Patents

Literature

173 results about "Vibratory fluidized bed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vibratory Fluidized Bed (VFB) is a type of fluidized bed where the mechanical vibration enhances the performance of fluidization process. Since the first discovery of vibratory fluidized bed, its vibration properties proves to be more efficient in dealing with fine particles which appears to be very difficult to achieve with normal fluidized bed. Even though numerous publications and its popularity in industrial applications, the knowledge about vibratory dynamics and properties are very limited. Future research and development are needed to further improve this technology to bring it to another level.

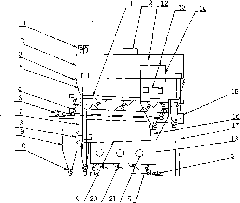

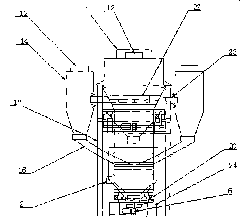

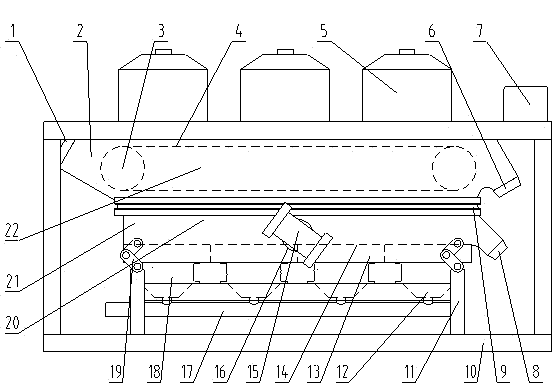

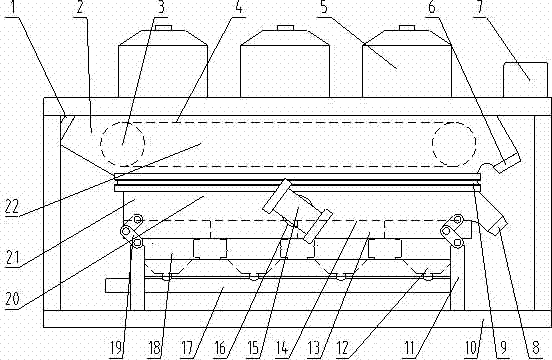

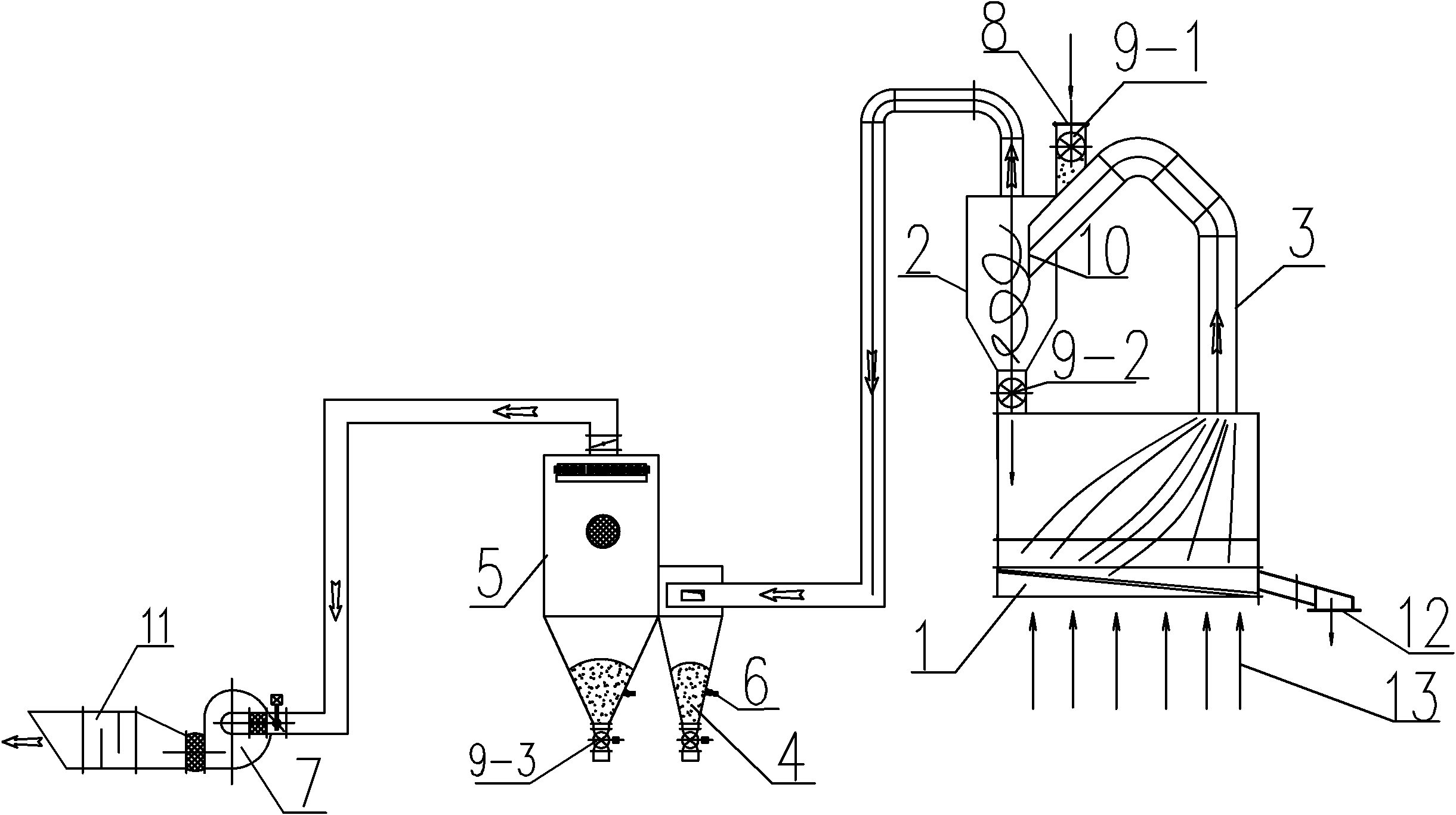

Continuous vibro fluidized bed roaster using flue gas

InactiveUS20040187709A1Reduction in human drudgeryClean and hygienic endGrain huskingGrain polishingCombustion chamberSolenoid valve

