Patents

Literature

39 results about "Kaolinite clay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

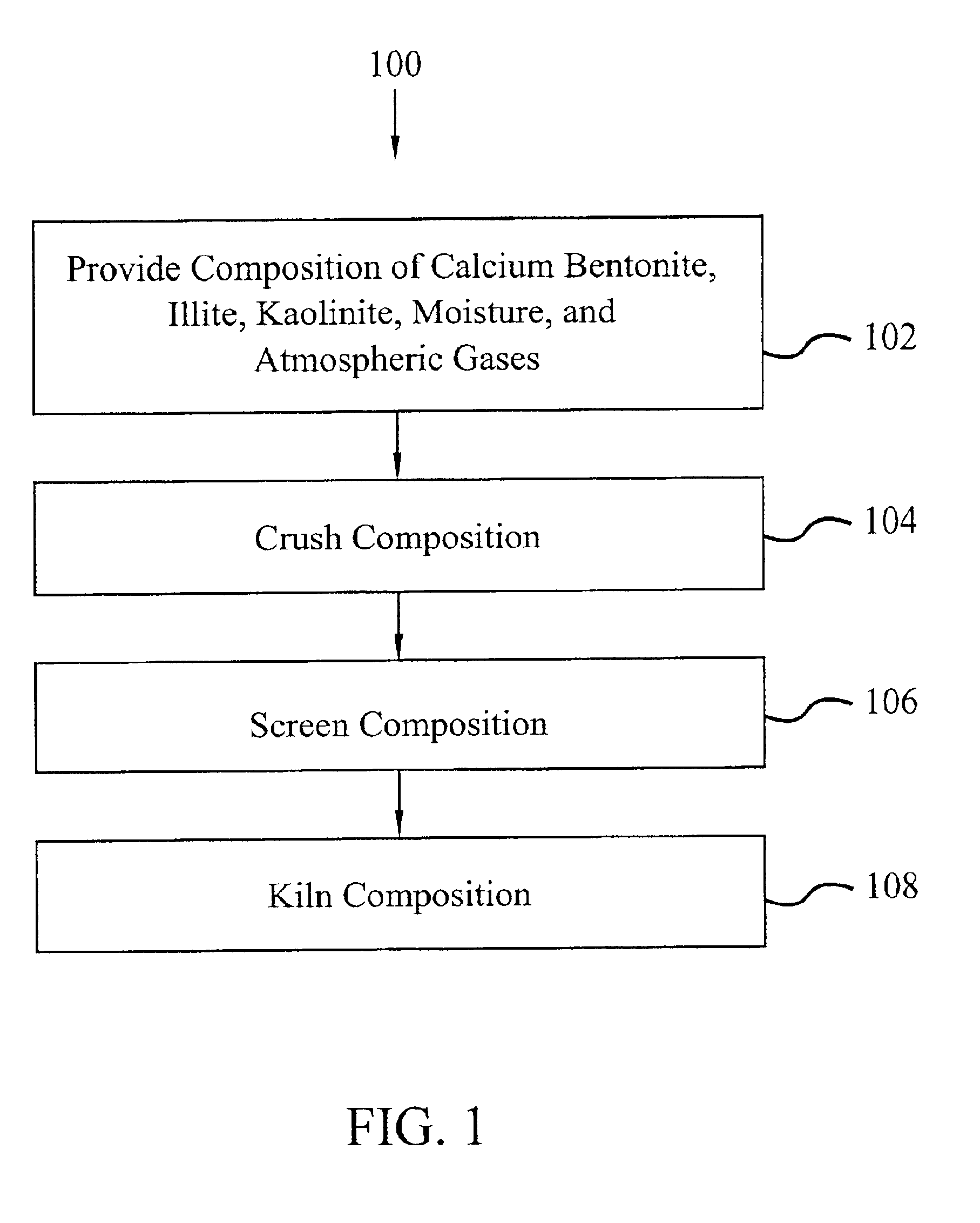

Animal litter and methods of fabricating same

InactiveUS20030209203A1Physical/chemical process catalystsOther chemical processesAnimal scienceSodium Bentonite

