Bulk storage container and bulk material handling assembly therewith

A technology for storage containers and bulk materials, applied in the field of bulk material storage containers, can solve the problems of toxic catalyst materials, containing carcinogens, health hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

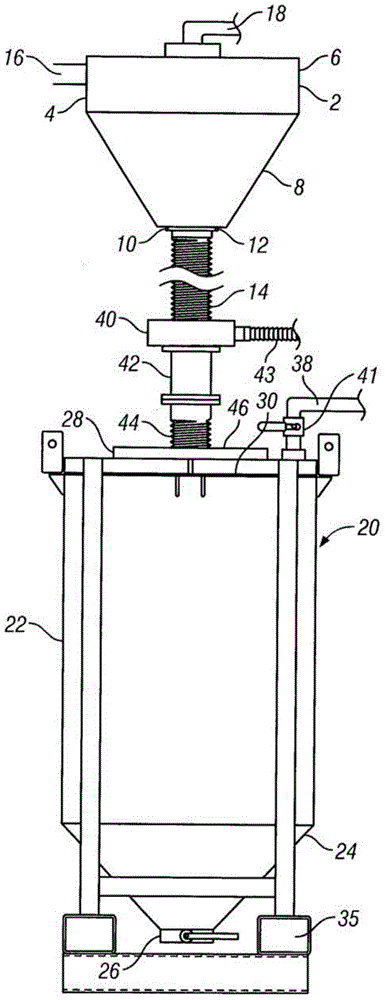

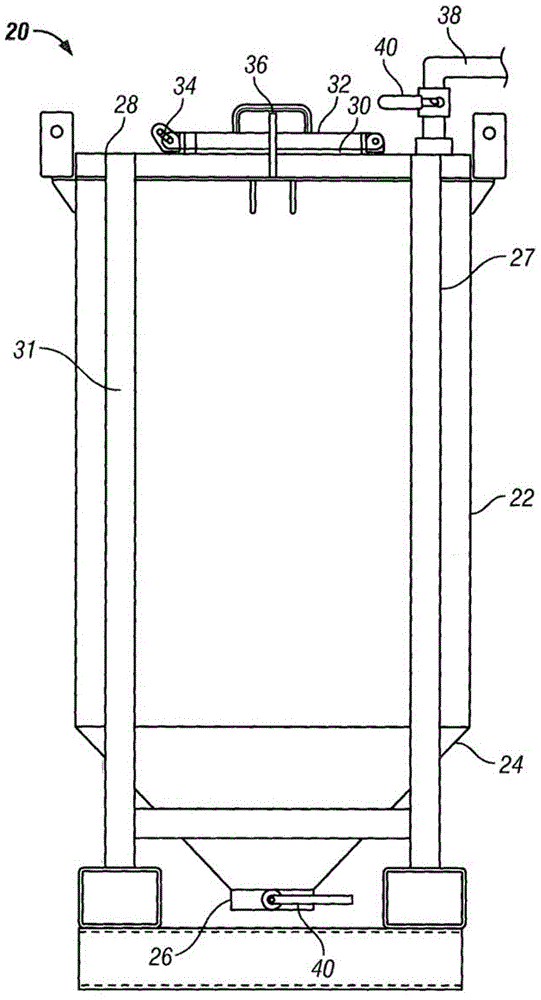

[0019] refer to figure 1 , the bulk material loading device 1 is arranged for transferring particulate catalyst material from a vessel within the reactor to a bulk material container for conveying the particulate catalyst material out of the reactor and / or for storage. The loading device comprises an intermediate hopper 2, also called interceptor hopper, which receives the catalyst material in the vessel of the reactor and transfers the catalyst material further to a bulk material container. The bulk catalyst material is drawn out of the vessel of the reactor using a vacuum and is entrained in the gas flow under the action of the vacuum and transferred to the interception funnel 2 .

[0020] The interception funnel 2 comprises a vessel body 4 of typical funnel configuration with a cylindrical upper part 6 and a conical lower part 8 tapering towards an opening 10 at its base end. The interception funnel 2 is supported by a sub-frame (not shown) that holds the funnel in a raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com