Patents

Literature

148results about "Flexible bulk container emptying systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

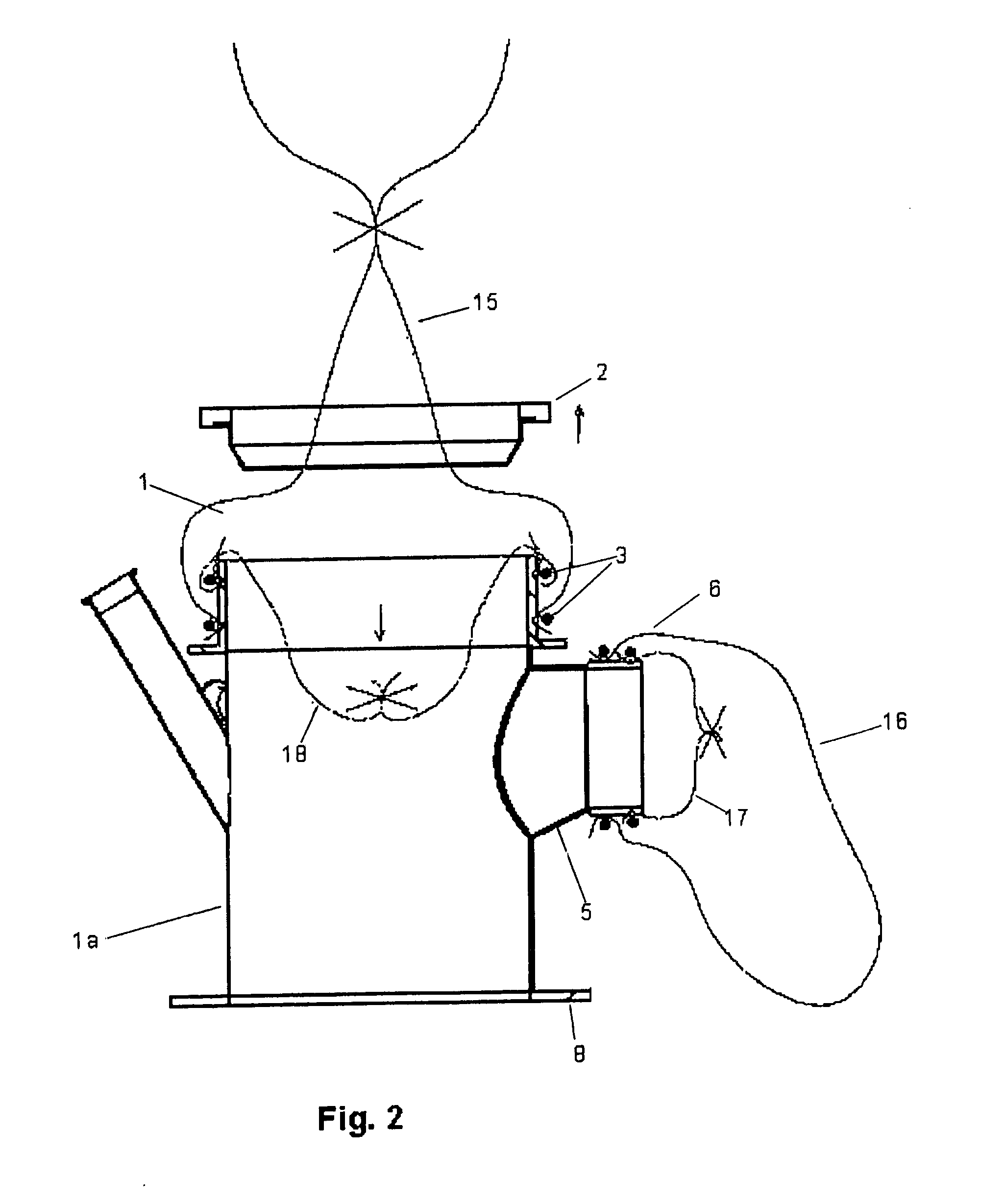

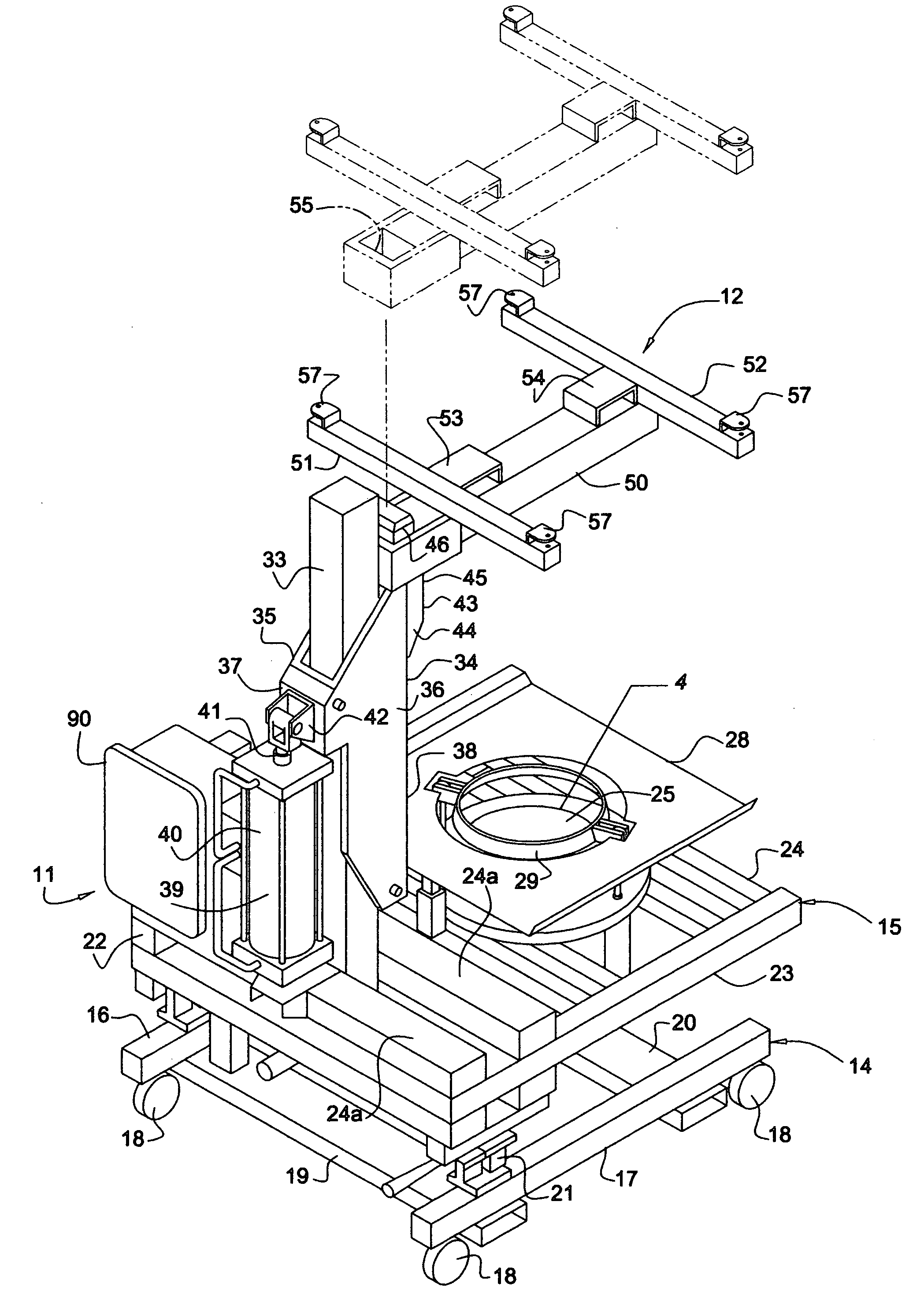

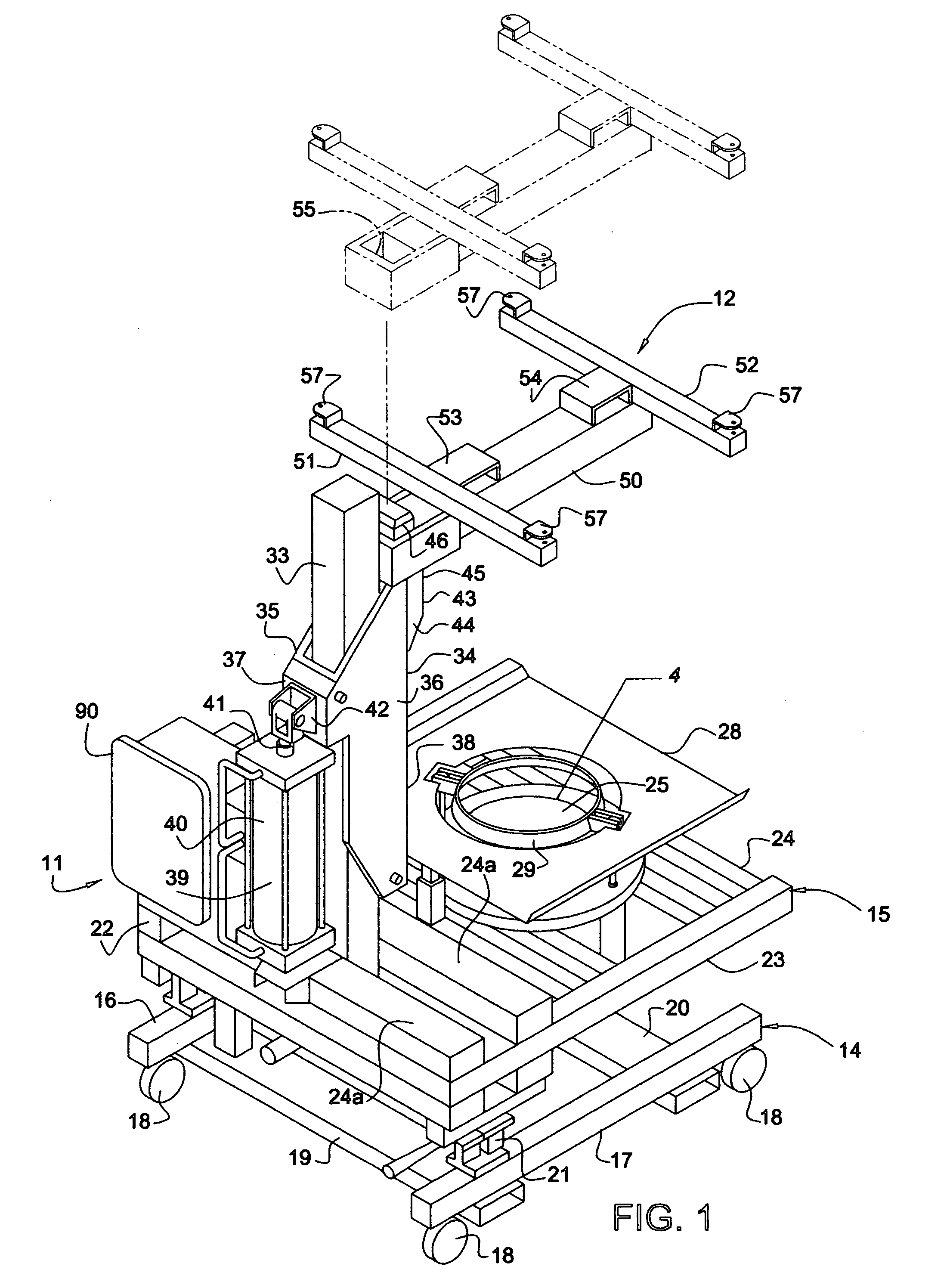

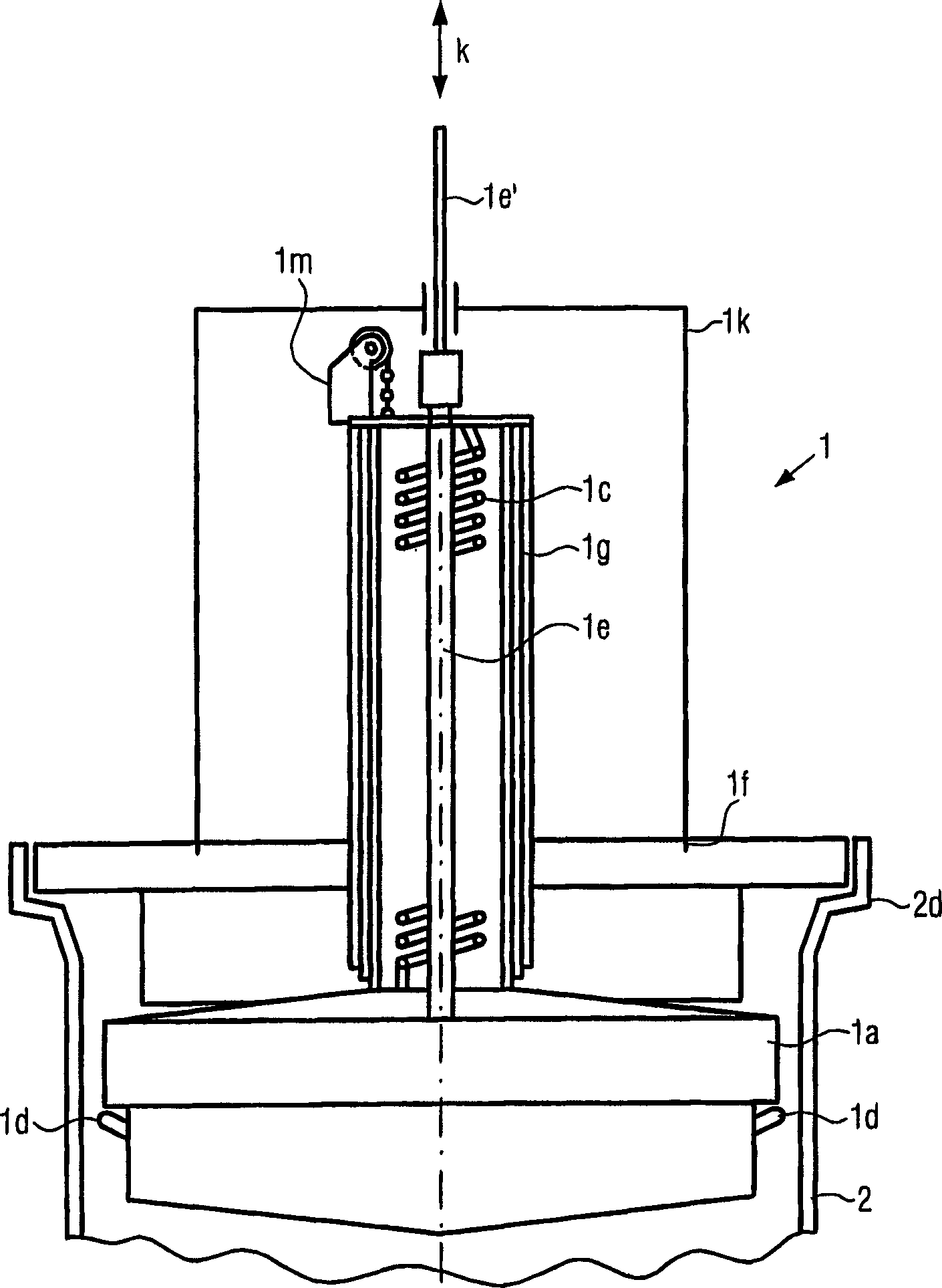

Device for large-volume containers

InactiveUS7140516B2Easy to fillSimple fashionFlexible bulk container emptying systemsClosuresMechanical engineeringLarge capacity

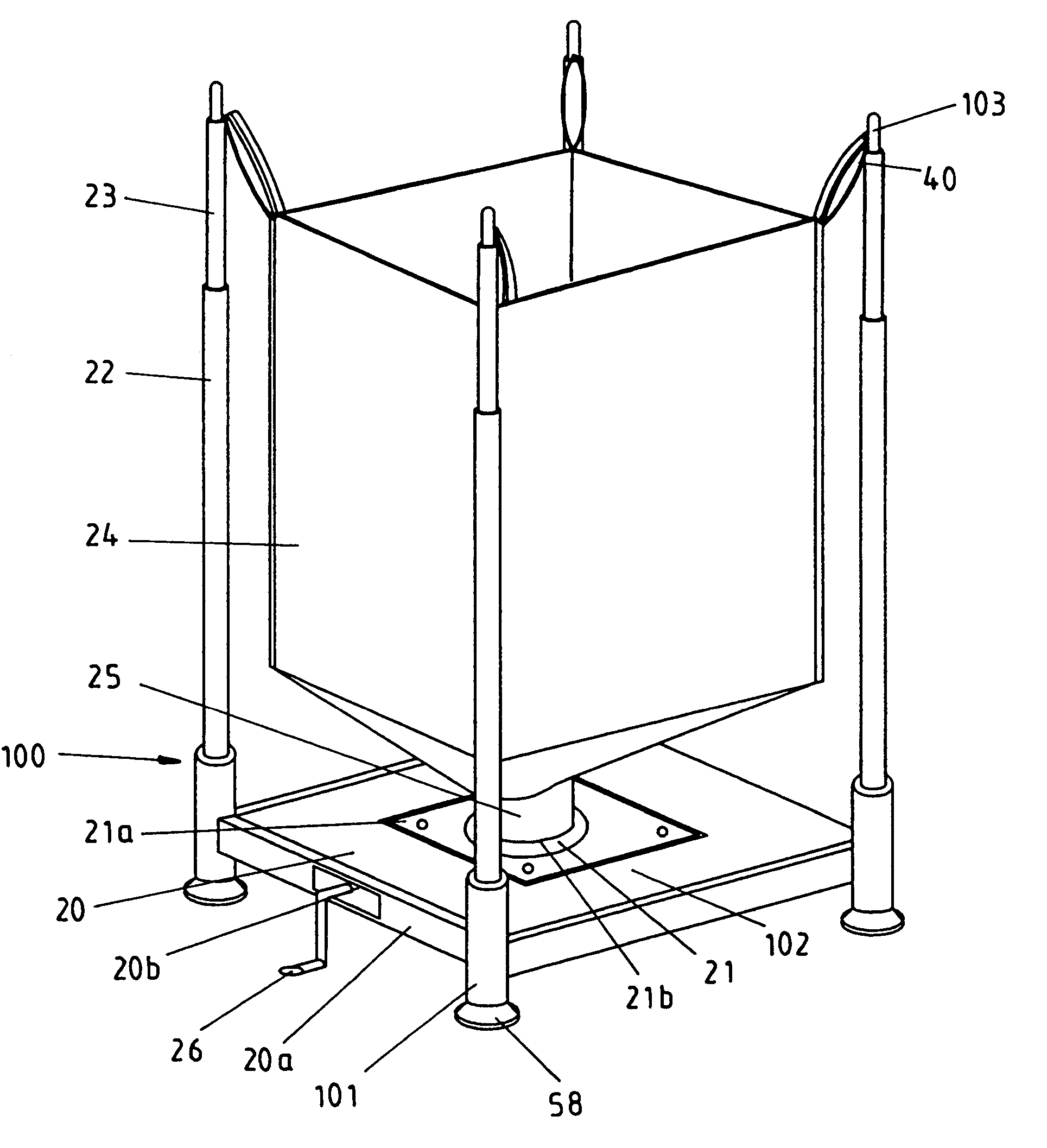

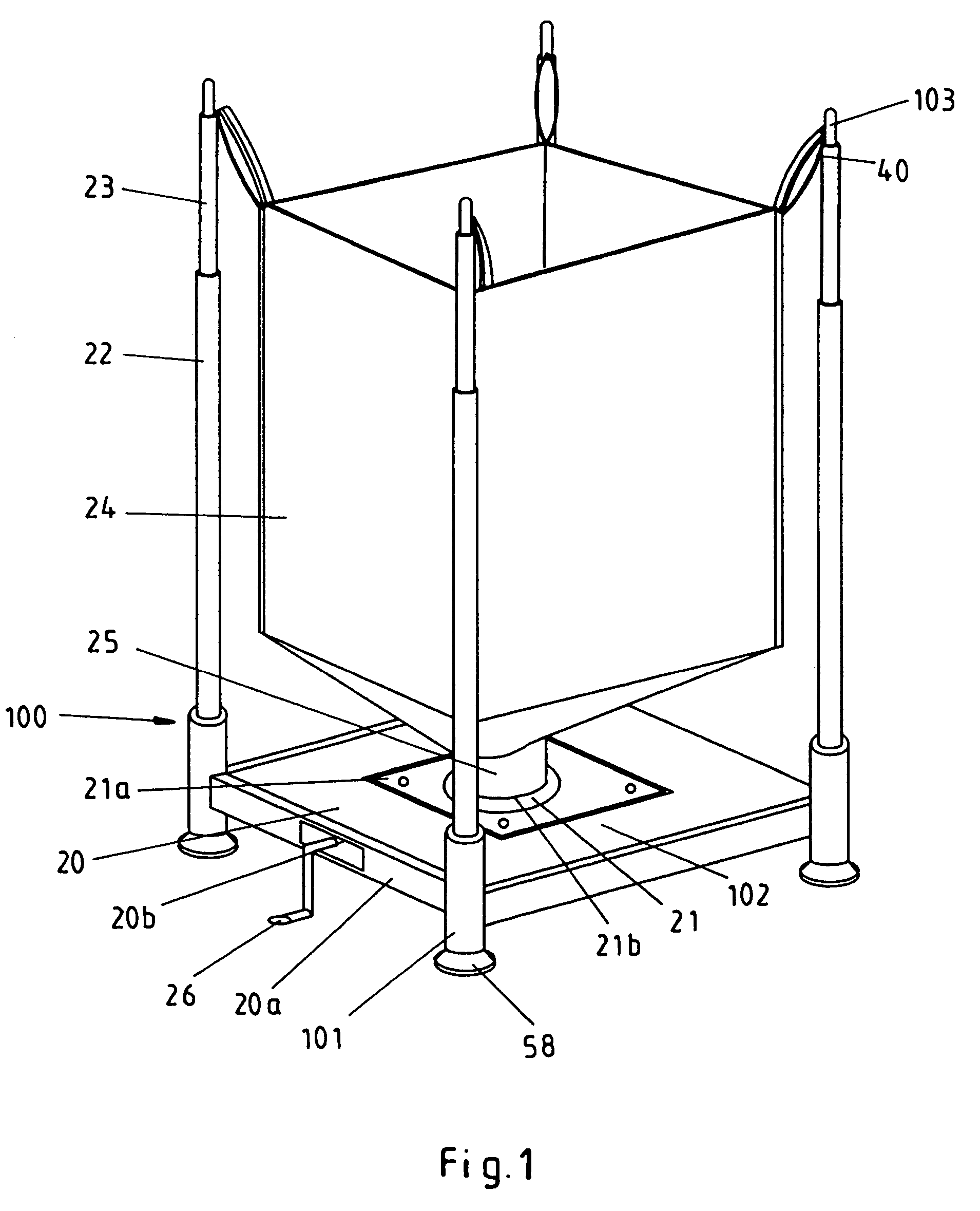

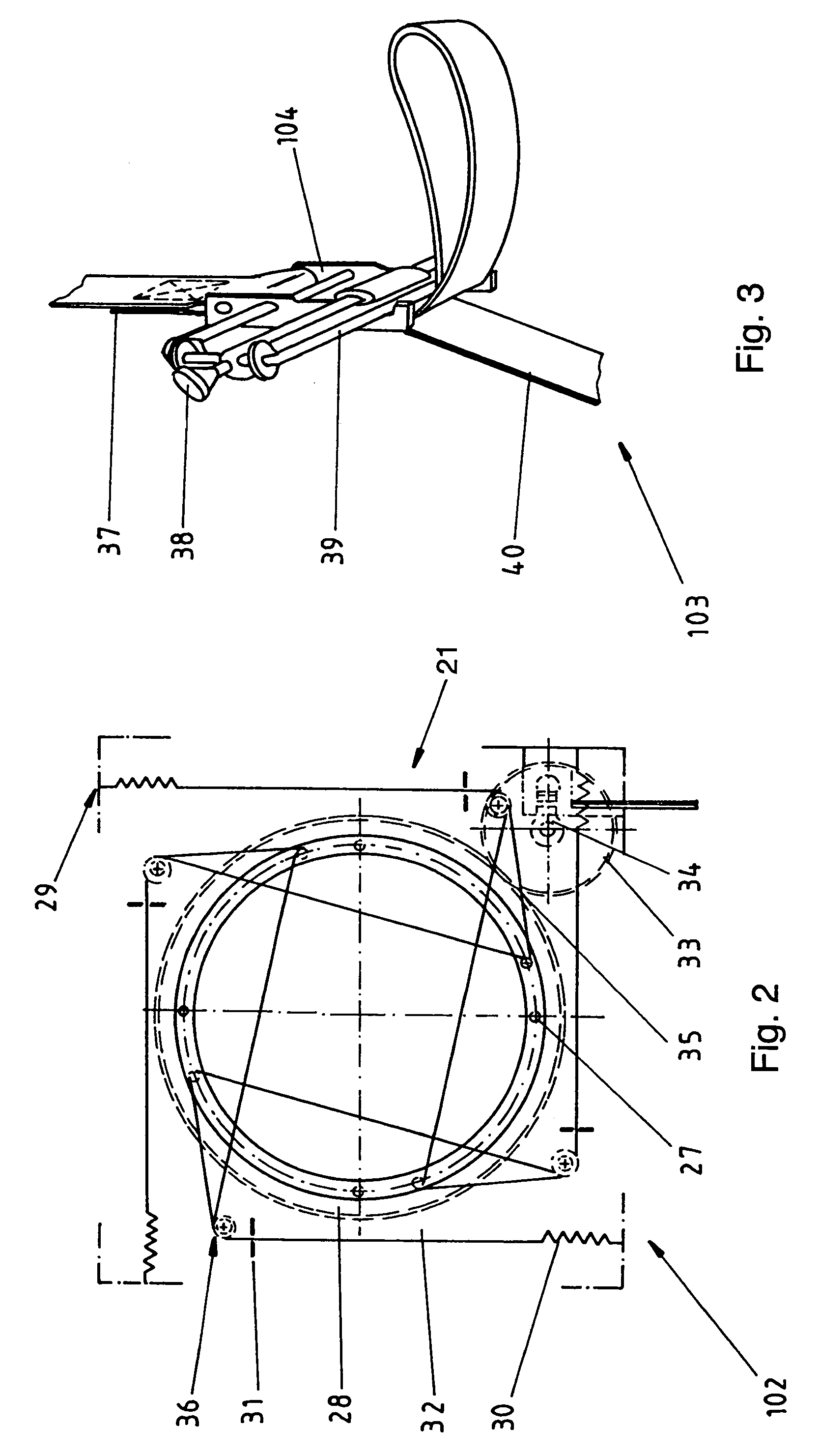

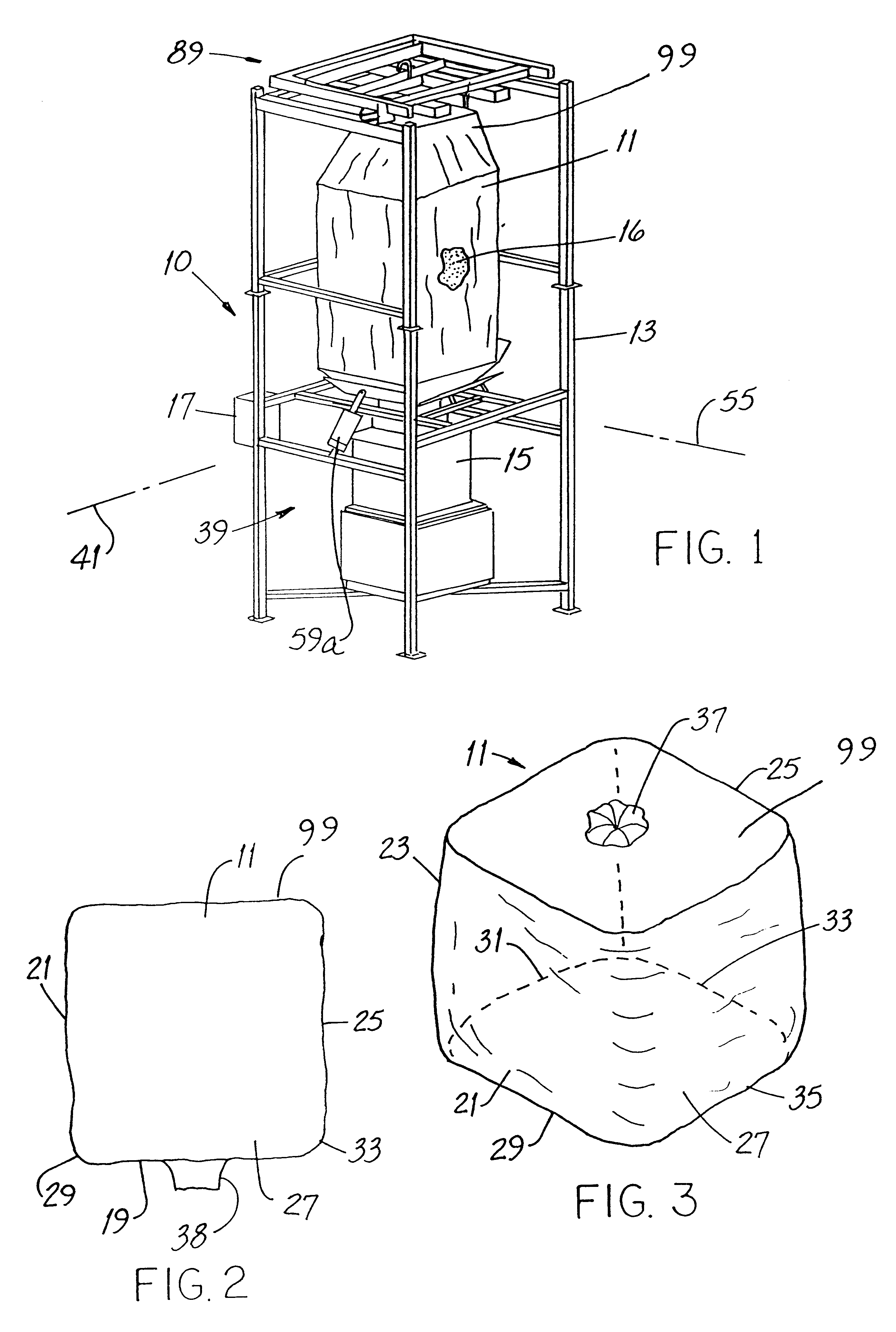

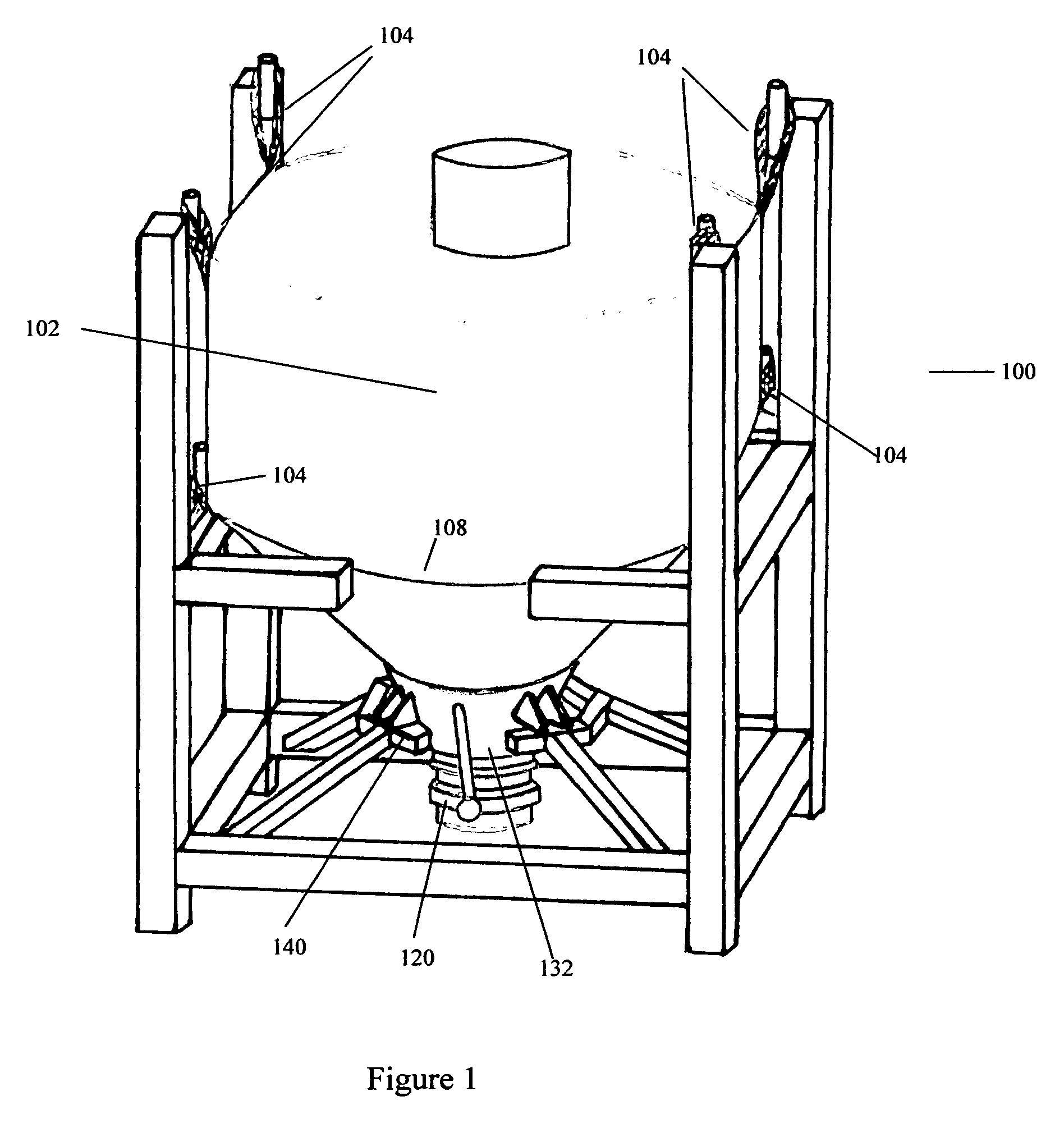

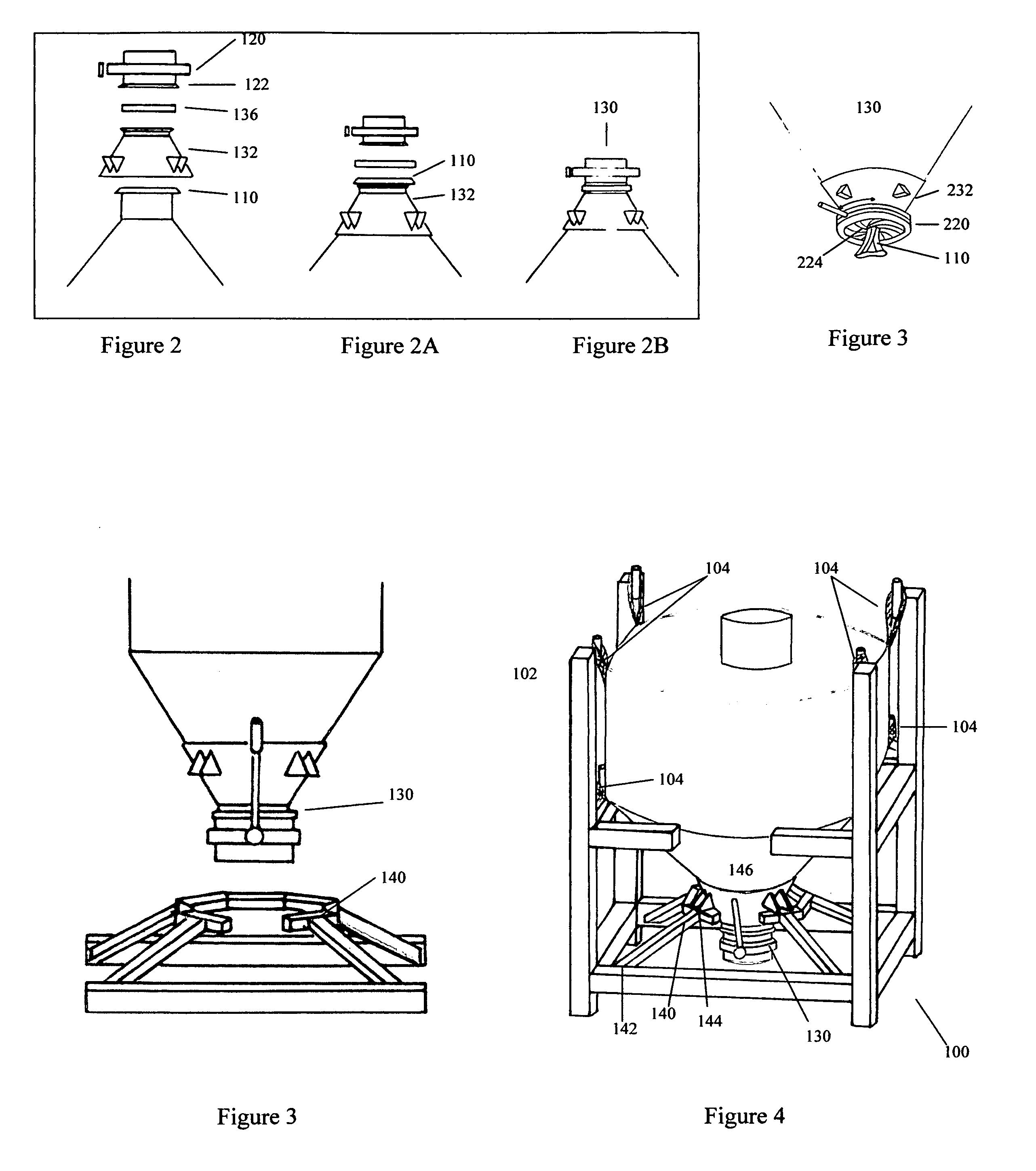

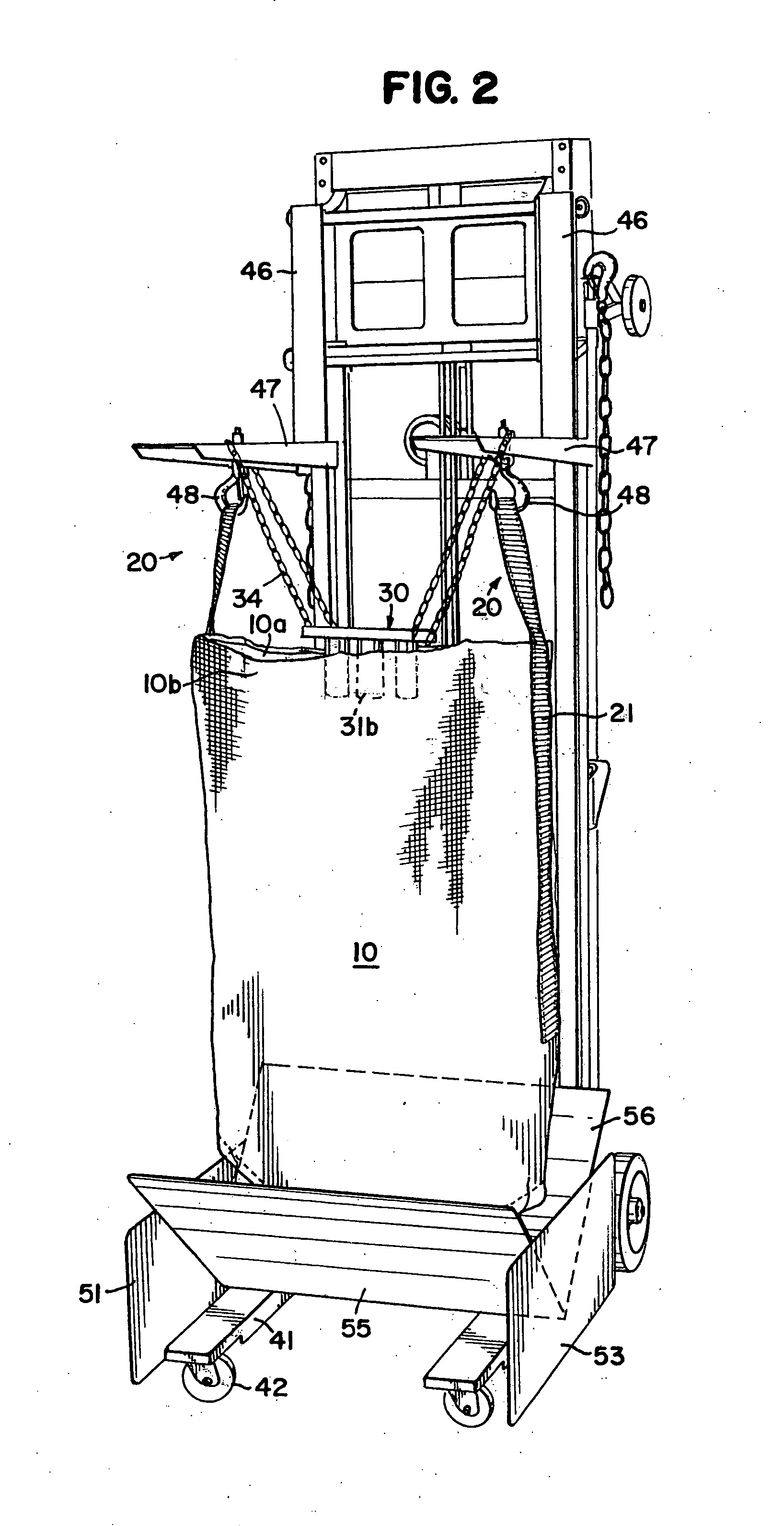

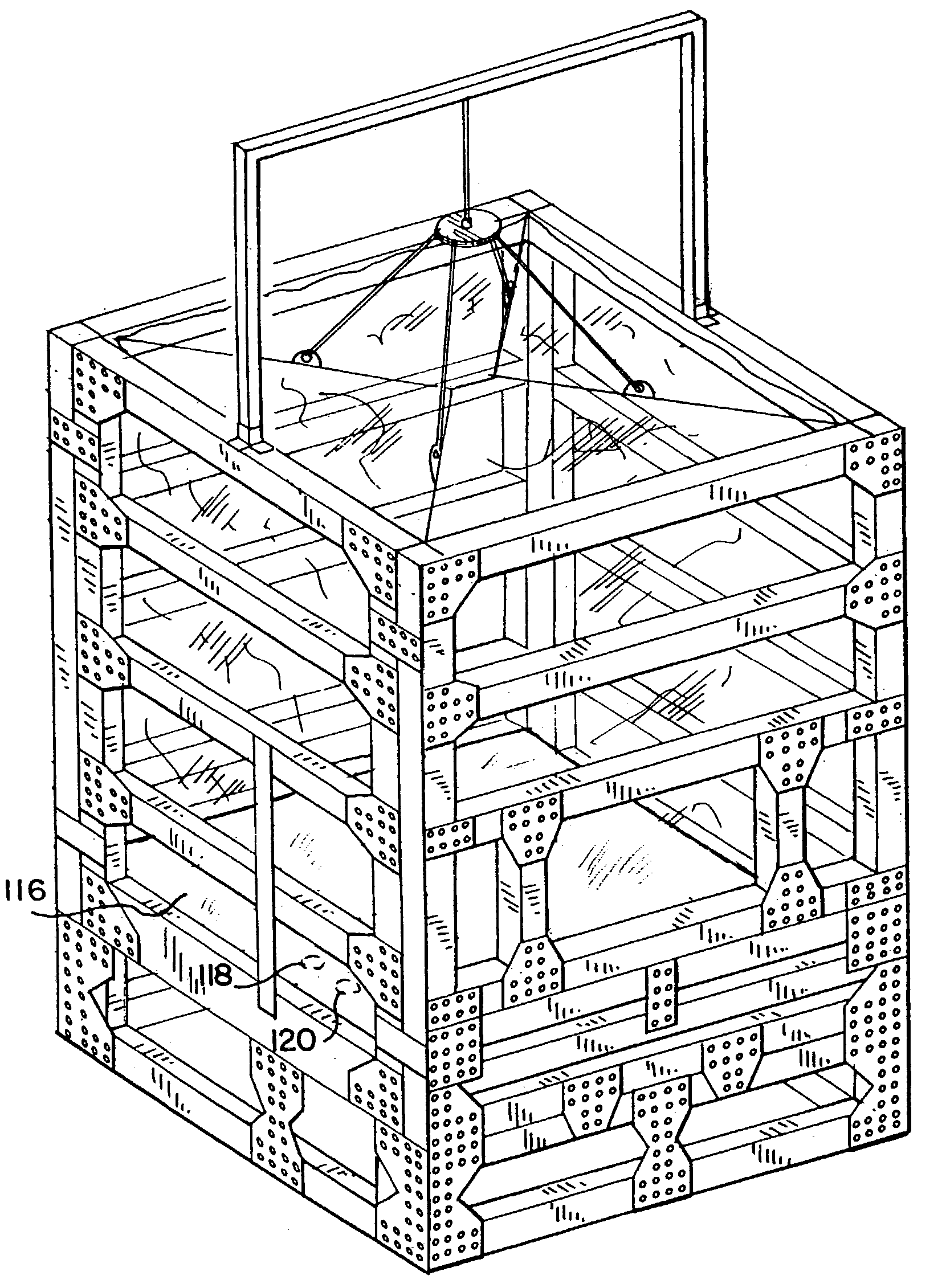

The invention pertains to an emptying device for large-volume receptacles which consists of an auxiliary transport apparatus that is composed of at least four uprights, on the lower ends of which one respective stacking leg is arranged and in the lower end of which one respective lifting mechanism is arranged. This lifting mechanism can be connected to the carrying straps of the large-volume receptacle by means of carrying strap holders, wherein the uprights are respectively connected to one another by means of transverse braces in their lower region in order to accommodate a bottom plate. The bottom plate contains a central opening for accommodating a shutter mechanism with a shutter that is situated in a base plate arranged on the bottom plate and can be actuated by means of a hand crank.

