Patents

Literature

41 results about "Bulk material handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bulk material handling is an engineering field that is centered on the design of equipment used for the handling of dry materials. Bulk materials are those dry materials which are powdery, granular or lumpy in nature, and are stored in heaps. Examples of bulk materials are minerals, ores, coal, cereals, woodchips, sand, gravel, clay, cement, ash, salt, chemicals, grain, sugar, flour and stone in loose bulk form. It can also relate to the handling of mixed wastes. Bulk material handling is an essential part of all industries that process bulk ingredients, including: food, beverage, confectionery, pet food, animal feed, tobacco, chemical, agricultural, polymer, plastic, rubber, ceramic, electronics, metals, minerals, paint, paper, textiles and more.

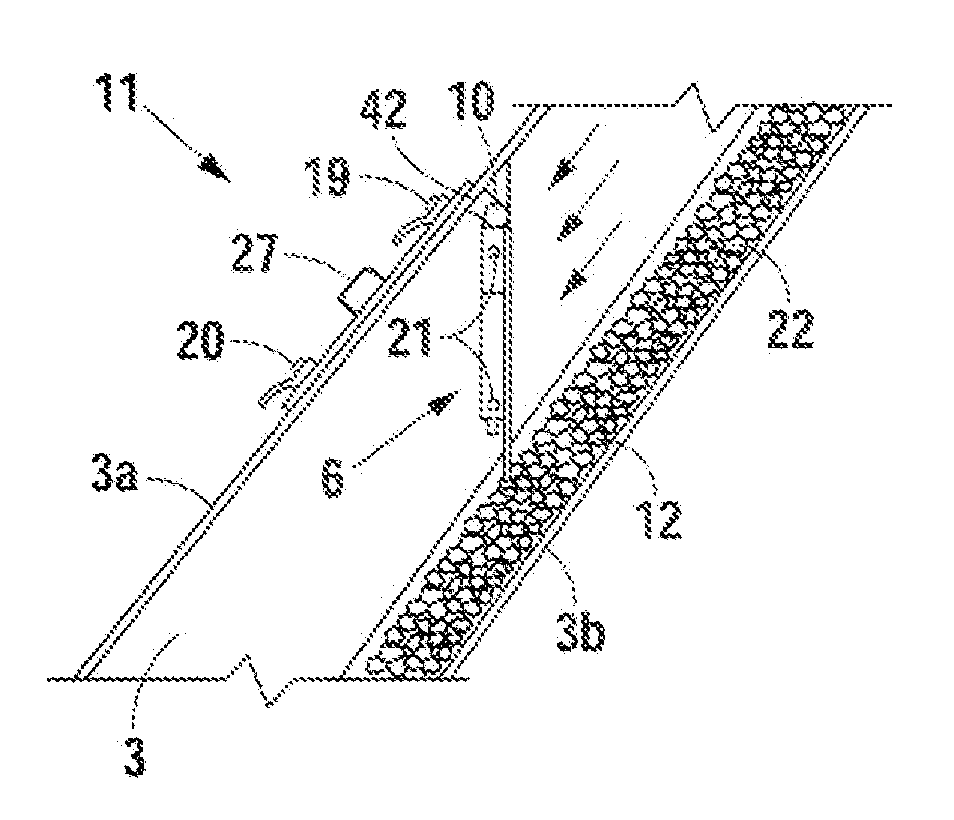

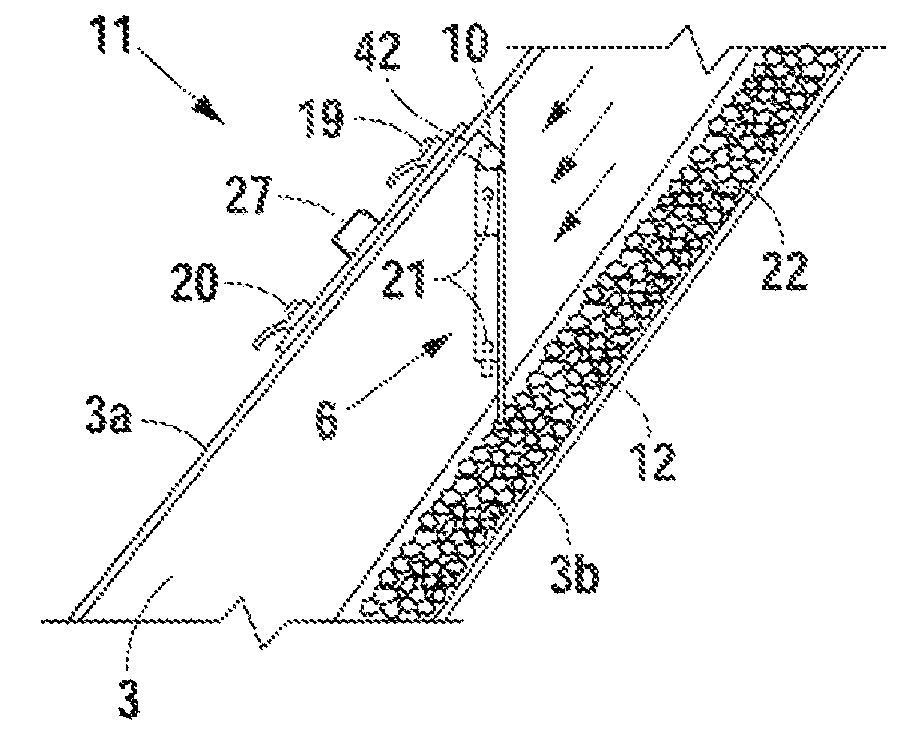

Apparatus and Method for Passive Dust Control in a Transfer Chute

InactiveUS20120090956A1Minimize air flowReduce dust emissionsLoading/unloadingConveyor partsTransfer systemDust control

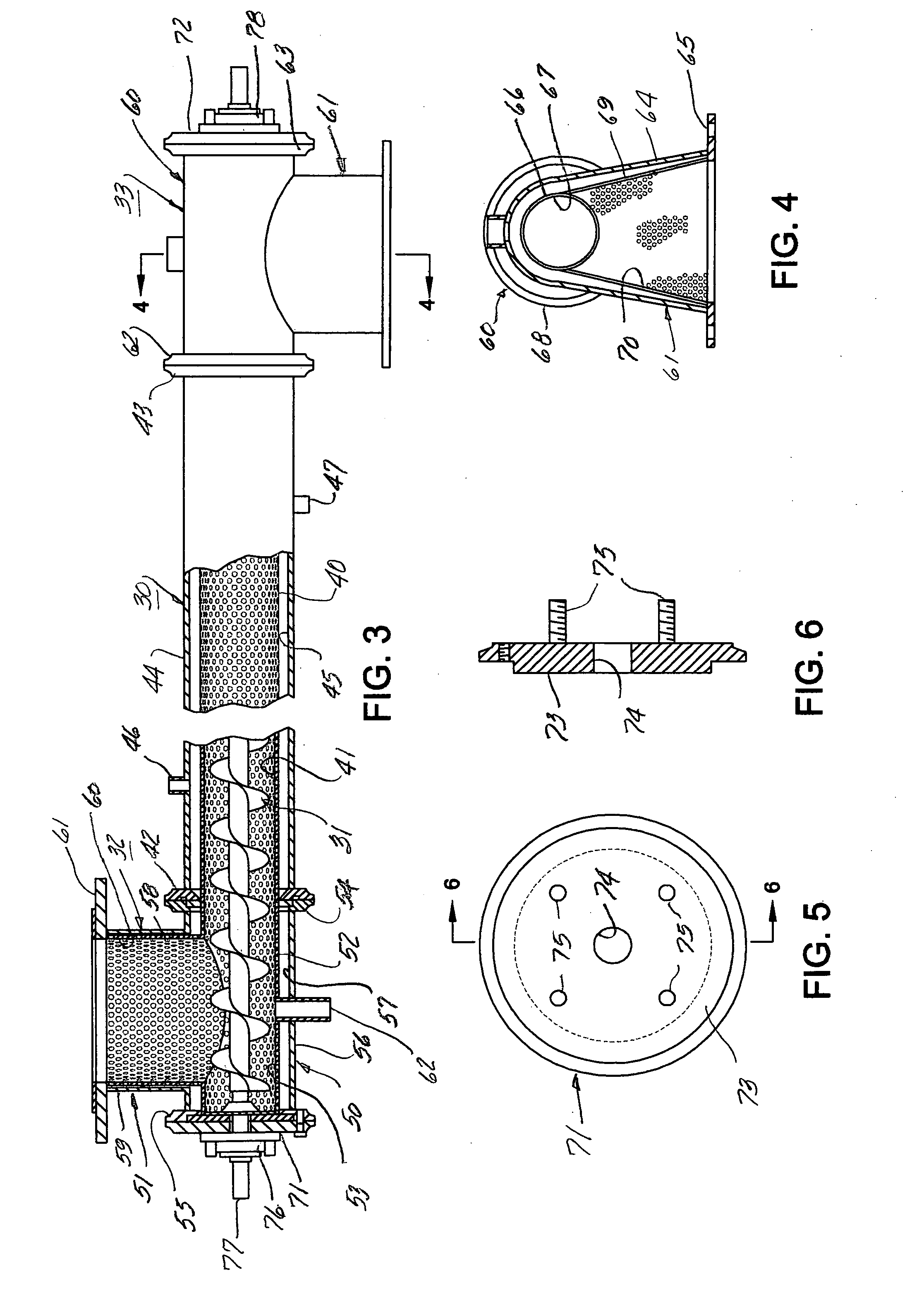

A dust control apparatus and method for a bulk material handling transfer system having a chute comprising a pathway there through for handling varying volumes of bulk material flowing through the chute using gravity flow. A self-adjusting air restrictor gate is mounted in the chute for engaging the upper surface of flowing bulk material through the chute for restricting the air pathway during material volume flow variations to reduce dust emissions. The gate member contacts the upper surface of flowing bulk material and moves up and down in response to the flow of bulk material through the chute to restrict the flow of air to reduce dust. A counterweight mechanism and a damper helps maintain controlled contact of the air restrictor gate with the upper surface of bulk material flowing through the chute.

Owner:BROBST STEVEN HAYS

System and method for handling bulk materials

ActiveUS7137759B1Facilitate material flowFlow rate may be more readily controlledBulk conveyorsMechanical conveyorsGuide tubeBulk material handling

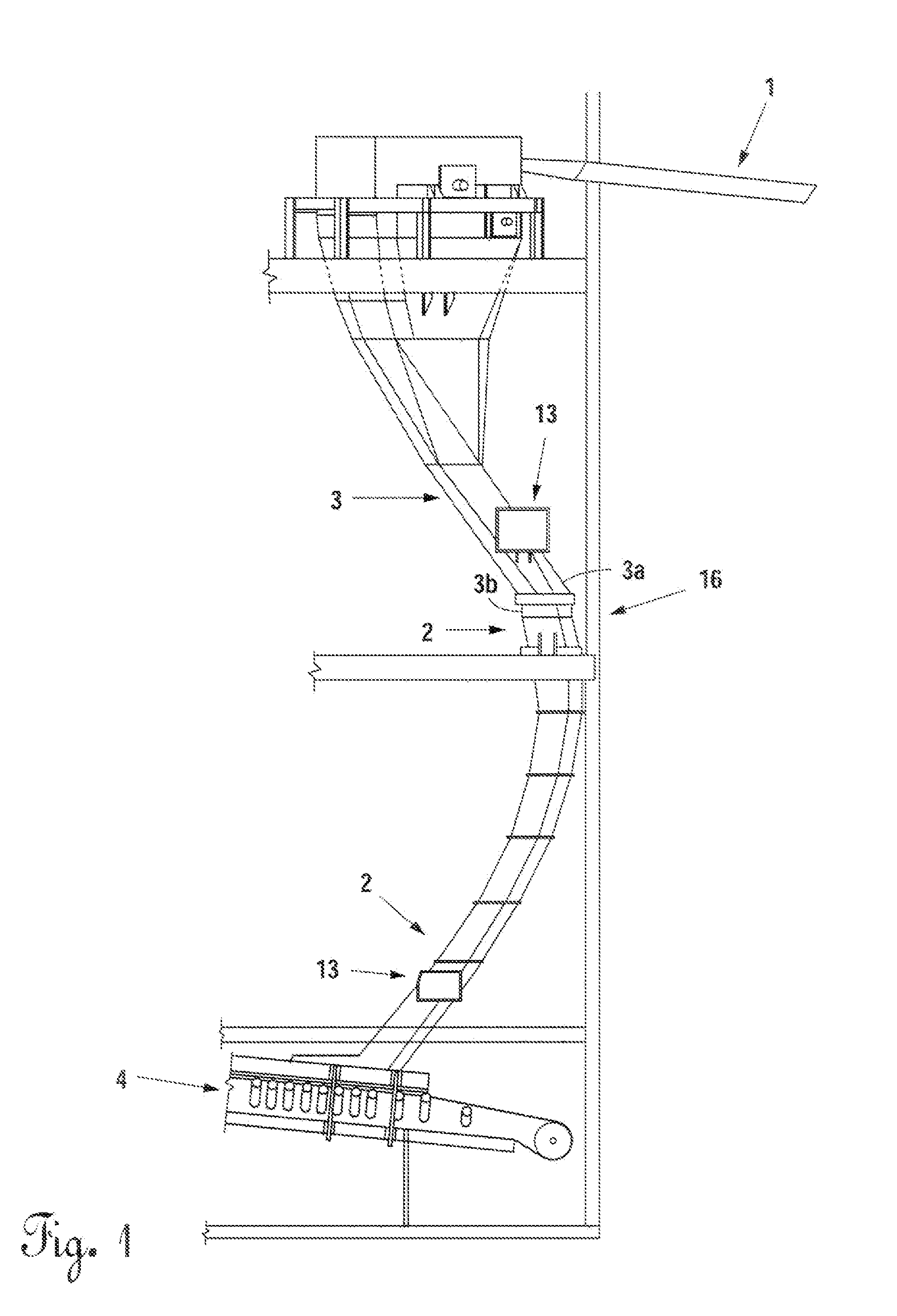

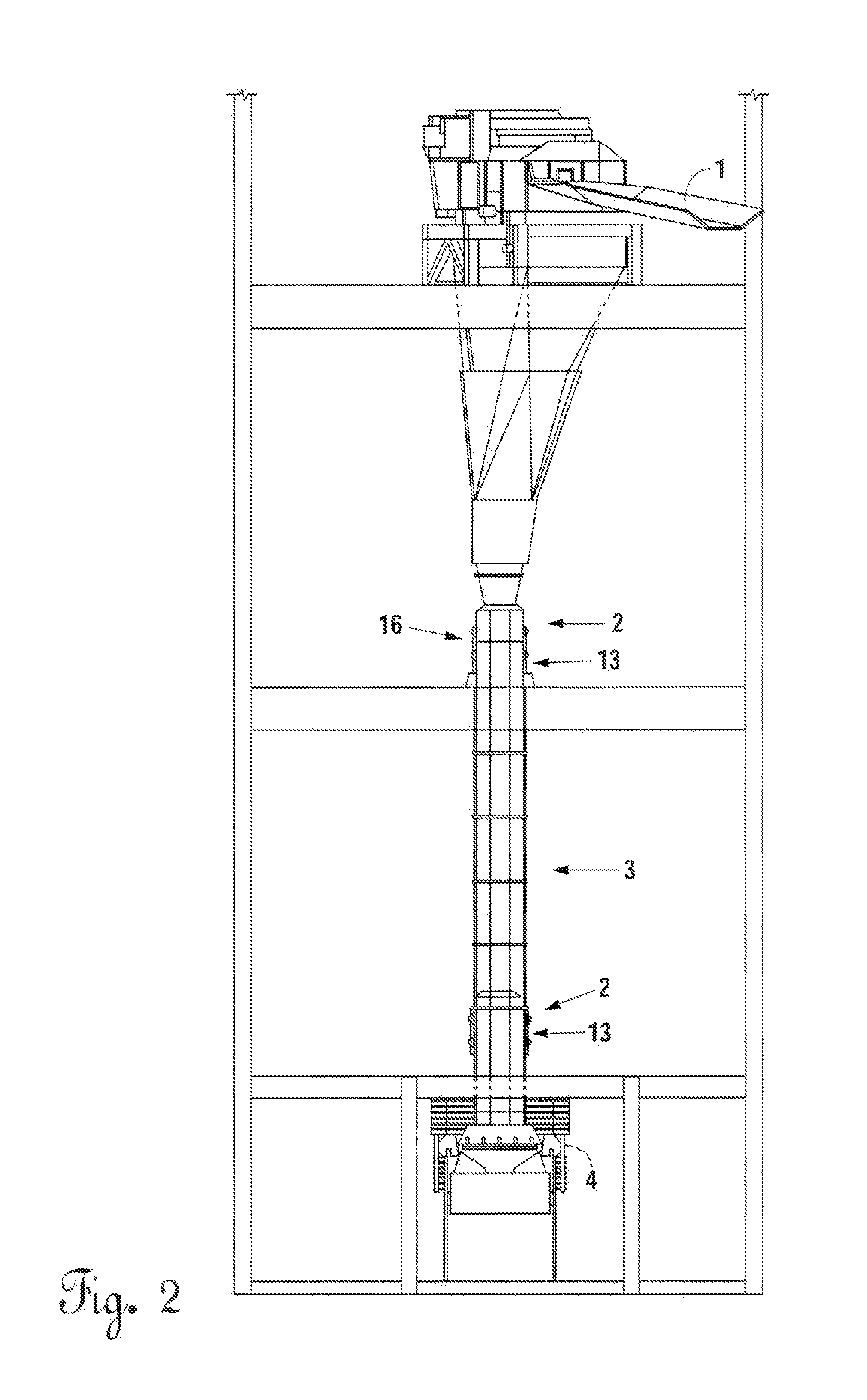

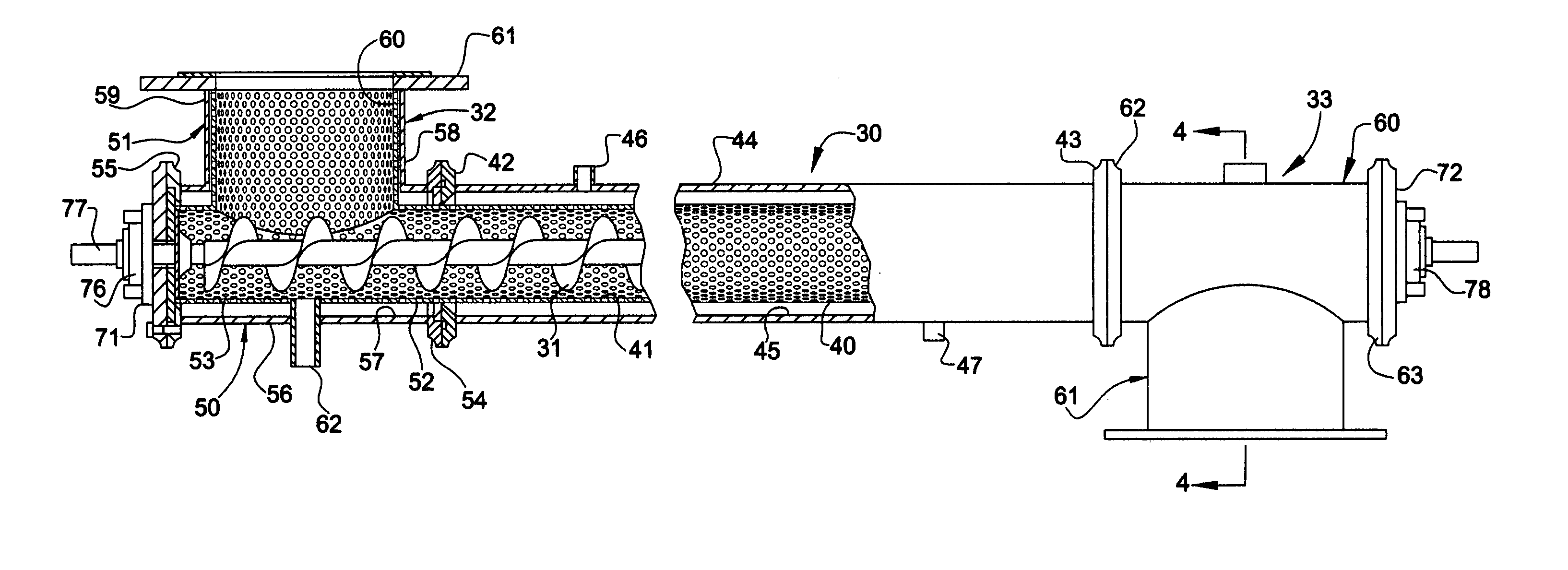

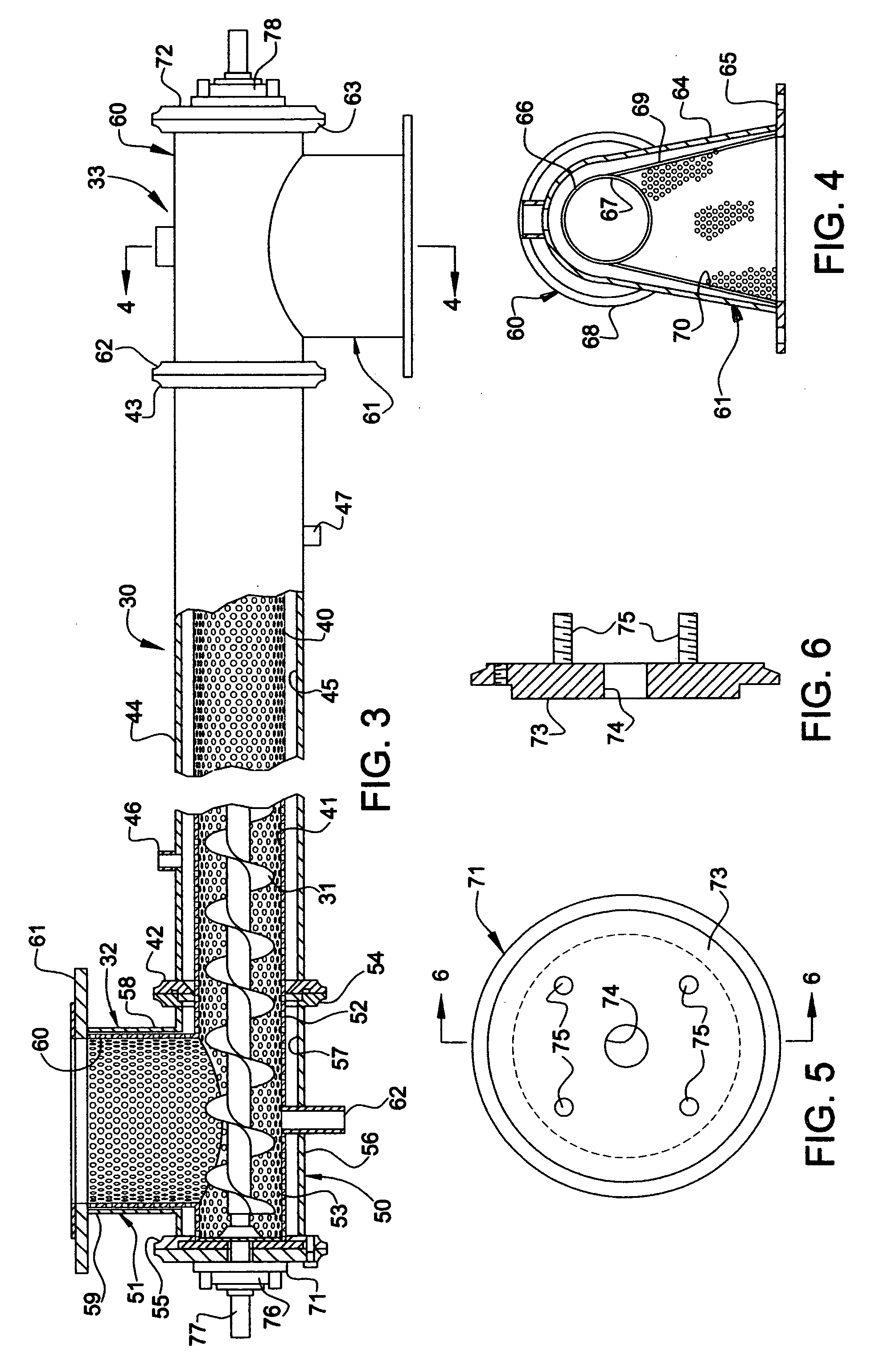

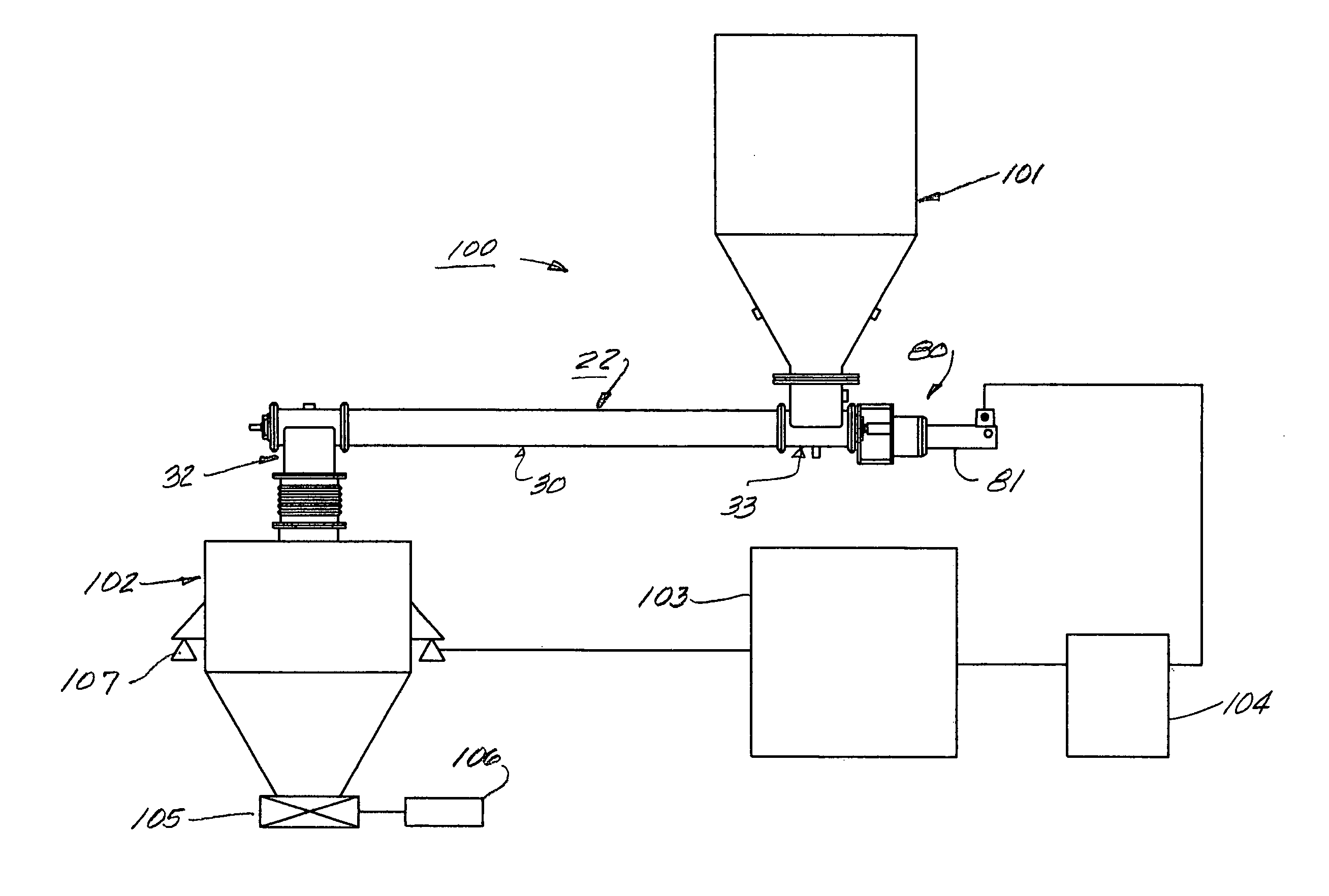

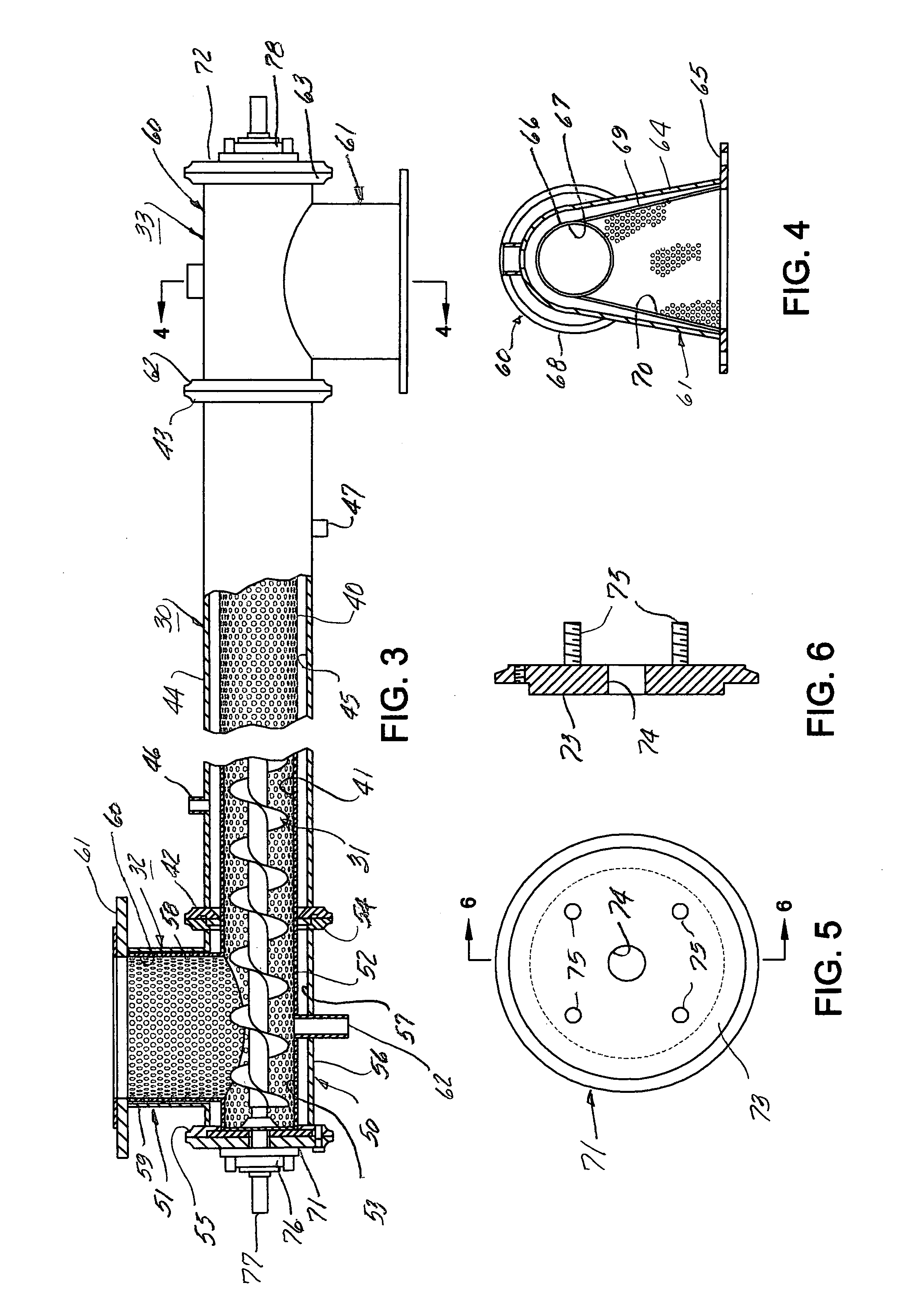

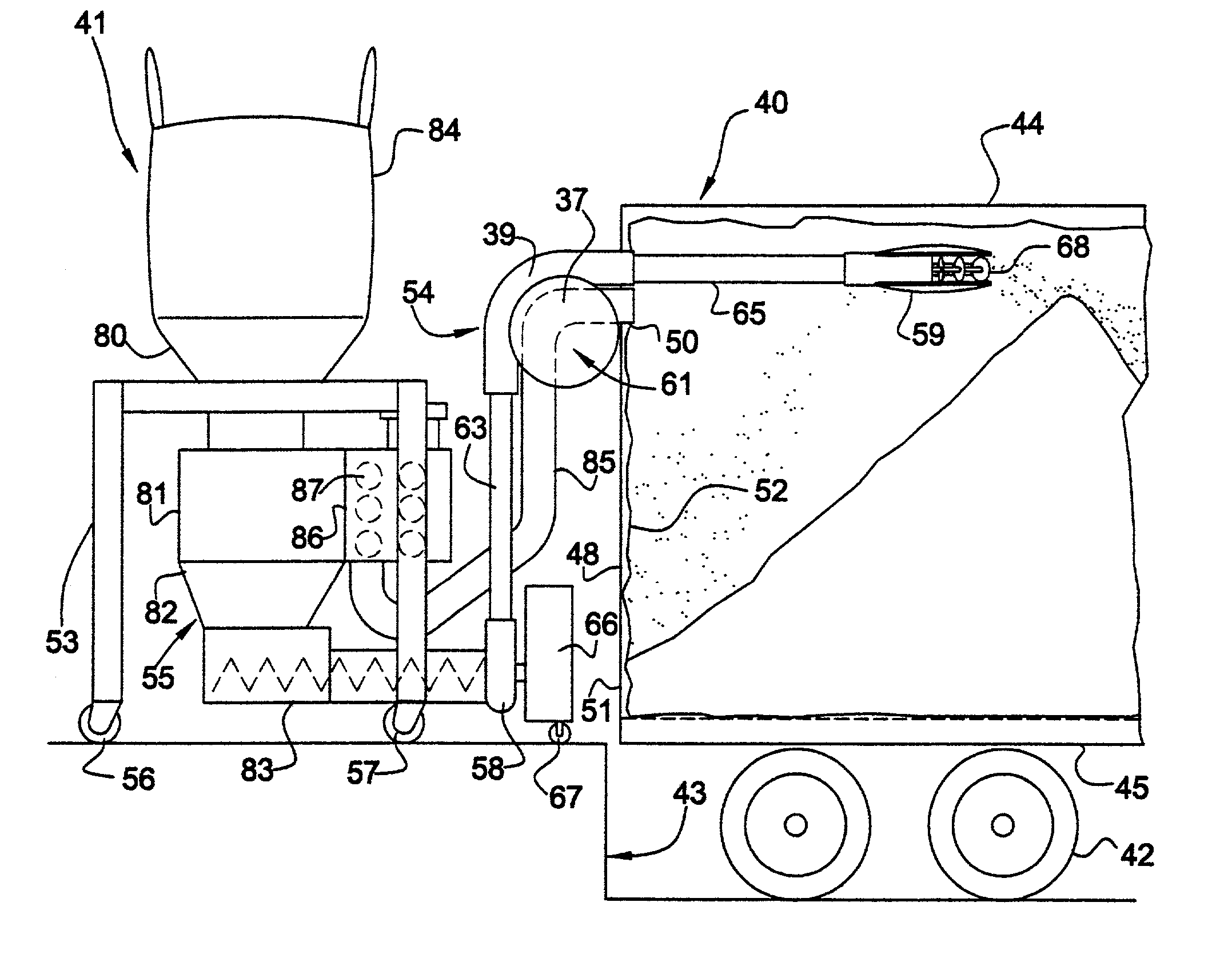

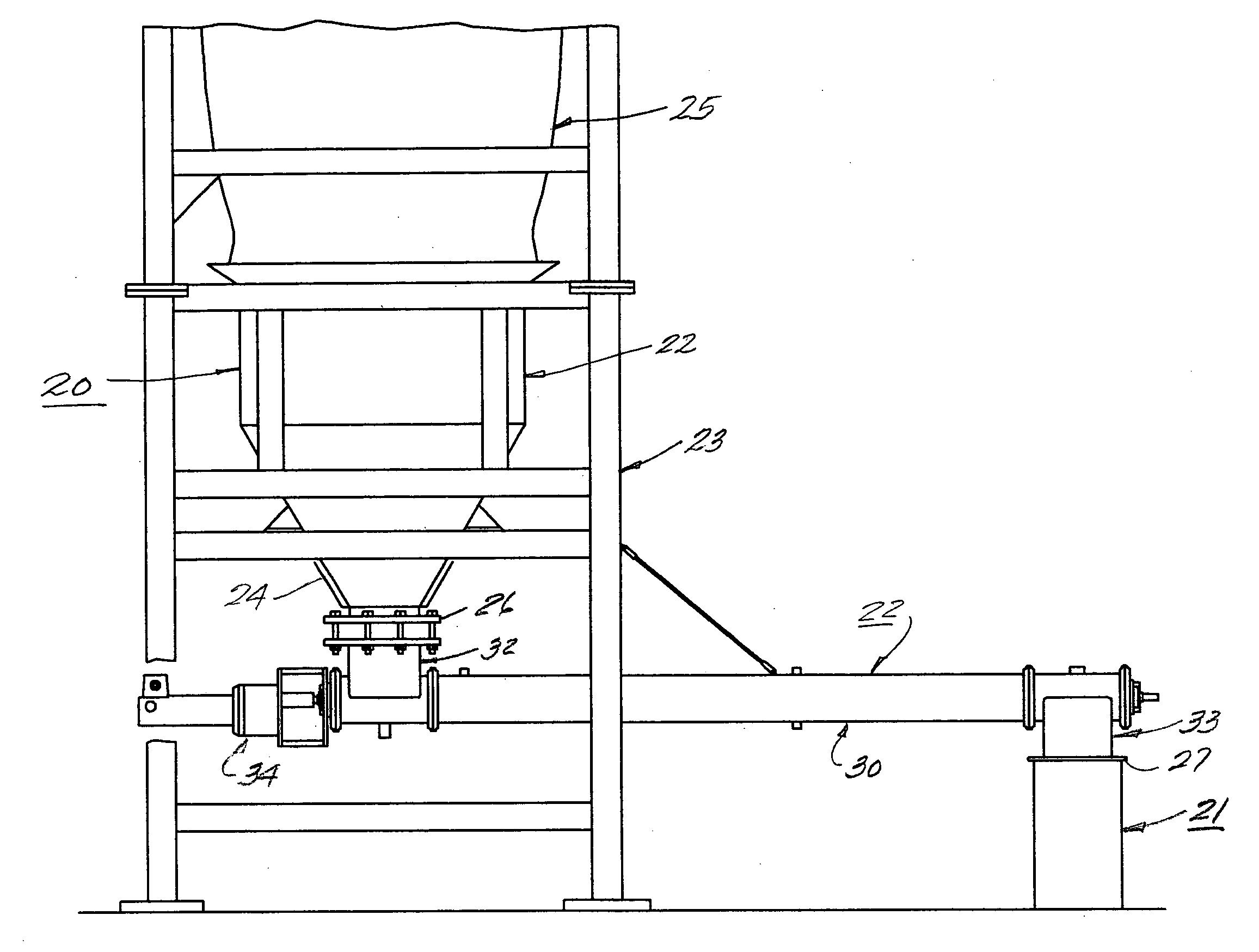

A bulk material handling system generally consisting of means for holding the material; means for conveying the material including a first conduit formed of a permeable material having an inlet communicating with an outlet of the material holding means and an outlet, a second conduit formed of an impermeable material encompassing and spaced from the first conduit, providing a chamber therebetween, and an auger disposed in the first conduit for transporting material received through the inlet to the outlet thereof; means for rotatably driving the auger; and means for supplying a fluidizing gas under pressure to the chamber between the first and second conduits.

