Vibrated fluidized bed electric separator

A technology of vibrating fluidized bed and electric separator, applied in electrostatic effect separation, chemical instruments and methods, solid separation, etc., can solve the problems of poor separation of fine-grained minerals and limited application range, etc. Wide range of well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to specific embodiments and accompanying drawings.

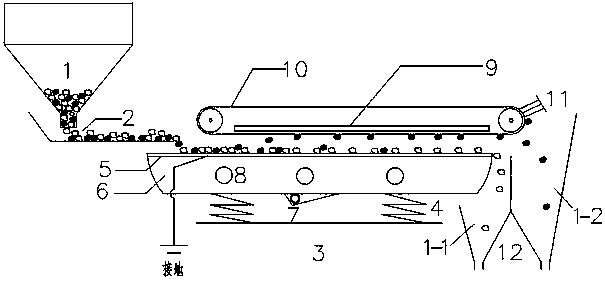

[0018] like figure 1 As shown, a vibrating fluidized bed electrical separator includes a material buffer bin 1, a feeding device 2, a base 3, a vibrating fluidized bed, a high-voltage electrode plate 9, a non-conductor belt 10 and a material collection device 12. The silo 1 is installed above the feeding device 2. The vibrating fluidized bed includes a vibration exciter 7, an air distribution chamber 6 and a conductive air distribution plate 5. The conductive air distribution plate 5 constitutes the conductive working surface of the vibrating fluidized bed. The conductive air distribution plate 5 is sealed and fixed above the air distribution chamber 6 through insulating materials, provides a constant airflow into the air distribution chamber 6 through the air inlet 8, and forms an upward airflow through the conductive air distribution plate 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com