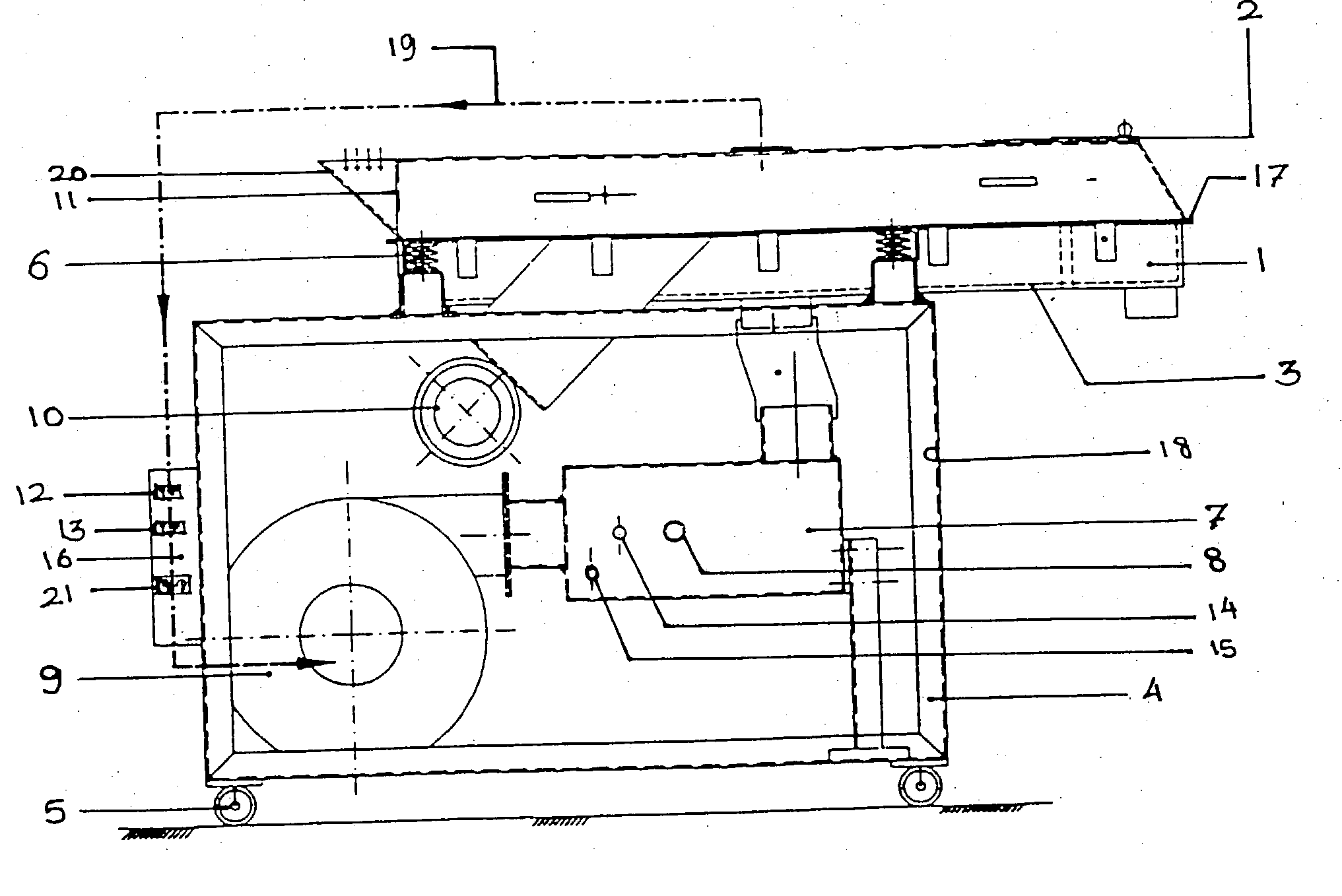

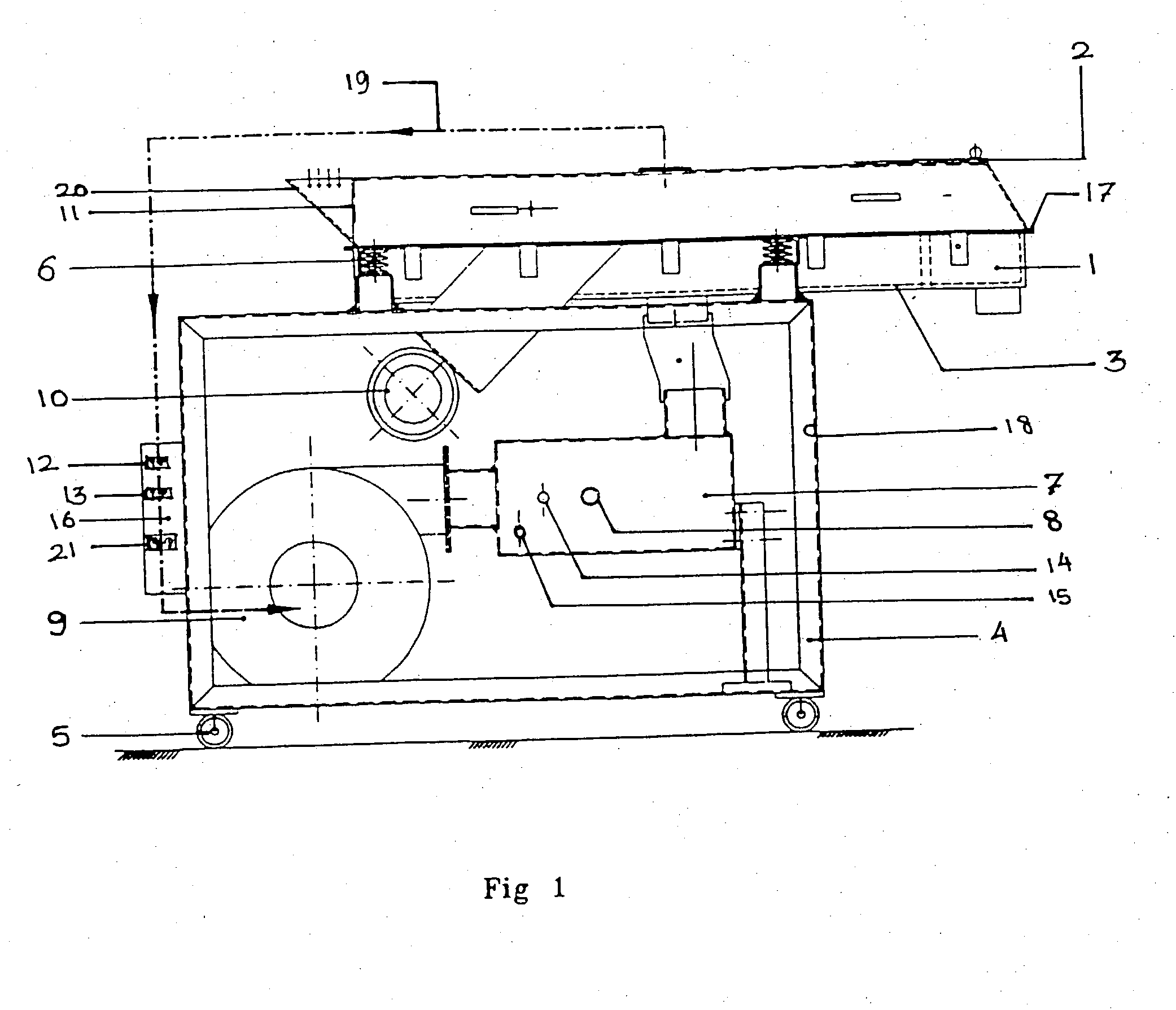

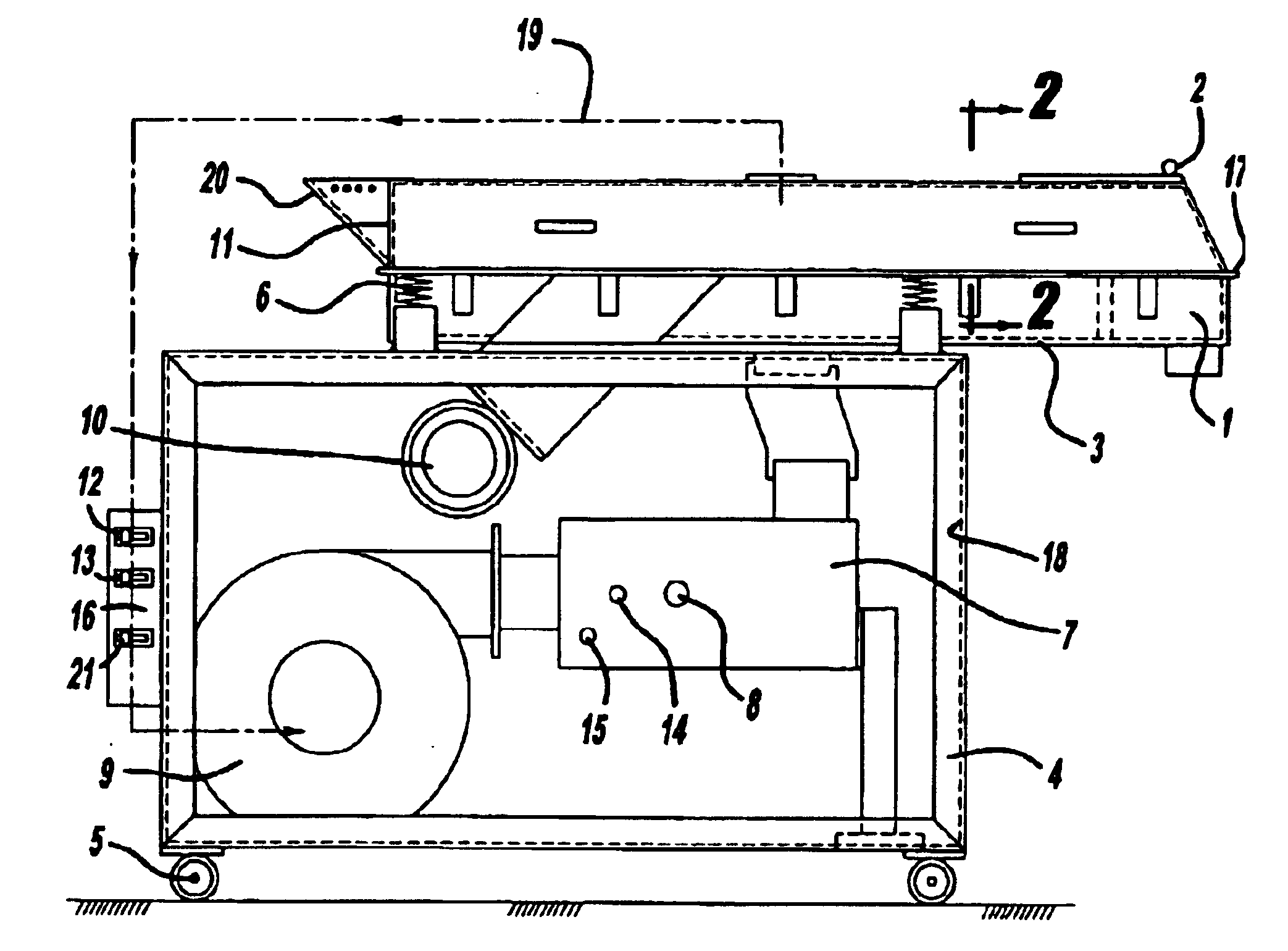

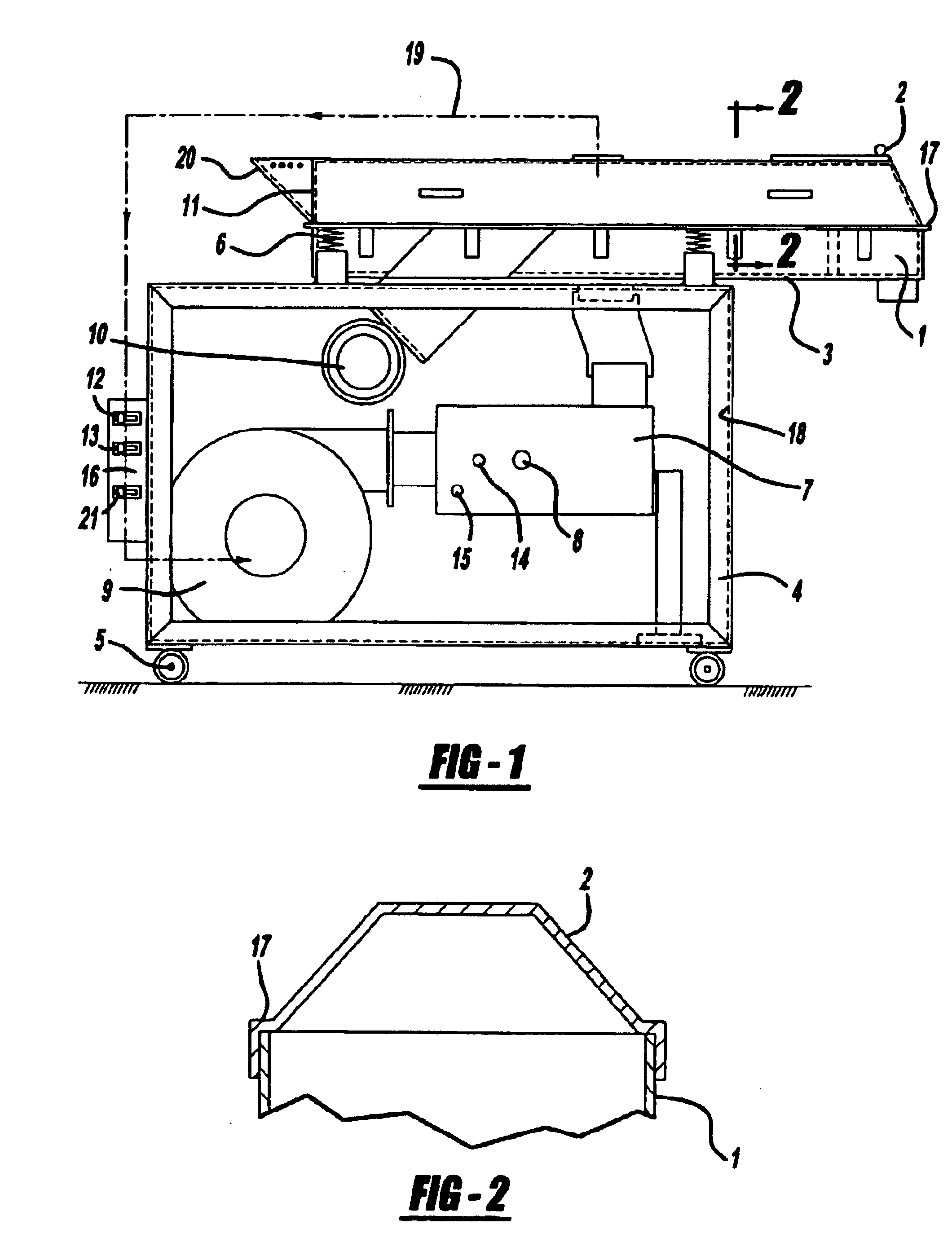

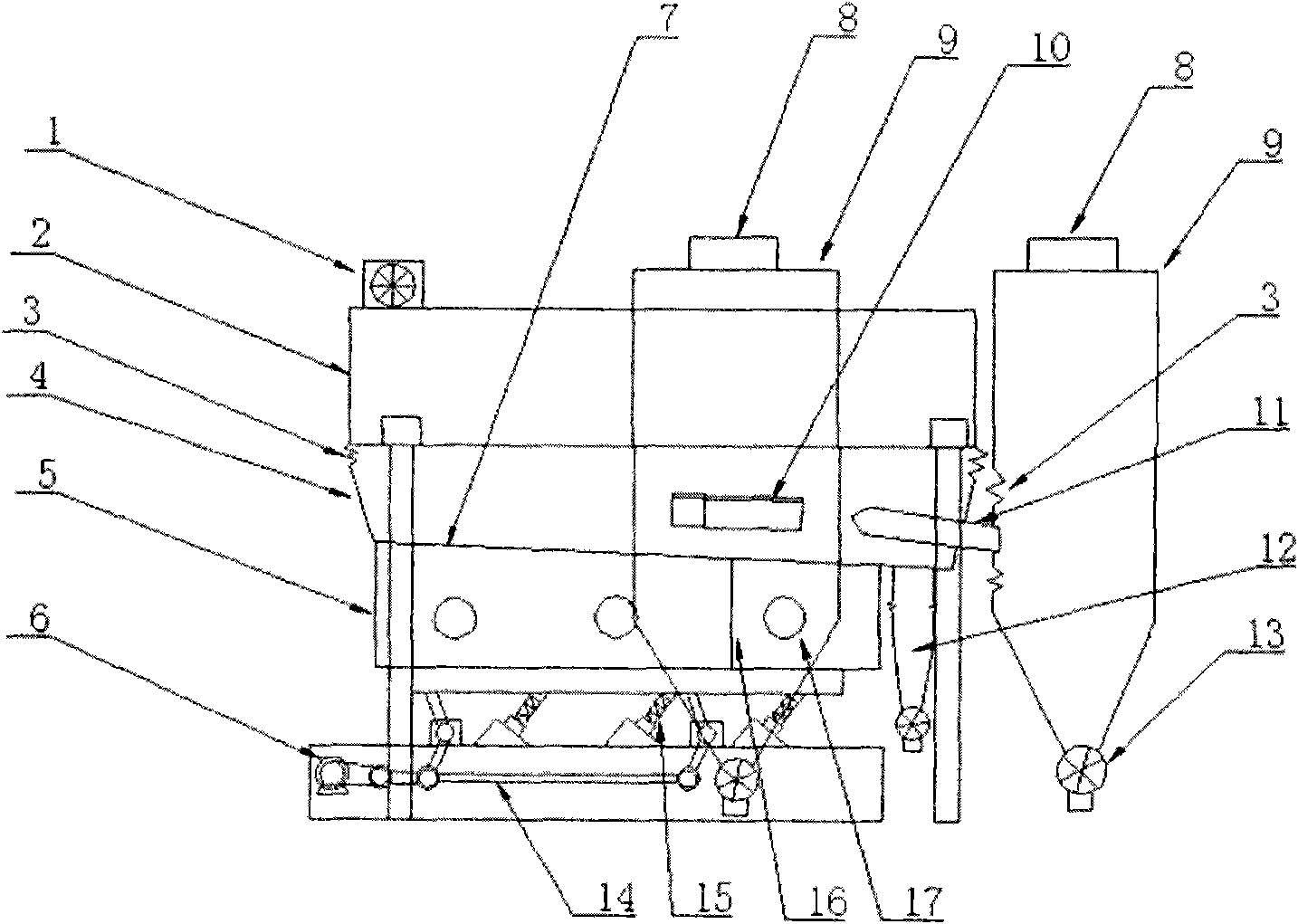

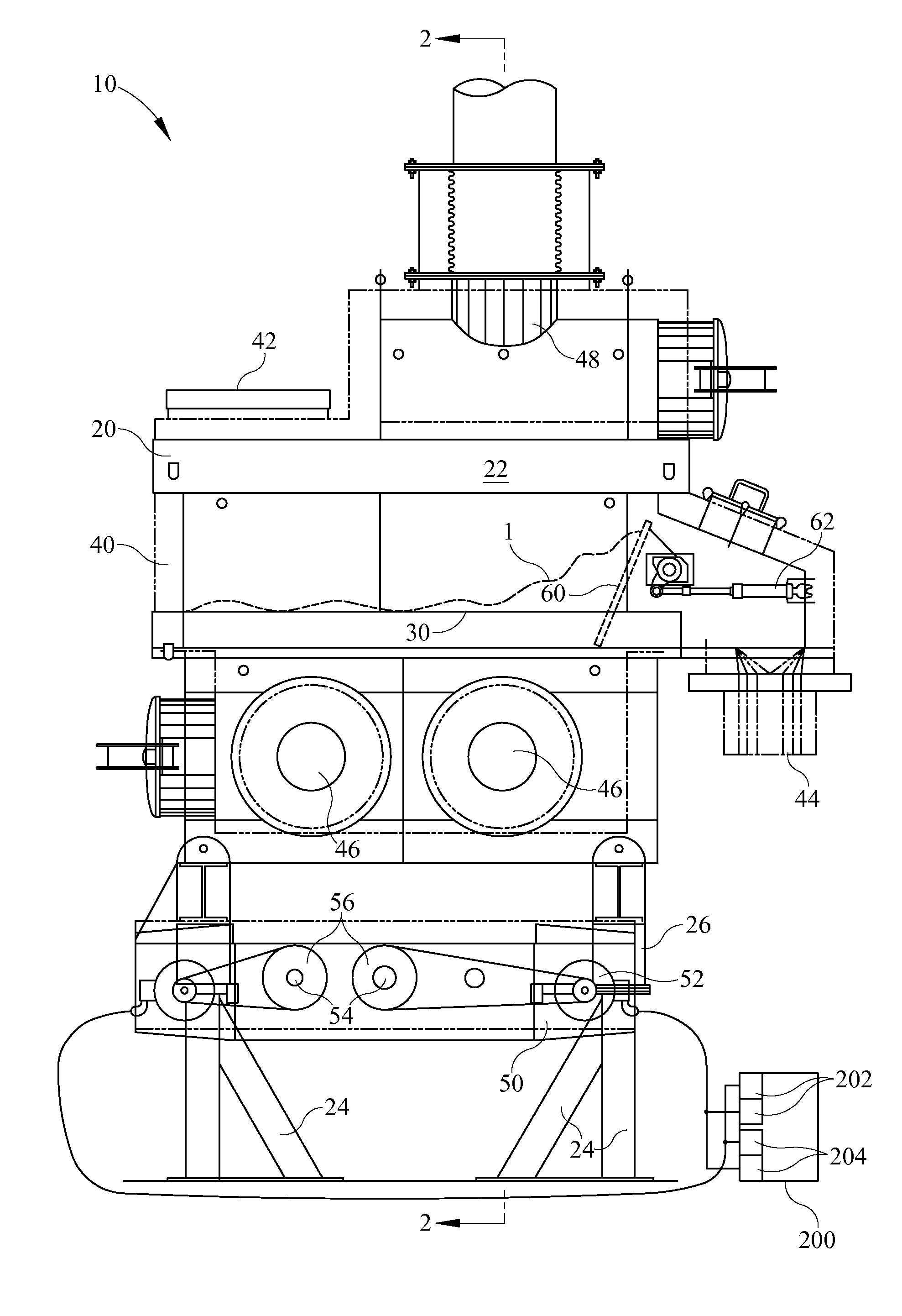

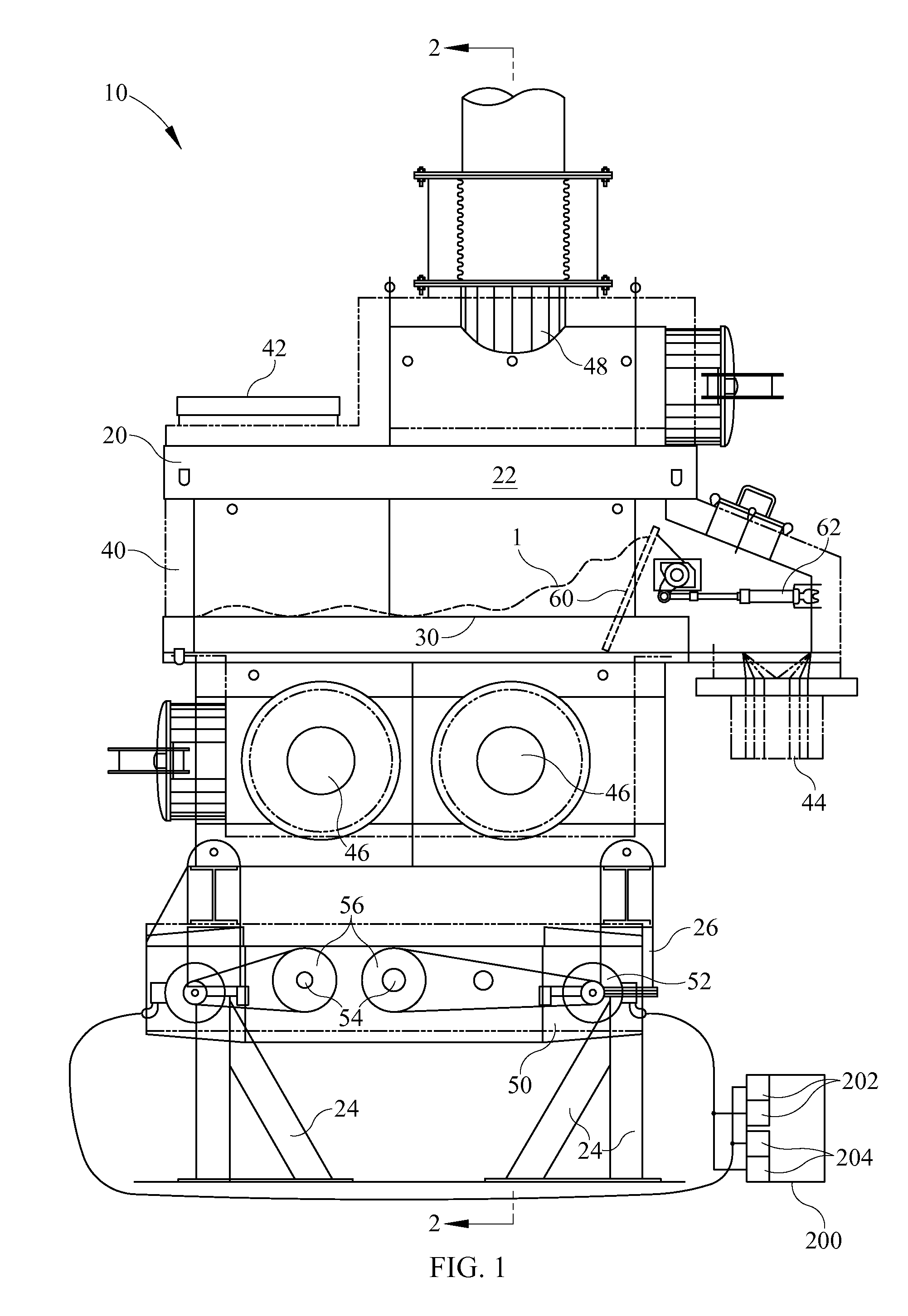

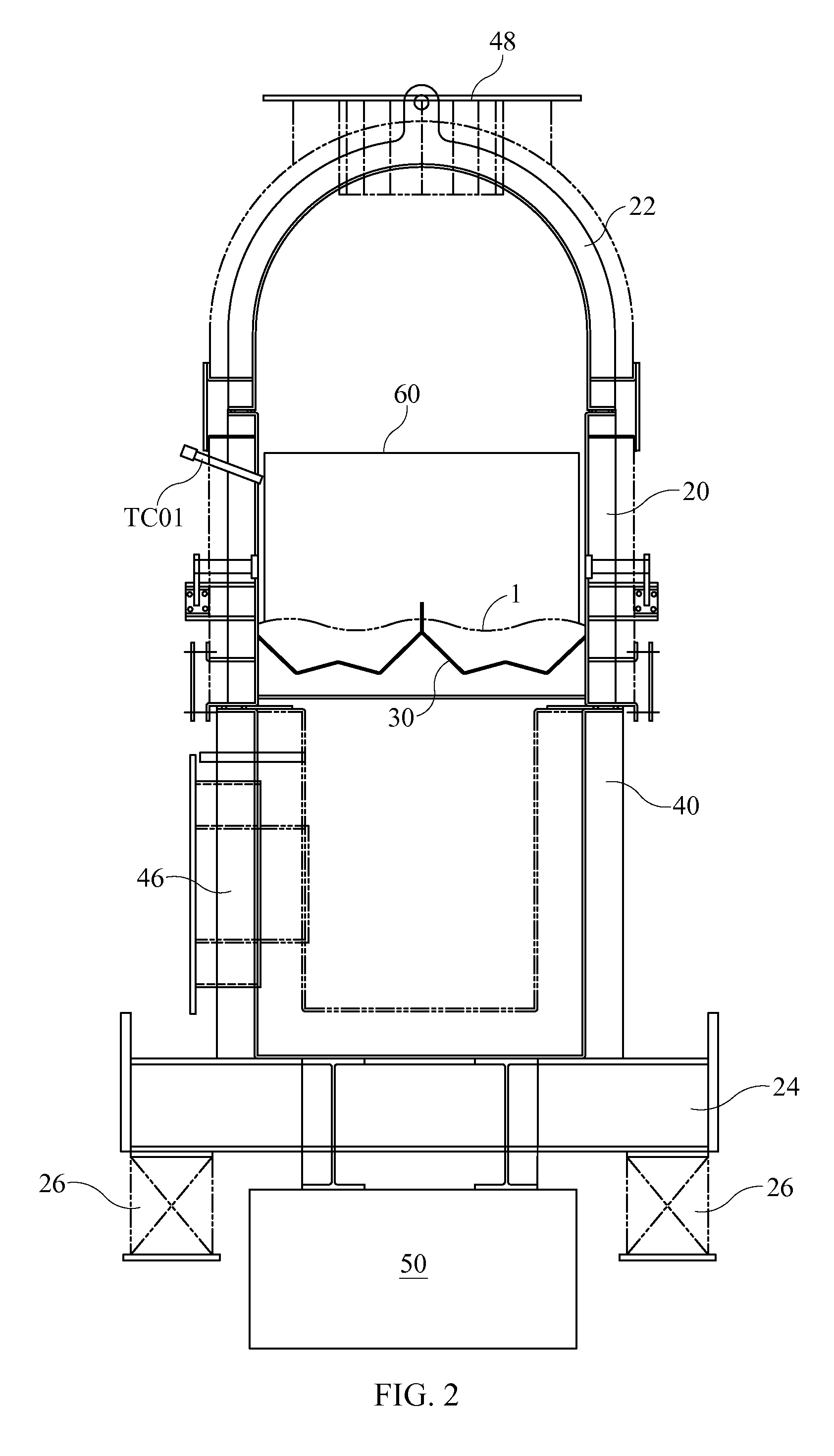

A continuous vibro fluidized bed roaster for roasting cereals, pulses, spices, oil seeds and ready-to-eat snack foods using flue gas, said roaster comprises of a main frame (4) which houses all the parts of the machine, the vibrating deck (1) is mounted on a set of coil springs (6) which is mounted on the main frame through screw fasteners, a perforated sieve (3) and a hood (2) are mounted on the vibrating deck (1) with rubber gasket (17) for sealing the hot air from leakage, a vibratory motor (10) is mounted on the feed end of the vibratory deck for imparting vibrations to the feed material, a vibratory feeder (11) is mounted on the feed side of the vibratory deck (1) for feeding the raw material in to the roaster through a hopper (20). A LPG burner (8) is fastened to the combustion chamber (7) using fasteners, a solenoid valve (14) mounted on the main frame (4) for regulating the LPG supply to the burner and also to close the LPG supply incase of electrical power failure with a signal for flame failure from the photo sensor (15), a blower (9) generates the air needed for the reducing the flue temperature is mounted at the end of the on the vibratory feeder (11) on to the main frame (4), a return duct (19) connects the hood (2) and the suction end of the blower (9), a temperature indicator is (21) is used for measuring the inlet temperature of the hot air admitted in to the roaster, an electrical panel (16) is mounted at the end of the main frame for housing all the required electrical controls and variable speed drive (13) for varying the residence time of travel of the raw material, a rheostat (12) for varying the feed rate of the raw material fed in to the vibrating deck, the roaster is covered by a set of covers (18) on all its sides, the complete machine is mounted on a set of castor wheels (5) for easy movement of the roaster to the required place, the materials of construction of the roaster are preferably of stainless steel but this shall not restrict the use of other materials as well.

Owner:COUNCIL OF SCI & IND RES

Vibration fluidization drying system

InactiveCN101354212ARealize the purpose of fluidized dryingEfficient screeningDrying solid materials with heatHearth type furnacesVibratory fluidized bedProcess engineering

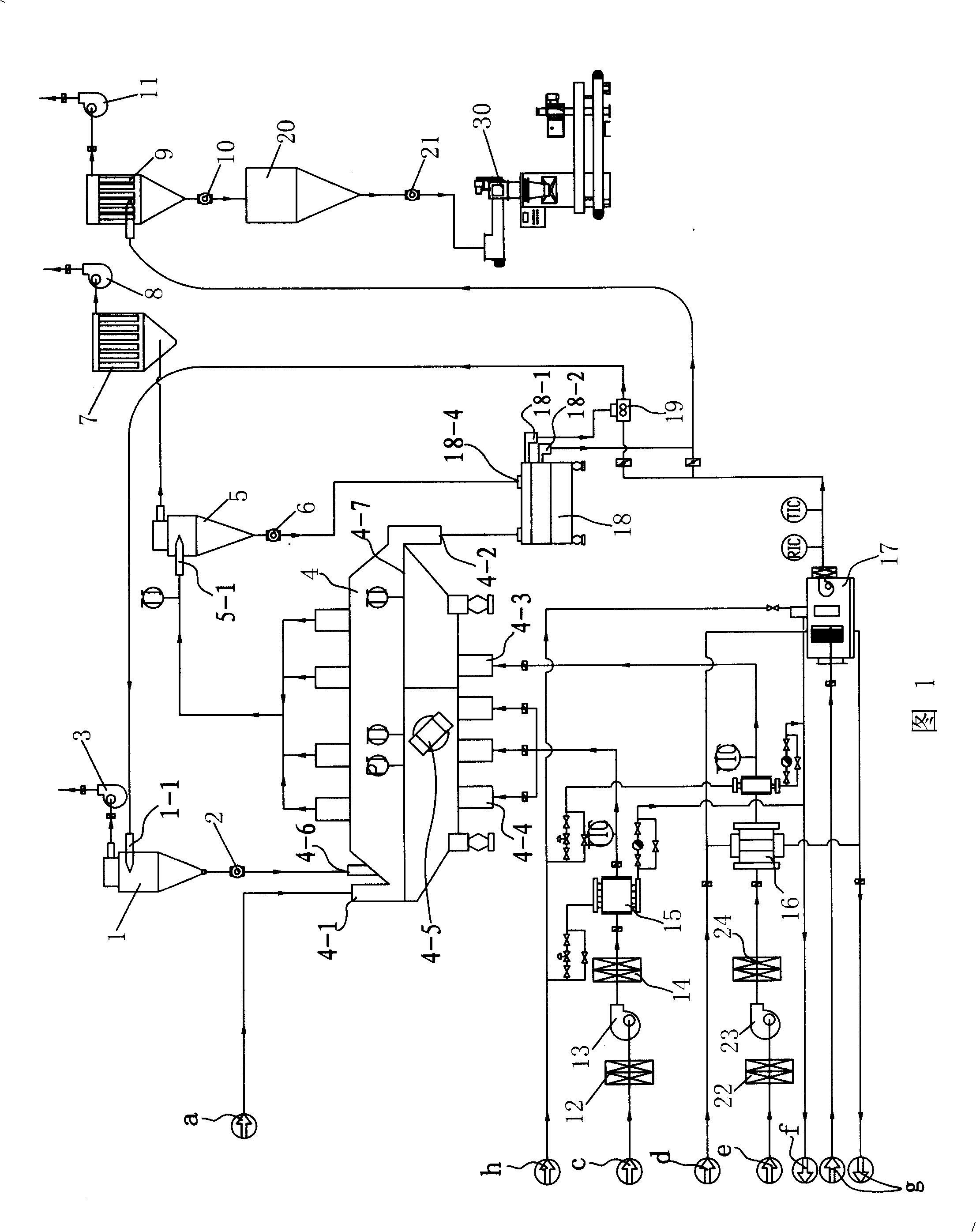

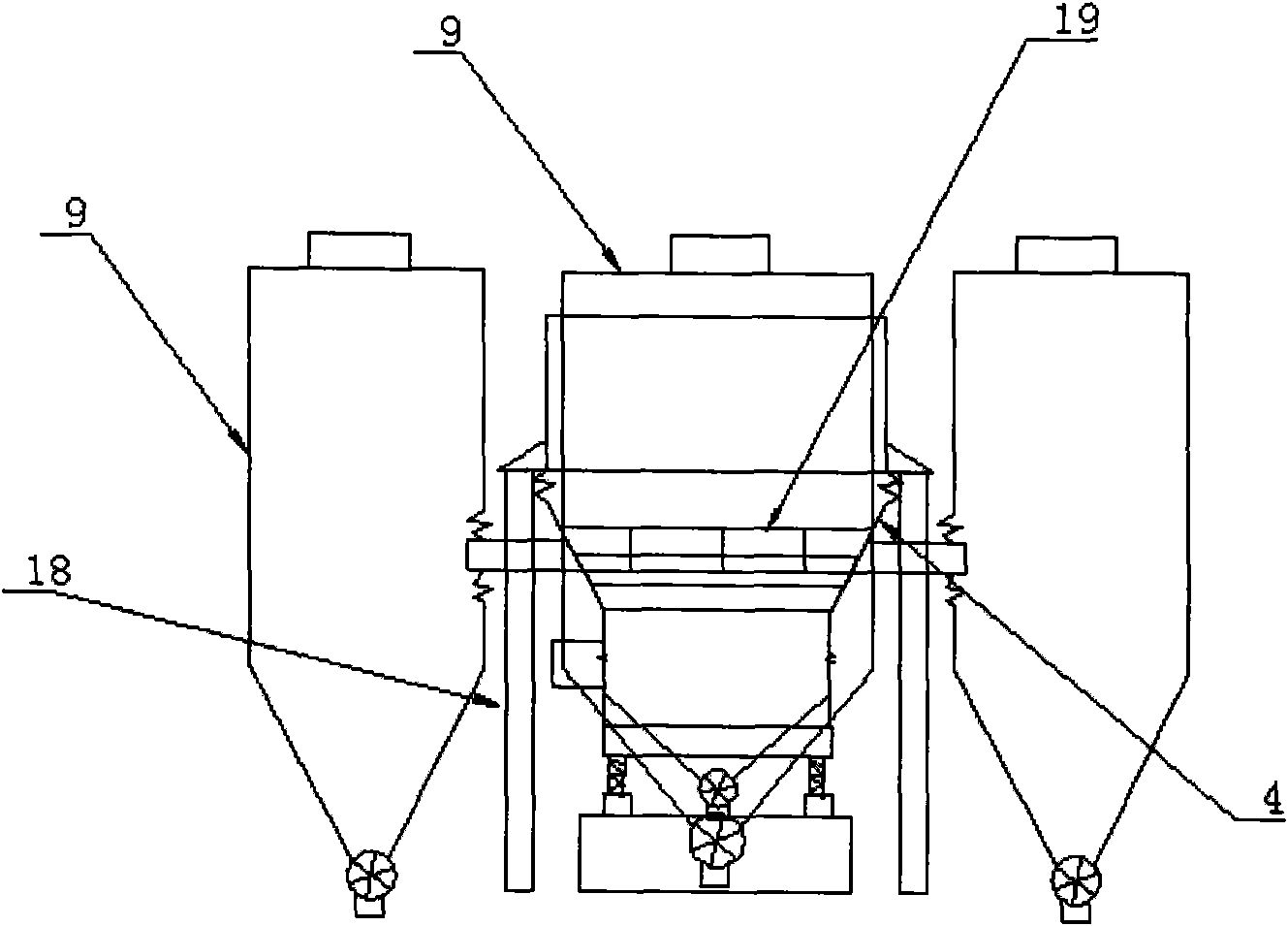

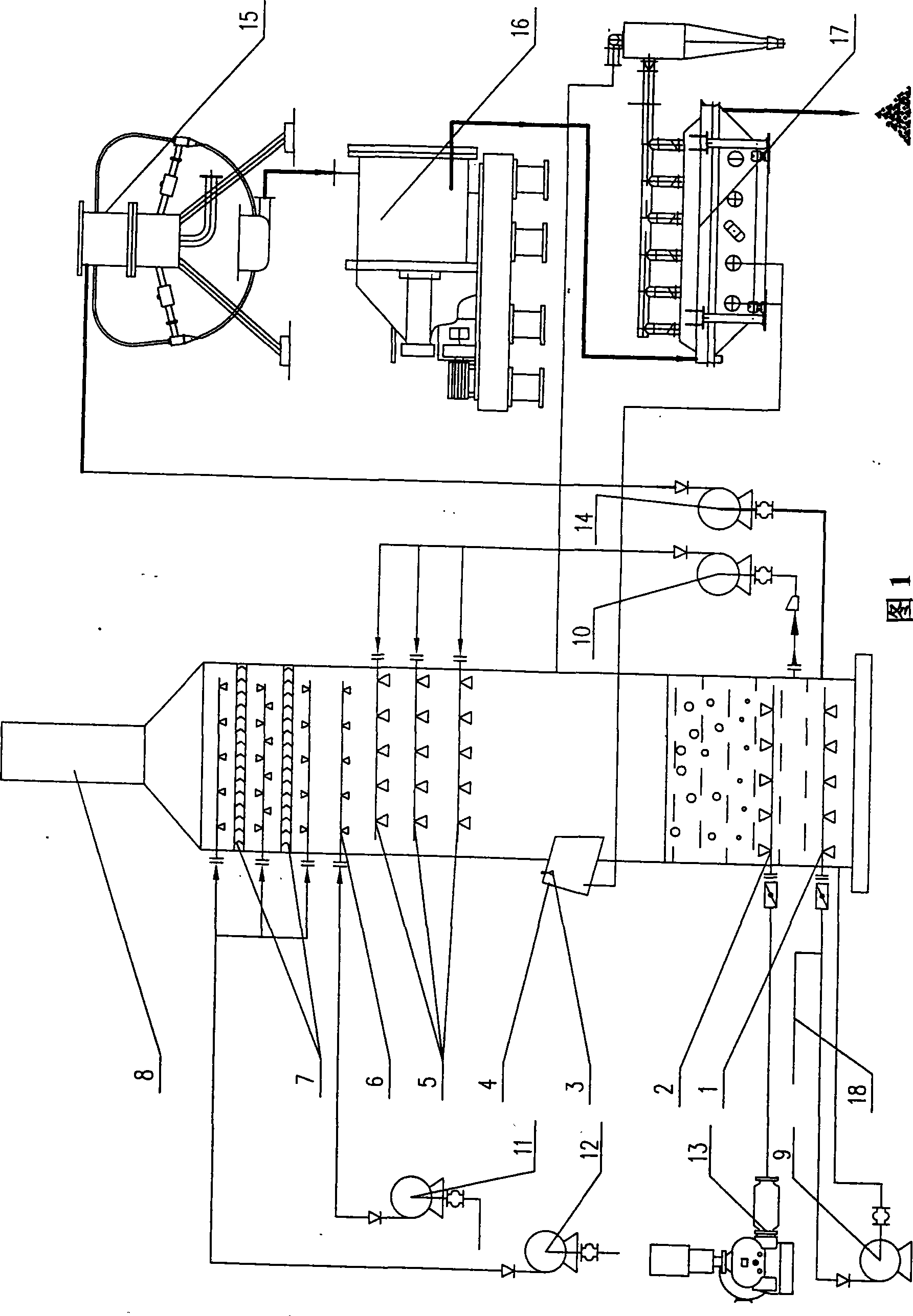

The invention relates to a vibrating-fluidized drying system, aiming at carrying out fluidized drying to wet alcohol raw materials. The vibrating-fluidized drying system comprises a vibrating-fluidized bed, a vibrating screen, a monolith crusher, a first gas-solid separator and a first gas valve; the vibrating screen connected with a discharge opening of the vibrating-fluidized bed comprises: a big grain-diameter outlet and a small grain-diameter outlet; the big grain-diameter outlet is connected with an intake opening of the first gas-solid separator by the monolith crusher, and a discharge opening of the first gas-solid separator is connected with an intake opening of the vibrating-fluidized bed. A big grain-diameter material dried and output by the vibrating-fluidized bed is effectively screened and crushed by the vibrating screen and the monolith crusher in sequence, then the big grain-diameter material is crushed to be small grain-diameter and delivered by the first gas-solid separator and the first gas valve to the vibrating-fluidized bed for being continuously dried and finally output from the small grain-diameter outlet of the vibrating screen, thereby realizing the purpose of carrying out vibrating-fluidized drying to the wet alcohol raw materials liable to form bigger blocks.