Owner:BOTHOR KERIM PATRICK +1

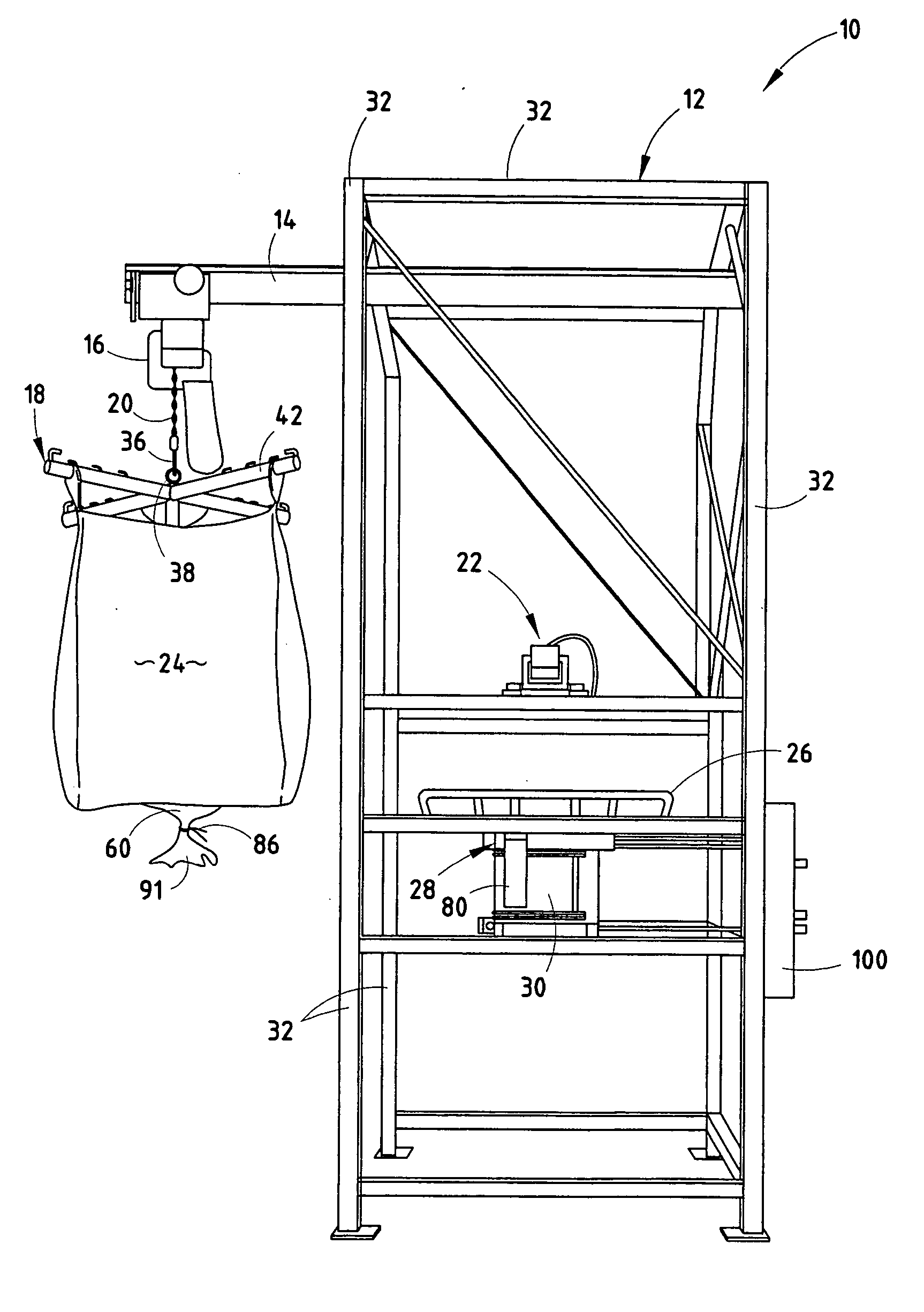

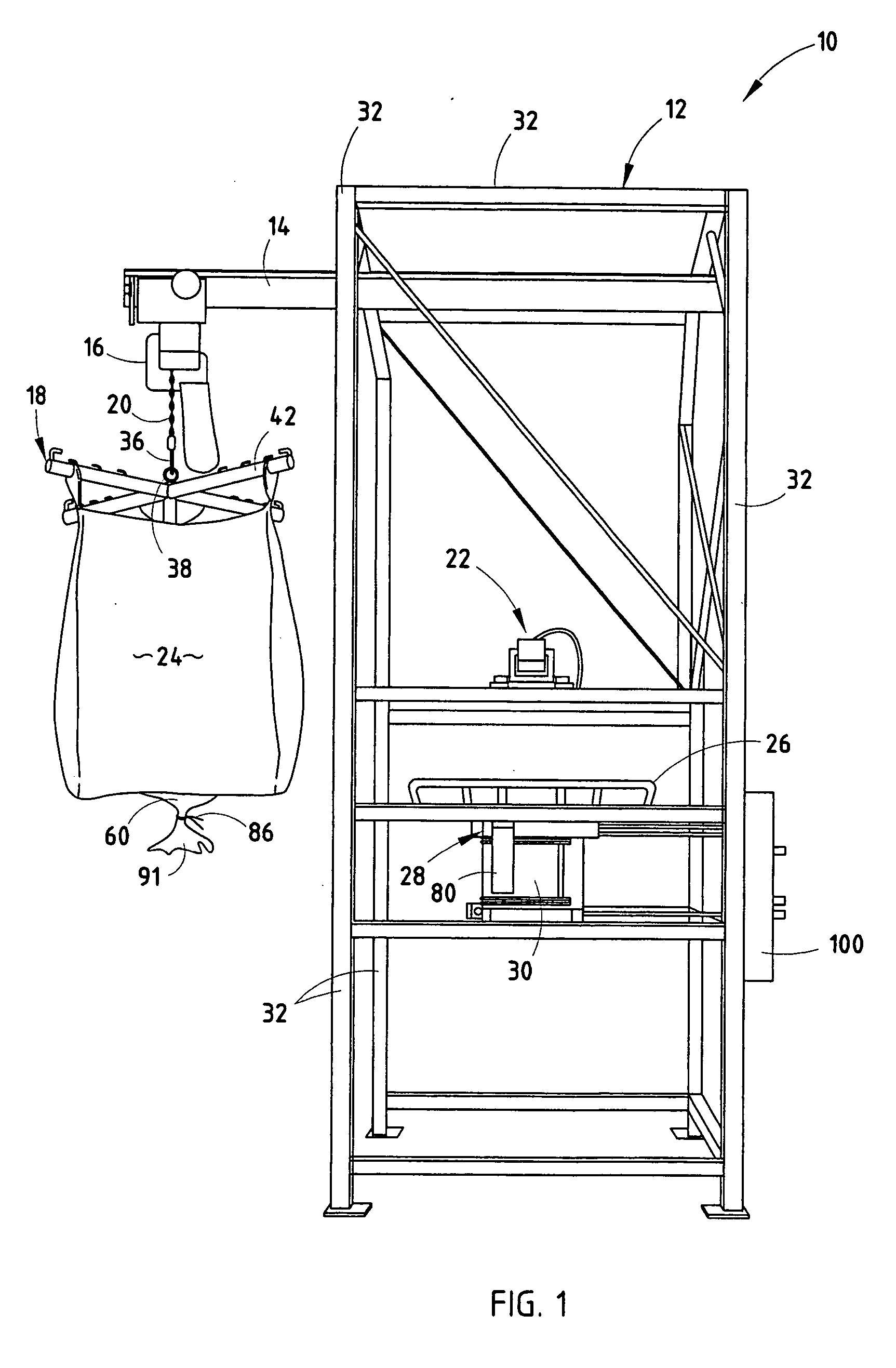

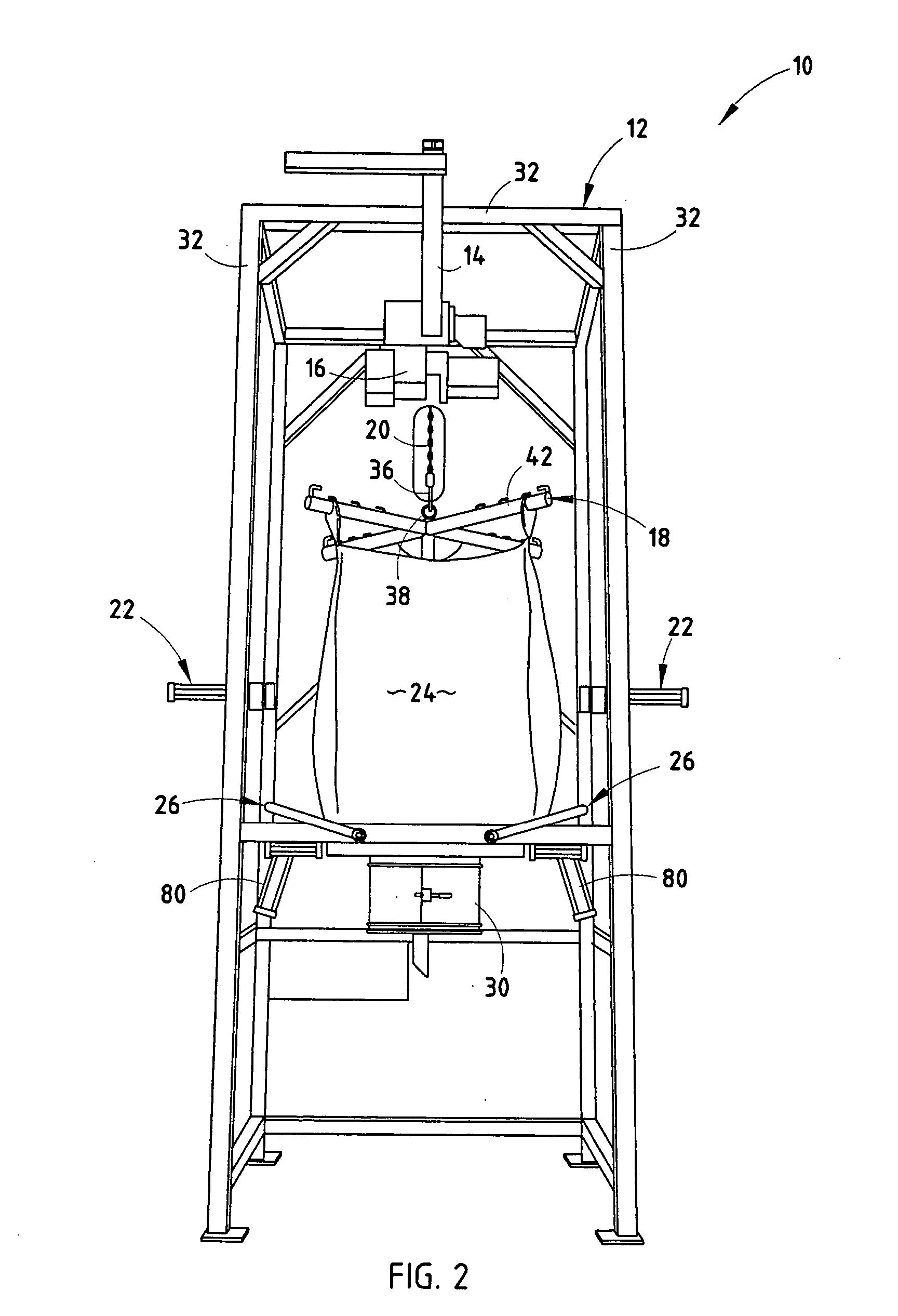

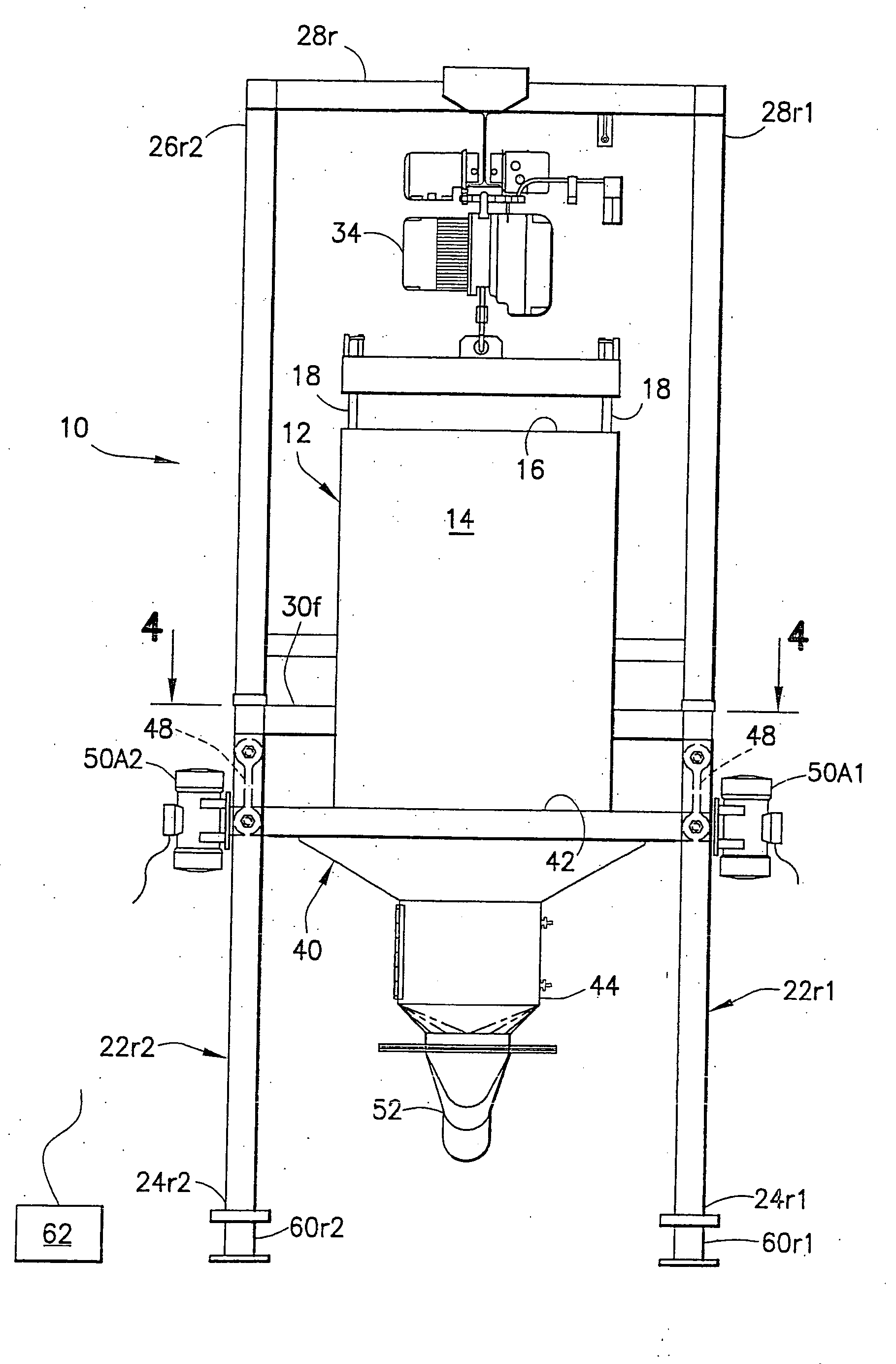

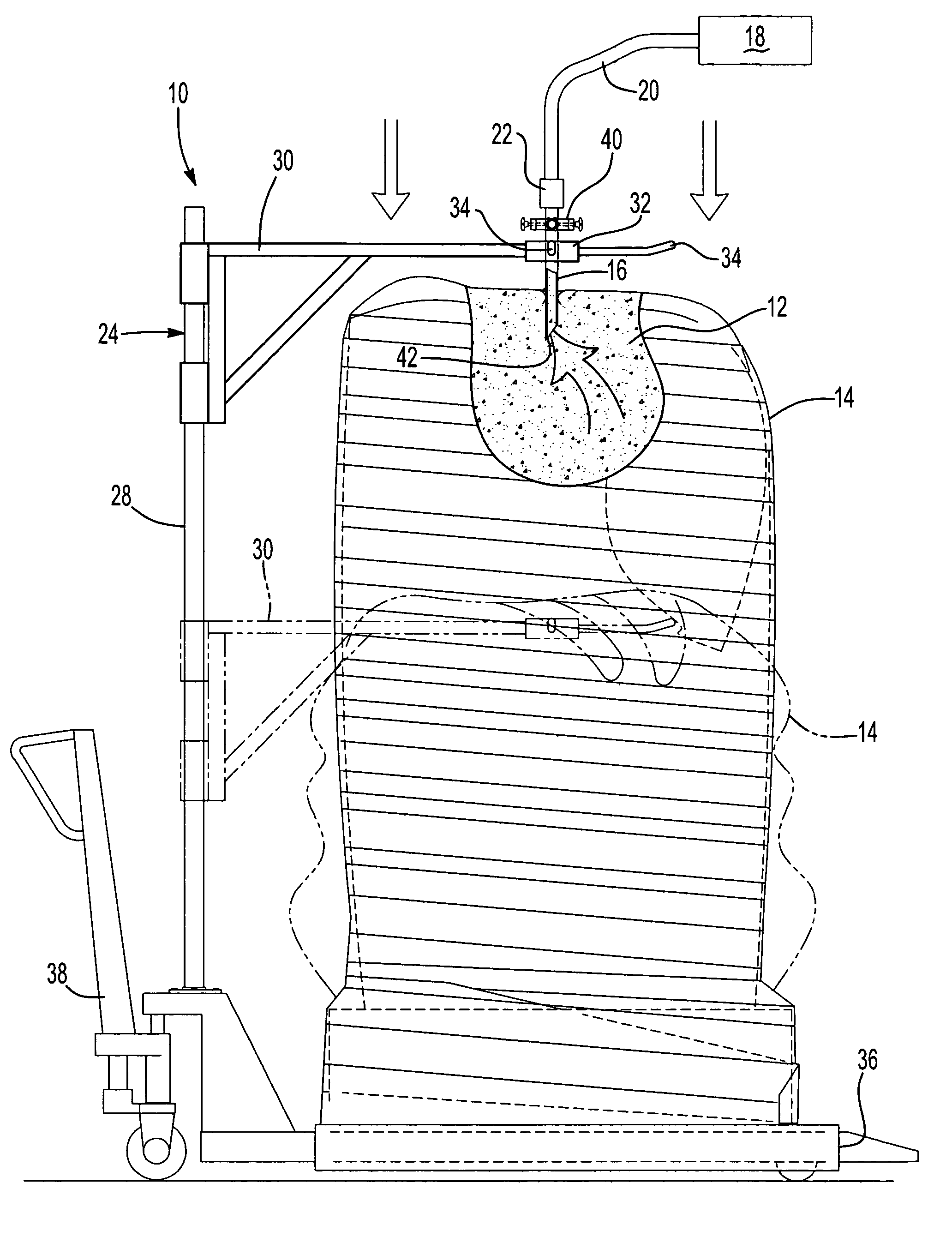

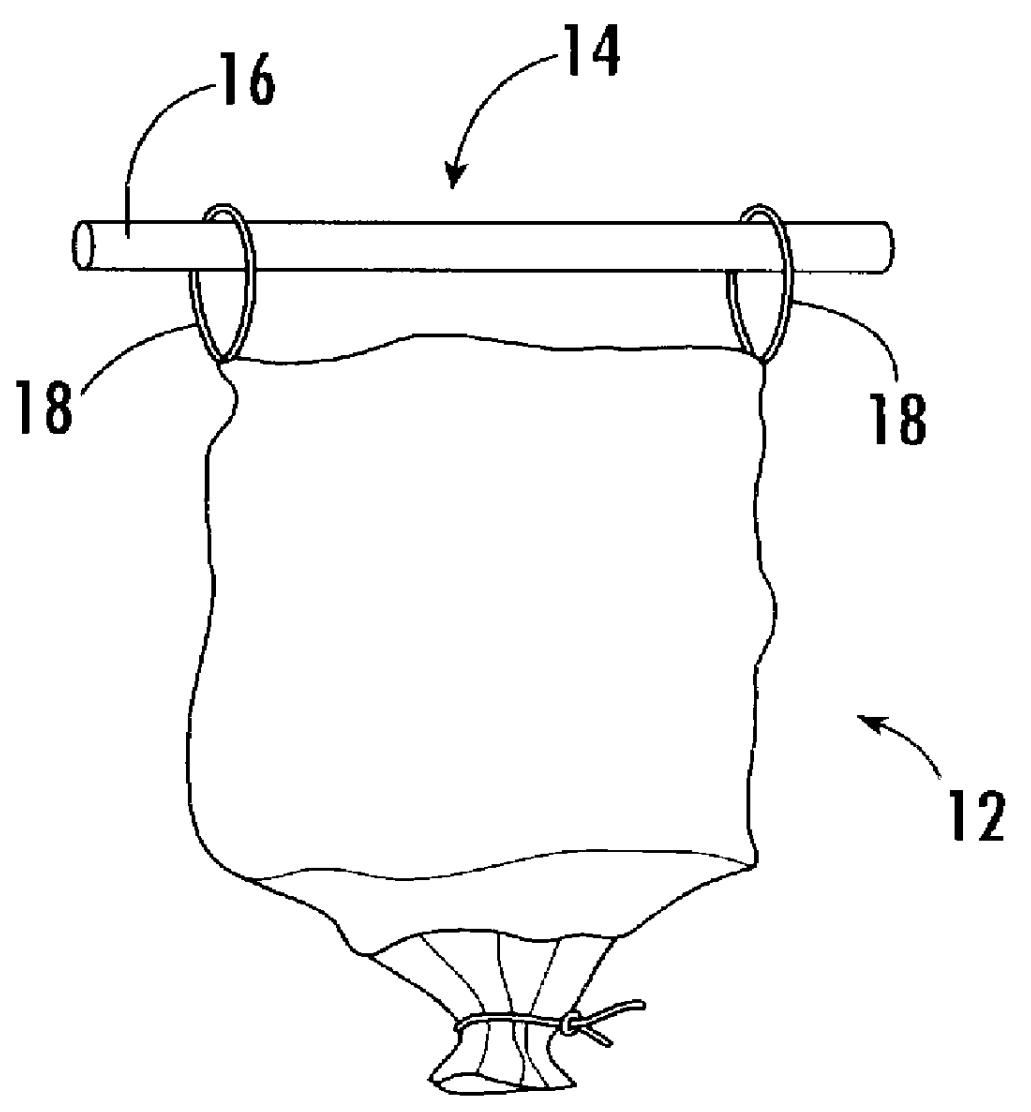

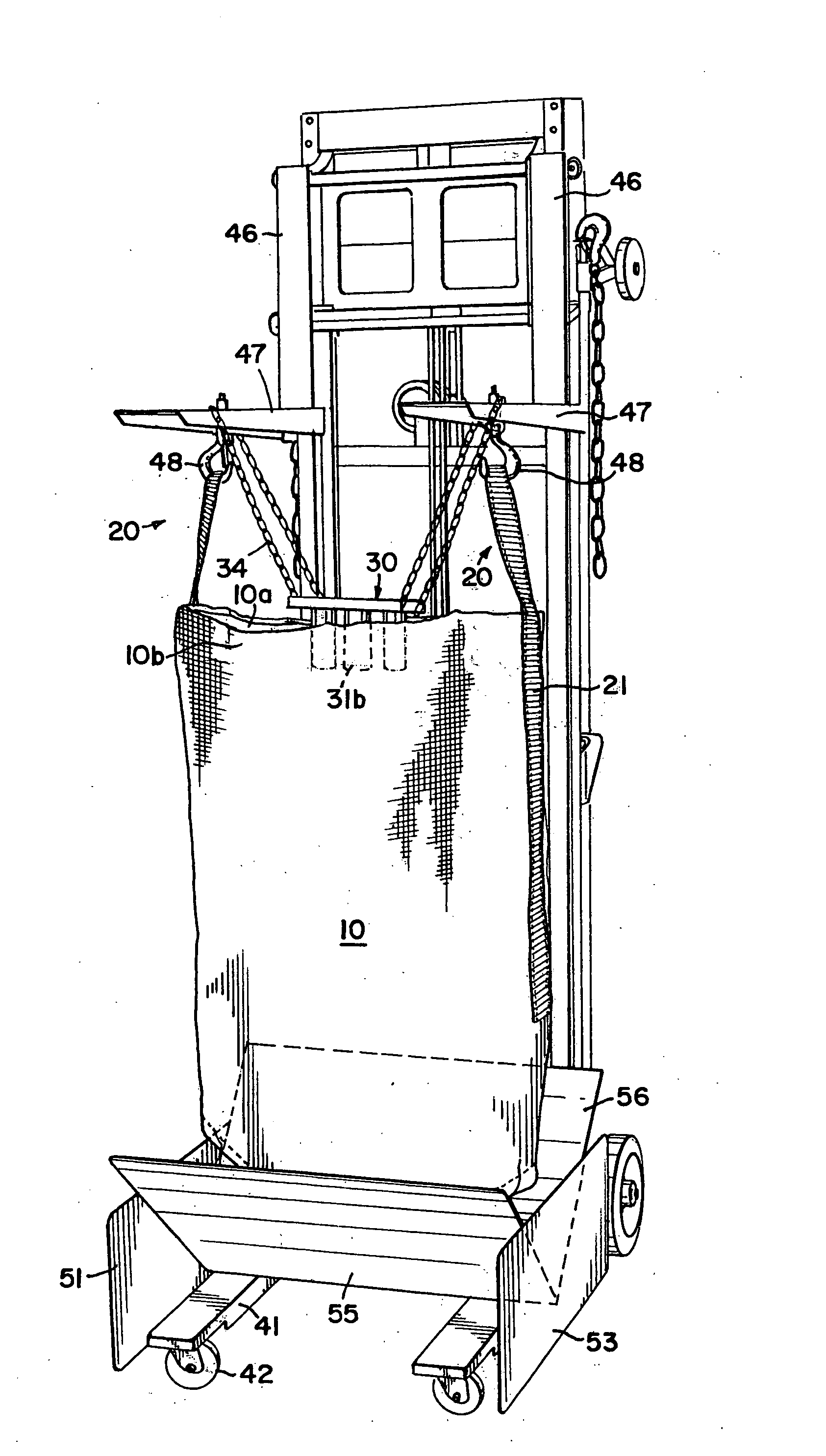

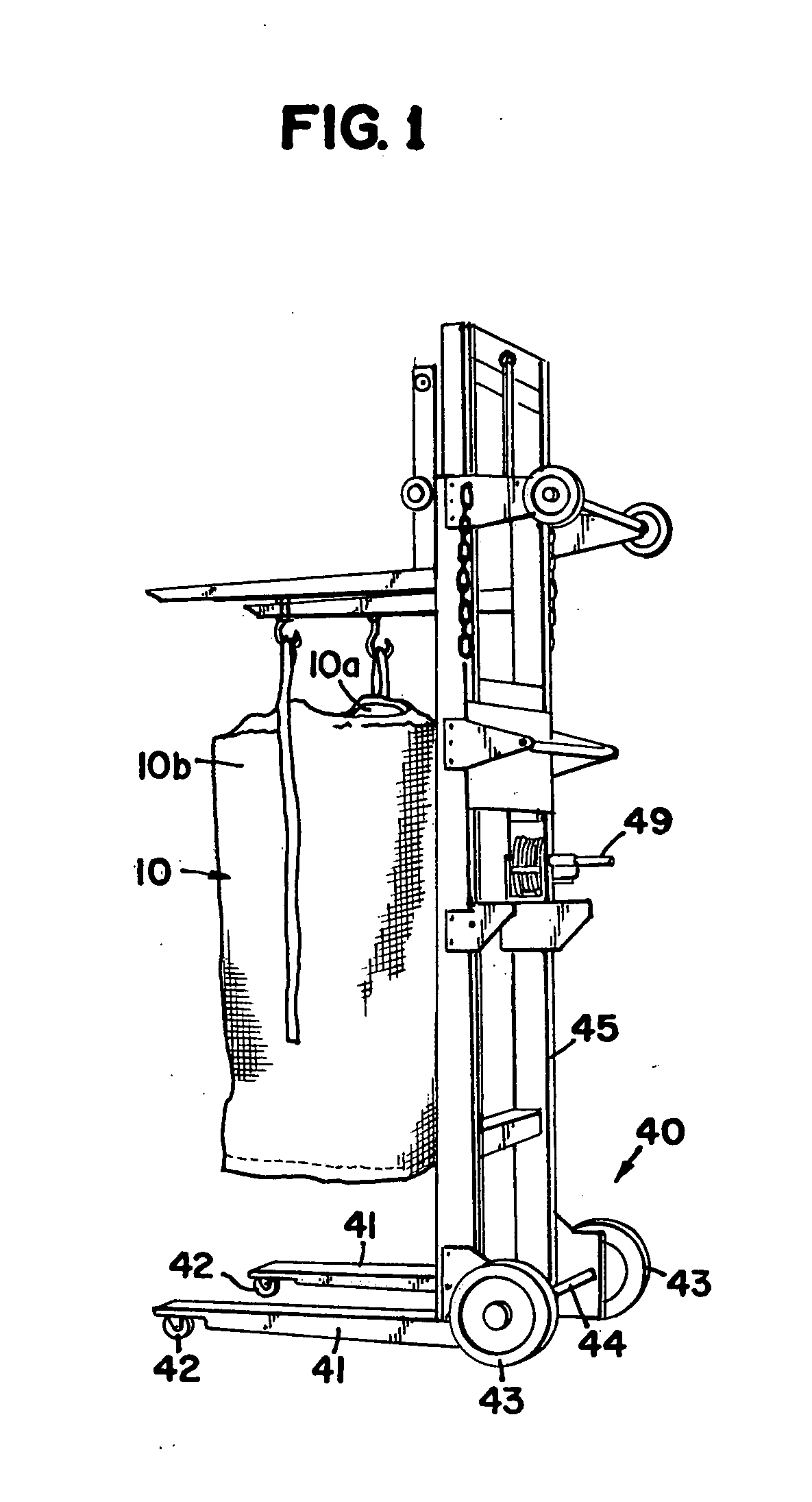

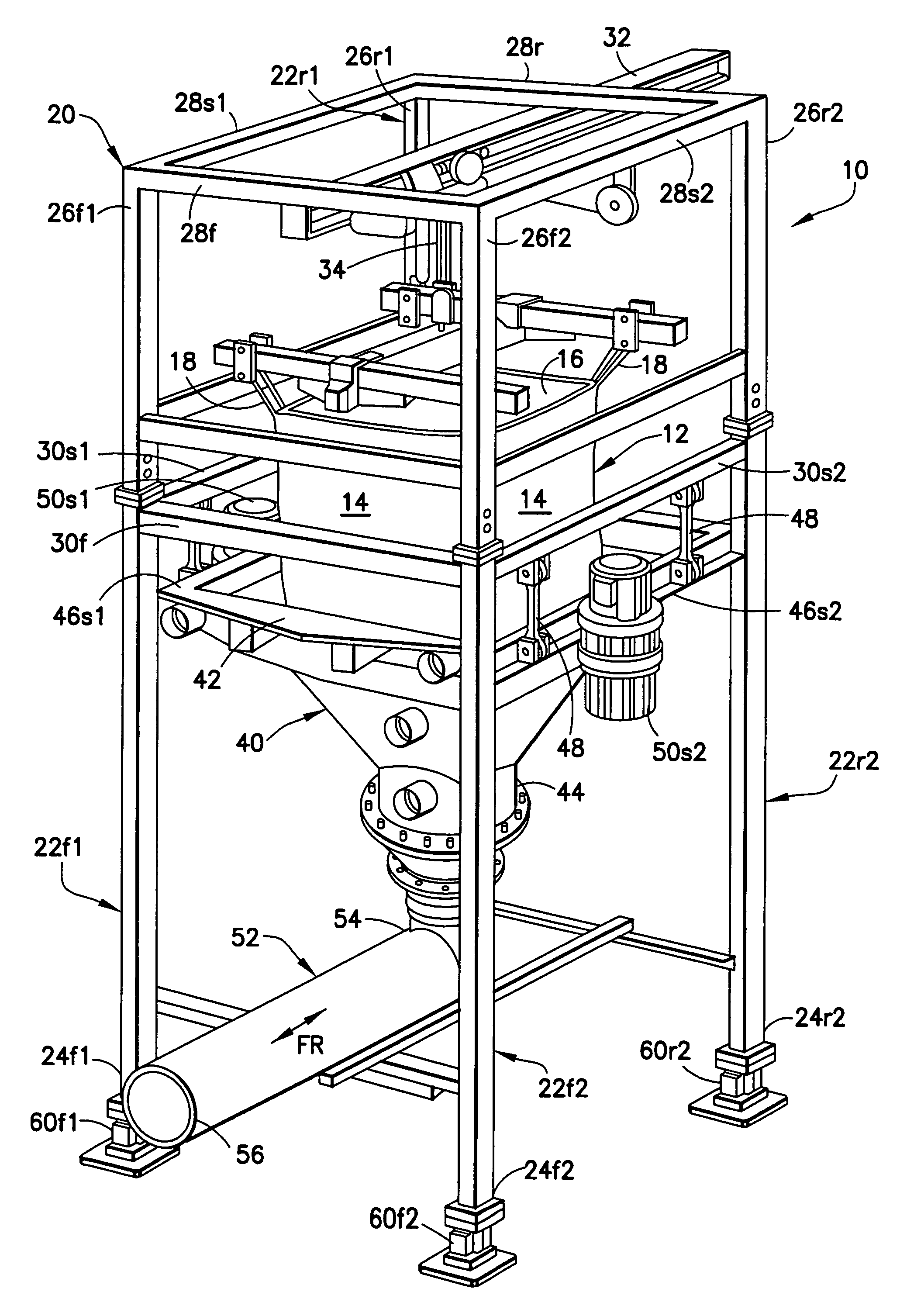

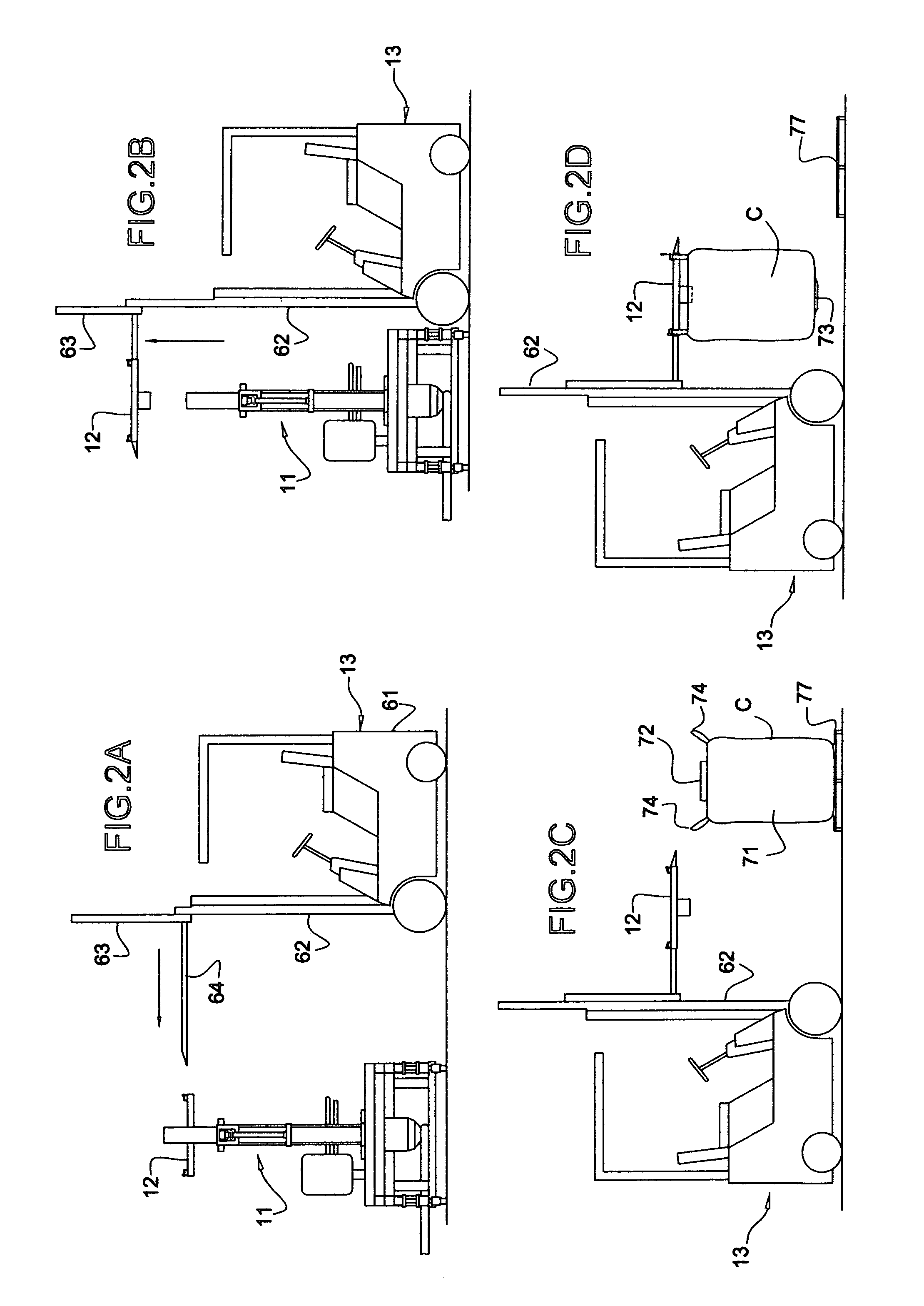

Machine and method for unloading a bulk-material bag

InactiveUS6186360B1Reduce distanceFacilitate material flowOpening closed containersBottle/container closureCompressibilityEngineering