Owner:YOUNG INDS

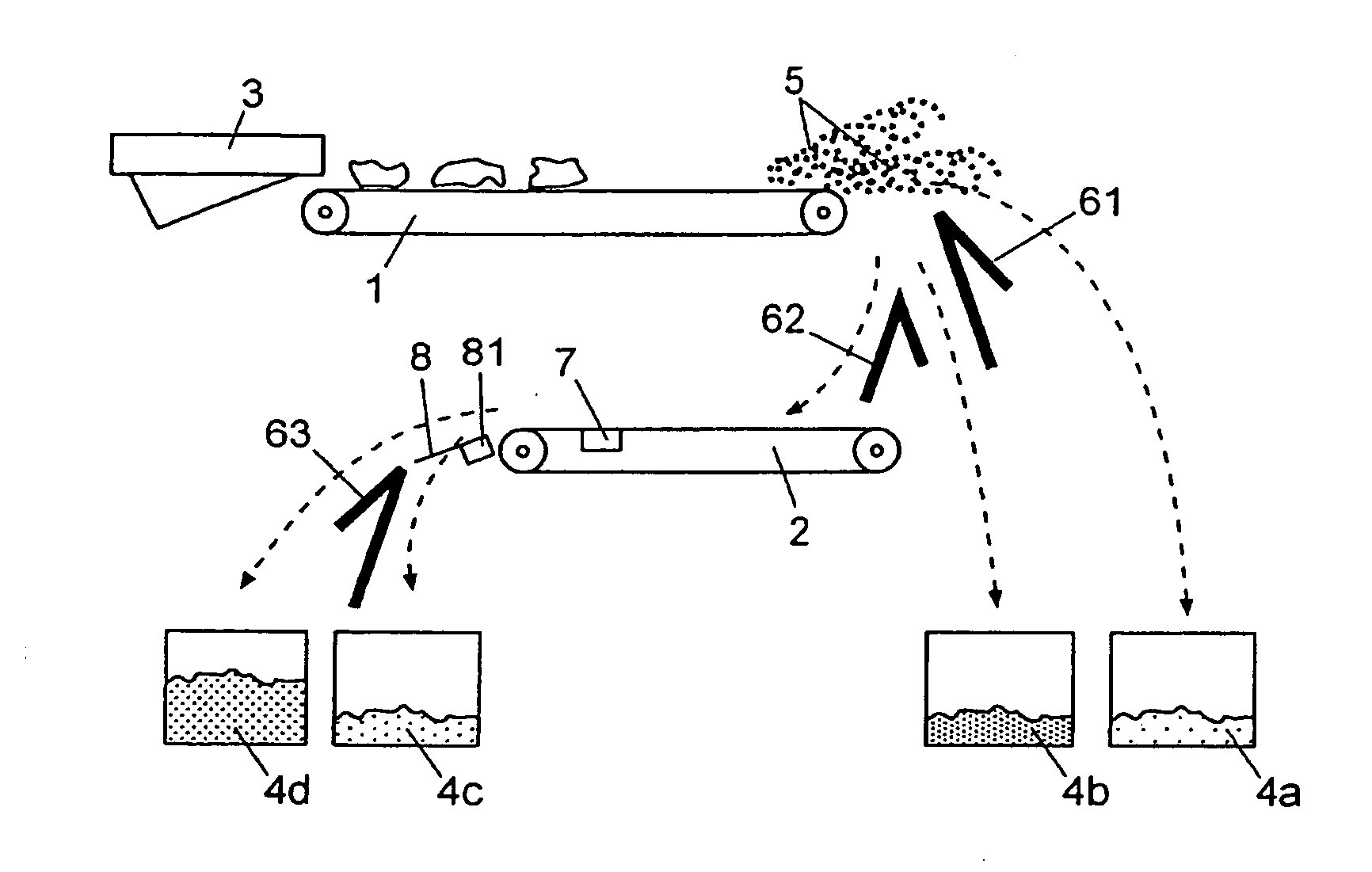

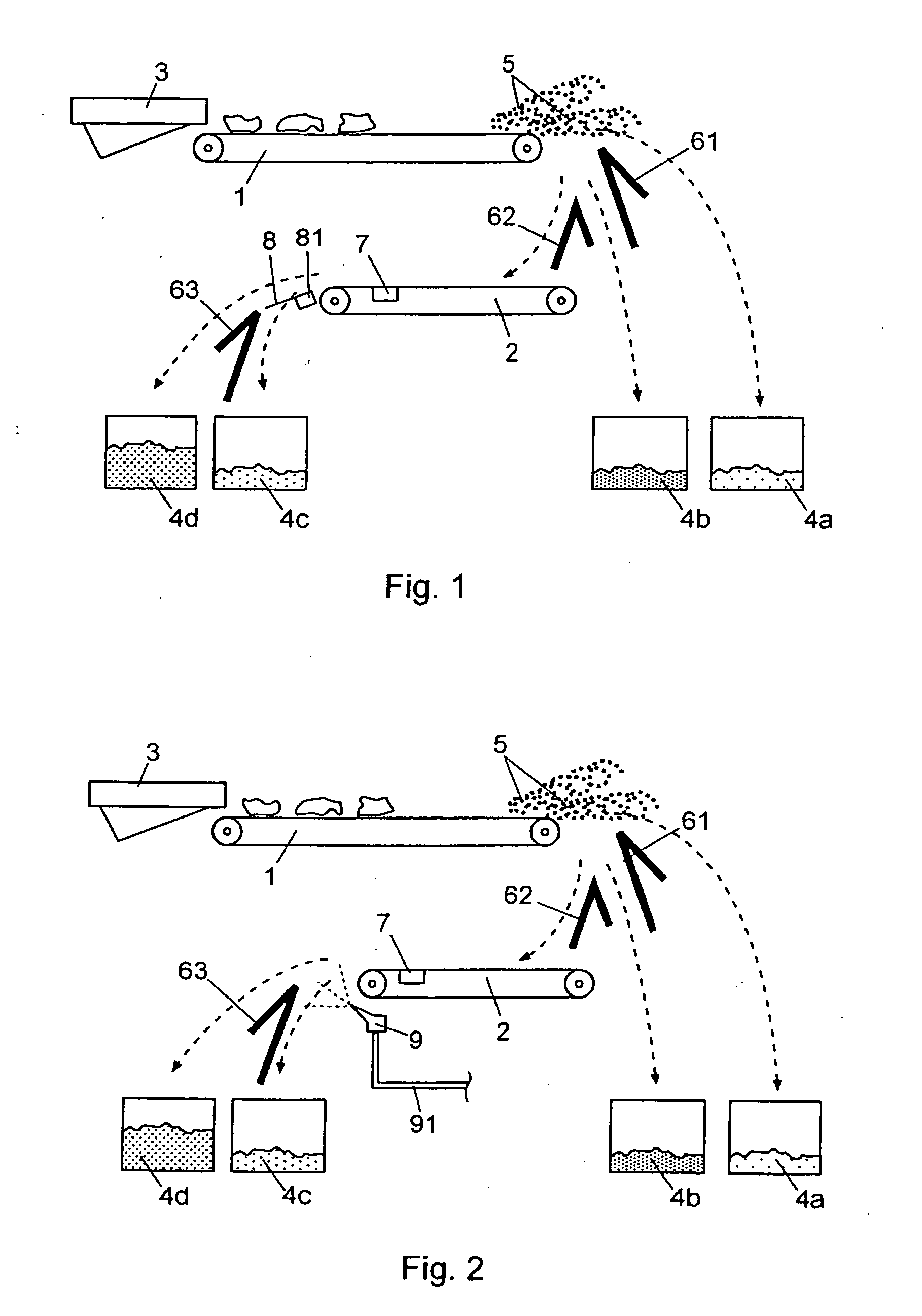

Method and unit for the separation of non-ferrous metals and stainless steel in bulk material handling

InactiveUS20100282646A1Reduce investmentCentrifugesMagnetic separationMetallic materialsConductive materials

A method and unit for the separation of non-ferrous, ferrous and non-metal portions in bulk material handling, particularly for the recycling of materials for subsequent use, wherein the method comprises: the application of eddy currents for the separation of portions of non-ferrous and conductive materials that jump with respect to portions of the remaining material stream; the detection of metals in portions of materials by means of an analysis of the metals using electromagnetic sensors, and the separation of said metals by mechanical expulsion means, achieving the separation of metallic material portions, such as stainless steel, and others from the portions of non-metals. The unit comprises a first conveyor belt of the portions and eddy current (Foucault) separators, while a second conveyor belt includes electromagnetic metal sensors and selective expulsion means which are controlled by said electromagnetic metal sensors.