Owner:JIANGSU XIANFENG DRYING ENG

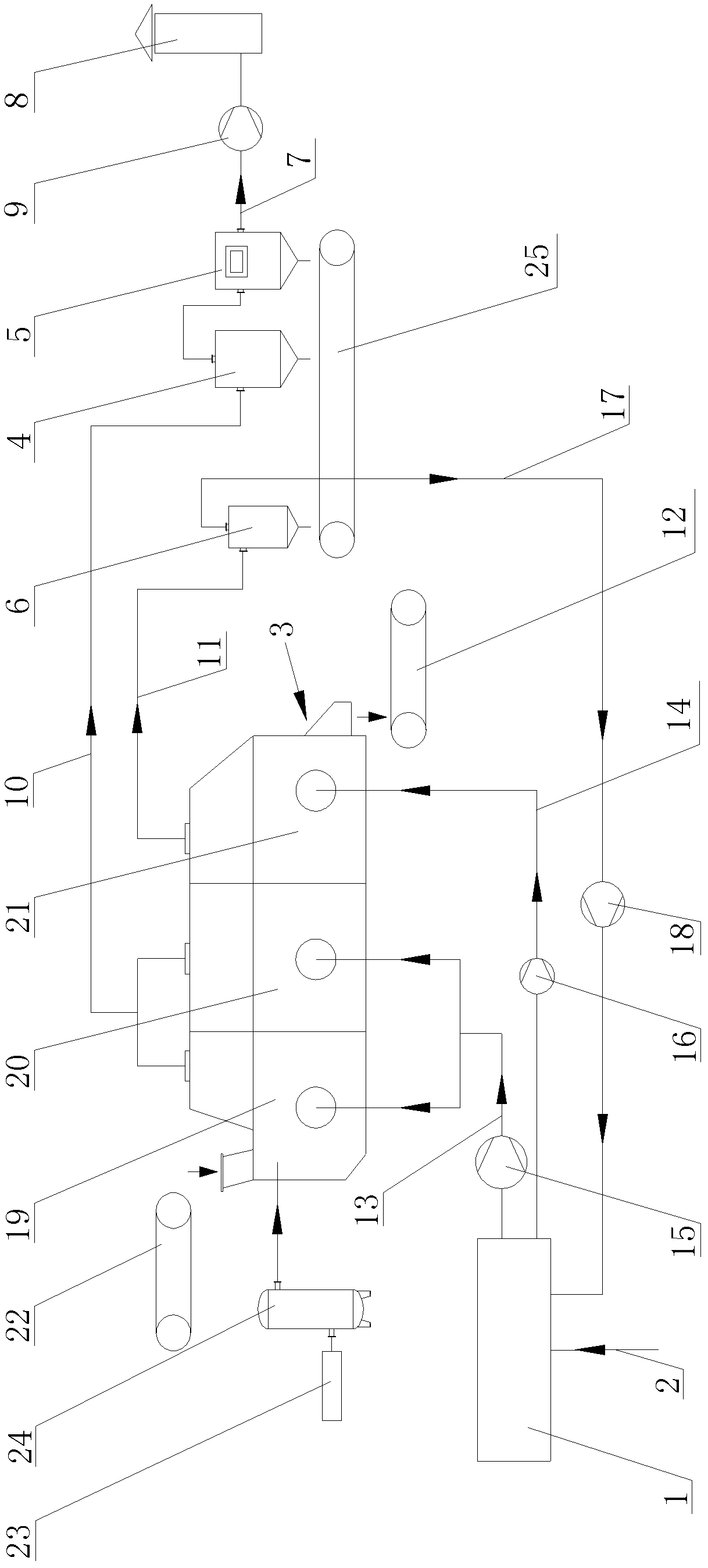

Method and device for drying and quality enhancement of lignite

InactiveCN101776370AImprove qualityIncrease useDrying solid materials with heatDrying machine combinationsLow oxygenCoal

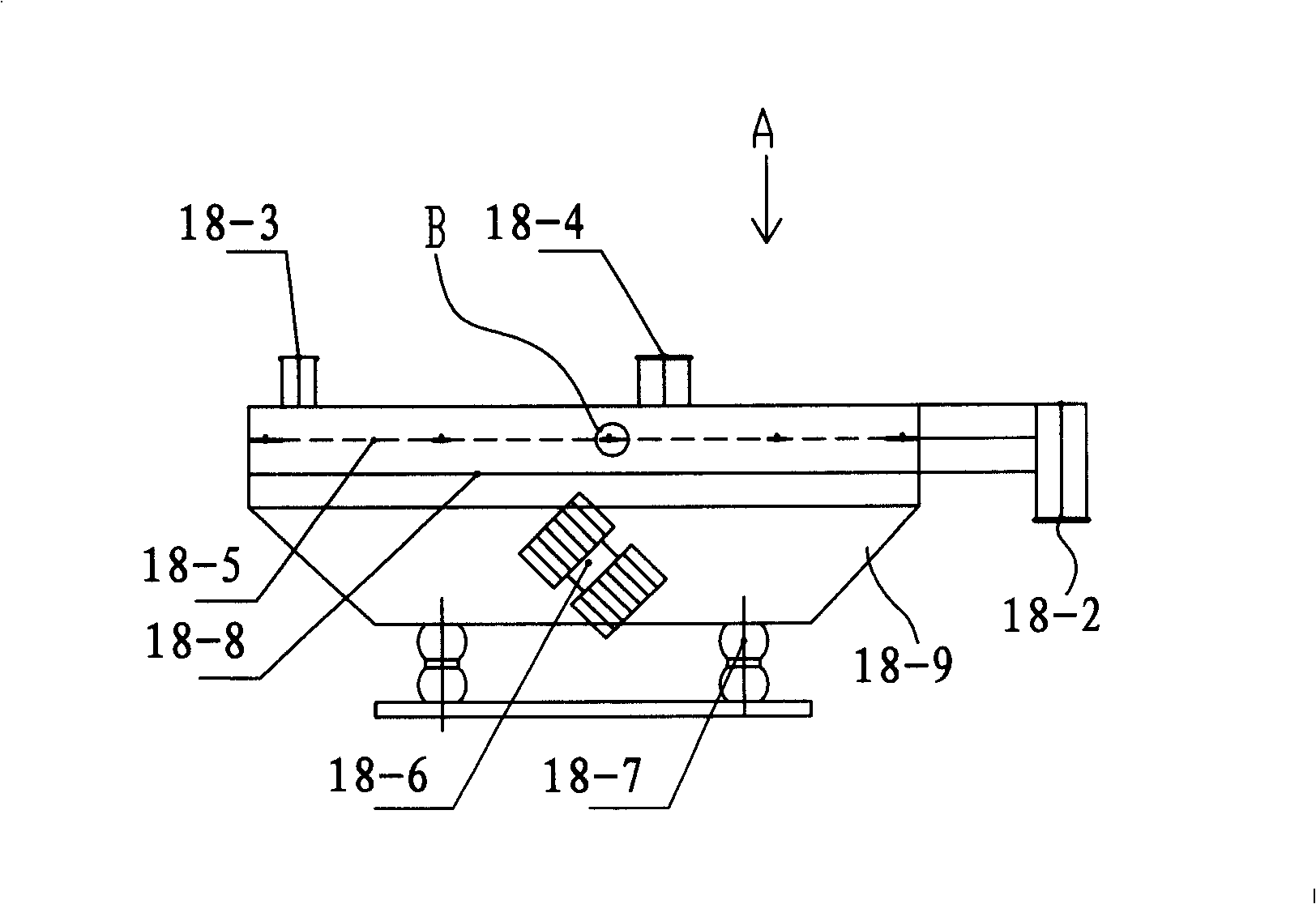

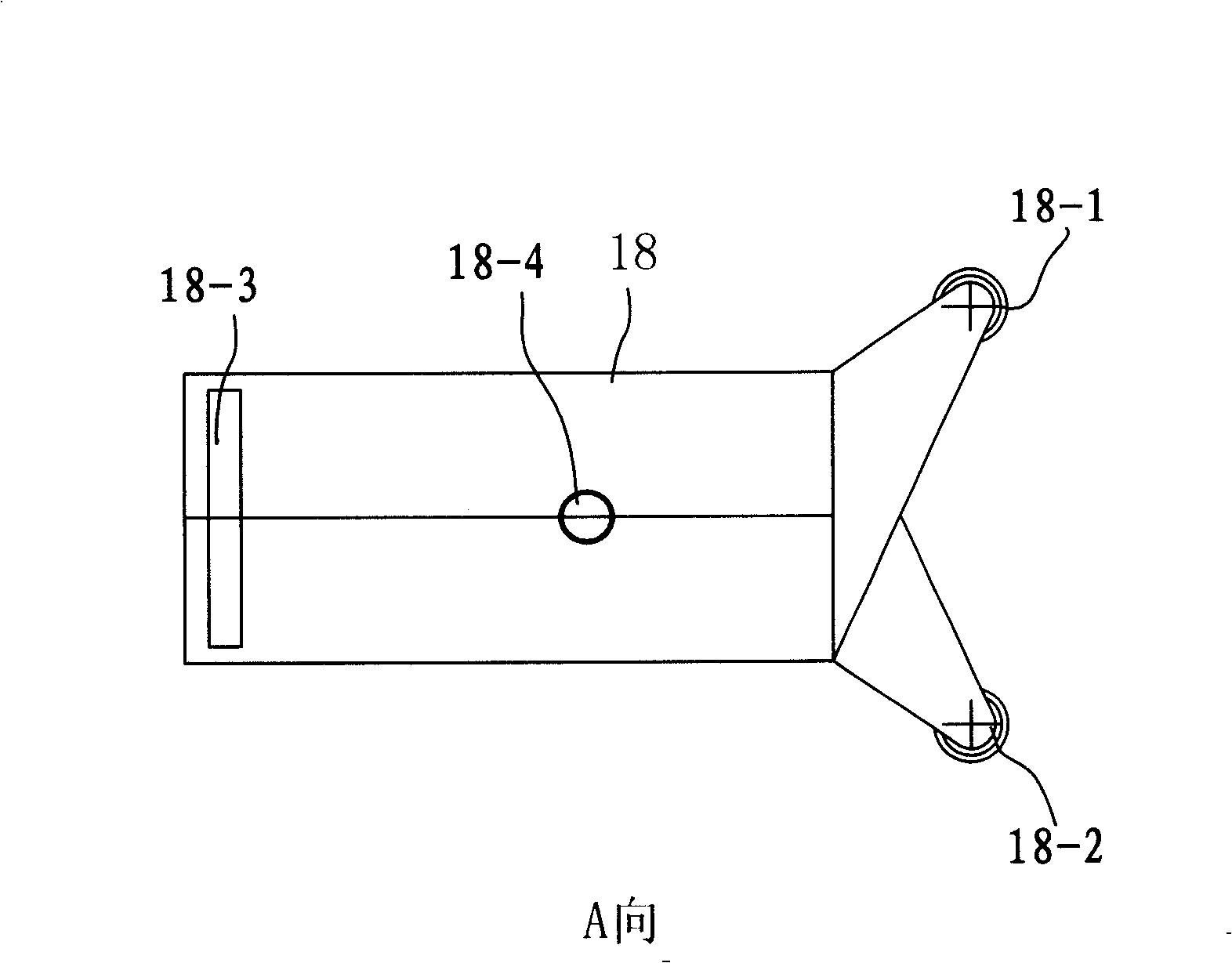

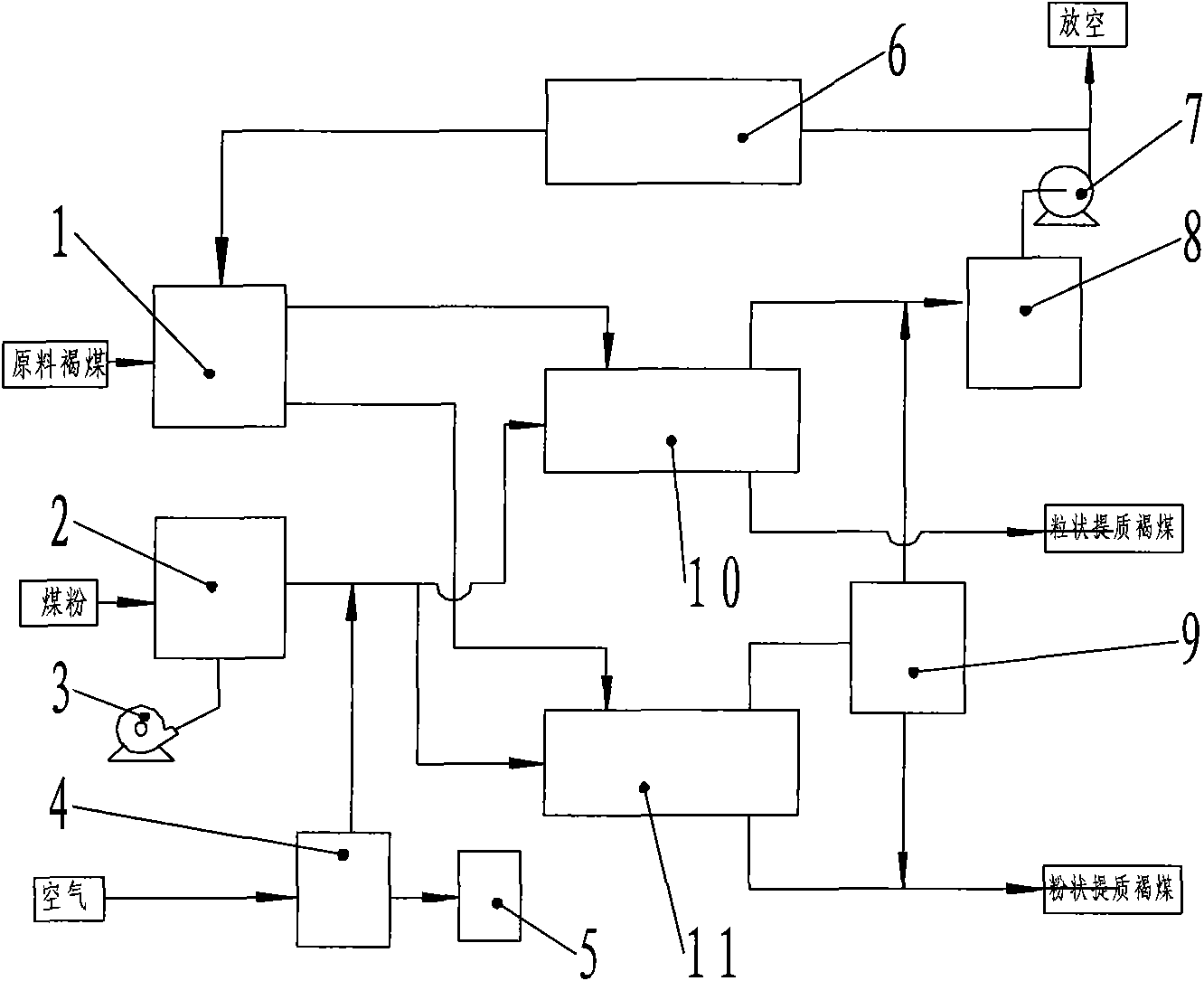

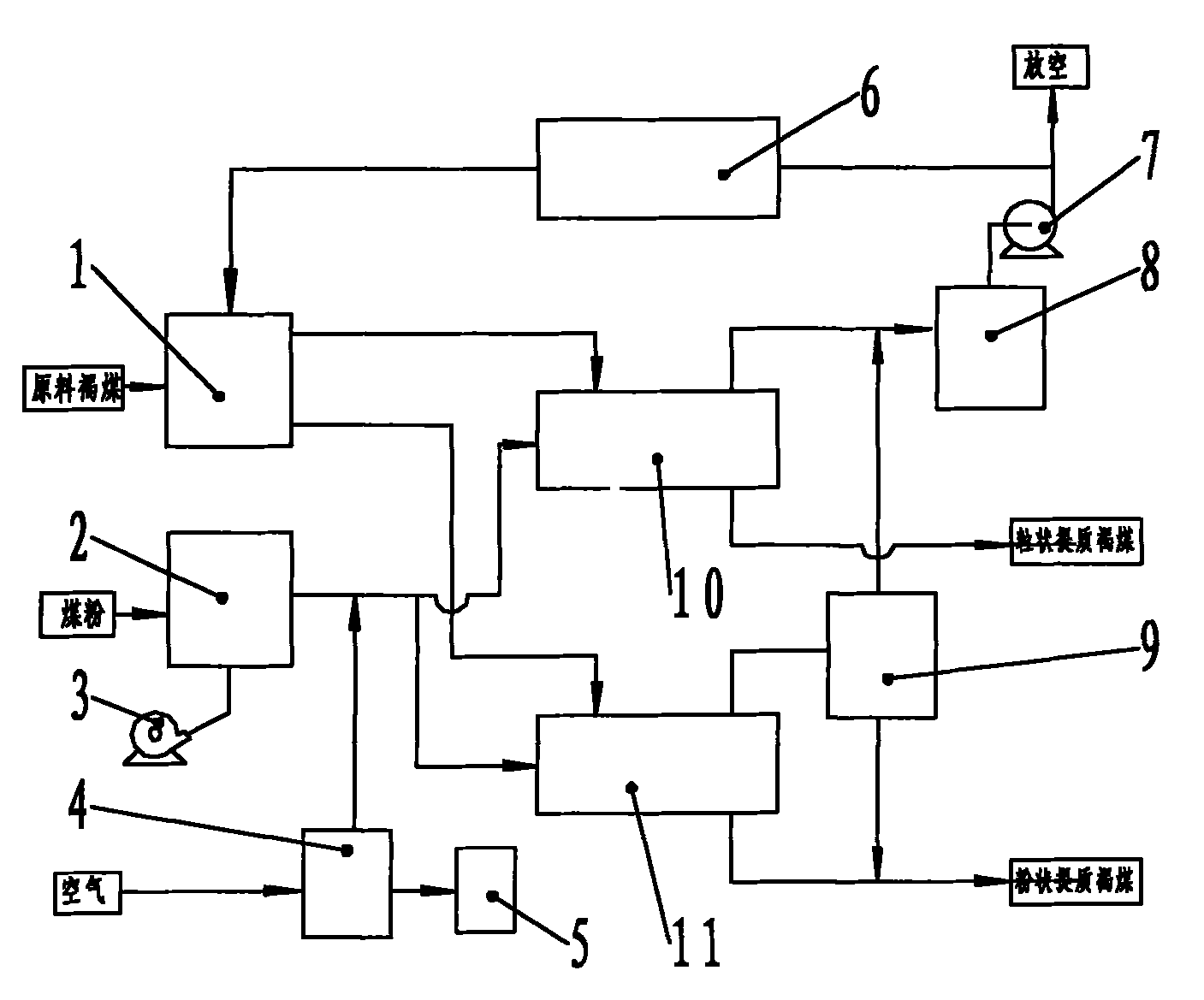

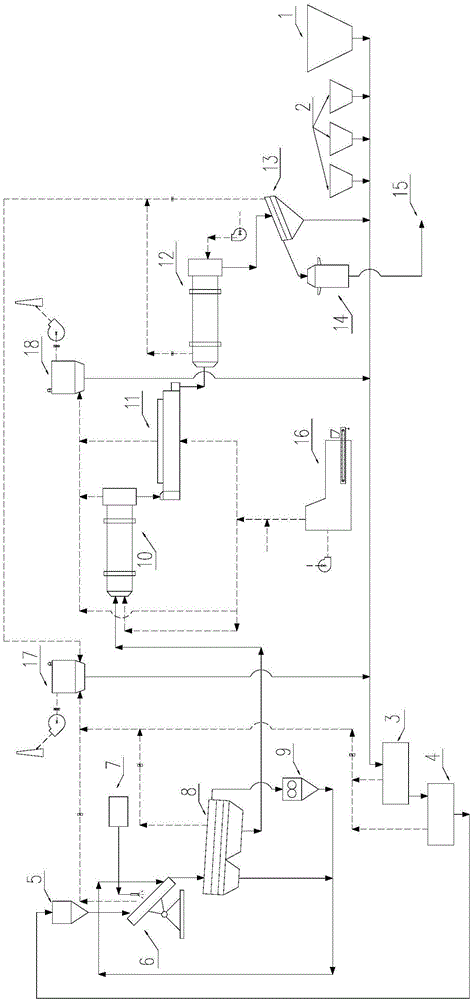

The invention provides a method and a device for the drying and the quality enhancement of lignite. The device comprises a drying / sieving device, a preheating and drying / sieving device, a hot blast heater, a drying drum, a vibration fluidized bed, a cyclone separator, a defogger and a dust remover. The hot blast heater is respectively connected to the drying drum and the vibration fluidized bed, and an outlet of the preheating and drying / sieving device is respectively connected with the drying drum and the vibration fluidized bed. The preheating and drying / sieving device divides the lignite into two stages of big particle diameter and small particle diameter, high-temperature flue gas generated by the hot blast heater is used as a heating medium, the temperature of the flue gas is regulated by the residual low-oxygen gas after oxygen gas is separated by using an air separation system, the drying drum and the vibration fluidized bed are used for producing the quality-enhanced lignite with the big particle diameter and the small particle diameter, different production requirements are met, and part of exhausted tail gas is circularly used for preheating the raw materials of the lignite after being defogged. The invention respectively carries out drying and quality enhancement on the lignite according to the sizes of the particle diameters by grading equipment, eliminates the problem of uneven drying caused by different particle diameters, realizes the effective quality enhancement and the comprehensive utilization of coal resources, and is used for the large-scale process of drying and quality enhancement of the lignite.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Application of complex-mode vibration-fluidized beds to the separation of granular materials of different density

InactiveUS6907996B1Reduce churnMinimizing decrepitationWet separationParticulatesVolumetric Mass Density

