Automatic feeding system of numerical control lathe

An automatic feeding, CNC lathe technology, applied in automatic/semi-automatic lathes, turning equipment, accessories of tool holders, etc., can solve the problems of waste of manpower, low degree of automation, low efficiency, etc., to save man-hours and ensure feeding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

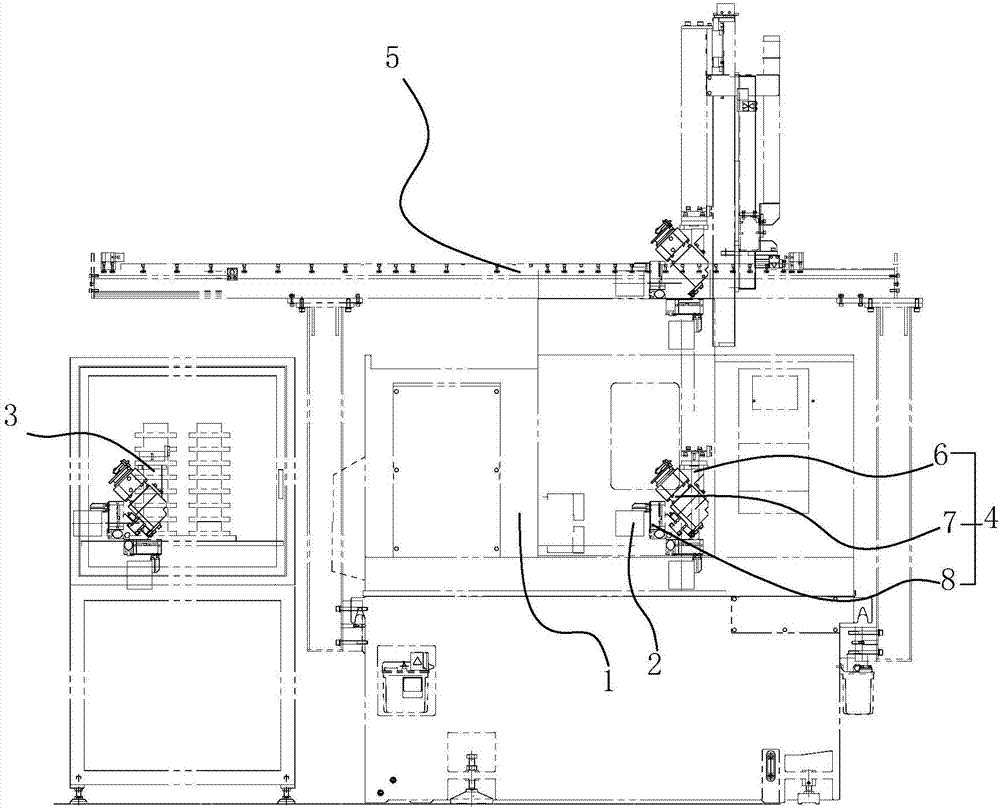

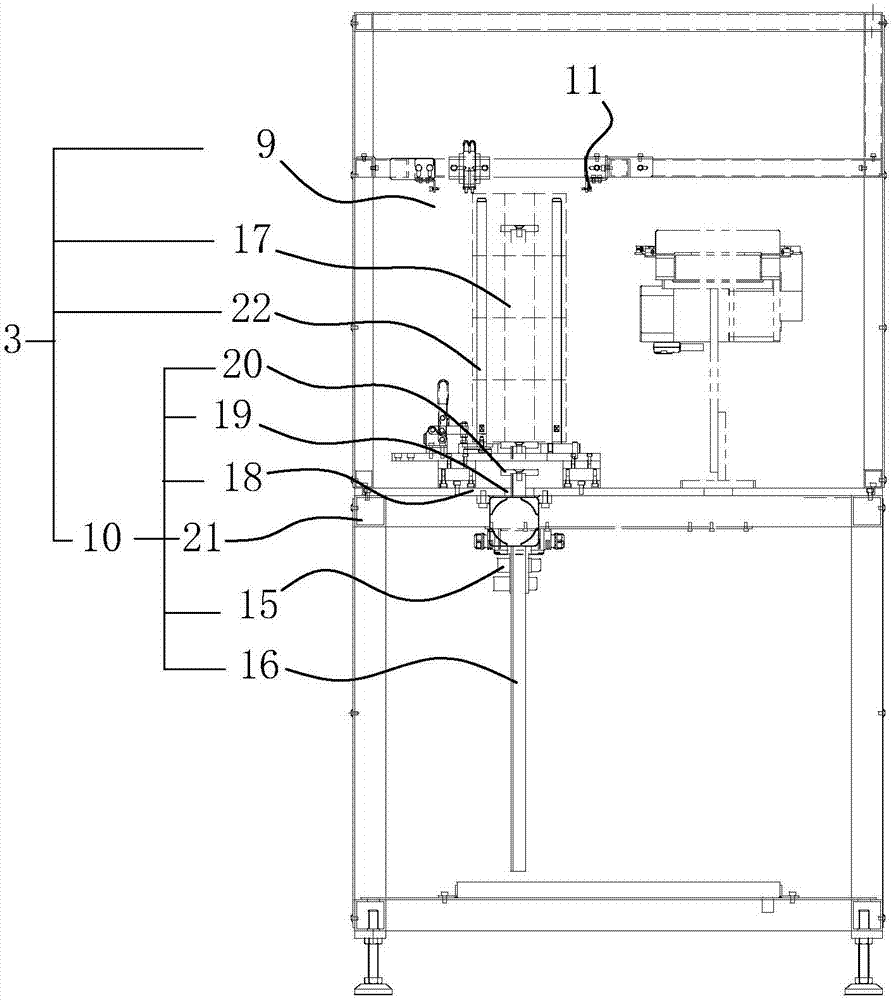

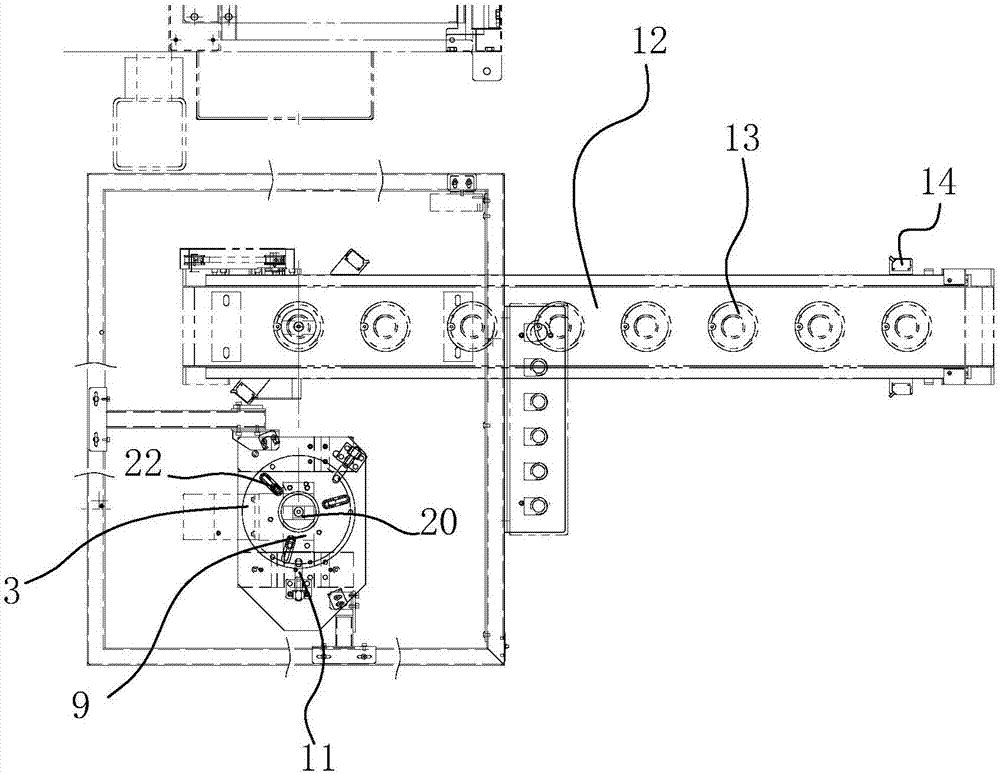

[0032] A kind of CNC lathe automatic feeding system, such as figure 1 As shown, it includes a machining center 1, where the machining center 1 is the mother machine of the CNC lathe, including the main shaft 2, which is used for cutting, grinding, milling and other operations on the workpiece, and also includes the feeding mechanism 3, which is used for To load the blanks to be processed, and then clamp the blanks through the operating mechanism 4 and run them to the main shaft 2 of the machining center 1, first remove the processed workpieces on the main shaft 2, and then place the clamped The blank is installed on the main shaft 2, and the running mechanism 4 clamps the completed workpiece and moves it to the blanking mechanism 5. After the workpiece is placed on the blanking mechanism 5, the workpiece is transported out by the blanking mechanism 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com