Ingredient distributing element on a container for flowable or dumpable bulk goods

A technology for dispensing components and bulk materials, applied in the field of filling free-flowing or pourable bulk materials, to save manpower and cost, save time, and improve the effect of danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

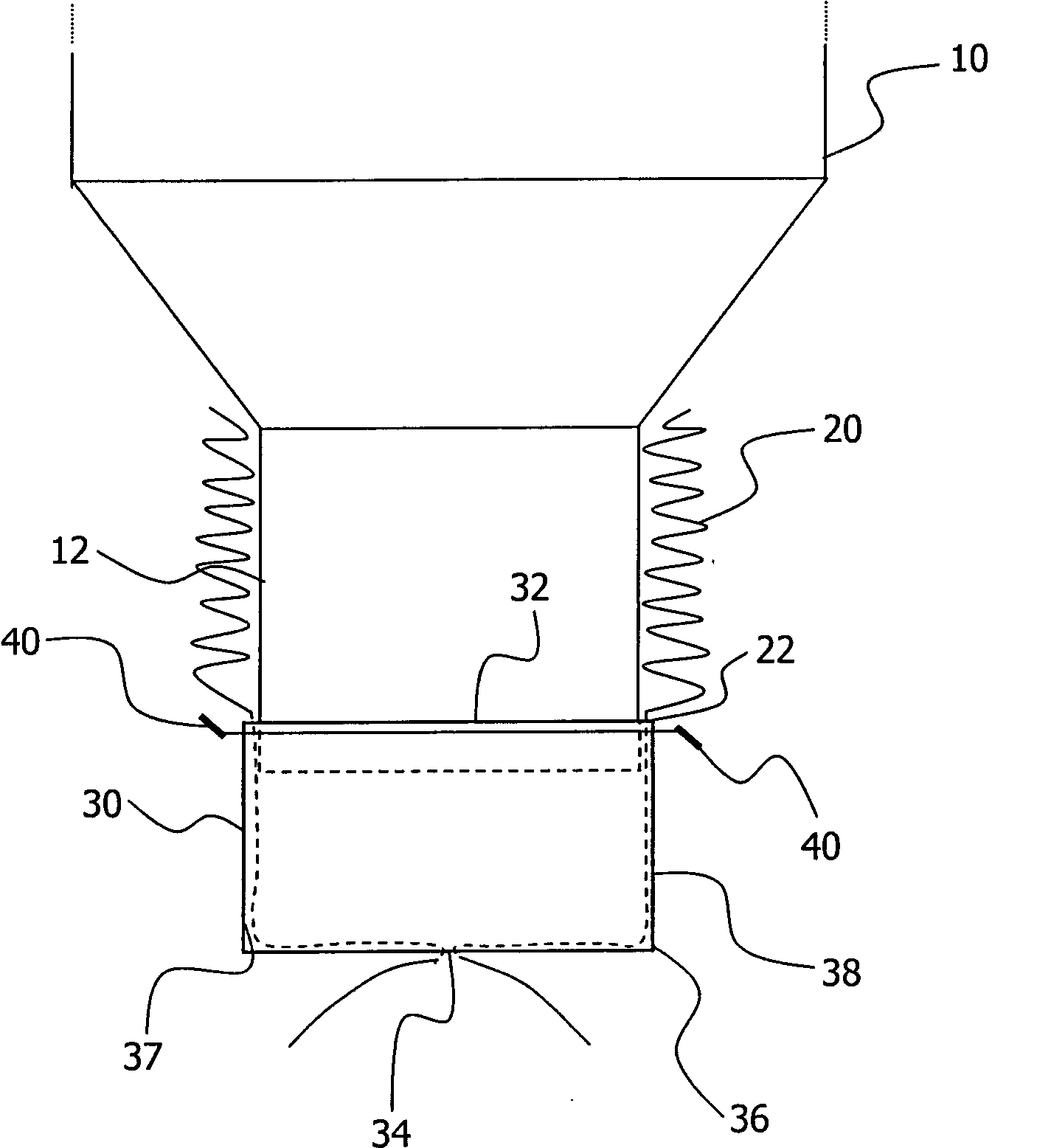

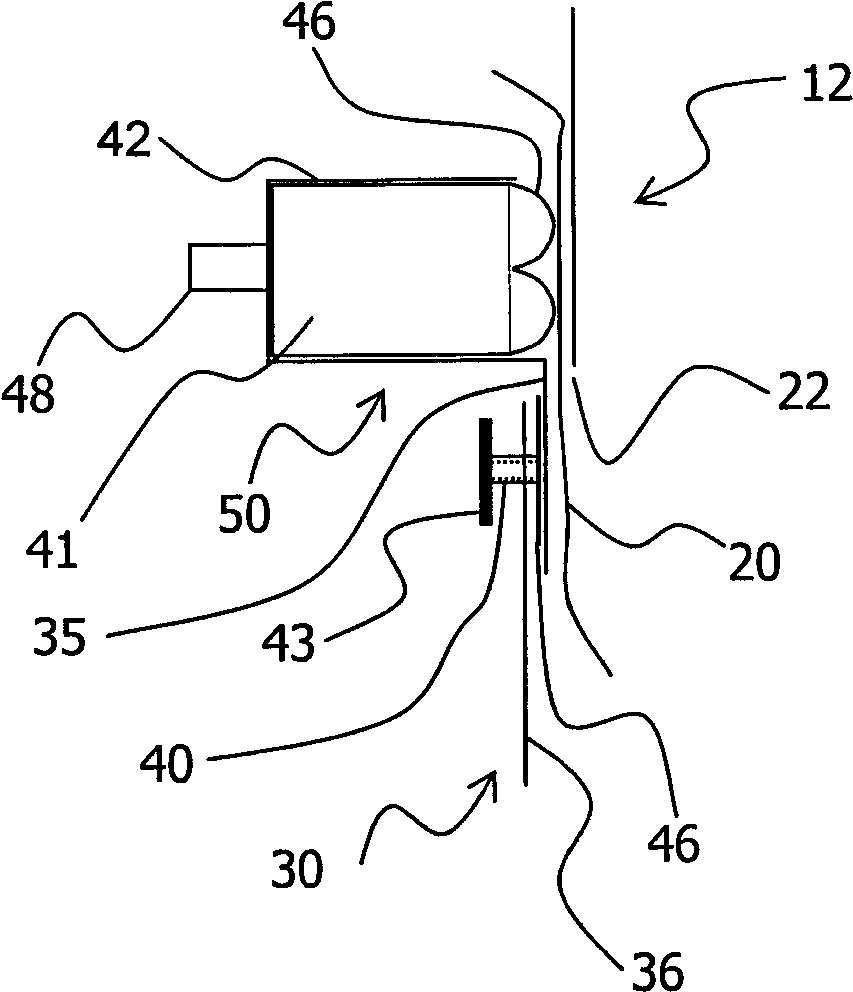

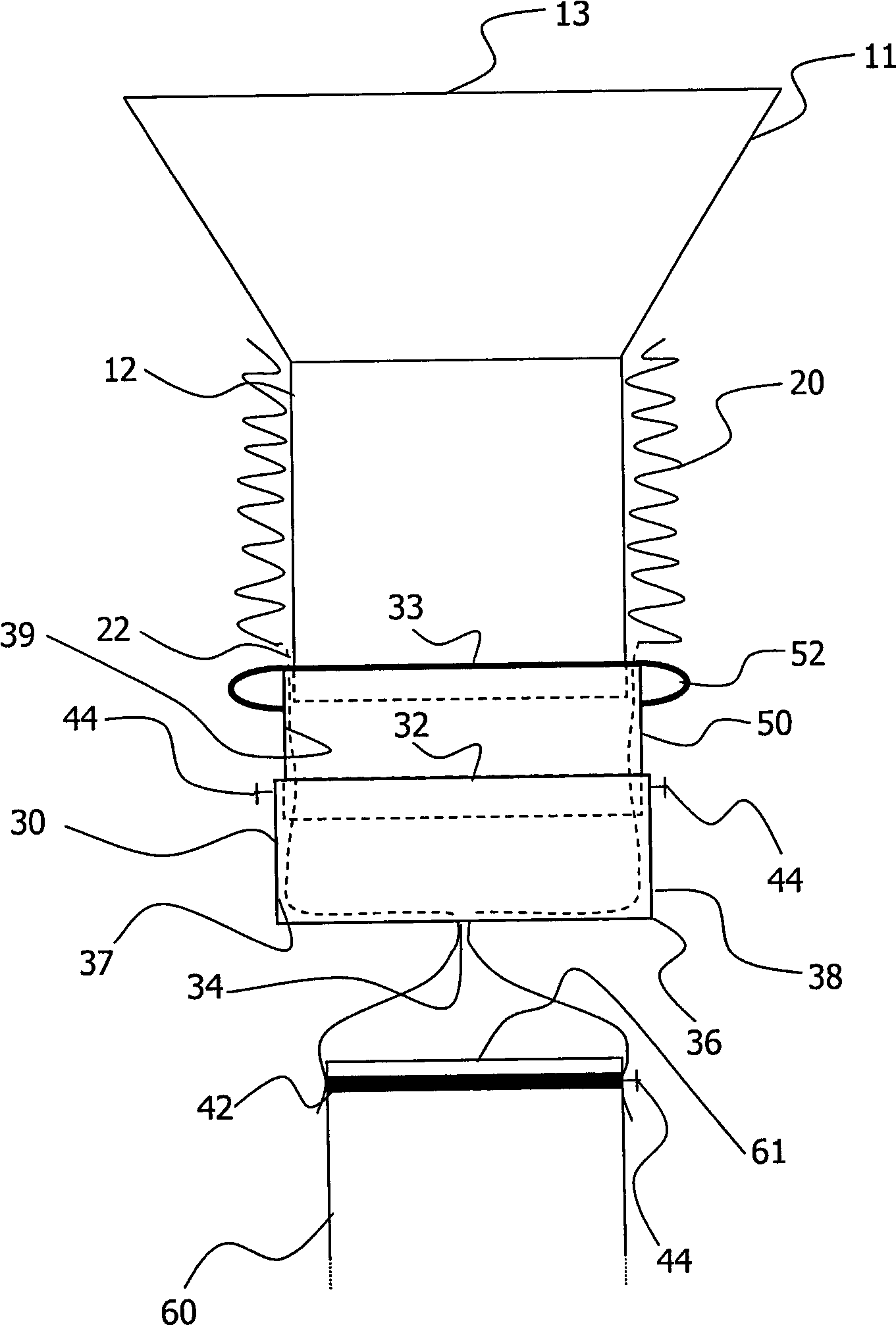

[0033] exist figure 1 In an embodiment of the present invention, the ingredient dispensing element 30 is fixed to the hopper 10 for pourable bulk material. The foil-shaped material 20 in the form of a continuous hose is stored in the region of the discharge connection 12 . The ingredient distribution element 30 is held firmly in the lower part of the outlet connection 12 by means of clamps 40 . Before fixing the ingredient-dispensing element 30 , the foil-shaped material 20 is threaded into the ingredient-distributing element 30 through the annular gap 22 and passed through the ingredient-dispensing element 30 . Thus, the inner side is covered with the foil-shaped material 20 , as is the access opening 32 . Since the foil-shaped material 20 is passed through the slit-shaped discharge opening 34 to the outside of the ingredient-dispensing element 30, the discharge opening 34 is likewise covered with the foil-shaped material, so that the ingredient-dispensing element 30 does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com