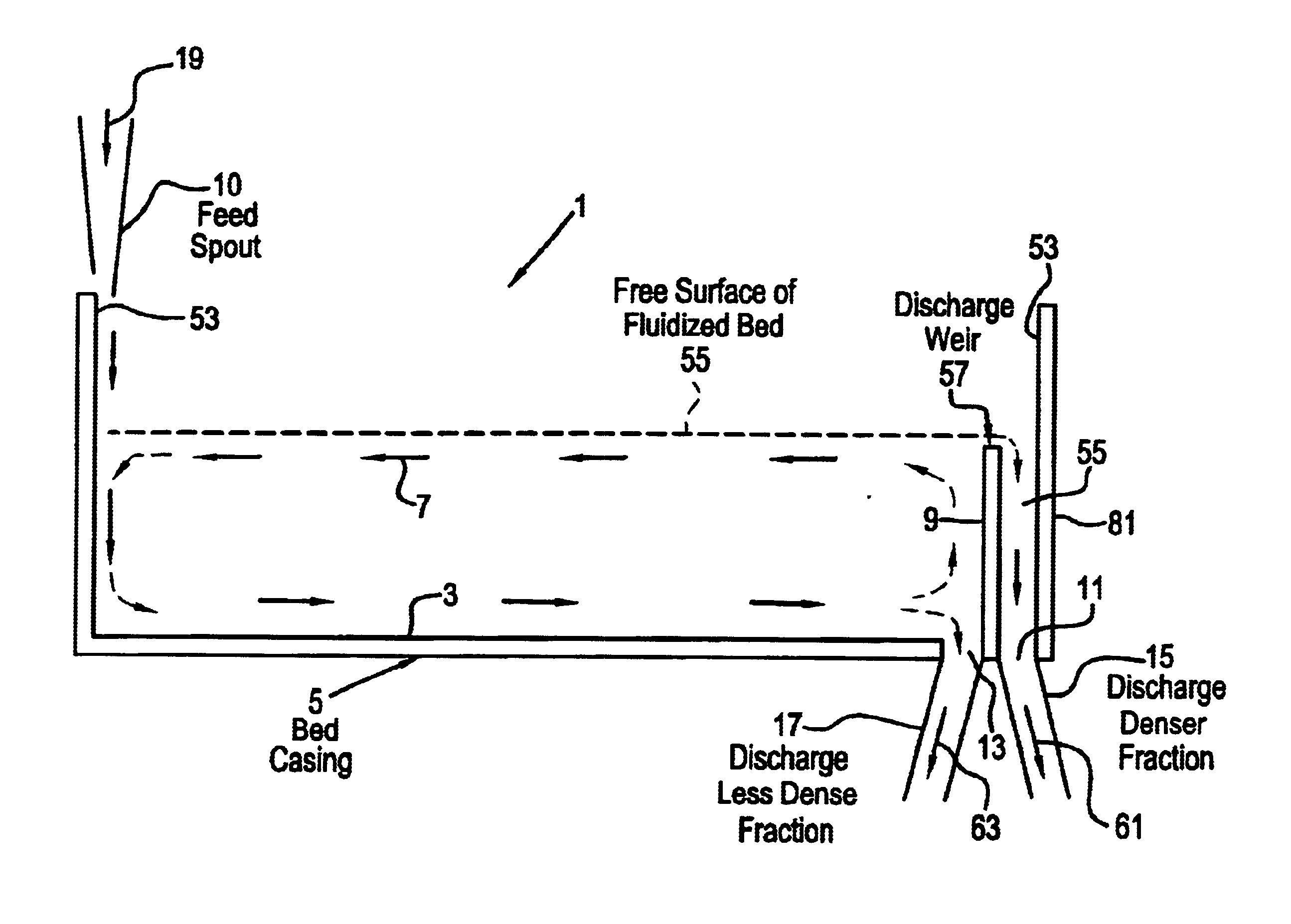

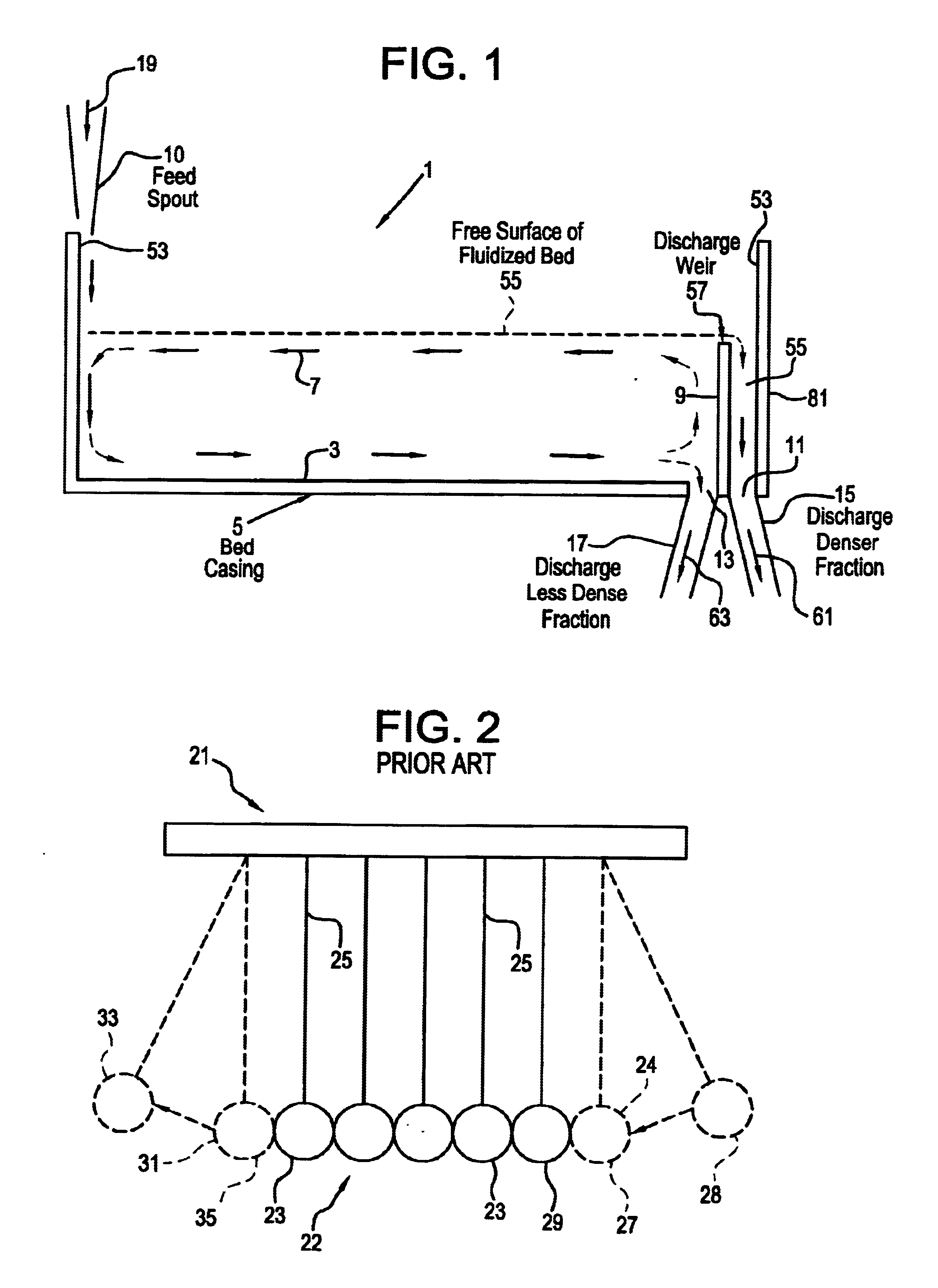

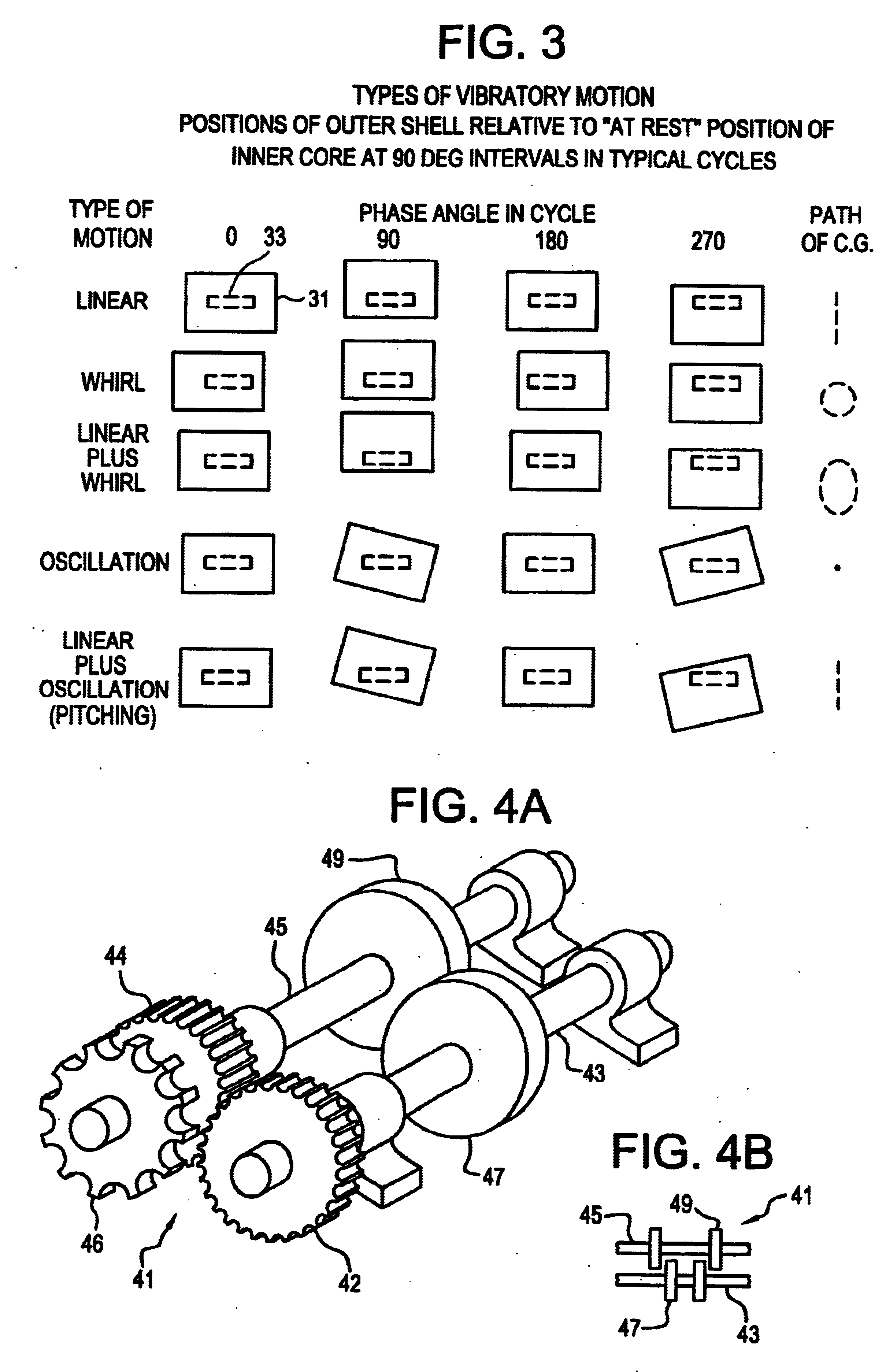

Opposite ends of a dry vibration-fluidized separator are moved with complex vibrations, including linear, whirl, linear plus whirl, oscillation, linear plus oscillation, pitch and roll. Near zero to large amplitudes up to about ±0.050 inches and low frequencies of about 30 Hz are used. Mixed particulate materials are fed into a first end and circulate across and along the separator in a shallow depth. More dense materials move linearly along a floor and are removed through an opening in a second end of the floor. The less dense materials flow over a weir at the second end of the separator.

Owner:MACLEAN MATTHEW J

Continuous vibro fluidized bed roaster using flue gas

InactiveUS6810794B2Reduction in human drudgeryClean and hygienic endGrain huskingGrain polishingFlue gasCoil spring

A continuous vibro fluidized bed roaster for roasting cereals, pulses, spices, oil seeds and ready-to-eat snack foods using flue gas, said roaster comprises of a main frame (4) which houses all the parts of the machine, the vibrating deck (1) is mounted on a set of coil springs (6) which is mounted on the main frame through screw fasteners, a perforated sieve (3) and a hood (2) are mounted on the vibrating deck (1) with rubber gasket (17) for sealing the hot air from leakage, a vibratory motor (10) is mounted on the feed end of the vibratory deck for imparting vibrations to the feed material, a vibratory feeder (11) is mounted on the feed side of the vibratory deck (1) for feeding the raw material in to the roaster through a hopper (20).

Owner:COUNCIL OF SCI & IND RES

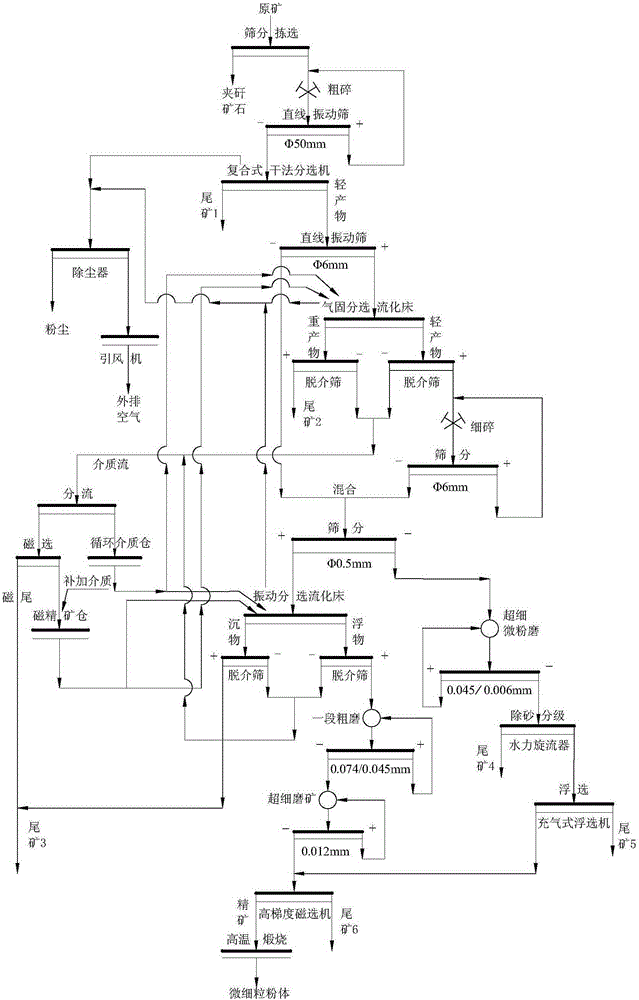

Wide-particle-size coal series kaolinite upgrading process based on fluidization sorting

The invention discloses a wide-particle-size coal series kaolinite upgrading process based on fluidization sorting, and belongs to coal series kaolinite upgrading processes. The process comprises the steps that coal series kaolinite raw ore is firstly subjected to mechanical sorting, coarse crushing, screening and drying, the raw ore of -50 mm enters a composite dry method sorting machine to be pre-sorted, and light products are screened by a vibration screen of 6 mm; the ore of 6 mm to 50 mm passes through a dense gas-solid fluidized bed sorting machine to obtain coarse-grained concentrate and tailings, the concentrate is subjected to medium removal and then finely ground to obtain ore of -6 mm, and the ore of -6 mm and the original ore of -6 mm are evenly mixed and screened by a classifying screen of 0.5 mm; the ore of 0.5 mm to 6 mm passes through a vibrated fluidized bed sorting machine to obtain fine-grained concentrate and tailings; the ore of -0. 5 mm is subjected to ore grinding, sand removal and classification and then passes through a flotation machine to obtain flotation concentrate and tailings; the concentrate of 0.5 mm to 6 mm is ground after being subjected to medium removal, and is mixed with the flotation concentrate, and then titanium and iron-containing high-magnetic mineral is removed through magnetic separation. Medium solids are separated through a medium removal screen and are subjected to dry type magnetic separation and recycled as circulating media. According to the process, efficient sorting of the wide-particle-size coal series kaolinite raw ore is achieved, and great significance for development and utilization of coal series kaolinite resources in our country is achieved.

Owner:CHINA UNIV OF MINING & TECH

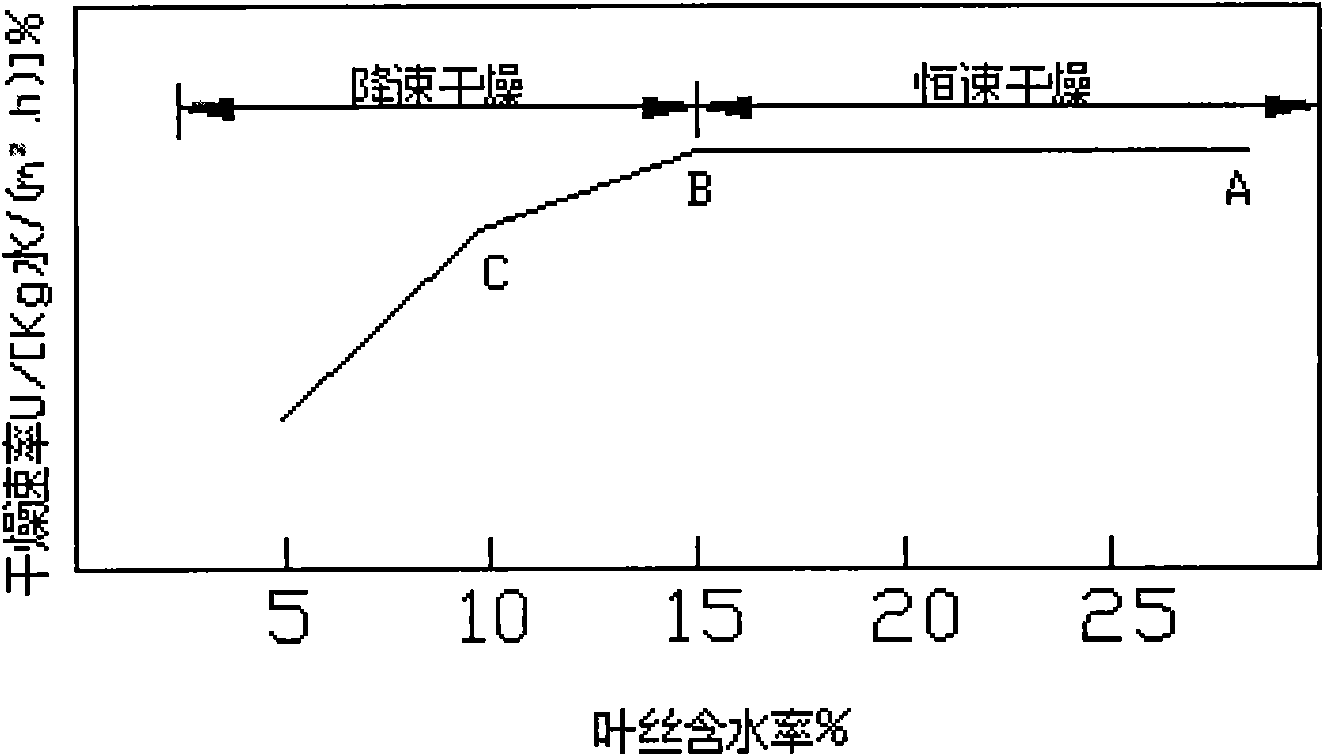

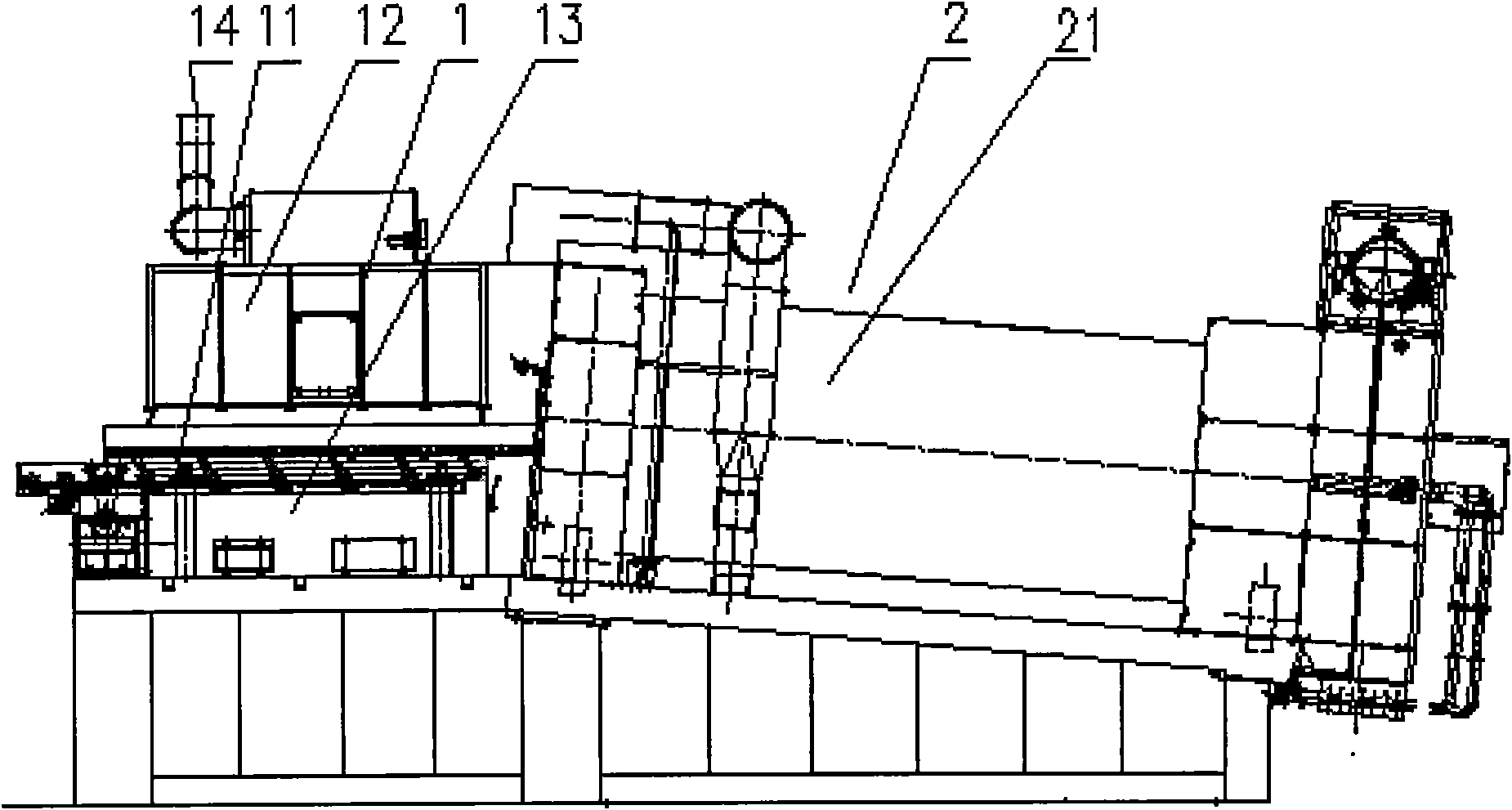

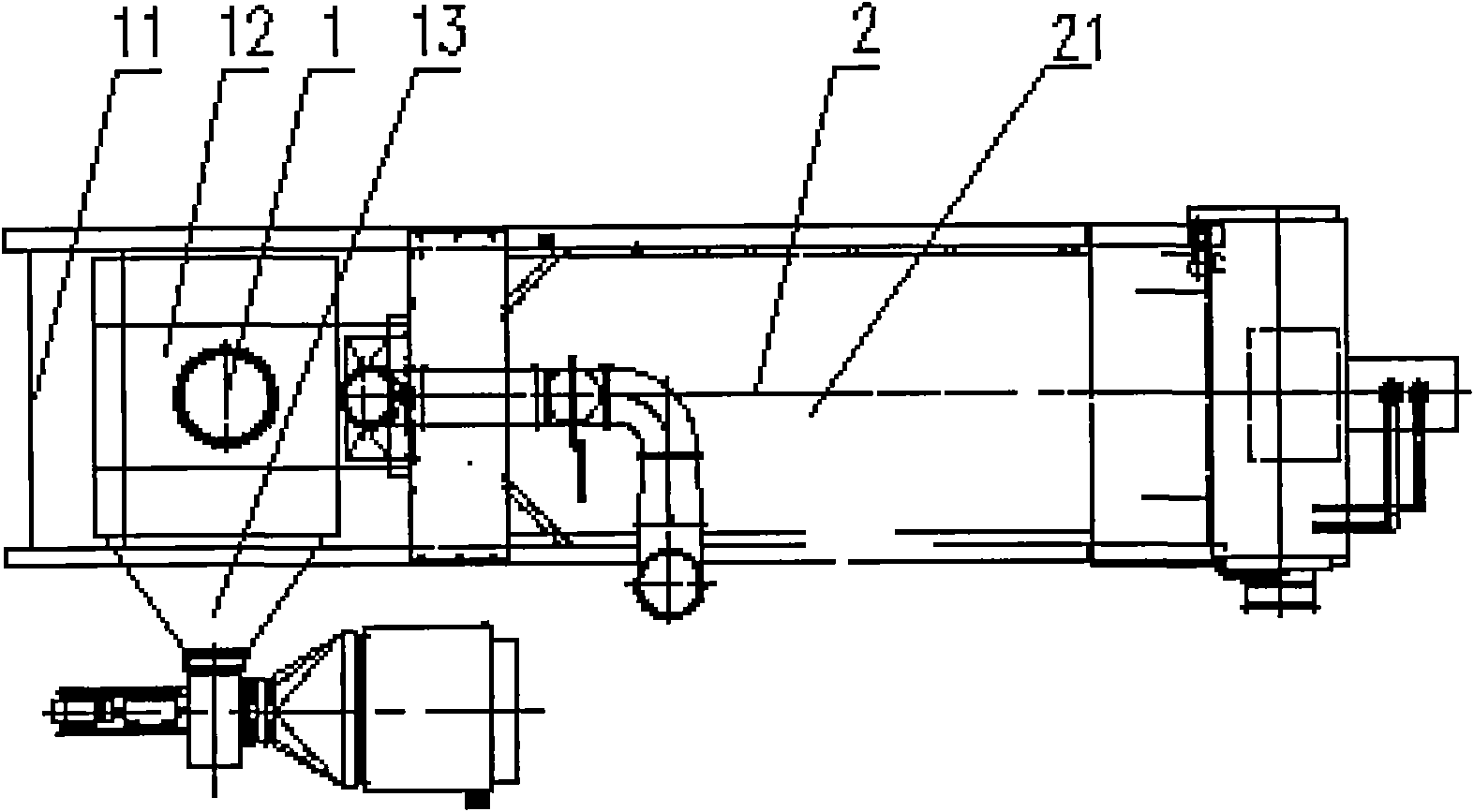

Method for drying leaf-silk in a grading way and equipment thereof

InactiveCN101601499AReduce the temperatureReduce contentTobacco preparationTemperature controlPulp and paper industry

The invention provides a processing method for drying leaf-silk in a grading way and equipment thereof; the method comprises two process steps: a first stage is a fluidization drying stage and the hot air drying temperature is controlled at 110 DEG C to 160 DEG C, so as to lead leaf silks to be dehydrated to 15 percent rapidly; a second stage is a roller silk drying stage, the temperature of roller wall is controlled at 60 DEG C to 100 DEG C, and the leaf silks with 15 percent of water content is dried to about 12 percent; the equipment comprises a fluidization drying functional area and a roller silk drying functional area; the fluidization drying functional area comprises a vibration fluidized bed and a wind-collecting guide cover arranged above the vibration fluidized bed; the roller silk drying functional area comprises a silk drying roller, the material inlet of the silk drying roller is communicated with a vibration tank. The invention can effectively utilize different drying characteristics of leaf silks in the constant-speed drying stage and speed-reduction drying stage, so as to improve the filling value of the leaf silks on the premise of not improving the processing temperature of the leak silks; meanwhile, aroma loss of the leaf silks is reduced in the drying process.