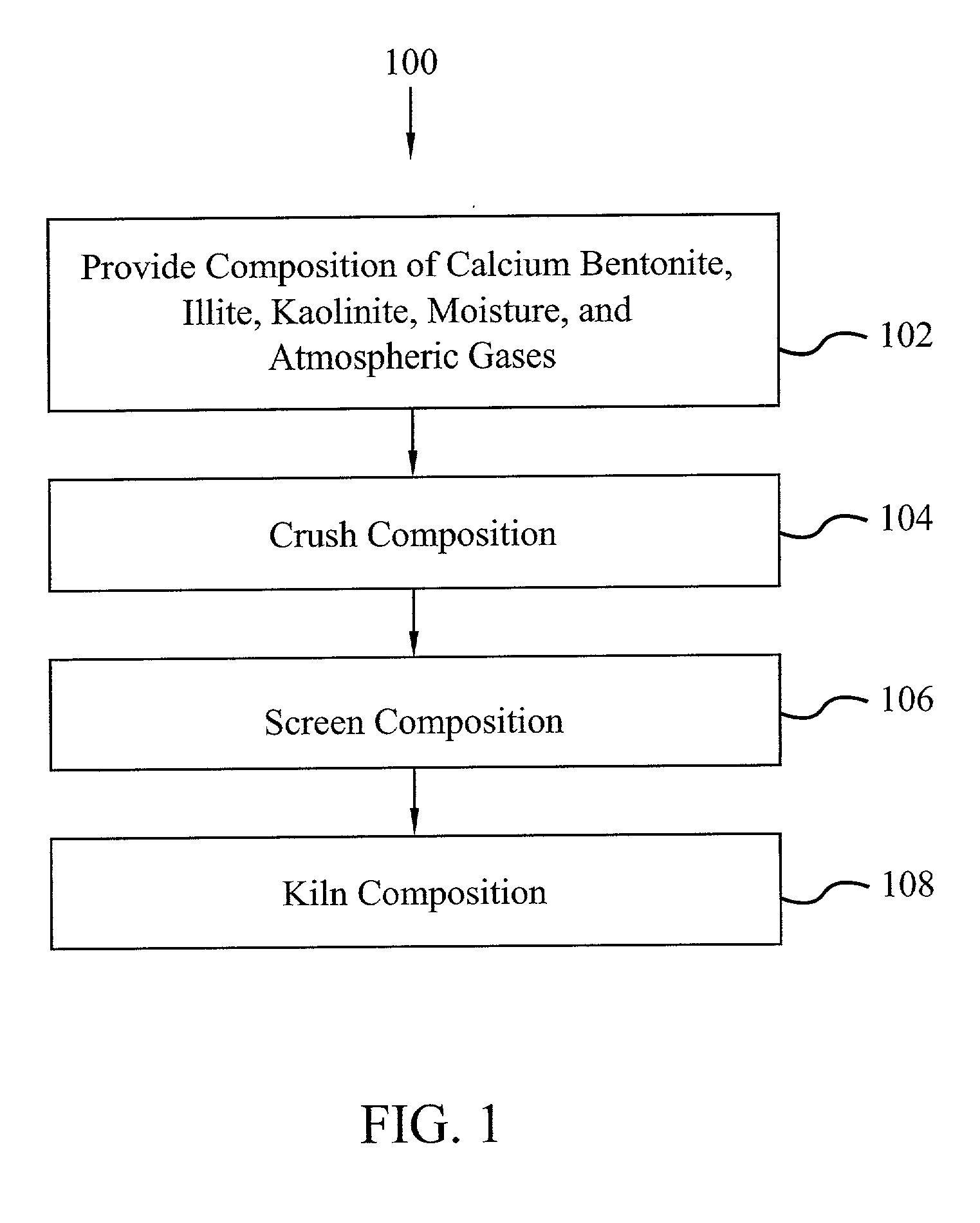

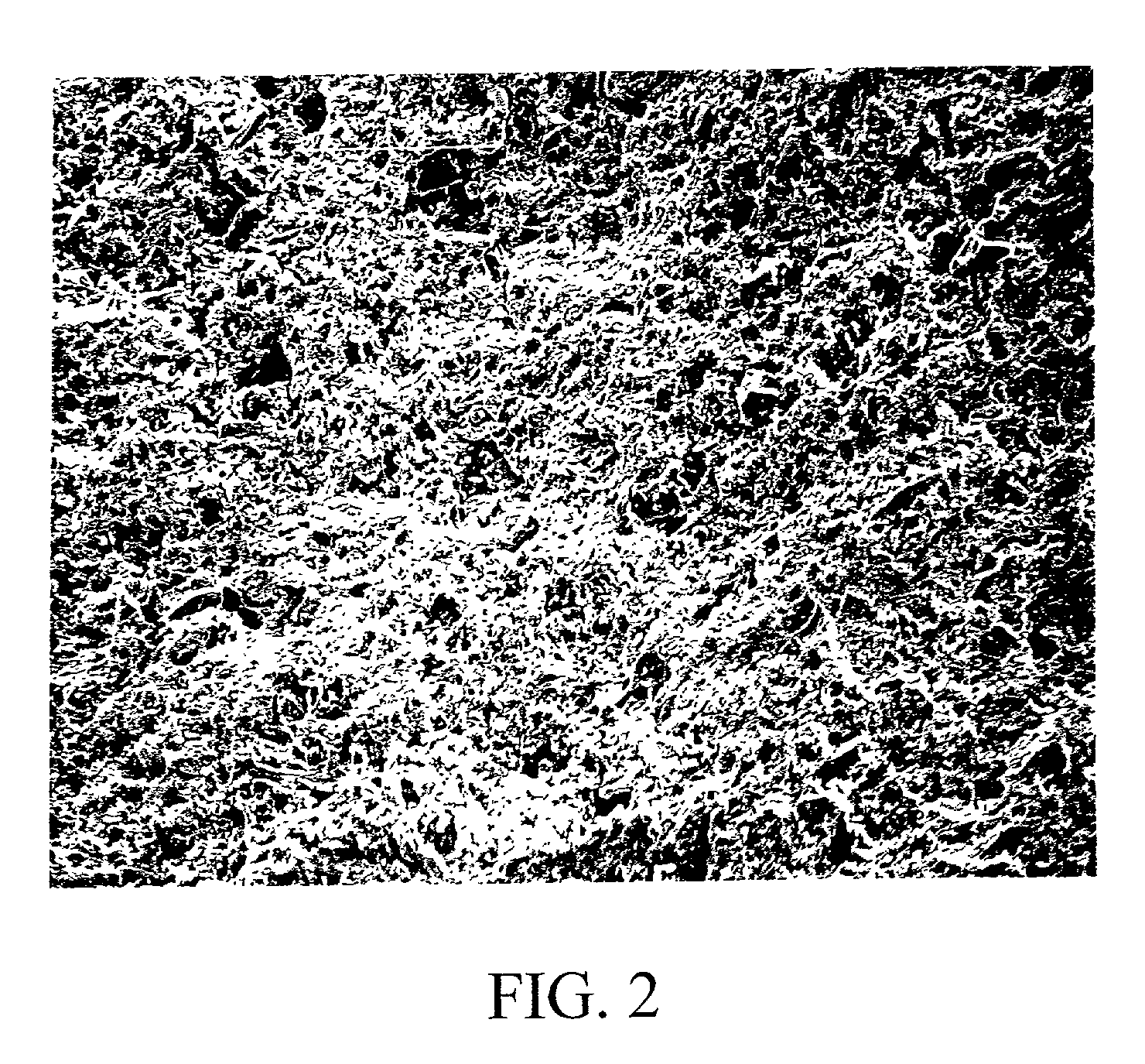

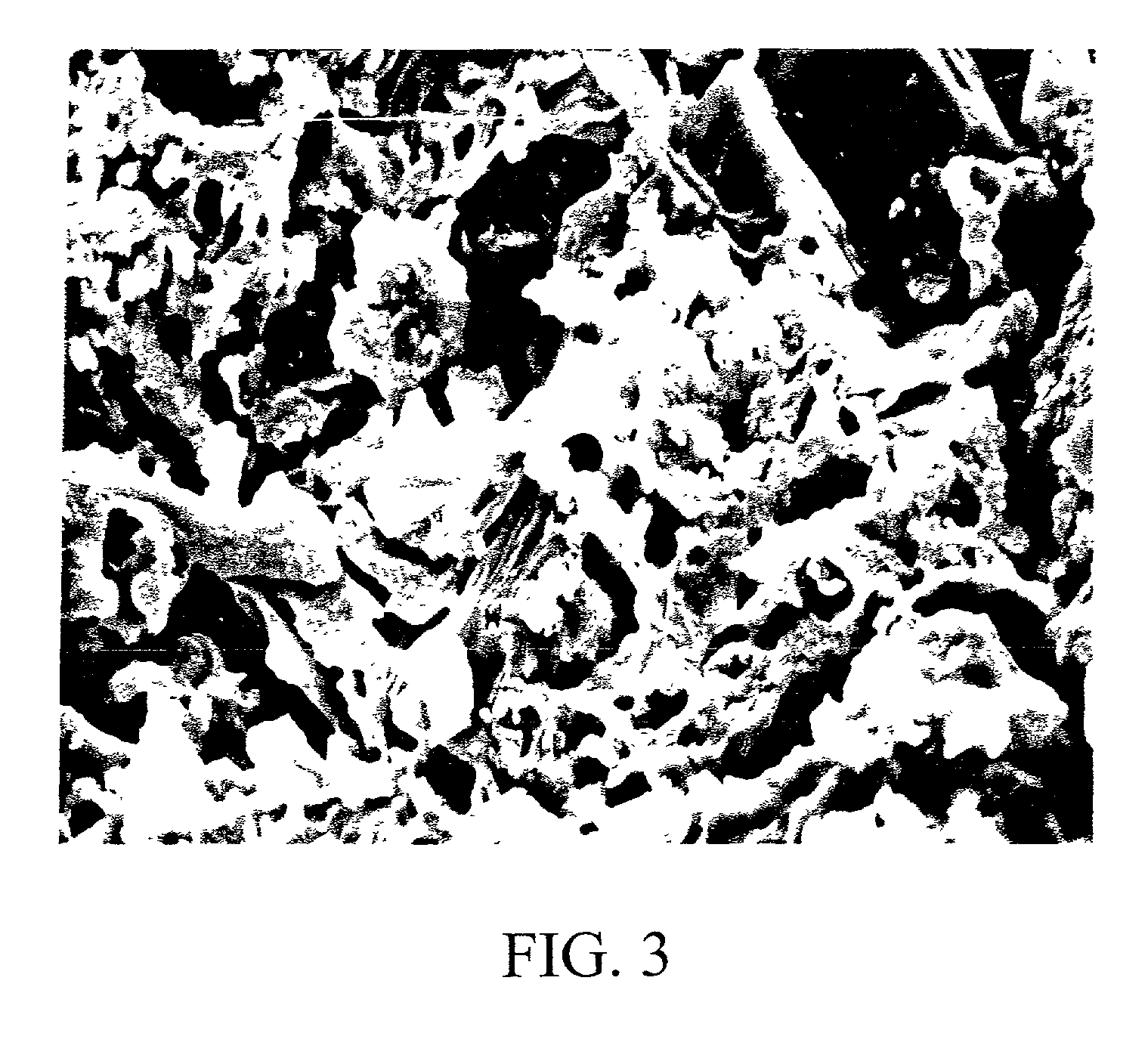

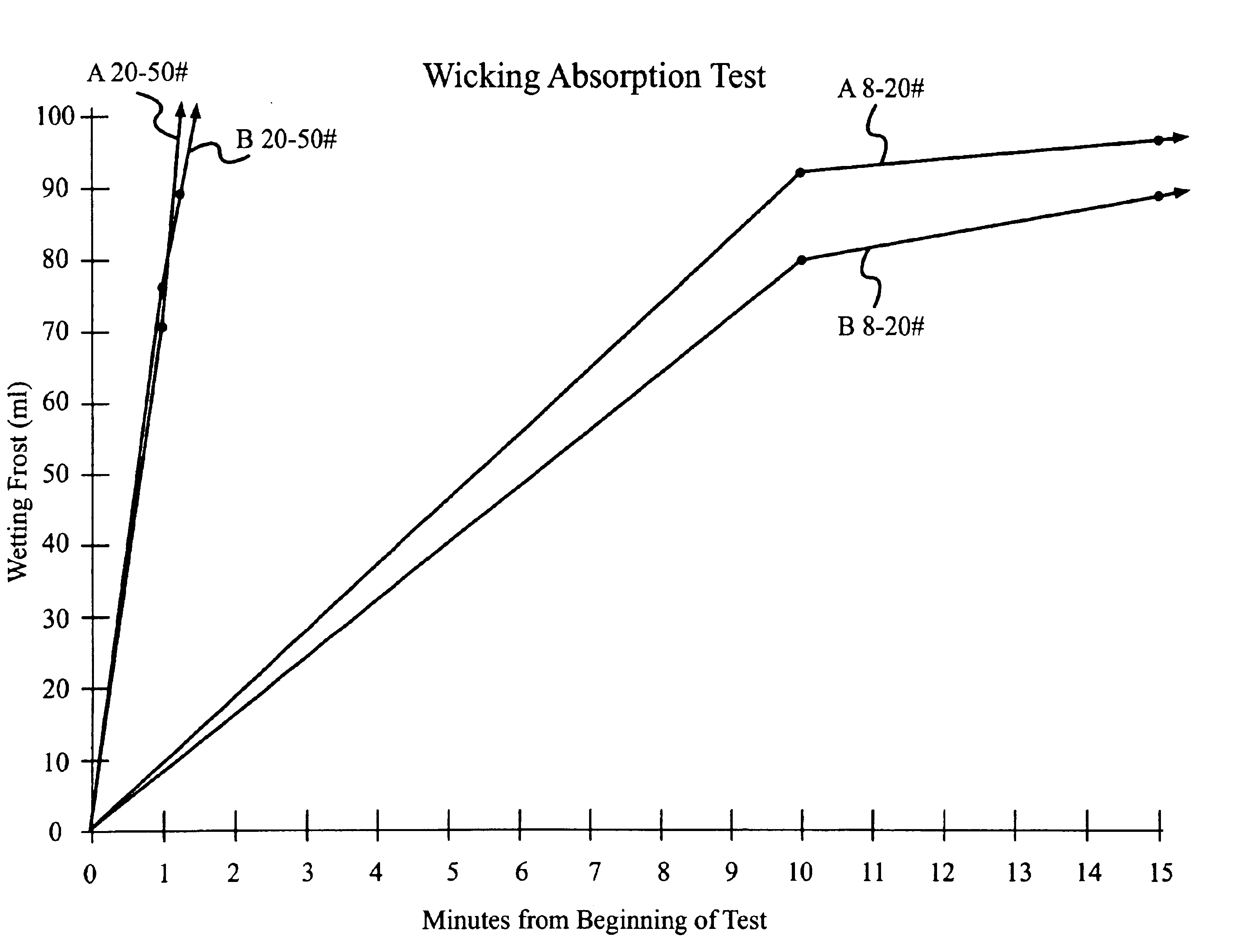

An improved animal litter with granules having high hardness coupled with high absorbency, thereby rendering the animal litter long lasting and durable, dust and odor free, easy to clean and maintain, and inexpensive in contrast to conventional animal litters. The improved animal litter is a composition comprising granules having calcium bentonite clay, illite clay, and / or kaolinite clay. A method of fabricating the improved animal litter includes the step of providing a composition comprising granules having calcium bentonite clay, illite clay, and / or kaolinite clay. Additional steps may also be included, namely: crushing the composition; screening the composition; kilning the composition; and washing the composition.

Owner:EQUIDRY BEDDING PRODS

Nano crystallite composite filter material and supplement of manufacture method thereof

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

Kaolinite-clay-containing in situ crystallizing ZSM-5 and Y type molecular sieve static bed catalyst and preparation thereof

The present invention provides a fixed bed catalyst containing kaolin home position crystallization and Y type molecular sieve and its preparing method, the preparing step is firstly baking kaolin under the temperature 1000-1400 Celsius, then mixing with inoculating seed molecular sieve, adhesive, structure addition agent and water, then extruding, further processing quadratic baking under the temperature 600-900 Celsius after forming, then hydrothermal crystallizing according to the NaY molecular sieve or ZSM-5 molecular sieve synthesis condition, the catalyst product is obtained by modifying treating crystallization product. The catalyst prepared by the invention has ZSM-5 and Y molecular sieves at the same time, the molecular sieve has a high content, high activity and stability.

Owner:广西北海惠尔能源科技有限公司

Animal litter and methods of fabricating same

InactiveUS6854421B2Highly hardLong lastingPhysical/chemical process catalystsOther chemical processesAnimal scienceSodium Bentonite

An improved animal litter with granules having high hardness coupled with high absorbency, thereby rendering the animal litter long lasting and durable, dust and odor free, easy to clean and maintain, and inexpensive in contrast to conventional animal litters. The improved animal litter is a composition comprising granules having calcium bentonite clay, illite clay, and / or kaolinite clay. A method of fabricating the improved animal litter includes the step of providing a composition comprising granules having calcium bentonite clay, illite clay, and / or kaolinite clay. Additional steps may also be included, namely: crushing the composition; screening the composition; kilning the composition; and washing the composition.

Owner:EQUIDRY BEDDING PRODS

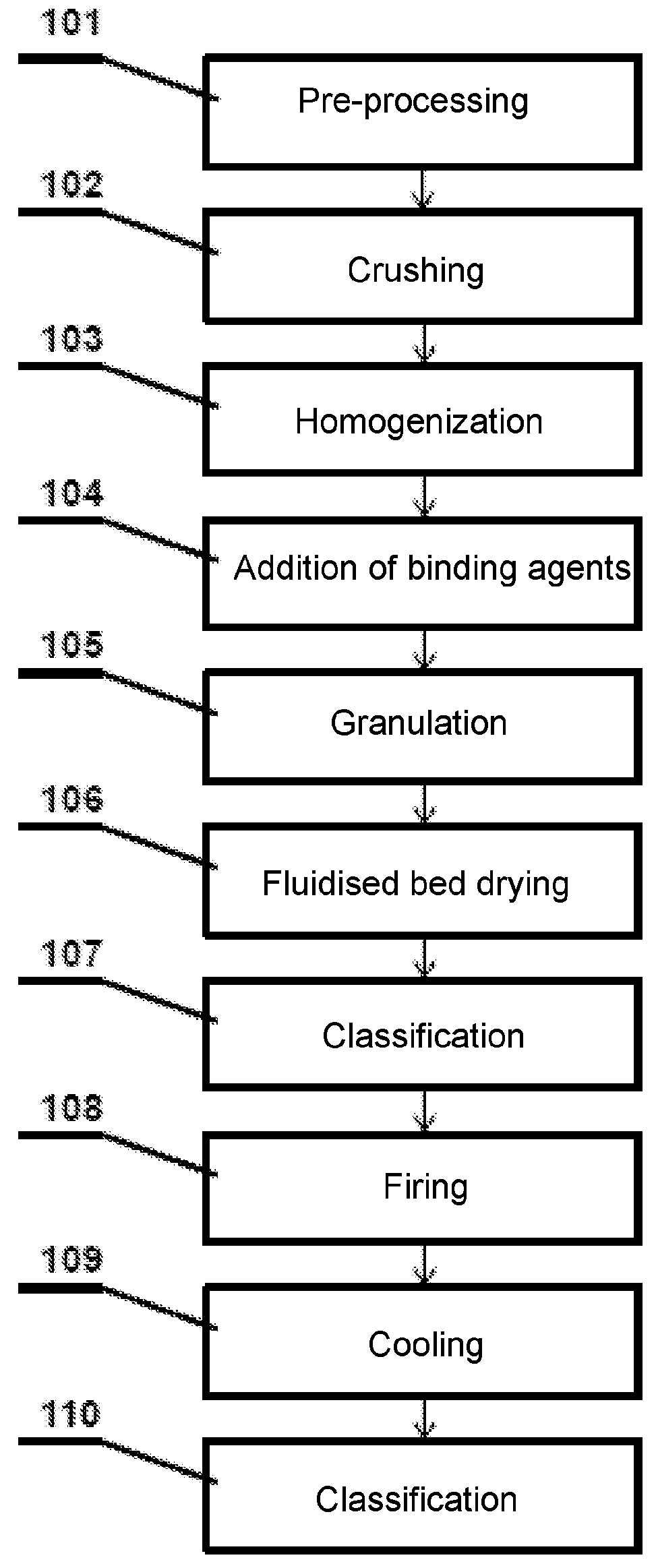

Method of manufacturing of light ceramic proppants and light ceramic proppants

InactiveUS20160053162A1High strengthLow specific gravityFluid removalFlushingFluidized bed dryingMoisture

A method for manufacturing of light ceramic proppants made from a mixture of raw materials that is mechanically granulated in a granulator or that is granulated in a spray dryer from a pourable ceramc mass, to obtain granulate having a granule size of 150-1700 μm (12-100 U.S. Mesh, ASTM E11-04, ISO 13503-2), and next the granulate is fired and the fired granulate is fractioned. The mixture of raw materials is prepared from: illite-beidellite-ka-olinite high-plastic clays of the Poznan series in the amount of 10% to 40% by weight; kaolinite clays in the amount of 10% to 45% by weight; kaolin in the amount of 20% to 40% by weight; fly ash from brown coal combusted in a power plant in the amount of 10% to 35% by weight; and treatment agents in the amount of up to 10% by weight. The mixture of raw materials is mixed and homogenized in a homogenizer, and the obtained granulate is fed to a fluidised bed dryer, in which it is dried to a moisture content below 3%, and the granulate is fired in a rotary furnace in a temperature from 1150° C. up to 1410° C. in time from 120 to 600 min, obtaining proppants which contain from 18% to 32% by weight of Al203, from 40% to 76% by weight of SiO2, and have a specific gravity from 2.15 Mg / m3 to 2.90 Mg / m3 and a bulk density from 1.35 Mg / m3 to 1.70 Mg / m3, depending on the firing time.