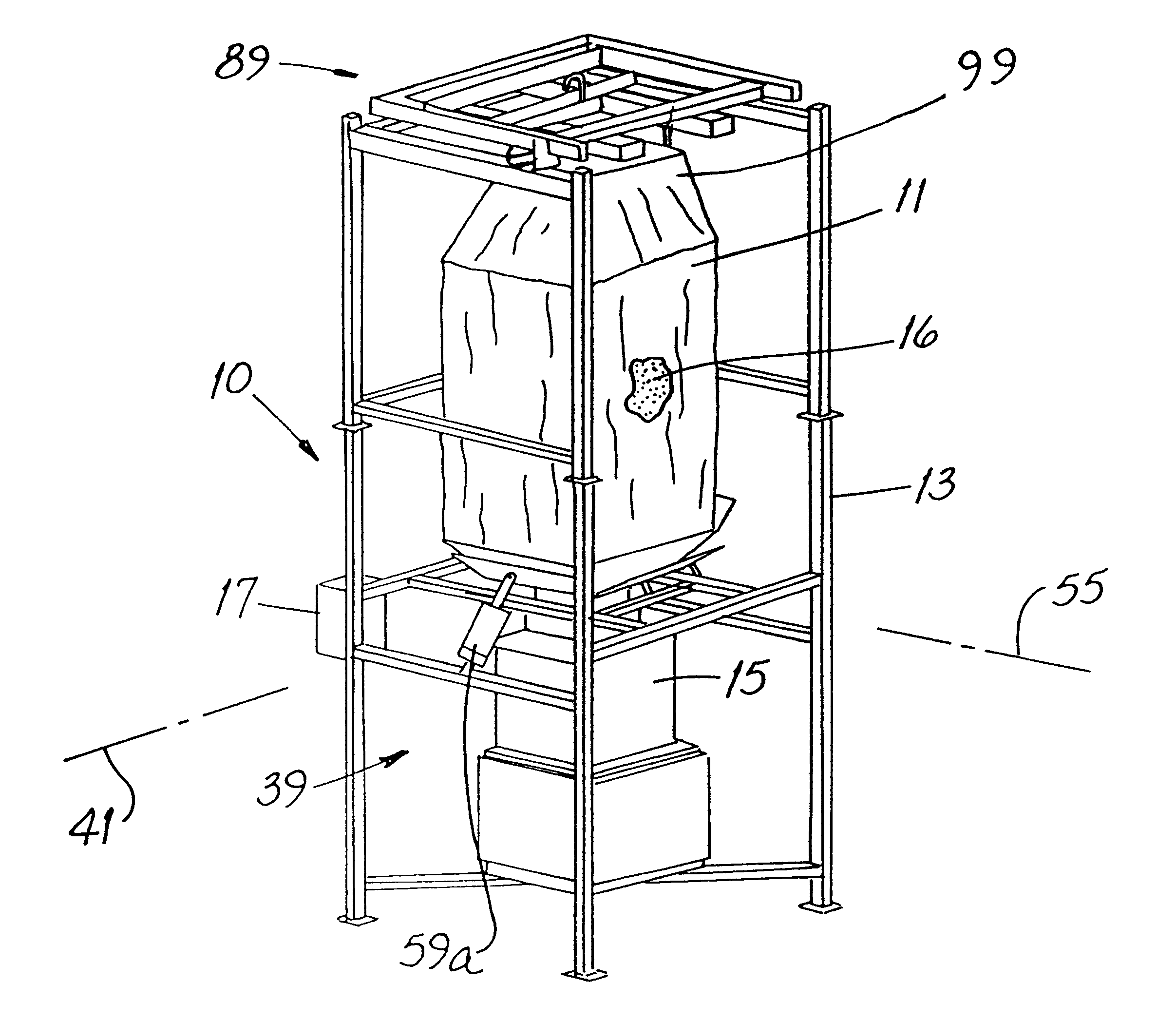

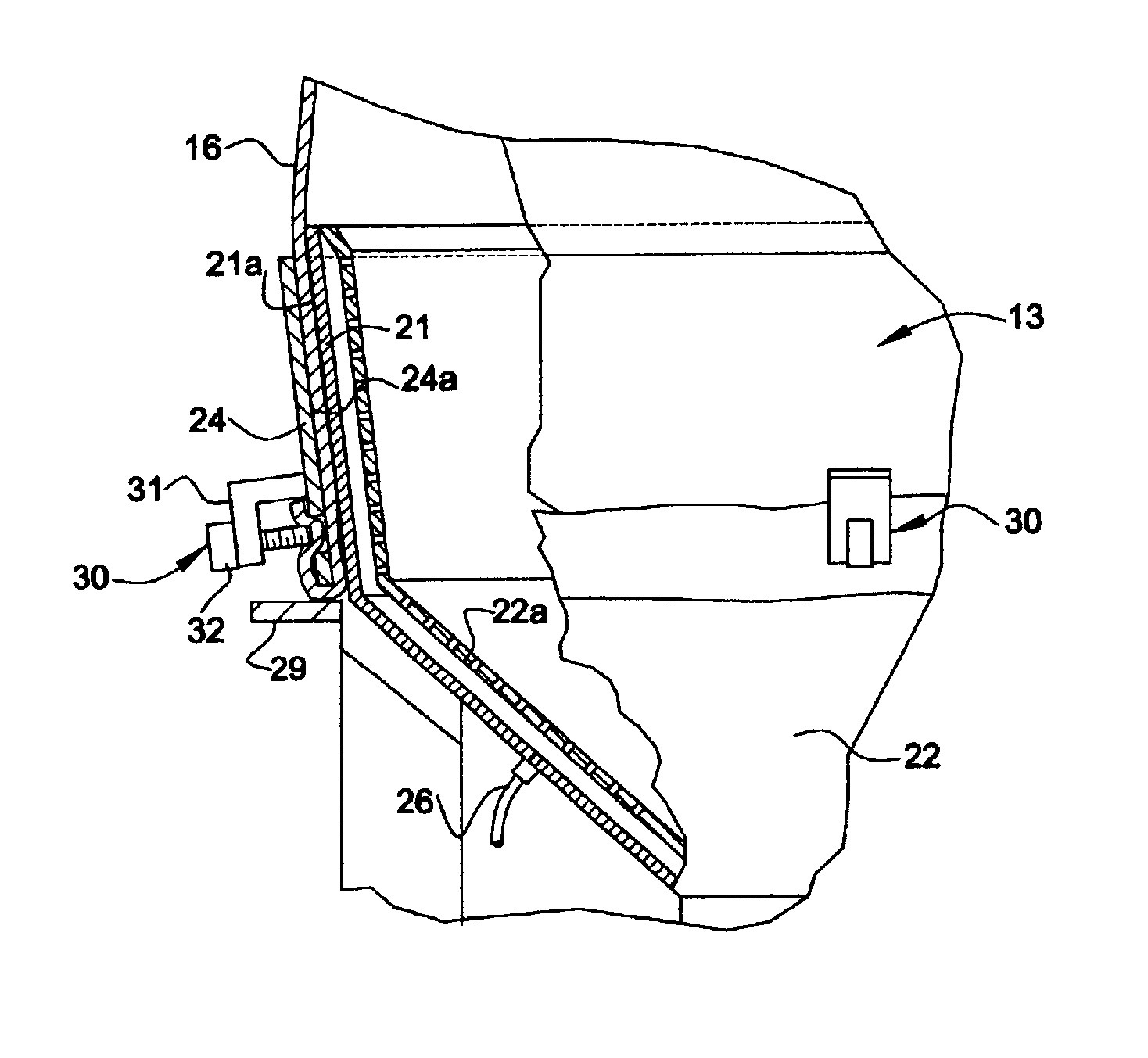

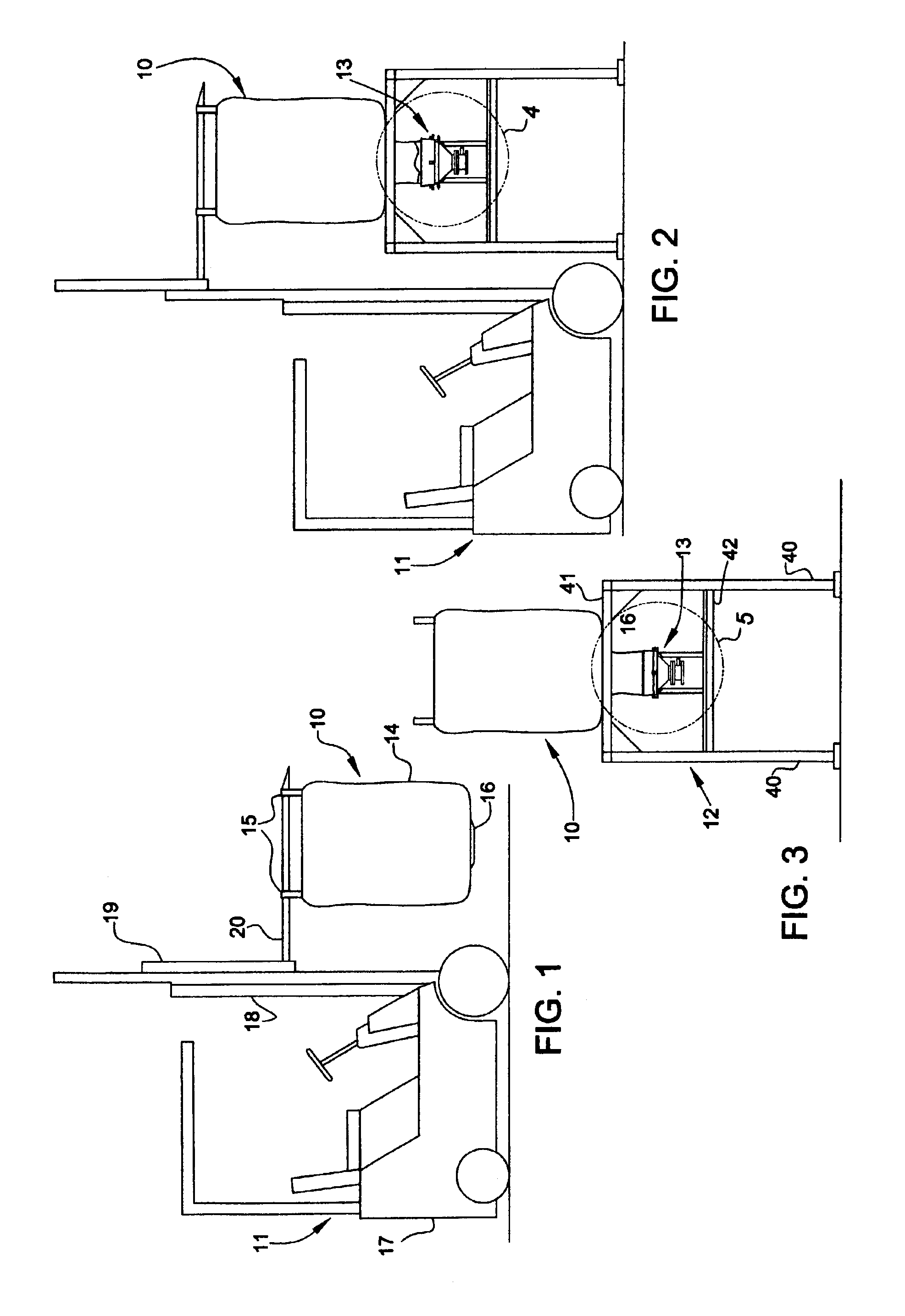

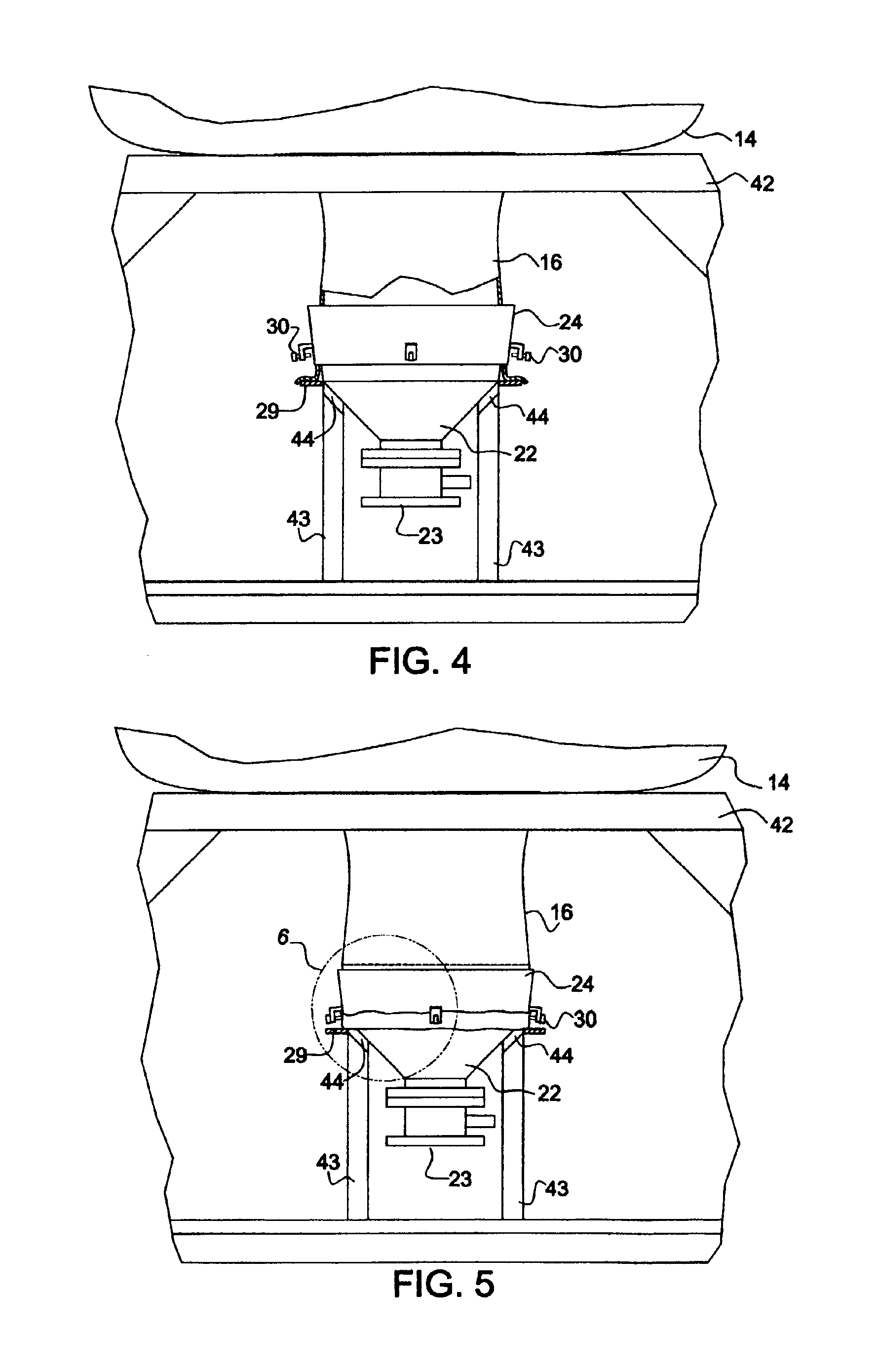

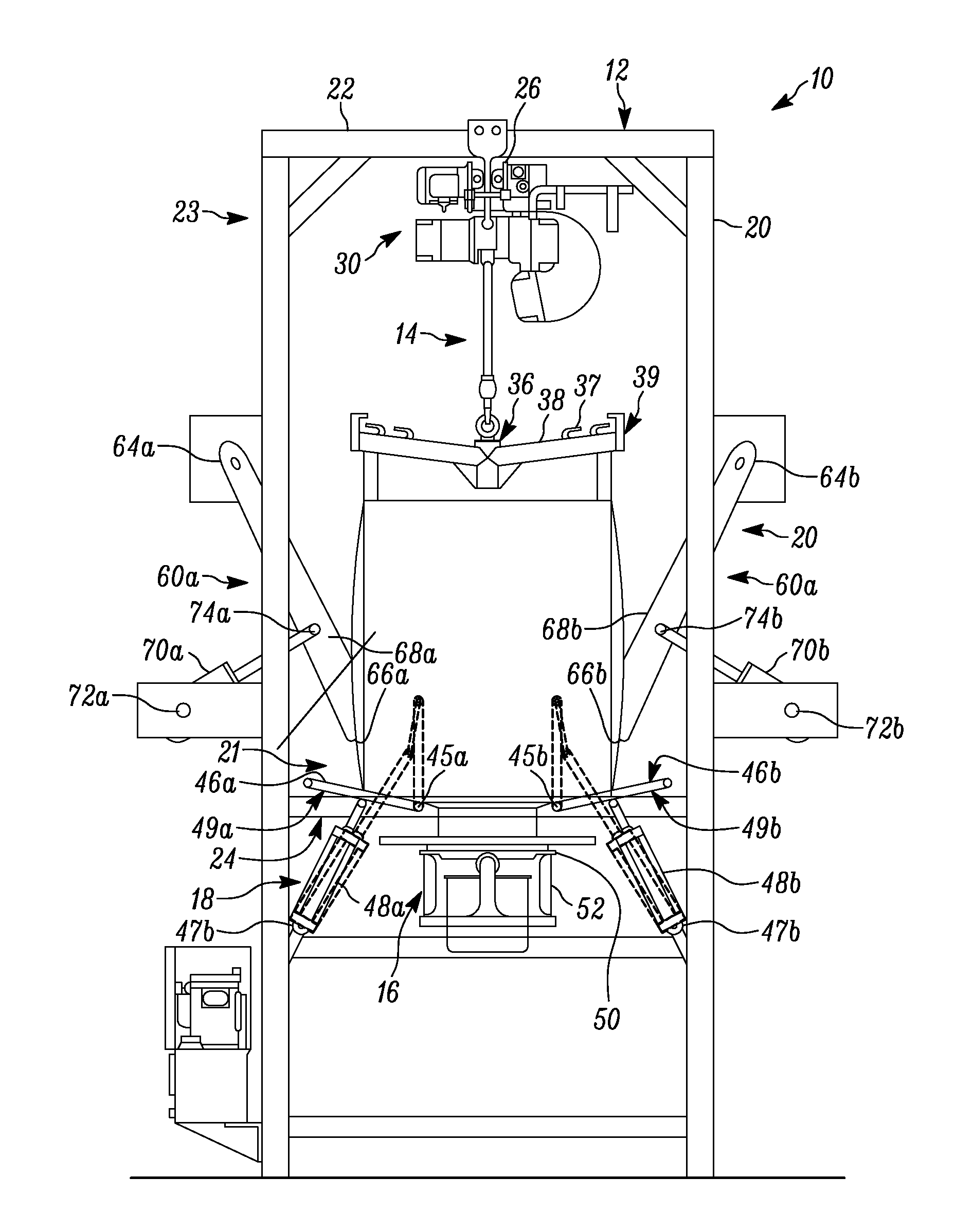

Disclosed is a machine for unloading a bulk-material bag of the type having a bottom portion, a side portion and a transition portion between the bottom and side portions. The machine includes an apparatus aiding discharge of the material from the bag. In the improvement, the apparatus includes a tri-section panel mounted for movement on the machine, thereby configuring the panel to sequentially contact the bottom, transition and side portions of the bag. The panel has first, second and third segments angle-mounted to one another. In a specific embodiment, the segments are substantially planar. A microprocessor-based controller is coupled to the actuator and regulates its movement as a function of a process parameter, e.g., the compressibility of the bag and / or the weight of the material contained in the bag. A highly preferred embodiment of the machine also has a bag lifting mechanism above the tri-section panel. Such mechanism includes an extensible device coupled to the controller for regulating extension of such device as a function of the weight, volume or level of the material contained in the bag. A new method for unloading a bulk material bag is also disclosed.

Owner:SCHENCK PROCESS LLC

Apparatus for the discharge of product from a bulk bag

InactiveUS20080142549A1Improve efficiencyImprove ergonomicsFlexible bulk container emptying systemsBagsControl armEngineering

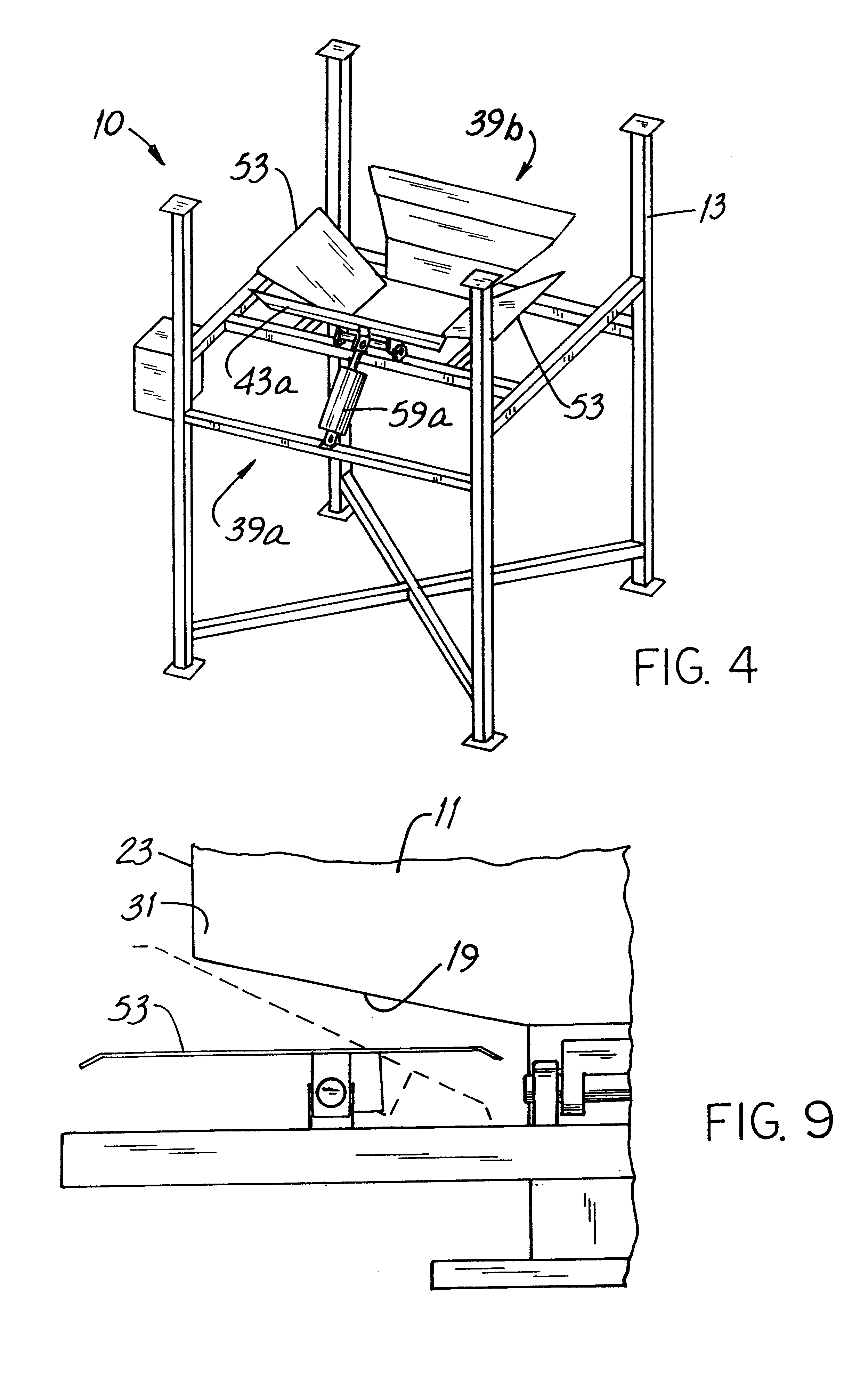

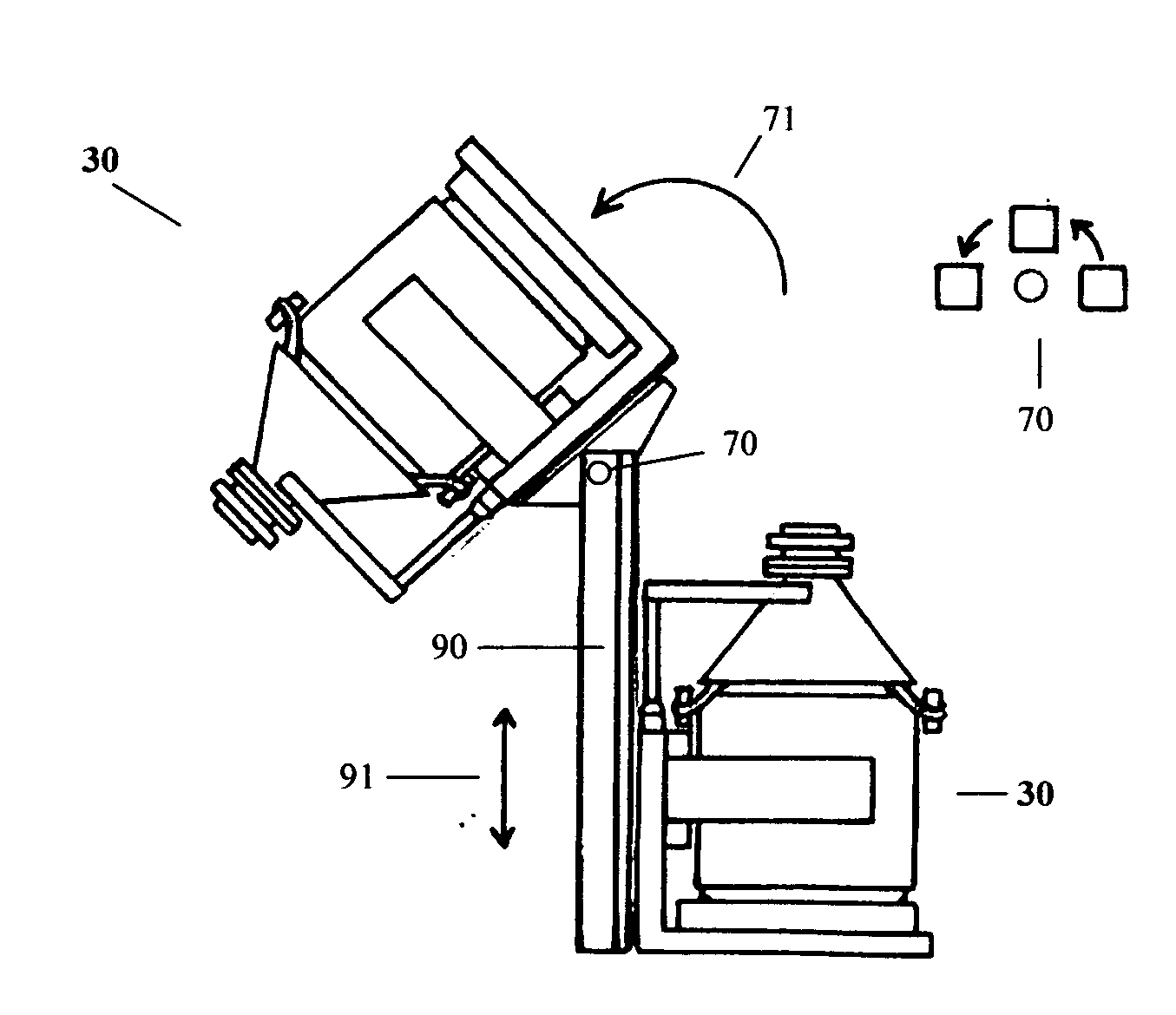

An apparatus for the discharge of product from a bulk bag utilizing a container inverter has an enclosure with a floor, plurality of side walls, horizontal arm and outlet spout adapter. Vertical lifting and lowering to control the floor or horizontal control arm participate in securing the bulk bag. An outlet spout adapter attaching to the horizontal arm has components to secure an outlet spout in place and also a valve or flow control device. By inverting the container inverter up to one-hundred and eighty degrees, product stored within the bulk bag can be discharged. Prior to inverting, the bulk bag can be secured in place by loop or sleeve holders and the bag sides can be held in place by vacuum to interior surfaces of the enclosure. The apparatus can be mounted on a lifting and pivoting mechanism to position the enclosure over a desired discharge point.

Owner:KOSICH MARK MICHAEL

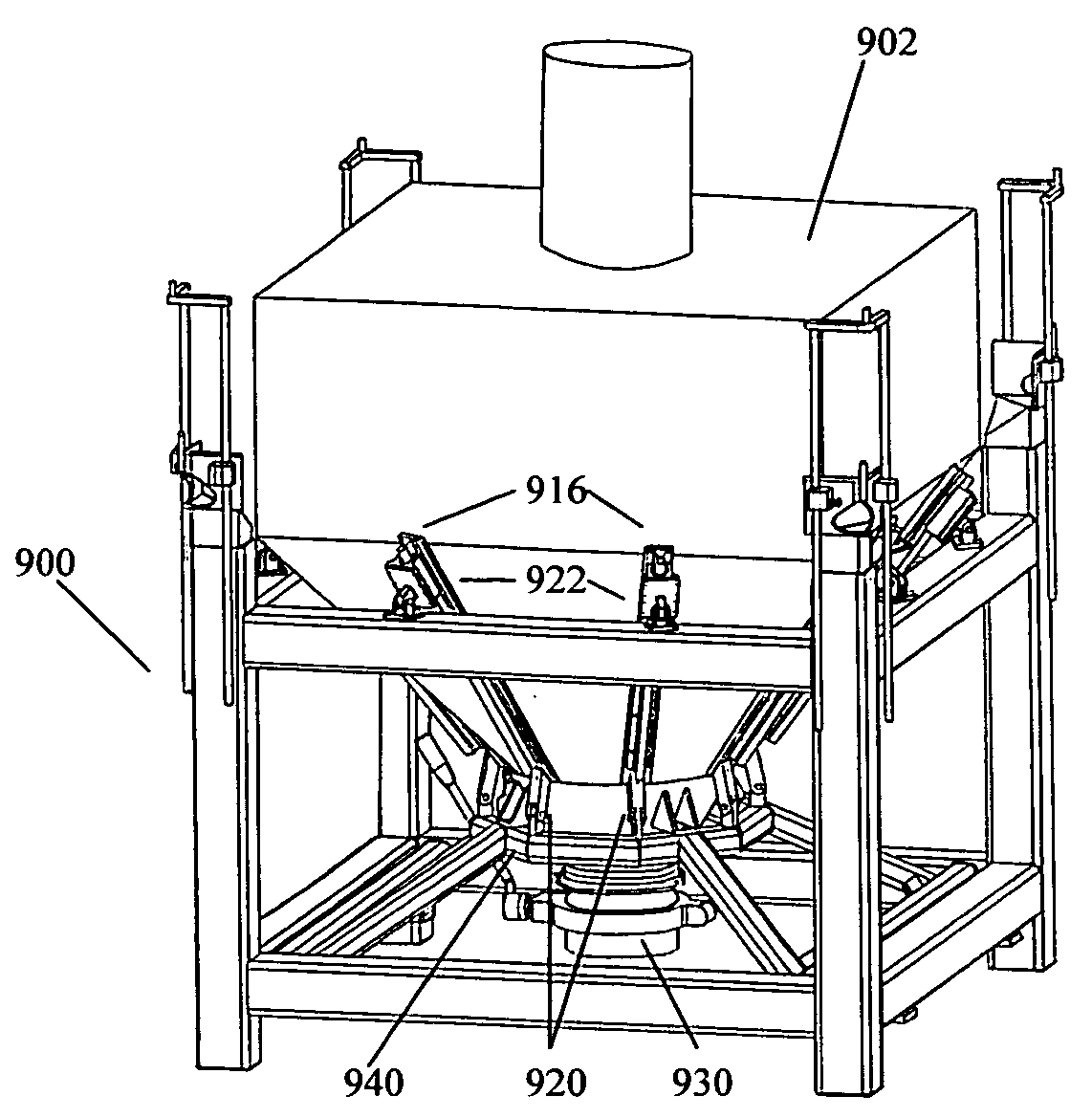

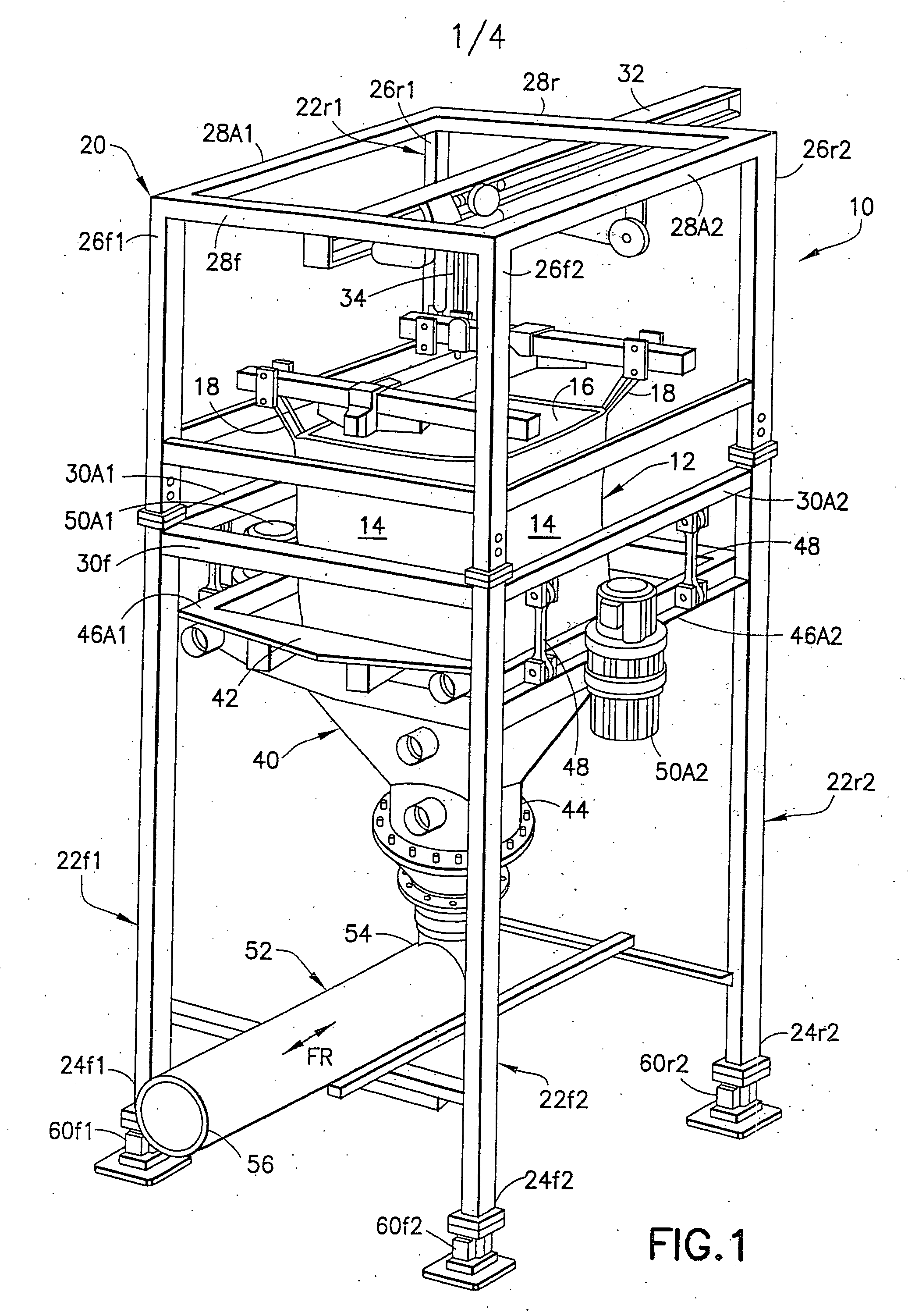

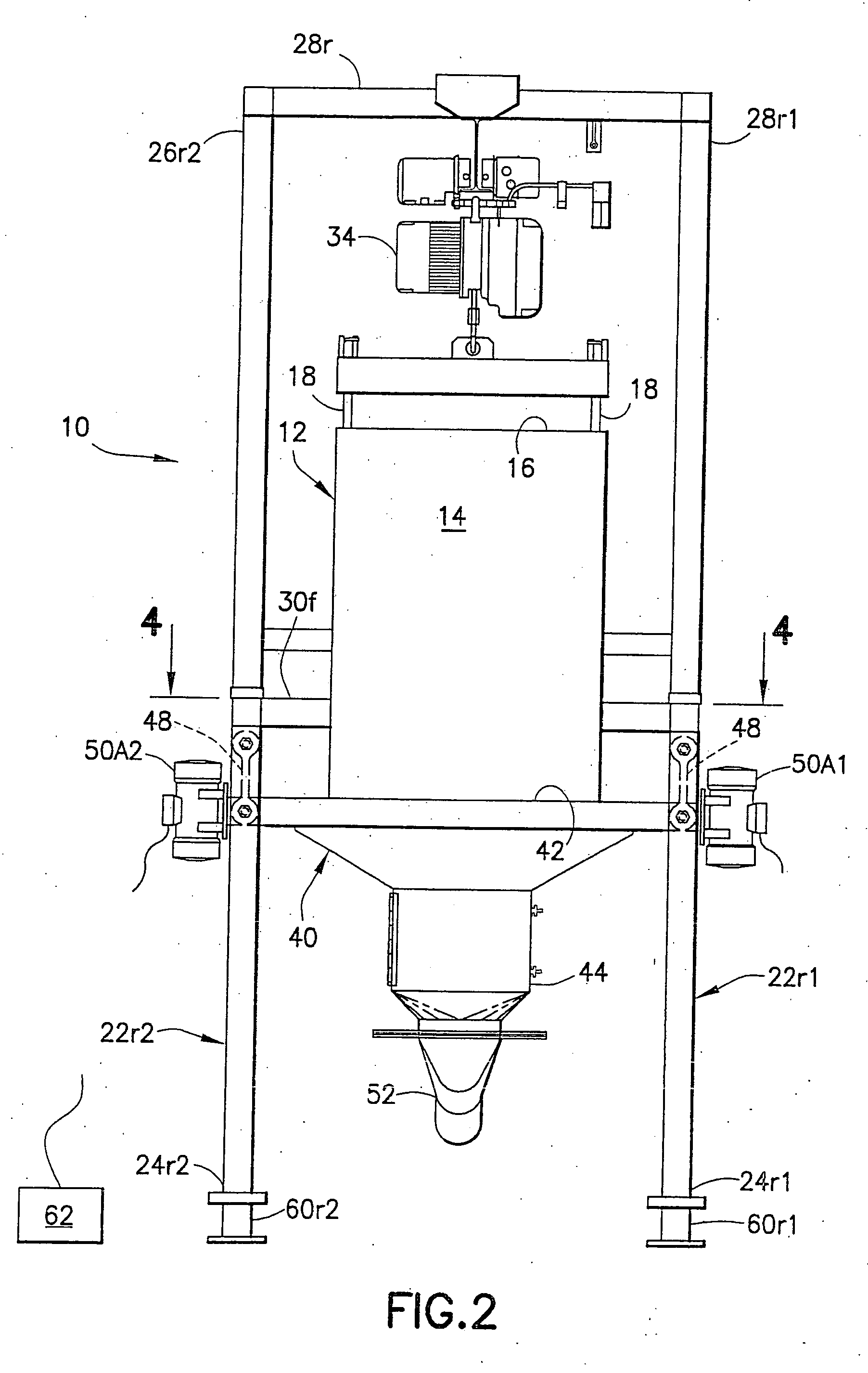

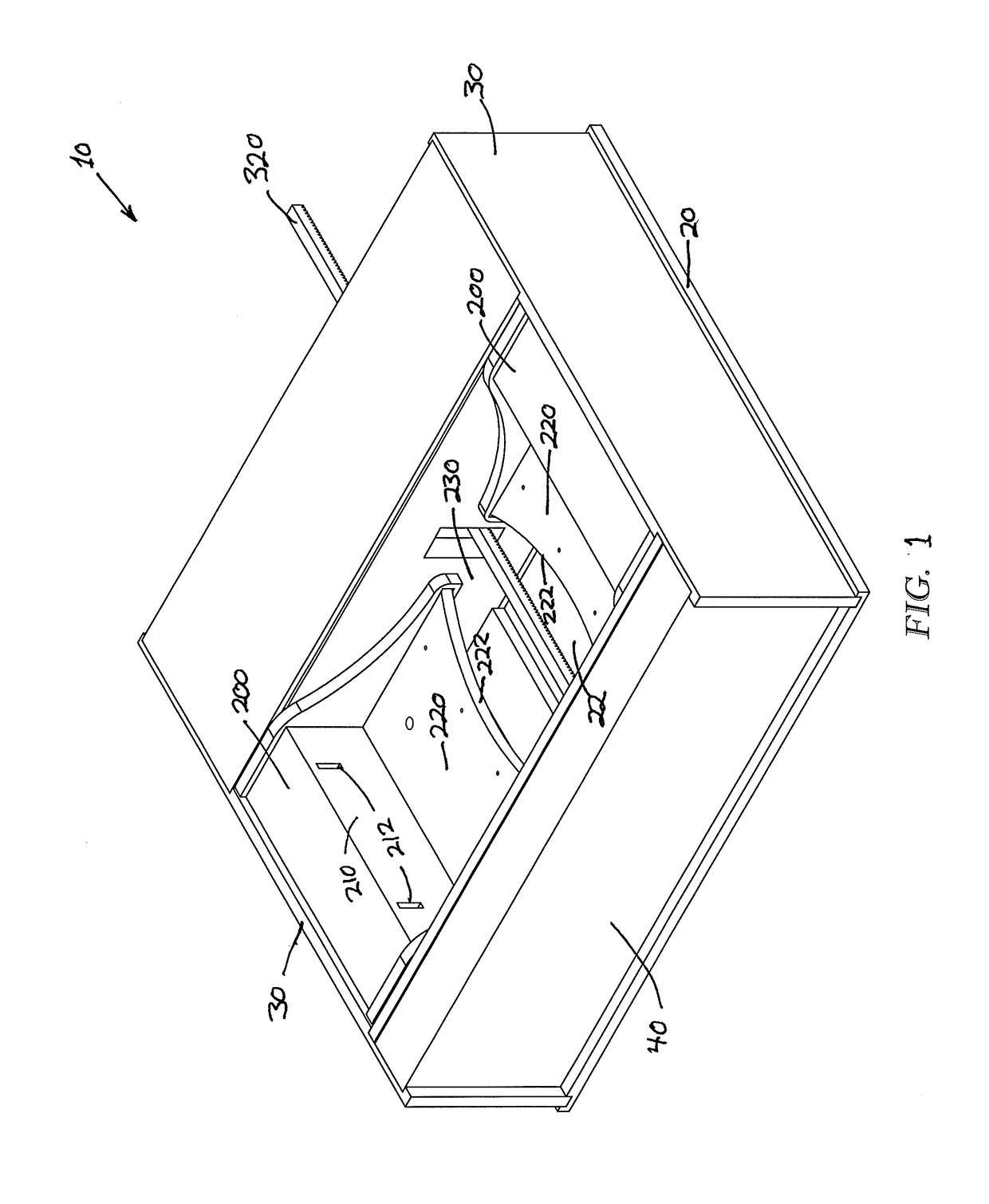

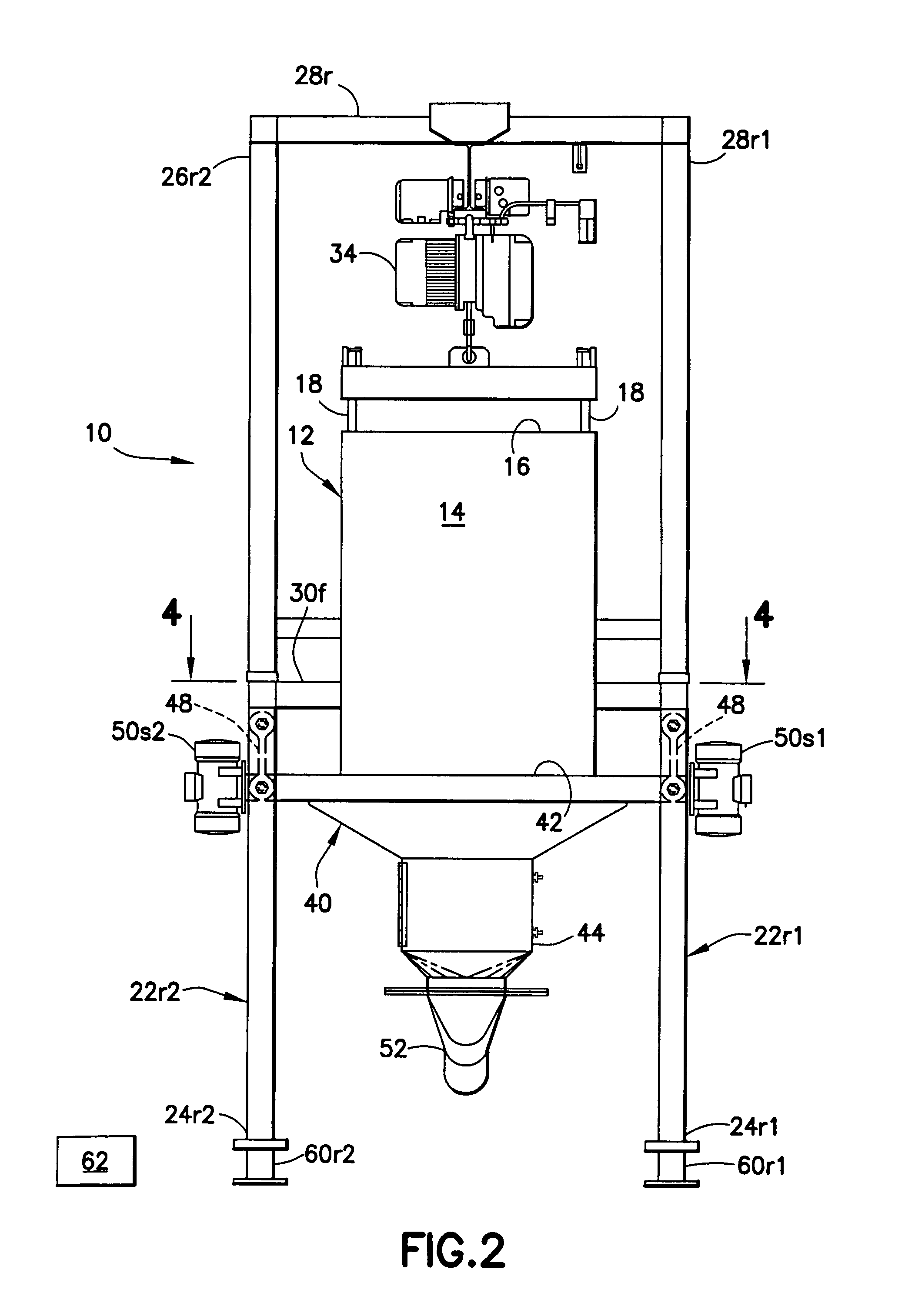

Bulk bag discharging system assembly

In one embodiment of the present invention, a material container discharge assembly includes: a main frame assembly; material container impactors engaged to the main frame assembly; a discharge receiving gate having a material container receiving aperture and first, second, and third movable plates, where the first and third plates are movable between an open and closed position and further define a second plate receiving area for receiving the opposed second plate when the second plate and the first and third plates are in the closed position; and a substantially circular access chamber spaced below the material container receiving aperture that includes at least two access doors on substantially opposite sides of the chamber that operate to substantially air tight seal when closed and a sealing system having a sealing device movable between a disengaged position and an engaged position, where the engaged position operates to seal the container in position.

