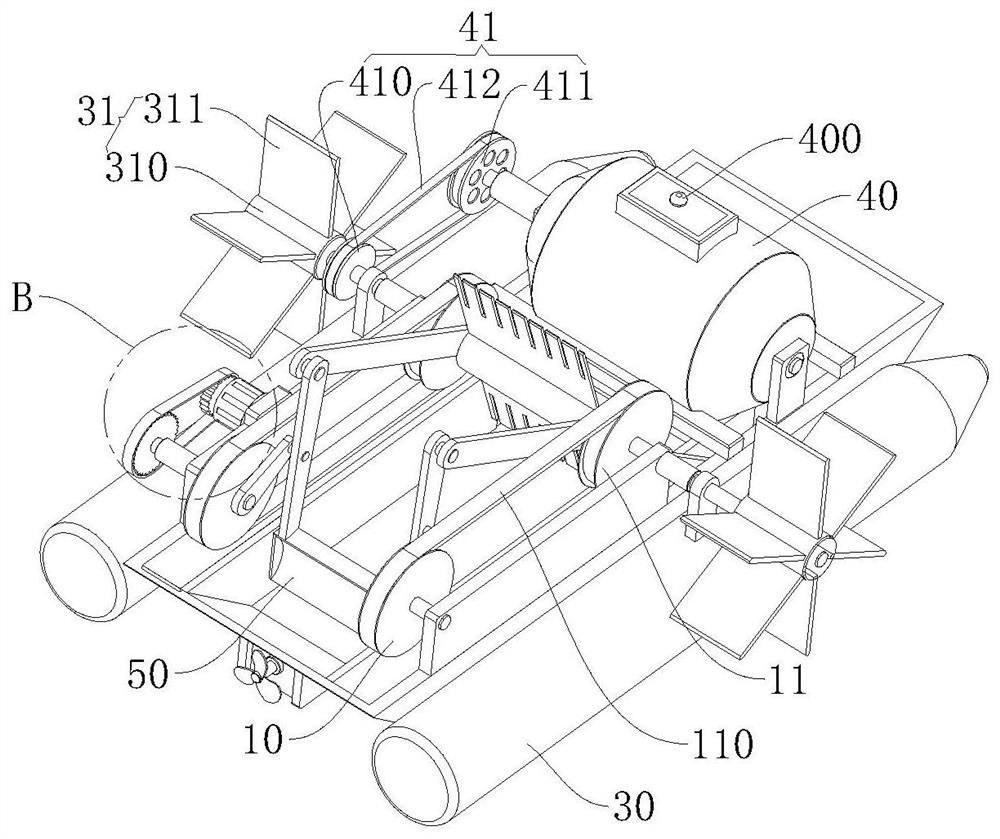

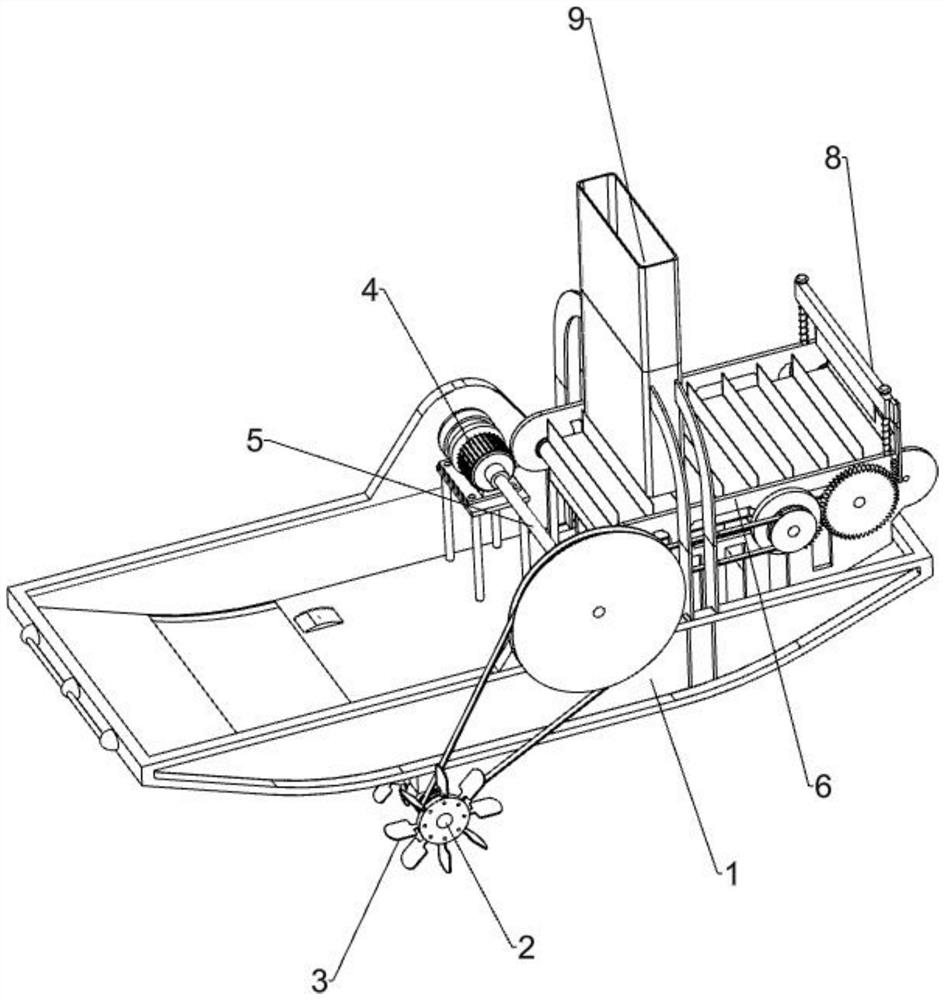

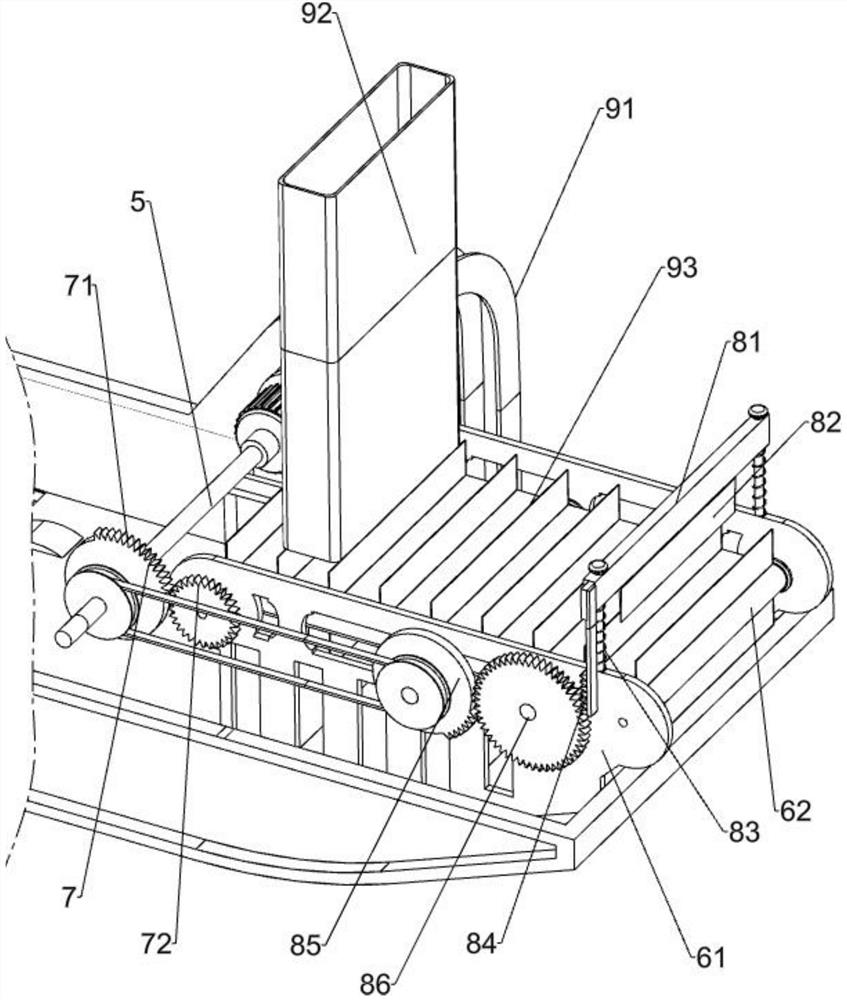

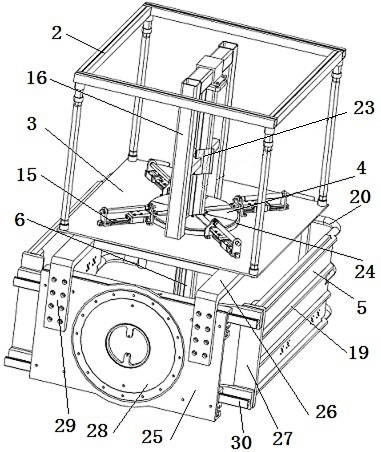

Working method of feed putting equipment for aquaculture

InactiveCN112335590AReduce resistanceImprove driving efficiencyWaterborne vesselsRotary stirring mixersEngineeringShovel

The invention relates to the technical field of aquaculture feed throwing, in particular to a working method of feed putting equipment for aquaculture. The equipment comprises a ship body, and furthercomprises a controller, traveling mechanisms, a uniform stirring mechanism and a spreading mechanism, and the traveling mechanisms are arranged at the two sides of the ship body to support travelingof the ship body; and each traveling mechanism comprises two supporting air bags and two rotating assemblies, the uniform stirring mechanism comprises a feeding kettle, a transmission assembly and twostirring assemblies, the spreading mechanism is arranged in the ship body and used for throwing feed, the spreading mechanism comprises a throwing shovel, a driving assembly and connecting rod assemblies, and the driving assembly is electrically connected with a controller. According to the method of the feed throwing equipment for aquaculture, feed can be prevented from falling on the water surface in a centralized manner, the feed can be thrown dispersedly, the feeding area is increased, meanwhile, the process is simple, the throwing efficiency is high, and the feeding cost can be reduced.