Owner:BALTIC CERAMICS

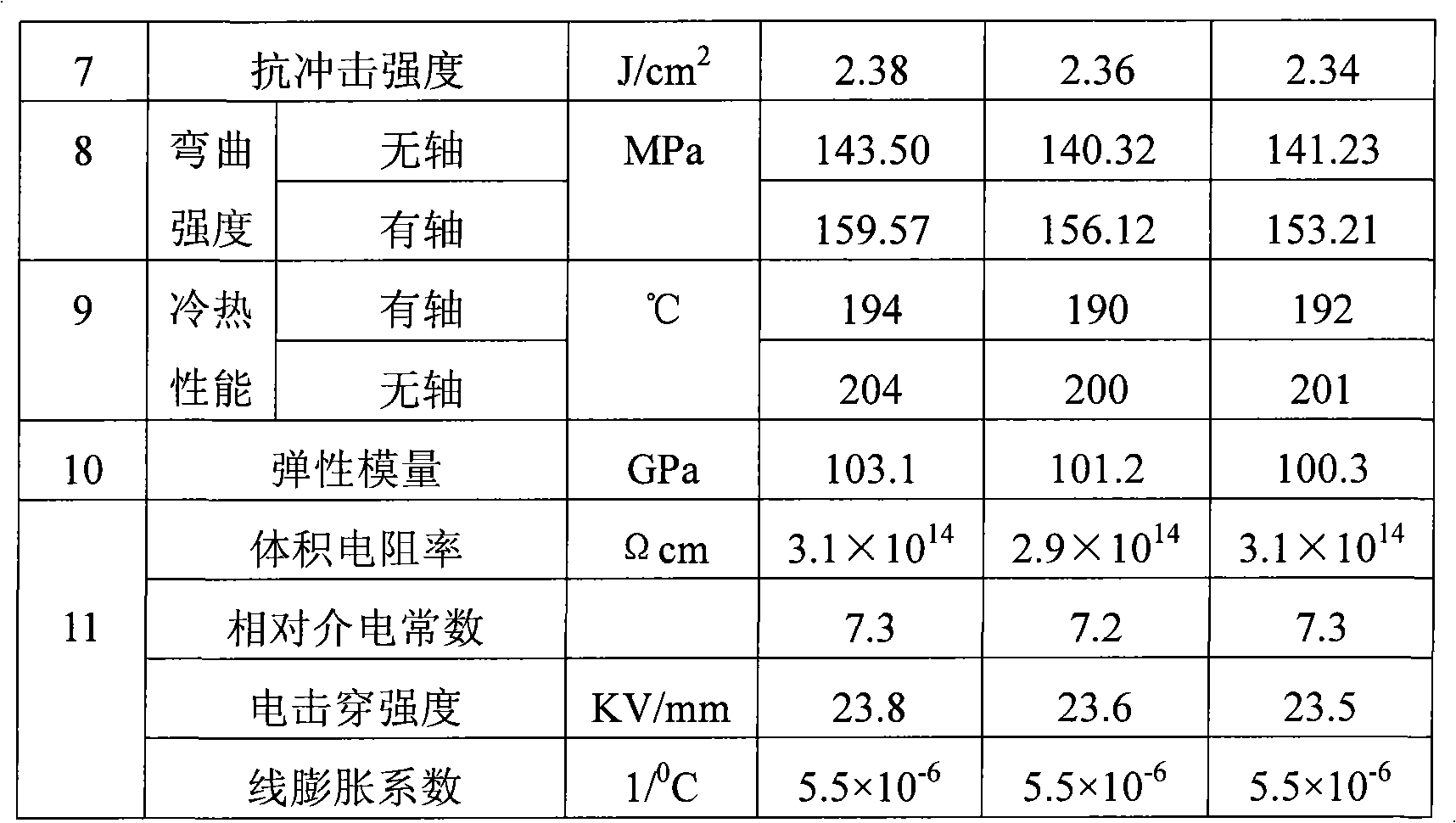

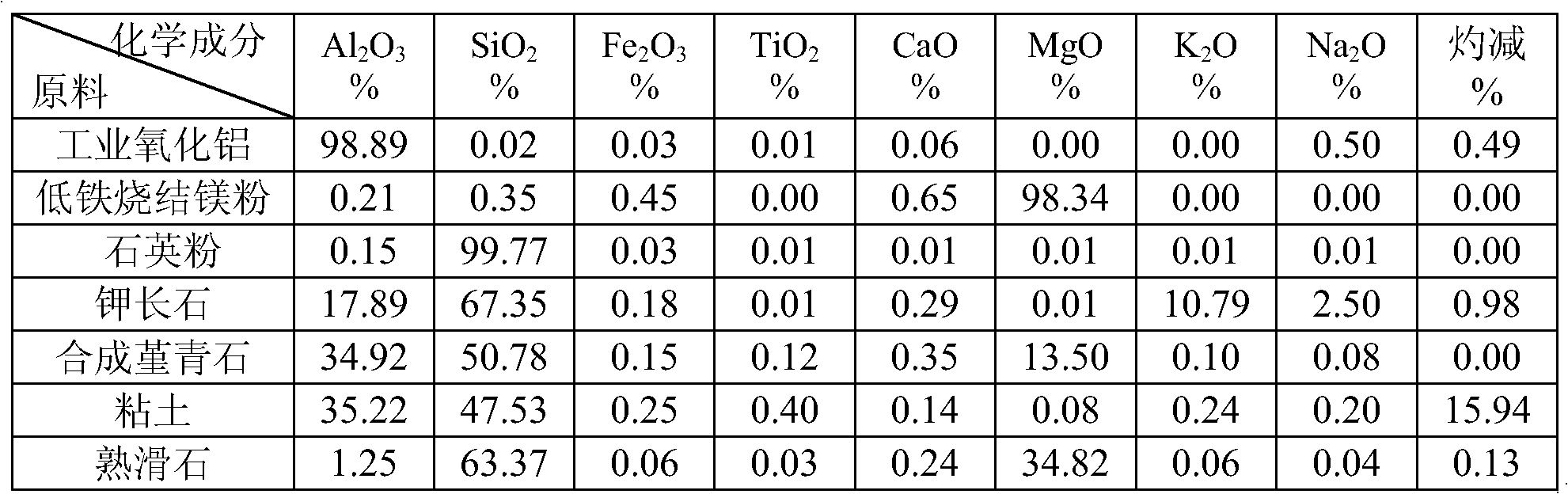

Method for selecting and preparing raw materials of 550kN-grade suspension-type porcelain insulator glaze

InactiveCN101921137AImprove electromechanical performanceImprove insulation performanceFlexural strengthTalc

The invention relates to a method of selecting and preparing raw materials of 550kN-grade suspension-type porcelain insulator glaze. A 550kN-grade porcelain insulator glaze green body can be prepared by selecting 6-20 percent of kaolinite clay, 7-15 percent of talc, 20-40 percent of feldspar, 25-40 percent of refined quartz, 10-20 percent of calcined bauxite, 3-15 percent of calcium carbonate, 0-10 percent of medium porcelain powder and 0.001-1 percent of sodium silicate. The granularity of the clay is 20-40mu, and the granularity of other raw materials is 180-200mu.The glaze is prepared by using the raw materials and the method has good flowability and little multiviscosity, and is convenient for glazing operation; and the glazed and sintered porcelain green body has bending strength of being improved by 25-40 percent, therefore, the electromechanical properties and the insulating property of a porcelain insulator are improved and the quality of the porcelain insulator product is guaranteed.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI +1

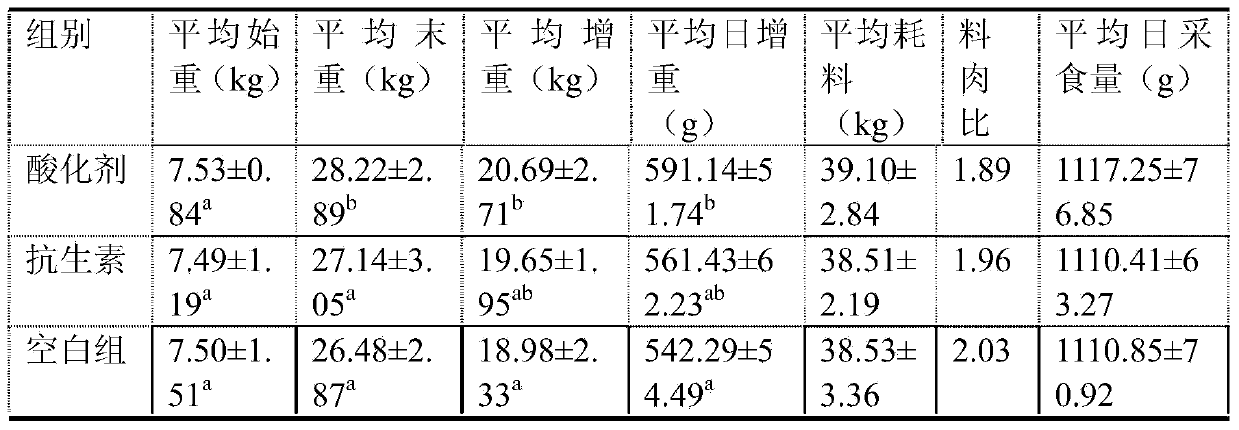

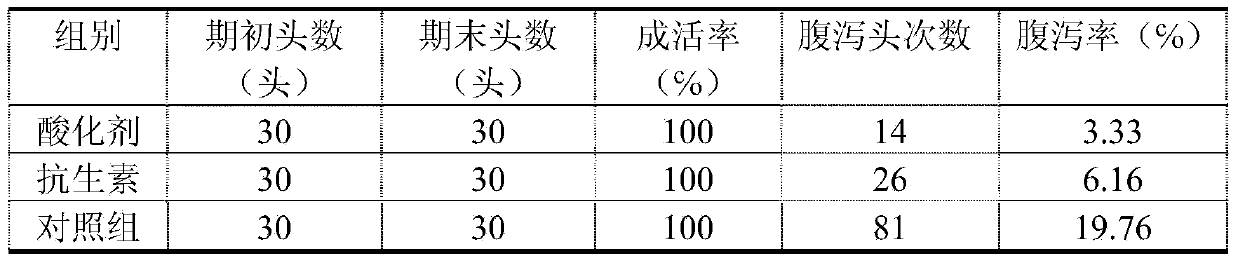

Novel acidifying agent and preparation method thereof

The invention provides a novel acidifying agent which comprises organic acid and organic salt; the organic salt selects preferably organic potassium / calcium salt synthesized by some organic acid and alkaline substances containing a potassium source or a calcium source. The invention further provides an acidifying agent carrier, namely an excipient carrier formed by mixing kaolinite clay and white carbon black. The acidifying agent provided by the invention can enhance the digestion and absorption capacity of the weaning piglets, and achieve the purposes of preventing excessive fluctuation of gastric acid, thereby improving the digestion capacity of the weaning piglets and reducing medicine taking of the piglets; besides, the organic acid / potassium salt can make up the partial deficiency in the utilization of mineral substances in the feed and improve the balance of electrolyte in the bodies of domestic animals.

Owner:安徽泰格维生素实业有限公司

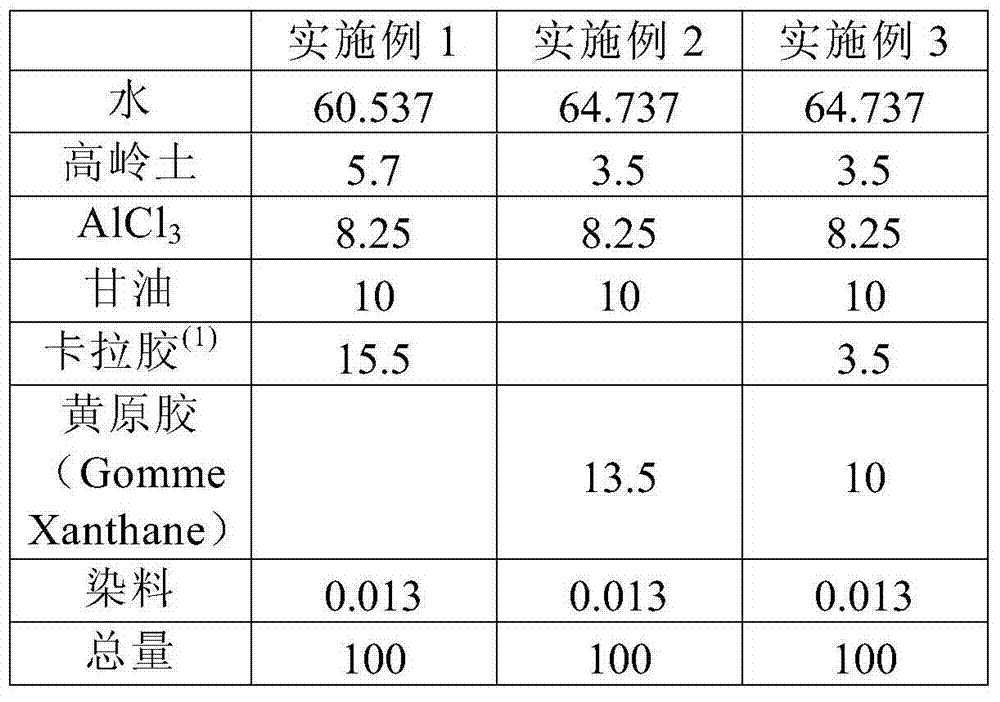

Novel haemostatic composition

InactiveCN103687581AAvoid loss of mechanical propertiesSufficient cohesionOrganic active ingredientsHeavy metal active ingredientsAluminium chloridePlant fibre

