Patents

Literature

92results about How to "Guaranteed feeding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

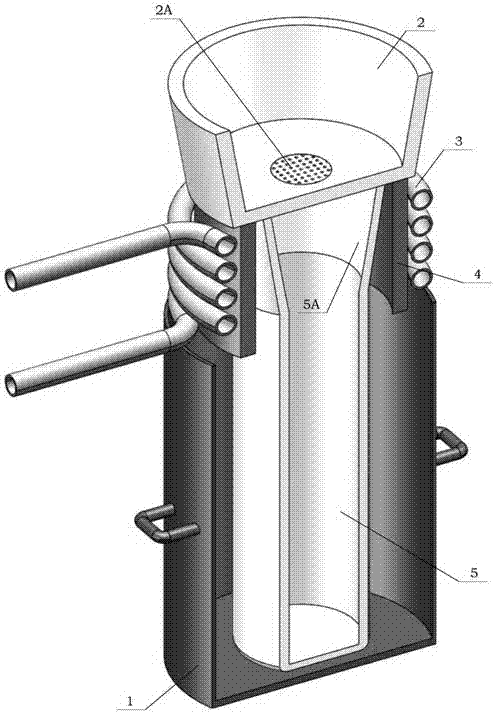

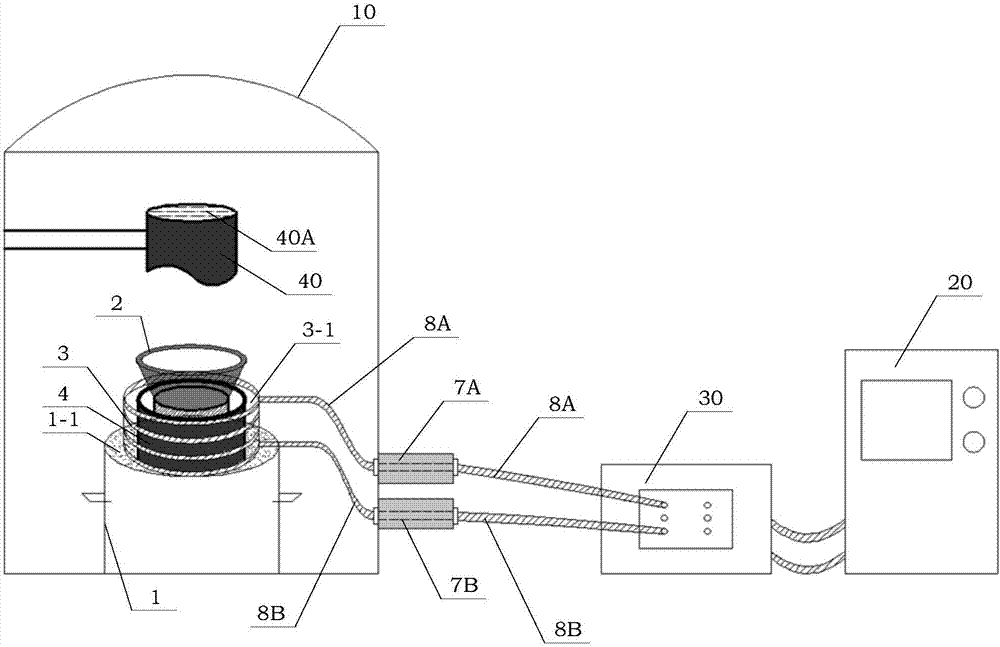

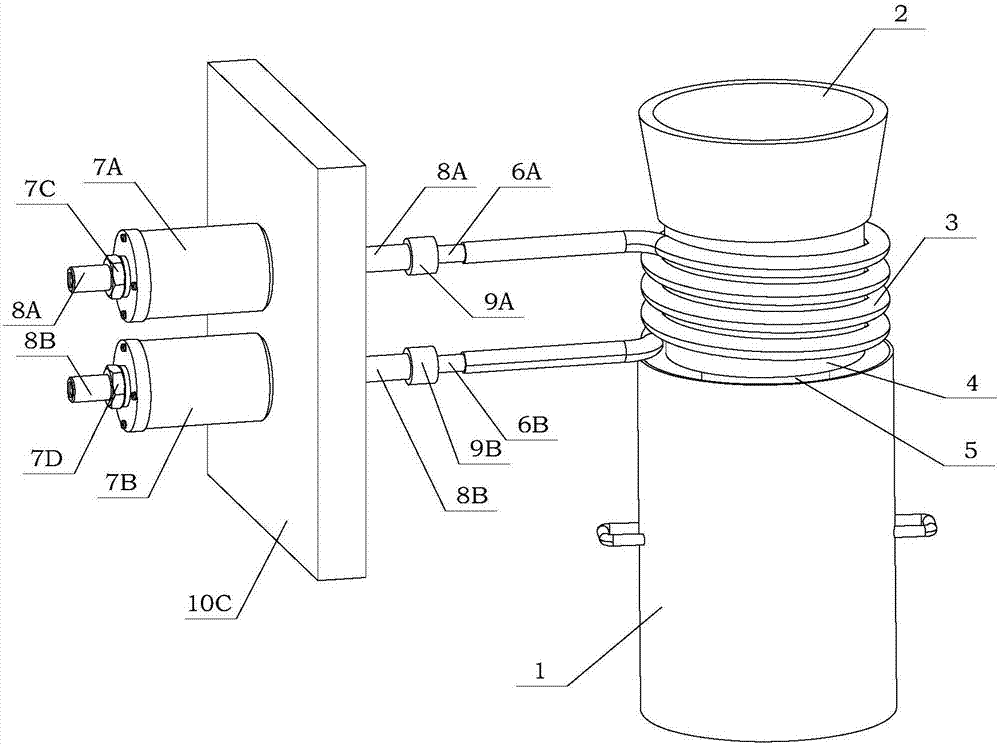

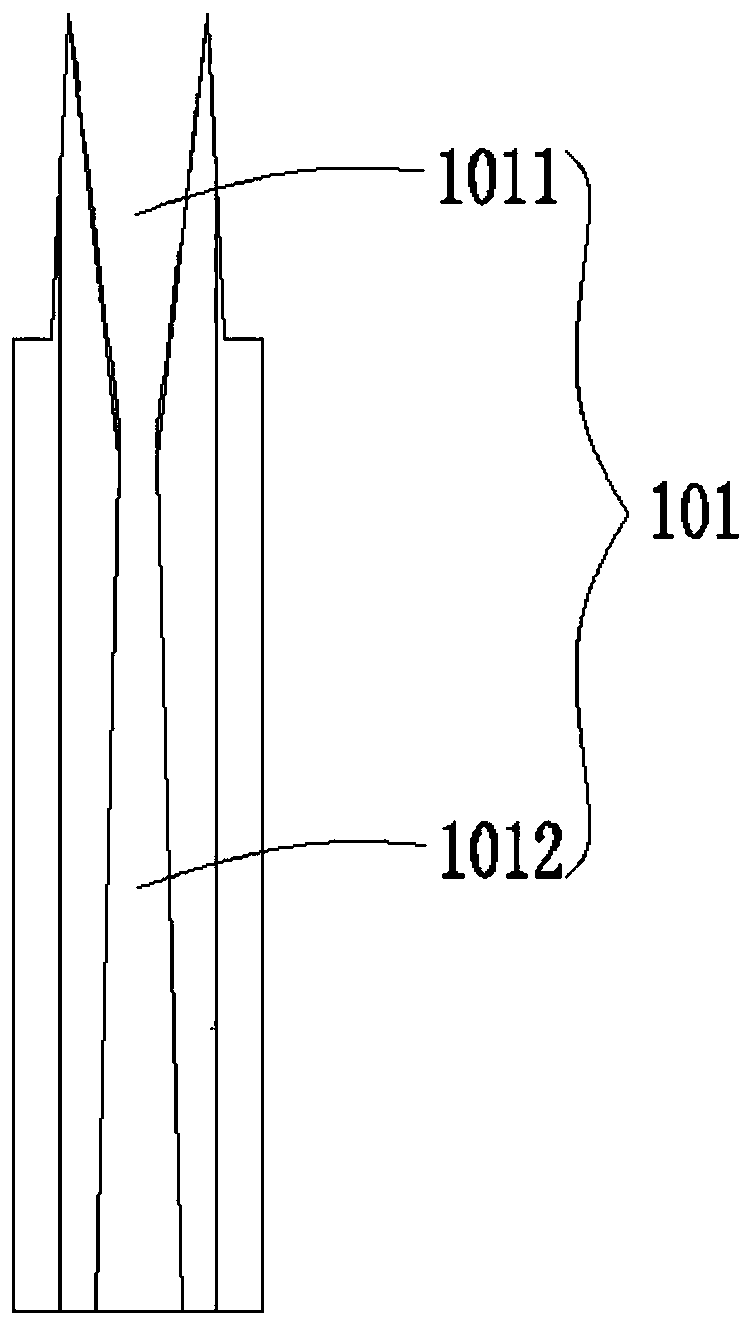

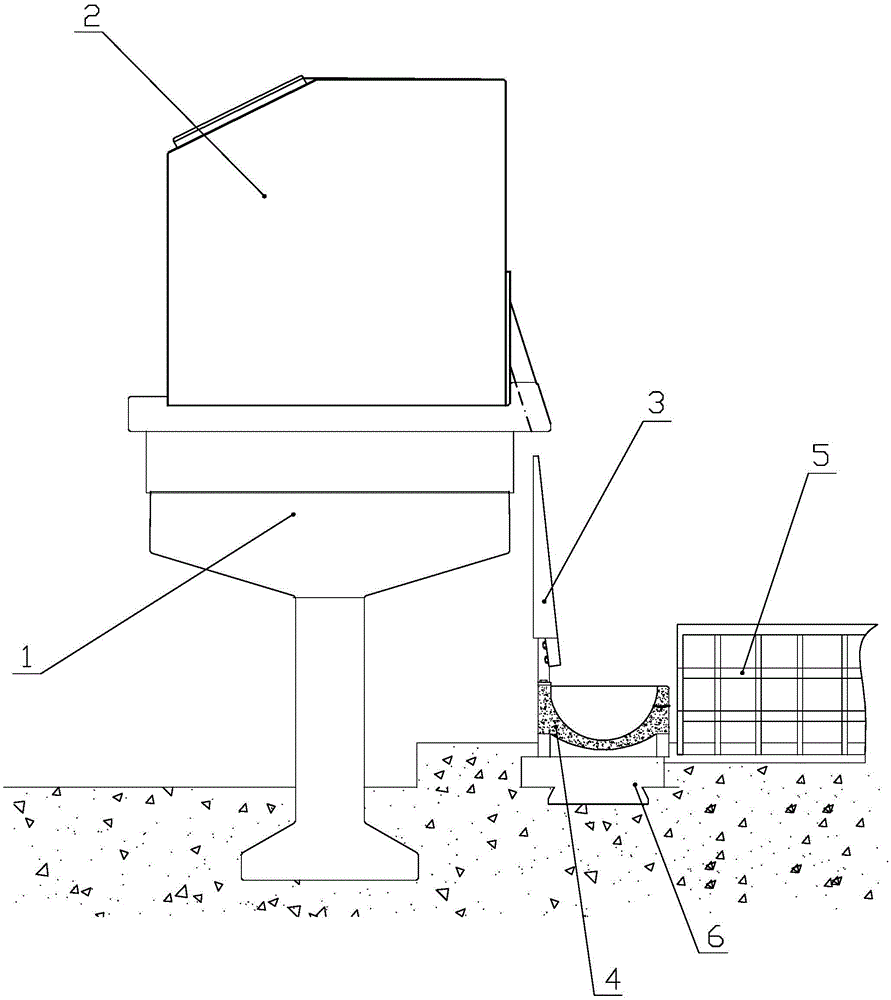

Sequential solidification technology device and method used in vacuum smelting equipment

The invention discloses a sequential solidification technology device and method used in vacuum smelting equipment. An induction heating coil is placed in a dead head section of an ingot die, and the feeding capacity of metal liquid in a dead head is enhanced through an induction heating method; a bottom cooling device with the cooling area smaller than the area of the cross section, at the bottom position of the ingot die, of a casting is arranged at the bottom of an ingot die base, the solid-liquid interface angle is reduced, and the metal liquid in the ingot die after pouring can be sequentially solidified from bottom to top. The solidification process control method is applicable to production of metal bar castings in the vacuum smelting equipment. Through the sequential solidification technology device and method, macroshrinkage and shrinkage porosity in alloy bar castings can be eliminated, the casting quality and the technology yield are improved, and the production efficiency is greatly improved.