Owner:ANHUI HUATENG AGRI TECH CO LTD

Casting powder for casting magnesium aluminum alloy

The invention relates to a casting powder for casting magnesium aluminum alloy. The casting powder comprises the following components at weight percentage: 55-69% of a deflocculant and 31-45% of a fire retardant. The casting powder can be added with a binder accounting for 5-6% of the casting powder by weight, and the binder can be chosen from silicasol or aluminum phosphate. The deflocculant can be chosen from micanite, bentonite, diatomite, palygorskite clay and the like. The fire retardant can be chosen from alkyl sodium sulfonate, boric acid and the like. The casting powder has better temperature retention, fire retardancy and paintability, excellent floatability, and is uneasy for deposition in use. The casting powder reduces hot crack trend of magnesium aluminum alloy castings. The casting powder forms a layer of reducing protective atmosphere on a riser magnesium aluminum interface in casting, which prevents the magnesium aluminum alloy from oxidation, prevents the magnesium aluminum alloy from burning in a cast mould in casting, and ensures sequential cooling of the magnesium aluminum alloy so as to improve feeding effect during solidification of the magnesium aluminum alloy, thus producing the magnesium aluminum alloy casting with small surface but without internal crystallographic direction defect and oxide scale.

Owner:大连核心铸造技术工程研究所

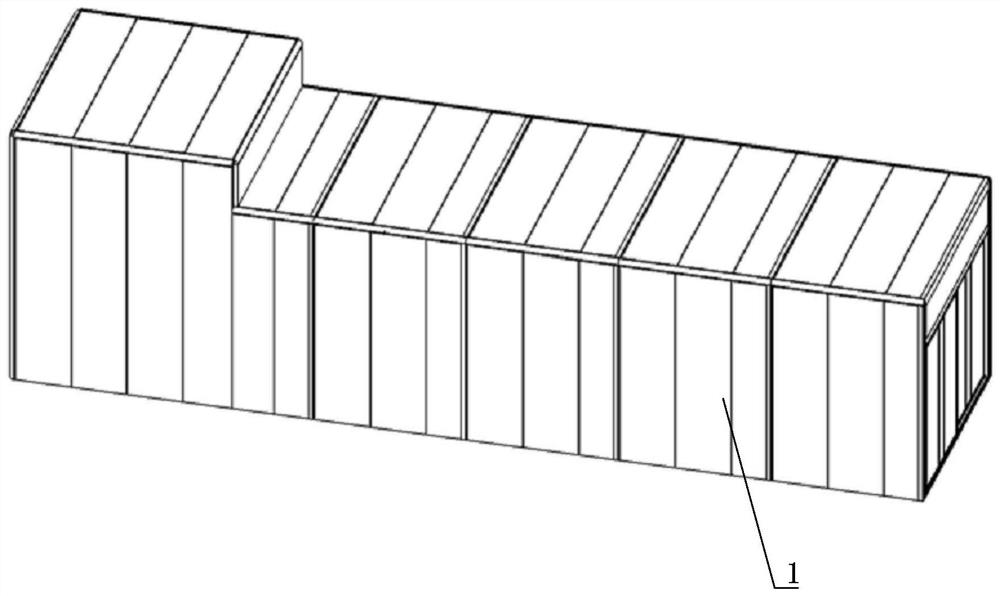

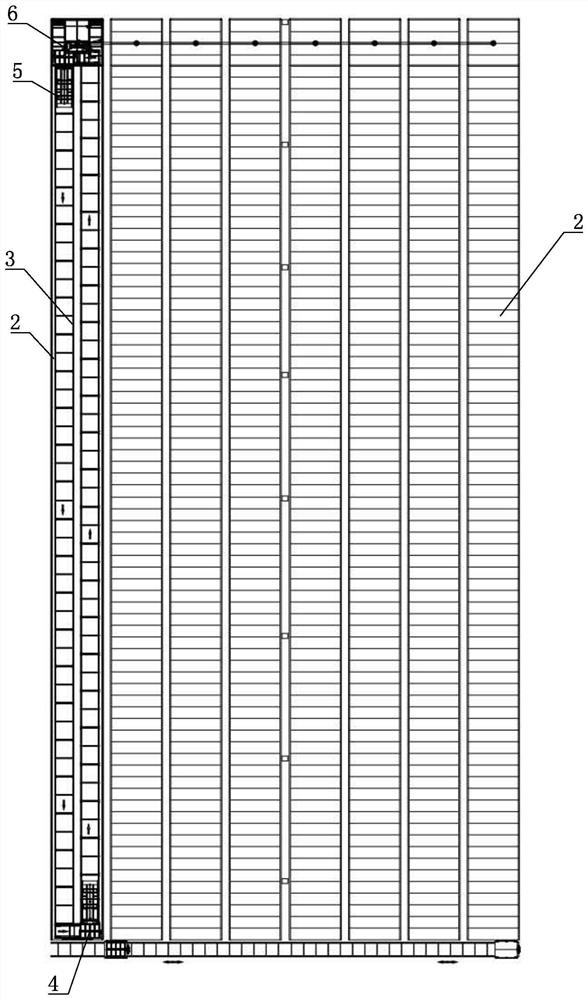

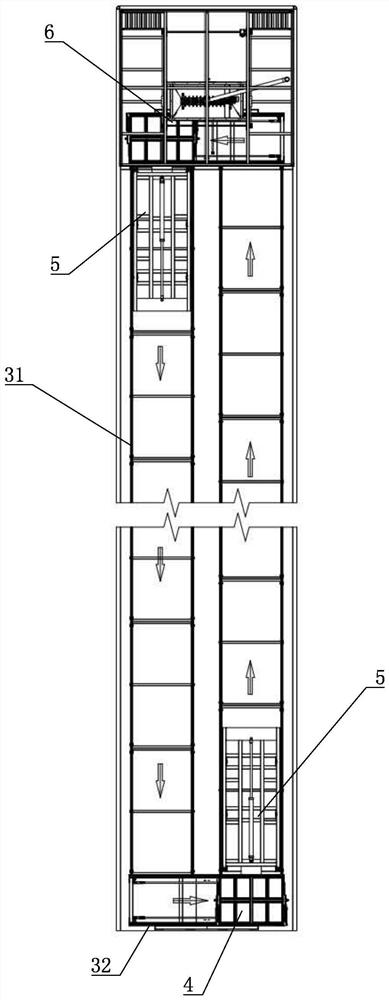

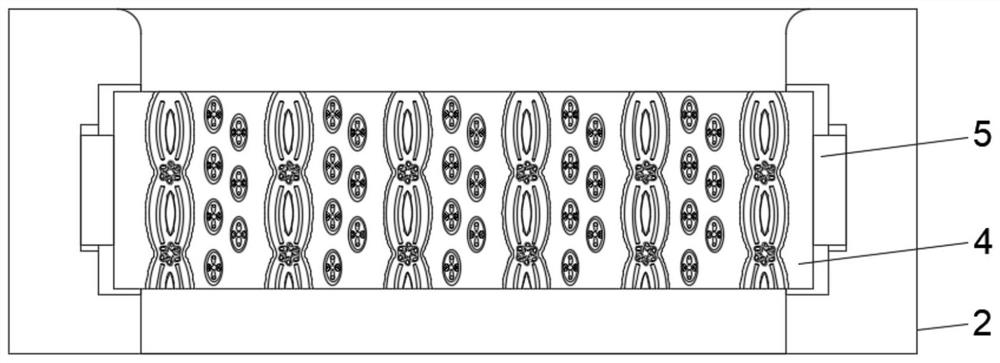

Roadway type hermetia illucens automatic feeding system

PendingCN112335612AGood feeding effectRealize industrial automation farmingTransportation and packagingRotary stirring mixersAnimal scienceTrackway

The invention discloses a roadway type hermetia illucens automatic breeding system. The system comprises a breeding frame circulating track, the breeding frame circulating track is in a hollow squareshape, and the breeding frame circulating track comprises a longitudinal circulating track body and a transverse circulating track body arranged at the end of the longitudinal circulating track body.A breeding frame conveying device for a roadway is arranged on the longitudinal circulating track body, and a breeding frame transverse moving device is arranged on the transverse circulating track body. A foodstuff feeding machine is arranged at the position, located at one end of the longitudinal circulating track body, of the transverse circulating track body. According to the roadway type hermetia illucens automatic feeding system, large-scale hermetia illucens breeding can be achieved, hermetia illucens bred on a large scale can be automatically, regularly and quantitatively fed, industrial automatic breeding is achieved, the feeding effect is good, the work efficiency is high, the environment in the breeding process can be effectively controlled, and the waste organic matter conversion efficiency is high.

Owner:潍坊星美生物科技股份有限公司

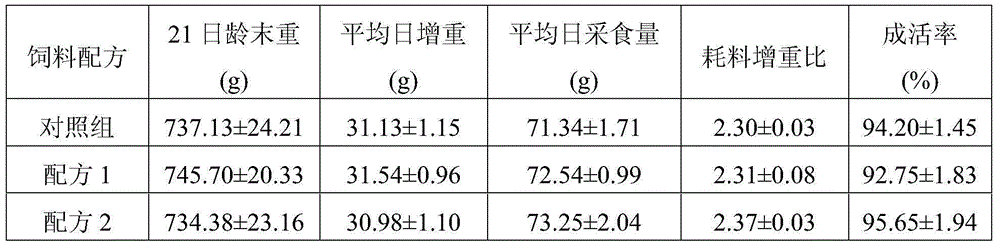

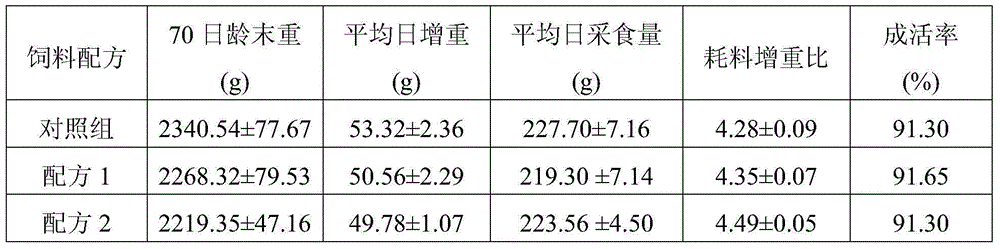

Complete feed and premix for promoting body type and skeletal development of laying chicks and preparation method of complete feed and premix

PendingCN111357885AImprove developmentLowers gastrointestinal pHFood processingAnimal feeding stuffBiotechnologyAnimal science

The invention discloses a complete feed and a premix for promoting body type and skeletal development of laying chicks and a preparation method of the complete feed and the premix. The premix comprises mineral elements, compound vitamins, compound amino acids, functional substances, protein raw materials, energy raw materials and carriers, and aims to solve the technical problems of poor body typeuniformity and skeletal development inhibition due to unbalanced nutrition of the laying chicks. Compared with commercially available feeds, the premix and the complete feed for the chicks prepared by the method can remarkably improve the feed intake and the weight of the chicks, reduce the death and culling rate, effectively improve the uniformity of chicken flocks, and increase the shin lengthof the chicks.