Owner:ZHISI HLDG GRP

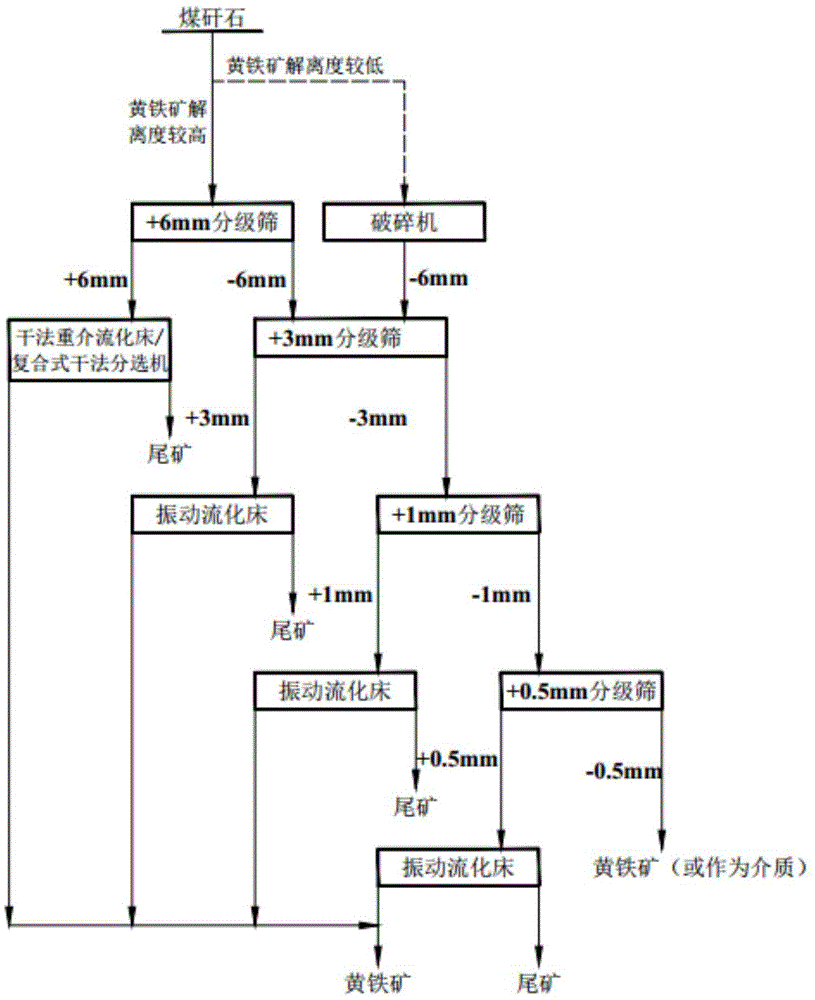

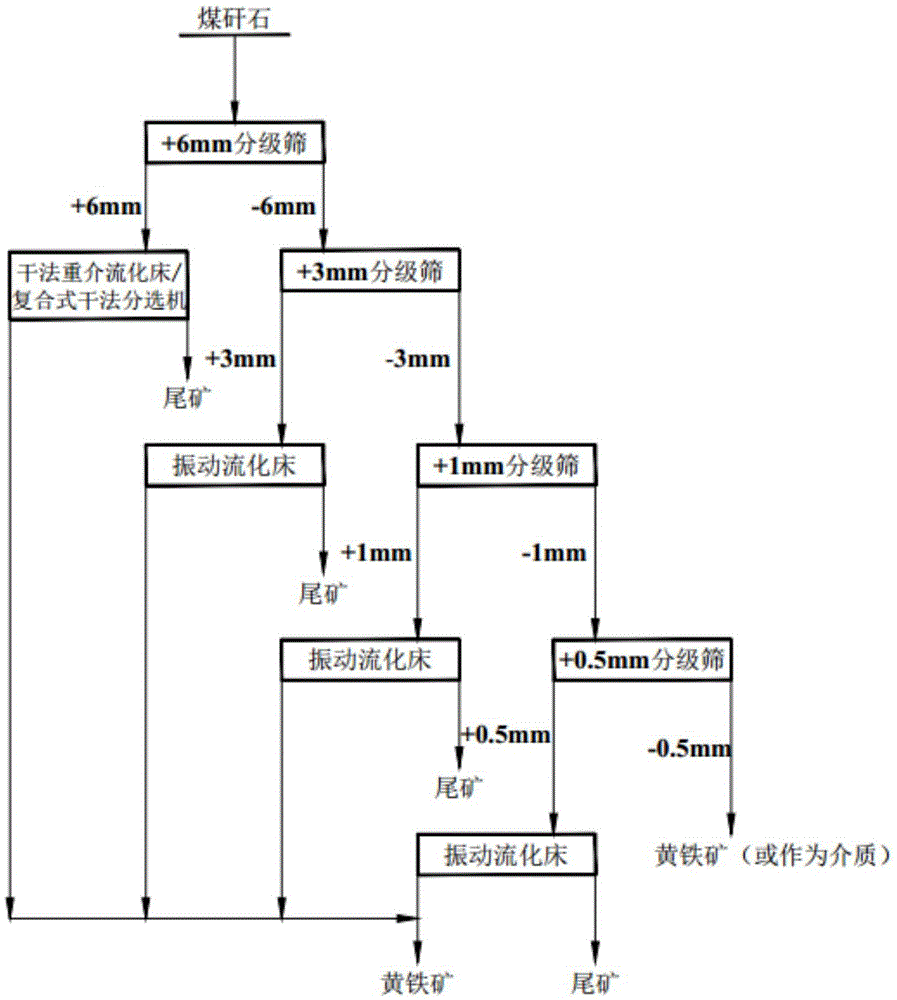

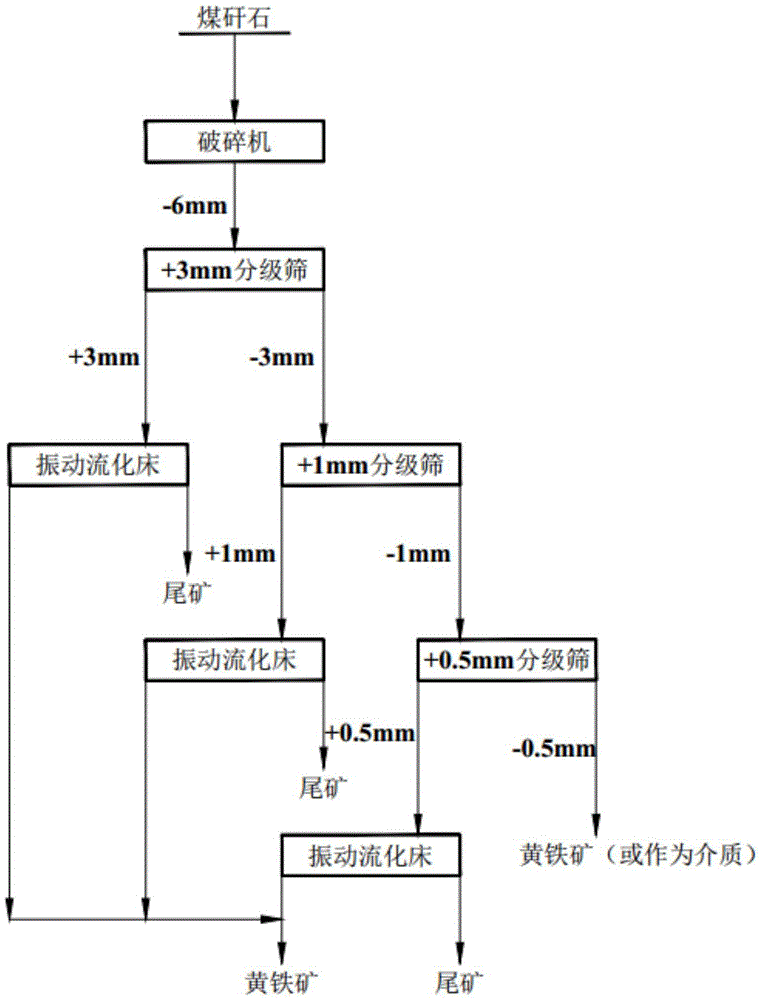

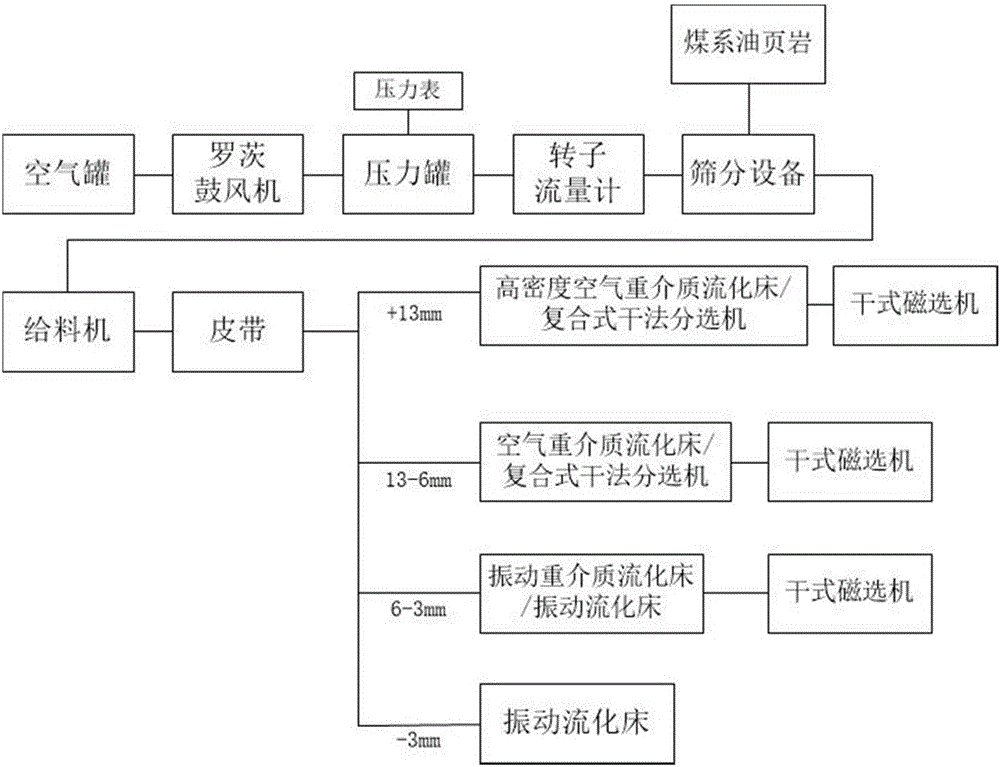

Efficient coal derived pyrite dry-method enrichment process and system

The invention belongs to mineral processing separation processes and systems, and relates to an efficient coal derived pyrite dry-method enrichment process and a system. When pyrite is inlaid in a coarse aggregate manner and the degree of dissociation is high, no breaking operation is needed. A dry-method dense medium fluidized bed separation machine or a composite dry-method separation machine and a vibration fluidized bed separation machine are combined with the enrichment process. When the disseminated grain size of pyrite in high-sulfur gangue is lower than the fine degree of dissociation, breaking and dissociation operation is carried out on samples, and the vibration fluidized bed separation machine is adopted for carrying out enrichment on brasses in fine-grain high-sulfur gangue. Gangue materials of +6 mm in a pyrite buffer bin are recycled by the dry-method dense medium fluidized bed separation machine and the composite dry-method separation machine and enter the separation machine through a feeder and a belt conveyor, high-density pyrite enters the bottom of a bed layer to be separated from gangue, concentrates and tailings enter a concentrate bin and a tailing bin respectively, the concentrates are pyrite, and the tailings are gangue. The process is simple in procedure, reasonable in technical path, large in handling capacity and stable in running, and running cost is effectively reduced.

Owner:CHINA UNIV OF MINING & TECH

Vegetable chicken essence and production method thereof

The invention discloses vegetable a chickens' extract and method for making the same. The chickens' extract has the following raw materials: green vegetables, carrots, mushrooms, chicken reaction solution, salt, sugar, monosodium glutamate, hydrolyzed vegetable protein, and natural pigment. The method includes; firstly selecting green vegetables, carrots, and mushrooms; performing blanching and color protecting after the rough cut, and then performing microwave drying, and finally carrying out ultra-fine crushing; and then scattering the crushed vegetable power into the chicken reaction solution, and adding the salt, sugar, monosodium glutamate, hydrolyzed vegetable protein, and natural pigment; fully mixing evenly, granulating through a granulator, vibrating a fluidized bed for drying, to obtain the chickens' extract. The invention adds dry powder of green vegetables, which not only enriches the flavor of chickens' extract, but also adds the necessary vitamins of humans to the chickens' extract; and adds hydrolyzed vegetable protein, which has high amino acid content and makes the invention to be more nutritious.

Owner:浙江正道生物科技有限公司

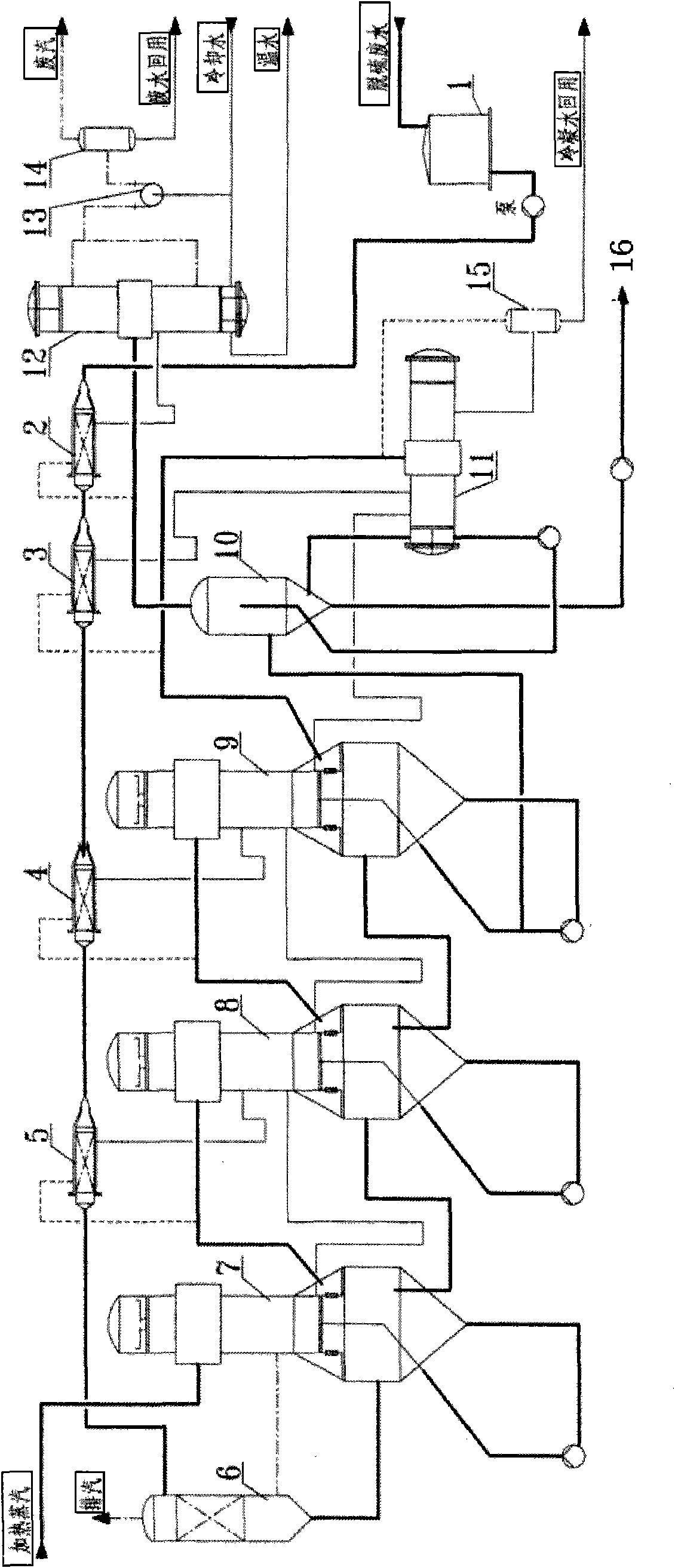

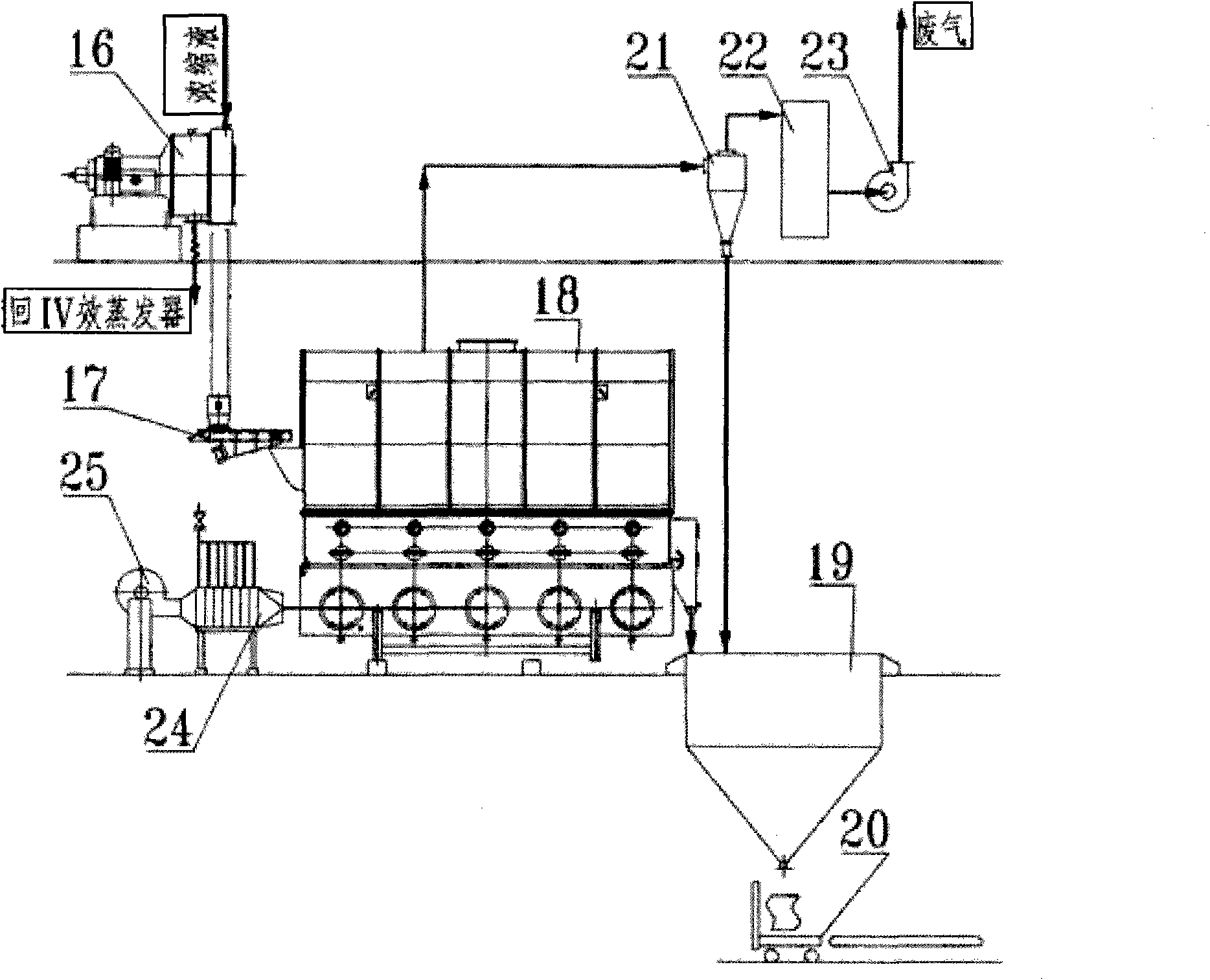

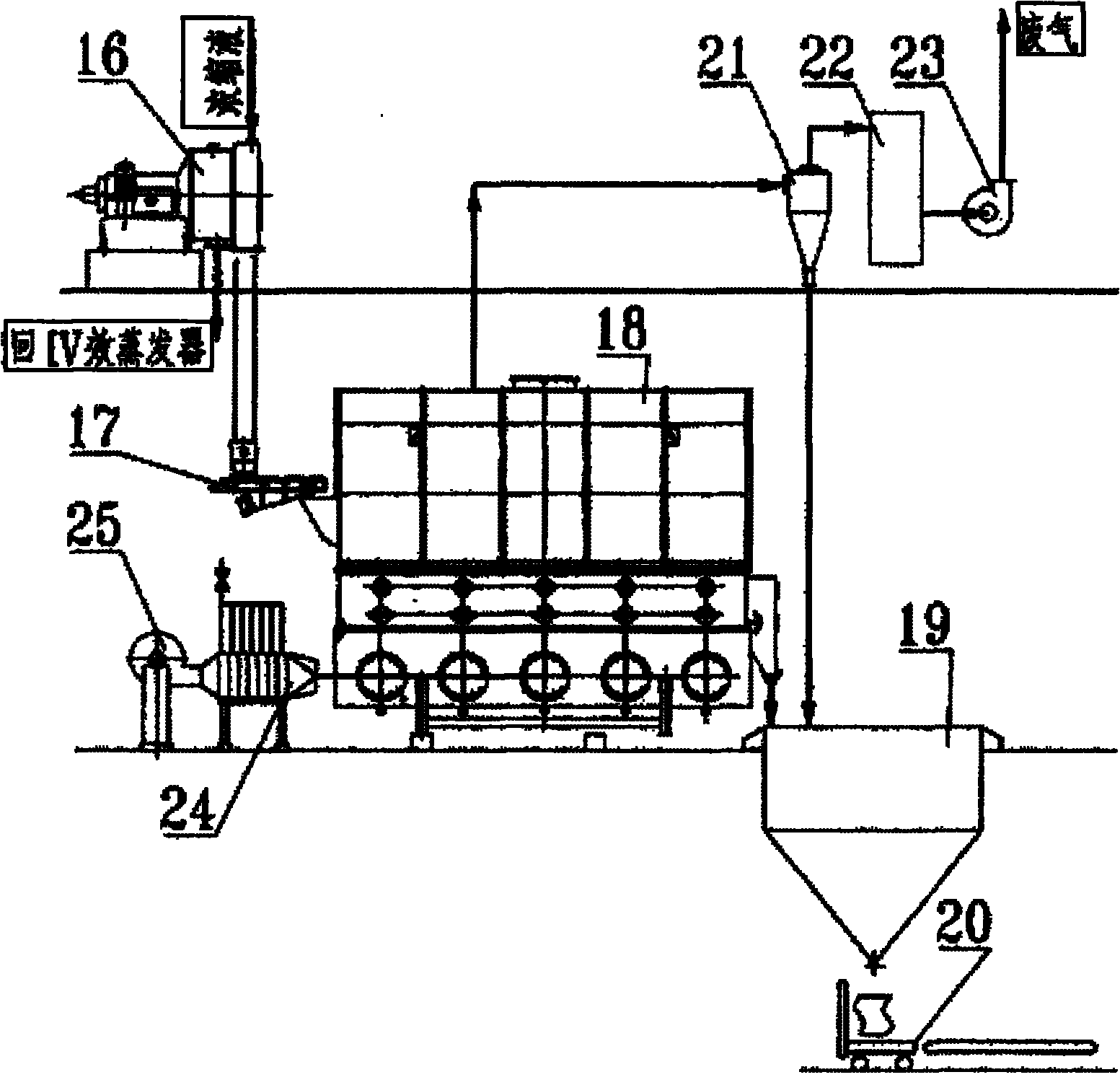

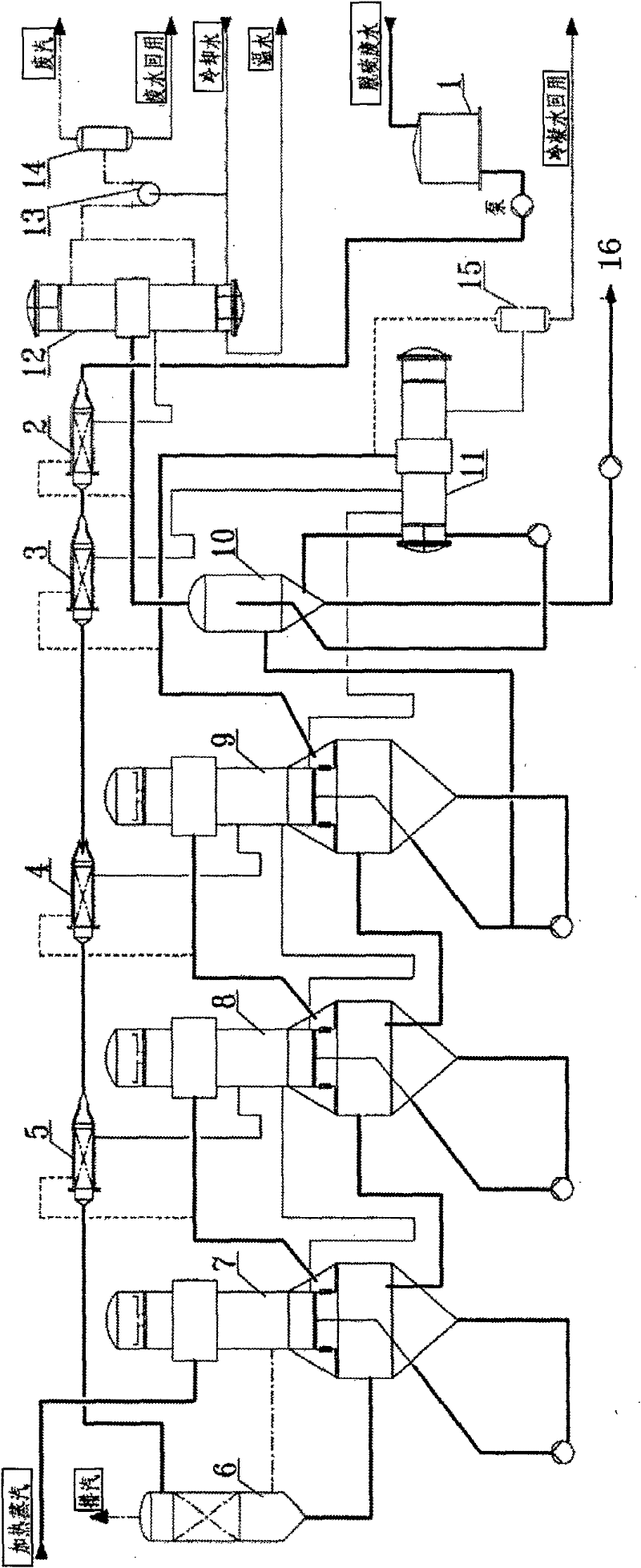

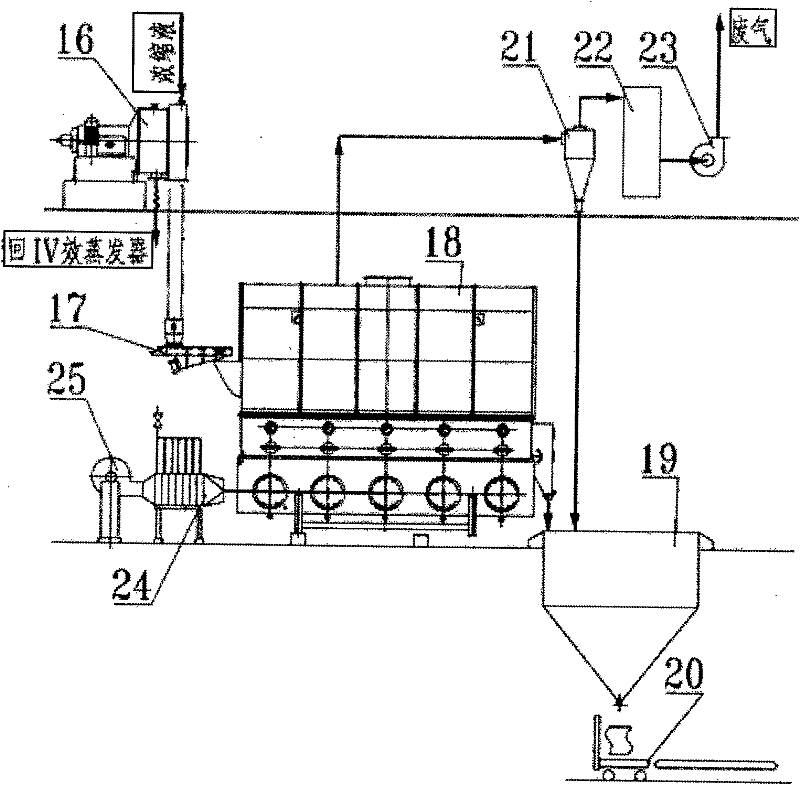

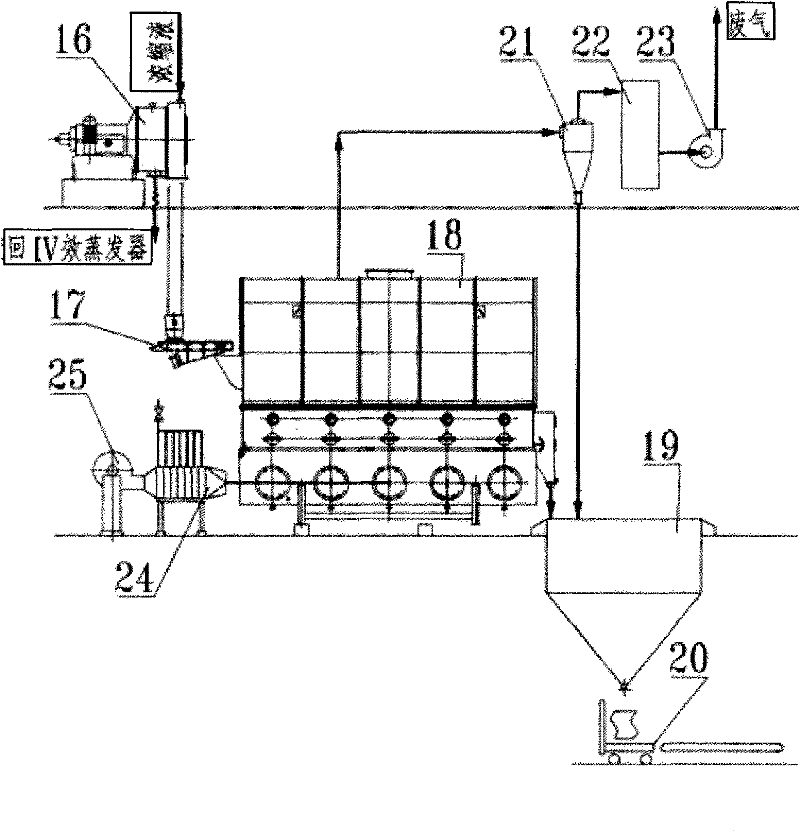

Method and device for realizing zero release in desulfuration wastewater deepening treatment