Owner:BEIHANG UNIV

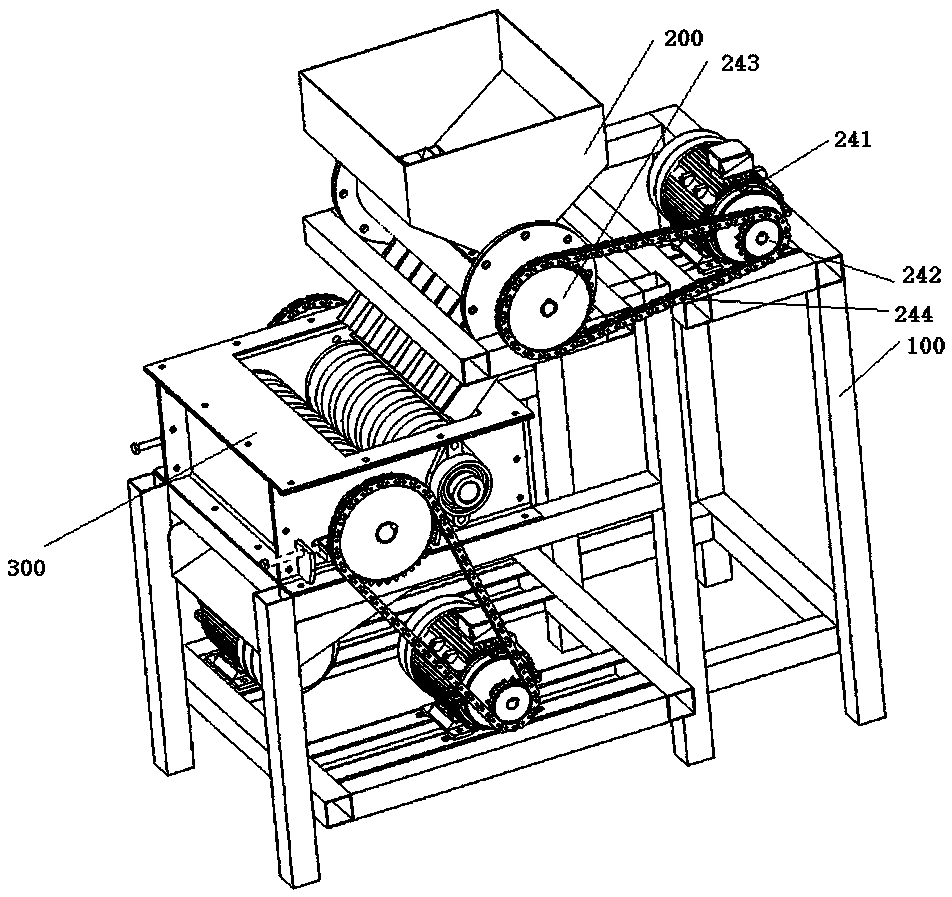

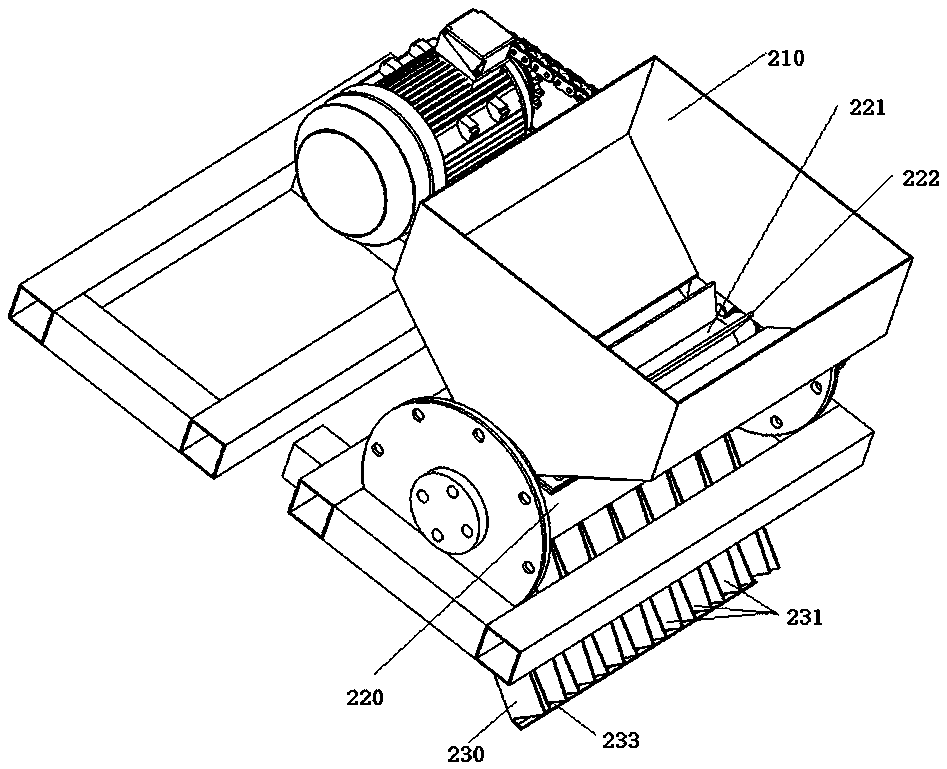

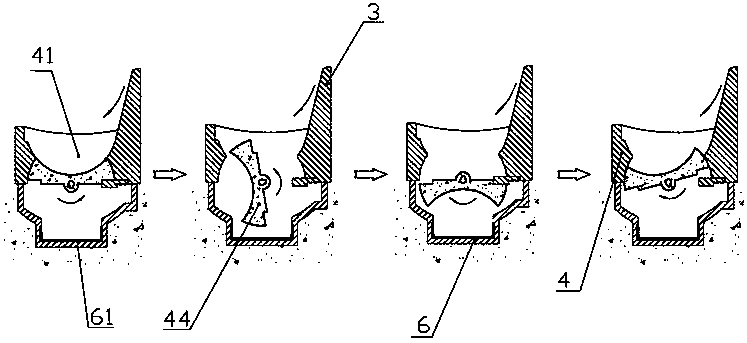

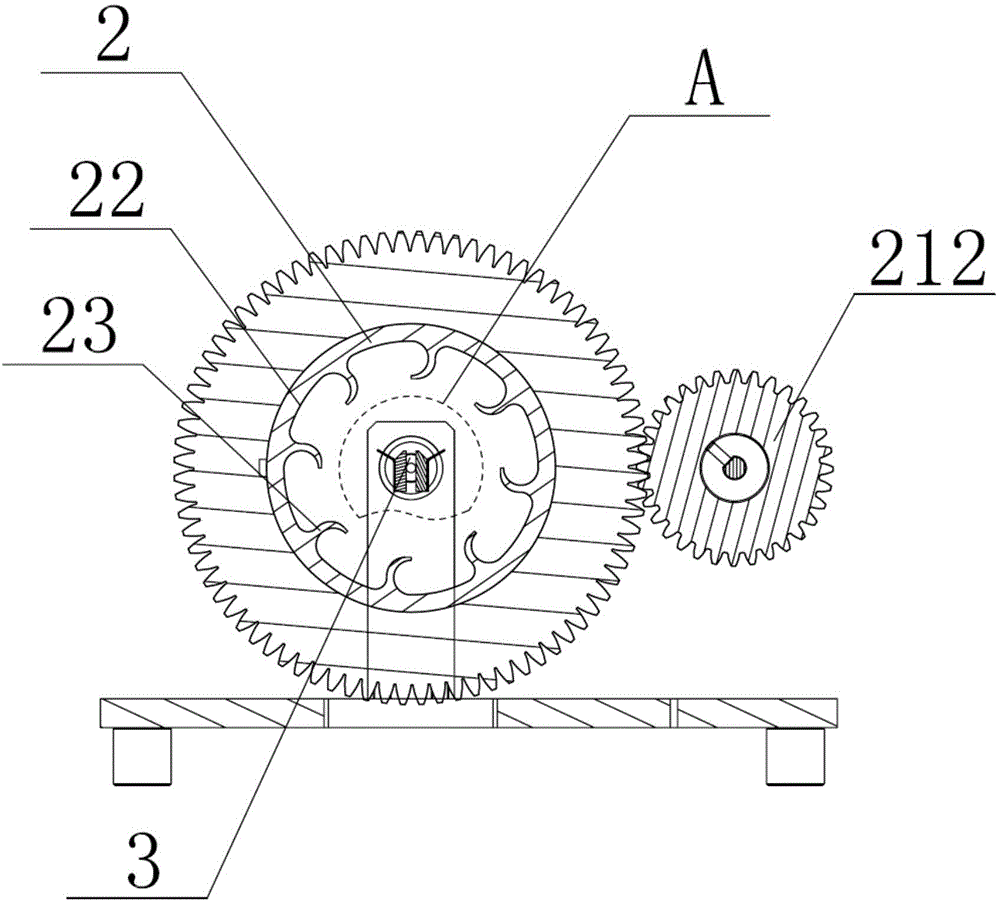

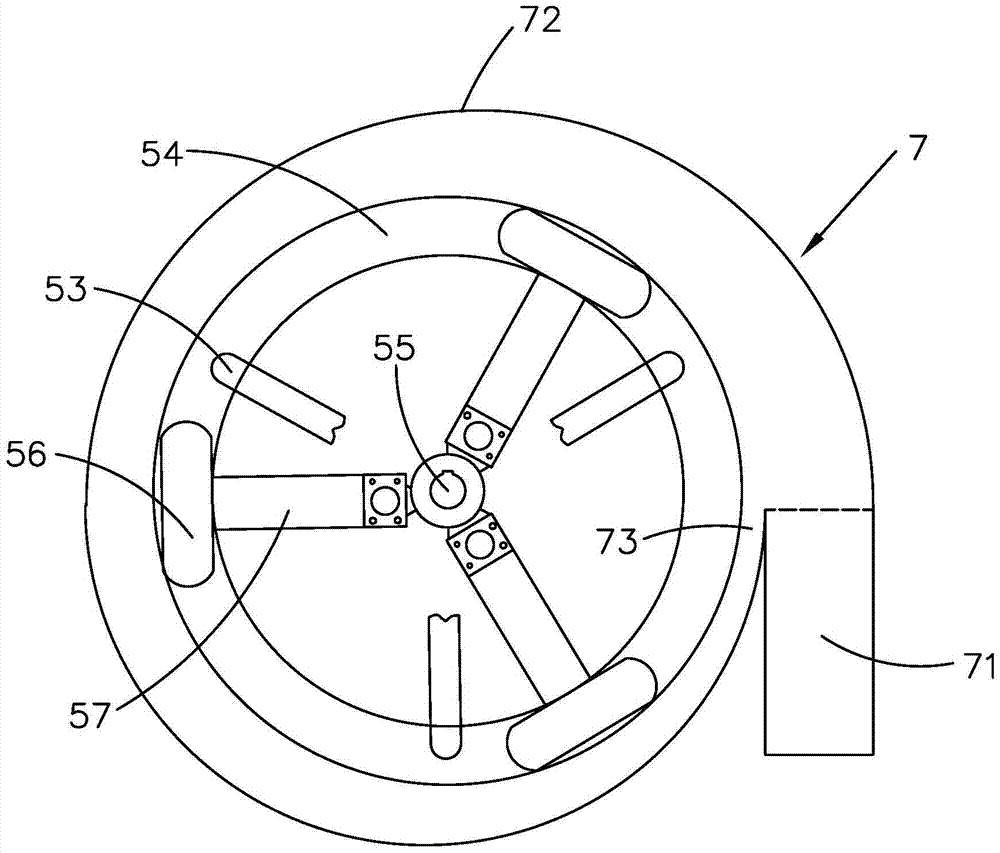

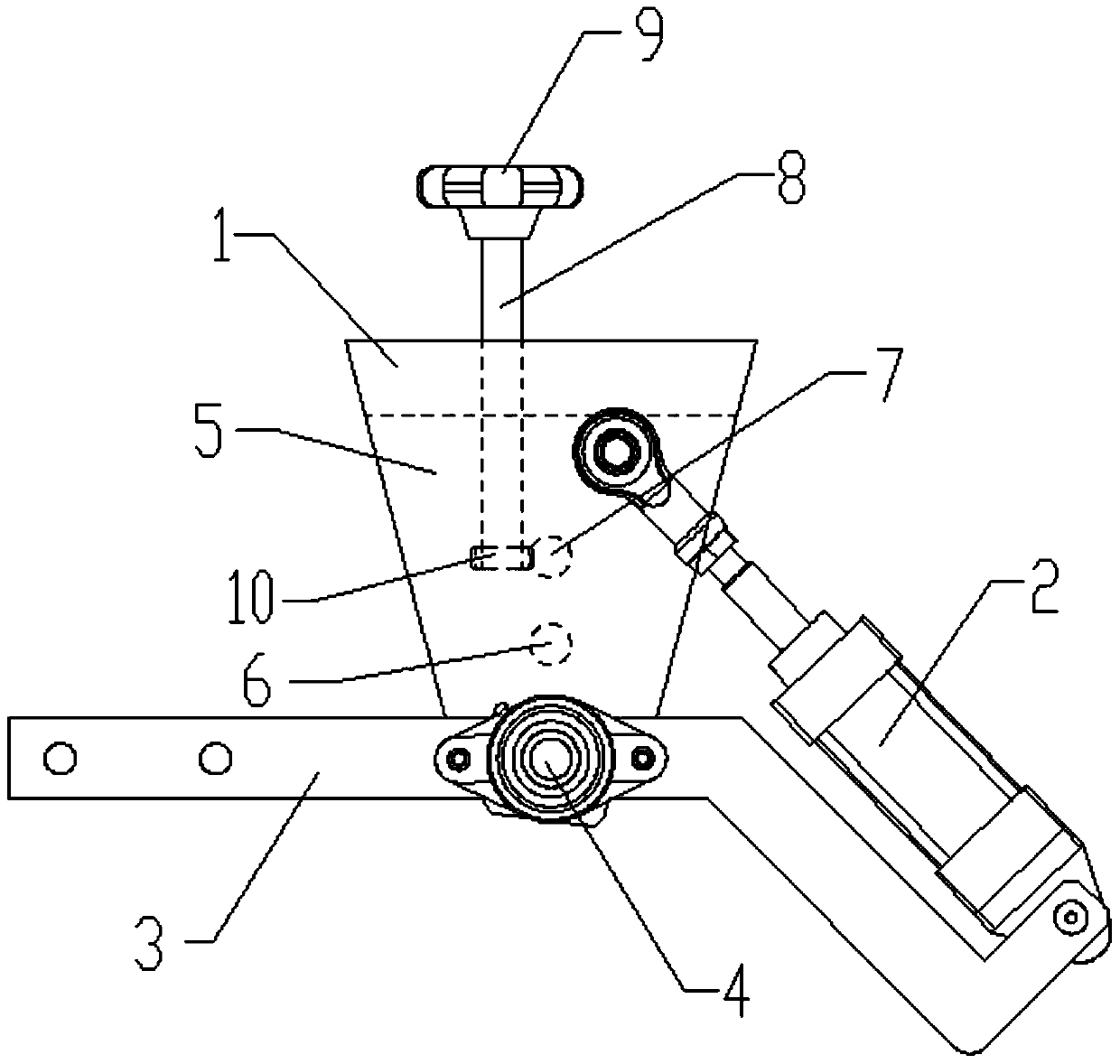

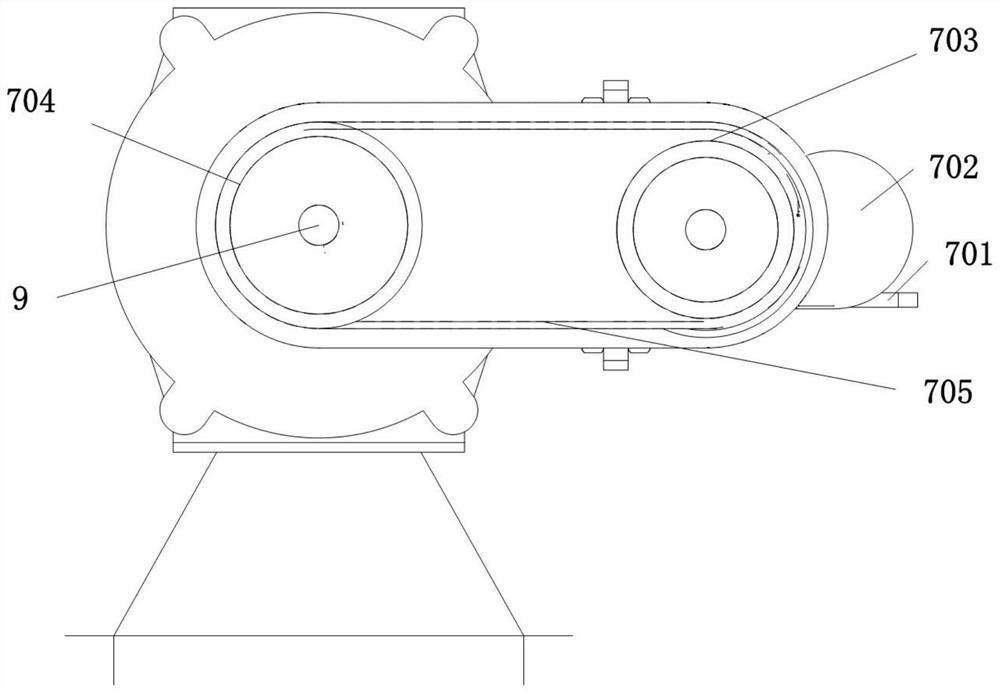

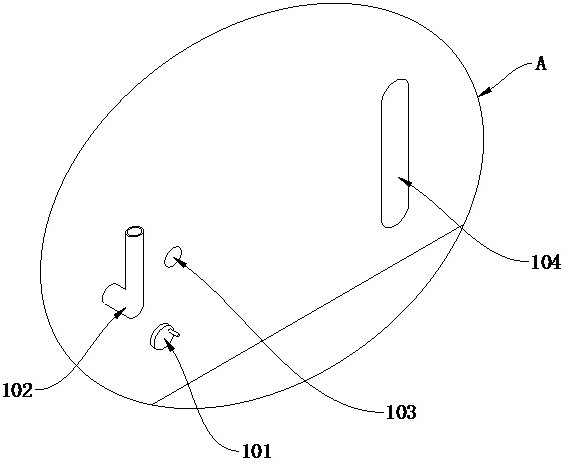

Hull breaking machine based on pretreated walnuts

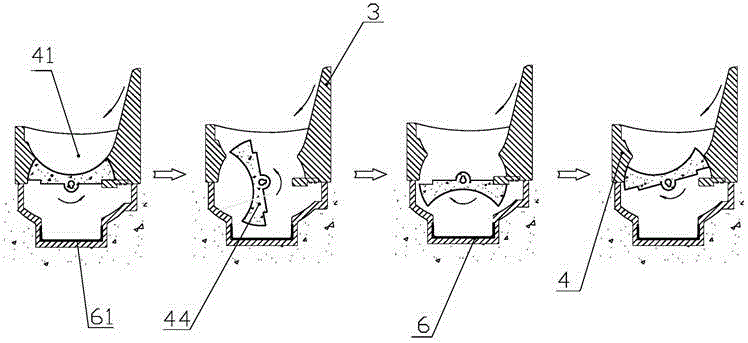

The invention discloses a hull breaking machine based on pretreated walnuts, and relates to the field of walnut deep processing equipment. The hull breaking machine comprises a rack, an impeller feeding device and an opposite roller extrusion device; the impeller feeding device conducts feeding through an impeller to enable the walnuts to fall into the opposite roller extrusion device orderly, sothat the feeding efficiency is ensured; rollers of the opposite roller extrusion device are structurally optimized, V-shaped annular grooves in the rollers of the opposite roller extrusion device areformed alternately with roller sections to avoid mutual interference of the walnuts and improve the hull breaking efficiency, meanwhile one of the rollers is fixedly arranged, and the other roller isadjustable so as to adapt to hull breaking of the walnuts with different sizes and increase the kernel exposure rate; the impeller feeding device and the opposite roller extrusion device are both driven in a chain transmission mode, the driving speed of the impeller feeding device and the driving speed of the opposite roller extrusion device are matched to enable the materials to be smooth, the work continuity of the hull breaking machine is ensured, and the efficiency is improved; the outer surfaces of the rollers are wrapped with a PVC belt, jumping of the walnuts during falling is reduced,the extrusion efficiency is improved, meanwhile the adaptability of the walnuts in an extrusion work area is improved through the PVC belt, and the high kernel exposure rate is achieved.