Owner:MATERIAL TRANSFER & STORAGE

Bulk bag discharging system assembly

InactiveUS20050199650A1Flexible bulk container emptying systemsTrolley cranesEngineeringMechanical engineering

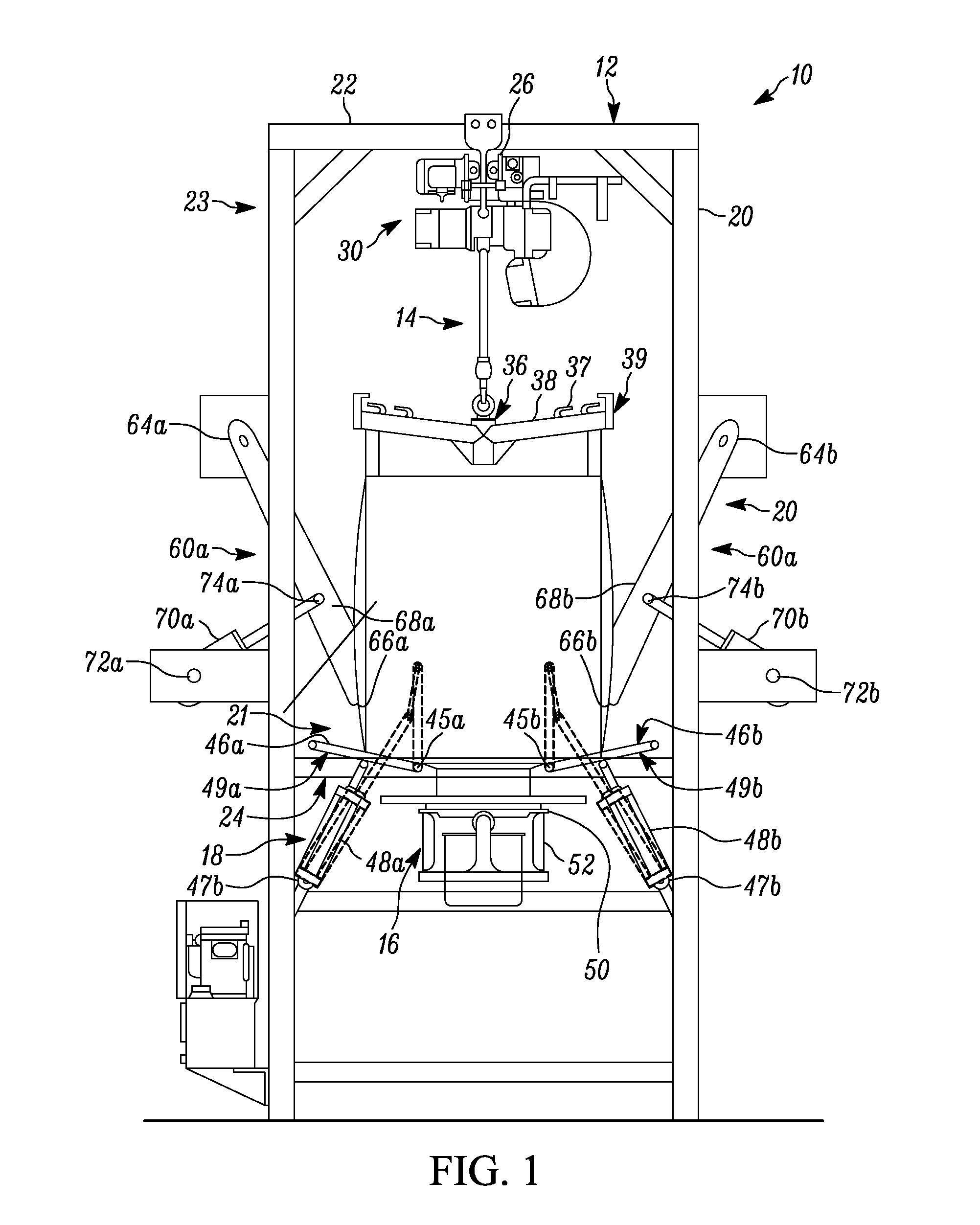

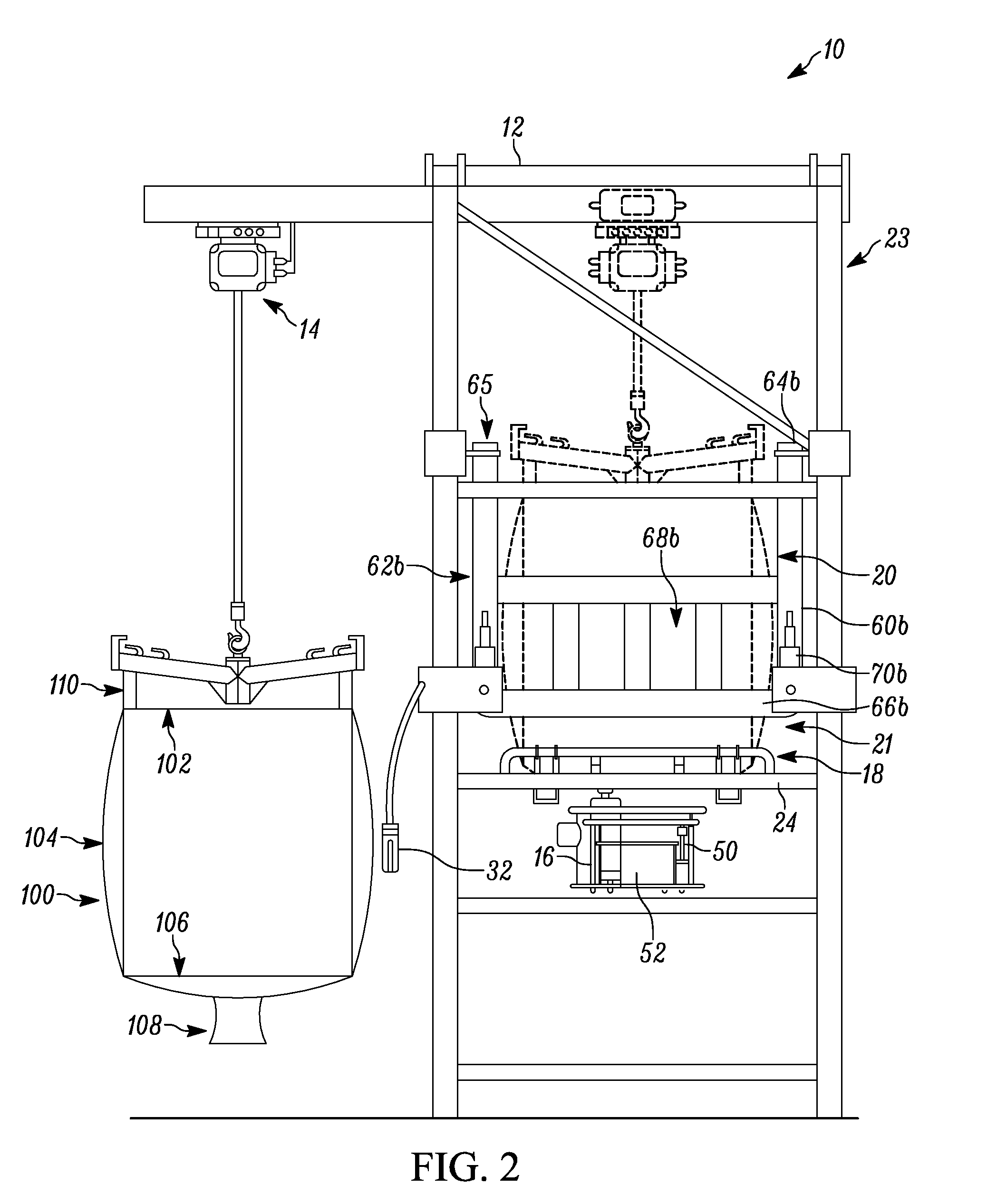

A material container discharge assembly including a main frame assembly; a spout access chamber engaging the main frame assembly; at least two independently movable material container impactors engaged to the main frame assembly and adapted to engage a material container when the material container is positioned within the main frame assembly and above the spout access chamber; and wherein the material container impactors include a conditioning frame.

Owner:MATERIAL TRANSFER & STORAGE

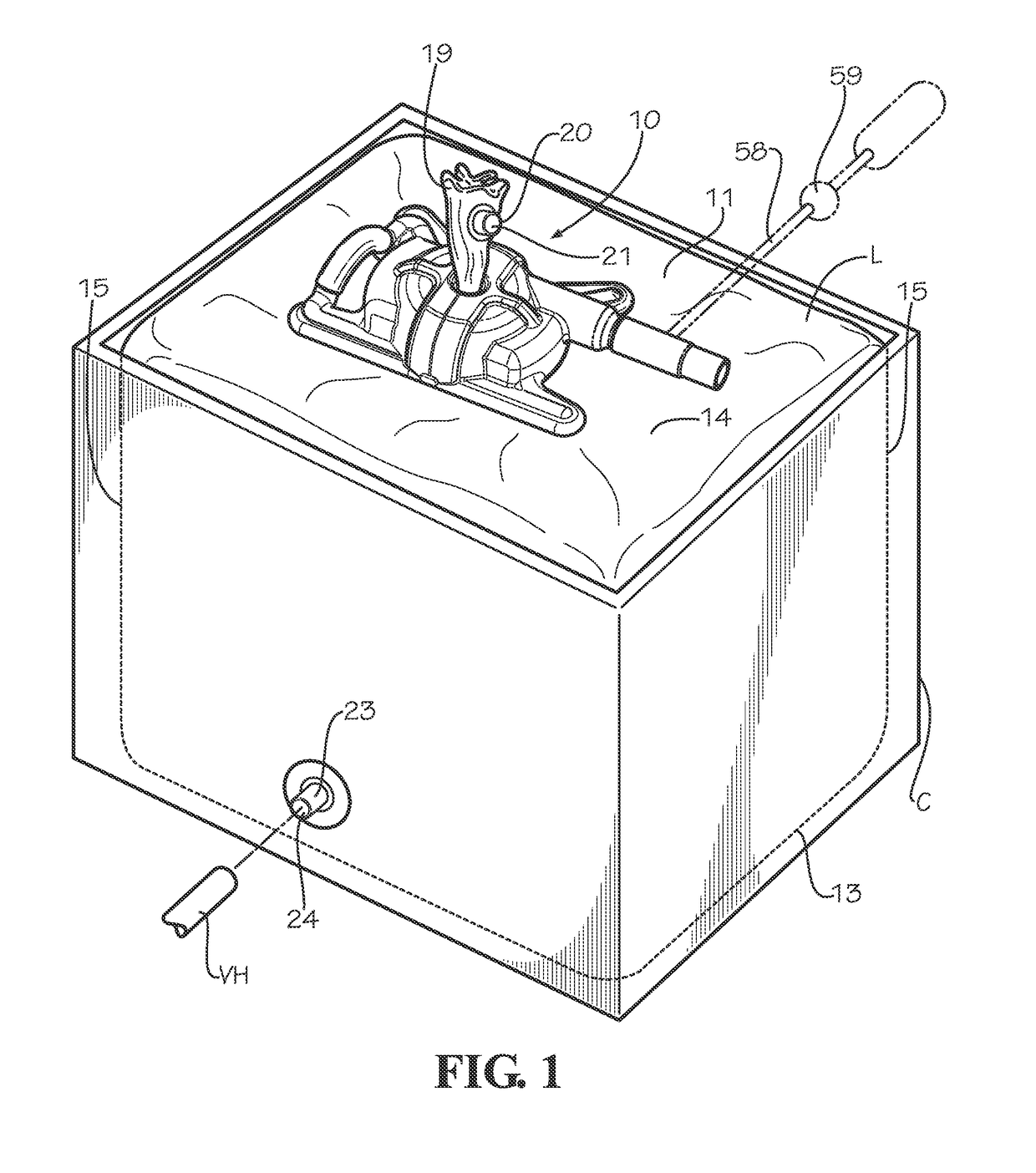

Flexible silo apparatus having a top removable valve or flow control device

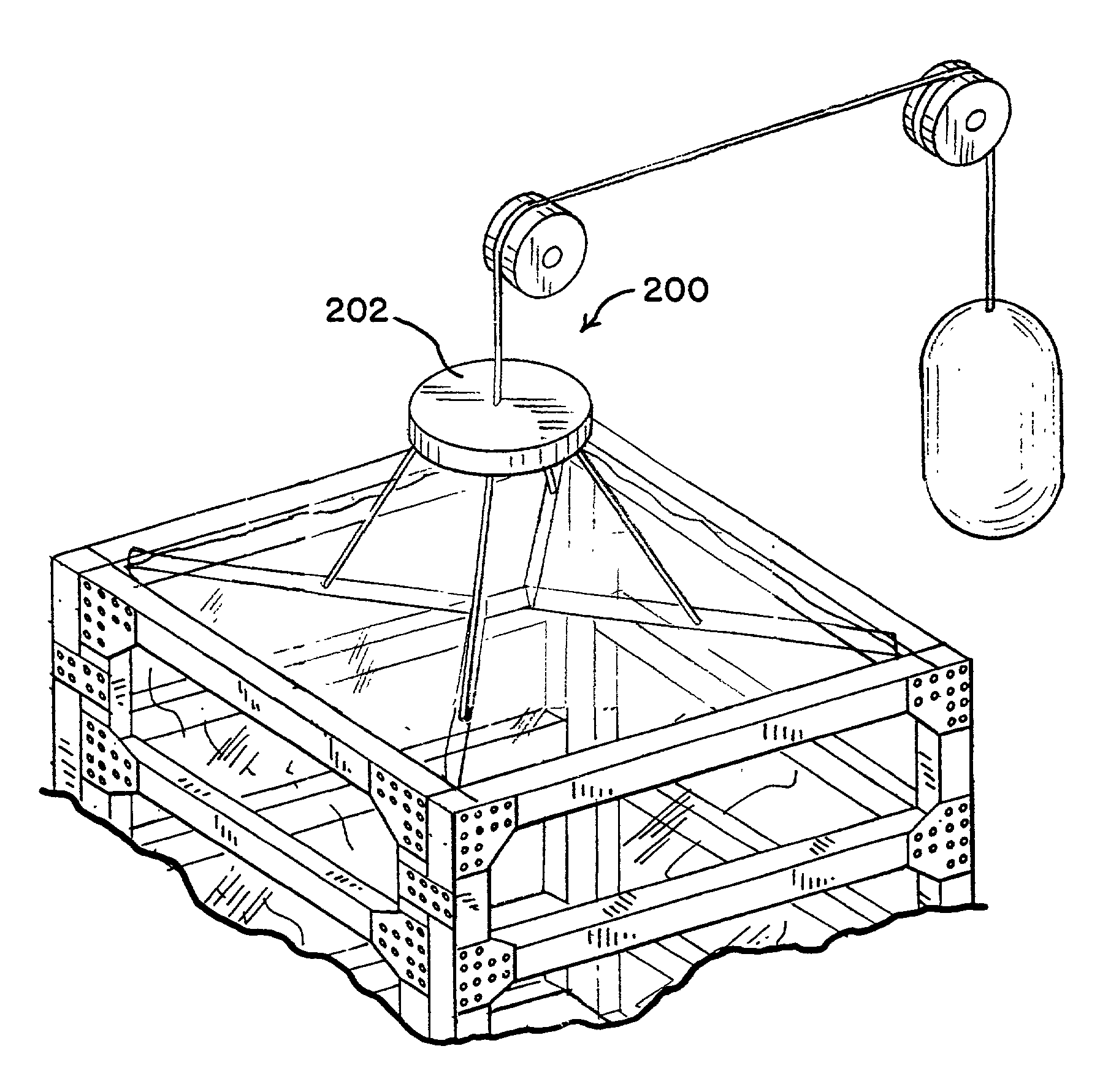

A flexible silo apparatus having a top removable valve or flow control device assembly has a top removable valve or flow control device that has components to interface with the outlet of a flexible container and that can be supported upon a bridge. Various cone configurations can be added to support the cone section or bottom of a flexible container including a rigid cone, multi member cone, or “y Axis dynamic cone system. The apparatus is further enhanced with a floating bridge and the addition of a powered lifting and lowering device for the advantage of manipulating the flexible container in a vertical motion for improving the filling of product into or the discharging of product out of a flexible container.

Owner:KOSICH MARK MICHAEL

Liner connecting device and liner filling device

InactiveUS20080145198A1Wrapping material feeding apparatusFlexible bulk container emptying systemsEngineeringAccess port

A liner emptying device and a liner filling device as well as methods using them for contamination-free filling and emptying of a liner. This contamination-free filling and emptying prevents any danger to the health of the people working with the packaged substances. Both the liner emptying device and the liner filling device are connected to the liner via a fastening device and the residual films sealing off the device can be removed via an access port, whereby the liner can be filled or emptied without contaminating the surroundings.

Owner:HECHT ANLAGENBAU GMBH

Bulk bag unloader with flow regulation

InactiveUS20060151525A1Flow regulation is enhancedEasy to adjustFlexible bulk container emptying systemsLarge containersSystem requirementsEngineering

A bulk bag unloader includes a frame, a bag support, a hopper beneath the bag support and an outlet chute beneath the hopper. The hopper and the outlet chute are mounted to the frame for movement substantially in unison relative to the frame. Two vibrators are mounted respectively on opposite sides of the hopper and synchronized to generate vibratory movement substantially along the axis of the outlet chute. Thus, the vibrators function to achieve an efficient and continuous discharge from the bulk bag and employ the outlet chute to regulate or stop the flow in accordance with system requirements.

Owner:WAHL RICHARD C

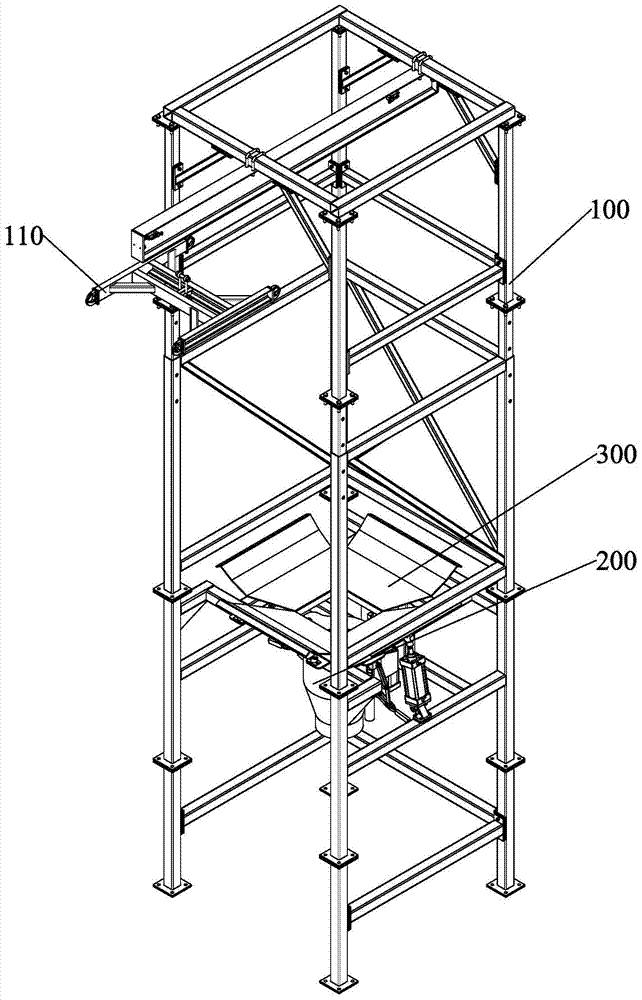

Ton bag unloading mechanism

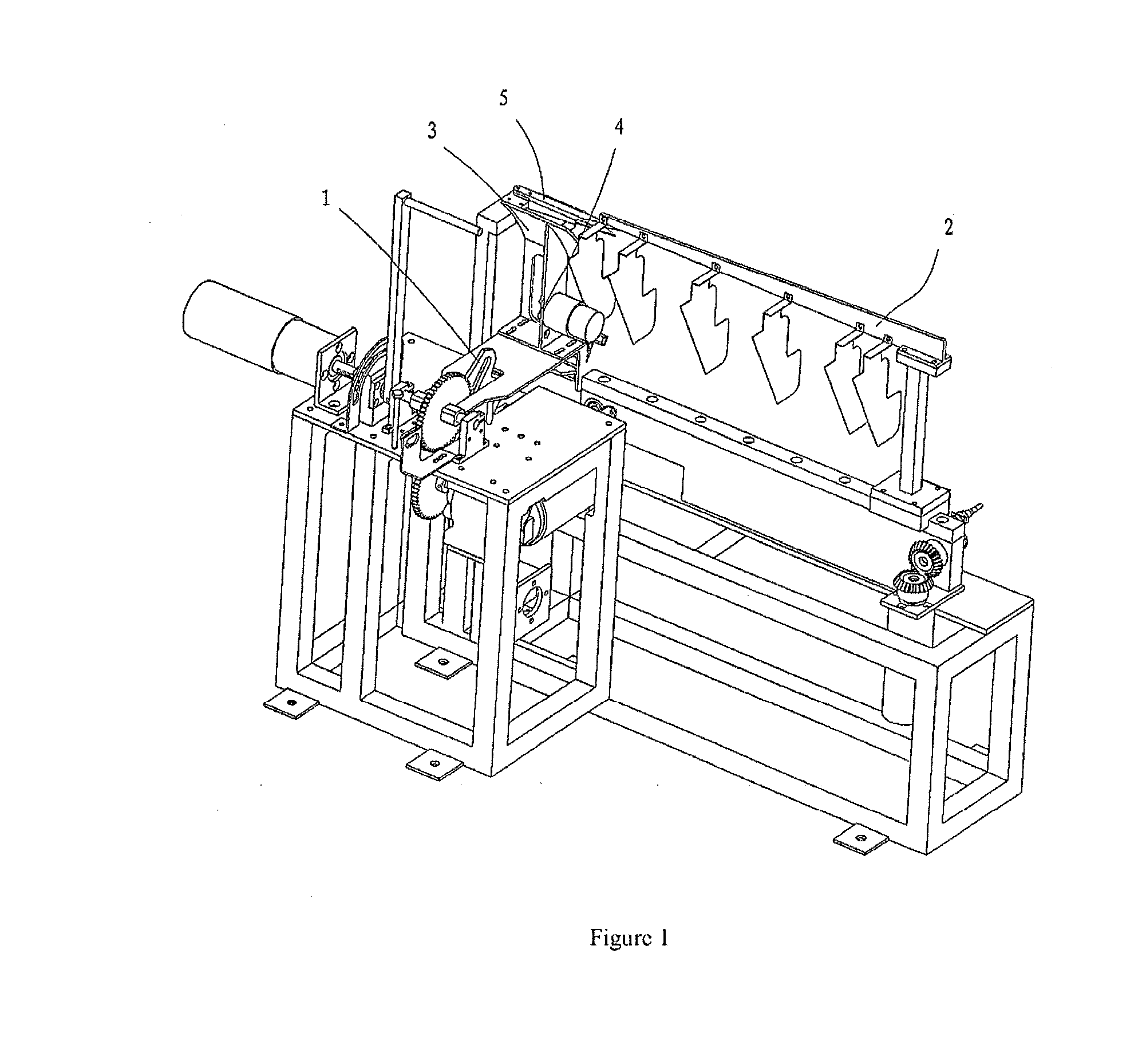

ActiveCN104326274AConvenient direct unloadingReduce lossesFlexible bulk container emptying systemsBottle emptyingMechanical engineeringTon

The invention discloses a ton bag unloading mechanism. The ton bag unloading mechanism comprises a carrying device and an unloading device, wherein the carrying device is used for bearing ton bags and putting the ton bags above the unloading device; the unloading device comprises a vertically arranged unloading cylinder; the unloading cylinder comprises an outer cylinder and an inner cylinder arranged on the inner side of the outer cylinder in a clearance way; the upper end of the unloading cylinder is provided with a feeding hole of the unloading device; the lower end of the unloading cylinder is provided with a discharge hole of the unloading device; the feeding hole is right opposite to a bag opening of each ton bag. According to the ton bag unloading mechanism, the unloading cylinder is of a double-layer structure with the outer cylinder and the inner cylinder, inner bag openings are positioned in the inner cylinder, outer bag openings are positioned between the inner cylinder and the outer cylinder, and channels for materials in the ton bags with the outside are reduced, so that dust diffusion is reduced and the working environment is effectively improved; meanwhile, dust is settled and recycled, so that the material loss is reduced.

Owner:ONGOAL MATERIAL AUTOMATION EQUIP

Vacuum wand assembly for extracting a product from a container

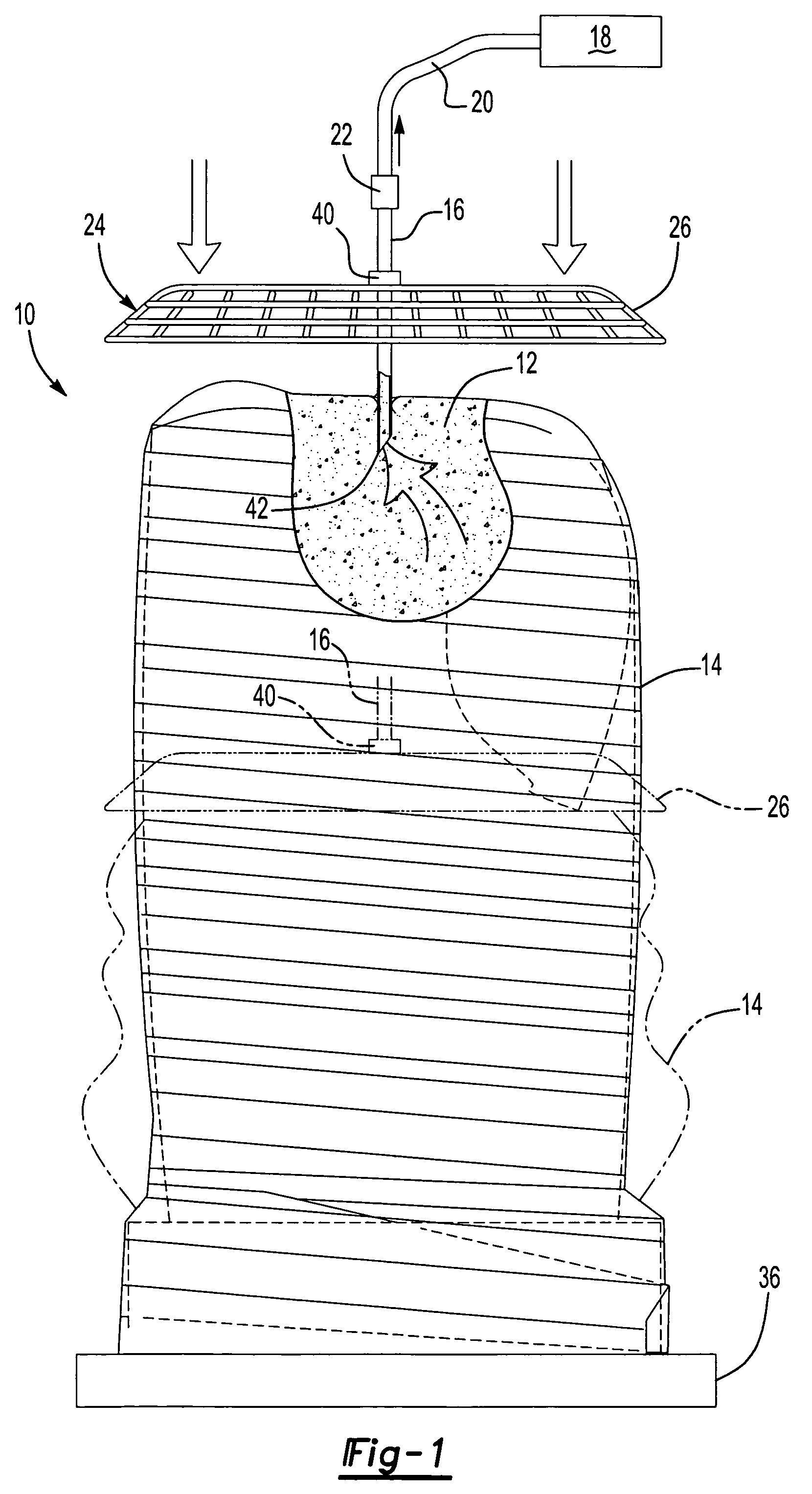

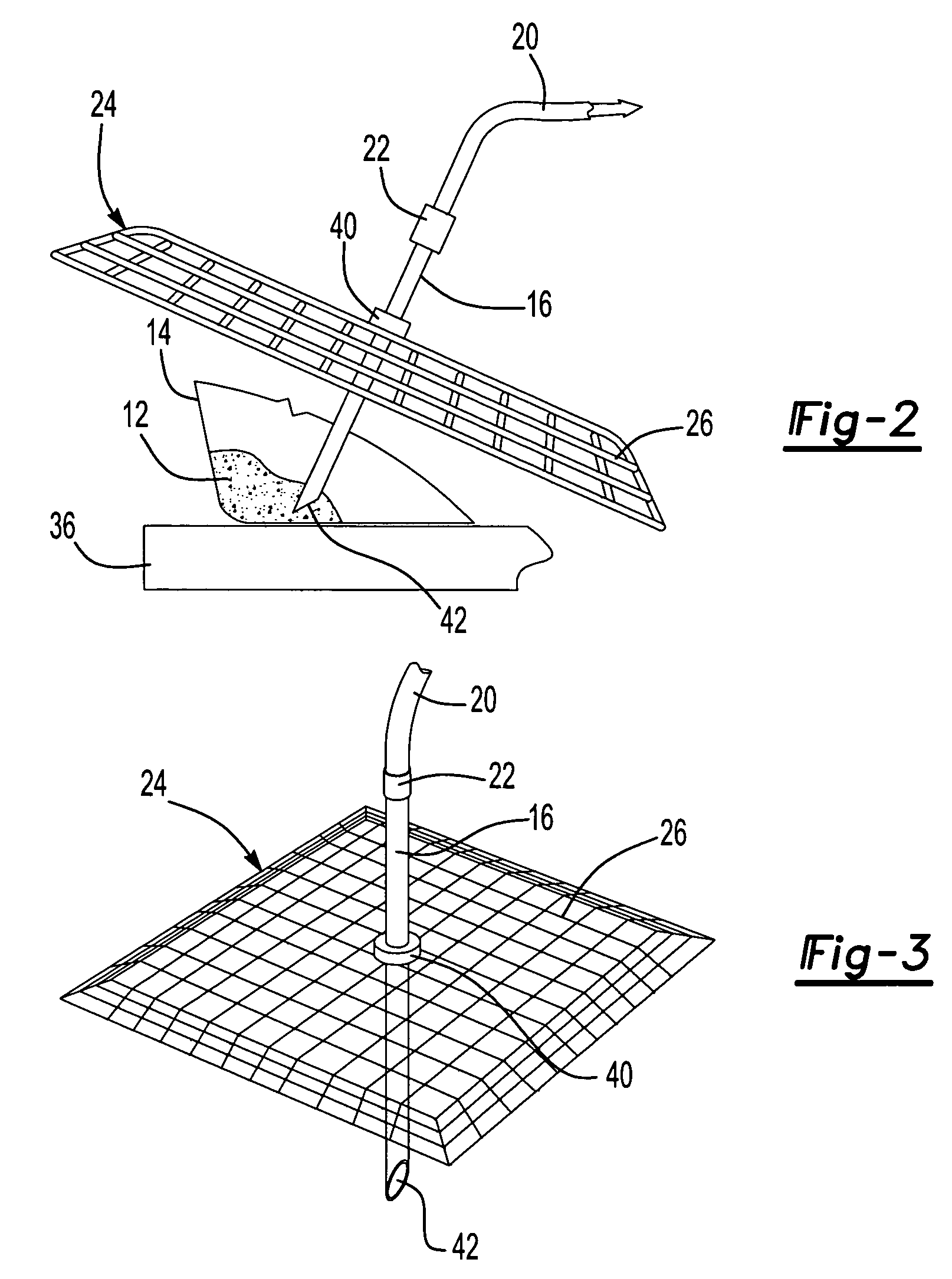

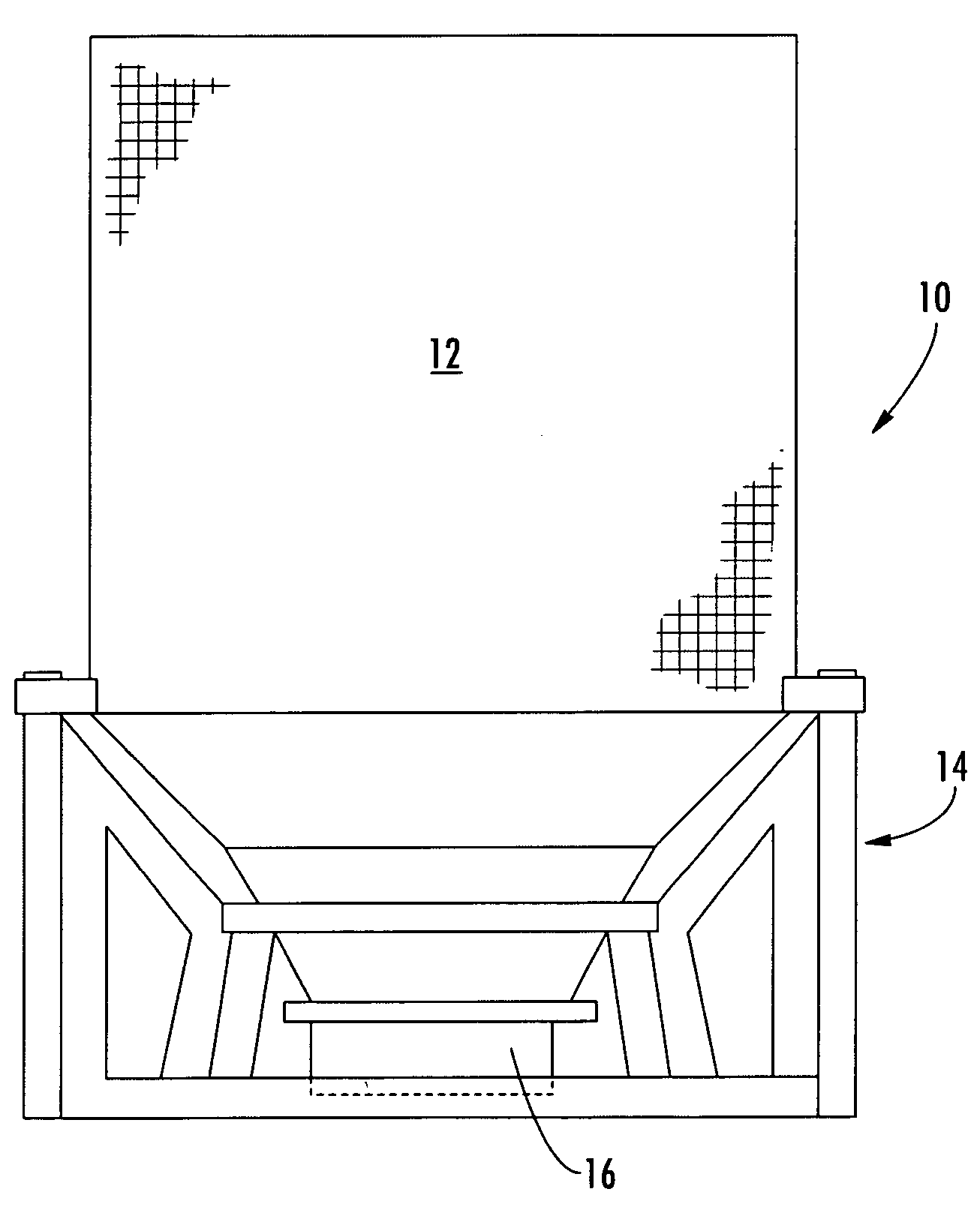

ActiveUS6979166B2Overcome deficienciesFlexible bulk container emptying systemsBulk conveyorsEngineeringMechanical engineering

The subject invention relates to a vacuum wand assembly for extracting a product from a container, especially a non-self supporting container that collapses as the product is extracted. The assembly includes a wand for extending into the container and for withdrawing the product therefrom. A vacuum source is connected to the wand for applying a vacuum to extract the product through the wand. A supporting structure supports the wand and is moveable relative to the container for carrying the wand as the product is extracted from the container. The wand is limited in a vertical direction by the supporting structure. This keeps the wand at the pre-determined level relative to the product within the container.

Owner:KELLOGG CO

Bulk bag handling apparatus and method

InactiveUS20050194405A1Reduce weightLow costFlexible bulk container emptying systemsBagsFlangeEngineering

A method and apparatus for handing and discharging bulk bags includes positioning an adapter assembly on a flexible bulk bag having a spout, inverting the bulk bag, and selectively discharging the contents. The adapter includes a rigid annular adapter ring with an annular, radially-outwardly extending flange adapted for being engaged by a surrounding clamp, The bulk bag is secured to the adapter ring by folding the edge of the spout opening over the flange and clamping the edge to the flange. With the adapter assembly installed a bulk bag may be manipulated in the same manner as a rigid drum.

Owner:KOSICH MARK MICHAEL

Shuttle bin

ActiveUS20090202325A1Flexible bulk container emptying systemsLarge containersEngineeringMaterial storage

An apparatus such as a shuttle bin includes an upper frame, a lower frame hingeably connected to the upper frame, a storage body operatively connected to the upper frame for storing material and a roller assembly operatively connected to the upper frame. The roller assembly is adapted to draw the storage body taut to unload the material stored in the storage body as the upper frame hinges away from the lower frame. The storage body may be formed of a pliable material such as a mesh or canvas.