Owner:BEST TORATEC SL

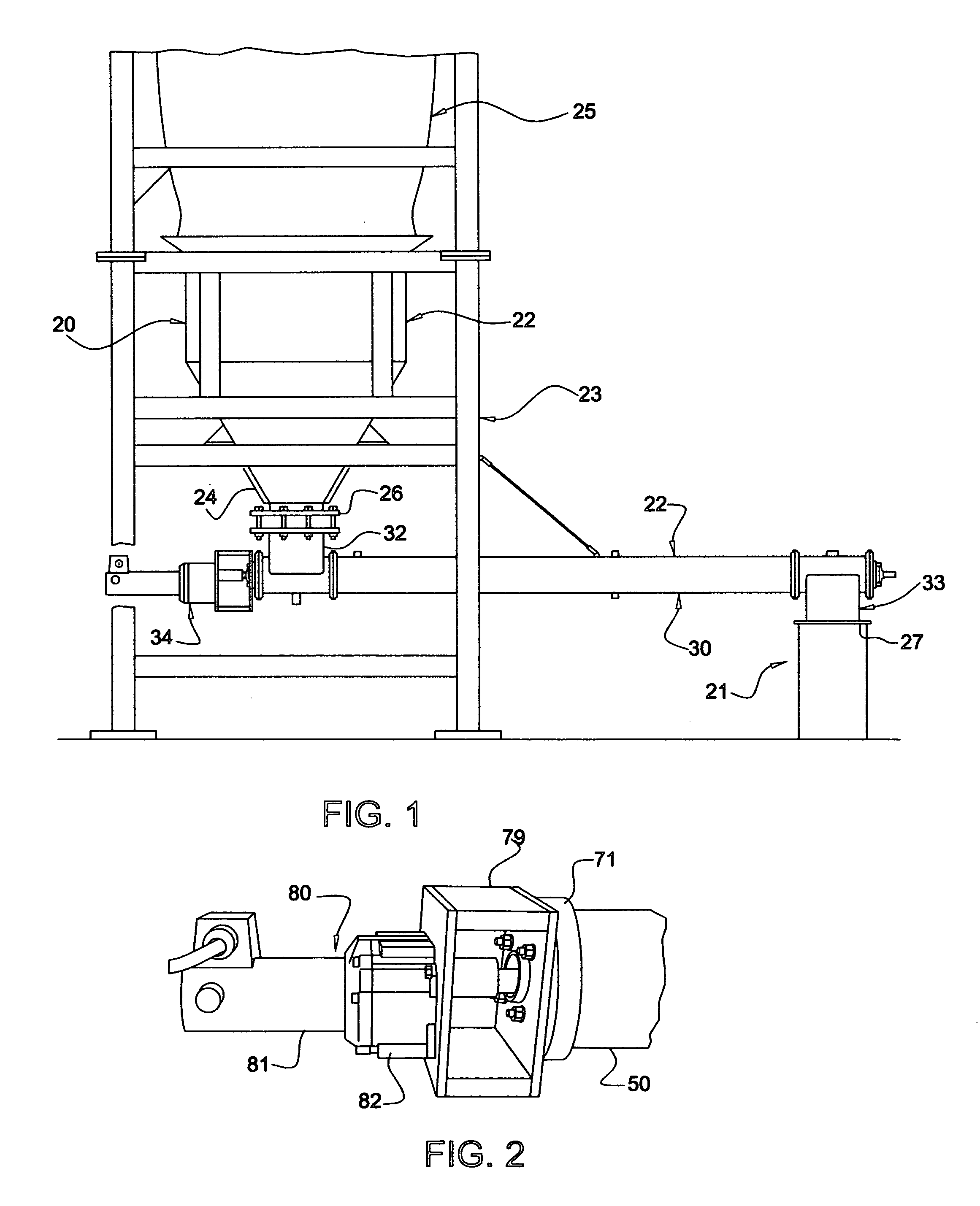

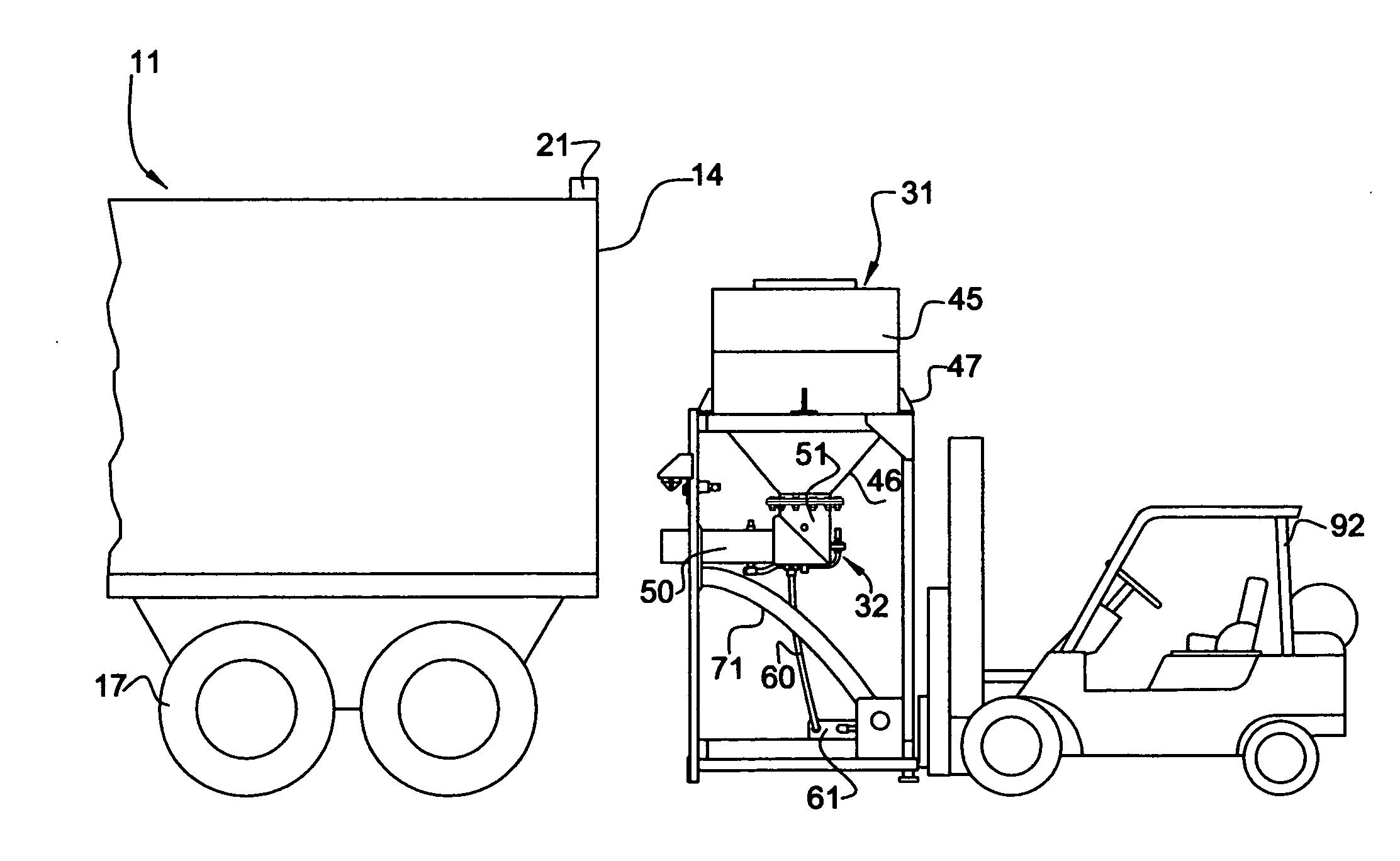

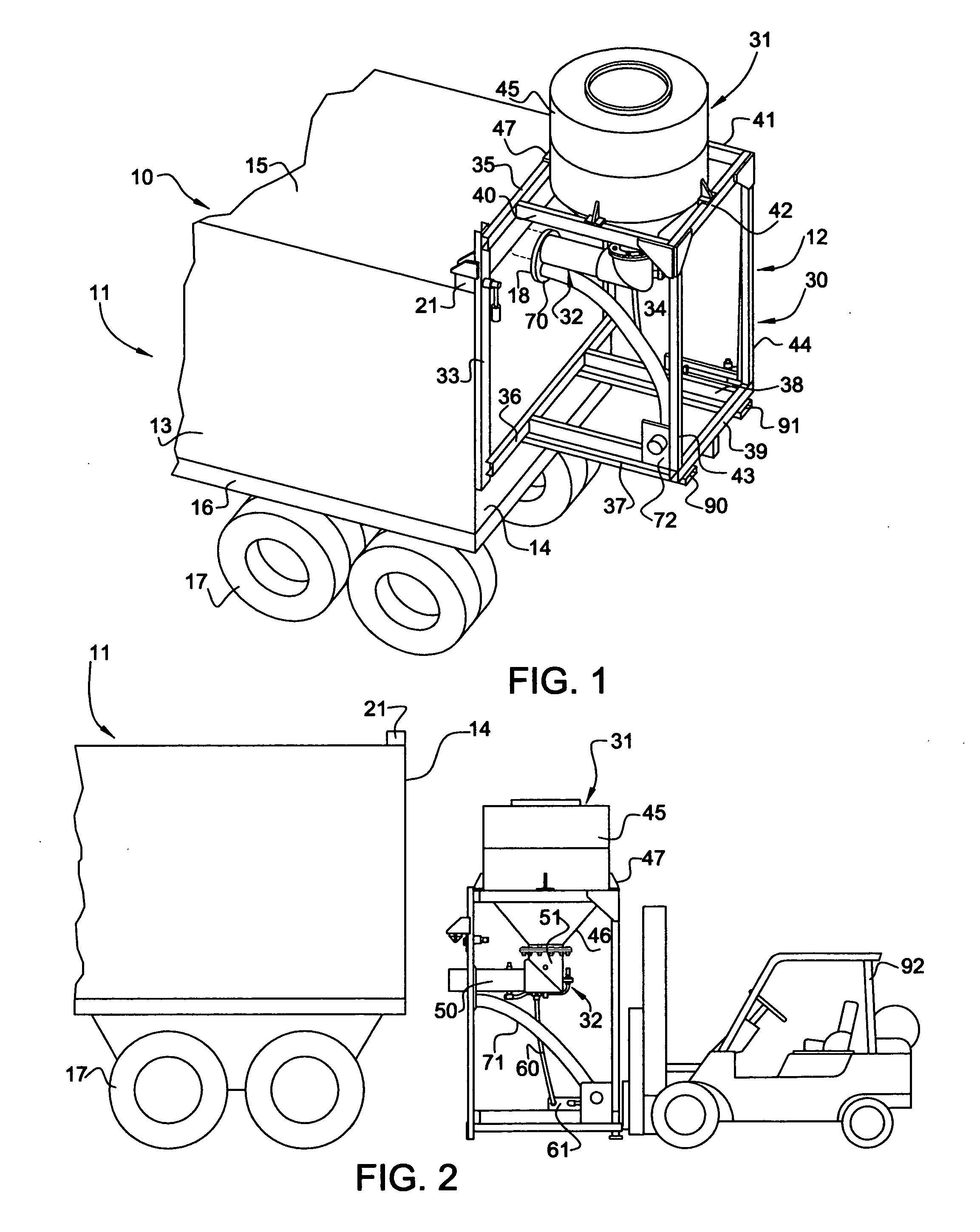

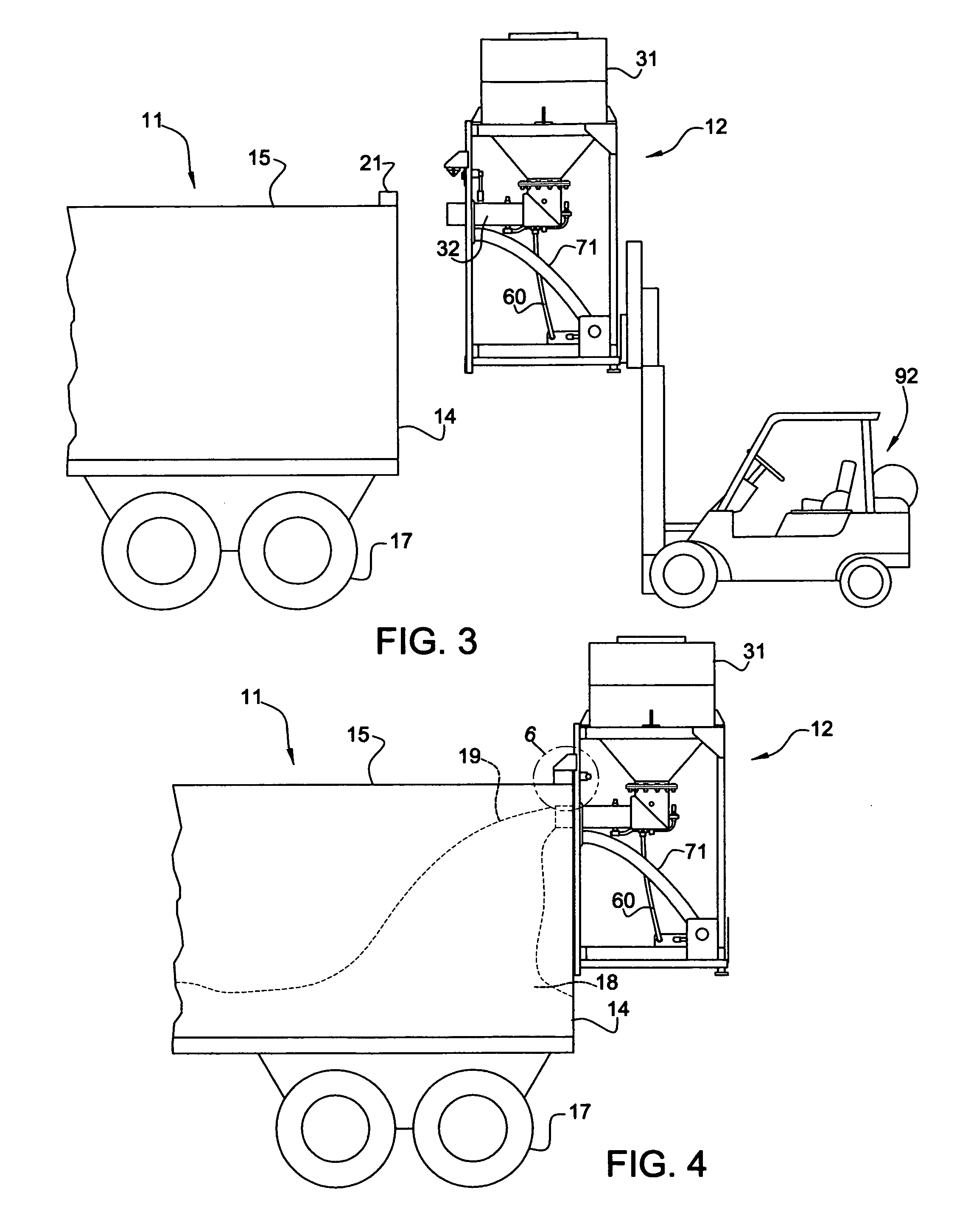

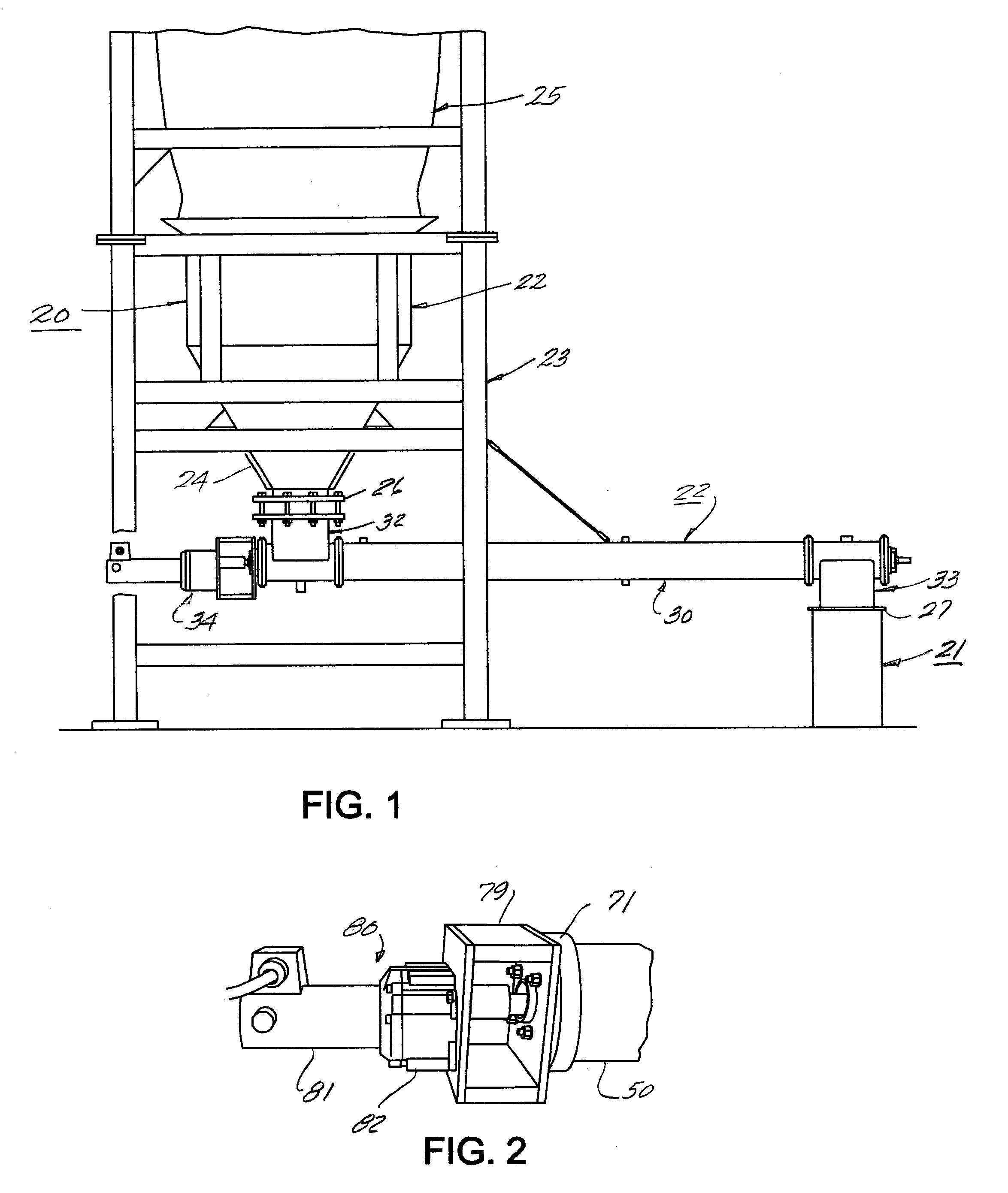

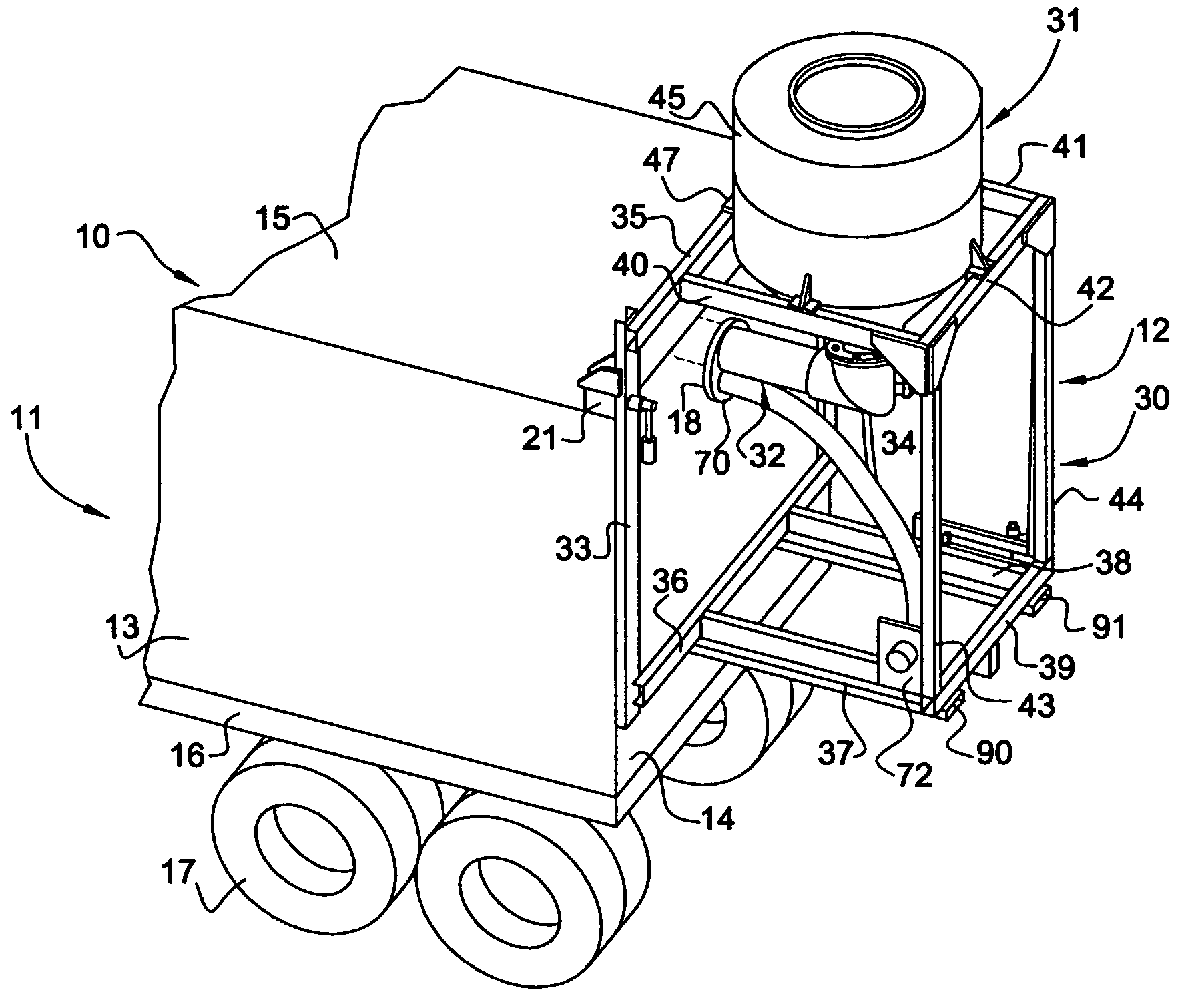

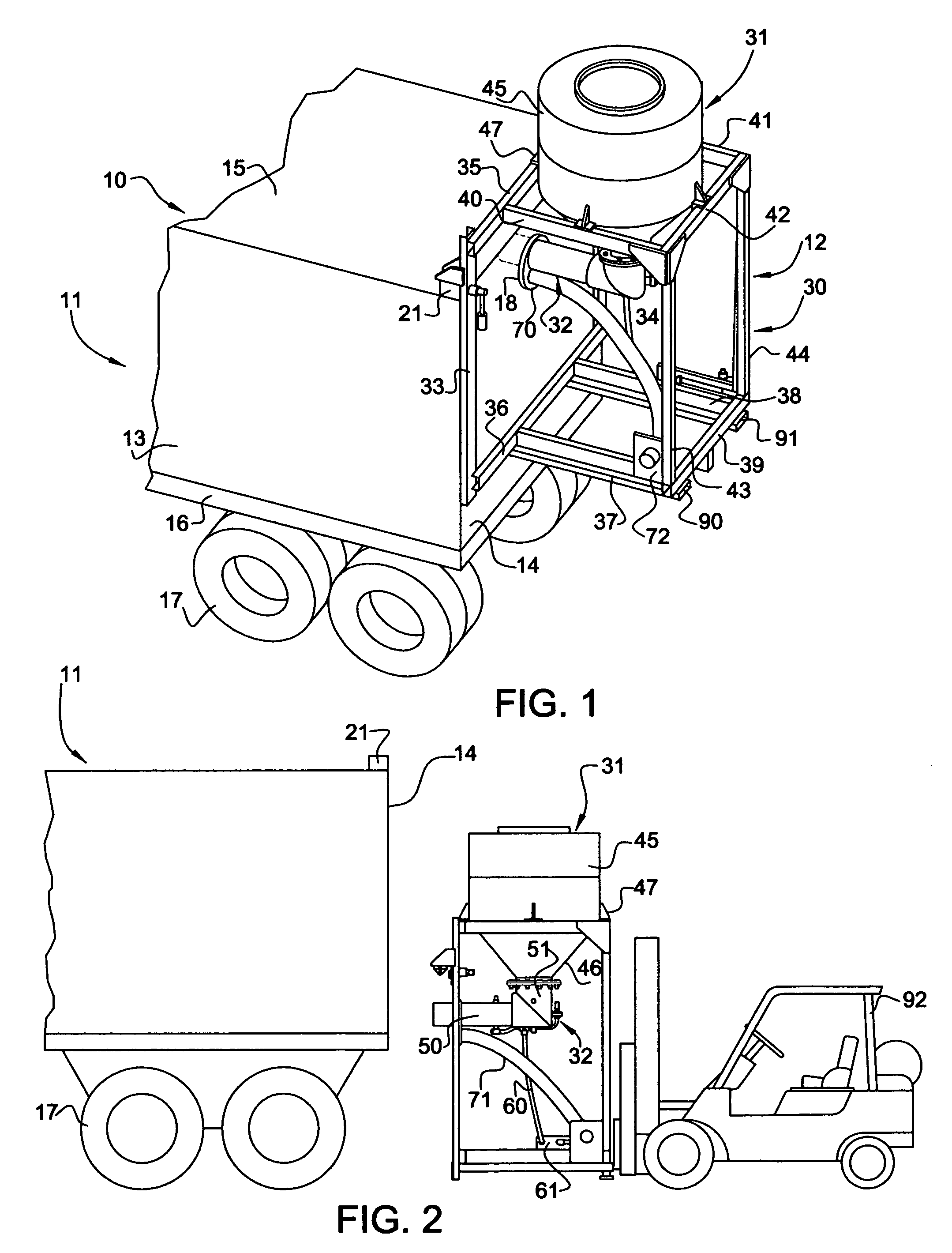

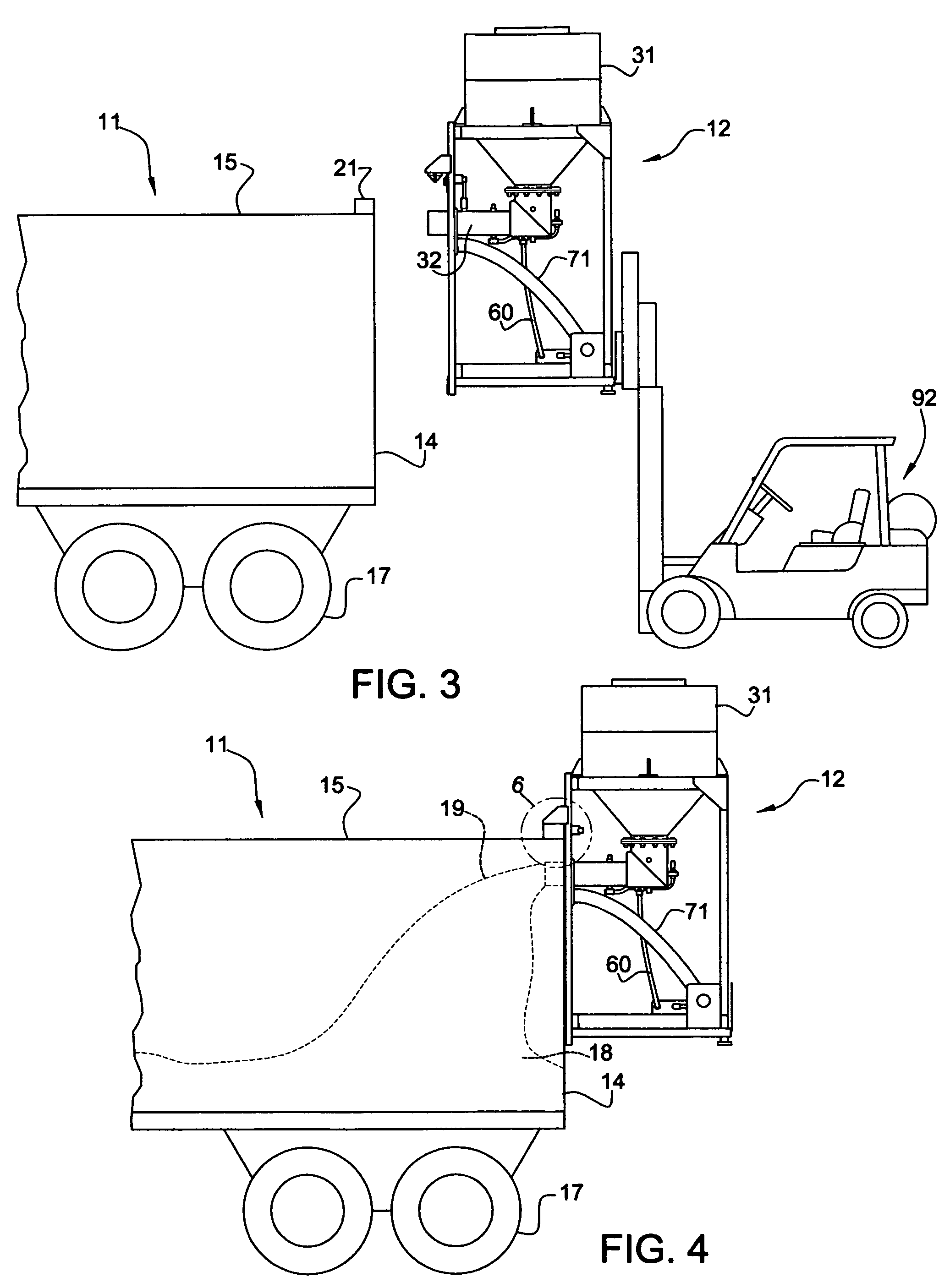

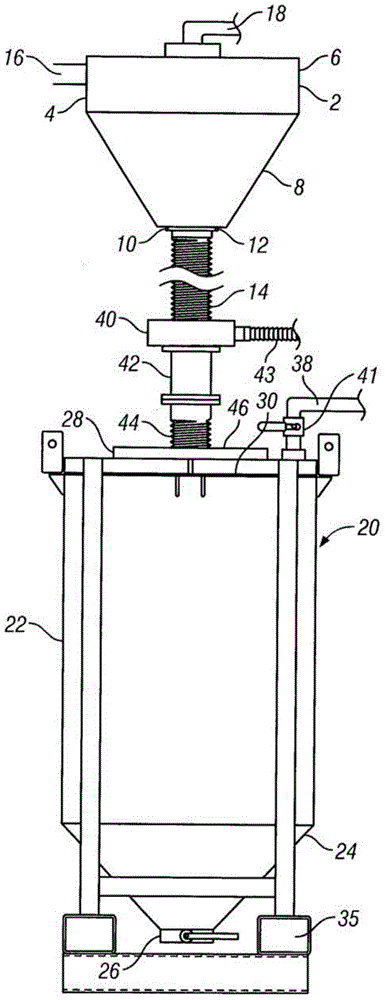

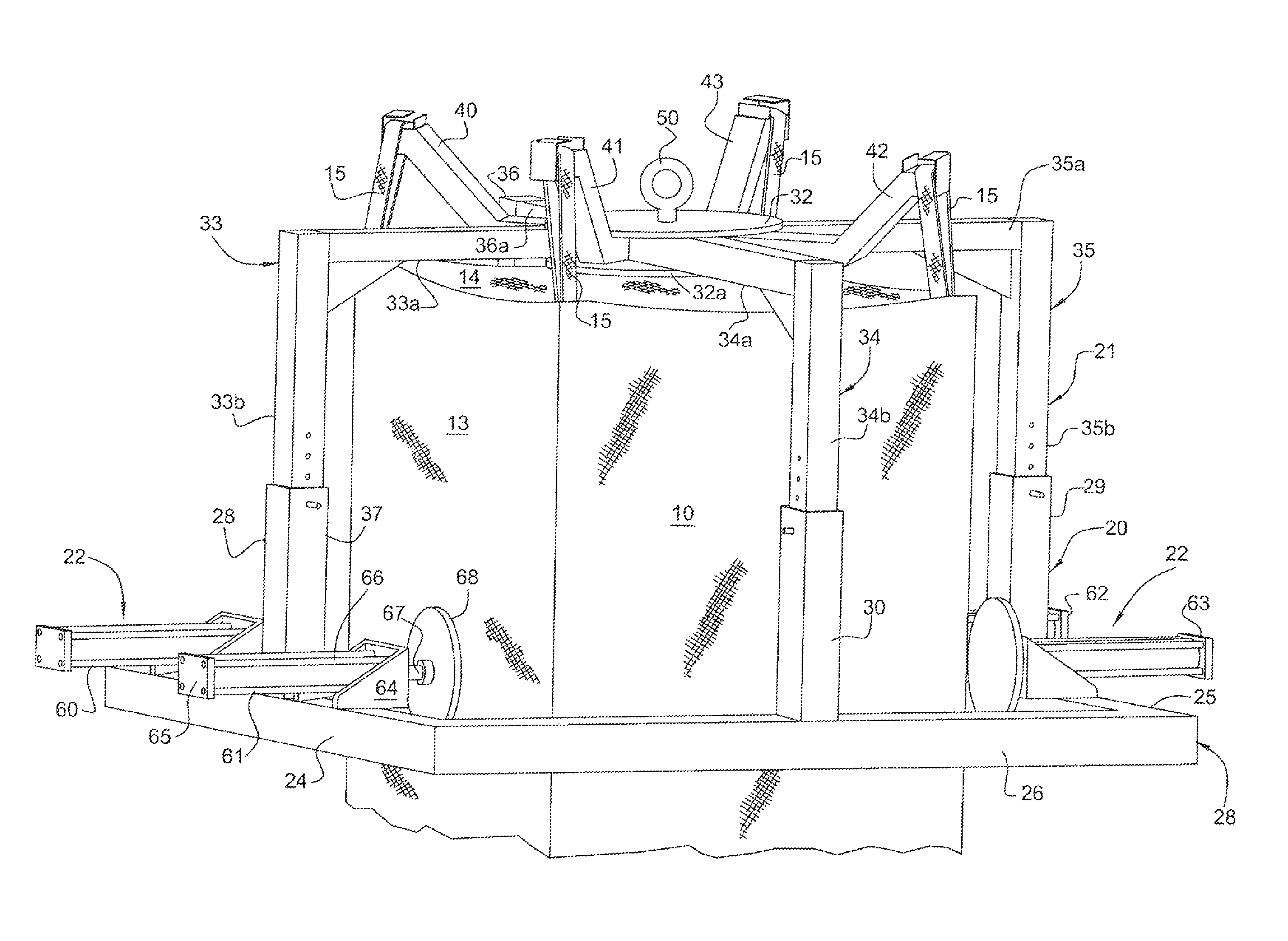

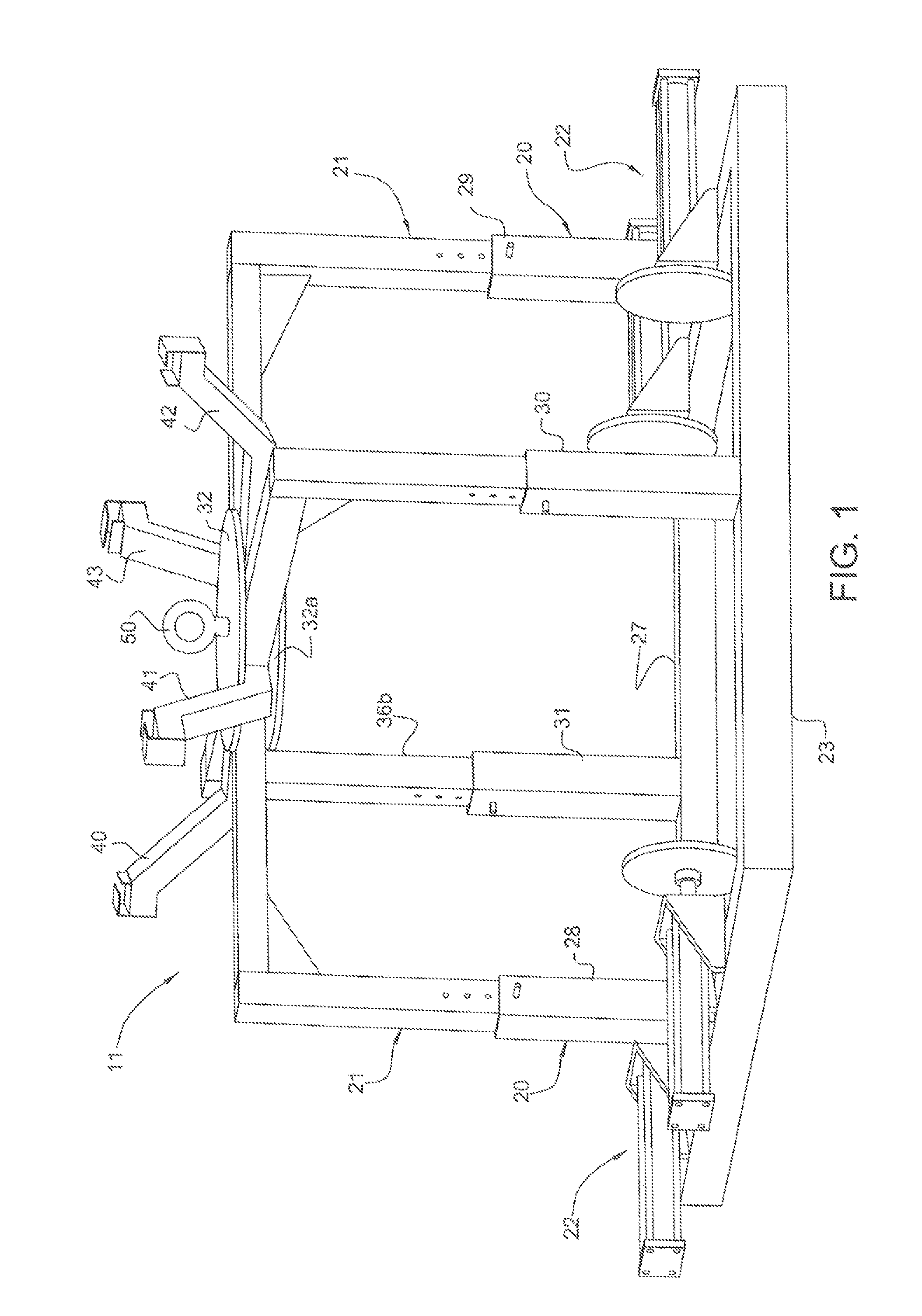

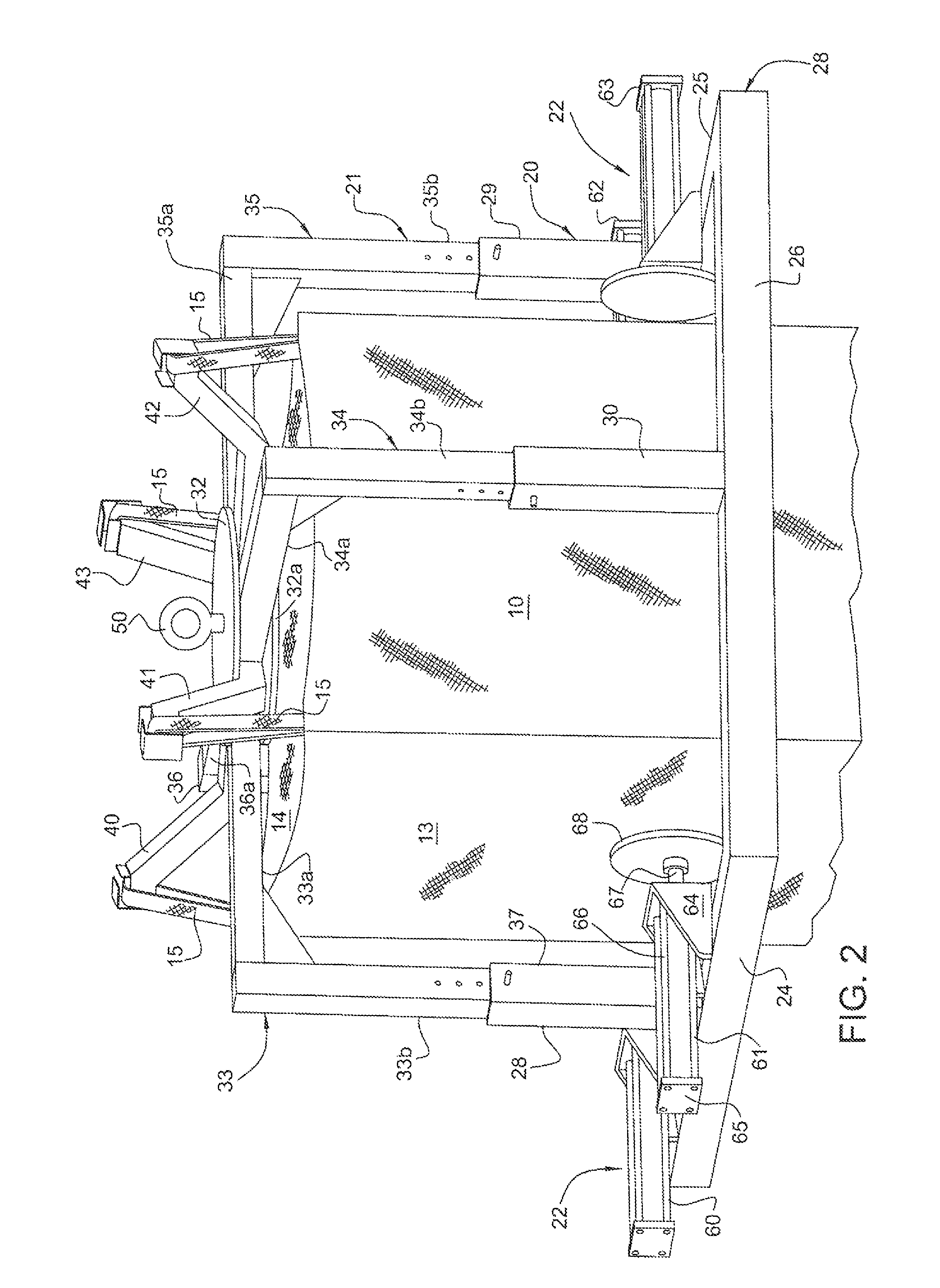

Bulk material handling system and portable loading apparatus thereof

InactiveUS20070048110A1Facilitate material flowLoading/unloading vehicle arrangmentRefuse transferringProduct gasEngineering

A bulk material system generally consisting of a container having an upper wall, a vertical wall and an opening in the vertical wall; a support frame detachably mountable on the upper and vertical walls of the container; a hopper mounted on the support frame; a material conveying conduit mounted on the frame having an inlet communicating with an outlet of the hopper for receiving material therefrom and an end portion with an outlet insertable through the vertical wall opening of the container when the frame is detachably mounted on the container; and a conduit supported on the support frame having an outlet communicating with the material conveying conduit and an inlet communicable with a source of gas under pressure, function to supply gas under pressure to the material conveying conduit for pneumatically conveying material fed from the hopper into the material conveying conduit, therethrough, into the container.

Owner:YOUNG INDS

System and method for handling bulk materials

ActiveUS7320561B2Facilitate material flowFlow rate may be more readily controlledBulk conveyorsMechanical conveyorsHandling systemGuide tube

A bulk material handling system generally consisting of means for holding the material; means for conveying the material including a first conduit formed of a permeable material having an inlet communicating with an outlet of the material holding means and an outlet, a second conduit formed of an impermeable material encompassing and spaced from the first conduit, providing a chamber therebetween, and an auger disposed in the first conduit for transporting material received through the inlet to the outlet thereof; means for rotatably driving the auger; and means for supplying a fluidizing gas under pressure to the chamber between the first and second conduits.