Owner:LESAGE

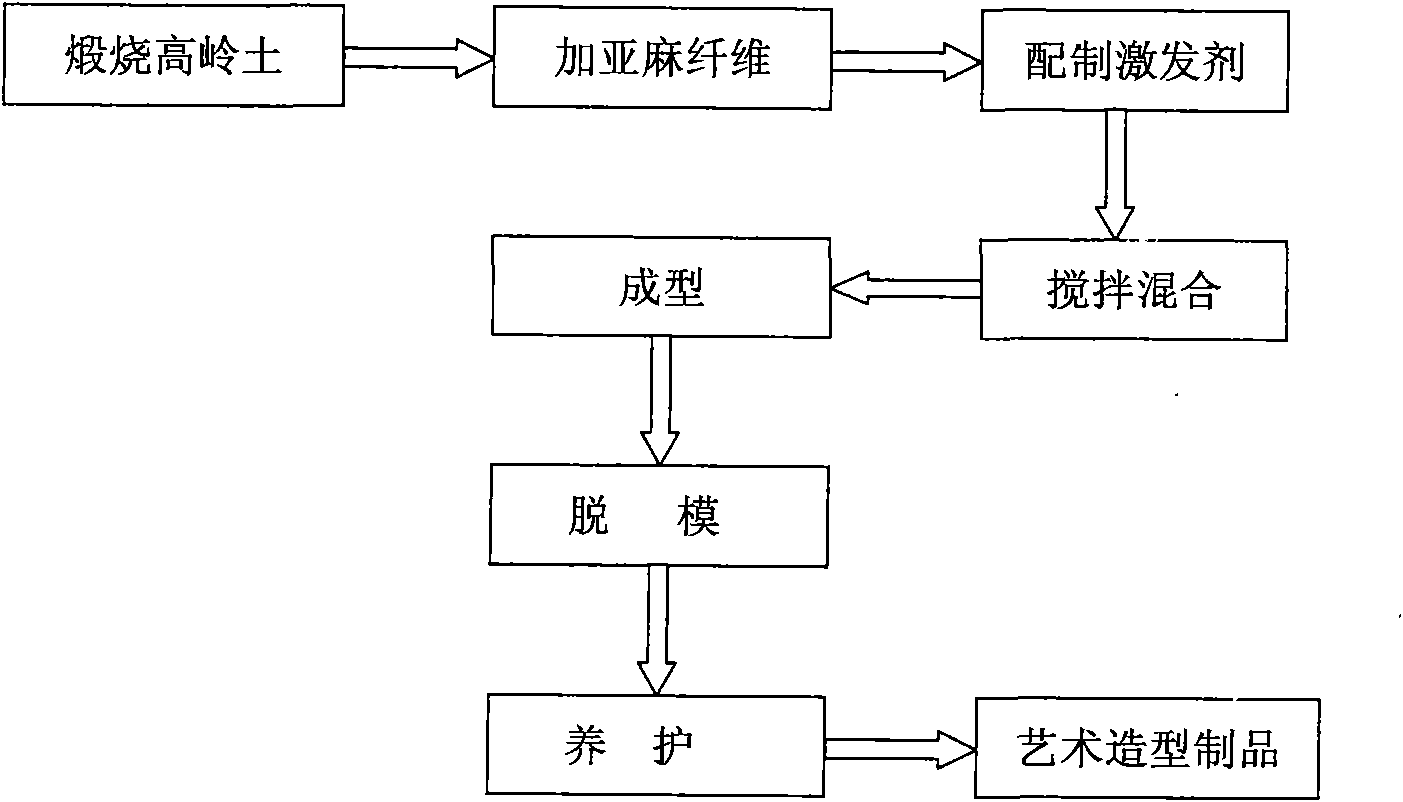

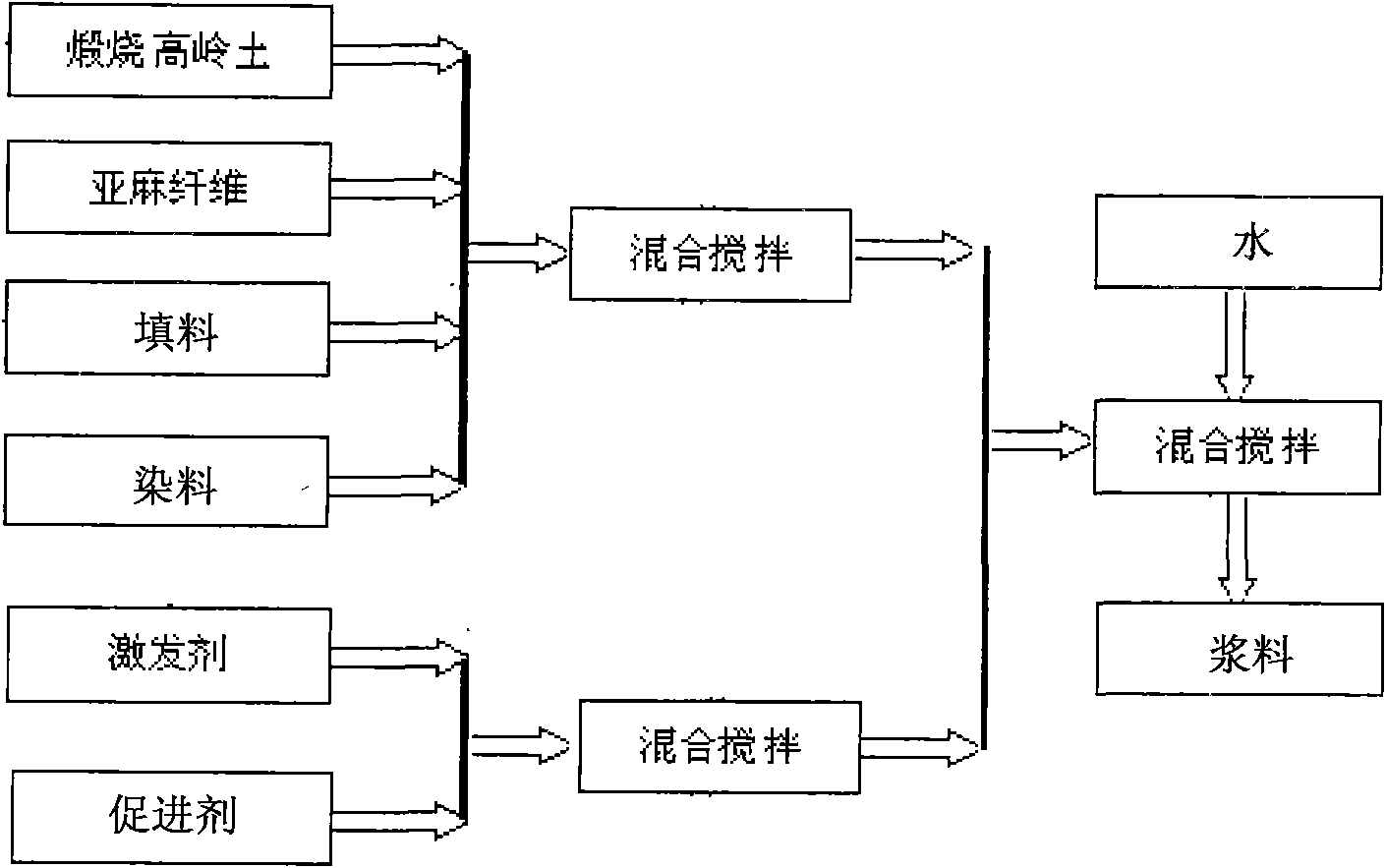

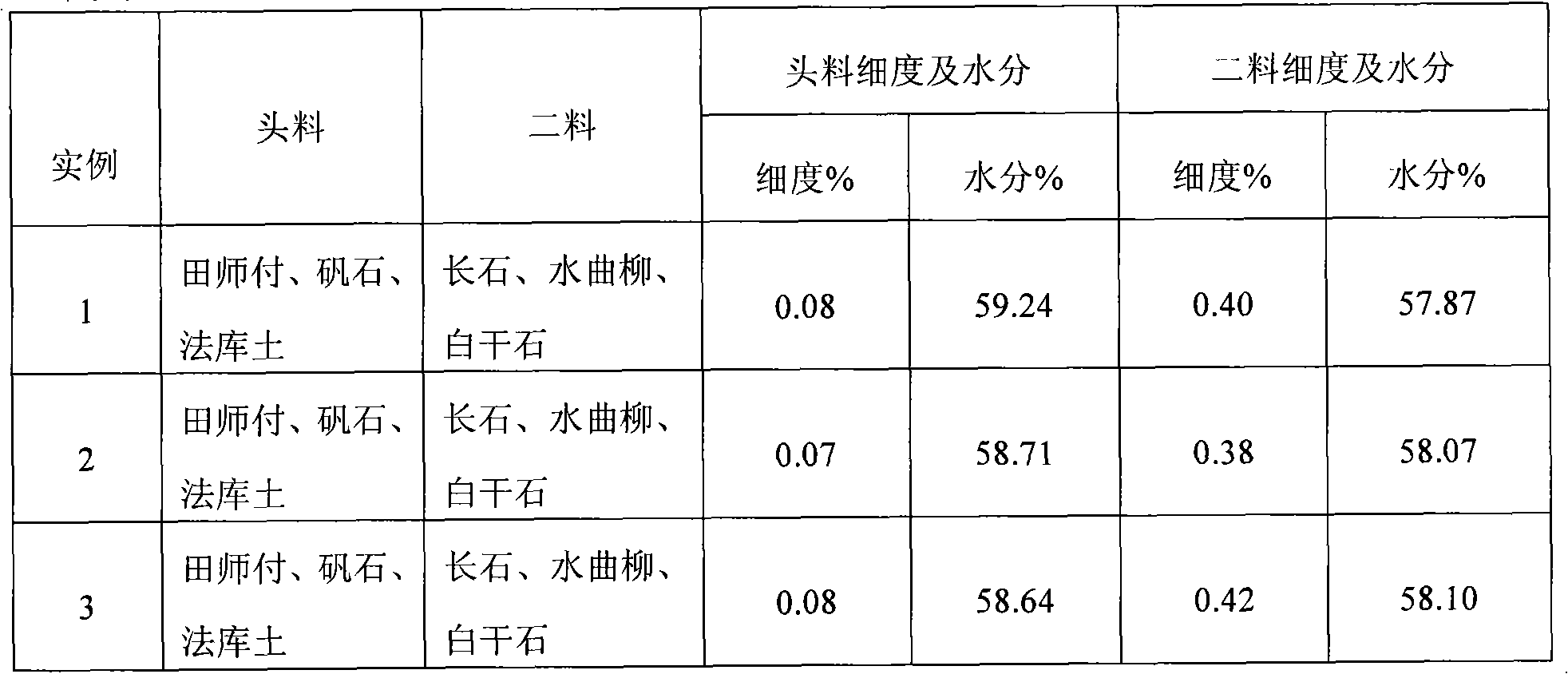

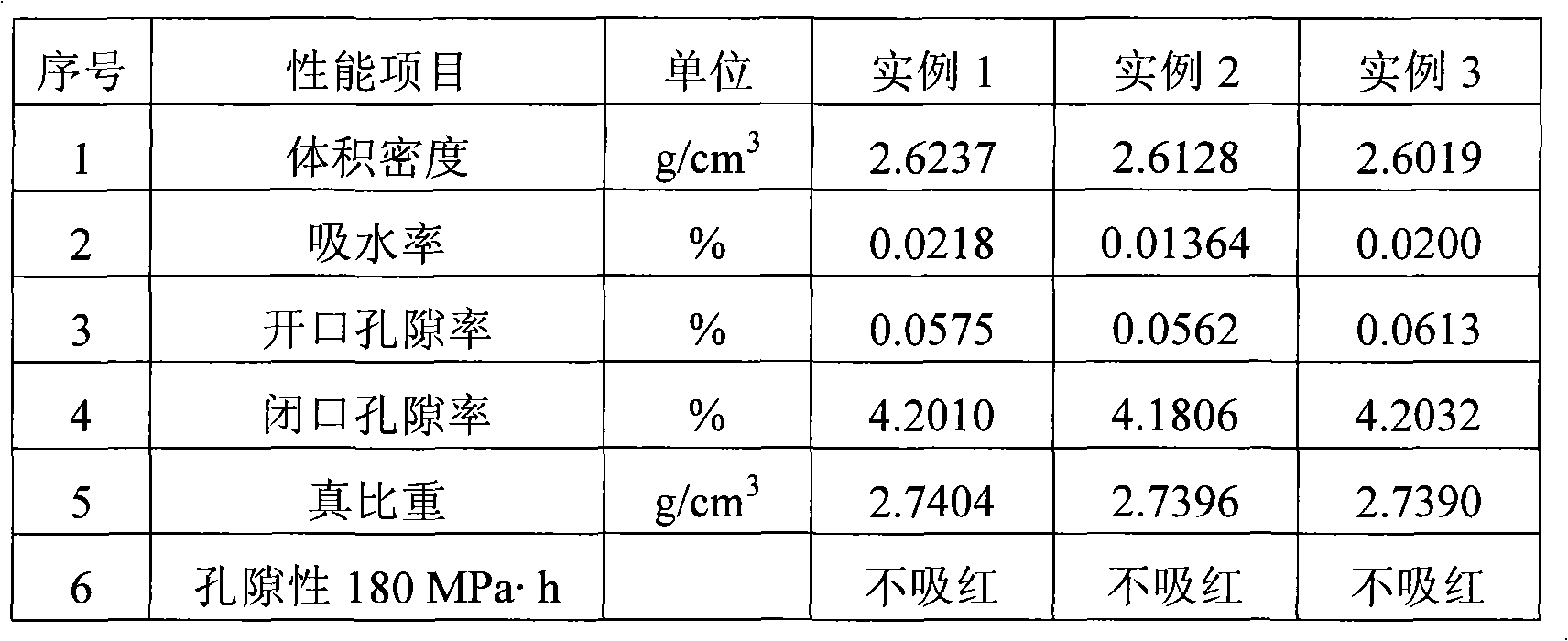

Flax ultrashort fiber geopolymer composite ornamental molding material

InactiveCN101570036AStrong weather resistanceHigh hardnessMixing operation control apparatusCeramic shaping apparatusBrickSlag

The invention relates to a natural vegetable fiber reinforced geopolymer composite material and a preparation method thereof, belonging to the field of ornamental molding and environmental-friendly materials. The composite ornamental molding material comprises the following materials according to weight percentage, 30 to 70 percent of low-temperature calcination kaolinite clay grain diameter of which is 200 meshes, 5 to 40 percent of waste flax ultrashort fiber, 0 to 30 percent of fly ash of power plants or 0 to 30 percent of carbide slag degree of fineness of which is 150 meshes, 5 to 10 percent of booster, 4 to 5 percent of accelerant, NaHO water solution, hardener concentration of which is 12 percent, and 0 to 1 percent of paint, wherein the accelerant is industrial sodium silicate; and modulus M equals to 3.3. The composite ornamental molding material can replace the traditional ornamental molding materials like plaster, cement and clay, is suitable for manufacturing such products as ashlar artwork, embossed wall bricks, sculptures, floor bricks, and the like for architectural ornaments, and has low cost and better performance than traditional materials.

Owner:宗明明 +1

Cristobalite high strength porcelain formula

The invention provides a cristobalite high strength porcelain formula, aiming to solve the technical problem that in the traditional high strength electric porcelain formula, the proportion of aluminite reaches 35-45 percent and the proportion of feldspar is 15-20 percent, and if the high strength electric porcelain is expected to be obtained, the production cost of the electric porcelain is bound to increase because the price of the aluminite is highest in the raw materials used by the electric porcelain formula. In the cristobalite high strength porcelain formula, the key point is that the blank formula comprises 21-28 percent of aluminite, 5-10 percent of feldspar, 11-17 percent of kaolinites clay containing quartzose, 19-25 percent of hard kaolinites clay and the balance of illite clay. The invention is used for producing high-voltage electric porcelain.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