Owner:河南宏展生物科技有限公司

Method for detecting igloss amount of cast heat-preservation dead head

InactiveCN104048898AEffective quality controlQuality assuranceWeighing by removing componentMaterials scienceCasting

The invention discloses a method for detecting the igloss amount of a cast heat-preservation dead head. The igloss amount percentage of the cast heat-preservation dead head is calculated for judging whether a feeding effect of the heat preservation dead head in a simulated real casting environment meets a casting use requirement according to an obvious relation between the igloss amount of the heat preservation dead head and the feeding effect of the heat preservation dead head in a casting process. The invention mainly aims to provide a detection method which is simple, convenient and low in cost and can effectively reflect the feeding effect of the heat preservation dead head in the casting process.

Owner:SUFA HENGDIAN MACHINERY CNNC

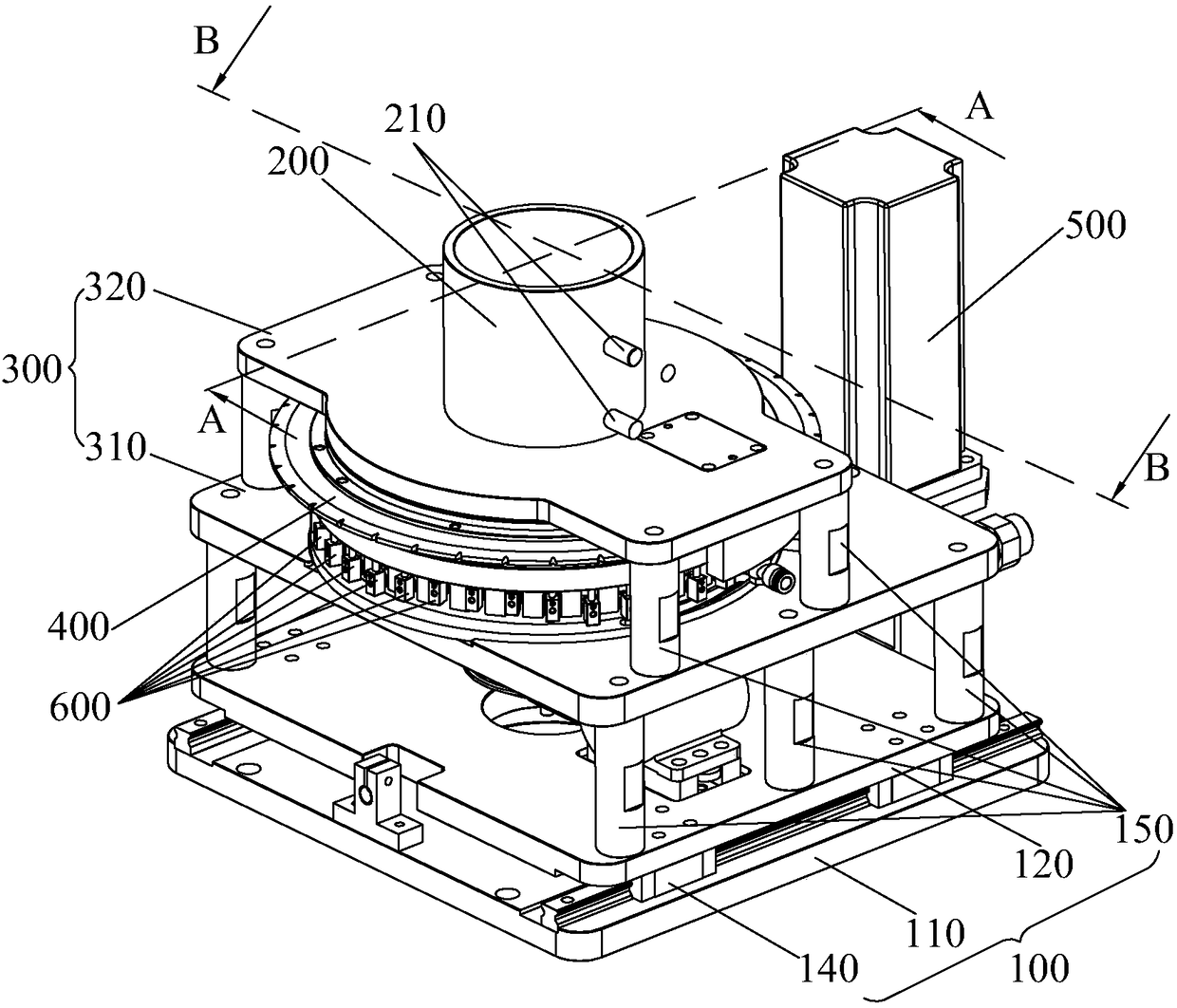

Spherical blasting ball high-speed planting machine

ActiveCN108128603AEasy to throw outPrevent reboundAgriculture gas emission reductionRotary conveyorsEngineeringHeight difference

A spherical blasting ball high-speed planting machine provided by the invention comprises a material storing cabin, a material planting opening, a fixed seat, a rotatable seat capable of rotating relative to the fixed seat, a first pushing mechanism, a second pushing mechanism and an air collecting mechanism. A plurality of inner material feeding channels communicating with the material storing cabin and a plurality of outer material feeding channels communicating with the material planting opening are sequentially formed in the circumferential side of the rotatable seat, and the height difference exists between the inner material feeding channels and the outer material feeding channels in the vertical direction. The first pushing mechanism is used for pushing spherical blasting balls in the inner material feeding channels to the outer material feeding channels, and the second pushing mechanism is used for pushing the spherical blasting balls in the outer material feeding channels to the outer side of the material planting opening. The fixed seat comprises a first cam driving plate and a second cam driving plate, and the first cam driving plate and the second cam driving plate arearranged on the upper side and the lower side of the rotatable seat correspondingly to drive the first pushing mechanism and the second pushing mechanism correspondingly. The air collecting mechanismis used for positioning the spherical blasting balls, the material storing cabin is fixedly arranged on the fixed seat, and a flow guiding block is fixedly arranged on the lower side of the inner wallof the cylindrical material storing cabin.