Owner:YOUNG INDS

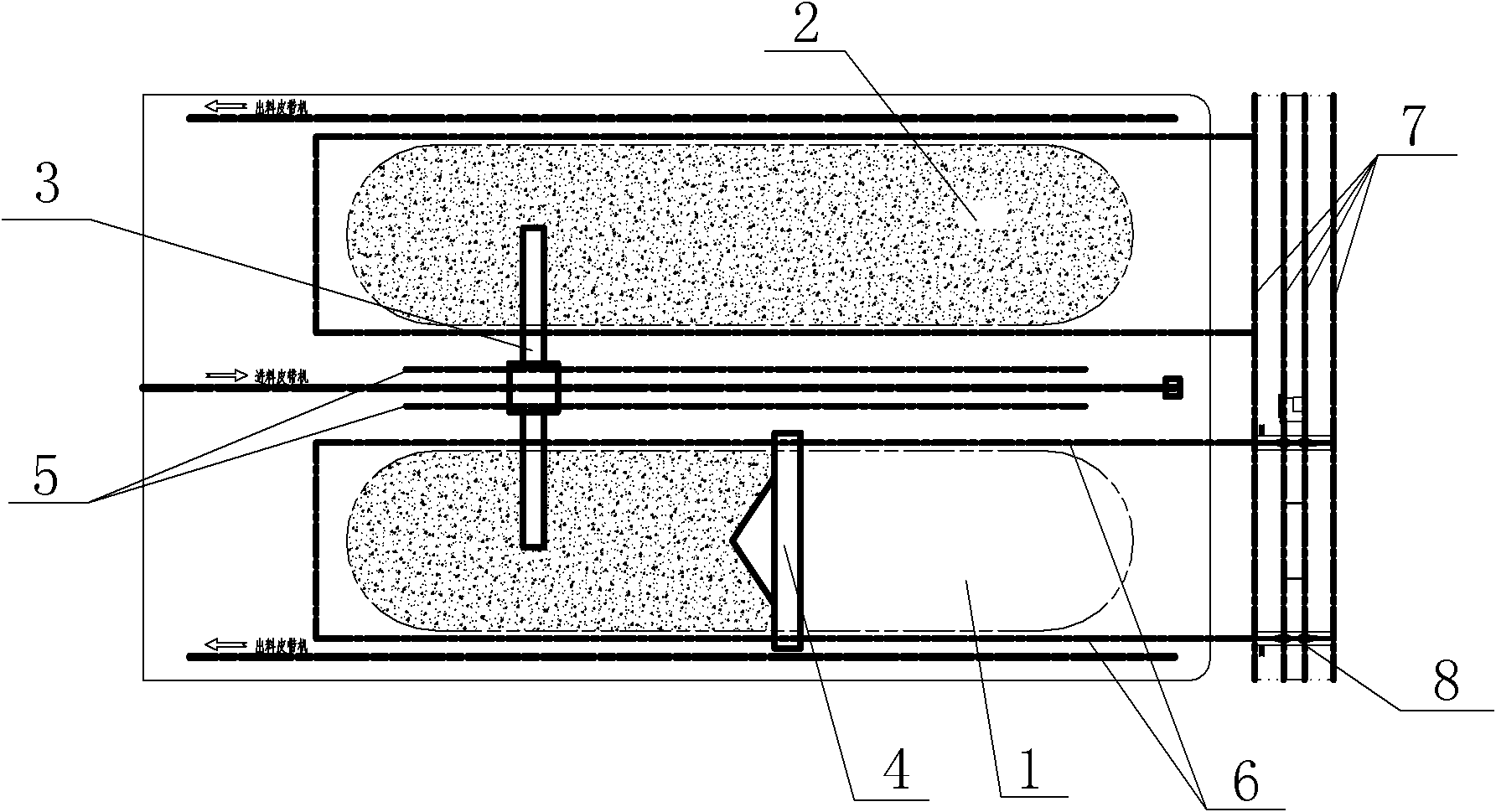

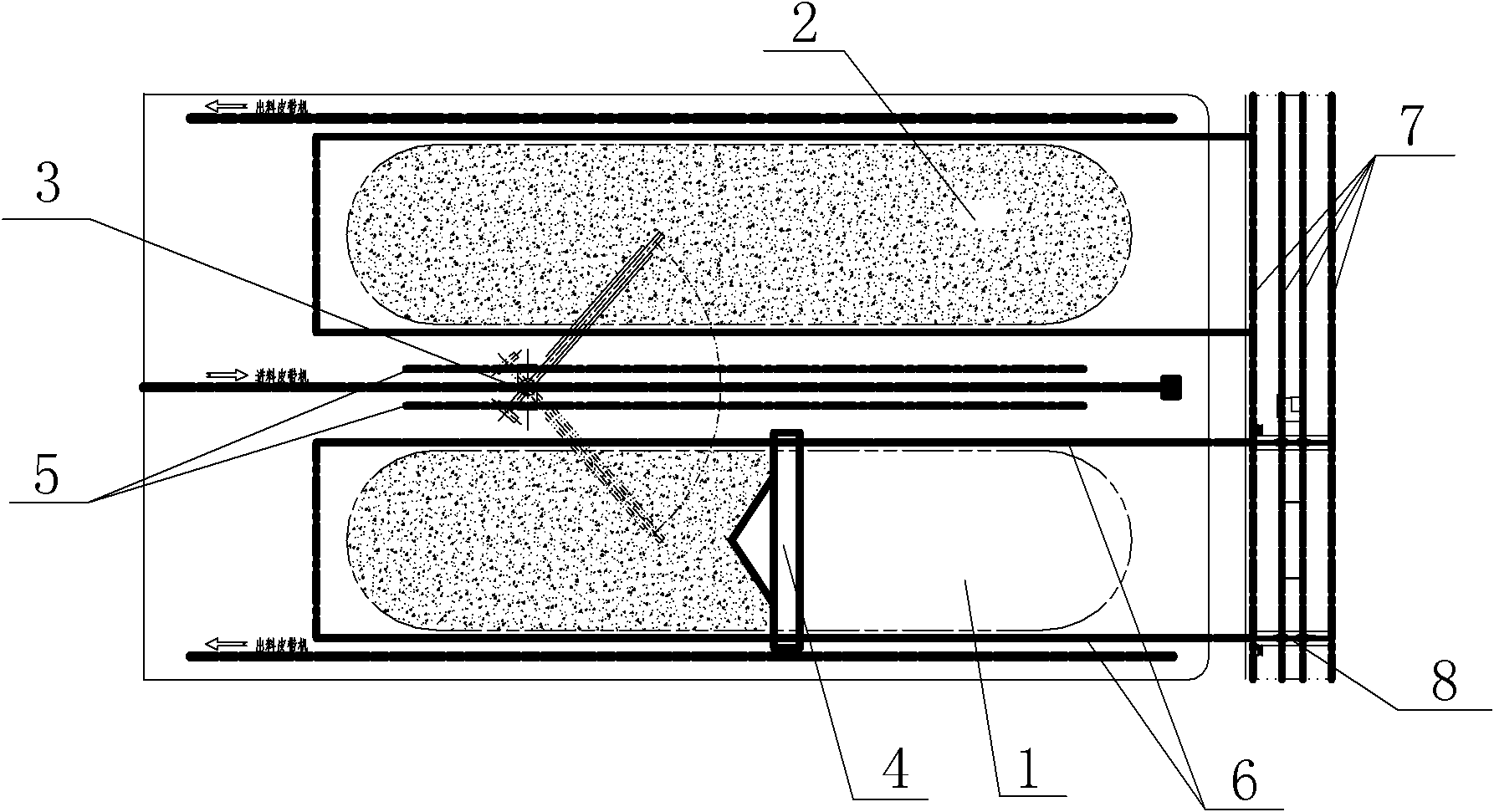

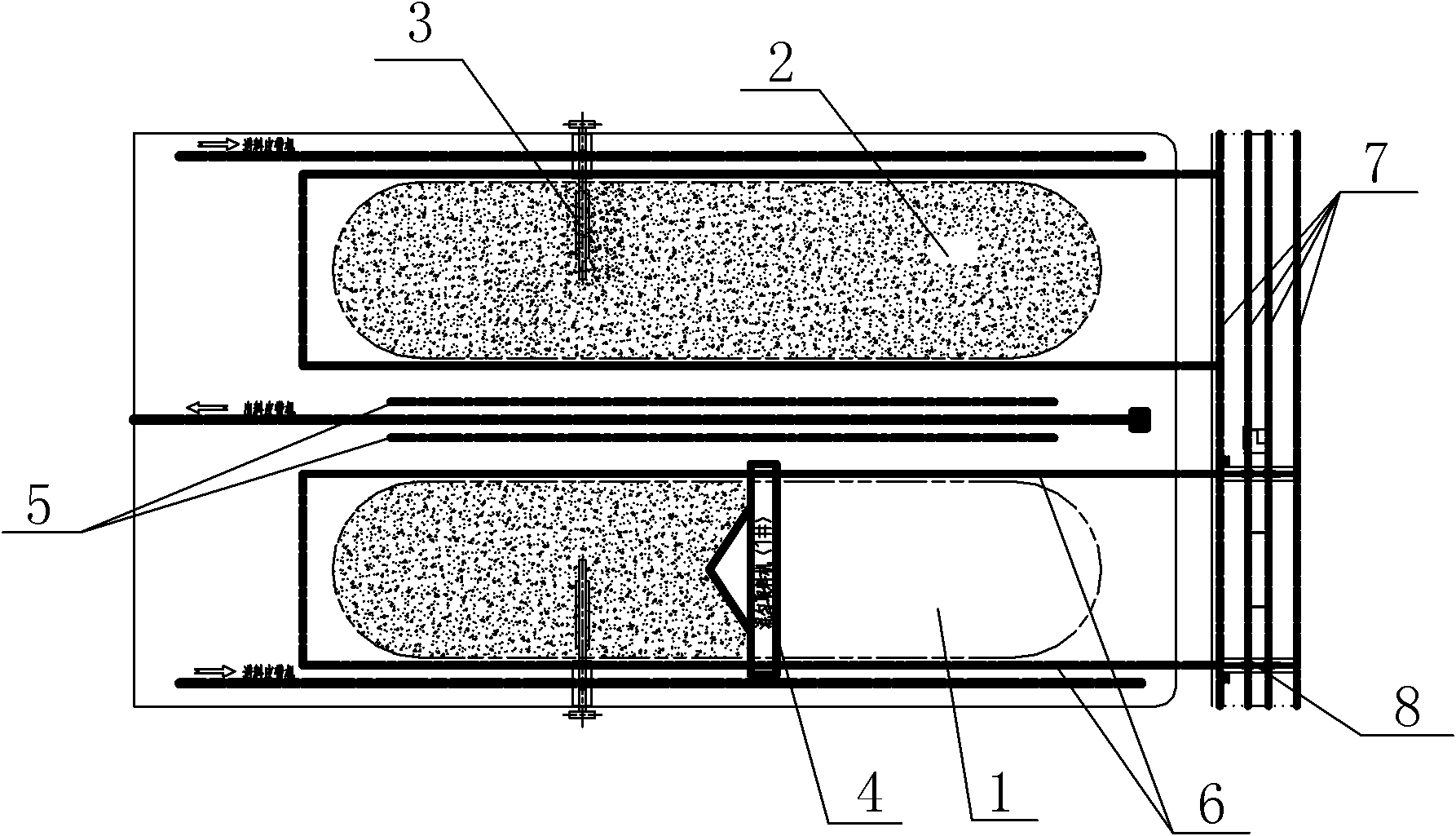

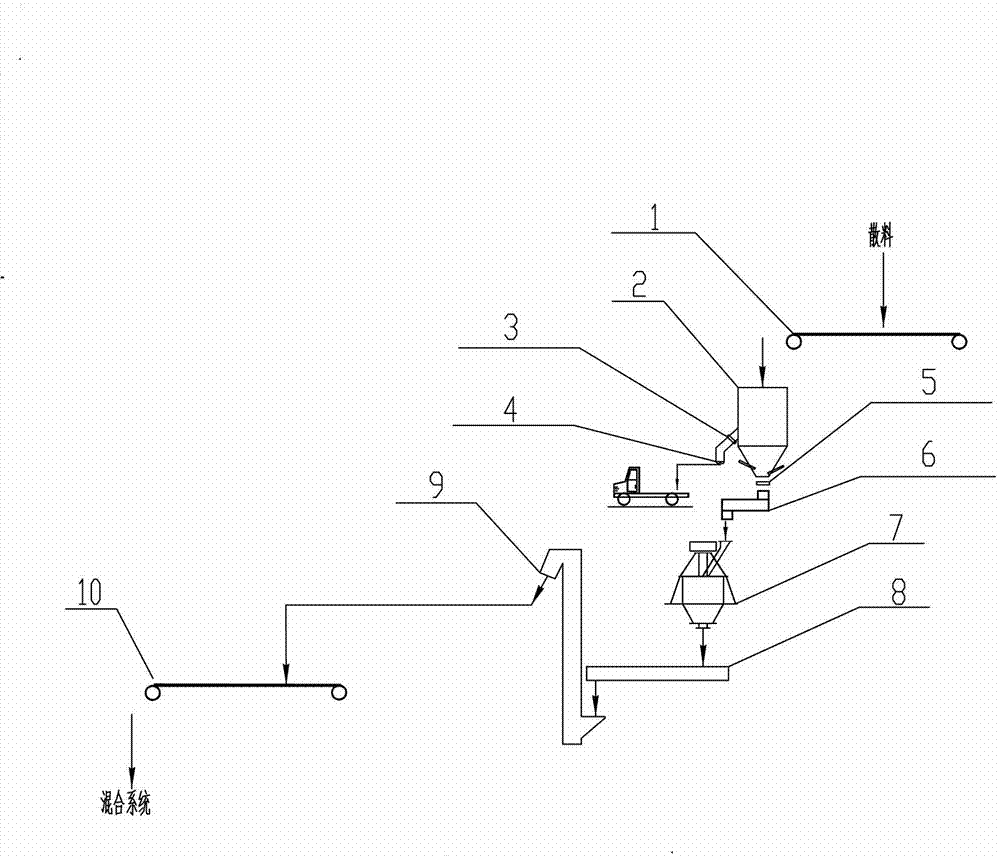

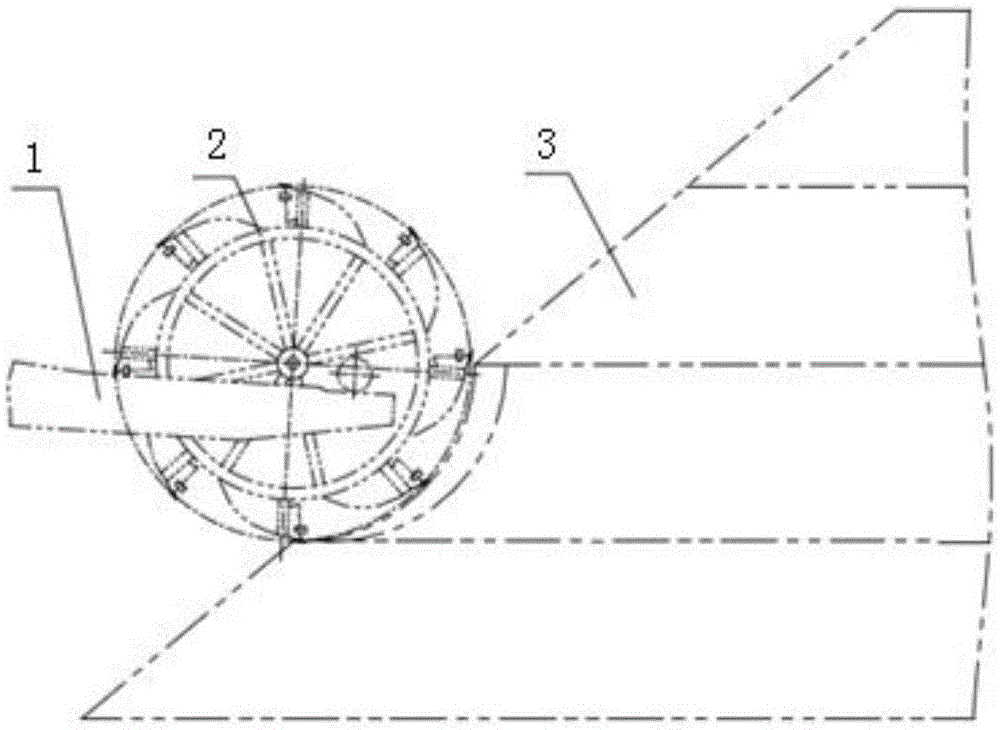

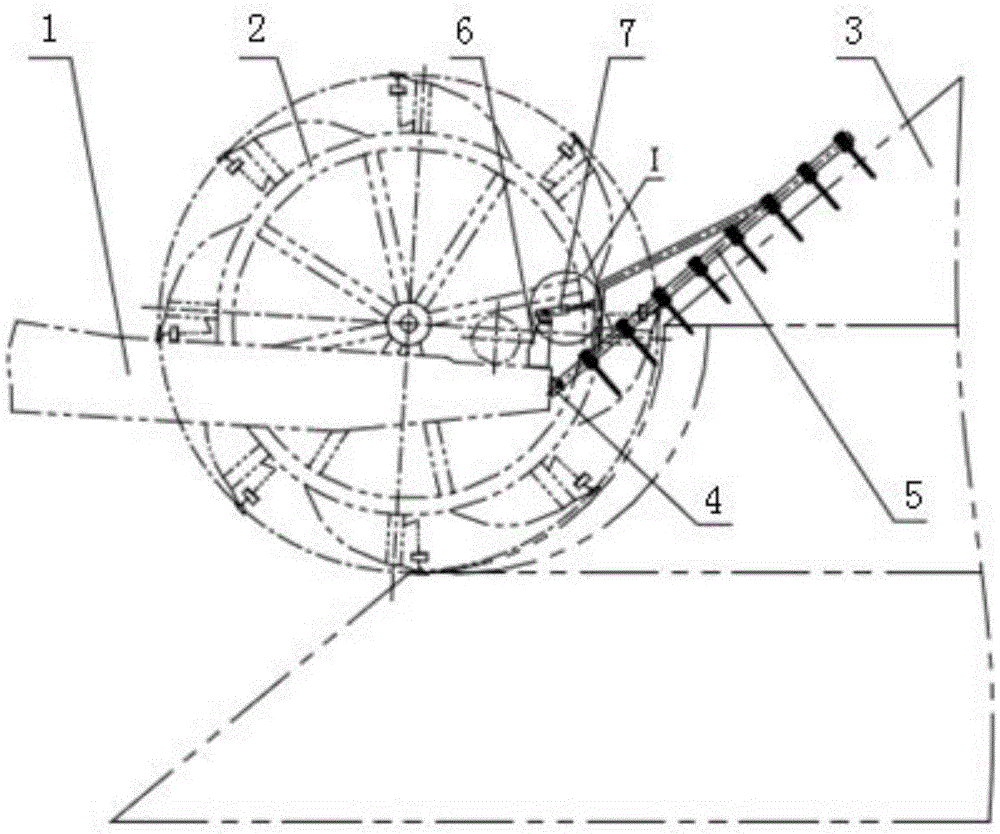

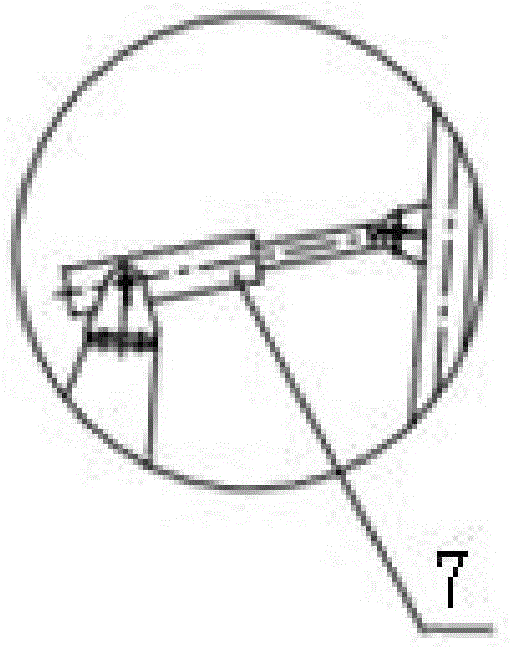

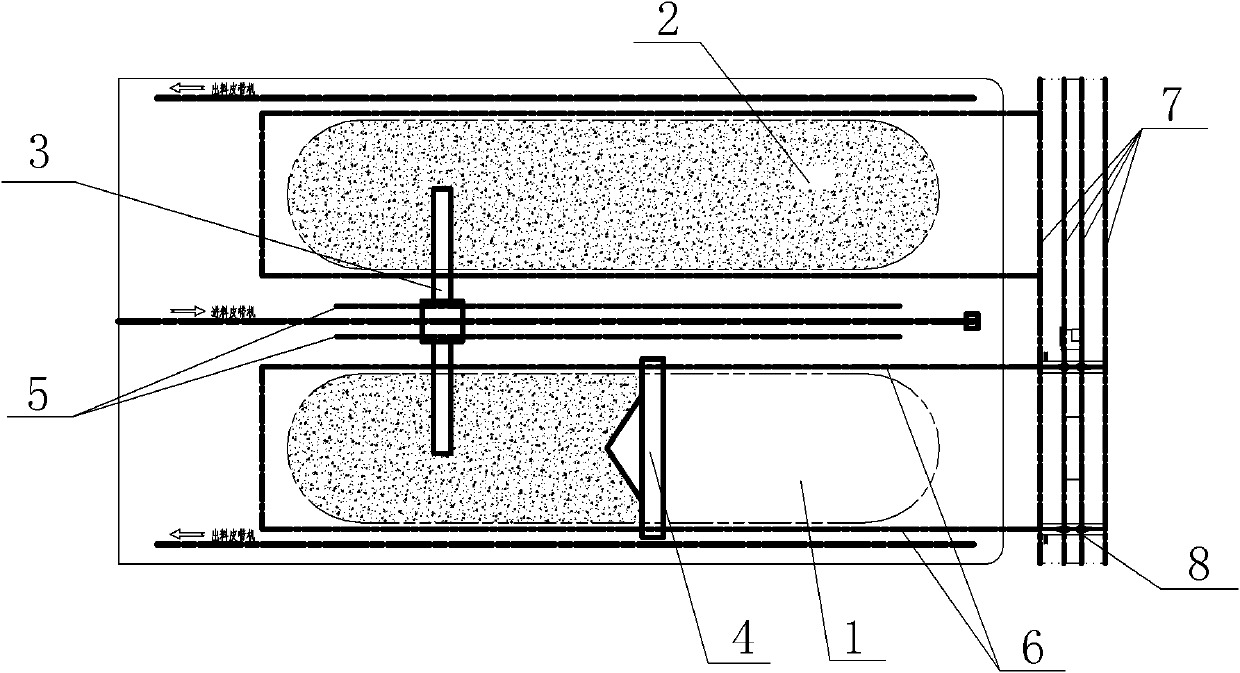

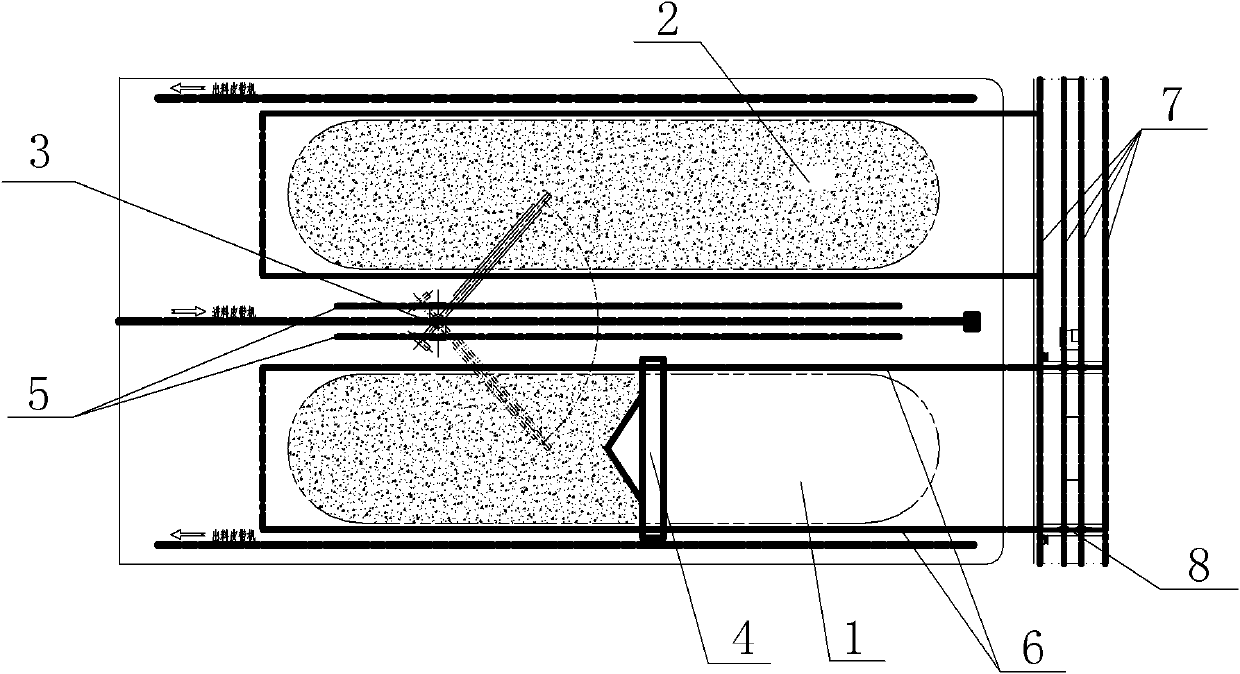

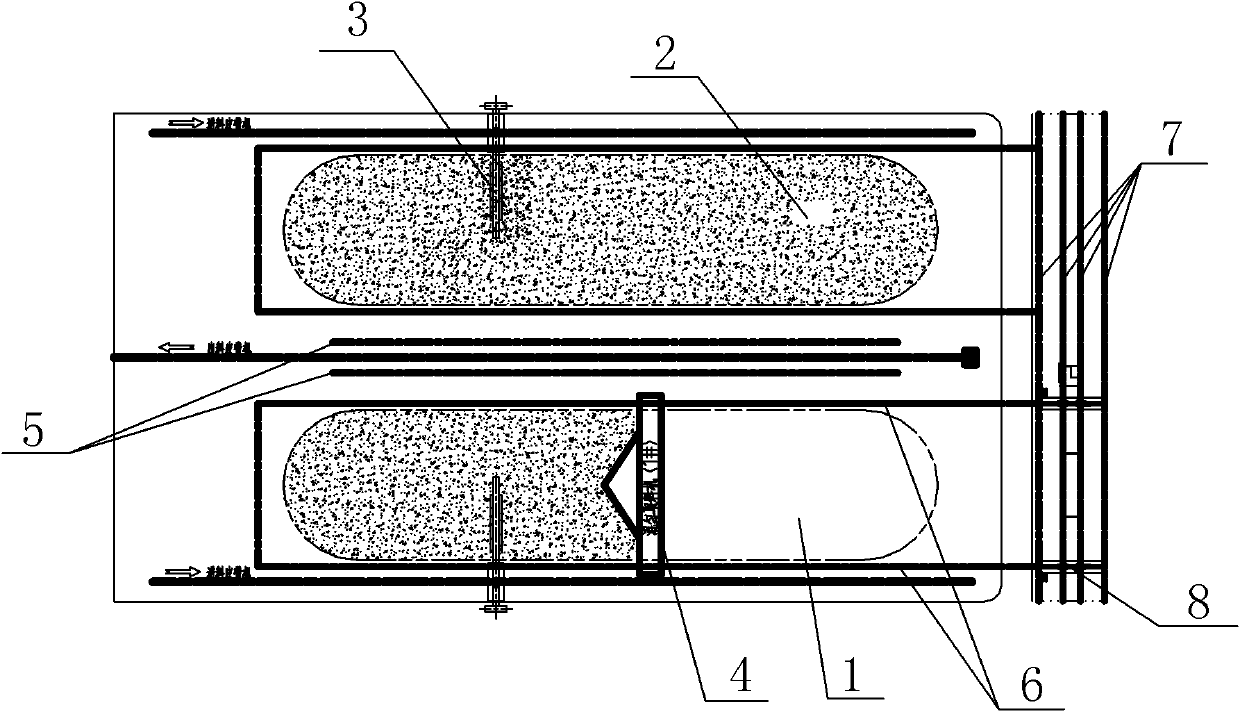

Bulk material handling system process and bulk material handling equipment

The invention discloses a bulk material handling system process and bulk material handling equipment. A bulk material handling system comprises a plurality of multi-span material yards, a track operation type material piling machine, a track operation type material taking machine and a transport truck, wherein the track operation type material piling machine is arranged in the plurality of multi-span material yards and is used for piling materials to a material yard; and the track operation type material taking machine is required to be driven onto the transport truck on the end part of the material yard after material taking operation in the material yard is finished, and is transported to other material yards in the plurality of multi-span material yards through the transport truck for continuous operation. In the invention, the problems of high early-stage investment of the bulk material handling equipment, low utilization rate of the equipment during operation and heavy later-stage maintenance tasks of the equipment at present can be solved; and the system and the equipment are easy and convenient to operate, are easy to link through electric control and are particularly suitable for occasions where the equipment in the bulk material handling system has higher vacancy rate in the plurality of multi-span material yards.