Owner:SHIHEZI UNIVERSITY

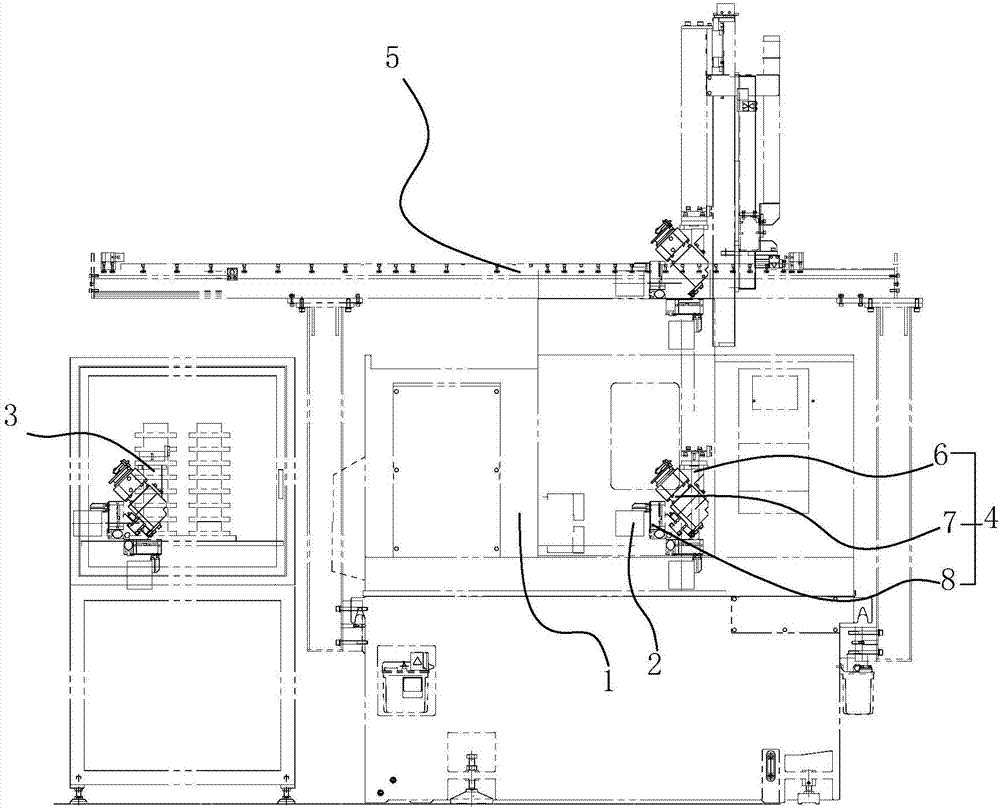

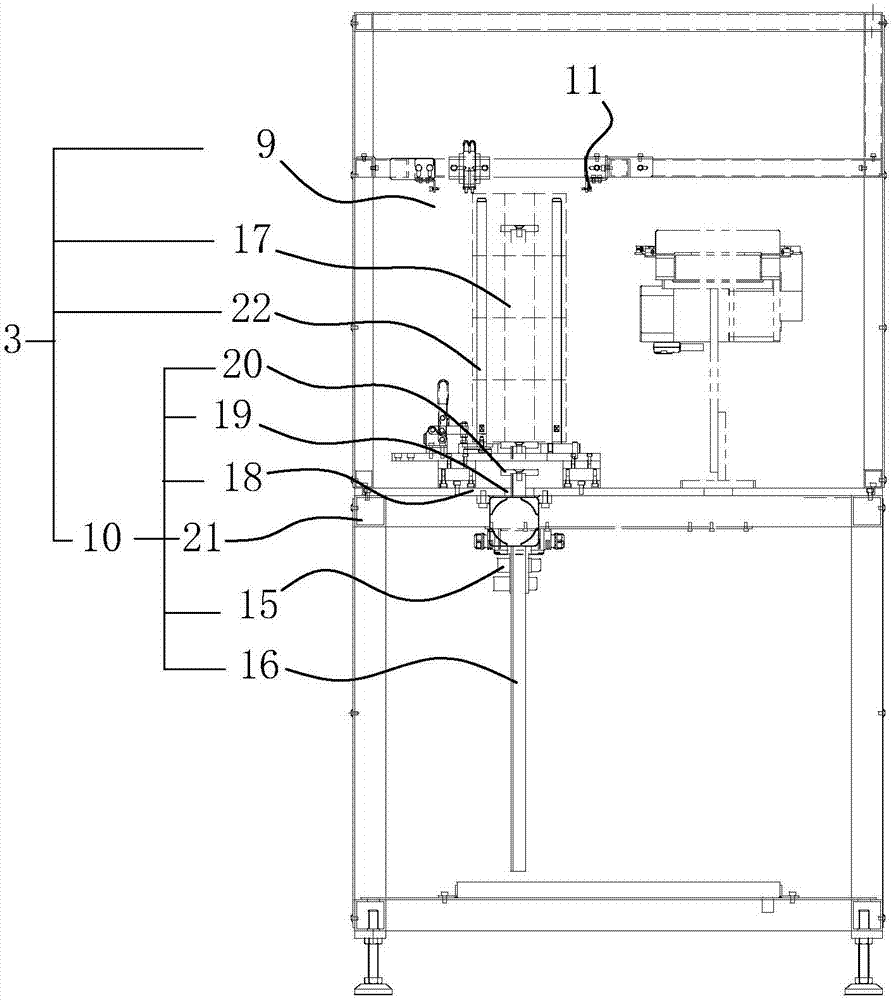

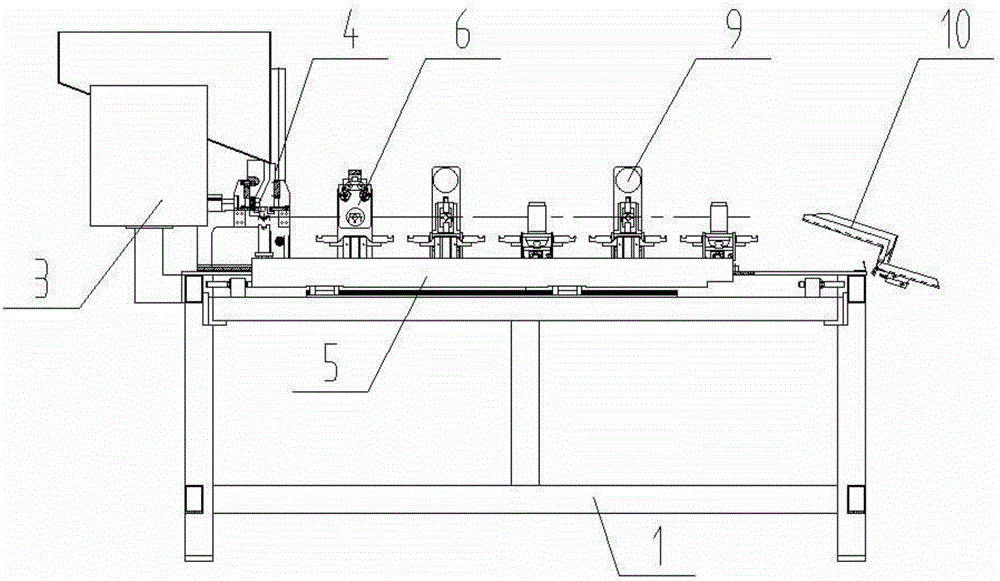

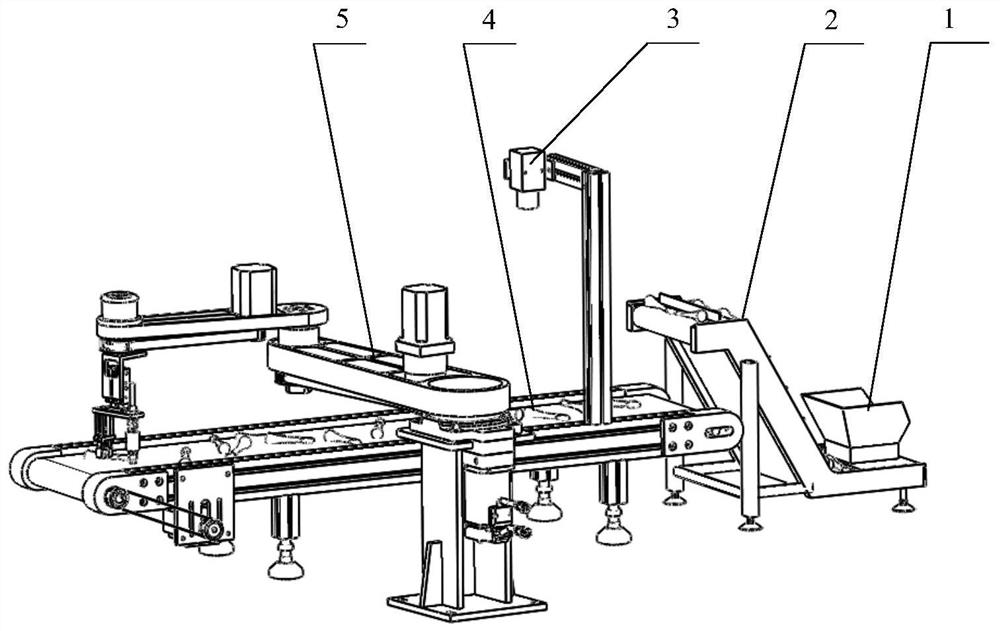

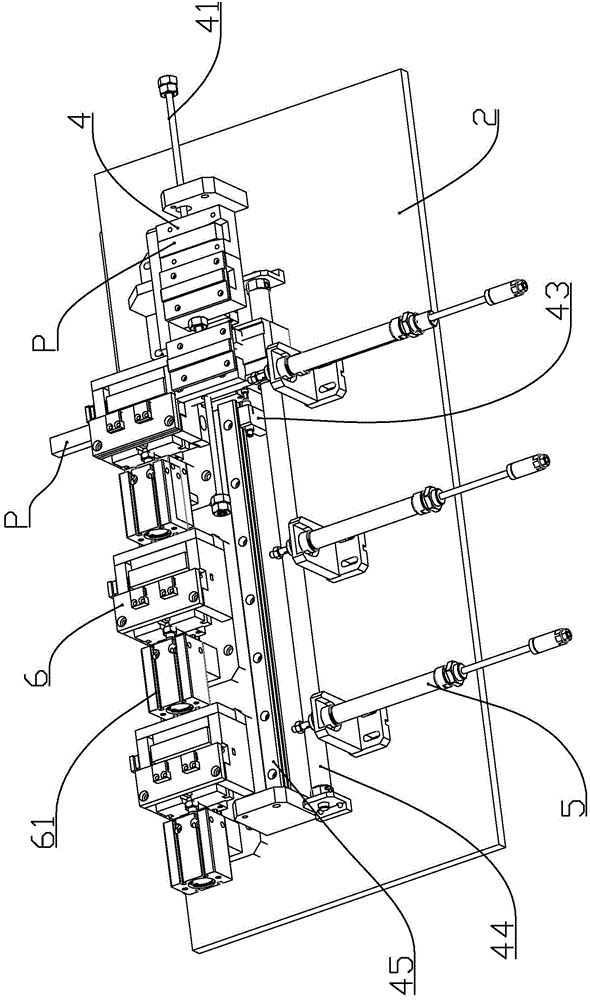

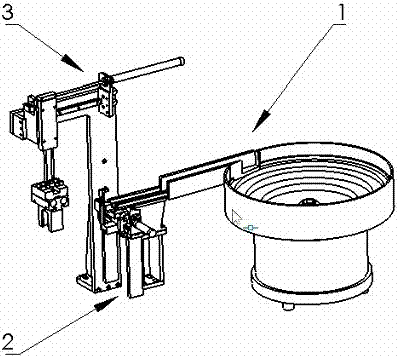

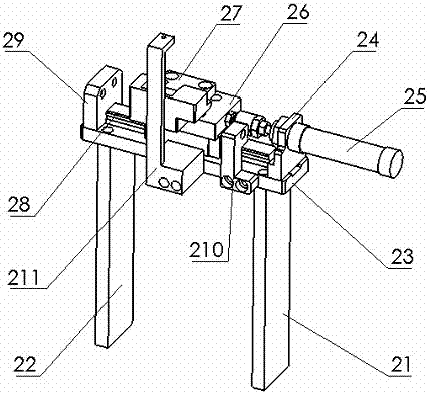

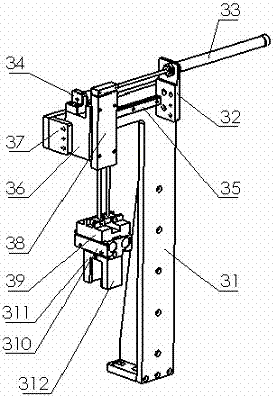

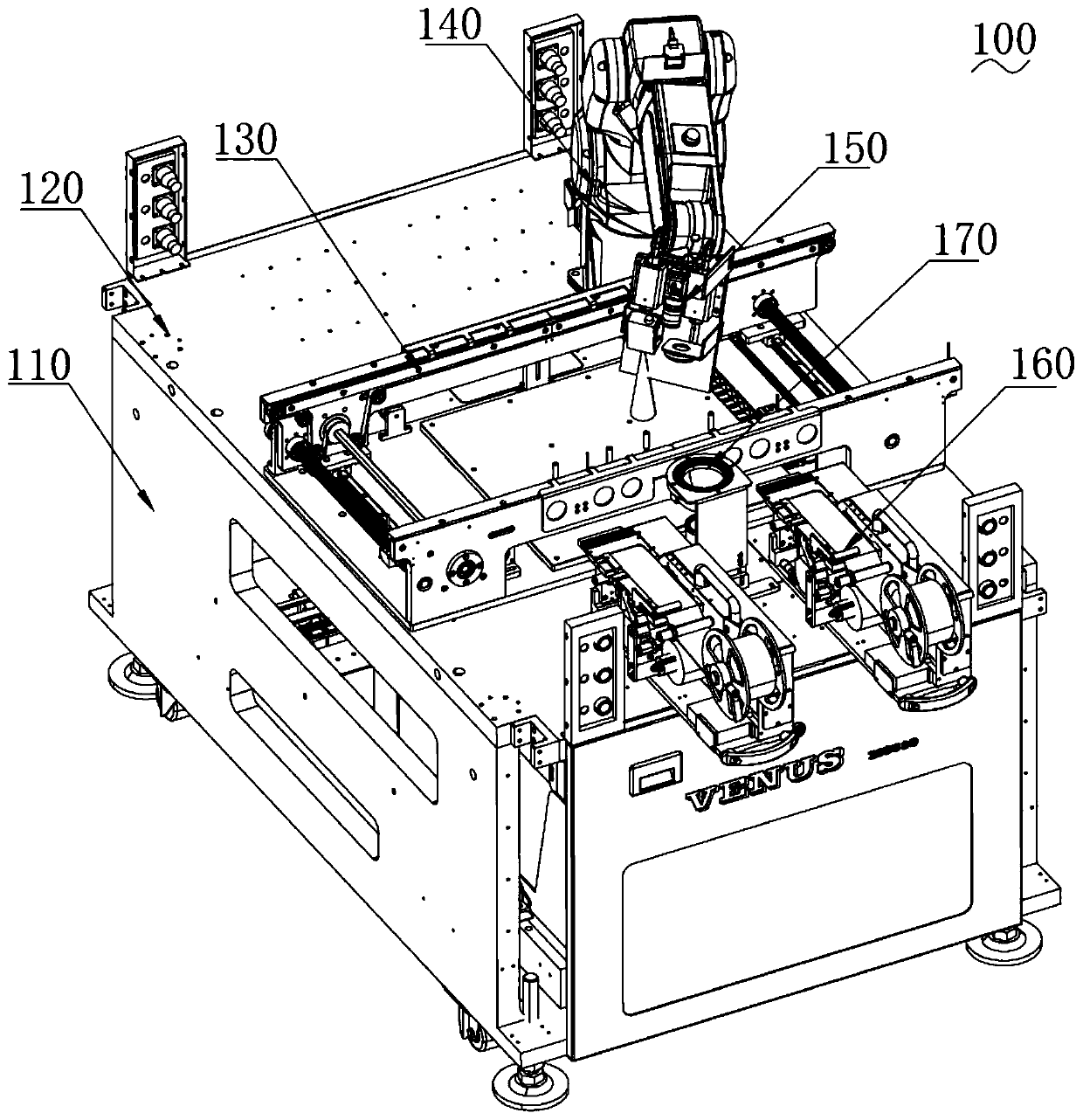

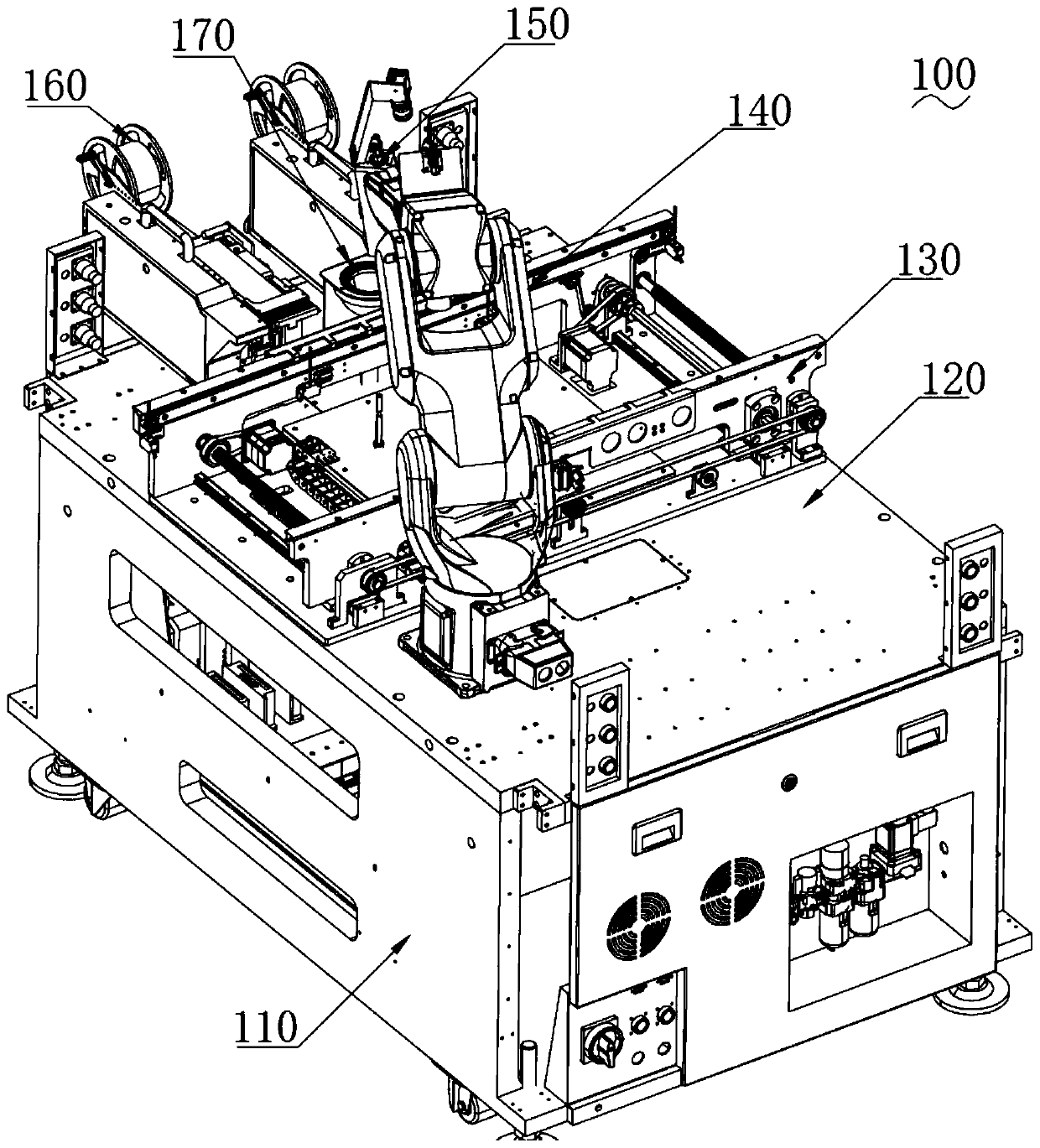

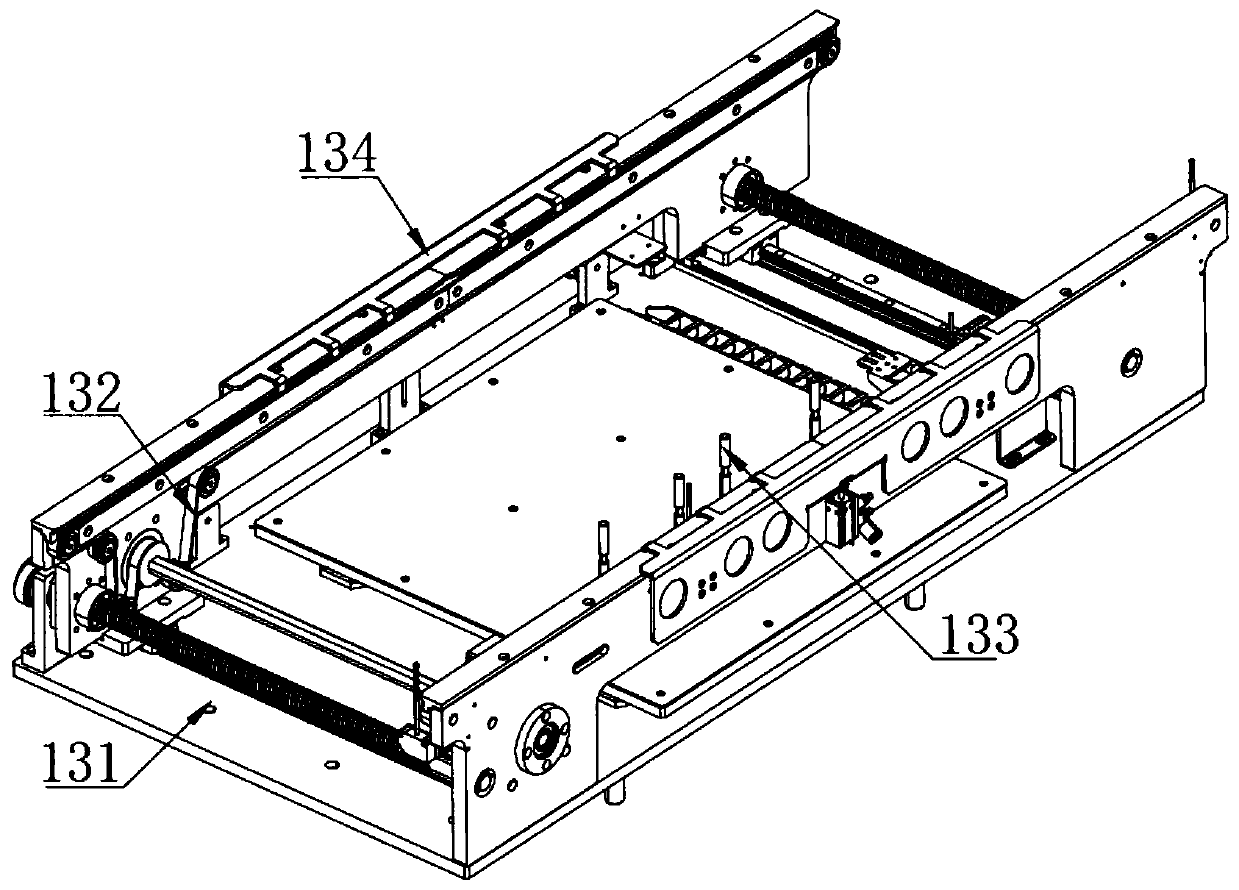

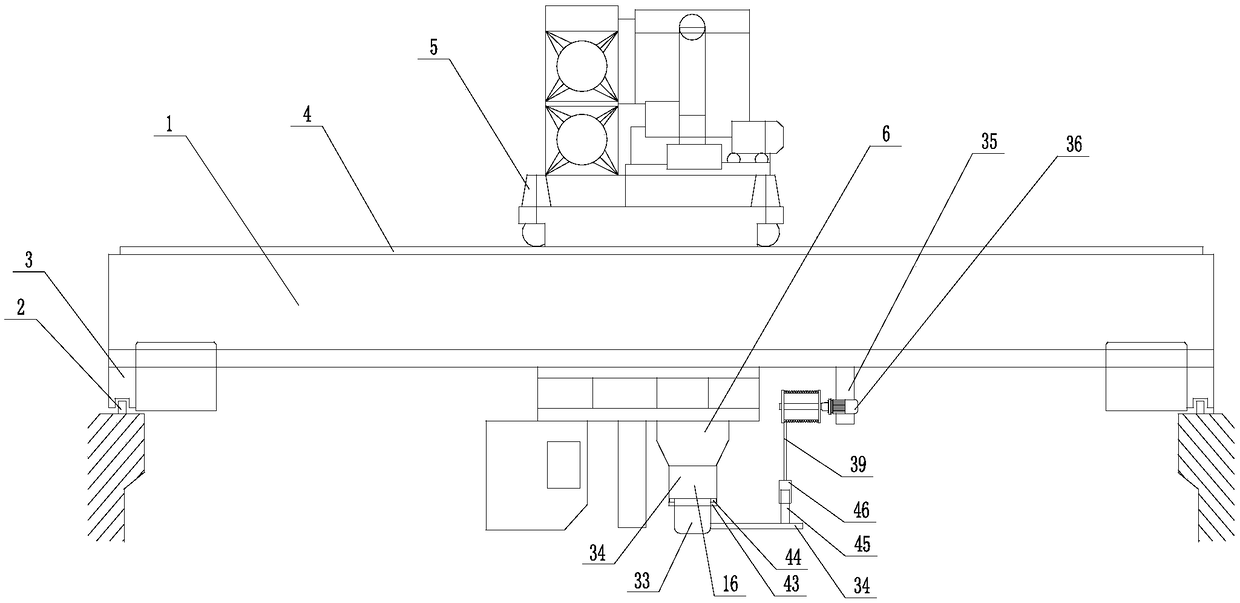

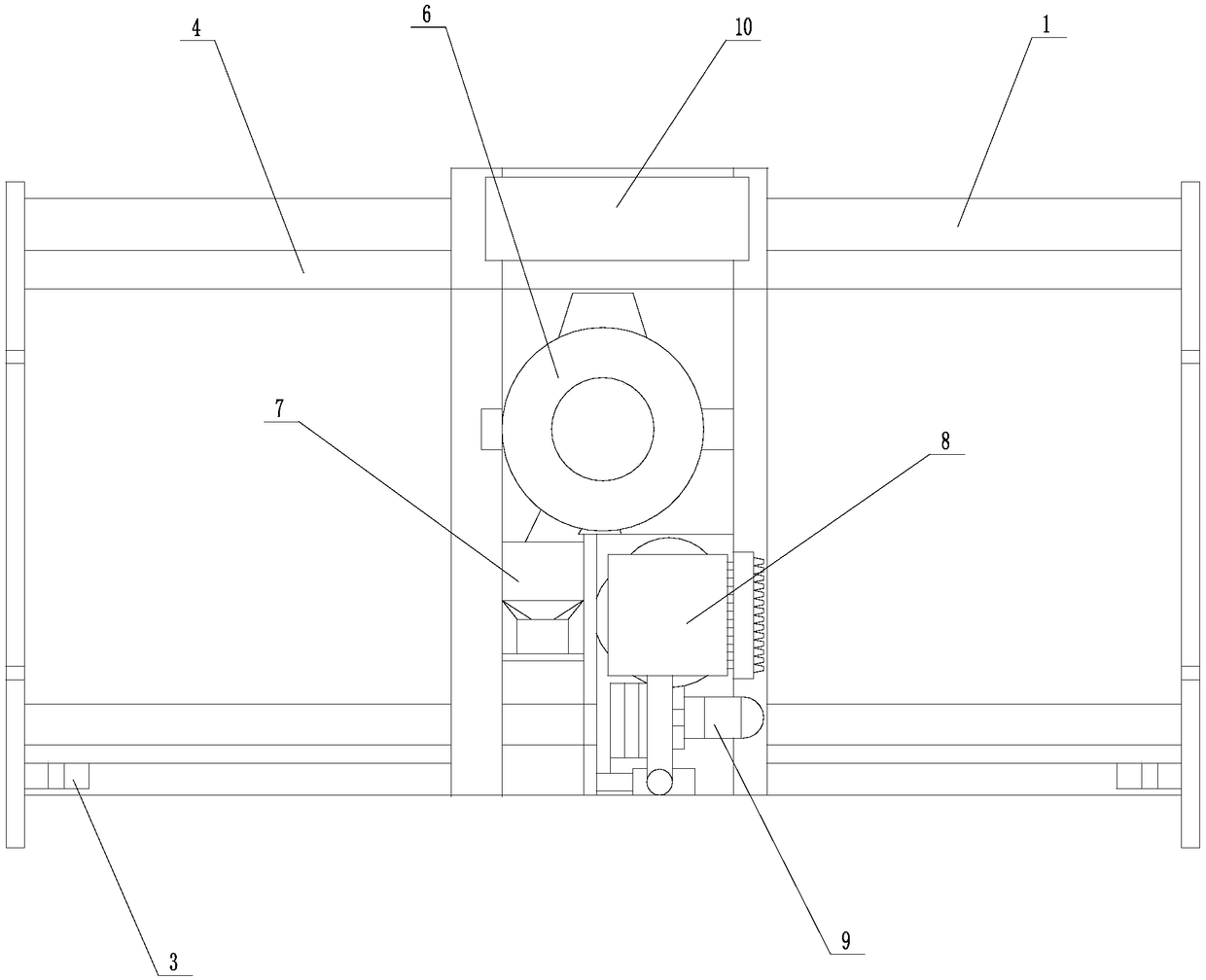

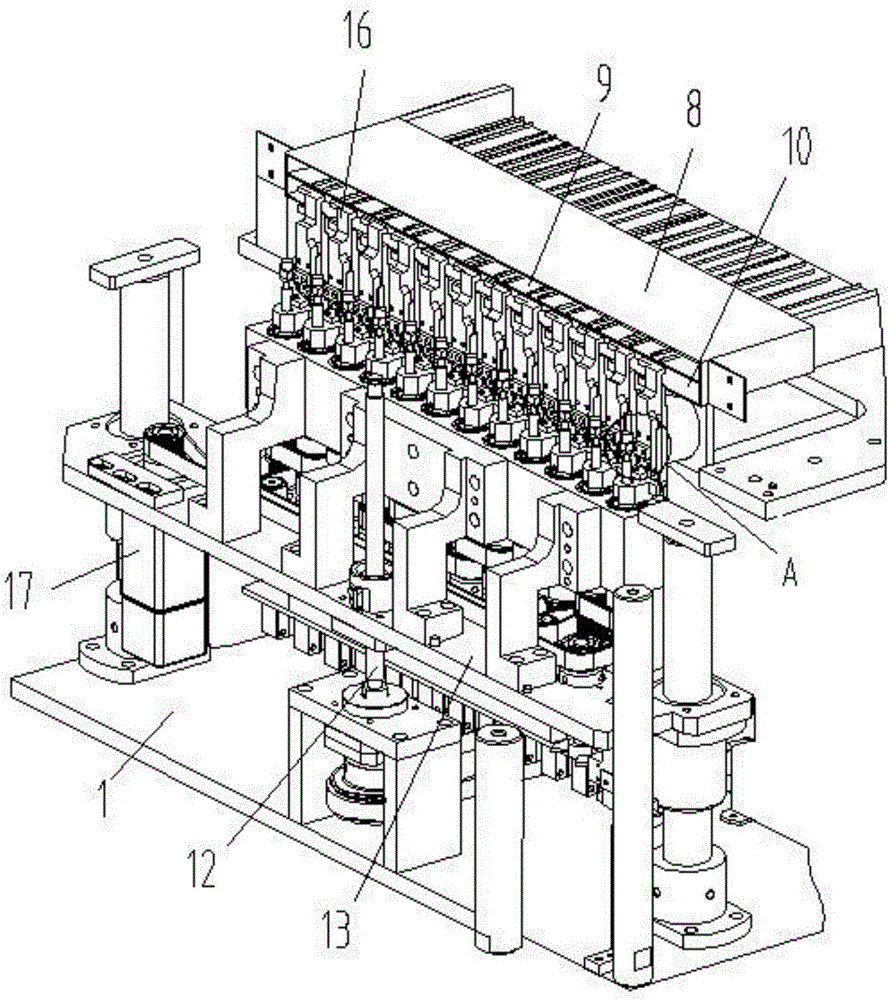

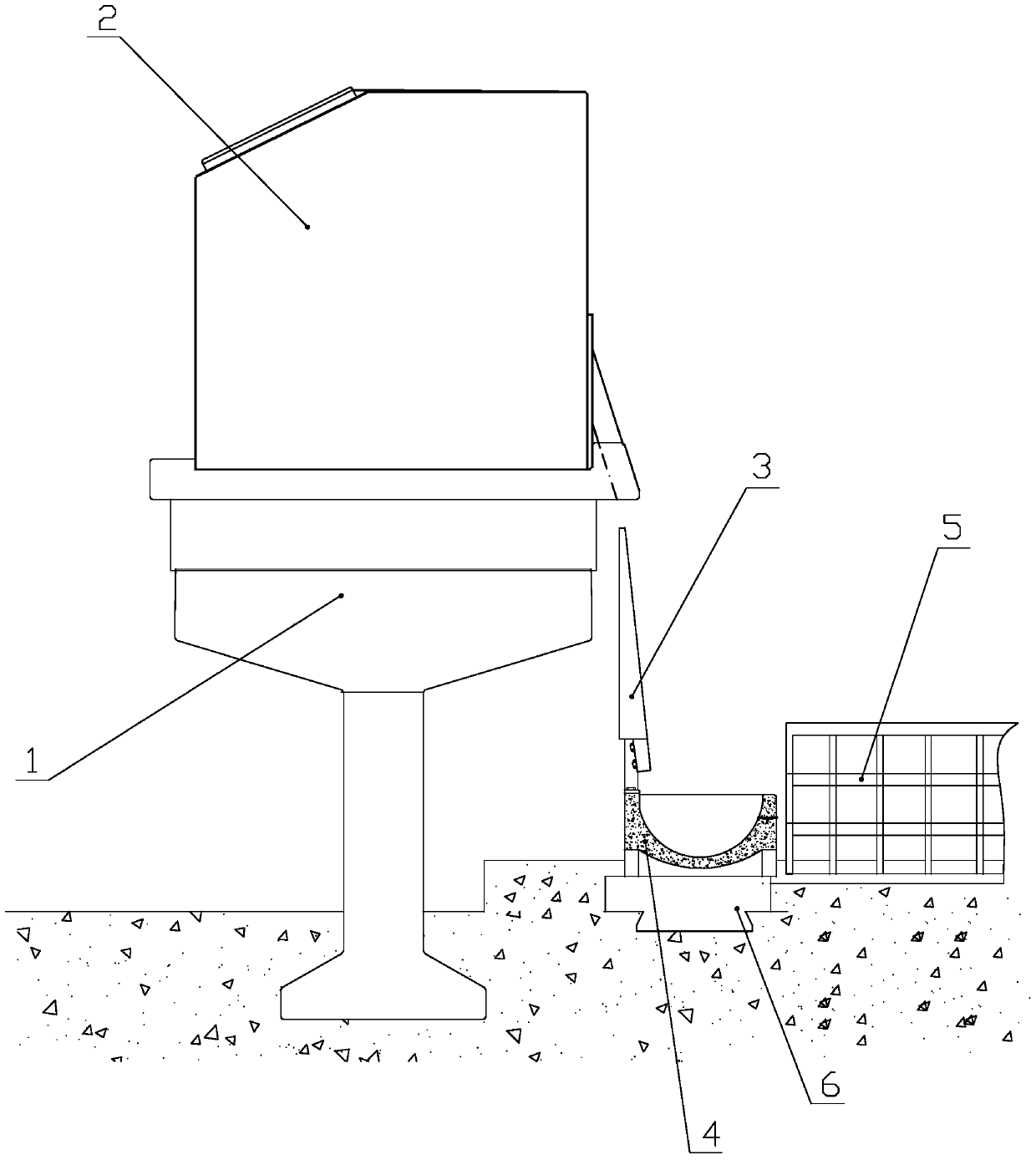

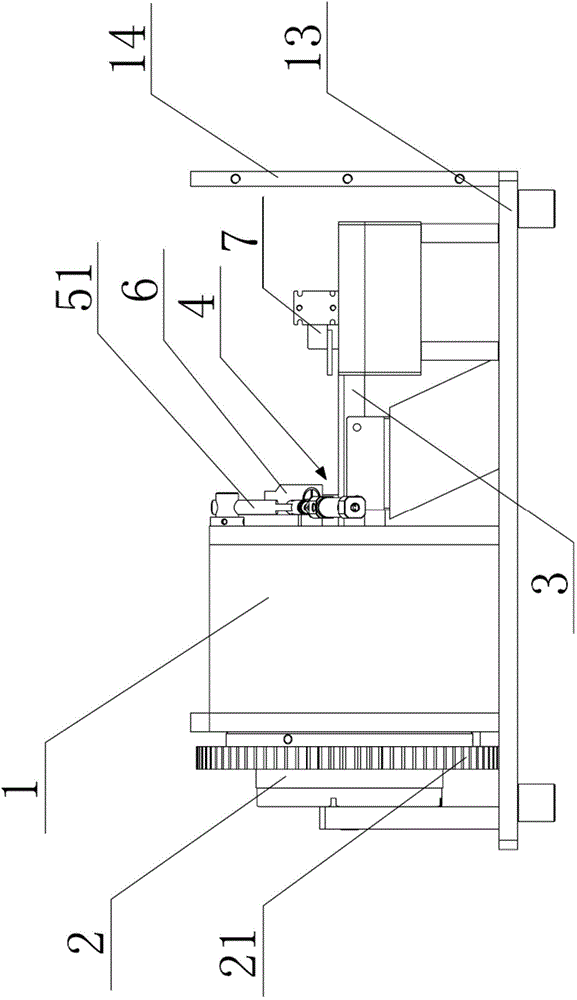

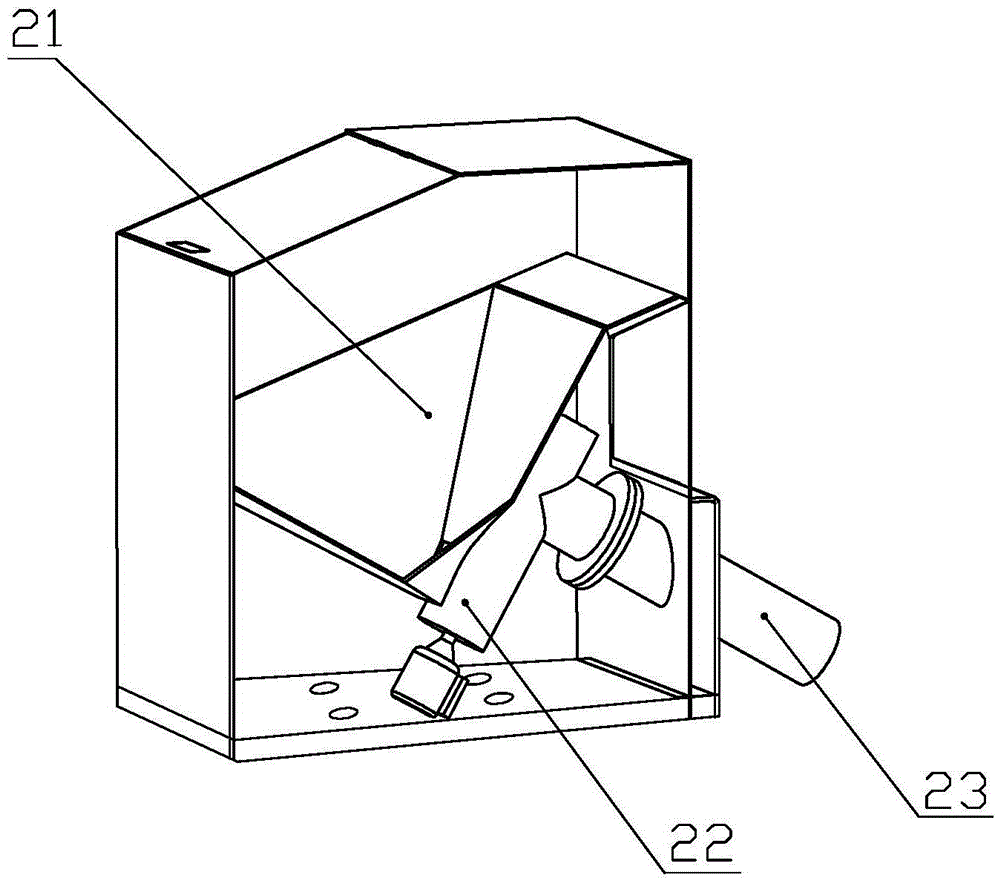

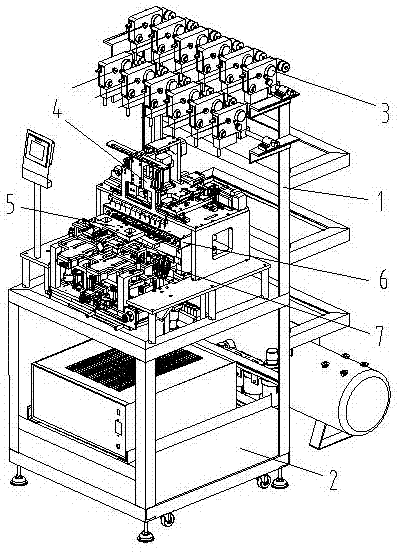

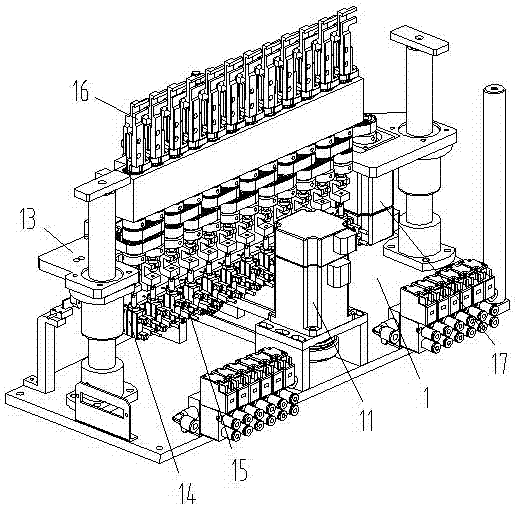

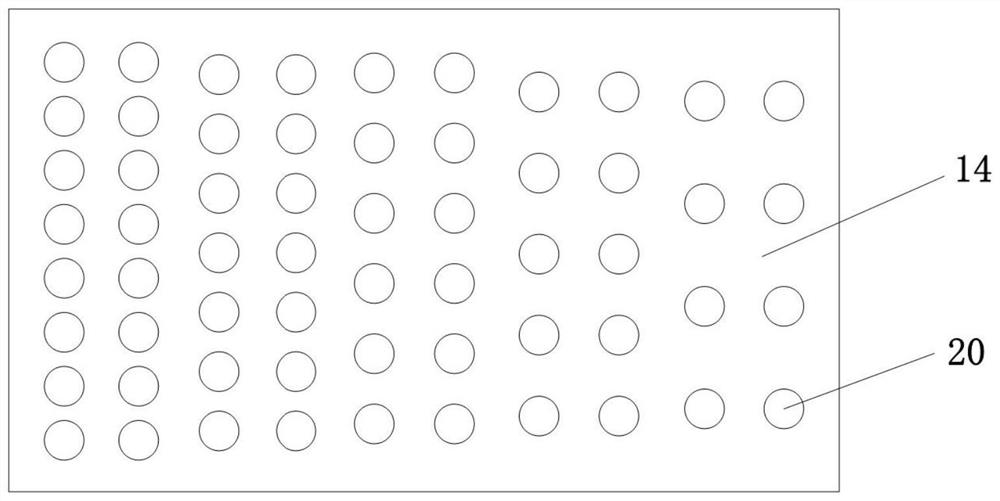

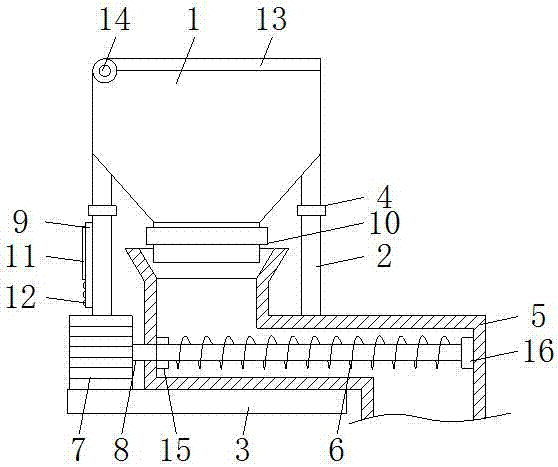

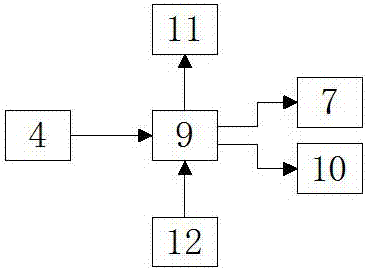

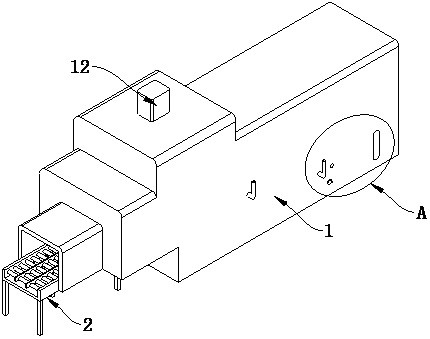

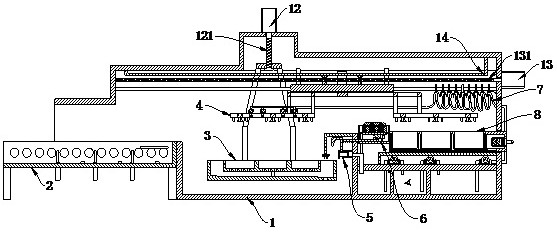

Automatic feeding system of numerical control lathe

InactiveCN107262743AGuaranteed feeding efficiencyRealize blankingAutomatic conveying/guiding stockNumerical controlEngineering

The invention discloses an automatic feeding system of a numerical control lathe, and aims to solve the problem that a traditional machine tool is low in processing and carrying efficiency. The main point of the technical scheme is that automatic feeding is carried out through a feeding mechanism, a transfer mechanism transfers and moves workpieces to a processing zone to be processed, and then, automatic discharge is carried out through a discharge mechanism. According to the automatic feeding system of the numerical control lathe, automation degree is high, and processing and transfer efficiency is high.

Owner:津上精密机床(浙江)有限公司

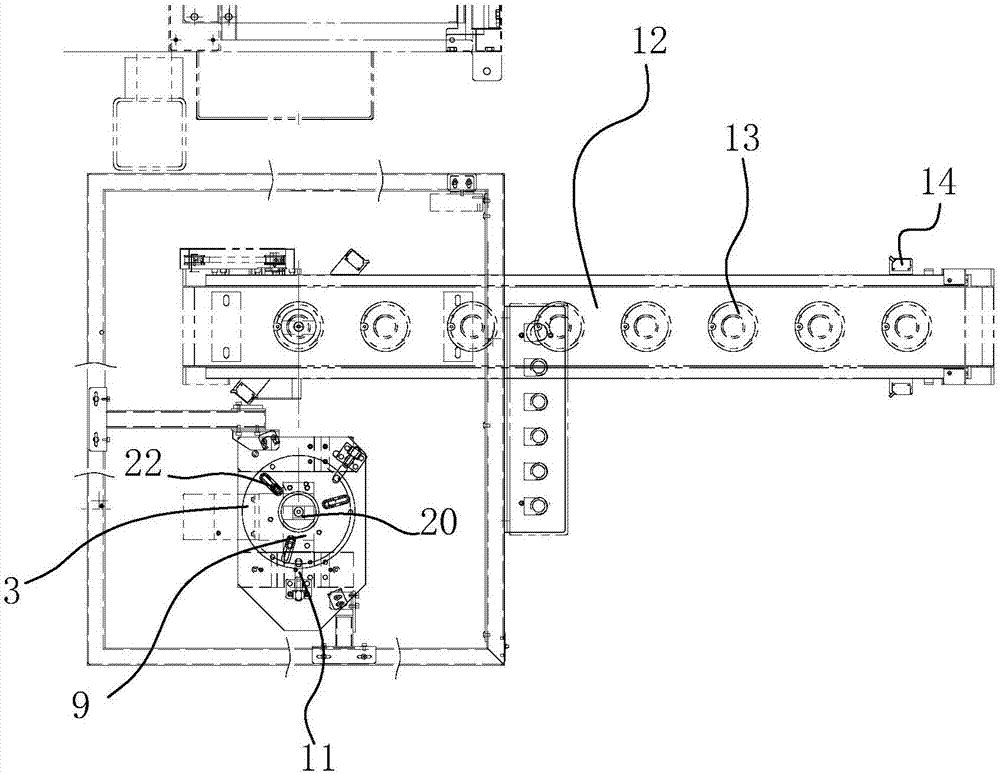

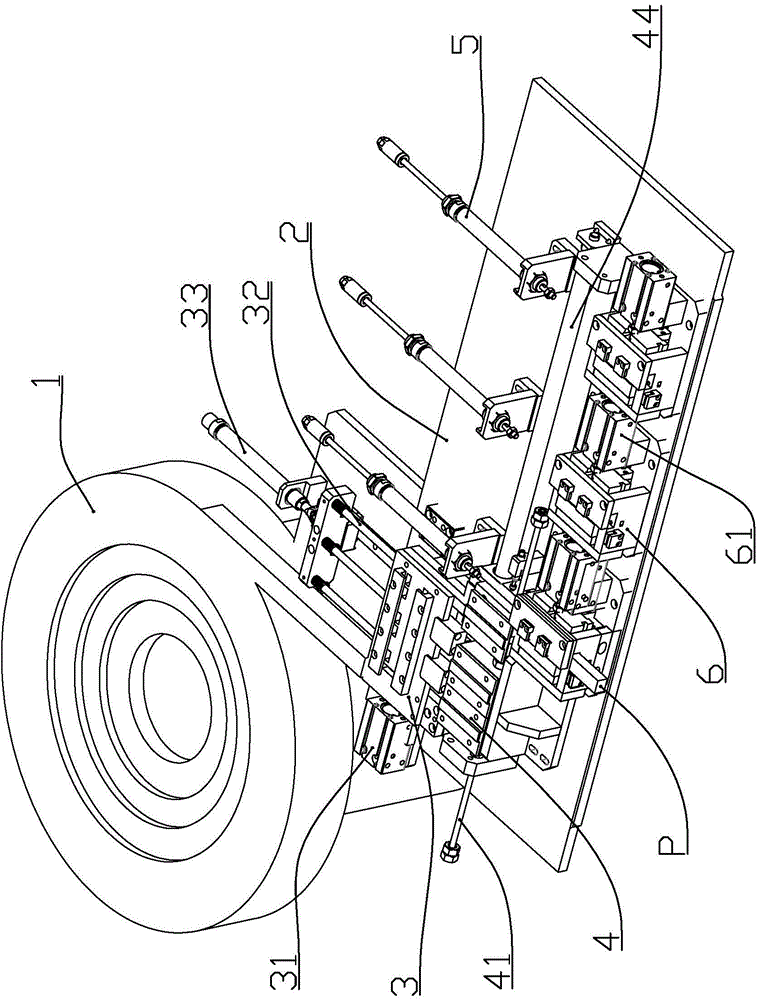

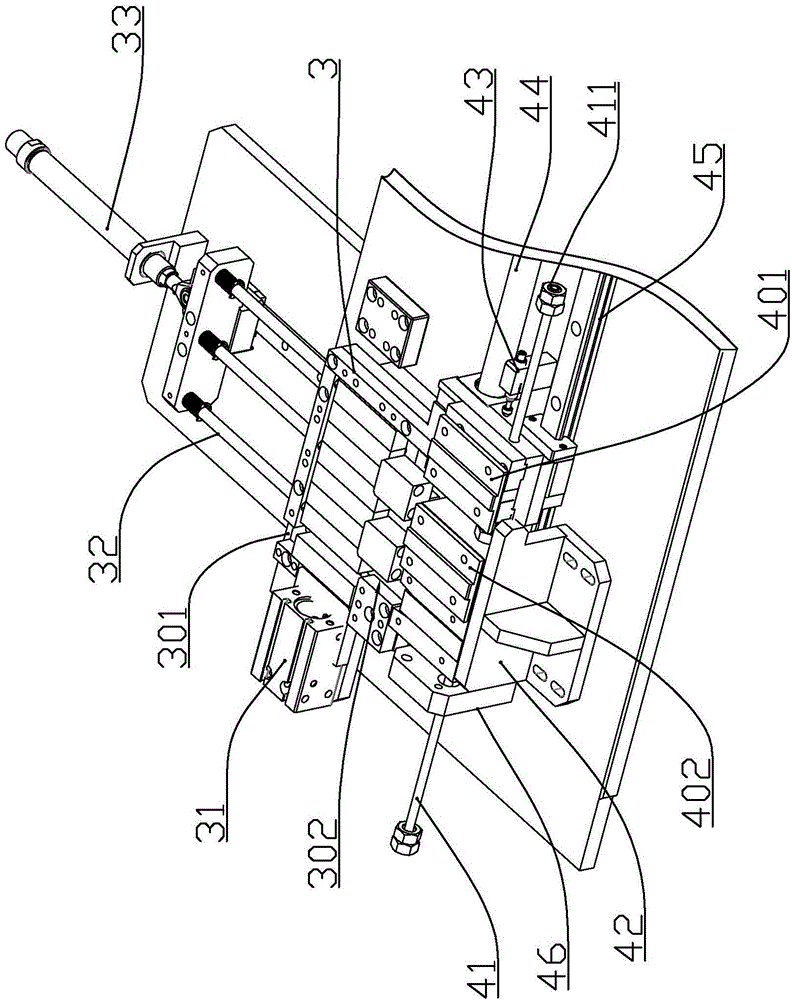

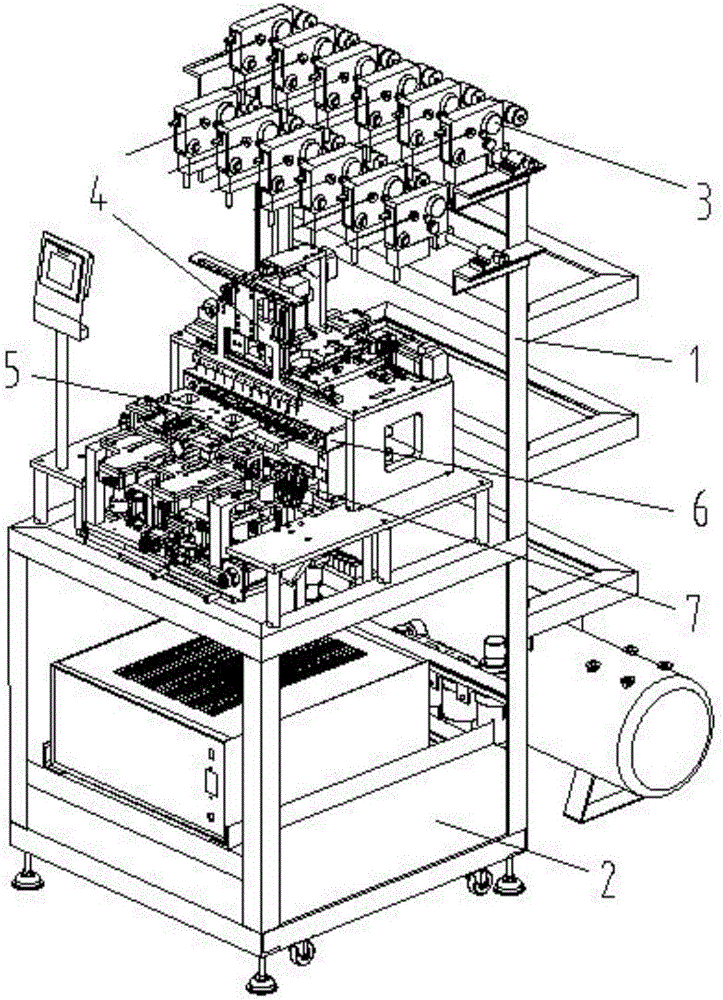

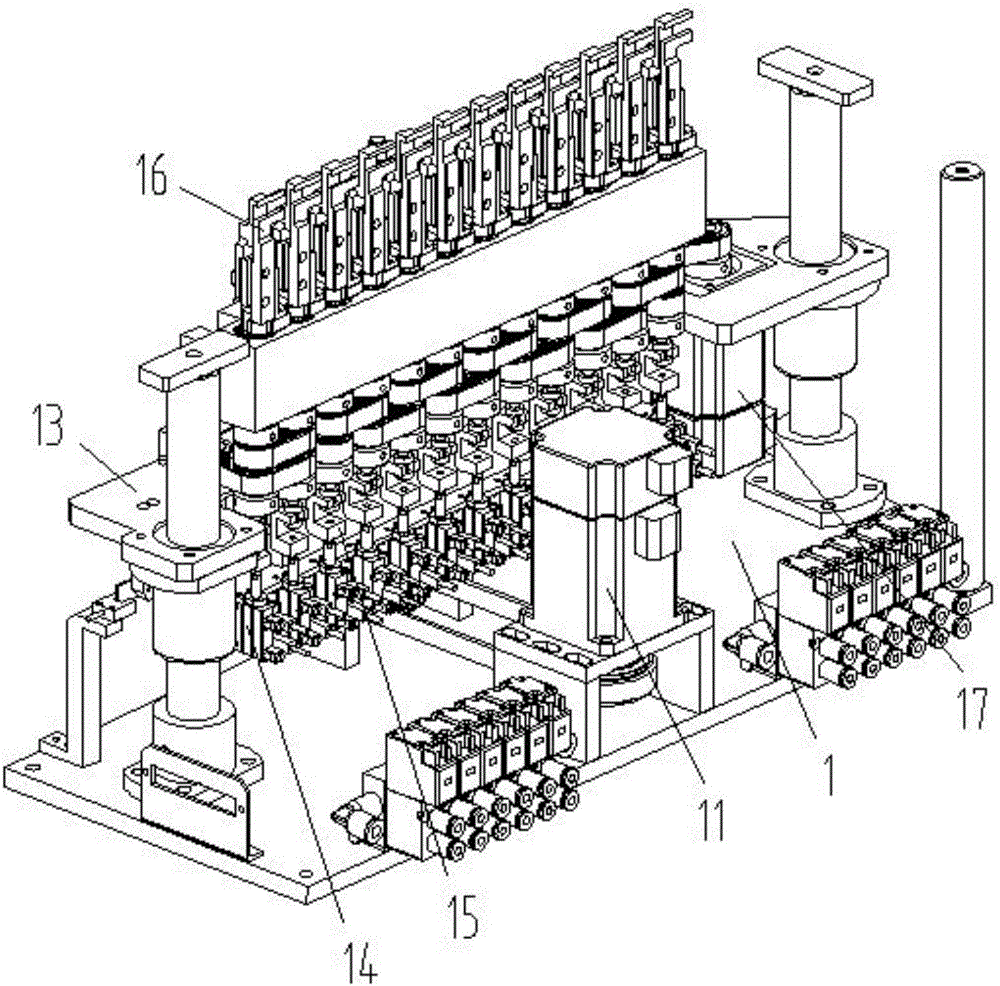