Owner:WAHLS STEPHEN L

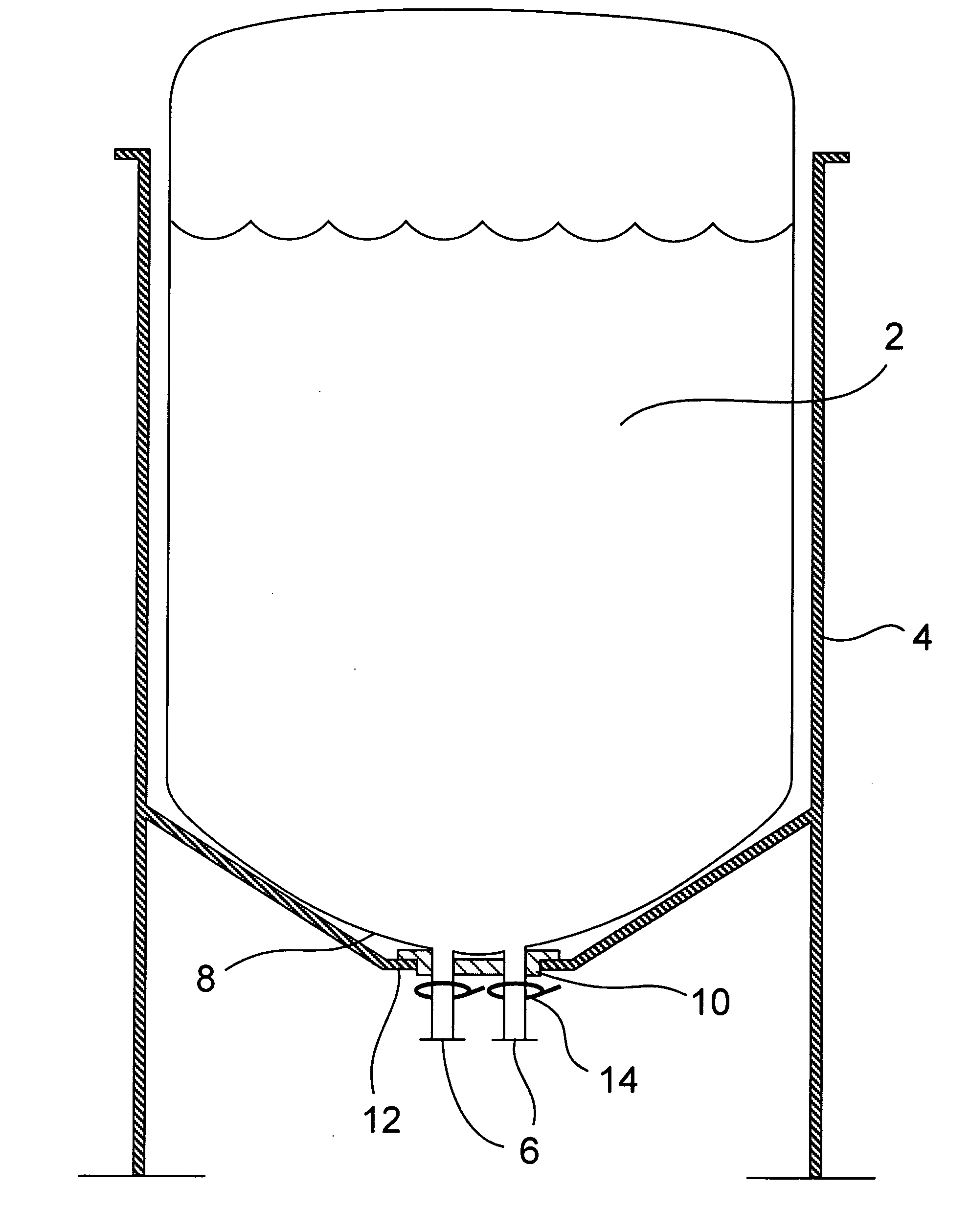

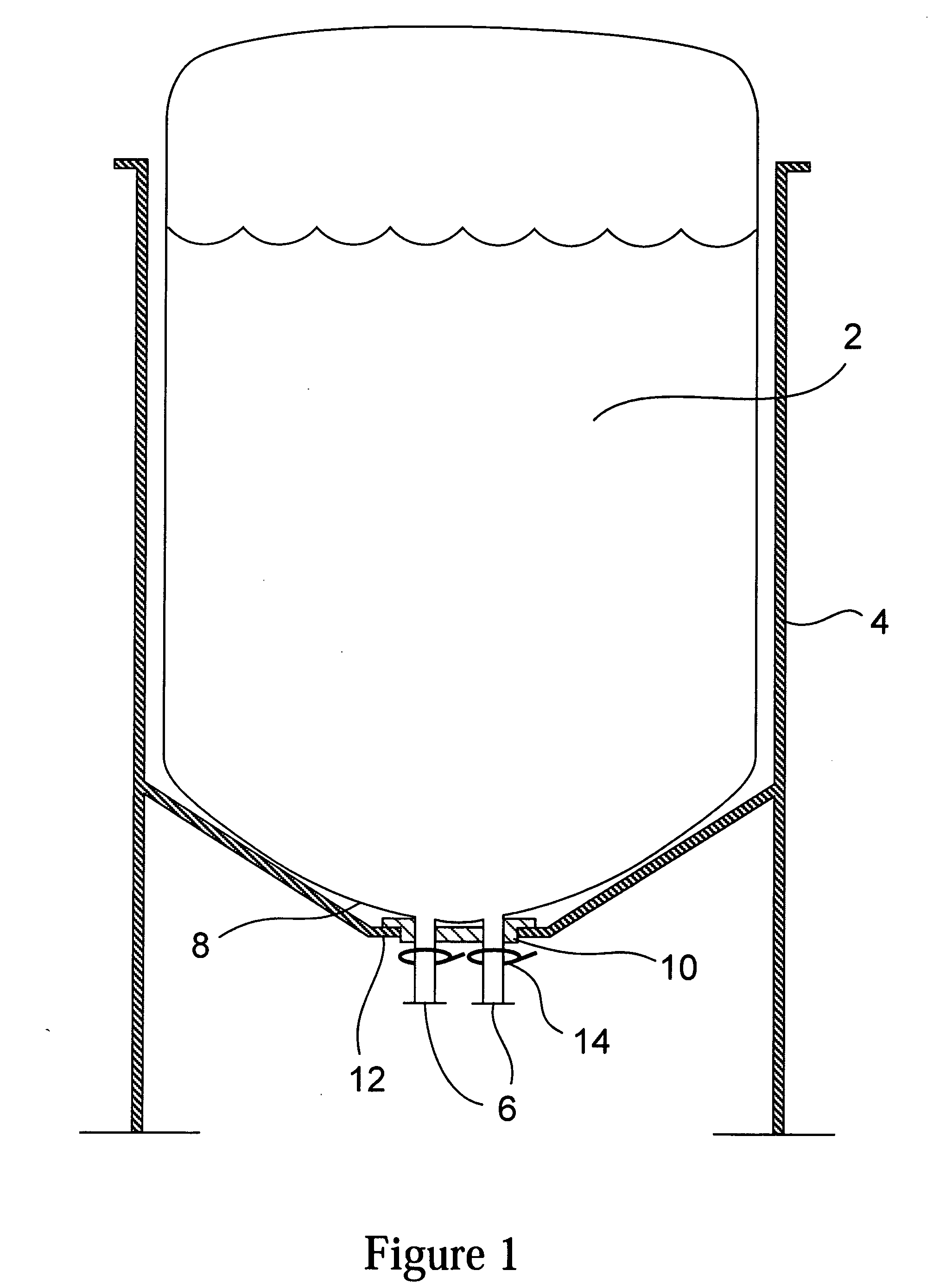

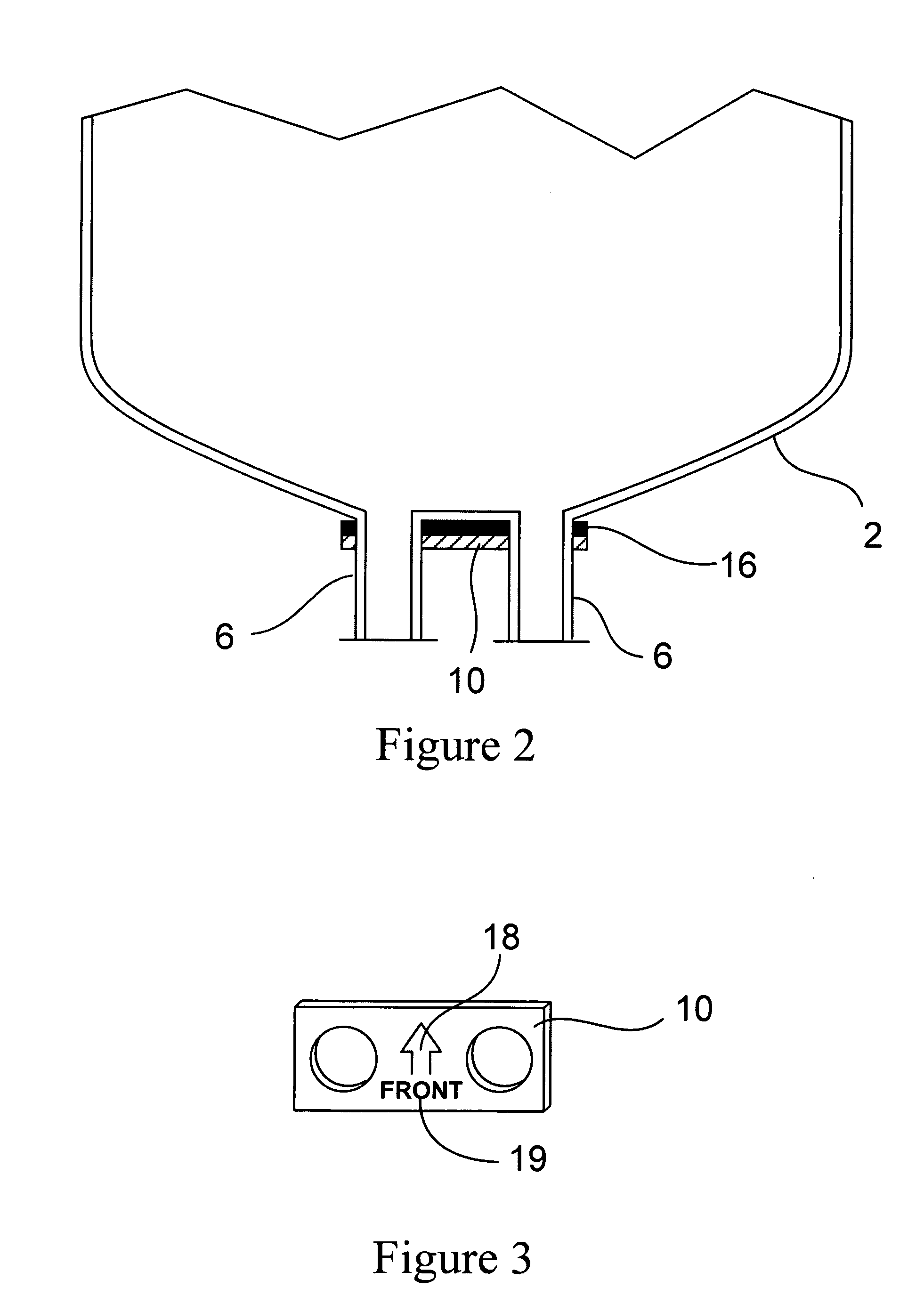

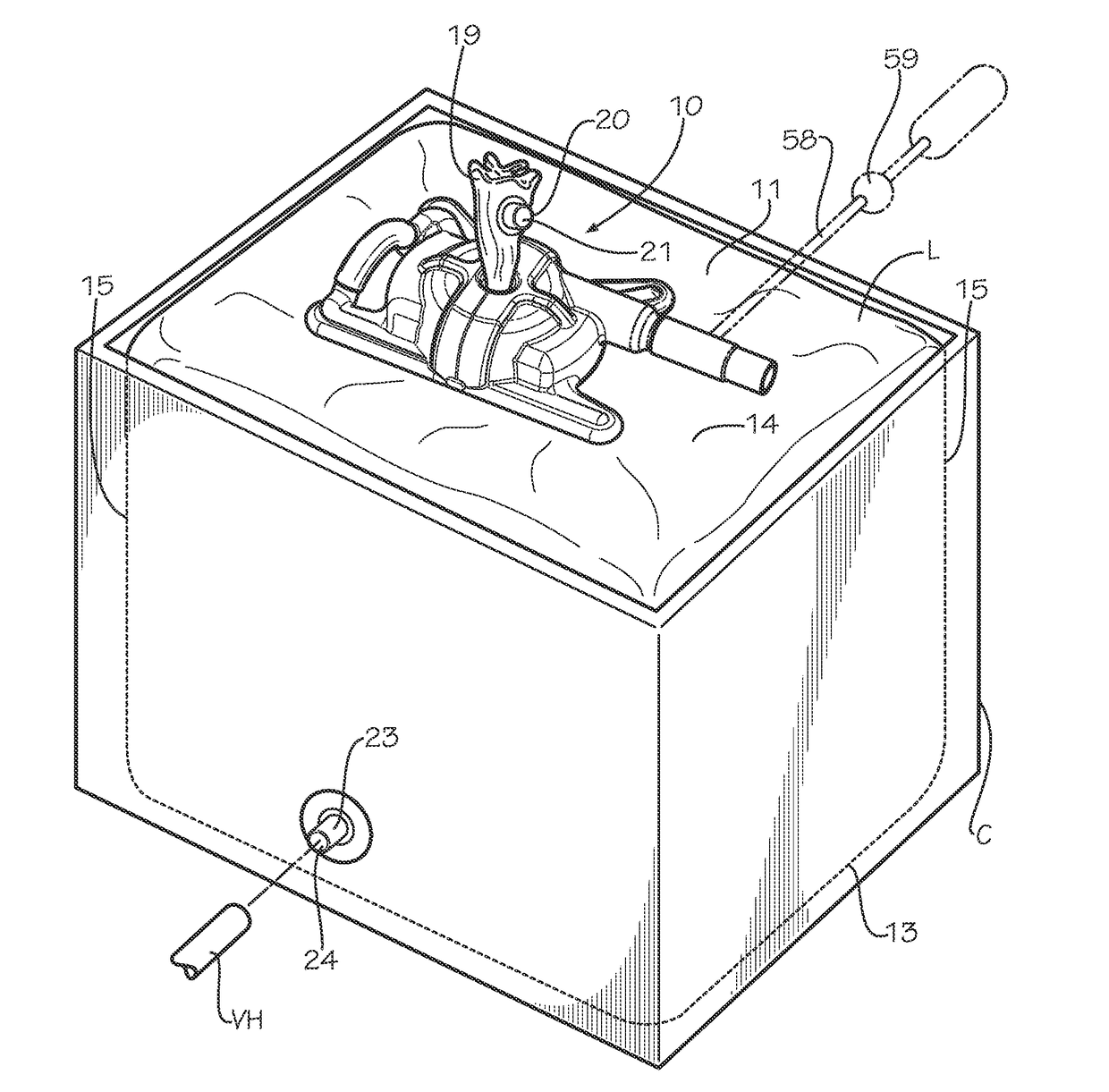

Disposable processing bag with alignment feature

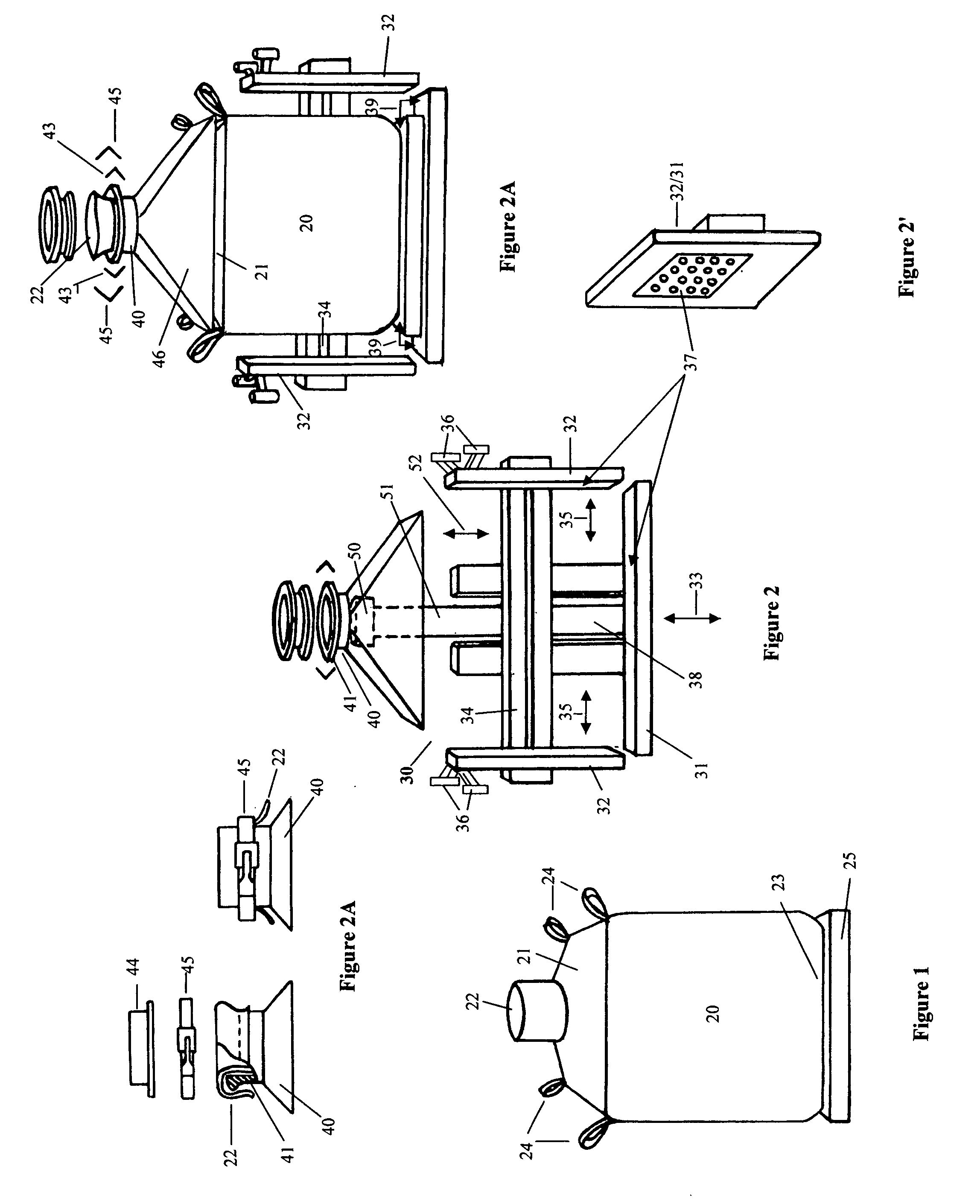

The present invention is an alignment device for a bag containing one or more ports wherein the alignment device is attached to either the one or more ports such as by wire ties, clamps or cable ties or to the bag adjacent the one or more ports via adhesives or welding or molding such as overmolding. The plate has either an indicator or a unique outer edge shape that is designed to fit into a corresponding unique opening in a bag holder such as a carboy or tote to ensure proper alignment of the bag and its port(s) in the holder. In one embodiment the plate formed of plastic, metal, wood or composite material has a series of holes equal to and in alignment with the one or more ports of the bag and the port(s) are extended through the holes of the plate and the plate is attached to the bag by retainers on the port(s) below the plate. Such retainers can be plastic cable ties, wire ties, tube clamps and the like. Alternatively, the plate may be fitted over the port(s) and attached to the bag such as by thermal bonding or welding or overmolded to the bag or the bag is formed and molded to the plate. The plate may have any unique design that ensures that the alignment of the bag in the holder is correct and cannot be reversed or incorrectly aligned. Such designs use a plate that is affixed to the bag or its port(s) in such a way that it cannot be realigned or moved out of register. Such designs include but are not limited to graphic indicators and unique shapes.

Owner:MILLIPORE CORP

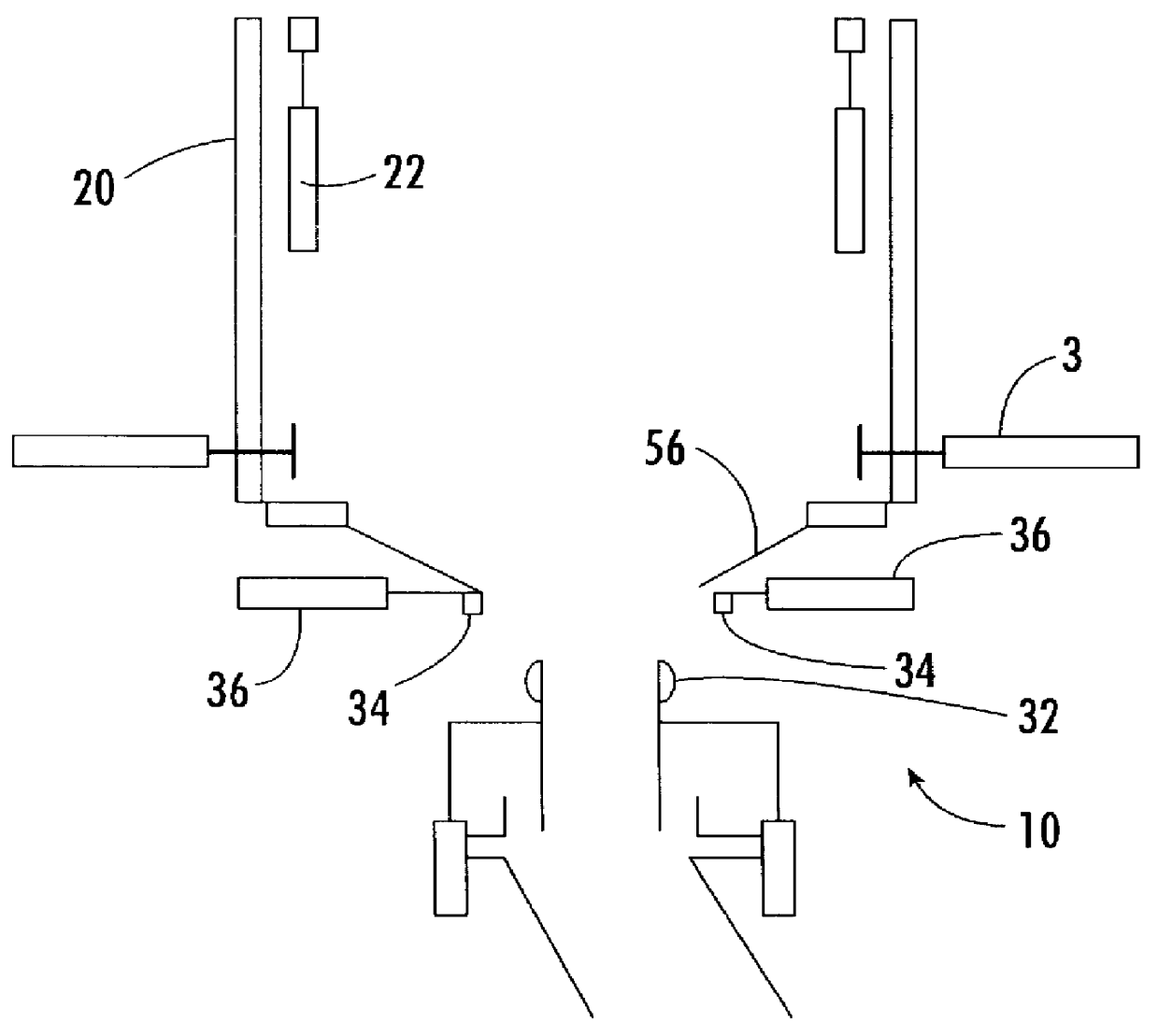

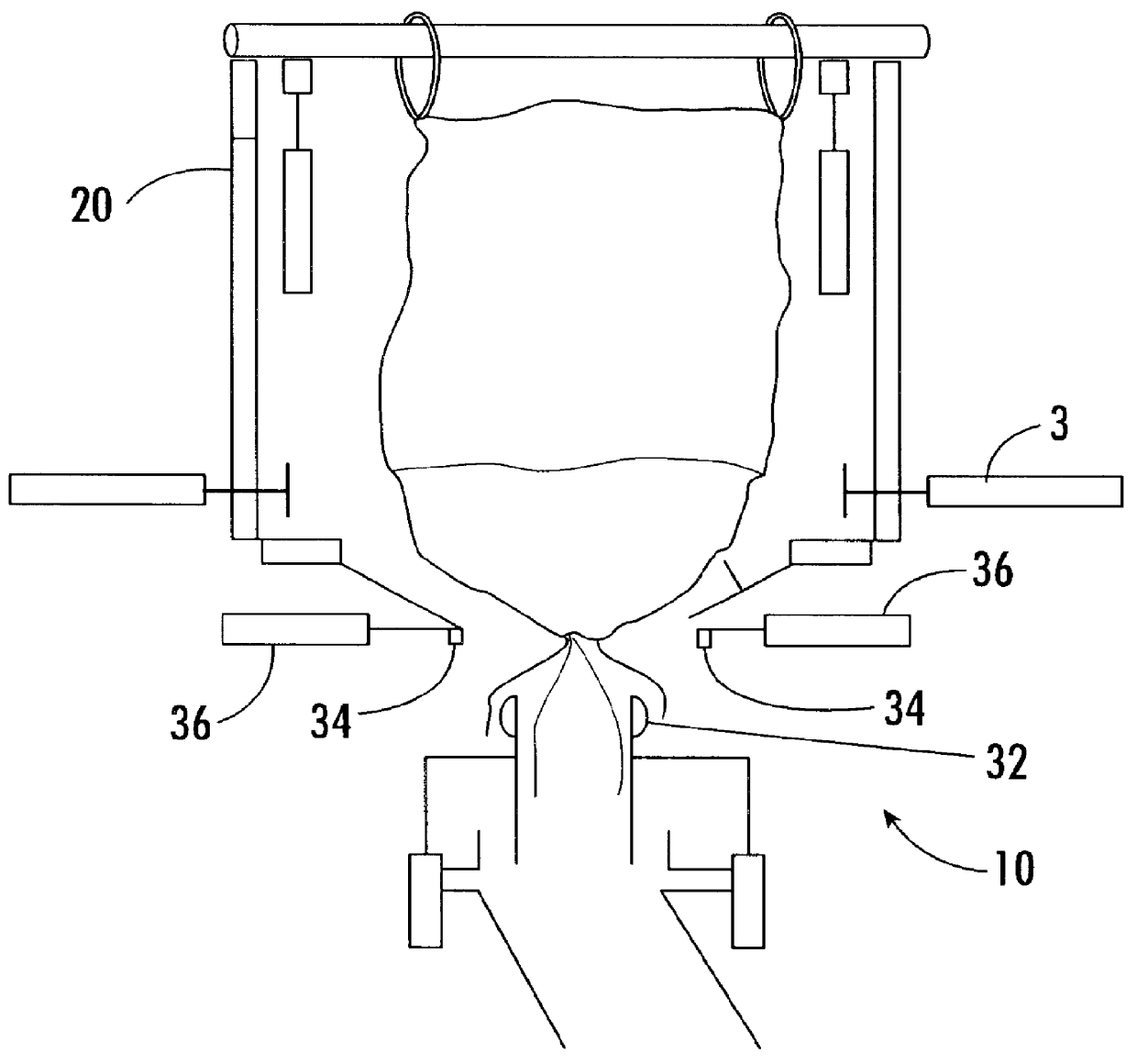

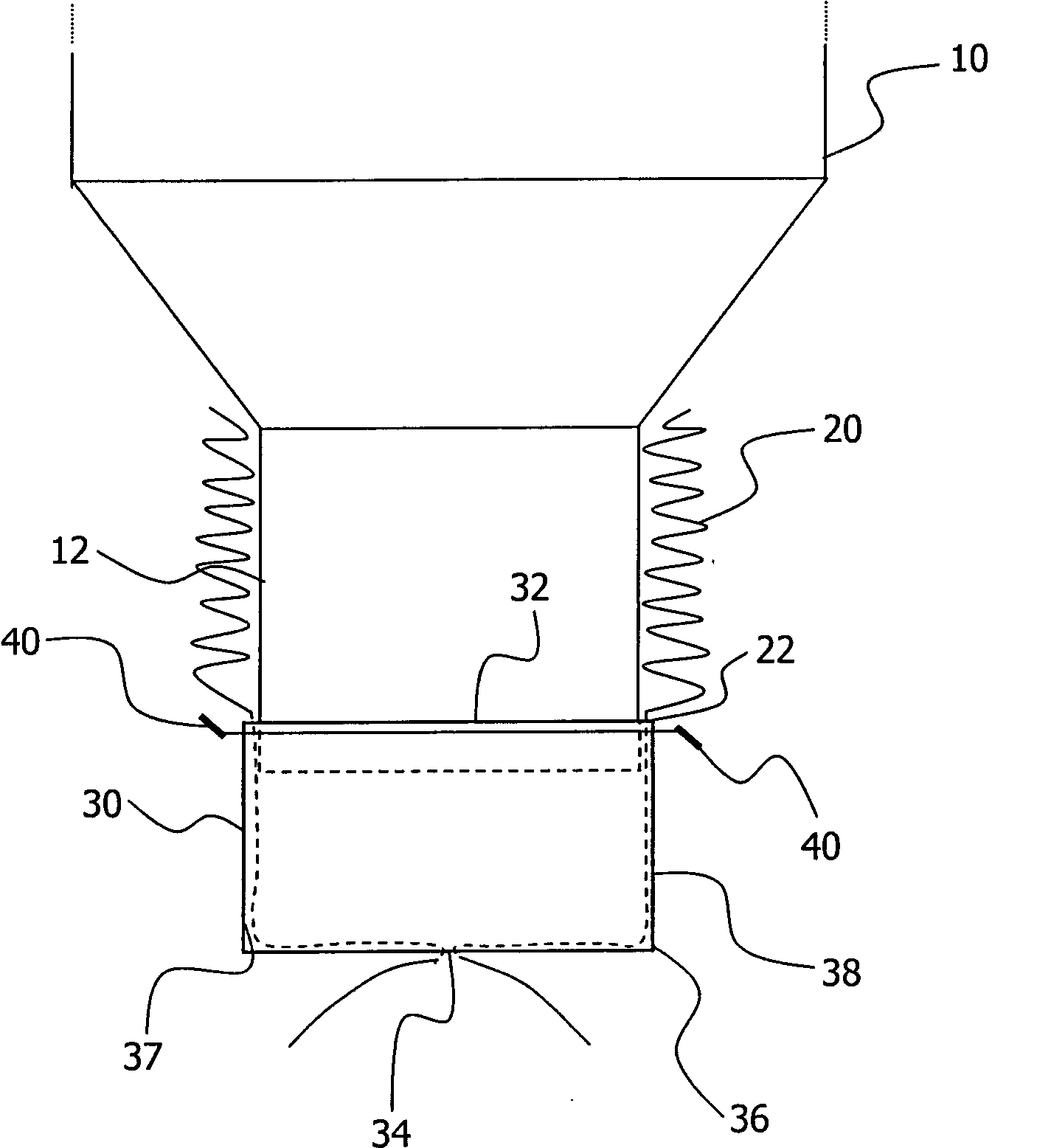

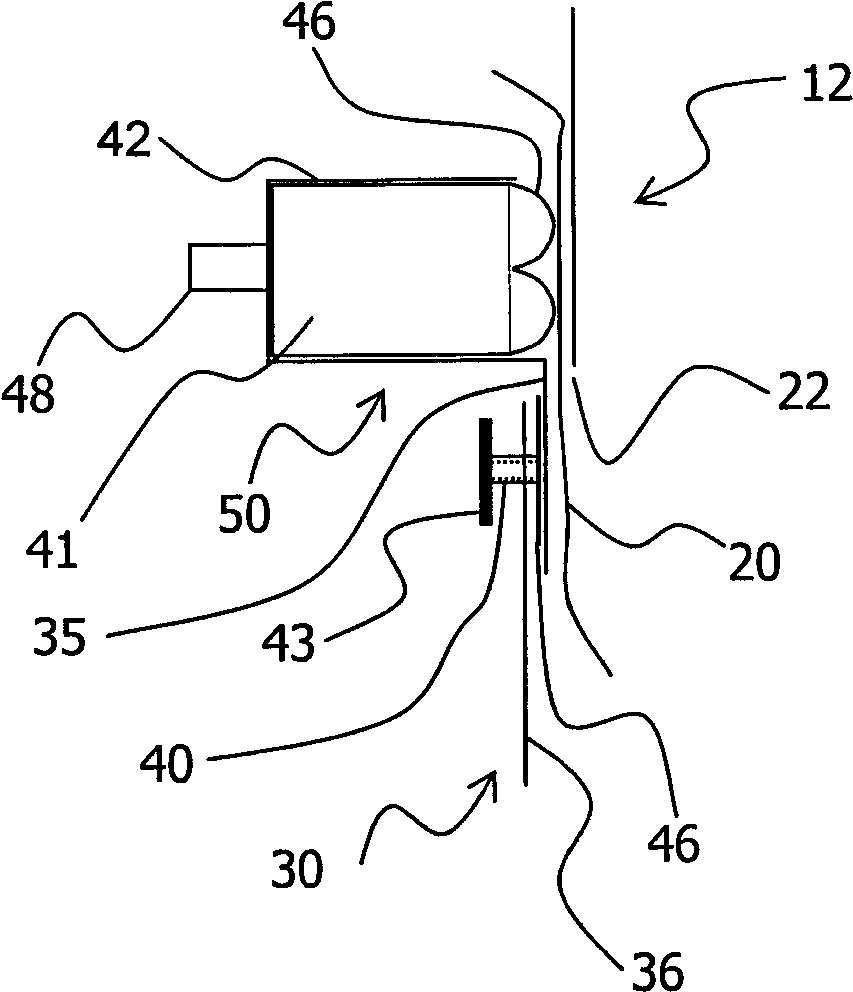

Bag discharge apparatus

InactiveUS6138443AOpening closed containersBottle/container closureEngineeringMechanical engineering

A tie 24 seals an outer bag 26 and an inner line bag 28 of a container. The inner liner bag 28 is fed into a tubular discharge chute 30 and the tubular end of the outer liner bag is passed over the outside of a chute 30 to extend over an inflatable seal 32. Then two opposed pinch bars 34 on either side of the container, just below the tie 24, are actuated by pneumatic cylinders 36 to move towards each other and to pinch the inner and outer bags 26 and 28 just below the tie. Then a seal 32 is inflated to urge the seal against the inner face of the outer bag. Then the tie 24 is removed and the pinch bars are retracted before moving the chute 30 downwardly by retracting pneumatic cylinders 38 to take the lower end of the outer bag downwardly.

Owner:SPIROFLOW

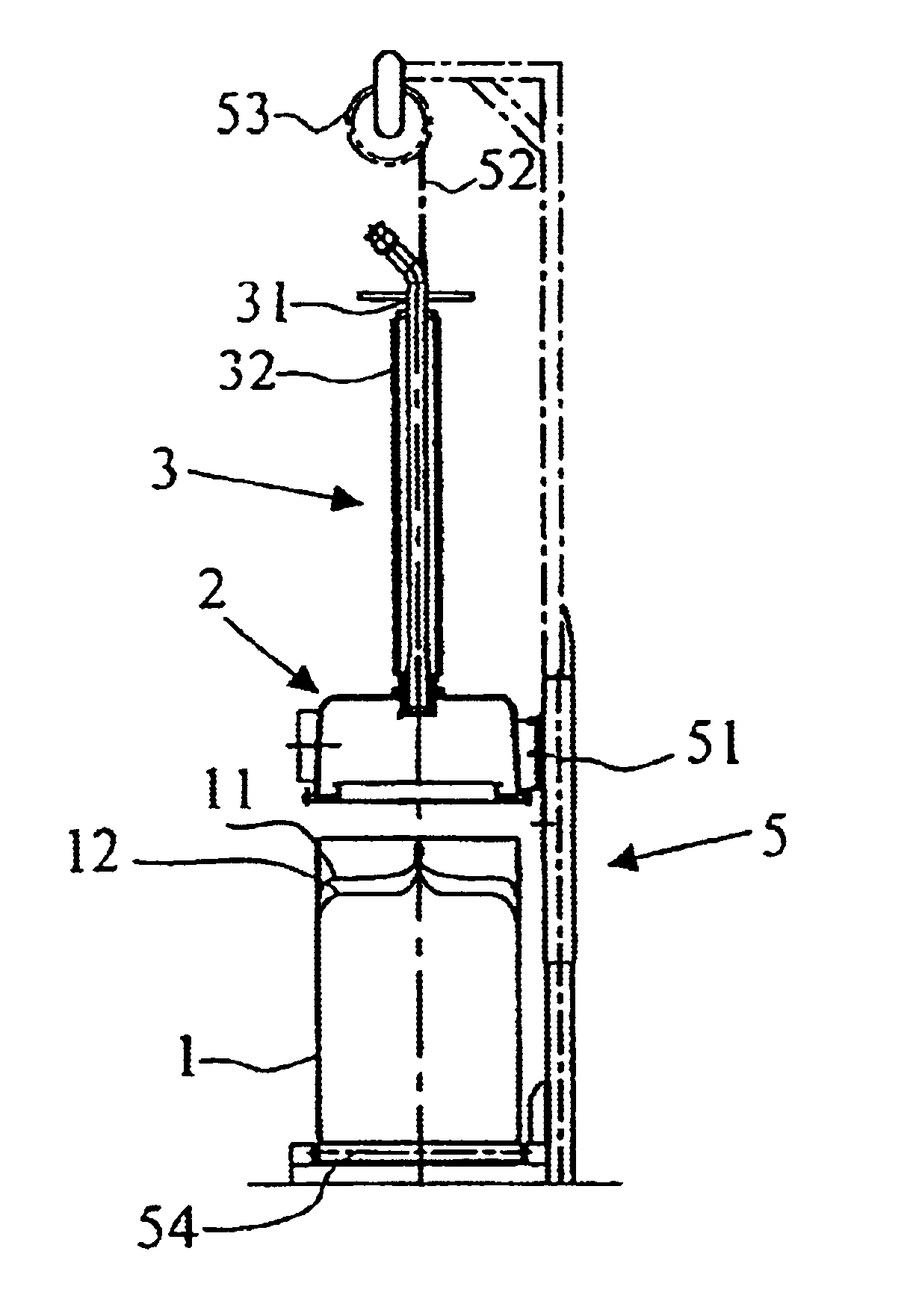

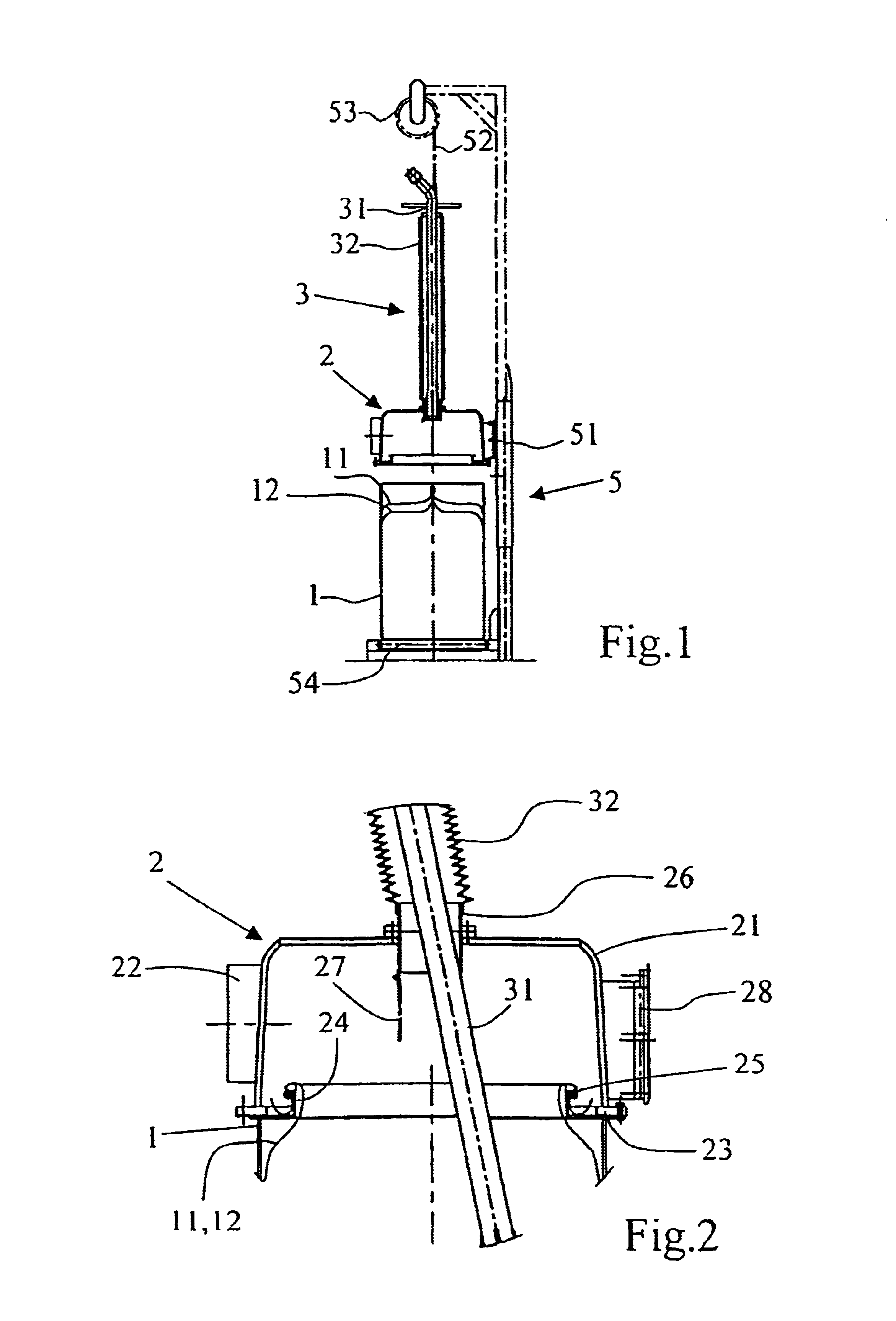

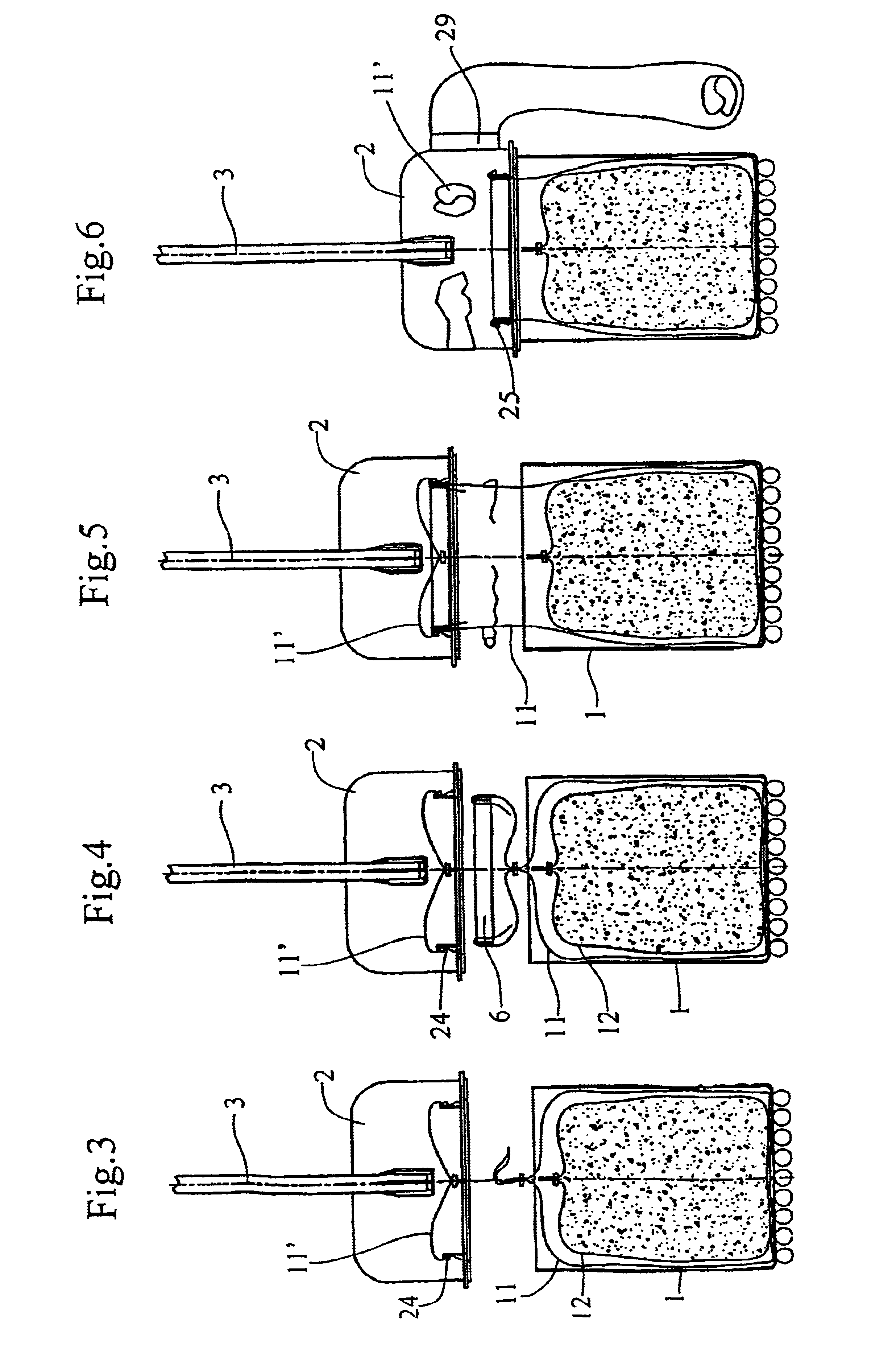

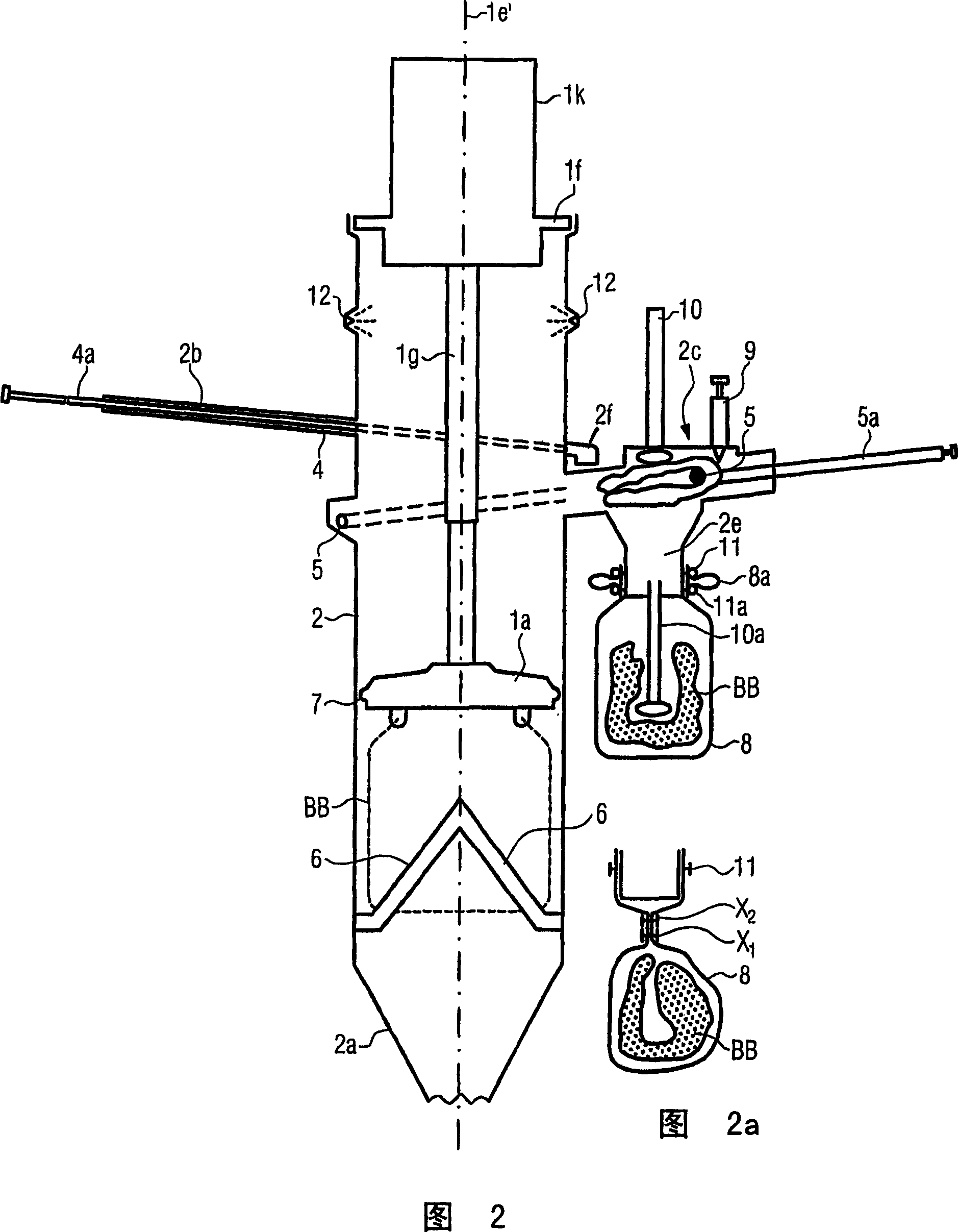

Method and installation for emptying casks

InactiveUS6843283B2Easy to placeEnsure sealing performanceLiquid fillingFlexible bulk container emptying systemsEngineeringVertical displacement

The invention concerns an installation for emptying casks (1) equipped with an external bag (11) and an internal bag (12) containing powdery products. It comprises a glove box (12) consisting of a bell made of a transparent material. It is provided, on its upper part, with an opening for the passage of a suction rod (3, 31, 32) equipped with sealing means between said pipe and the bell. The lower part of the bell is provided with means adapted to be urged in sealed position on the upper part of a cask (1). The bell (2) is suspended to a frame (5, 15) for its vertical displacement.

Owner:DIETRICH FREDERIC DIETRICH YVES

Emptying device for storage containers of granular materials or the like

ActiveUS9663263B2Minimizes and eliminates leftoverAvoid problemsFlexible bulk container emptying systemsLoading/unloadingMechanical engineeringGranular material

Owner:MORETTO SPA

System and method for storing, transporting and dispensing bulk particulate materials and dispensing apparatus therefor

InactiveUS6923340B2Flexible bulk container emptying systemsTank vehiclesEngineeringMechanical engineering

An apparatus attachable to a bag containing a bulk particulate material and having a discharge spout for dispensing material from the bag generally consisting of first and second annular clamping members displaceable axially between a first, spaced apart condition permitting a portion of the spout to be drawn in position therebetween, and a second, adjacent condition clamping the spout portion position therebetween, and means for releasably retaining the members in the clamping condition.