Owner:武汉大坦智能装备科技有限公司

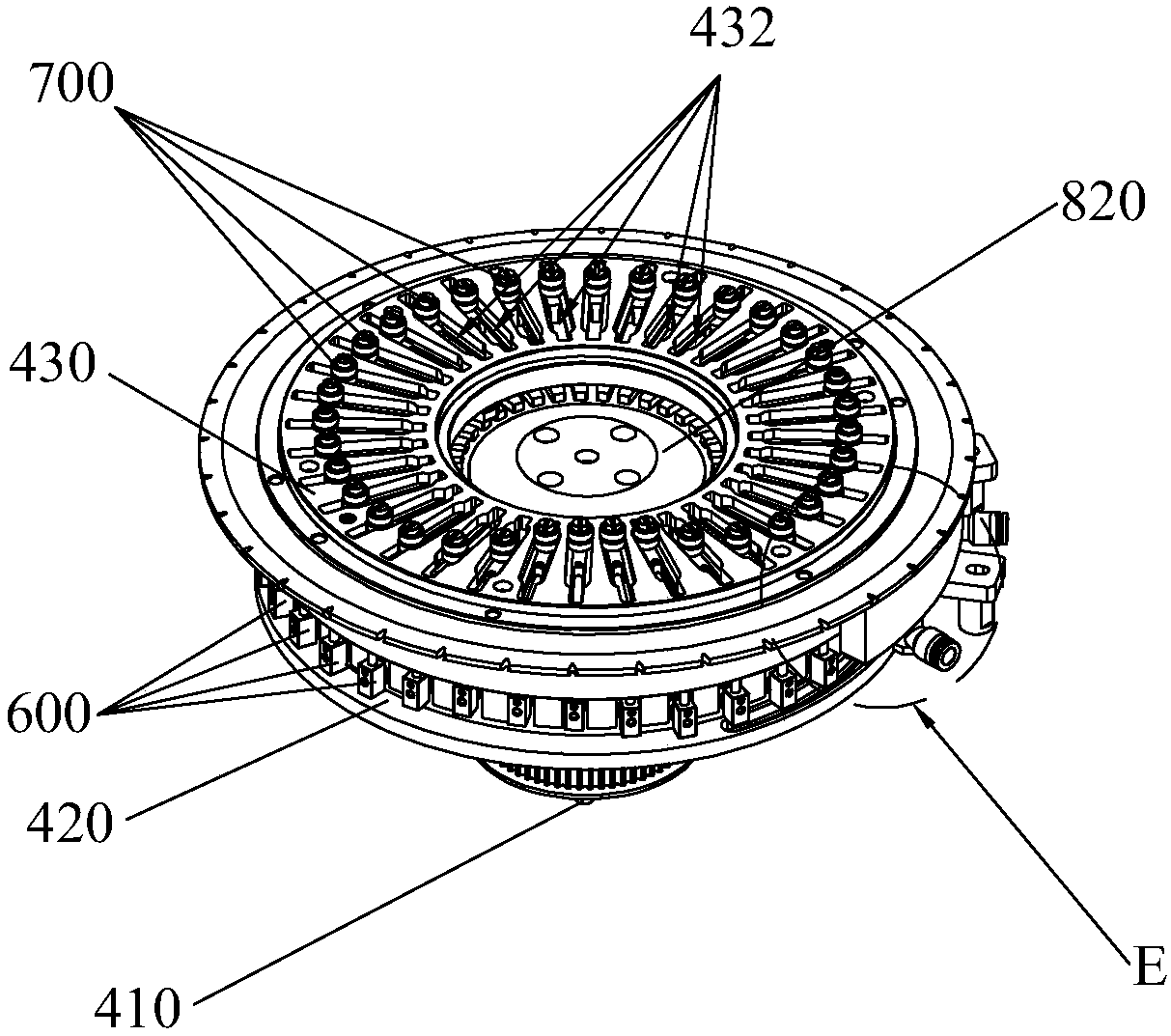

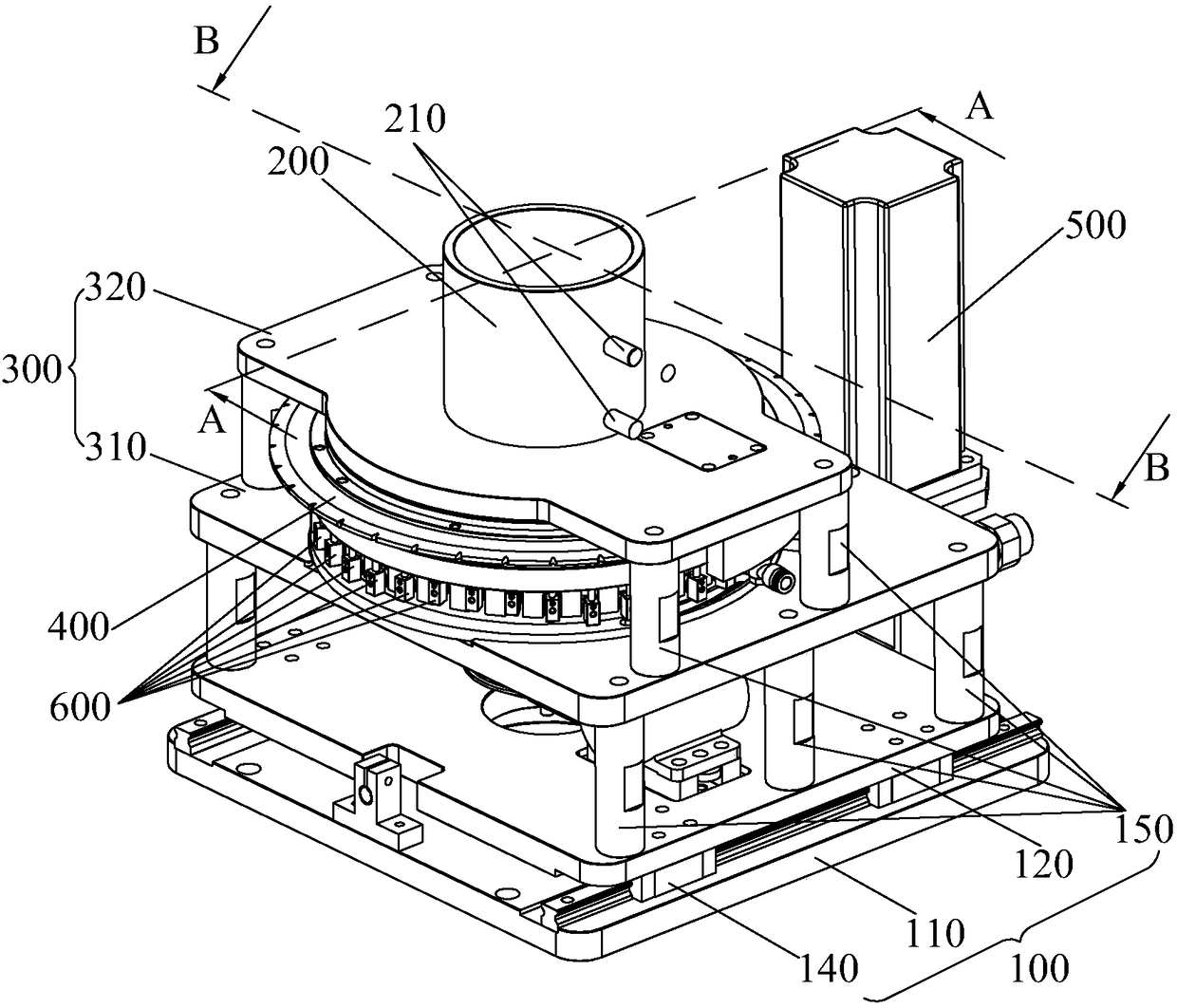

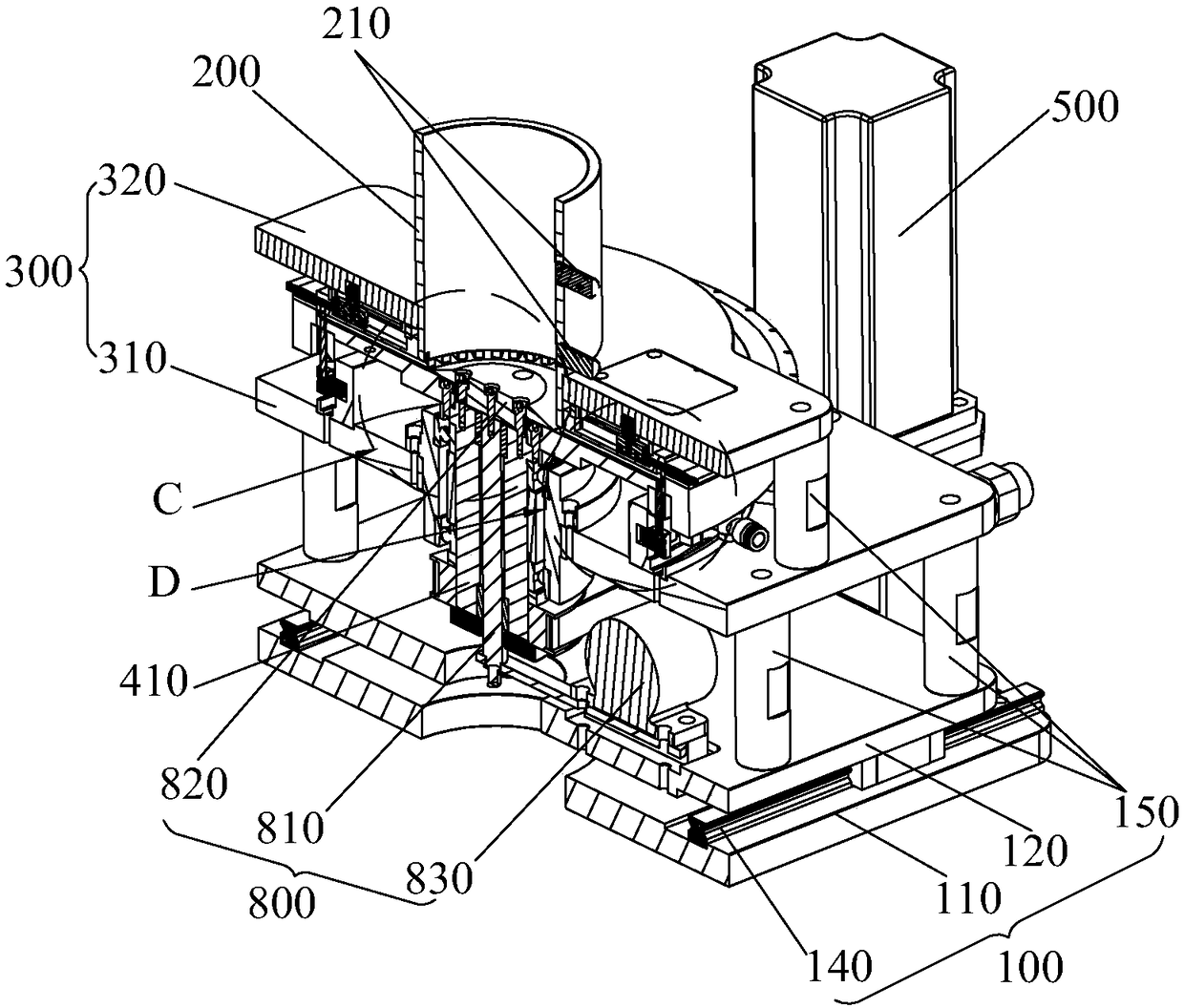

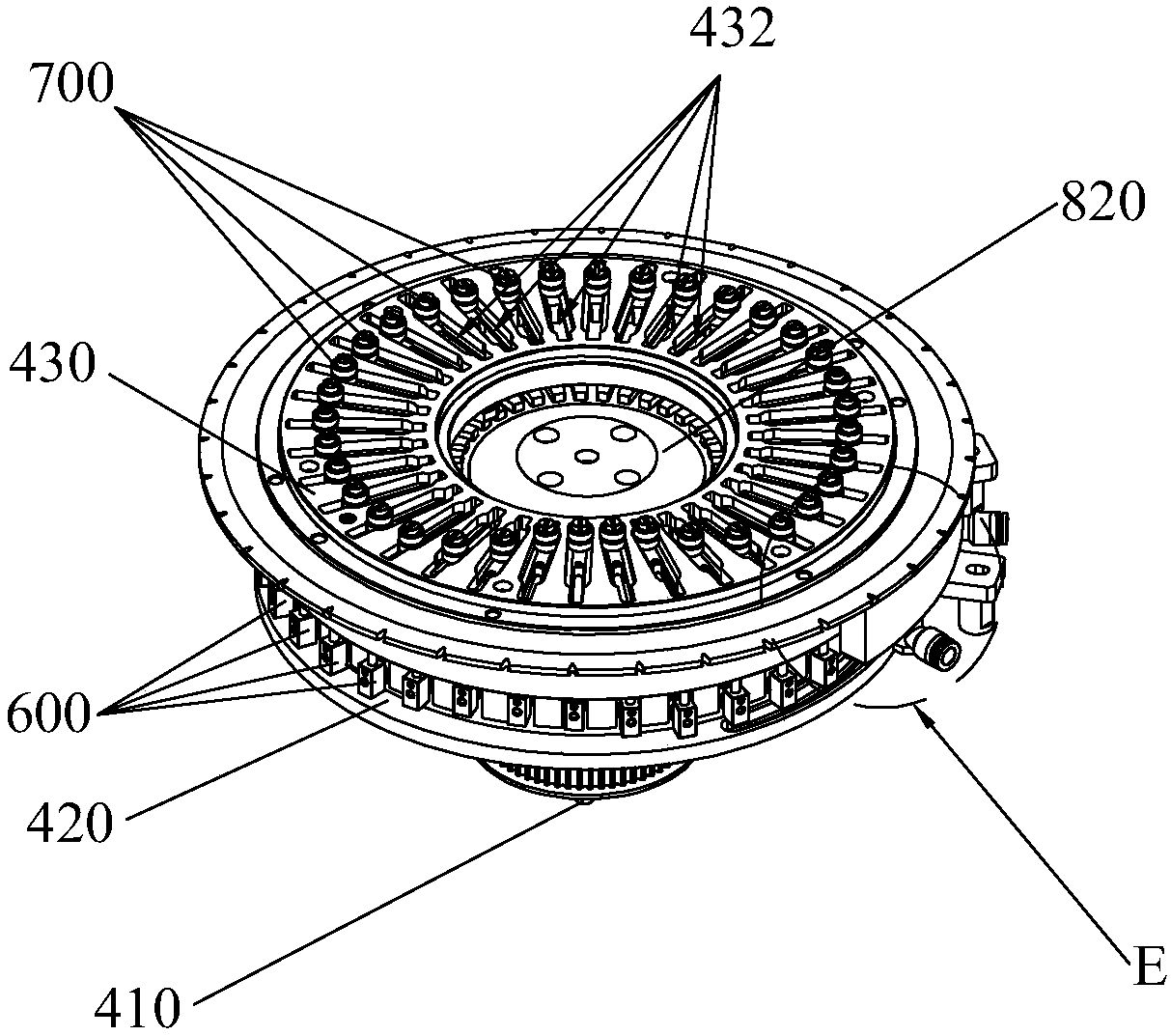

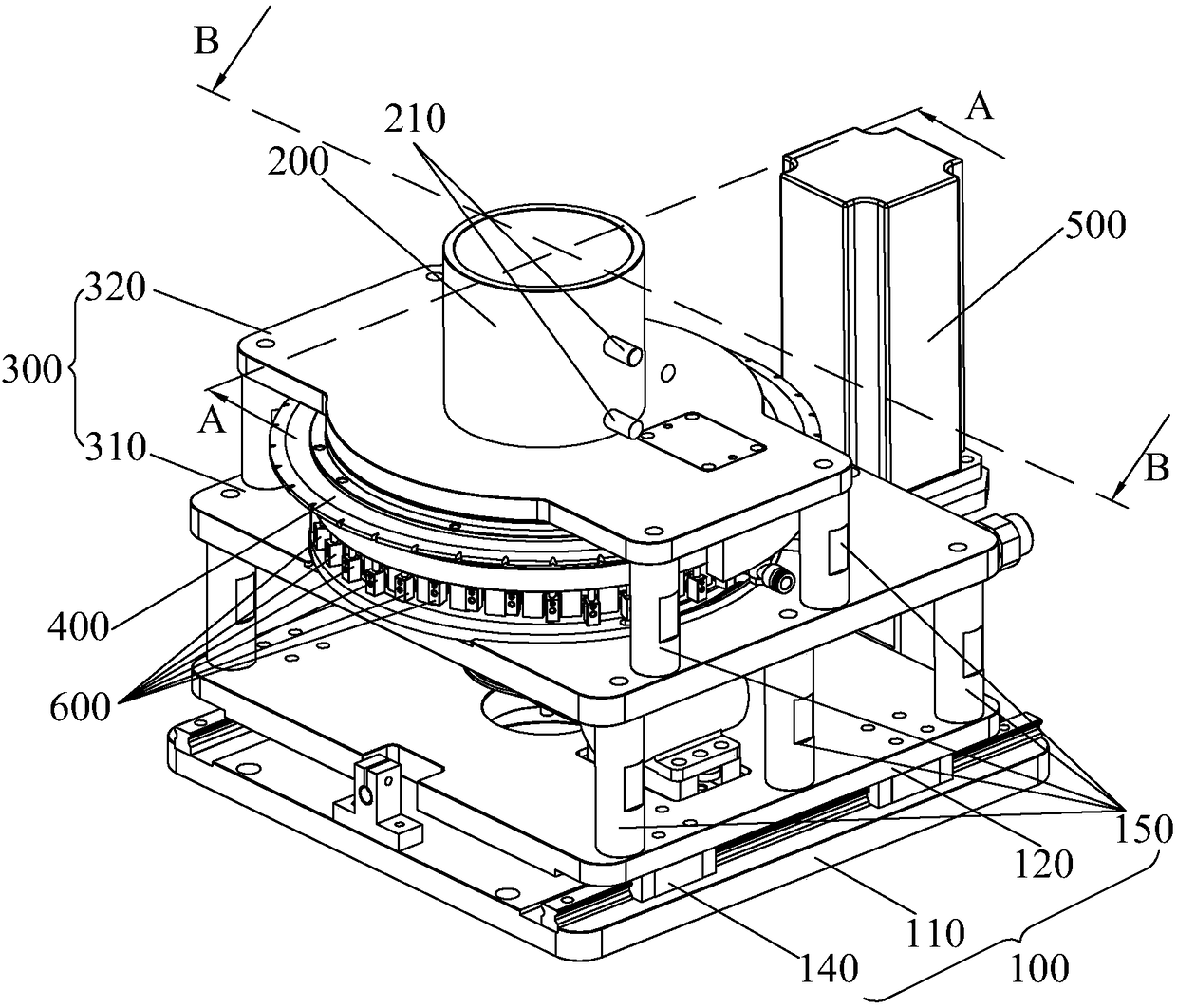

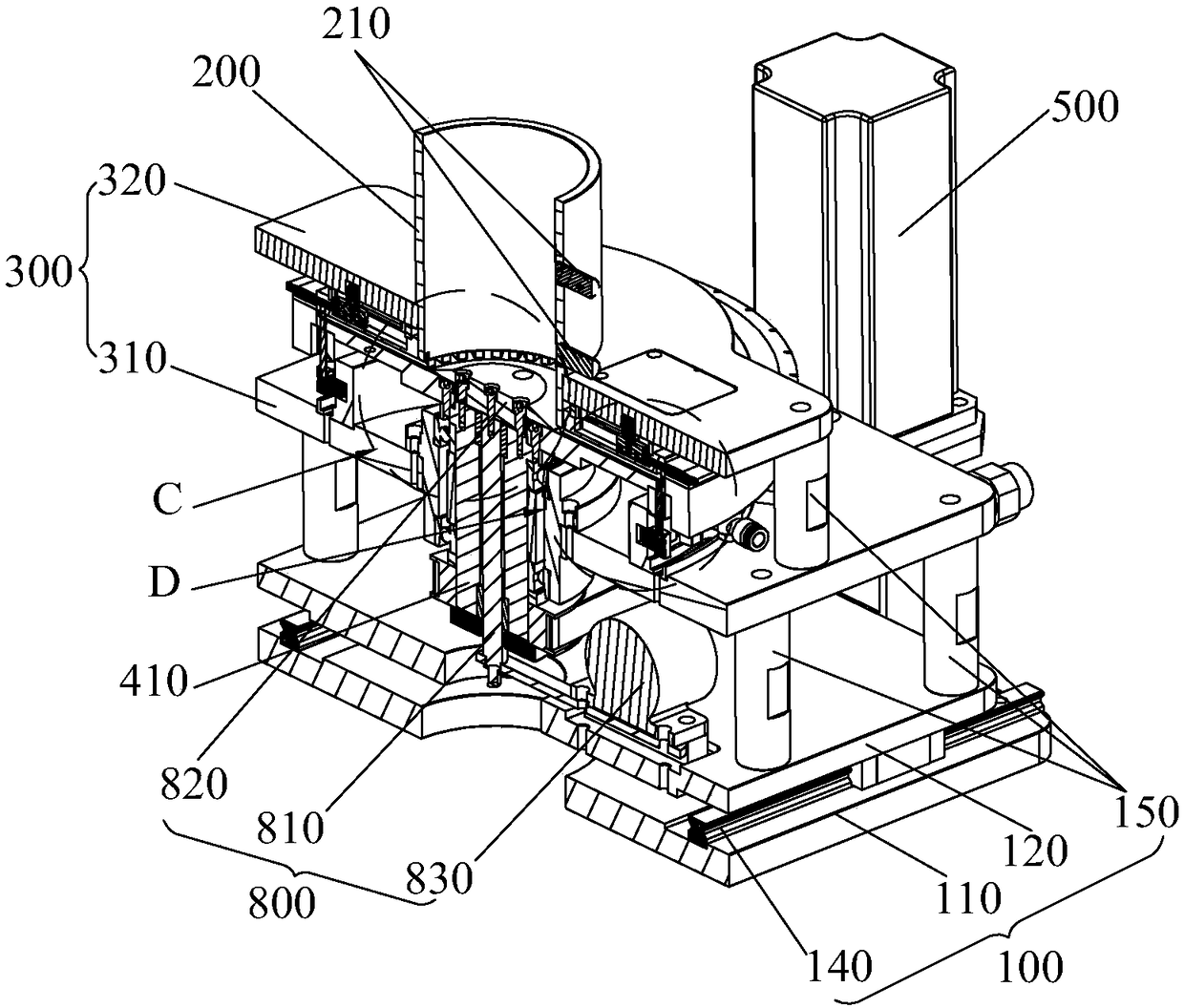

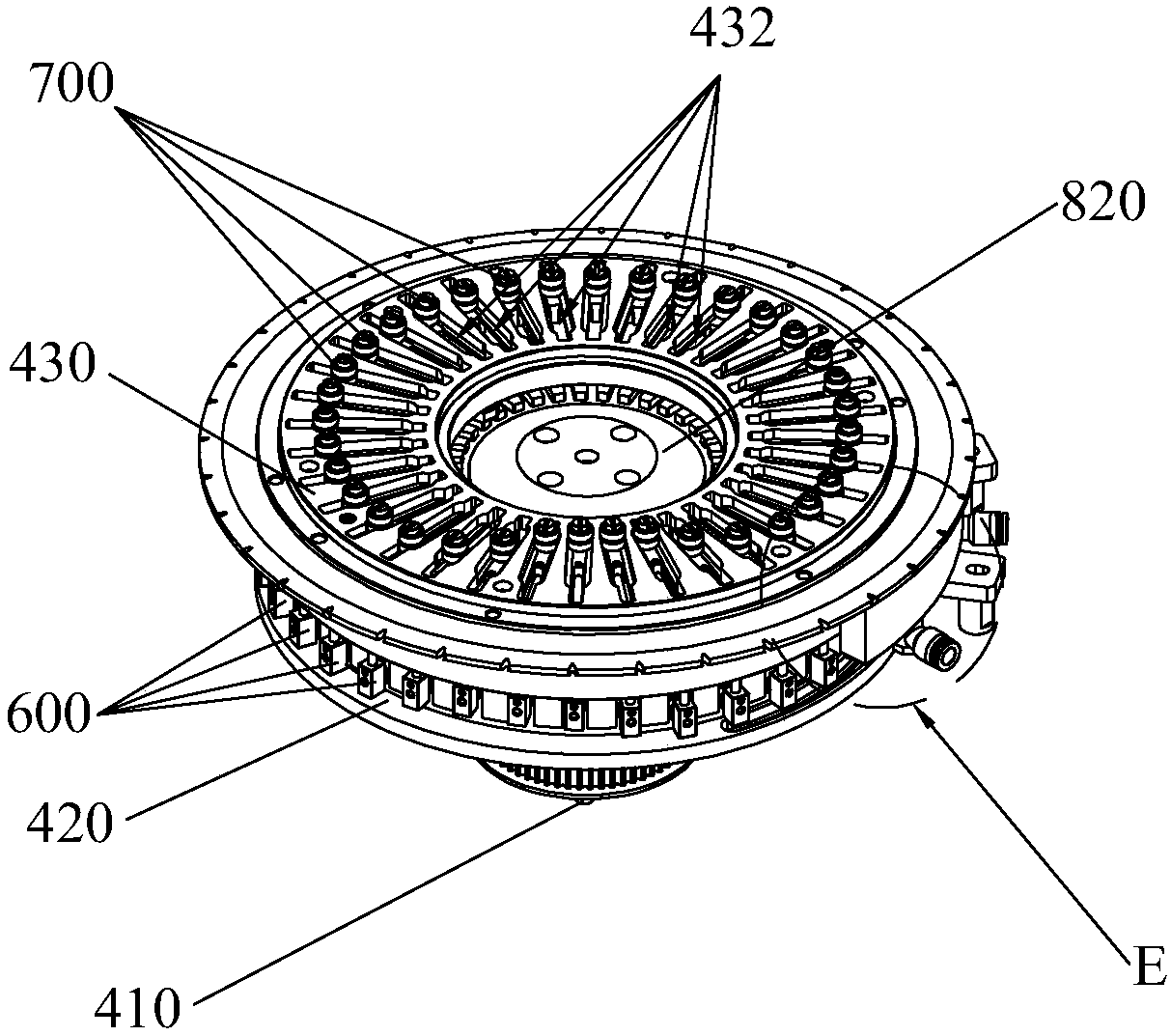

Horizontal-type particle high-speed implanting device

PendingCN108128602AEasy accessEasy to throw outRotary conveyorsImplanted deviceMechanical engineering

A horizontal-type particle high-speed implanting device provided by the invention comprises a material storing cabin, a material implanting opening, a fixed seat, a rotatable seat capable of rotatingrelative to the fixed seat, a first pushing mechanism, a second pushing mechanism and an air collecting mechanism. A plurality of inner material feeding channels communicating with the material storing cabin and a plurality of outer material feeding channels communicating with the material implanting opening are sequentially formed in the circumferential side of the rotatable seat, and the heightdifference exists between the inner material feeding channels and the outer material feeding channels in the vertical direction. The first pushing mechanism is used for pushing particles in the innermaterial feeding channels to the outer material feeding channels, and the second pushing mechanism is used for pushing the particles in the outer material feeding channels to the outer side of the material implanting opening. The fixed seat comprises a first cam driving plate and a second cam driving plate, and the first cam driving plate and the second cam driving plate are arranged on the upperside and the lower side of the rotatable seat correspondingly to drive the first pushing mechanism and the second pushing mechanism correspondingly. The gas collecting mechanism is used for positioning the particles, the material storing cabin is fixedly arranged in the fixed seat, and a flow guiding block is fixedly arranged on the lower side of the inner wall of the cylindrical material storingcabin.

Owner:武汉大坦智能装备科技有限公司

Tortoise pool grass-feeding ship used for aquaculture

InactiveCN111685081AFeeding reachedSave human effortCargo handling apparatusPassenger handling apparatusEngineeringZoology

The invention discloses a tortoise pool grass-feeding ship used for aquaculture. The tortoise pool grass-feeding ship comprises a ship body, a servo motor, a conveying component and a driving component, wherein the bottom of the ship body is rotatably connected with a shaft rod; two sides of the shaft rod are independently connected with water paddling blades; the servo motor is installed on one side of the top of the ship body, the output shaft of the servo motor is connected with a rotary shaft; the rotary shaft is in transmission connection with a