Ton bag feeding system

A ton bag and feeding board technology, applied in bulk container emptying system, loading/unloading, packaging and other directions, can solve the problems of large impact on staff health, high labor intensity, low feeding efficiency, etc., to improve the clamping effect, The effect of reducing labor intensity and improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

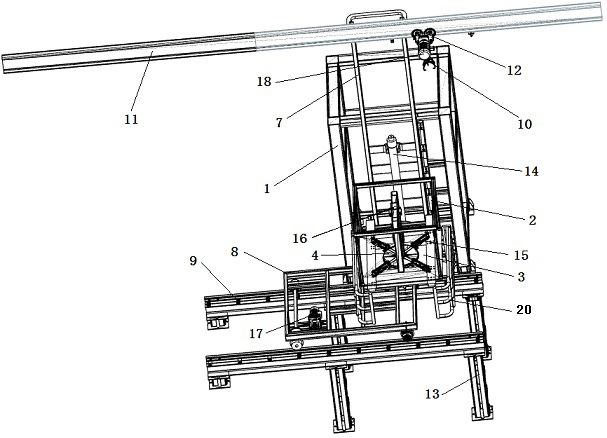

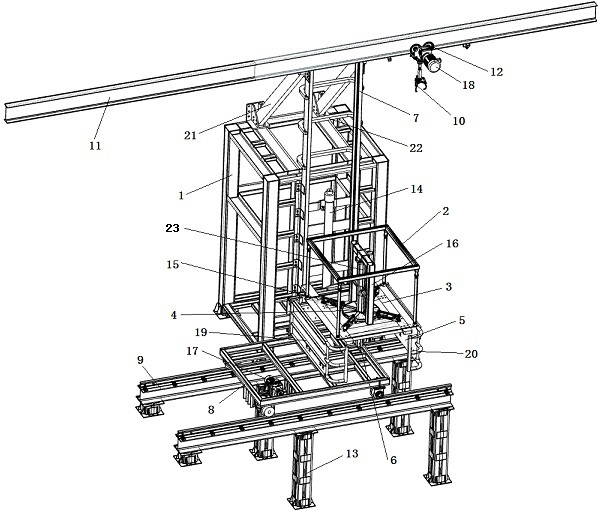

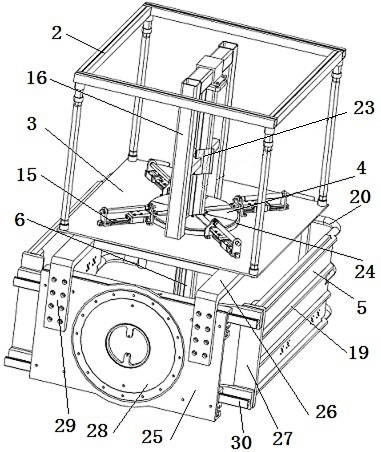

[0048]CombineFigure 1~Figure 5It can be seen that the ton bag feeding system of the present invention includes a ton bag feeding device arranged on the front end surface of the stand 1, and the ton bag feeding device moves up and down along the stand 1 directly above the ton bag feeding port. There is also a horizontally moving ton bag turnover vehicle 8 between the ton bag feeding device and the ton bag feeding port, and a horizontally moving ton bag removal device 10 is also provided above the ton bag feeding device. 8 After moving to just below the ton bag feeding device, the ton bag feeding device that moves down to the corresponding position grabs the ton bags from the ton bag turnover car 8 and feeds them after the ton bag turnover car 8 leaves. After the removal device 10 is moved directly above the large bag feeding device, the large bag on the large bag feeding device that moves upward after the feeding is completed is removed.

[0049]The ton bag feeding device includes a fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com