Owner:HUADIAN HEAVY IND CO LTD

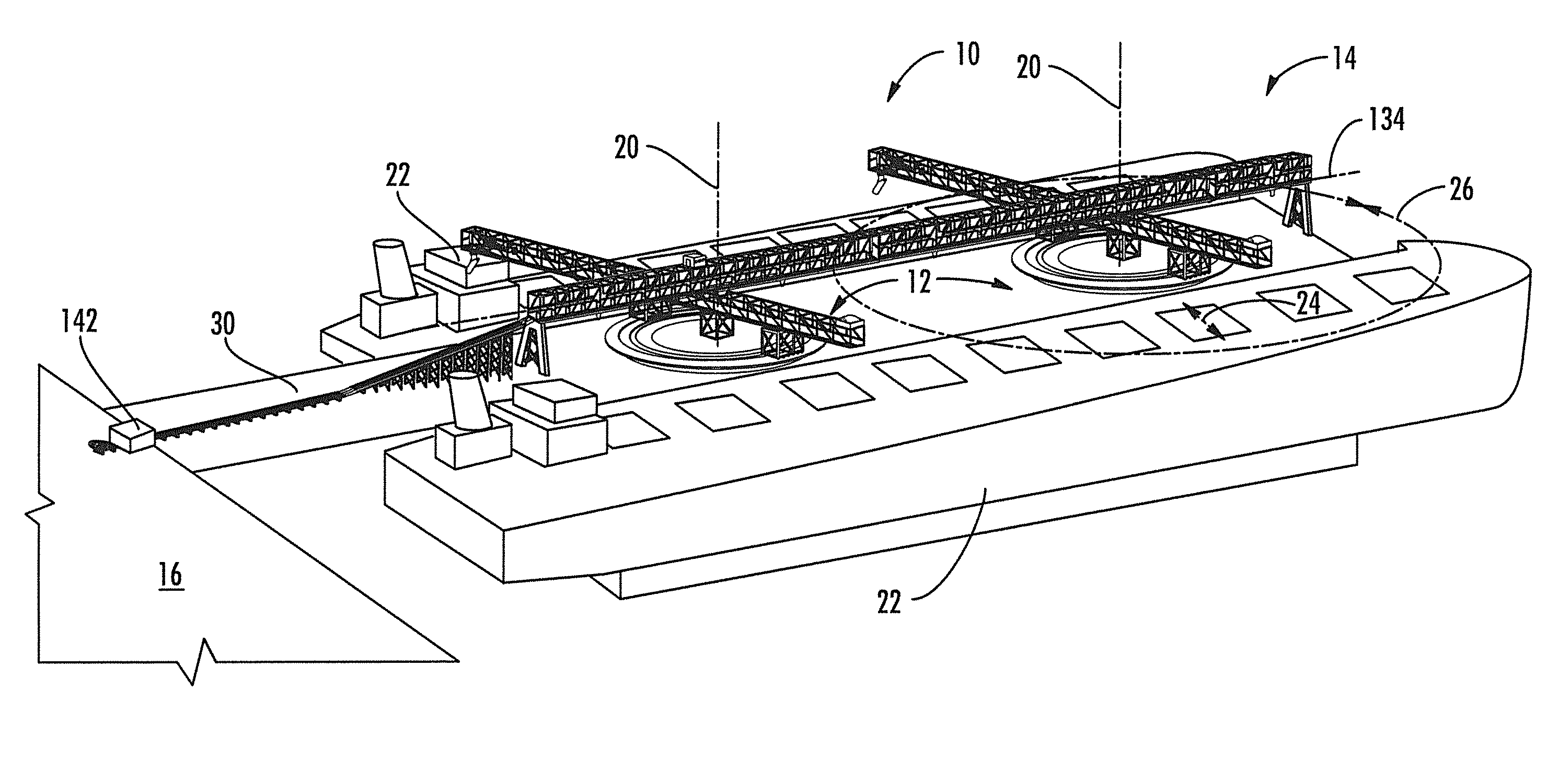

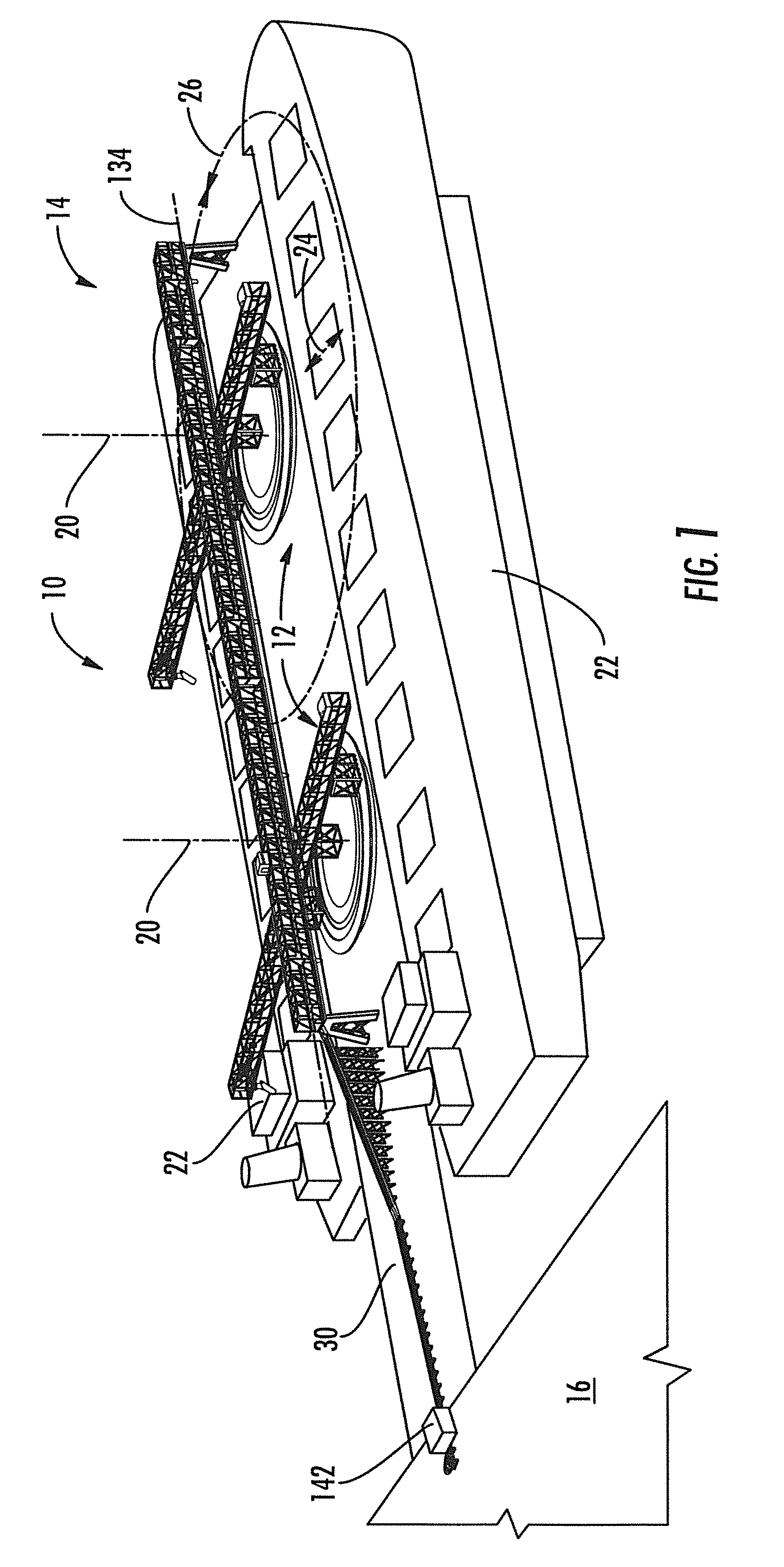

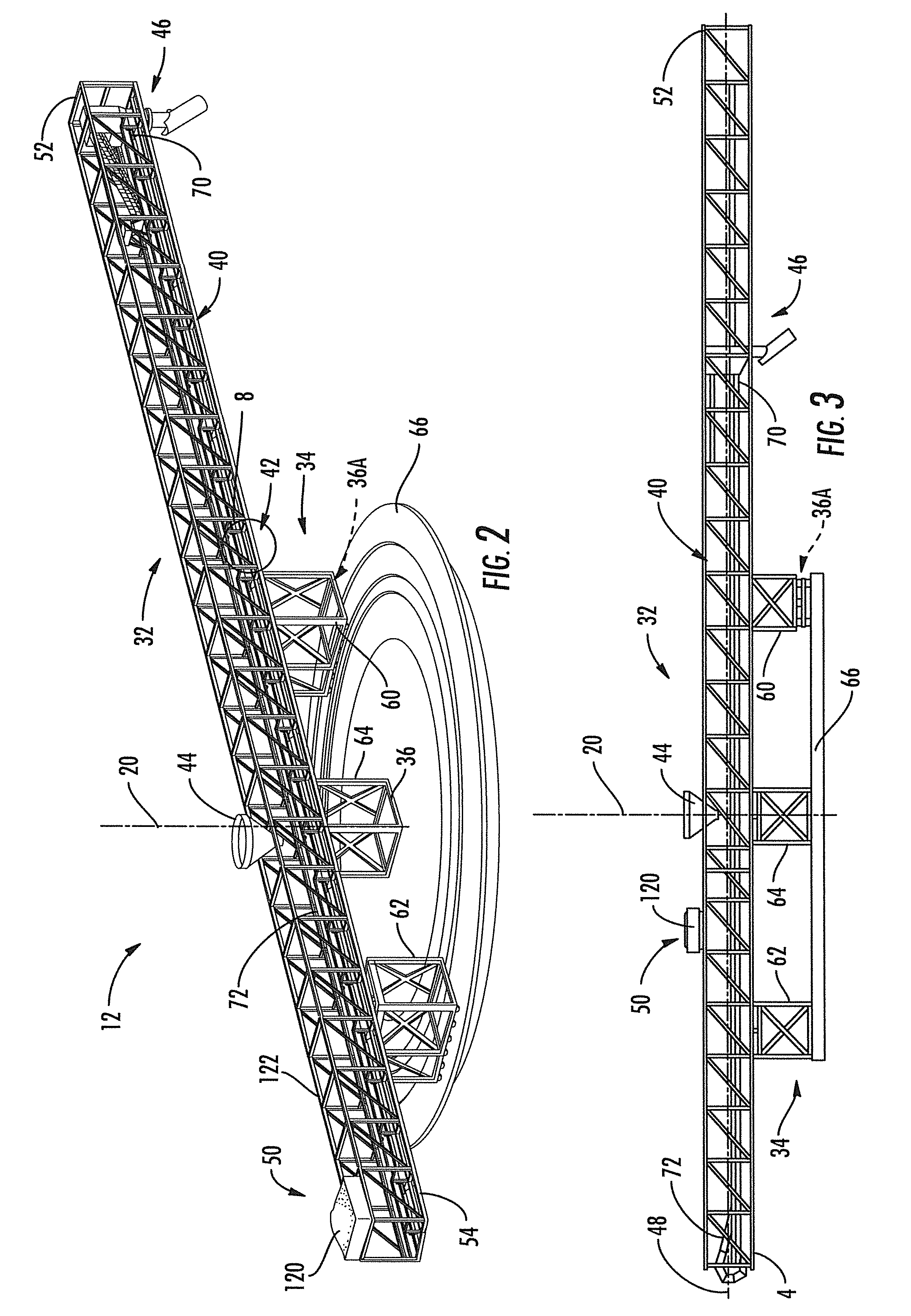

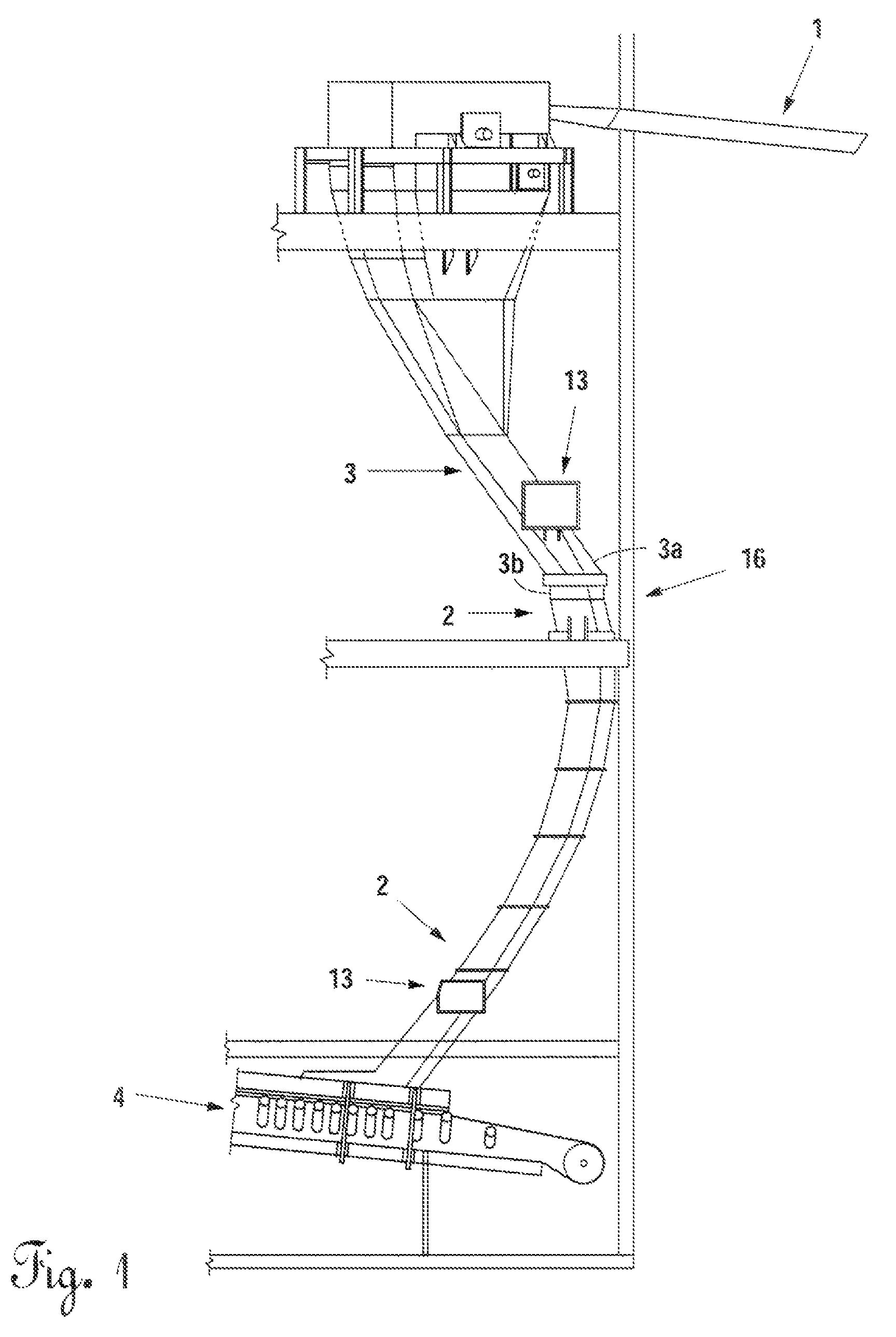

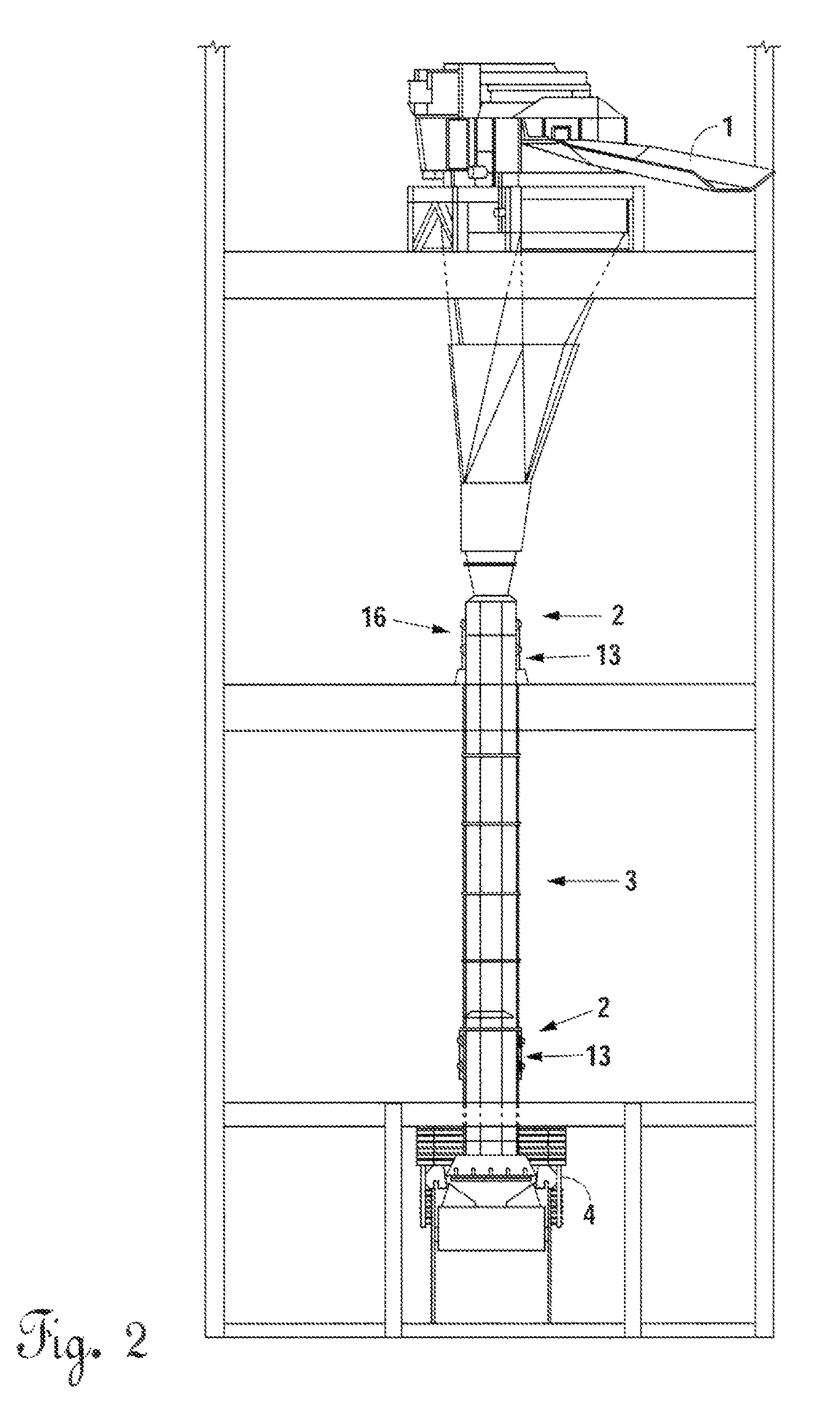

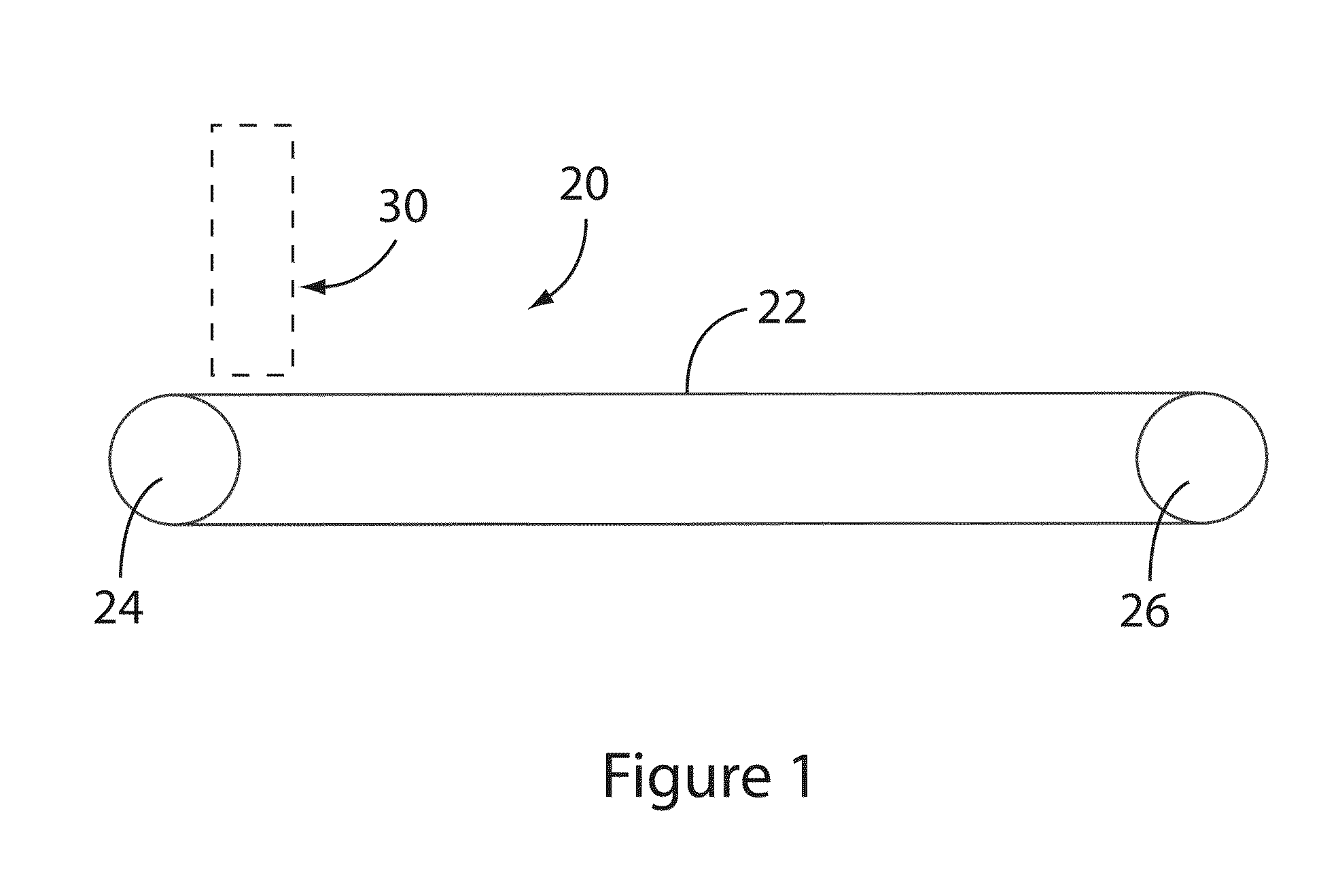

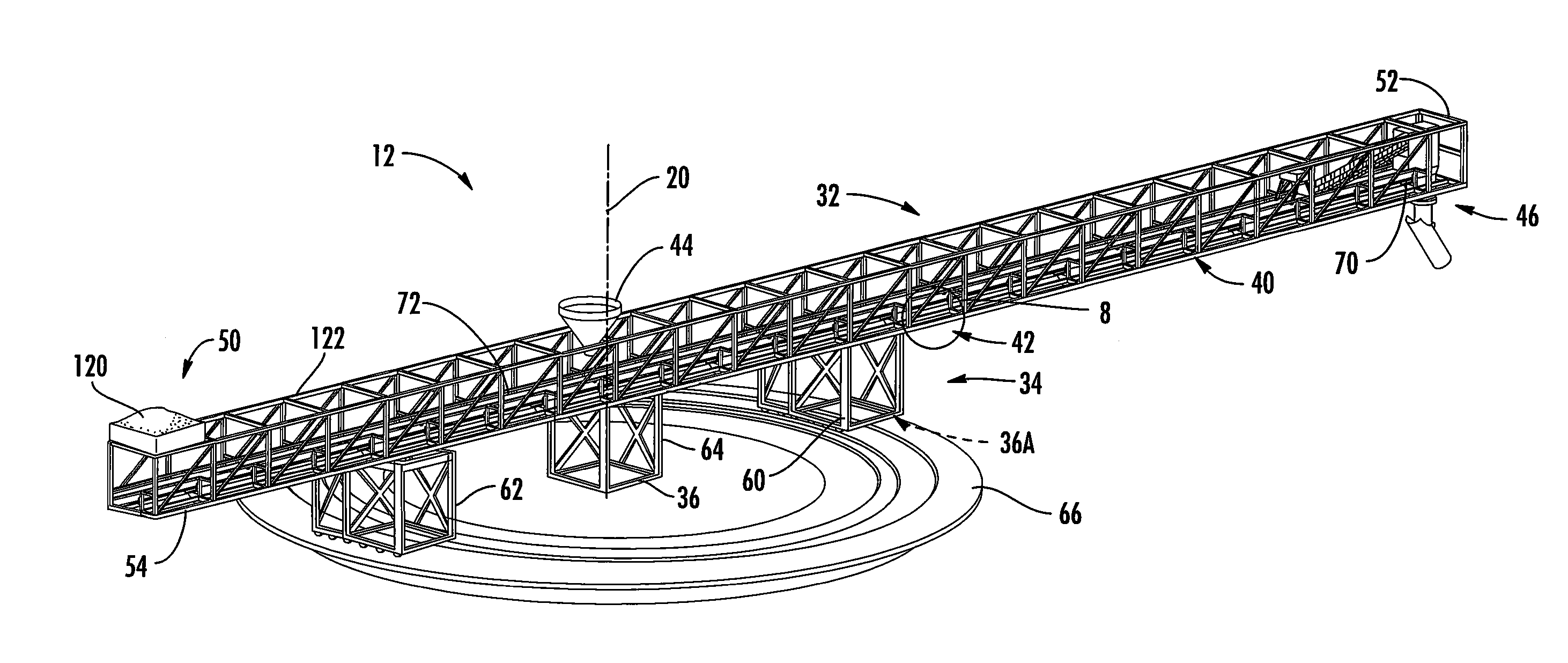

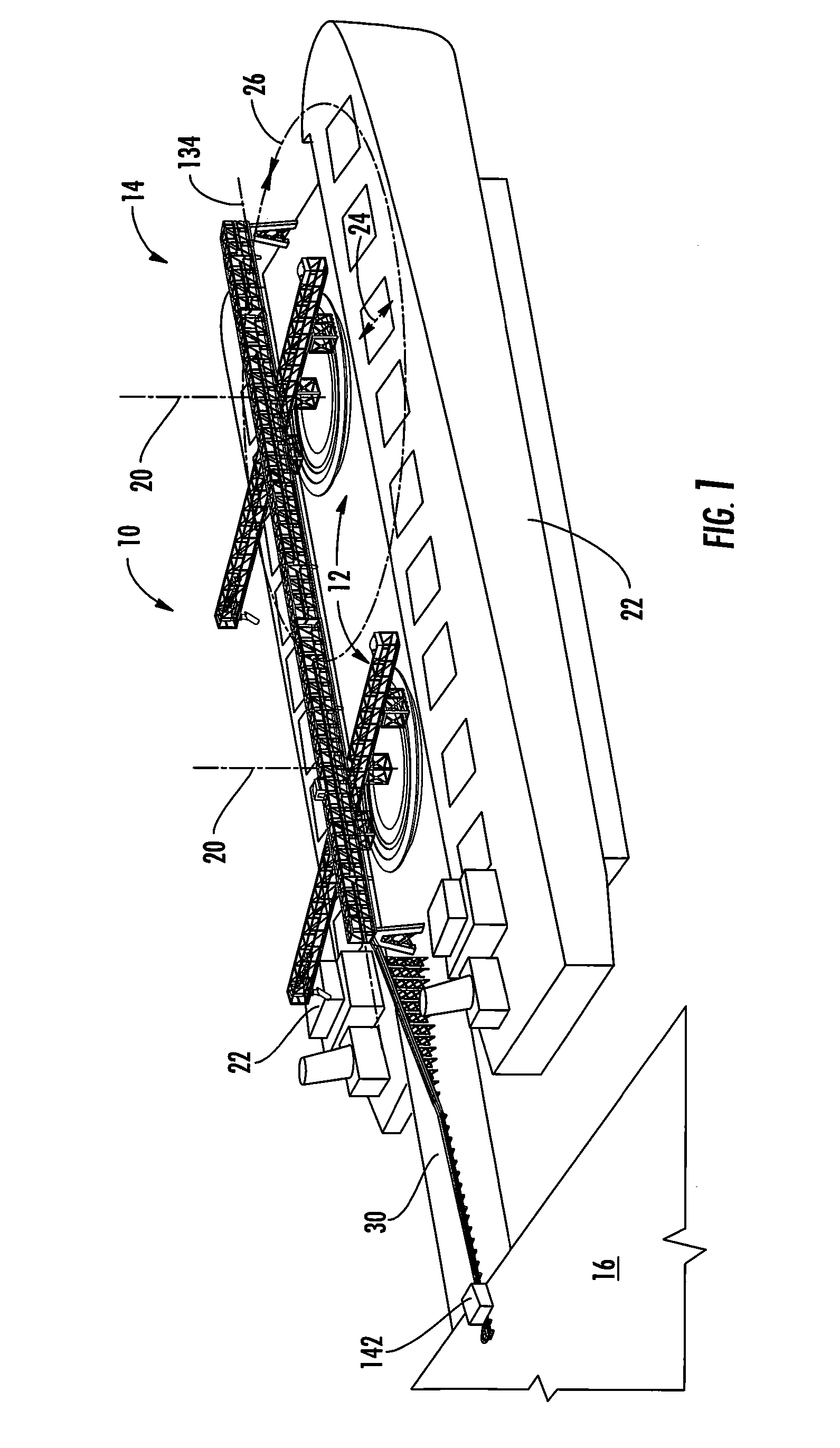

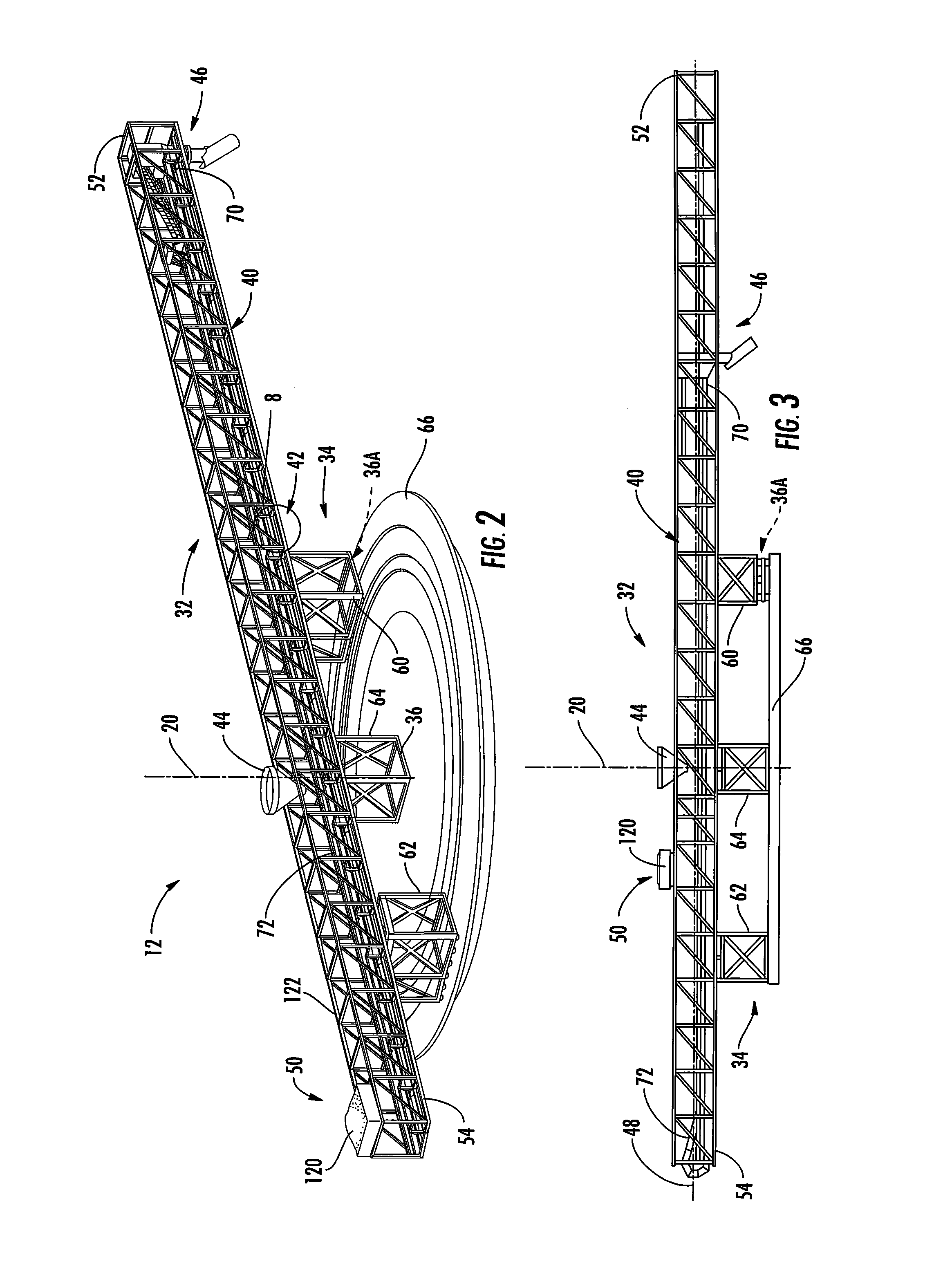

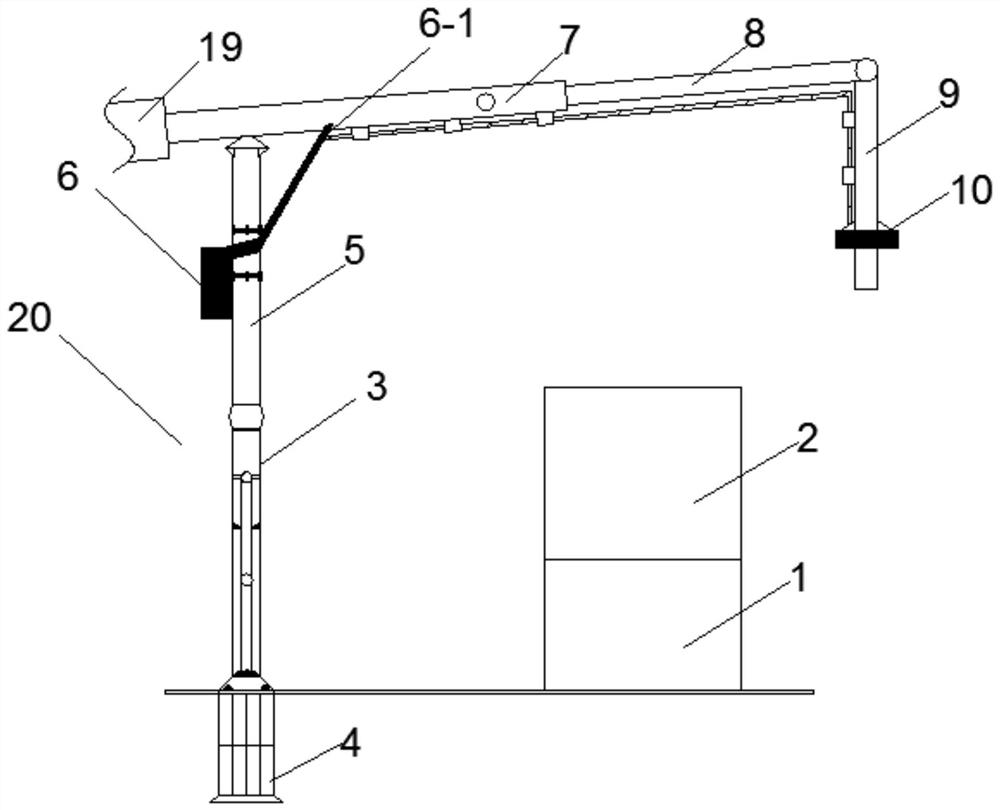

Bulk material handling system and method

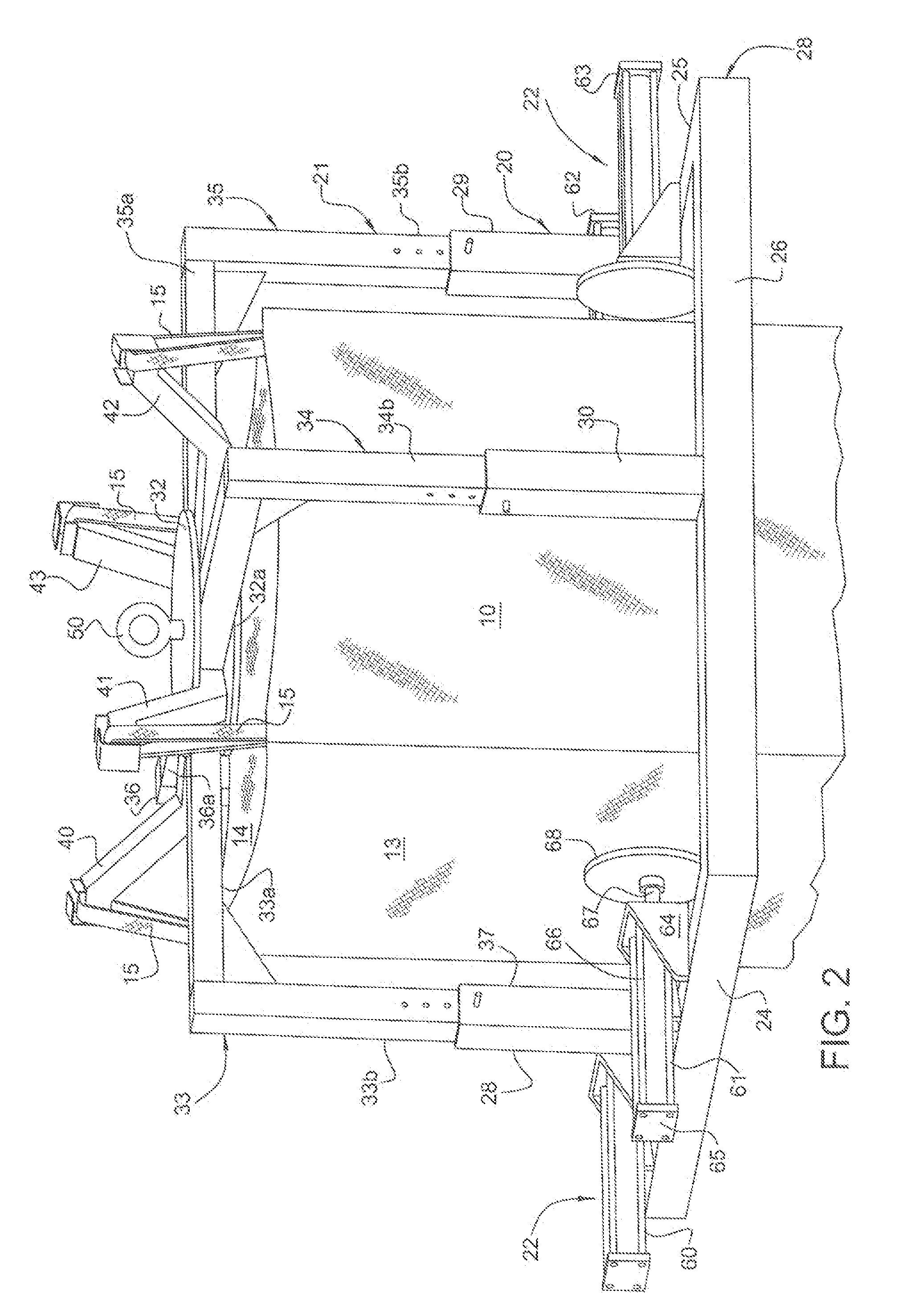

ActiveUS8955667B1Easy to optimizeCargo handling apparatusPassenger handling apparatusEngineeringHandling system

A bulk material handling system and method use a horizontal boom frame supporting a conveyor mechanism for bulk material that is slidable relative to the horizontal boom frame. The conveyor mechanism is positioned such that, with bulk material received at a fixed location, or loading axis, on the horizontal boom frame, a portion of the conveyor mechanism will always be positioned to receive bulk material. The horizontal boom frame can also be made rotatable about the loading axis. By rotating the horizontal boom frame and advancing or withdrawing the conveyor mechanism, the discharge point for bulk materials relative to the loading axis can be altered radially and angularly without interrupting the flow of bulk materials through the system. A supply bridge assembly can be employed to bring the bulk materials to the loading axis of the boom.

Owner:RAIL VEYOR TECH GLOBAL

Bulk material handling system and portable loading apparatus thereof

A bulk material system generally consisting of a container having an upper wall, a vertical wall and an opening in the vertical wall; a support frame detachably mountable on the upper and vertical walls of the container; a hopper mounted on the support frame; a material conveying conduit mounted on the frame having an inlet communicating with an outlet of the hopper for receiving material therefrom and an end portion with an outlet insertable through the vertical wall opening of the container when the frame is detachably mounted on the container; and a conduit supported on the support frame having an outlet communicating with the material conveying conduit and an inlet communicable with a source of gas under pressure, function to supply gas under pressure to the material conveying conduit for pneumatically conveying material fed from the hopper into the material conveying conduit, therethrough, into the container.

Owner:YOUNG INDS

Bulk material handling system and control

A bulk material handling system includes a bulk material handling apparatus to convey bulk material and a bulk material handling accessory to aid the bulk material handling apparatus in conveying the bulk material. The bulk material handling accessory includes a controller having one or more sensors. The controller generates a control signal to adjust operation of the bulk material handling accessory based upon at least one status signal of the one or more sensors. The controller also generates the control signal in accordance with a status signal to control signal response pattern defined by system parameter values. The system parameters include a minimum value to define a minimum level of the control signal associated with fail-safe operation and a maximum value to define a maximum level of the control signal associated with stable operation the bulk material handling accessory.

Owner:MARTIN ENG

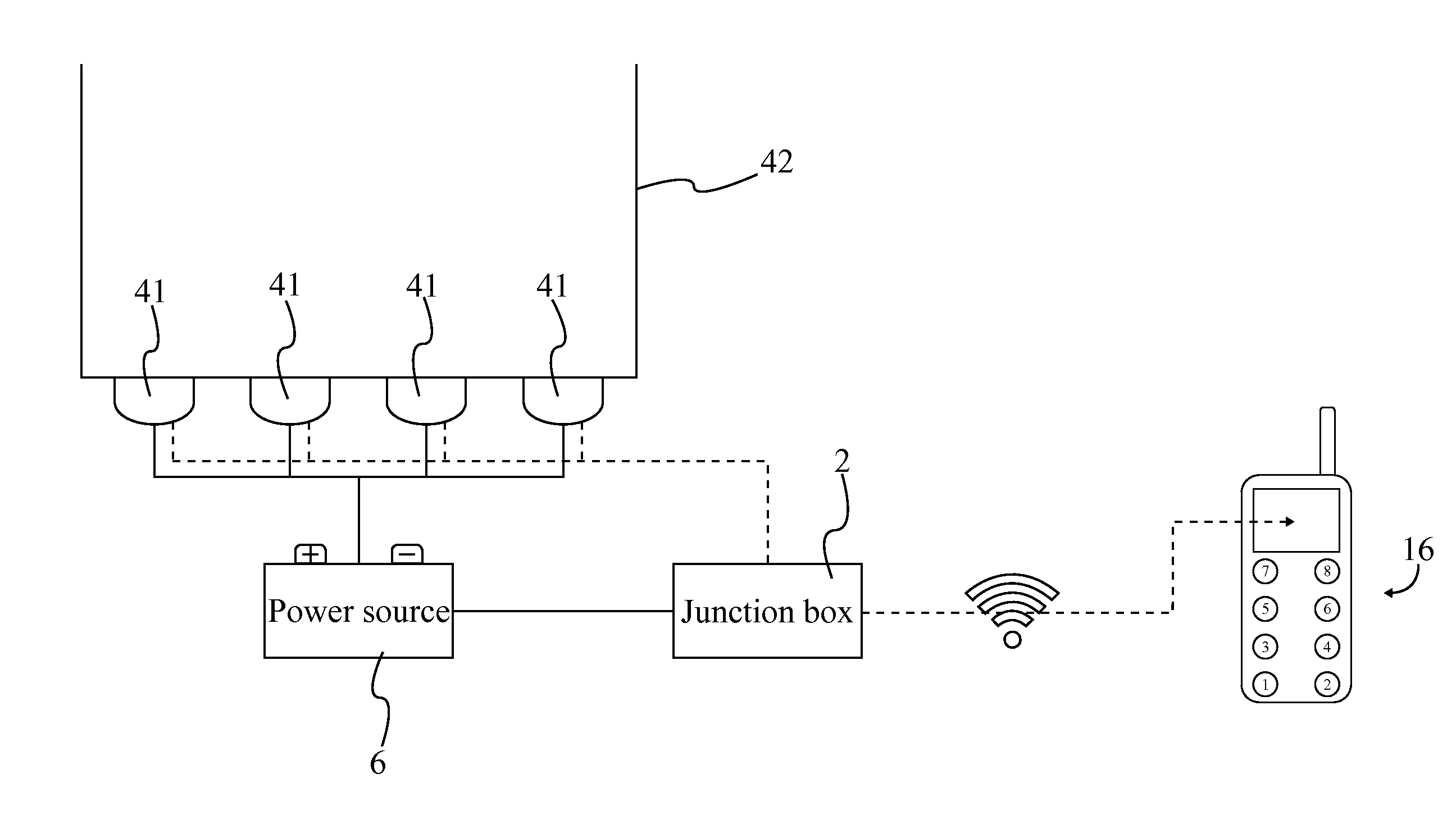

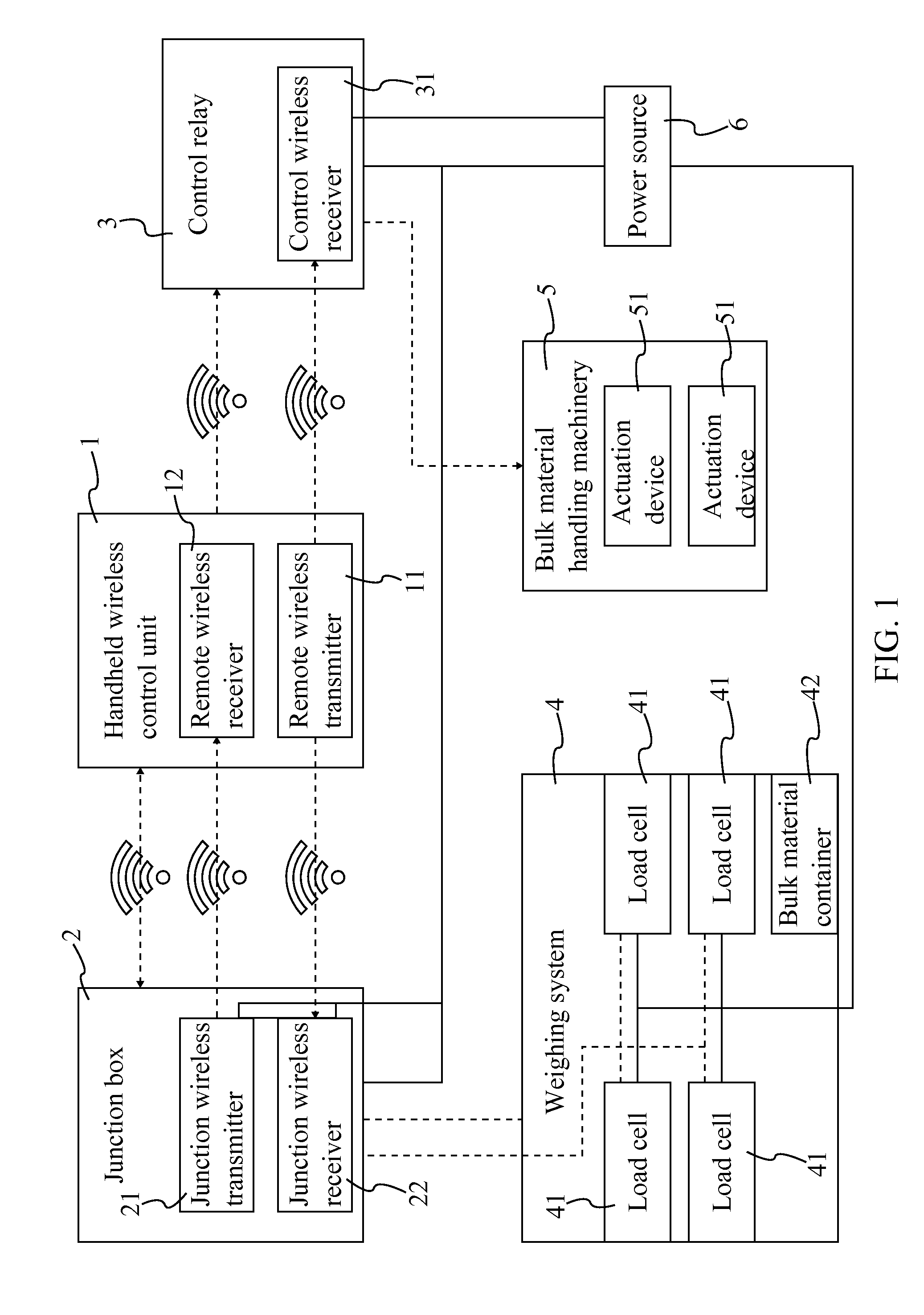

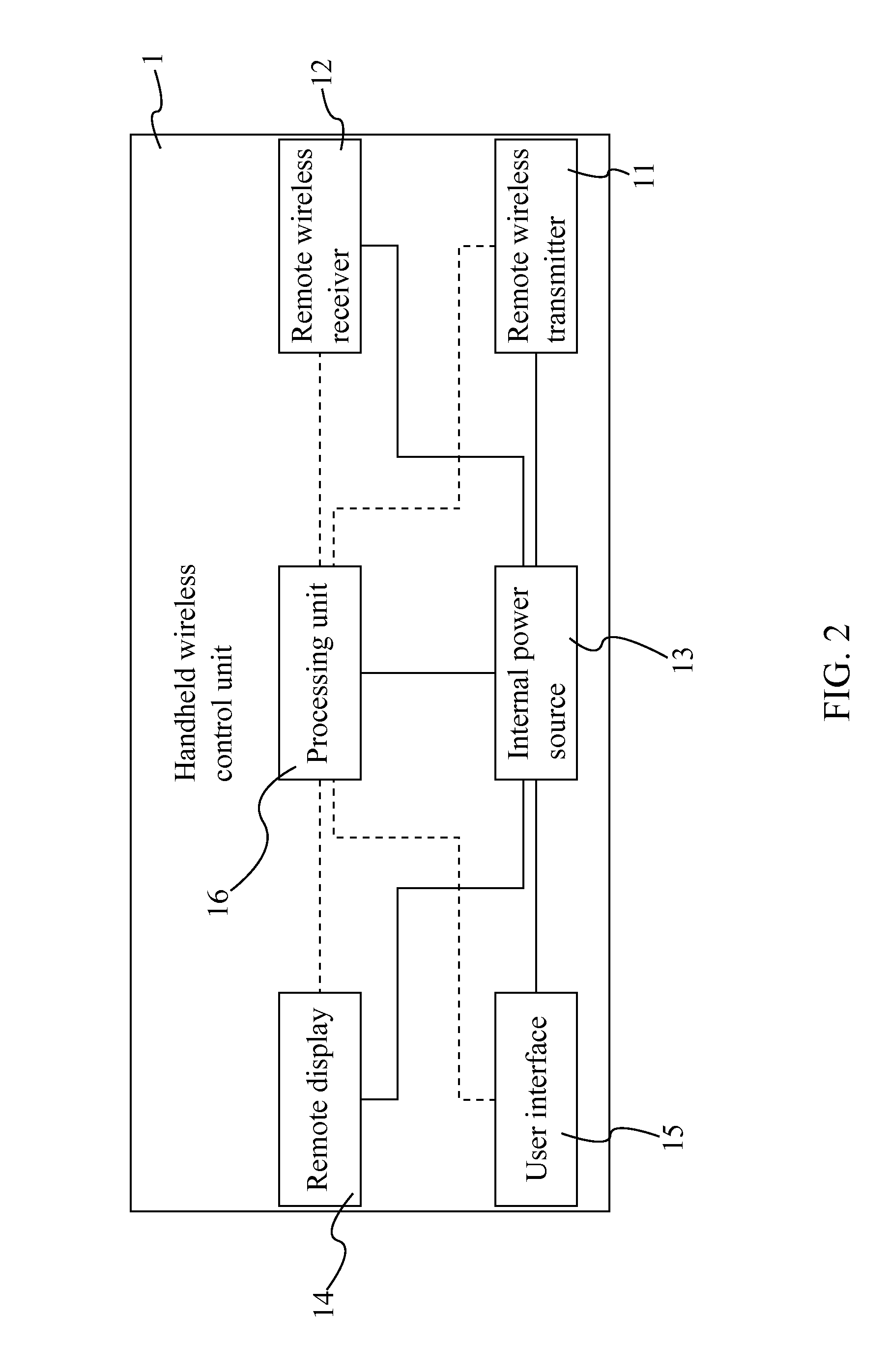

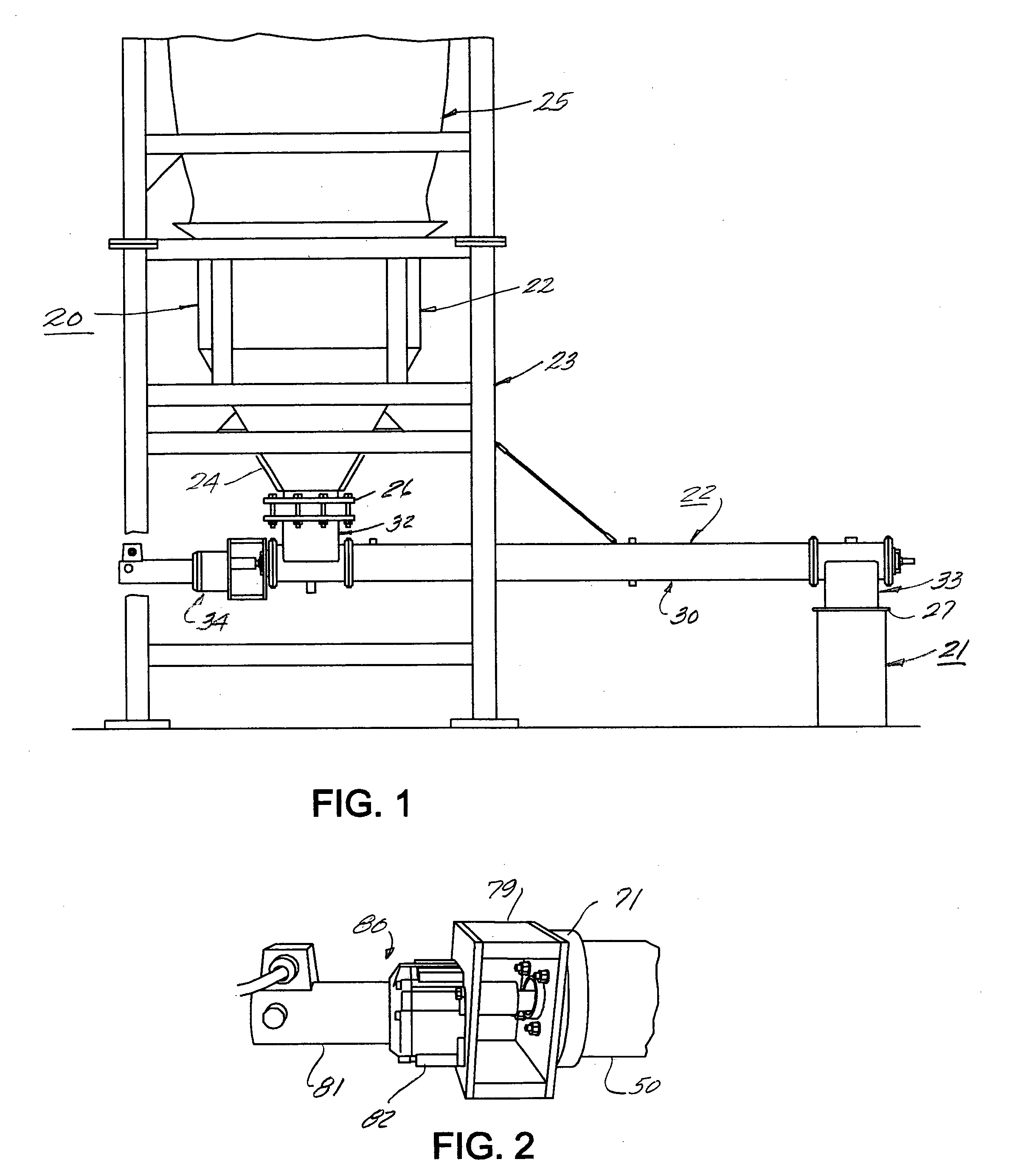

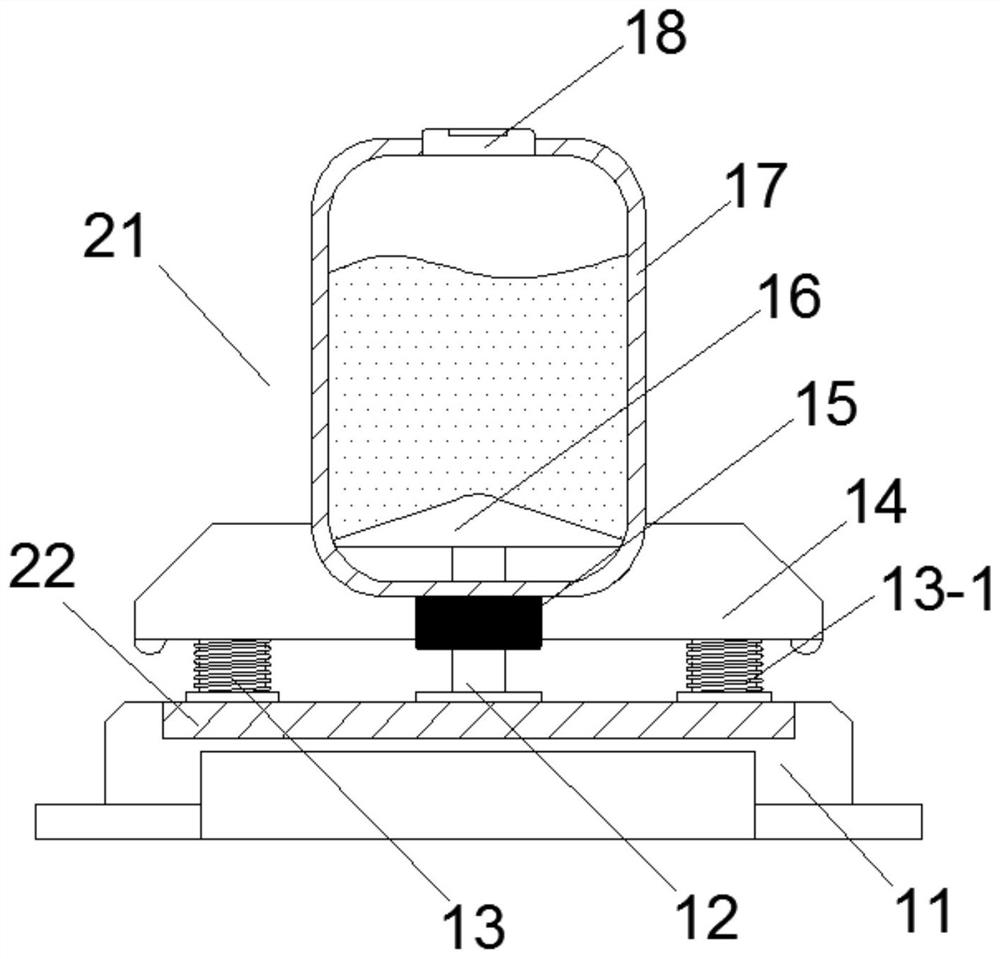

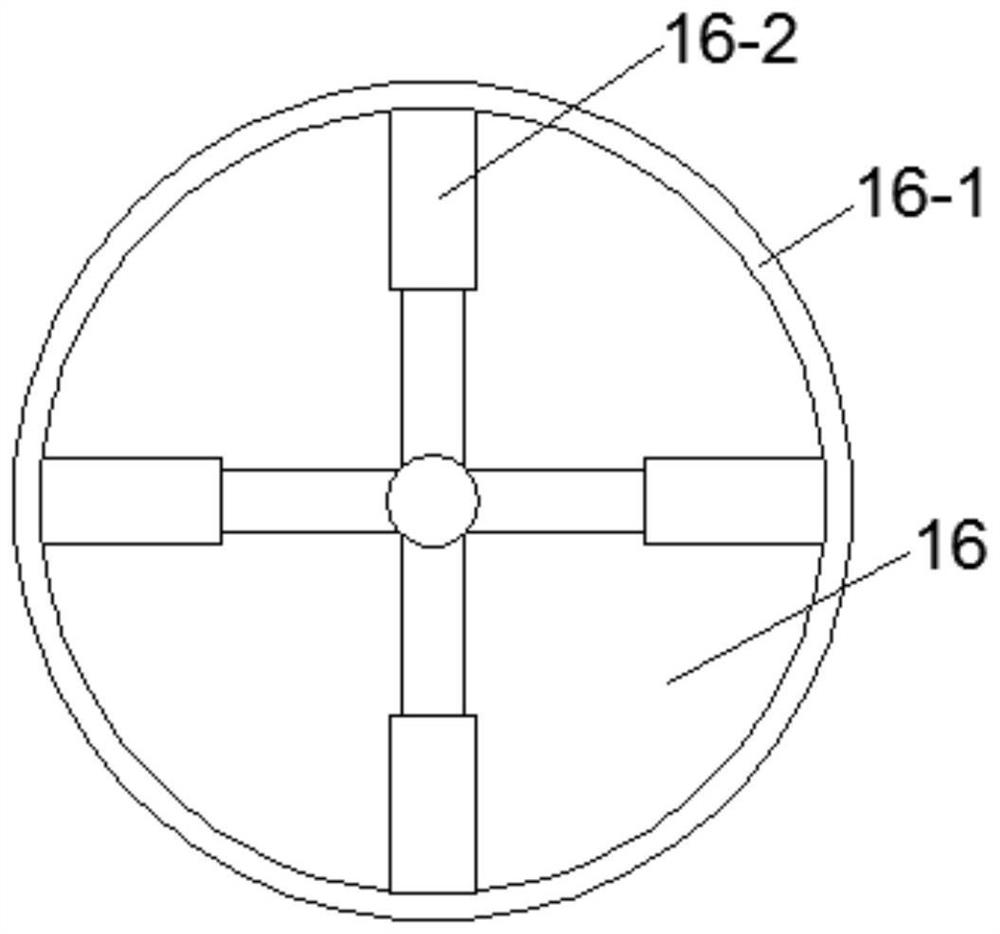

Wireless Scale Operation System

InactiveUS20140262554A1Weighing auxillary devicesSpecial purpose weighing apparatusWireless controlOperational system

A system is provided for operating a weighing system and a bulk material handling machinery through a single remote terminal, the terminal being a handheld wireless control unit. The hand held wireless control unit includes a transmitter and receiver which use near field communications to send and receive messages to the weighing system and bulk material handling machinery through a junction box (with its own transmitter and receiver) and control relay (with its own receiver). The junction box can be used to configure the weighing system as well as return data about measured weight recorded by the weighing system. The control relay can pass commands to actuation device that engage mechanisms of the bulk material handling machinery, allowing for remote stopping and starting of the machinery. The system provides improved efficiency by allowing wireless operation of components through a single terminal.

Owner:NEW WORLD IND

Apparatus and method for passive dust control in a transfer chute

InactiveUS8640855B2Minimize air flowReduce dust emissionsLoading/unloadingConveyor partsTransfer systemDust control

A dust control apparatus and method for a bulk material handling transfer system having a chute comprising a pathway there through for handling varying volumes of bulk material flowing through the chute using gravity flow. A self-adjusting air restrictor gate is mounted in the chute for engaging the upper surface of flowing bulk material through the chute for restricting the air pathway during material volume flow variations to reduce dust emissions. The gate member contacts the upper surface of flowing bulk material and moves up and down in response to the flow of bulk material through the chute to restrict the flow of air to reduce dust. A counterweight mechanism and a damper helps maintain controlled contact of the air restrictor gate with the upper surface of bulk material flowing through the chute.