ActiveCN101851041AImprove heat transfer coefficientLarge vaporization surface areaMultistage water/sewage treatmentWater/sewage treatment by heatingDegasserWastewater

The invention provides a method and a device for realizing zero release in desulfuration wastewater deepening treatment. The device comprises a waste liquid storage tank, a pre-heater, a degasser, a I-effect evaporator, a II-effect evaporator, a III-effect evaporator, a IV-effect evaporator, a centrifuge, a feeder, a vibrating fluidized bed dryer, an intermediate bunker and a packer which are connected in turn. The method comprises the following steps of: pre-heating and degassing the desulfuration wastewater; and conveying the desulfuration wastewater to the centrifuge to perform solid-liquid separation after four-level evaporation, and drying the solid. The invention has the advantages that the device is simple and the cost is low.

Owner:CHINA HAISUM ENG

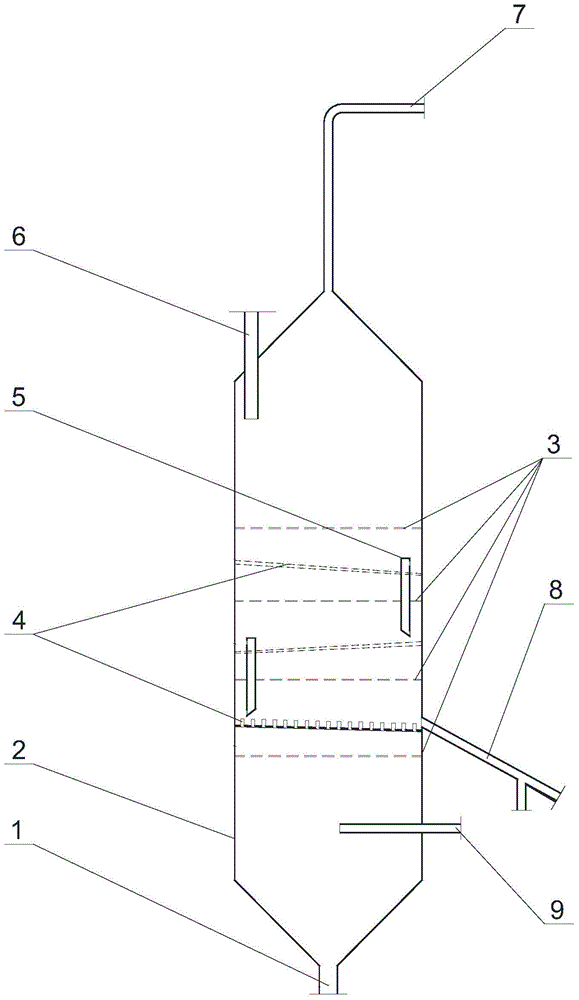

Double-layered vibrating fluidized-bed drying-classification apparatus

InactiveCN101825390AEmission reductionImprove classification efficiencyGas current separationDrying solid materials with heatFluidized bed dryingClosed chamber

The invention relates to a double-layered vibrating fluidized-bed drying-classification apparatus, in particular to a doubled-layered vibrating fluidized apparatus for the moisture control and classification of coking coal, which belongs to the technical field of drying equipment. The drying-classification apparatus comprises steel supports, a fluidized drying-classification chamber, a coal feed inlet, a large coal particle outlet and a sealed fine coal particle buffer bin, the fluidized drying-classification chamber is connected with the steel supports, the coal feed inlet, the large coal particle outlet and the sealed fine coal particle buffer bin are respectively communicated with the fluidized drying-classification chamber, the fluidized drying-classification chamber is a closed chamber which consists of an upper fluidized drying-classification chamber arranged on the upper part and a lower fluidized drying-classification chamber arranged on the lower part, and a pressure-equalized bellows is arranged on the bottom of the fluidized drying-classification chamber. The invention has the advantages of simple structure, little investment, high coal classification efficiency and smooth operation, and is particularly applicable to the particle size classification and humidity regulation of coking coal in the coking industry.

Owner:LAIWU IRON & STEEL GRP

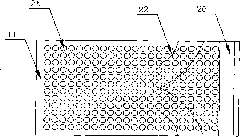

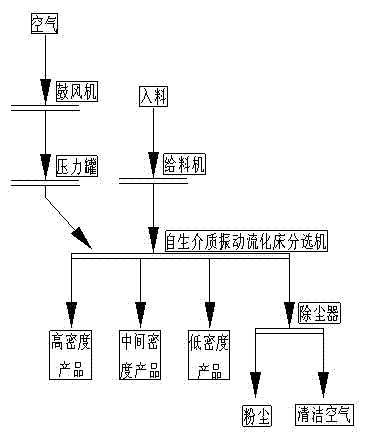

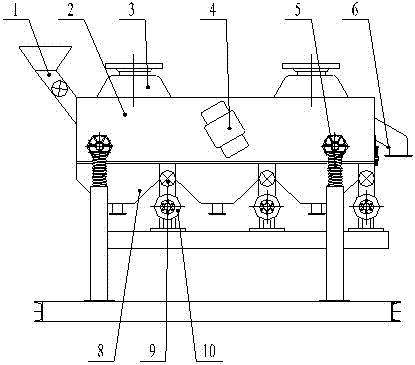

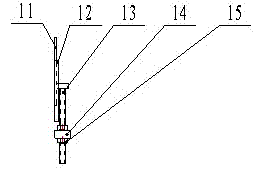

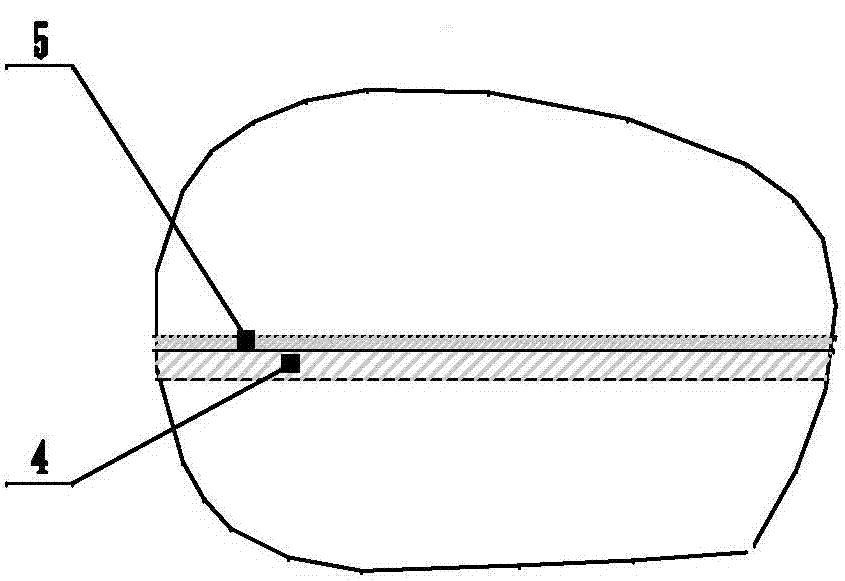

Authigenic medium vibrated fluidized bed dry separating method and separating machine

ActiveCN102921636AImprove reliabilityReduce sorting loadGas current separationHigh densityDust control

Owner:CHINA UNIV OF MINING & TECH

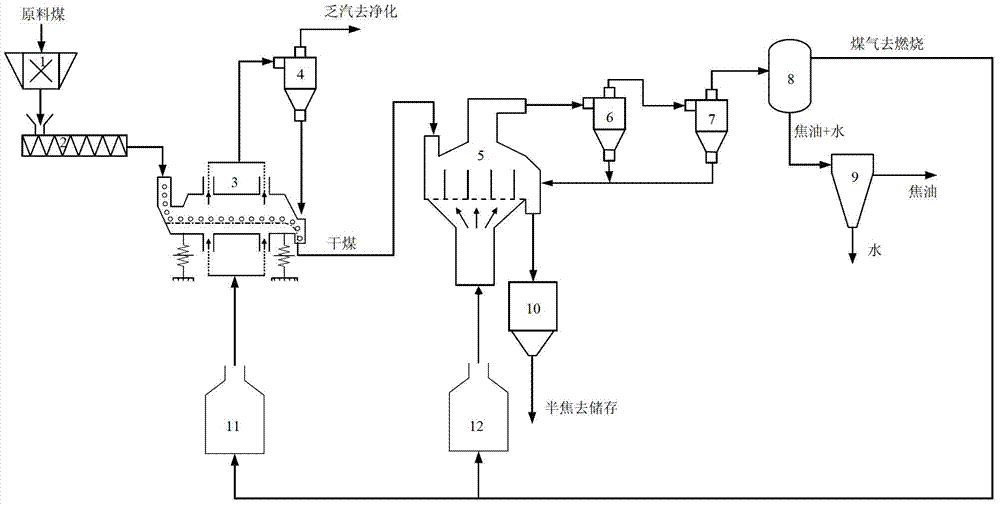

Method and system for performing drying and dry distillation on fluidized bed pulverized coal based on overheating steam medium

ActiveCN102766475AReduce consumptionImprove thermal efficiencyDrying solid materials with heatDirect heating destructive distillationFluidized bed dryingEngineering

The invention provides a method and a system for performing drying and dry distillation on fluidized bed pulverized coal based on an overheating steam medium. The method comprises the following steps of: heating and drying pulverized coal by taking overheating steam as a drying medium, performing the dry distillation in a horizontal multichamber fluidized bed dry distillation furnace on the dried pulverized coal by utilizing the overheating steam as a fluidizing medium, dedusting high-temperature dry distillation gas by a cyclone separator, conveying the dedusted high-temperature dry distillation gas to an oil gas cooling separation system for cooling, and performing oil-water separation on the cooled mixture; conveying discharged semicoke to a coke quenching system, and cooling for storing; and allowing gas generated by the dry distillation to be used as heating fuel for a low-temperature overheating steam boiler and a high-temperature overheating steam boiler, and conveying the generated overheating steam to vibrated fluidized bed drying equipment and the horizontal multichamber fluidized bed dry distillation furnace. By the method and the system, the overheating steam is low in consumption and low in energy consumption, and the dried pulverized coal is low and uniform in moisture content; and the quality and yield of tar generated by the pyrolysis of the pulverized coal can be improved, a process is simple, and the system is operated safely in an anaerobic environment.

Owner:SHENWU TECH GRP CO LTD

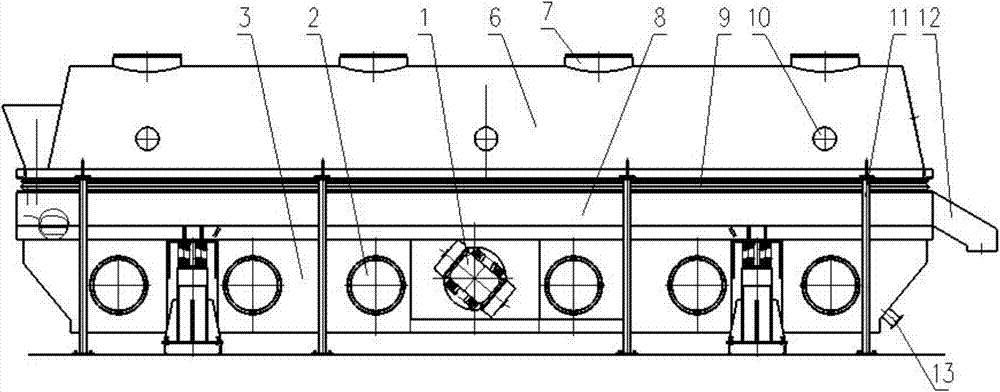

Vibratory air dense media fluidized bed dry method sorting machine

InactiveCN102211086AAvoid destructionAvoid cloggingGas current separationEngineeringVolumetric Mass Density

Owner:CHINA UNIV OF MINING & TECH

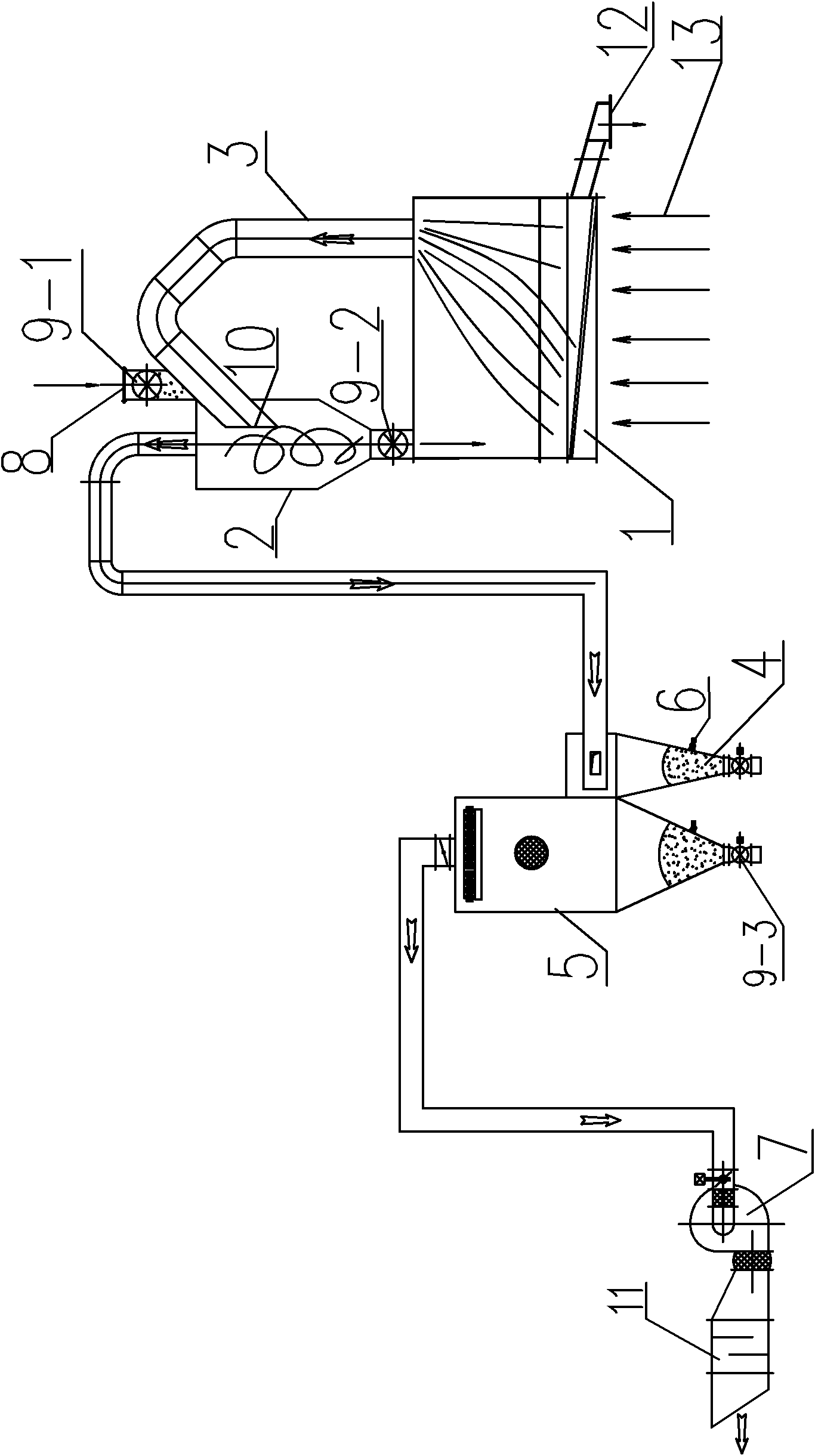

Drying process for humidifying coals by using coke oven flue gas and device

The invention relates to a drying process for humidifying coals by using coke oven flue gas and a device. The drying process comprises the following steps of: putting coal materials into a cyclone separator and a vibrating fluidized bed; humidifying and drying the coal materials in the vibrating fluidized bed by using unsaturated coke oven flue gas; carrying the coal materials with smaller grain size to leave the vibrating fluidized bed by the coke oven flue gas after executing thorough heat and moisture exchange of the coke oven flue gas and the coal materials; and entering the cyclone separator by a heat preserving pipeline, wherein the coal materials entering the cyclone separator from a raw original inlet can be firstly exchanged in heat and moisture with the flue gas which still has a drying function from the fluidized bed in the cyclone separator so that raw coals enter the vibrating fluidized bed after being primarily dried in the cyclone separator. In the process and the device, the coke oven flue gas is used for humidifying and drying the raw coals; therefore, a pollution problem caused by the discharge of the flue gas generated by coking can be effectively solved; simultaneously, the flue gas is used as a heat source for drying the humid coals; and therefore, the invention largely saves energy sources, has high heat exchange efficiency, saves energy and reduces carbon emission.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

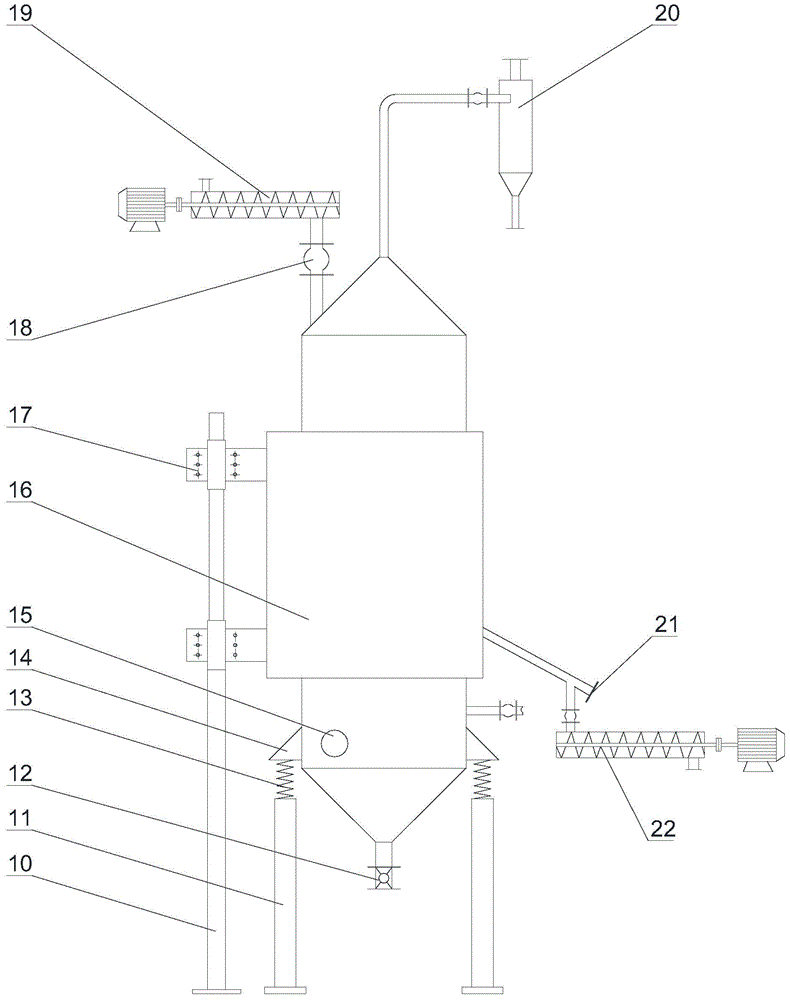

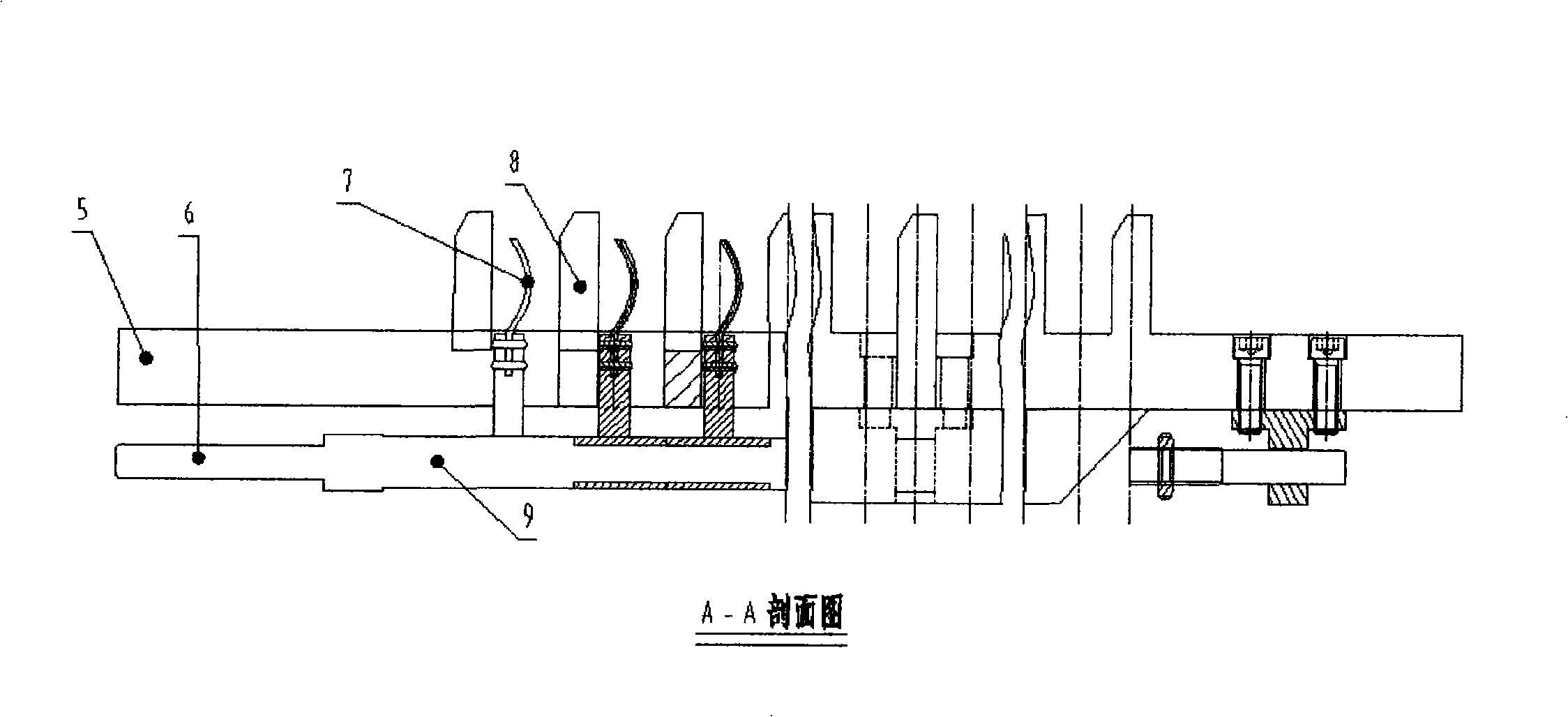

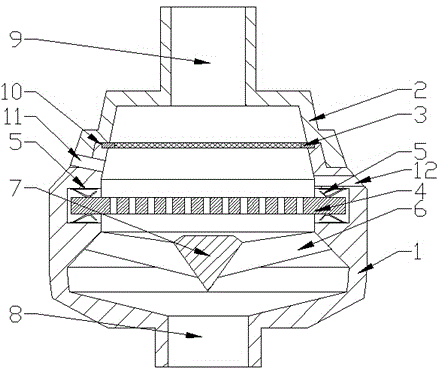

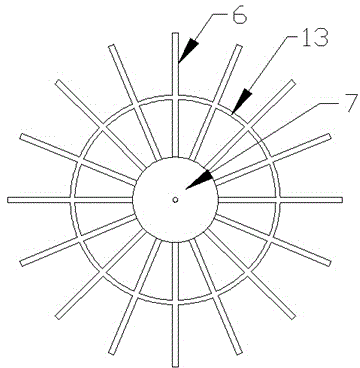

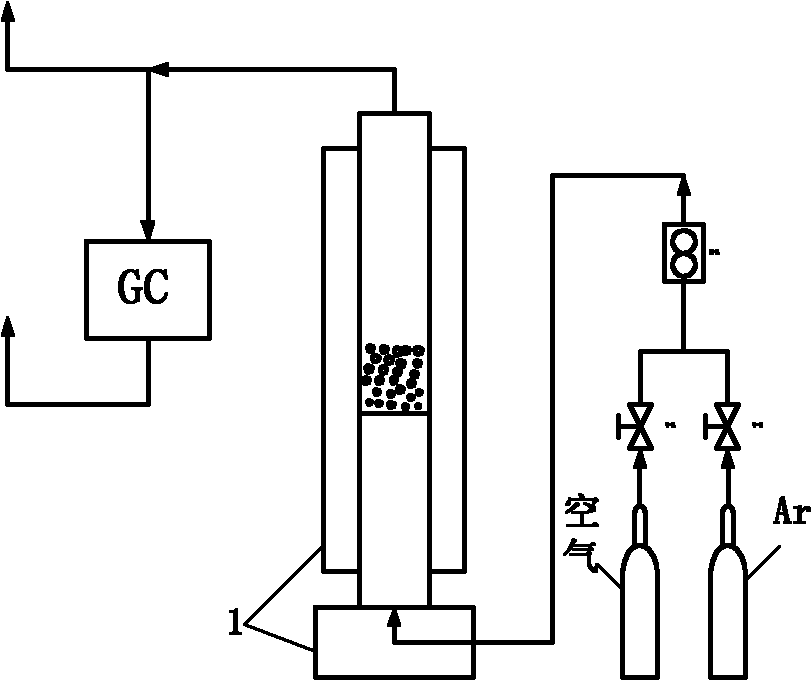

Vibratory fluidized bed reactor for continuous production of rare earth fluorides and production method