Owner:YOUNG INDS

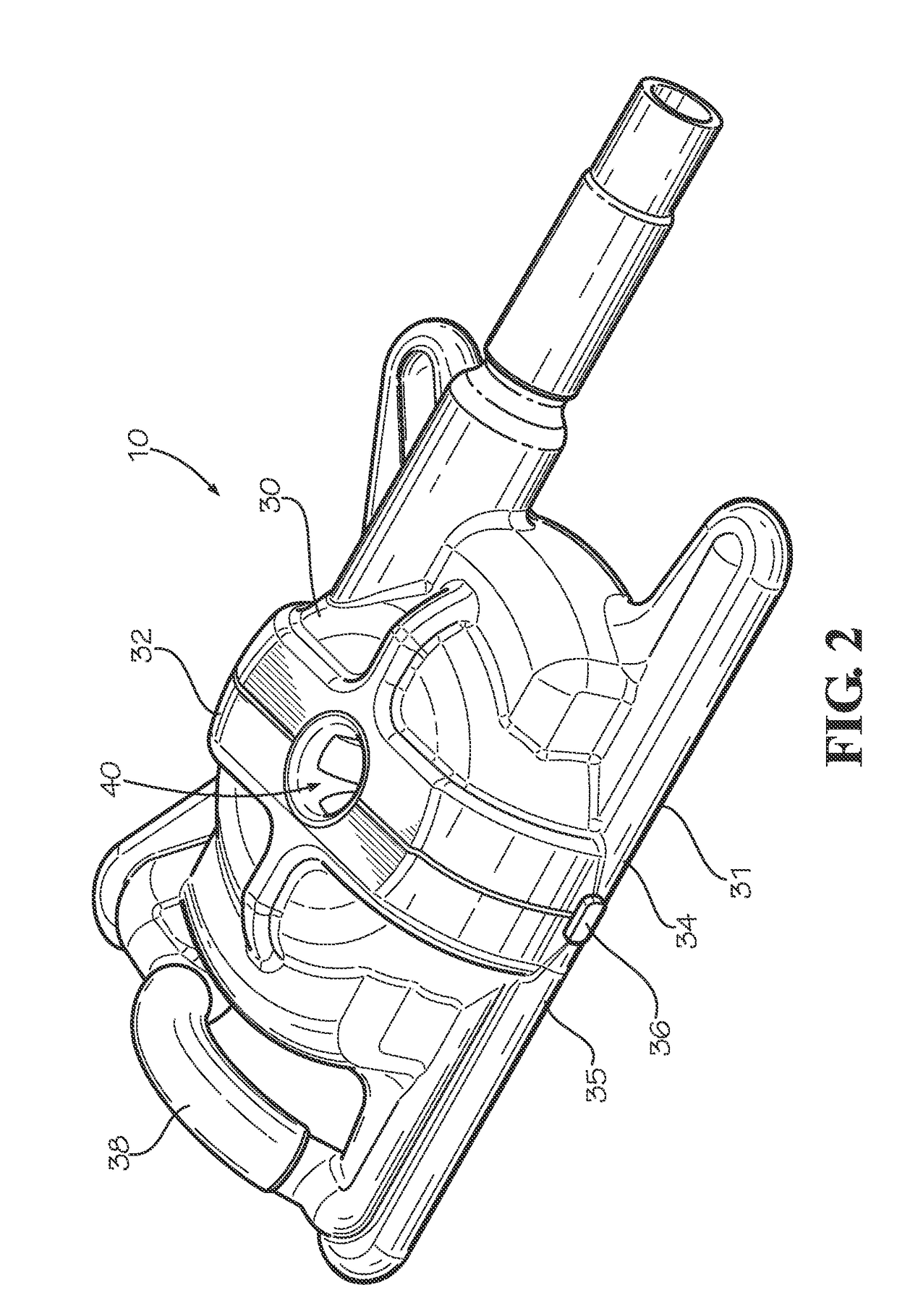

Flexible container liner wringing device

ActiveUS20170096293A1Flexible bulk container emptying systemsLarge containersMechanical componentsDrive shaft

A liner wringing device (10) is disclosed for use with a container liner. The wringing device includes a housing (30) with an internal cavity which houses the mechanical components of the wringing device. The housing defines a central liner compression channel (40). The internal components include a bottom support plate (42) with a central opening 43 aligned along the central channel. The wringing device also includes a drive assembly (44) formed by four elastomeric rollers (45) positioned so that the peripheral contact surfaces (50) are aligned generally tangentially with the central channel. The four rollers are each mounted to a drive shaft / axle which includes bevel gears which are meshed so that all four rollers rotate in simultaneous, synchronic rotation through the actuation of a pneumatic air gear motor (57).

Owner:ILC DOVER LP

Method and apparatus for powder delivery system

InactiveUS20070169843A1Facilitates powder deliveryFlexible bulk container emptying systemsSupporting partsEngineeringFeeding tube

Owner:SWIMC LLC

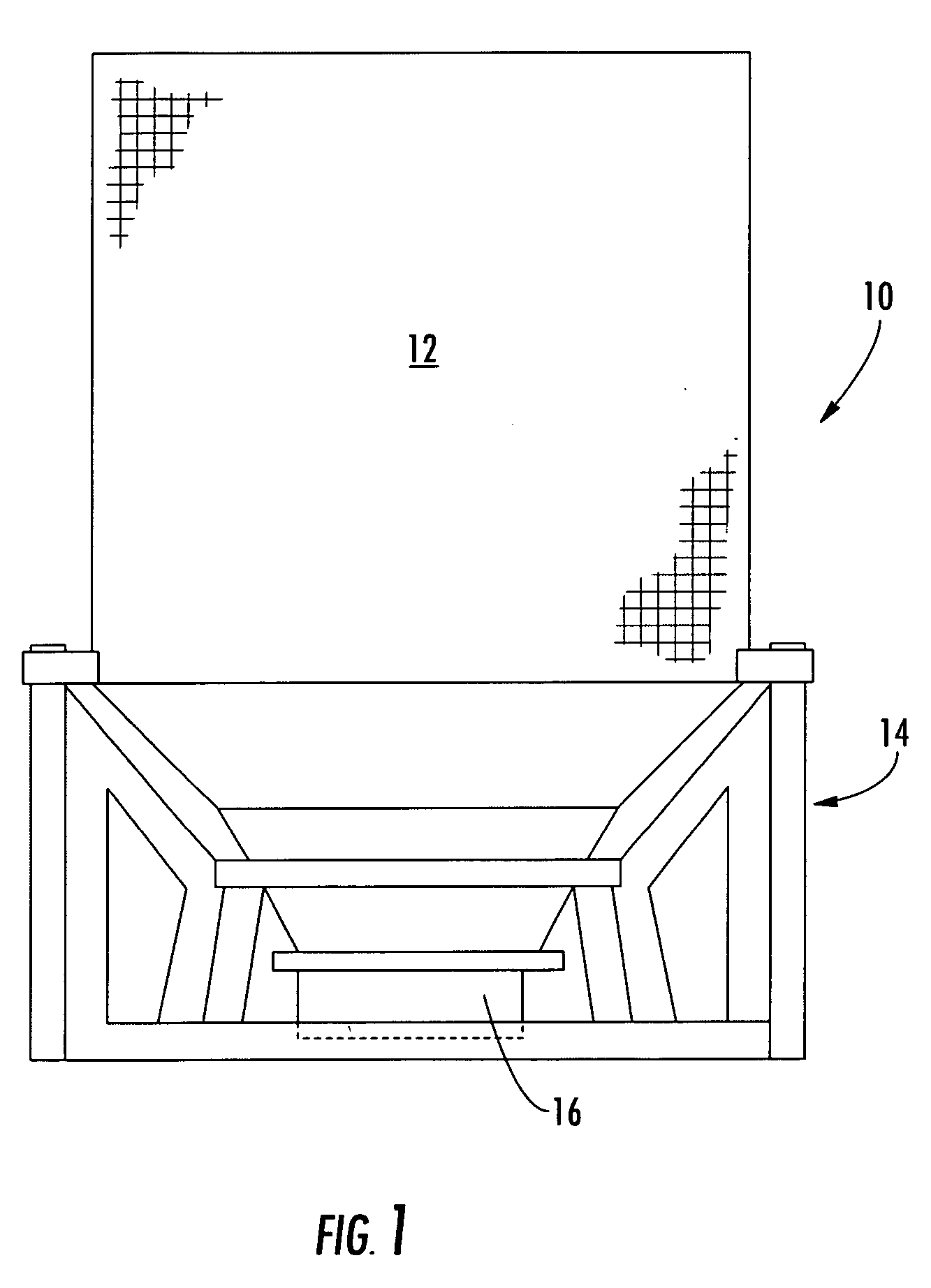

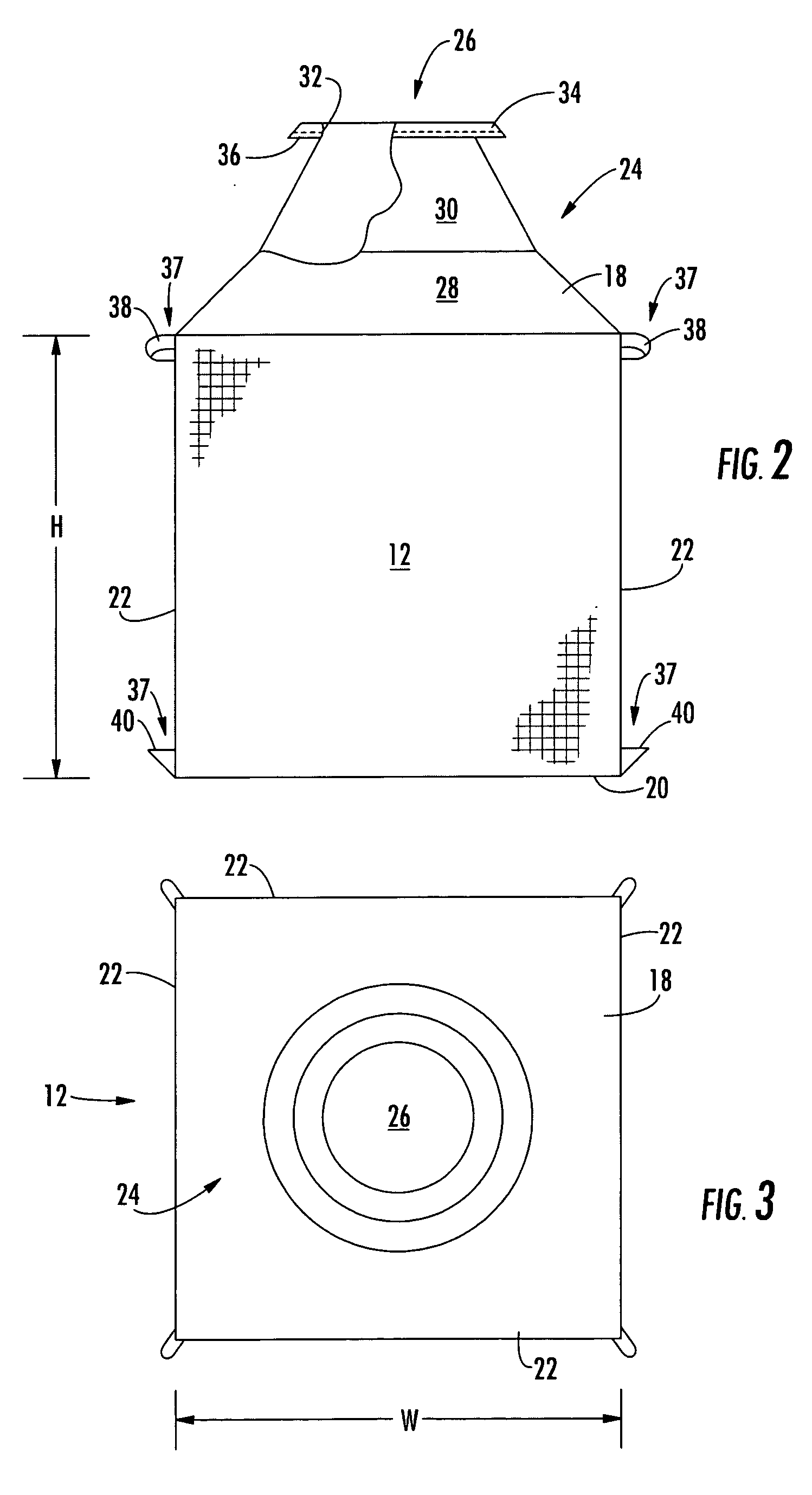

Container support

InactiveUS7025318B2Flexible bulk container emptying systemsLarge containersEngineeringMechanical engineering

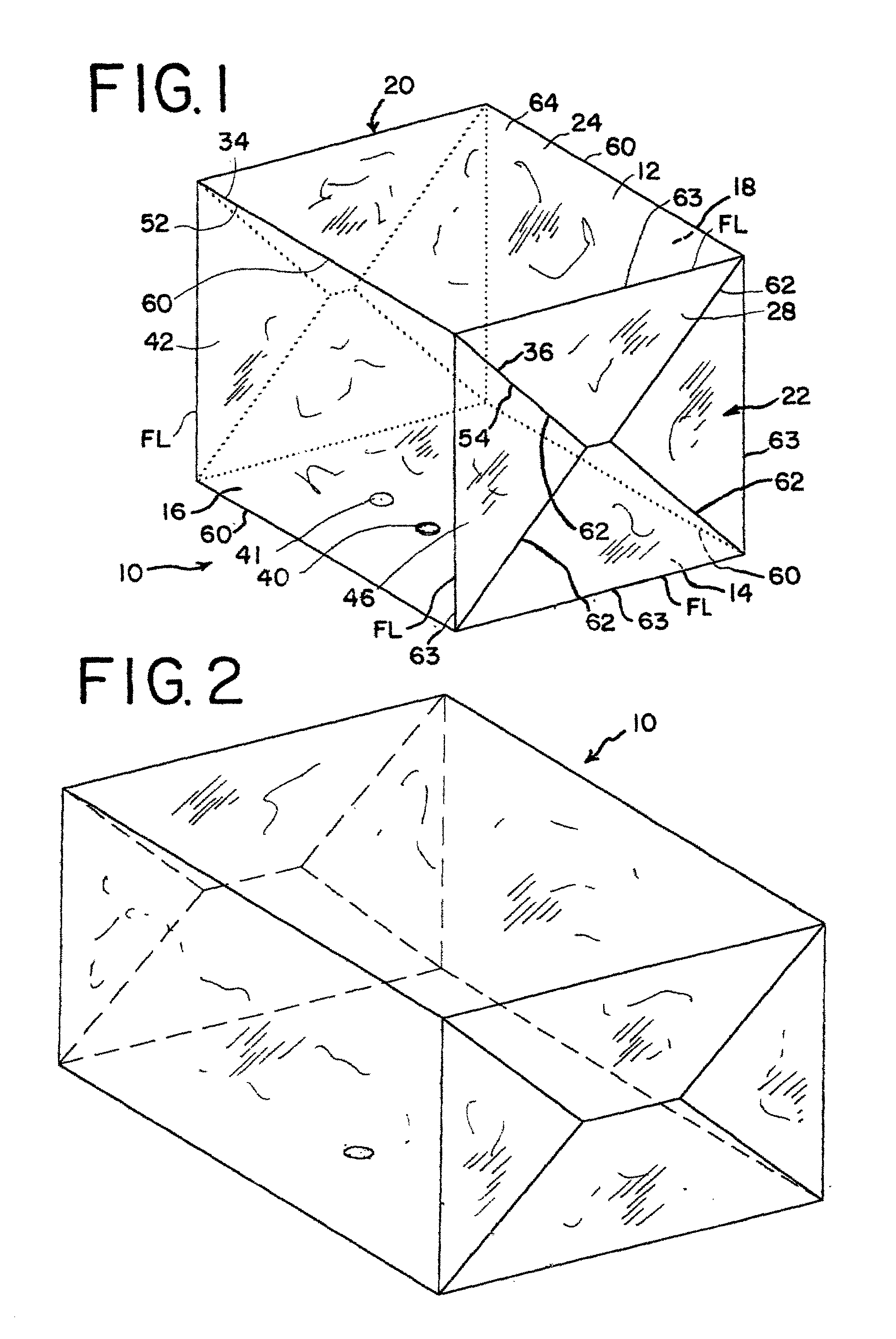

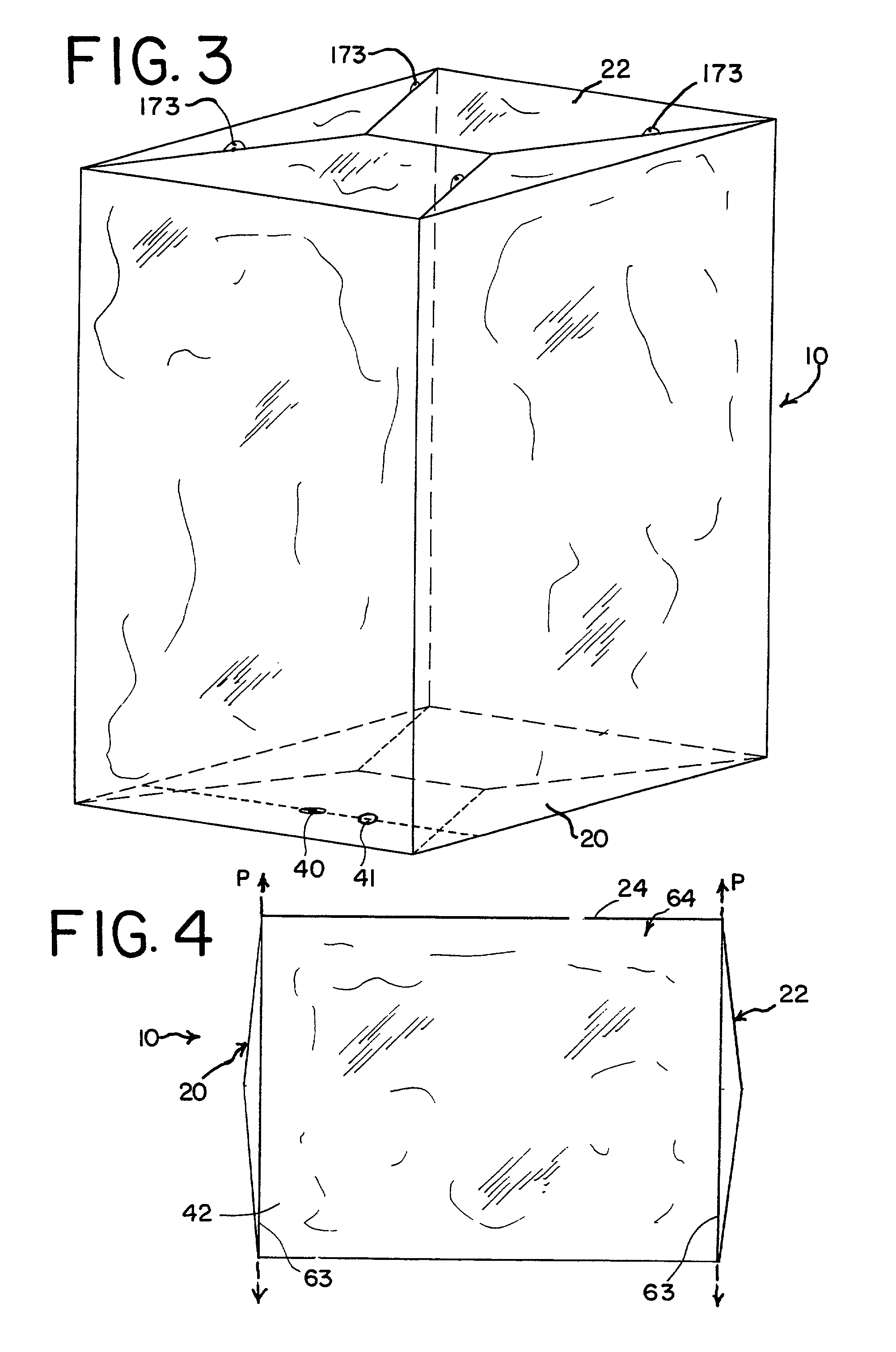

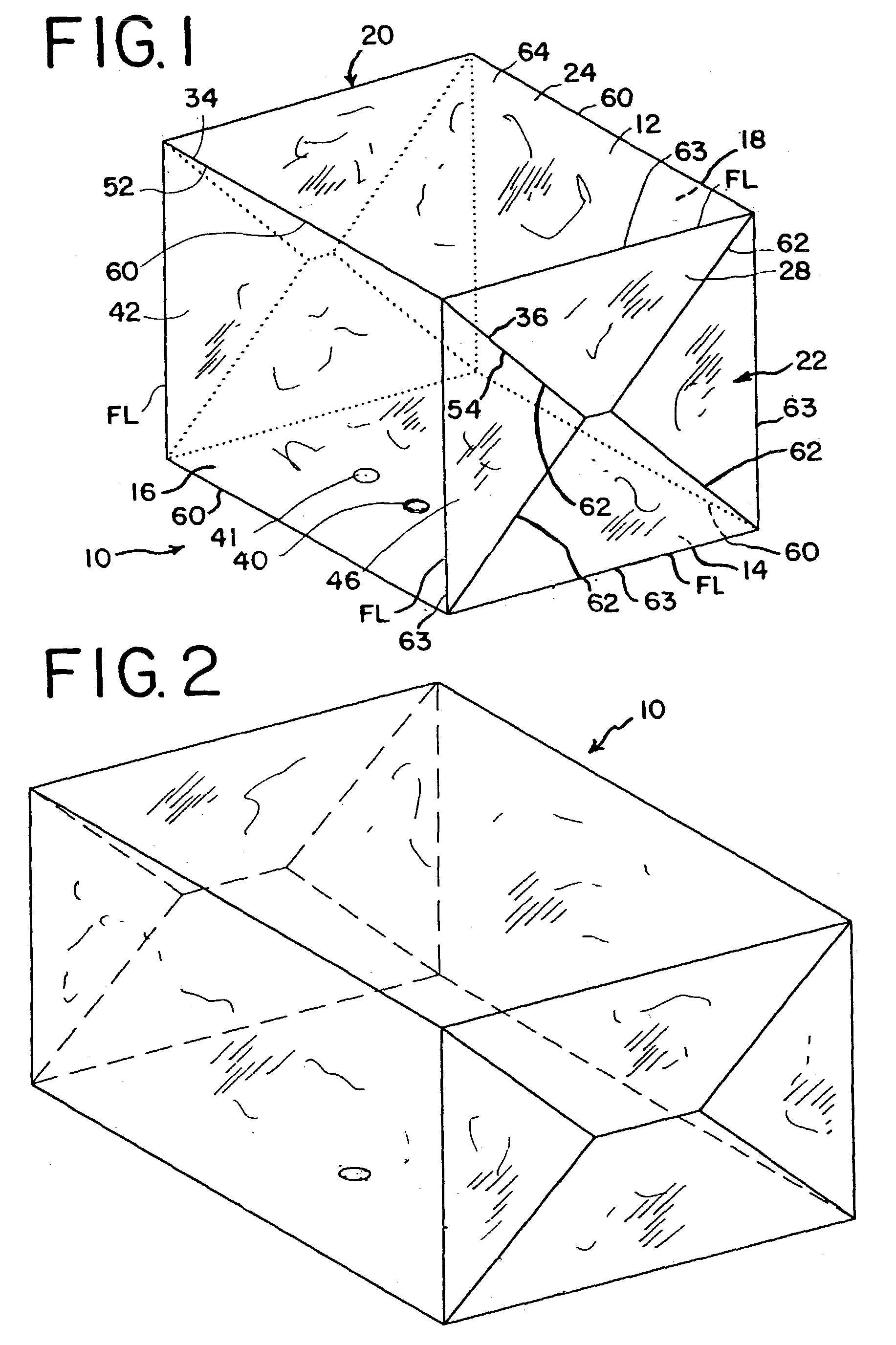

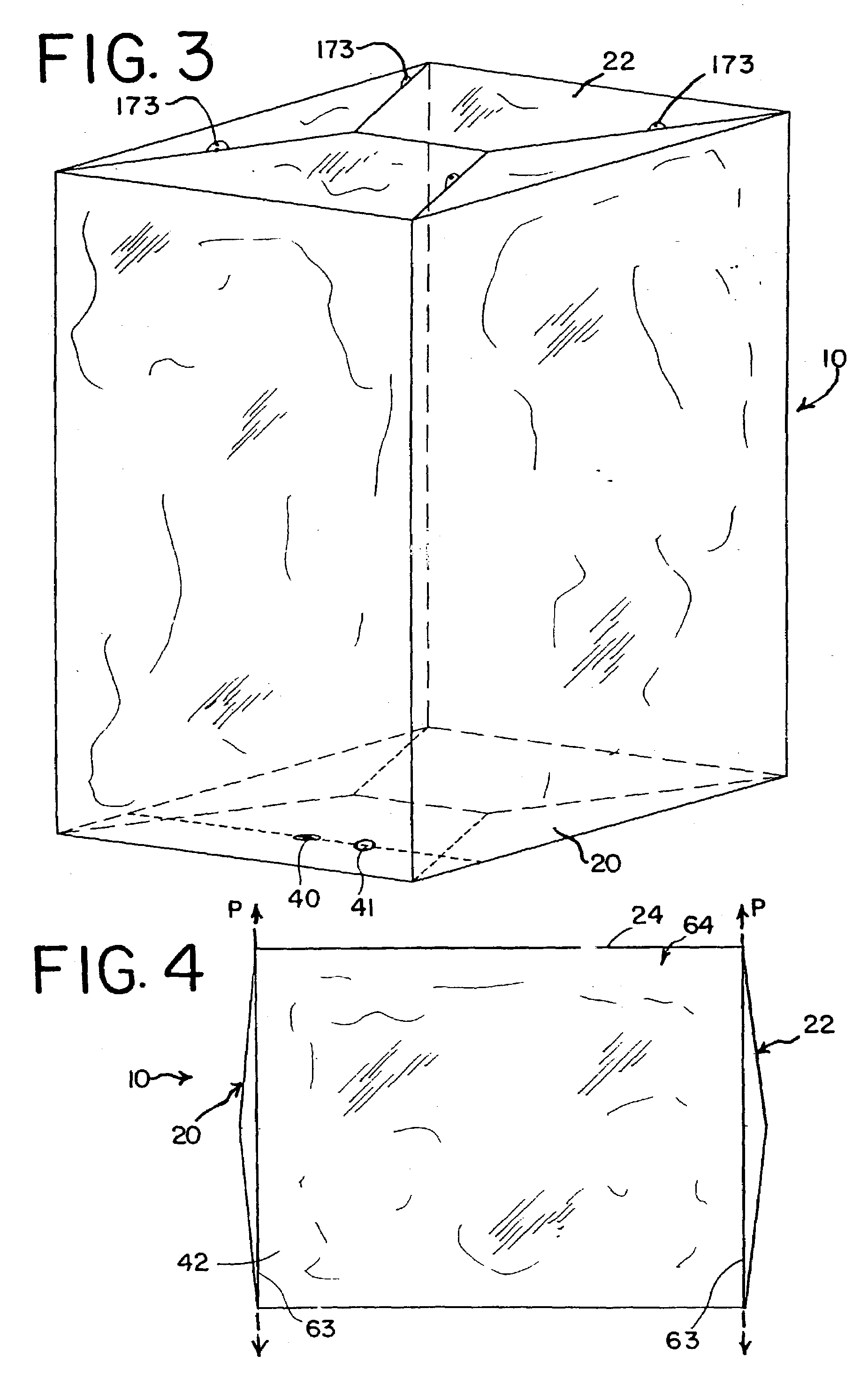

A container (10) having a plurality of panels (12–18) joined together to form a sleeve (64). The panels (12–18) each have an end edge that cooperate to define an imaginary plane (P) at one end of the sleeve (64). The container (10) further has an end panel (20,22) connected to the panels (12–18) at the one end of the sleeve (64). The end panel (20,22) has at least one portion extending beyond the imaginary plane (P). The supporting box (100) is provided to support the container (10). A hanger system (150) is provided and is attached to the box (100). The hanger system (150) supports an upper portion of the container (10) within the box (100). The container (10) is also provided with a port closure (300) that provides both a sterile and gas permeable barrier.

Owner:BAXALTA GMBH

Bag Opening System

ActiveUS20180361047A1Securely holdEasy to useFlexible bulk container emptying systemsDialysis systemsLinear motionEngineering

A system and apparatus for opening and emptying a bag of material includes a base having a pair of opposed sides and a central aperture through which material may flow. The system includes a pair of opposed doors rotatably mounted on a pair of door shafts, the edges of the pair of opposed doors forming an opening and a plurality of piercing blades pivotally mounted to the base on a pivot rod, the blades capable of pivoting to pierce said bag. The system further includes a cutting blade mounted transversely below the opening of the opposed doors, the cutting blade capable of linear motion across the opening.

Owner:ISOPURE CORP

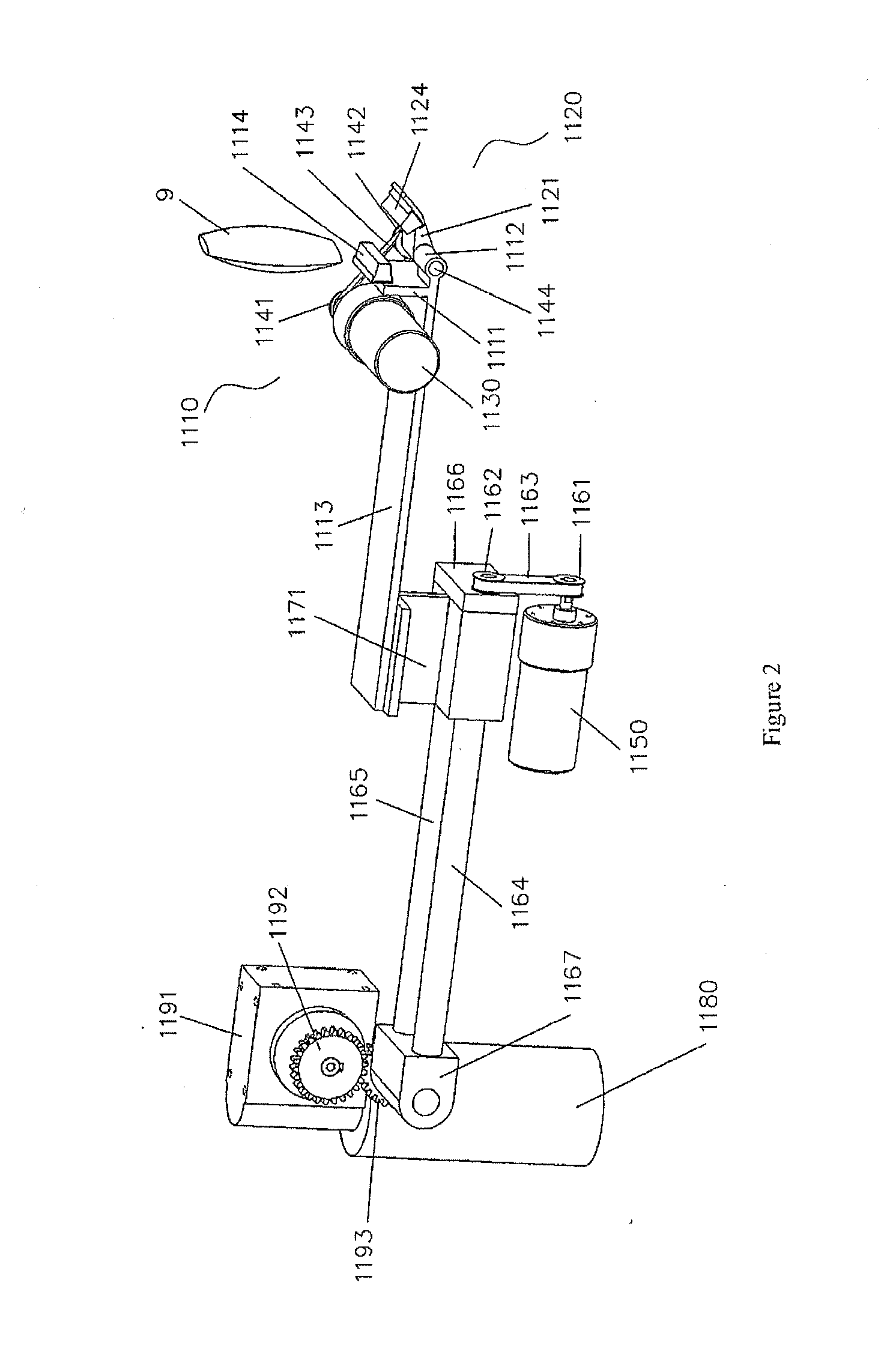

Cooking material dispensing method and dispensing system

ActiveUS20150128536A1Convenient and swift and simplified cooking processMove preciselyOpening closed containersBottle/container closureEngineeringCooking process

Disclosed are a cooking material dispensing system and dispensing method. The dispensing method comprises the following steps: setting a material bag (9) clamping station in a position near a cooking pot opening but outside the range of the pot opening, and clamping the material bag (9) containing a cooking material at the material bag (9) clamping station; confining the material bag (9), such that the material bag (9) is kept in a clamped state to control the deformation thereof during the dispensing procedure; flipping and / or tipping the material bag (9), and when in a position near the cooking pot opening, dispensing the cooking material in the material bag (9) into the cooking pot; and once the cooking material has been dispensed, shifting the material bag (9) from the range of the cooking pot opening and releasing the clamping of the material bag (9). The cooking material dispensing system comprises a dispensing device capable of clamping, confining, and transferring the material bag (9) and flipping the opened material bag and / or tipping the cooking material into the cooking pot. The dispensing system and dispensing method take a material packaged in the material bag (9) and can accurately move the material bag (9) into the dispensing position, making the cooking process convenient, fast and simple, and the entire process will not be contaminated.

Owner:LIU XINYU

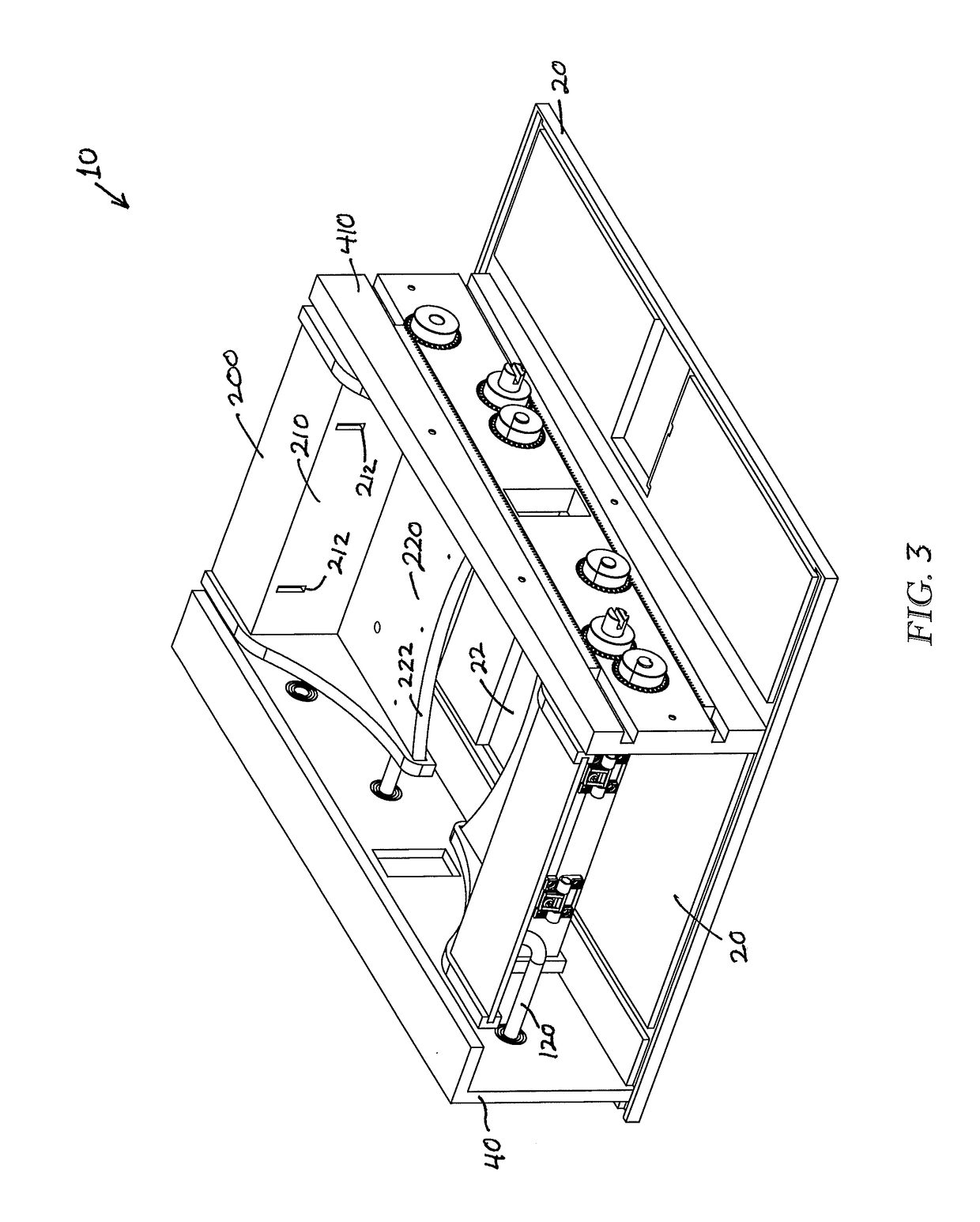

Bulk bag unloader with flow regulation

InactiveUS7475793B2Easy to adjustConsiderable accuracyFlexible bulk container emptying systemsLarge containersSystem requirementsMechanical engineering

A bulk bag unloader includes a frame, a bag support, a hopper beneath the bag support and an outlet chute beneath the hopper. The hopper and the outlet chute are mounted to the frame for movement substantially in unison relative to the frame. Two vibrators are mounted respectively on opposite sides of the hopper and synchronized to generate vibratory movement substantially along the axis of the outlet chute. Thus, the vibrators function to achieve an efficient and continuous discharge from the bulk bag and employ the outlet chute to regulate or stop the flow in accordance with system requirements.

Owner:WAHL RICHARD C

Liner connecting device and liner filling device

InactiveUS7634896B2Wrapping material feeding apparatusFlexible bulk container emptying systemsEngineeringContamination

A liner emptying device and a liner filling device as well as methods using them for contamination-free filling and emptying of a liner. This contamination-free filling and emptying prevents any danger to the health of the people working with the packaged substances. Both the liner emptying device and the liner filling device are connected to the liner via a fastening device and the residual films sealing off the device can be removed via an access port, whereby the liner can be filled or emptied without contaminating the surroundings.

Owner:HECHT ANLAGENBAU GMBH

Container support

A container (10) having a plurality of panels (12–18) joined together to form a sleeve (64). The panels (12–18) each have an end edge that cooperate to define an imaginary plane (P) at one end of the sleeve (64). The container (10) further has an end panel (20,22) connected to the panels (12–18) at the one end of the sleeve (64). The end panel (20,22) has at least one portion extending beyond the imaginary plane (P). The supporting box (100) is provided to support the container (10). A hanger system (150) is provided and is attached to the box (100). The hanger system (150) supports an upper portion of the container (10) within the box (100). The container (10) is also provided with a port closure (300) that provides both a sterile and gas permeable barrier.