shaft rod; the conveying component is arranged on the ship body; and the driving component is arranged between the conveying component and the rotary shaft. According to the tortoise pool grass-feeding ship disclosed by the invention, the conveying component and the driving component are cooperated to operate to feed feed grass so as to achieve an effect of feeding the feed grass. Through a baiting component and a segmentation component, during an operation, more feed grass can be simultaneously placed in one time, the feed grass does not need to be frequently manually added, and manpower is effectively saved. During the operation, manual feeding is not required, manpower is effectively saved, in addition, the movement distance of the grass feeding ship is consistent when tortoises are fed each time, and a feeding effect is effectively guaranteed.

Owner:漳州市同丰科技服务有限公司

Method for preparing silage

The invention discloses a method for preparing silage and belongs to the technical field of silage. The method comprises (1) silage raw material preparation: cutting peanut seedlings and the whole corn plant, carrying out triturating and carrying out uniform mixing, (2) addition of a silage starter and water, and (3) silage container filling with the mixture, compaction, sealing and storage at the normal temperature for 30-60 days. The silage has silage effects better than that of the peanut seedlings having content of 100%, has high silage quality and a nutrition value similar to that of the corn silage, and has low pH and ammonia nitrogen / total nitrogen and ADF content and high lactic acid content.

Owner:INST OF CEREAL & OIL CROPS HEBEI ACAD OF AGRI & FORESTRY SCI

Refractory material processing device

InactiveCN110665424AReduce stirring pressureExtended service lifeRotary stirring mixersTransportation and packagingRefractoryStructural engineering

The invention relates to the technical field of refractory material processing, and concretely relates to a refractory material processing device. The device comprises a circular base and a box body,the box body is arranged on the circular base, partition plates are arranged at the inner side of the box body in the length direction of the box body, the two partition plates are arranged up and down and are combined to form a material storage space, and the device further comprises a stirring assembly mounted in the circular base, a feeding assembly mounted in the box body, a driving assembly for driving the feeding assembly to move up and down, and a crushing and scraping assembly arranged in the material storage space and driven by the driving assembly. The feeding assembly is driven by the driving assembly to move in order to form intermittent feeding, the crushing and scraping assembly moves up and down along with the feeding assembly to make a material in the storage space be fullycrushed and then fall into the stirring assembly for stirring, and the material is primarily crushed before being stirred to reduce the stirring pressure of the stirring assembly in order to prolongthe service life of the device.