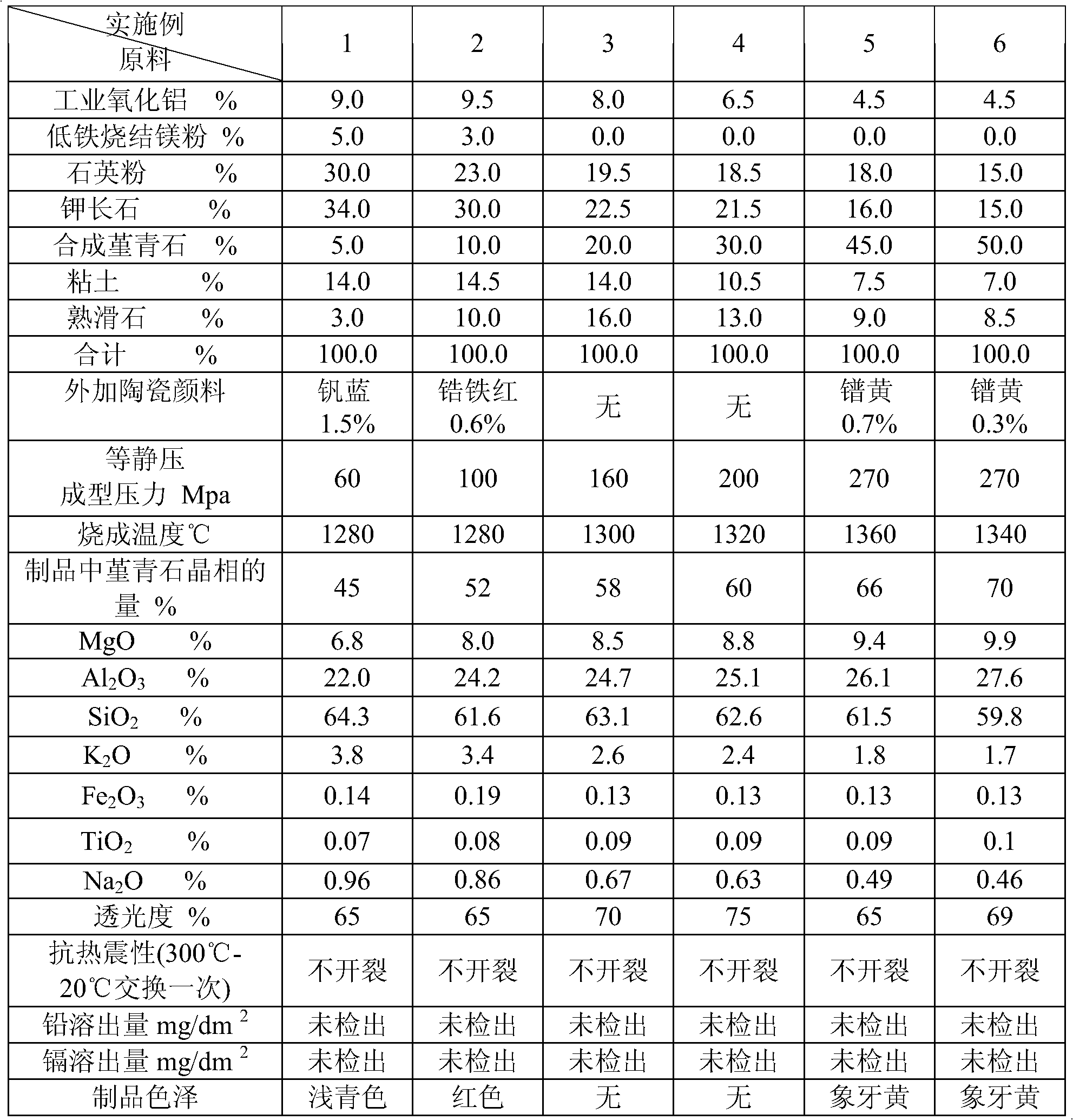

Artificial jade dishware and preparation method thereof

The invention belongs to the field of artificial synthesis of jades, in particular to an artificial jade dishware and a preparation method thereof. The artificial jade dishware comprises the following components by weight percent: 6.5-10.0% of MgO, 22-28% of A12O3, 60-67% of SiO2, 1.7-4.0% of K2O, less than or equal to 0.2% of Fe2O3 and less than or equal to 0.2% of TiO2. The preparation method of the artificial jade dishware comprises the following steps of material preparation, grinding, granulation, blank making and firing. The invention has the advantages that: the artificial jade dishware is prepared by synthetic cordierite, industrial alumina, high-purity kaolinite clay, quartz and other common inorganic raw materials, and the surface of the prepared product has no glaze layer, and the prepared product does not contain lead, cadmium or other heavy metals compared with the traditional ceramics, The appearance is moist and smooth and has a jade texture, and the light transmittance, the hardness and the thermal shock resistance are much higher than those of bone china, magnesia strengthening porcelain and other traditional ceramics.

Owner:ZIBO GT INDAL CERAMICS

Modified bone cement

InactiveCN106267360AImprove mechanical propertiesImprove antibacterial propertiesPharmaceutical delivery mechanismTissue regenerationCarrageenanPolyvinyl alcohol

The invention discloses modified bone cement. The modified bone cement is prepared from, by mass, 2-5 parts of phosphorus pentoxide, 10-12 parts of bioactive glass, 5-6 parts of polyvinyl chloride, 8-10 parts of microcrystal kaolinite clay, 4-6 parts of sodium hydrogen phosphate, 3-5 parts of polyvinyl alcohol, 4-5 parts of ferroferric oxide, 4-6 parts of potassium chloride, 50-55 parts of ammonium sulfate, 10-12 parts of silicon carbide whiskers, 6-8 parts of urea, 5-6 parts of graphite powder, 3-4 parts of sodium polyacrylate, 3-5 parts of polyvinylpyrrolidone, 4-5 parts of carrageenan, 5-8 parts of titanium dioxide, 3-4 parts of ethylparaben, 2-3 parts of 2-amino-2-methyl-1-propanol and 10-12 parts of deionized water. According to the modified bone cement, mechanical performance, antibacterial performance, water collapse resistance, injection performance and bio-compatibility are improved, the degradation rate of the bone cement can be controlled, the degradation rate is matched with the bone formation rate, it is guaranteed that alling or stripping of residues and powder is avoided during operation of the bone cement, no solid-liquid separation phenomenon exists, the process is easy and convenient, and the modified bone cement can be widely used for bio-materials.