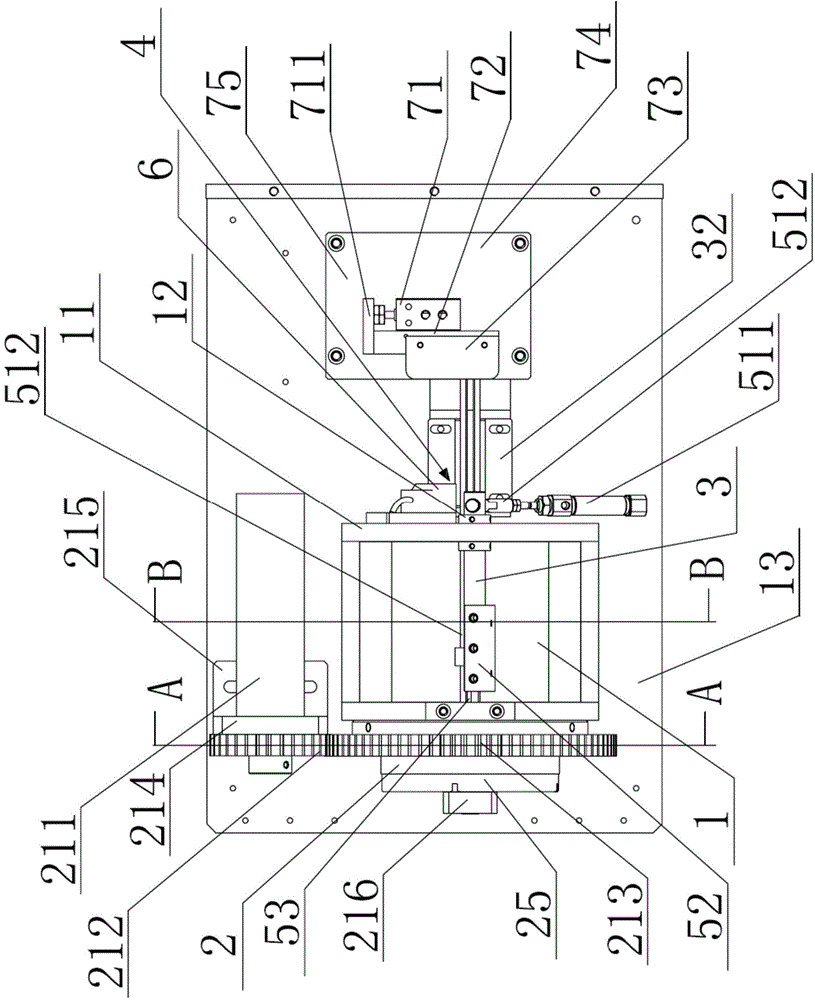

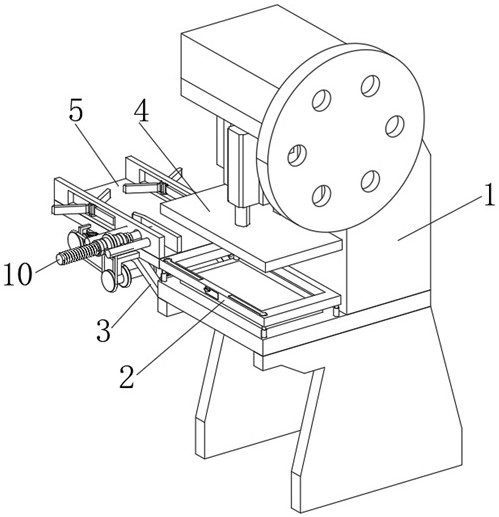

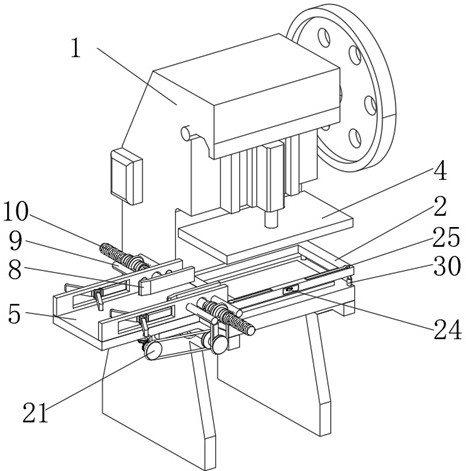

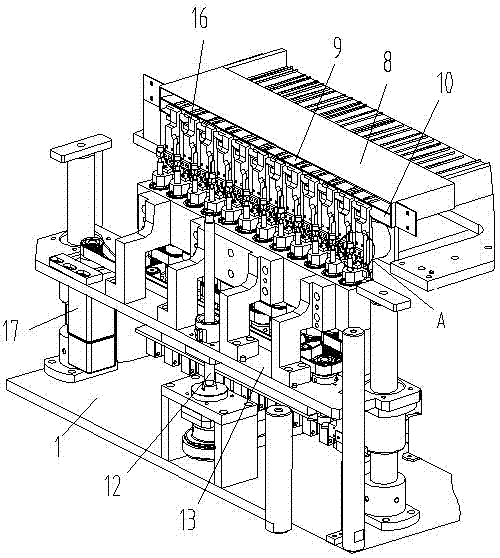

Umbrella handle rod automatic continuous stamping equipment

ActiveCN106623609AReasonable distributionHigh degree of automationMetal-working feeding devicesMetal working apparatusPunchingEngineering

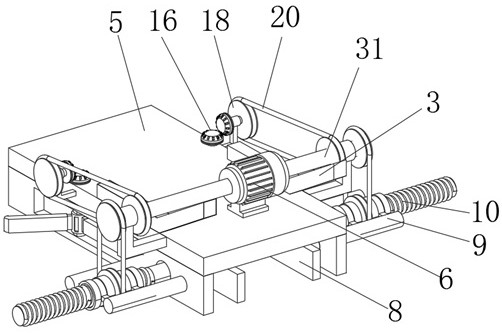

The invention discloses umbrella handle rod automatic continuous stamping equipment. The umbrella handle rod automatic continuous stamping equipment comprises an automatic material distribution and feeding module used for automatically discharging umbrella handle rods to be machined one by one, a discharging module used for receiving finished umbrella handle rods to be machined, an X-direction reciprocating feeding module for supporting and clamping the umbrella handle rods to be machined and sending the umbrella handle rods to be machined from the automatic material distribution and feeding module to the discharging module, a symmetric clamping and circumferential positioning module used for clamping the umbrella handle rods to be machined and determining the zero position, a Y-direction feeding and machining module for conducting Y-direction feeding and punching on the umbrella handle rods to be machined passing the Y-direction feeding and machining module, a digital control module and a machine tool bed used for fixing the devices. According to the umbrella handle rod automatic continuous stamping equipment, the seven-position series connection layout is adopted, distribution is reasonable, and the automation degree is high; all the positions move synchronously, the machining efficiency is greatly improved, and the production quality is improved; moreover, on the premise of guaranteeing the production efficiency, convenient conditions are provided for fault self-diagnosis of the equipment, machining quality detection of products in each position, statistics of the rate of finished products and the like.

