Flexible silo apparatus having a top removable valve or flow control device

a flexible silo and valve technology, applied in the field of flexible silo or bulk bag apparatus, can solve the problems of unreliable product flow from such containers, vibration can contribute to unreliable or no-flow conditions, and blended products become unblended

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066]A detailed description of the invention is provided herein. It is to be understood, however, that the present invention may be embodied in various forms. Therefore, specific details disclosed herein are not to be interpreted as limiting, but rather as a basis for the claims and as a representative basis for teaching one skilled in the art to employ the present invention in virtually any appropriately detailed system, structure or manner.

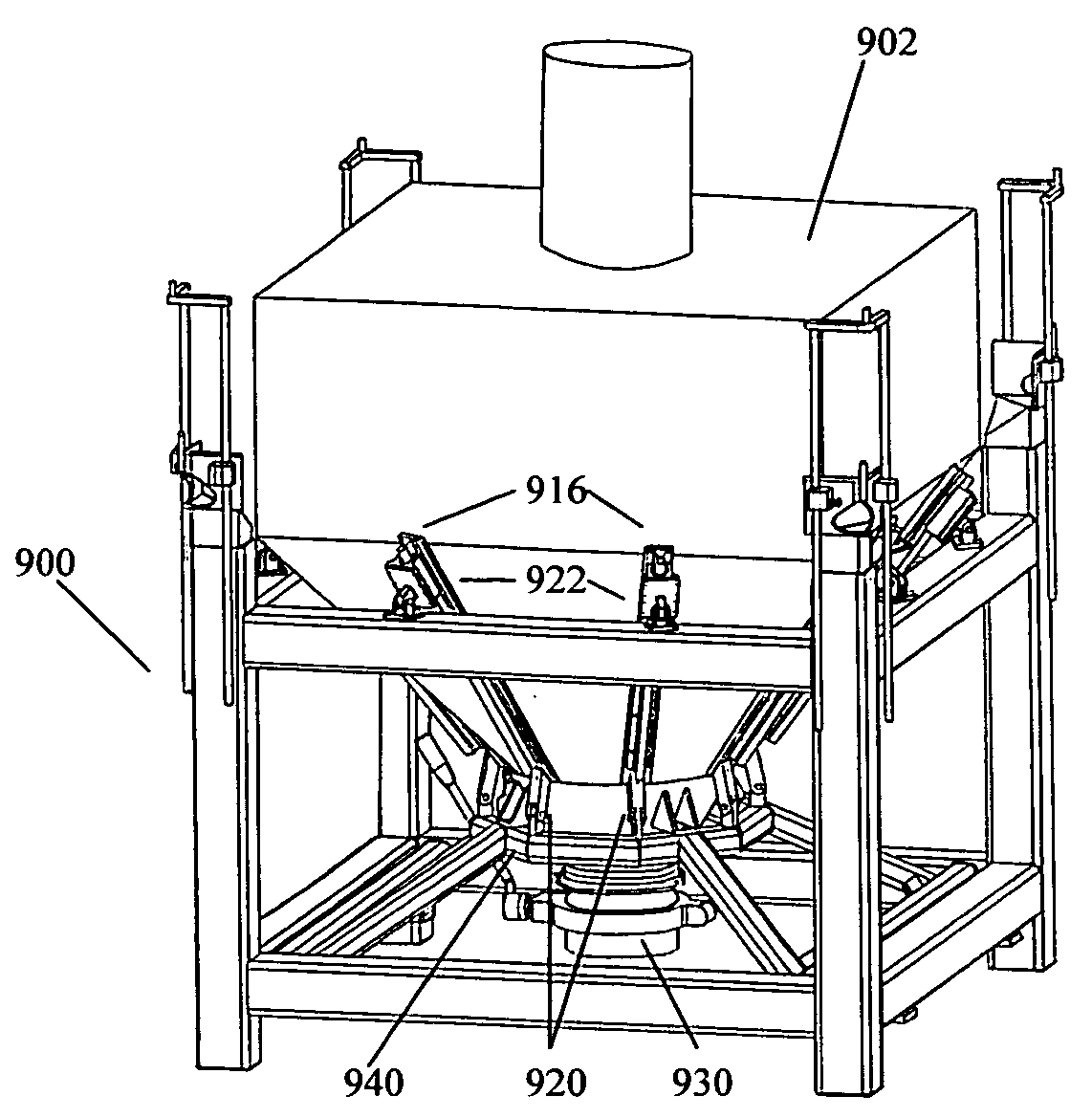

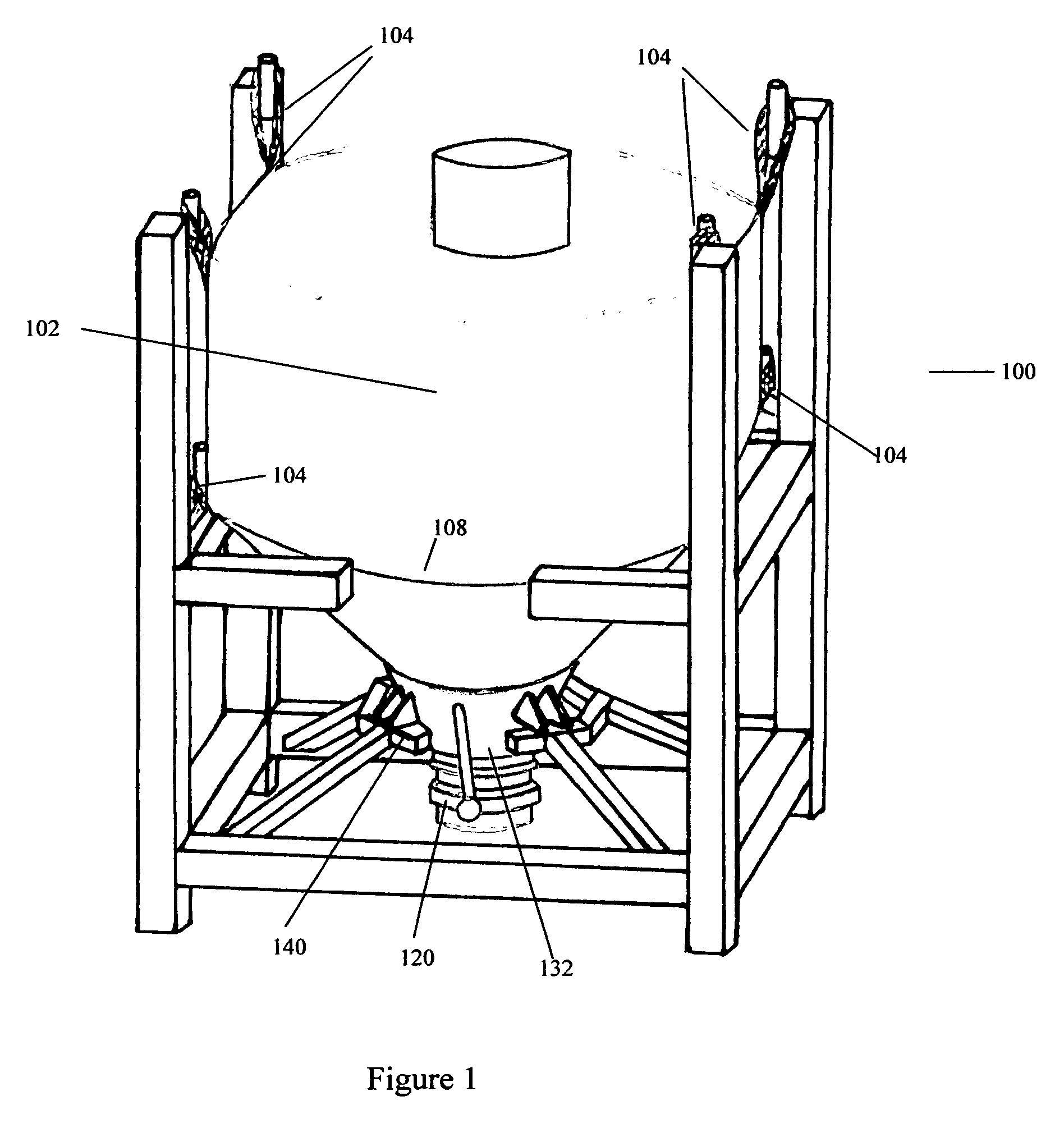

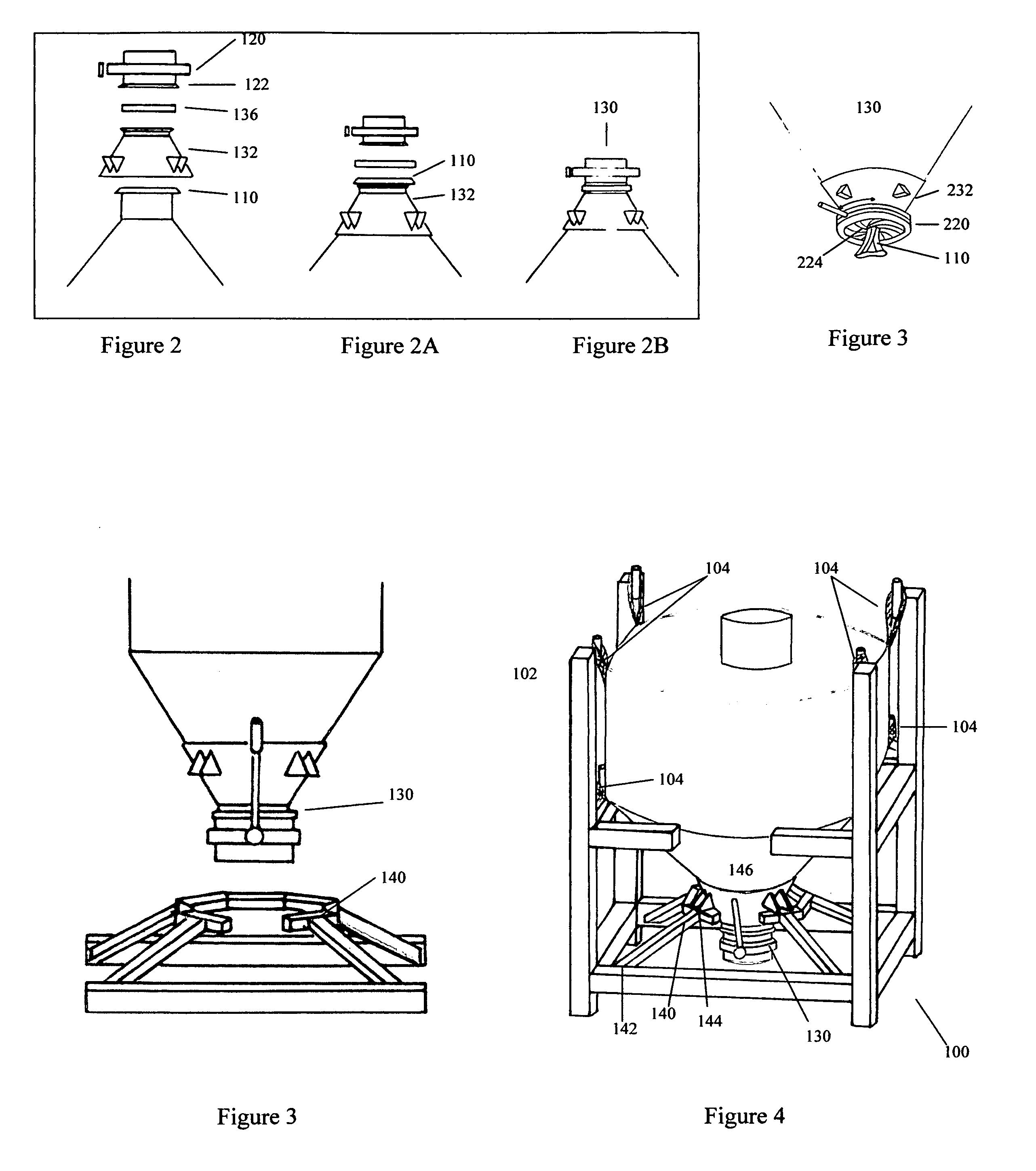

[0067]Turning first to FIG. 1, a preferred embodiment of the invention is shown having a support structure 100 constructed of a plurality of members to support a flexible silo. The length, height and width of the support structure 100 is in proportion to the dimensions of the flexible silo 102 that is supported upon the structure by connectors 104 located on flexible silo 102. Connectors 102 are typically recognized as, yet not limited to, loops or sleeves by one skilled in the art. For illustrative purposes, this detailed description will show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com