Owner:BROBST STEVEN HAYS

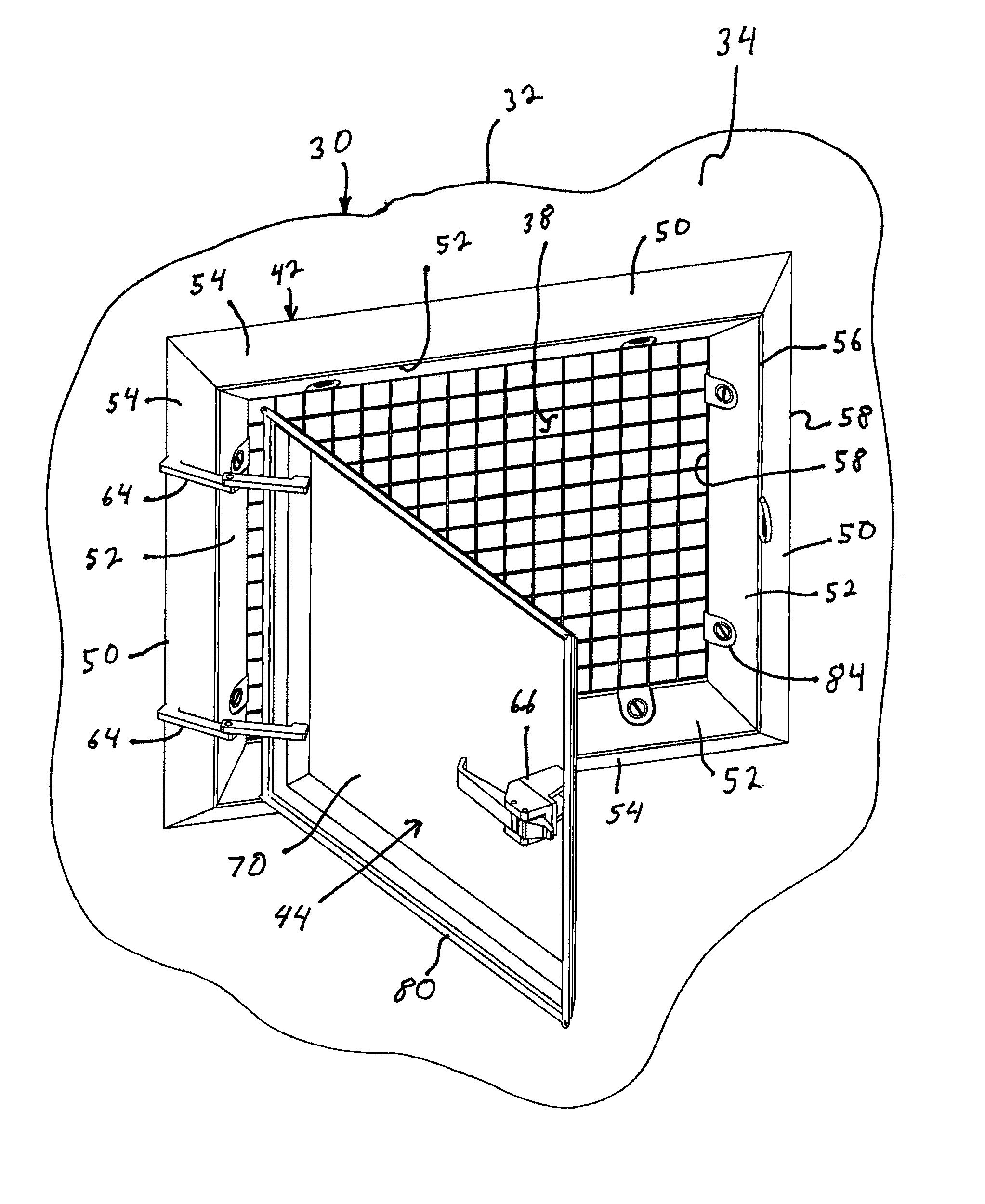

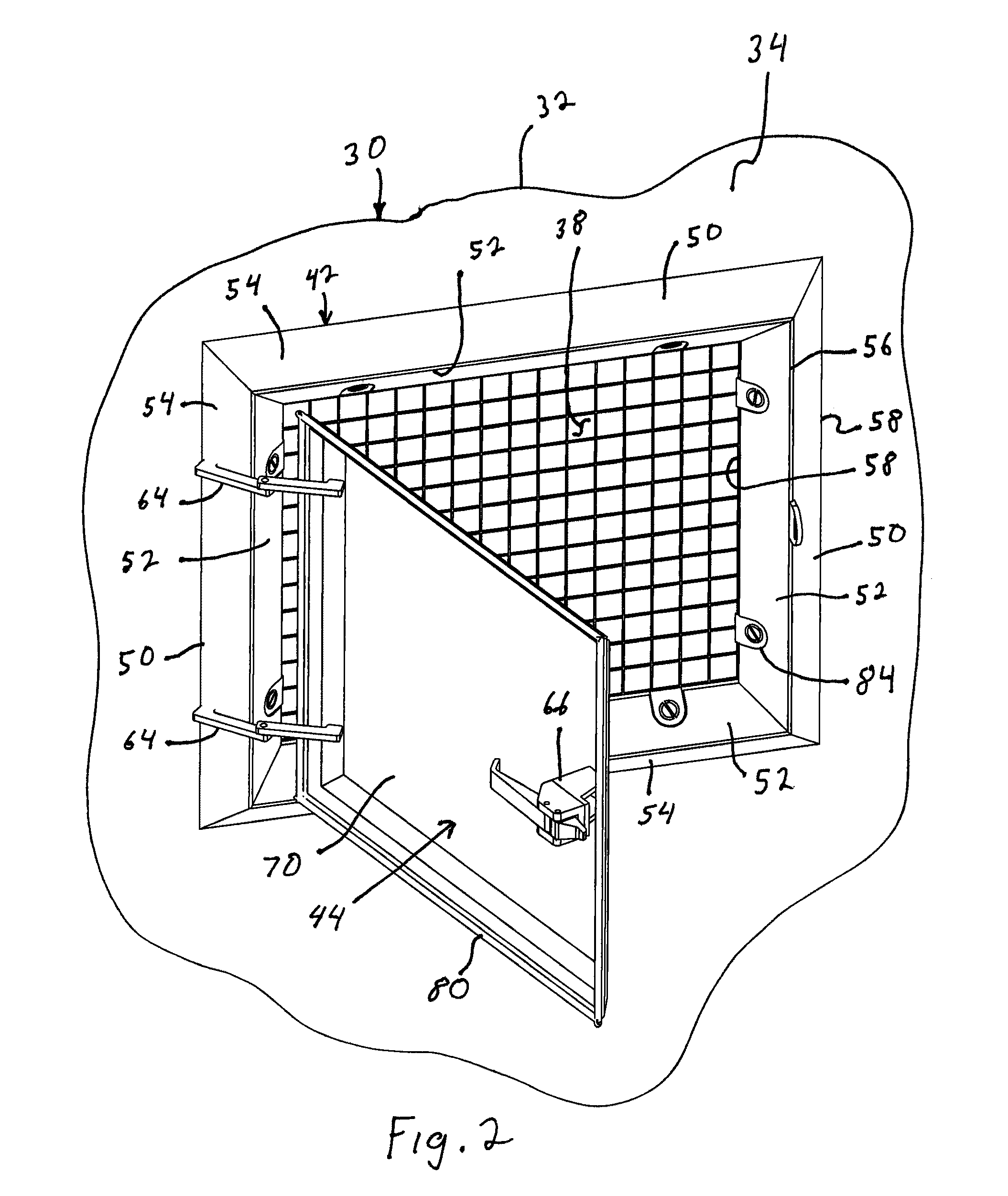

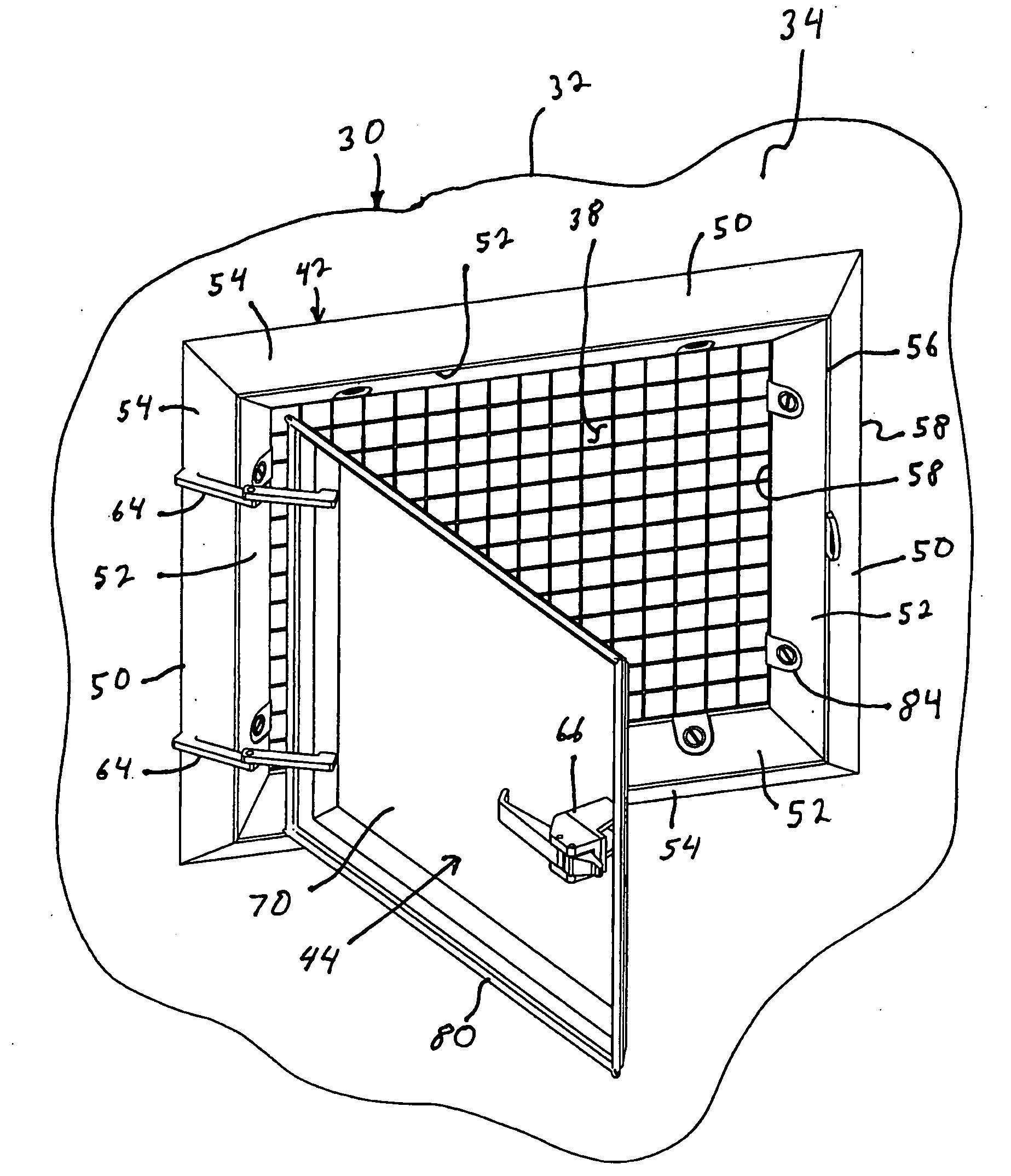

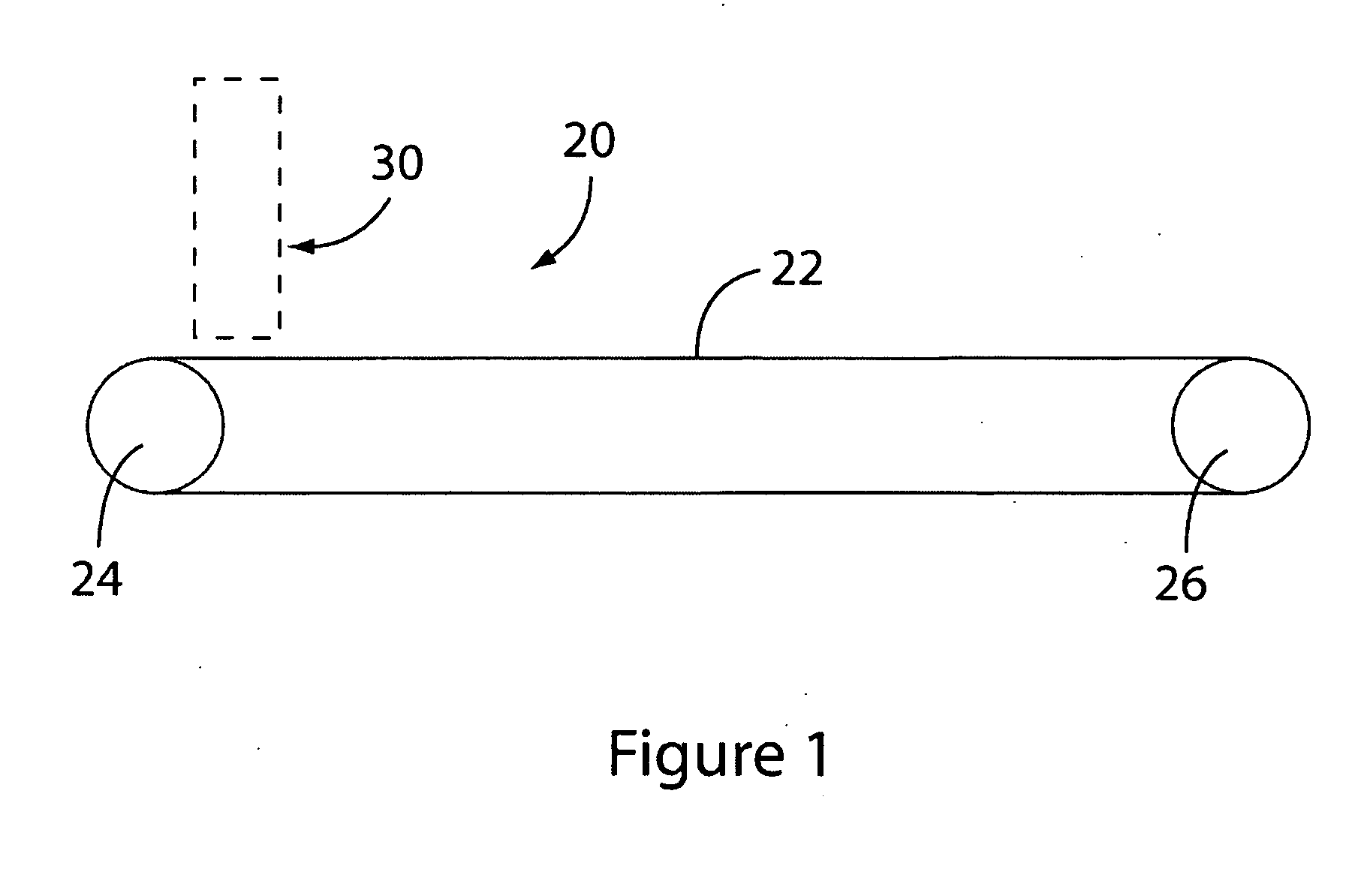

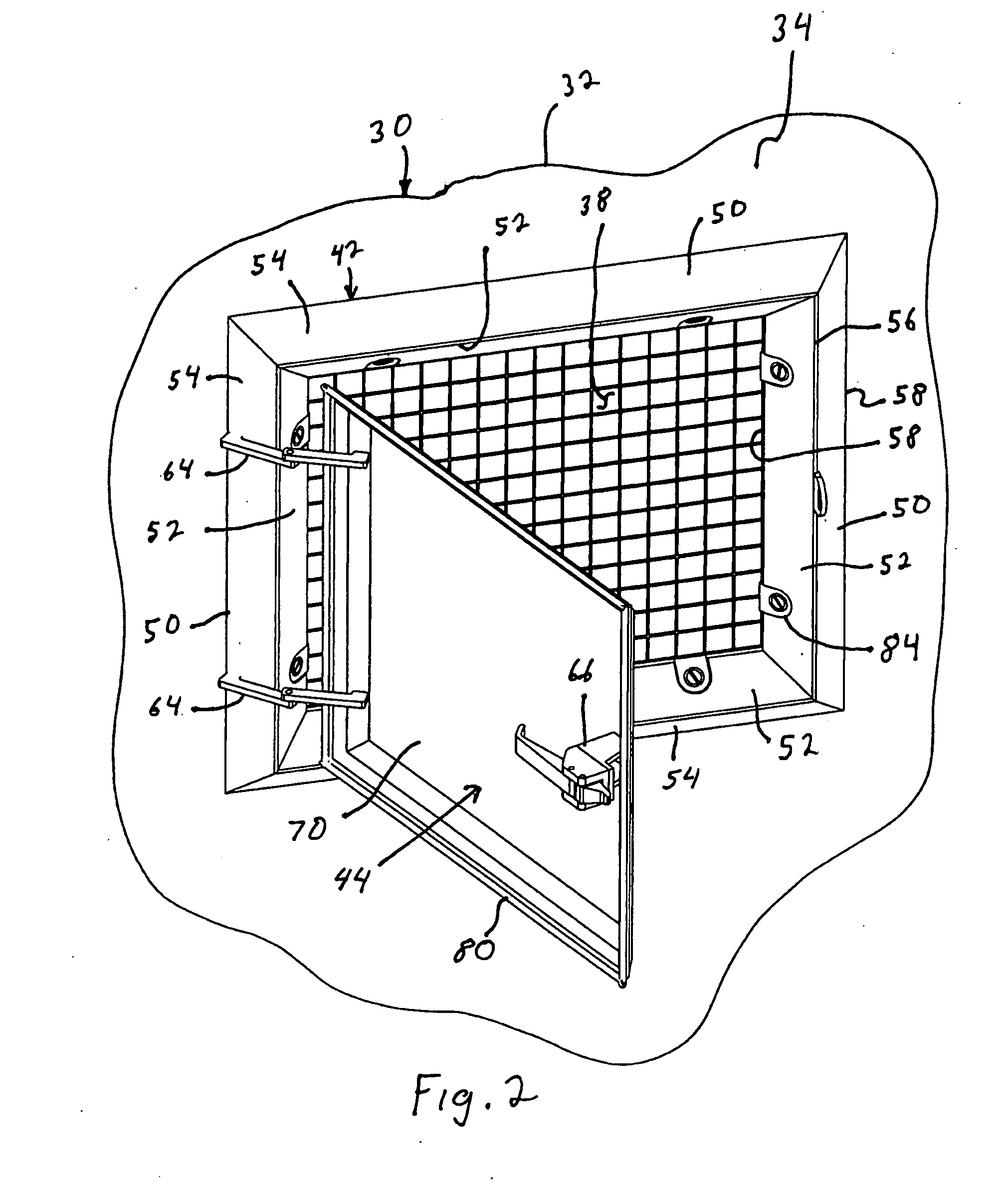

Dust buildup resistant access door and door frame of a bulk material handling system