Owner:杭州萧山进化镇徐峰五金机械厂

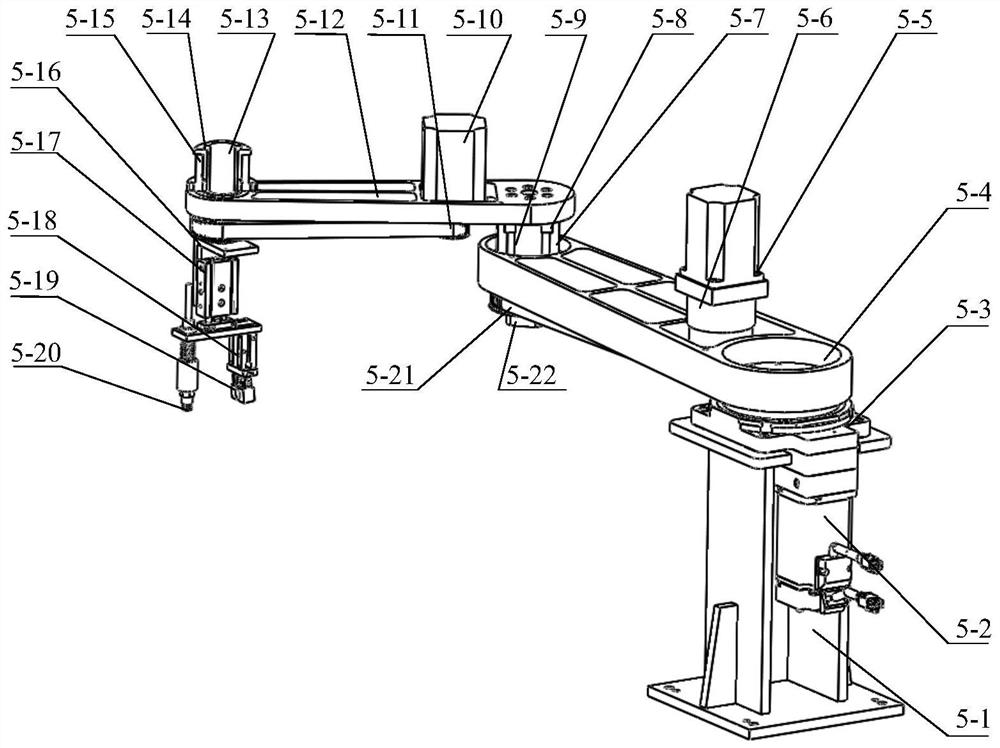

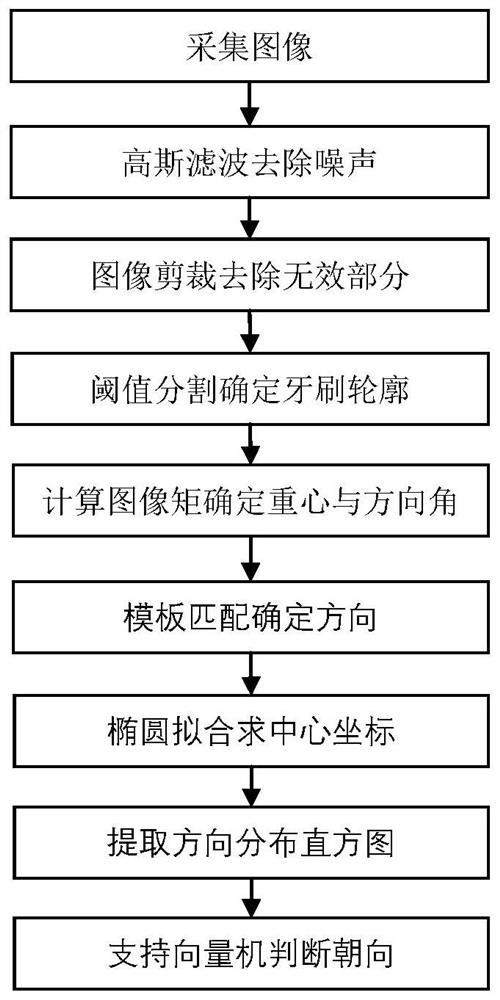

Electric toothbrush head dynamic feeding system based on vision

ActiveCN113911728AIncrease the feeding speedSimple structureConveyorsControl devices for conveyorsBristleTabu search

The invention relates to an electric toothbrush head dynamic feeding system based on vision. The system comprises a conveying device, a visual detection device and a control module, system calibration, brush head recognition and positioning, grabbing sequence optimization and robot trajectory planning are conducted, toothbrush heads are conveyed to a robot working space from a hopper through the conveying device, images are collected through the visual detection device, and a support vector machine and an ellipse fitting method are adopted to identify the toothbrush heads and calculate the poses, and meanwhile, the poses are updated in real time. After the toothbrush head pose information is obtained, an improved tabu search algorithm is adopted to plan a grabbing sequence, a robot carries out trajectory planning after receiving an instruction, and the toothbrush heads are conveyed to a target position from a grabbing position. The electric toothbrush head dynamic feeding system can adapt to feeding of various toothbrush heads, has higher automation and flexibility compared with a feeding mode in the prior art, can shorten the movement distance of the robot while completing feeding, and can be used for feeding in the processes of bristle planting, packaging and the like of the toothbrush heads.

Owner:江苏白王口腔护理用品有限公司

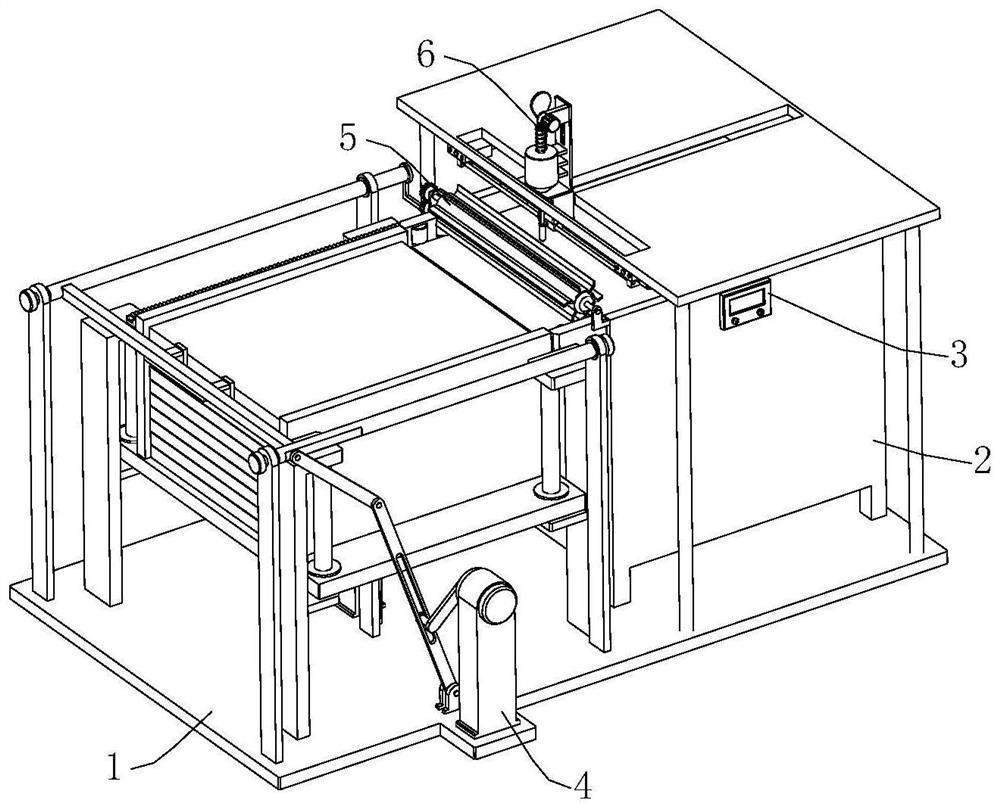

Automatic feeding device for wood block precision carving machine

InactiveCN104972813AAvoid position deviationSolve the problem of blocked feedingModel makingEngravingCarvingFlue

The invention discloses an automatic feeding device for a wood block precision carving machine. The automatic feeding device for the wood block precision carving machine comprises a base, a storage flue, clamping and positioning bases, a plurality of distribution bases and a third pushing air cylinder, wherein the multiple distribution bases are installed on the base in a sliding mode and used for conveying multiple wood blocks to the clamping and positioning bases from the storage flue at the same time; the third pushing air cylinder is used for pushing the wood blocks to the clamping and positioning bases from the distribution bases; the distribution bases are arranged on a track in a sliding mode; one of the distribution bases is a driving distribution base while the rest are driven distribution bases; the base is provided with a rodless air cylinder; the rodless air cylinder is parallel with the track and is used for driving the driving distribution base from moving; the driving distribution base and the driven distribution bases are connected through a linkage rod. The automatic feeding device for the wood block precision carving machine solves the problem that feeding is hindered by dimension errors of wood blocks. By cooperation of the air cylinder and the linkage rod, the multiple distribution bases can feed wood blocks to the clamping and positioning bases at different positions at the same time, and the feeding efficiency is guaranteed.

Owner:台州市惠华自动化设备科技有限公司

Automatic colloidal coating gluing mechanism suitable for plastic plates

ActiveCN113070180AImprove gluing efficiencyAvoid confusionLiquid surface applicatorsSpraying apparatusStructural engineeringManufacturing engineering

The invention relates to the technical field of gluing, in particular to an automatic colloidal coating gluing mechanism suitable for plastic plates. The automatic colloidal coating gluing mechanism comprises a base and a processing table, and further comprises a controller, a feeding device, an impurity removal device and a spraying device, the feeding device comprises a lifting plate, a jacking assembly and a pushing assembly, and the impurity removal device comprises a rolling brush and a traction assembly; and the spraying device comprises a spray head, an extrusion assembly and a sliding assembly, a top plate is fixedly arranged at the top of the base, the sliding assembly is arranged at the bottom of the top plate, the spray head and the extrusion assembly are both arranged on the sliding assembly, and the jacking assembly, the pushing assembly and the extrusion assembly are electrically connected with the controller. The plates are prevented from being clamped effectively, and feeding efficiency is high; and meanwhile, the gluing surface can be cleaned before gluing, smooth gluing is guaranteed, bubbles are prevented from being generated, and it is guaranteed that follow-up products adhere to the gluing surface firmly.

Owner:深圳市广德盛科技有限公司

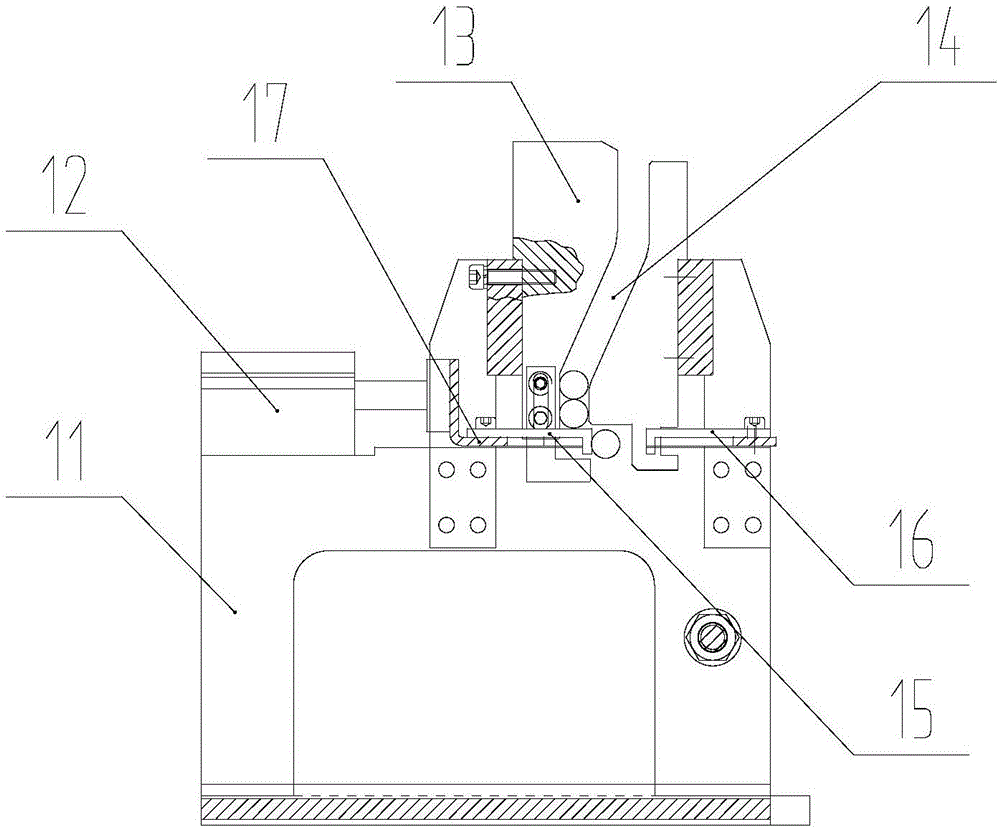

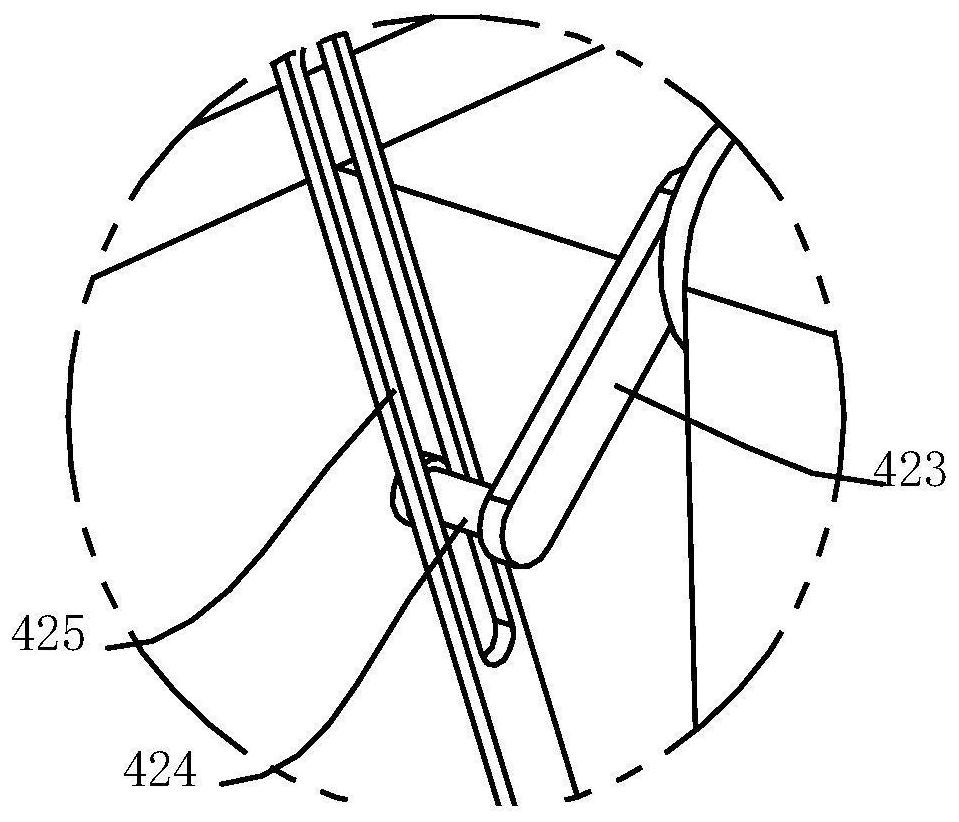

LED lamp head feeding device

ActiveCN107150218AGuaranteed feeding efficiencyWork reliablyMetal working apparatusEngineeringLED lamp

The invention discloses an LED lamp head feeding device. The LED lamp head feeding device comprises a supply module, a separation module is arranged in front of the supply module, a feeding module is arranged on the left of the separation module, a vibration plate is adopted for the supply module to supply materials in order, the separation module accurately separates products one by one, single ordered feeding is achieved, and the feeding module moves the products from a separation station to a feeding station. Generally, the LED lamp head feeding device has the advantages of being low in failure rate and high in work efficiency.

Owner:深圳市微恒自动化设备有限公司

Multi-station labeling device based on mechanical arm

PendingCN109703850AImprove work efficiencySave manpower and material resourcesLabelling machinesMaterial resourcesEngineering

The invention relates to the technical field of automatic equipment, in particular to a multi-station labeling device based on a mechanical arm. The multi-station labeling device comprises a rack, a workbench arranged on the surface of the rack, a conveying device transversely arranged on the workbench, a robot arranged on the side, provided with the conveying device, of the workbench, a labelingdevice arranged at the driving end of the robot, and label unwinding devices arranged on the worktable and used for label discharging, wherein at least two groups of label unwinding devices are arranged, and the robot drives the labeling device to take labels on the label unwinding devices and attach the labels to products conveyed by the conveying device. According to the multi-station labeling device, the products are labeled through the robot in the automatic conveying mode, manual operation control is not needed, automatic material taking and labeling is achieved, working efficiency is high, automation degree is high, manpower and material resources are saved and labeling effect is good.