Owner:长兴县威尔特耐火材料有限公司

A molding runner with a wax discharge port and its preparation and plugging method

ActiveCN105458180BPrevent leakageGood product consistencyFoundry mouldsFoundry coresInvestment castingEngineering

The invention aims at solving the problems existing in blockage of a dewaxing opening in the prior art, provides a forming pouring gate with a dewaxing opening and a preparing and blocking method of the forming pouring gate, and belongs to the field of large thin-wall casting investment castings. The forming pouring gate is a wax pipeline with openings in the two ends and is composed of a left section, a middle section and a right section. The right section is a wax pipeline cavity. The middle section is a wax pipeline cavity with a thick end and a thin end, the thin end is connected with the right section, and the thick end is connected with the left section. The left section is a wax pipeline cavity with a boss on the side wall, and the dewaxing opening not opened is formed in the upper surface of the boss. The production consistency of the forming pouring gate is good, and the production process can be conveniently controlled. Meanwhile, the dewaxing opening is blocked through a special ceramic stop block, appropriate coatings are matched, the pheromone of leakage of molten steel during casting can be prevented, the feeding effect is guaranteed, and metallurgical defects such as hole shrinkage, loosening and blending can be reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Compound orange peel residue feed for geese and preparation method of compound orange peel residue feed

InactiveCN105053601ASolve wasteGuaranteed feeding effectFood processingAnimal feeding stuffChemistryFish meal

The invention belongs to the technical field of feeds for geese, and discloses a compound orange peel residue feed for geese and a preparation method of the compound orange peel residue feed. The feed comprises the following components in percentage by weight: 44.4-48.68% of corn, 4-8% of orange peel residues, 11.8-16.71% of soybean meal, 1.82-3.61% of fish meal, 2.65-7.4% of corn protein powder, 4.81-12.2% of wheat bran, 0.61-6.19% of crude unite bran, 0.6-4.82% of rice husk powder, 3.37-4.7% of fatty powder, 2.37-5.37% of bentonite, 1.25-1.47% of dicalcium phosphate, 0.24-0.76% of stone powder, 0.4% of salt, 0.31-0.46% of lysine hydrochloride, 0.18-0.19% of DL methionine, 0.02-0.11% of DL threonine, 0.1-0.15% of choline chloride, 0.04% of multivitamins, 0.08-0.1% of multi-minerals and 0.1% of a mildewproof agent.