Owner:BAXALTA GMBH

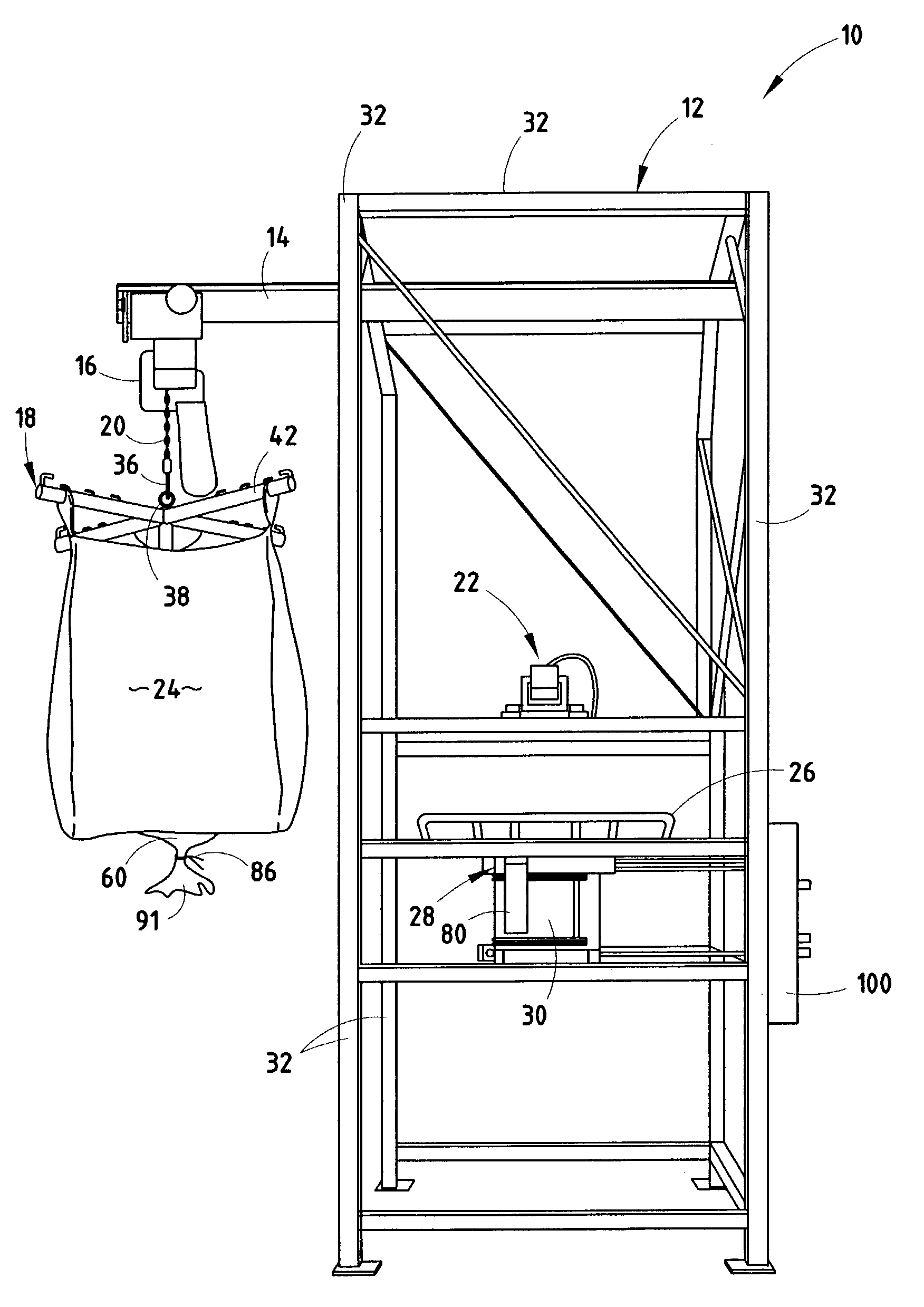

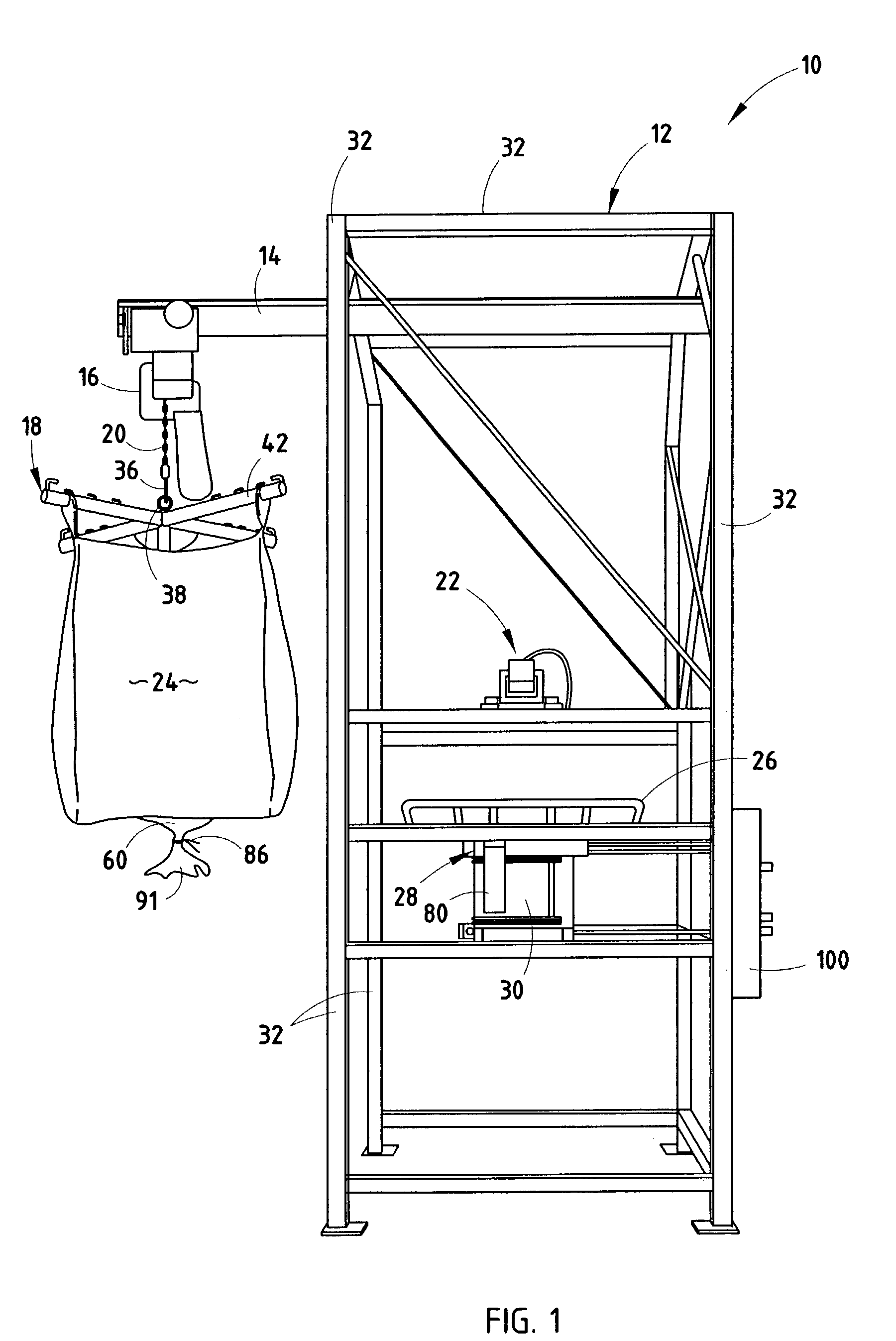

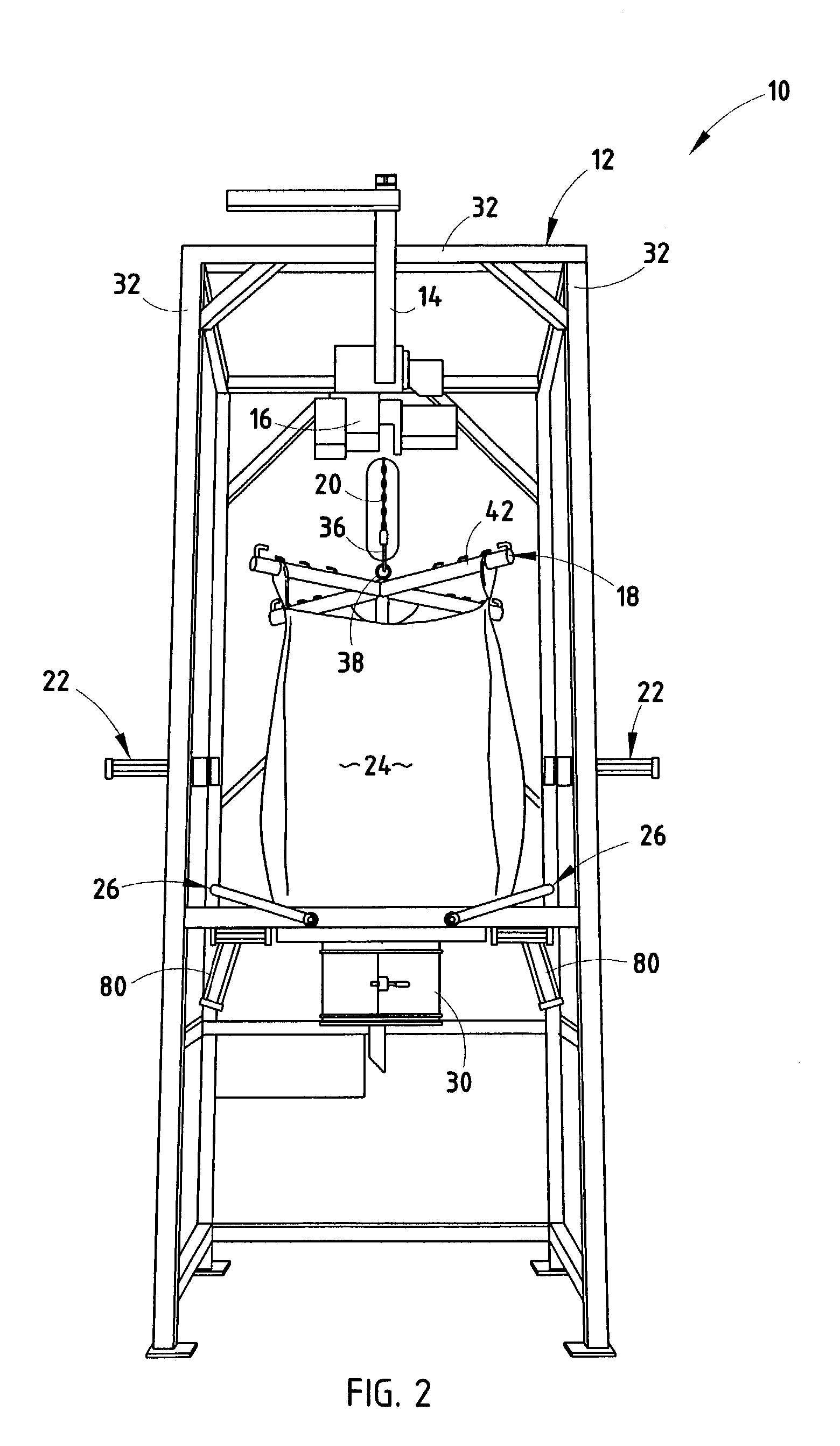

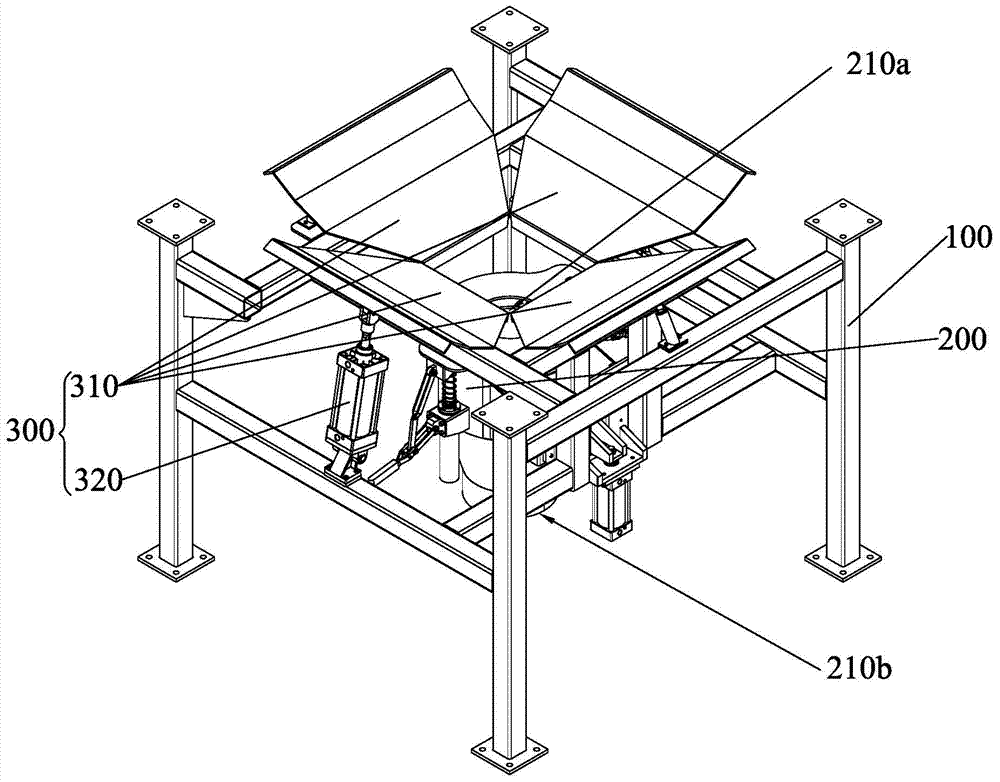

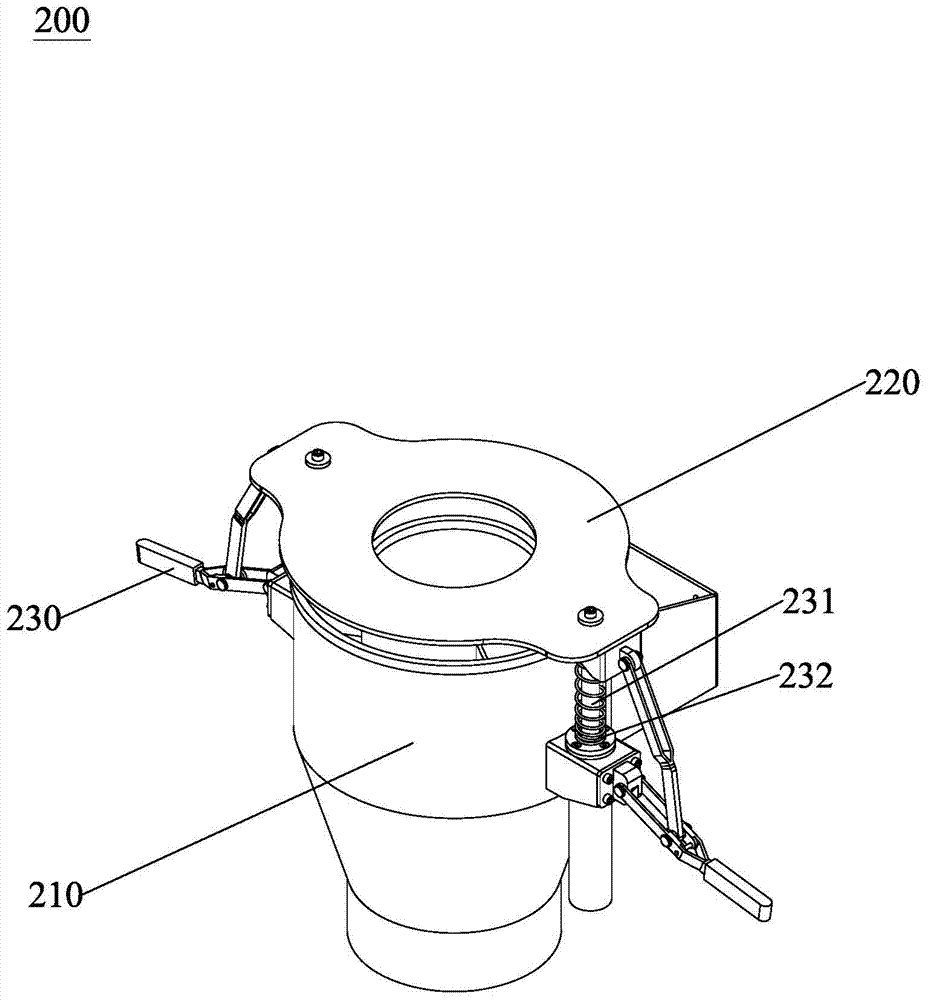

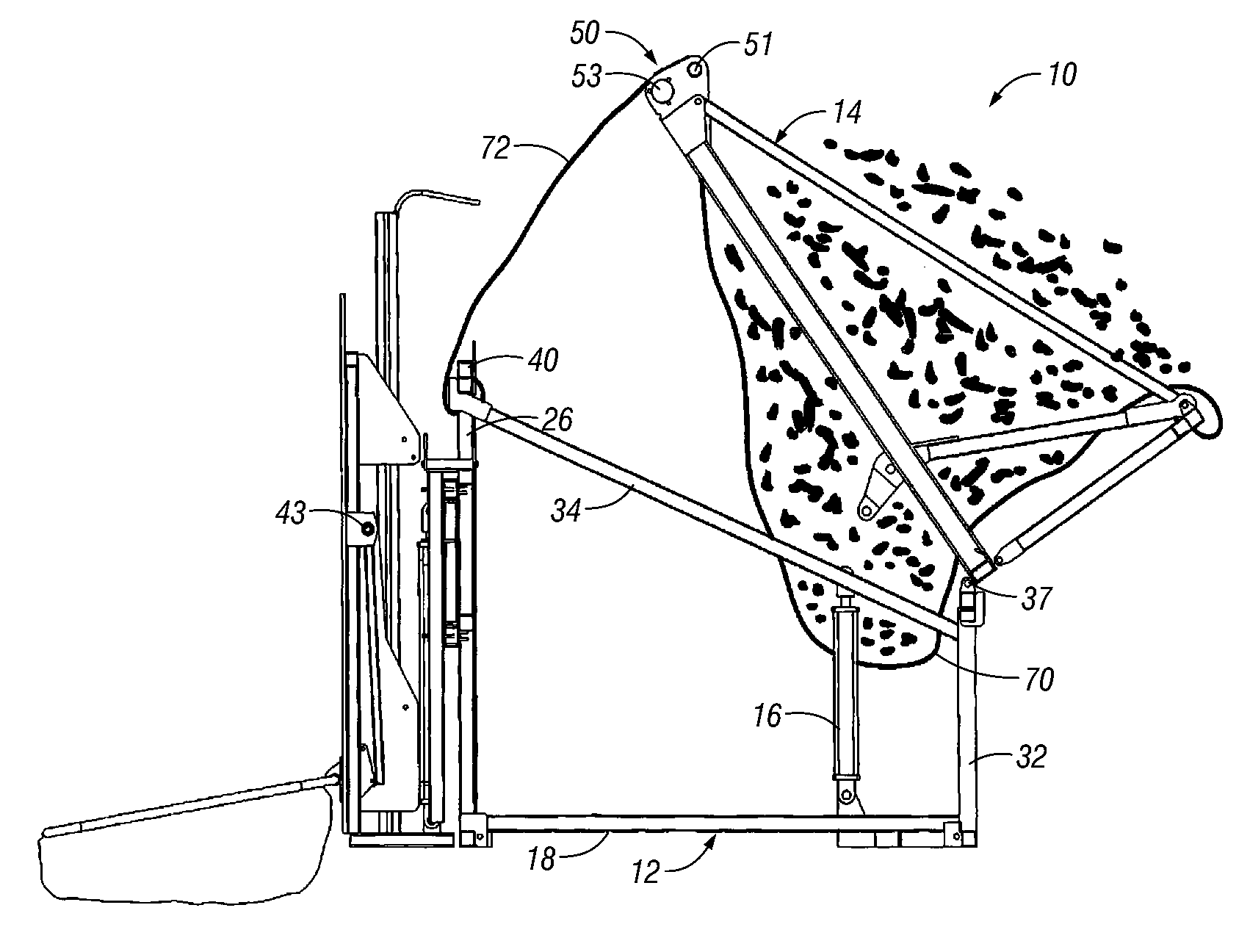

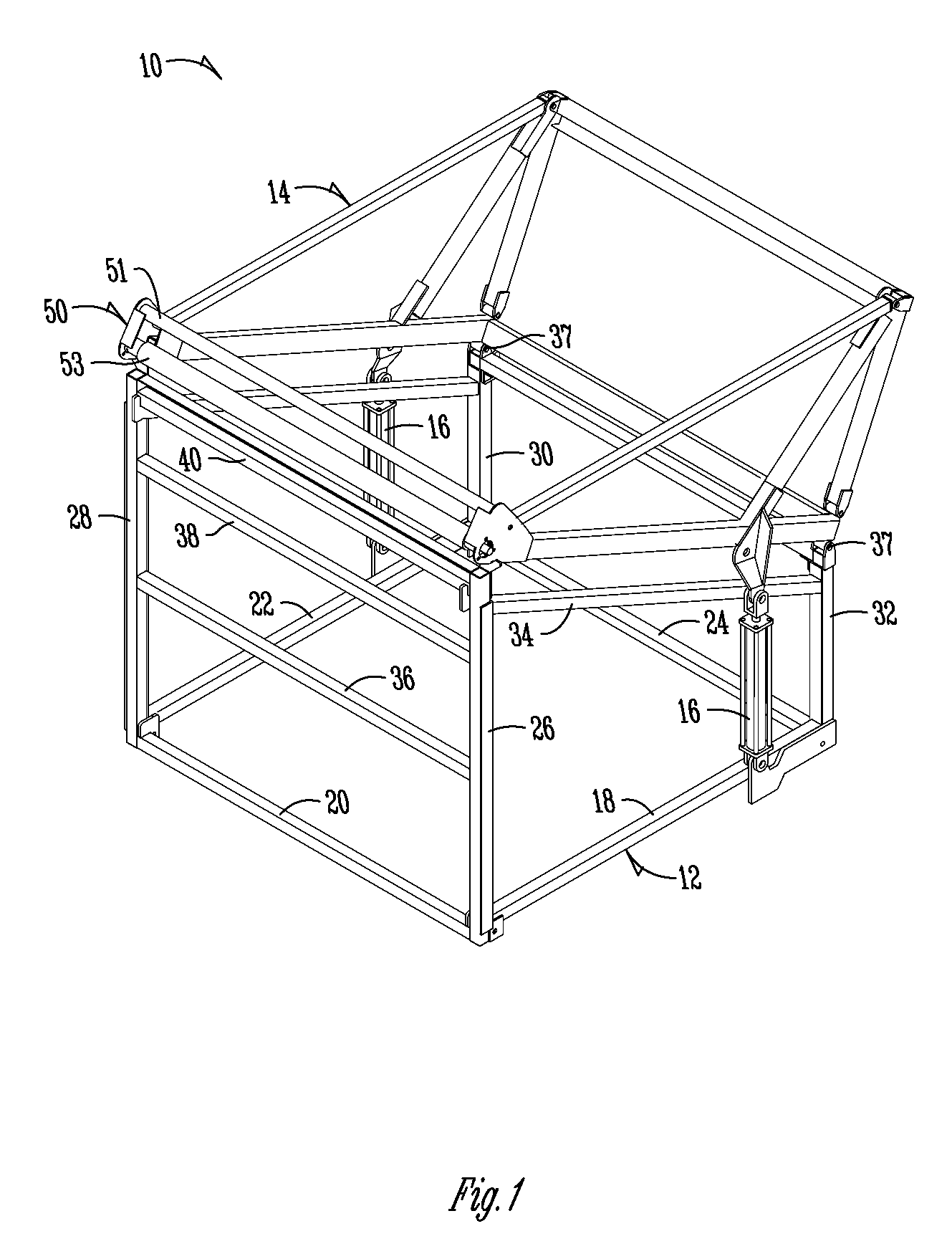

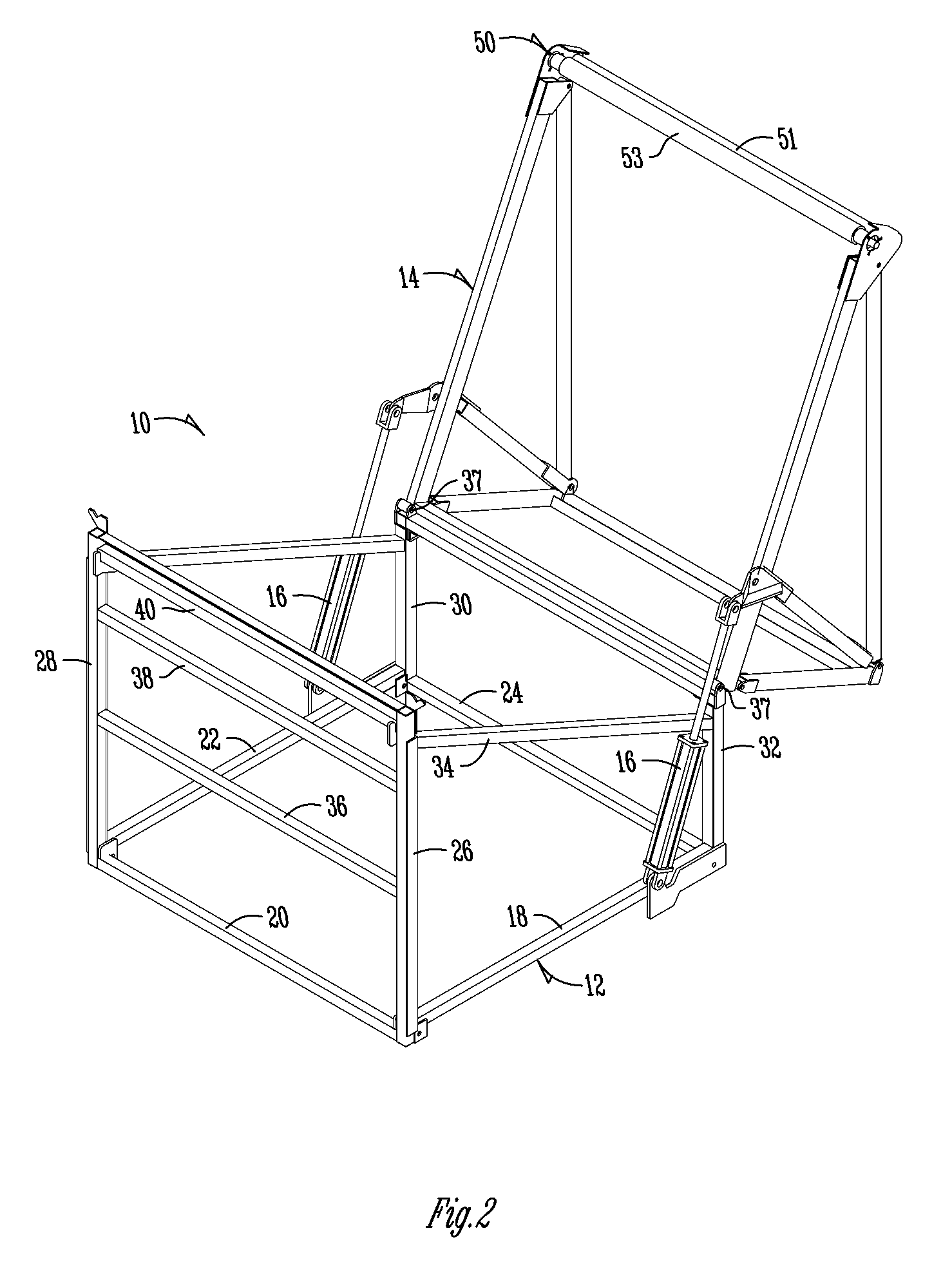

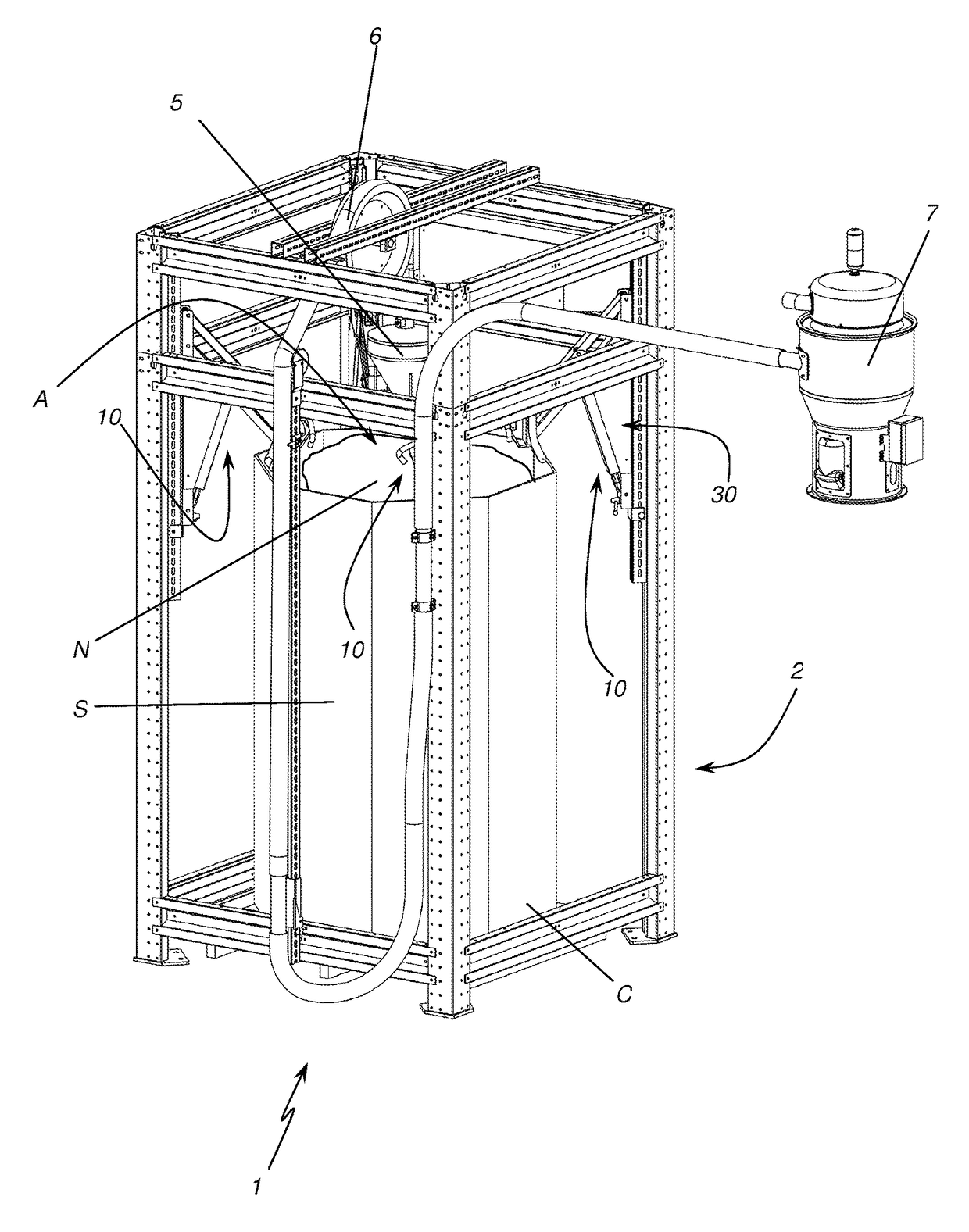

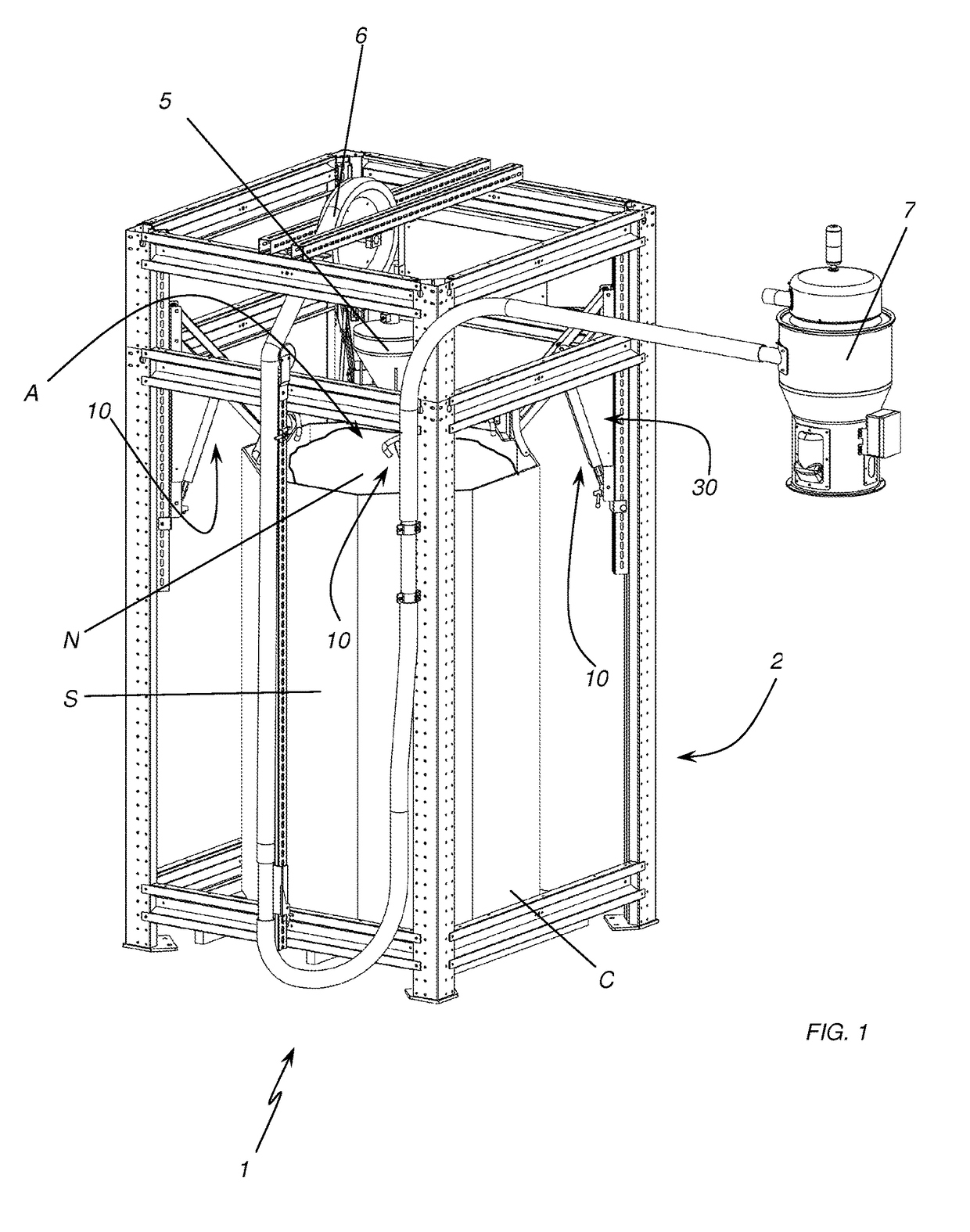

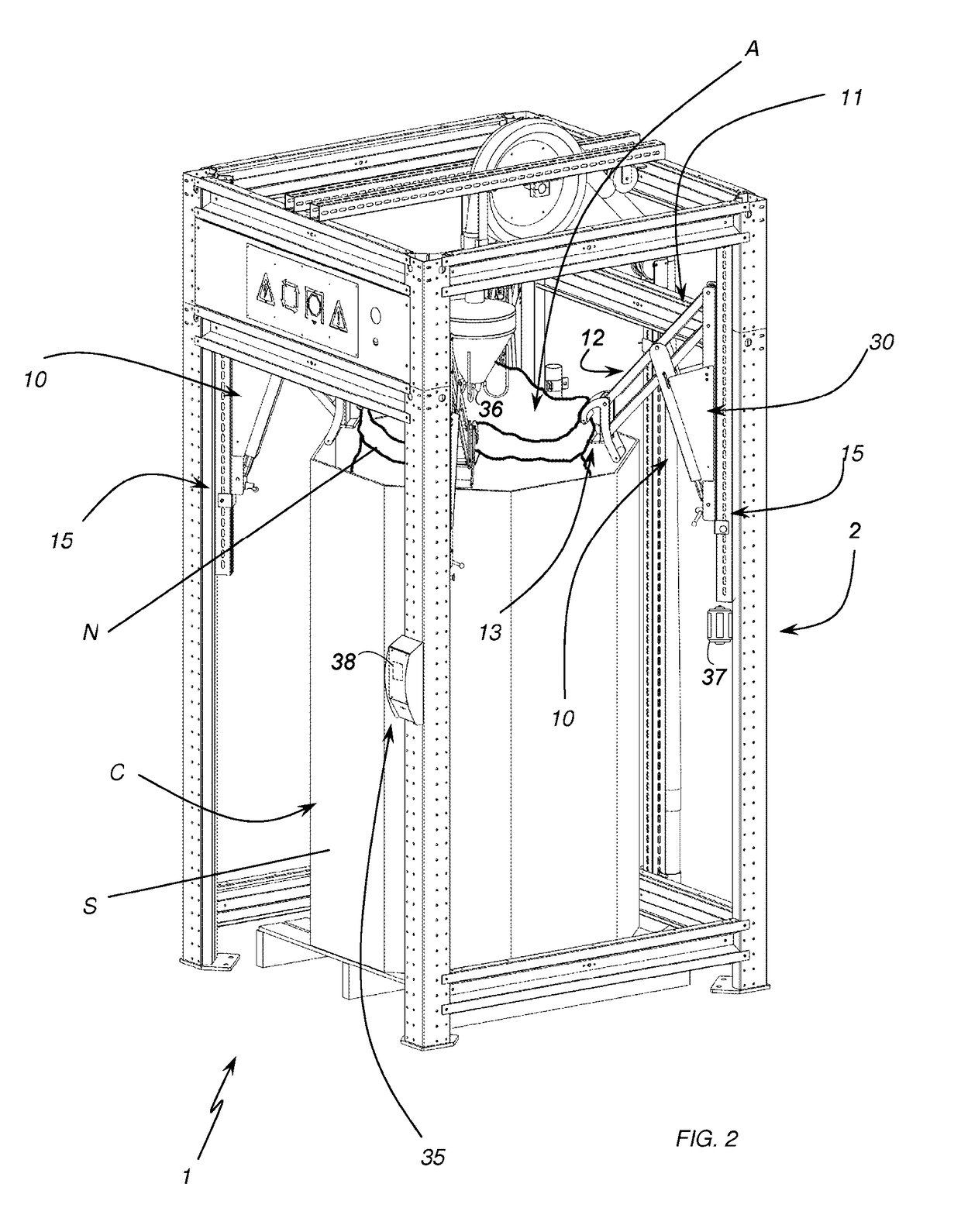

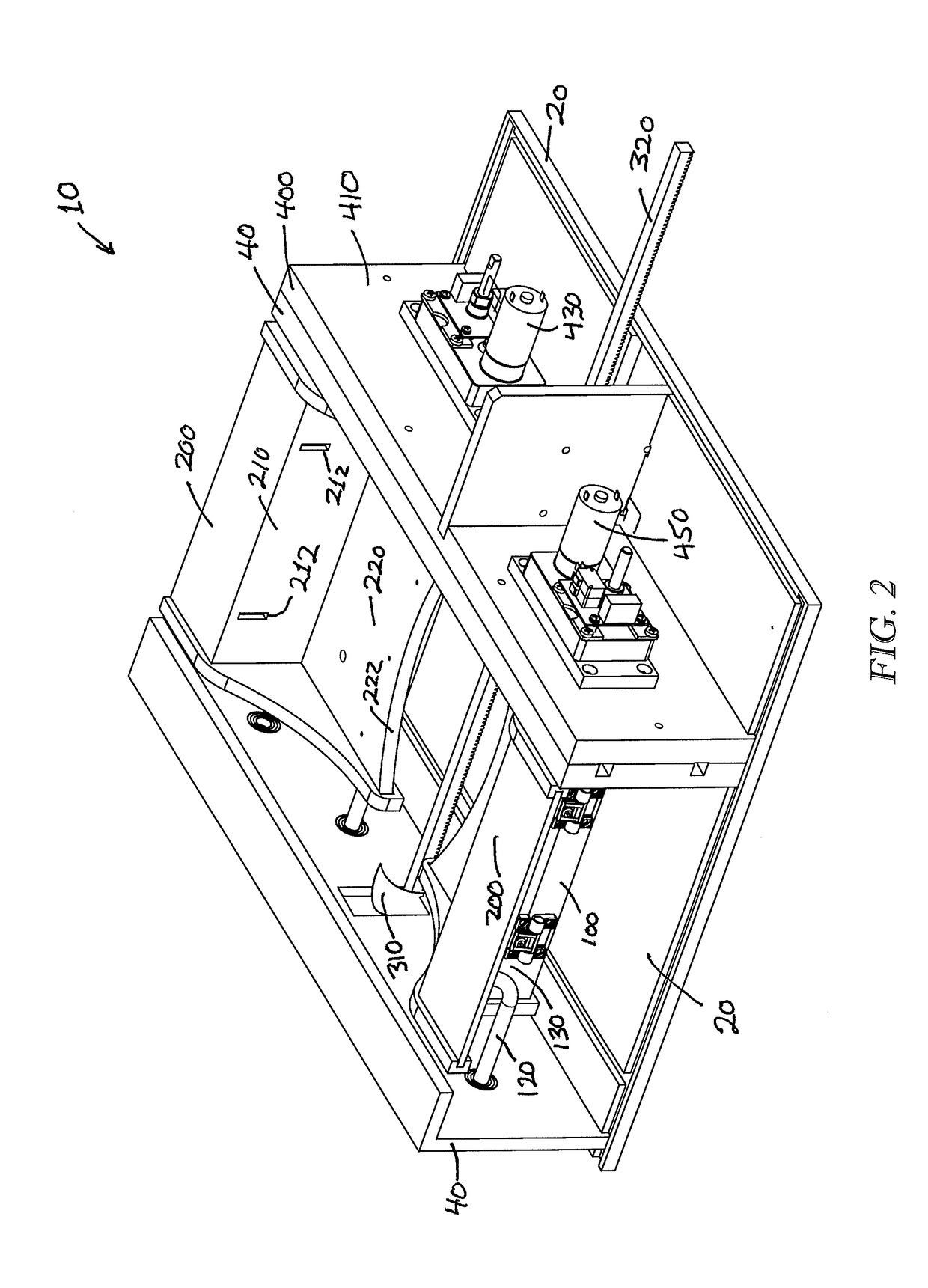

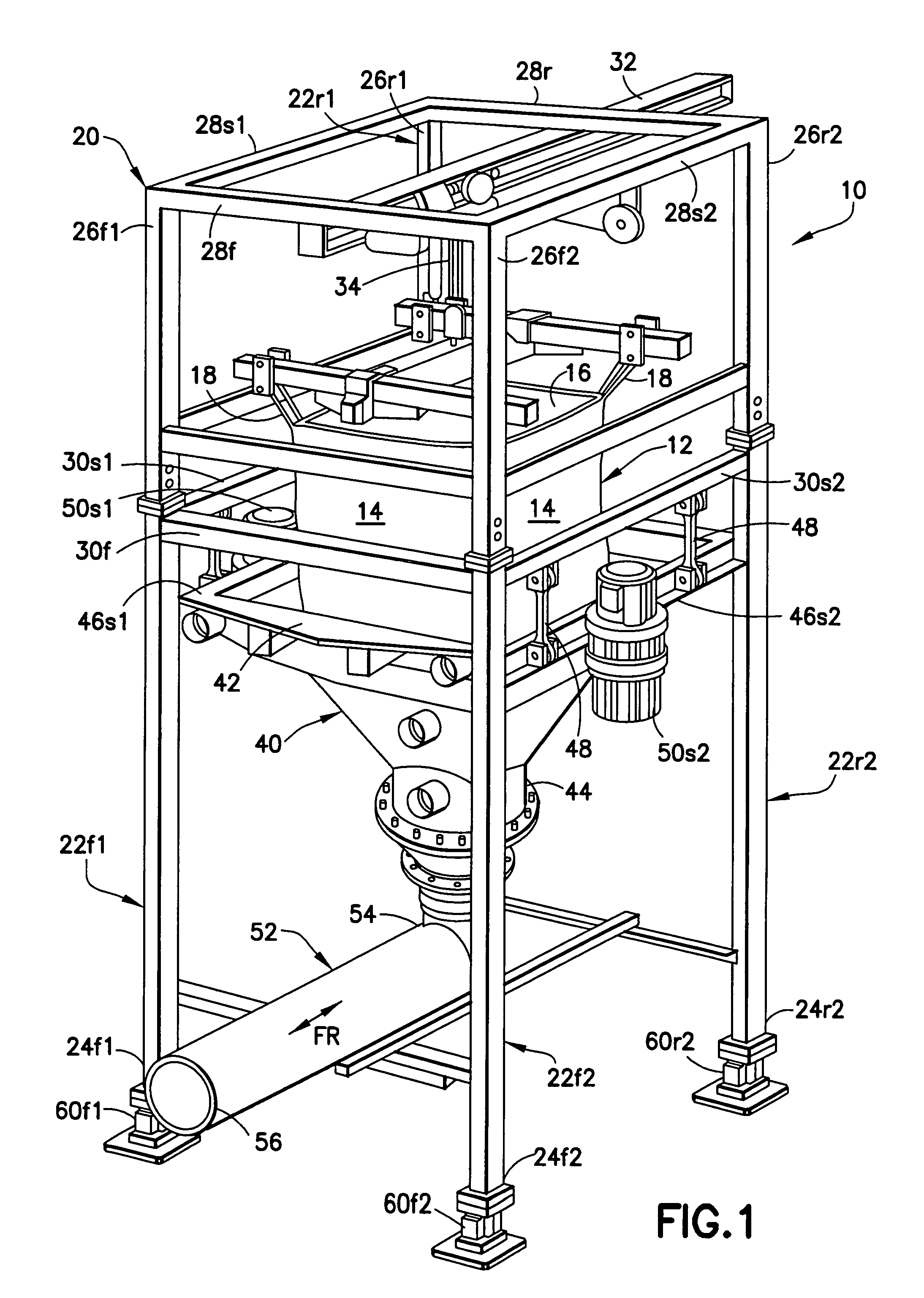

Bulk bag discharge assembly including a conditioning assembly

ActiveUS9387950B2Improve translationShaking/oscillating/vibrating mixersFlexible bulk container emptying systemsEngineeringMechanical engineering

A bulk bag discharge and hoist assembly comprising a main frame assembly, a hoist assembly and a bag conditioning assembly. The main frame assembly includes a bulk bag receiving region. The bag conditioning assembly having a first conditioner frame and a powered cylinder. The powered cylinder is structurally configured to extend the first conditioner frame from outside of the bulk bag receiving region into the bulk bag receiving region, whereupon entry into the bulk bag receiving region, the distal end of the first conditioner frame is directed at least partially in an upward direction.