Owner:广东钮铂尔科技有限公司

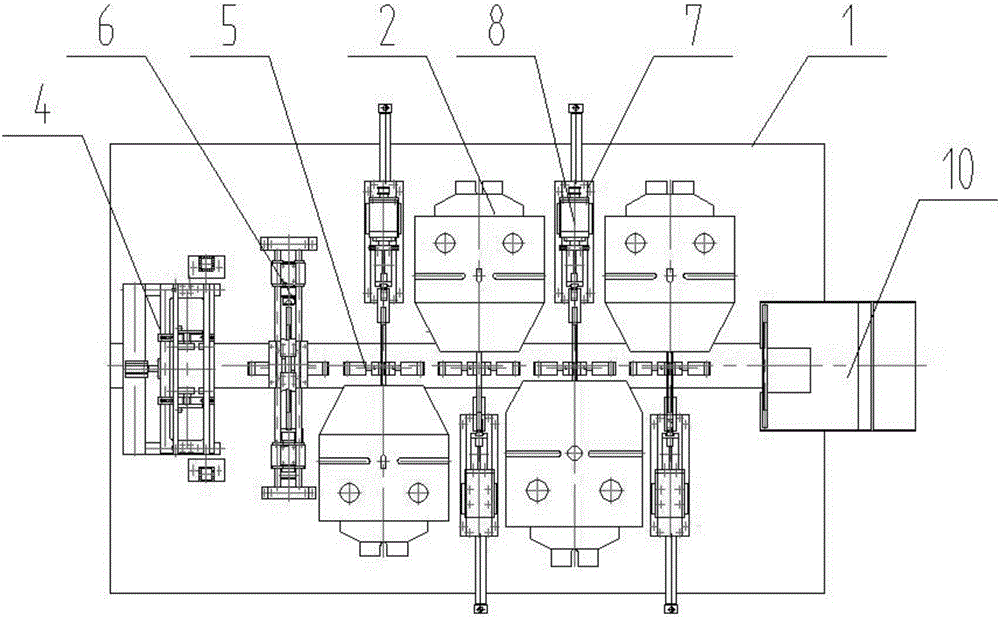

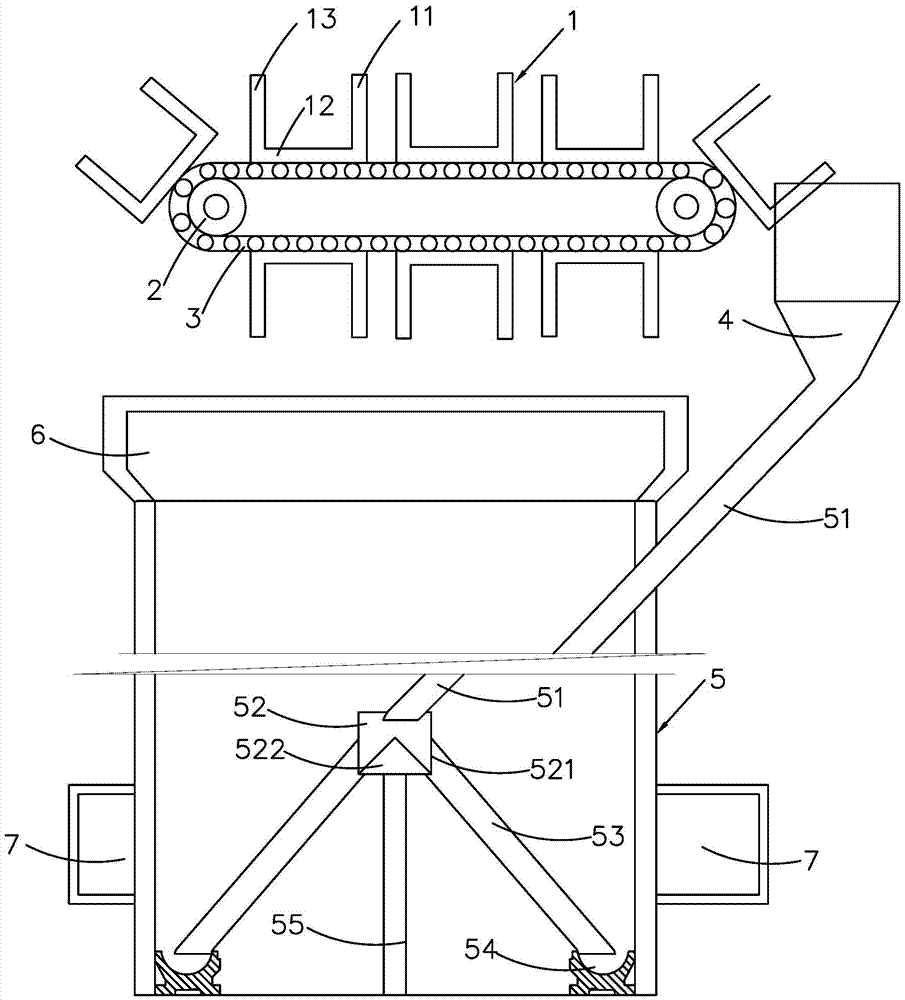

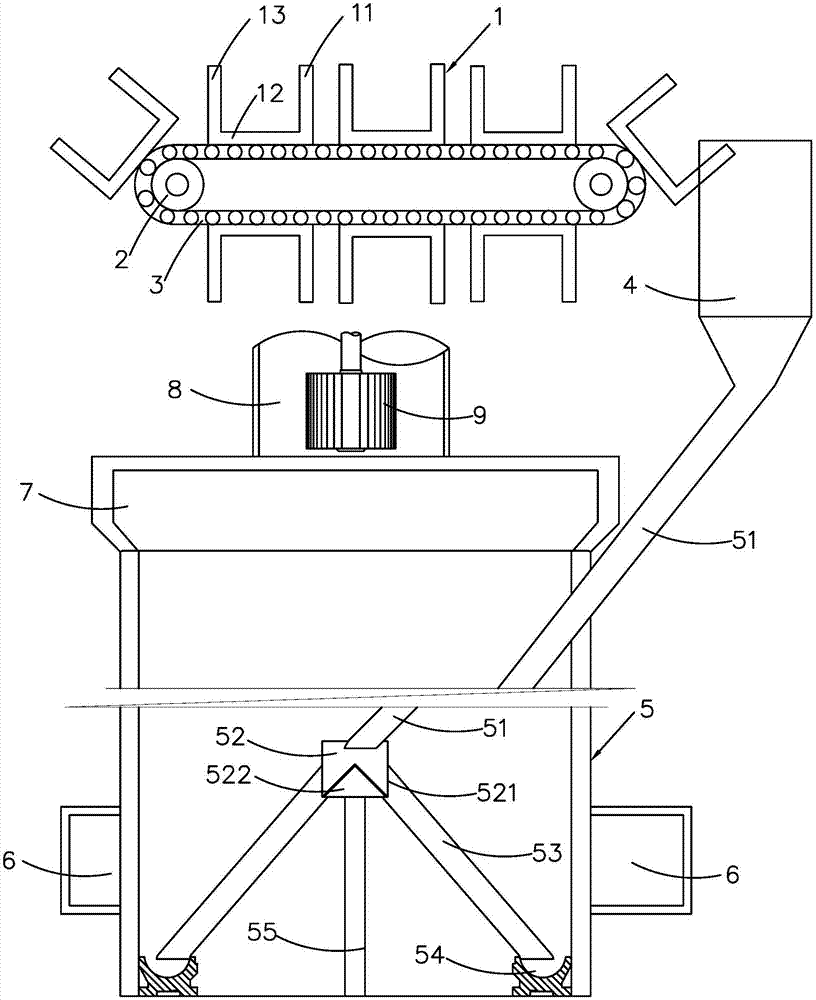

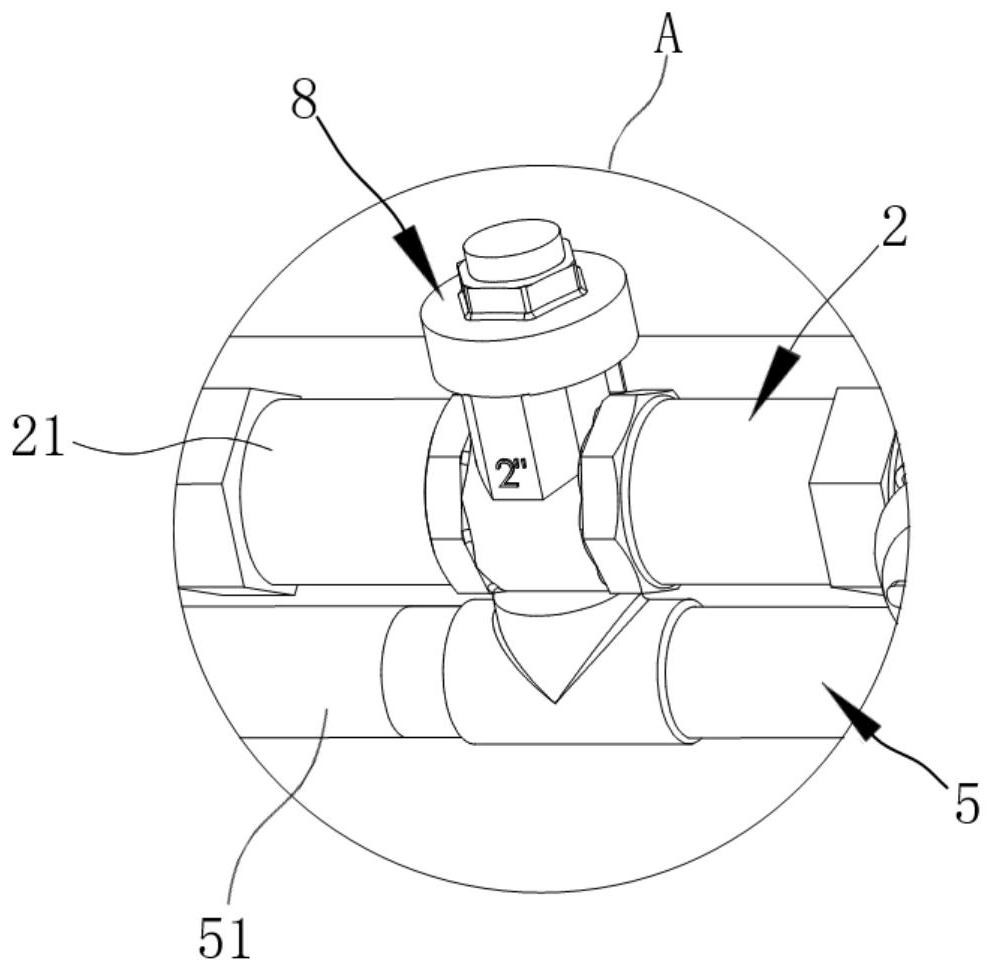

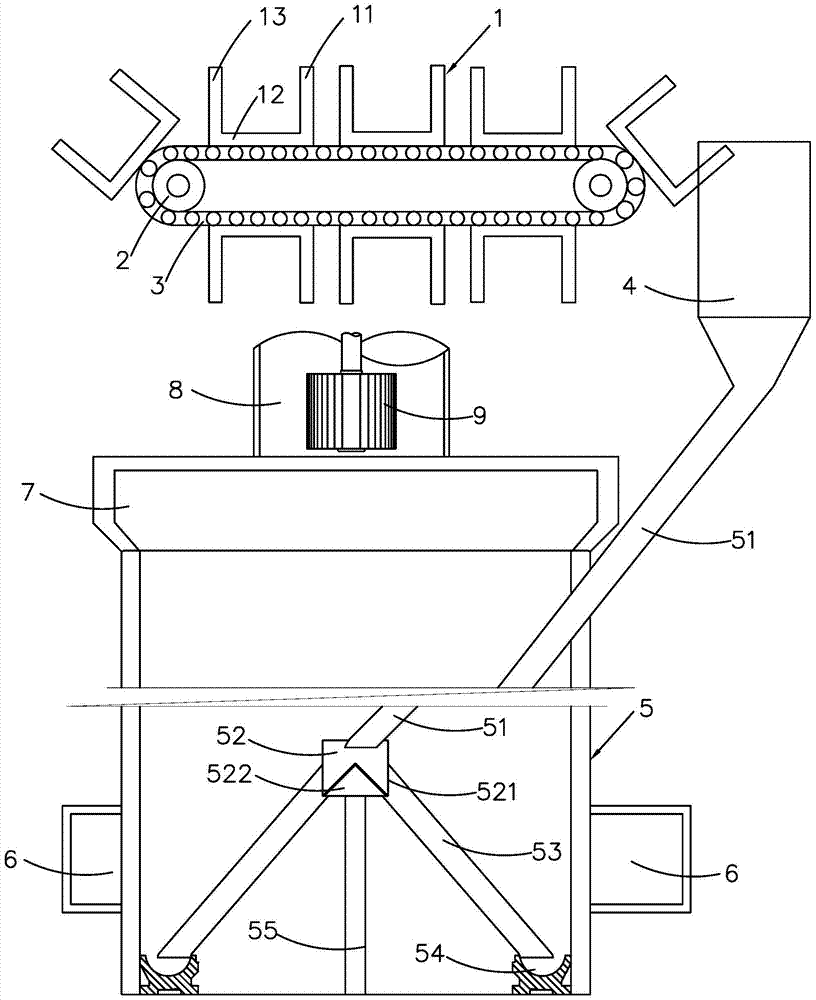

Multi-stage feeding equipment for conveying particle materials

PendingCN110155533AEasy to useAvoid situations where a large amount of power is consumedLarge containersBulk conveyorsCircular discEngineering

The invention relates to multi-stage feeding equipment for conveying particle materials. The multi-stage feeding equipment for conveying the particle materials comprises a first-stage material tank, adust remover arranged at the top of the first-stage material tank as well as a hopper arranged on the lower side of the first-stage material tank; an upper level gage is arranged on the upper part ofthe first-stage material tank; a plurality of weighing sensors which are distributed uniformly and circumferentially are arranged on the middle part of the first-stage material tank; a lower level gage is arranged on the lower part of the first-stage material tank; a plurality of uniformly distributed gas hammers are arranged on the hopper; a disk feeder is arranged at the lower end of the hopper; the lower end of the disk feeder is connected with two or more than two material distributing pipes; a first transmission mechanism is arranged at the lower end of the disk feeder; and a pneumatic butterfly valve positioned above the material distributing pipes is arranged at the lower end of the disk feeder. The multi-stage feeding equipment for conveying the particle materials can automatically detect the bridging condition, can eliminate the bridge at the first time of detecting the bridging condition, and can realize an automatic loading function and improve the feeding efficiency.

Owner:JINHUA DIPU ENVIRONMENTAL TECH CO LTD

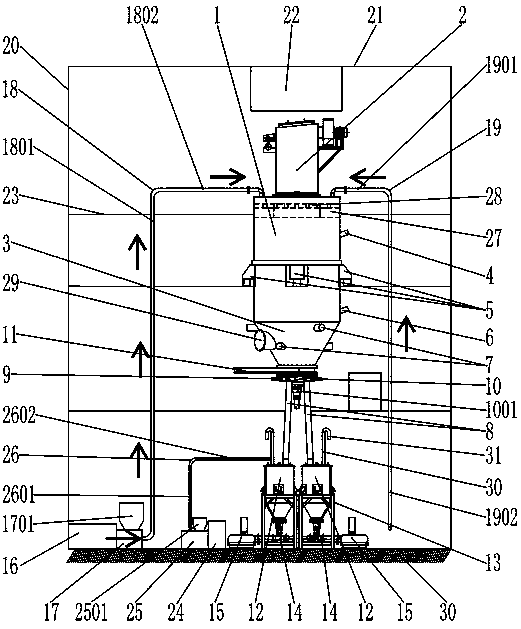

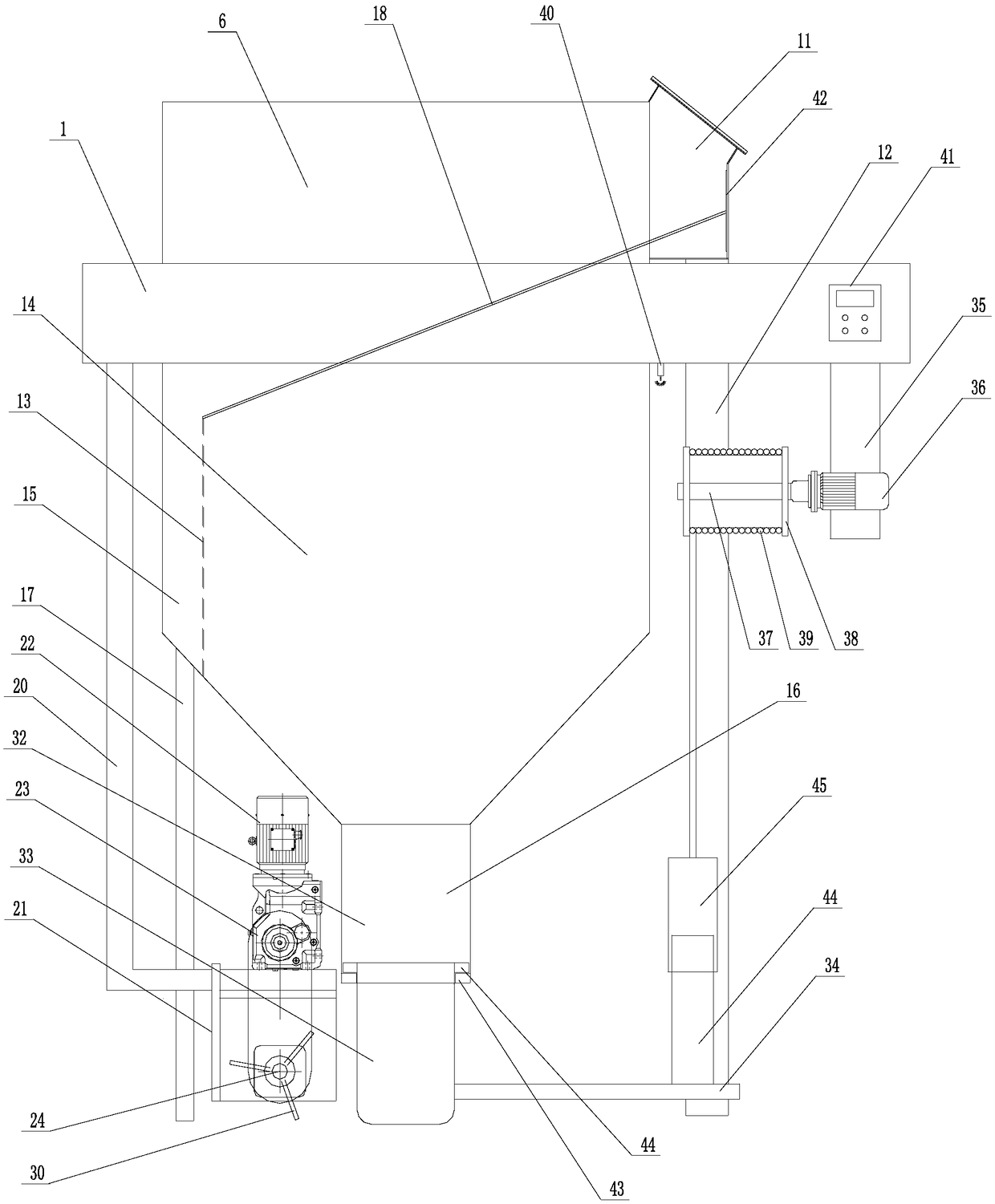

Filling material sucking and unloading crown block for graphite refining

The invention relates to a filling material sucking and unloading crown block for graphite refining. The filling material sucking and unloading crown block for graphite refining comprises a bridge frame, a cart running track, a cart running mechanism, a trolley running track, a trolley running mechanism, a stock bin, a cooler, a dust collector, a negative pressure fan and an electric control system; the bridge frame is fixedly connected with an L-shaped fixing plate, and an agglomeration crushing device is fixedly mounted on the L-shaped fixing plate; and a discharging pipe fixedly connected to the lower end of the stock bin and an unloading pipe arranged in the discharging pipe in a sleeved manner are further included, and the lower end of the unloading pipe is provided with a telescopiclifting device. By means of the filling material sucking and unloading crown block, large filling material agglomerates and small filling material agglomerates in a workshop can be crushed to be in apowder shape, and then a negative pressure feeding device on the stock bin sucks filling materials into the stock bin, so that the large agglomerates and the small agglomerates are prevented from blocking a sucking pipe, the filling materials can guarantee that the unloading pipe is attached to the ground of the workshop all the time, the filling materials inside the stock bin are unloaded throughthe discharging pipe and the unloading pipe, dust generated in the discharging process of the filling materials is reduced, the visibility of the work environment is ensured, and the body health of workers is ensured.

Owner:河南科特尔机械制造有限公司

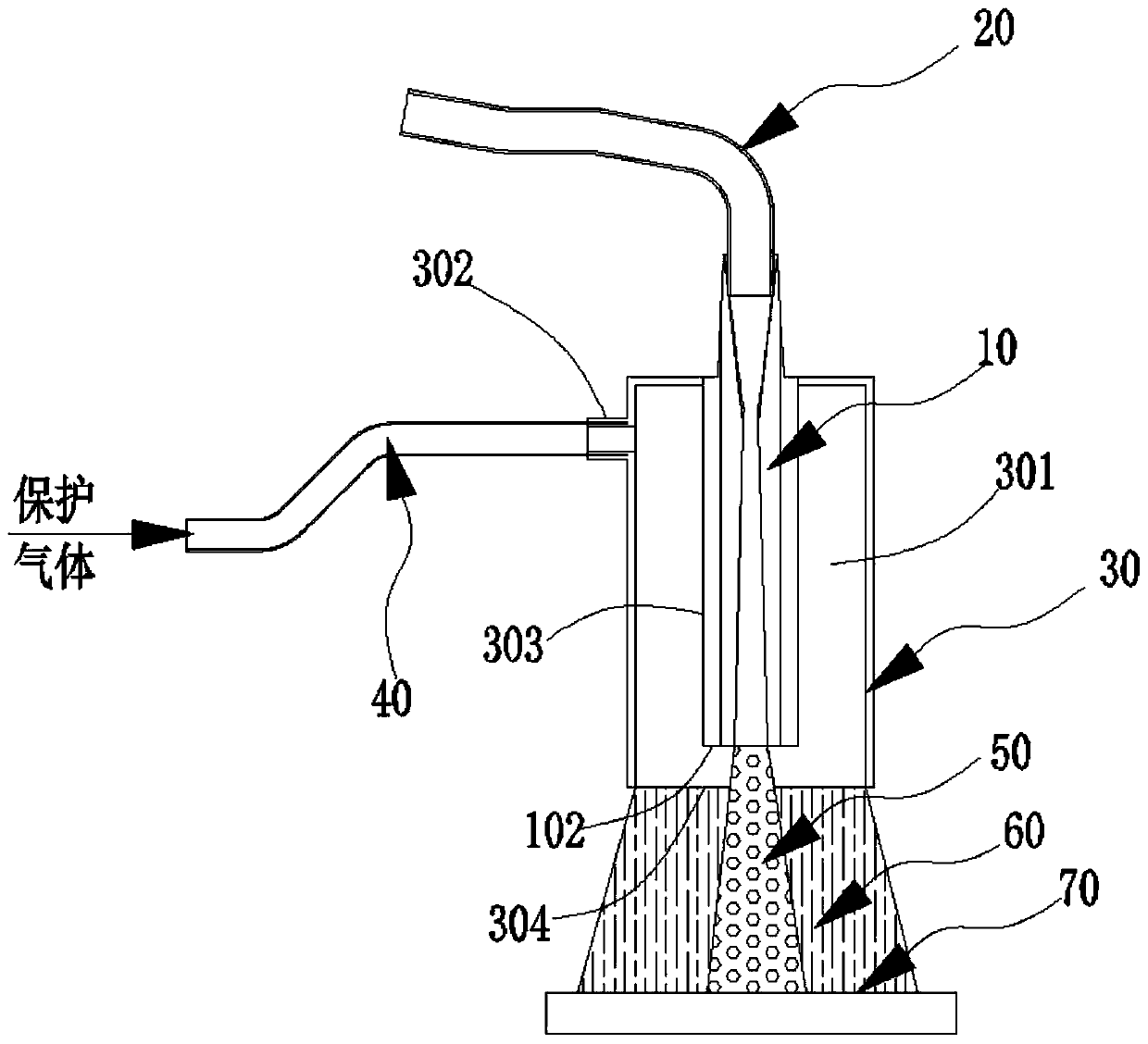

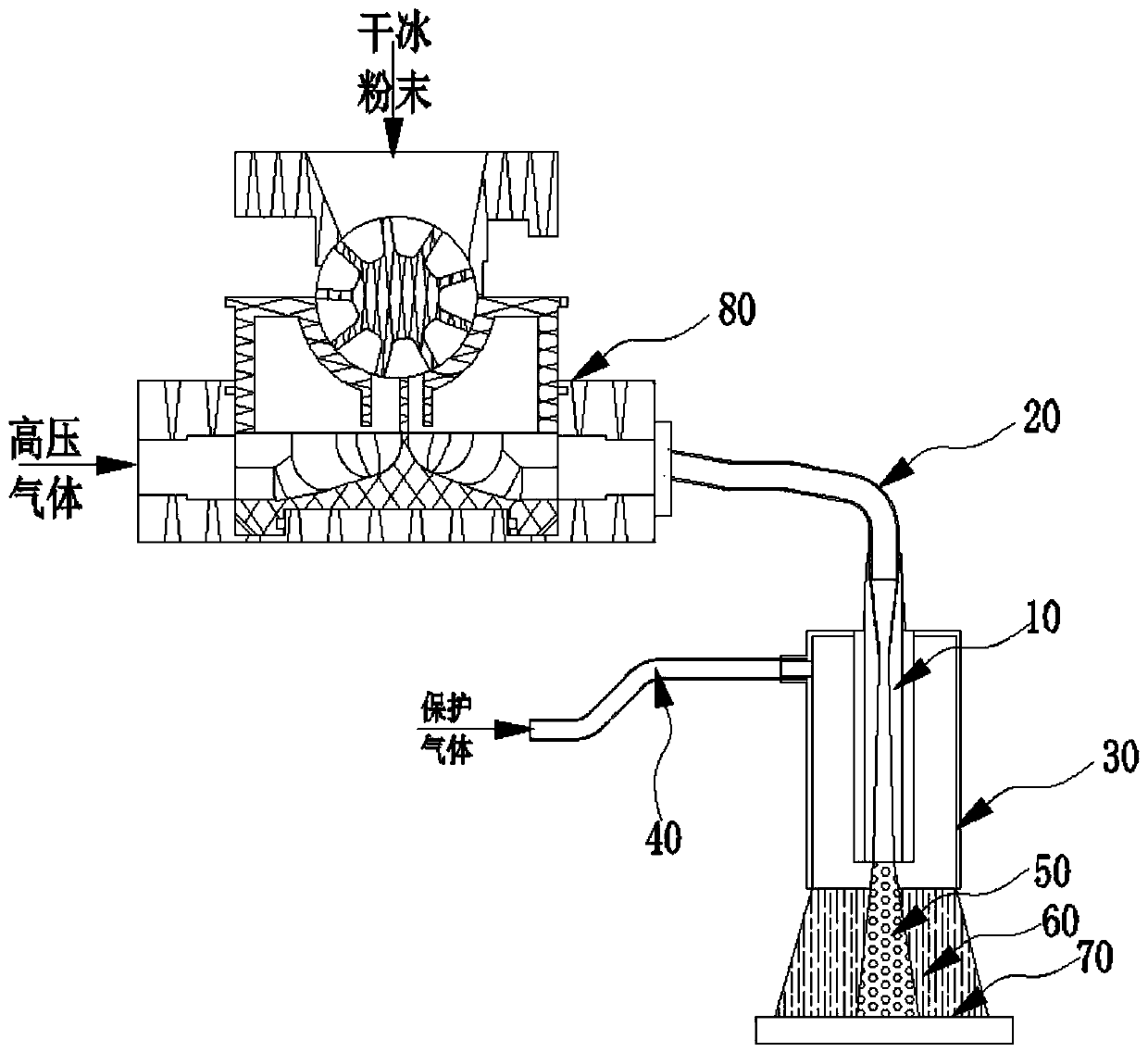

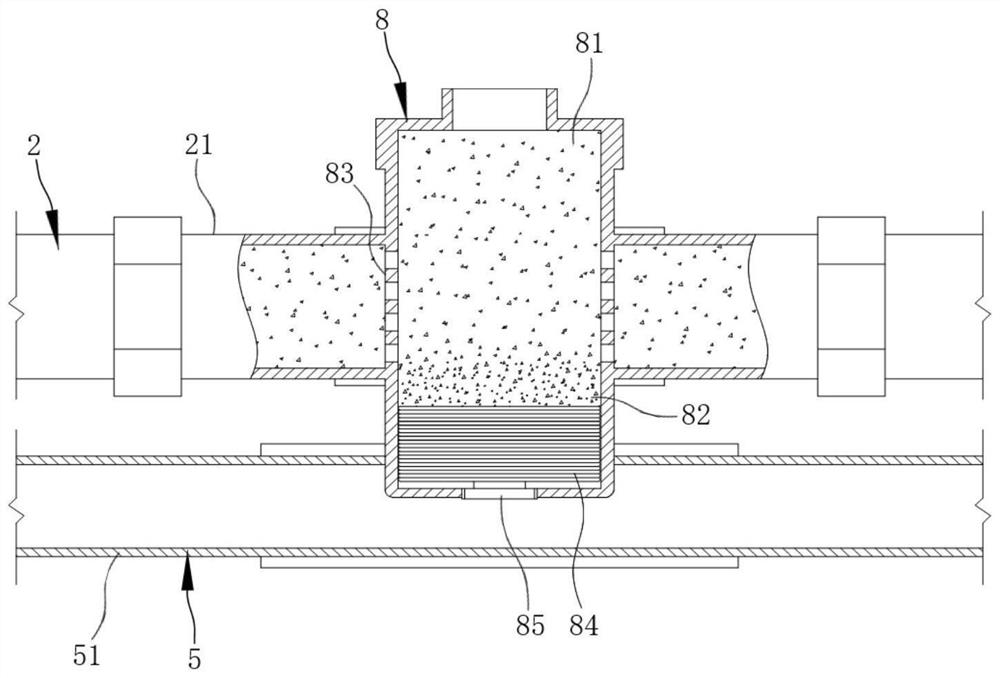

Dry ice cleaning spray nozzle, dry ice cleaner and secondary pollution preventing dry ice cleaning method

PendingCN110369403AAvoid contactSolve the problem of condensation foggingCleaning using gasesPollutantDry ice

The invention discloses a dry ice cleaning spray nozzle, a dry ice cleaner and a secondary pollution preventing dry ice cleaning method. The dry ice cleaning spray nozzle comprises a spray nozzle mainbody, and a gas curtain spray nozzle, wherein the spray nozzle main body is provided with a structure connecting a dry ice conveying tube and a dry ice gas flow injection channel; the gas curtain spray nozzle surrounds the periphery of the spray nozzle main body, and comprises an inner cavity which surrounds the periphery of the spray nozzle main body and a connecting hole which communicates withthe inner cavity, and is connected to a protective gas source through a protective gas tube; and the gas curtain spray nozzle defines a protective gas curtain which surrounds the periphery of dry icejet flow jetted by the spaying nozzle main body. According to the scheme adopted by the invention, the protective gas curtain formed by protective gas is arranged at the periphery of the dry ice jetflow, and a cleaning surface can be effectively isolated from outside air, so that pollutants such as impurities and water vapor are prevented from being in contact with the cleaning surface; and meanwhile, the cleaned surface is swept through the protective gas curtain, so that the cleaned surface can be dried and can be restored to the room temperature, and therefore, the problem that water vapor is condensed and fogged is solved, protection can be performed throughout the process, and the cleaning effect is guaranteed.

