Method and arrangement for emptying big bags

A bag and emptying technology, which is used in the field of emptying large bags and devices, can solve the problems of hazards and health hazards in the emptying process for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

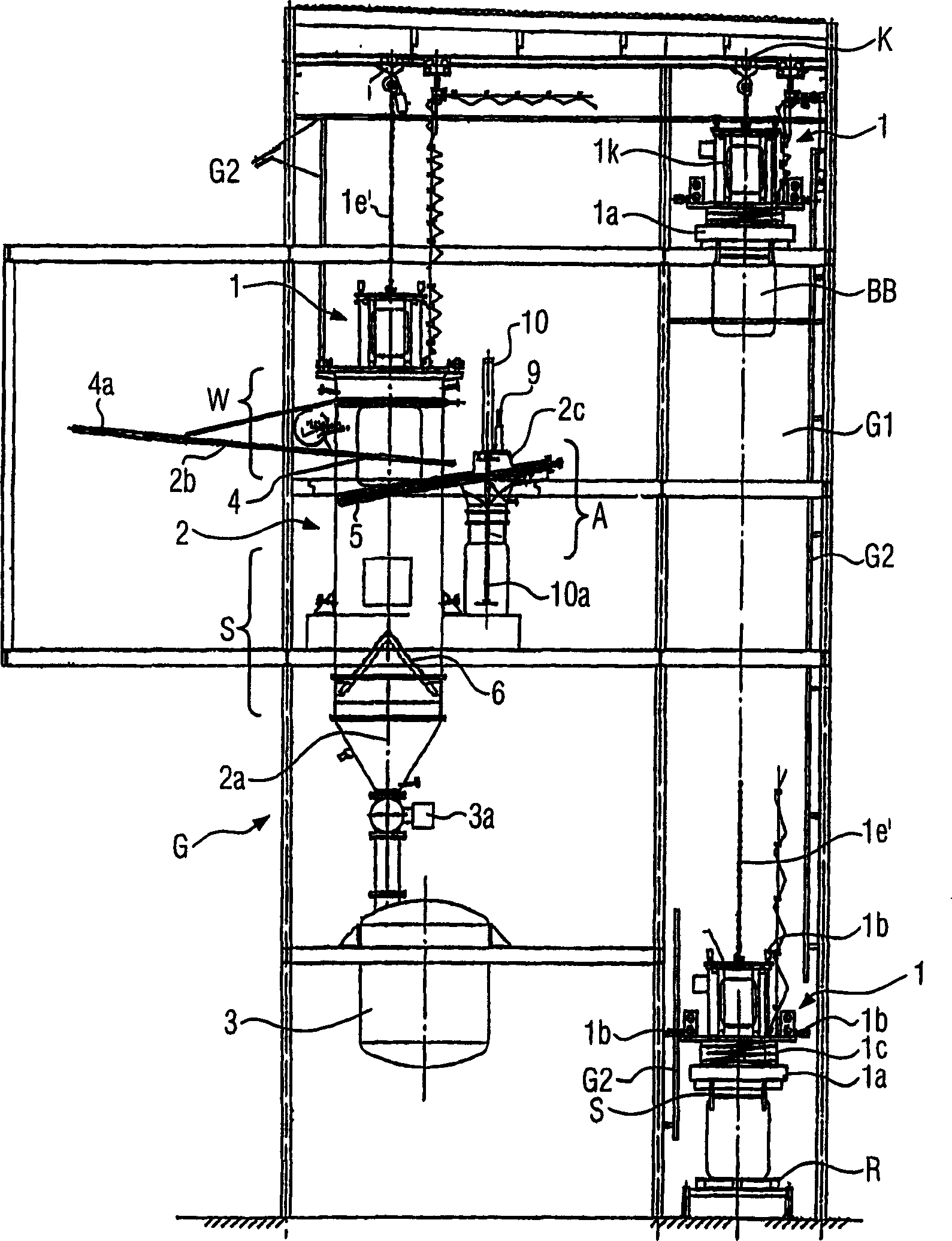

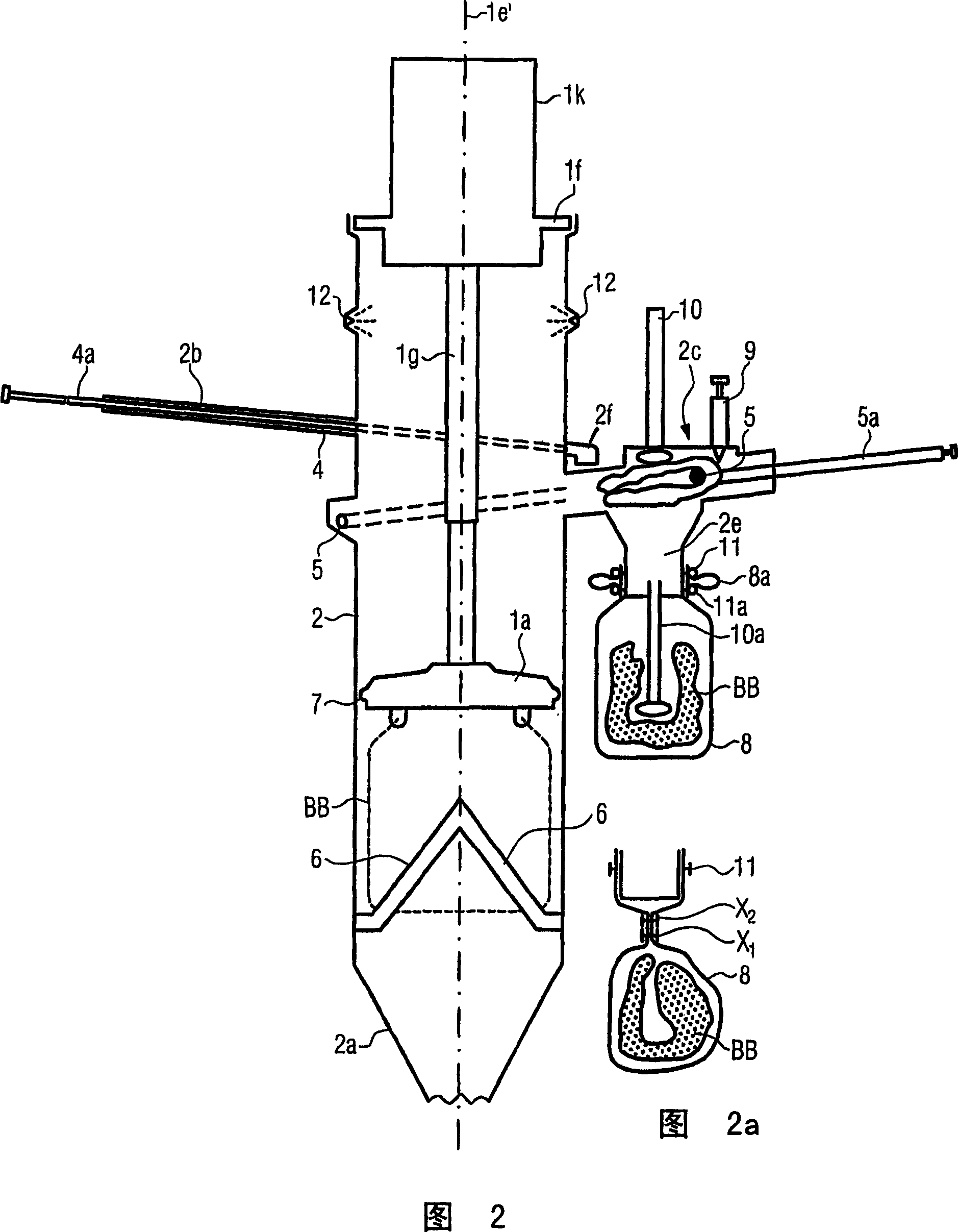

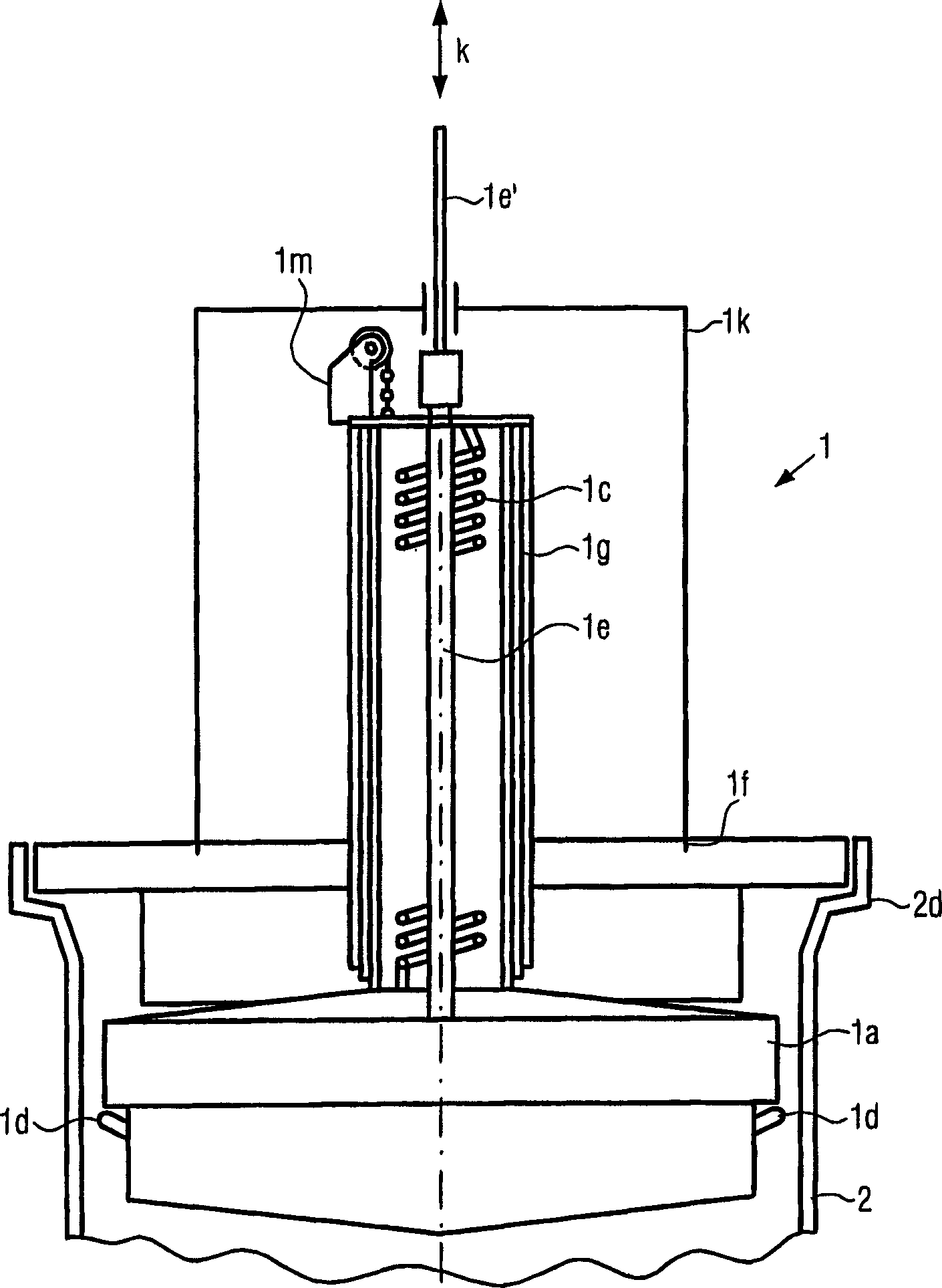

[0012] figure 1 A tower-shaped building G is shown schematically with a conveying shaft G1 and an emptying device arranged alongside it. On the conveying path (for example, the roller conveying path R), the big bag BB is inserted in the conveying hoistway G1. The big bag is usually provided with four hanging rings S distributed around its upper periphery, these hanging rings S are manually hooked on the conveying plate 1a of the conveying unit 1, and the lifting device K lifts the conveying unit upwards in the conveying shaft G1 1, such as figure 1 shown. The lifting device K moves the conveying unit 1 horizontally from the upper position to figure 1 The conveyor unit 1 is then lowered until it abuts against the upper edge of the discharge device 2 .

[0013] In the conveying shaft G1 and above the unloading device 2, guide rails G2 are mounted on the sides, and the guide rollers 1b engage with the guide rails G2 at the conveyor unit 1 so that no twist. In addition, a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com