Owner:MATERIAL TRANSFER & STORAGE

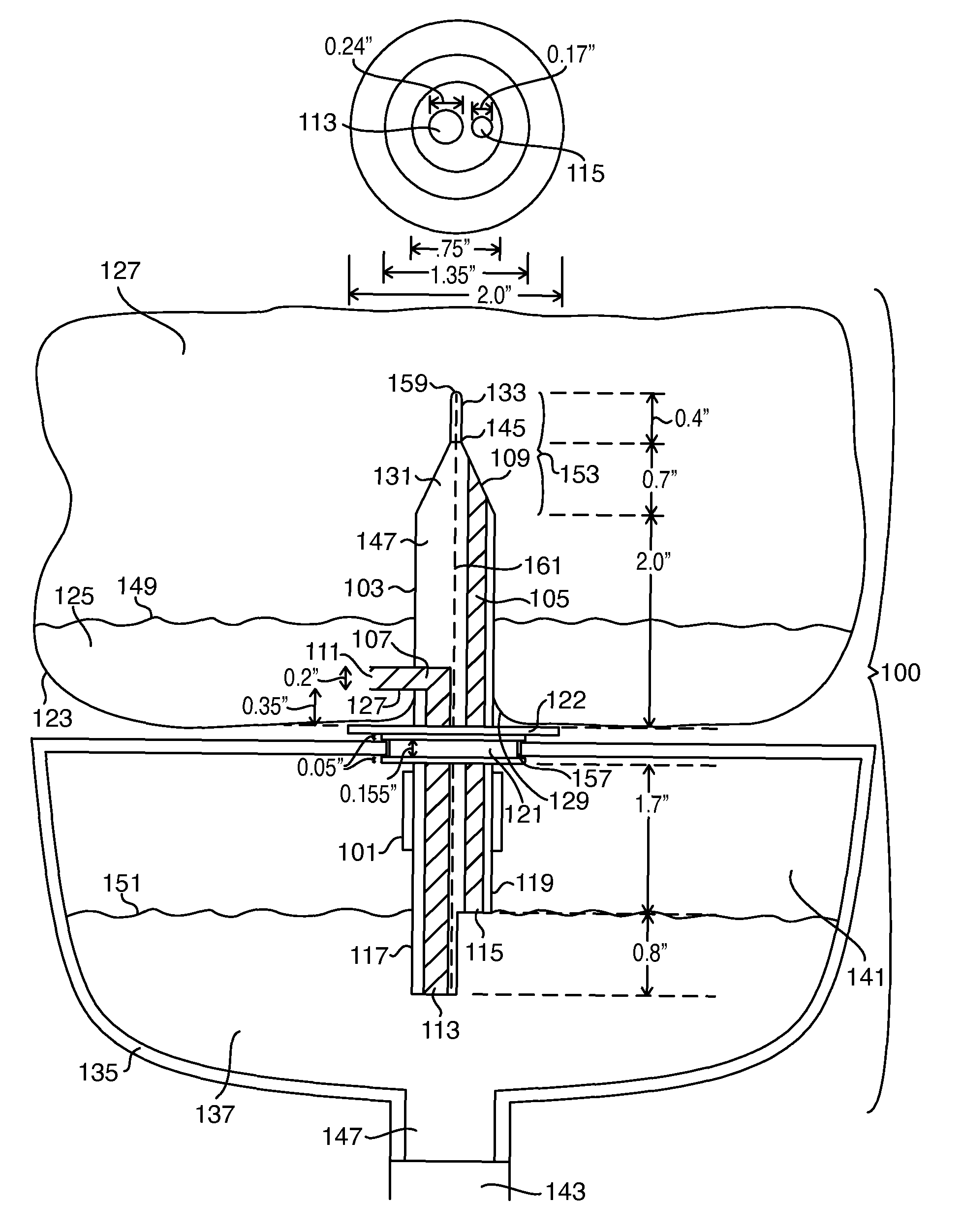

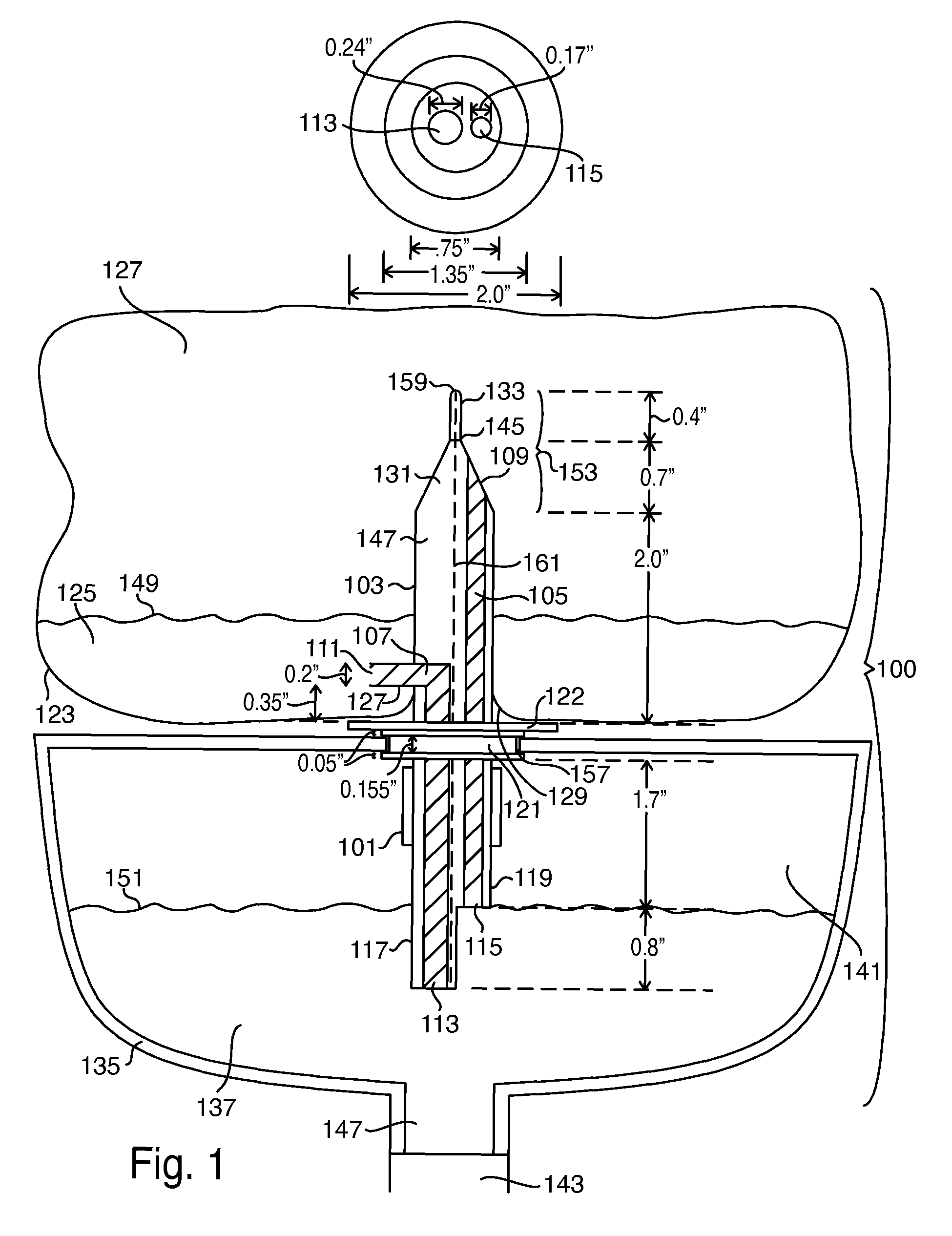

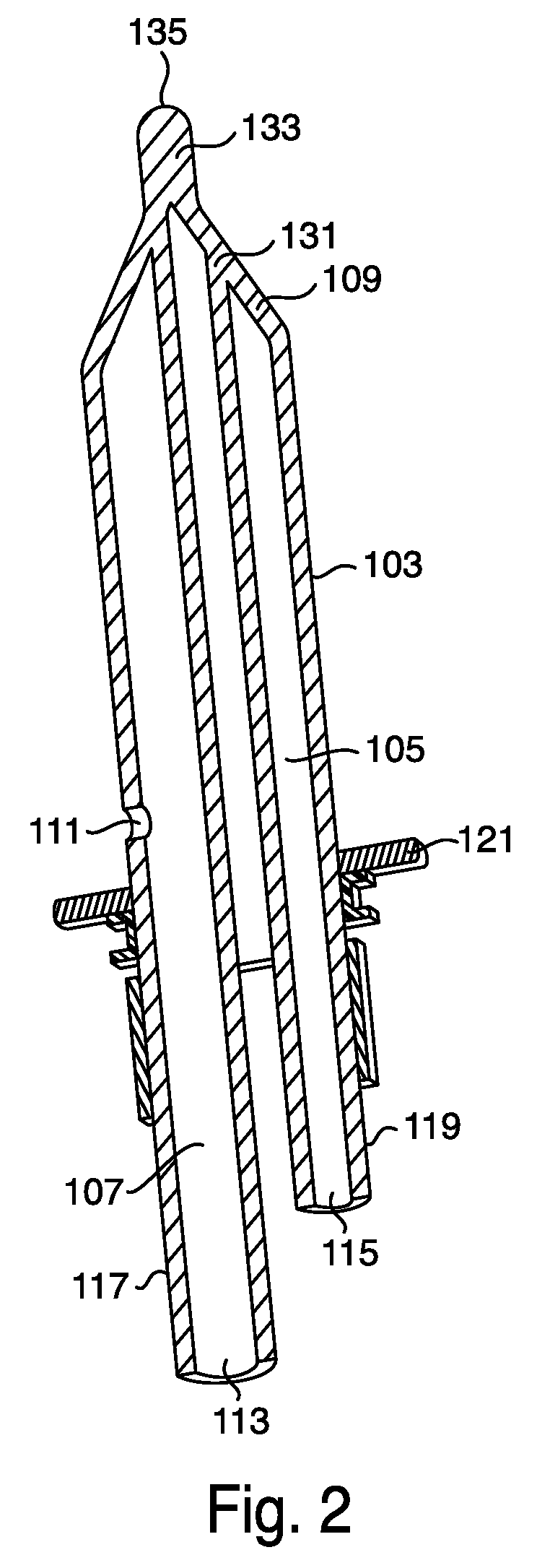

Multiple channel single spike for a liquid dispensing system

A spike for dispensing fluids from a flexible bag, wherein the spike includes multiple fluid channels which transfer liquids from the bag to an enclosed dispensing chamber and air from the enclosed chamber to the bag to permit and control fluid flow within the system.

Owner:INT PACKAGING INNOVATIONS

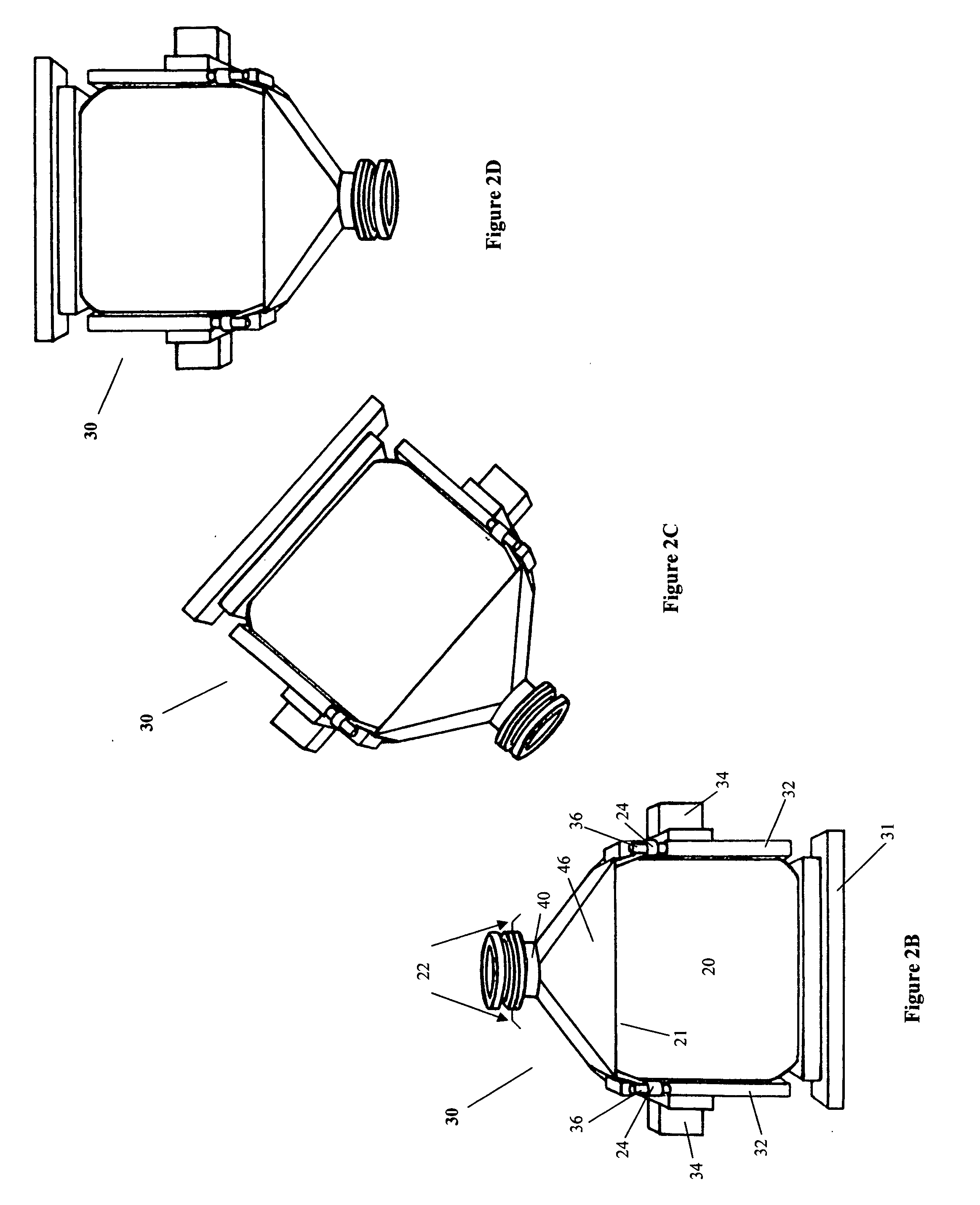

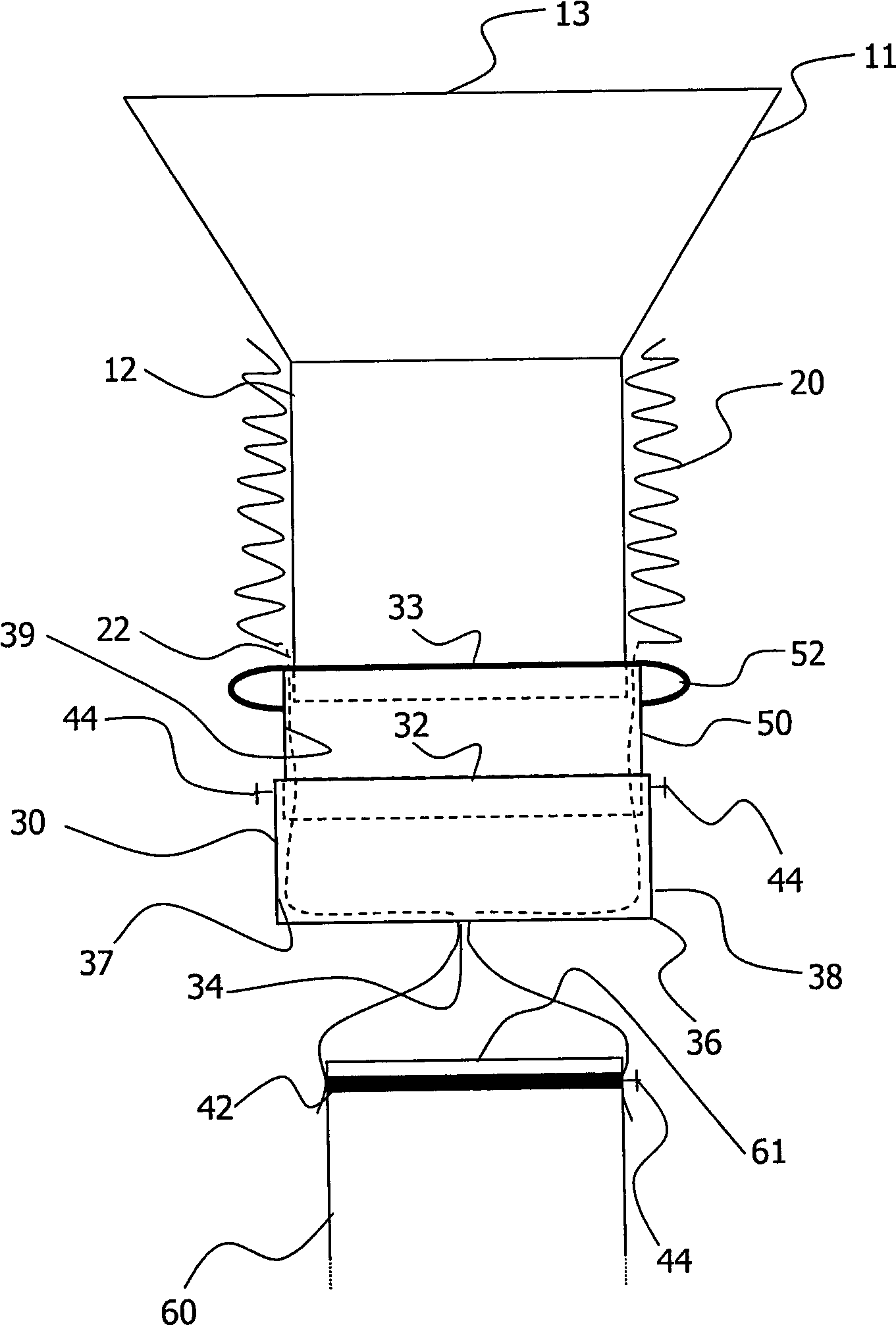

Ingredient distributing element on a container for flowable or dumpable bulk goods

InactiveCN101500895AIncreased riskShorten the timeFlexible bulk container emptying systemsLoading/unloadingElastomerAdditive ingredient

The invention relates to a metering element (30) on a container (10, 11) for flowable or bulk goods having an outlet nozzle (12) which protrudes into the metering element (30), comprising an inlet opening (32) on that side which faces the container (10, 11), a clamping profile (42) and / or a quick-action tensioning apparatus (46) for the releasable connection of the outlet nozzle (12) and the metering element (30), a slot-shaped outlet opening (34) in that side which faces away from the container (10, 11), an annular gap (22) between the outlet nozzle (12) and the inlet opening (32), a wall (36) which extends between the inlet opening (32) and the outlet opening (34) and has an inner side (37) and an outer side (38), and a film-shaped material (20) which is individual or is stored in the region of the outlet nozzle (12), in particular a plastic or elastomer film tube or film section. For uncontaminated use and simple cleaning, it is proposed that the inlet opening (32), the inner side (37) of the wall (36) and the slot-shaped outlet opening (34) are covered with the film-shaped material (20). In addition, a method for discharging batch or bulk goods is proposed, wherein a tubular film material (20) is fed into a metering element (30) via an annular gap (22), is then guided through the metering element (30) and is finally guided out of the metering element (30) via a slot-shaped outlet opening (34).

Owner:METTLER TOLEDO INC

System and method for handling containers of bulk particulate materials

InactiveUS7063493B2Flexible bulk container emptying systemsLifting devicesMechanical engineeringParticulate material

Owner:YOUNG INDS

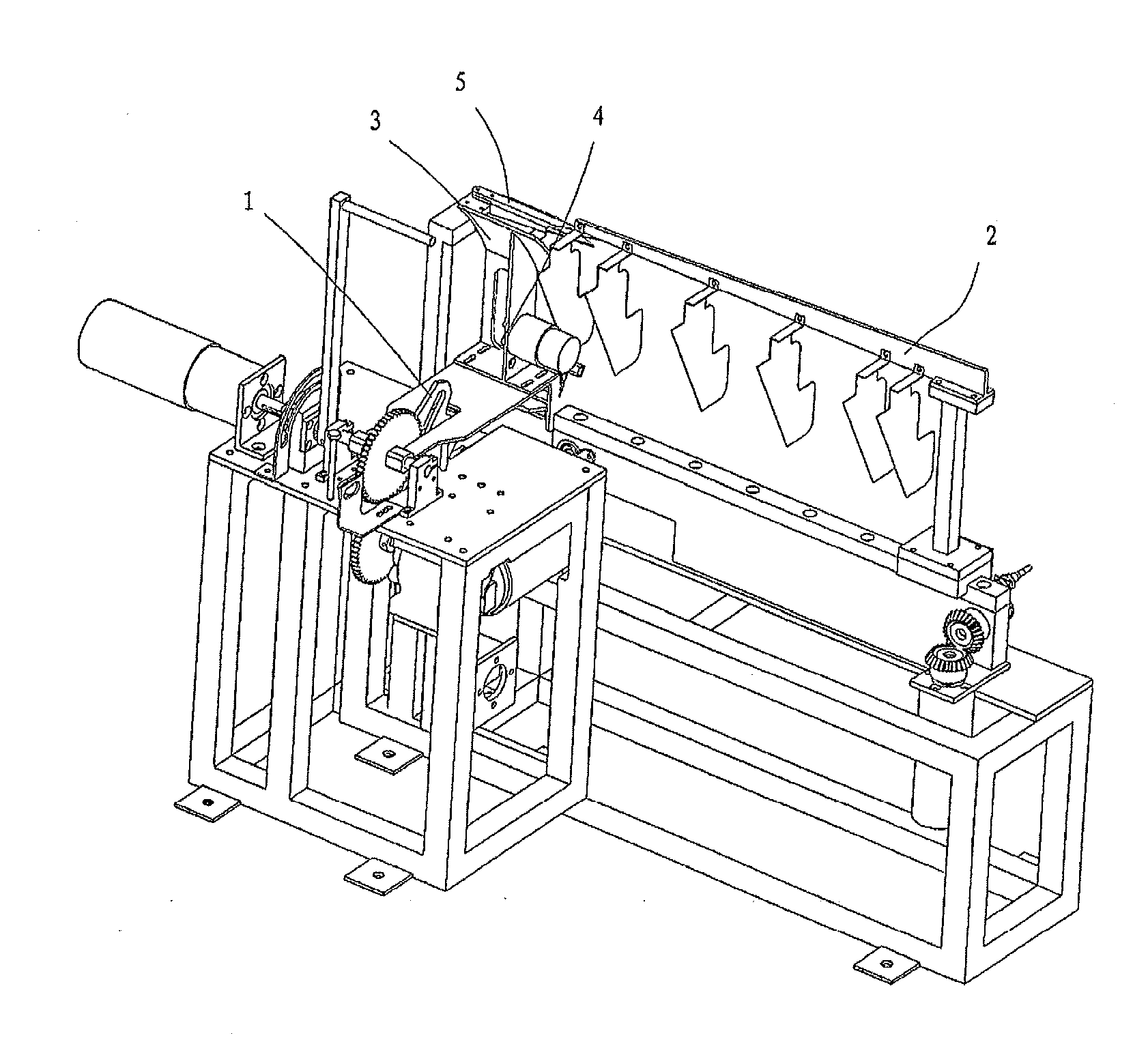

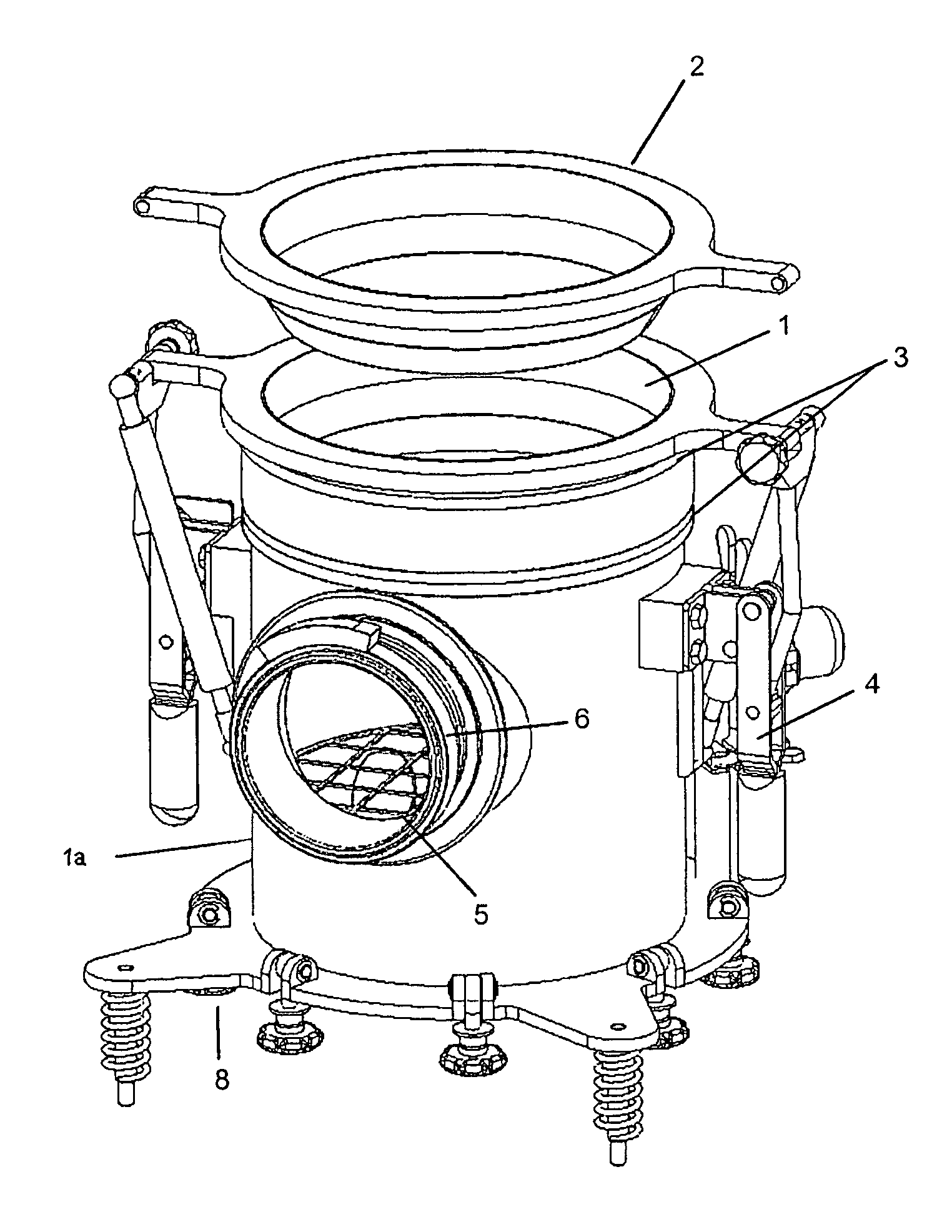

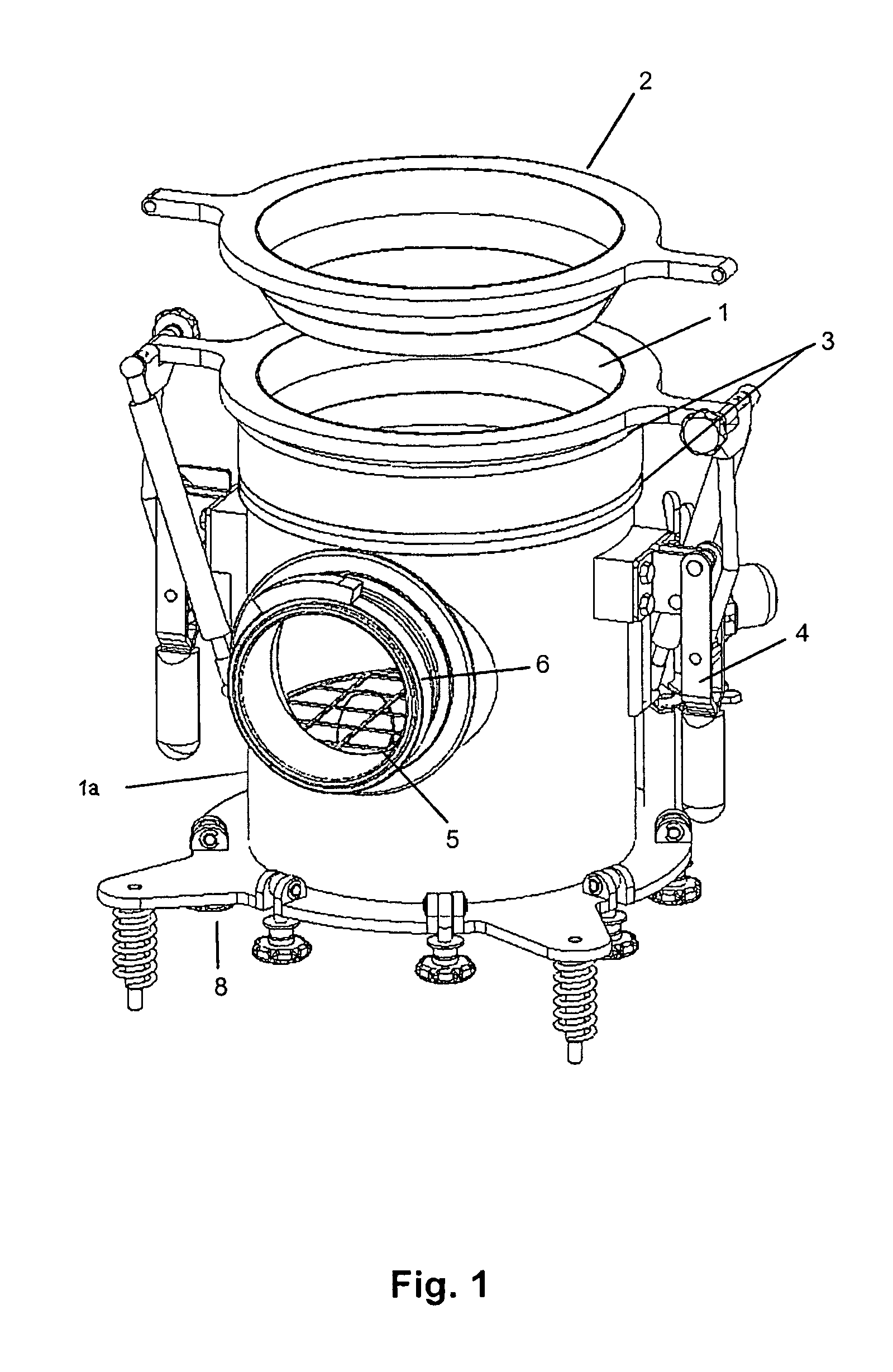

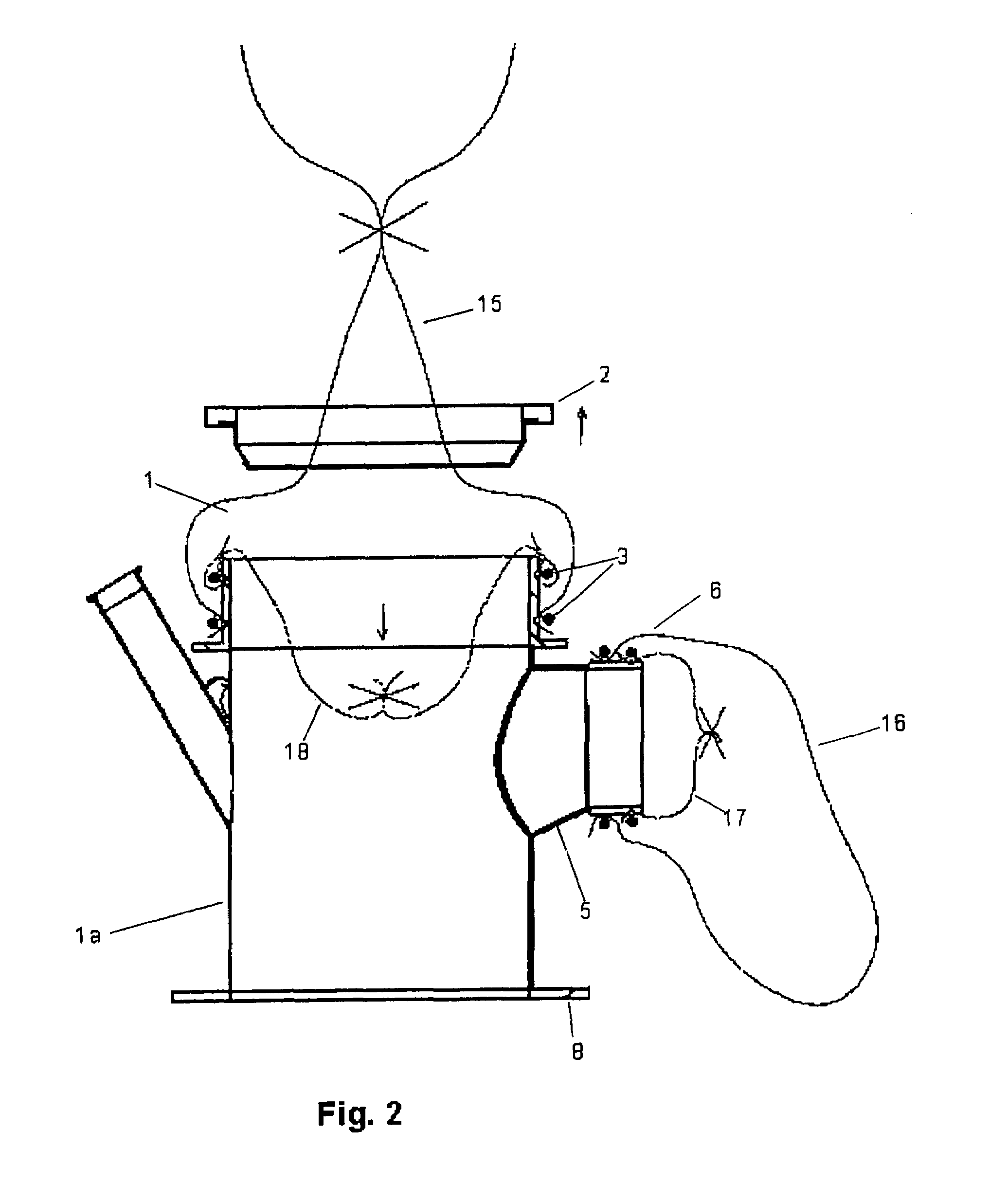

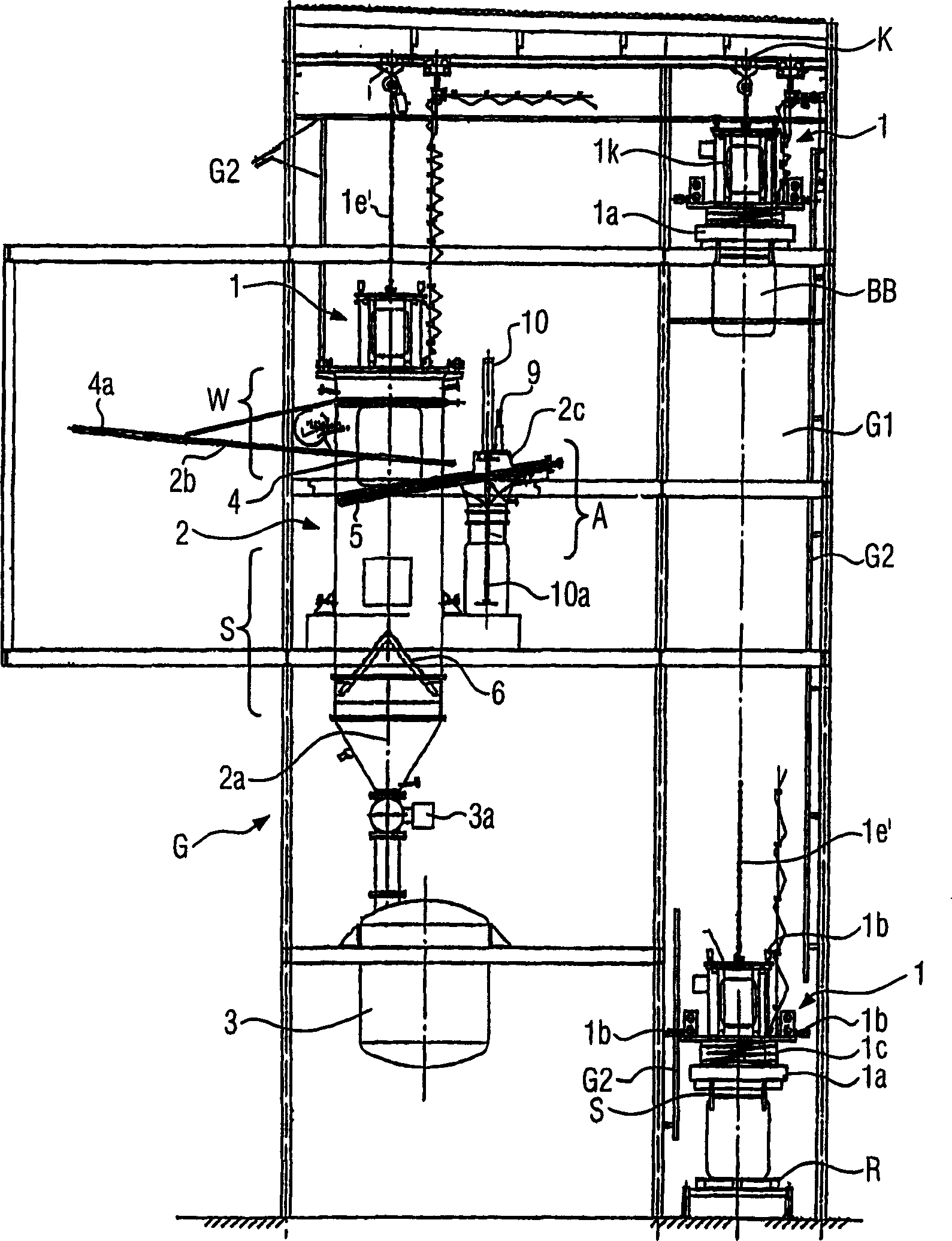

Method and arrangement for emptying big bags

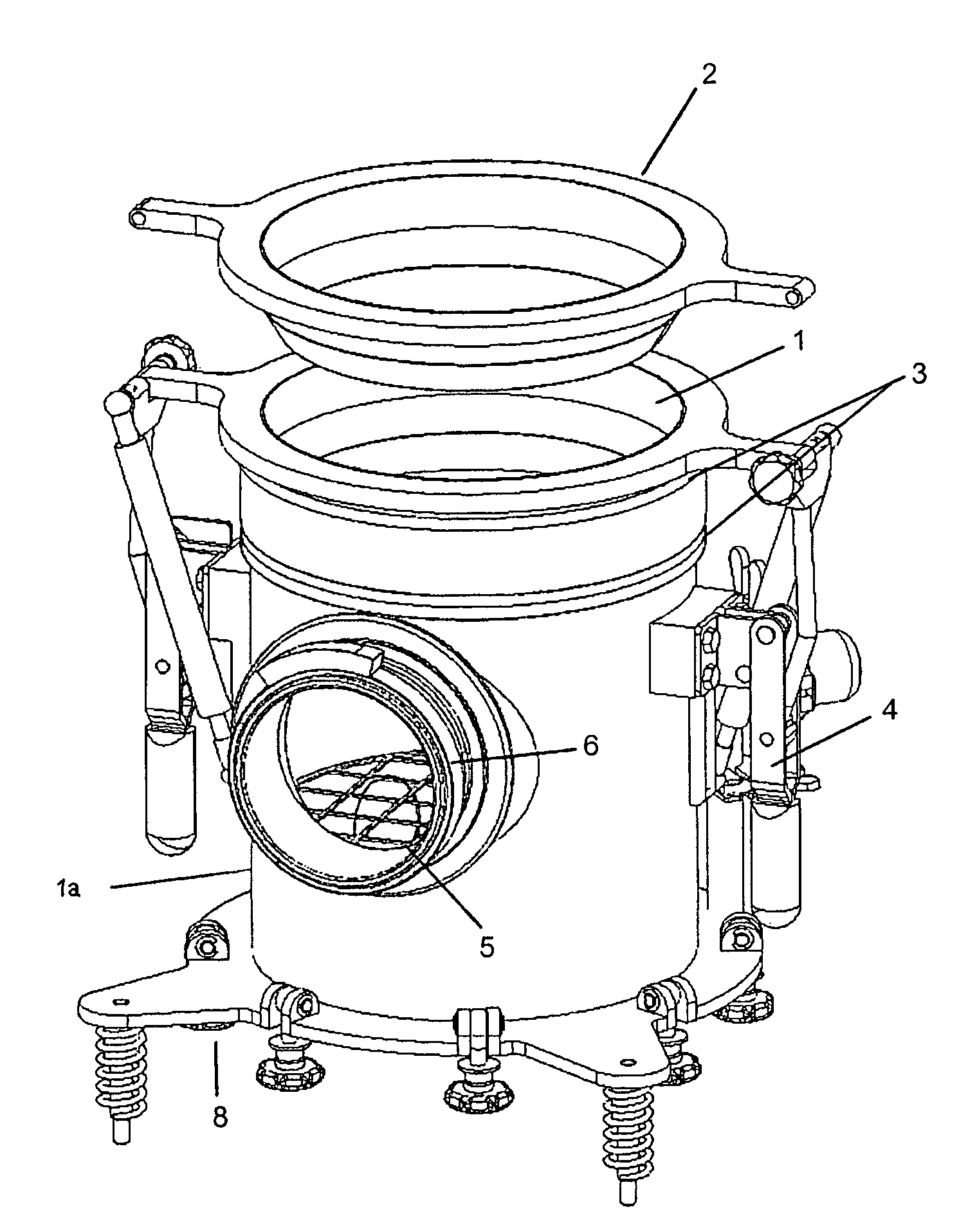

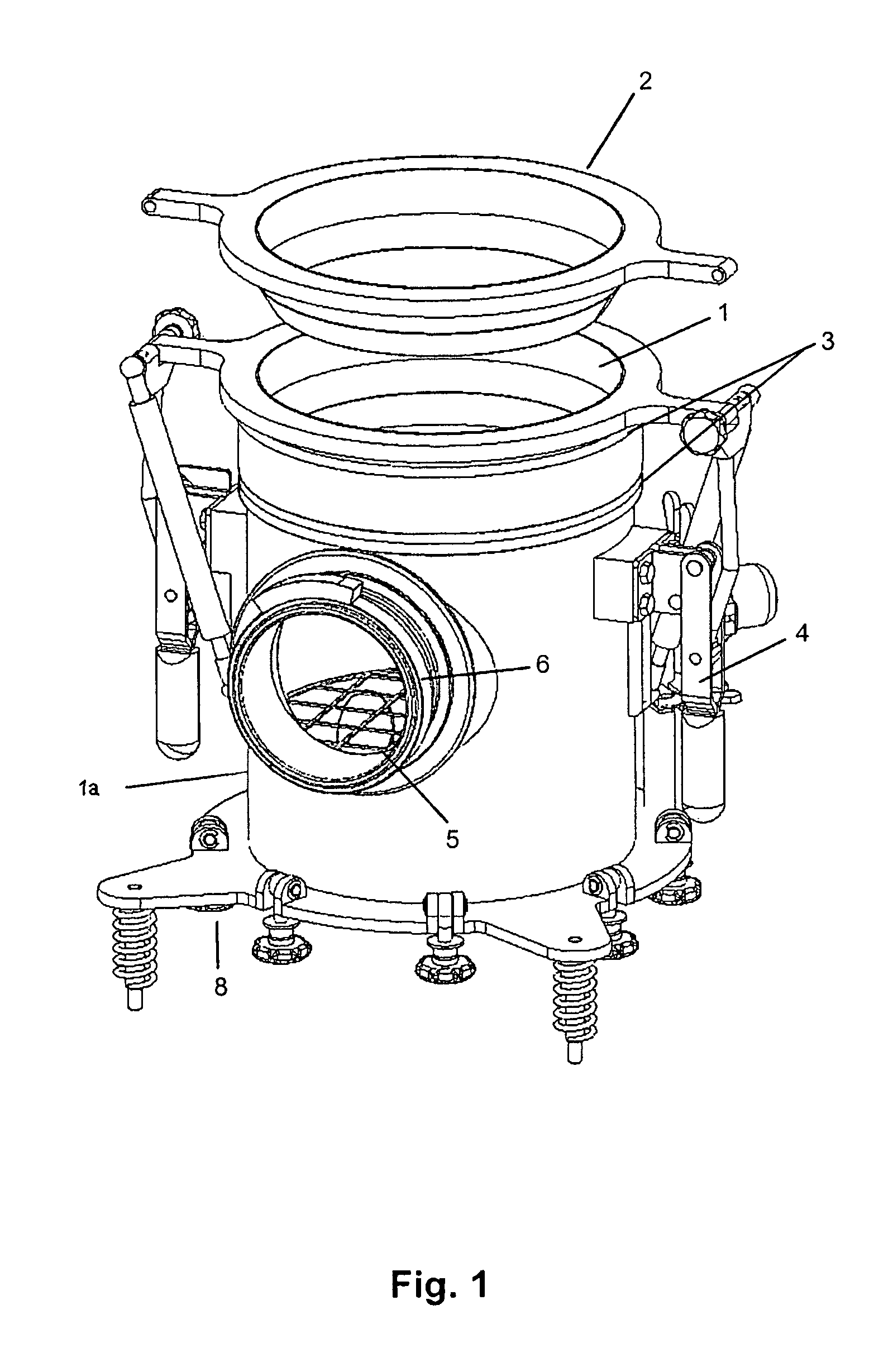

InactiveCN1863706ASimple structureAntibacterial agentsFlexible bulk container emptying systemsEngineeringPlastic bag

A method and an arrangement are provided for emptying a Big Bag or similar transport container which is filled with pourable, especially pulverized goods which are not to come into contact with their surroundings, wherein the Big Bag is inserted in a sluice means (2) which is closed off from the surroundings, with simultaneous sealing of the sluice means, which communicates with a processing container (3) for receiving the contents of the Big Bag, whereupon the Big Bag is cut open inside the sluice means by a cutting means (6) provided therein. The empty Big Bag is compressed in a removal zone (A) inside the sluice means (2) and removed into a plastic sack (8) attached to the sluice means (2).

Owner:CIBA SPECIALTY CHEM HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com