Bulk material handling system process and bulk material handling equipment

A technology of handling equipment and handling system, which is applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of low utilization rate of equipment, heavy maintenance tasks in the later stage, and high investment in the early stage, and achieve the effect of reducing input costs and reducing the cost of operation and maintenance in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

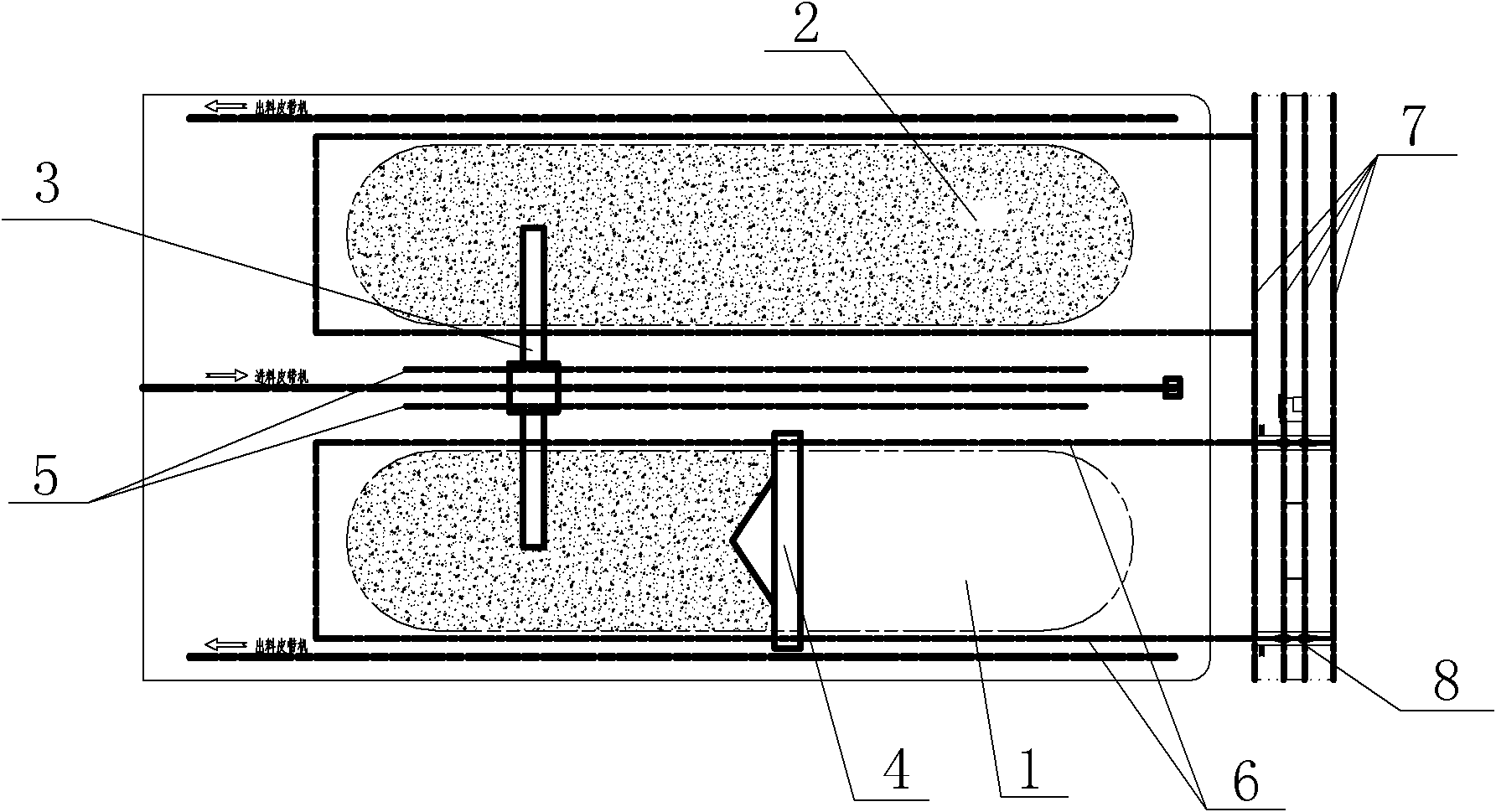

[0024] Embodiment 1 of the present invention: a process method of a bulk material handling system, including a multi-span stockyard, a rail-type stacker, a rail-type reclaimer and a transfer vehicle, and the rail-type stacker is located in a multi-span In the stockyard, it is responsible for stacking materials into the stockyard; the rail-type reclaimer first performs the reclaiming operation in a stockyard, and when the reclaiming operation in this block of stockyard is completed, the rail-type reclaimer Drive to the transfer vehicle at the end of the material yard, and transport the rail-type reclaimer to other material yards in the multi-span material yard through the transfer vehicle to continue the reclaiming operation. When driving the rail reclaimer to the transfer car at the end of the stockyard, it is necessary to position the rail reclaimer and the transfer car first. After positioning, open the transition section track on the transfer car. At this time, the rail The...