Owner:陈新堂

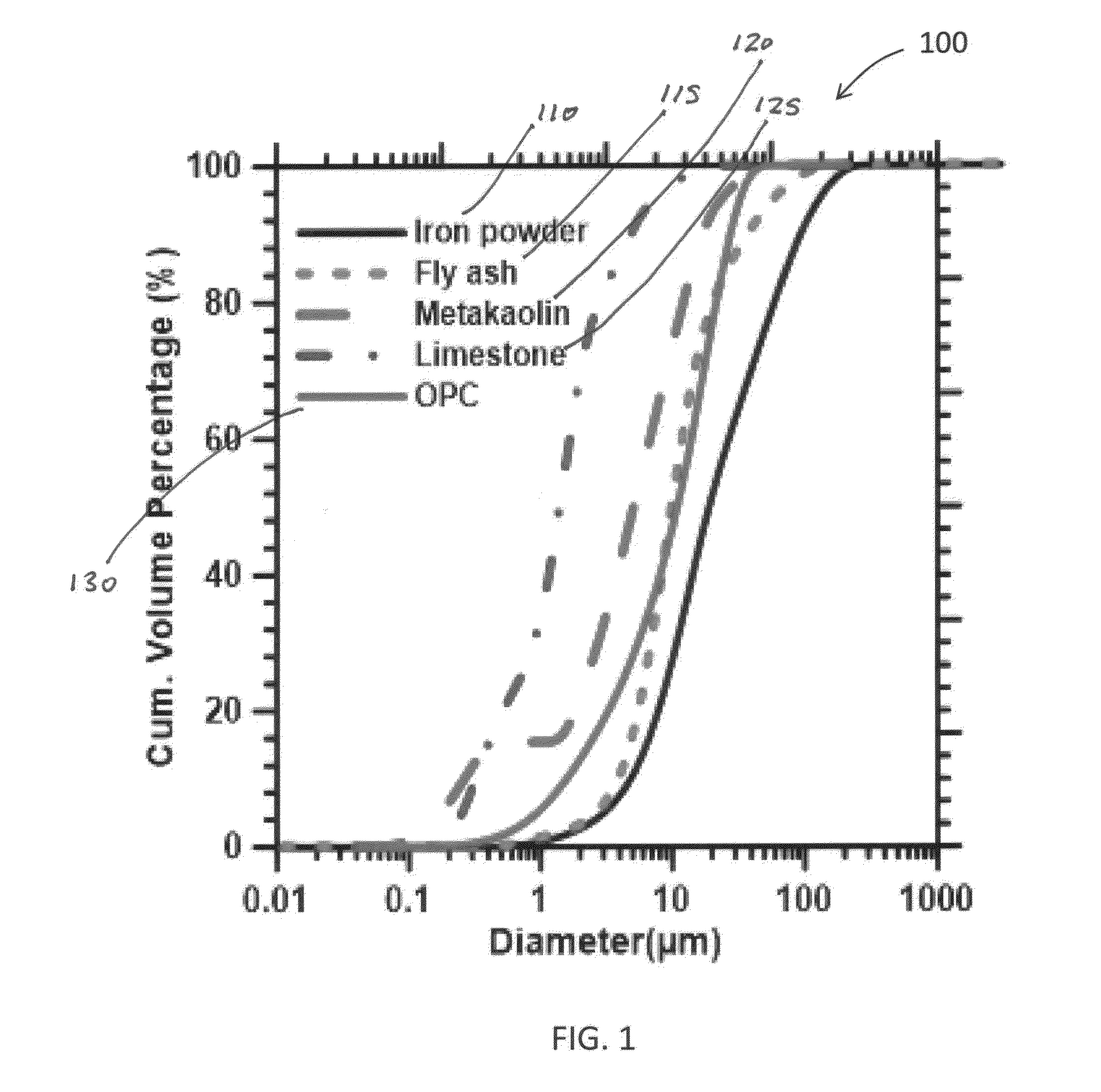

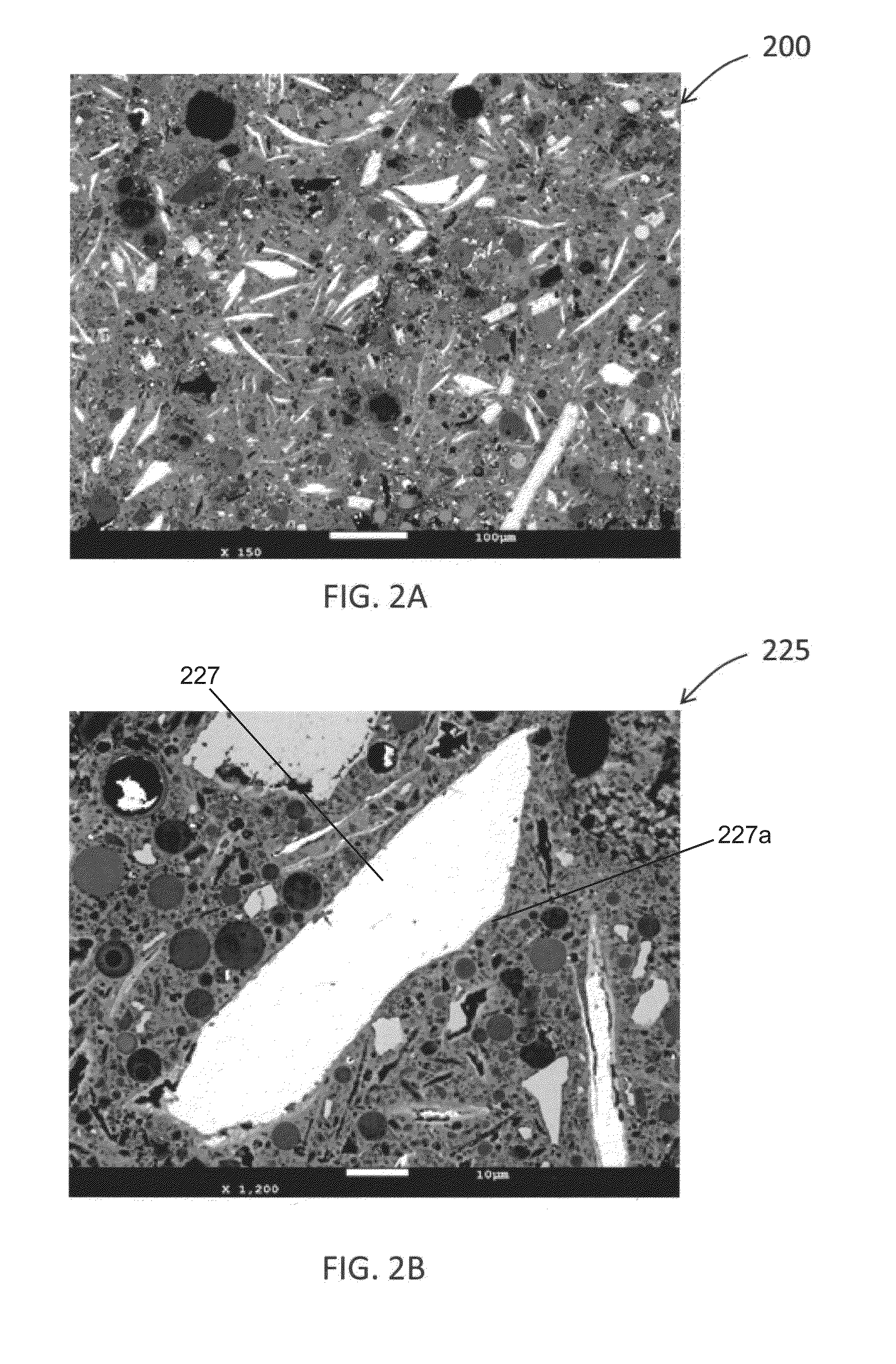

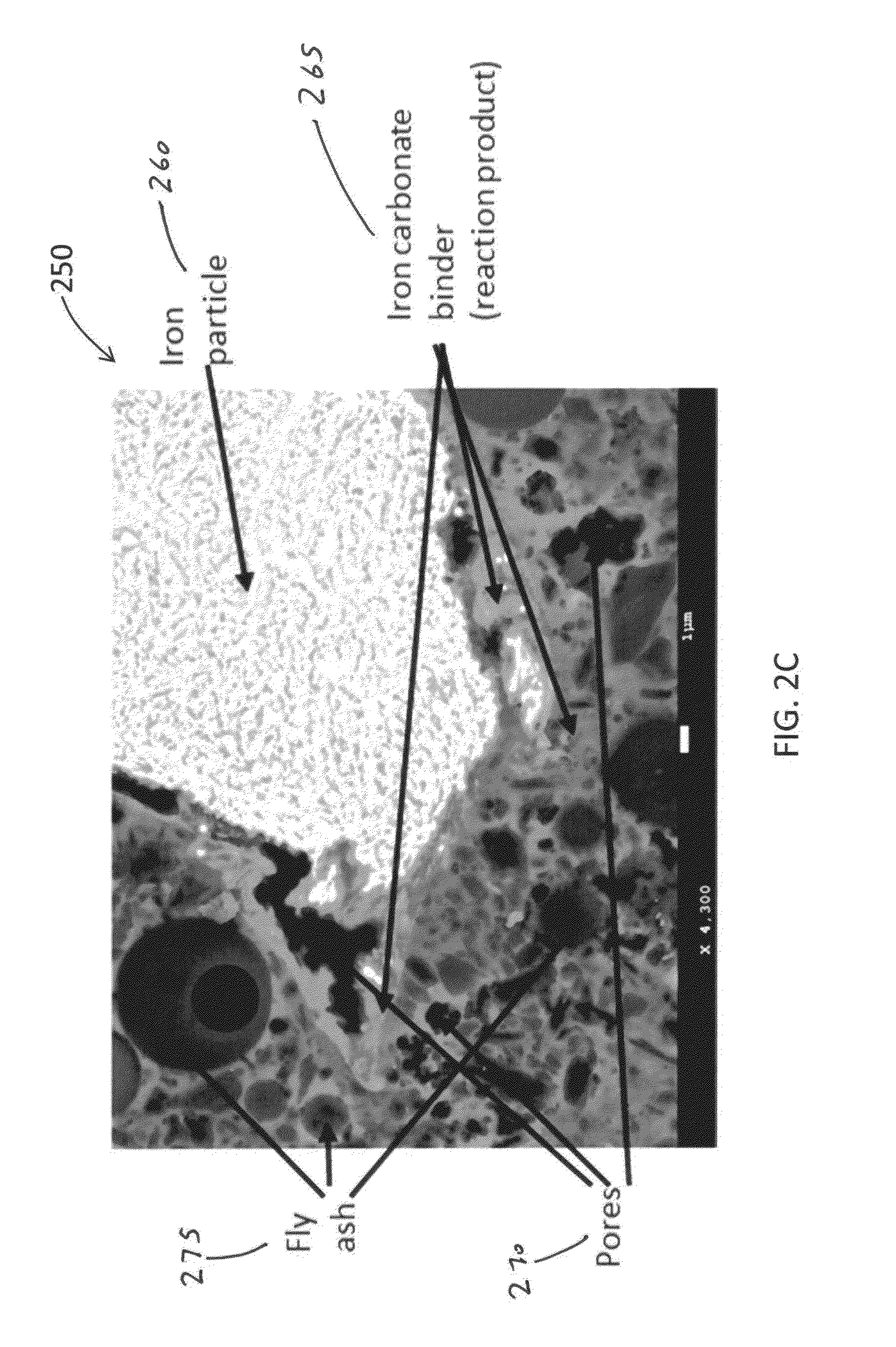

Binder compositions and method of synthesis

Some embodiments of the invention include cementitious iron carbonate binder precursor compositions that includes powdered iron or steel, a first powdered additive including silica, a second powdered additive including calcium carbonate, at least one powdered clay, and a fibrous and / or woven additive. In some embodiments of the invention, the precursor composition includes an alumina additive. In some further embodiments, the powdered clay includes kaolinite clay and / or metakaolin clay. In some further embodiments, the precursor composition includes an organic reducing agent such as oxalic acid. Some embodiments include up to about 60% by weight of powdered iron or steel, up to about 20% by weight of the first powdered additive, up to about 8% by weight of the second powdered additive, up to about 10% by weight of at least one powdered clay, and up to about 2% by weight of an organic acid.

Owner:ARIZONA STATE UNIVERSITY

Caramel clay pottery preparation method

The present invention discloses a caramel clay pottery preparation method, which comprises: uniformly mixing 50-80 parts of kaolinite clay, 10-30 parts of sand soil, and 10-40 parts of Huize glaze soil, crushing, adding water to prepare a mud slurry, filtering to remove the water to obtain billet mud having a water content of 25-40%, carrying out billet throwing molding on the billet mud, and firing in a kiln so as to obtain the caramel clay pottery. According to the present invention, compared with the traditional clay pottery process, the process of the present invention has characteristics of simple material preparing, low cost and simple production process; the yield of the produced clay pottery product is more than or equal to 95%, the produced clay pottery product naturally presents the caramel color, the color is simple, generous, beautiful and looking resistant so as to substantially improve the grade of the clay pottery product, and the produced clay pottery product further has characteristics of durability, no breaking after firing and water soaking, strong high temperature resistance, good gas permeation, and odor eliminating; and the benefit is provided for the body health after long term use of the produced clay pottery product, and the produced clay pottery product is the pure natural, original ecological, green health household container suitable for general consumers.

Owner:赵剑

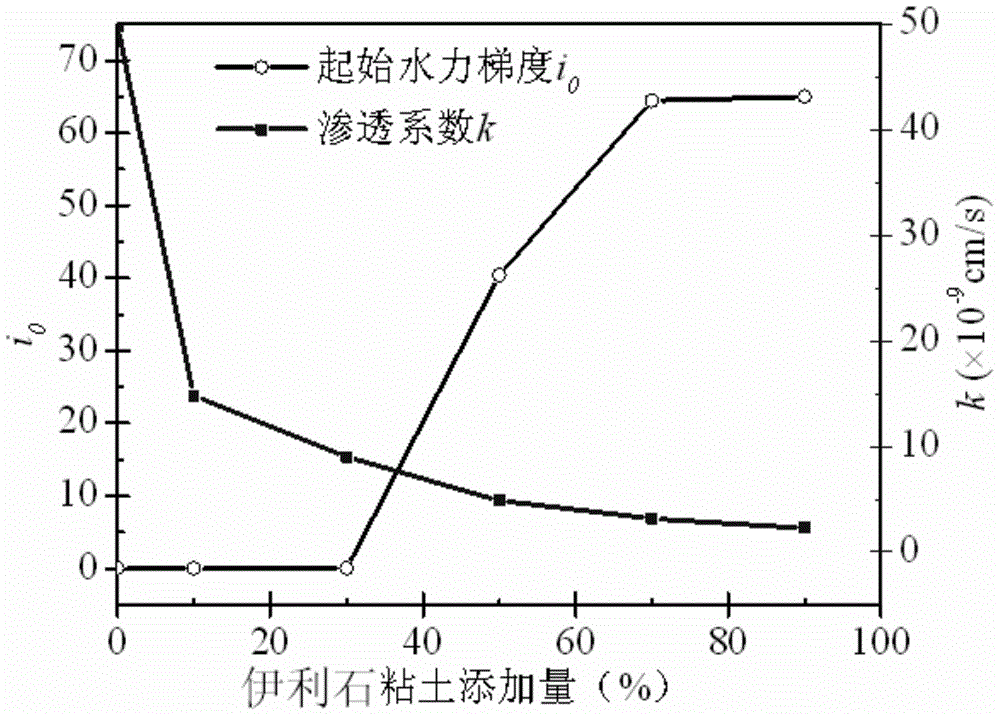

Impermeable clay liner at bottom of refuse landfill and application thereof

The invention relates to an impermeable clay liner at the bottom of a refuse landfill and application thereof. The clay liner is formed by mixing kaolinite clay, illite clay and water and then crushing the mixture, and the porosity is smaller than or equal to 40 percent; the percentage of the mass of the kallinite clay accounting for the total mass of the kallinite clay and the illite clay is denoted as X, wherein 10%<=X<70%; the percentage of the mass of the illite clay accounting for the total mass of the kallinite clay and the illite clay is denoted as Y, wherein 30%<Y<=90%. By seriously controlling the porosity of the clay liner and the proportion of the kaolinite clay and the illite clay, the unexpected effect that a start hydraulic gradient (i0) starts to occur in the clay liner is generated, and therefore permeation of pollutant leachate can be stopped.

Owner:HOHAI UNIV

Filter material for treating industrial waste water and preparation method of filter material

InactiveCN105964058AImprove purification effectImprove work efficiencyTreatment involving filtrationMembrane filtersSodium bicarbonateIndustrial waste water

The invention discloses a filter material for treating industrial wastewater, which is composed of the following raw materials in parts by weight: 3-13 parts of zeolite powder, 5-15 parts of kaolinite clay, 2-10 parts of silicon dioxide, and 1 part of montmorillonite ‑7 parts, expanded perlite 3‑9 parts, tourmaline powder 2‑10 parts, sodium bicarbonate 2‑12 parts, binder 1‑7 parts, pore forming agent 2‑8 parts. The invention has the advantages of good purification effect, high working efficiency, convenient processing and the like.

Owner:ANHUI GUONENG YISHENG ENVIRONMENTAL PROTECTION SCI & TECH

Kaolinite-clay-containing in situ crystallizing ZSM-5 and Y type molecular sieve immobilized bed catalyst and preparation thereof

The present invention provides a fixed bed catalyst containing kaolin home position crystallization and Y type molecular sieve and its preparing method, the preparing step is firstly baking kaolin under the temperature 1000-1400 Celsius, then mixing with inoculating seed molecular sieve, adhesive, structure addition agent and water, then extruding, further processing quadratic baking under the temperature 600-900 Celsius after forming, then hydrothermal crystallizing according to the NaY molecular sieve or ZSM-5 molecular sieve synthesis condition, the catalyst product is obtained by modifying treating crystallization product. The catalyst prepared by the invention has ZSM-5 and Y molecular sieves at the same time, the molecular sieve has a high content, high activity and stability.

Owner:广西北海惠尔能源科技有限公司

Formula and production process of kaolin and white afrodite mixed powder

The invention relates to the technical field of mineral raw materials, and discloses a formula of kaolin and white afrodite mixed powder. The kaolin and white afrodite mixed powder comprises the following raw materials in percentage by weight: 70-85% of white afrodite and 15-30% of kaolin. According to the formula of the kaolin and white afrodite mixed powder and a production process of the kaolinand white afrodite mixed powder, the white afrodite is added, and the white afrodite is a silicon natural rock which is formed by binding quartz sand with silicate minerals. The white afrodite is extremely rich in mineral resources and is abundant in Sichuan, Hubei, Guangxi and the like, mining is convenient, price is low, cost is low, and high transportation cost can be avoided due to abundant production in many places, so that production cost of glass fibers can be reduced. The kaolin is added, and the kaolin is clay and clay rocks which are common in nature and are mainly composed of kaolinite clay minerals. Mixed glass fiber powder components of the kaolin and the white afrodite are very close to pyrophyllite, so that the formula provided by the invention can be used to replace an original formula comprising pyrophyllite powder for carrying out fiber drawing operation, so that the glass fiber drawing operation rate is improved, pyrophyllite resources are saved, and an active promotion effect of reducing cost of glass fiber raw materials is achieved.

Owner:重庆远嘉矿业有限公司

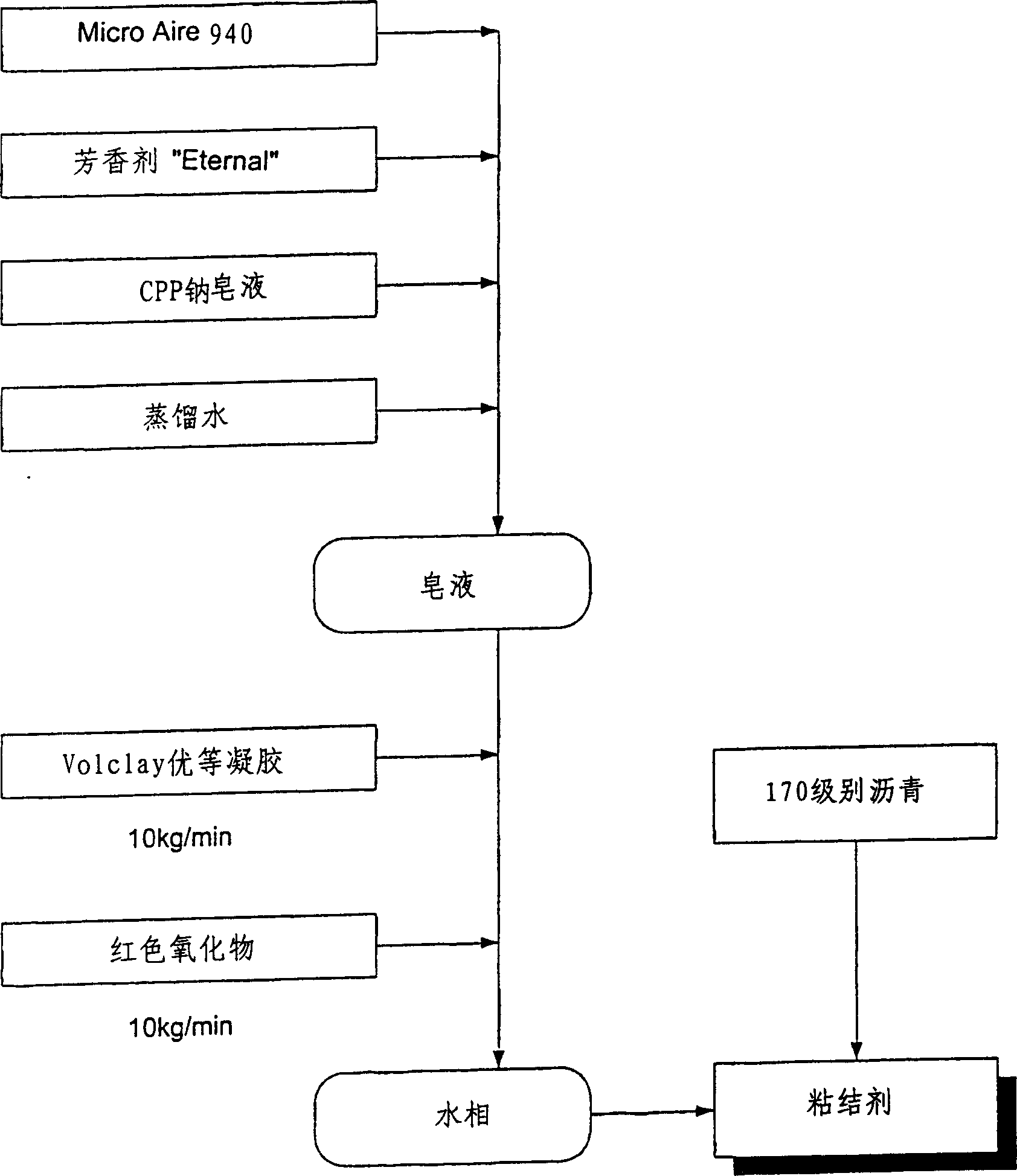

Lightweight aggregate binder formulation

The invention relates to a thermally stable composition, and methods for the preparation thereof, for use in the manufacture of a lightweight aggregate including a continuous bituminous phase, a discontinuous aqueous phase, an anionic oxide suspended in the discontinuous aqueous phase and at least one emulsifying agent. The anionic oxide may be a naturally occurring metal oxide having a needle-like crystal structure such as red oxide (CuO) or yellow oxide. The continuous bituminous phase may be for example grade 170 bitumen or crude oil, hydrocarbons or mixtures thereof. The emulsifying agent may be a clay emulsifier such as sodium bentonite, or a hydrous aluminium silicose or montmorillonite clay. The invention also relates to lightweight aggregate particles coated with such compositions and building materials formed from the lightweight aggregate in combination with a cementitious material.