InactiveCN104084095AImprove fluidization qualityOptimizing the gas-solid fluidization reaction processRare earth metal compoundsChemical/physical processesHydrogen fluorideFluoride products

The invention discloses a vibratory fluidized bed reactor for continuous production of rare earth fluorides. The vibratory fluidized bed reactor comprises a feeding device, a discharging device, a fluidized bed, a vibrator and a heating device, wherein a rare-earth-containing material feeding hole is formed in the upper part of a fluidized bed body; a rare earth fluoride product discharge opening communicated with the discharging device is formed in the lower part of the fluidized bed body; a hydrogen-fluoride-containing gas inlet is formed in the bottom of the fluidized bed body; gas distribution plates through which hydrogen-fluoride-containing gas passes and uniform air distribution is realized are arranged in the cavity of the fluidized bed body; an exhaust pipe is arranged on the top of the fluidized bed body; the heating device is arranged on the outer side of the fluidized bed body and covers the fluidized bed body; the vibrator is arranged on the outer wall of the fluidized bed body; the bottom of the fluidized bed body is connected to supports through elastic supporting pieces. According to the scheme in the invention, the fluidization quality can be improved, the mass transfer and heat transfer effects are improved, the production efficiency is high, and the product is uniform and stable in quality, high in fluorination rate and low in process cost.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Vibrational fluidized bed device for controlling humidity and grading coking coal and fluidizing process thereof

InactiveCN101838540AAchieve humidity regulationEfficient separationDrying solid materials with heatGas current separationFailure rateCoal

The invention relates to a vibrational fluidized bed device for controlling humidity and grading coking coal and a fluidizing process thereof and belongs to the field of fluidizing and humidifying of the coking coal. The device and the process can realize humidity adjustment and efficient separation of the coking coal. The device comprises a linear driving device, a non-uniform pressure air box, a fluidized drying and grading chamber, gas material separation chambers and a large-particle coal collecting chamber and is characterized in that: the gas material separation chambers are positioned on both sides and the tail end side of the fluidized drying and grading chamber respectively; the linear driving device is connected with the bottom of the non-uniform pressure air box; an air distribution plate is arranged between the top of the non-uniform pressure air box and the fluidized drying and grading chamber; and a plurality of small-particle coal scraper plates are arranged above the air distribution plate and lead to the gas material separation chambers. The device and the process have the advantages of capability of effectively solving blocking and material leaking problems on the air distribution plate, uniform fluidization, remarkable drying effect, high thermal efficiency, good fluidized bed delamination and high separation accuracy. Moreover, the small-particle coal scraper plate has the advantages of simple structure, low failure rate and remarkable separation effect.

Owner:LAIWU IRON & STEEL GRP

Round granule ore fertilizer pelleting process and device

ActiveCN106495811AAvoid cloggingHigh ball rateCalcareous fertilisersMagnesium fertilisersEngineeringUltimate tensile strength

The invention discloses a round granule ore fertilizer pelleting process which comprises the following steps: I) preparing raw materials; II) performing stirring mixing; III) performing pelleting; IV) screening wet granules; V) performing first-stage drying; VI) performing second-stage drying; VII) cooling; VIII) screening a finished product; IX) packaging the finished product. The invention further discloses a pelleting device with the process. The pelleting device comprises a mixing machine, a disc pelleting machine, a staged rotary screen, a rotary drying machine, a vibration fluid bed dryer, a rotary cooling machine and a vibration screen. The round granular ore fertilizer pelleting process is high in pelleting disc balling yield, low in granule crushing rate in the drying procedure, high in yield of the whole system, advanced in pelleting process, low in drying cost, small in water amount, high in granule strength of a round granule ore fertilizer product, good in sphericity degree and high in market acceptance degree.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

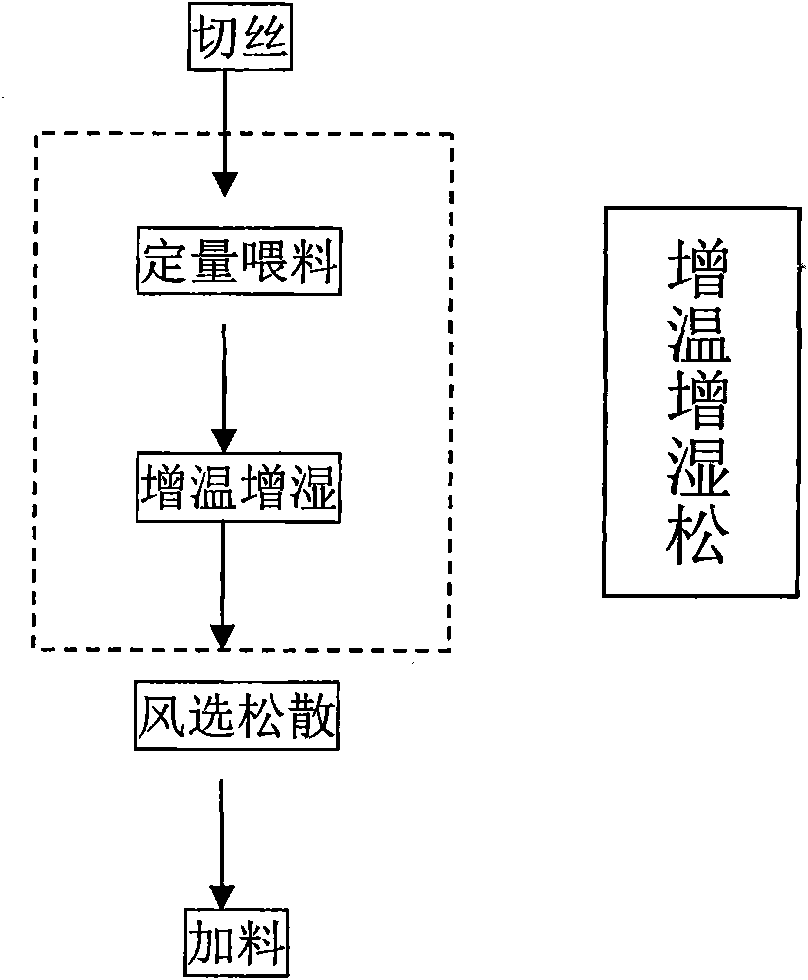

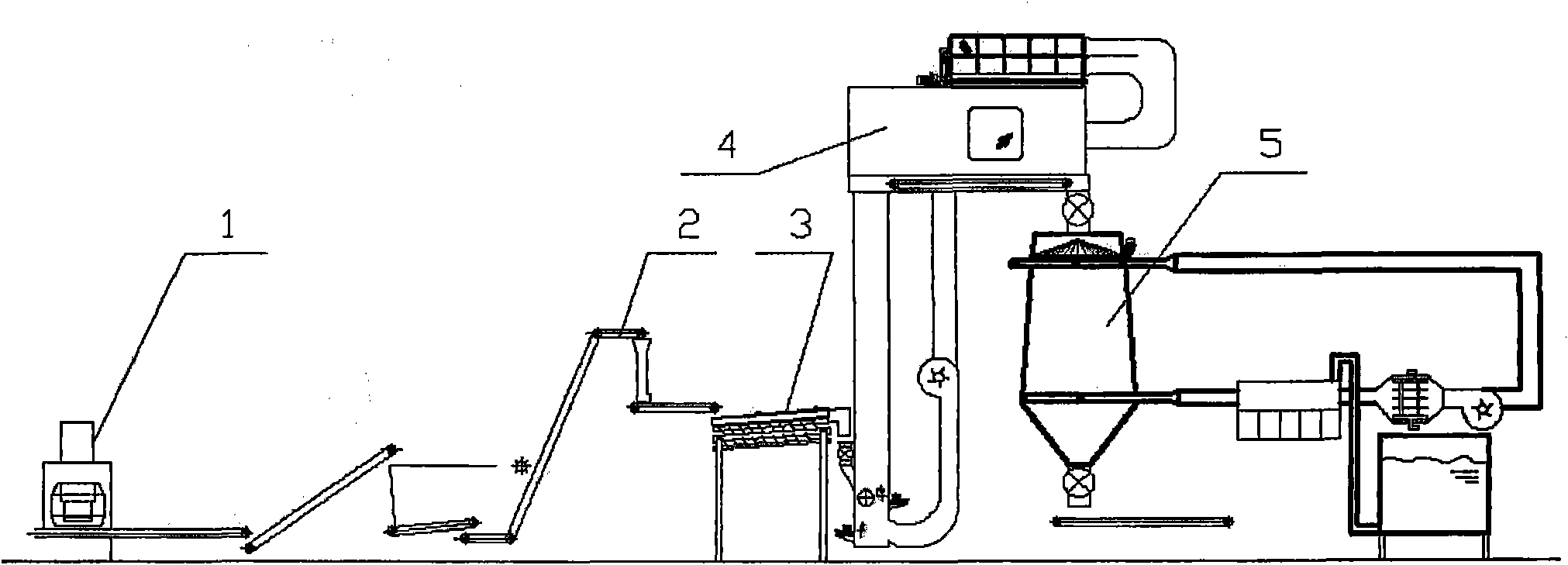

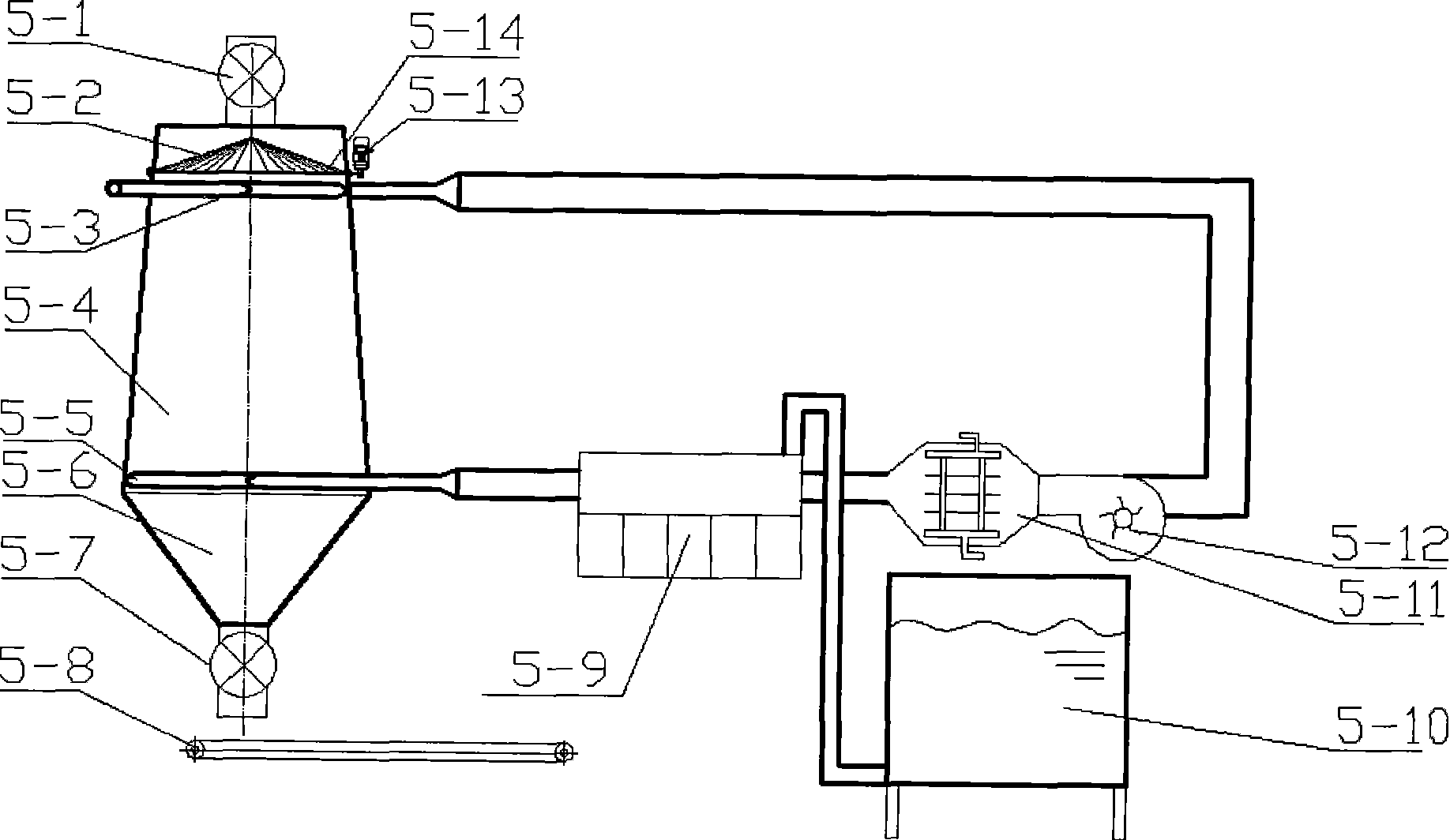

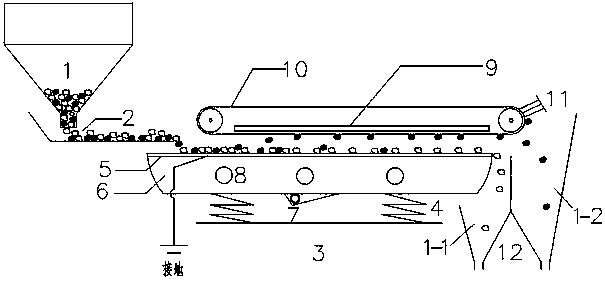

Leaf thread material feeding process and equipment

ActiveCN101773279AReduce sticking and drawingLoosely fullTobacco preparationTobacco treatmentVulcanizationMaterial scattering

The invention relates to a leaf thread material feeding process and equipment, which belong to the technical field of tobacco processing. The invention is characterized in that the leaf thread feeding process sequentially comprises the working procedures of thread cutting, temperature increasing and humidifying loosening, air separation loosening and material feeding. The equipment applicable to the process comprises a thread cutting machine, a quantitative material feeding machine, a vibration vulcanization bed, an air separation loosening device and a vertical material feeding machine which are sequentially ranged, wherein each equipment is connected through material conveying mechanisms, the vertical material feeding machine comprises a material feeding cavity, a material inlet airlock and a material outlet airlock are respectively arranged on the top and the bottom of the material feeding cavity, a material scattering mechanism is fixed on the upper part of the material feeding cavity, a material liquid atomizing system is communicated with the material feeding cavity through an air inlet pipe and a air return pipe of a hot air circulation system, and a sealed cyclic feeding system is formed. The process and the equipment can solve the problems of large thread cutting pulverization products of low-water-content tobacco flakes and material feeding aggregation of tobacco threads, the material liquid atomizing effect is good, the material liquid absorption velocity by the tobacco threads is high, the material feeding uniformity and the effectiveness are improved, in addition, the material storing time after the material feeding is shortened, and the production efficiency is high.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

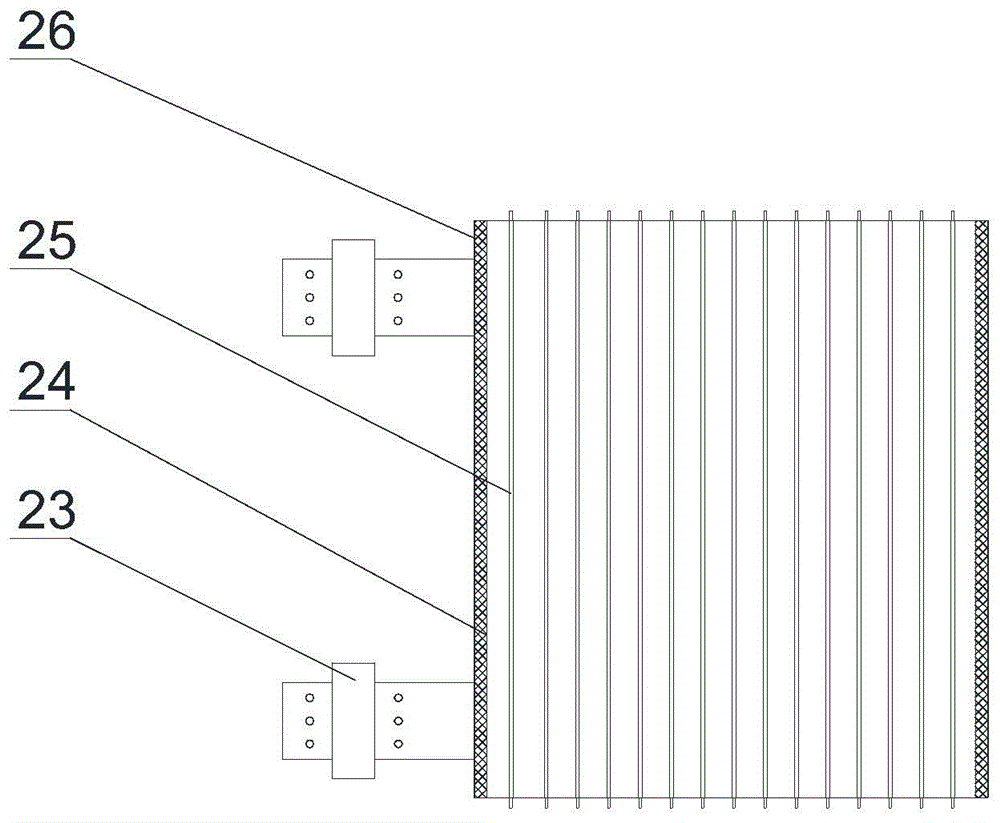

Vibrated fluidized bed electric separator

InactiveCN104289316ARaise the gradeReasonable designElectrostatic separationElectrical conductorContinuous flow

The invention discloses a vibrated fluidized bed electric separator which comprises a feed device, a base, a vibrated fluidized bed, a high-voltage electrode plate, a non-conductor belt and a material collection device. The vibrated fluidized bed is arranged on the base by virtue of a spring; the conductive working surface of the vibrated fluidized bed is earthed, and the non-conductor belt which externally wraps the high-voltage electrode plate is arranged above the working surface; the high-voltage electrode plate and the working surface are arranged in parallel and are connected with a high-voltage power source by virtue of a wire; the feed device is arranged on one end of the vibrated fluidized bed while the material collection device is arranged on the other end thereof; the material collection device comprises an ore concentrate groove and a tailing groove; the tailing groove is arranged near the vibrated fluidized bed; the ore concentrate groove is arranged by corresponding to the end part of the non-conductor belt. The vibrated fluidized bed electric separator is reasonable in design and wide in application range and can separate any mineral; the electric separator is particularly suitable for size fraction ranging from -1 mm to 0.2 mm and can perform continuous flow state separation and production to obtain target minerals in higher quality.

Method for producing variable-pressure adsorption silica gel

ActiveCN101053819ALarge specific surface areaChemically stableSilicon compoundsWater vaporSilica gel

The invention discloses a method for producing a silica gel used for pressure swing adsorbing, characterized that the method comprises the following steps: preparing sodium silicate and concentrated sulfuric acid into dilute solutions which are enhancing mixed to perform neutralization reaction, thus aquagel are obtained; aging the aquagel by acid soaking and water washing for second times, whereby the silica gel after water washed secondly has acid content of 0.008-0.015%; and fishing out the silica gel water washed secondly after saturated with static water, drying the gel firstly, and then secondly drying the screened silica gel after dried firstly, wherein the second drying is performed on a vibrational fluidized bed rapidly in short time, wherein, the water content is controlled within 2%, finally, a product is prepared. The invention has advantages of higher specific surface area, stable chemical property, no poison and no smell, with strong adsorption capacity for carbon dioxide and water vapour, etc.

Owner:RUSHAN DAYANG SILICA GEL FACTORY

Vibratory Flash Dryer

InactiveUS20100146814A1Drying solid materials with heatDrying gas arrangementsCycloneFluidized bed drying

An apparatus for drying and conveying a material includes a vibratory fluid bed dryer having a perforated drying deck on which material is deposited, said fluid bed dryer including a vibratory drive system capable of imparting a variable angle vibratory force to the deck. A flash dryer is also provided, having a fan and heater for supplying hot air through the fluid bed dryer deck and a cyclone for collecting finished, dried material particles.

Owner:CARRIER VIBRATING EQUIP

In-hollow column intercrystalline ammonia process of desulfurization, recovery system and method thereof

The invention relates to a crystallization ammonia process desulfurization and recycling system in an empty tower and a method thereof, which belong to the technical field of environment-friendly equipment. The system comprises a sprinkling desulfurizing tower, a hydrocyclone, a centrifuger, and a vibrating fluidized bed dryer. The method comprises the following steps: hot flue gas enters the middle part of the sprinkling desulfurizing tower, reaches the optimal temperature for ammonia process desulphurization after being cooled by process water sprinkling at the inlet of the tower, and then is subjected to absorption by a sprinkling layer, and finally gets rid of most of free water which is removed by a defogger; clean flue gas is directly sent out by a steel chimney on the top of the sprinkling desulfurizing tower; absorption liquid in a stock tank at the lower part of the tower reaches the state of supersaturation after being subjected to circulating absorption a plurality of times, is forced to be oxidized by oxygen in air and flue gas in the bottom of the tower, and finally produces an ammonium sulphate saturated solution containing a certain amount of solid; the ammonium sulphate saturated solution containing a certain amount of solid is further concentrated by a water cyclone; the concentrated solution forms powder through the centrifuger; and after being dried by the drier, ammonium sulphate products with water content of less than 0.3% can be obtained.

