A bucket wheel stopper device for a bucket wheel stacker and reclaimer

A bucket-wheel stacker-reclaimer and material-stopping device technology, which is applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problem of overloading of bucket wheels and booms, overload of bucket wheels and booms, and landslides of the upper material pile, etc. problems, to achieve the effect of strong adaptability of materials, prevention of material collapse, and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

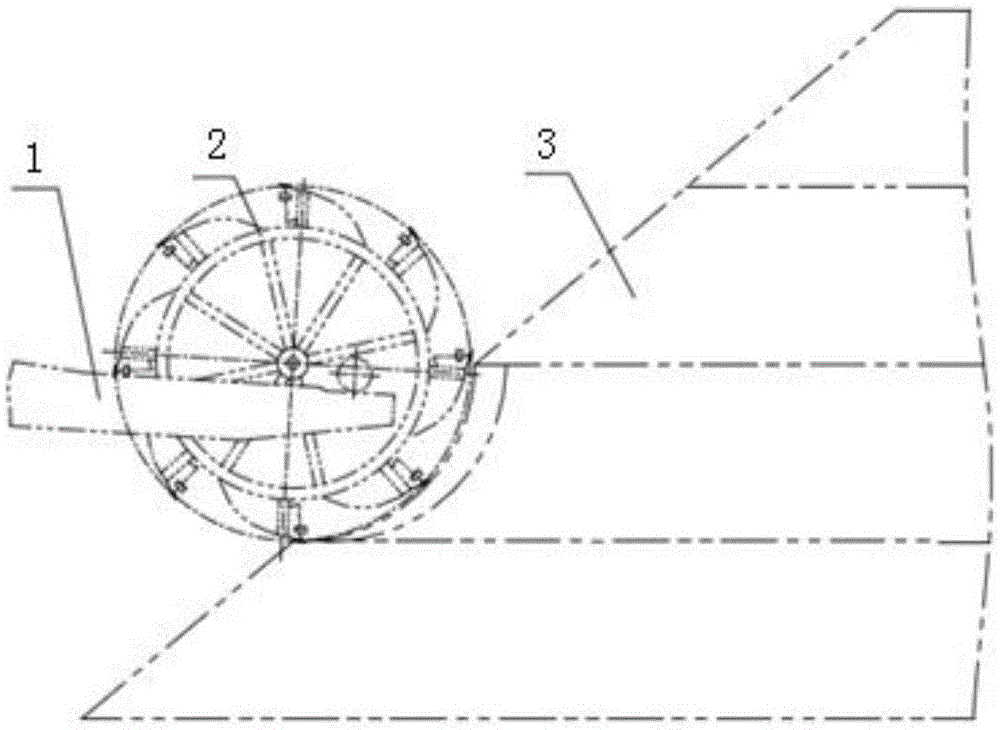

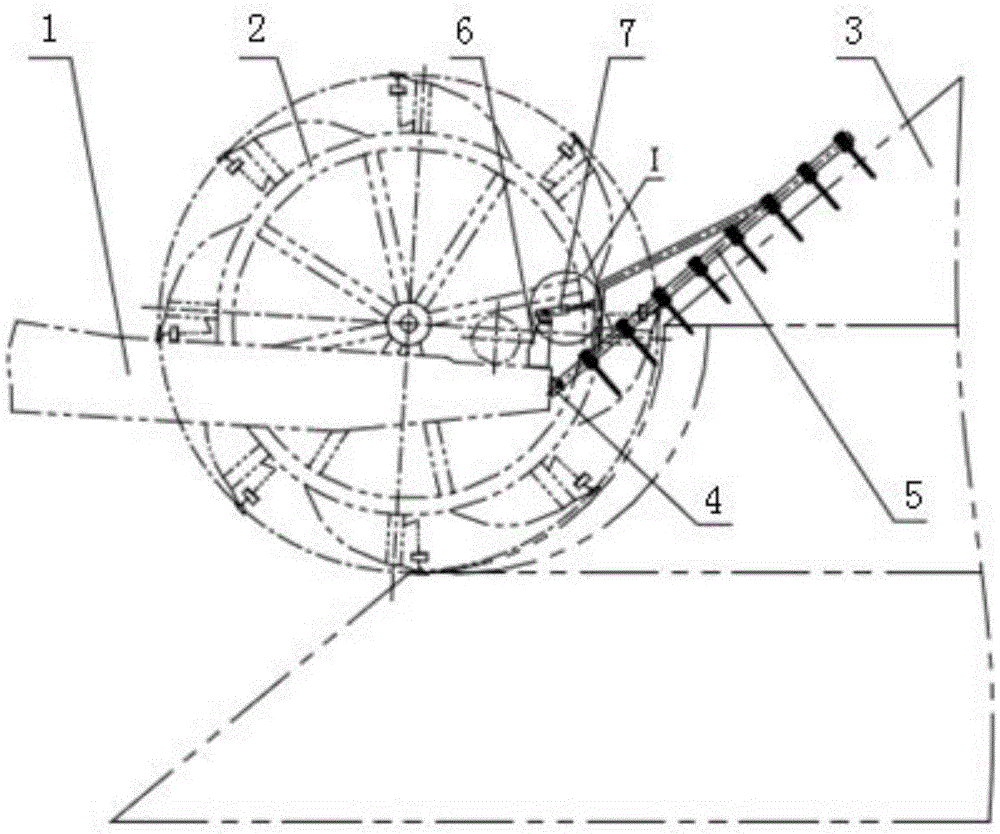

[0033] see figure 1 , figure 2 , the present embodiment includes a material rake base 4, a material retaining rake 5, a mounting seat 6 and an electric push rod 7; The lower end of the rake is hinged with the rake base 4, and the mounting seat 6 is fixed on the top of the front part of the arm frame main beam 1 of the bucket wheel stacker-reclaimer. The electric push rod 7 is mounted on the mounting seat 6 in a hinged manner. The upper part is hinged with the electric push rod 7. By adjusting the length of the electric push rod 7 during assembly, the angle of the retaining rake 5 can be adjusted, which can meet the angle requirements of the retaining rake at different pitch angles of the boom, and can also meet the requirements of different materials for the retaining rake angle. Adapts well to various materials.

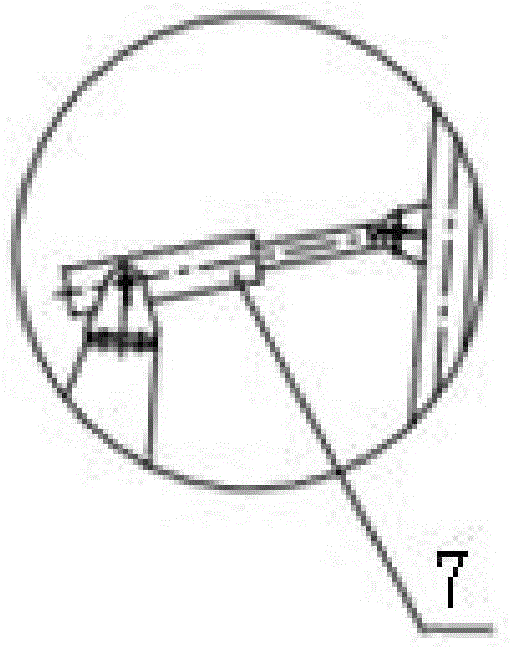

[0034] see Figure 4 , Figure 5 The retaining rake 5 includes a roof truss-shaped rake frame 51 with a pyramid-shaped top. This structure has the function of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com