Owner:BST HLDG PTY LTD

A formula of a glaze material showing purple-white ripples in furnace transmutation

The invention relates to a formula of a glaze material showing purple-white ripples in furnace transmutation. Raw materials of the glaze material include feldspar, calcite, iron ore, cattle bone ash,fluorite, kaolinite clay rock, glaze stone, frit, zinc oxide, talc powder, copper oxide and stannic oxide, and particularly include, by weight, 60-70 parts of the feldspar, 30-40 parts of the calcite,15-20 parts of the iron ore, 7-20 parts of the cattle bone ash, 8-15 parts of the fluorite, 7-15 parts of the kaolinite clay rock, 5-10 parts of the glaze stone, 5-9 parts of the frit, 3-5 parts of the zinc oxide, 0.5-1 part of the talc powder, 0.1-0.3 part of the copper oxide and 0.1-0.3 part of the stannic oxide. The glaze material has bright and gorgeous color, novel and beautiful patterns, uniform cracks, high artistic value and ornamental and collection value, a high firing yield, and high production value, and the production efficiency is increased.

Owner:温书强

Cement rotary kiln body sealing castable

A cement rotary kiln body sealing castable is characterized by comprising, by weight, aluminate cement, high-aluminum clay, iron ore slag powder, kaolin clay, high-aluminum cement, acrylic powder, silicon dioxide aerogel, illite powder, hard calcium silicate, zirconia, zinc oxide, titanium dioxide, glycerol, tributyl phosphate and triphenyl phosphate. The aluminate cement, cobblestone powder and the iron ore slag powder are adopted as main raw materials, so that the castable has excellent performances like stability at high and low temperature and resistance to oxidative degradation, and weatherability, antiaging strength and tensile strength in bonding between the sealing castable and refractory bricks are overcome effectively; a filler and related auxiliaries are added, so that the castable has the advantages of being high in heat insulativity, resistant to high temperature, high in strength and pollution-free.

Owner:余贤祥

Metakaolin Production and Enhancement of Industrial Minerals

Methods for preparing metakaolin-enhanced industrial minerals. Mixing and heating kaolinite clay with an industrial mineral, such as activated carbon, that is between 750° F. and 1400° F. results in a metakaolin / activated carbon complex that provides good mercury sorbent qualities while producing a fly ash (after use as a sorbent in emissions applications) that has a lower foaming index.

Owner:PNEUMATIC PROCESSING TECH

Kaolin-based binding agent as well as preparation method and application thereof

The invention belongs to the technical field of inorganic binding agents, and provides a kaolin-based binding agent which is prepared from the following raw materials: kaolin and phosphoric acid in a mass ratio of 100: (50-300). The kaolin-based binding agent is prepared by taking kaolin as a raw material and phosphoric acid as a binding agent; kaolin is clay and clay rock mainly comprising kaolinite clay minerals, is wide in source and low in cost, and has relatively strong acid resistance; the kaolin can be subjected to chemical reaction with the phosphoric acid, and aluminum dihydrogen phosphate, aluminum monohydrogen phosphate and silica gel which are high in adhesive property are generated by controlling the mass ratio of phosphoric acid to kaolin. A result of the embodiment shows that the compressive strength of a product prepared from the kaolin-based binding agent provided by the invention, quartz sand and magnesium oxide is 11.59 MPa.

Owner:NANHUA UNIV

Composite material, its manufacture and use in gas purification

InactiveCN109310981AReduce adsorption efficiencyReduce adsorptionHydrogen separation by selective and reversible uptakeGas treatmentSodium BentoniteCarboxylic acid

Disclosed herein is a composite material formed from an inorganic mesoporous, or mesoporous-like, material, including mesoporous silica, mesoporous carbon, mesoporous zinc oxide, bentonite and kaolinite clay that is dispersed throughout a polymeric matrix formed by a crosslinked polymer. The crosslinked polymer has acidic- or basic-residues, wherein the basic residues are formed from a monomeric material with at least one ethylenic bond and an amide functional group (e.g. acrylamide), and the acidic residues are formed from a monomer material with at least one ethylenic bond and a carboxylic acid functional group (e.g. acrylic acid). Said composite material may also optionally have further acidic- or basic-residues grafted onto the inorganic mesoporous material. The resulting composite material may be used to remove acidic or basic impurities from a gas in need thereof and can be easily regenerated.

Owner:NANYANG TECH UNIV

Metakaolin production and enhancement of industrial minerals

Methods for preparing metakaolin-enhanced industrial minerals. Mixing and heating kaolinite clay with an industrial mineral, such as activated carbon, that is between 750° F. and 1400° F. results in a metakaolin / activated carbon complex that provides good mercury sorbent qualities while producing a fly ash (after use as a sorbent in emissions applications) that has a lower foaming index.

Owner:PNEUMATIC PROCESSING TECH

Ceramic proppants of medium strength and a method for manufacturing thereof

InactiveUS20160194554A1Medium compression strengthLow specific gravityFluid removalFlushingMetallurgyKaolinite clay

Ceramic proppants made of a mixture of raw components, characterized in that at least 90% of the mixture of raw components consists of: plastic kaolinite clay from 10% to 50% by weight of the mixture; white-firing clay loam from 10% to 50% by weight of the mixture; and bauxite from 40% to 60% by weight of the mixture.

Owner:BALTIC CERAMICS

Nano crystallite composite filter material

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

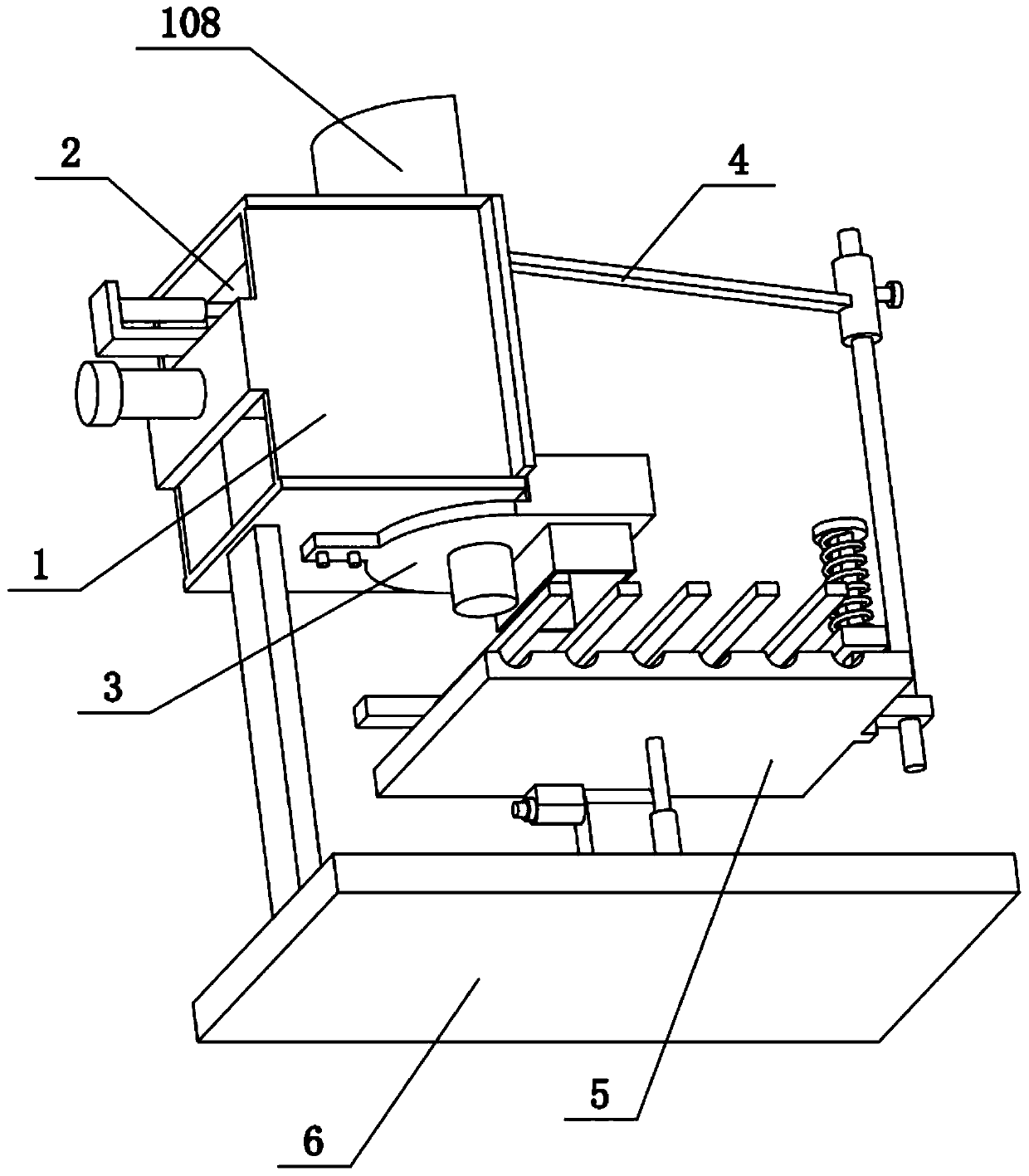

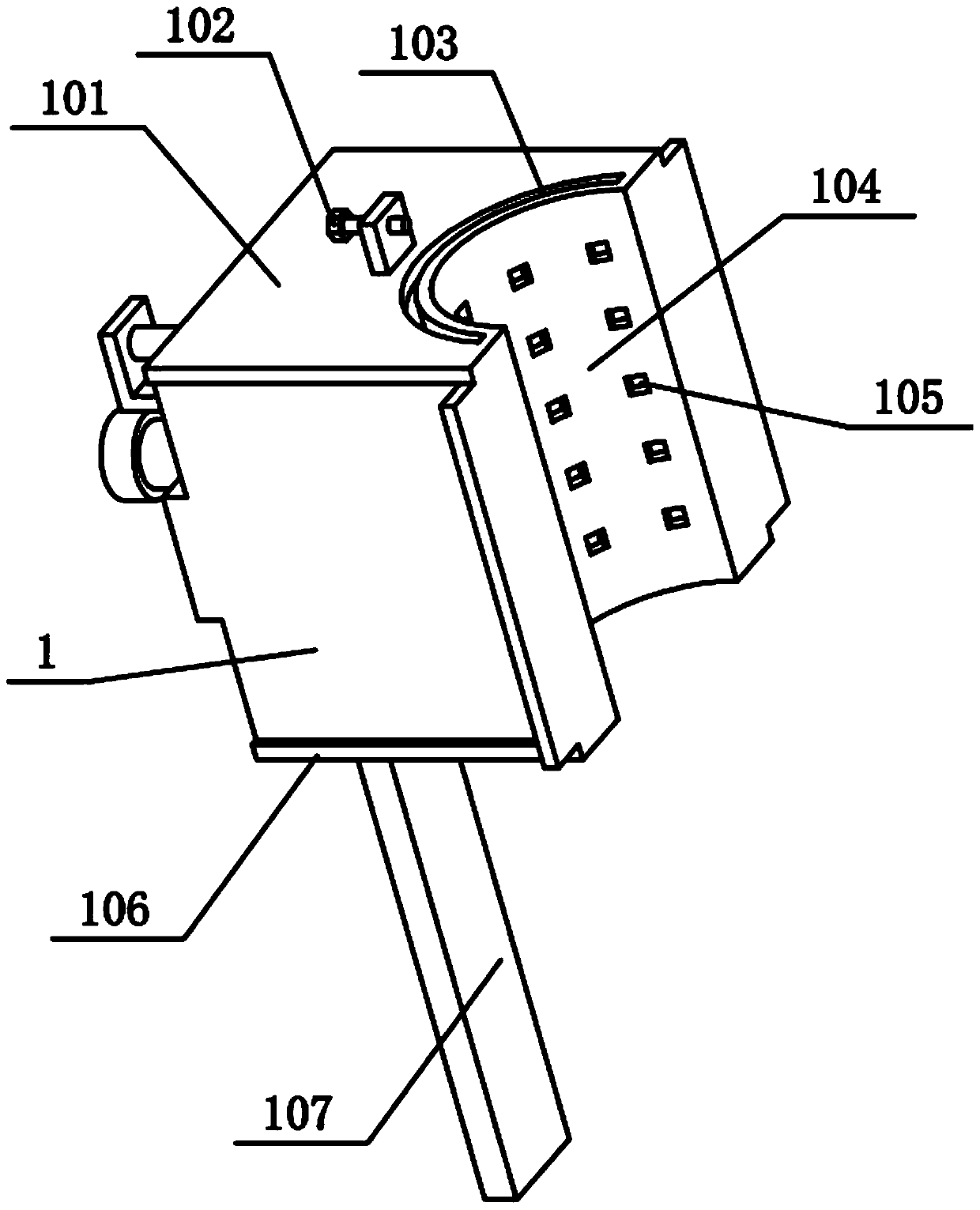

Ceramic particles, and processing system and processing method thereof

ActiveCN110813189AFast processingGranulation by material expressionCircular discReciprocating motion

The invention provides ceramic particles, and a processing system and a processing method thereof. The ceramic particles are prepared by adding deionized water and an adhesion promoter into ground kaolinite clay for rolling, wherein the volume ratio of the kaolinite clay to the deionized water to the adhesion promoter is 100: 5: 2. The method comprises the following steps: 1, the kaolinite clay isadded with water and then placed into a material storage box, and the kaolinite clay is extruded out of a plurality of extrusion holes; 2, a motor rotates to drive a vertical shaft to rotate, while the vertical shaft rotates to drive a scraping plate to rotate, and extruded kaolinite clay is scraped off to form the ceramic particles; 3, the motor rotates to drive the vertical shaft and a disc torotate simultaneously, and when the disc rotates, left and right moving rods and a plurality of pressing rods can be driven to do left-and-right reciprocating motion through an inclined connecting rodand a round inserting rod, and operations of scraping the extruded clay off and rolling of the extruded clay into a cylindrical shape are simultaneously carried out; 4, when an electric telescopic rod II is retracted and the front end of a flat plate inclines downwards, cylindrical ceramic particles are taken down; and 5, the cylindrical ceramic particles are placed into a firing furnace for firing.