Owner:北京中大能环工程技术有限公司

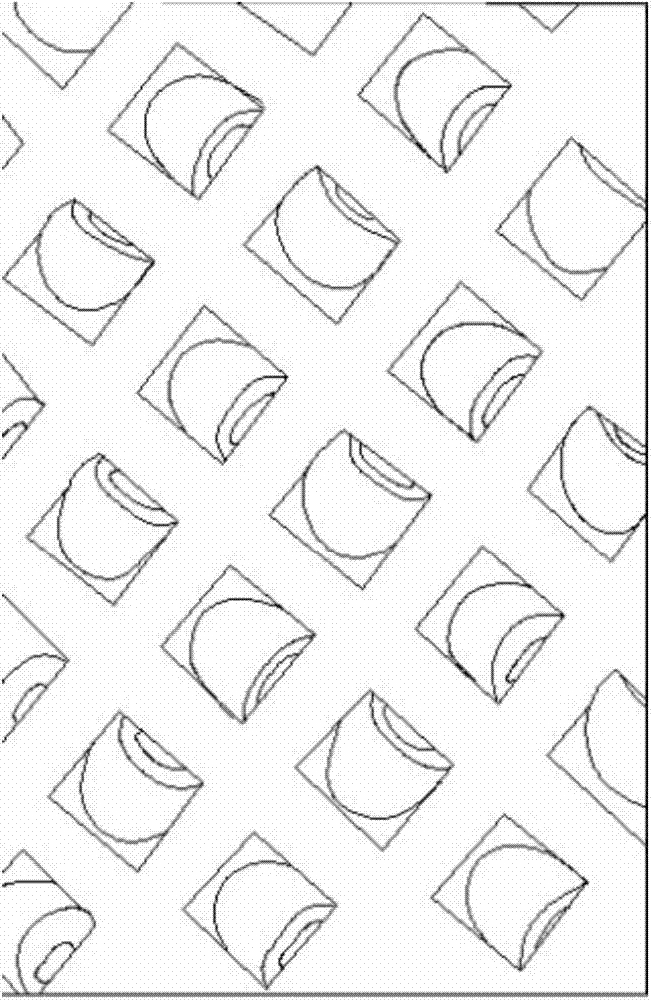

White granulated sugar vibrated fluidized bed

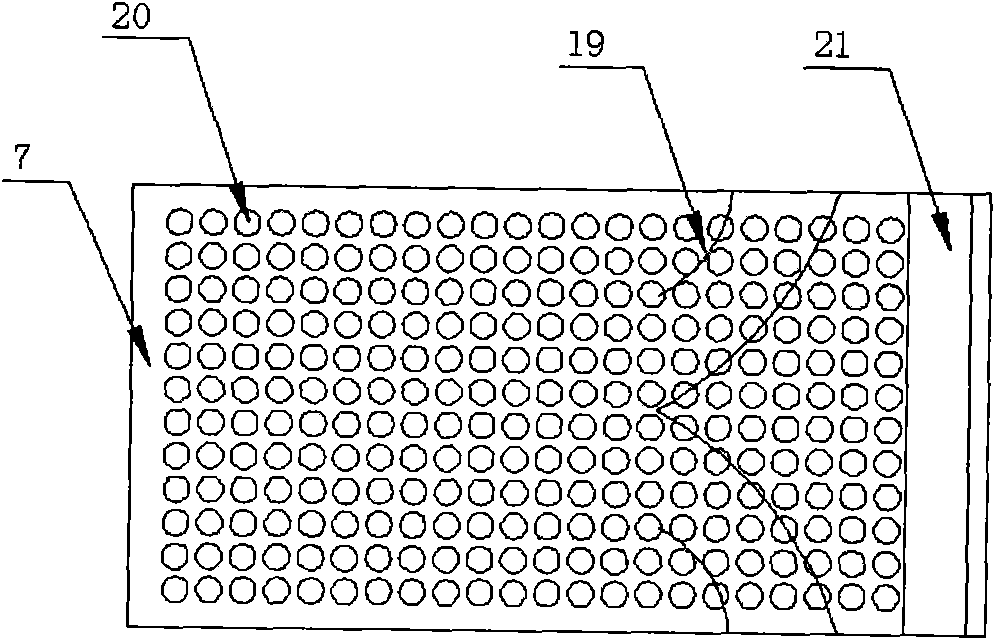

InactiveCN103571975AHigh strengthFluidized state is goodSugar dryingDrying solid materials with heatSeashellVibratory fluidized bed

The invention discloses a white granulated sugar vibrated fluidized bed. The white granulated sugar vibrated fluidized bed comprises a main machine box, a vibration motor and a macroporous plate and a seashell-type pore plate, wherein the main machine box is of a hollow structure with a ventilation cavity, and a vibration bed is arranged at the upper part of the main machine box; the vibration motor is used for driving the vibration bed to vibrate in an upper and down slant direction, and the slant direction is the white granulated sugar advancing direction; the macroporous plate is arranged on the vibration bed and vibrates along with the vibration bed under the driving of the vibration bed, and multiple straight-through holes are formed in the macroporous plate and are communicated with the ventilation cavity; the seashell-type pore plate is arranged on the macroporous plate, multiple seashell-shaped raised seashell through holes are formed in the seashell-type pore plate and are two groups of seashell-shaped through holes which are arranged in a staggering manner, and the opening directions of the seashell-shaped through holes are vertical to each other; white granulated sugar to be fluidized is fed into the seashell-type pore plate. Materials in the white granulated sugar vibrated fluidized bed are at good mixing and boiling state under the effect of wind power, and as vertical surfaces are not provided with openings, the materials are unlikely to block the openings and leak below the bed.

Owner:广西幸丰科技有限责任公司

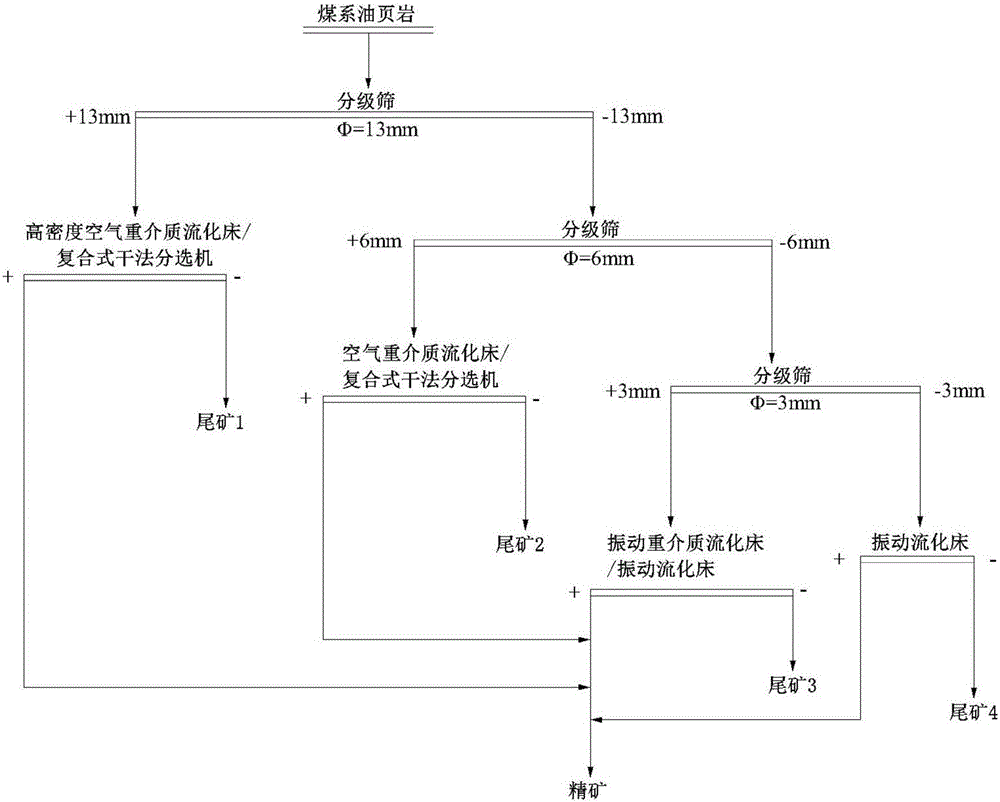

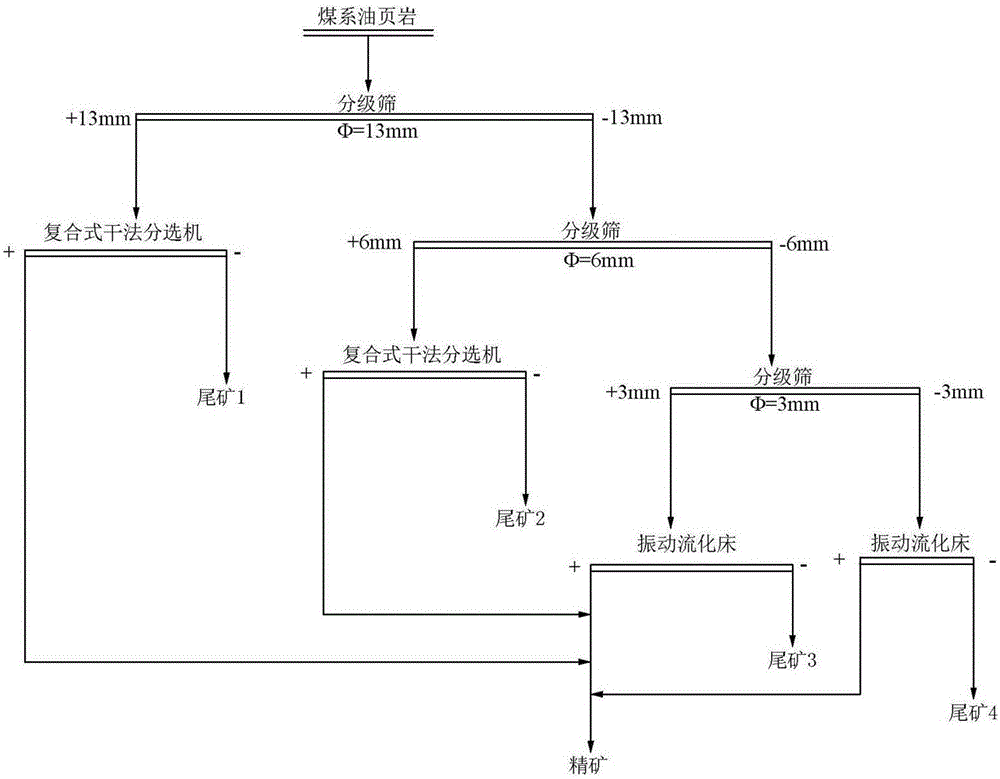

Modular high density coal system oil shale quality promoting technology and quality promoting system

The invention provides a modular high density coal system oil shale quality promoting technology and quality promoting system, and belongs to the oil shale quality promoting technology and quality promoting system. The moisture content of the oil shale acts as the indictor, when the moisture of the oil shale is less than 10%, the technology comprises the steps that +13mm materials are separated by using an air dense medium fluidized bed, 13-6mm materials are separated by using the air dense medium fluidized bed, 6-3mm materials are separated by using a vibration dense medium fluidized bed, -3mm materials are separated by using a vibration fluidized bed, and the media are recycled by using the magnetic separation technology to be used as cycling media; and when the moisture of the oil shale is greater than 10%, the +13mm materials are separated by using a composite dry separator, the 13-6mm materials are separated by using the composite dry separator, the 6-3mm materials are separated by using the vibration fluidized bed, and the -3mm materials are separated by using the vibration fluidized bed. The raw ore of the oil shale is separated into the concentrate ore and the tailing ore by separation of each level of fraction. The technical line of the technology is concise and clear and the technology flow is simple so that efficient separation of the coal system oil shale can be realized, and the quality promoting technology and the quality promoting system have quite important meaning for development and utilization of the coal system oil shale resource of our country.

Owner:CHINA UNIV OF MINING & TECH

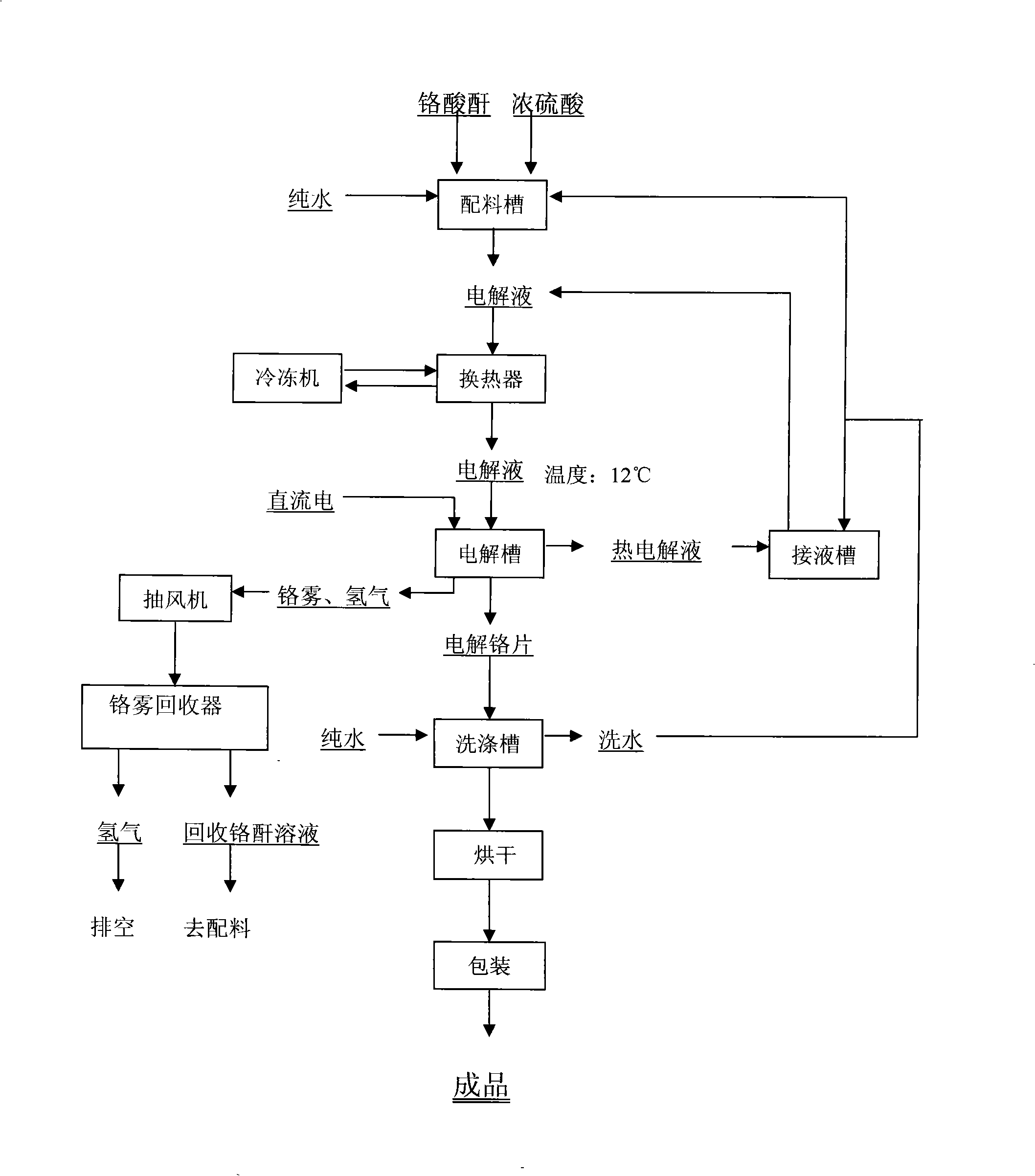

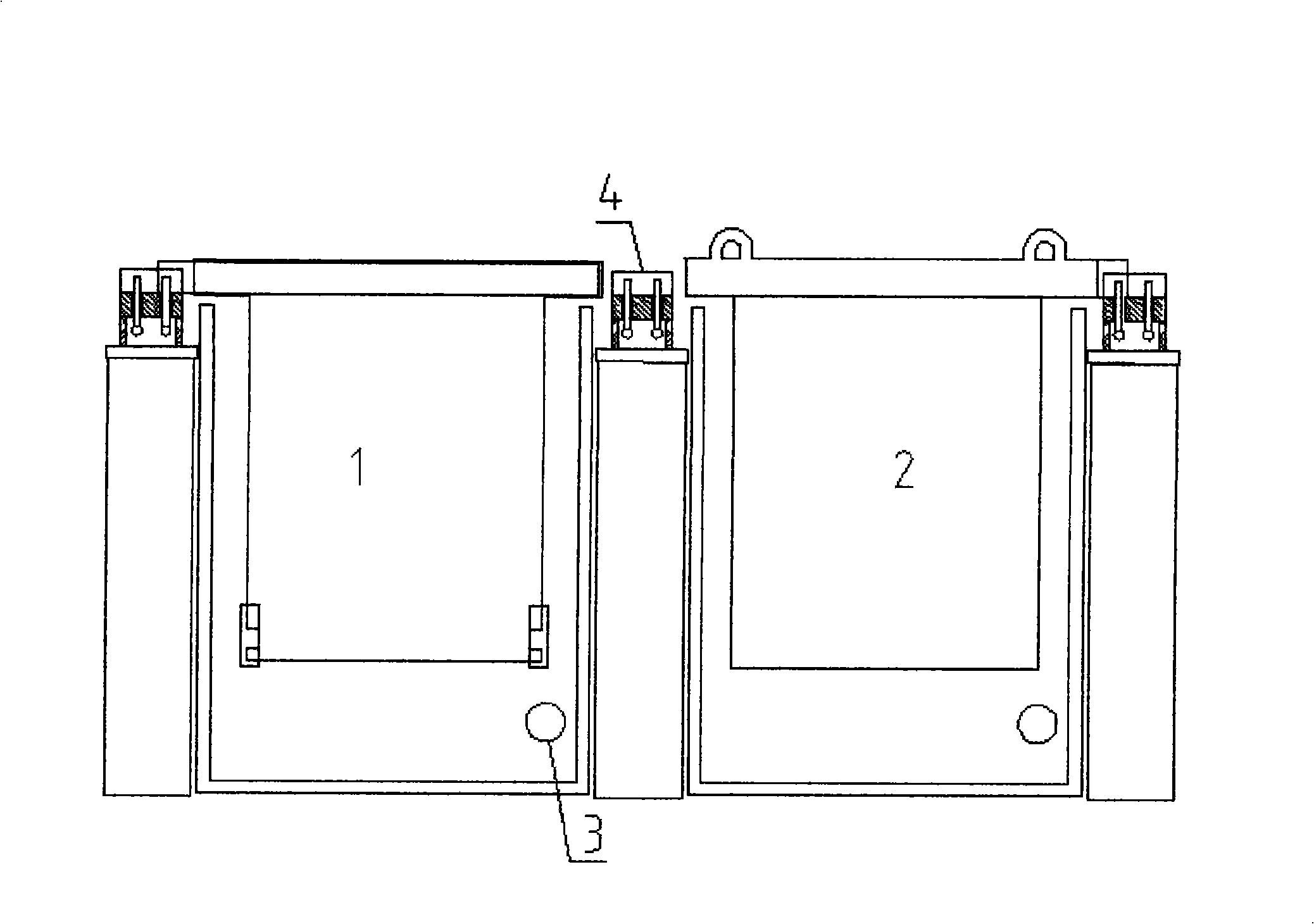

Method for producing high-purity metal chromium by electrolysis

ActiveCN101260537AAchieve the purpose of dryingPhotography auxillary processesProcess efficiency improvementLithium bromideMetal

The invention discloses a method for electrolytic production of high purity chromium metals, wherein, chromic anhydride and concentrated sulfuric acids are mixed into electrolytes according to a certain proportion which are thrown into a liquid receiving tank and then cooled by an acid-proof pump through a super stainless steel plate heat exchanger, and cooling water is provided by a steam lithium bromide refrigerating machine; the electrolytes after cooling are thrown into an electrolytic cell, pass through a liquid separation device in the cell and uniformly arrive between cathode plates and anode plates for electrolytic reaction; the electrolytes after electrolysis flow into the liquid receiving tank from an overflow weir of the electrolytic cell, and then the circulation is repeated to and fro. After the thickness of chromium plates reaches 1 to 2 millimeters through electrolysis of 24 hours or so, the cathode plates of the electrolytic cell are entirely moved out by a hanger frame through a pole plate switching device under the condition of no power failure, and then the electrolytic reaction is continued after replacement of a set of novel cathode plates. The chromium plates are knocked off manually from the replaced cathode plates, and the content of chromium can reach 99.99 percent after third-stage countercurrent washing and drying through a vibrated fluidized bed. The method reduces the cost and improves the production efficiency.

Owner:XINJIANG SING HORN GRP CO LTD

Method and device for realizing zero release in desulfuration wastewater deepening treatment

ActiveCN101851041BImprove heat transfer coefficientLarge vaporization surface areaMultistage water/sewage treatmentWater/sewage treatment by heatingDegasserWastewater

Owner:CHINA HAISUM ENG

Vibrated fluidized bed

InactiveCN104613734AReduce weightReduce noiseDrying solid materials with heatHearth type furnacesMechanical engineeringVibratory fluidized bed

The invention relates to a vibrated fluidized bed. The vibrated fluidized bed comprises a drying cavity and an excitation source, two axial ends of the drying cavity are provided with an air inlet and an air outlet respectively, a vibration screen plate is arranged in the middle of the drying cavity, the wall surface of the hollow middle of the drying cavity is provided with an annular groove corresponding to the vibration screen plate, an annular spring piece is arranged at each of upper and lower ends of the annular groove, the vibration screen plate is fixed into the middle of the annular groove through the spring pieces, and a plurality of air guide holes are densely distributed in the vibration screen plate. A filter screen is arranged between the drying cavity and a vibration mechanism, the wall surface of the drying cavity between the lower surface of the filter screen and the vibration mechanism is provided with a feeding port, the wall surface of one side, opposite to the feeding port, of the wall surface of the drying cavity is provided with a discharging port, and height of the feeding port relative to the upper surface of the vibration screen plate is larger than that of the discharging port. The vibration screen plate inclines towards the discharging port, and the excitation source comprises a pulse valve which is connected onto an exhaust port.

Owner:WUXI HAOYU ENERGY SAVING ENVIRONMENTAL PROTECTION EQUIP CO LTD

Lignite drying system and lignite drying method

InactiveCN103134270ADry fastRealize large-scaleDrying solid materials with heatDrying gas arrangementsFlue gasNitrogen

The invention discloses a lignite drying system and a lignite drying method. The lignite drying system comprises a hot air system, a vibrating fluidized bed dryer, a nitrogen system and a dust removal system, wherein the hot air system is used for injecting work flue gas into the vibrating fluidized bed dryer through a gas inlet pipeline for drying lignite materials, the vibrating fluidized bed dryer is connected with the dust removal system through a gas outlet pipeline, and the nitrogen system is used for injecting nitrogen into the vibrating fluidized bed dryer. According to the lignite drying method, the lignite materials are evenly distributed on a bed surface of the vibrating fluidized bed dryer; the work flue gas at the temperature of 240-320 DEG C and with less than 14% of oxygen content is injected through the bottom of the vibrating fluidized bed dryer; under the combined action of exciting force and the buoyancy of the work flue gas, the lignite materials move towards the rear portion of the vibrating fluidized bed dryer in a fluidized state; and the lignite materials quickly exchange heat with the work flue gas for dehydration and then are discharged through a discharge end of the vibrating fluidized bed dryer. The lignite drying system and the lignite drying method can be used for drying the lignite materials quickly and effectively, and can guarantee safety in the drying process.

Owner:QINHUANGDAO QINYE HEAVY IND

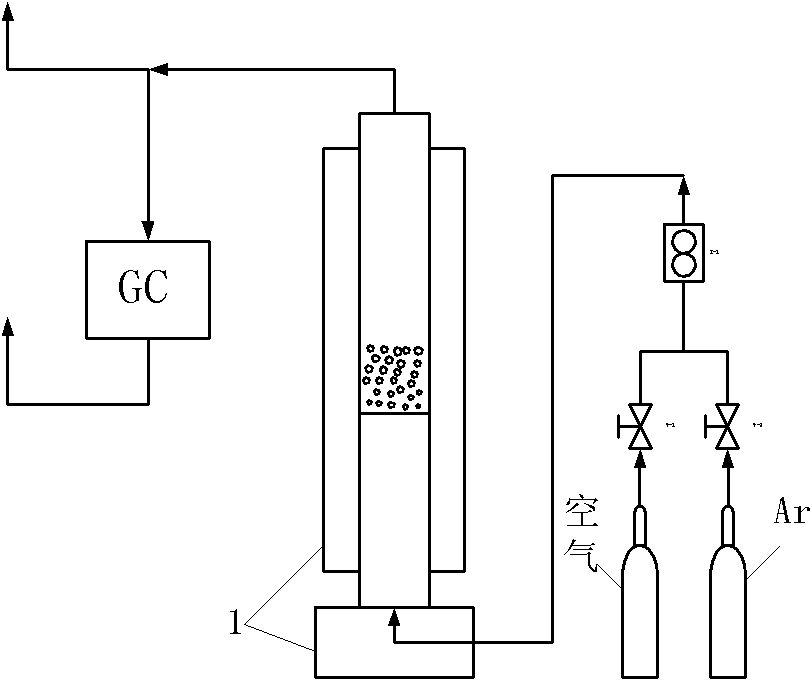

Method for decomposing phosphogypsum through coupling reaction heat and vibration fluidizing

InactiveCN102320640AReduce transmission lossImprove decomposition rateSolid waste disposalSulfur compoundsDry weightDecomposition

The present invention relates to a method for decomposing phosphogypsum through coupling reaction heat and vibration fluidizing. The method for decomposing the phosphogypsum through coupling the reaction heat and vibration fluidizing is characterized in that, the method comprises the following steps: 1) selecting phosphogypsum and coke according to a dry weight ratio of the phosphogypsum to the coke of (5-35):1; selecting an additive, wherein the adding amount of the additive is 12.5% of the weight of the phosphogypsum; uniformly mixing the phosphogypsum, the coke and the additive to obtain a mixed material; 2) adding the mixed material to a vibrating fluidized bed, heating the vibrating fluidized bed to a temperature of 800-1100 DEG C under a condition of argon introducing; then turning the argon off when the vibrating fluidized bed is heated to the temperature of 800-1100 DEG C, synchronously introducing air, wherein the flow rate of the air is 0.0004-0.008 m / s, the temperature of the vibrating fluidized bed is controlled to 800-1100 DEG C, the reaction time is 10-60 minutes. With the method provided by the present invention, the energy consumption can be effectively reduced, the decomposition rate of the phosphogypsum can be improved, and the product is not easy to be agglomerated.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com