Owner:SOUTH CHINA AGRI UNIV

Hay crushing device and working method thereof

InactiveCN113557857AExpand the range of crushingGuaranteed feeding effectDrying gas arrangementsBalingKnife bladesBall joint

The invention relates to the field of smashing devices, in particular to a hay smashing device and a working method thereof. The hay smashing device comprises a smashing box, a plurality of sets of smashing assemblies arranged in the smashing box and annularly and evenly distributed and a driving mechanism used for driving the smashing assemblies, the crushing assembly comprises a mounting sleeve, a mounting plate, a ball groove, a rotating shaft, a rotating ball, a crushing blade and a transmission mechanism, the mounting sleeve is arranged in the crushing box in the horizontal direction and fixedly connected with the crushing box, the mounting plate is fixedly connected to the end of the mounting sleeve, the ball groove penetrates through the mounting plate, the rotating shaft penetrates through the ball groove, wherein one end of the rotating shaft extends into the mounting sleeve, the rotating ball is fixedly connected to the rotating shaft and is in ball joint with the interior of the ball groove, the crushing blade is arranged on the rotating shaft and is positioned outside the mounting sleeve, the transmission mechanism is used for enabling the rotating shaft to rotate and enabling one end, positioned in the mounting sleeve, of the rotating shaft to revolve around a rotating ball, and the driving mechanism is in transmission connection with the transmission mechanism. The hay crushing device has the effect of more uniformly crushing hay.

Owner:于辉 +11

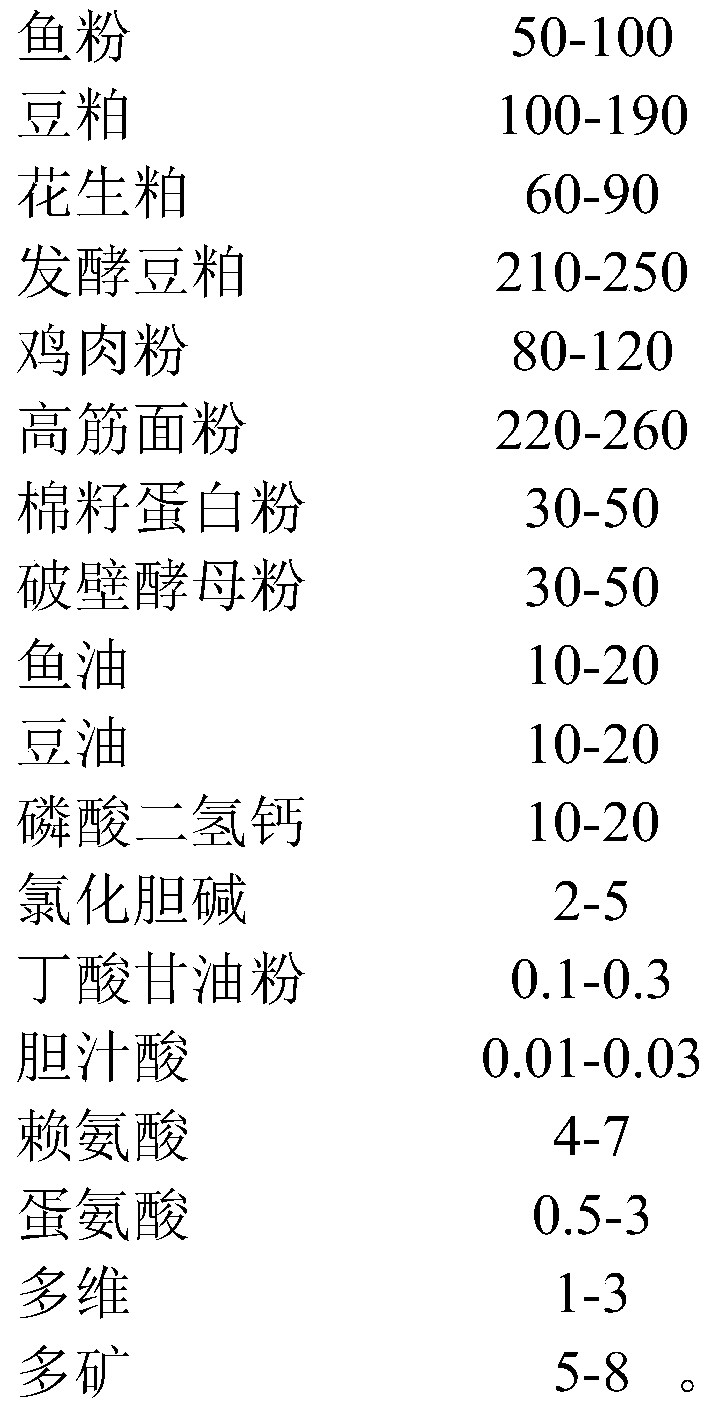

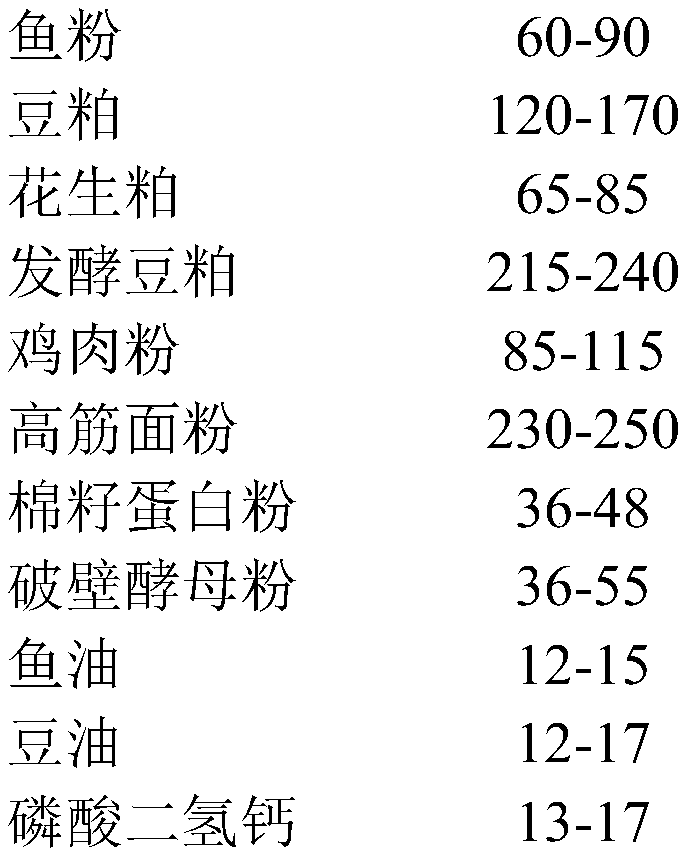

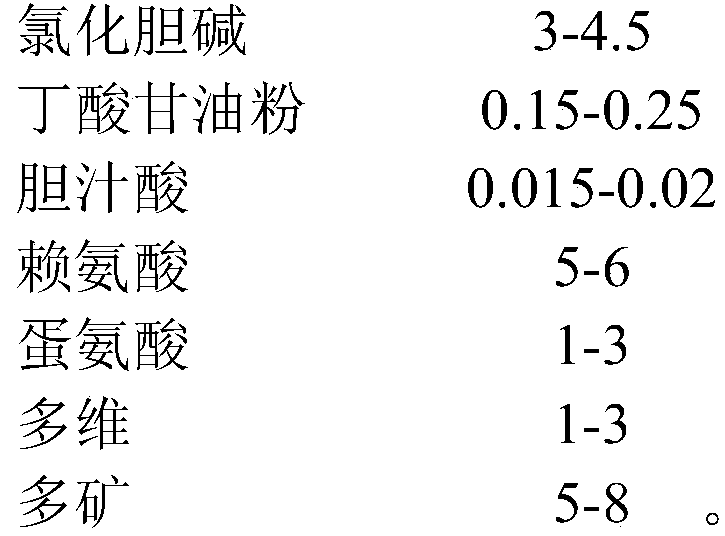

Low-fish meal bullfrog compound feed, and preparation method and application thereof

PendingCN110973375AGuaranteed amino acid balanceImproving bullfrog feedingFood processingAnimal feeding stuffSOYBEAN SEED OILButyric acid

The invention relates to a low-fish meal bullfrog compound feed, and a preparation method and application thereof. The low-fish meal bullfrog compound feed comprises the following raw materials in parts by weight: 50-100 parts of fish meal, 100-190 parts of soybean meal, 60-90 parts of peanut meal, 210-250 parts of fermented soybean meal, 80-120 parts of chicken meal, 220-260 parts of high-glutenflour, 30-50 parts of cottonseed protein powder, 30-50 parts of wall-broken yeast powder, 10-20 parts of fish oil, 10-20 parts of soybean oil, 10-20 parts of calcium dihydrogen phosphate, 2-5 parts ofcholine chloride, 0.1-0.3 part of glycerol butyrate powder, 0.01-0.03 part of bile acid, 4-7 parts of lysine, 0.5-3 parts of methionine, 1-3 parts of multivitamins, 5-8 parts of multiminerals. Compared with common commercial feeds in the market, the low-fish meal bullfrog compound feed can obviously reduce use of feed fish meal, has a good feeding effect and low production cost, and has good popularization, application and development prospects.