Owner:儒众智能科技(苏州)有限公司

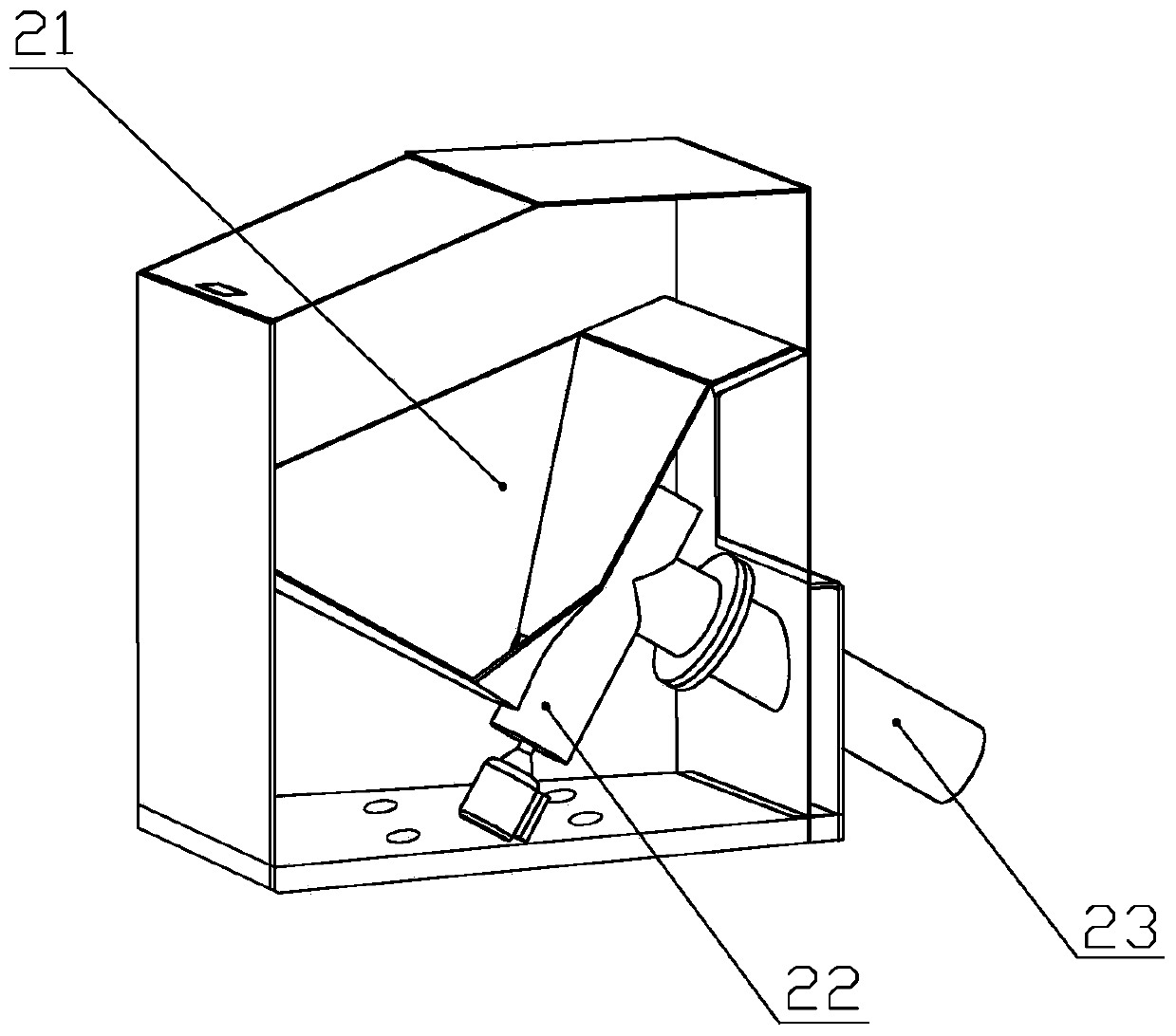

Automatic feed winding machine for inductance

ActiveCN106783143AQuality assuranceAvoid shakingInductances/transformers/magnets manufactureWinding machineDistribution control

The invention relates to an automatic feed winding machine for inductance. The automatic feed winding machine comprises a rack and a distribution control box, a load rotating device is arranged in the middle of the rack, the upper portion of the load rotating device is matched with a wire plugging device and a wire conveying device, a feed docking device is fittingly arranged at the front portion of the load rotating device, the feed docking device is matched with a feeding device at the lower portion of the rack, the feed docking device comprises a docking seat arranged on the rack, a docking lifting cylinder is arranged on the docking seat and is connected with a docking lifting seat, a forward and backward receiving motion cylinder is arranged at the lower portion of the docking lifting seat and is connected with a receiving block made from electromagnet, receiving grooves matched with products are evenly formed in the receiving block, a forward and backward pushing motion cylinder is arranged at the upper portion of the docking lifting seat and is connected with a forward and backward pushing motion seat, and rotating pushing heads matched with the products are evenly arranged on the forward and backward pushing motion seat. By the arrangement, feeding efficiency is guaranteed, and meanwhile, quality in feeding and subsequent winding is guaranteed as well.

Owner:TONGXIANG YAORUN ELECTRONICS

Pig farm automatic feeding device

ActiveCN105580744BAdequate and timely supplyEnsuring scientific growthAnimal feeding devicesPig farmsEngineering

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

Novel feeding device

InactiveCN104440015AReduce institutional settingsSimple structureMetal working apparatusEngineeringMechanical engineering

Owner:YIHE PRECISION IND SUZHOU

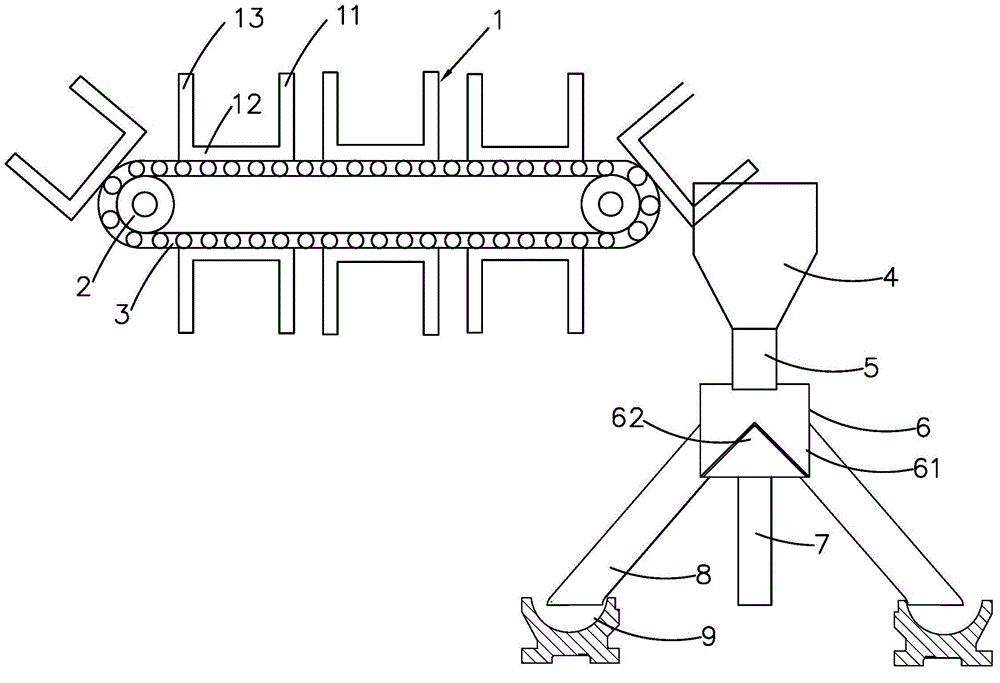

Full-automatic roller-slitting grinding mill

The invention discloses a full-automatic roller cutting and grinding machine. The conveying and feeding device includes a chain, a feeding slot and a sprocket; Material pipe, silo, discharge pipe, U-shaped ring groove and grinding wheel, the discharge port of the feed pipe is connected to the silo, and the discharge port of the silo on the side of the silo is fixedly connected with the corresponding discharge pipe respectively. The pipe is connected to the U-shaped ring groove, and there are multiple grinding wheels in the U-shaped ring groove, and the grinding wheels are fixedly connected to the rotating shaft through the rotating arm; the outlet of the silo is evenly distributed on the side of the silo, The lower opening of the mouth is at the same height as the bottom surface of the silo; a vertebral body with the bottom surface of the silo as the bottom surface is arranged in the silo, and the height of the vertebral body is lower than the height of the silo. The invention realizes automatic feeding through chain transmission, and the materials can slide down by themselves without manual feeding, and after stopping feeding, all the materials in the hopper can enter the U-shaped ring groove without manual cleaning.

Owner:CHENGDU CHENHONG TECH

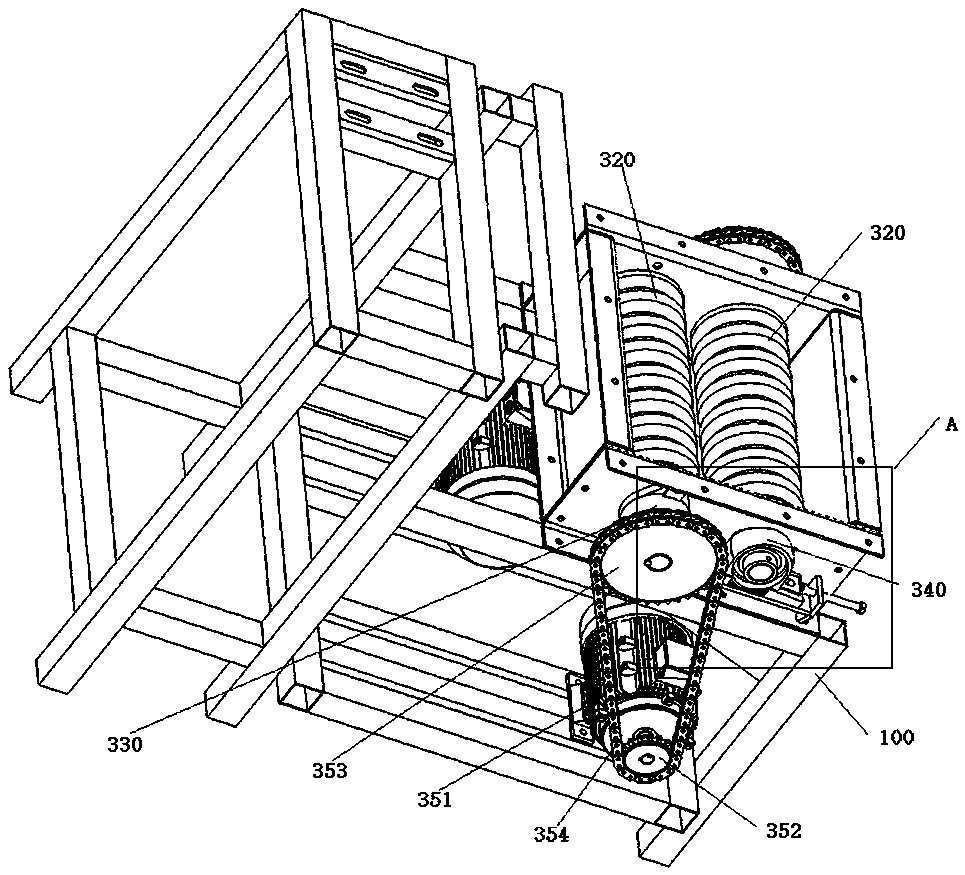

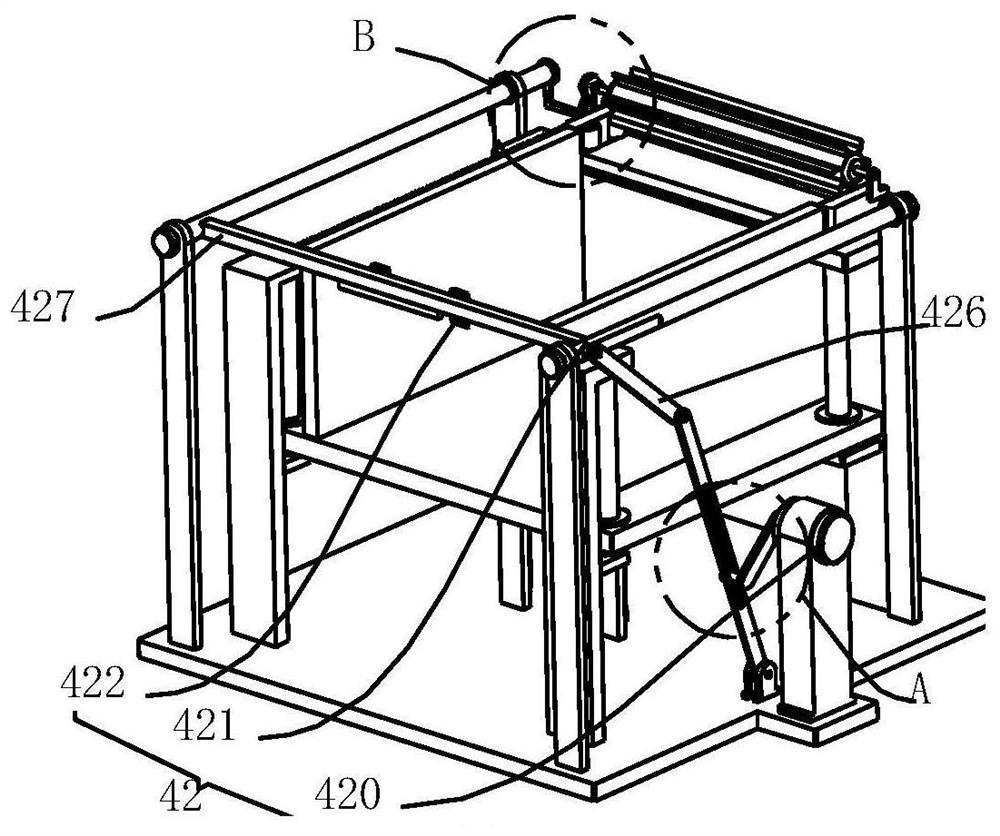

Automatic feeding system of grinding mill

InactiveCN105032589ARealize automatic transportationRealize automatic feedingGrain treatmentsSprocketMachine tool

The invention discloses an automatic feeding system of a grinding mill, which comprises a chain, feeding clamping grooves fixedly connected with the chain, chain wheels engaged with the chain, and a first storage bin connected with the feeding clamping grooves, wherein a material outlet of the first storage bin is fixedly connected with a feeding pipe; a material outlet of the feeding pipe is fixedly connected with a second storage bin; the second storage bin is in a cylinder structure with both the bottom surface and the top surface being in regular polygon shapes; a second storage bin material outlet is formed in a place, close to the bottom surface of the second storage bin, of each rectangular side surface of the second storage bin; the second storage bin material outlets are fixedly connected with discharge pipes; the discharge pipes are connected with U-shaped circular grooves; the feeding clamping grooves consist of clamping groove seats, front baffles and rear baffles; the clamping groove seats are fixedly connected with the chain; the front baffles and the rear baffles are arranged on the two sides of the clamping groove seats; and the feeding clamping grooves are arranged on the chain in series. The automatic feeding system can automatically feed material to a feeding device, and can ensure that no material is prevented from sliding down due to stacking in the storage bins; effective operation of a machine tool is facilitated; the feeding efficiency and the feeding stability are ensured; and the production efficiency is improved.

Owner:CHENGDU CHENHONG TECH

Workpiece punching device with sectional type auxiliary pushing mechanism

PendingCN112475080AConvenient segmented feedingEasy to cleanMetal-working feeding devicesCleaning using toolsPunchingStructural engineering

The invention relates to the technical field of workpiece punching, in particular to a workpiece punching device with a sectional type auxiliary pushing mechanism. The workpiece punching device comprises a punching device body, the punching device body comprises a punching machine, a punching table is connected with the surface of one side of the punching machine, a sectional type pushing mechanism is connected with the outer surface of the punching table, a first supporting rod is connected to the surface of one end of the punching machine, and a cleaning mechanism is connected to the surfaceof one side of the first supporting rod. By arranging the sectional type pushing mechanism, periodic sectional type feeding can be conveniently carried out on a first carrier plate, so that the feeding efficiency of the device is effectively improved; and by arranging the cleaning mechanism, small leftover materials existing on the surface of the punching table can be effectively and convenientlycleaned through cleaning of the first supporting rod, and therefore, the product quality of the device during workpiece machining can be effectively improved.

Owner:合肥市擎海信息科技有限公司

Automatic feeding device for pig farm breeding

ActiveCN105580744AAdequate and timely supplyEnsuring scientific growthAnimal feeding devicesPig farmsEngineering

The invention discloses an automatic feeding device for pig farm breeding. A cuboid-shaped storage box is fixed to a support, rows of conical bins are arranged in an inner cavity of the storage box in the length direction, an auger conveying mechanism is arranged at the lower end of each conical bin, a discharge outlet is formed in the lower end of each conical bin to be connected with a feed inlet in the lower end of the corresponding auger conveying mechanism, and an outlet in the upper end of each auger conveying mechanism is connected with a guiding cylinder; each guiding cylinder inclines downwards in the axial direction, and a feeding trough is arranged under the storage box and located at one side of the guiding cylinders; trough cavities are formed in the feeding trough corresponding to each guiding cylinder, and a guiding plate is arranged between each guiding cylinder and the corresponding trough cavity; a limiting fence is arranged at one side of the outside of the feeding trough. By the adoption of the device, fixed-point quantitative feed supply can be achieved, labor intensity of workers is relieved, and feeding efficiency and timeliness are improved; by arranging the limiting fence, pigs can eat from one direction only and can not push feed in the feeding trough out, the sanitation of a breeding house is guaranteed, and waste is avoided.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

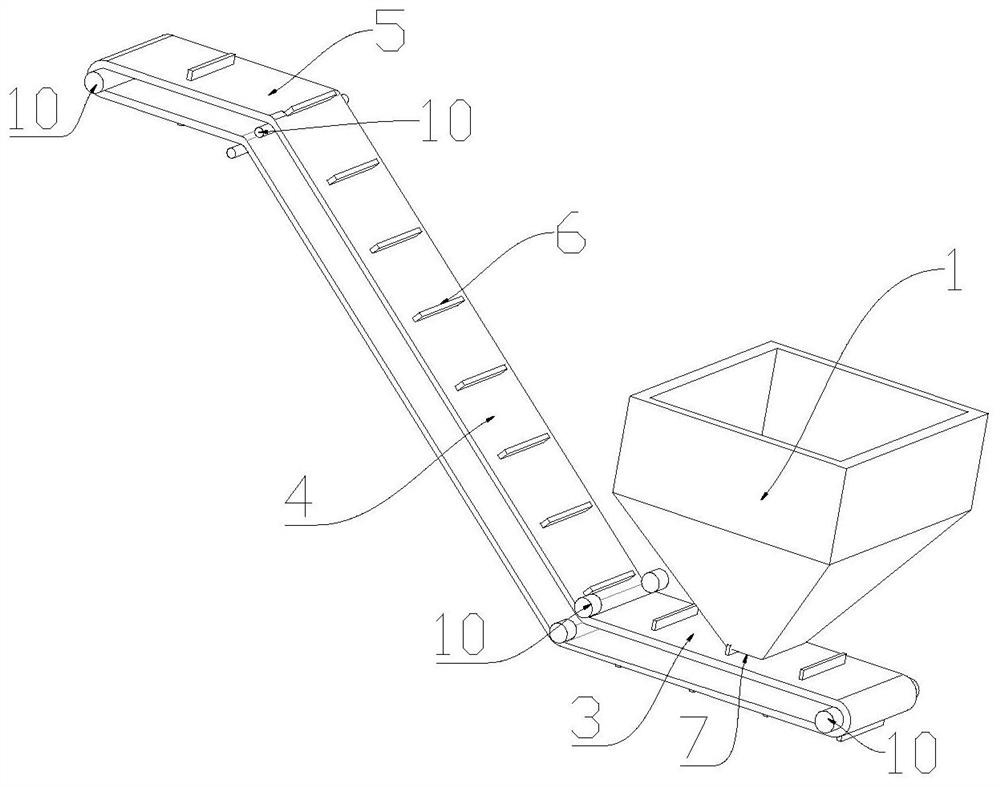

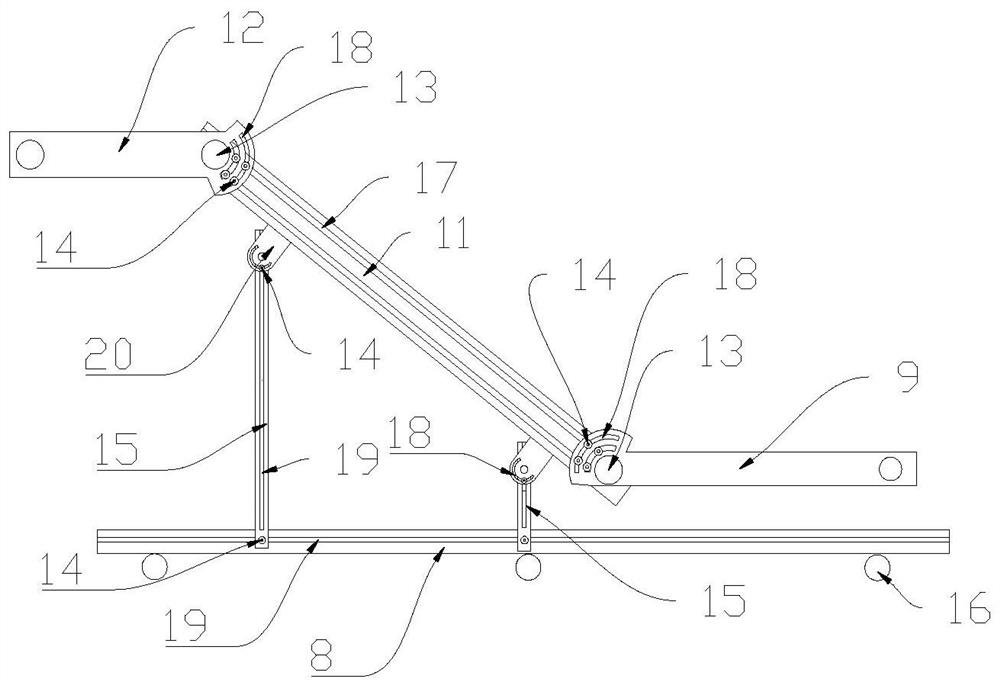

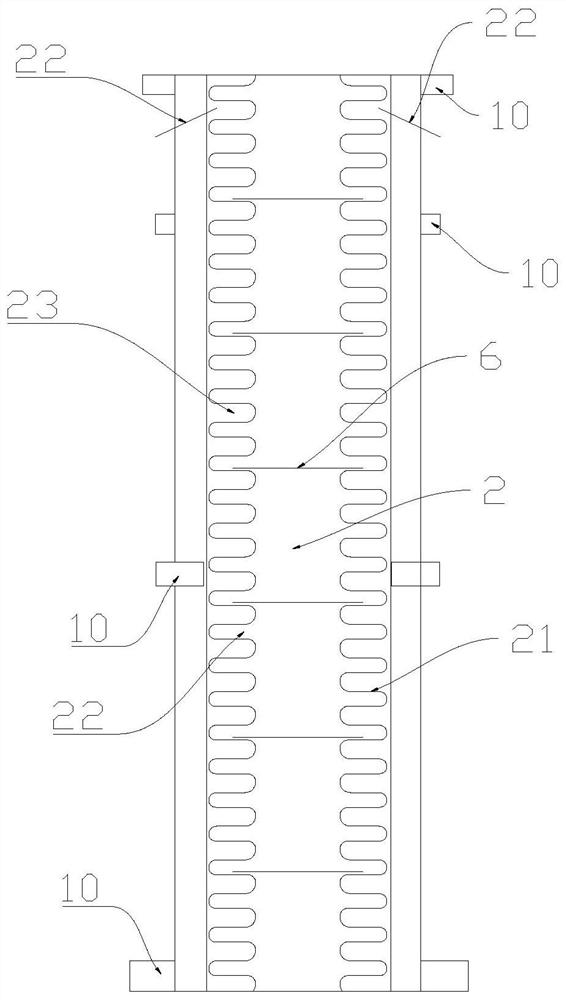

Automatic powder feeding device

PendingCN112777273ARealize automatic feeding processLabor savingConveyorsLoading/unloadingProduction lineElectric machinery

The invention discloses an automatic powder feeding device which comprises a storage hopper and a conveying device. The conveying device comprises a belt and a mounting frame, wherein a material receiving section, an ascending section and a discharging section are arranged on the belt and sequentially connected, the belt is installed on the mounting frame, the belt is driven by a motor to operate, and baffles are arranged on the belt and are perpendicular to the conveying direction of the belt. A discharging opening is formed in the lower end of the storage hopper, a cover plate which can be pulled away is installed in the discharging opening, the discharging opening is located above the material receiving section, the angle between the material receiving section and the ascending section is adjustable, and the angle between the ascending section and the discharging section is adjustable. According to the automatic powder feeding device, when feeding is required, the belt is started to operate, automatic feeding is achieved, the labor can be effectively saved, and the feeding efficiency is guaranteed. The automatic powder feeding device can be adjusted according to site conditions and production line conditions and is suitable for being additionally installed on a traditional production line to be used.