Owner:MARTIN ENG

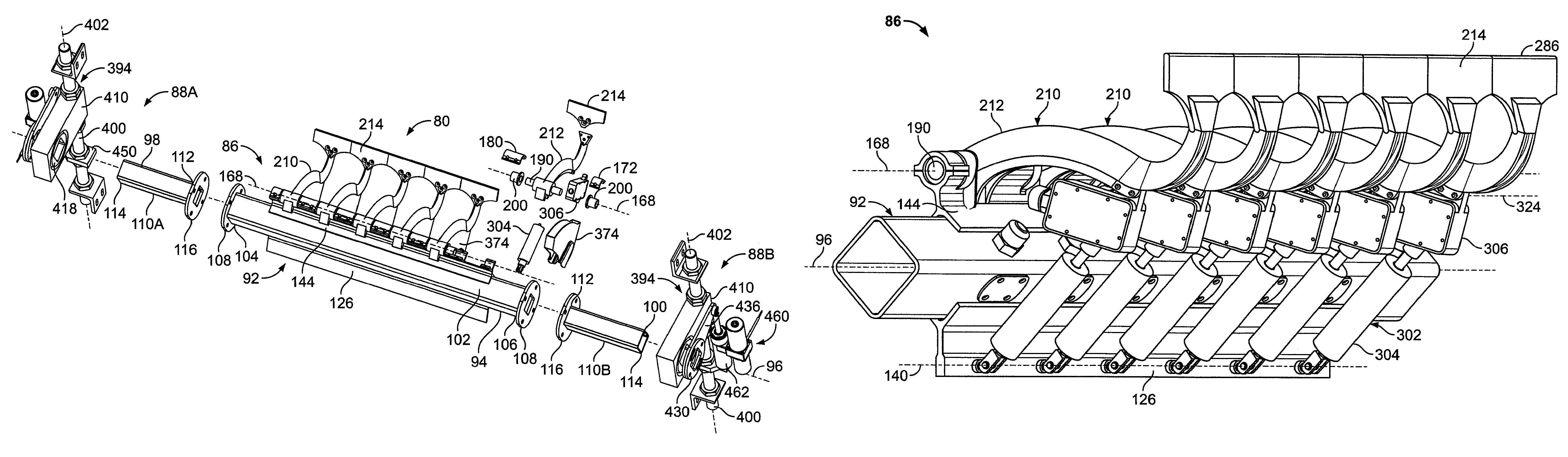

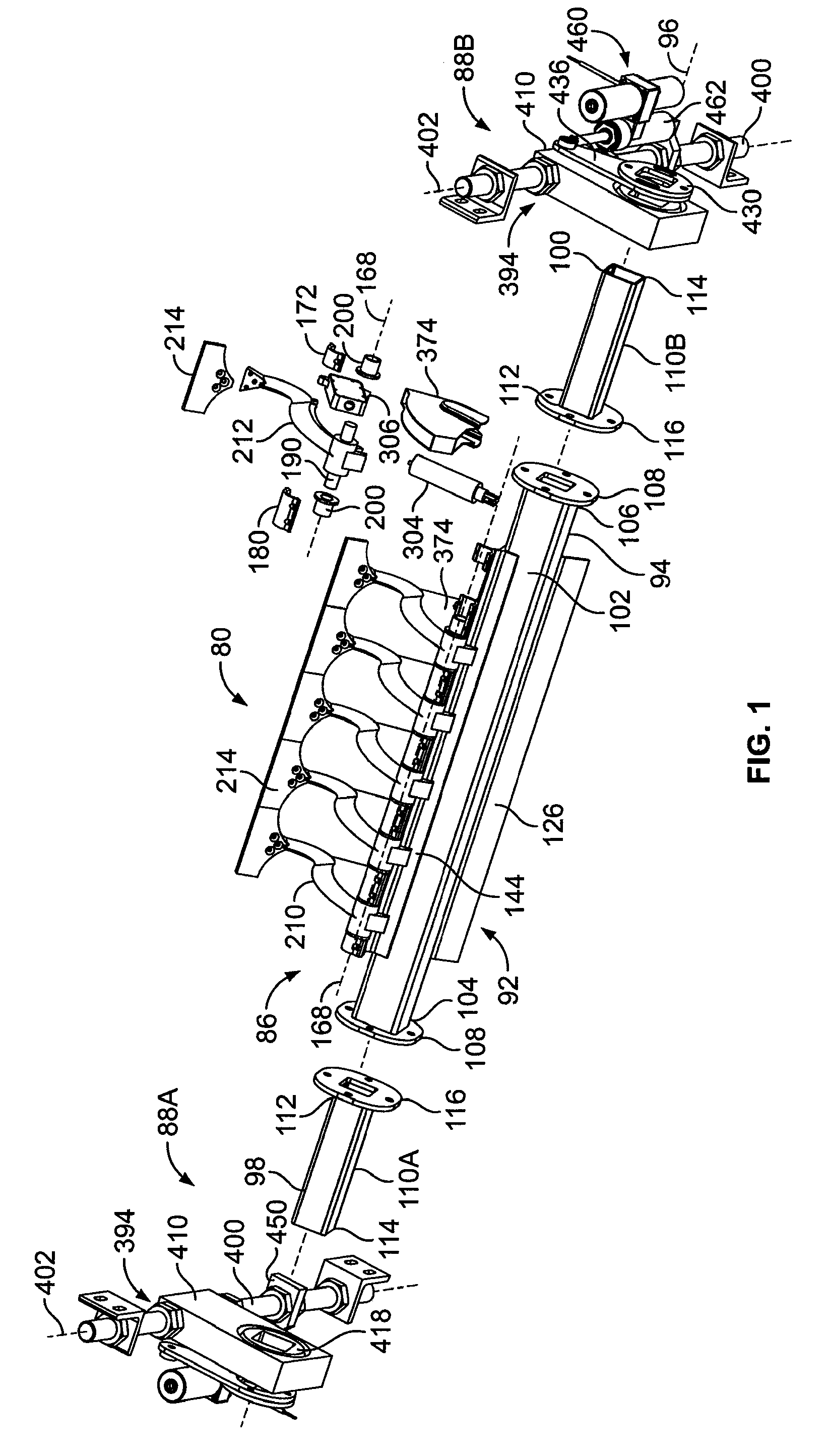

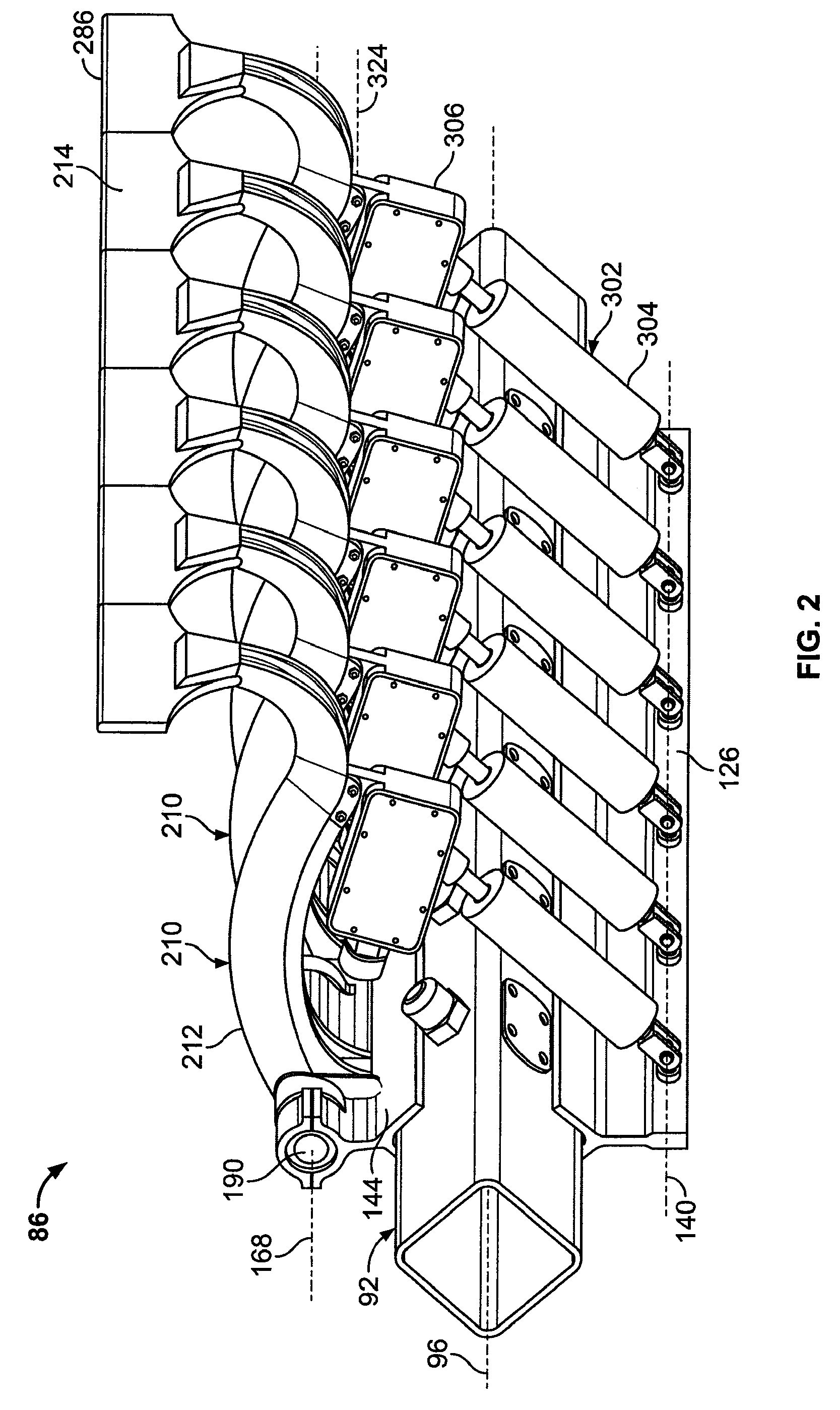

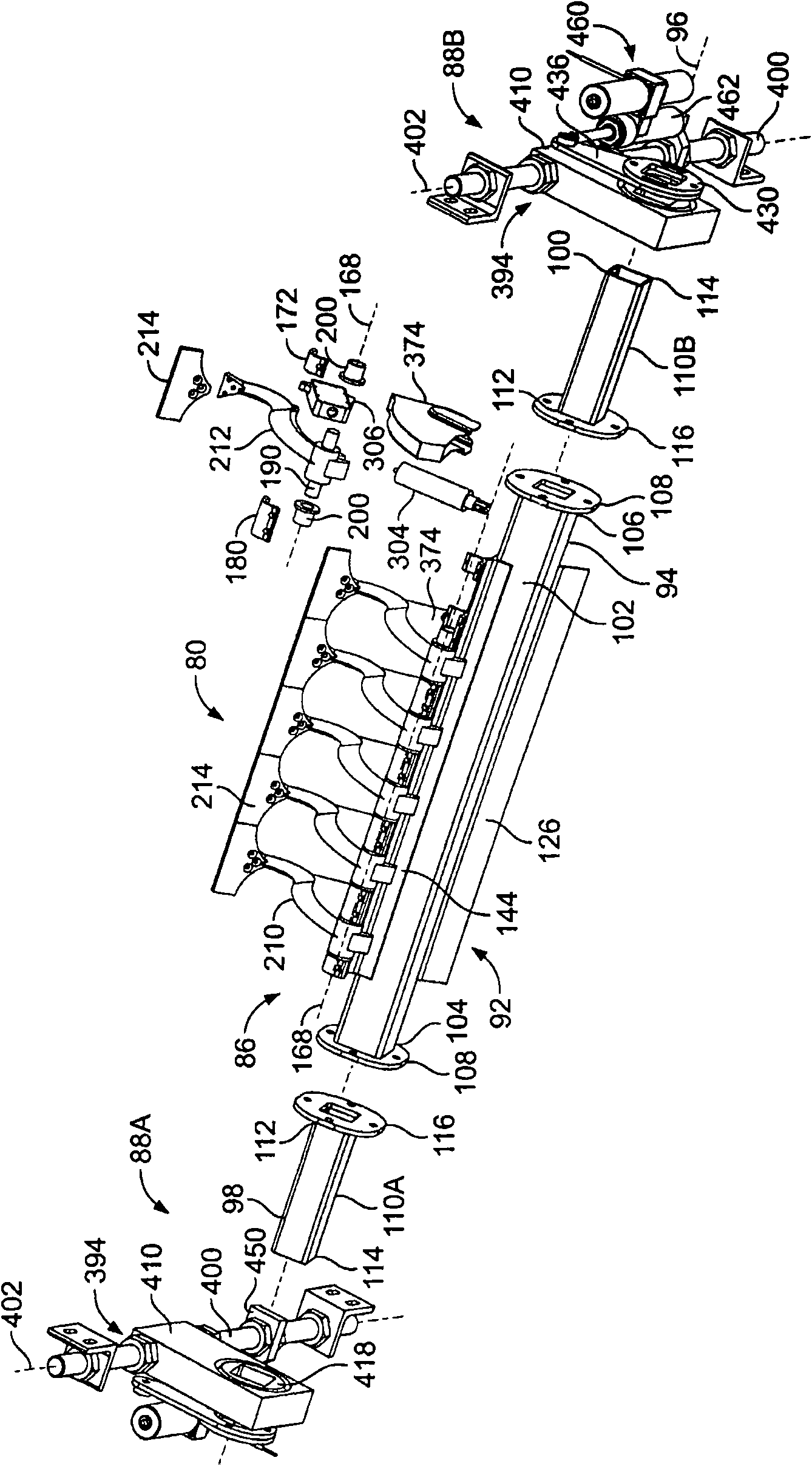

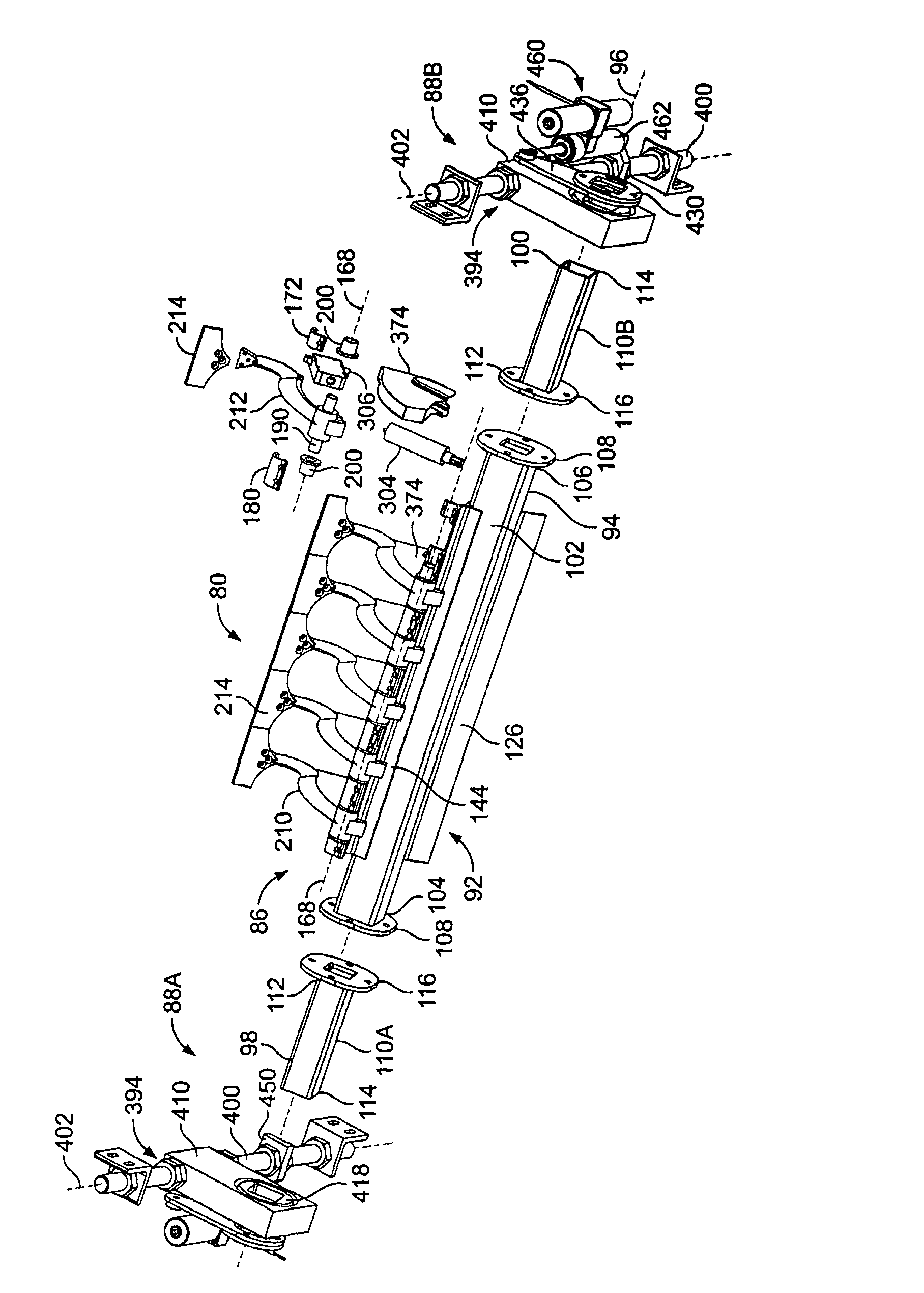

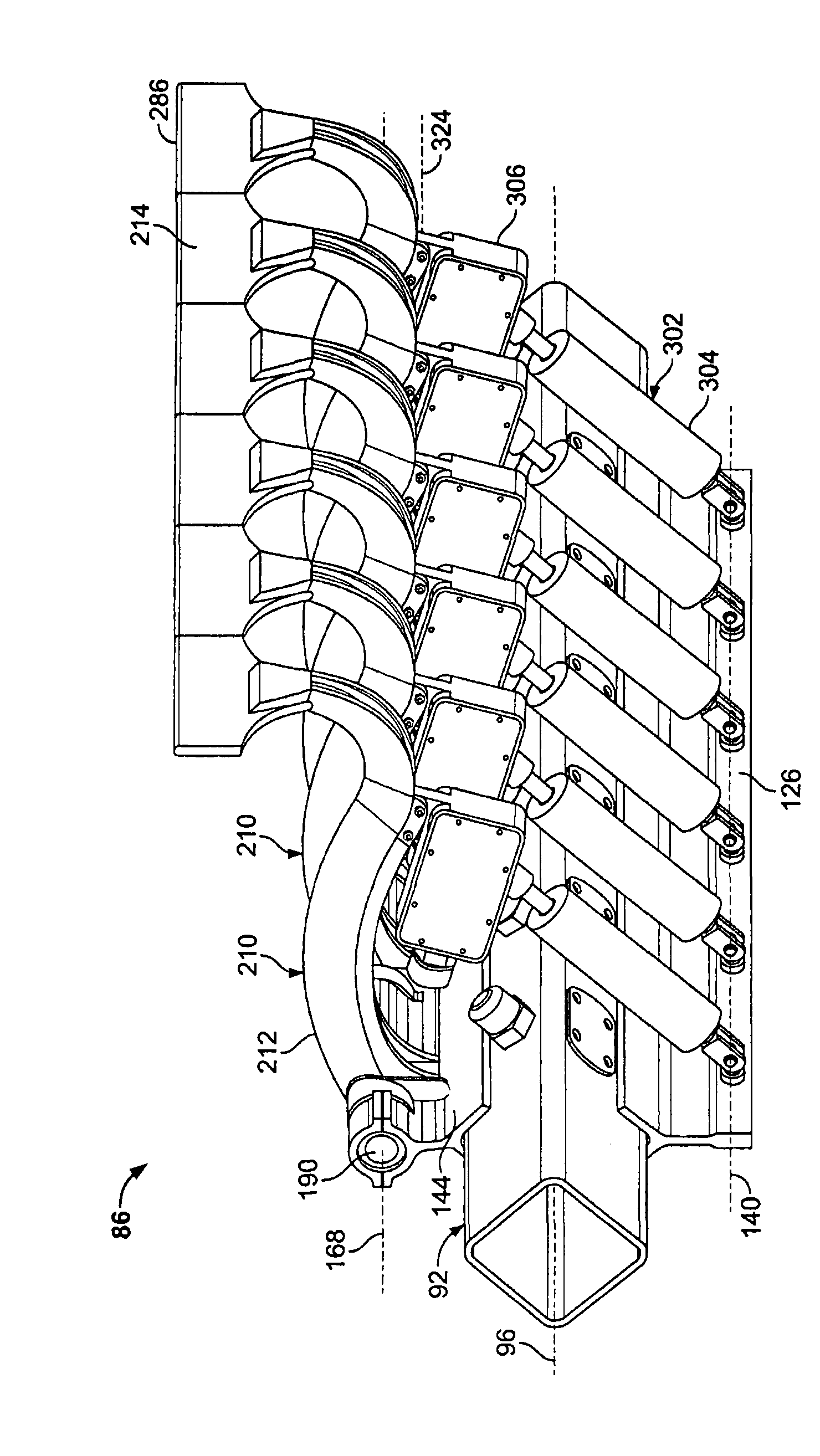

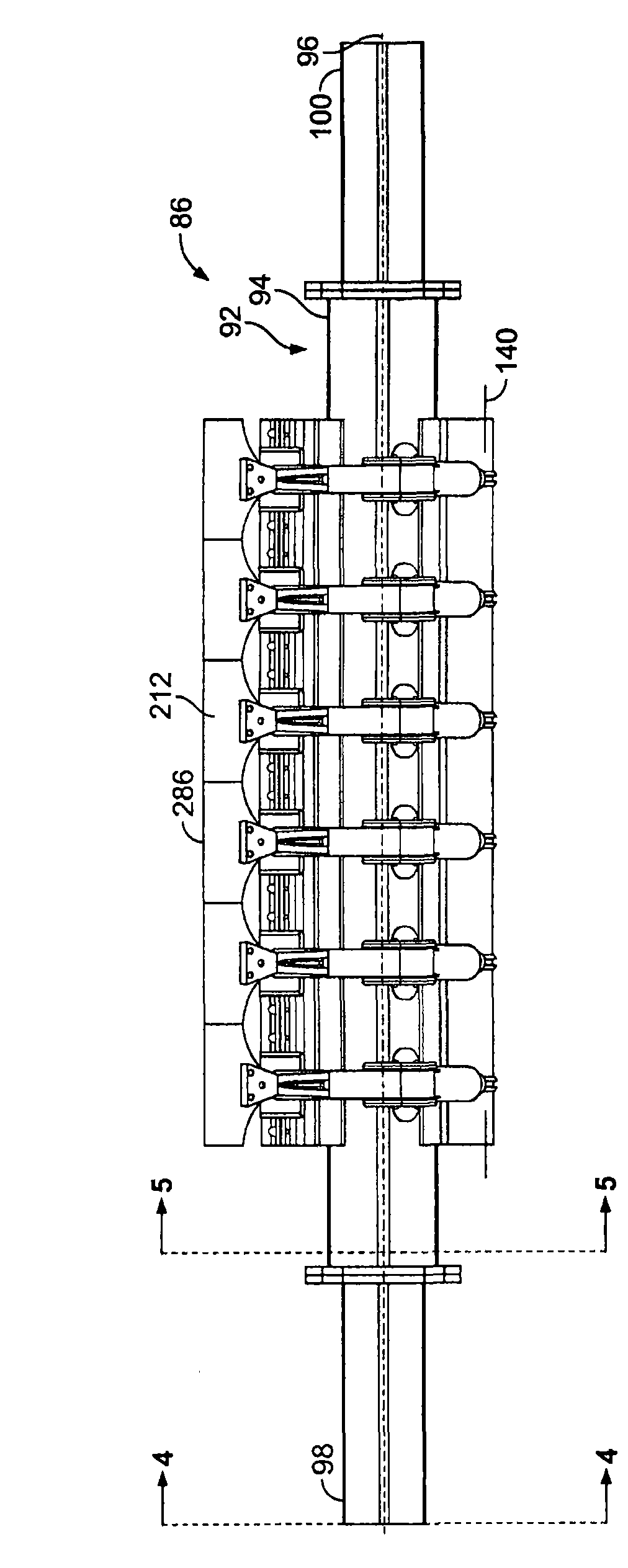

Bulk material handling system

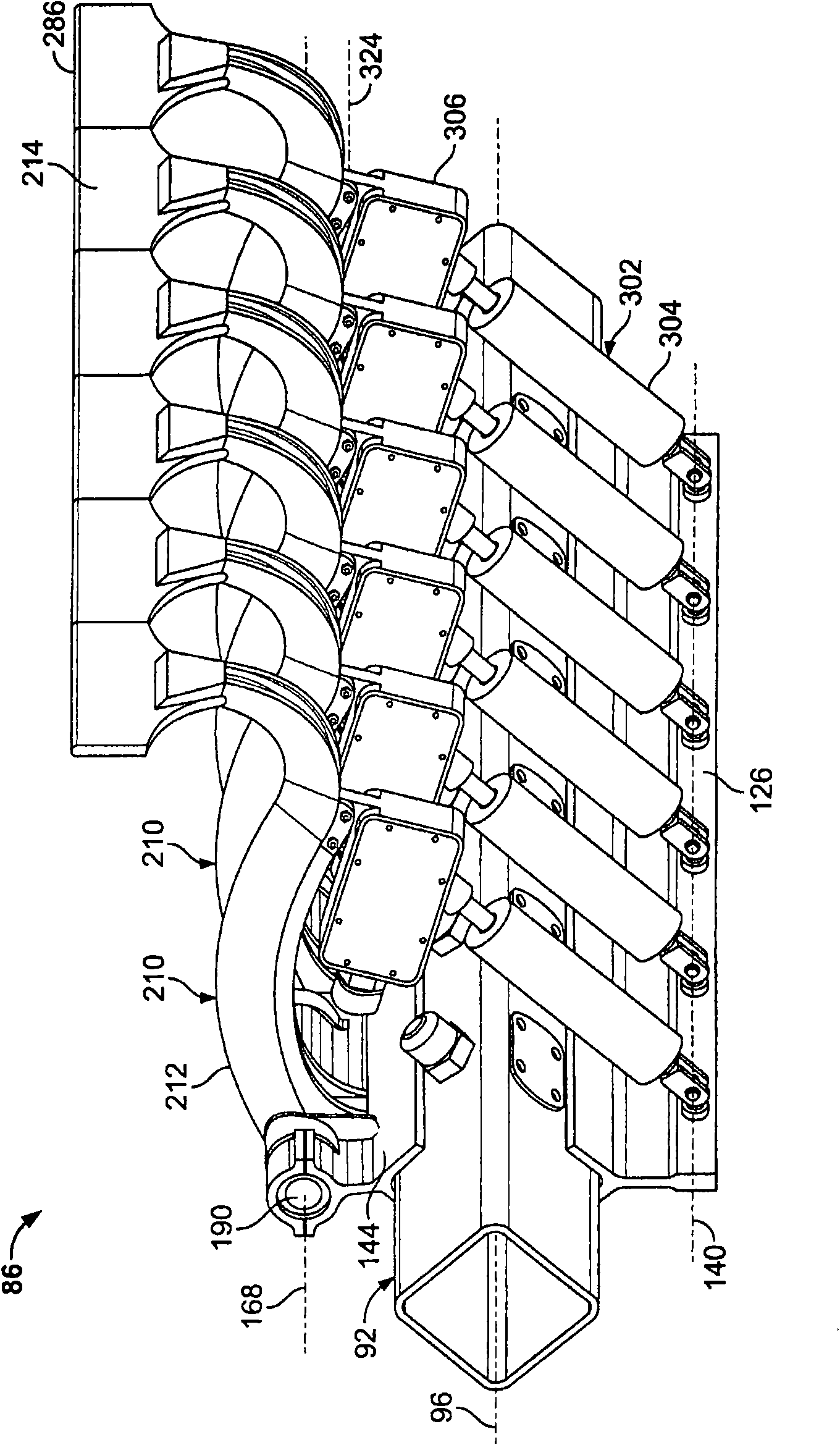

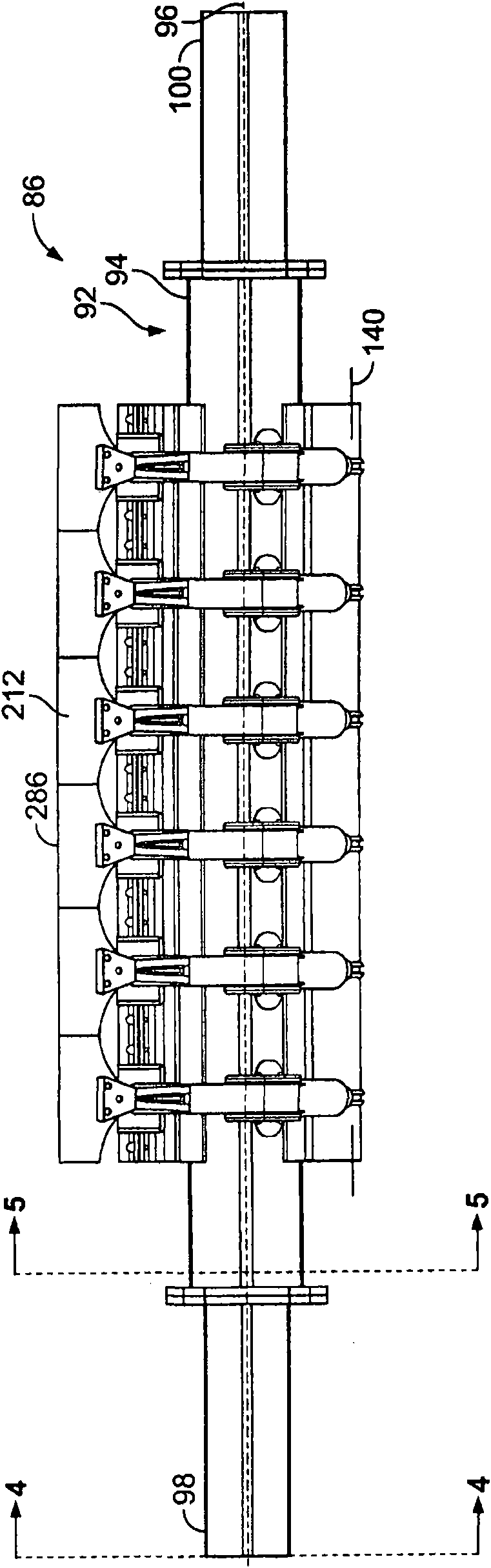

The preset invention provides a bulk material handling accessory (6) such as a conveyor belt cleaner (80) for use in connection with a bulk material handling system. The bulk material handling accessory includes a main frame (92), a scraping member (210) including an arm (252) and a scraper blade (214) pivotally attached to the main frame, and a damper mechanism (302) coupled at one end to the main frame and at another end to the scraping mechanism. A mounting mechanism (232) is attached to the main frame for providing linear and rotational movement of the main frame and the associated scraping member and damper mechanism. The damper mechanism includes a damper (304) having a piston (354) and a housing (338) having a fluid chamber (340). The viscosity of the fluid within the fluid chamber is selectively changeable to change the damping characteristics of the damper mechanism to accommodate changes in operating conditions.

Owner:MARTIN ENG

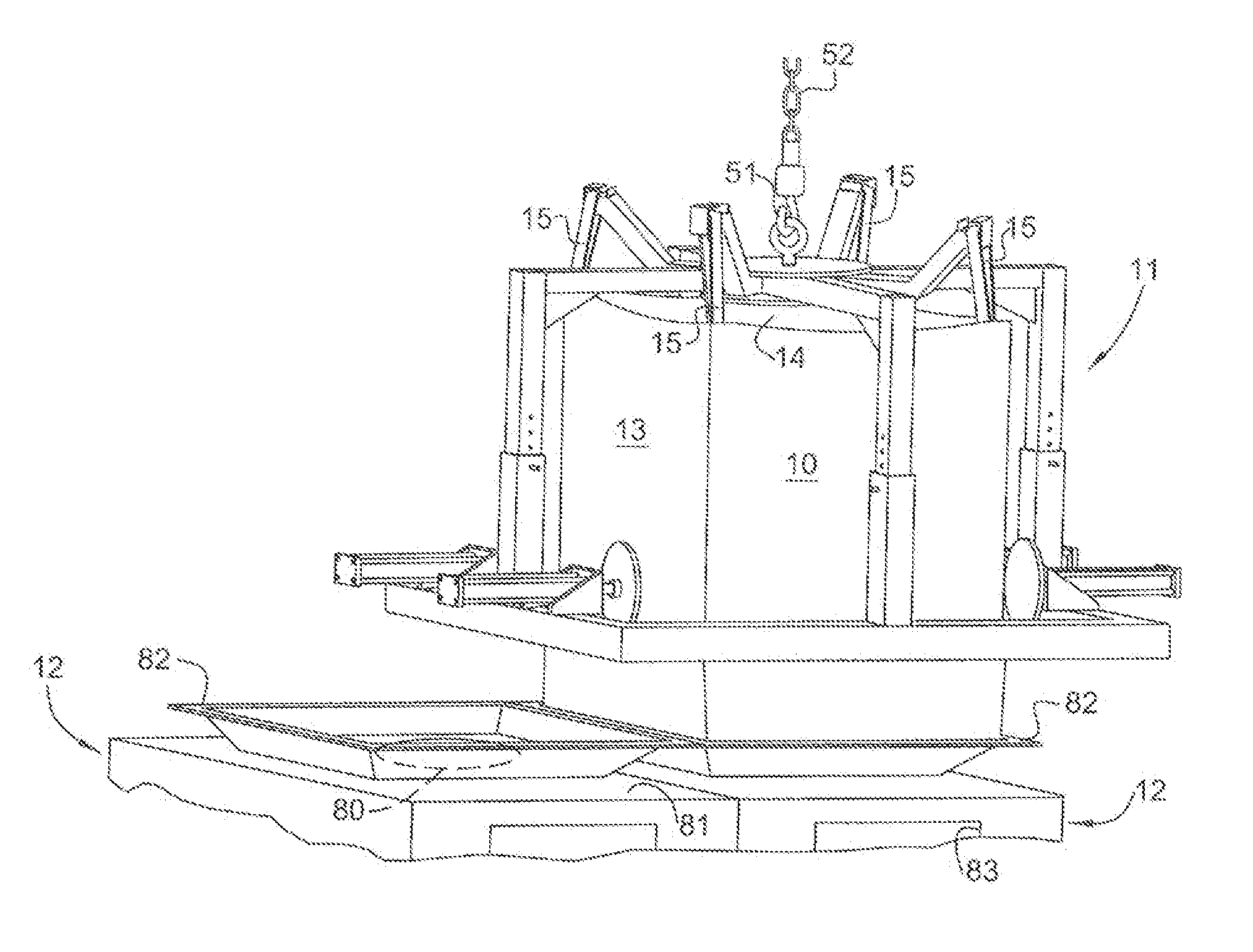

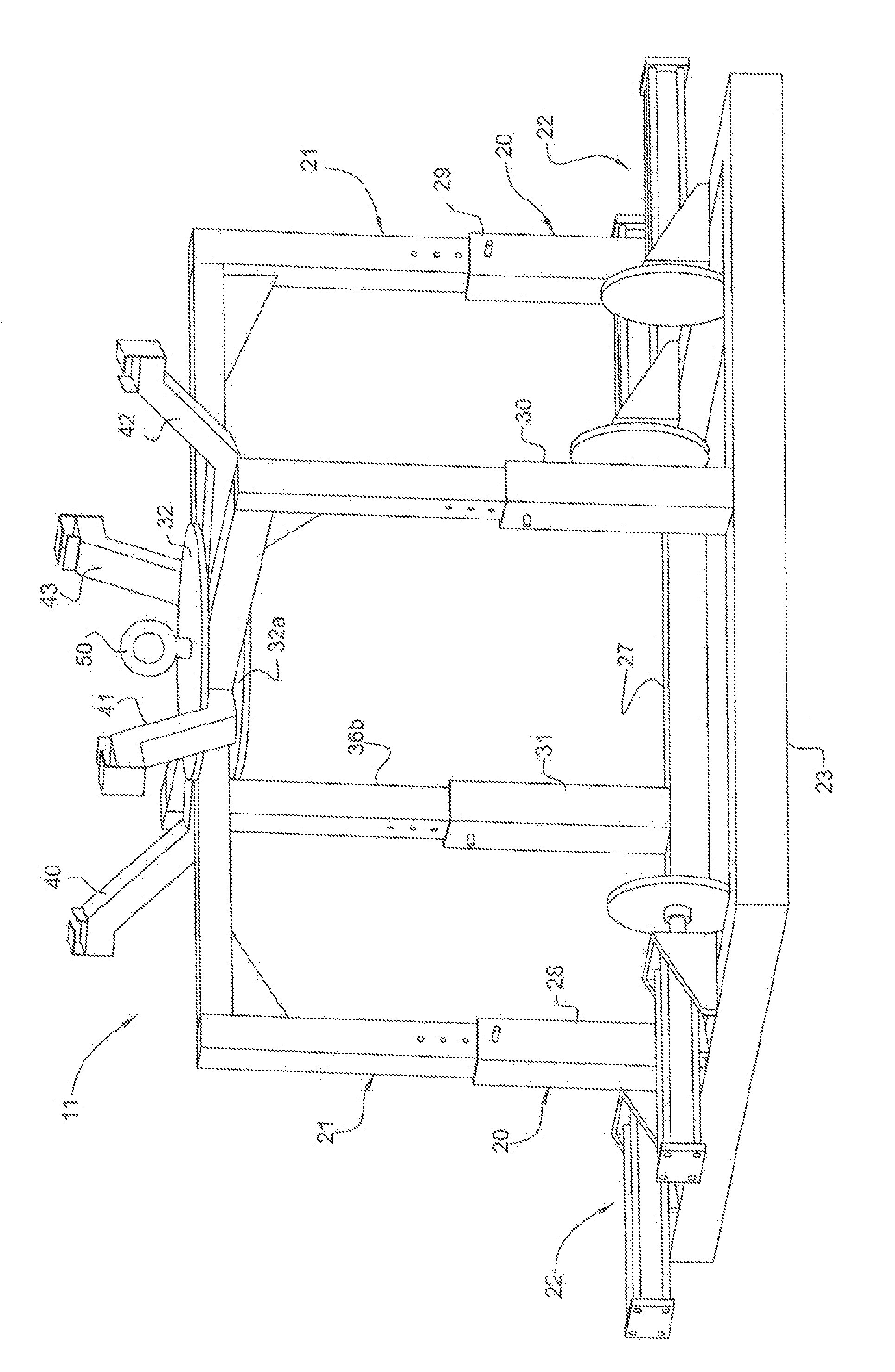

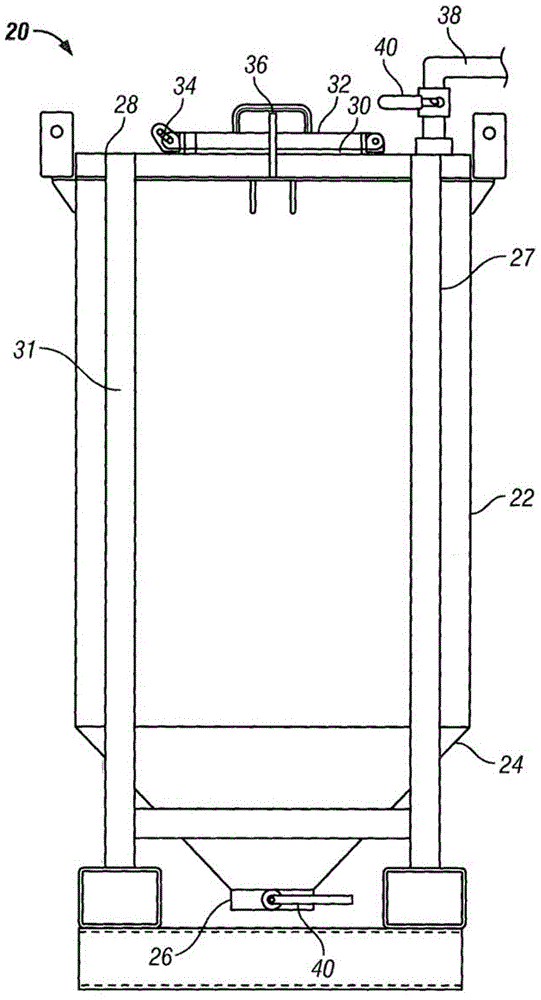

Bulk Material Handling System and Carrier Therefor

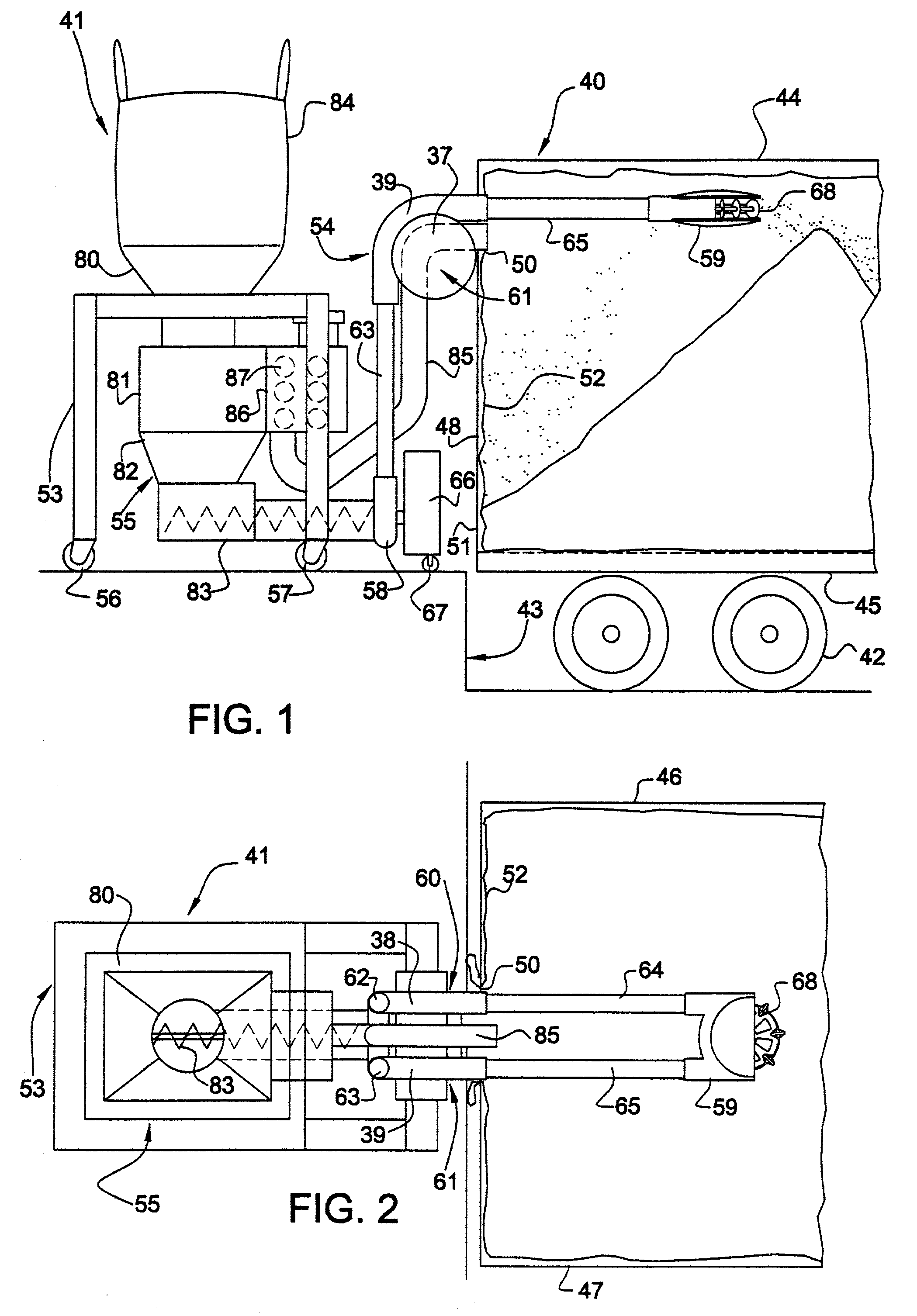

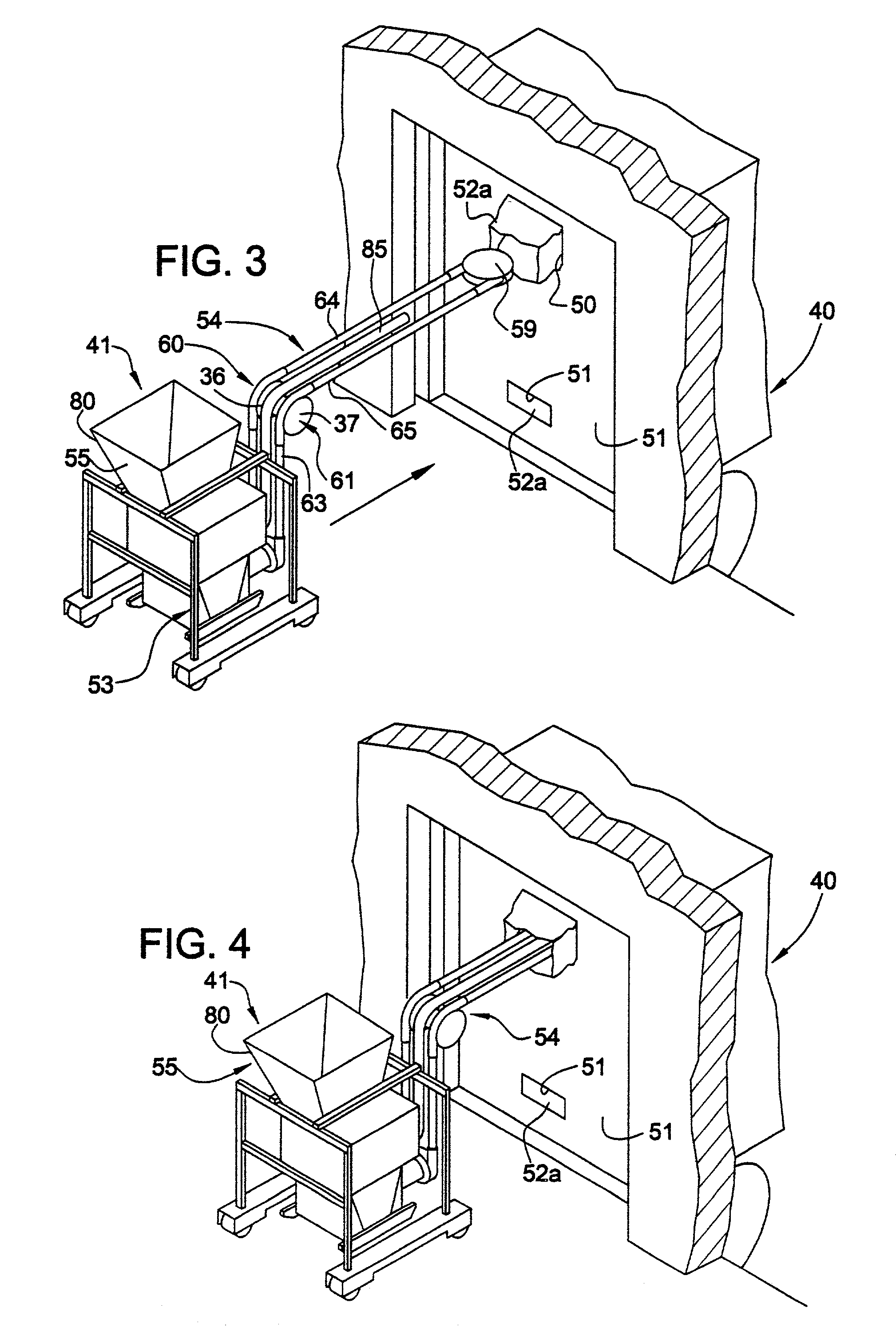

InactiveUS20130058744A1Easy dischargeFlexible bulk container emptying systemsBagsEngineeringMaterial handling

A system including a receptacle having an inlet for receiving a poke material therethrough and a carrier for supporting a flexible bag with a closable discharge spout, containing a bulk material to be deposited in such receptacle, and means operable upon a bag loaded with bulk material being supported thereon such spout being aligned with such receptacle inlet and such spout being opening for jostling such bag to enhance the discharge of material through such spout into such receptacle, wherein such carrier and such receptacle are provided with cooperating configurations facilitating the positioning of such carrier relative to such receptacle with said bag spout aligned with such receptacle inlet.

Owner:YOUNG INDS

Bulk material handling system

An apparatus for conveying bulk material generally consisting of a support, a guide member defining a passageway providing a circuitous path, having a base section supported on the support and a section cantilevered relative to the support; at least two sprockets disposed in such passageway and rotatably supported on the guide member, one of such sprockets being disposed in the cantilevered section of the guide member and having a substantially vertically disposed axis of rotation; a rope assembly including an endless rope disposed in the passageway along the circuitous path and reeved around the sprockets, and a plurality of discs spaced along such rope, and a motor for driving one of the sprockets, wherein the guide member includes a inlet communicating with the passageway for feeding material therein and a discharge outlet communicating with the passageway about a portion of the periphery of the one socket.

Owner:YOUNG INDS

Bulk storage container and bulk material handling assembly therewith

An intermediate bulk storage container (1) for the storage or transport of particulate catalyst material comprises a vessel (2) having an inner wall defining a containment volume for particulate catalyst material. The vessel (20) comprises a cylindrical wall section (22), a top panel (28) closing the upper end of the cylindrical wall section (22) and a conical base section (24) connected to and tapering inwardly away from the lower end of the cylindrical wall section (22). An opening (30) is provided in the top panel (28) of the container (20) for receiving the catalyst material and a closure member (32) is provided for closing the opening (30). An air tight seal is provided when the opening (30) is closed by the closure member (32). A gas duct (38) is in fluid connection with the vessel (20) for supplying an inert gas to the sealed container (20) or removing gas from the vessel (20) to place the container (20) under a vacuum to mitigate the risk of combustion. The gas duct is closed by a valve (40) for transit or storage.

Owner:DIALOG CONSTR

Bulk material handling system and method

A bulk material handling system and method use a horizontal boom frame supporting a conveyor mechanism for bulk material that is slidable relative to the horizontal boom frame. The conveyor mechanism is positioned such that, with bulk material received at a fixed location, or loading axis, on the horizontal boom frame, a portion of the conveyor mechanism will always be positioned to receive bulk material. The horizontal boom frame can also be made rotatable about the loading axis. By rotating the horizontal boom frame and advancing or withdrawing the conveyor mechanism, the discharge point for bulk materials relative to the loading axis can be altered radially and angularly without interrupting the flow of bulk materials through the system. A supply bridge assembly can be employed to bring the bulk materials to the loading axis of the boom.

Owner:RAIL VEYOR TECH GLOBAL

System and method for handling bulk materials

ActiveUS20070154271A1Facilitate material flowFlow rate may be more readily controlledBulk conveyorsMechanical conveyorsEngineeringGuide tube

A bulk material handling system generally consisting of means for holding the material; means for conveying the material including a first conduit formed of a permeable material having an inlet communicating with an outlet of the material holding means and an outlet, a second conduit formed of an impermeable material encompassing and spaced from the first conduit, providing a chamber therebetween, and an auger disposed in the first conduit for transporting material received through the inlet to the outlet thereof; means for rotatably driving the auger; and means for supplying a fluidizing gas under pressure to the chamber between the first and second conduits.

Owner:YOUNG INDS

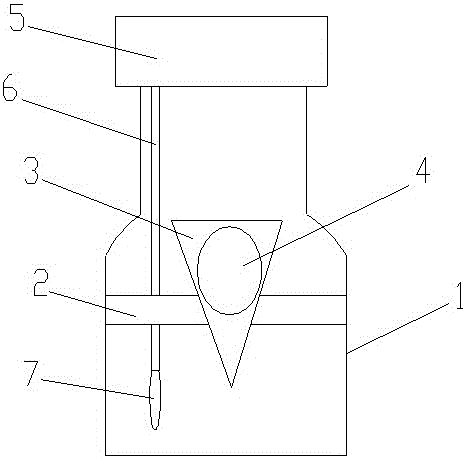

Glassware with triangular block used in inner part for stirring materials

The invention discloses glassware with a triangular block used in the inner part for stirring materials. The glassware comprises a glassware main body, wherein a rotating shaft support rod is transversely and horizontally arranged in the glassware main body, the two ends of the rotating shaft support rod are separately fixed to the inner side walls at the two sides of the glassware main body, the triangular block is pivoted to the rotating shaft support rod, the triangular block is connected to the rotating shaft support rod in a rotating manner, the inner part of the triangular block is a hollow cavity, a rolling ball body is arranged in the triangular block, the upper end of the glassware main body is provided with a bottle cap, a stirring rod is arranged on the bottom end surface of the bottle cap, the arrangement position of the stirring rod is staggered from that of the triangular block, and an ellipsoidal sieve body is further mounted at the lower end of the stirring rod. Through the mode, the glassware can utilize the self rolling property of the rolling ball body to drive the triangular block to carry out stirring and scattering treatment on the materials in the glassware and prevent the quality from being affected by material caking.

Owner:WUXI KUAKE MICRONUTRIENT

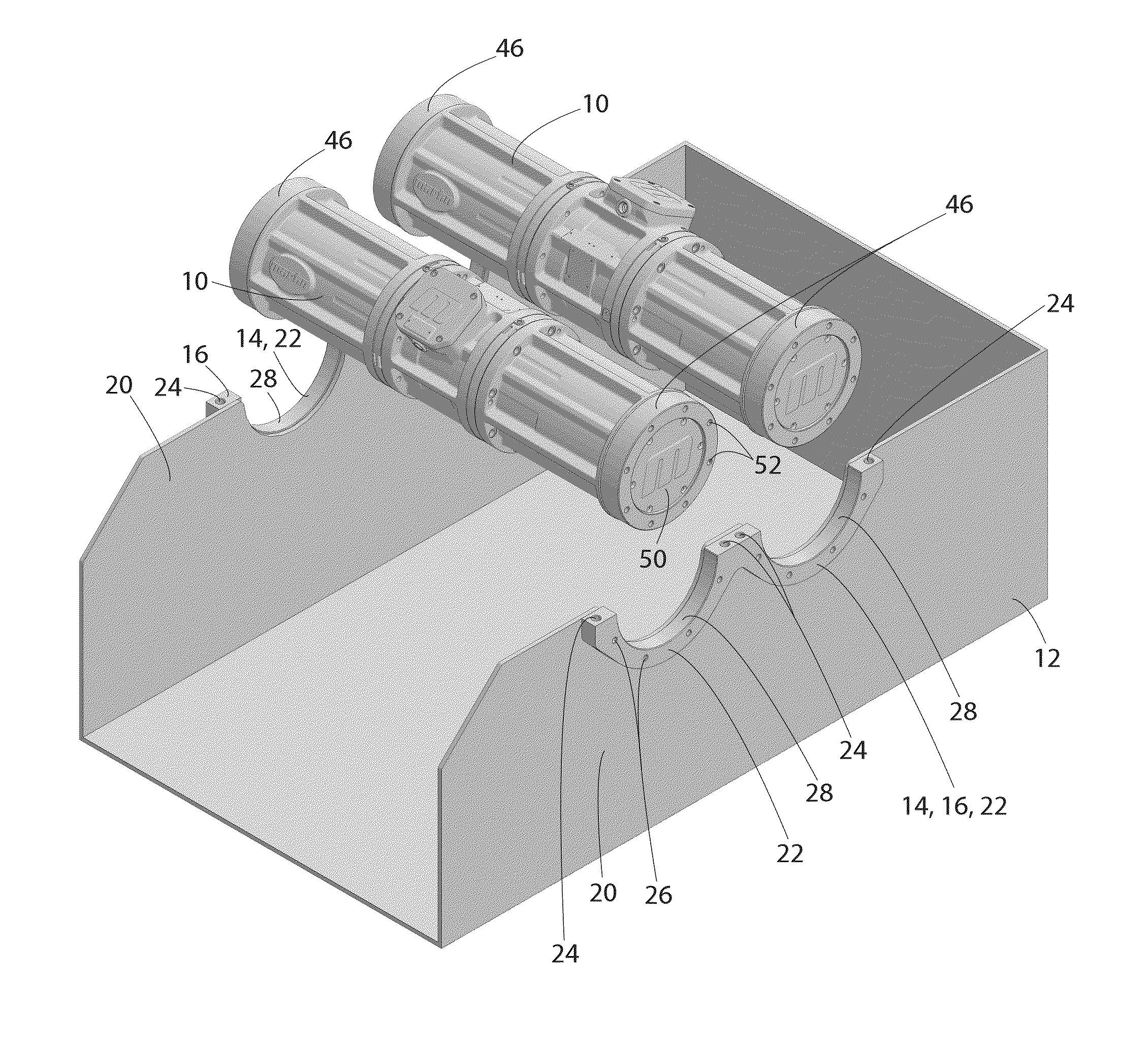

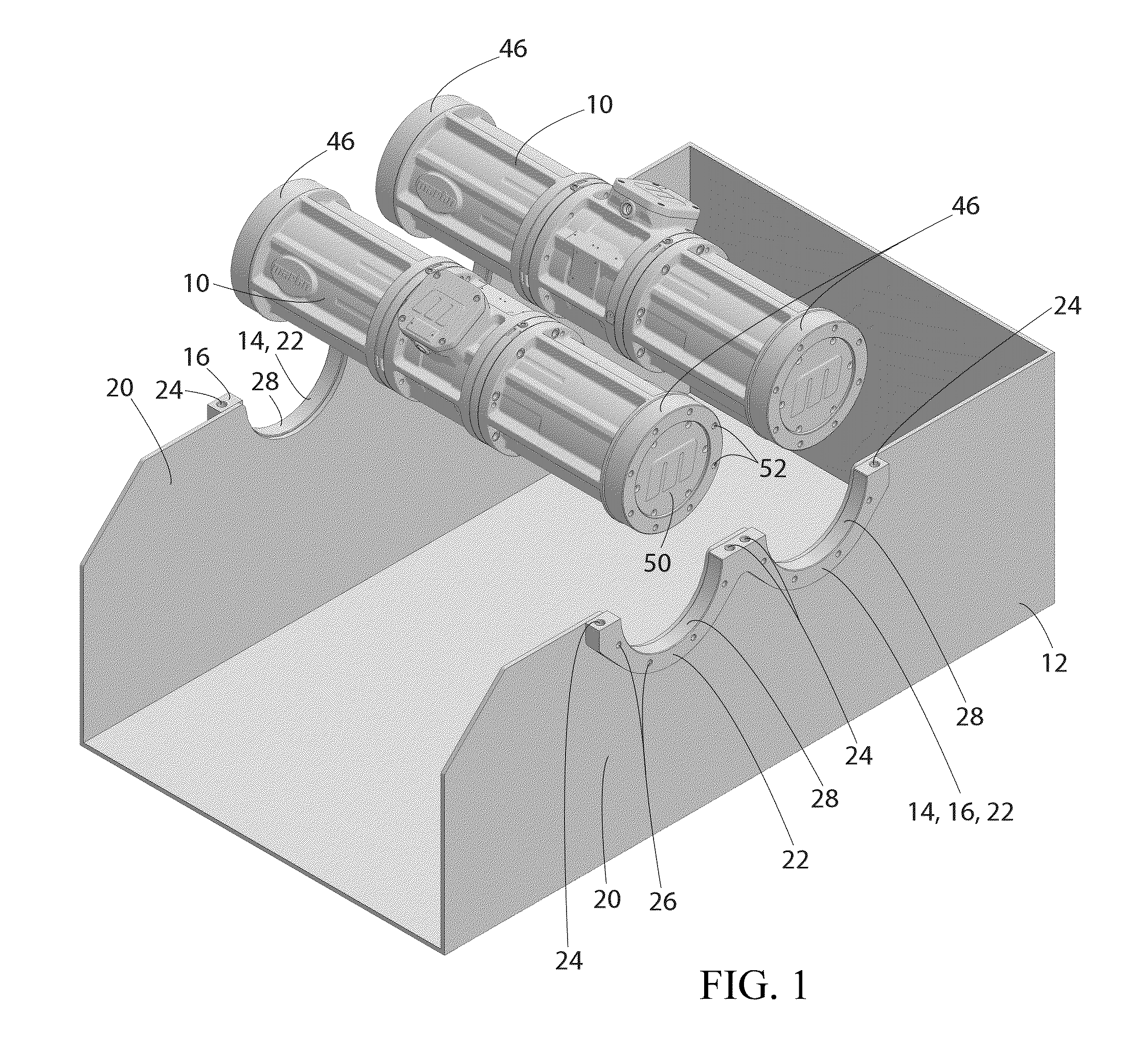

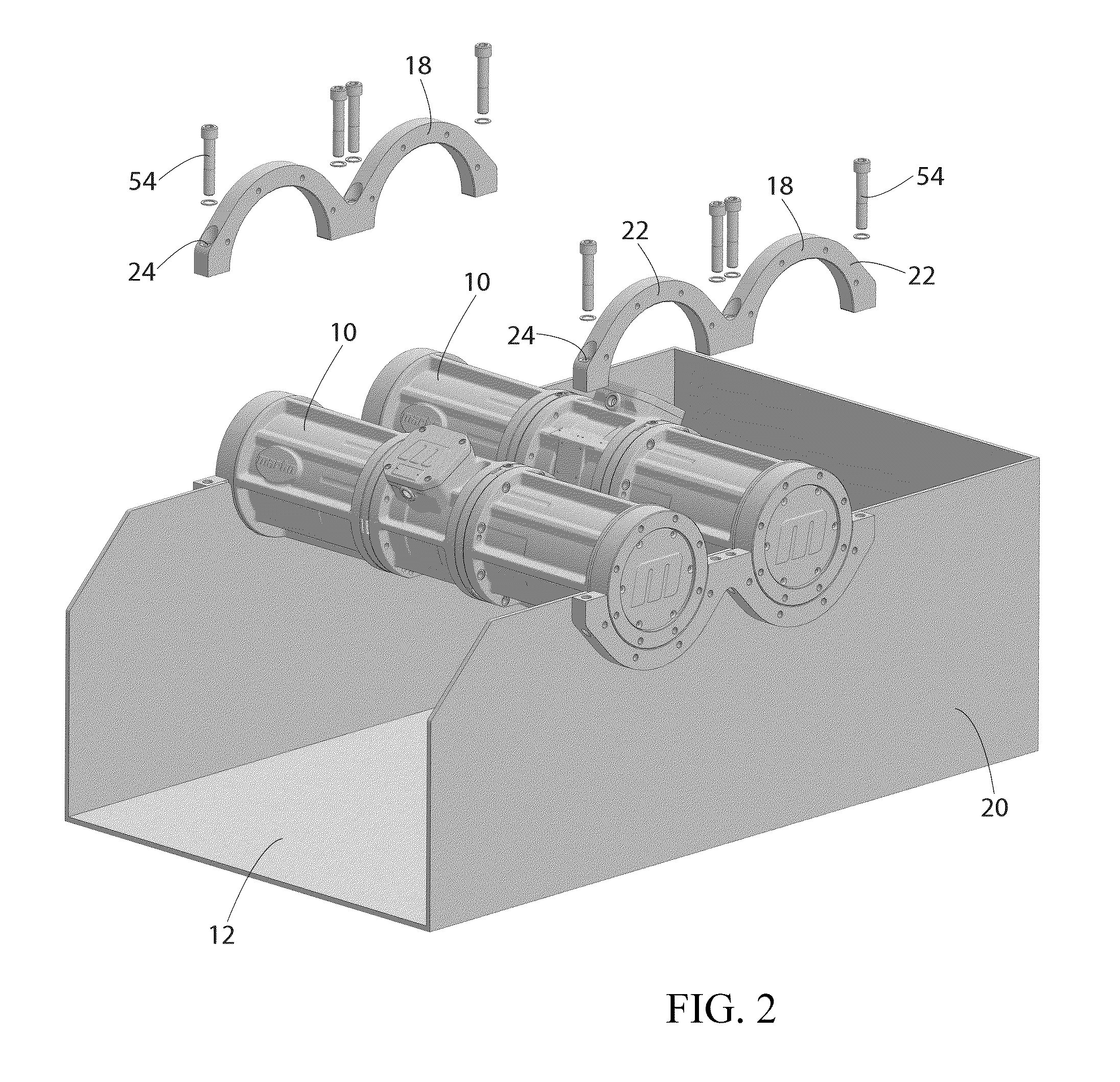

Bulk material handling assembly having a clamp mounted vibrator and method related to the same

InactiveUS20140269150A1Induce vibrationSievingShaking/oscillating/vibrating mixersBulk material handlingEngineering

A bulk material handling assembly comprises a pair of spaced-apart walls, an elongate vibrator, a pair of saddle clamps, and a pair of locking members. The saddle clamps encircle and releasably secure the axial end portions of the vibrator to the spaced-apart walls of the bulk material handling assembly. The locking members are secured to the saddle clamps and to the end portions of the vibrator.