Embodiment 2

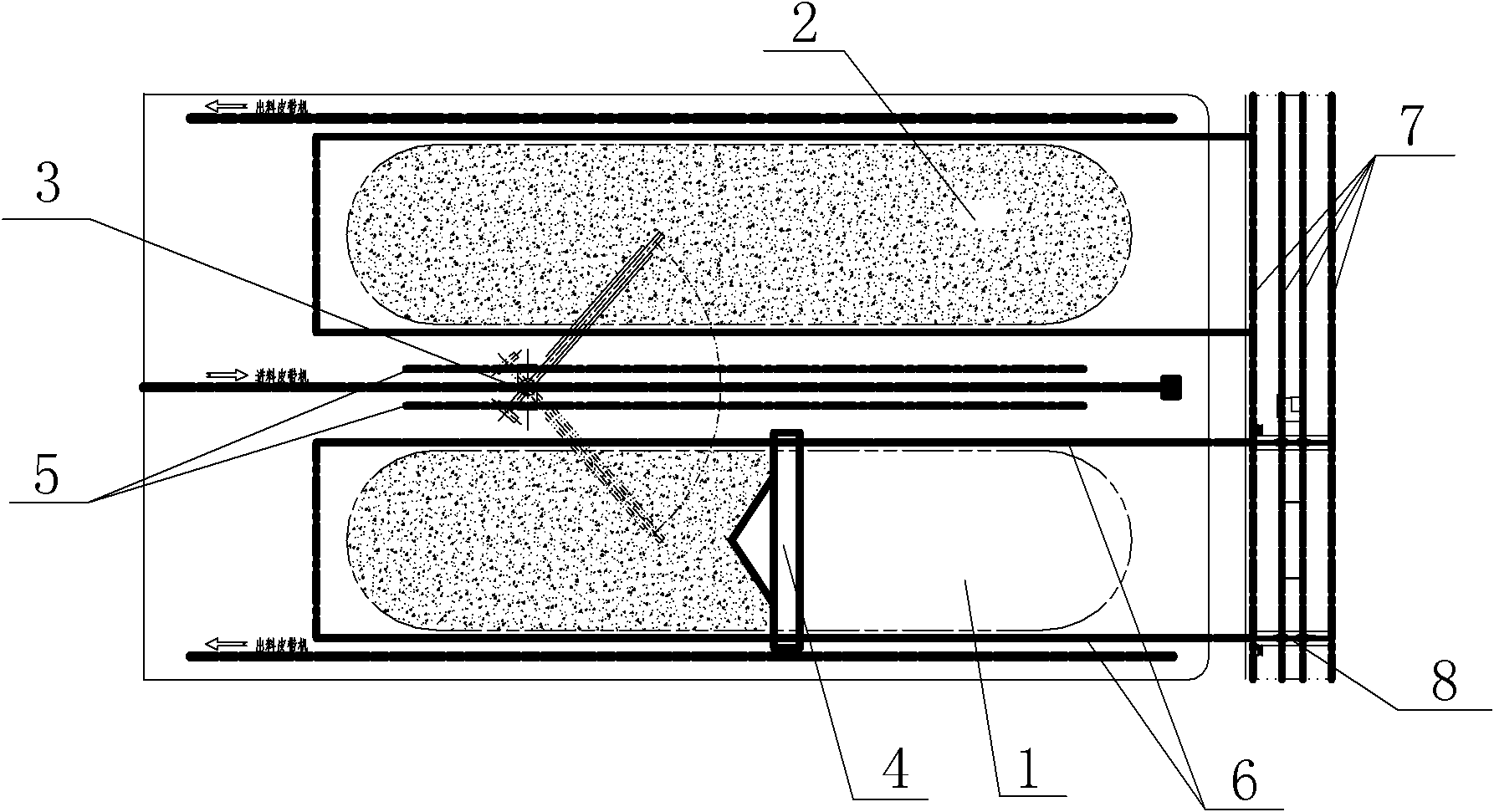

[0026] Embodiment 2 of the present invention: a process method of a bulk material handling system, including a multi-span stockyard, a rail-type stacker, a rail-type reclaimer and a transfer vehicle, and the rail-type stacker is located in a multi-span In the stockyard, it is responsible for stacking materials into the stockyard; the rail-type reclaimer first performs the reclaiming operation in a stockyard, and when the reclaiming operation in this block of stockyard is completed, the rail-type reclaimer Drive to the transfer vehicle at the end of the material yard, and transport the rail-type reclaimer to other material yards in the multi-span material yard through the transfer vehicle to continue the reclaiming operation. When driving the rail reclaimer to the transfer car at the end of the stockyard, it is necessary to position the rail reclaimer and the transfer car first. After positioning, open the transition section track on the transfer car. At this time, the rail The...