Owner:JIMEI UNIV

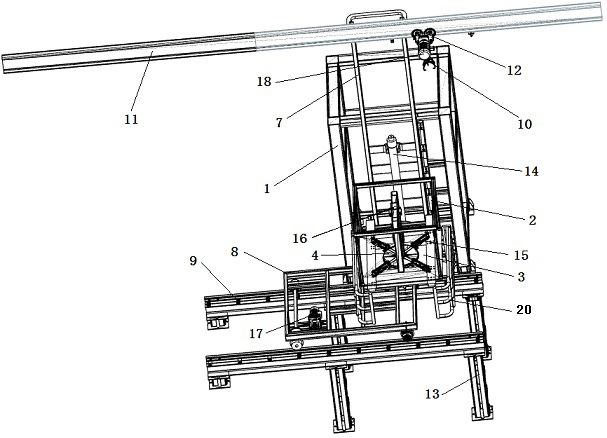

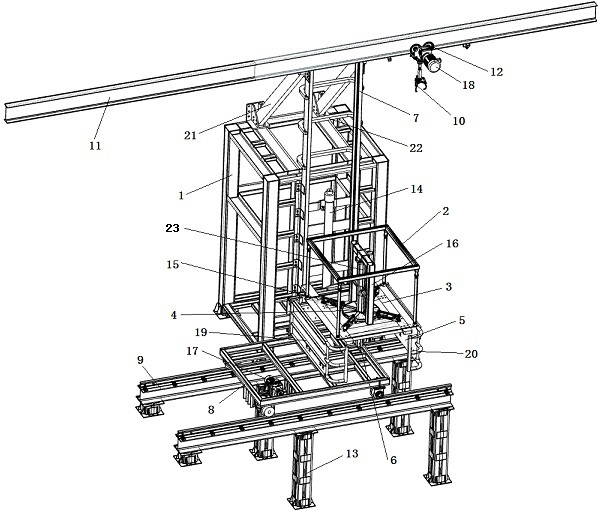

Ton bag feeding system

PendingCN112158430AImprove feeding efficiencyFully automatedFlexible bulk container emptying systemsLoading/unloadingMechanical engineeringFully automated

The invention discloses a ton bag feeding system. The ton bag feeding system is characterized in that a ton bag feeding device moves up and down along a vertical frame right above a ton bag feeding port, a ton bag turnover vehicle moving horizontally is further arranged between the ton bag feeding device and the ton bag feeding port, and a ton bag removing device moving horizontally is further arranged above the ton bag feeding device; and after the ton bag turnover vehicle moves to the position under the ton bag feeding device, the ton bag feeding device moving downwards to the correspondingposition grabs ton bags from the ton bag turnover vehicle, feeding is conducted after the ton bag turnover vehicle leaves, and after the ton bag removing device moves to the position over the ton bagfeeding device, the ton bags on the ton bag feeding device which moves upwards after feeding are removed. According to the structure, the ton bag feeding system achieves full automation of ton bag loading, feeding as well as ton bag clamping, transferring and recycling, the ton bag feeding efficiency is improved, and the labor intensity is reduced.

Owner:江阴市恒都机械有限公司

Method for removing dust by using electric furnace

ActiveCN112813227AGuarantee product qualityWon't happenProcess efficiency improvementDust controlCarbonization

The invention discloses a method for removing dust by using an electric furnace, and belongs to the technical field of dedusting ash recycling in the metallurgical industry. According to the method, the recycled electric furnace dedusting ash is used for replacing a covering agent, the recycled electric furnace dedusting ash is filtered, dried, stored and prepared, when the liquid level of molten steel poured by a bottom pouring steel ingot rises to the elevation of a riser, firstly, carbonized rice husks are put into ingot mould riser molten steel and spread flatly, then prepared electric furnace dedusting ash is directly put into the carbonized rice husks spread flatly on the ingot mould riser molten steel, and the dedusting ash is spread flatly to cover the ingot mould riser end through an iron rake. According to the method, on the premise that the quality of steel ingot products is guaranteed, the electric furnace dedusting ash is used for replacing a covering agent, waste electric furnace dedusting ash generated by enterprises is fully utilized, the production cost can be reduced, and meanwhile smoke pollution can be avoided.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Heat-preservation and flame-retardant casting covering slag

The invention relates to heat-preservation and flame-retardant casting covering slag. The covering slag comprises, by weight, 50%-70% of a suspending agent, 30%-40% of a flame retardant and 5%-10% of high-aluminum bauxite powder. A binder with the total quantity of 3%-5% can further be added to the covering slag. Silica sol or aluminum phosphate can be used as the binder. Artificial mica, bentonite, diatomite, palygorskite clay and the like can be used as the suspending agent. Alkyl sodium sulfonate, boric acid and the like can be used as the flame retardant. The covering slag has high heat preservation performance, flame retardance and coating performance, also has an excellent suspension property and is not prone to precipitation in the using process. The covering slag reduces the hot crack tendency of an aluminum-magnesium alloy casting. During casting, the covering slag forms a layer of reductive protective atmosphere on the molten magnesium interface of a riser, so that aluminum-magnesium alloy is protected against oxidization and is prevented from burning in a casting mould during casting; sequential cooling of the aluminum-magnesium alloy is guaranteed, the feeding effect in the solidification process of the aluminum-magnesium alloy is improved, and the aluminum-magnesium alloy casting free of inside crystal orientation defects, smooth in surface and free of oxidized wrinkled skin is obtained.

Owner:QINGDAO WEIYE FORGING & STAMPING MACHINERY CO LTD

Open-end spinning device with cleaning device

ActiveCN113249831ANeatly arranged in groupsUniform force distributionContinuous wound-up machinesOpen-end spinning machinesYarnPolymer science

The invention provides an open-end spinning device with a cleaning device, and relates to the field of open-end spinning. The open-end spinning device comprises a spinning box; a feeding pipe is installed at the front end of the spinning box; a discharging opening is formed in the top end of the spinning box; two sets of separation wheels are installed on the inner side of the feeding pipe, and a connecting shaft rod is installed at the end penetrating through the separation wheels; the two ends of the connecting shaft rod are both movably connected with the inner side of the feeding pipe; a rotor spinner is arranged on the inner side of the spinning box; by matching with the arrangement of dispersing grooves in the outer sides of the separating wheels, silk yarn bundles can be clamped into the dispersing grooves in different groups in batches, the silk yarn bundles can be arranged in order in groups during feeding, and therefore stress of the silk yarn bundles is evenly distributed in the feeding process, and silk yarn bundle winding caused by uneven stress of silk yarns in the silk yarn bundles is reduced; and connected adsorption rods can form a blocking net, thread ends or sundries on the outer sides of the silk yarns can be blocked and stripped, and therefore the spinning quality and the safety of the device are guaranteed.

Owner:安义普利丝纺织有限公司

Hub casting system

ActiveCN104338903AEliminate shrinkage defectsEliminate pouring defectsFoundry mouldsFoundry coresEngineeringFlange

The invention provides a hub casting system. The exterior of a hub is structurally divided into a first step, a second step, a flange and a straight barrel in sequence, and a bearing mounting position is arranged in the hub in a penetration way, wherein a mounting groove is formed in the flange; a feeding head is arranged on the outer circle of the second step, and is connected with a straight runner through a transverse runner; a gap is formed between the root of the feeding head and the root of the flange, and is 3 to 5mm; a fracture is formed in the root of the feeding head and the second step. According to the hub casting system, the casting position of a casting is shifted to a position to be fed, that is, the feeding head is shifted to the second step on the flange, the feeding head is directly used for feeding to the second step, the straight runner and the transverse runner are continuous, and the casting is cast by virtue of the feeding head, so that the defect of shrinkage is substantially eliminated, and a result meets the requirement of a product.

Owner:SHIYAN KAIQI CASTING

Spherical capsule high speed ejection feeding machine

ActiveCN108128613AEasy accessPrevent reboundConveyorsAgriculture gas emission reductionEngineeringHeight difference

The invention provides a spherical capsule high speed ejection feeding machine. The spherical capsule high speed ejection feeding machine includes a storage bin, feeding ports, a fixing seat, a rotating seat which can rotate relative to the fixing seat, a first pushing mechanism and a second pushing mechanism; a plurality of inner feed channels communicating with the storage bin and a plurality ofouter feed channels communicating with the feeding ports are disposed in sequence on the peripheral side of the rotating seat, and a height difference exists in the vertical direction between the inner feed channels and the outer feed channels; the first pushing mechanism is used for pushing spherical capsules in the inner feed channels to the outer feed channels, and the second pushing mechanismis used for pushing the spherical capsules in the outer feed channels to the outside of the feeding ports; the fixing seat includes a first cam drive board and a second cam drive board, the first camdrive board and the second cam drive board are separately disposed on the upper and lower sides of the rotating seat to separately drive the first pushing mechanism and the second pushing mechanism in a corresponding mode; and the storage bin is fixedly arranged at the fixing seat, and flow guiding blocks are fixedly disposed at the lower side of the inner wall of the cylindrical storage bin.

Owner:武汉大坦智能装备科技有限公司

Poultry farm quantitative feeding mechanism utilizing new-generation information technology

InactiveCN112344042AEasy to startAchieve intelligent controlOperating means/releasing devices for valvesSlide valveAnimal scienceAgricultural science

The invention relates to the technical field of feed equipment, and discloses a poultry farm quantitative feeding mechanism utilizing a new-generation information technology. The quantitative feedingmechanism comprises a frame cage, a feeder is fixedly connected to the outer part of the frame cage, a containing hopper is arranged at the top of the feeder, and a discharging channel is arranged atthe bottom of the containing hopper. An air outlet is formed in the discharging channel, an air valve is arranged in the feeder, an air channel is fixedly connected to the outer part of the air valve,an ejector block is slidably connected to the bottom of the containing hopper, and a copper ring is fixedly connected to the outer part of the ejector block. Through cooperative use of the ejector block, the copper ring, a magnetic block, a positioning rod, a positioning spring and a cam, the feeding amount of feed fed to a feed trough each time is fixed, automatic feeding is achieved in a scattered mode, the feeding effect is effectively guaranteed, the feeding uniformity and feeding determinacy are guaranteed, thus the feeding effect is effectively guaranteed, excessive feeding is avoided,the health condition of poultry is effectively guaranteed, and the waste of the feed is effectively reduced.

Owner:黄丽容

A pouring system for a wheel hub

ActiveCN104338903BEliminate shrinkage defectsEliminate pouring defectsFoundry mouldsFoundry coresControl theoryFlange

The invention provides a hub casting system. The exterior of a hub is structurally divided into a first step, a second step, a flange and a straight barrel in sequence, and a bearing mounting position is arranged in the hub in a penetration way, wherein a mounting groove is formed in the flange; a feeding head is arranged on the outer circle of the second step, and is connected with a straight runner through a transverse runner; a gap is formed between the root of the feeding head and the root of the flange, and is 3 to 5mm; a fracture is formed in the root of the feeding head and the second step. According to the hub casting system, the casting position of a casting is shifted to a position to be fed, that is, the feeding head is shifted to the second step on the flange, the feeding head is directly used for feeding to the second step, the straight runner and the transverse runner are continuous, and the casting is cast by virtue of the feeding head, so that the defect of shrinkage is substantially eliminated, and a result meets the requirement of a product.

Owner:SHIYAN KAIQI CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com