Filling material sucking and unloading crown block for graphite refining

A technology of filler and graphite, which is applied in the direction of load pulley, solid separation, filter screen, etc., can solve the problem of large dust when discharging from the discharge pipe, and achieve the effect of convenient operation, enhanced strength and guaranteed feeding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

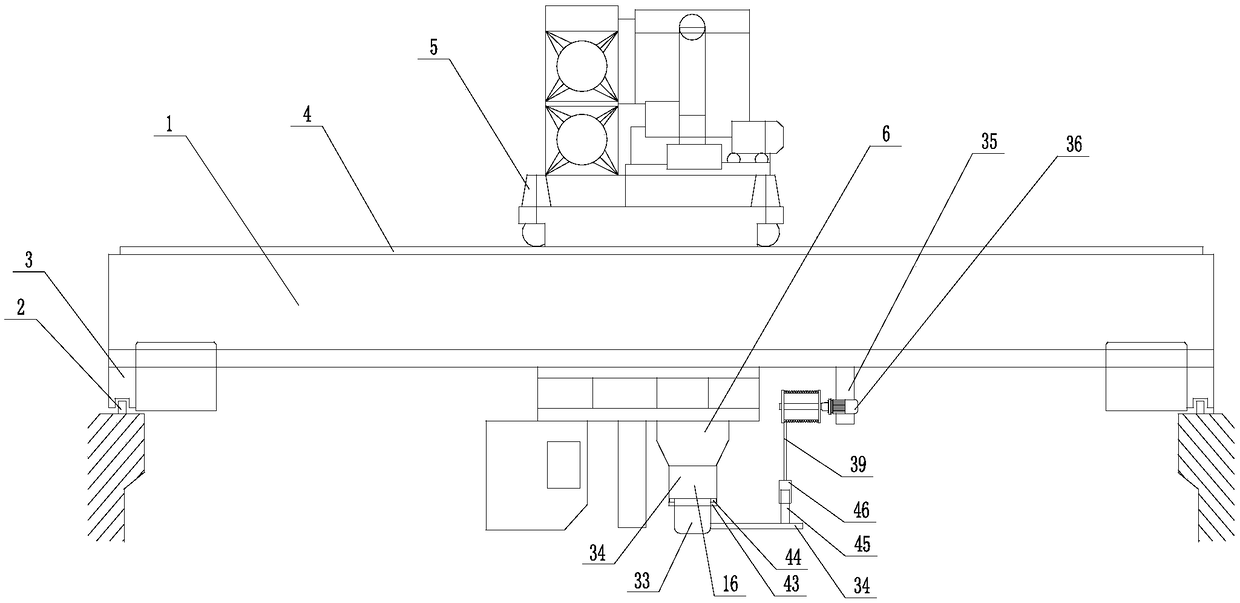

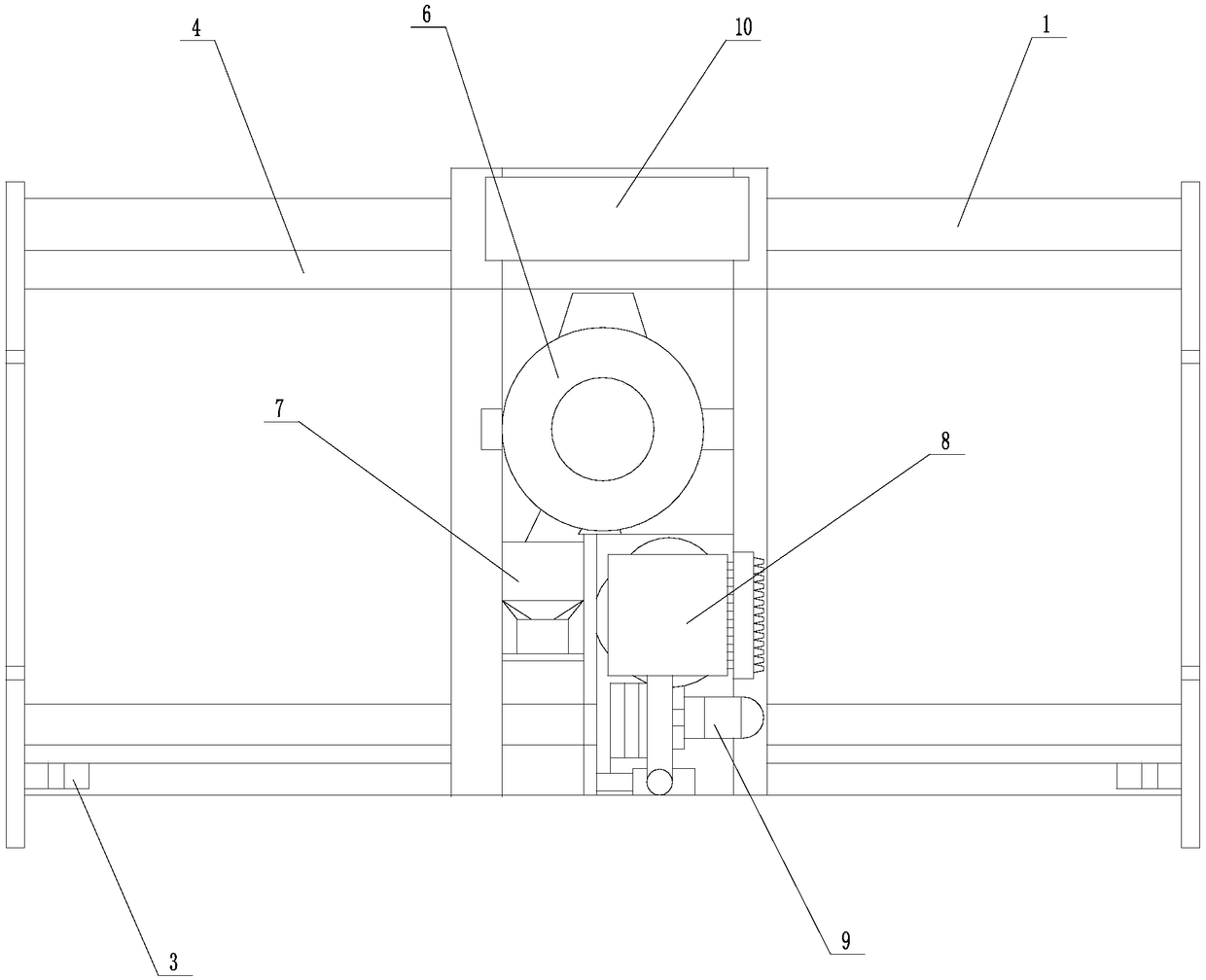

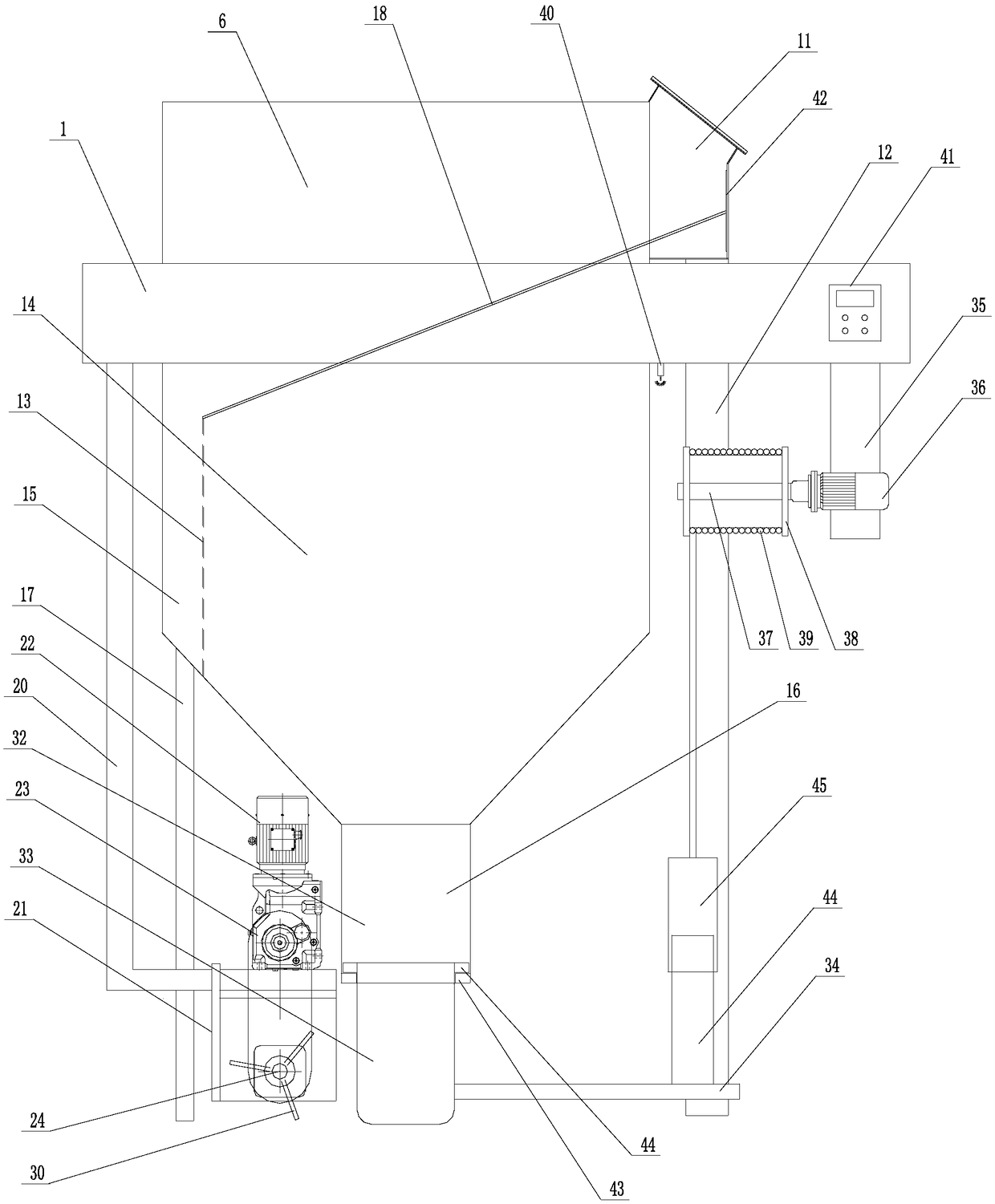

[0026] Such as figure 1 , figure 2 As shown, the present invention provides a filling material suction and unloading crane for graphite refining, including a bridge frame 1, a cart running track 2, a cart running mechanism 3, a trolley running track 4, a trolley running mechanism 5, a material The warehouse 6, the cooler 7, the dust collector 8, the negative pressure fan 9, and the electric control system 10 are all conventional settings in the prior art, and will not be described too much here. The lower end of the silo 6 is conical, which can prevent the filling material from adhering to the inner wall of the silo 6 and reduce the generation of a large amount of dust when the filling material falls. The side of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com