Embodiment 3

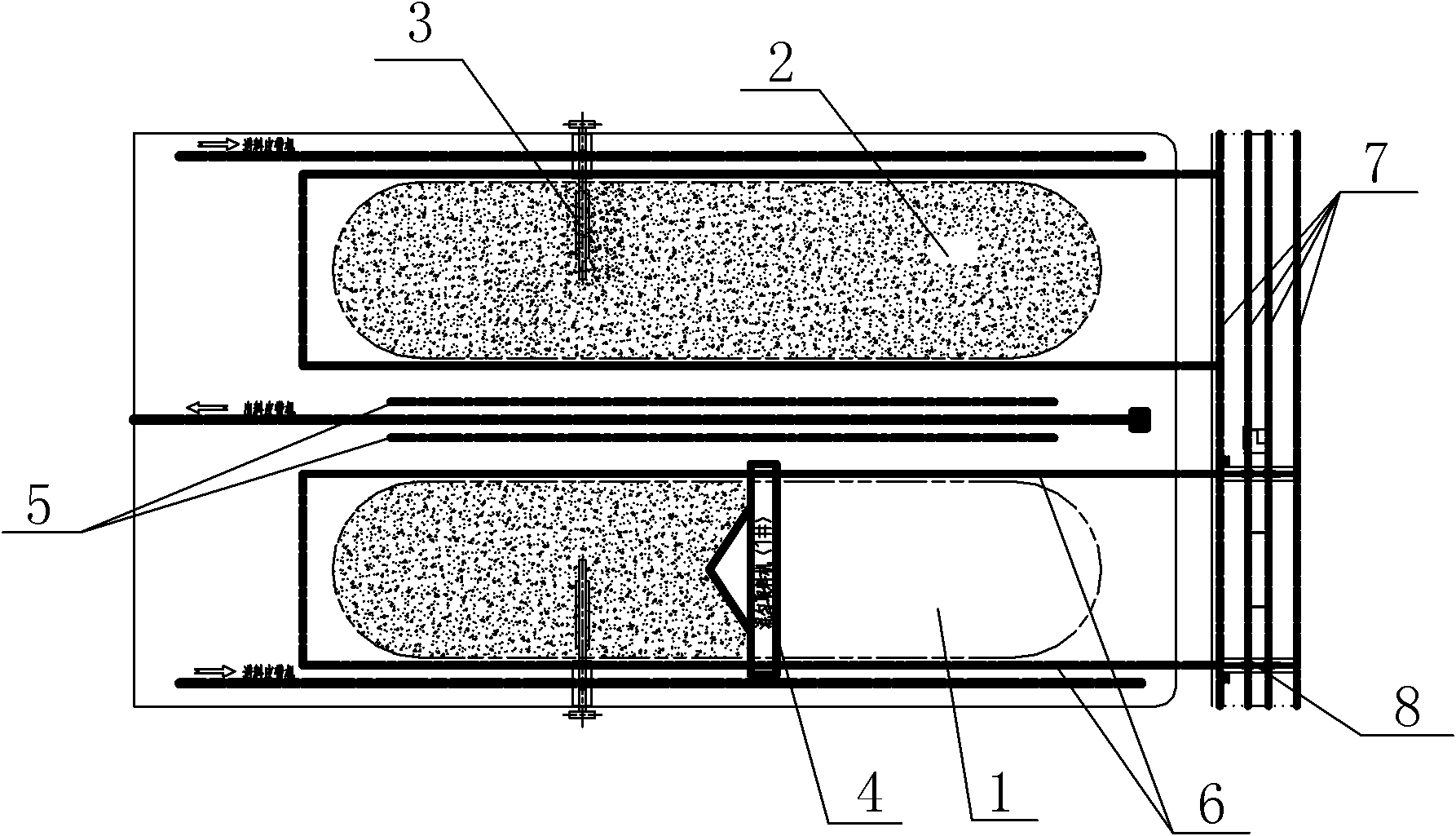

[0028]Embodiment 3 of the present invention: a process method of a bulk material handling system, including a multi-span material yard, a rail-type stacker, a rail-type reclaimer and a transfer vehicle, and the rail-type stacker is located in a multi-span In the stockyard, it is responsible for stacking materials into the stockyard; the rail-type reclaimer first performs the reclaiming operation in a stockyard, and when the reclaiming operation in this block of stockyard is completed, the rail-type reclaimer Drive to the transfer vehicle at the end of the material yard, and transport the rail-type reclaimer to other material yards in the multi-span material yard through the transfer vehicle to continue the reclaiming operation. When driving the rail reclaimer to the transfer car at the end of the stockyard, it is necessary to position the rail reclaimer and the transfer car first. After positioning, open the transition section track on the transfer car. At this time, the rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com