Owner:HANDAN HEYI CERAMICS

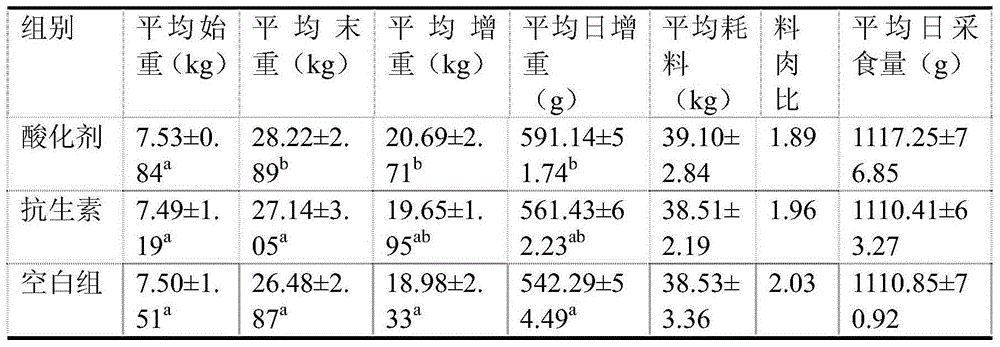

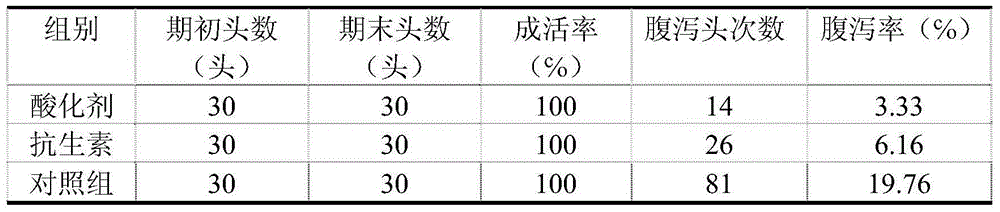

A kind of acidulant and preparation method thereof

The invention provides a novel acidifying agent which comprises organic acid and organic salt; the organic salt selects preferably organic potassium / calcium salt synthesized by some organic acid and alkaline substances containing a potassium source or a calcium source. The invention further provides an acidifying agent carrier, namely an excipient carrier formed by mixing kaolinite clay and white carbon black. The acidifying agent provided by the invention can enhance the digestion and absorption capacity of the weaning piglets, and achieve the purposes of preventing excessive fluctuation of gastric acid, thereby improving the digestion capacity of the weaning piglets and reducing medicine taking of the piglets; besides, the organic acid / potassium salt can make up the partial deficiency in the utilization of mineral substances in the feed and improve the balance of electrolyte in the bodies of domestic animals.

Owner:安徽泰格维生素实业有限公司

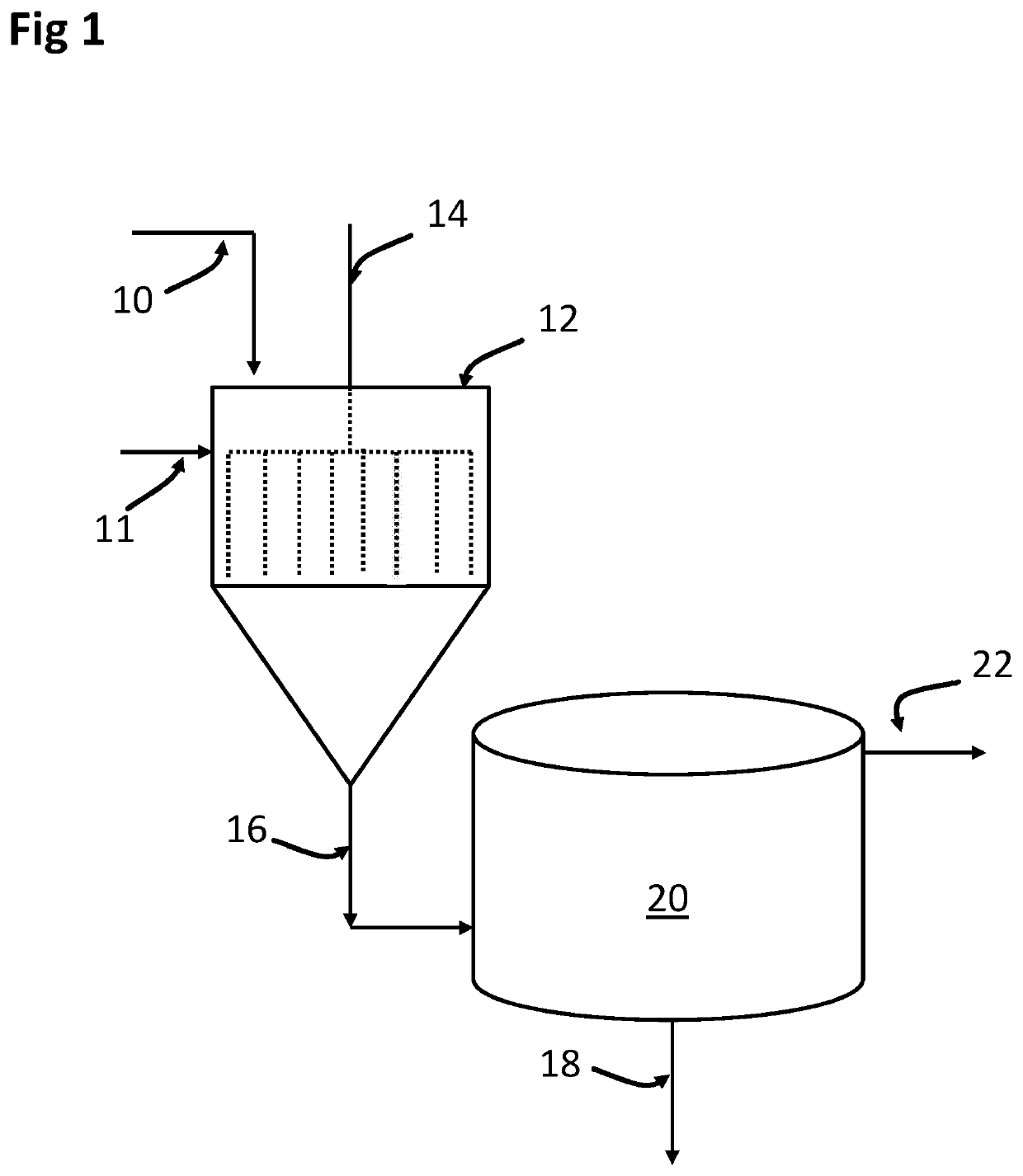

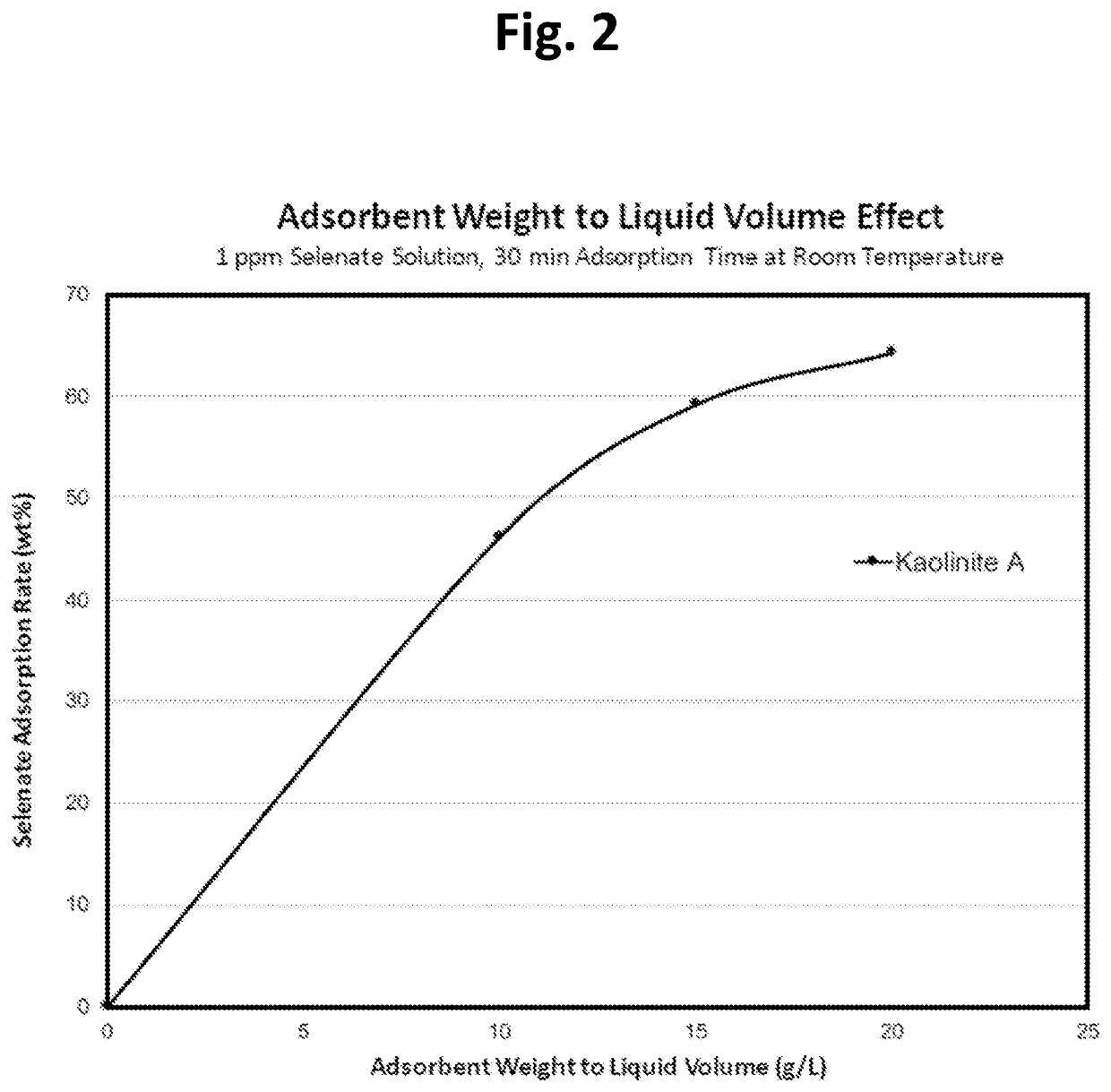

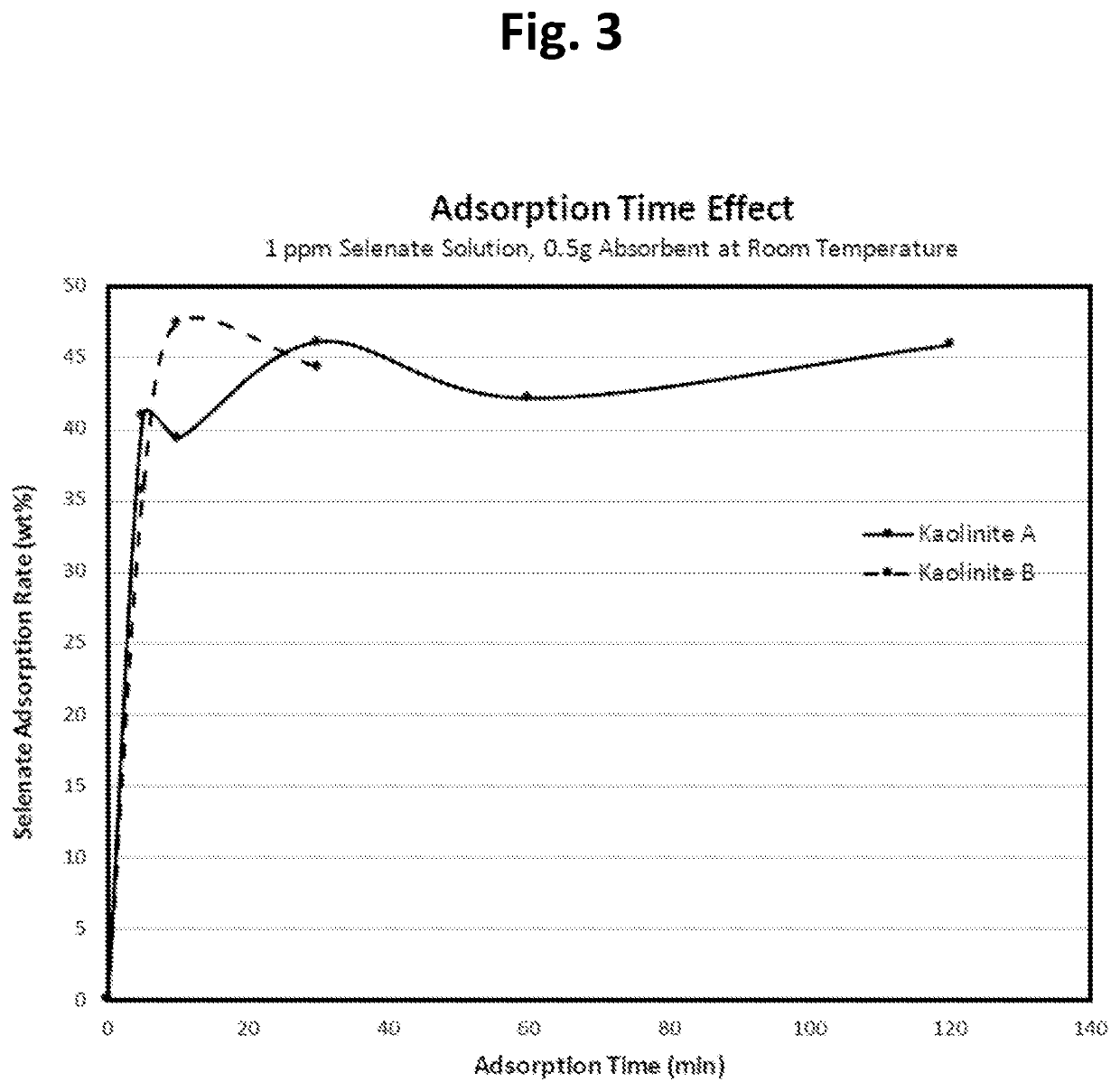

Removal of Selenium from Water with Kaolinite

ActiveUS20210053845A1Mitigate Se issue in different wastewater treatmentsOther chemical processesWater contaminantsSoil scienceKaolin clay

The description relates to a composition and a method for reducing the concentration of selenium in water. Contaminated water is contacted with a kaolinite clay characterized by a removal efficiency for selenatearsenate of at least 40 wt % at ambient temperature. The adsorption process is fast. Following sufficient contact, the water is separated from the kaolinite clay. In a preferred form, the kaolinite clay has high surface acidity.

Owner:FUEL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com