Wide-particle-size coal series kaolinite upgrading process based on fluidization sorting

A technology for coal-measure kaolin and kaolin, which is applied in the field of wide-grained coal-measure kaolin upgrading technology, can solve the problems of low recovery rate of kaolin concentrate, extensive processing and utilization technology, and high energy consumption in the production process, so as to improve the added value of products. , The effect of recycling is simple and energy consumption is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

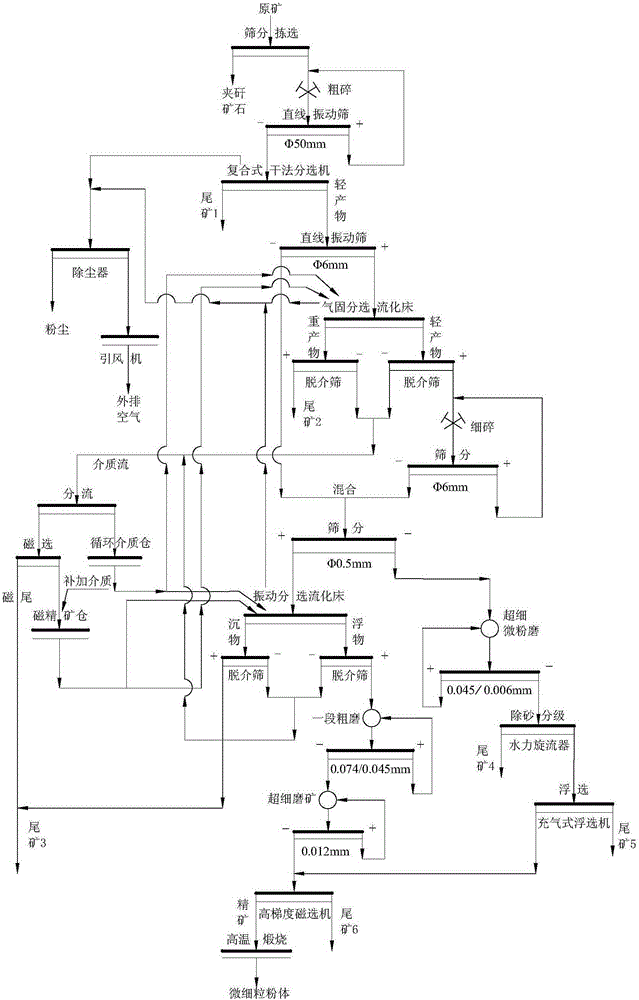

[0027] The separation and purification process of the present invention includes: raw ore preparation stage, pre-sorting stage, separation stage, grinding stage, magnetic separation stage, medium purification cycle stage, induced wind and dust removal stage; the raw ore preparation stage includes mechanical sorting, Coarse crushing and drying process, to provide raw materials with particle size and feed moisture that meet the requirements for fluidized bed separation; the pre-separation stage is to conduct preliminary separation of -50mm raw ore through a compound dry separator, Exclude dense gangue and other impurities; the separation stage includes dense gas-solid fluidized bed separation, vibrating fluidized bed separation and inflatable flotation machine separation, in order to realize the separation of coal series kaolin with different particle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com