Bulk cargo treatment device and method for metallurgy pellets

A processing device and pelletizing technology, which is applied in the field of bulk material processing devices for metallurgical pellets, can solve the company's profit impact, uneconomical and other problems, and save the cost of the original cooked pellet bulk material conveying equipment, recycling equipment, and noise low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

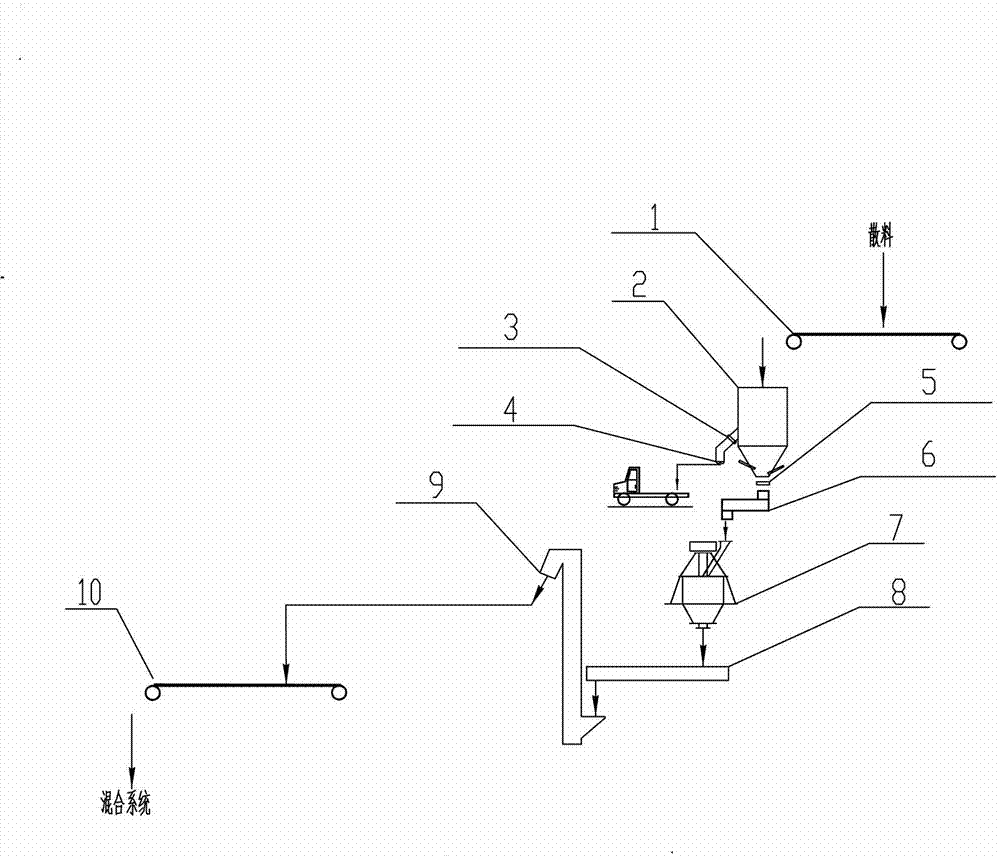

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] Such as figure 1 As shown, a bulk material processing device for metallurgical pellets of the present invention is characterized in that it includes an aggregate belt conveyor 1, and a bulk material buffer storehouse 2 arranged below the aggregate belt conveyor 1 is arranged in this bulk material buffer The bypass discharge pipe on the side of the warehouse 2, the bypass electro-hydraulic flat gate valve 3 on the bypass discharge pipe, the electro-hydraulic sector gate 4 below the bypass electro-hydraulic flat gate valve 3, when When the electro-hydraulic fan gate is overhauled, the electro-hydraulic flat gate valve can cut off the material flow. The electro-hydraulic flat gate valve 5 located at the bottom of the bulk material buffer bin 2 can cut off the material flow when the closed vibrating feeder and the cone mill are overhauled. . The closed vibrating feede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com