Owner:嘉兴市小月亮电池有限公司

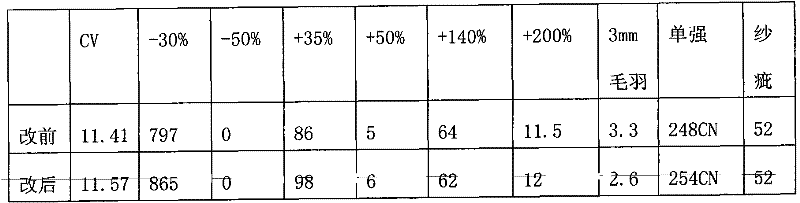

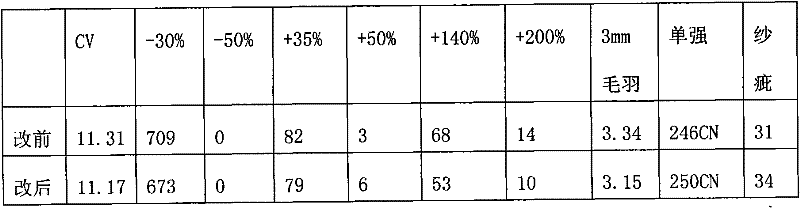

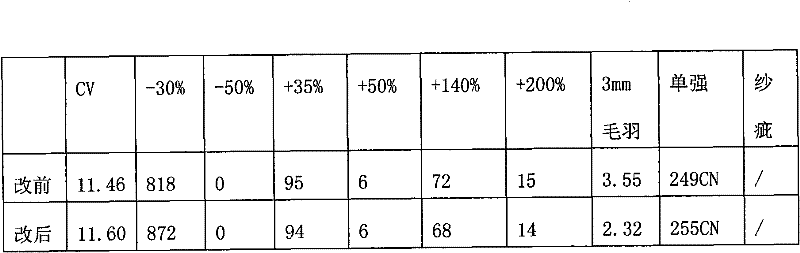

Process for producing high-grade weaving yarns with heavy weight per unit of card silver in a carding machine from Zhengzhou Textile Machinery Co., Ltd

InactiveCN101748518AIncrease speedIncrease productivityContinuous processingCarding machinesYarnCombing

A process for producing high-grade weaving yarns with heavy weight per unit of card silver in a carding machine from Zhengzhou Textile Machinery Co., Ltd relates to the textile technical field, in particular to a process for producing high-grade weaving yarns. The process includes: ZTM blowing-carding process- pre-drawing- lap drawing- combing- drawing (with auto leveling) - roving- cheese winding -bale packing- yarn sales. Under the circumstance of constant card clothing of the carding machine, the linear weight of card silver can be increased to 21g / 5m increased by nearly 17 percent by, increasing the RPM of cubing rolls, cylinders and cover plates, blocking up a support trunnion for feed roller and reducing the spacing between the feed roller and the cubing roll, thus not only increasing the production efficiency and saving the energy consumption but also addressing the problem of dissatisfaction with the supply of card silvers.

Owner:江苏省华强纺织有限公司

Roller-slitting grinding mill feeding and discharging assembly

InactiveCN107051703AAutomatic feed implementationGood dispersionGrain treatmentsDecompression chamberEngineering

The invention discloses a roller-slitting grinding mill feeding and discharging assembly. The roller-slitting grinding mill feeding and discharging assembly comprises a belt, a belt pulley, a feeding clamping groove fixedly connected with the belt, a first stock bin, a grinding bin, a decompression chamber, an air outlet pipe and an air inlet pipe. The grinding bin internally comprises a feeding pipe, a second stock bin, discharging pipes and a U-shaped ring groove. The bottom face and the top face of the second stock bin are each of a regular polygon cylinder structure, discharging openings of the second stock bin are formed in the positions, close to the bottom face of the second stock bin, of all rectangular side faces of the second stock bin, and lower openings of the discharging openings of the second stock bin are equal to the bottom face of the second stock bin in height. A cone with the bottom face being the bottom face of the second stock bin is arranged in the second stock bin, and the cone is lower than the second stock bin. According to the roller-slitting grinding mill feeding and discharging assembly, materials can be automatically fed into the grinding bin through a chain transmission system, automatic material feeding is achieved, the condition that owing to the fact that material downward sliding is not in time, material stocking in the second stock bin is caused can be avoided from occurring, no manual work is needed for material clearing work, manpower is saved, and production efficiency is improved.

Owner:CHENGDU CHENHONG TECH

Electrical inductance winding machine convenient for plugging wire

ActiveCN108010716AQuality assuranceAvoid shakingInductances/transformers/magnets manufactureWinding machineDistribution control

The invention relates to an electrical inductance winding machine convenient for plugging a wire. The winding machine comprises a rack and a power distribution control box, the middle of the rack is provided with a material loading rotation device, the upper part of the material loading rotation device is in cooperation with a wire transporting device through a wire plugging device, the front partof the material loading rotation device is cooperatively provided with a material loading butt joint device which is in cooperation with a material loading device arranged at the lower part of the rack, the material loading butt joint device comprises a butt joint seat arranged on the rack, the butt joint seat is provided with a butt joint lifting air cylinder, the butt joint lifting air cylinderis connected with a butt joint lifting seat, the lower part of the butt joint lifting seat is provided with a material-receiving front-back movement air cylinder which is connected with a material-receiving block made of an electromagnet, the material receiving block is uniformly provided with material-receiving grooves which are in cooperation with products, the upper part of the butt joint lifting seat is provided with a material butting front-back movement air cylinder which is connected with a material butting front-back movement seat, and the material butting front-back movement seat isuniformly provided with rotational material butting heads which cooperate with the products. The electrical inductance winding machine guarantees the quality of material loading and subsequent wire winding when guaranteeing the material loading efficiency simultaneously.

Owner:DONGKOU HUICHUANG ELECTRONICS CO LTD

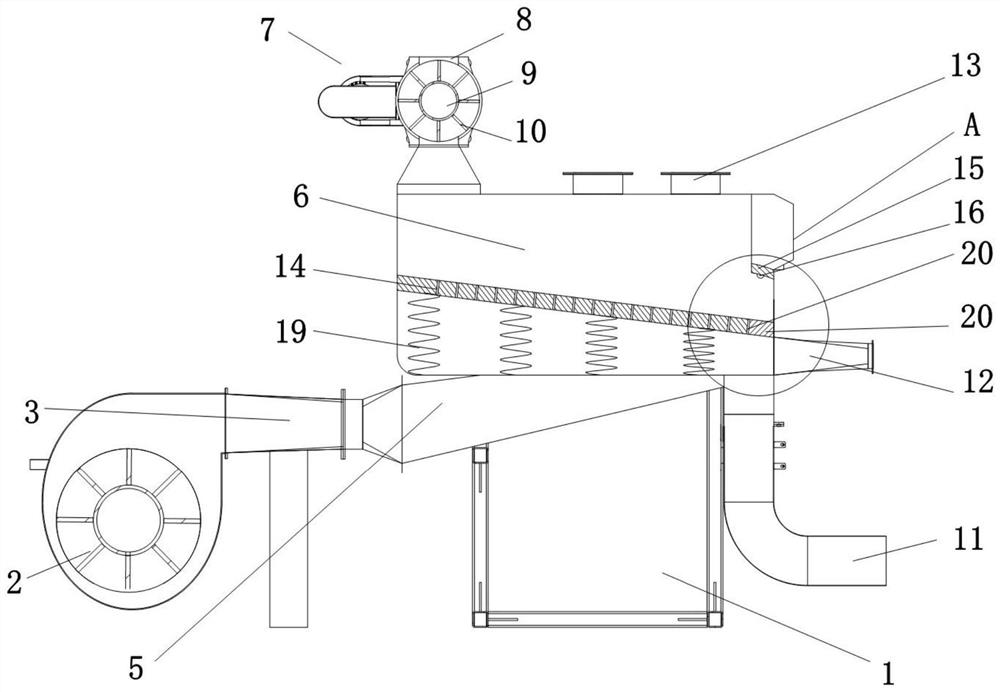

A boiler feeding device

InactiveCN104913327BReduce spillageReduce wasteLump/pulverulent fuel feeder/distributionEngineeringMaterial transfer

The invention discloses a boiler feeding device, which includes a feeding hopper. The feeding device also includes a swing arm cylinder and a cylinder support arm. The cylinder support arms have a pair, and the feed hopper is arranged on a pair of cylinders. Between the support arms, a support shaft runs through the lower end of the feed hopper. The pusher plate support rods are fixed at both ends of the feed hopper, the feed hopper is provided with a rack, the rack passes through the pusher plate, and the upper end of the pusher plate is connected to the handwheel through a rotating shaft. This kind of feeding device is beneficial to reduce the spillage and waste of biomass particles in the feeding process. Compared with the feeding screw pushing material, the efficiency is higher, and it solves the common problems of blockage and surplus in the feeding process. , which ensures the feed efficiency, not only saves the amount of biomass fuel used, but also reduces the production cost.

Owner:长春亚泰热力有限责任公司

Preparation device for carrier surface recrystallization

PendingCN113532024AReduce consumptionSmooth feedingDrying solid materials with heatDrying gas arrangementsMetallurgyVibratory fluidized bed

The invention belongs to the technical field of recrystallization, and discloses a preparation device for carrier surface recrystallization. Materials can be efficiently and uniformly dried and cooled by virtue of a vibrated fluidized bed dryer, the drying position of the materials is continuously changed, and continuous pulsating vibration is also realized by a sieve plate, so that the drying efficiency of the device is improved, and the drying effect is ensured.

Owner:高君

Plastic feeding device

The invention discloses a plastic feeding device. The plastic feeding device comprises a storage box, supporting columns are fixedly connected to the two sides of the bottom of the storage box, the bottoms of the supporting columns are fixedly connected with a bottom plate, pressure sensors are arranged between the storage box and the supporting columns, a conveying pipe is fixedly arranged at theposition, corresponding to the storage box, of the top of the bottom plate, the surface of the inner wall of the conveying pipe is rotatably connected with a conveying roller, the left side of the top of the bottom plate is fixedly connected with a motor, the output end of the motor is fixedly connected with a rotating shaft, the right end of the rotating shaft penetrates the conveying pipe and is fixedly connected with the conveying roller, a control box is fixedly connected to the surfaces of the supporting columns, and the surface of the storage box is fixedly connected with an electric valve. According to the plastic feeding device, through cooperation of the pressure sensors, the conveying pipe, the conveying roller, the motor, the rotating shaft, the control box and the electric valve, the problems that an existing feeding device cannot well control the feeding amount, and the efficiency and quality of machining the plastic strips into particles cannot be ensured are solved.

Owner:湖南新融创科技有限公司

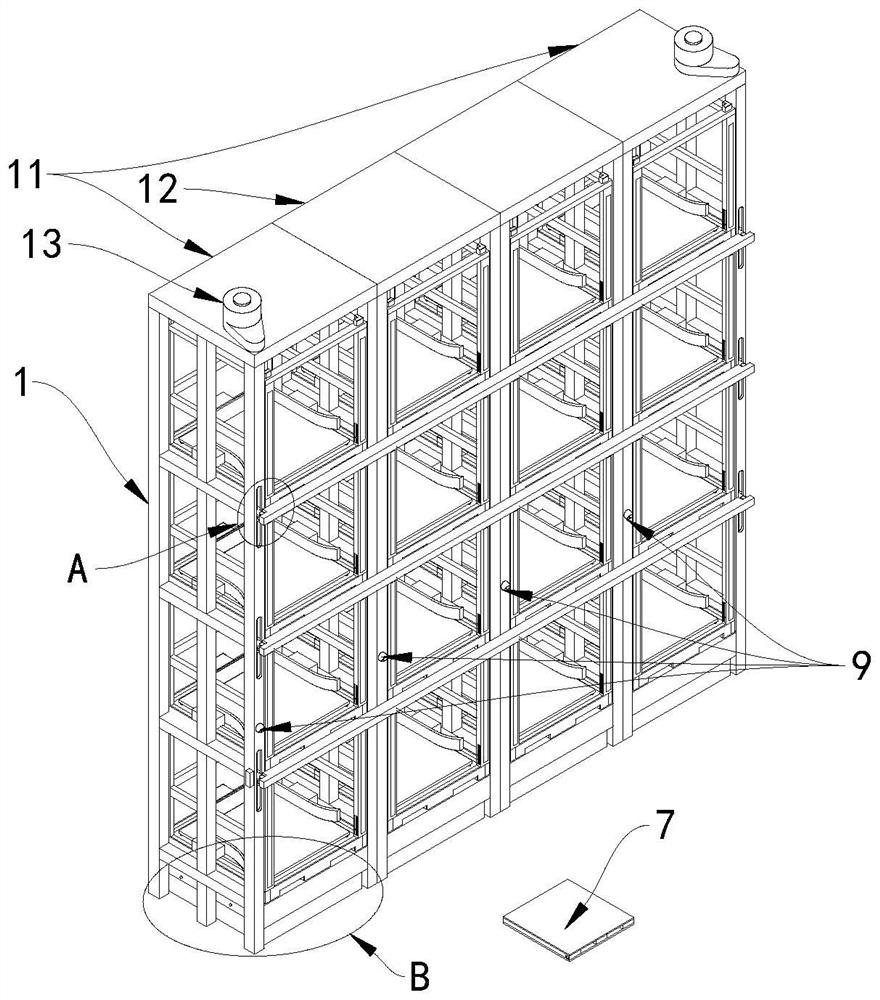

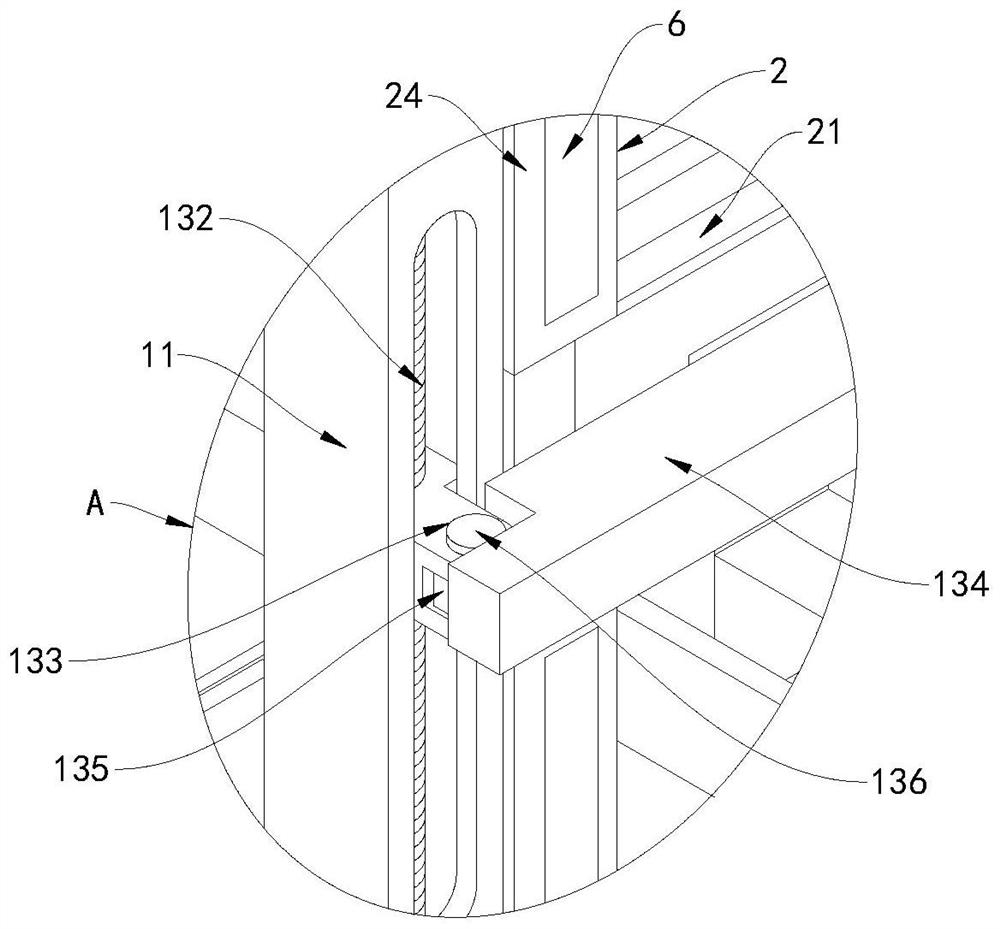

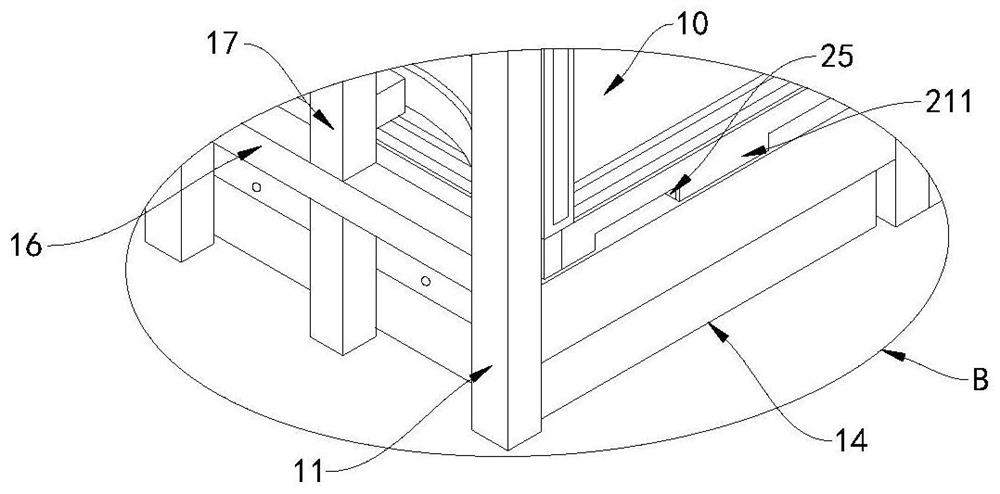

Traceable intelligent straw and pipe storage combined goods shelf and storage management system

ActiveCN114834803AGuaranteed feeding efficiencyEnsure safetyBio-packagingCo-operative working arrangementsAgricultural engineeringStorage management

The invention discloses a traceable intelligent straw and pipe storage combined shelf and a storage management system.The pipe shelf management system comprises a storage unit, a feeding unit and a discharging unit, and the storage unit comprises a two-dimensional code generation module for generating pipe information; the feeding unit comprises a discharging alarm module, an information recording module, a weighing module and an information updating module. The discharging unit comprises a material taking module, an excess material detection module and an information emptying module. The goods shelf comprises a shelf body, the shelf body comprises a plurality of unit frames arranged in a matrix mode, a base is arranged at the bottom of the shelf body, a movable seat capable of being lifted and locked is arranged on the base, and the movable seat supports the unit frames on the bottom layer; according to the scheme, the warehouse management system can record and update information of each stage of pipe feeding, manual statistics of workers is not needed, the pipe feeding efficiency is guaranteed, the practical performance is high, and the application range is wide.

Owner:NANJING PRIDE PLASTIC TECH

Processing production equipment and processing method of packaging substrate

ActiveCN113257682AGuaranteed feeding efficiencyAvoid harmSemiconductor/solid-state device manufacturingCopper foilIndustrial engineering

The invention discloses processing production equipment and a processing method of a packaging substrate, and relates to the technical field of packaging substrate processing. The equipment comprises a base plate body, a machine body, a conveying mechanism, a lifting mechanism, a feeding mechanism, a drainage mechanism, a wiping mechanism, a pipeline mechanism and a drying mechanism, wherein the machine body is used for automatically carrying out feeding, acid pickling, clean water washing and drying operation on the base plate body; the base plate body comprises a ceramic substrate; and an inner layer thick copper foil and an outer layer thin copper foil are sequentially arranged on the two sides of the ceramic substrate. Through the arrangement of the machine body, the conveying mechanism, the lifting mechanism and the feeding mechanism, the base plate body to be subjected to acid pickling is automatically fed through conveying rollers, the base plate body is transferred among the acid pickling, wiping and drying procedures in cooperation with a feeding frame capable of moving left and right, and compared with a conventional manual feeding mode, the substrate body feeding efficiency is guaranteed, and meanwhile, the harm of the pickling solution to workers is avoided, and the usability of the device is guaranteed.

Owner:深圳和美精艺半导体科技股份有限公司

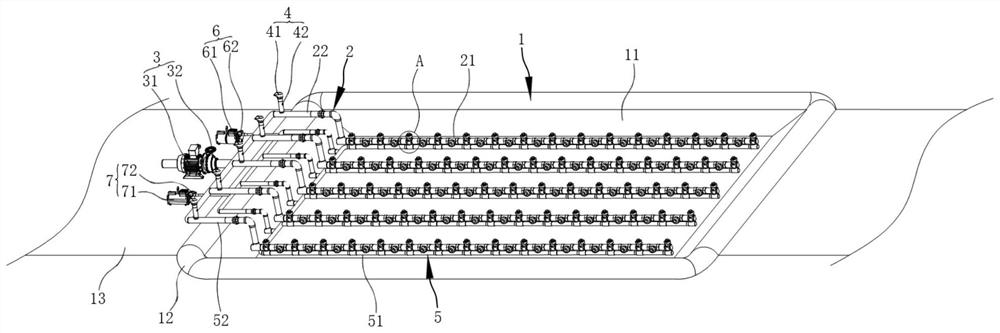

Automatic whole-pond balanced bait feeding system and method for freshwater fish culture

PendingCN114145254AGuaranteed uniformityUniform eruptionClimate change adaptationPisciculture and aquariaWater dischargeEngineering

The invention discloses an automatic whole-pond balanced bait feeding system and method for freshwater fish culture, and the system is characterized in that a bait flow guide pipe body is fixedly connected to a culture pond; the water driving module is provided with a water suction end and a water discharge end, the water suction end is arranged in the culture pond, and the water discharge end is communicated with the bait flow guide pipes; the feeding structure is communicated and fixedly connected to the bait flow guide pipe body; the airflow guide pipe bodies are evenly and fixedly connected to the culture pond, and the airflow guide pipe bodies are arranged under the airflow guide pipe bodies in a right opposite mode. The air inflation and exhaust module is fixedly connected to the installation ground and communicates with the airflow guide pipe body, and air inflation and exhaust are conducted on the airflow guide pipe body through the air inflation and exhaust module. The discharging structure is fixedly connected between the bait flow guide pipe body and the airflow guide pipe body. The technical problems that according to a feeding mode of freshwater fish culture bait, the feeding range is limited, efficiency is low, labor intensity is high, bait throwing is locally concentrated and uneven, regular and quantitative feeding is difficult, and consequently freshwater fish culture is difficult to achieve the expected effect are solved.

Owner:山东省海洋科学研究院青岛国家海洋科学研究中心 +1

Grinding mill feeding system capable of automatically discharging

InactiveCN107051646AEven material distributionImprove work efficiencyGrain treatmentsGrinding millTransmission system

The invention discloses a grinding mill feeding system capable of automatically discharging. The grinding mill feeding system capable of automatically discharging comprises a chain, a feeding clamping groove, a chain wheel, a first stock bin, a grinding bin, a decompression chamber, an air outlet pipe and an air inlet pipe. The grinding bin comprises a feeding pipe, a second stock bin, discharging pipes and a U-shaped ring groove. The second stock bin is fixedly installed on a rotary shaft and is of a cylinder structure, discharging openings of the second stock bin are evenly distributed in the side face of a cylinder and formed in the positions close to the bottom face of the second stock bin, and lower openings of the discharging openings of the second stock bin are equal to the bottom face of the second stock bin in height; and a cone with the bottom face being the bottom face of the second stock bin is arranged in the second stock bin, and the cone is lower than the second stock bin. According to the grinding mill feeding system capable of automatically discharging, materials can be automatically fed into the grinding bin through a chain transmission system, automatic material feeding is achieved, the condition that owing to the fact that material downward sliding is not in time, material stacking of the second stock bin is caused can be avoided from occurring, no manual work is needed for material clearing work, manpower is saved, and production efficiency is improved.

Owner:CHENGDU CHENHONG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com