Owner:MARTIN ENG

Bulk material handling system and carrier therefor

InactiveUS9254935B2Easy dischargeFlexible bulk container emptying systemsStorage devicesEngineeringHandling system

A compact, portable carrier for a flexible bag containing a comminuted material and having a bottom discharge spout, including a frame structured to encompass such bag and attach such bag in suspended relation thereto, be transported to a spaced site and be operated to jostle the material contained in such suspended bag to facilitate the discharge thereof through the spout thereof.

Owner:YOUNG INDS

Bulk cargo treatment device and method for metallurgy pellets

InactiveCN103614550AFine granularityQuality improvementProcess efficiency improvementGranularityEconomic benefits

The invention relates to a bulk cargo treatment device and method for metallurgy pellets. The bulk cargo treatment device is characterized by comprising an aggregate sealing-tape machine, a bulk cargo buffering cabin, a bypass electrohydraulic flat gate valve, an electrohydraulic sector gate, an under-cabin electrohydraulic flat gate valve, a sealed type vibration feeding machine, a cone mill, a burying scraper, a bucket elevator and a finished-product sealing-tape machine. Bulk cargoes are conveyed into the bulk cargo buffering cabin by the aggregate sealing-tape machine and then are fed into the sealed type vibration feeding machine by the under-cabin electrohydraulic flat gate valve; the sealed type vibration feeding machine is used for feeding the bulk cargoes into the cone mill; the burying scraper is used for conveying a finished-product material to the finished-product sealing-tape machine by the bucket elevator; the finished-product sealing-tape machine is used for conveying the finished-product material to a mixing system to be pelletized again. According to the bulk cargo treatment device and method for the metallurgy pellets, the granularity and the quality of prepared pellet bulk cargoes are improved effectively and the pelletizing is easy to carry out again. The pelletized can be recovered within short time and considerable economic benefits are created.

Owner:中冶北方(大连)工程技术有限公司

Dust Buildup Resistant Access Door and Door Frame of a Bulk Material Handling System

A bulk material handling system comprising an enclosure, a door frame, and an access door. The door frame is secured to a wall of the enclosure adjacent an access opening. The exterior surface of the door frame is devoid of horizontal surface portions when the enclosure is oriented with the wall of the enclosure in a vertical position. The access door is releasably secured to the door frame and is movable between a closed position and an open position. The exterior surface of the door is devoid of horizontal surface portions when the access door is in the closed position and the enclosure is oriented with the wall of the enclosure in the vertical position.

Owner:MARTIN ENG

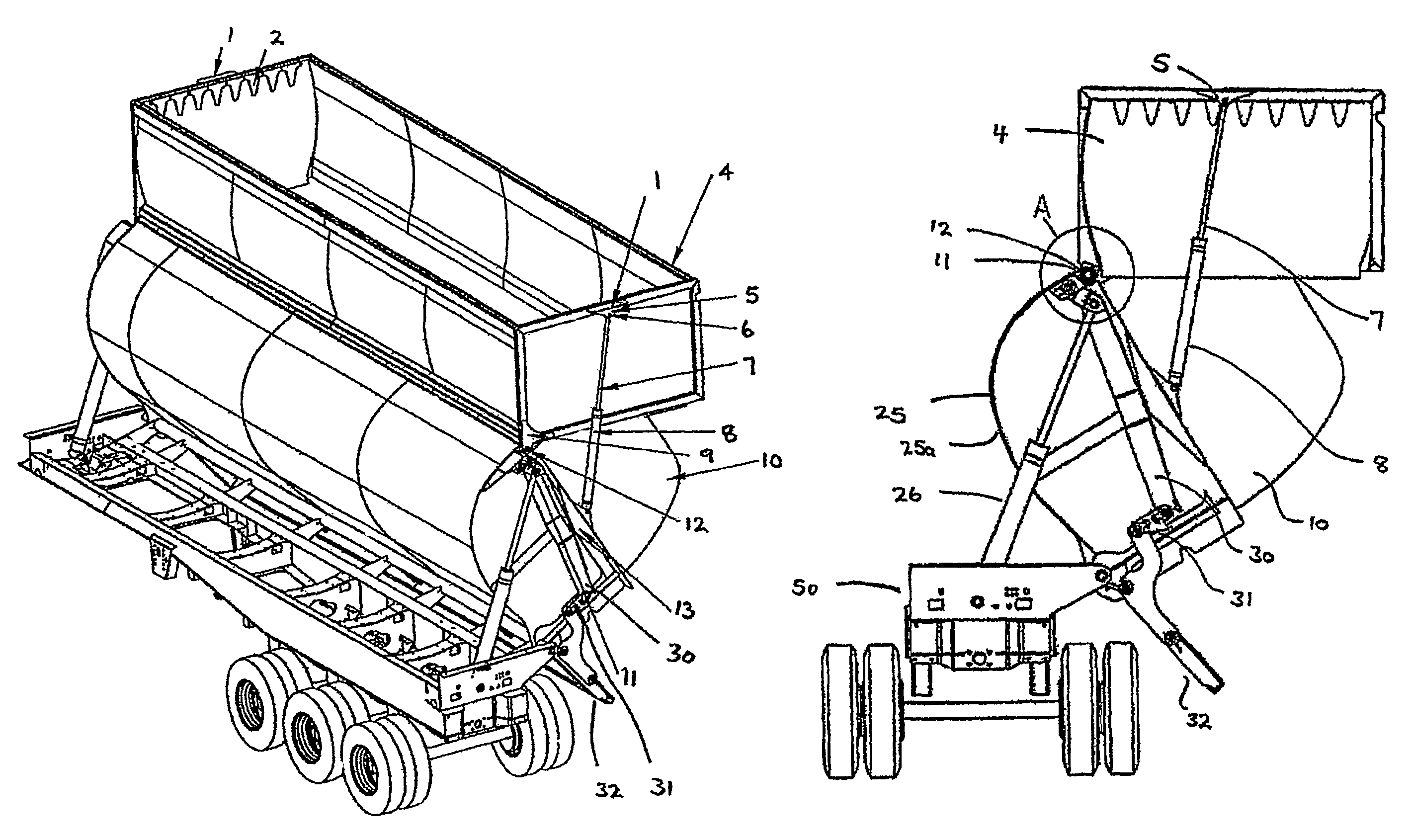

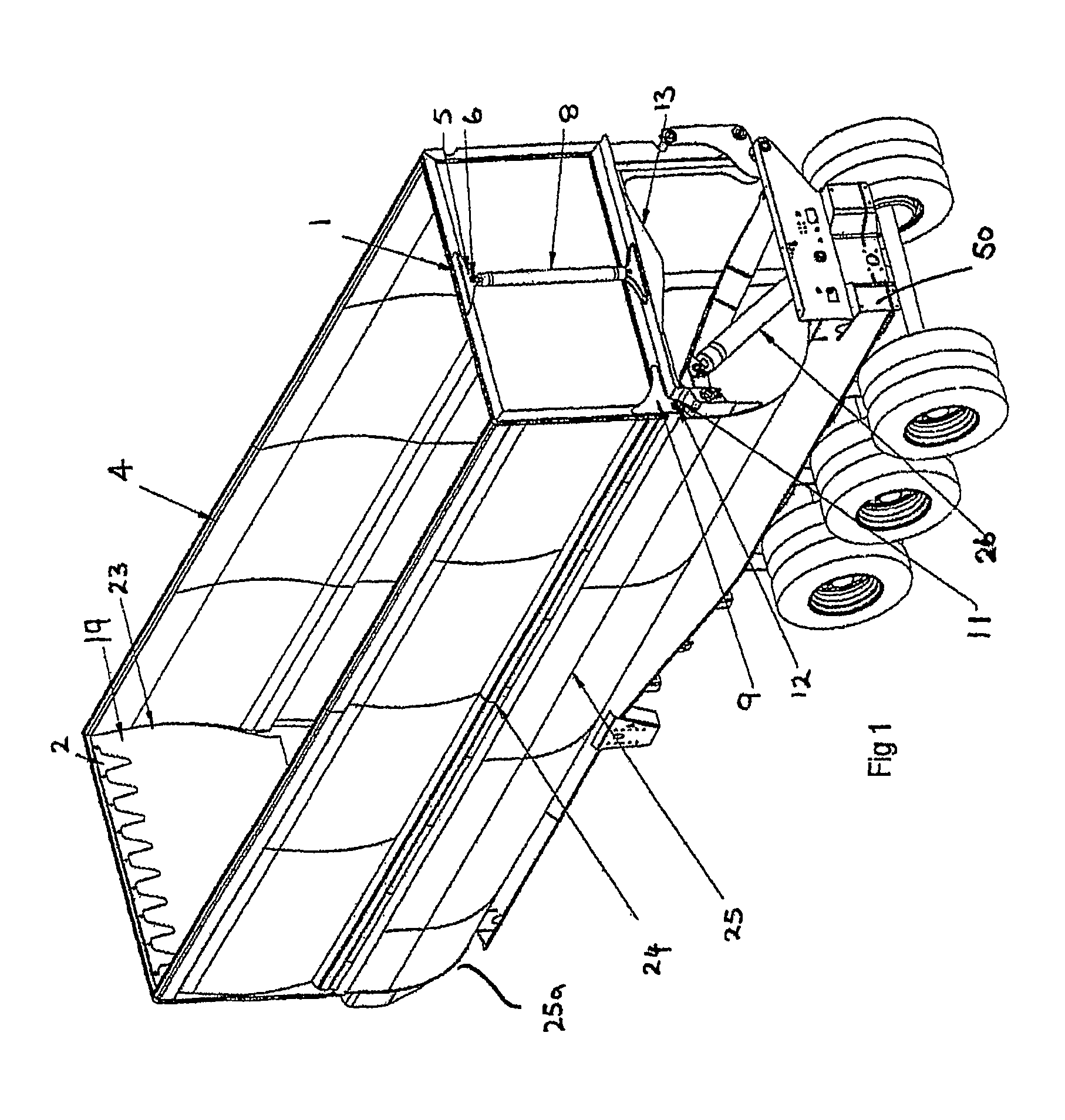

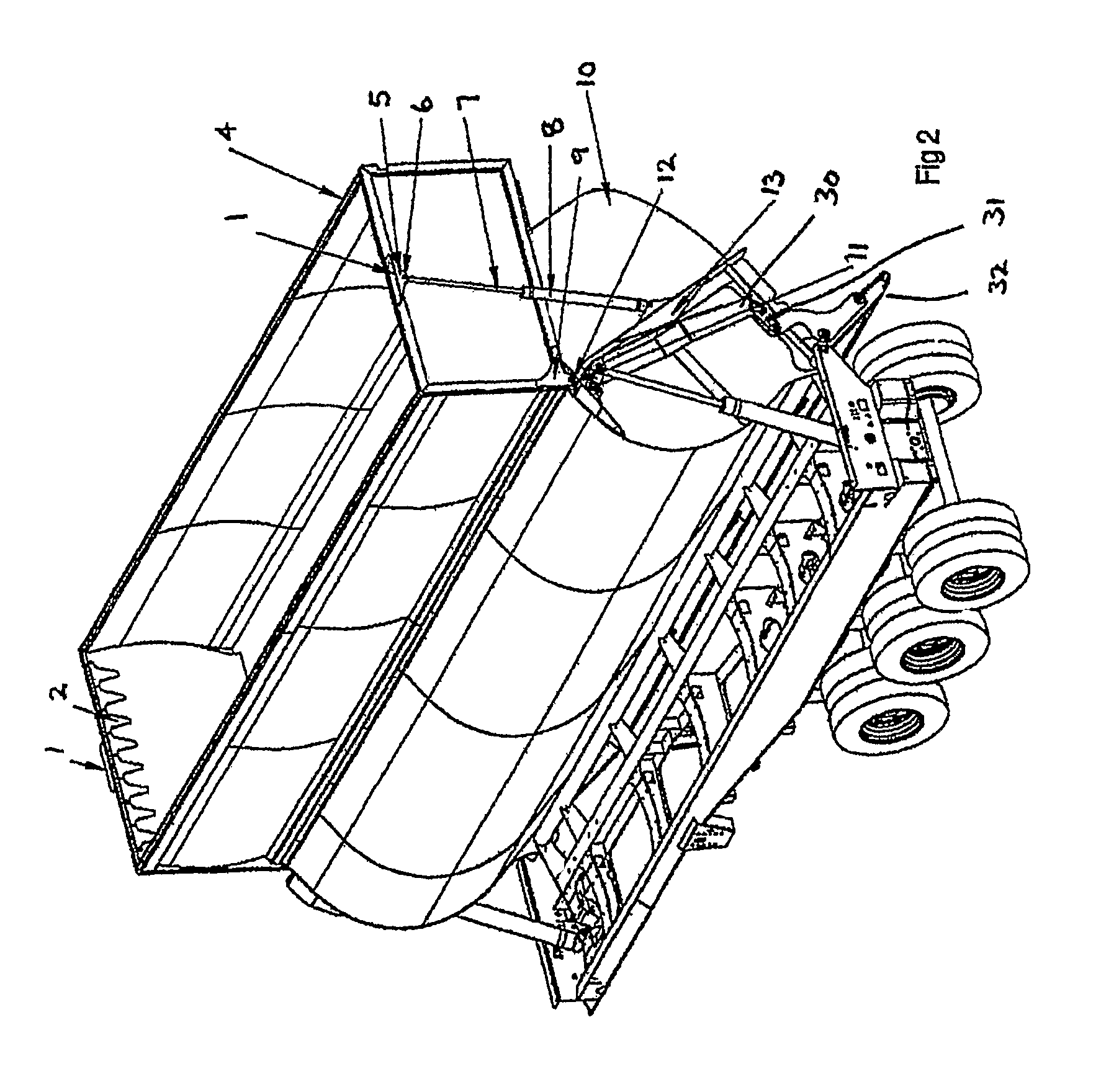

Bulk material handling vehicle

ActiveUS8708420B2High volume loadStable maintenanceHopper carsLoading/unloadingLoad carryingBulk material handling

A vehicle including a chassis (50) and a load carrying container supported thereon, the container arranged for pivotable movement relative to the chassis of the vehicle to discharge material from the container in a lateral direction to a side of the chassis, the container including a lower container body (25) and an upper container body (4) mounted thereto for operable movement with fespect to said lower container body to provide a selectively openable discharge passage e.g., via openable side discharge door (32), between the upper and lower container bodies when the upper and lower bodies pivot with respect to one another.

Owner:MAXITRANS AUSTRALIA

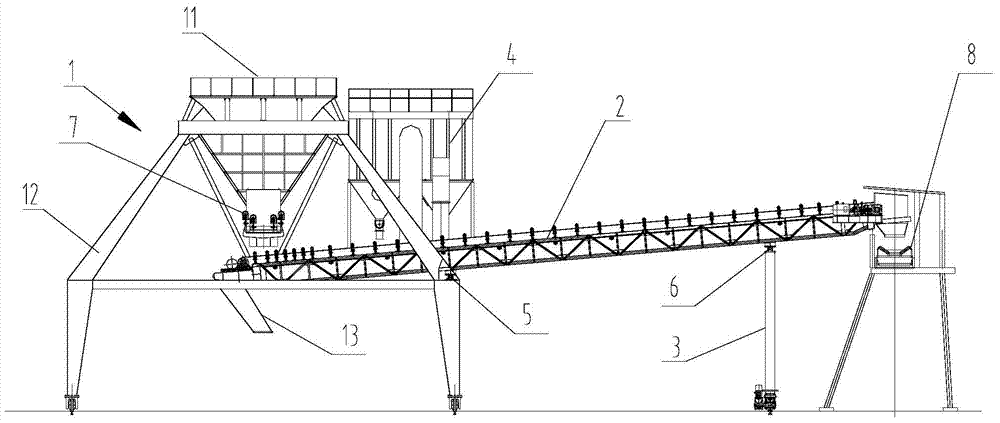

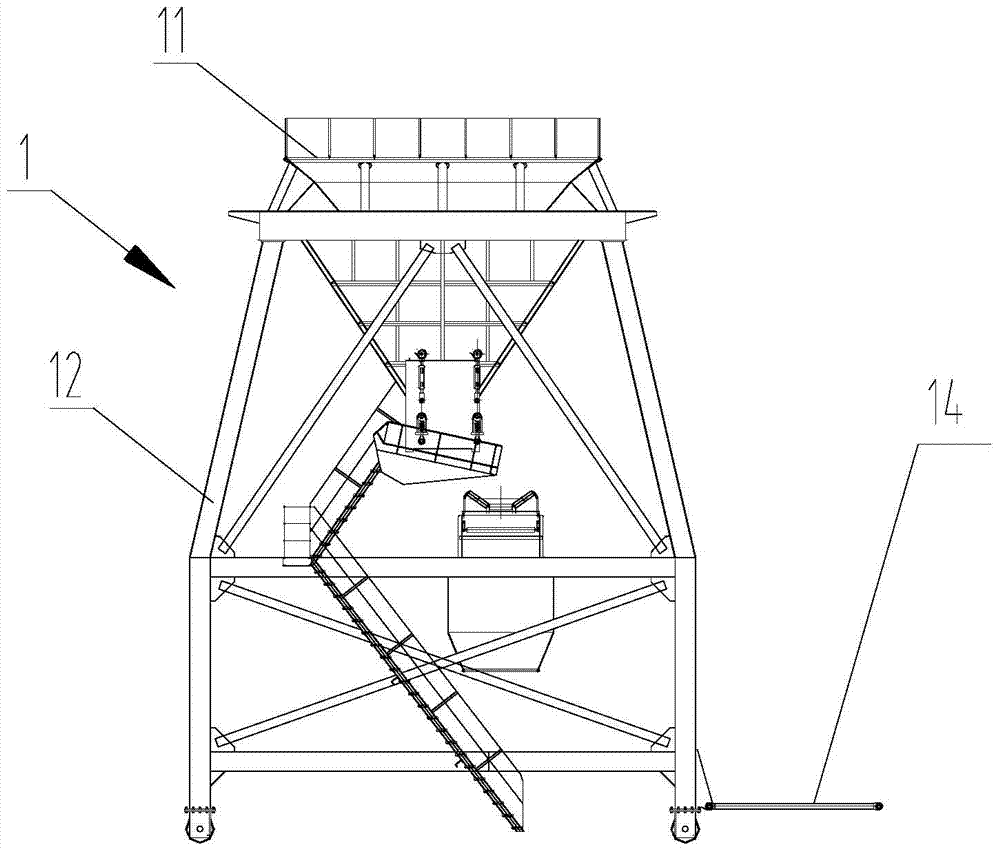

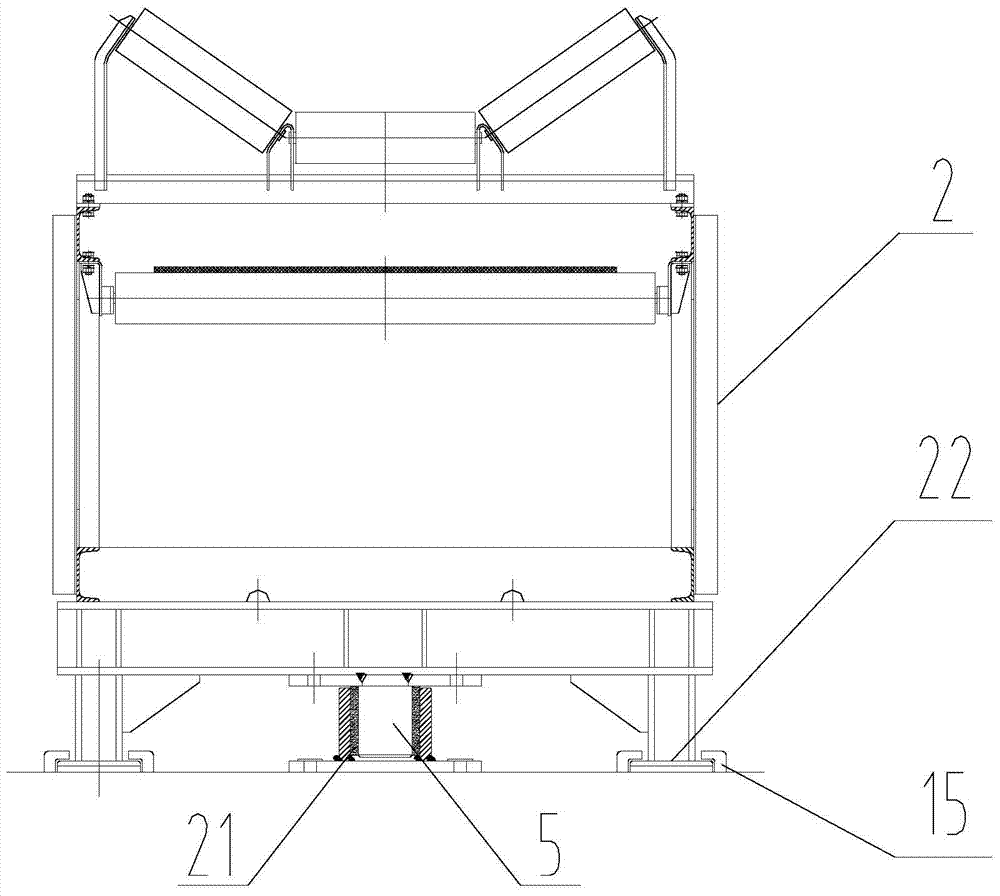

Bulk Material Handling Equipment

InactiveCN105383900BPrevent leakageConveyorsControl devices for conveyorsEngineeringAngular displacement

Owner:SANY MARINE HEAVY IND

Intelligent bulk material suction system

ActiveCN108974928BSufficient stockFast and effective suction alignmentConveyor partsTransport systemControl engineering

The invention relates to an intelligent bulk material suction system, which includes a cargo rack and a material suction device; the cargo rack is loaded on the roof of a transport vehicle, and several storage systems are loaded in the cargo rack. A suction device is arranged on the side, and the suction device stands on the ground through a load-bearing base. It is movably connected with the feeding casing, and a vertical suction pipe is installed on the telescopic tube at the front end of the feeding casing. In the present invention, an electromagnet is added to the vertical suction pipe, so that material suction alignment can be carried out quickly and effectively. In the process of material suction, the material storage system can send a signal through the gravity alarm to remind the staff whether the stock of the pellets in the material storage tank is sufficient. At the same time, in order to cooperate with the vertical straw suction, a push turntable is installed at the bottom of the material storage tank, and the remaining pellets are pushed up through the push turntable for the vertical straw suction.

Owner:JIANGSU NEWBLUE INTELLIGENT EQUIP CO LTD

A bucket wheel stopper device for a bucket wheel stacker and reclaimer

ActiveCN104192577BEasy to assemble and disassembleAdjustable lengthLoading/unloadingEngineeringReclaimer

Owner:TIDFORE HEAVY IND

Bulk material handling system process and bulk material handling equipment

ActiveCN102145816BRealize electronic control chainLow input costStorage devicesProcess engineeringMachine

The invention discloses a bulk material handling system process and bulk material handling equipment. A bulk material handling system comprises a plurality of multi-span material yards, a track operation type material piling machine, a track operation type material taking machine and a transport truck, wherein the track operation type material piling machine is arranged in the plurality of multi-span material yards and is used for piling materials to a material yard; and the track operation type material taking machine is required to be driven onto the transport truck on the end part of the material yard after material taking operation in the material yard is finished, and is transported to other material yards in the plurality of multi-span material yards through the transport truck for continuous operation. In the invention, the problems of high early-stage investment of the bulk material handling equipment, low utilization rate of the equipment during operation and heavy later-stage maintenance tasks of the equipment at present can be solved; and the system and the equipment are easy and convenient to operate, are easy to link through electric control and are particularly suitable for occasions where the equipment in the bulk material handling system has higher vacancy rate in the plurality of multi-span material yards.

Owner:HUADIAN HEAVY IND CO LTD

Bulk material handling system and control

A bulk material handling system includes a bulk material handling apparatus to convey bulk material and a bulk material handling accessory to aid the bulk material handling apparatus in conveying the bulk material. The bulk material handling accessory includes a controller having one or more sensors. The controller generates a control signal to adjust operation of the bulk material handling accessory based upon at least one status signal of the one or more sensors. The controller also generates the control signal in accordance with a status signal to control signal response pattern defined by system parameter values. The system parameters include a minimum value to define a minimum level of the control signal associated with fail-safe operation and a maximum value to define a maximum level of the control signal associated with stable operation the bulk material handling accessory.

Owner:MARTIN ENG

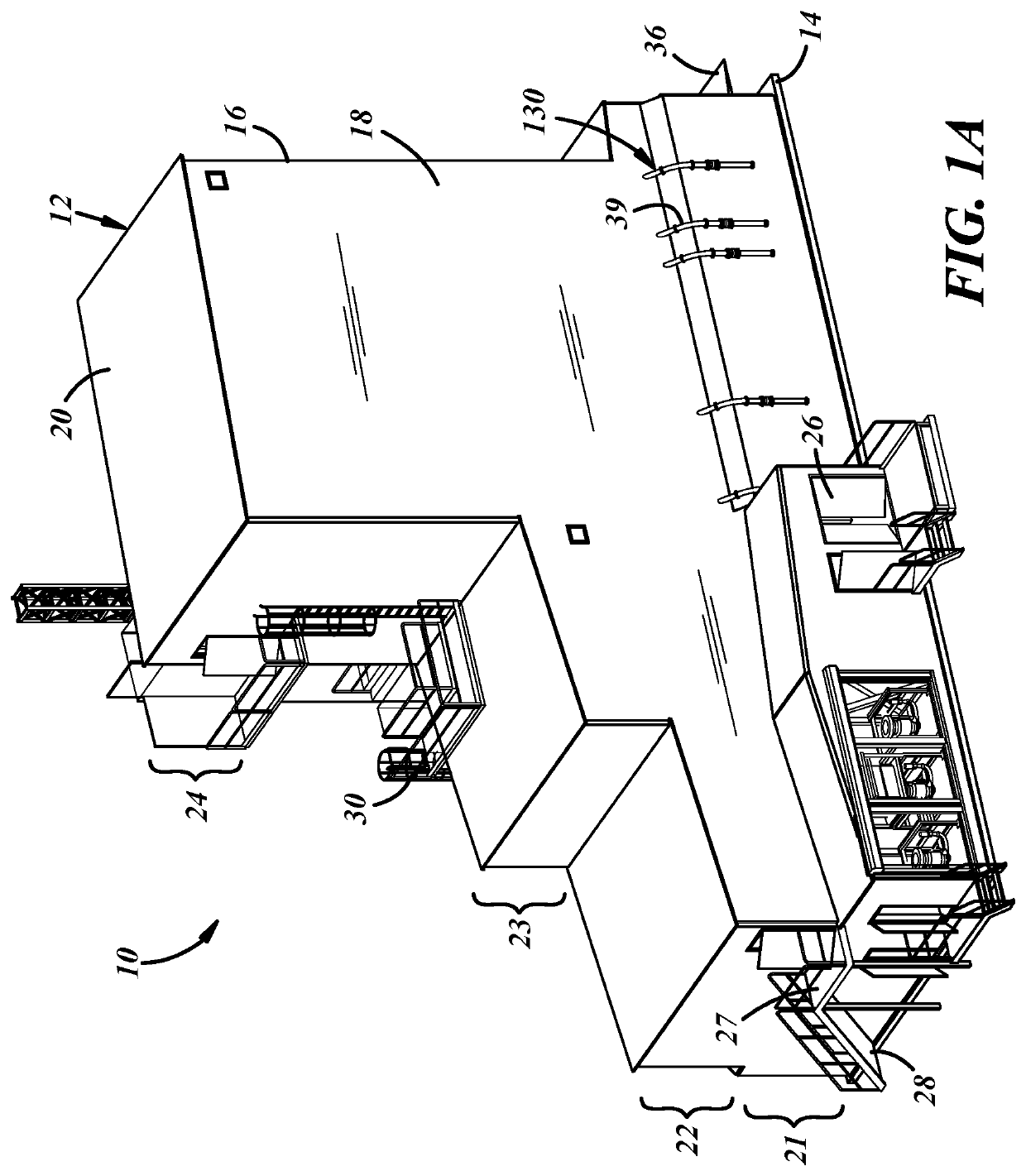

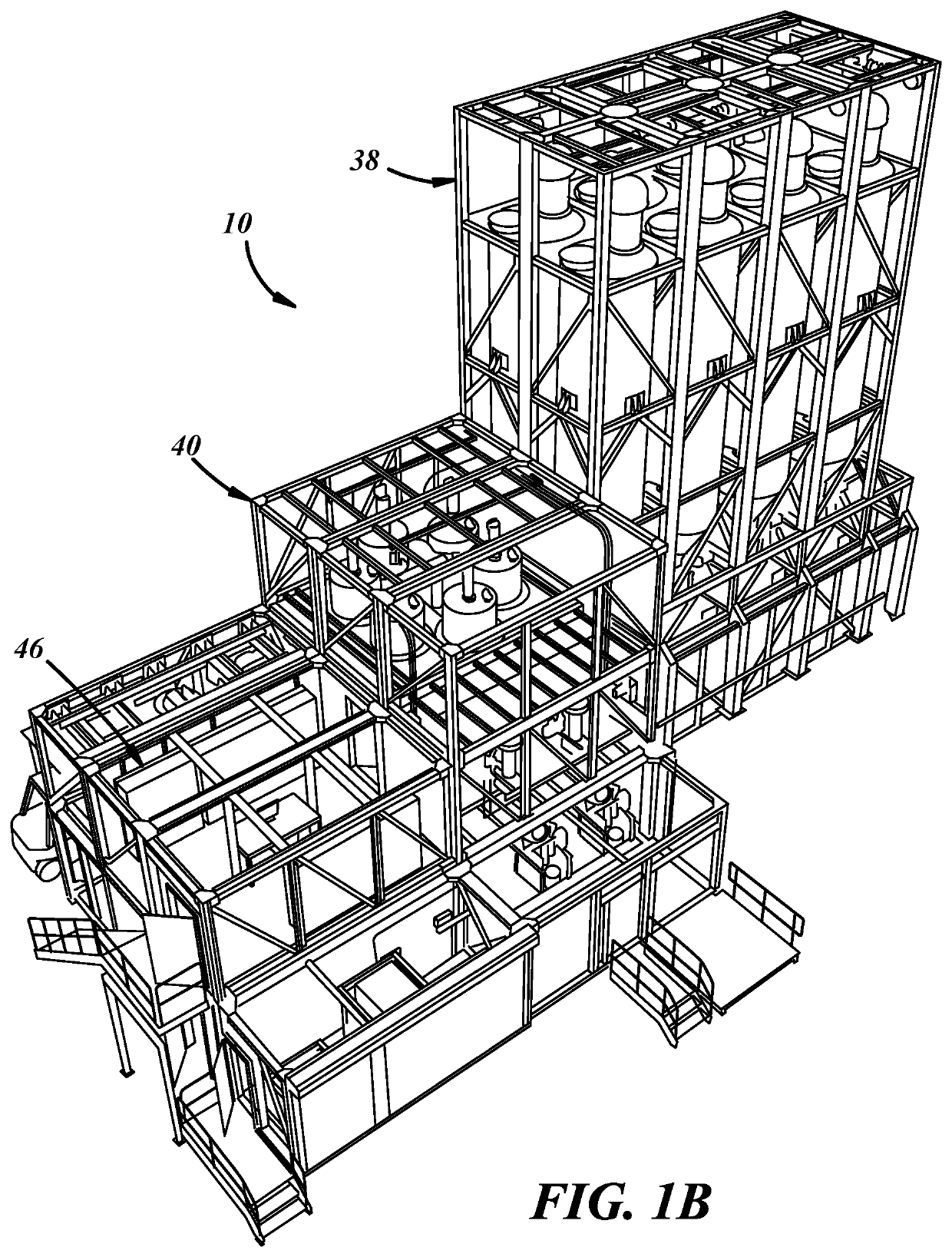

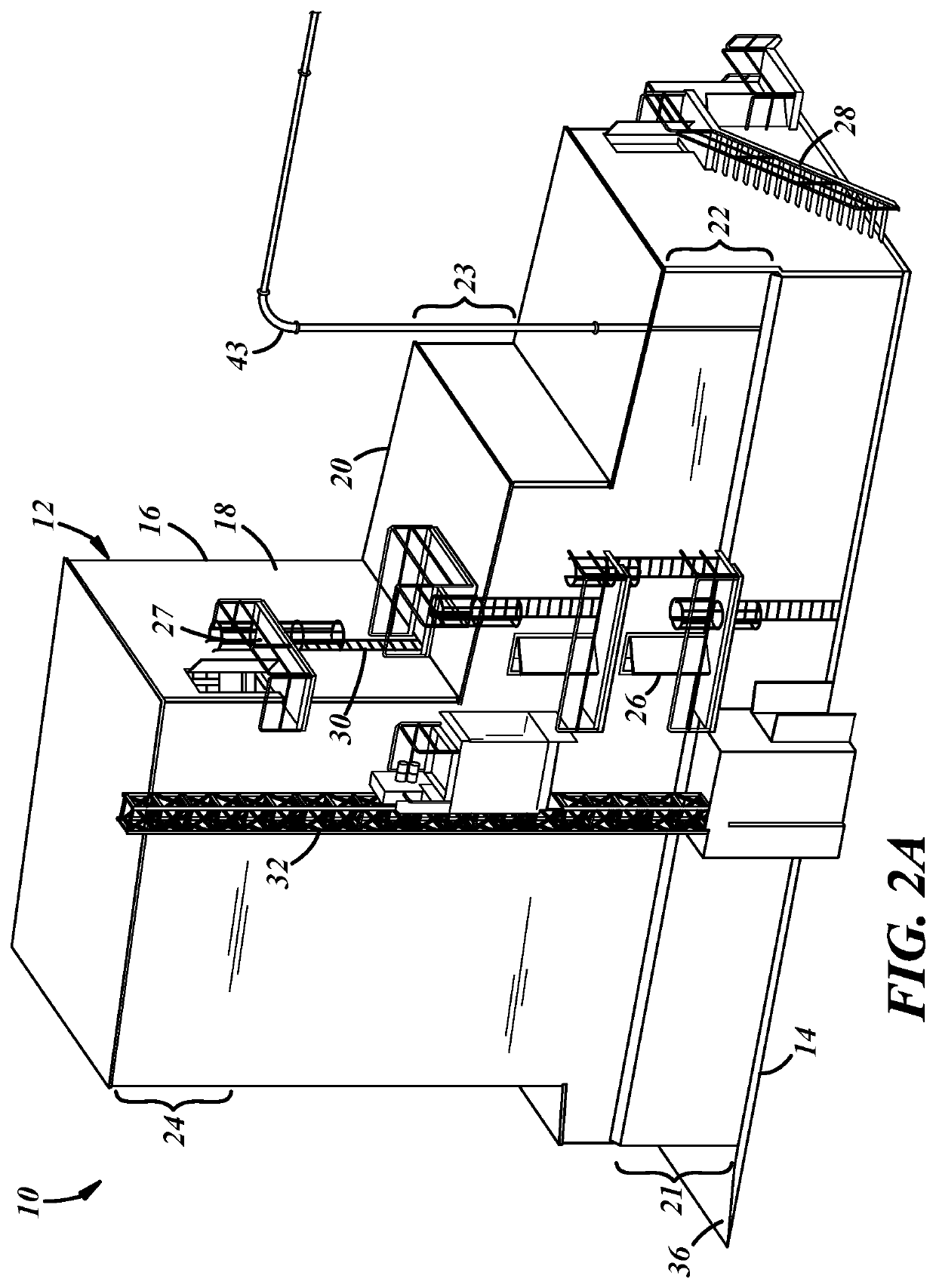

Bulk material receiving, conveying, storing, and dispensing

A bulk material handling system includes a majors material handling system including bulk material storage modules and bulk material dispensing modules. The dispensing modules include bulk material dosing assemblies and docking assemblies. A bulk material handling method includes conveying bulk material from a mobile bulk material container into a stationary bulk material container at a glass manufacturing facility via dense phase pneumatic conveying.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com